Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

77 results about "Mercury intrusion porosimetry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mercury intrusion porosimetry is based on the premise that a non-wetting liquid (one having a contact angle greater than 90 ) will only intrude capillaries under pressure. The relationship between the pressure and capillary diameter is described by Washburn[3] as:

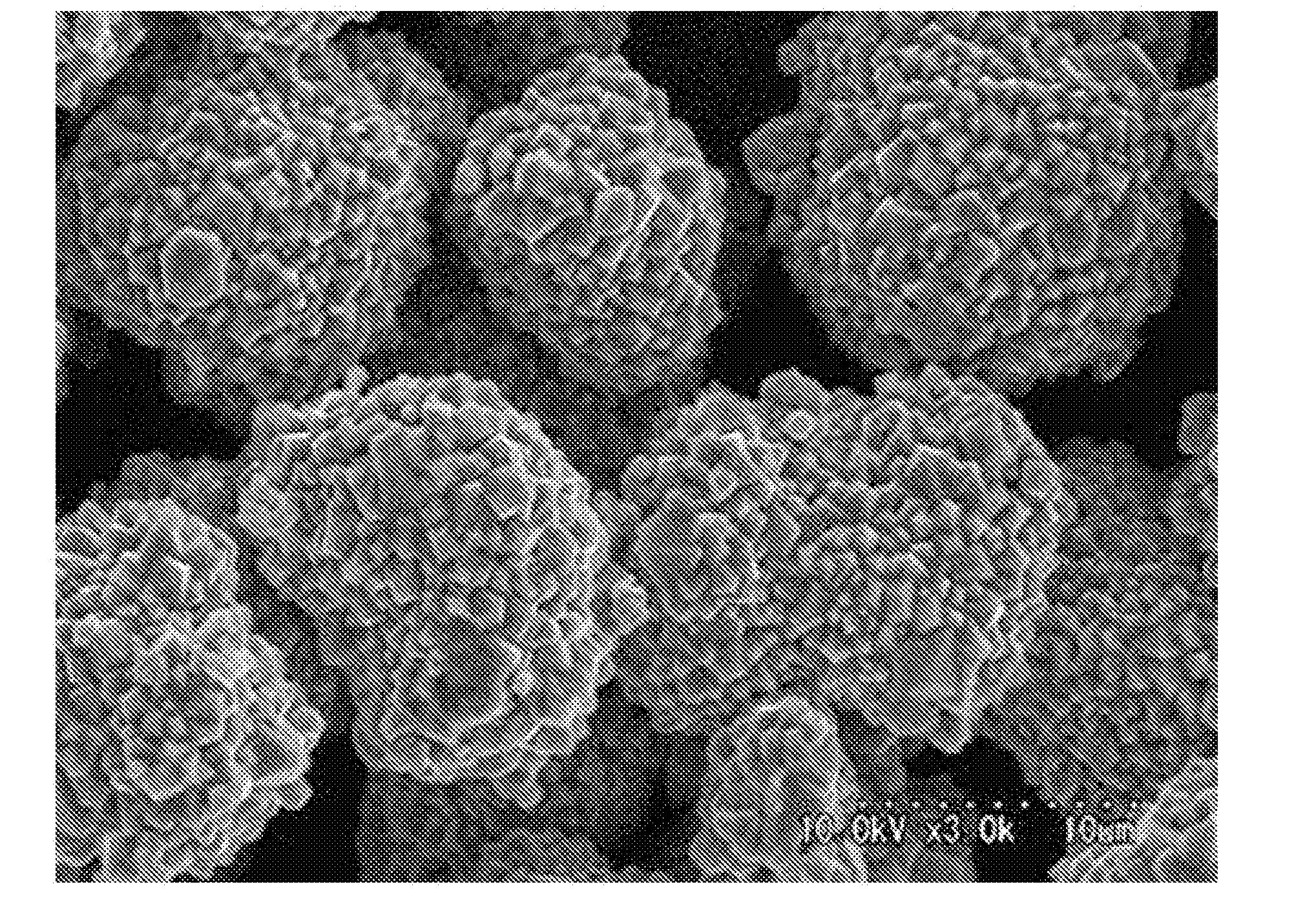

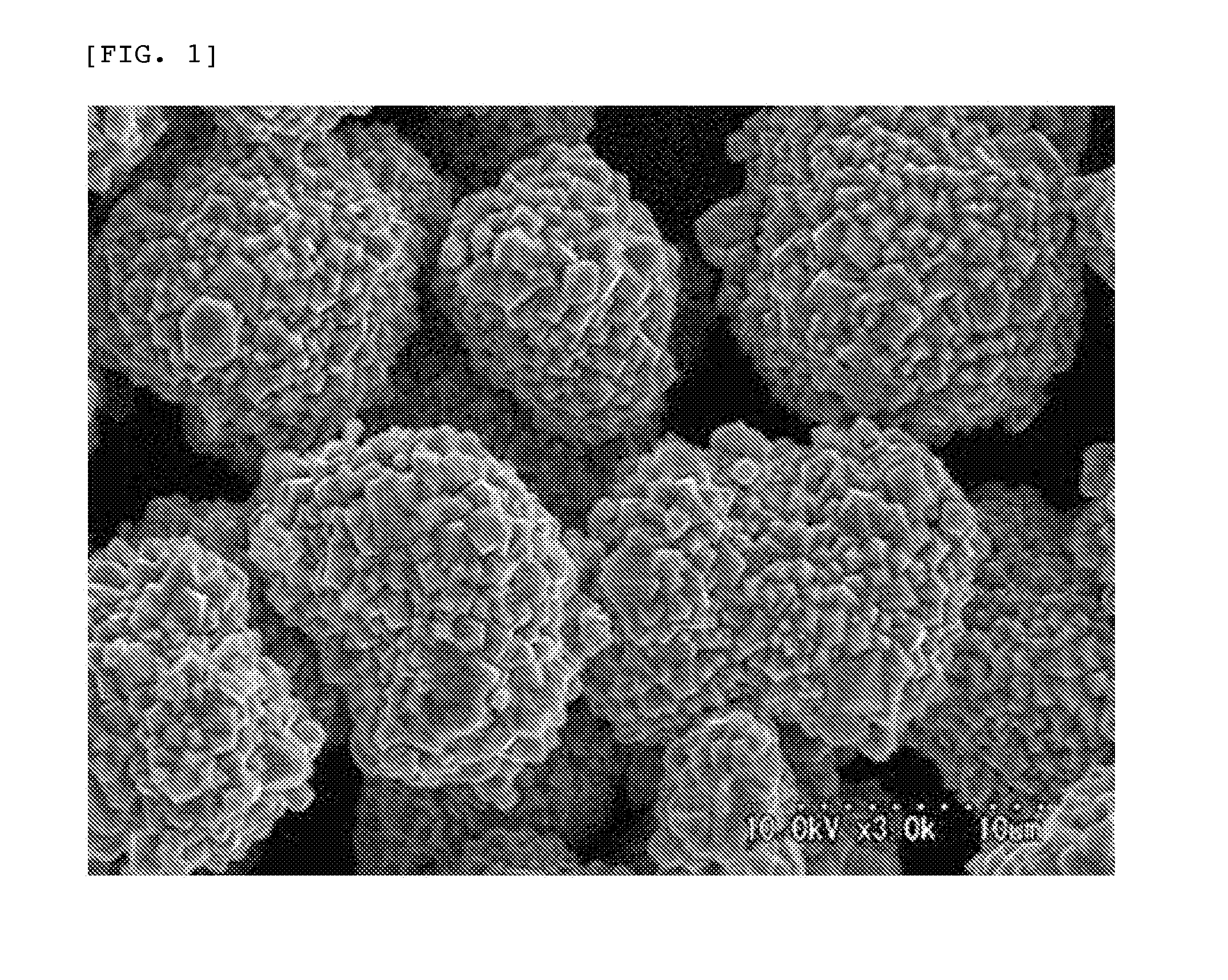

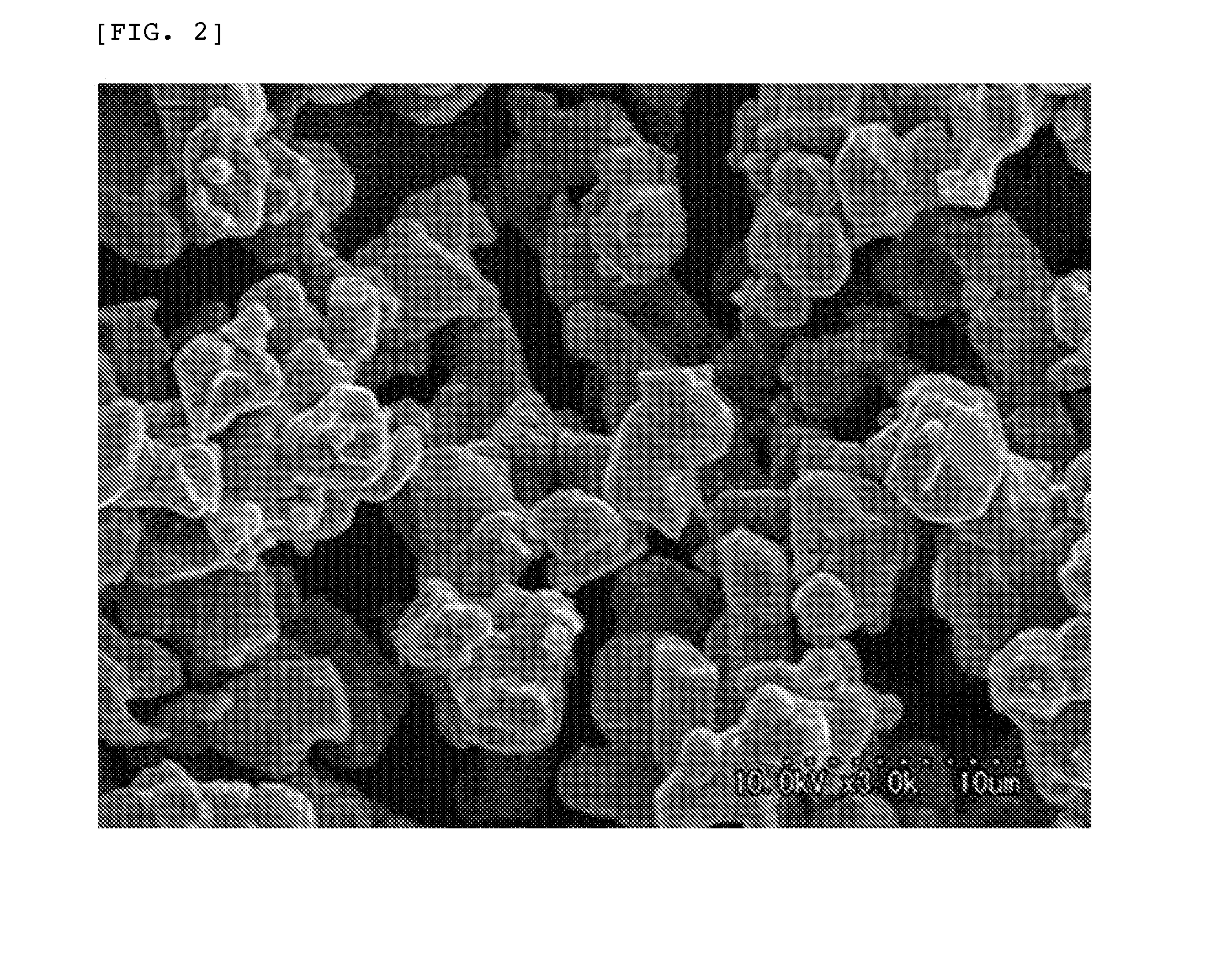

Lithium transition metal-based compound powder for positive electrode material in lithium rechargeable battery, method for manufacturing the powder, spray dried product of the powder, firing precursor of the powder, and positive electrode for lithium rechargeable battery and lithium rechargeable battery using the powder

ActiveUS20090104530A1Low costImprove security levelElectrode manufacturing processesNon-aqueous electrolyte accumulator electrodesMetalHigh voltage

There is provided a powder of a lithium transition-metal compound for a positive-electrode material in a lithium secondary battery, in which the use of the powder as that of a positive-electrode material in a lithium secondary battery achieves a good balance among improvement in battery performance, cost reduction, resistance to a higher voltage, and a higher level of safety. The powder of the lithium transition-metal compound for a positive-electrode material in a lithium secondary battery is characterized in that in a mercury intrusion curve obtained by mercury intrusion porosimetry, the amount of mercury intruded is in the range of 0.8 cm3 / g to 3 cm3 / g when the pressure is increased from 3.86 kPa to 413 MPa.

Owner:MITSUBISHI CHEM CORP

Lithium composite oxide particle for positive electrode material of lithium secondary battery, and lithium secondary battery positive electrode and lithium secondary battery using the same

InactiveUS20060134521A1Improving low-temperature load characteristicGood paintabilityRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsAlkali metal oxidesElectrical batteryComposite oxide

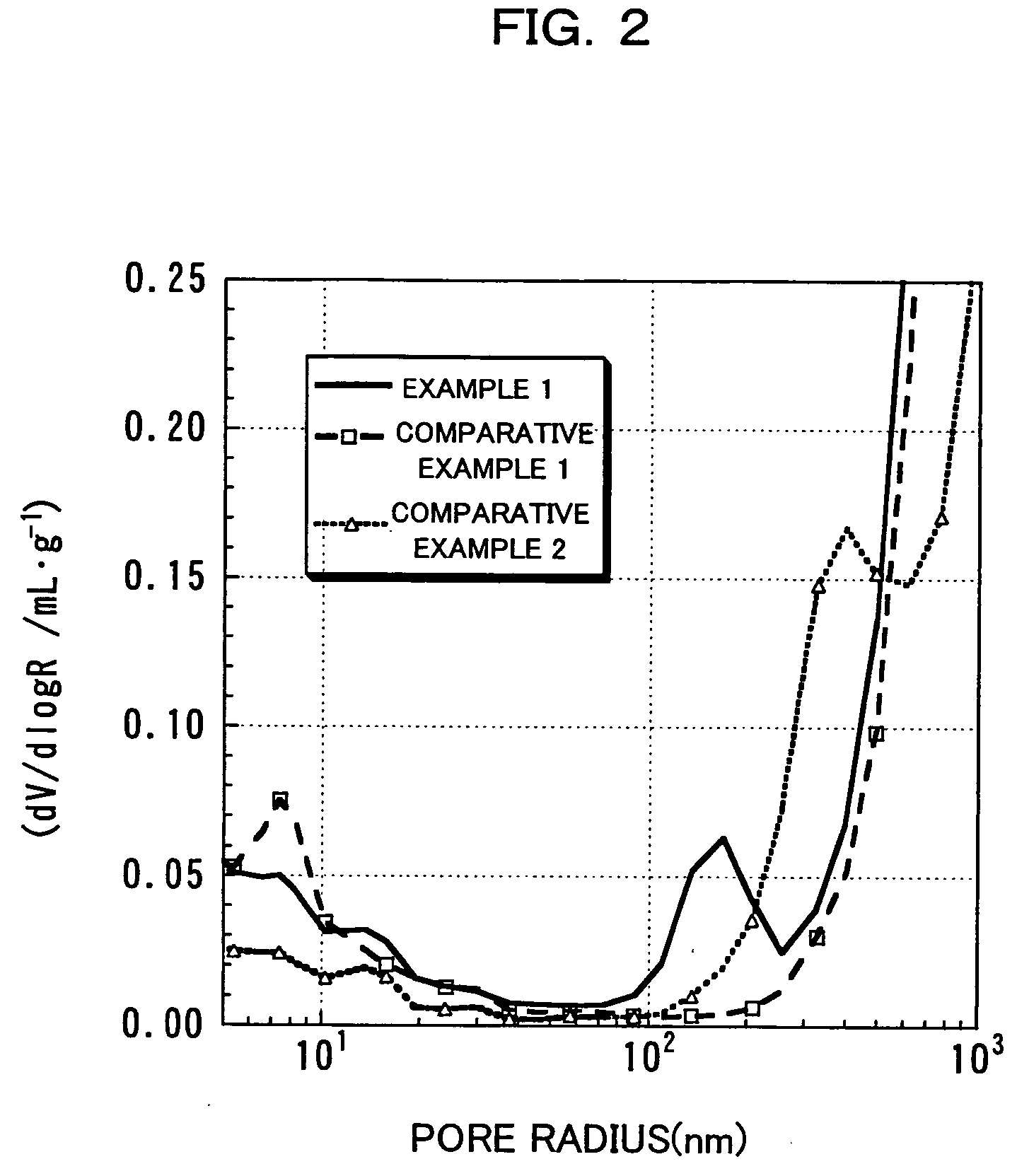

An excellent positive electrode material for a lithium secondary battery is provided that can increase low-temperature load characteristics of the battery as well as improving coatability. When measured by mercury intrusion porosimetry, the material meets Condition (A) and at least either Condition (B) or Condition (C). Condition (A) : on a mercury intrusion curve, the mercury intrusion volume from 50 MPa to 150 MPa is 0.02 cm3 / g or smaller. Condition (B): on the mercury intrusion curve, the mercury intrusion volume from 50 MPa to 150 MPa is 0.01 cm3 / g or larger. Condition (C): the average pore radius is within 10-100 nm, and the pore-size distribution curve has a main peak (with peak top at a pore radius of within 0.5-50 μm) and a sub peak (with peak top at a pore radius of within 80-300 nm).

Owner:MITSUBISHI CHEM CORP

Separator for nonaqueous secondary battery

ActiveUS20110143185A1Improve heat resistanceImprove securitySecondary cellsCell component detailsFiberPolyolefin

