Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46 results about "Machine orders" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Machine orders data (also known as machine tool order data) is a figure issued by Japan Machine Tool Builders Association (JMTBA) every month. It serves as one indicator of the Japanese economy. In the forex market, the release of such data is often followed by sharp change in currency exchange rate.

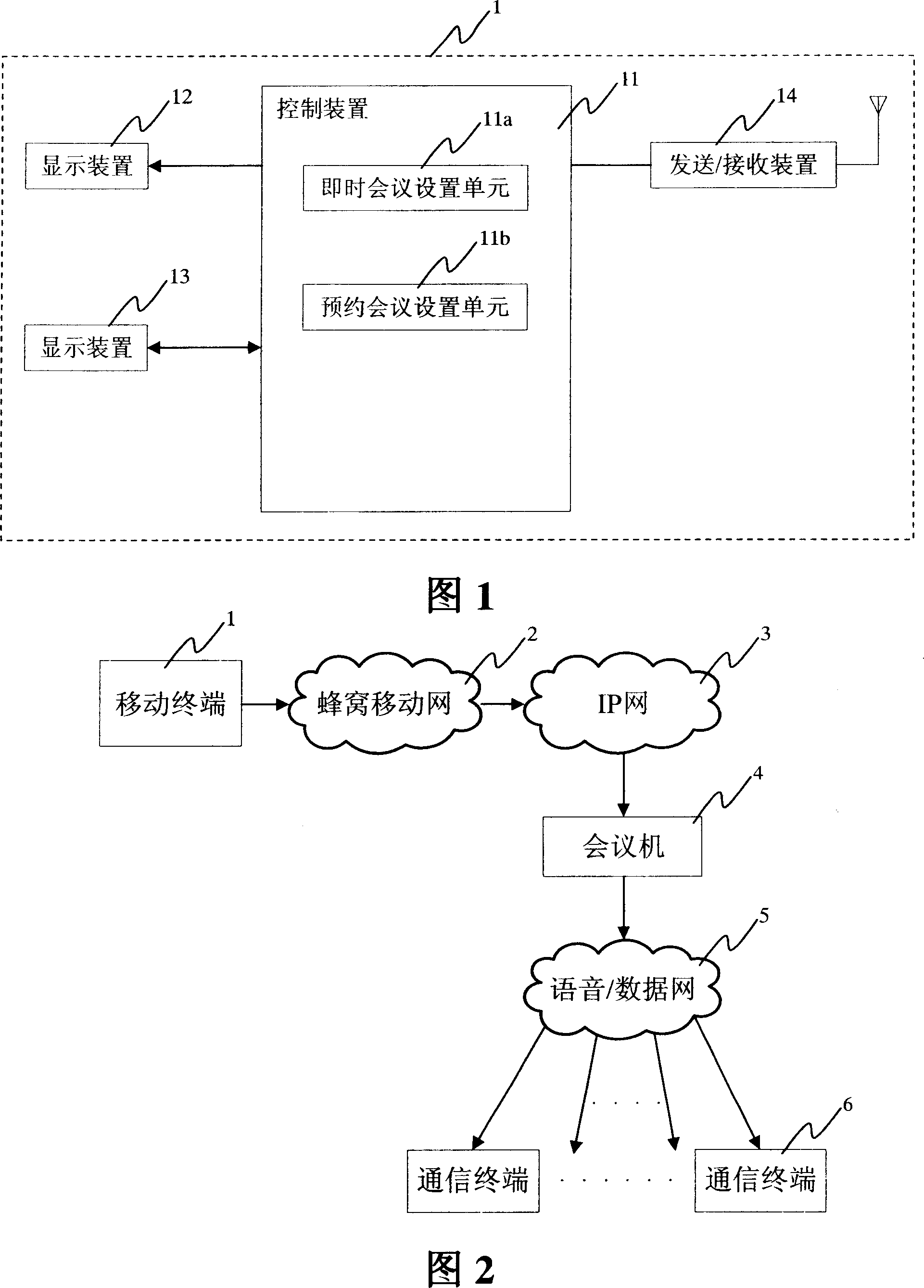

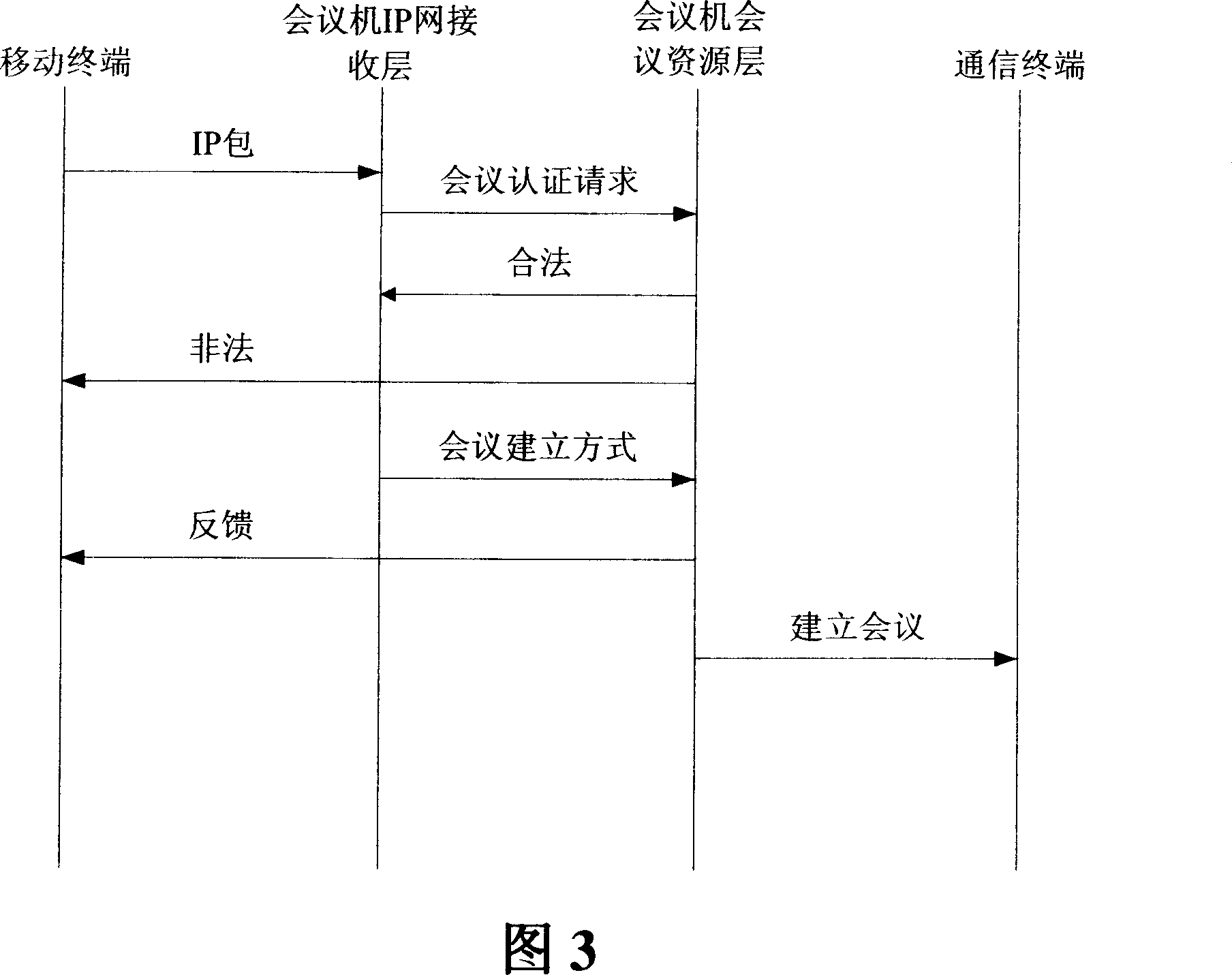

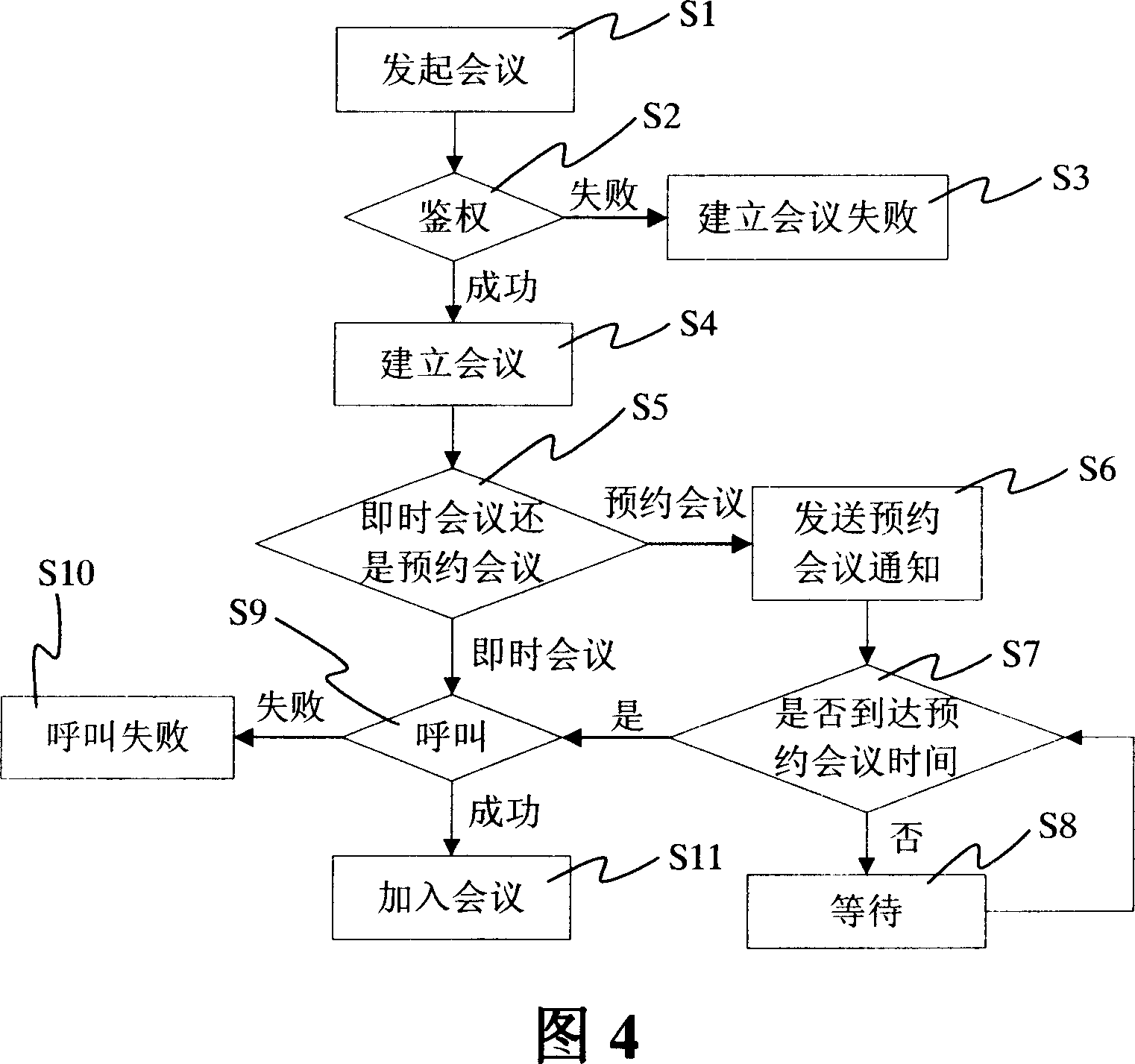

A multi-party conference system originated by mobile terminal and its method

InactiveCN101102145AImprove compatibilitySpecial service for subscribersRadio/inductive link selection arrangementsReal-time computingMachine orders

The invention is concerned with a kind of multi-side meeting system and method initiated by moving terminal, using for initiating multi-side meeting with some communication terminals by moving terminal. Set group claim to initiate multi-side meeting in moving terminal, and the said group claim relating to the number of moving terminal for attending the multi-side meeting, and the said moving terminal sends group claim to meeting machine through cellular mobile network and IP net, and the meeting machine resolves the said group claim to get the said number of moving terminal for attending the multi-side meeting. And the meeting machine orders sound / data net to send call to the said communication terminals for attending the multi-side meeting, and the communication terminals will answer the call send by sound / data net.

Owner:北京艾易信息通信有限责任公司

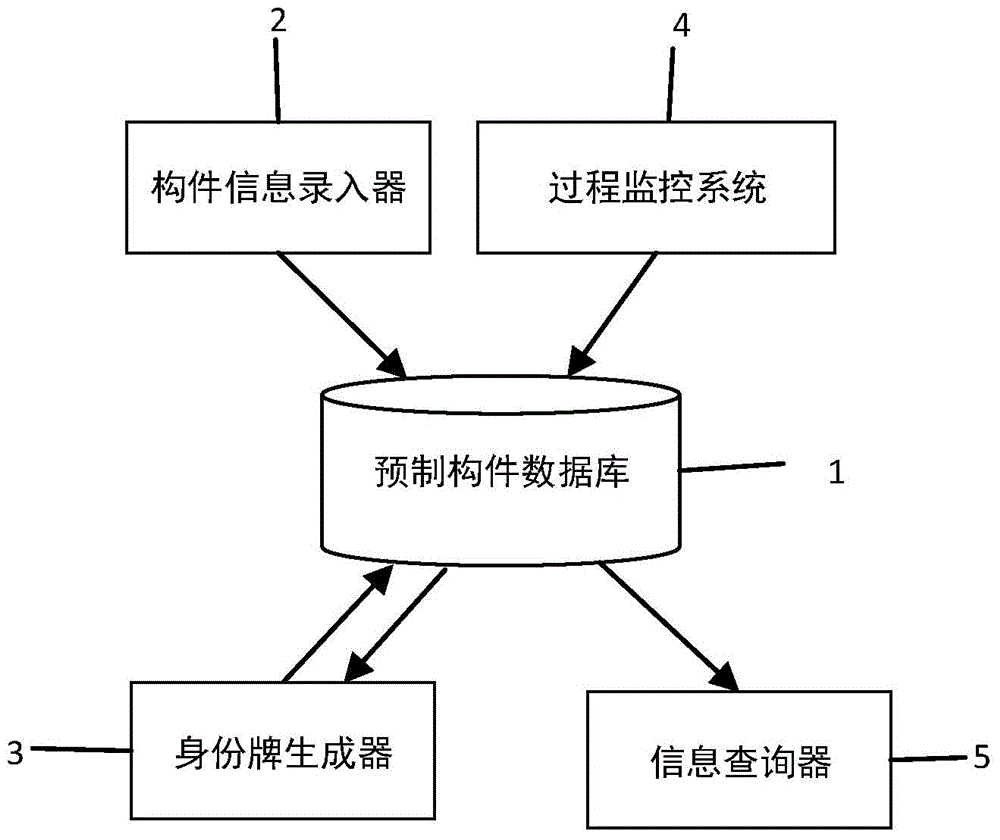

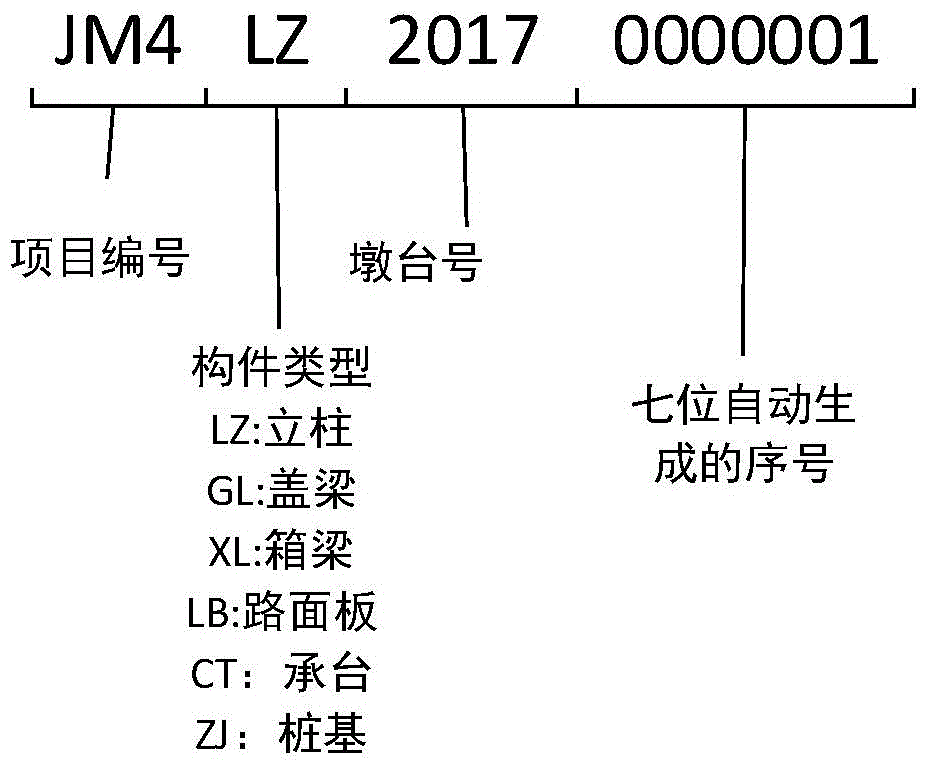

Bridge precast concrete member monitoring system based on two-dimensional code and control method thereof

InactiveCN104636873AReduce backlogSafe and Stable Data SupportResourcesMonitoring systemDimensional modeling

The invention discloses a bridge precast concrete member monitoring system based on a two-dimensional code and a control method thereof, belongs to the technical field of network communication and management, and aims to solve the problem of influence on the construction period due to member overstock caused by extensive management in the production, transportation, storage and installation processes of the conventional bridge precast concrete member. The process monitoring system comprises a database, an information input device, an identity card generator, a process monitoring system and an information inquiry device. The control method comprises the following steps: inputting the two-dimensional code information of a precast member; making a machining order and identity card of the precast member; inputting and storing information of a reinforcement cage machining process; inputting and storing pouring process information; inputting and storing delivery information; inputting and storing construction field material information; inputting and storing installation information. The process monitoring system and the control method are easy to operate and manage, the overstock of precast members is reduced, and the construction period and construction cost are saved.