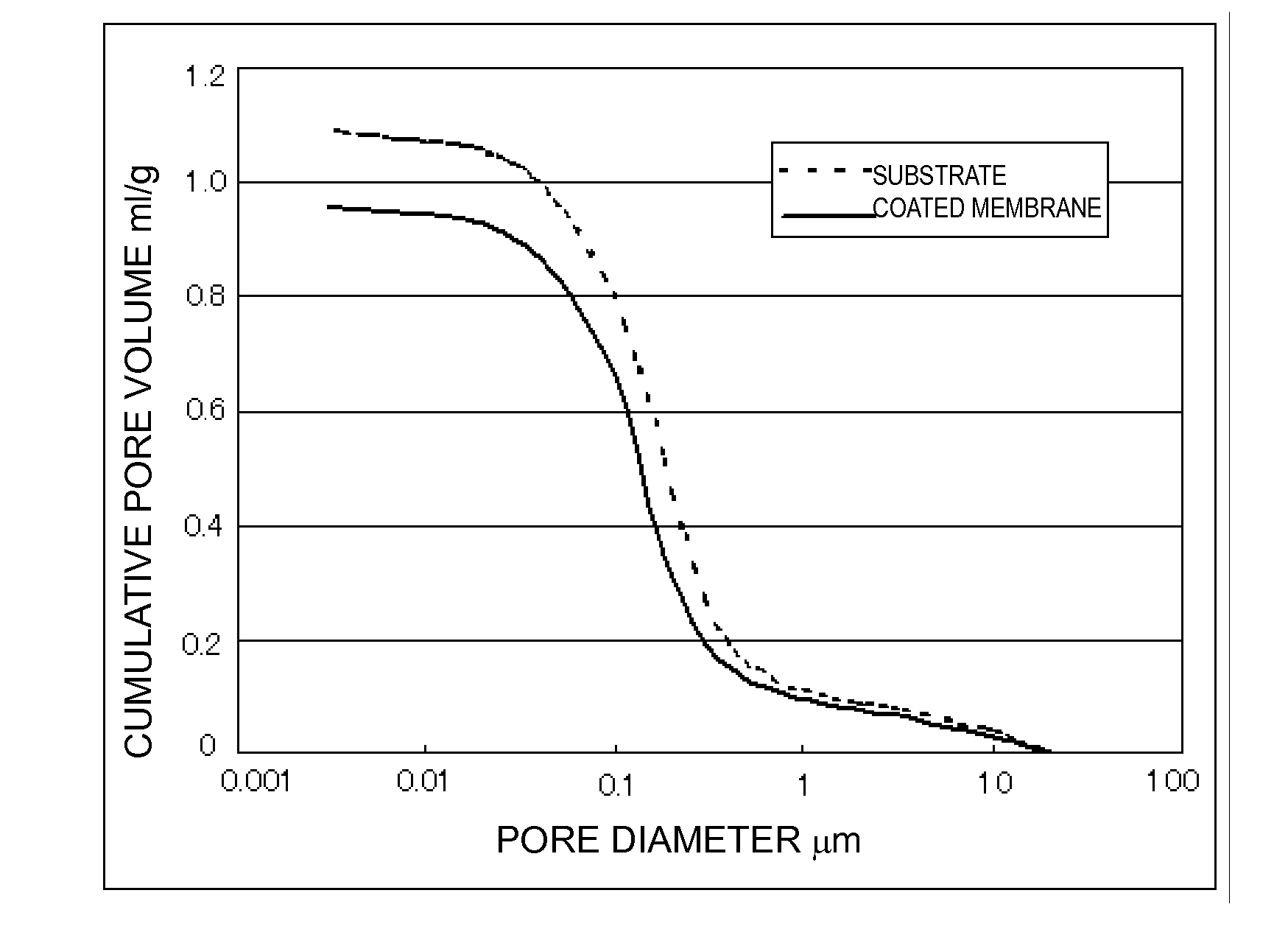

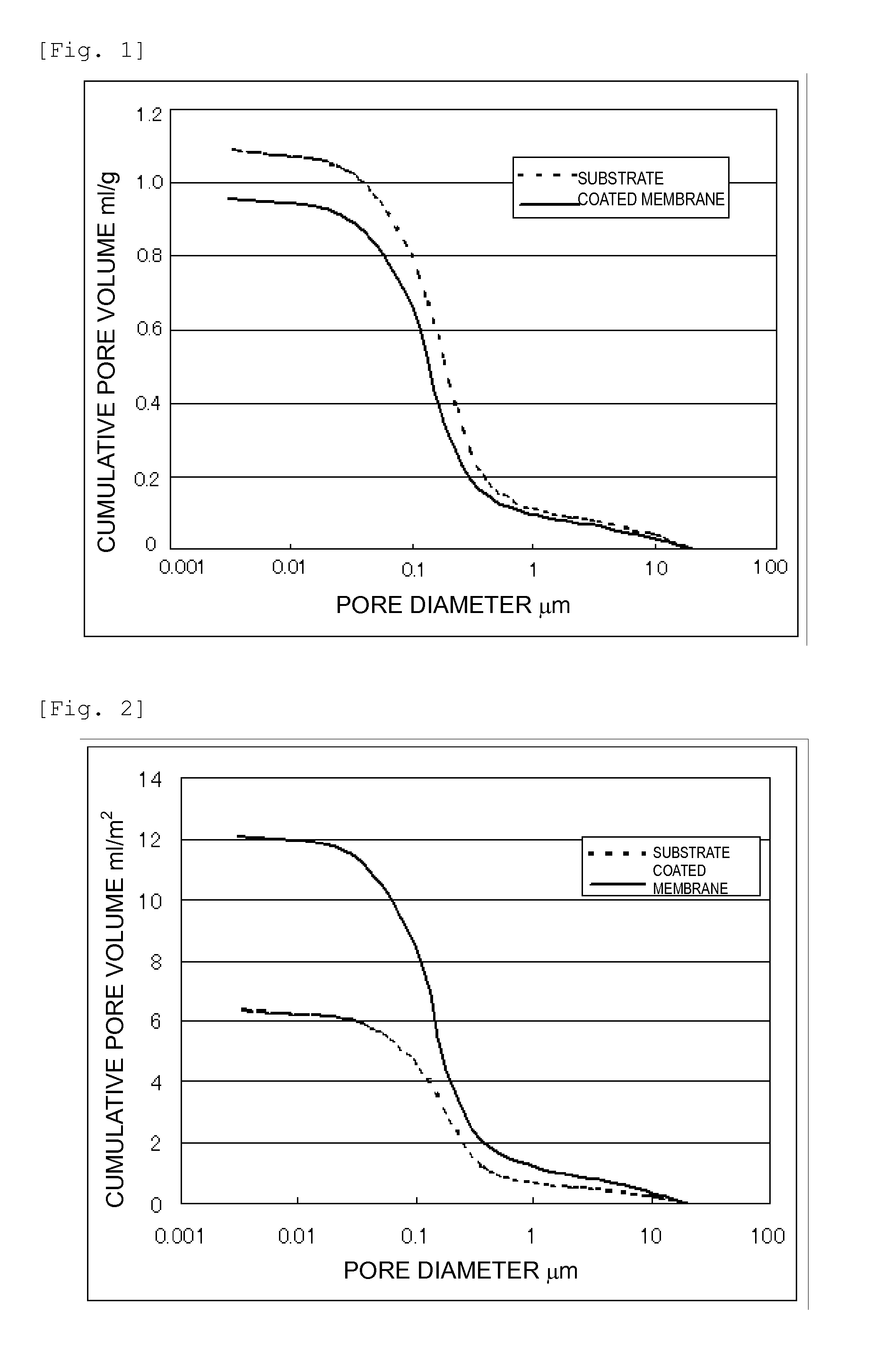

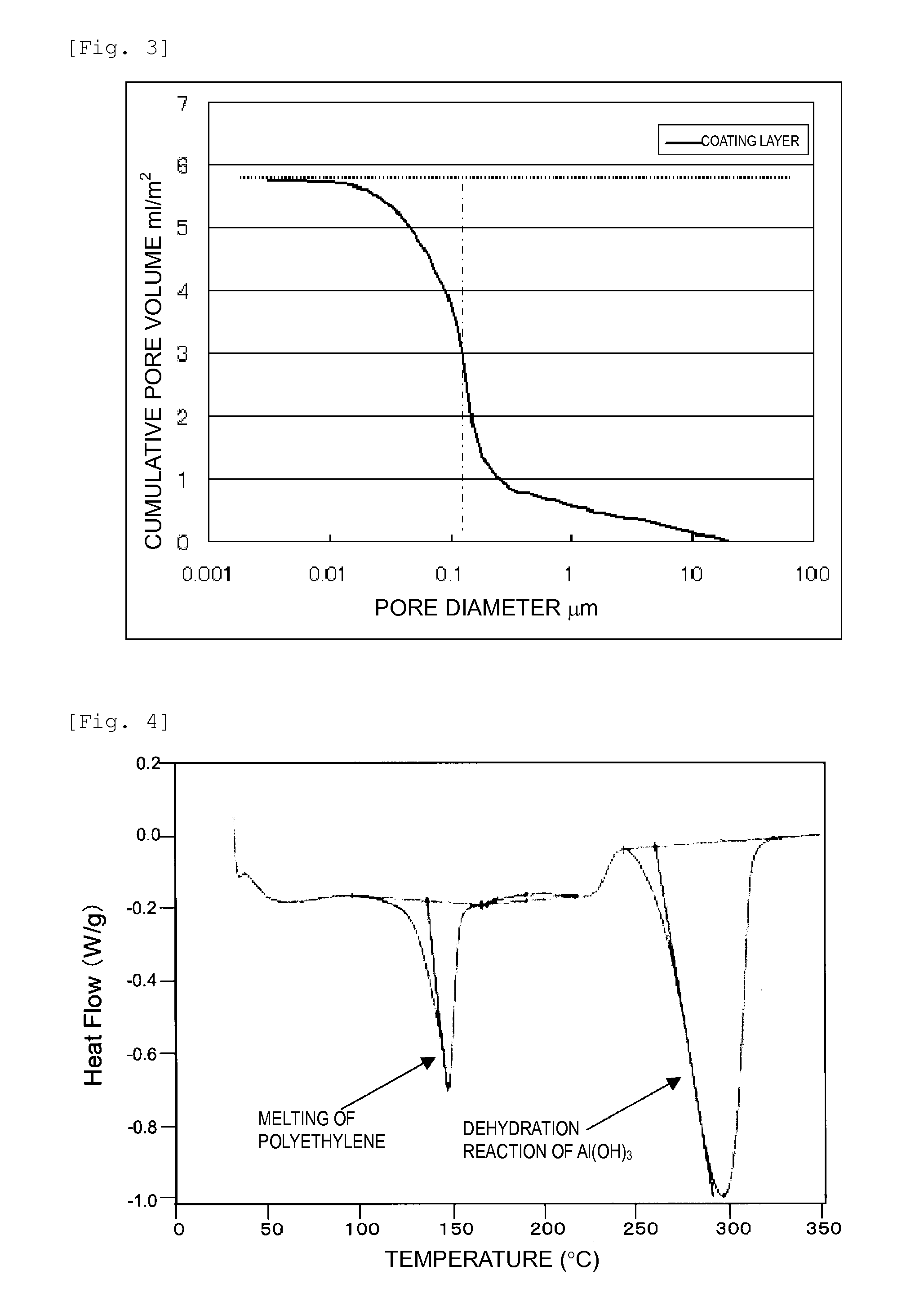

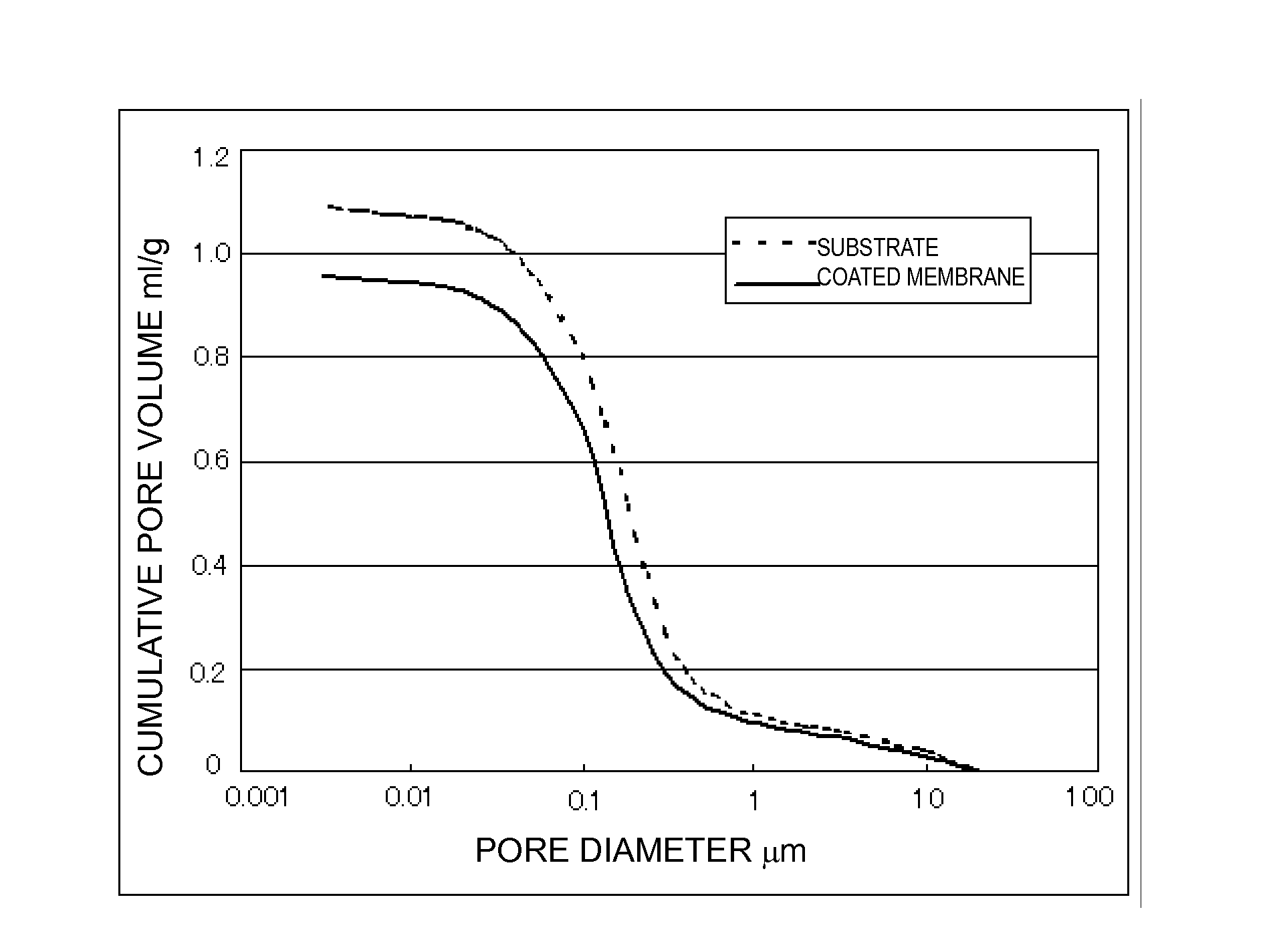

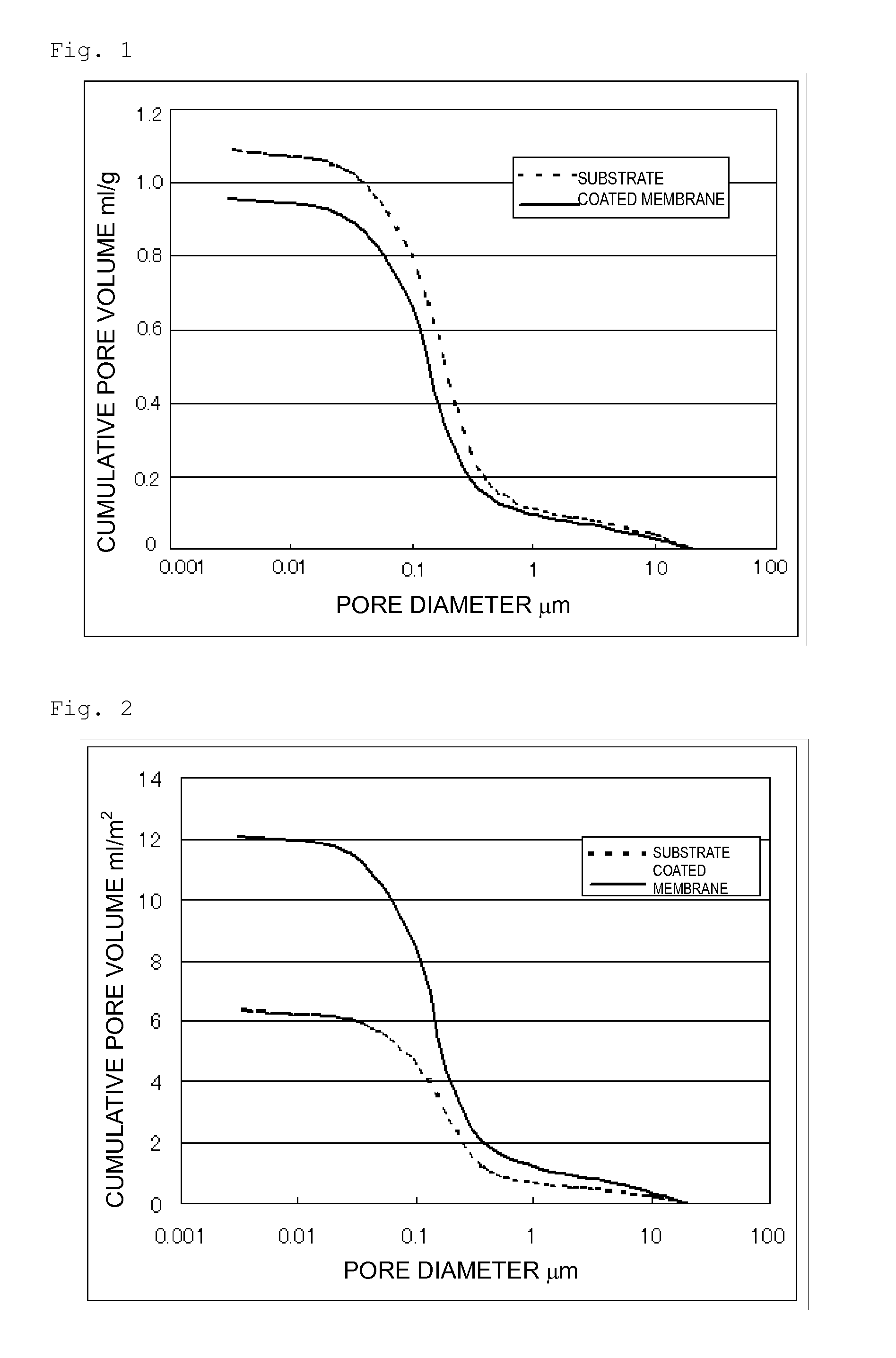

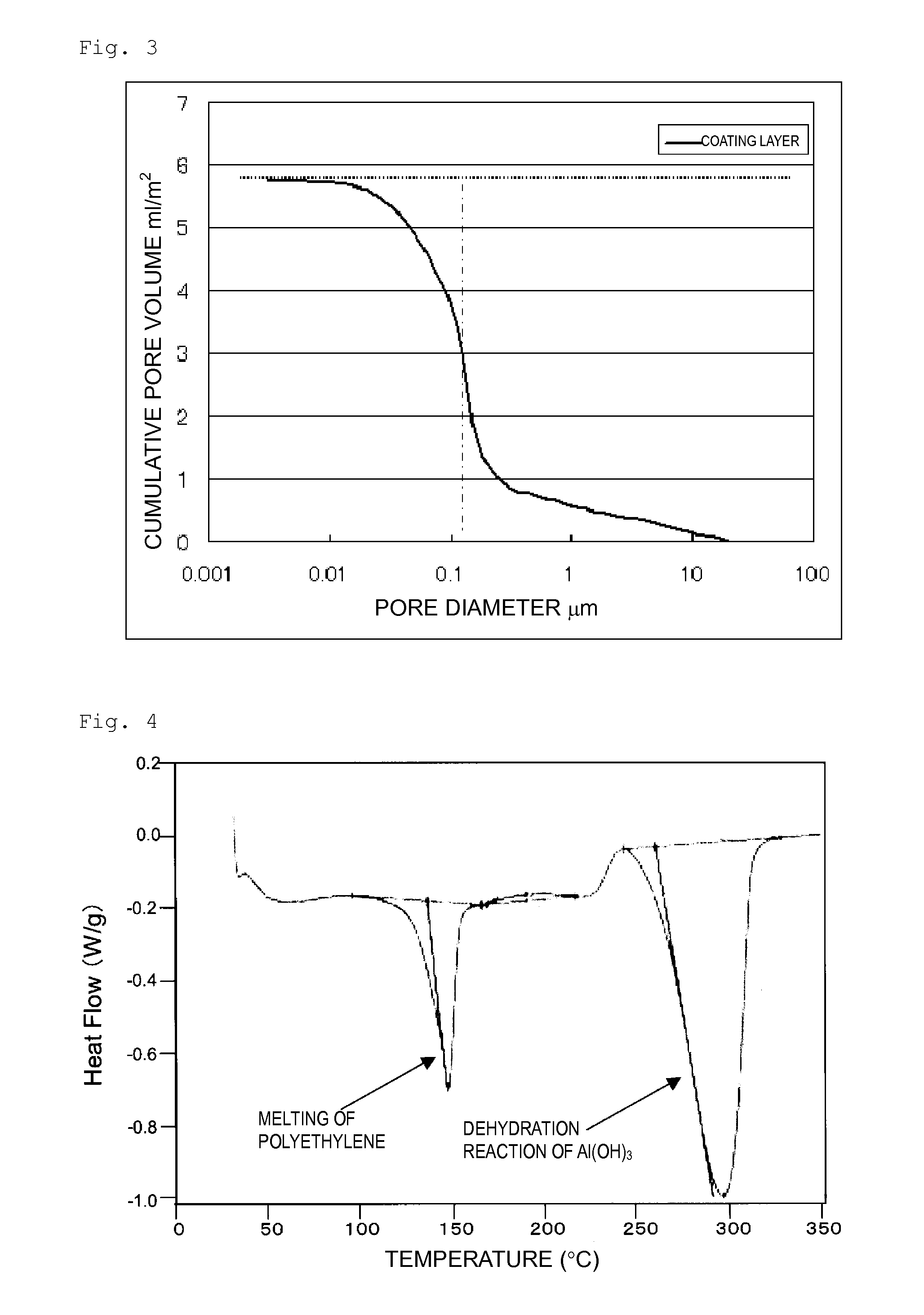

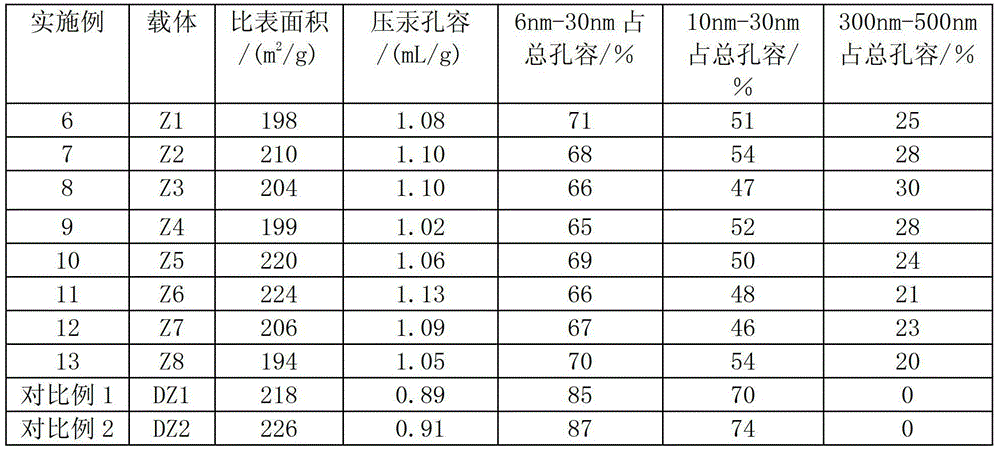

An object of the present invention is to provide a separator for a nonaqueous secondary battery having excellent heat resistance and excellent ion permeation as well as shut-down properties. The first invention is a separator for a nonaqueous secondary battery, comprising a porous composite membrane which includes a substrate comprising a polyolefin microporous membrane and a heat-resistant porous layer comprising a heat-resistant resin, the heat-resistant porous layer being formed on at least one surface of the substrate, wherein the separator is characterized in that the sheet resistance (A) of the substrate, the Gurley value (B) of the substrate, the sheet resistance (C) of the porous composite membrane, and the Gurley value (D) of the porous composite membrane satisfy a specific relationship. The second invention is characterized in that the heat-resistant porous layer has an average pore size of 0.1 to 0.2 μm as measured by mercury intrusion porosimetry. The third invention is characterized in that the heat-resistant resin fibrils have an average fibril diameter of 10 to 80 nm, and the pores in the heat-resistant porous layer have an average pore size of 50 to 250 nm.

Owner:TEIJIN LTD

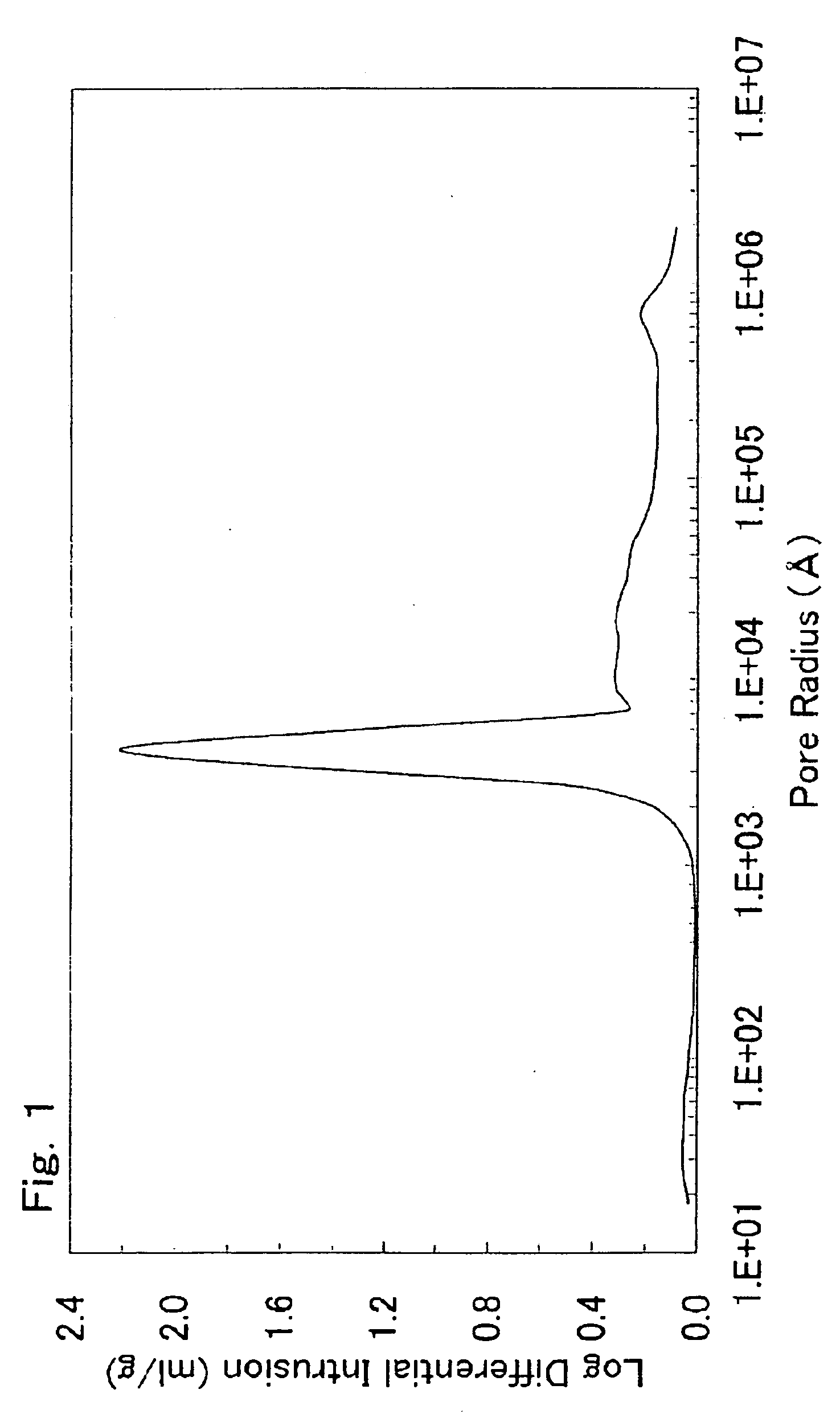

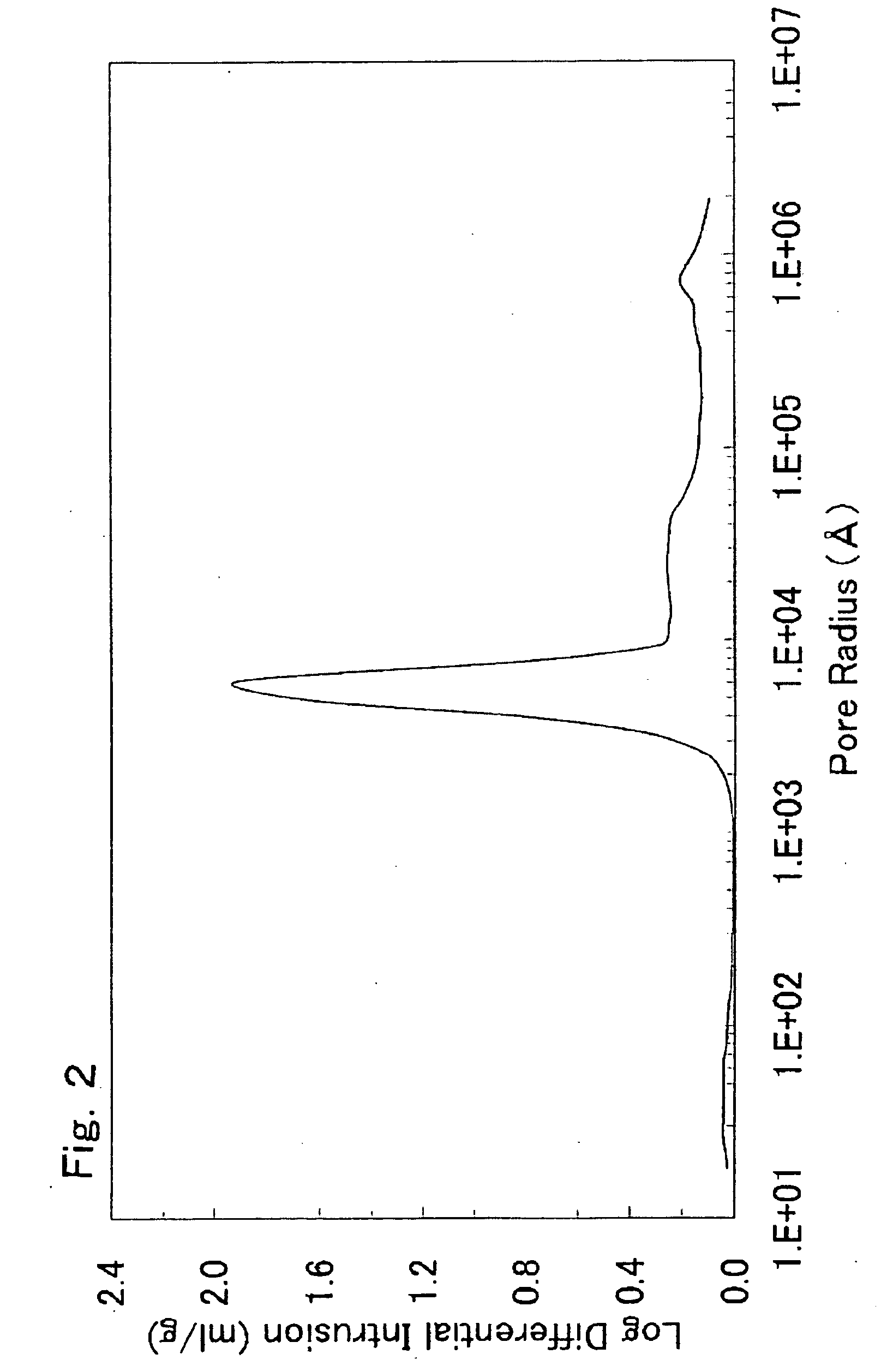

Hydrocracking catalyst having a unique silica-alumina substrate

A hydrocarbon conversion catalyst contains at least one silica-alumina having the following characteristics: A content by weight of silica SiO2 of between 10 and 60% by weight; an Na content less than 300 ppm by weight; a total pore volume of between 0.5 and 1.2 m / g measured by mercury porosimetry; a porosity of said silica-alumina wherein: the volume of mesopores whose diameter is between 40 Å and 150 Å, and whose mean diameter varies between 80 and 120 Å represents between 30 and 80% of the total pore volume, and (ii) the volume of macropores, whose diameter is greater than 500 Å and preferably between 1000 Å and 10,000 Å represents between 20 and 80% of the total pore volume; a specific surface area greater than 200 m<2> / g, and at least one hydro-dehydrogenating element selected metals of group VIB and group VIII, and optionally phosphorus, boron, silicon, or elements of group VIIA, VIIB or VB.