Owner:SHANGHAI HIGHWAY INVESTMENT CONSTR DEV CO LTD +1

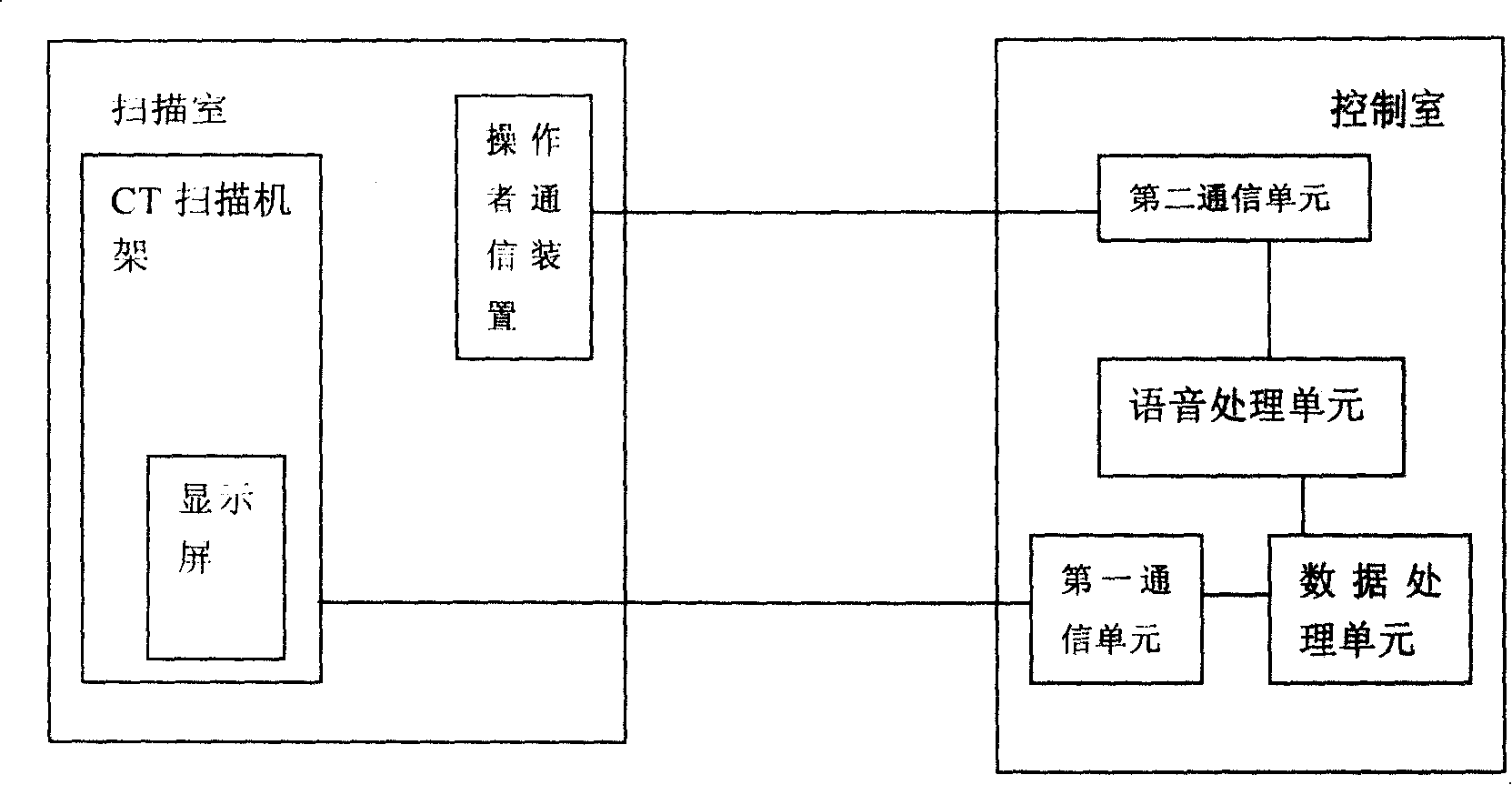

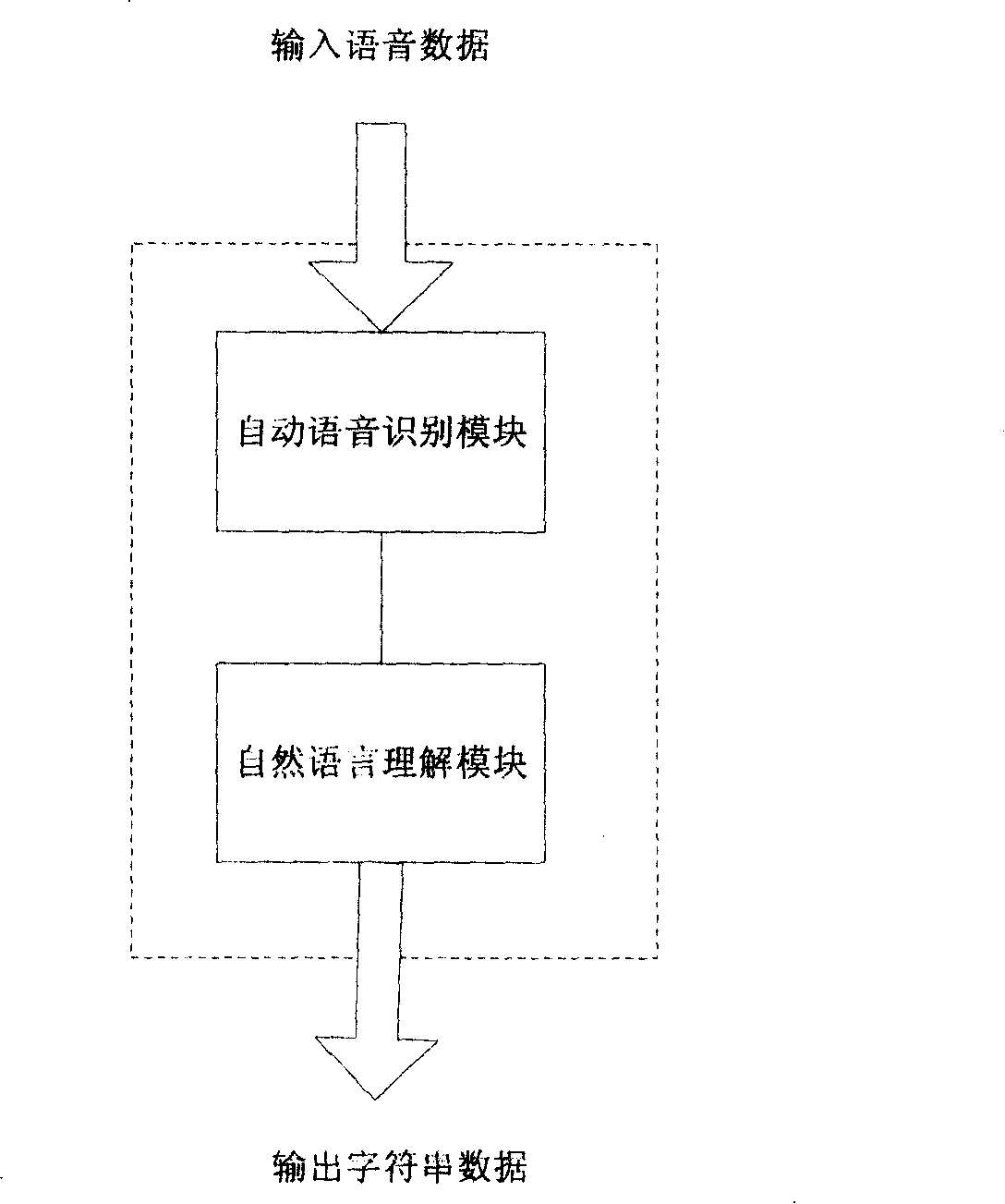

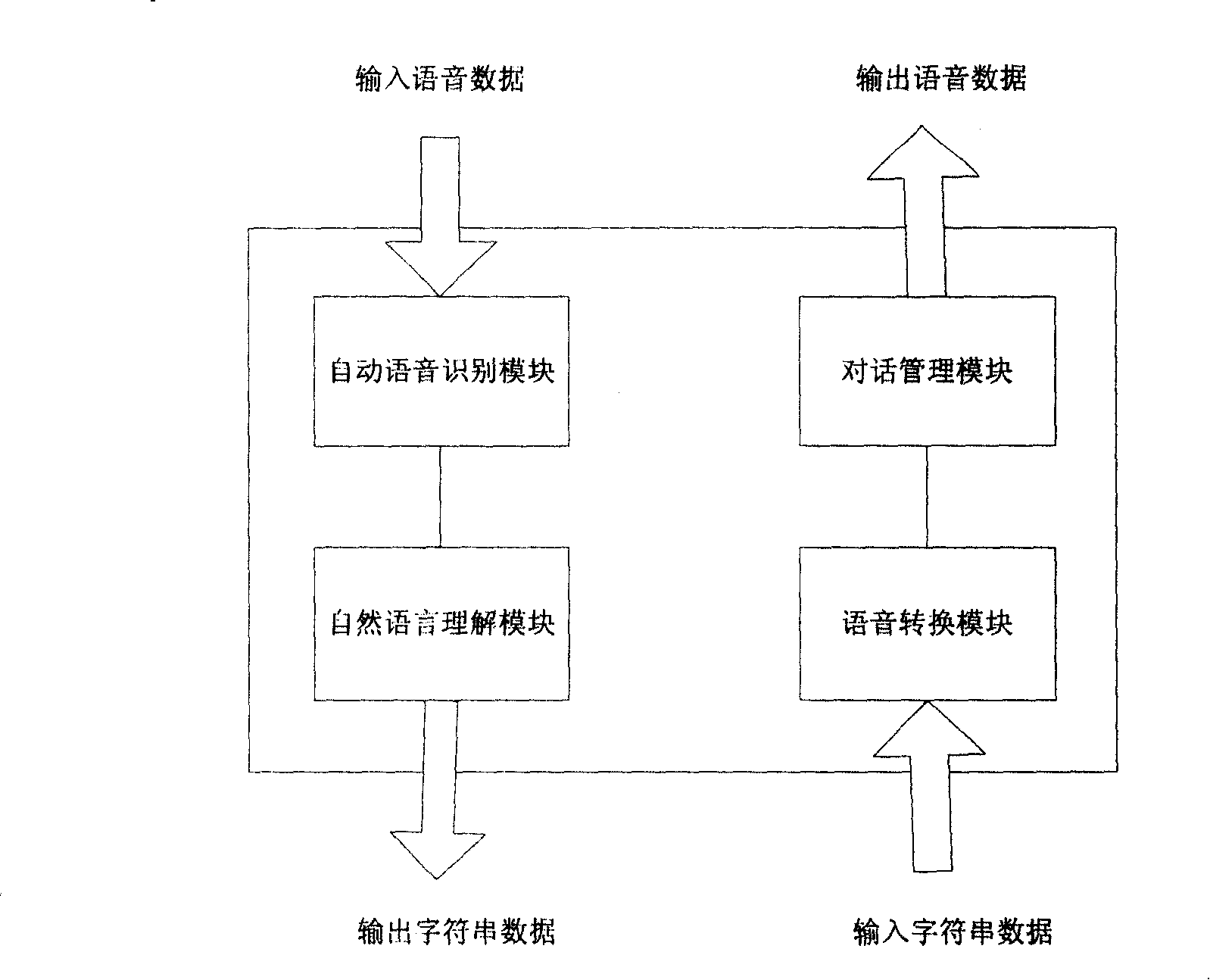

Human-computer interaction electronic medical system and human-computer interaction method thereof

InactiveCN101231582AReduce labor costsFacilitate medical diagnosis and treatment processInput/output for user-computer interactionComputerised tomographsMedical diagnosisHuman power

The invention relates to the field of electronic medical equipment, specifically a man-machine interactive electronic medical system and a man-machine interactive method thereof. The system comprises an execution device for performing medical imagining or therapy on a patient; a control device isolated from the execution device and having a data processing unit for transferring functional modules to executive commands and remotely controlling the execution device and a first communication unit for the data exchange between the execution device and the data processing unit; an operator-side communication device arranged beside the execution device for the voice command input of the operator; a voice processing unit for receiving and converting the voice command from the operator-side communication device into machine orders executed by the data processing unit, and sending the orders to the data processing unit for further execution. The invention can reduce the manpower cost, realize the remote access to the patient's information, and facilitate the medical diagnosis and treatment.

Owner:SIEMENS SHANGHAI MEDICAL EQUIP LTD

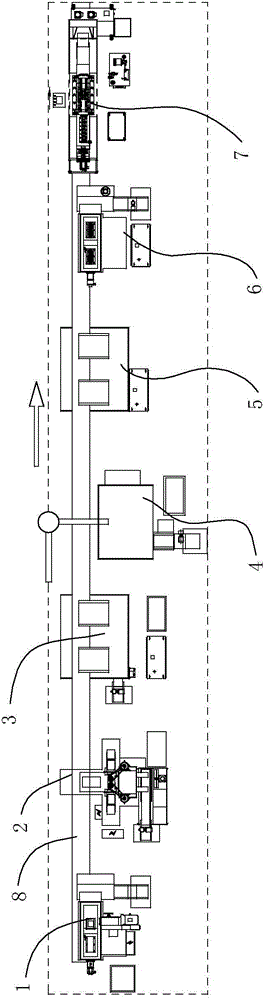

Automatic production technology and production line for tile covers

ActiveCN104942548AImprove processingImprove processing efficiencyOther manufacturing equipments/toolsSurface finishProduction line

The invention discloses an automatic production technology and a production line for tile covers. The automatic production technology and the production line include that multiple tile cover blanks which are sequentially connected are machined through seven procedures and are characterized in that the first procedure is a rough milling machining procedure, the second procedure is a milling procedure, the third procedure is a semicircular arc boring-milling procedure, the fourth procedure is a drilling procedure, the fifth procedure is a groove milling procedure, the sixth procedure is a cutting-milling procedure, the seventh procedure is a surface finish broaching procedure, and except the seventh procedure, the order of the other six procedures can be adjusted. According to the automatic production technology and the production line for the tile cores, the blanks of the tile covers are machined into complete finished single tile cover products, faces needing to be machined and steps are divided into seven parts to be conducted, the machining order is reasonably arranged, machining is fast, the machining efficiency and the machining precision are improved, and labor force and labor intensity are greatly lowered.

Owner:ZHEJIANG CHR INTELLIGENT EQUIP

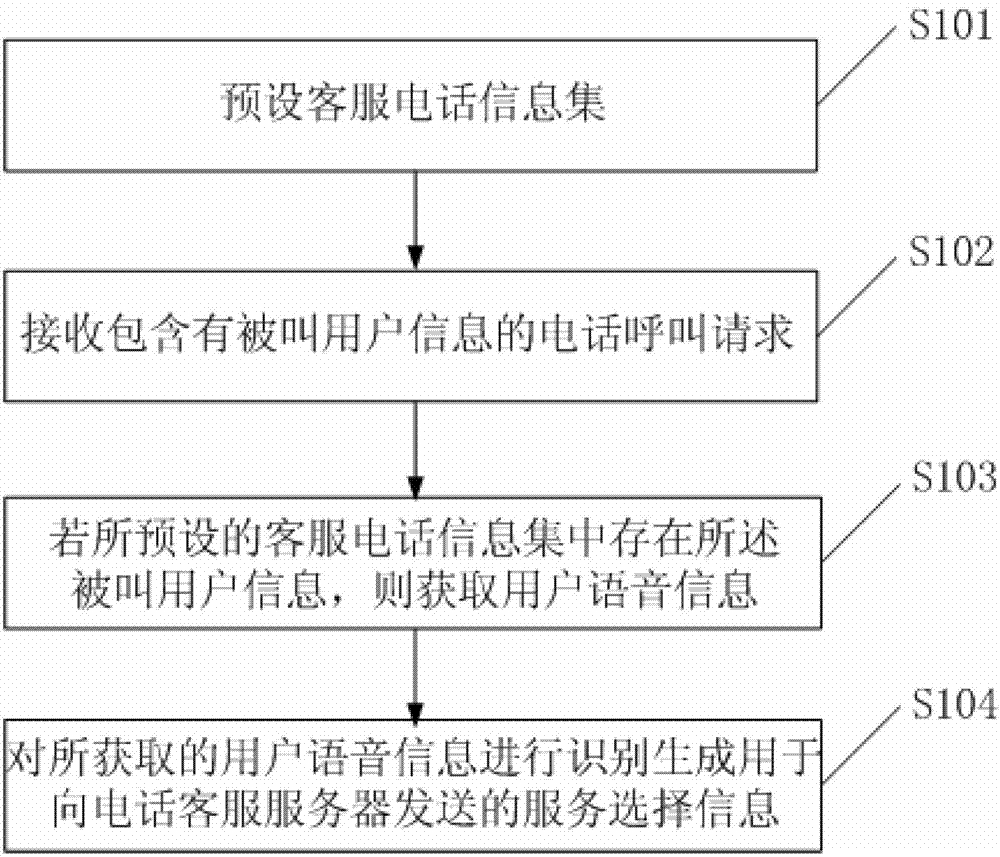

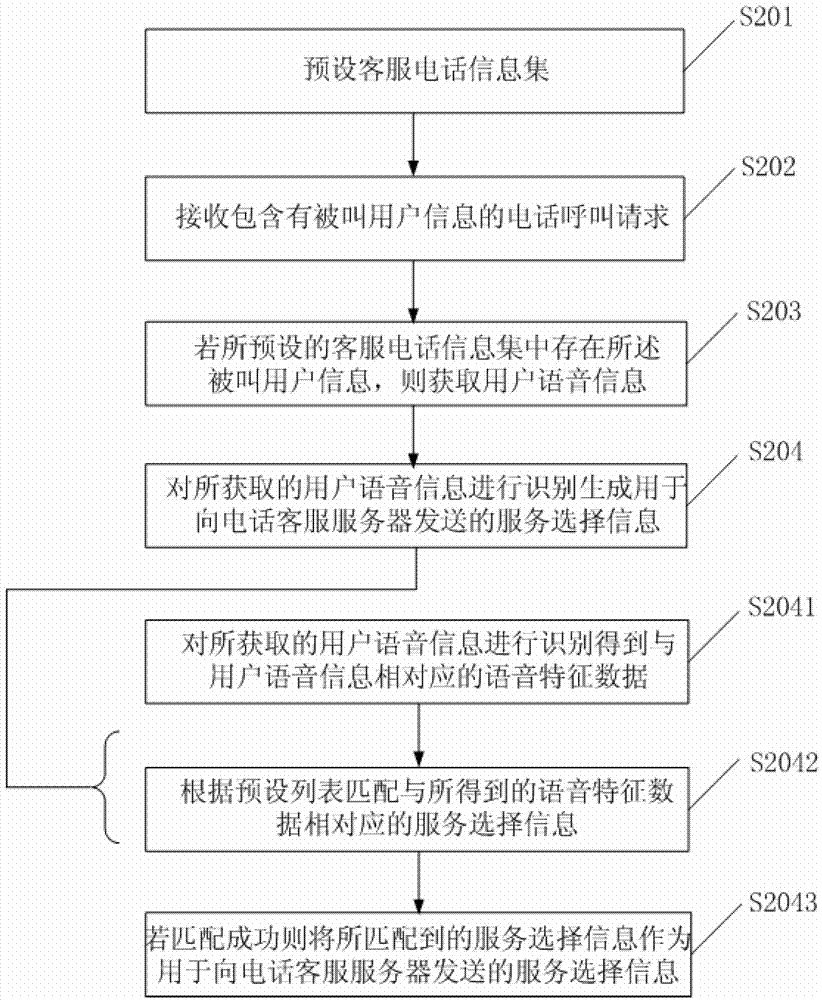

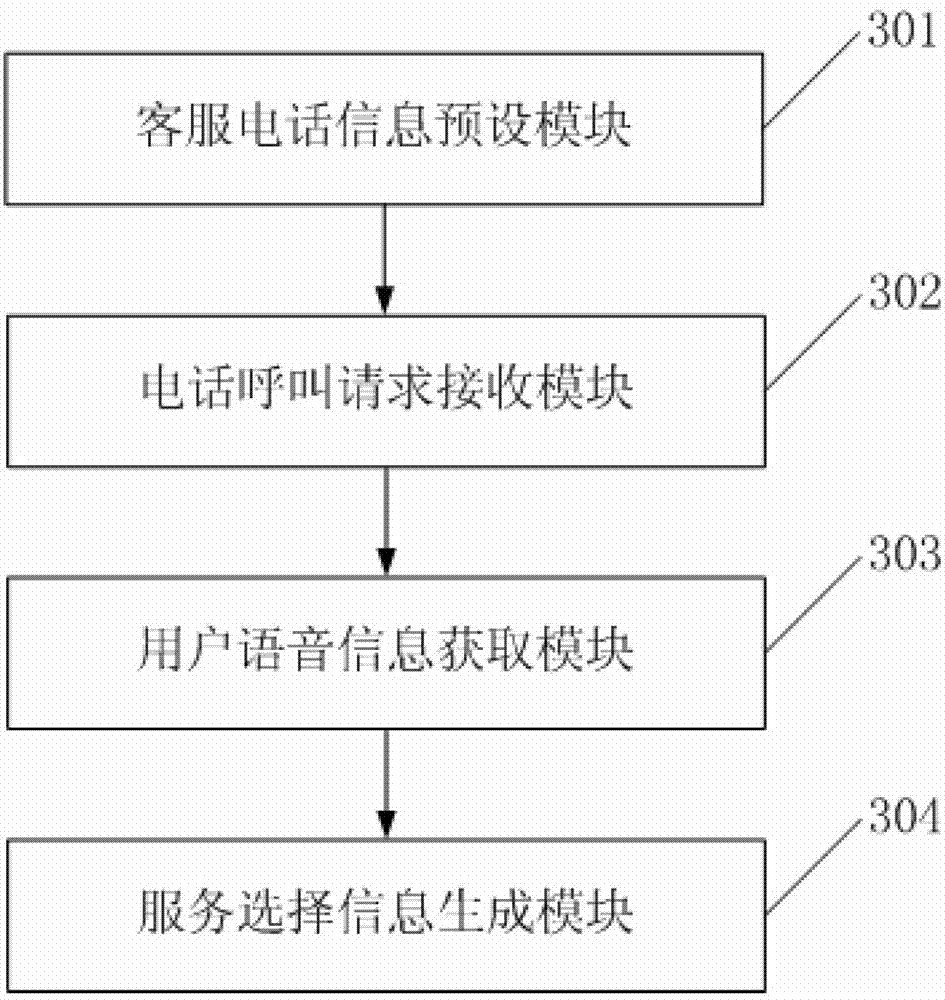

Method and device for selecting services in service calls

InactiveCN103402028ASave powerReduce occupancySpecial service for subscribersService selectionBroadband

The invention discloses a method and a device for selecting services in service calls. The method includes the following steps that a service call information set is preset; a telephone call request containing called customer information is received; if the called customer information is contained in the preset service call information set, then customer voice information is acquired; the acquired customer voice information is identified, and service selection information to be sent to a service call server is generated. The invention can select services in service calls by the way of dialogues, and a manual operation step is omitted, so that the whole call process becomes simple and smooth, consequently, the experience of the invention is better than the conventional machine order type experience, meanwhile, the electricity quantity of terminal batteries is saved, and less broadband resource is occupied.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

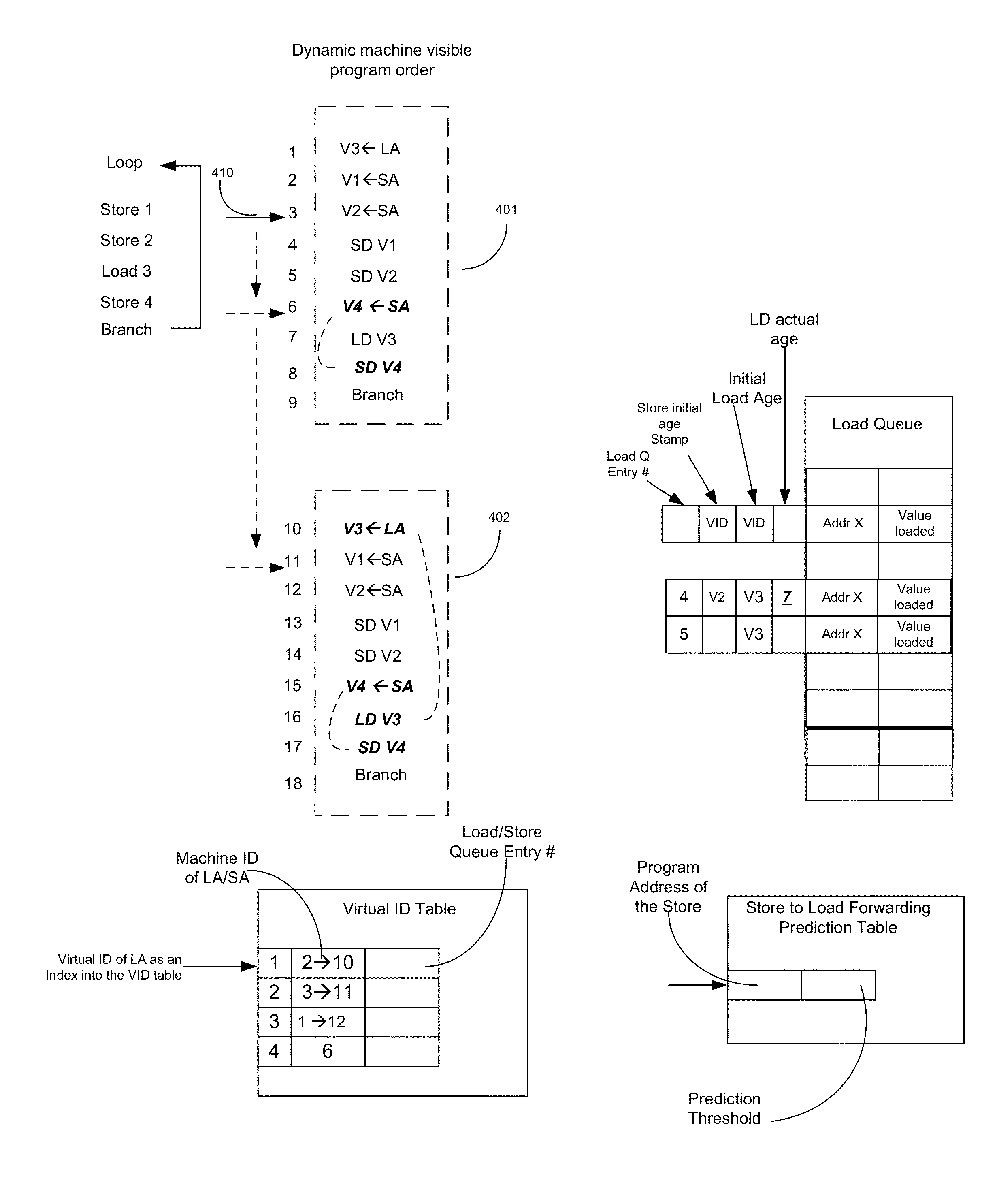

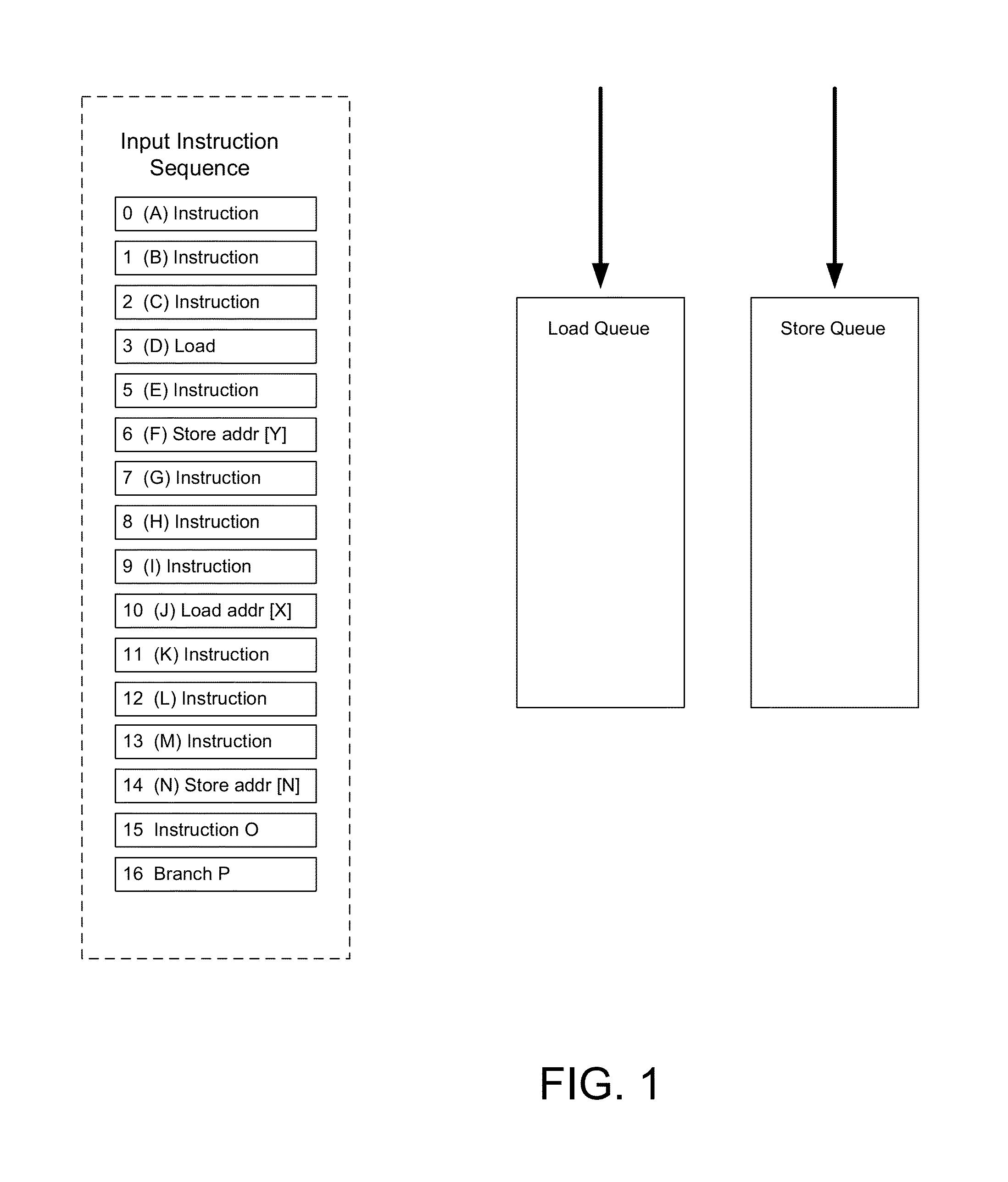

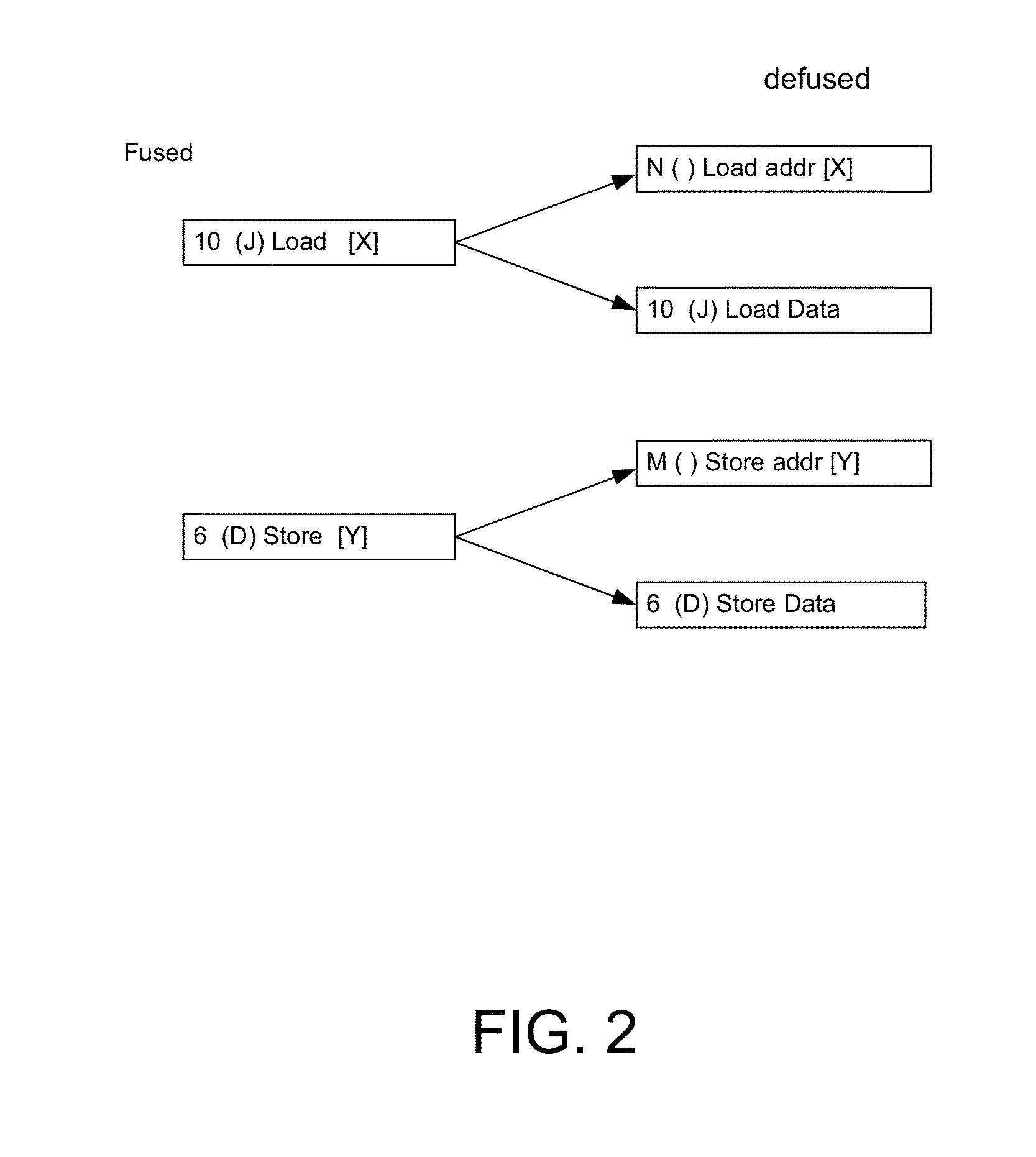

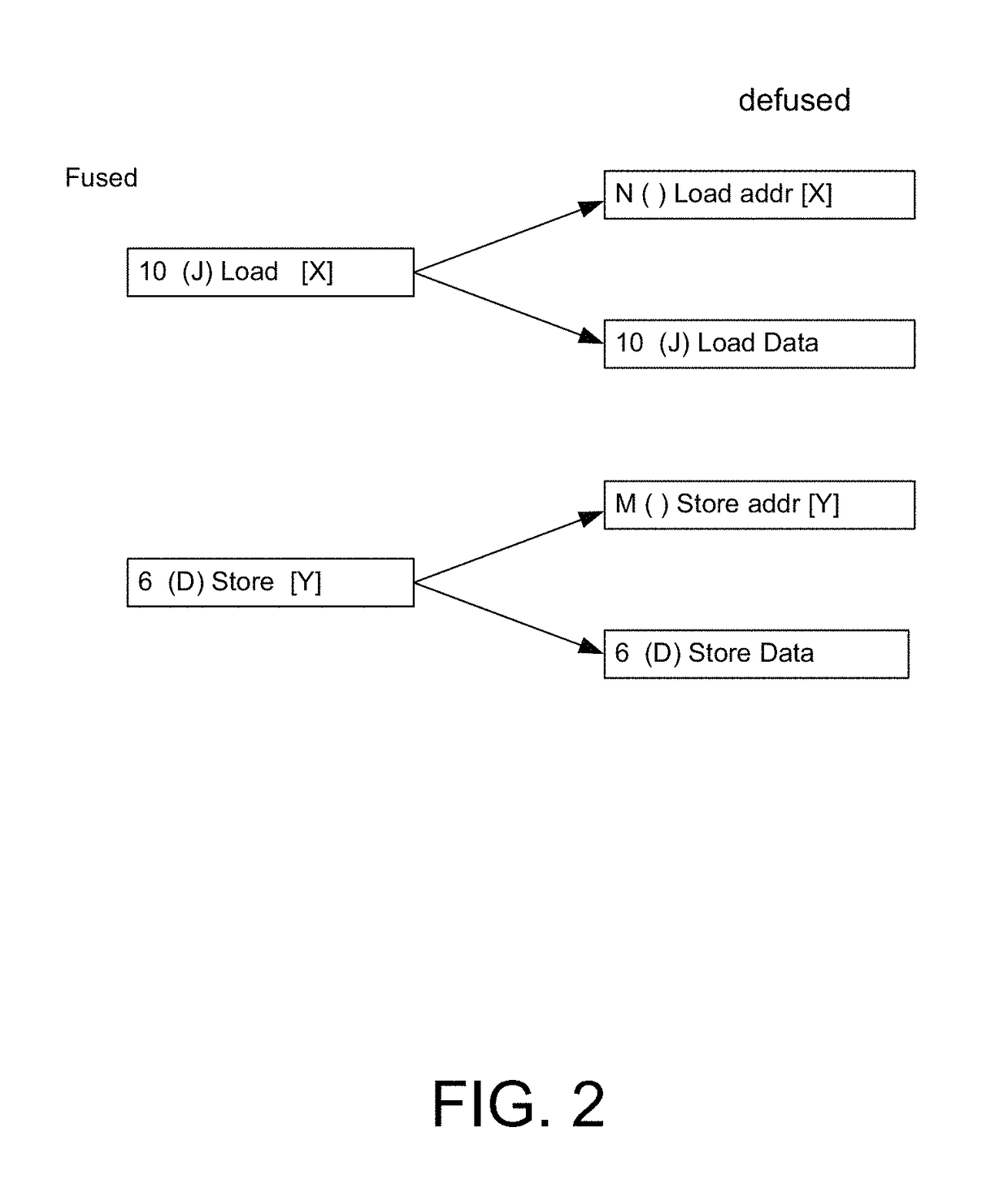

Method and system for implementing recovery from speculative forwarding miss-predictions/errors resulting from load store reordering and optimization

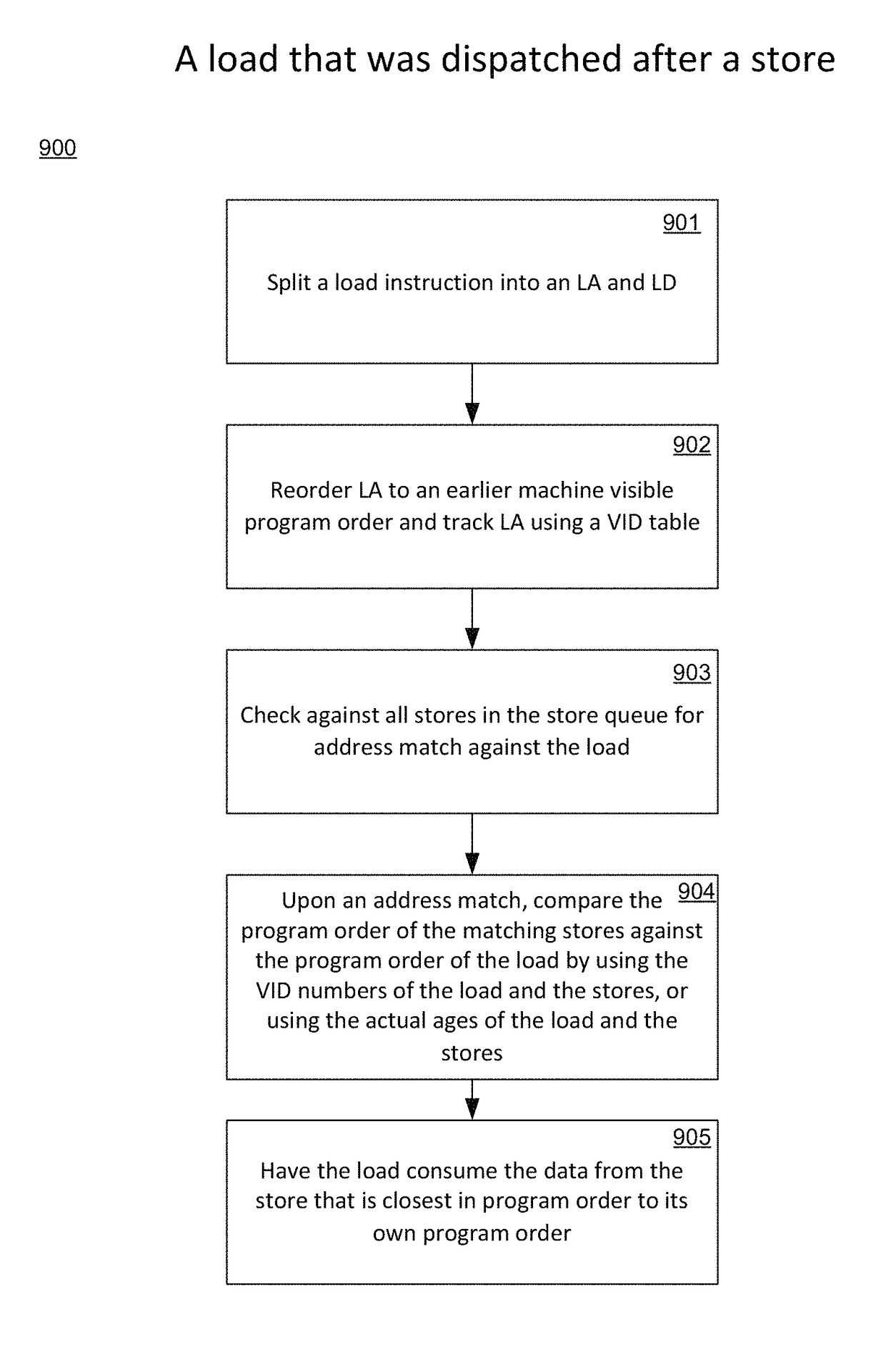

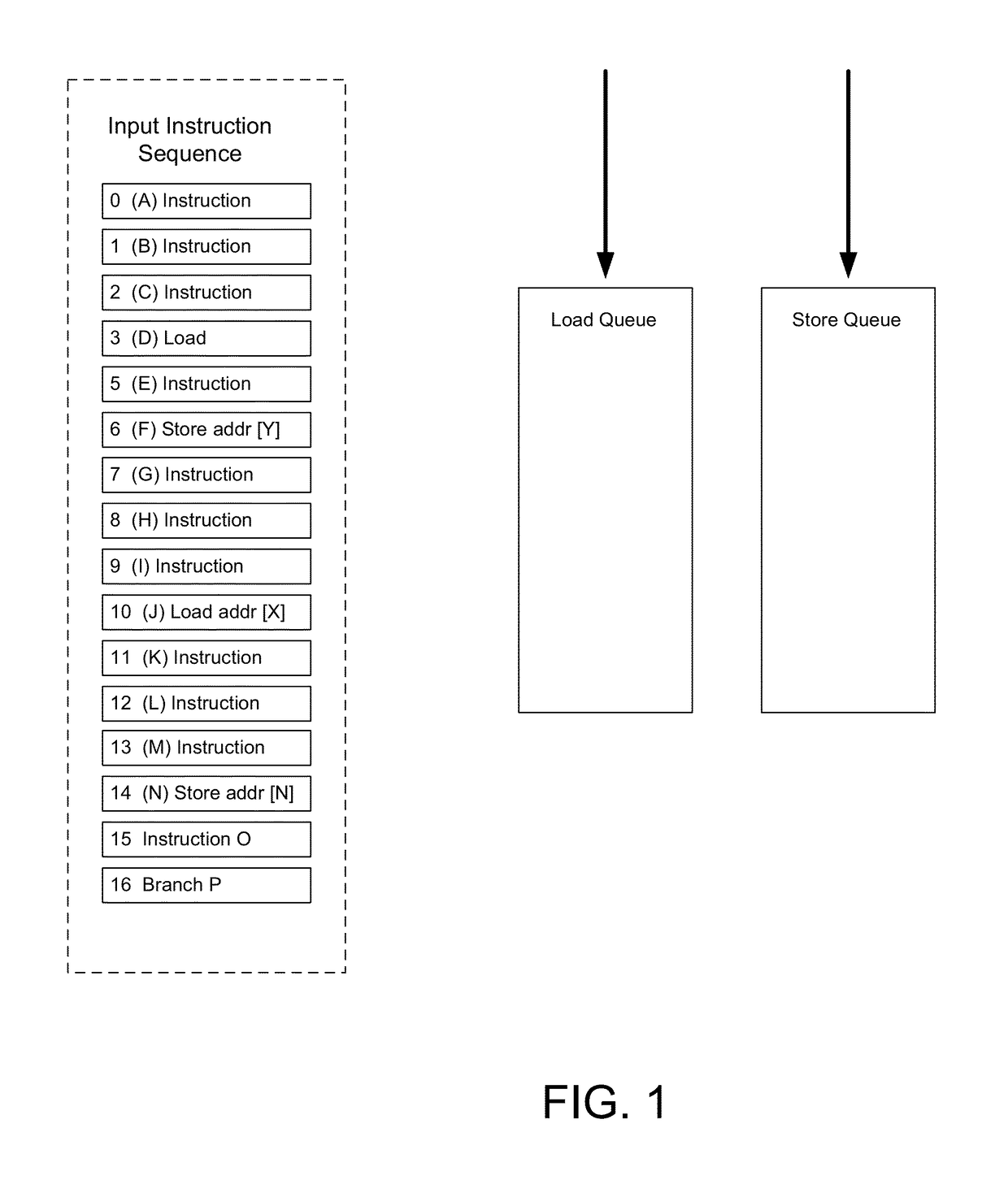

A method for forwarding data from the store instructions to a corresponding load instruction in an out of order processor. The method includes accessing an incoming sequence of instructions; reordering the instructions in accordance with processor resources for dispatch and execution; ensuring a closest earlier store in machine order for to a corresponding load, by determining if said store has an actual age but said corresponding load does not have an actual age, then said store is earlier than said corresponding load; if said corresponding load has an actual age but said store does not have an actual age, then said corresponding load is earlier than said store; if neither said corresponding load or said store have an actual age, then a virtual identifier table is used to determine which is earlier; and if both said corresponding load and said store have actual ages, then the actual ages are used to determine which is earlier.

Owner:INTEL CORP

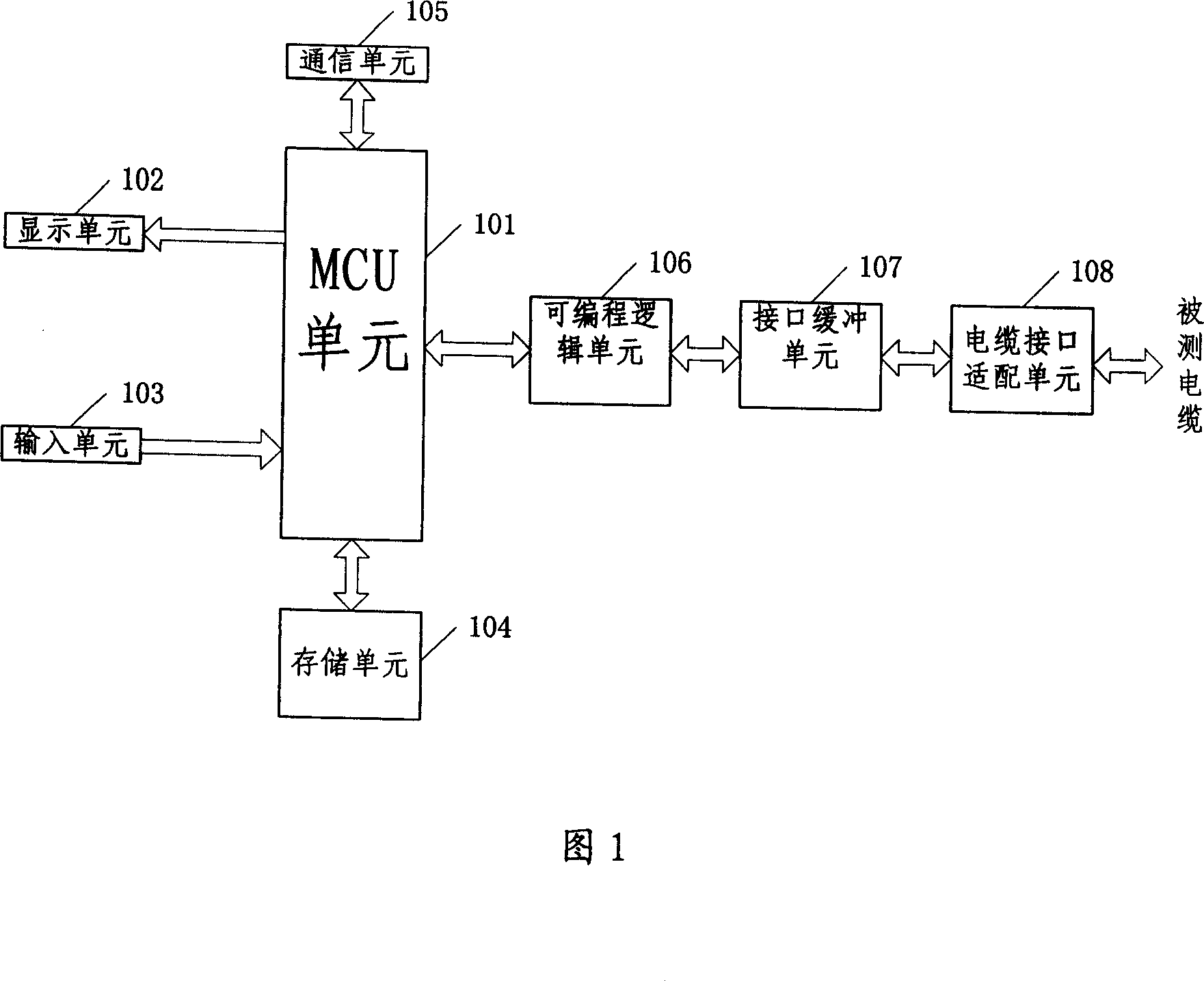

Cable detection apparatus and scanning method thereof

InactiveCN1924597AFlexible and convenient configurationFlexible and convenient replacementFault locationComputer hardwareElectric cables

This invention relates to cable test device and its scan method, wherein the device comprises the following parts: one MCU unit, communication connection unit, display unit and input unit to get human and machine order and to read reference cable information and to read cable information and to compare information and display the result; memory unit to store the test program and middle temporary data for MCU unit; interface buffer unit to provide test signal and cable matching unit buffer to provide several cable interface to send the signal to the cable interface and to get test signal from other end to form one ring test linkage together with the cable to be tested.

Owner:STATE GRID CORP OF CHINA +1

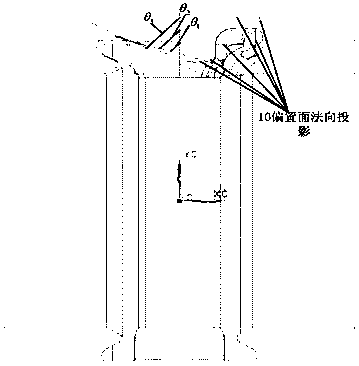

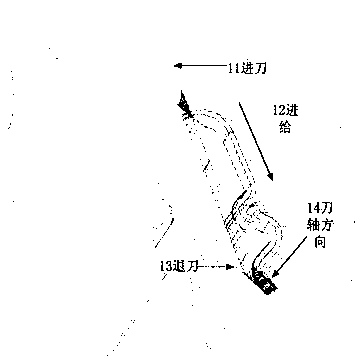

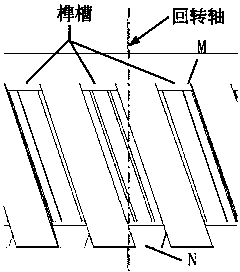

Numerical control machining method of mortise chamfering angles

ActiveCN104690350ASolve the problem of chamferingEliminate manual polishing and chamfering processMilling equipment detailsNumerical controlUltimate tensile strength

The invention discloses a numerical control machining method of mortise chamfering angles. The numerical control machining method comprises the following main steps: analyzing the structural features of an overall wheel disc; selecting a tool, a machine tool and a clamp for numerical control machining, and generating a numerical control machining cutter path of the mortise chamfering angles; sequentially machining chamfering angles on the single side of the single end surface of a wheel disc mortise, and machining chamfering angles on the other side of the same end surface; and after finishing machining of the chamfering angles of the first end surface, machining mortise round angles of the other end surface by turnover. By virtue of a point-milling machining method, firstly, the half position of the required chamfering angle is milled on one end surface of the wheel disc according to the mortise machining order; then, the other half position of the mortise chamfering angle is symmetrically milled according to the machining order; and finally, seamless splicing is performed on the two parts of the mortise chamfering angle. According to the method, the mortise chamfering angle is successfully machined; numerical control milling of the chamfering angles on the complicated structure of the wheel disc mortise is realized by virtue of the five-coordinate machine tool; the consistency of the machining quality and the size of the chambering angles is ensured; the production efficiency is improved; and the labor intensity of operators is greatly alleviated.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Surface treatment and finishing process of packaging box

InactiveCN101607455ASimple manufacturing processPromote softeningBox making operationsPaper-makingEngineeringMachine press

The invention provides a surface treatment and finishing process of a packaging box, for which a special die and a special press are used, and the process comprises the following steps: (1) machining an order datum on a selected material; (2) locating the material by a tooling mounted on a printing apparatus with the order datum; (3) printing; (4) arranging the die in a hot pressing layer of the press, and heating the die; (5) putting the material in the die, and locating the machined order datum on the material by a locating device on the die; (6) pressurizing the die and the material by the press; and (7) preserving heat and maintaining pressure. The process helps easily form rich multi-level patterns and textures on the material by pressurizing, heating and preserving heat and maintaining pressure of the die containing the material, and helps send a plurality of the dies containing materials to a plurality of hot pressing layers at the same time respectively for finishing and treatment, which saves energy, reduces cost, and enhances efficiency and single unit capacity.