Owner:INST FR DU PETROLE

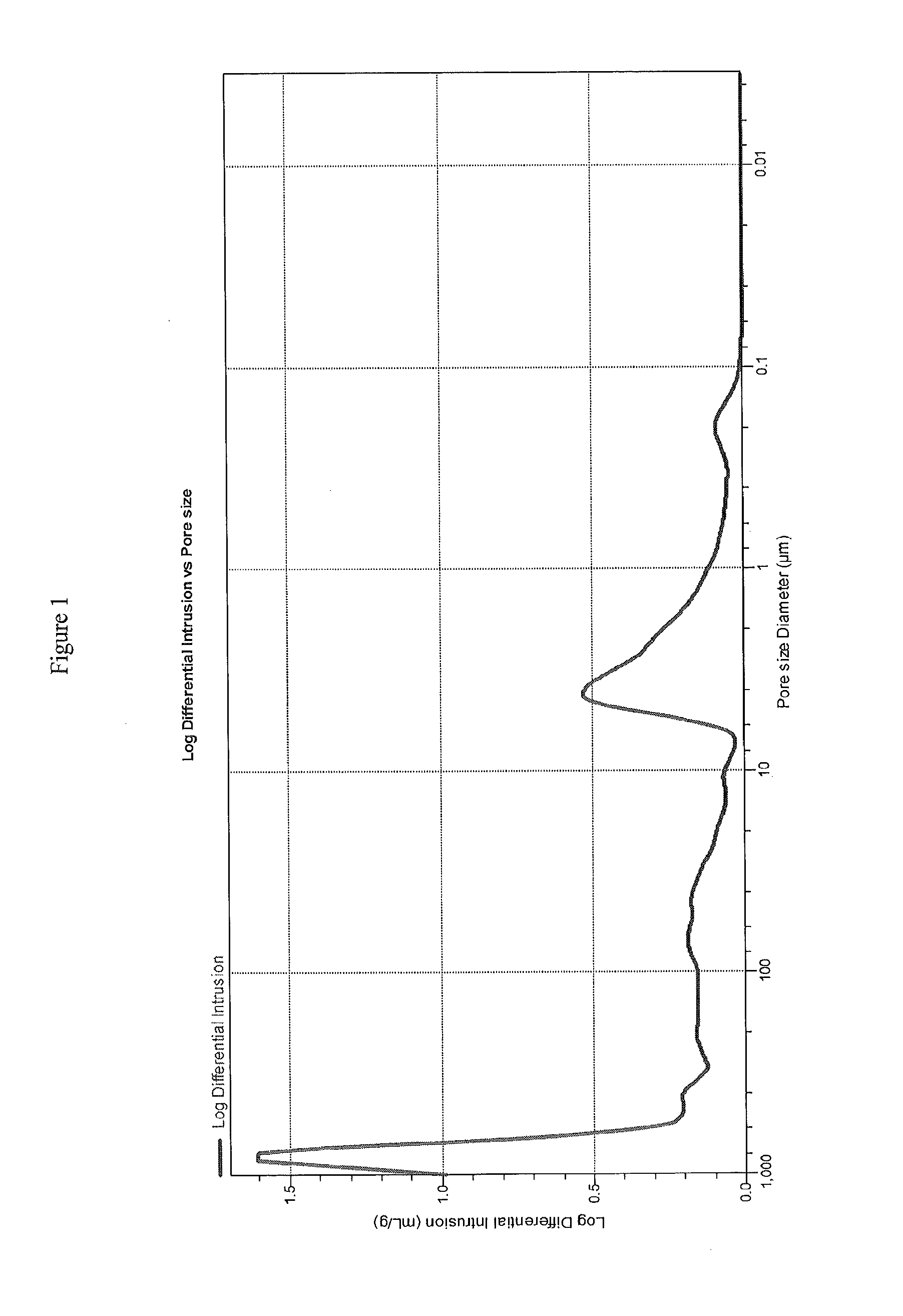

Microporous Polyolefin Membrane And Manufacturing Method

ActiveUS20090081543A1High mechanical strengthImprove permeabilityMembranesSemi-permeable membranesPolyolefinSolvent