Owner:JINCAI PRINTING & PACKAGING

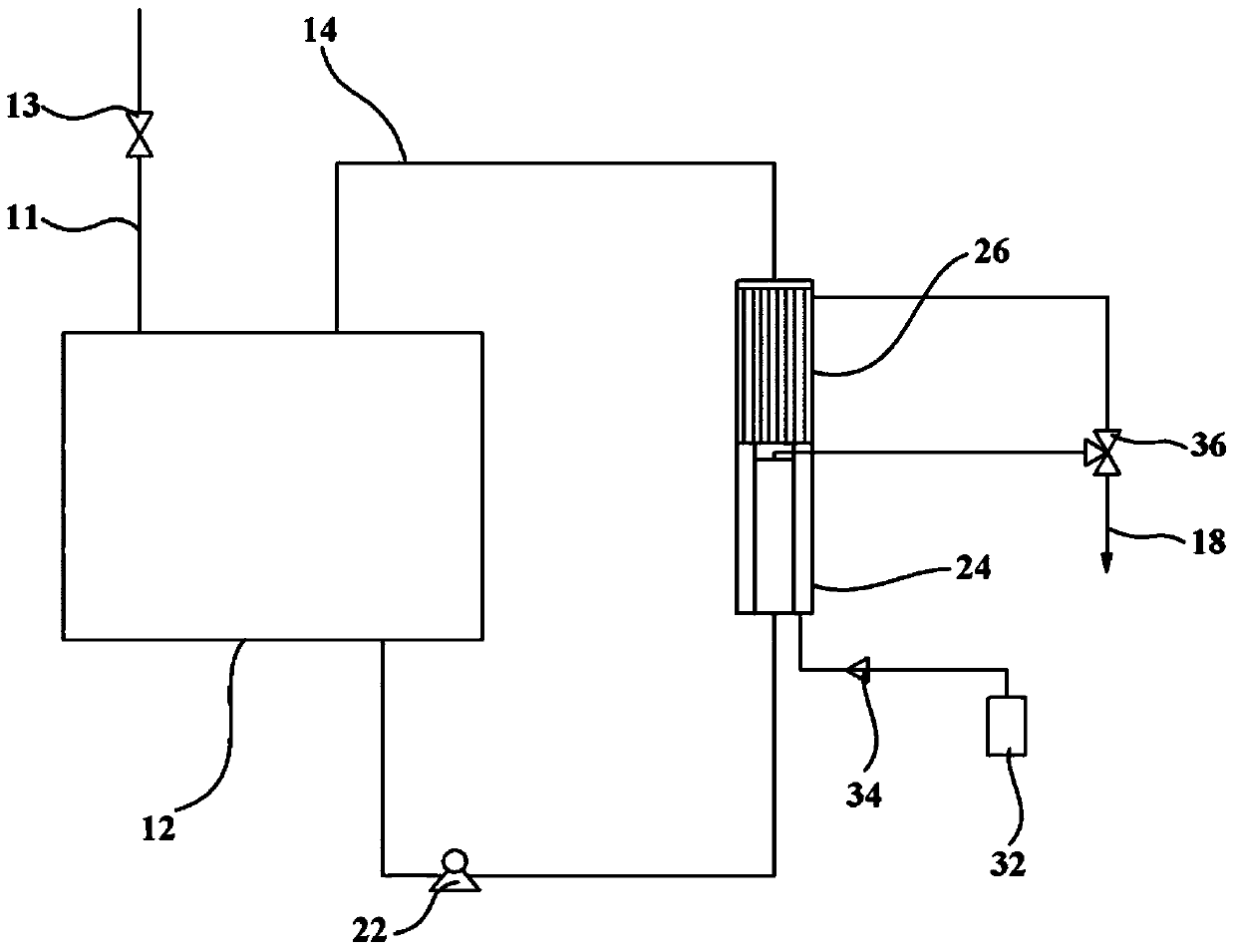

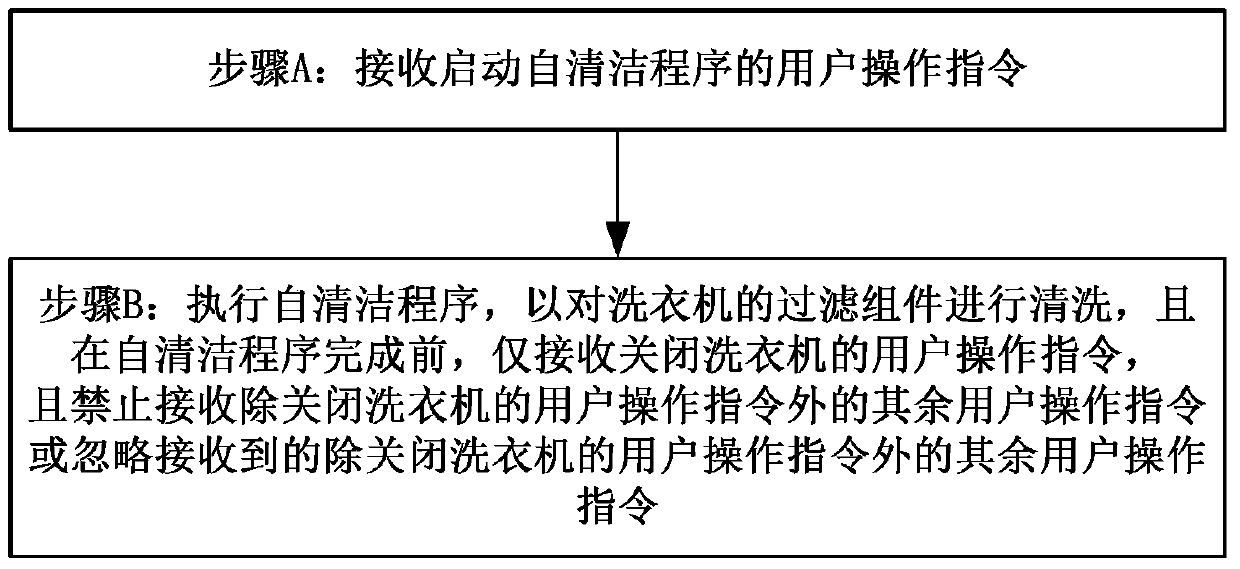

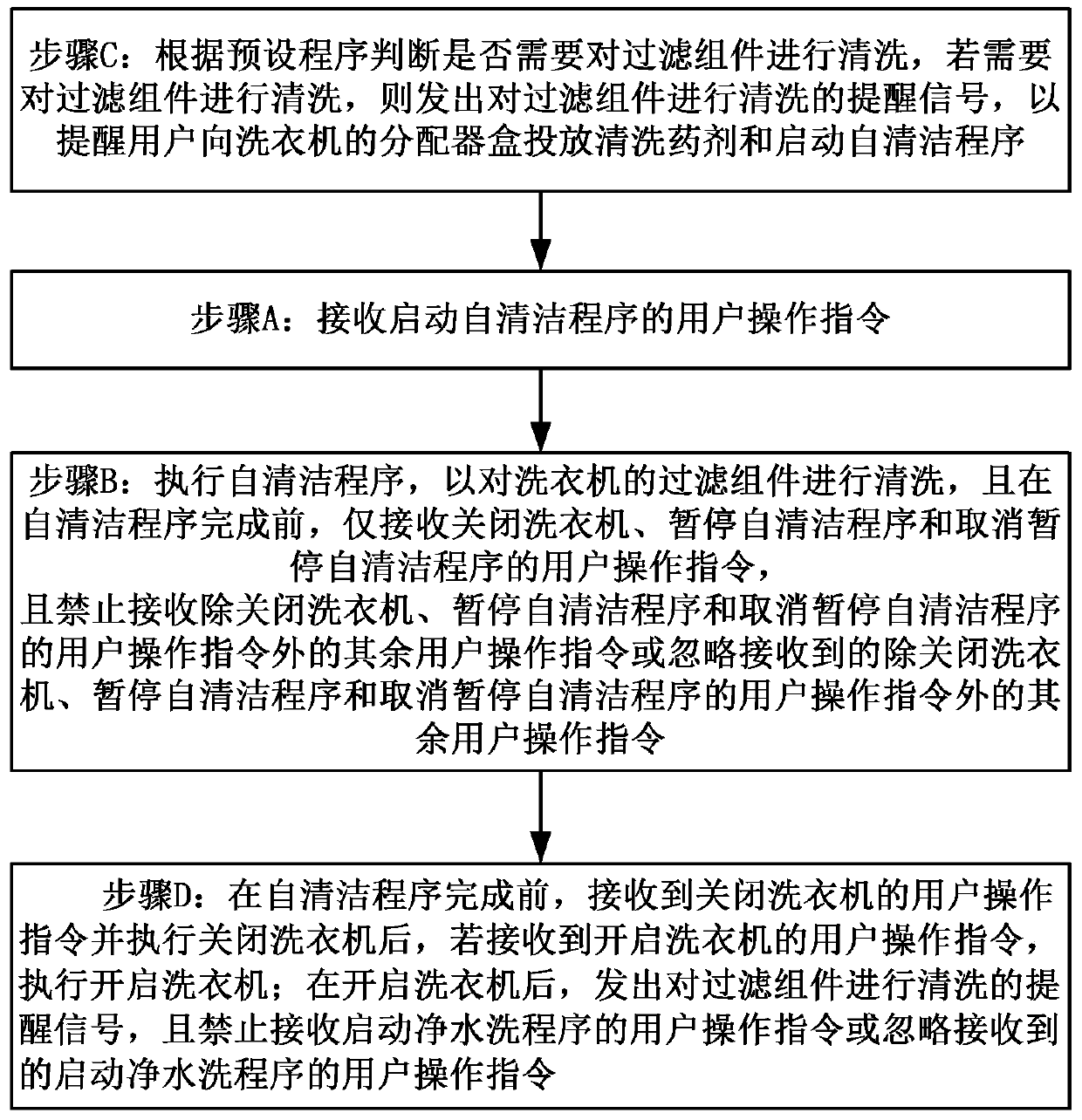

Washing machine filtering assembly self-cleaning method

ActiveCN105506934AAchieve cleaningExtend your lifeOther washing machinesControl devices for washing apparatusCleaning methodsComputer science

The invention provides a washing machine filtering assembly self-cleaning method comprising the following steps: receiving a user operation order used for starting a self-cleaning program; executing the self-cleaning program so as to clean a washing machine filtering assembly, and only receiving the following user operation orders before the self-cleaning program is finished: stopping the washing machine order, pausing the self-cleaning program order, and canceling the self-cleaning program pausing state order; other user operation orders besides the stopping washing machine order, pausing the self-cleaning program order, and canceling the self-cleaning program pausing state order are forbidden to receive or neglected. In a filtering assembly cleaning process of the self-cleaning program, the washing machine cannot receive or neglect other user operation orders besides the stopping washing machine order, pausing the self-cleaning program order, and canceling the self-cleaning program pausing state order, so the washing machine filtering assembly can be thoroughly cleaned, thus prolonging the filtering assembly life, and ensuring the filtering assembly to have a high filtering flux.

Owner:QINGDAO HAIER SMART TECH R & D CO LTD

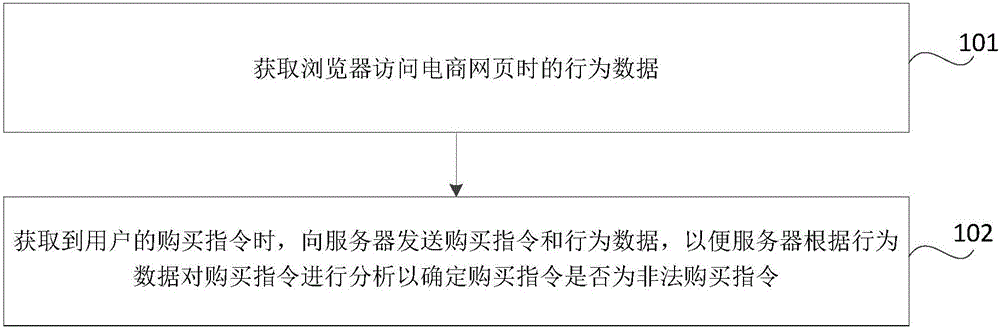

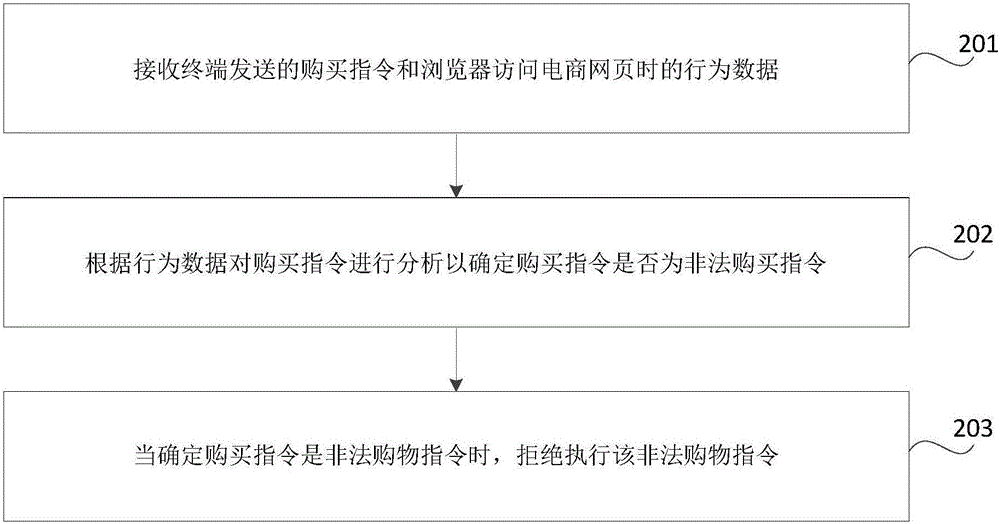

Purchase behavior monitoring method for electronic business system and device

ActiveCN105976201APrevent panic buyingProtect interestsMarket data gatheringComputer terminalSales promotion

The invention relates to a purchase behavior monitoring method for an electronic business system and a purchase behavior monitoring device for the electronic business system. The method includes the following steps that: a purchase instruction sent by a terminal and behavior data generated when a browser visits an electronic business webpage are received; the purchase instruction is analyzed according to the behavior data, so that whether the purchase instruction is an illegal purchase instruction is determined; and when it is determined that the purchase instruction is an illegal purchase instruction, the execution of the illegal purchase instruction is refused. With the purchase behavior monitoring method and device for the electronic business system of the invention adopted, a user can be prevented from rushing to purchase something by adopting a machine order placing mode, and a promotion activity of electronic business can benefit more normal users, and therefore, the interests of the electronic business and the users can be ensured. The system and device of the invention are used for monitoring the purchase behaviors of the electronic business system.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

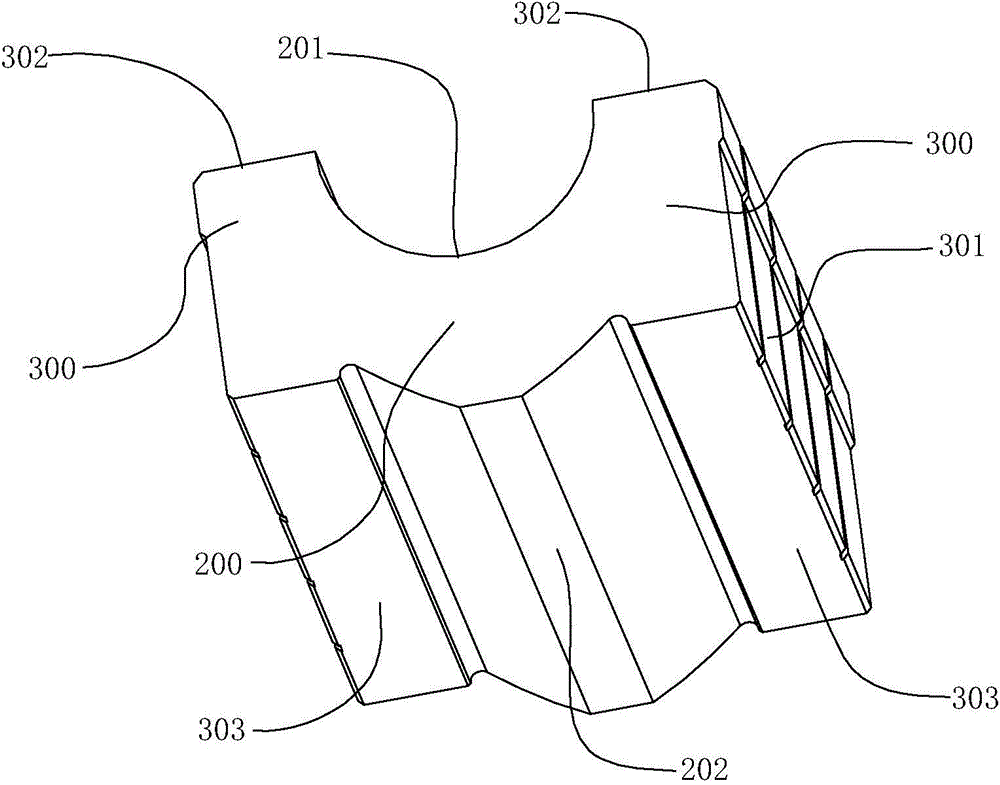

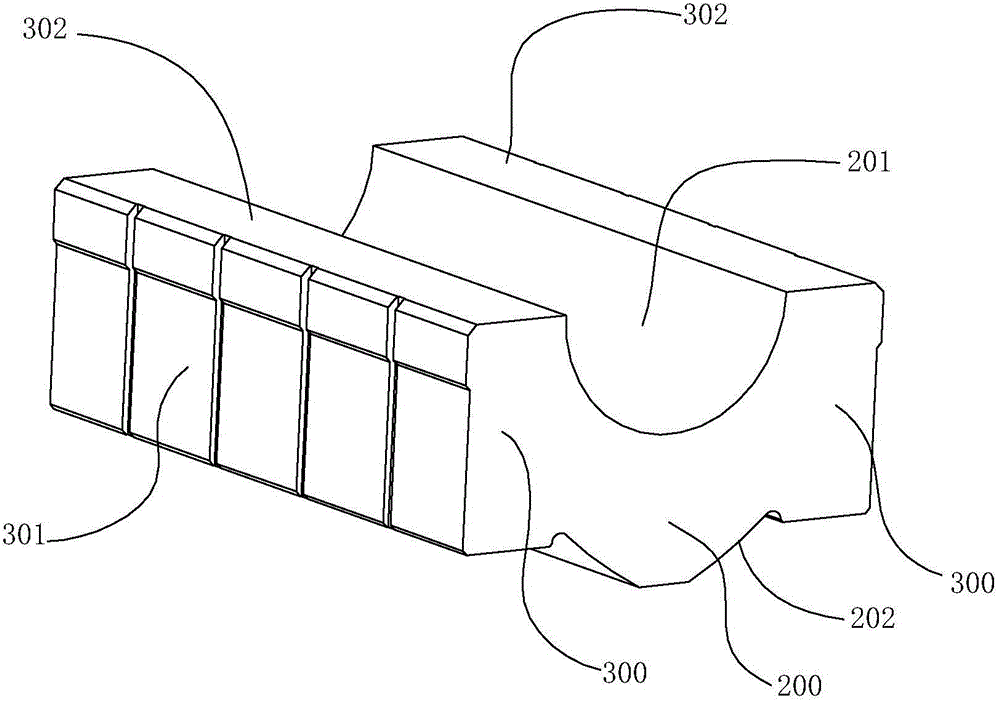

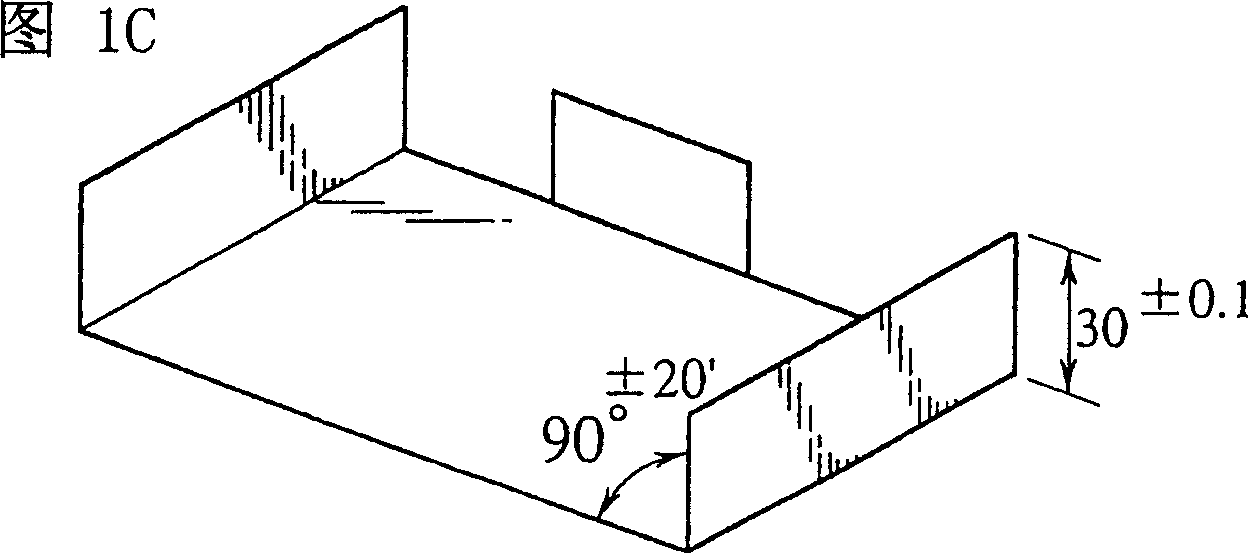

Integrated support system for supporting sheet metal machining

InactiveCN1601417AProcessing support data appliesHigh Precision Machining OperationsAutomatic control devicesComputer controlSupporting systemMachine parts

The present invention provides an integrated support system for supporting sheet metal machining adapted to store and reuse the know how of skilled machine operators and improve the quality of sheet metal products and the rate of operation of machine tools by improving the arrangement operation from the actual machining phase to the design phase. The system comprises a design part (A) for generating metal plate machining information; a machining part (B) for completing the practical machining operation based on the generated metal plate machining information; the design part (A) comprises: a machining analog unit (200) which can determine whether the derivation view data and machining order is true or false by displaying three-view diagram corresponding to the derivation view data based on the input design data and machining condition of the metal product to be machined, and thereby outputting best derivation view data; wherein: the metal plate machining information is generated after the determination based on the best derivation view data.

Owner:AMADA CO LTD

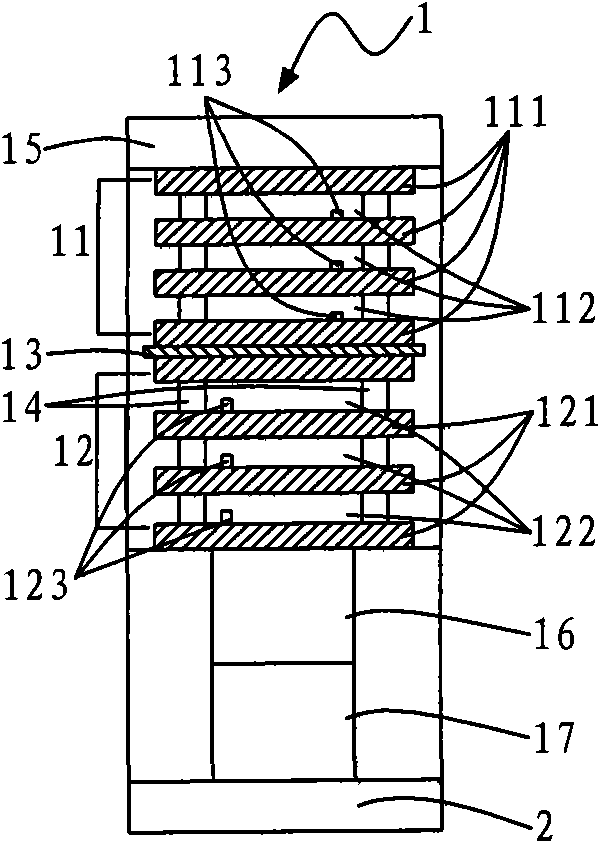

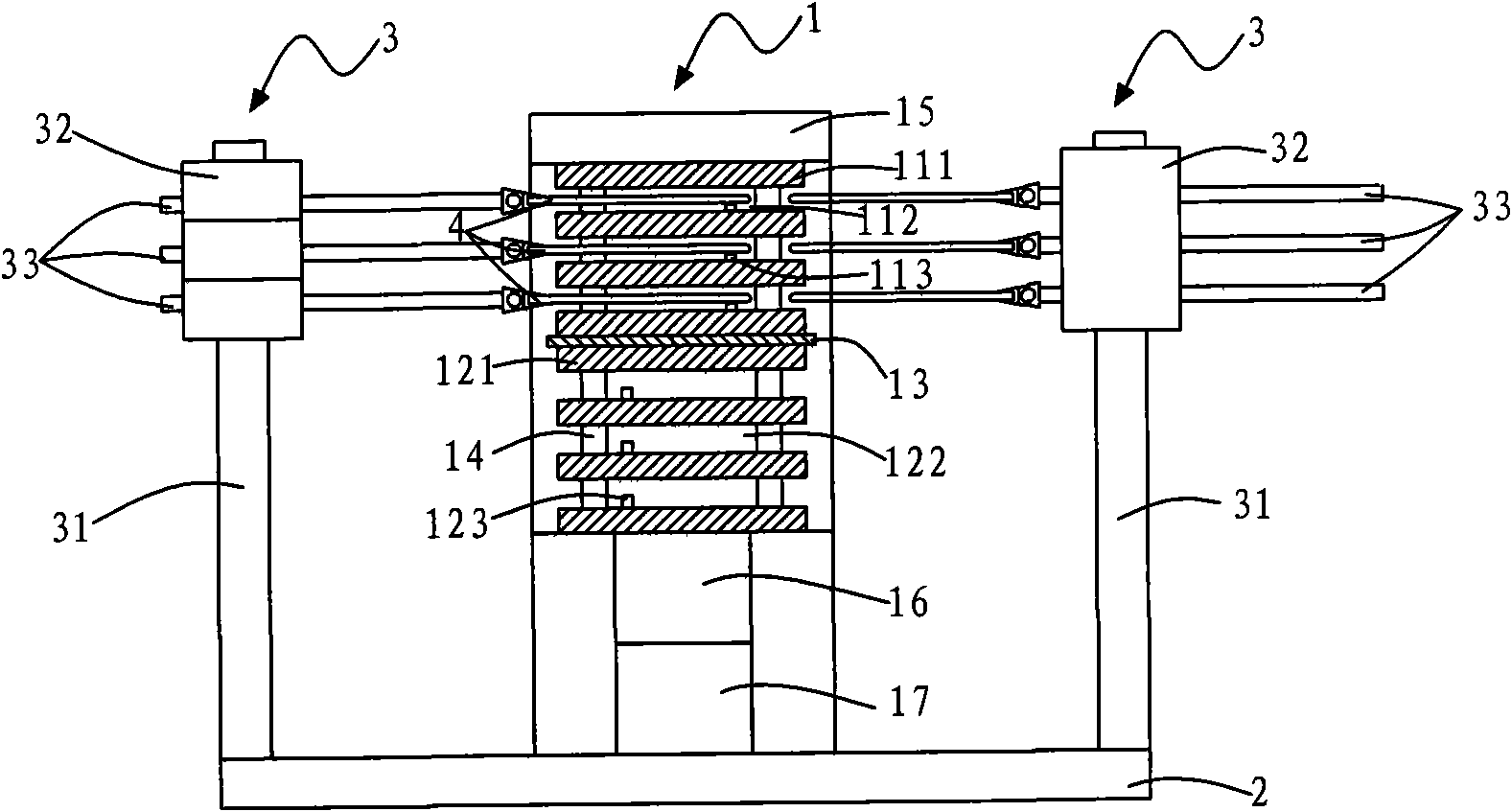

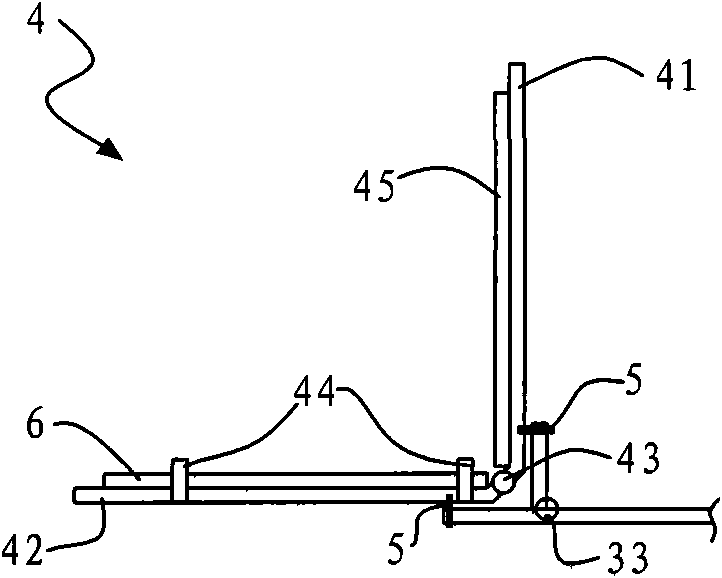

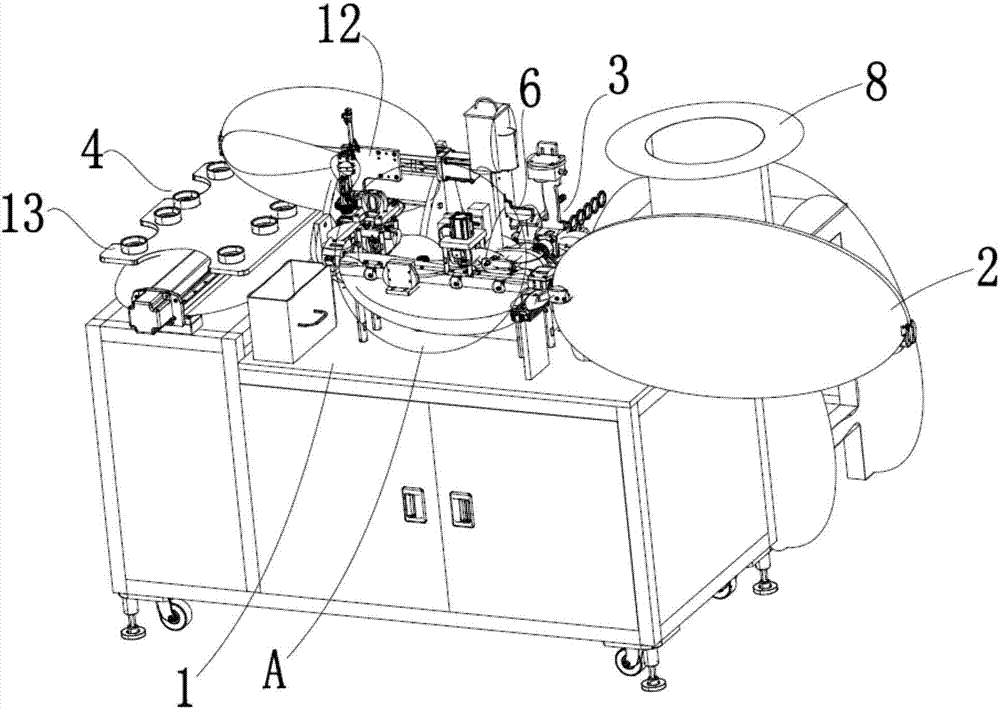

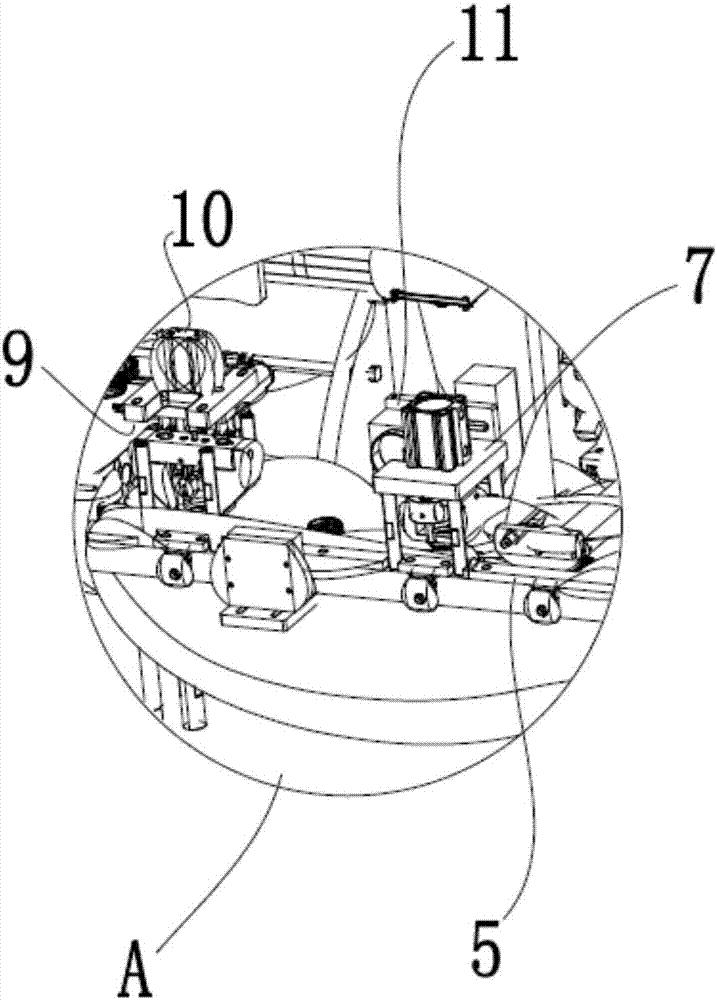

Oil tank cover assembling system with automatic seal ring mounting function and oil tank cover assembling method

The invention discloses an oil tank cover assembling system with an automatic seal ring mounting function. The oil tank cover assembling system comprises a machine table, an oil tank cover feeding device, an automatic assembling and detecting device and a disc loading device; a supporting frame and a supporting seat are arranged on the machine table; the oil tank cover feeding device, the automatic assembling and detecting device and the disc loading device are arranged according to the machining order of an oil tank cover and are arranged on the machine table; the automatic assembling and detecting device comprises a mounting and conveying material path, a sealing ring conveying assembly and a sealing ring mounting assembly; the mounting and conveying material path is arranged on the supporting seat; and the left and right ends of the mounting and conveying material path are connected with the oil tank cover feeding device and the disc loading device correspondingly. The invention further discloses an oil tank cover assembling method, an operator is replaced with full automatic equipment, the production efficiency is greatly improved, the errors, such as placement missing, misplacement and excessive placement, caused by manual operation are avoided, and the production quality of the oil tank cover is guaranteed.

Owner:东莞诚信电子塑胶有限公司

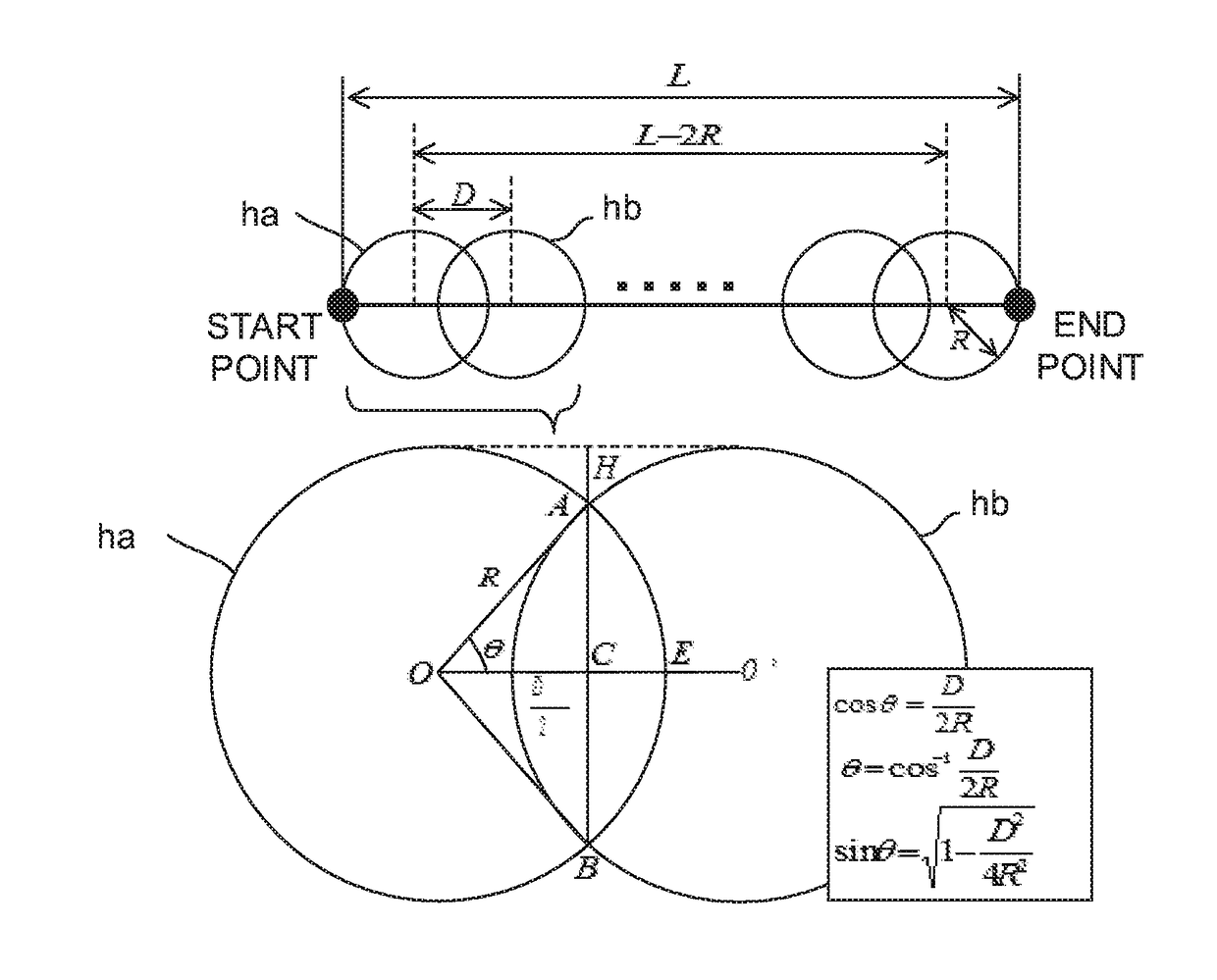

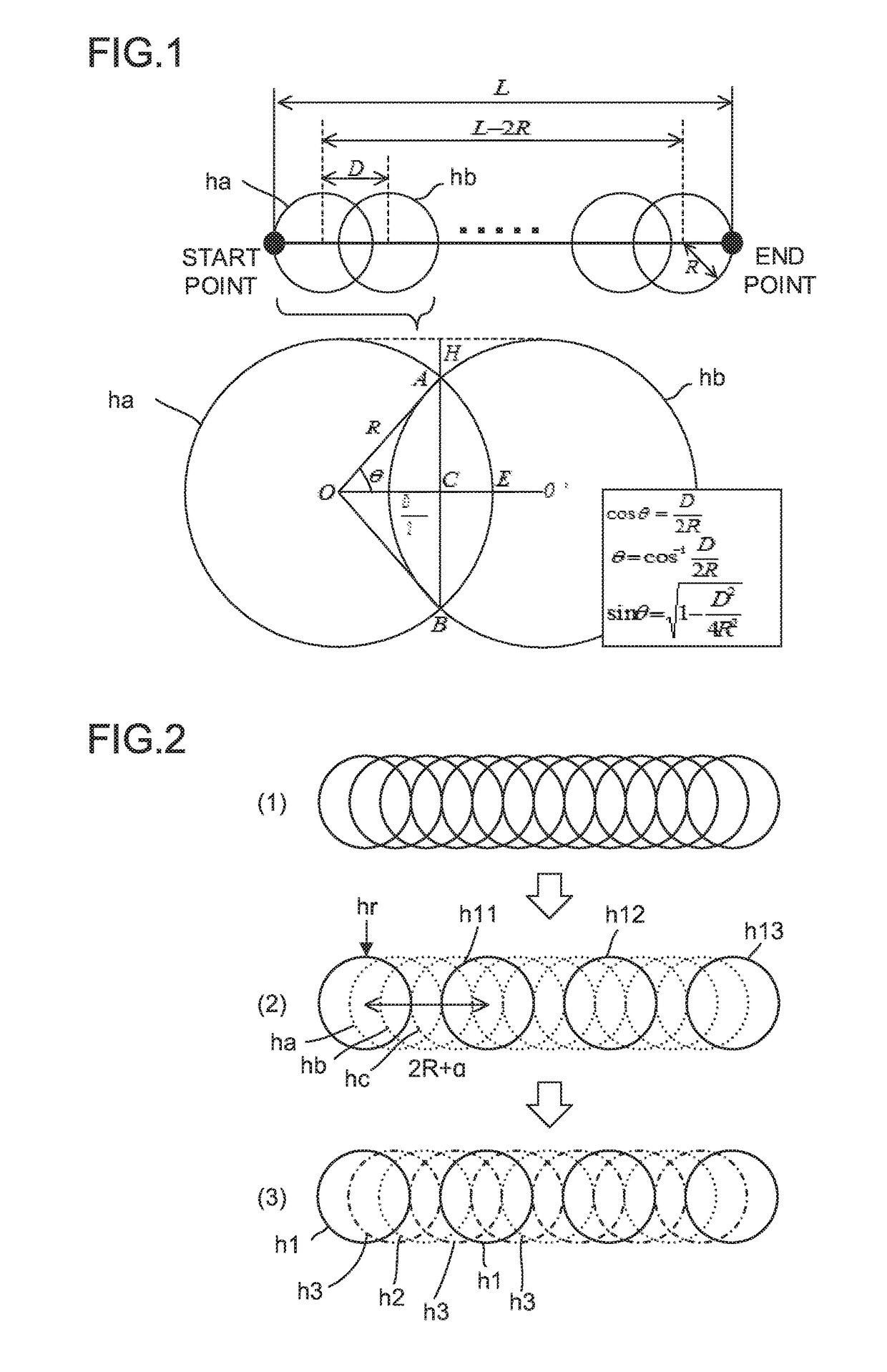

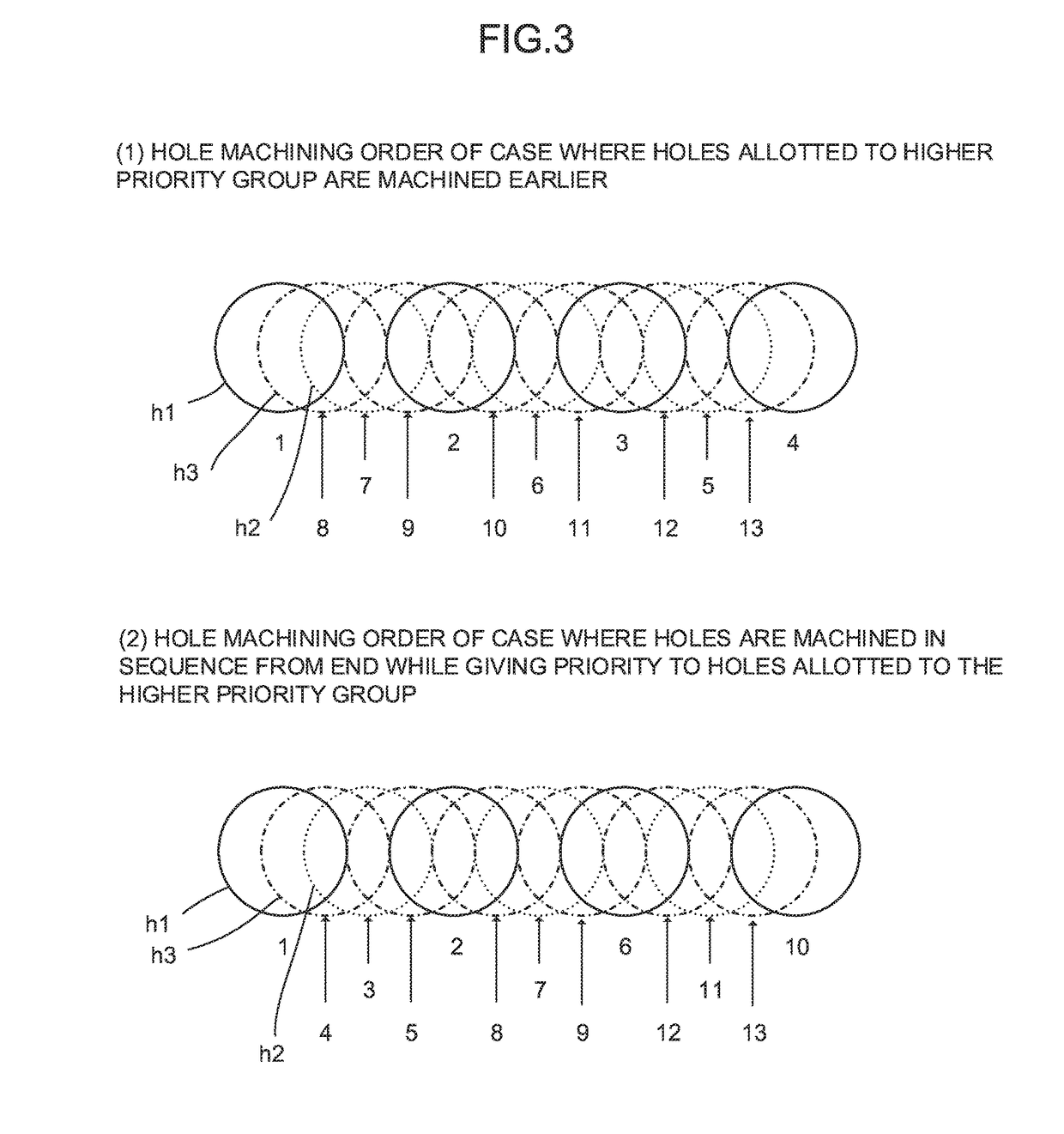

Program generation device generating program for groove machining by drilling

ActiveUS20170235289A1Promote generationReduce loadProgramme controlComputer controlEngineeringMachining

A program generation device generates a program for controlling machining of a groove which is performed by machining a plurality of holes on a workpiece. The program generation device receives specified values including a tool radius, a groove shape (a length of the groove), and a cusp height and calculates positions of the plurality of holes based on the specified values which are received. Then, the program generation device calculates a machining order of the plurality of holes based on the specified values and respective values calculated by a hole machining set value calculation unit so that a bias is not generated in a removal stock for a tool in machining.

Owner:FANUC LTD

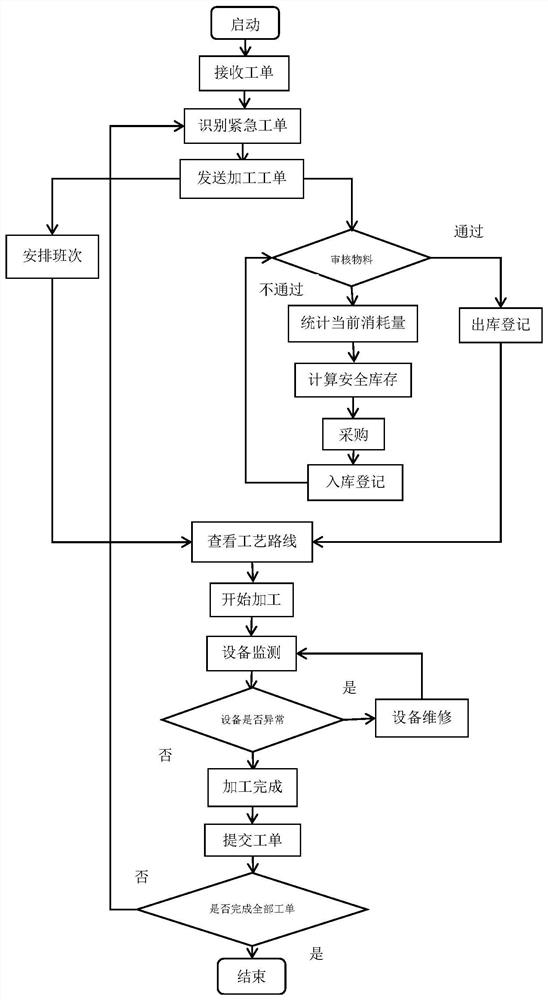

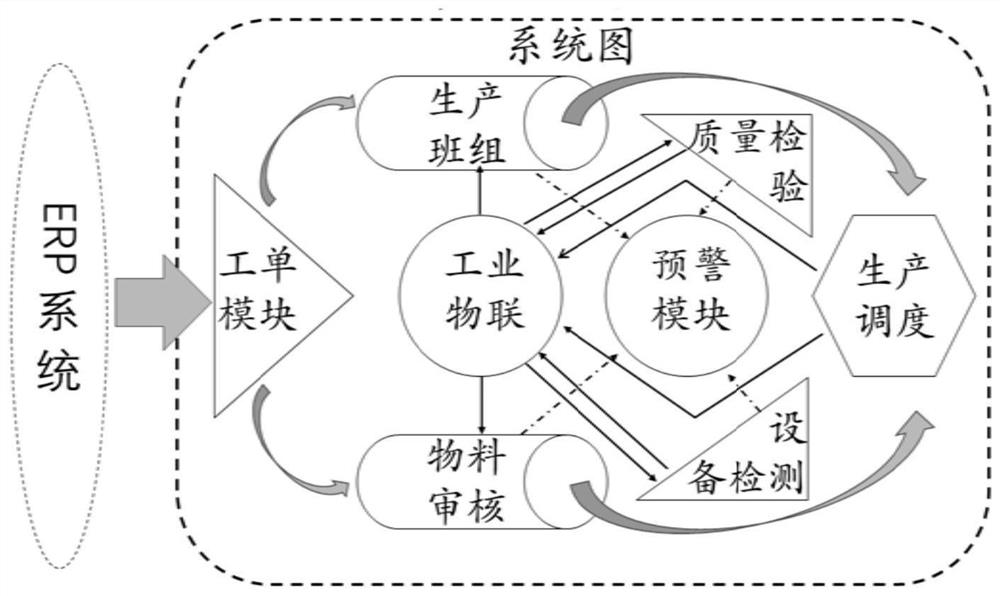

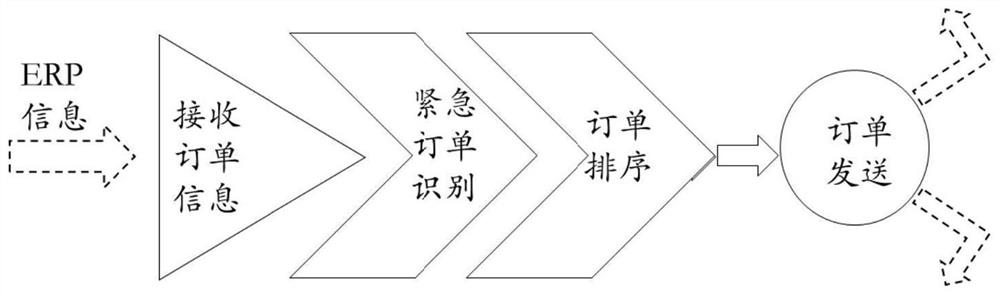

MES system management and control method and system for automobile synchronizer gear hub production line

PendingCN113052553AIncrease productivityReduce adverse effectsOffice automationFuzzy logic based systemsInformation controlSystems management

The invention discloses an MES system management and control method and system for an automobile synchronizer gear hub production line, and the method comprises the steps: receiving the machining order information of an automobile synchronizer gear hub, sorting the machining order information according to the emergency degree, and generating work order information; generating production shift information according to the work order information and production personnel information collected by the Internet of Things system; according to the work order information and material information collected by the Internet-of-Things system, judging whether the materials meet production requirements, if yes, generating material ex-warehouse information, and if not, generating material supplement information; generating process route information according to the process information collected by the Internet of Things system and a genetic algorithm based on a fuzzy theory; and generating production processing information according to the production shift information, the generated material ex-warehouse information and the process route information, and controlling production equipment to start production processing according to the production processing information. Lean management of automobile synchronizer gear hub production is enhanced, the production cost is reduced, and the production efficiency is improved.