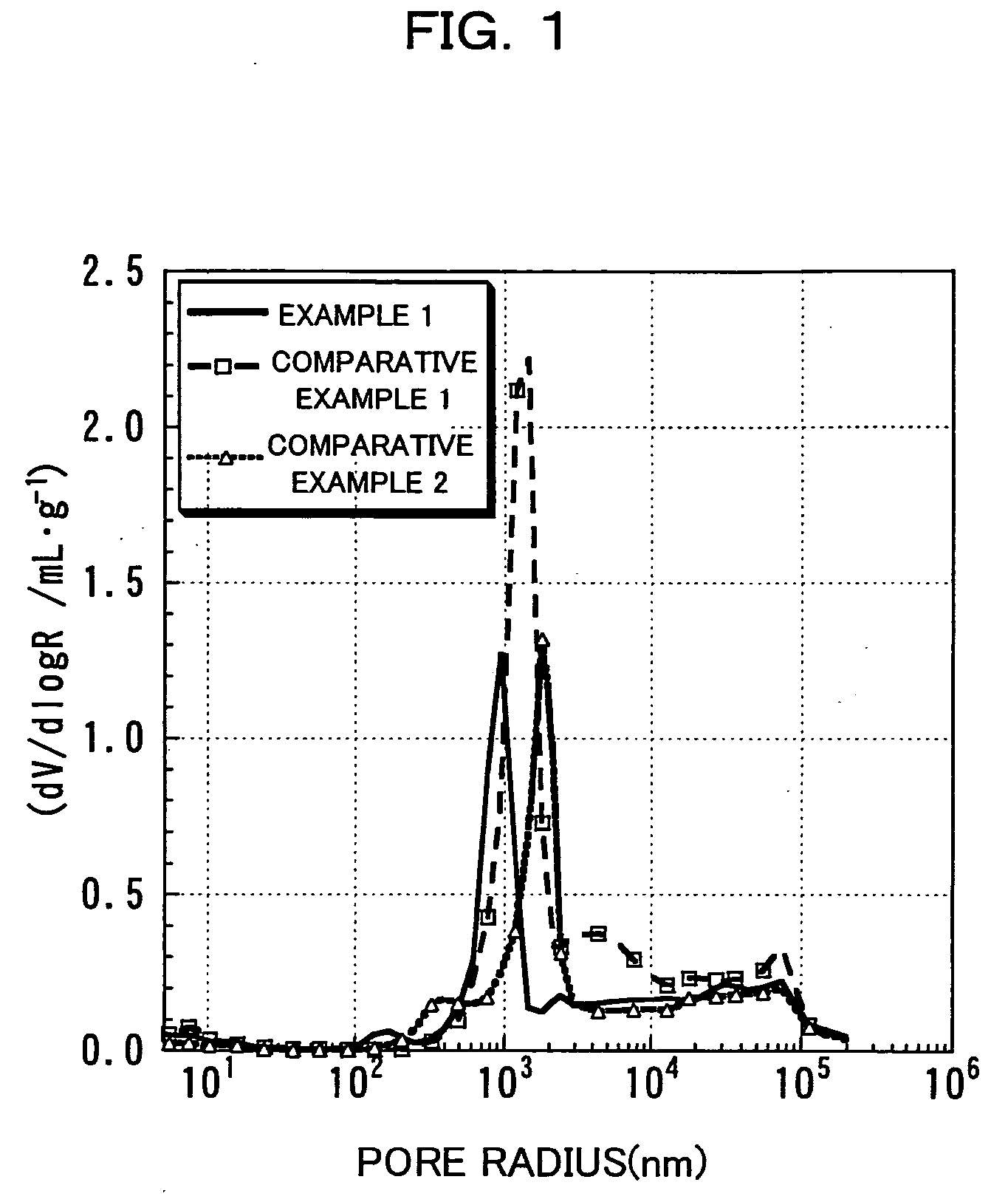

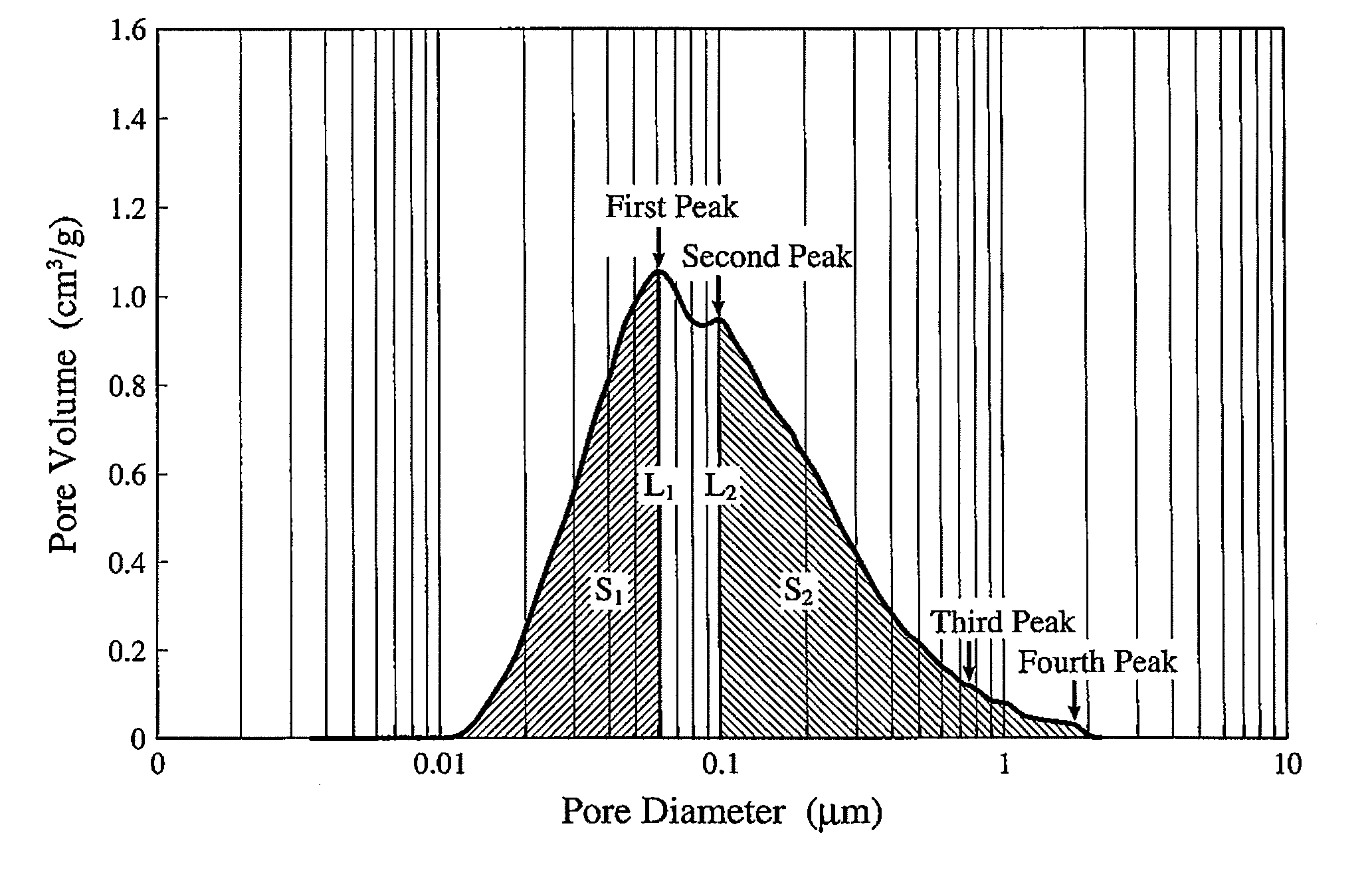

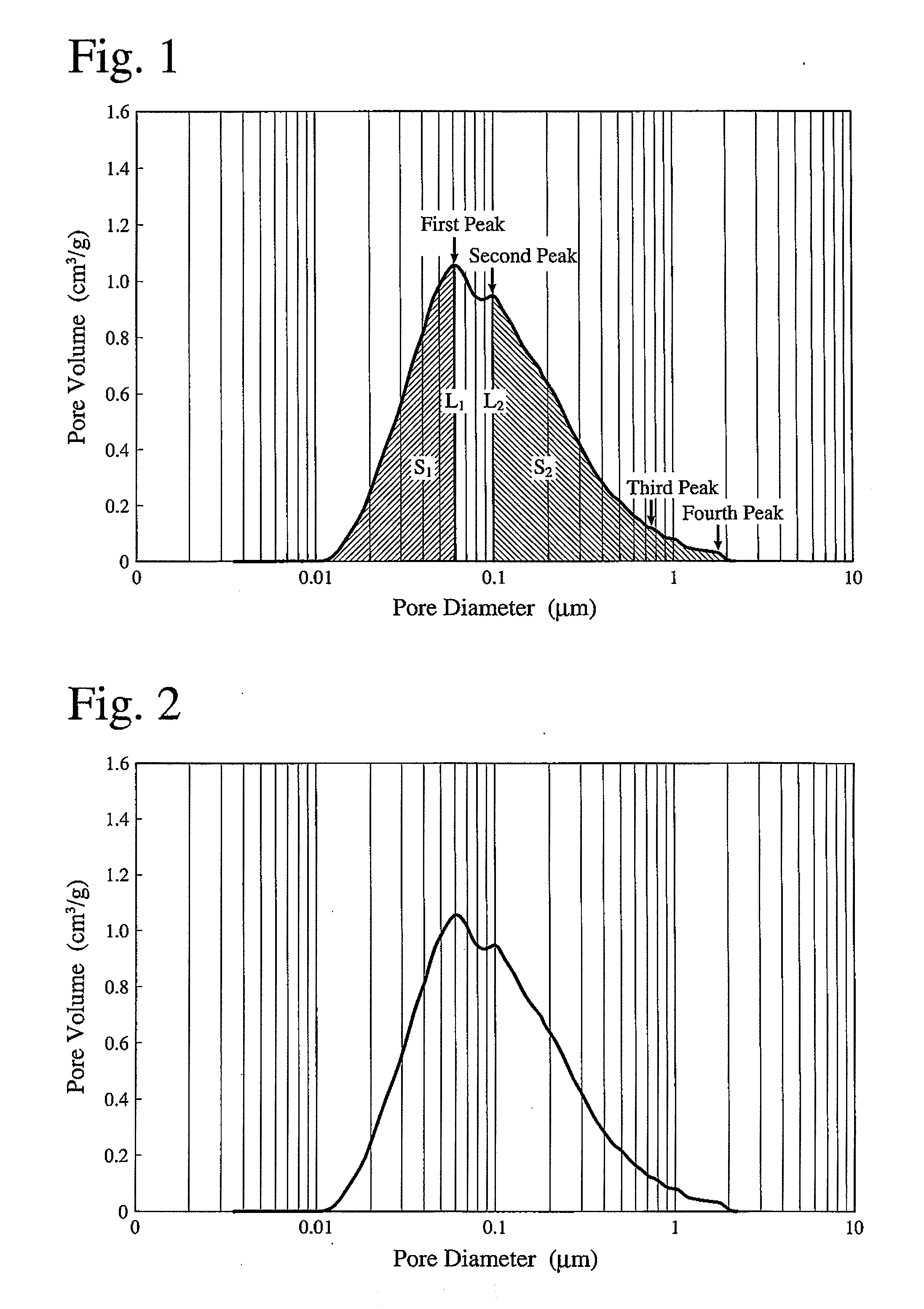

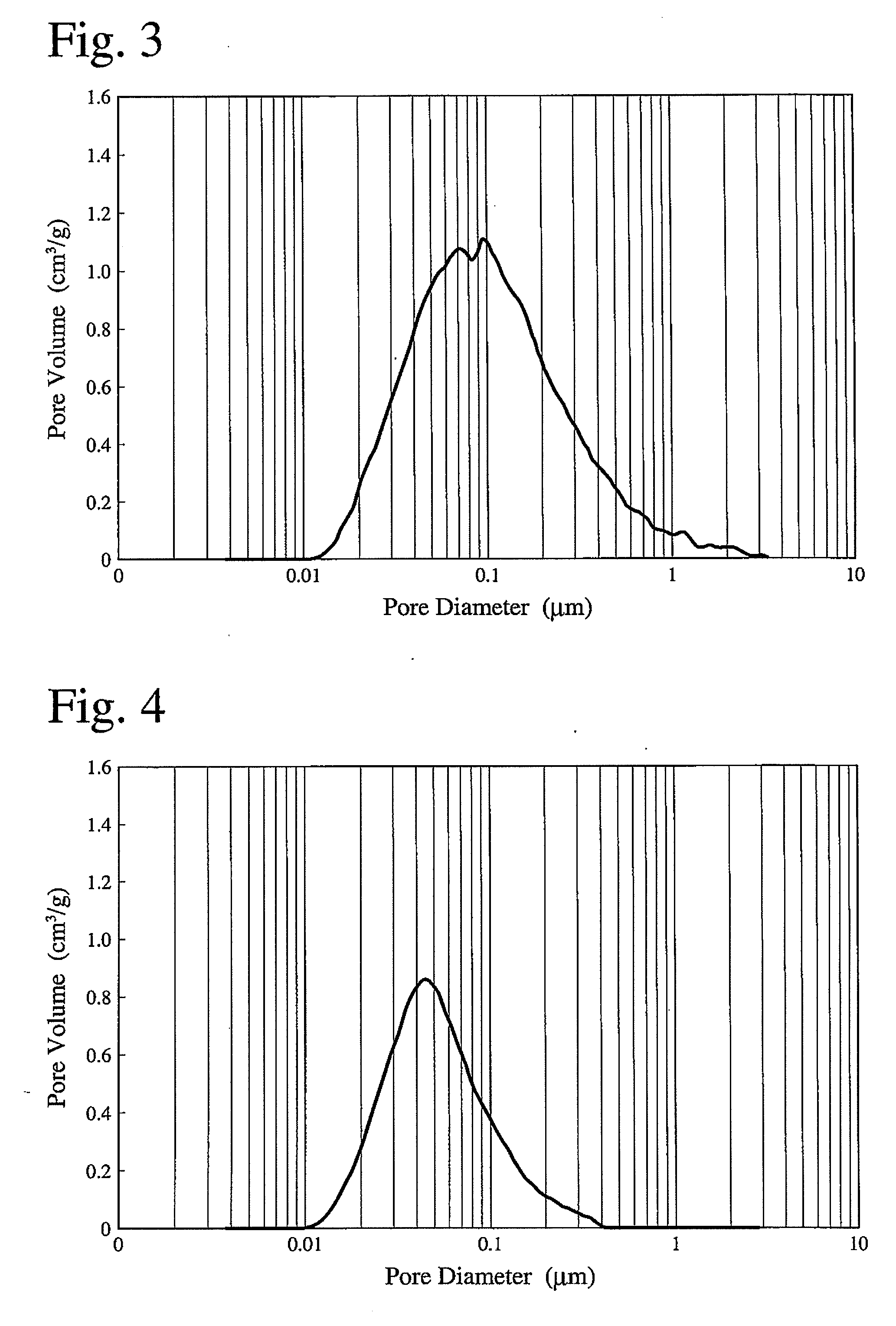

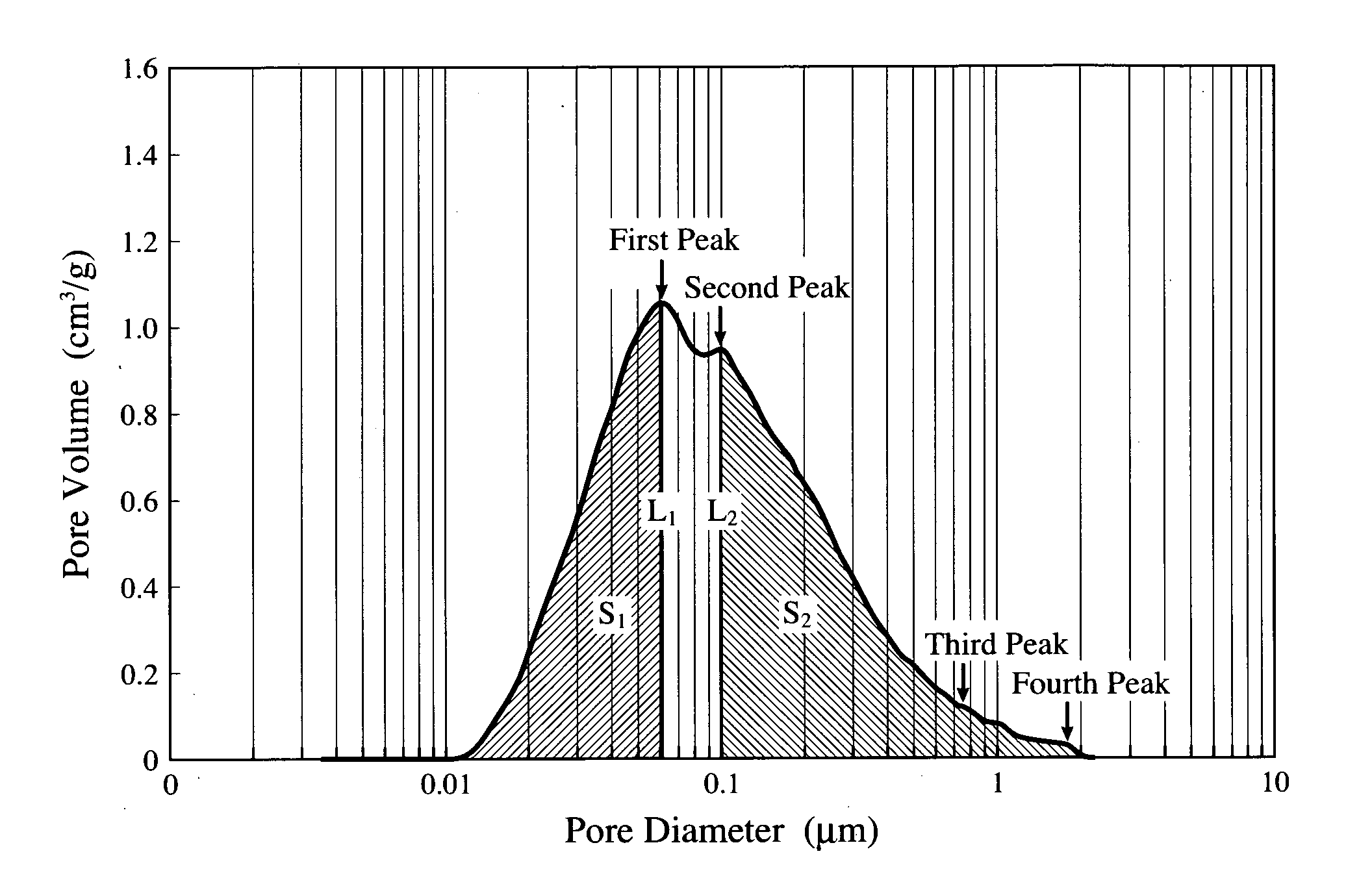

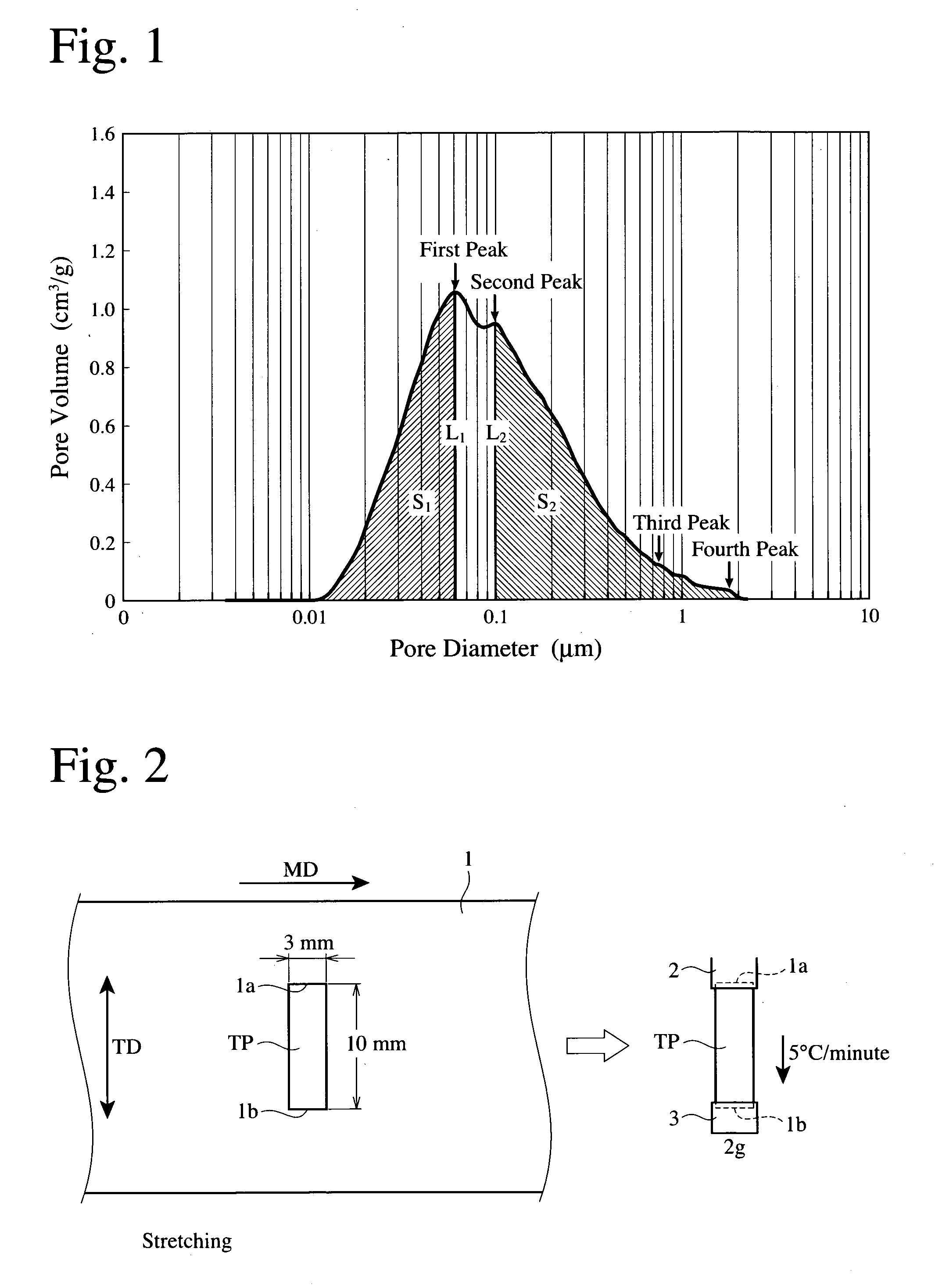

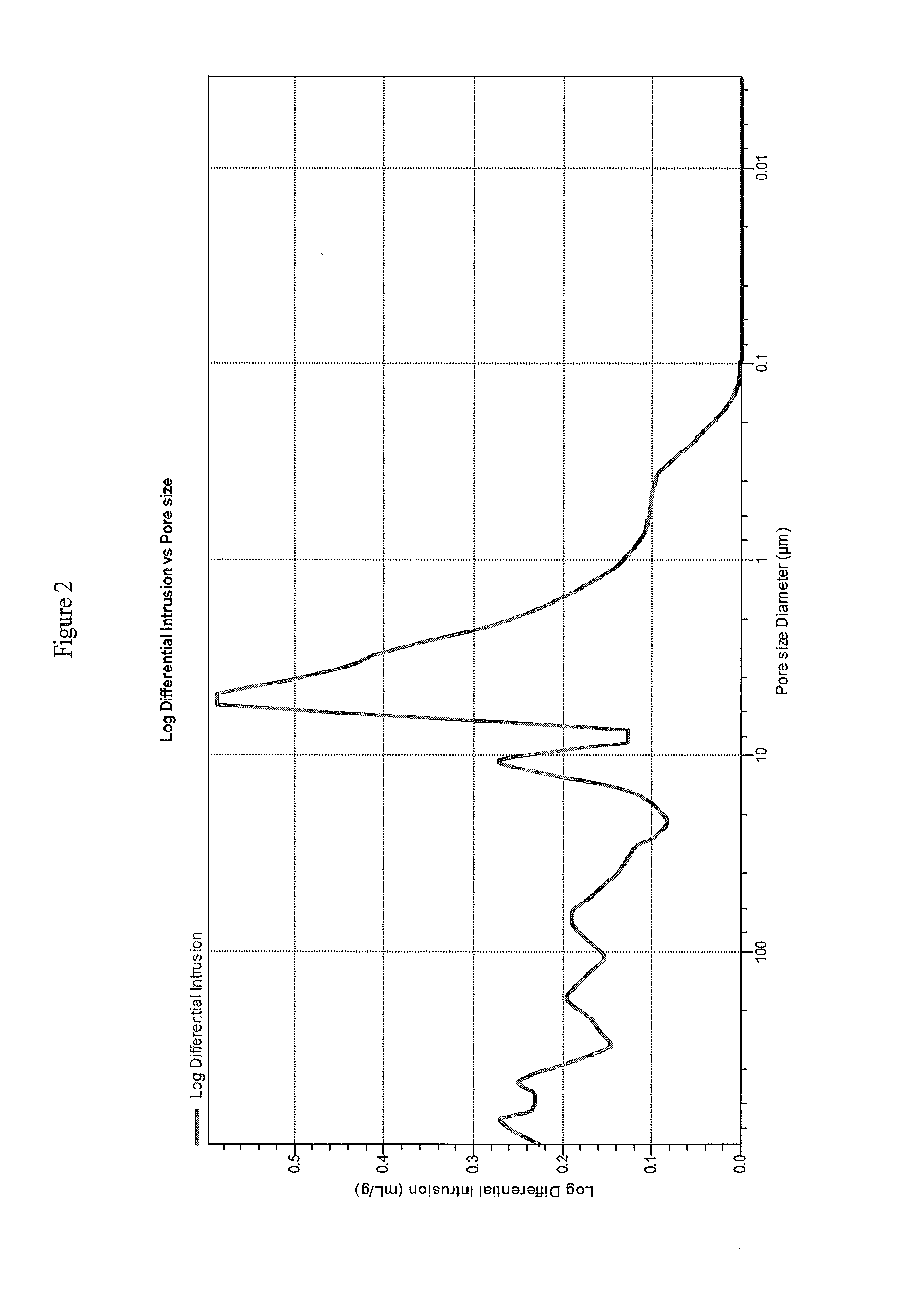

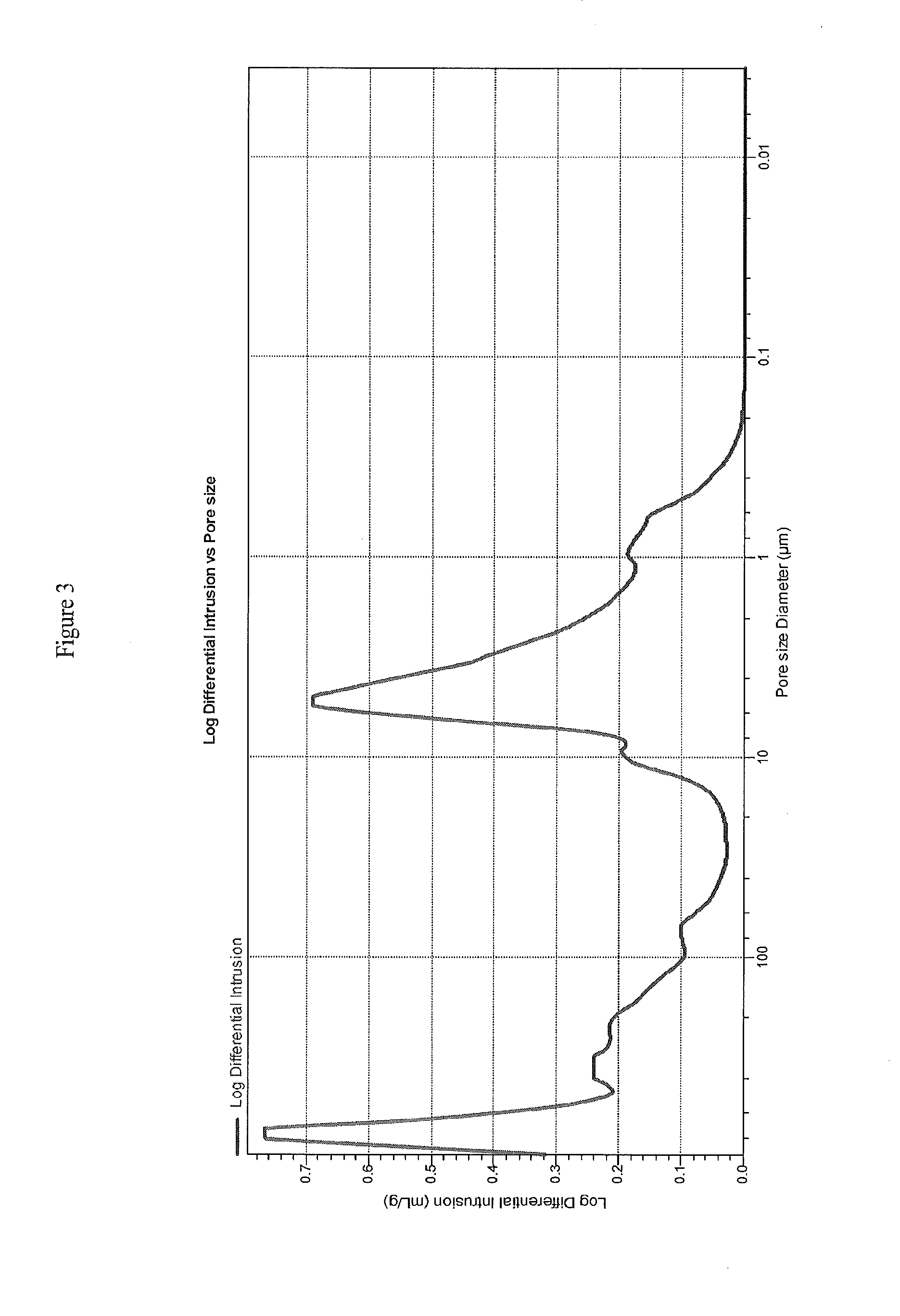

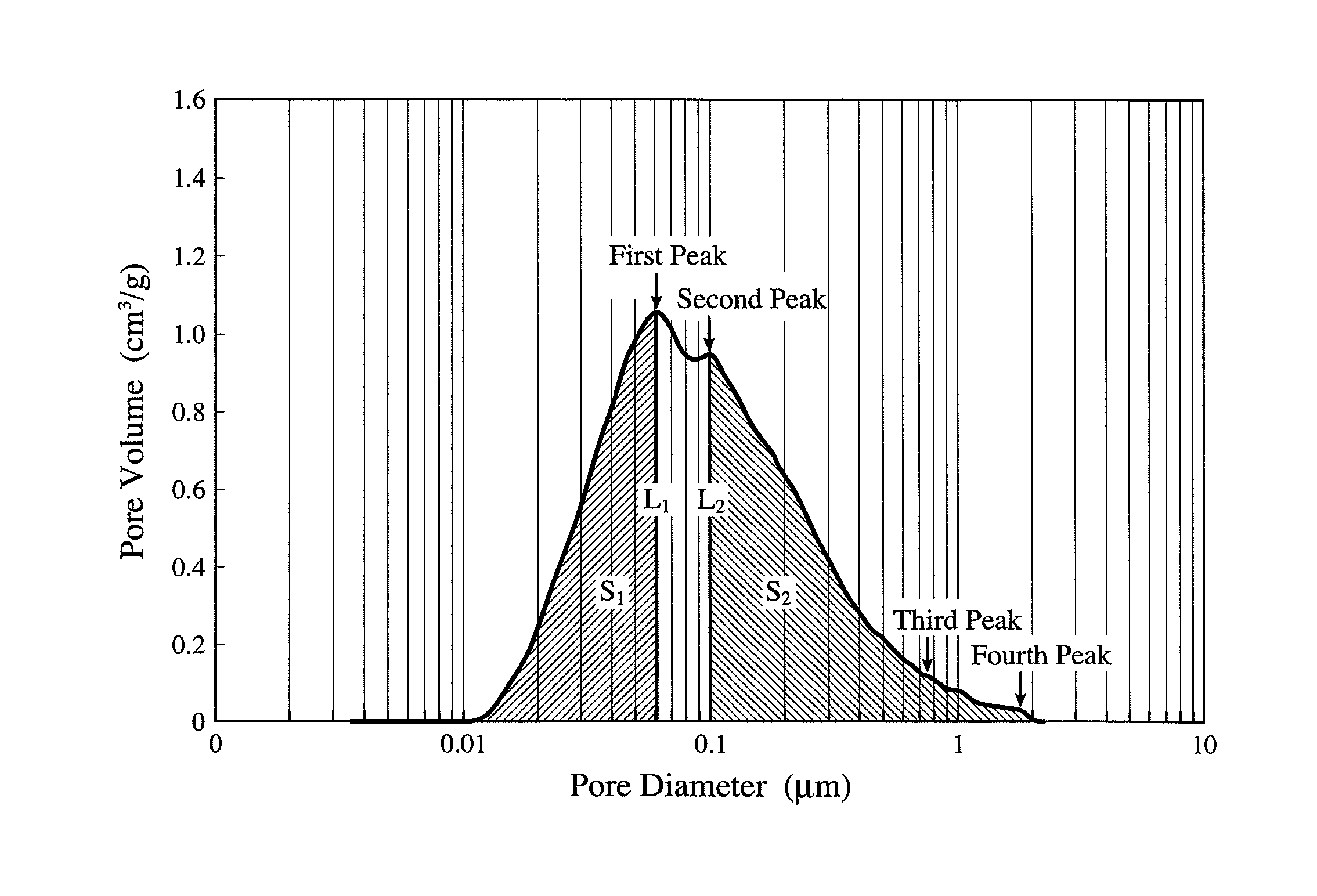

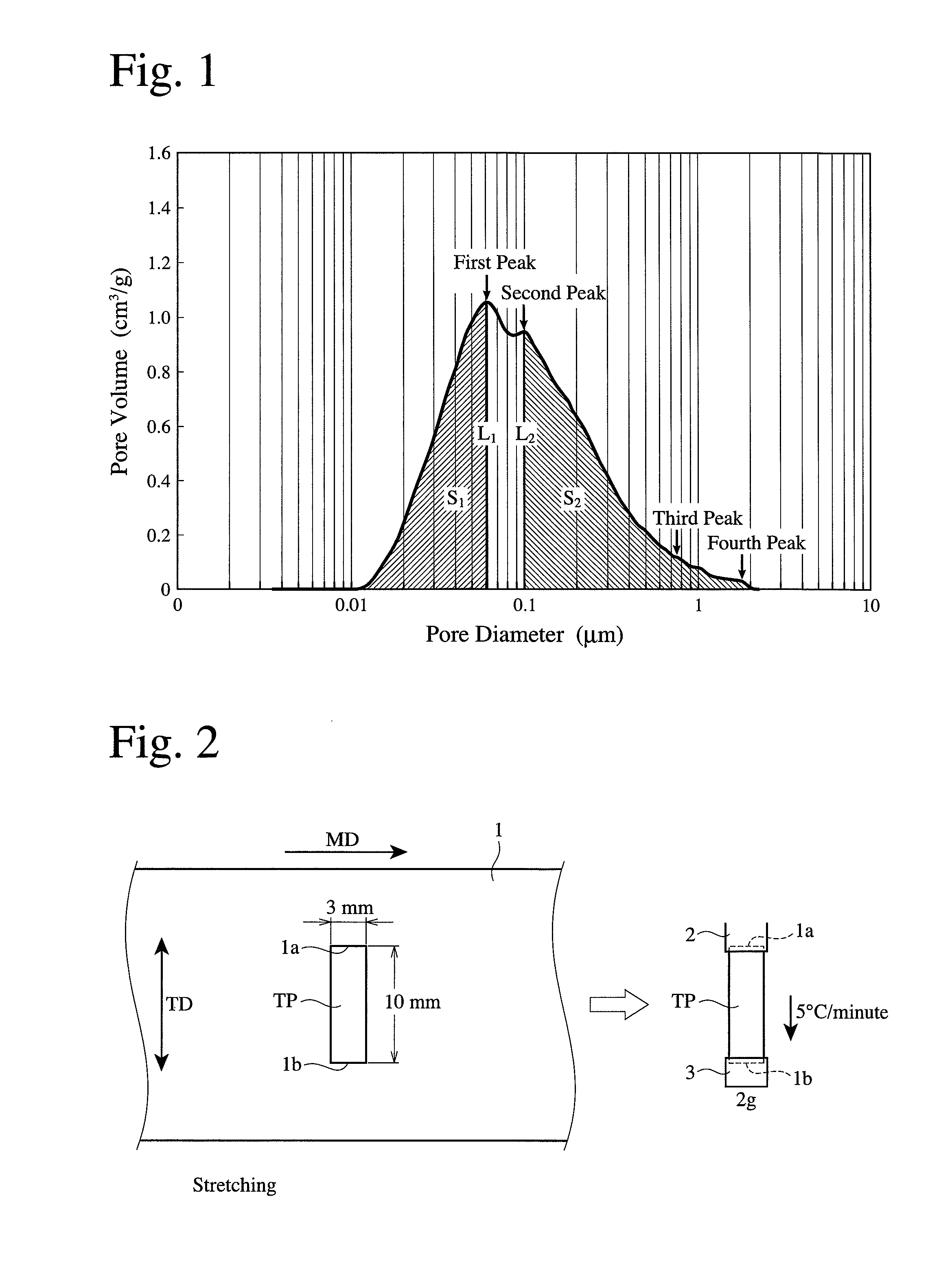

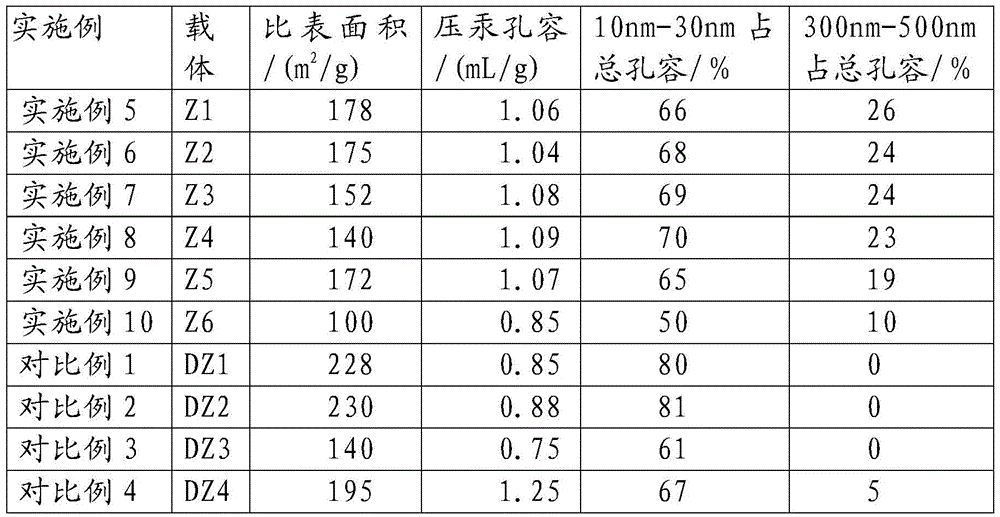

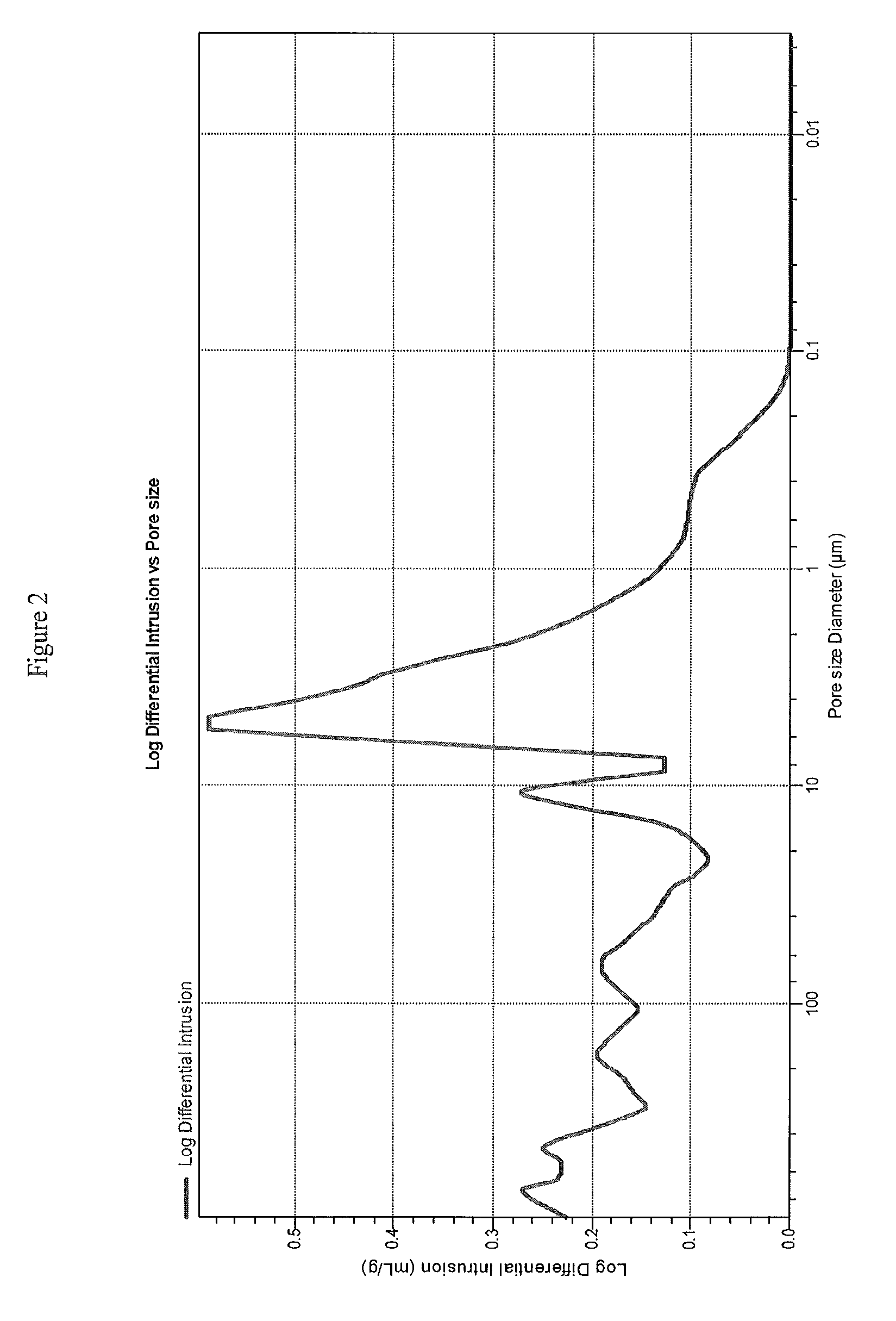

A microporous polyolefin membrane having a structure in which its pore size distribution curve obtained by mercury intrusion porosimetry has at least two peaks, which is produced by extruding a melt-blend of a polyolefin composition comprising (a) high density polyethylene resin having a weight average molecular weight of from about 2.5×105 to about 5×105 and a molecular weight distribution of from about 5 to about 100, (b) polypropylene resin having a weight average molecular weight of from about 3×105 to about 1.5×106 and a molecular weight distribution of from about 1 to about 100, and (c) ultra-high molecular weight polyethylene resin having a weight average molecular weight of about 5×105 or higher, and a membrane-forming solvent, cooling the extrudate to form a high resin content gel-like sheet, stretching the gel-like sheet at a high stretching temperature to form a stretched gel-like sheet, removing the membrane-forming solvent from the stretched gel-like sheet to form a membrane, stretching the membrane to a high magnification to form a stretched membrane, and heat-setting the stretched microporous membrane to form the microporous membrane.

Owner:TORAY IND INC

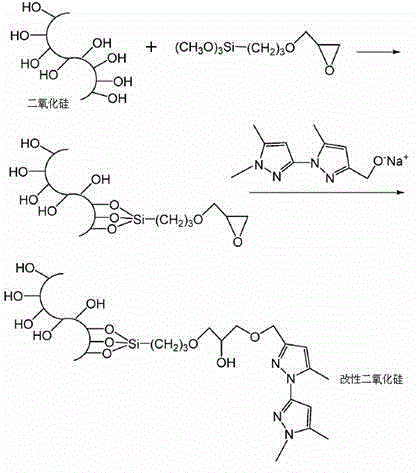

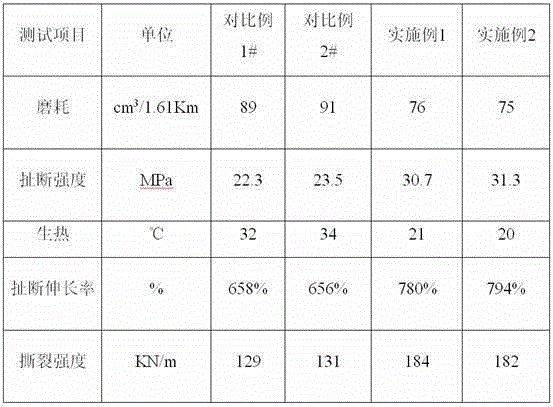

High-specific-area white carbon black and production method thereof

The invention provides a high-specific-area white carbon black and a production method thereof. The SBET of the white carbon black is 200-450 m<2> / g, the SBET / SCTAB is less than or equal to 1.2, and the total volume of pores with the diameter of 100-30nm is 40% greater than the total volume of pores with the diameter of less than or equal to 50nm when a mercury intrusion process is used for measuring pore size distribution. The high-specific-area white carbon black has high specific area and porous structure, so that the prepared rubber product has the advantages of favorable wear resistance, favorable tensile strength at break and the like.

Owner:QUECHEN SILICON CHEM

Microporous polyolefin membrane, its production method, battery separator, and battery

InactiveUS20090286161A1Promote absorptionImprove permeabilityNon-aqueous electrolyte accumulatorsCell component detailsPolymer sciencePolyolefin

Owner:TONEN CHEM CORP

Polyolefin composition, its production method, and a battery separator made therefrom

InactiveUS20100003591A1Promote absorptionExcellent characteristicsCell seperators/membranes/diaphragms/spacersSynthetic resin layered productsPolyolefinPolymer science

The invention relates to a polyolefin composition. The polyolefin composition can be in the form of a multi-layer, microporous polyolefin membrane comprising a first microporous layer containing 7% or less by mass of ultra-high-molecular-weight polyethylene having a weight-average molecular weight of 1×106 or more, and having a structure in which a pore size distribution curve obtained by mercury intrusion porosimetry has at least two peaks, and a second microporous layer containing 8% or more by mass of the ultra-high-molecular-weight polyethylene.