Owner:CHANGAN UNIV

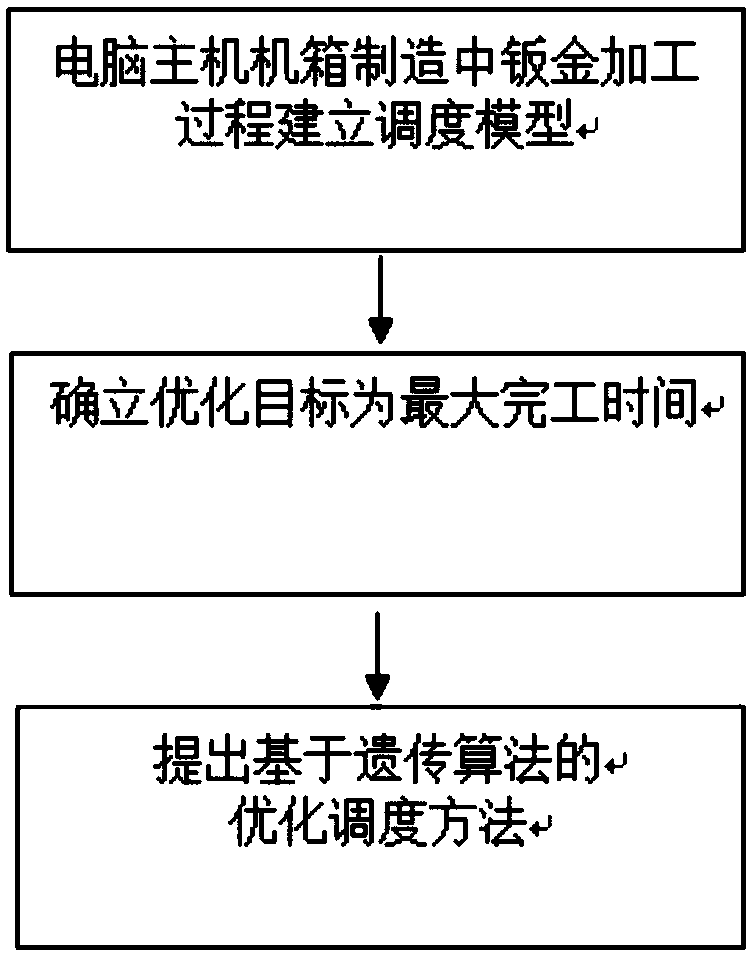

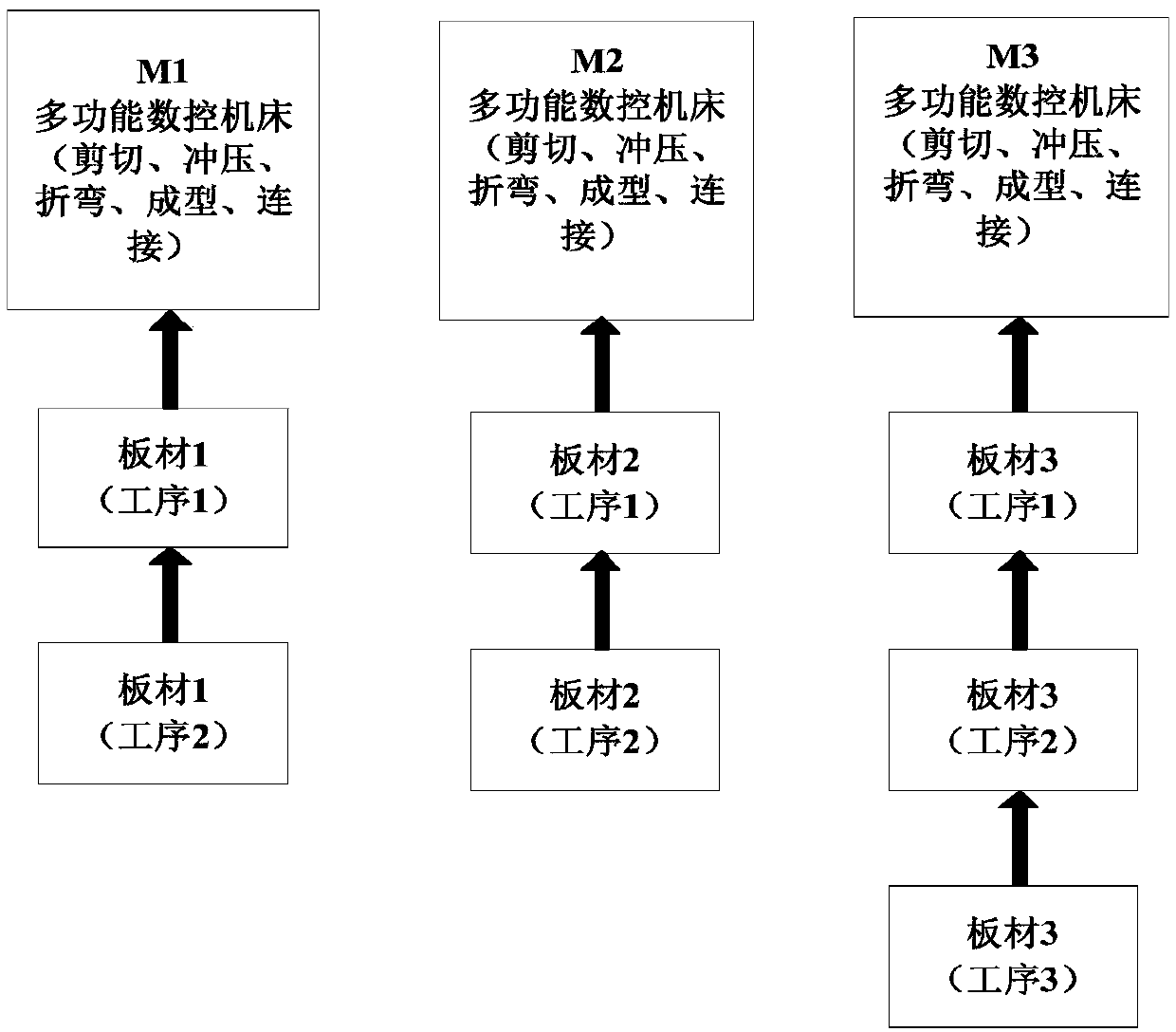

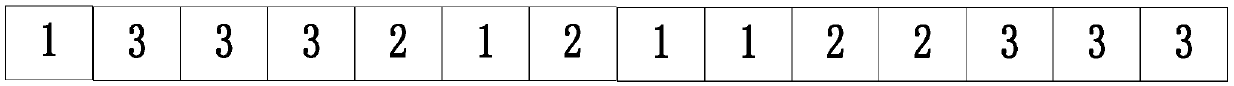

Optimization scheduling method for sheet metal machining process in manufacture of computer case

InactiveCN108983719AReduce processing timeIncrease productivityTotal factory controlProgramme total factory controlCompletion timeGenetic algorithm

The invention relates to an optimization scheduling method for the sheet metal machining process in the manufacture of a computer case, and belongs to the technical field of intelligent optimization scheduling in a production workshop. The method comprises firstly expressing the uncertain machining time by a fuzzy number by means of field measurement or prior knowledge; then determining a scheduling model and an optimization target of the sheet metal machining in the production process of the computer case, and optimizing an optimization objective by using an optimization scheduling scheme based on a genetic algorithm, wherein the scheduling model is established based on the machining completion time of computer case metal plates in each batch on each machine, and the optimization objective is the minimized earliest completion time. The method makes the sheet metal machining order and the machine distribution order clear by using a two-stage coding method, represents the uncertain machining time and the completion time by using the triangular fuzzy number, is close to an actual production situation, has global search guidance, can retain the historical information of dominant individuals to some extent, and guarantees the global search a certain width.

Owner:KUNMING UNIV OF SCI & TECH

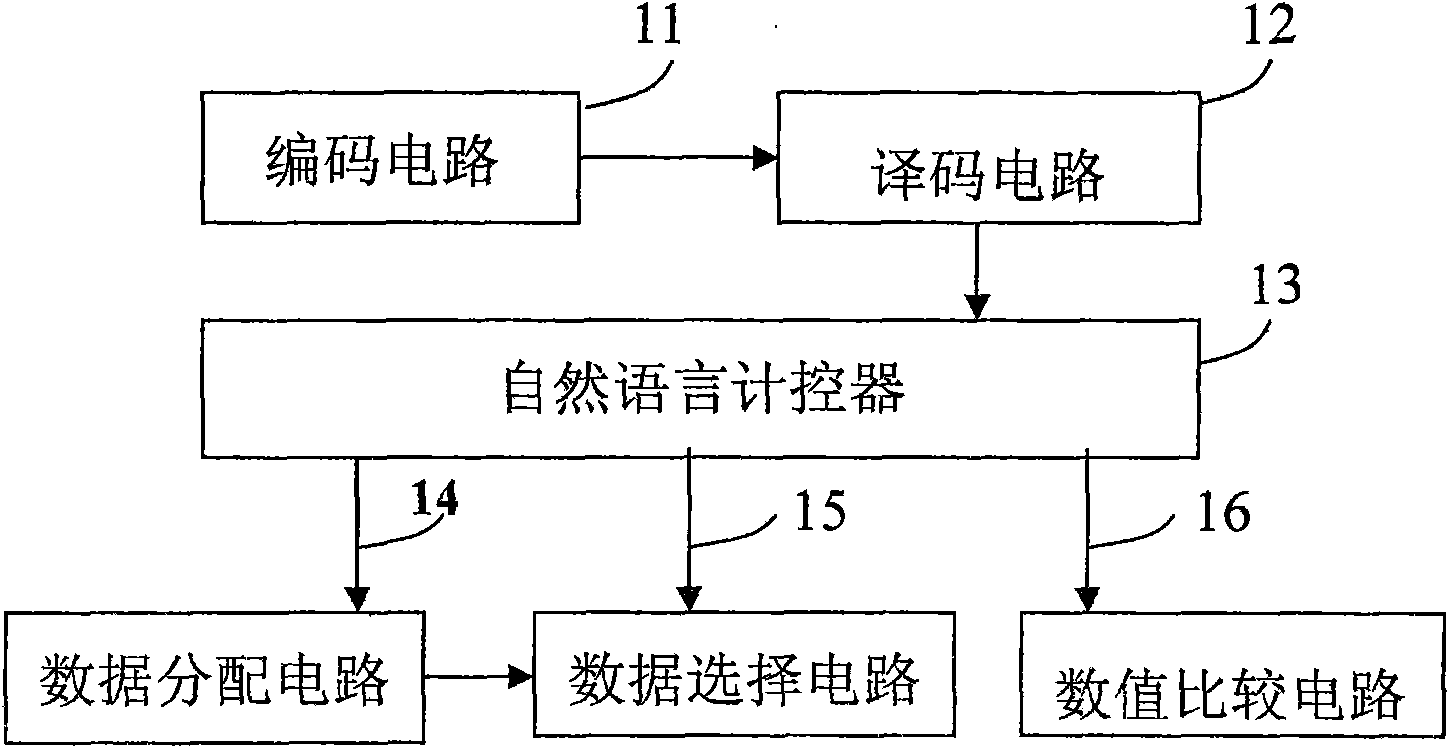

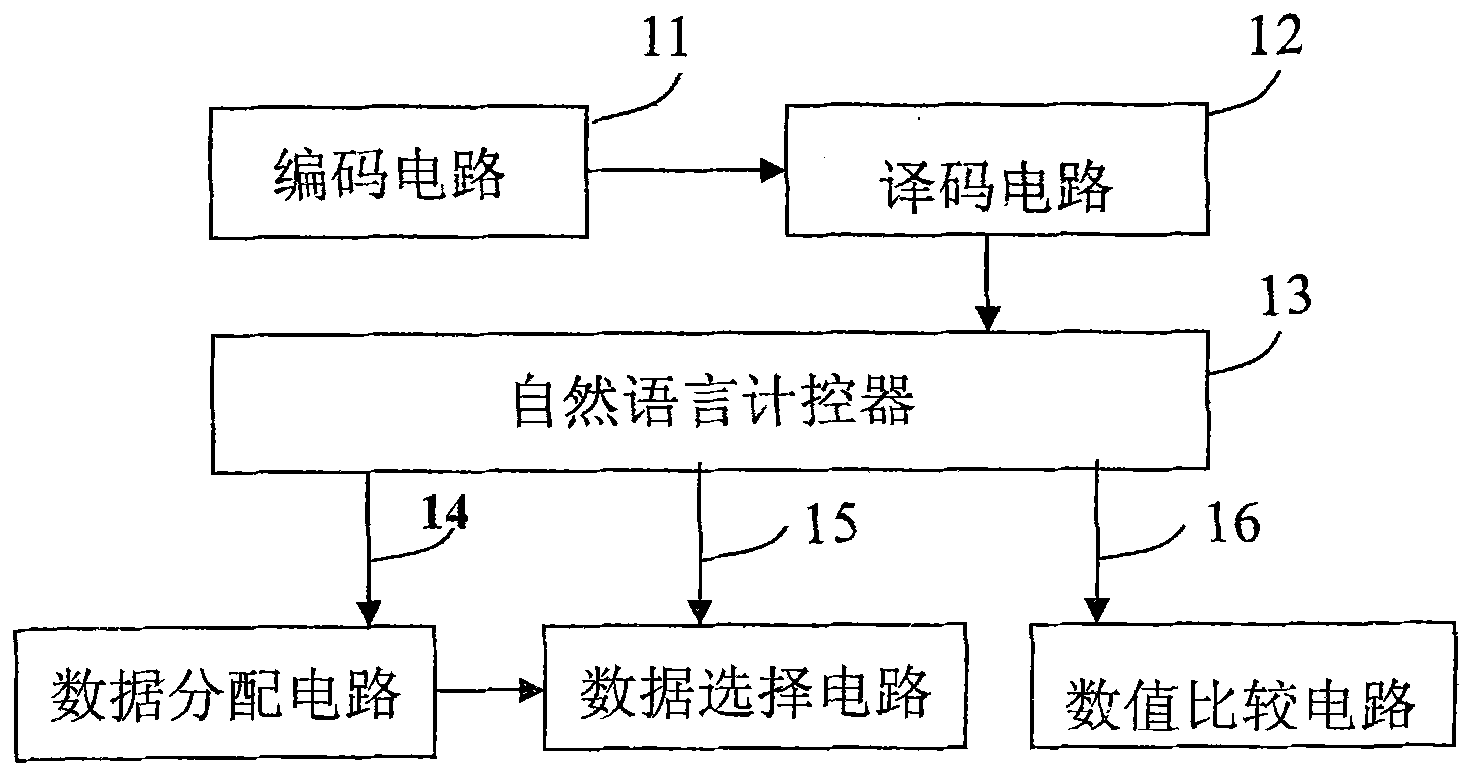

Logic control method of natural language program and computing method thereof

InactiveCN101931394AAchieve mechanical controlLogic circuits characterised by logic functionSpecial data processing applicationsSemantic propertyMachine instruction

The invention relates to a hardware processing method for controlling and computing a natural language program. The invention provides digital logical technology for controlling and computing the natural language program. The method comprises the following steps of: corresponding or designing the logical connection relationship being a subject and predicate conception and a sentence to be a machine order for controlling and computing a procedure; coding the positive and / or negative semantic property of the subject and predicate conception and the sentence to a binary code which is 0 or 1; corresponding the binary code which represents the 0 or 1 of the semantic property to be a high electrical level and a low electrical level of a computing program, a controlling program and / or a driving program; and designing a corresponding logic circuit and a device thereof with the high electrical level and the low electrical level of the computing program, the controlling program and / or the driving program which correspond to the binary code which represents the semantic property, thereby realizing the logic control and computation of the natural language program.