Owner:TORAY IND INC

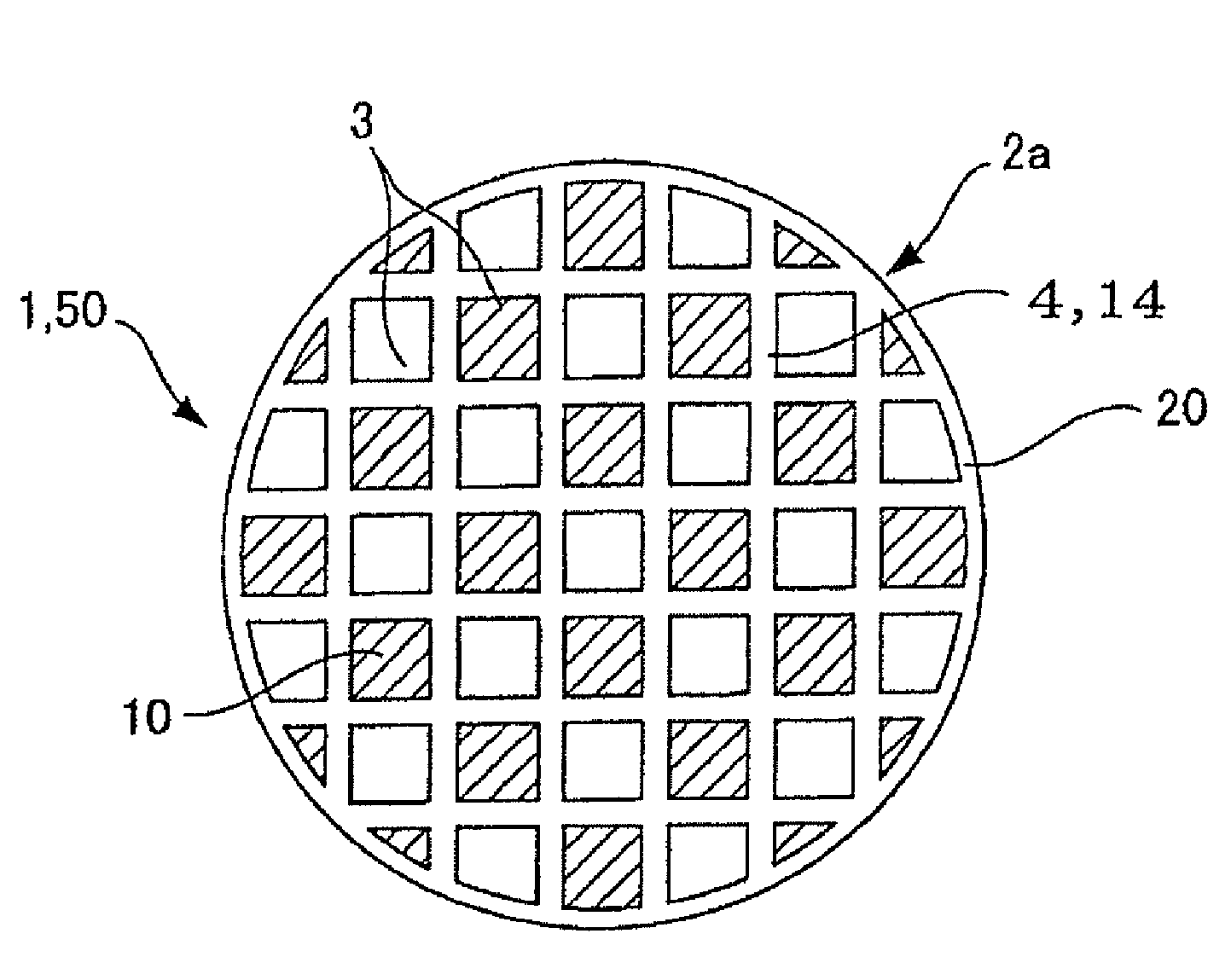

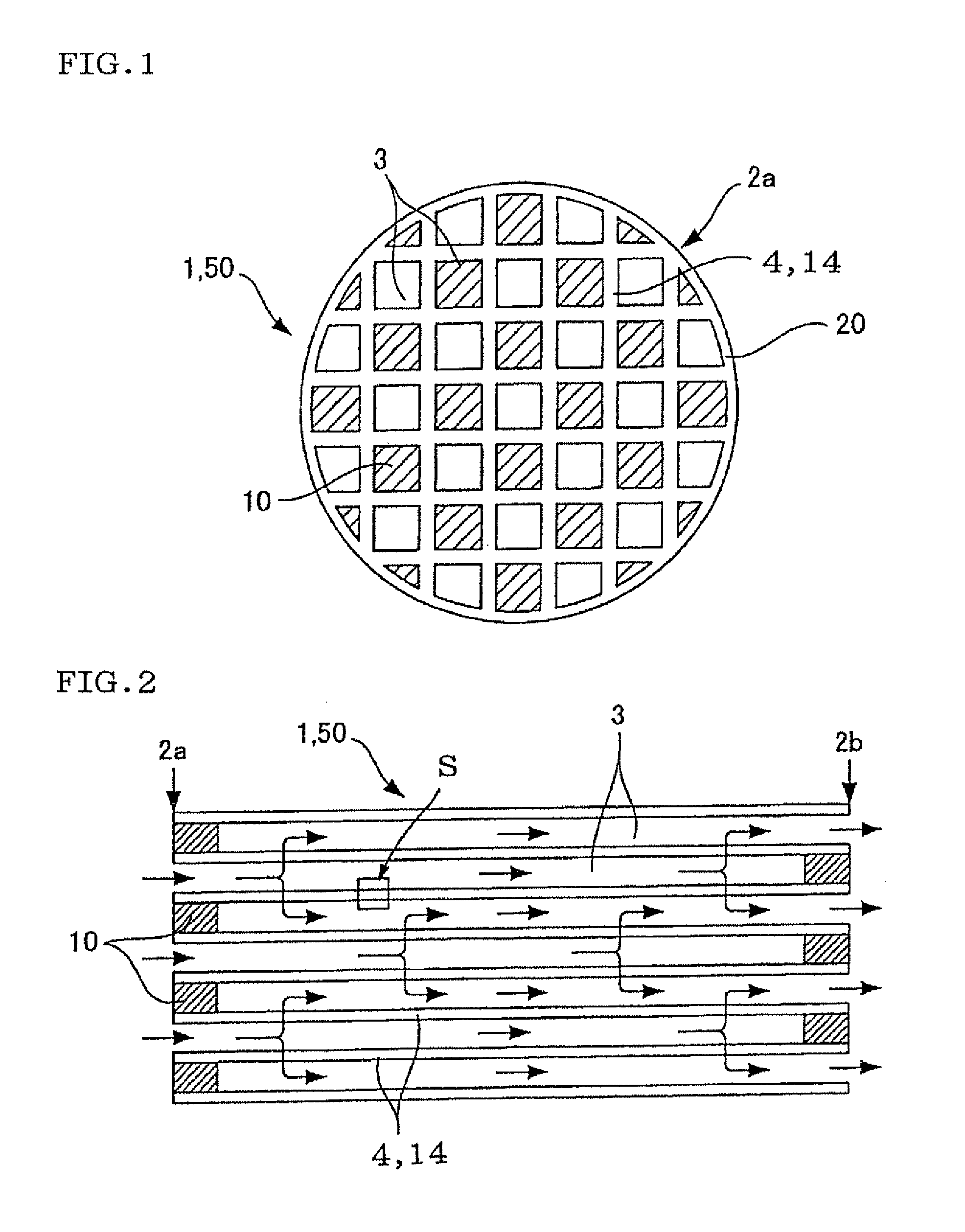

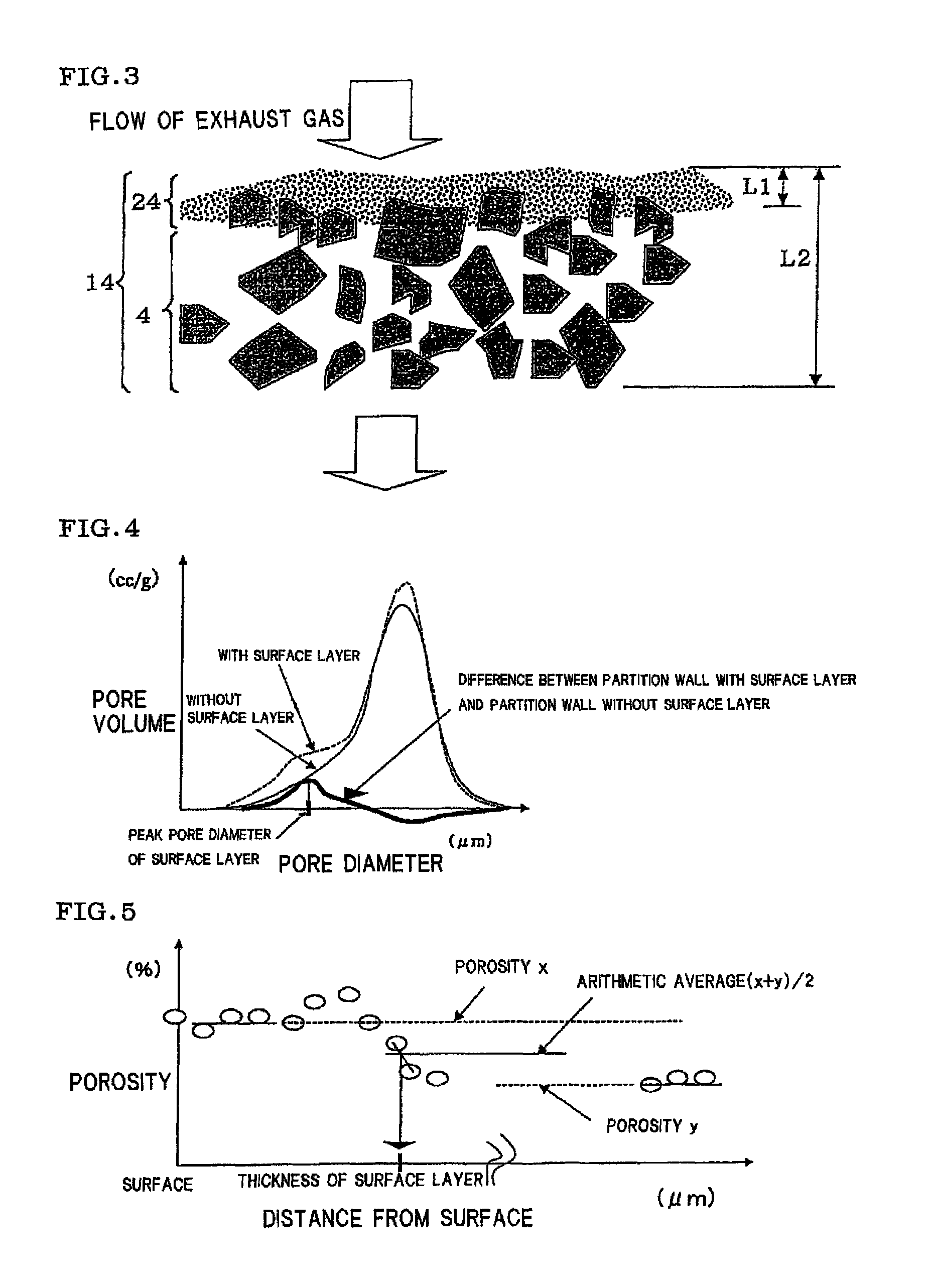

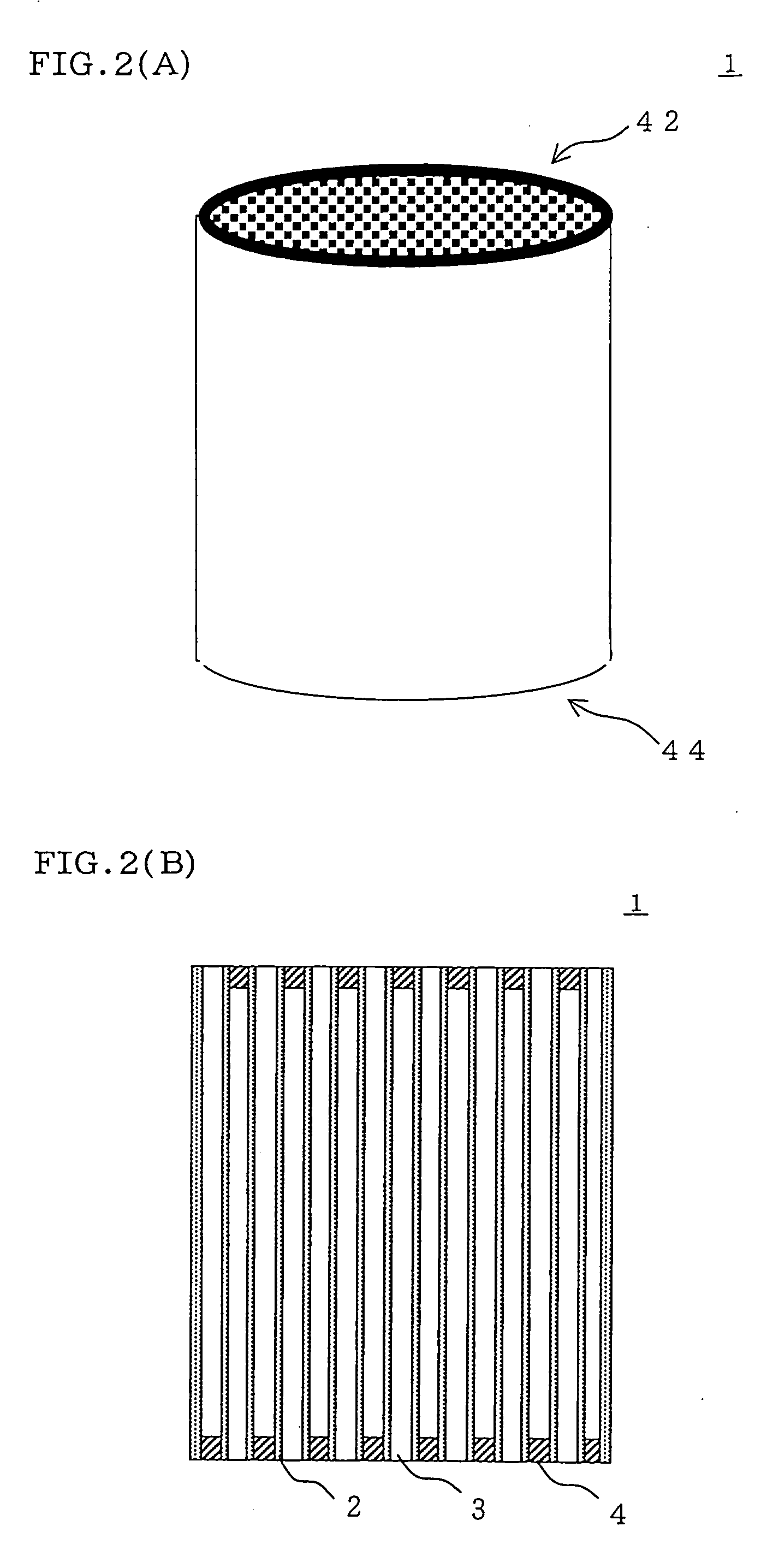

Honeycomb filter

ActiveUS8444739B2Efficient trappingLower performance requirementsCombination devicesGas treatmentSurface layerFiltration

Owner:NGK INSULATORS LTD

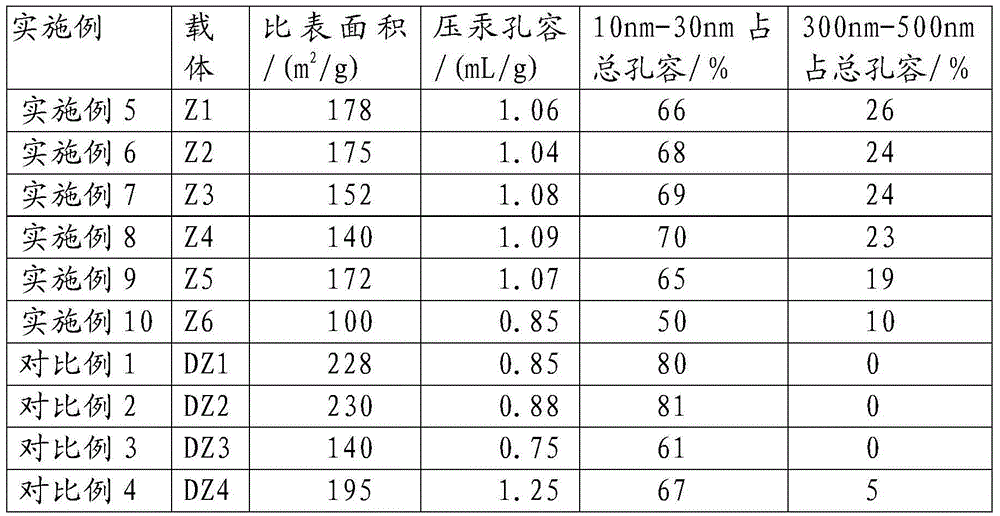

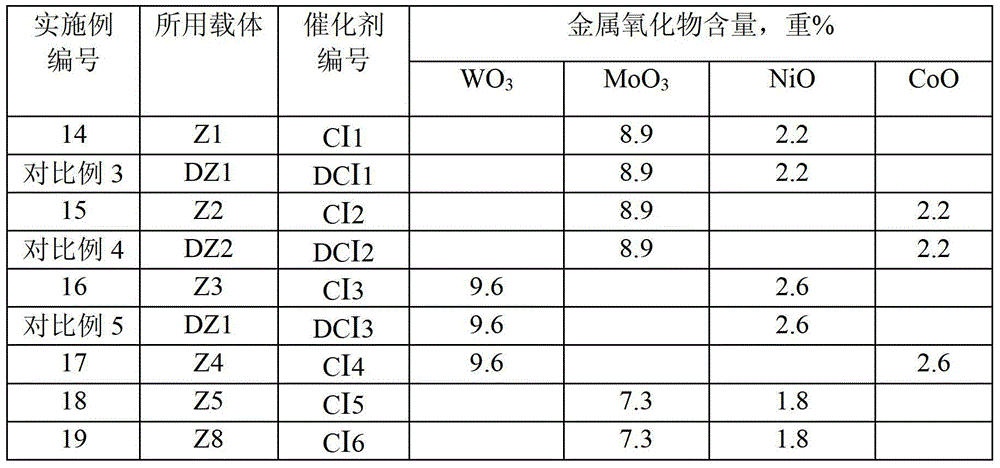

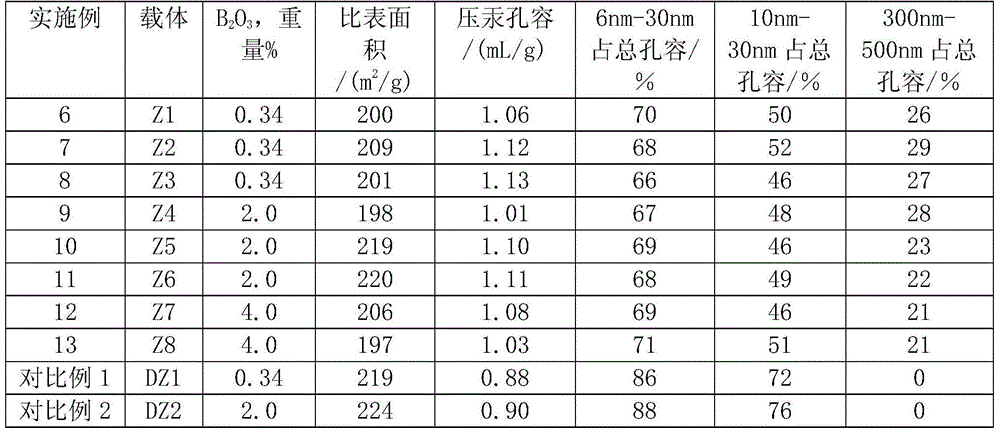

Selective hydrodesulfurization catalyst, and preparation and application thereof

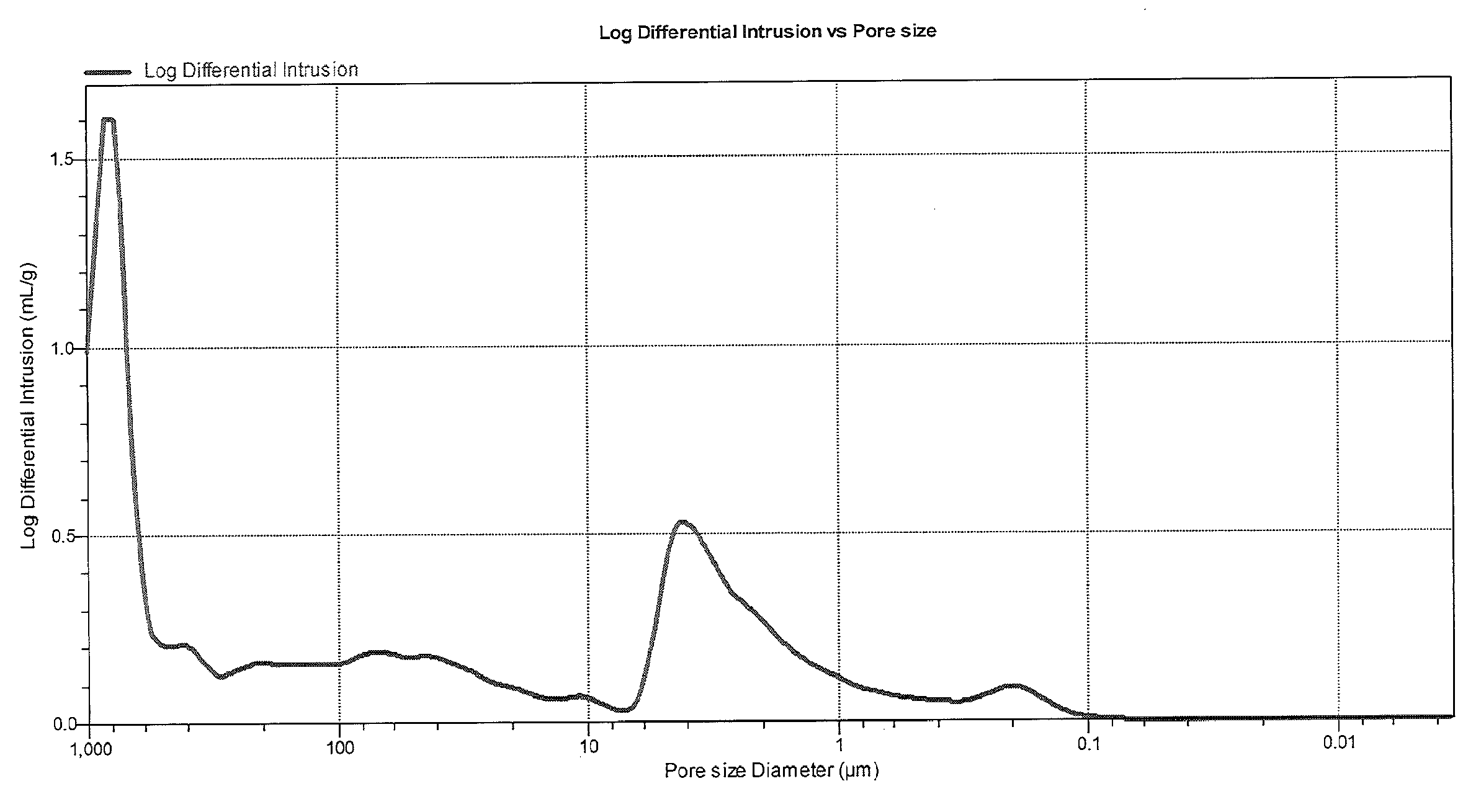

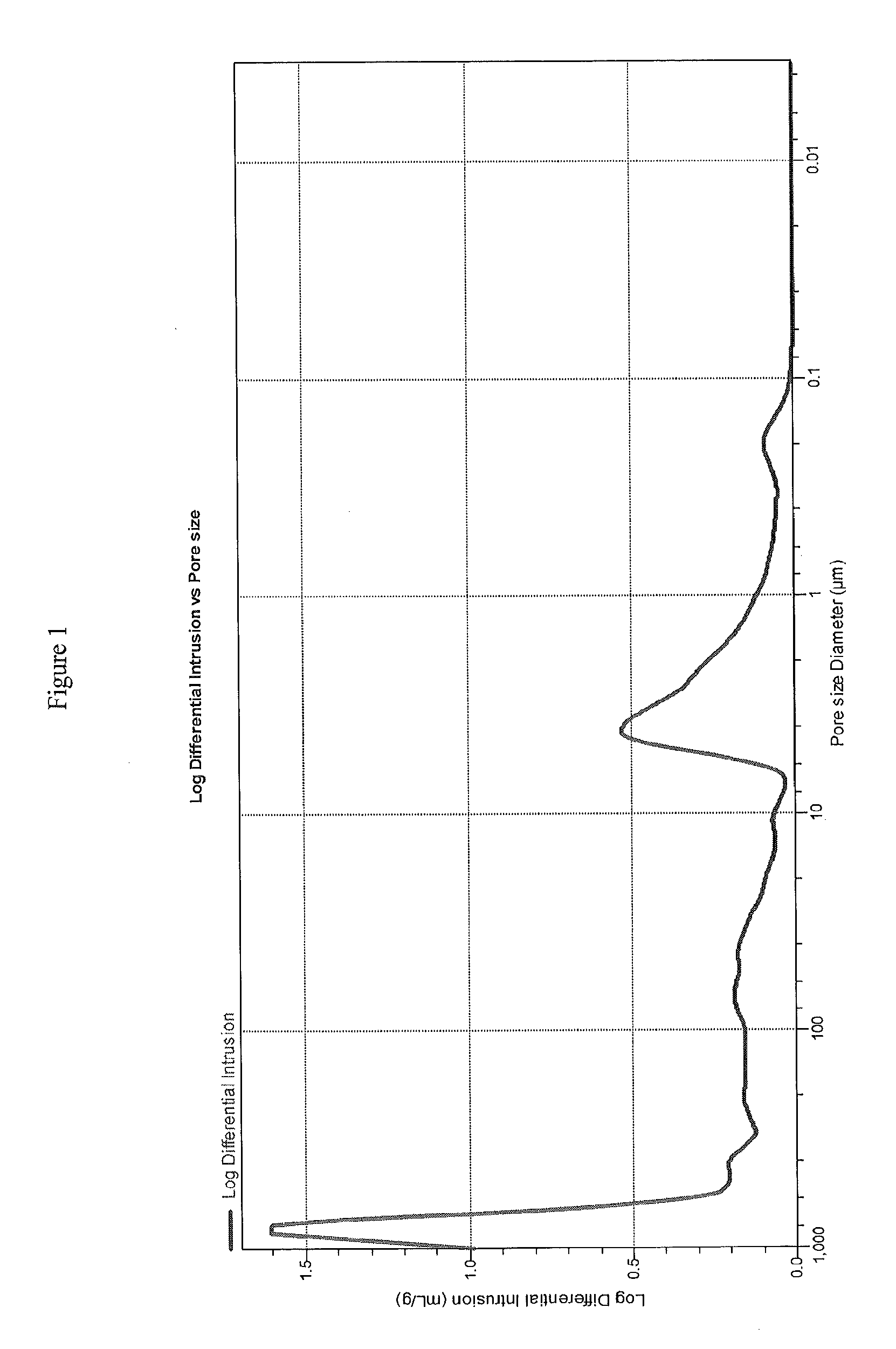

The invention discloses a selective hydrodesulfurization catalyst, and preparation and application thereof. The catalyst comprises a carrier, at least one non-noble metal composition selected from group VIII and supported on the carrier, at least one metal composition selected from group VI B, and one or more of organics selected from alcohols, organic acids and organic amines. Based on the catalyst in terms of oxides, the mass fraction of the group VIII metal composition is 0.1-6%, the mass fraction of the group VI B metal composition is 1-25%, and the molar ratio of the organic to the group VIII metal composition is 0.5-2.5. The carrier is double-peak porous aluminium oxide, and characterized by mercury intrusion porosimetry, the carrier has the pore volume of 0.9-1.2 mL / g and the specific surface area of 50-300 m<2> / g, the pore volume of pores with the diameter of 10-30 nm accounts for 55-80% of the total pore volume, and the pore volume of pores with the diameter of 300-500 nm accounts for 10-35% of the total pore volume. Compared with the prior art, the provided catalyst is especially applied to hydrofining processes of coked gasoline and catalytically-cracked gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

Porous inorganic body

InactiveUS20130231493A1Increase pressureOrganic chemistryLayered productsMicrometerMaterials science

The present invention relates to a porous inorganic body comprising pores A having a pore size SA in the range of from 0.005 to 20 micrometer and a total pore volume VA, and comprising pores B having a pore size SB in the range of from more than 20 to 1000 micrometer and a total pore volume VB, wherein the total pore volume of the pores having a pore size in the range of from 0.005 to 1000 micrometer is VC and wherein the ratio RA=VA / VC is in the range of from 0.3 to 0.7 as determined via mercury intrusion porosimetry.

Owner:BASF AG

Microporous Polyolefin Membrane And Manufacturing Method

ActiveUS20090087749A1High mechanical strengthImprove permeabilityElectric discharge tubesCell component detailsPolyolefinDiluent

A microporous membrane having a structure in which its pore size distribution curve obtained by mercury intrusion porosimetry has at least two peaks, which is produced by extruding a combination of a diluent or solvent and a polyolefin resin composition comprising from about 75 to about 99% of a polyethylene resin having a weight average molecular weight of from about 2.5×105 to about 5×105 and a molecular weight distribution of from about 10 to about 100, and from about 1 to about 25% polypropylene resin having a weight average molecular weight of from about 1×104 to about 4×106, a heat of fusion of 80 J / g or higher, and a molecular weight distribution of from about 1 to about 100, percentages based on the mass of the polyolefin composition; cooling the extrudate to form a high polyolefin content cooled extrudate; stretching the cooled extrudate at a high stretching temperature to form a stretched sheet; removing the diluent or solvent from the stretched sheet to form a membrane; stretching the membrane to a high magnification in at least one direction to form a stretched membrane; and heat-setting the stretched membrane to form the microporous membrane.

Owner:TORAY IND INC

Organic/inorganic composite filler and manufacturing method therefor

ActiveUS20130005846A1High strengthEasy to operateMaterial nanotechnologyLiquid surface applicatorsMean diameterMaterials science

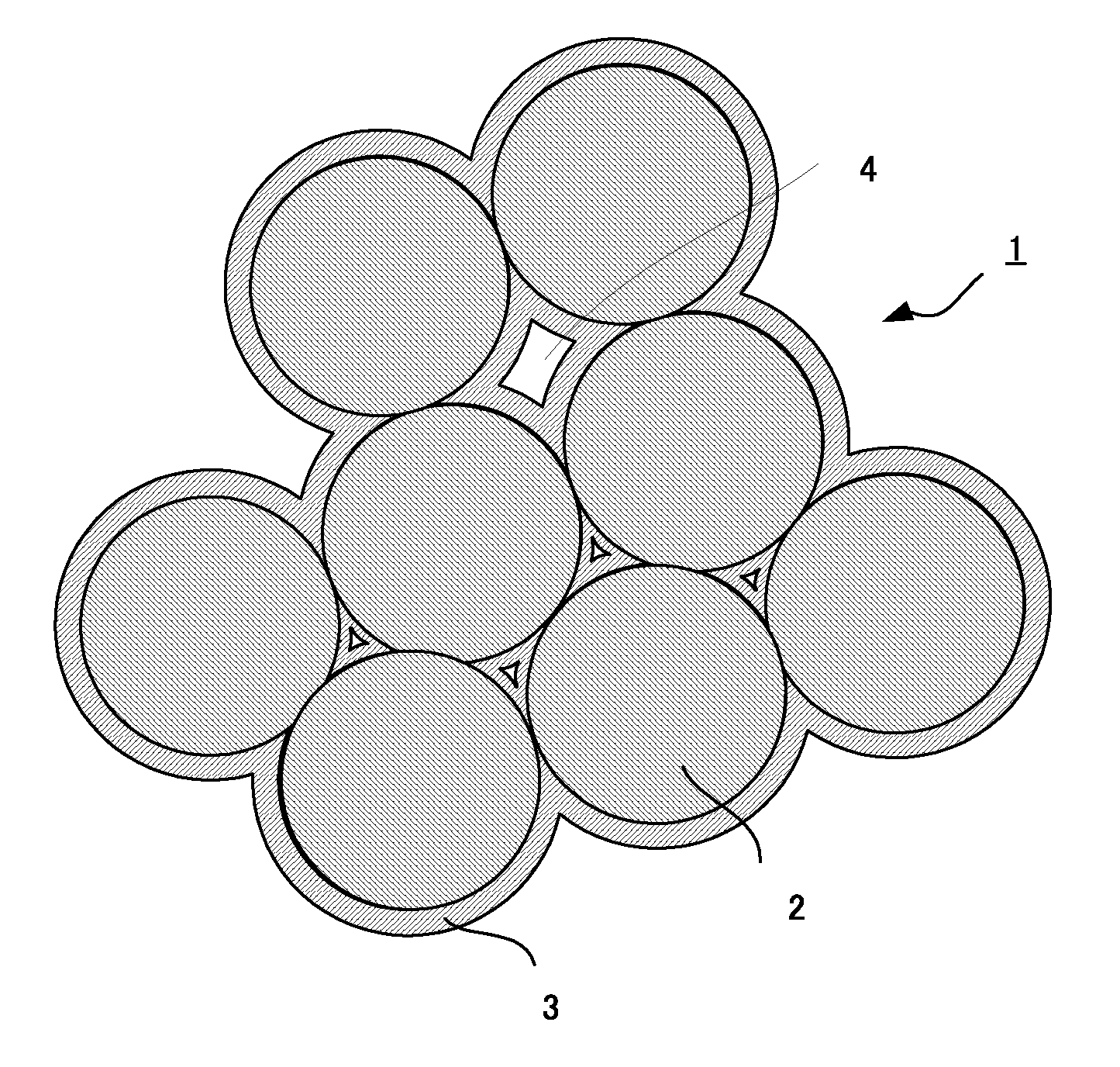

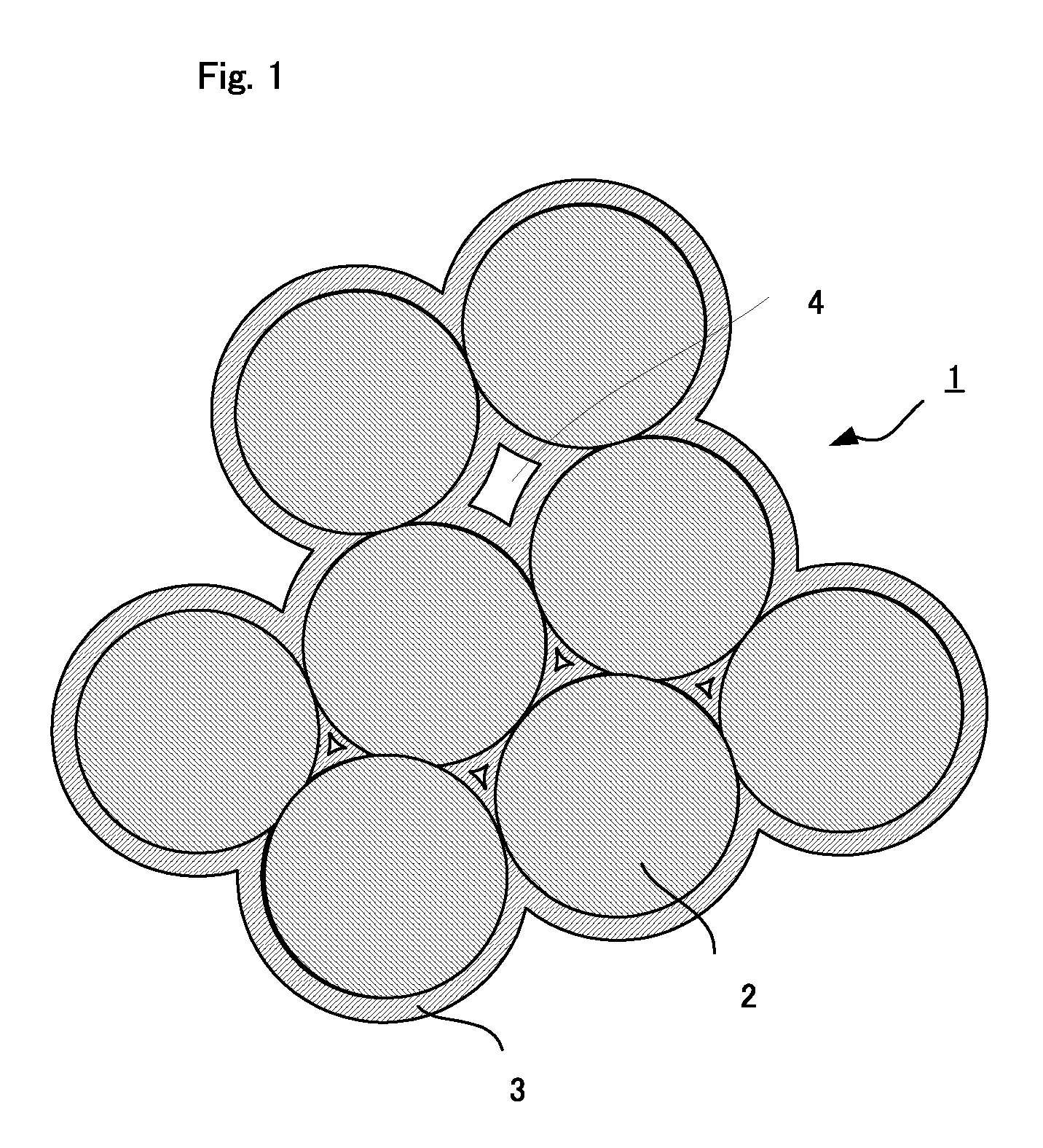

Disclosed is an organic / inorganic composite filler that contains: inorganic agglomerated particles comprising agglomerations of inorganic primary particles having a mean diameter between 10 and 1000 nm; an organic resin phase that covers the surface of each inorganic primary particle and binds the inorganic primary particles to each other; and intra-agglomerate voids, formed between the organic resin phase covering the surface of each inorganic primary particle, with a pore volume (here, “pore” refers to holes with diameters between 1 and 500 nm) between 0.01 and 0.30 cm3 / g as measured by mercury intrusion porosimetry. Also disclosed is a method for manufacturing the above organic / inorganic composite filler.

Owner:TOKUYAMA DENTAL CORP

Honeycomb filter and method of manufacturing the same

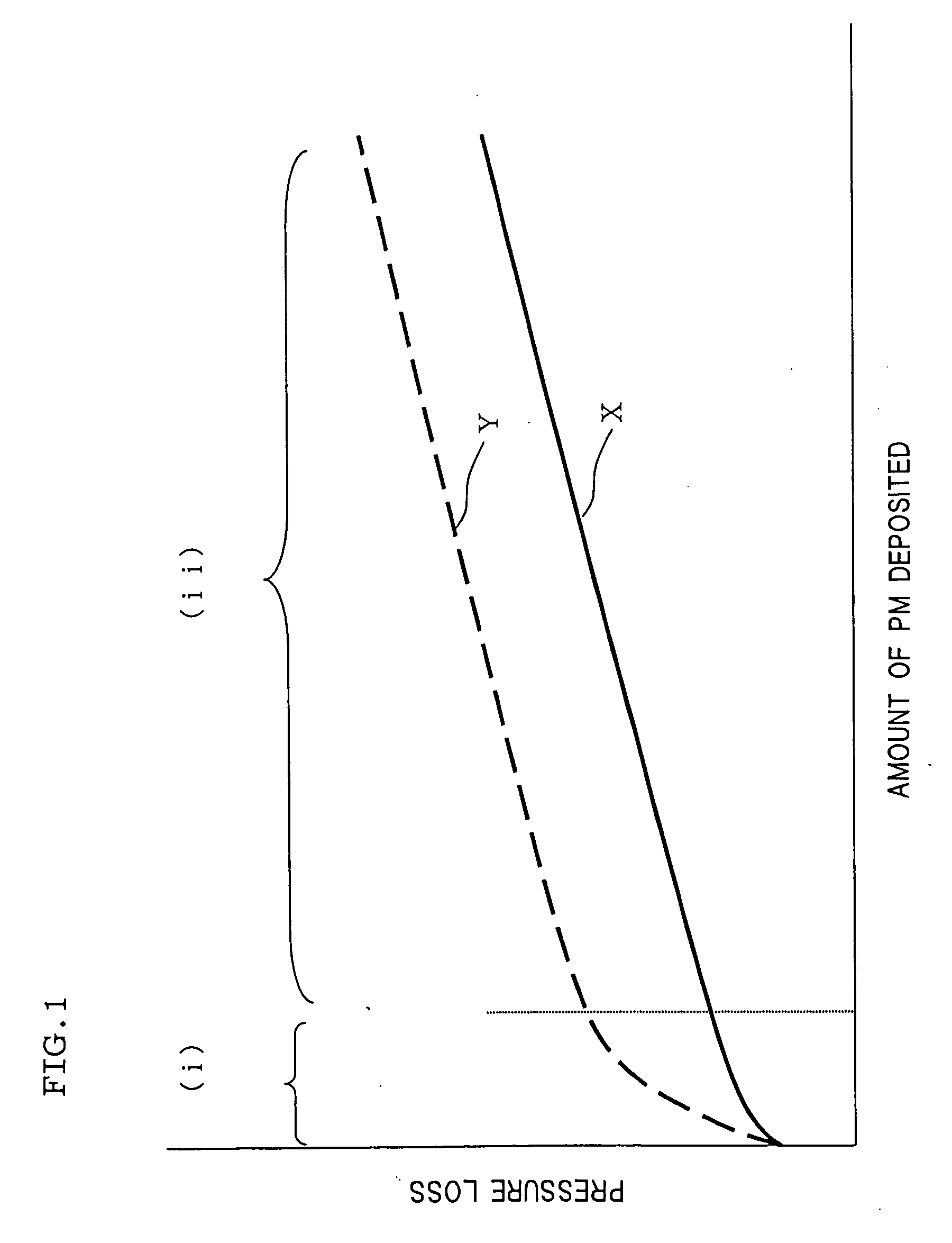

ActiveUS20060107641A1Increased pressure lossAccurate detectionCombination devicesAuxillary pretreatmentHoneycombPore diameter

A honeycomb filter includes partition walls forming a plurality of cells extending in one direction, and plugging sections alternately plugging the cells at the ends of the honeycomb filter, the partition walls being formed of a porous base material having a porosity of 45 to 70%. When the average pore size of the base material measured by mercury porosimetry is (A) μm and the average pore size of the base material measured by a bubble point method is (B) μm, the average pore size differential rate expressed by “{(A−B) / B}*100” is 35% or less, and the maximum pore size of the base material measured by the bubble point method is 150 μm or less.

Owner:NGK INSULATORS LTD

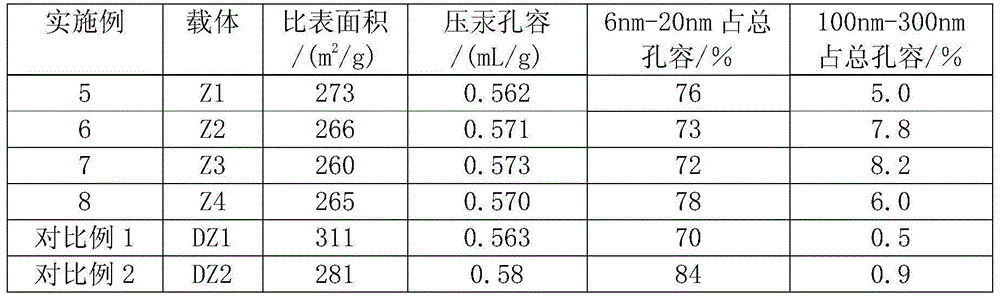

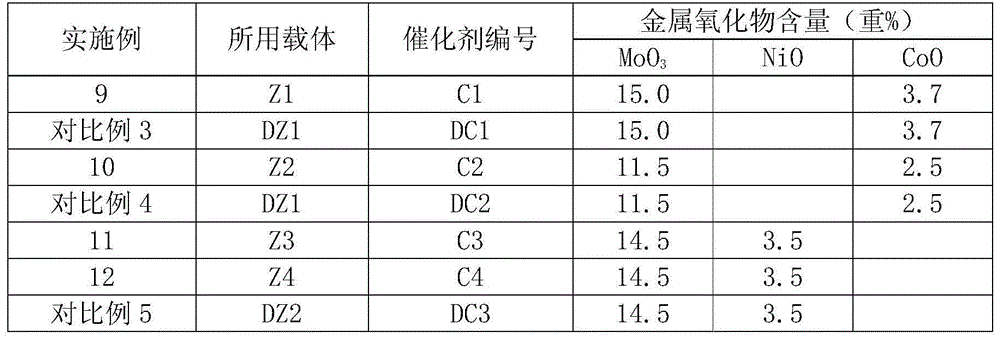

Heavy-oil hydrotreatment catalyst, and preparation and application thereof

ActiveCN104437517ACatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsHydrodesulfurizationFuel oil

The invention discloses a heavy-oil hydrotreatment catalyst, and preparation and application thereof. The catalyst comprises an aluminium oxide carrier and a hydrogenation active metal composition. The carrier has a double-peak pore structure, and characterized by mercury intrusion porosimetry, the carrier has the pore volume larger than 0.4 mL / g and less than 0.8 mL / g and the specific surface area of 100-400 m<2> / g, the pore volume of pores with the diameter of 6-20 nm accounts for 60-90% of the total pore volume, and the pore volume of pores with the diameter of 100-300 nm accounts for 3-20% of the total pore volume. Compared with the prior art, the provided catalyst has relatively good hydrodesulfurization performance when being applied to residuum hydrotreatment.

Owner:CHINA PETROLEUM & CHEM CORP +1

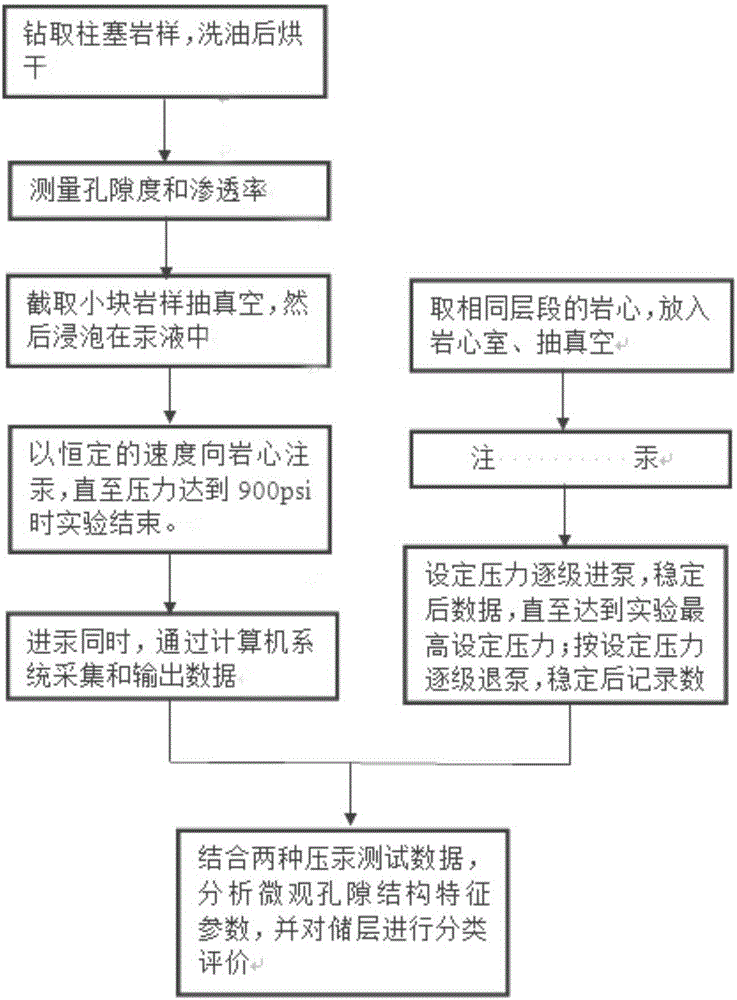

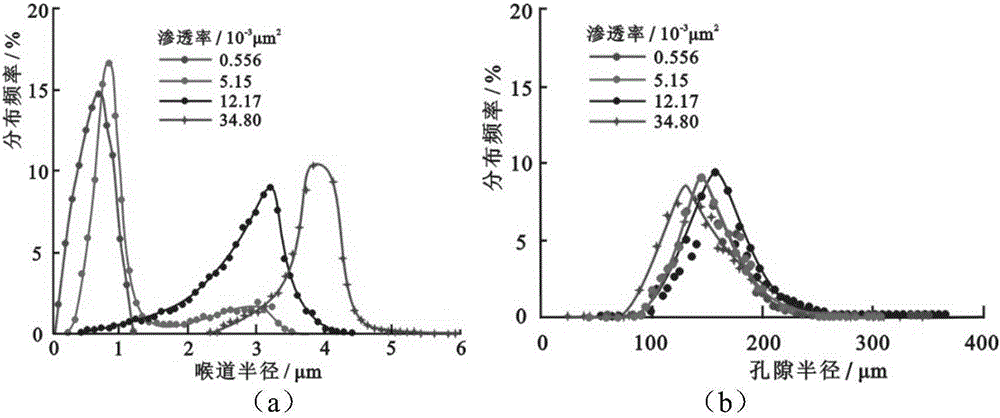

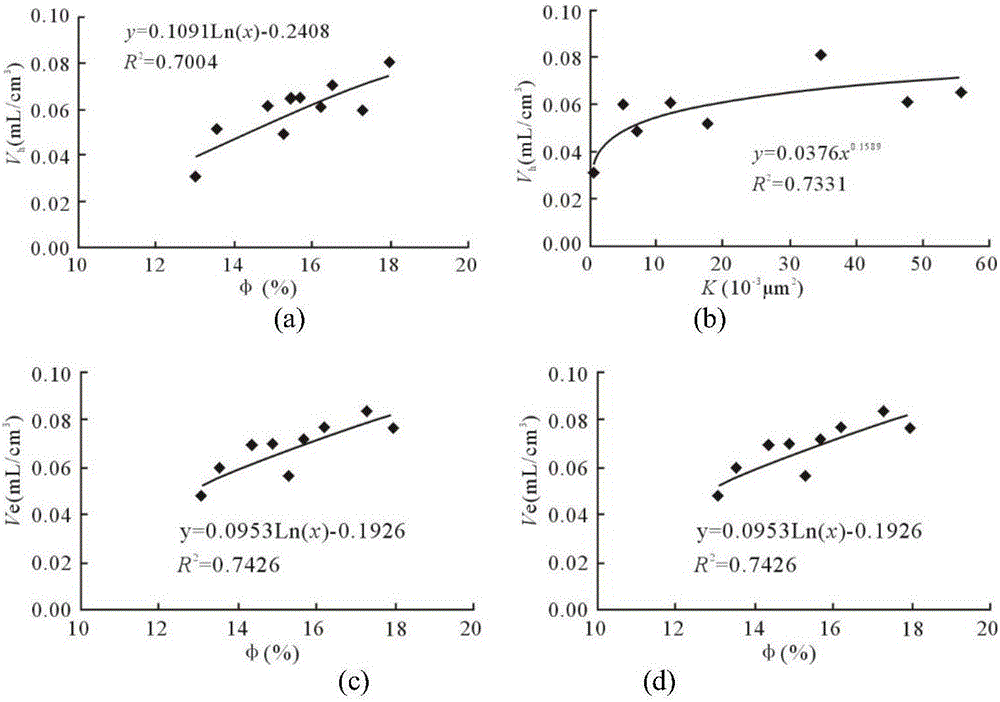

Method for quantitative evaluation of characteristics of micro-pore structure of deeply-buried high-pressure low-permeability sandstone reservoir stratum

InactiveCN106442262AAccurate minimum throat radiusPermeability/surface area analysisPorosityData acquisition

The invention discloses a method for quantitative evaluation of characteristics of a micro-pore structure of a deeply-buried high-pressure low-permeability sandstone reservoir stratum. The method comprises the following steps of: measuring the porosity and permeability of a standard rock core after oil washing and drying; vacuumizing a small rock sample cut from a plunger rock sample, and soaking the small rock sample in a mercury solution; injecting mercury into the rock core at a constant speed of 0.00005mL / min, and ending the experiment when the pressure reaches a highest value 900psi for a constant speed mercury injection apparatus; while the mercury is injected, performing real-time monitoring and automatic data acquisition and output by virtue of a computer; performing a high-pressure mercury injection experiment by using a standard plunger rock sample from a same stratum; and finally, taking a product of an efficiency of mercury ejection (EW) and the saturation degree of mercury ejection (SE) as a parameter index for classified evaluation of the micro-pore structure of the reservoir stratum, namely a comprehensive evaluation parameter E (E=EW*SE) of the micro-pore structure of the reservoir stratum, and judging the characteristics of the micro-pore structure according to distribution of E. According to the method disclosed by the invention, a relative accurate pore throat characteristic parameter is obtained by virtue of an experiment, and the defects of analysis with application of two mercury injection methods respectively are overcome.

Owner:XI'AN PETROLEUM UNIVERSITY

Microporous Membrane And Manufacturing Method

ActiveUS20090087750A1High mechanical strengthImprove permeabilityMembranesSemi-permeable membranesPolyolefinDiluent

A microporous membrane having a structure in which its pore size distribution curve obtained by mercury intrusion porosimetry has at least two peaks, which is produced by extruding a combination of a diluent or solvent and a polyolefin resin composition comprising (a) from about 74 to about 99% of a first polyethylene resin having a weight average molecular weight of from about 2.5×105 to about 5×105 and a molecular weight distribution of from about 5 to about 100, (b) from about 1 to about 5% of a second polyethylene resin having a weight average molecular weight of from about 5×105 to about 1×106 and a molecular weight distribution of from about 5 to about 100, and (c) from 0 to about 25% of a polypropylene resin having a weight average molecular weight of from about 3×105 to about 1.5×106, a molecular weight distribution of from about 1 to about 100, and a heat of fusion of 80 J / g or higher, percentages based on the mass of the polyolefin composition; cooling the extrudate to form a high polyolefin content cooled extrudate; stretching the cooled extrudate in at least one direction at a high stretching temperature to form a stretched sheet; removing at least a portion of the diluent or solvent from the stretched sheet to form a membrane; stretching the membrane to a high magnification in at least one direction to form a stretched membrane; and heat-setting the stretched membrane to form the microporous membrane.

Owner:TORAY IND INC

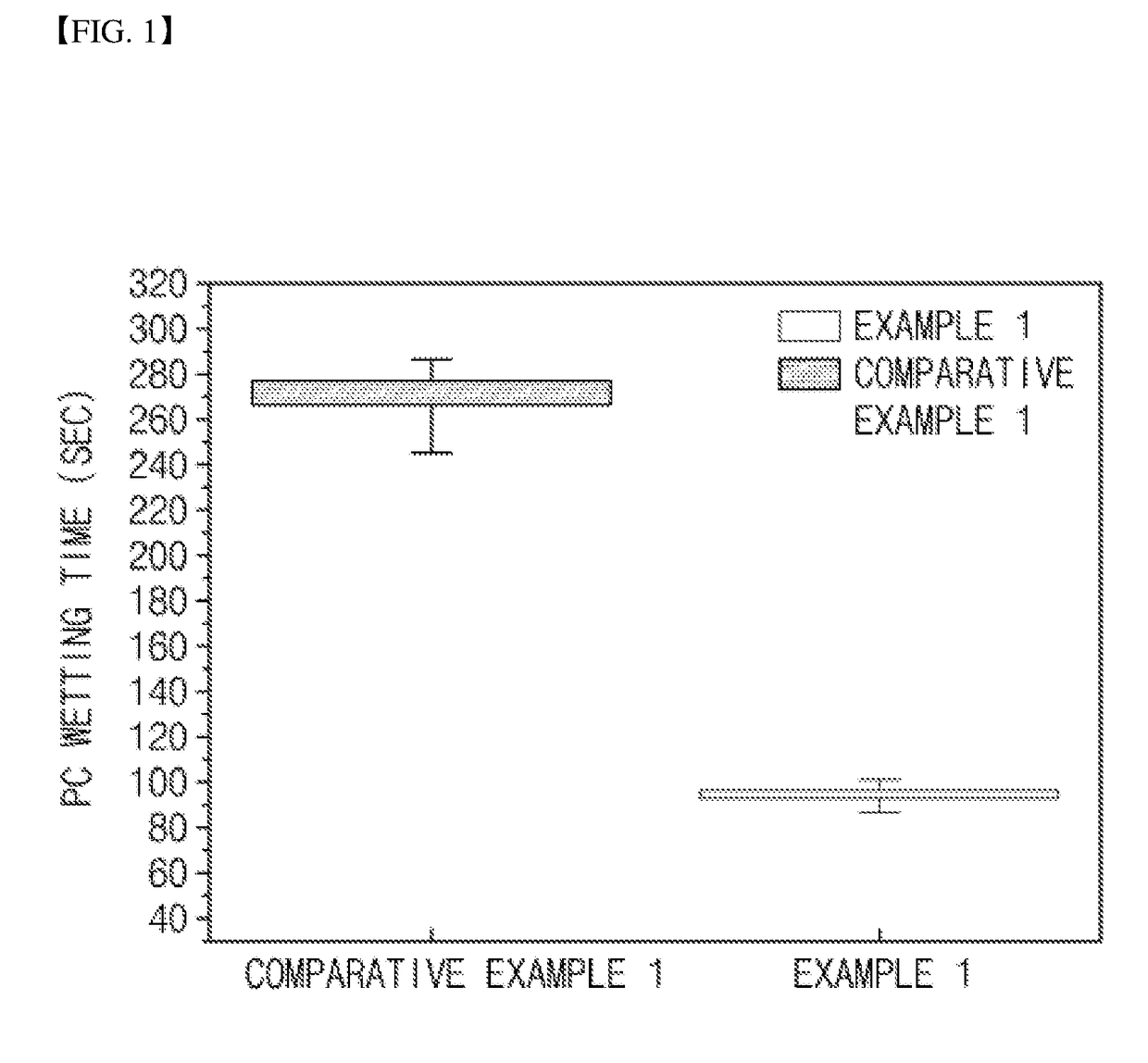

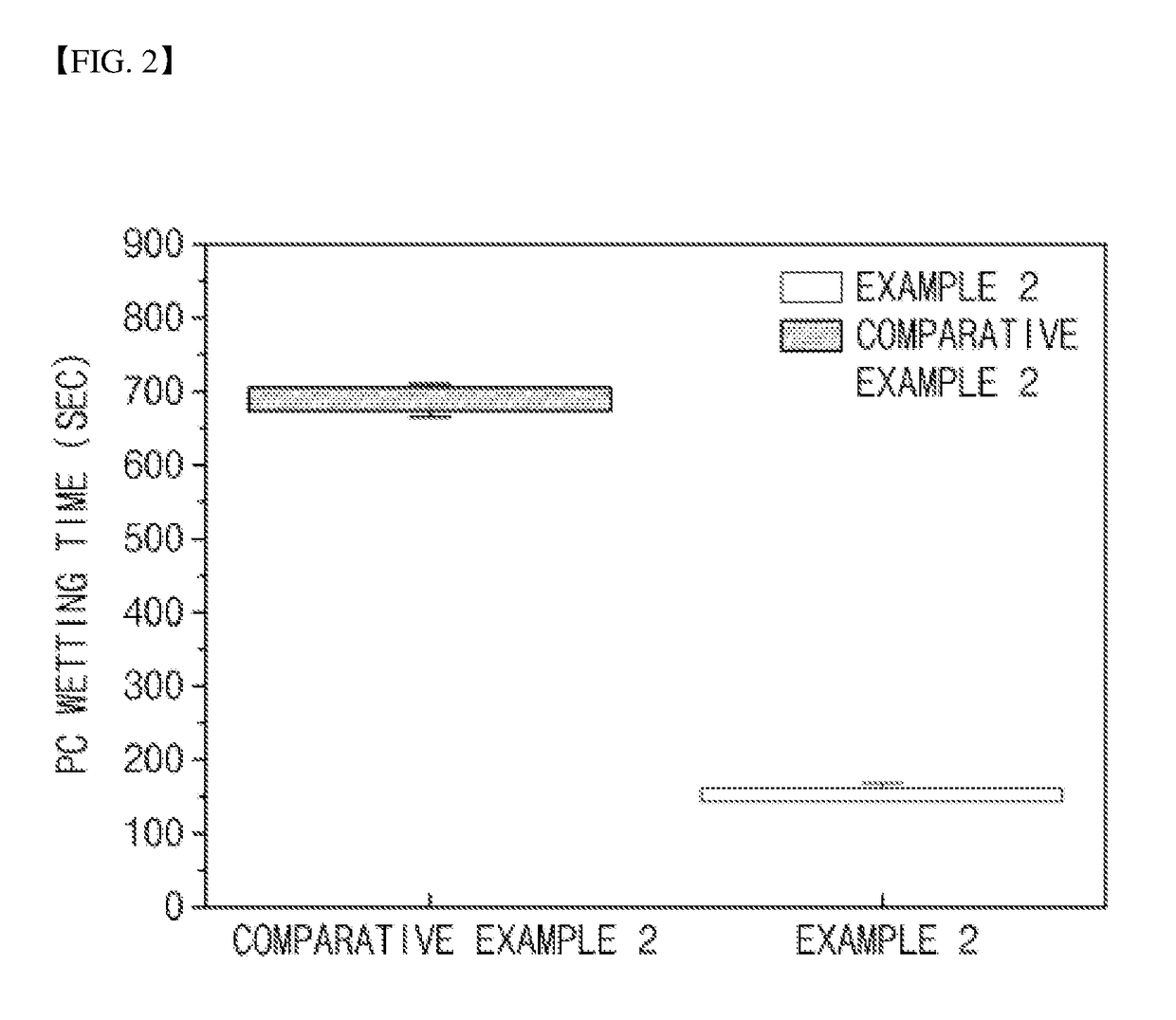

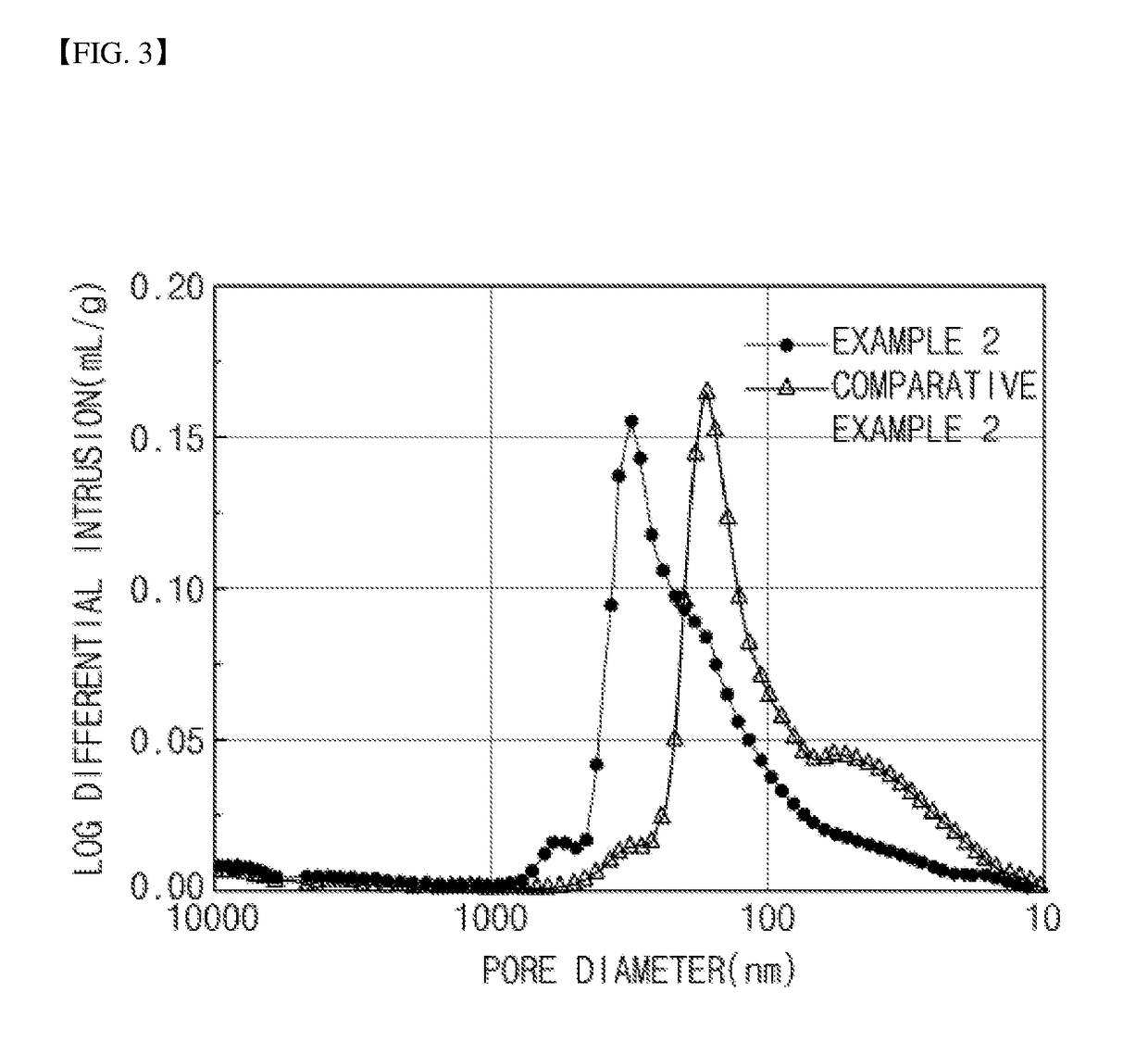

Positive electrode for secondary battery and secondary battery including the same

ActiveUS20180219212A1Improve pore structureImprove wettabilityPositive electrodesNon-aqueous electrolyte accumulator electrodesCarbon nanotubeEngineering

Provided herein are a positive electrode for a secondary battery and a secondary battery including the same. The positive electrode includes a positive electrode active material layer including a positive electrode active material, a conductive material, and a dispersant, wherein the conductive material includes bundle-type carbon nanotubes, units of which have an average strand diameter of 15 nm or less, and the positive electrode active material layer has a packing density of 3.0 g / cc or more, and has an average pore diameter of 0.1 μm to 0.5 μm at the packing density when a pore size distribution is measured by mercury intrusion porosimetry, and thus may exhibit excellent electrolyte wetting properties. As a result, when the positive electrode is applied to a battery, wetting time of the positive electrode is shortened, and an area of the positive electrode that is not filled with an electrolyte is reduced, resulting in enhanced battery performance.

Owner:LG ENERGY SOLUTION LTD

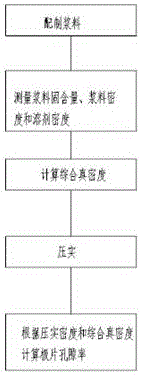

Electrode plate porosity measurement and calculation method

InactiveCN106684330AAccurate calculation of integrated true densityMeasurement calculation method is fastCell electrodesPermeability/surface area analysisPorosityData acquisition

The invention discloses an electrode plate porosity measurement and calculation method, which includes the following steps: materials are first chosen to prepare paste; paste density and paste solid content are measured; according to the paste density, paste solid content and the density of the chosen solvent, comprehensive true density is worked out; according to compaction density needed by an electrode plate, the paste is utilized to be applied on the surface of the electrode plate, and the surface of the electrode plate is compacted; and according to the compaction density and the comprehensive true density, the porosity of the electrode plate is worked out. The electrode plate porosity measurement and calculation method provided by the invention is efficient and effective, and can carry out data acquisition and calculation in the process of battery production without requiring a separate experiment; moreover, such a measurement and calculation method overcomes the problems of overhigh cost, menace engendered to the health of testers, difficulty in waste mercury treatment and great test errors existing in mercury intrusion porosimetry; and such a measurement and calculation method has guiding significance for both battery design and technological parameter optimization.

Owner:ZHONGTIAN ENERGY STORAGE TECH

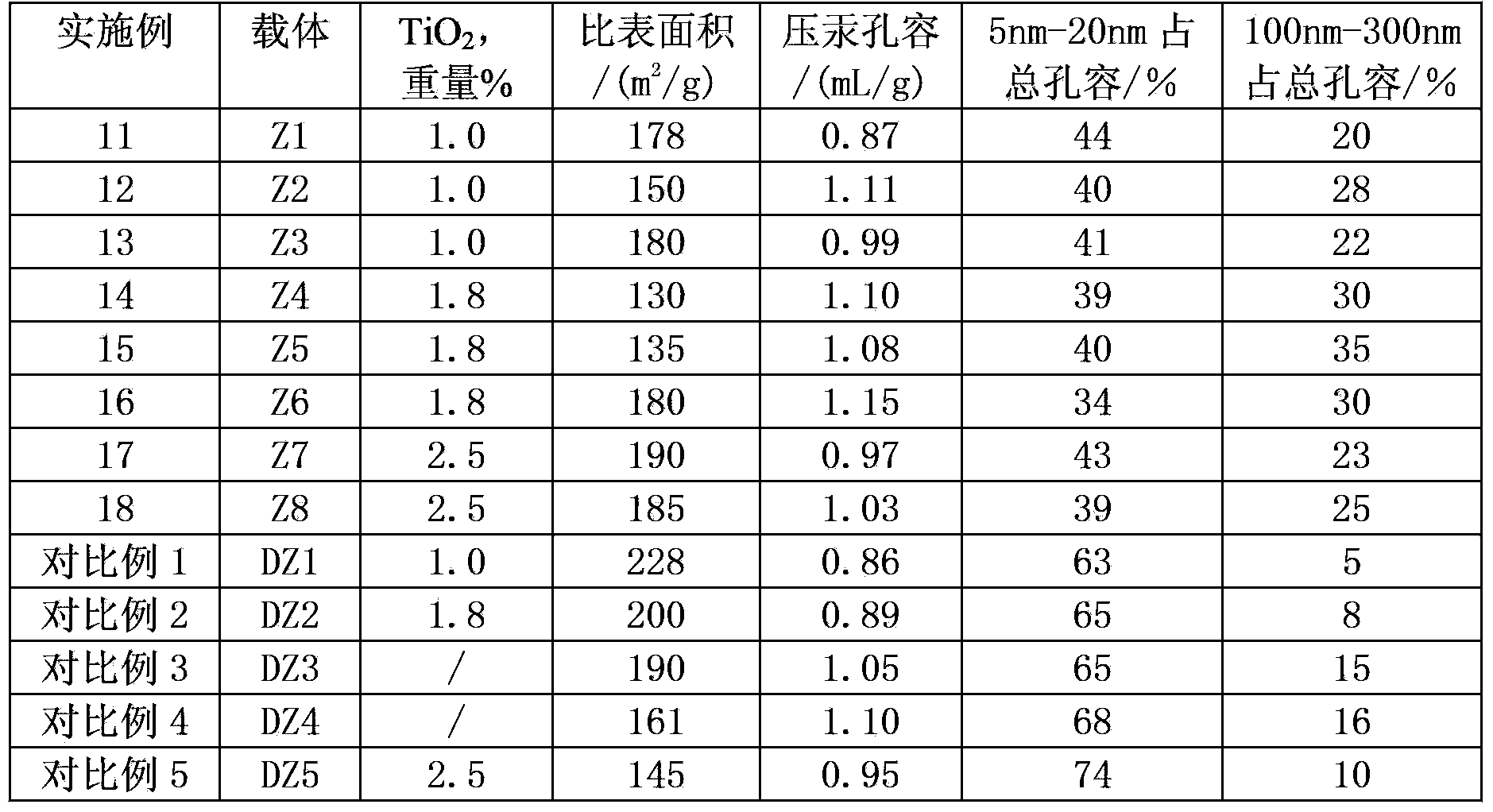

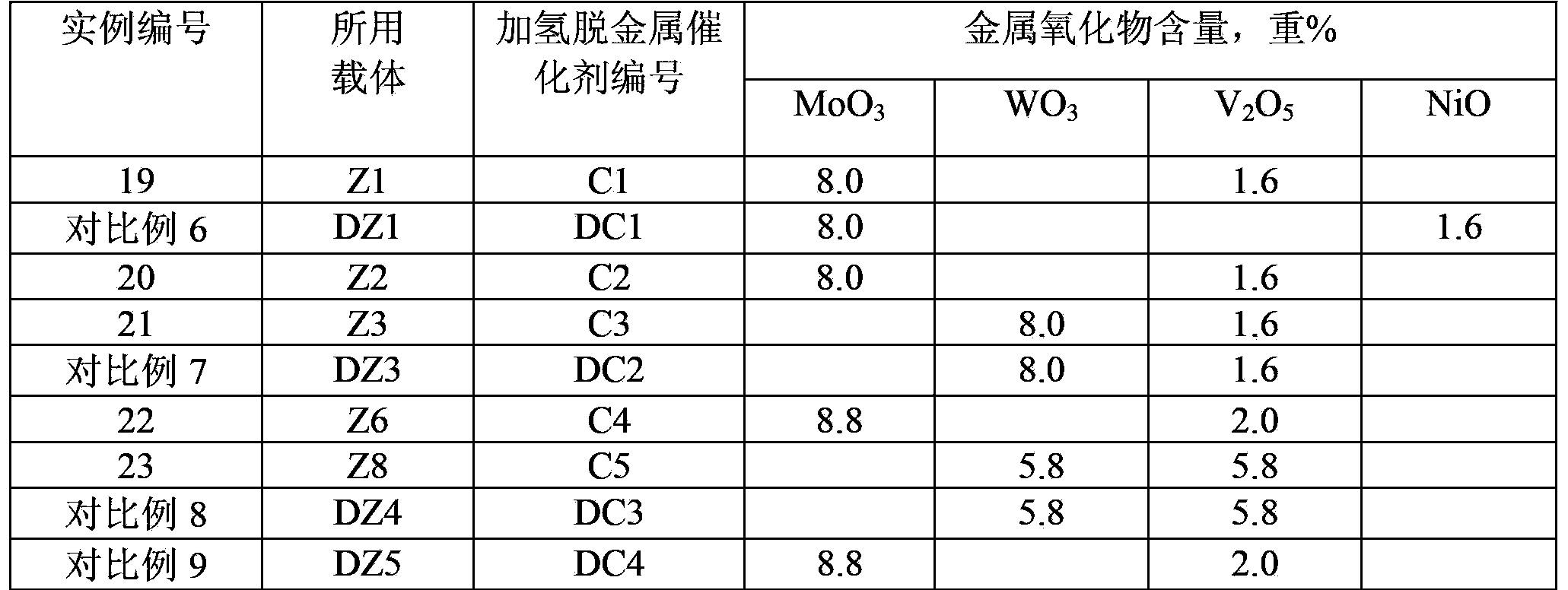

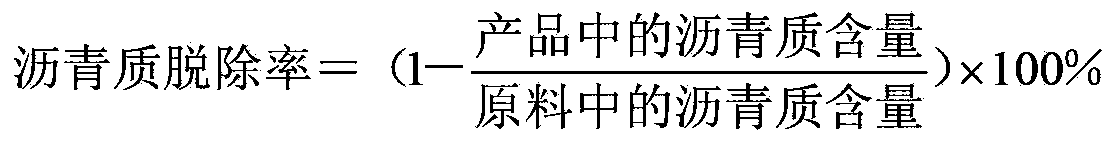

Heavy oil hydrogenation diasphaltene catalyst, and preparation method and application thereof

ActiveCN104338527ACatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsResidual oilAsphaltene

The invention relates to a heavy oil hydrogenation diasphaltene catalyst, and a preparation method and an application thereof. The catalyst comprises a carrier and hydrogenation active metal components. The hydrogenation active metal components are selected from at least one VIB-family metal component and at least one VB-family metal component. The carrier is a bimodal pore alumina carrier comprising an IVB-family metal component. Characterized by mercury intrusion porosimetry, the carrier has pore volume of 0.6-1.4 ml / g, and specific surface area of 80-400 m<2> / g. The pore volume of pores with diameters of 5-20nm accounts for 30-60% of the total pore volume. The pore volume of pores with diameters of 100-300nm accounts for 15-45% of the total pore volume. Compared with prior arts, when the catalyst provided by the invention is used in residual oil hydrogenation treatment, the catalyst has better hydrogenation diasphaltene and demetalization performances.

Owner:CHINA PETROLEUM & CHEM CORP +1

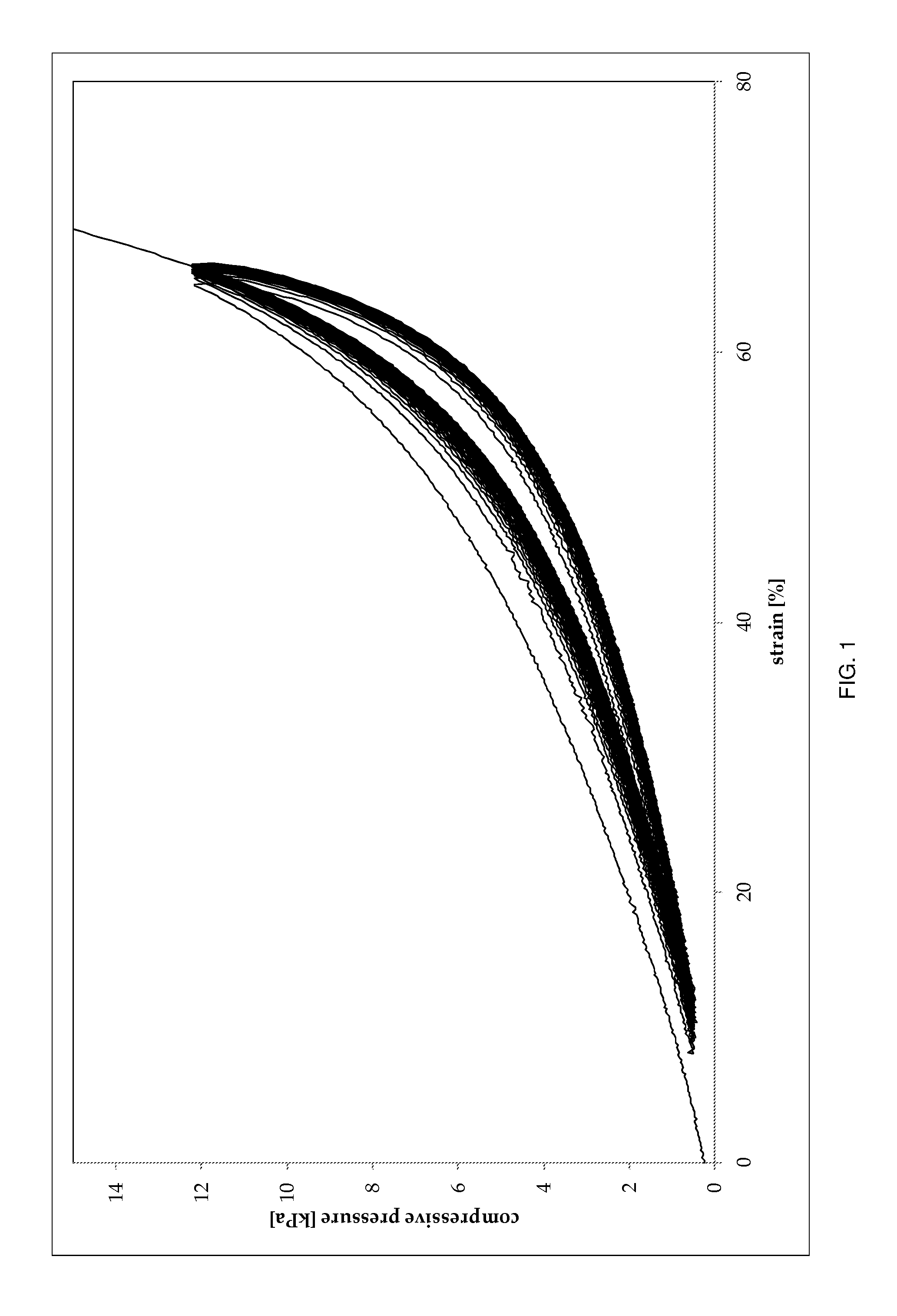

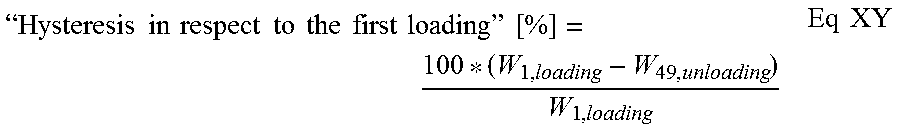

Collagen sponge

Owner:GEISTLICH PHARMA

Polyolefin composition, its production method, and a battery separator made therefrom

InactiveUS8906539B2Promote absorptionExcellent characteristicsCell seperators/membranes/diaphragms/spacersSynthetic resin layered productsPolyolefinPolymer science

Owner:TORAY IND INC

Porous Materials And Method Of Production Thereof

InactiveUS20070298239A1Easy to disperseHigh activityOrganic detergent compounding agentsSynthetic resin layered productsLiquid mediumWater dispersible

Water dispersible or water soluble porous bodies comprising a three dimensional open-cell lattice containing 10 to 95% by weight of a polymeric material which is soluble in water, and, less than 5% by weight of a surfactant, said porous bodies having an intrusion volume as measured by mercury porosimetry (as hereinafter described) of at least about 3 ml / g, and, with the proviso that said porous bodies are not spherical beads having an average bead diameter of 0.2 to 5 mm. And a method for making the same comprising the steps of: providing an intimate mixture of the polymeric material and any surfactant in a liquid medium: providing a fluid freezing medium at a temperature effective for rapidly freezing the liquid medium; cooling the liquid medium with the fluid freezing medium at a temperature below the freezing point of the liquid medium for a period effective to rapidly freeze the liquid medium; and freeze-drying the frozen liquid medium to form the porous bodies by removal of the liquid medium by sublimation.

Owner:IOTA NANOSOLUTIONS

A kind of selective hydrodesulfurization catalyst and its preparation and application

ActiveCN104437518BCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsOrganic acidChemical composition

The invention discloses a selective hydrodesulfurization catalyst, and preparation and application thereof. The catalyst comprises a carrier, at least one non-noble metal composition selected from group VIII and supported on the carrier, at least one metal composition selected from group VI B, and one or more of organics selected from alcohols, organic acids and organic amines. Based on the catalyst in terms of oxides, the mass fraction of the group VIII metal composition is 0.1-6%, the mass fraction of the group VI B metal composition is 1-25%, and the molar ratio of the organic to the group VIII metal composition is 0.5-2.5. The carrier is double-peak porous aluminium oxide, and characterized by mercury intrusion porosimetry, the carrier has the pore volume of 0.9-1.2 mL / g and the specific surface area of 50-300 m<2> / g, the pore volume of pores with the diameter of 10-30 nm accounts for 55-80% of the total pore volume, and the pore volume of pores with the diameter of 300-500 nm accounts for 10-35% of the total pore volume. Compared with the prior art, the provided catalyst is especially applied to hydrofining processes of coked gasoline and catalytically-cracked gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

Porous inorganic body

The present invention relates to a porous inorganic body comprising pores A having a pore size SA in the range of from 0.005 to 20 micrometer and a total pore volume VA, and comprising pores B having a pore size SB in the range of from more than 20 to 1000 micrometer and a total pore volume VB, wherein the total pore volume of the pores having a pore size in the range of from 0.005 to 1000 micrometer is VC and wherein the ratio RA=VA / VC is in the range of from 0.3 to 0.7 as determined via mercury intrusion porosimetry.

Owner:BASF SE

Process for producing propylene in the presence of a macroporous catalyst in the form of spherical beads

ActiveUS7880048B2Increase the number ofHigh selectivityMolecular sieve catalystsMolecular sieve catalystPtru catalystMaterials science

A process for once-through conversion of a hydrocarbon feed comprising at least olefins containing 4 carbon atoms and at least olefins containing 5 carbon atoms is described for the production of propylene, said process comprising passing said feed into at least one reaction unit provided with at least one catalyst in the form of spherical beads with a diameter in the range 1 to 3 mm, each of said spherical beads comprising at least one zeolite and at least one alumina-based support and having a pore distribution such that the macroporous volume, measured by mercury porosimetry, is in the range 0.10 to 0.20 ml / g and the mesoporous volume, measured by mercury porosimetry, is in the range 0.25 to 0.35 ml / g.

Owner:INST FR DU PETROLE

Separator for nonaqueous secondary battery

ActiveUS8815435B2Improve heat resistanceImproving battery in safety and battery propertySecondary cellsCell component detailsFiberPolyolefin

An object of the present invention is to provide a separator for a nonaqueous secondary battery having excellent heat resistance and excellent ion permeation as well as shut-down properties. The first invention is a separator for a nonaqueous secondary battery, comprising a porous composite membrane which includes a substrate comprising a polyolefin microporous membrane and a heat-resistant porous layer comprising a heat-resistant resin, the heat-resistant porous layer being formed on at least one surface of the substrate, wherein the separator is characterized in that the sheet resistance (A) of the substrate, the Gurley value (B) of the substrate, the sheet resistance (C) of the porous composite membrane, and the Gurley value (D) of the porous composite membrane satisfy a specific relationship. The second invention is characterized in that the heat-resistant porous layer has an average pore size of 0.1 to 0.2 μm as measured by mercury intrusion porosimetry. The third invention is characterized in that the heat-resistant resin fibrils have an average fibril diameter of 10 to 80 nm, and the pores in the heat-resistant porous layer have an average pore size of 50 to 250 nm.

Owner:TEIJIN LTD

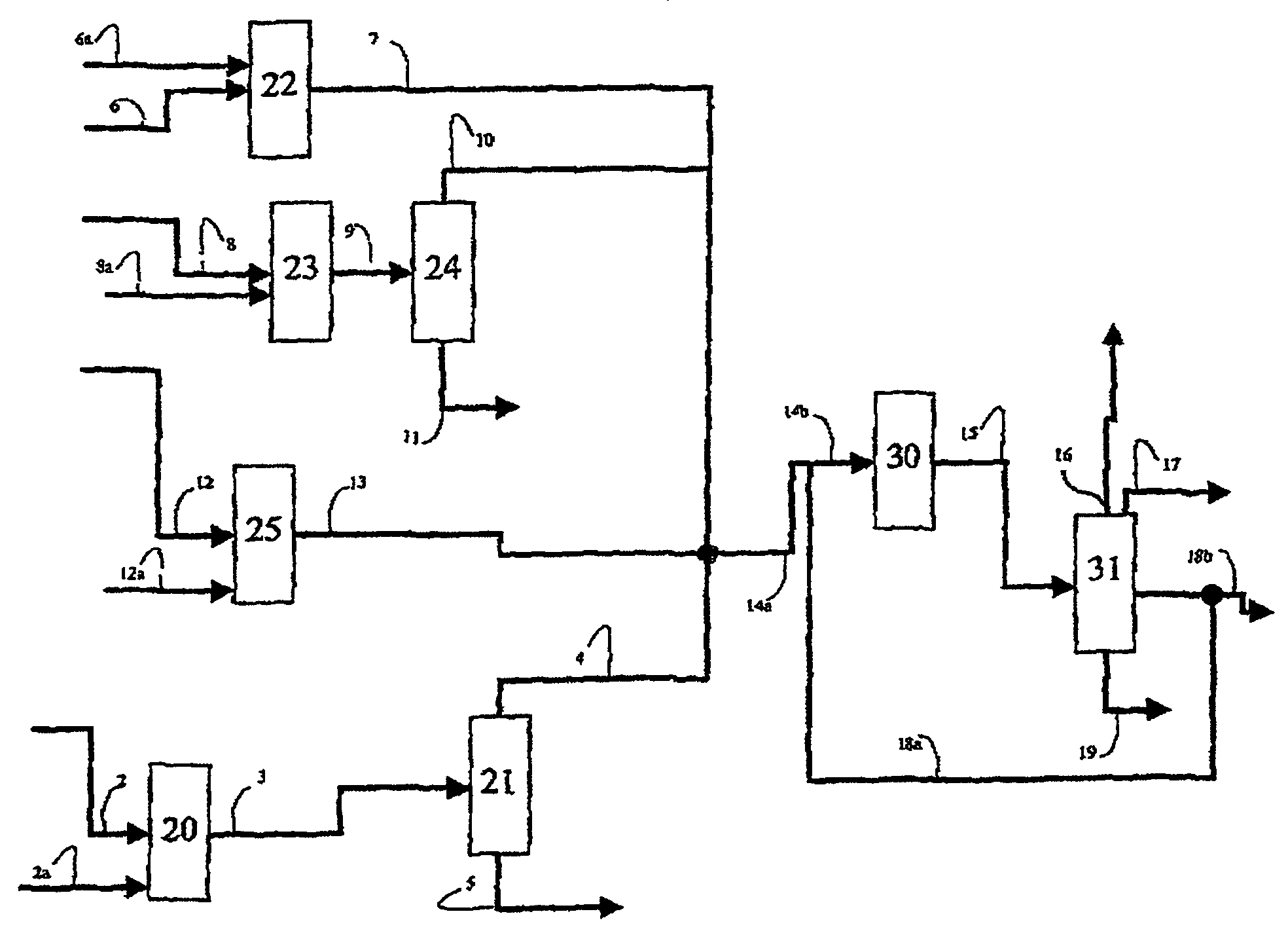

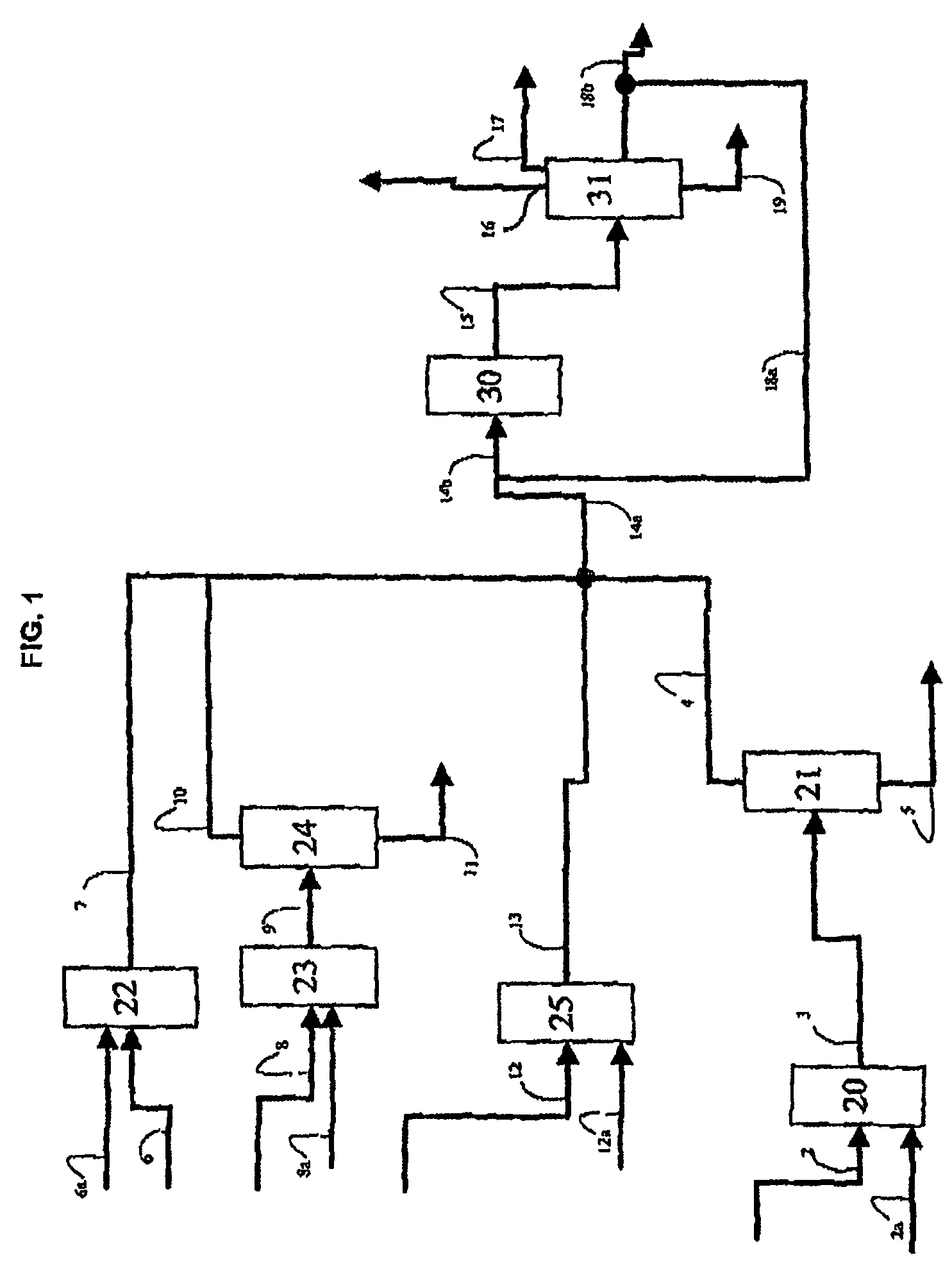

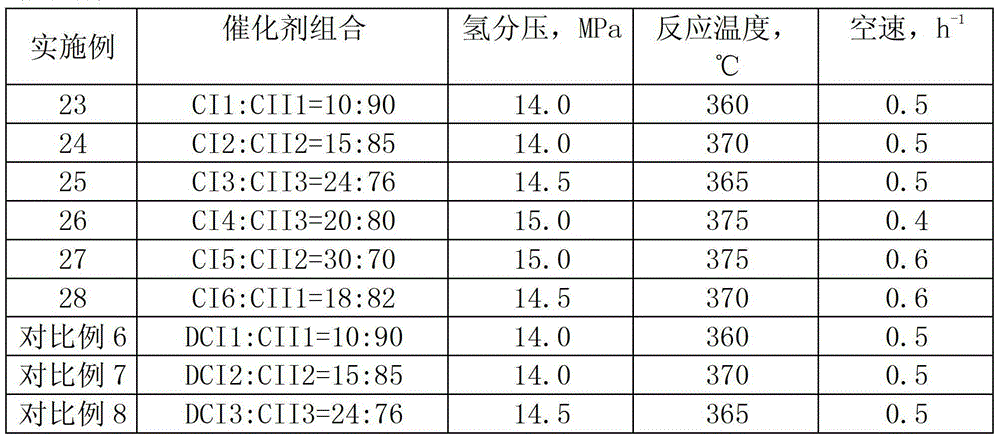

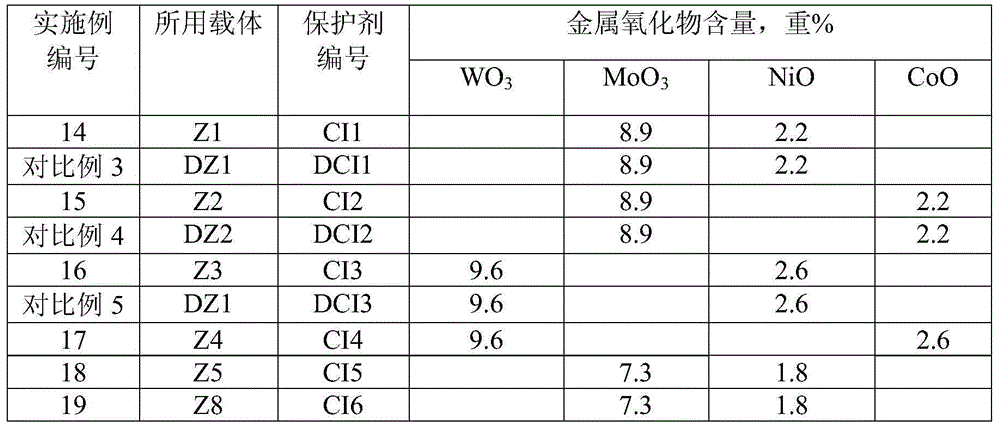

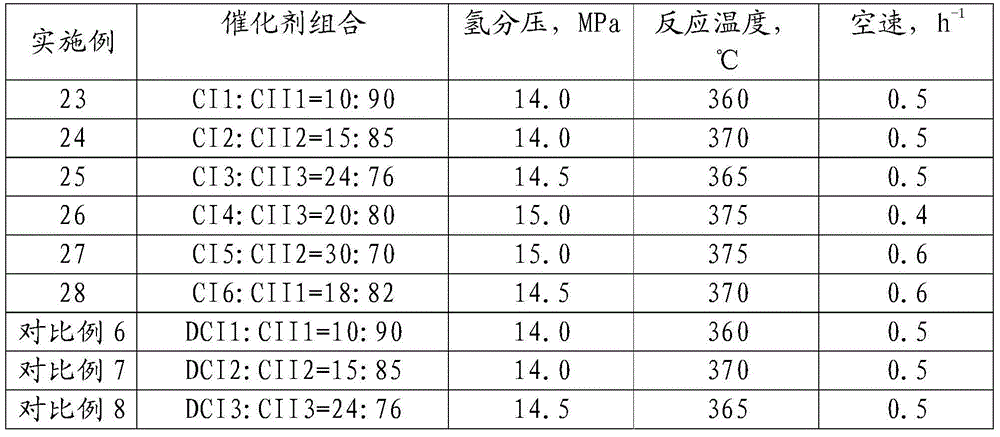

Hydrocarbon-oil hydrotreatment method

ActiveCN104449815ATreatment with hydrotreatment processesRefining to eliminate hetero atomsHydrocarbonMercury intrusion porosimetry

A hydrocarbon-oil hydrotreatment method comprises contacting raw oil with a catalyst combination under hydrotreatment reaction conditions. The catalyst combination comprises a hdyrotreatment catalyst I and a hydrotreatment catalyst II, and the arrangement of the catalyst I and the catalyst II enables raw oil to be successively contacted with the catalyst I and the catalyst II. Based on the total amount of the catalyst combination in terms of volume, the content of the catalyst I is 5-40% and the content of the catalyst II is 60-95%. The catalyst I contains an aluminium oxide carrier with a double-peak pore structure, and mercury intrusion porosimetry, the carrier has the pore volume of 0.8-1.2 mL / g and the specific surface area of 120-400 m<2> / g, the pore volume of pores with the diameter of 6-30 nm accounts for 58-80% of the total pore volume, the pore volume of pores with the diameter of 10-30 nm is less than 55% of the total pore volume, and the pore volume of pores with the diameter of 300-500 nm accounts for 10-35% of the total pore volume.

Owner:CHINA PETROLEUM & CHEM CORP +1

Lithium manganate particles for non-aqueous electrolyte secondary batteries and process for producing the same, and non-aqueous electrolyte secondary battery

InactiveUS20160126547A1Excellent in high-temperature characteristicSmall surface areaElectrode thermal treatmentLi-accumulatorsHigh temperature storagePhysical chemistry

The present invention relates to lithium manganate particles for non-aqueous electrolyte secondary batteries, having a spinel structure, an average primary particle diameter of 0.4 to 1.8 μm and an average secondary particle diameter (D50) of 8 to 20 μm, a ratio of the average secondary particle diameter (D50) to the average primary particle diameter (D50 / average primary particle diameter) being in the range of 10 to 30, and pore diameters of pores in the lithium manganate particles as measured by a mercury intrusion porosimetry method being in the range of 100 to 500 nm, and a process for producing the lithium manganate particles, and a non-aqueous electrolyte secondary battery. The lithium manganate particles according to the present invention are excellent in high-temperature storage characteristics.

Owner:TODA IND

Hydrogenation pretreatment method for catalytically-cracked raw oil

A hydrogenation pretreatment method for catalytically-cracked raw oil comprises enabling raw oil to be contacted with a catalyst combination under the conditions of a hydrogenation processing reaction. The catalyst combination comprises a hydrogenation processing catalyst I and a hydrogenation processing catalyst II, and the hydrogenation processing catalyst I and the hydrogenation processing catalyst II in the catalyst combination are arranged to enable raw oil to be successively contacted with the catalyst I and the catalyst II. Based on the total amount by volume of the catalyst combination, the content of the catalyst I is 5-40%, and the content of the catalyst II is 60-95%. The catalyst I contains a boron-containing aluminium oxide carrier with a double-peak pore structure, and characterized by mercury intrusion porosimetry, the carrier has the pore volume of 0.8-1.2 mL / g and the specific surface area of 120-400 m<2> / g, the pore volume of pores with the diameter of 6-30 nm accounts for 58-80% of the total pore volume, the pore volume of pores with the diameter of 10-30 nm is less than 55% of the total pore volume, and the pore volume of pores with the diameter of 300-500 nm accounts for 10-35% of the total volume.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com