Owner:万继华

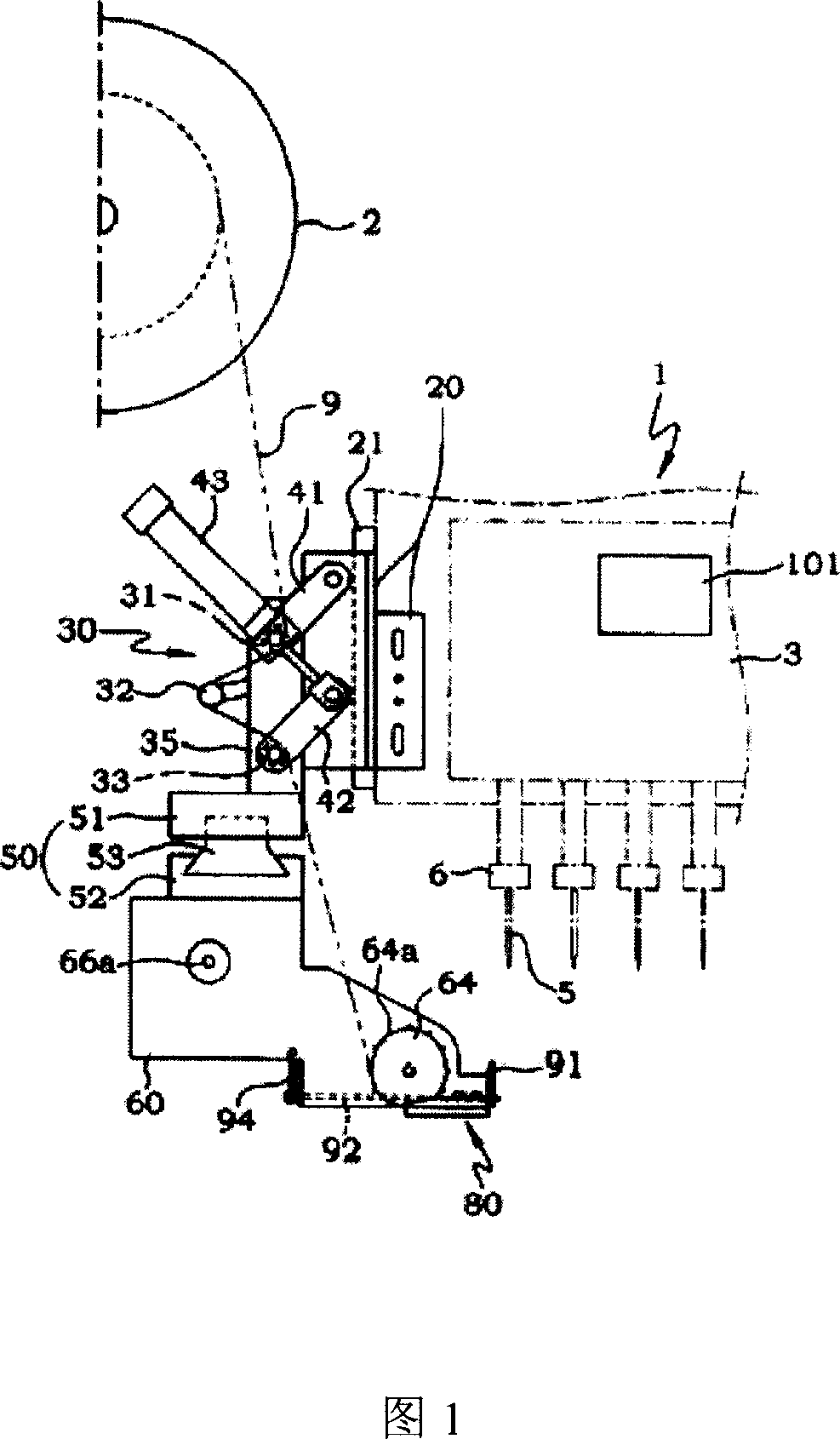

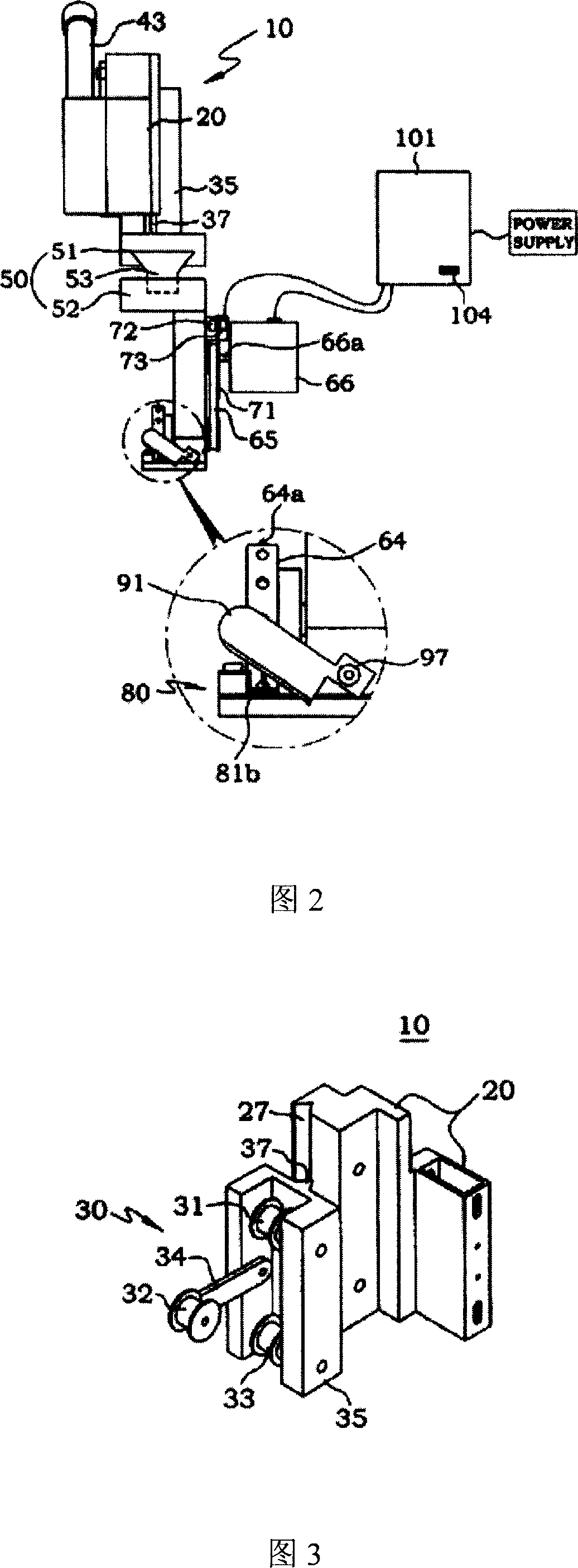

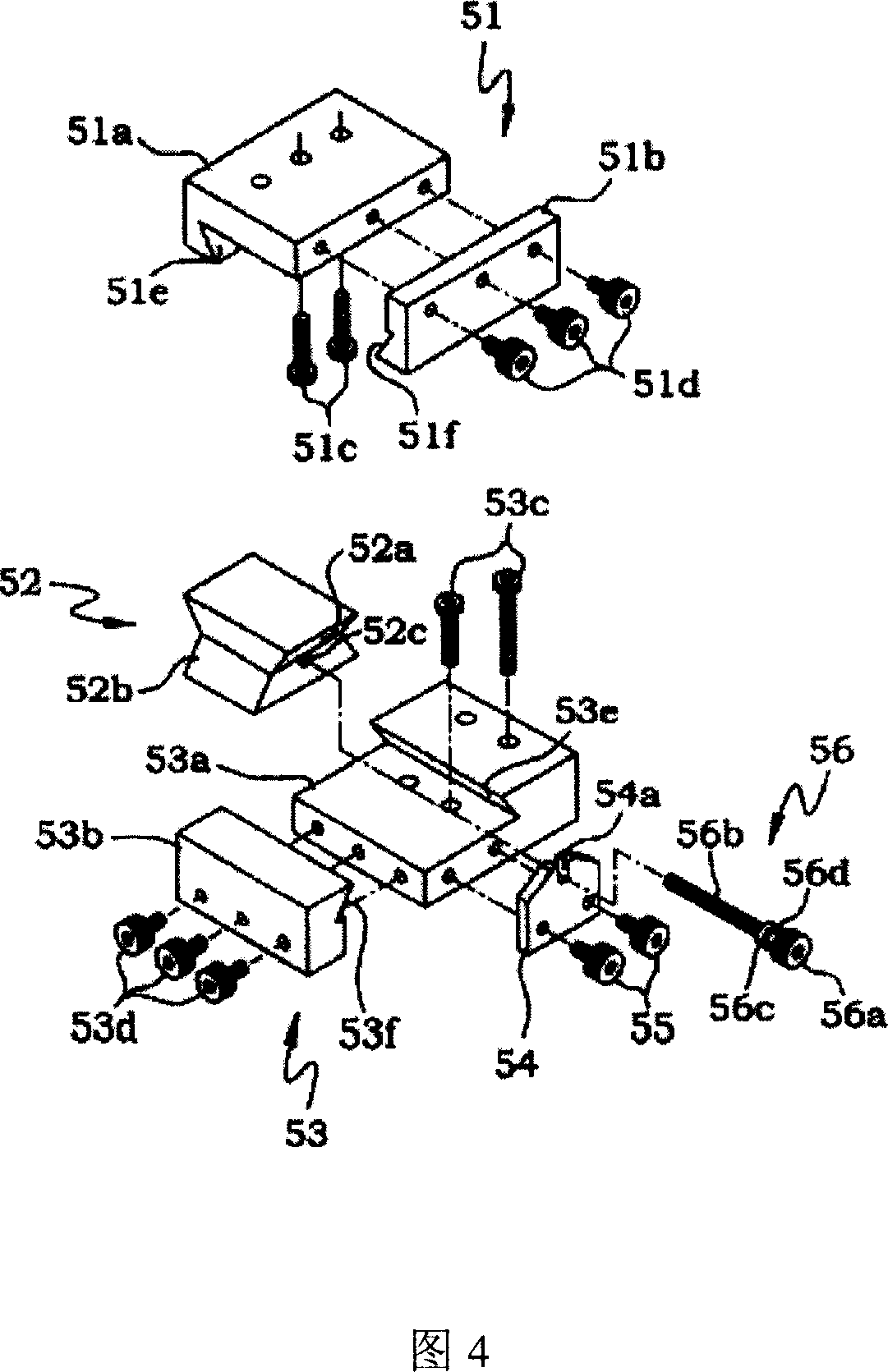

Spangle supplying apparatus

InactiveCN1989284APrecise positioningPrecise maintenanceAutomatic machinesAuxillary devicesPunchingEngineering

There is provided a spangle supplying apparatus. The spangle supplying apparatus includes a controller mounted on each head of any type of the embroidery machines regardless of a manufactured year, manufacturing company, and the number of heads, the controller having a drive and a controller. The controller is programmed to independently process a spangle jump signal system such that the spangle jump signal system by the punching design data inputted to a controller of the embroidery machine orders a stop command to a stepping motor mounted on each lower body through a main CPU of the embroidery machine according to a detected signal voltage difference of a terminal connected to a jump solenoid disposed on each head or the stepping motor to supply the spangle or stop the supply of the spangle to return the apparatus to a starting point when electric power is supplied again after being off.

Owner:DSE

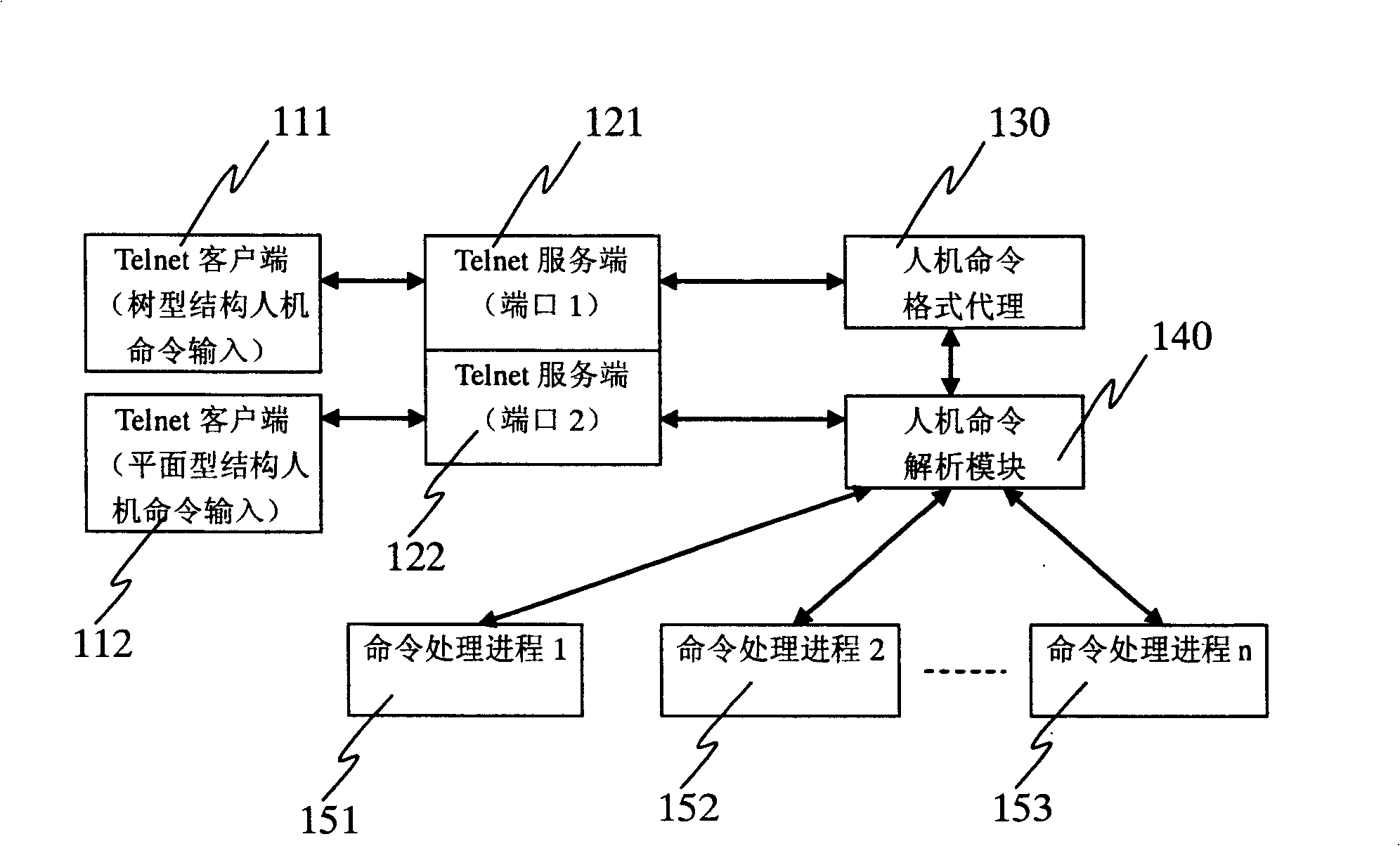

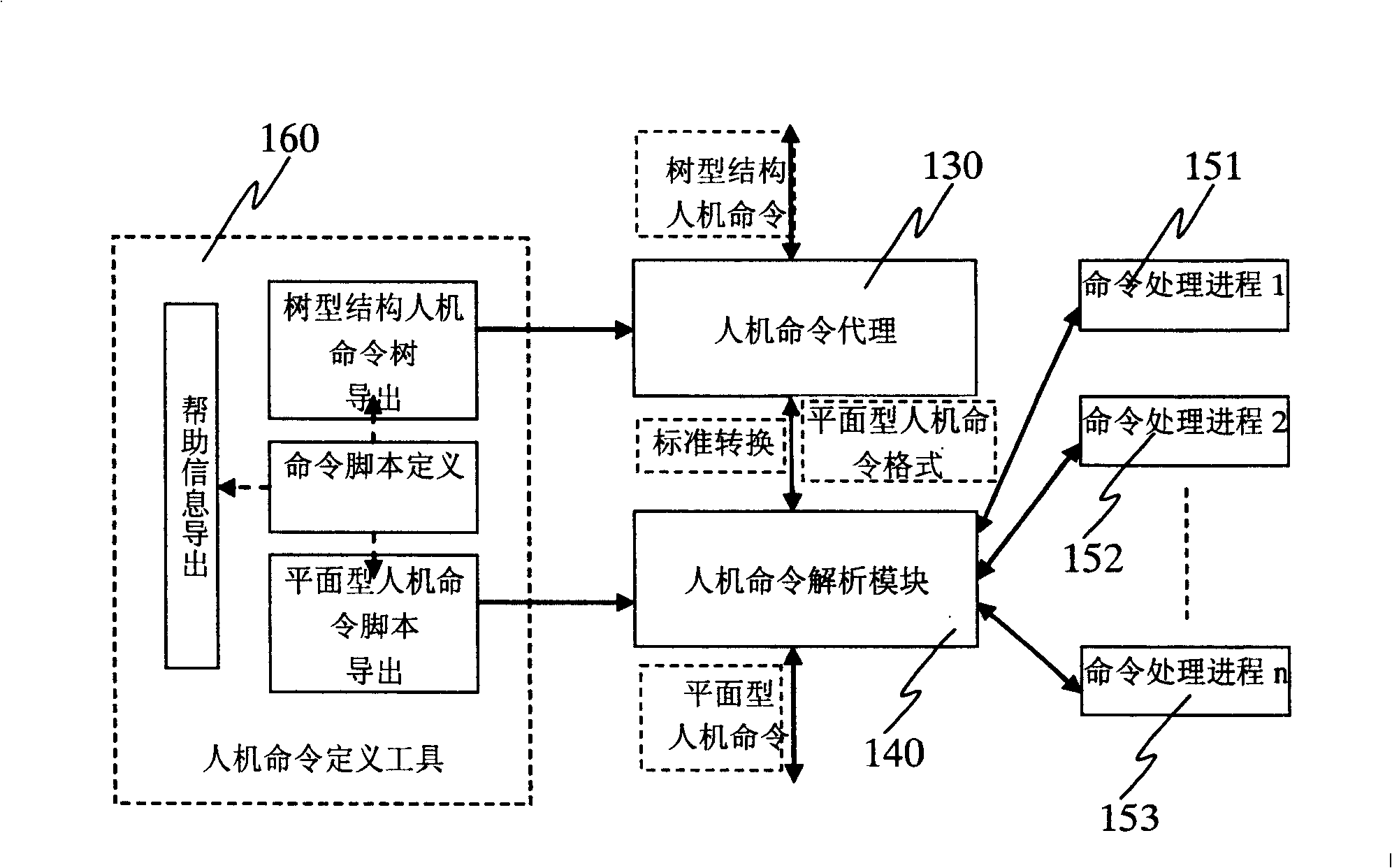

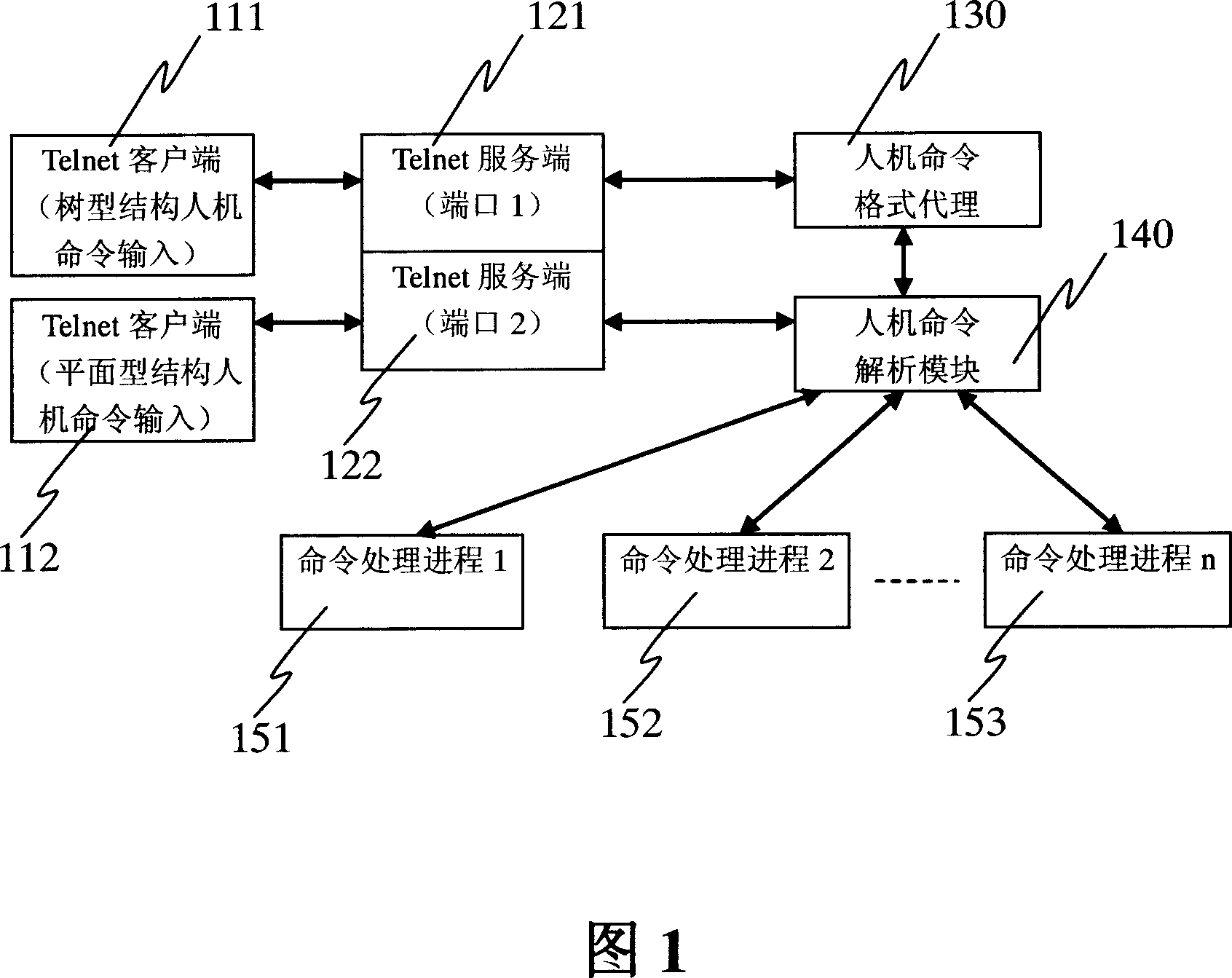

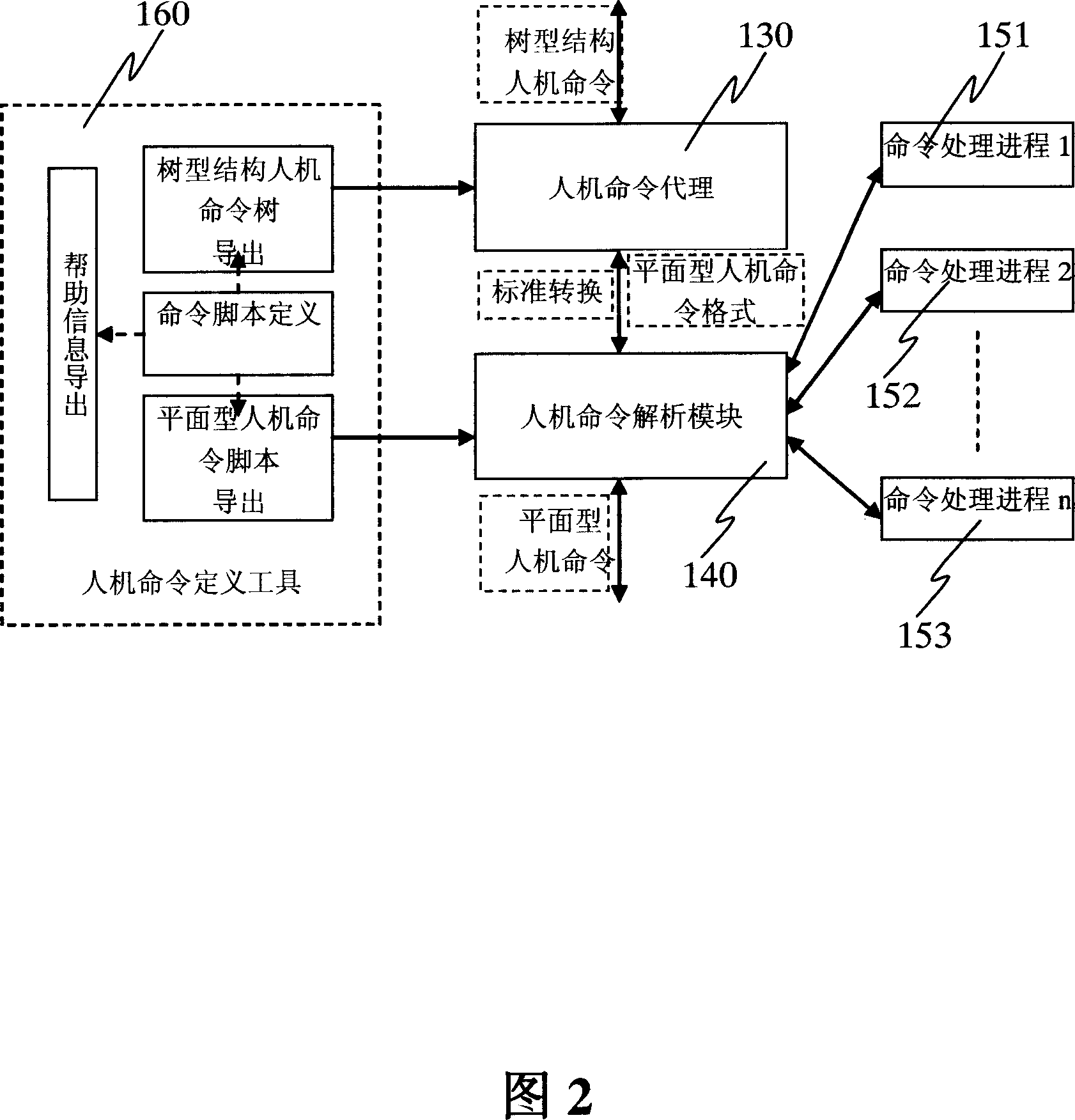

Transforming method and device for human-machine order format

ActiveCN1925482BSimplify development workloadImprove scalabilityTransmissionSpecial data processing applicationsEngineeringComputer engineering

This invention discloses one human to machine order form conversion method and device, which comprises the following steps: one human to machine agent process and advancing the relationship between human order and plane structure and converting the tree structure order into relative plane structure order; one human to machine analysis step to analyze order into human to machine order definition legs to realize tree structure and plane structure format switching to support human to machine orders.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO

Method and system for implementing recovery from speculative forwarding miss-predictions/errors resulting from load store reordering and optimization

A method for forwarding data from the store instructions to a corresponding load instruction in an out of order processor. The method includes accessing an incoming sequence of instructions; reordering the instructions in accordance with processor resources for dispatch and execution; ensuring a closest earlier store in machine order for to a corresponding load, by determining if said store has an actual age but said corresponding load does not have an actual age, then said store is earlier than said corresponding load; if said corresponding load has an actual age but said store does not have an actual age, then said corresponding load is earlier than said store; if neither said corresponding load or said store have an actual age, then a virtual identifier table is used to determine which is earlier; and if both said corresponding load and said store have actual ages, then the actual ages are used to determine which is earlier.

Owner:INTEL CORP

Transforming method and device for human-machine order format

ActiveCN1925482ASimplify development workloadImprove scalabilityTransmissionSpecial data processing applicationsSystem structureComputer engineering

This invention discloses one human to machine order form conversion method and device, which comprises the following steps: one human to machine agent process and advancing the relationship between human order and plane structure and converting the tree structure order into relative plane structure order; one human to machine analysis step to analyze order into human to machine order definition legs to realize tree structure and plane structure format switching to support human to machine orders.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO

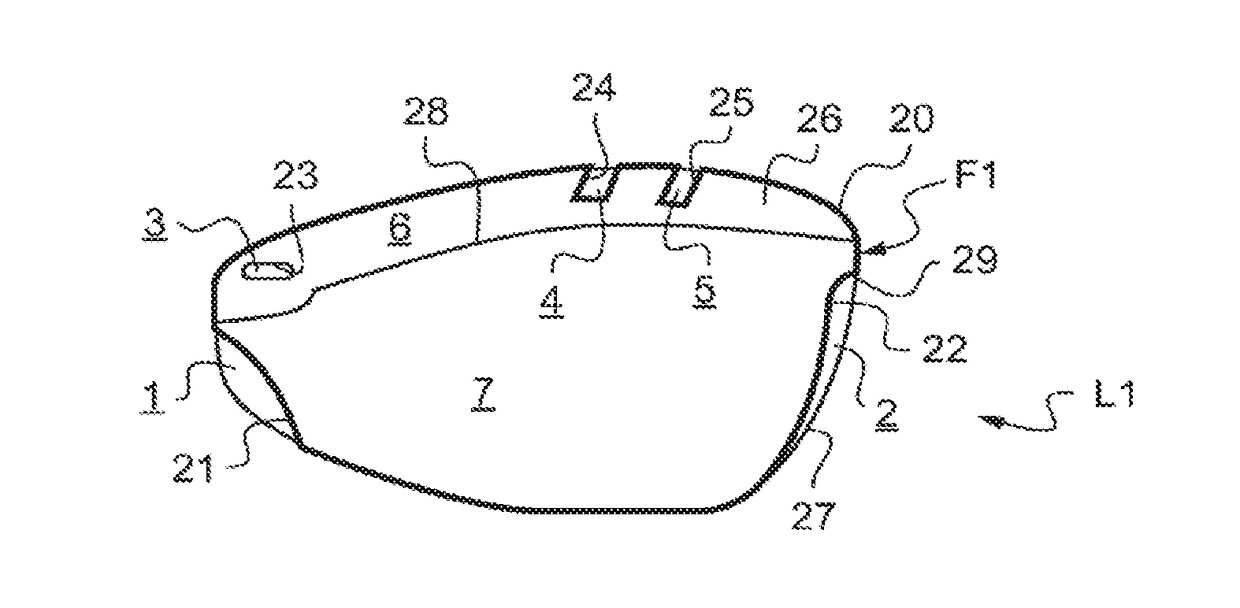

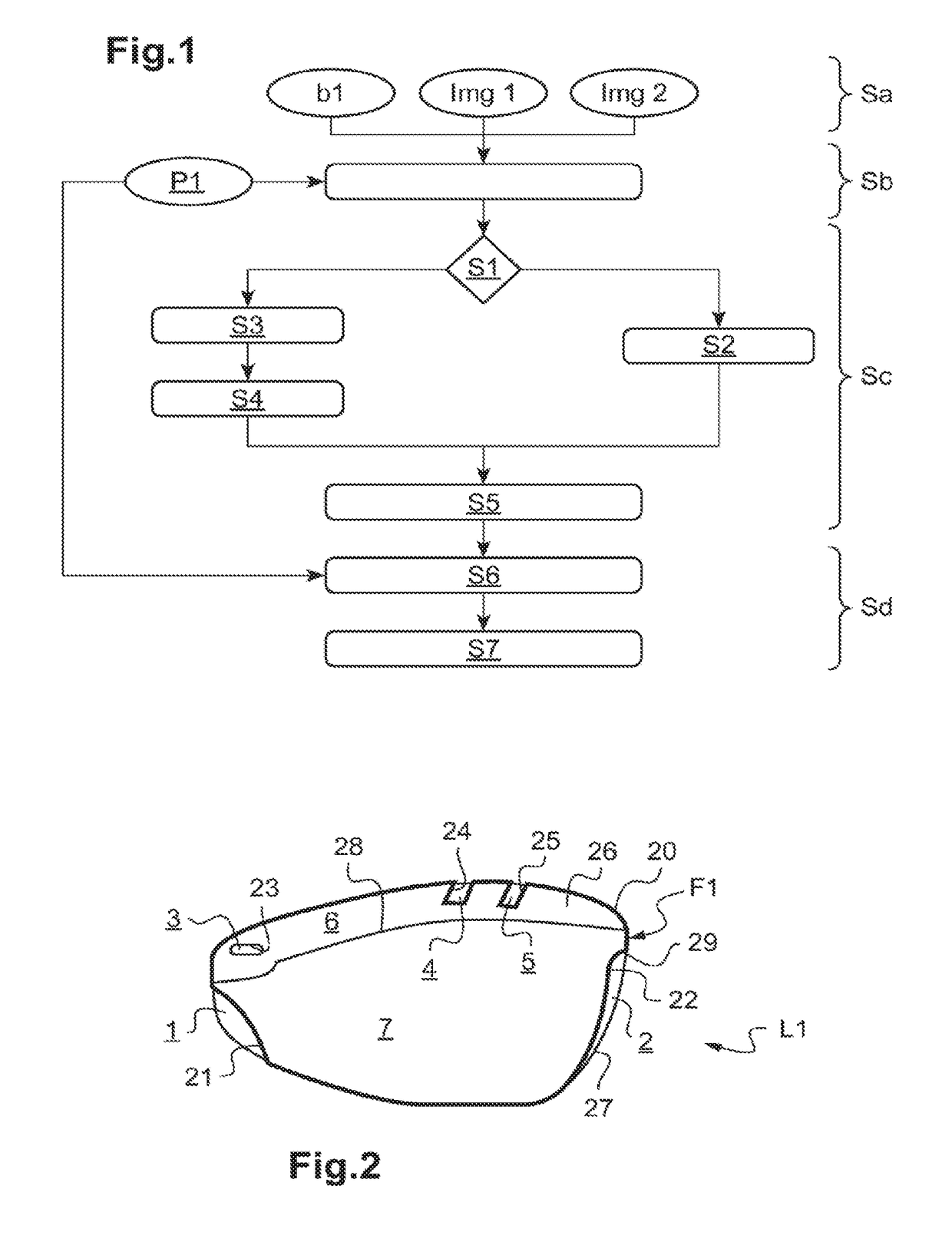

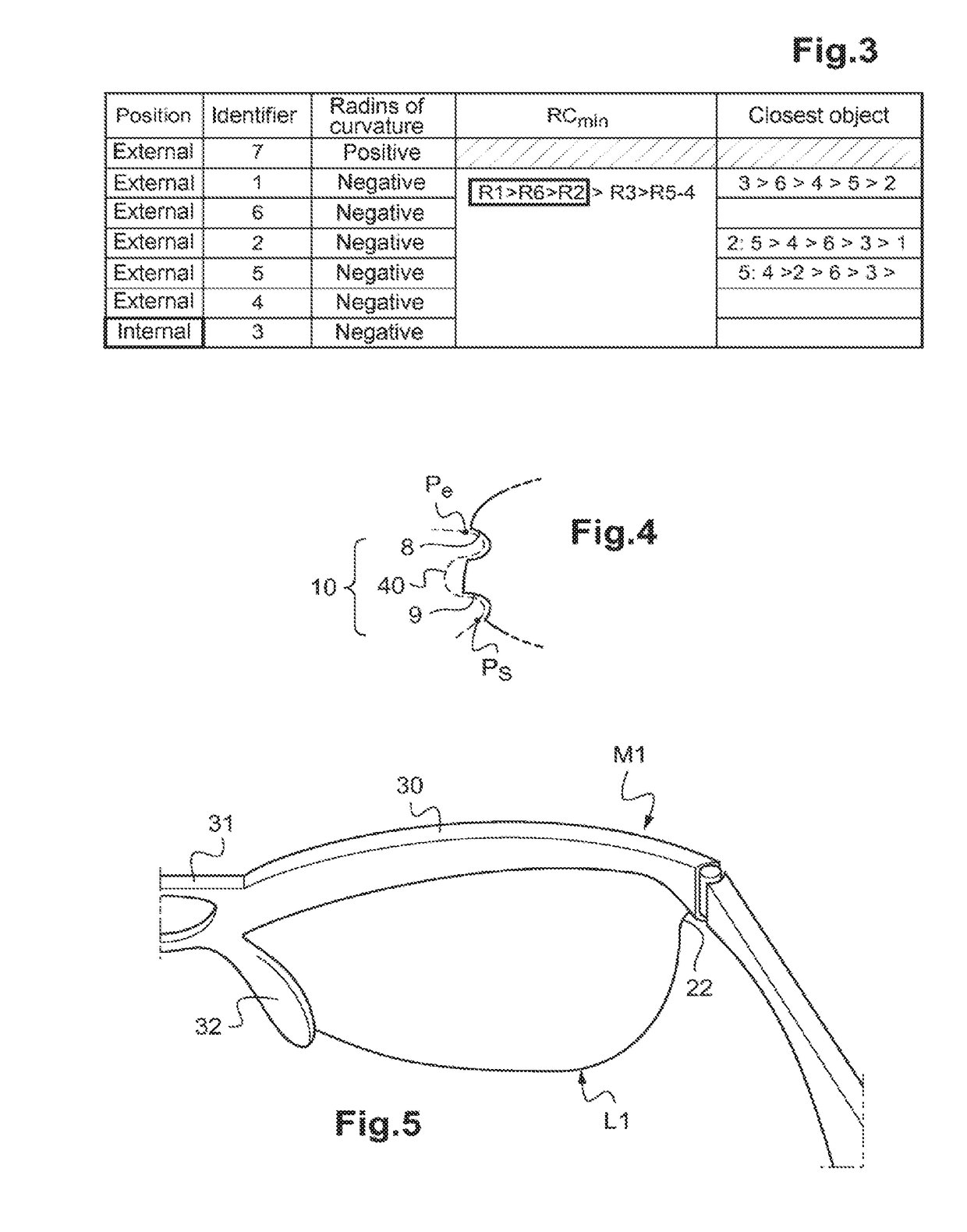

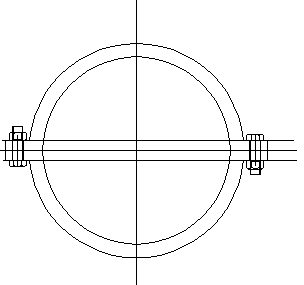

Method for generating settings for machining an optical lens

ActiveUS20180284728A1Shorten the construction periodEdge grinding machinesProgramme controlEngineeringMachine orders

Disclosed is a method for generating settings for machining an optical lens, including: a) acquiring a file characterizing the shape to which the optical lens must be machined in order to allow it to be mounted in a spectacle frame; b) decomposing the shape into a plurality of distinct objects, including an exterior envelope inside of which all the other objects are located; c) determining a machining order of the other objects; and d) generating the machining settings depending on the machining order.

Owner:ESSILOR INT CIE GEN DOPTIQUE

Combination fixture used for bearing bush machining and machining method of combination fixture

InactiveCN103506868AChange processing orderAvoid WeldingTurning machinesPositioning apparatusEngineeringMachining process

The invention relates to a combination fixture used for bearing bush machining and a machining method of the combination fixture. According to the combination fixture and the machining method, through ingenious match among all fixture bodies, the purpose of changing bearing bush machining orders is achieved. According to the machining method, two bearing bushes are located through the combination fixture and a three-jaw chuck, and outer flange machining and inner circle machining are conducted. Then, the three-jaw chuck is matched with the abutting type fixture body to conduct outer circle machining, the welding step and the final split step in a traditional bearing bush machining process are avoided, and therefore deformation of the combination fixture is small, and accuracy is effectively guaranteed.

Owner:YANGZHOU YIFENG BRONZE PROD

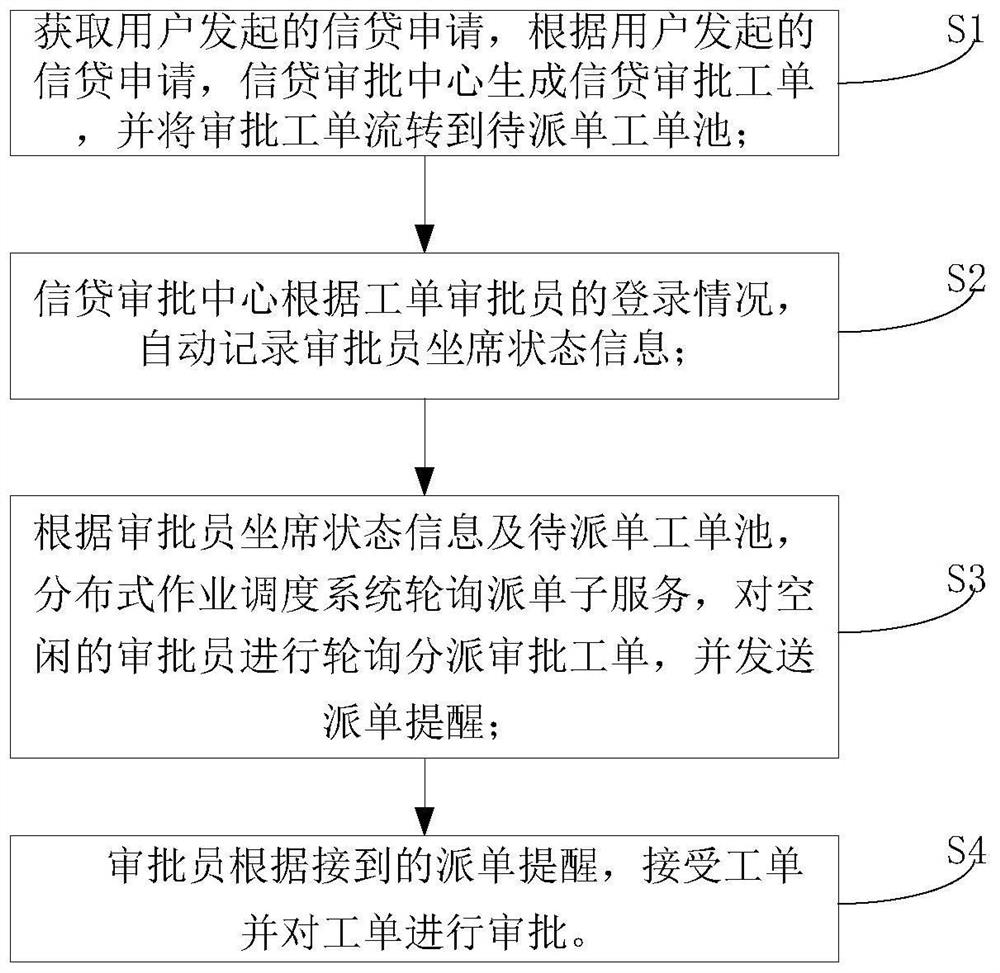

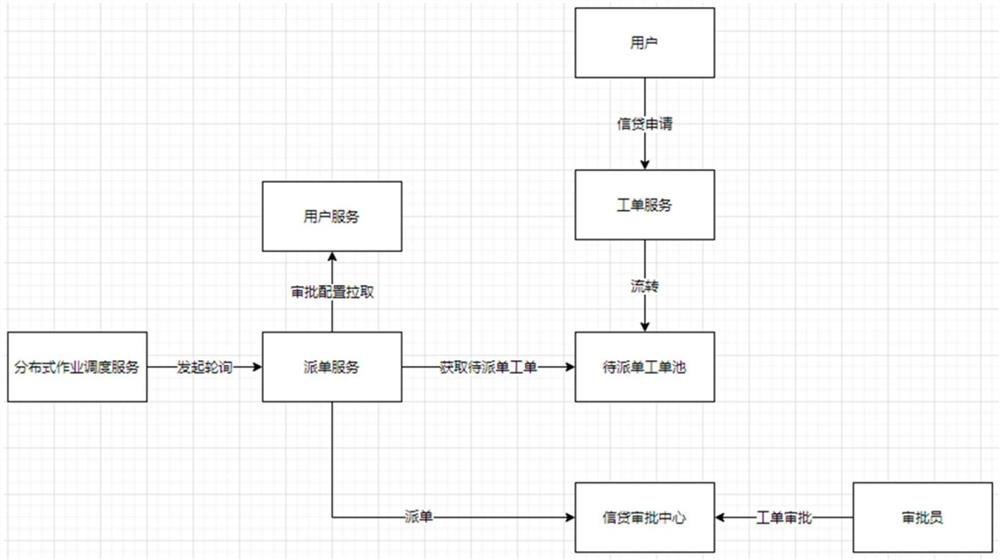

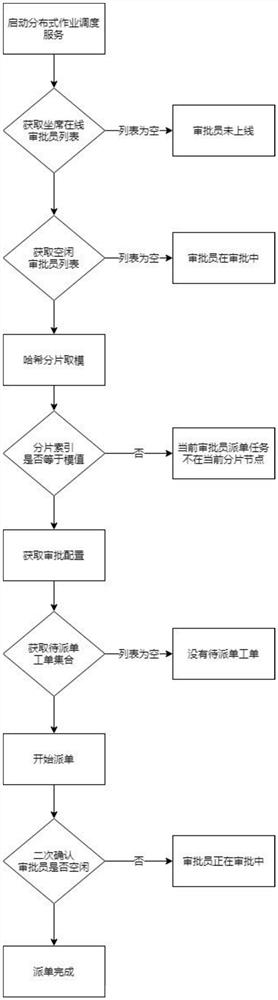

Distributed order dispatching method and system for credit approval work ordesr, equipment and medium

PendingCN113935659AImprove robustnessDecoupling strong dependenciesFinanceOffice automationOperation schedulingWorkflow engine

The invention discloses a distributed order dispatching method and system for credit approval work orders, equipment and a medium, and the method comprises the steps: obtaining a credit application initiated by a user, generating a credit approval work order by a credit approval center according to the credit application initiated by the user, and transferring the approval work order to a work order pool to be dispatched; enabling the credit approval center to automatically records the seat state information of the approver according to the login condition of the work order approver; according to the approver seat state information and the work order pool to be dispatched, enabling the distributed job scheduling system to poll order dispatching sub-service, poll and dispatch approval work orders for idle approvers, and send order dispatching reminding; and enabling the approver to accept the work order and approve the work order. The single-machine order dispatching bottleneck caused by centralized order dispatching adopted in an order dispatching method in the prior art is overcome, the order dispatching tasks are uniformly distributed to the node fragments, and the order dispatching throughput in unit time is greatly improved; according to the invention, the strong dependency of the integrated workflow engine configuration in the prior art is decoupled.

Owner:SICHUAN XW BANK CO LTD

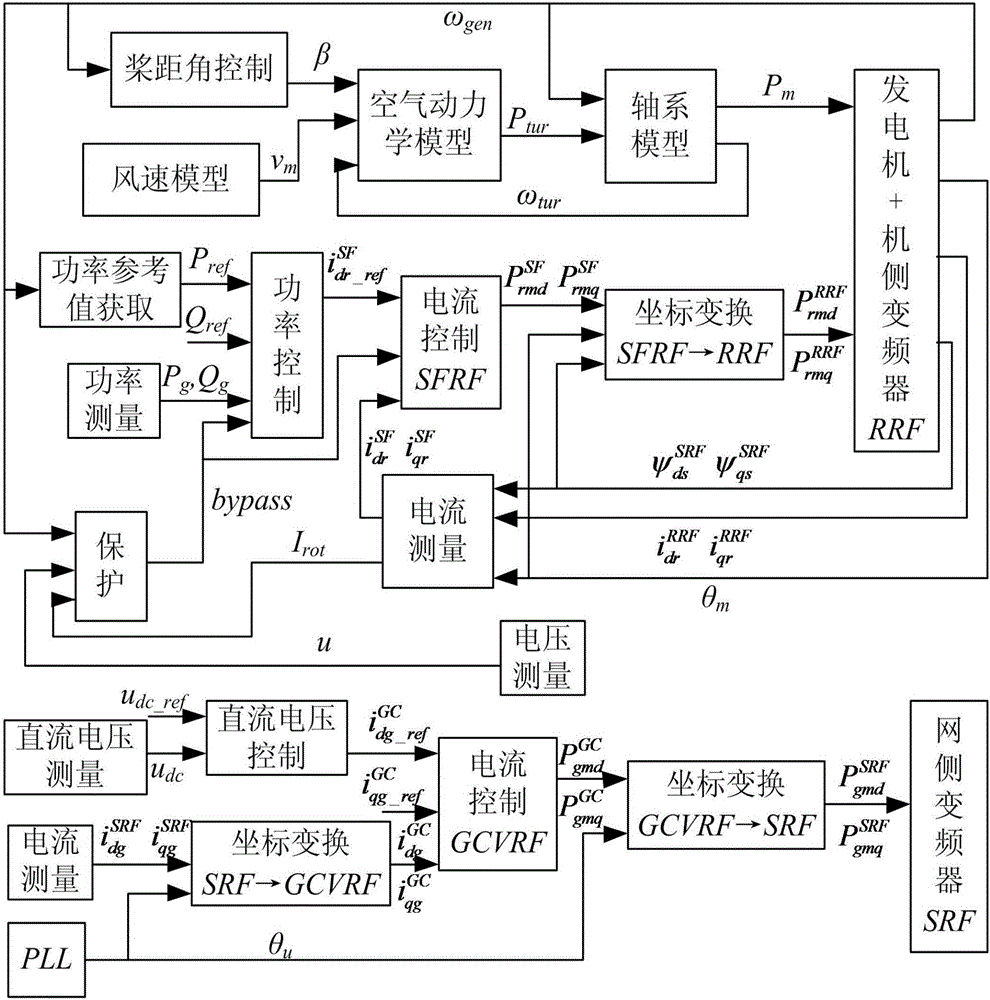

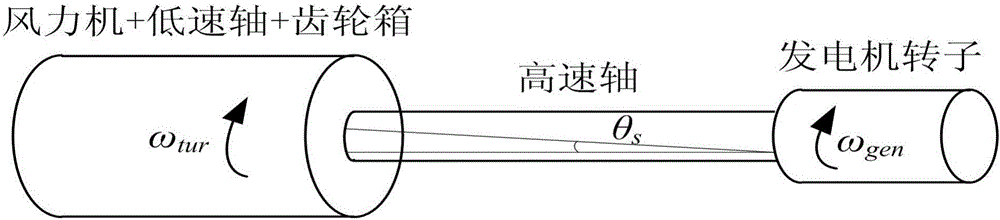

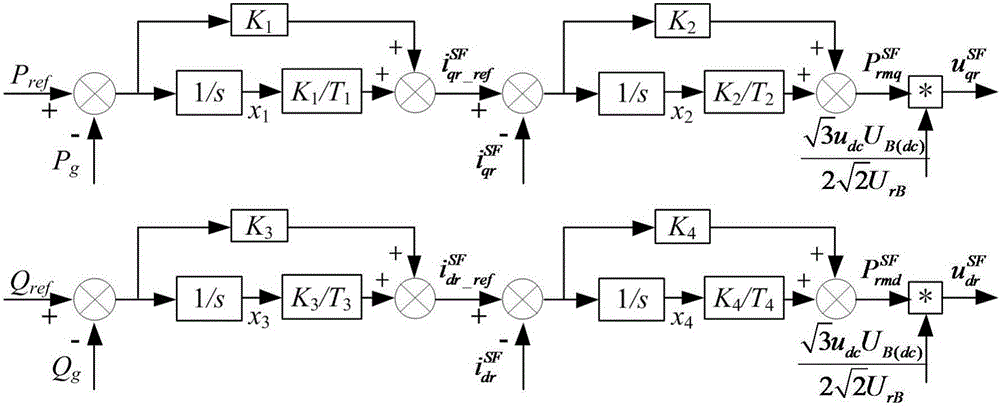

Wind power plant level multi-working-condition double-fed unit static and stable order reduction method

InactiveCN106096140AReduce model dimensionalityAccurately describe static stability propertiesData processing applicationsSpecial data processing applicationsTime domainCurse of dimensionality

The invention relates to a wind power plant level multi-working-condition double-fed unit static and stable order reduction method. The method is technically characterized by comprising the following steps that 1, a double-fed unit coordinate system is built, and detailed models of super-synchronous, subsynchronous and power limited working stations of a double-fed unit are built; 2, single machine order reduction models under different working conditions are built based on the Lyapunov first method and the dominant mode method, dominant modes under different working conditions are determined, and a time-dominant simulation method is adopted for verifying accuracy of the single machine order reduction models; 3, the single machine order reduction models are expanded to a wind power plant, and applicability is verified. The built order reduction models completely cover the dominant state variables obtained after different operation working stations have access to a system, the model dimensionality of the double-fed unit is reduced to the largest degree on the premise that the dominant mode is not omitted, expansion can be carried out to achieve wind power plant level static and stable analysis, and curse of dimensionality is avoided.

Owner:STATE GRID TIANJIN ELECTRIC POWER +3

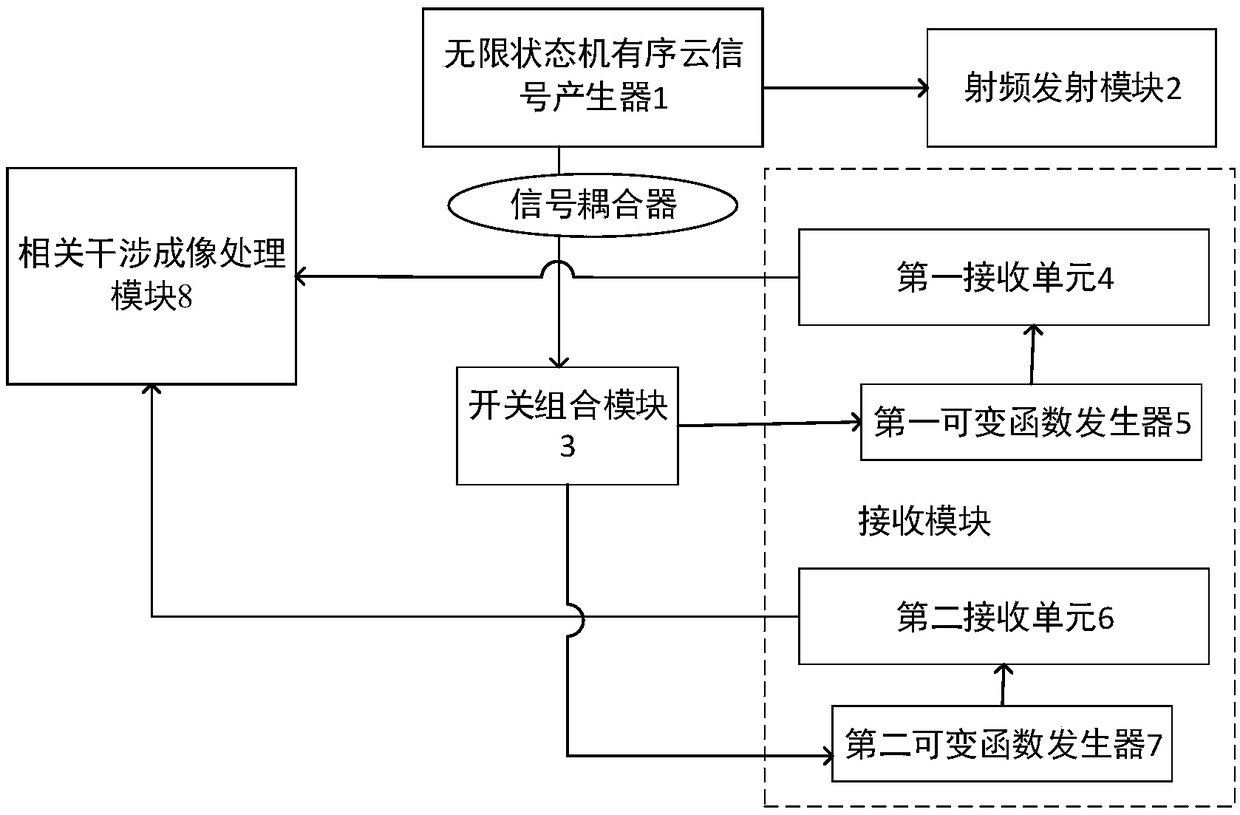

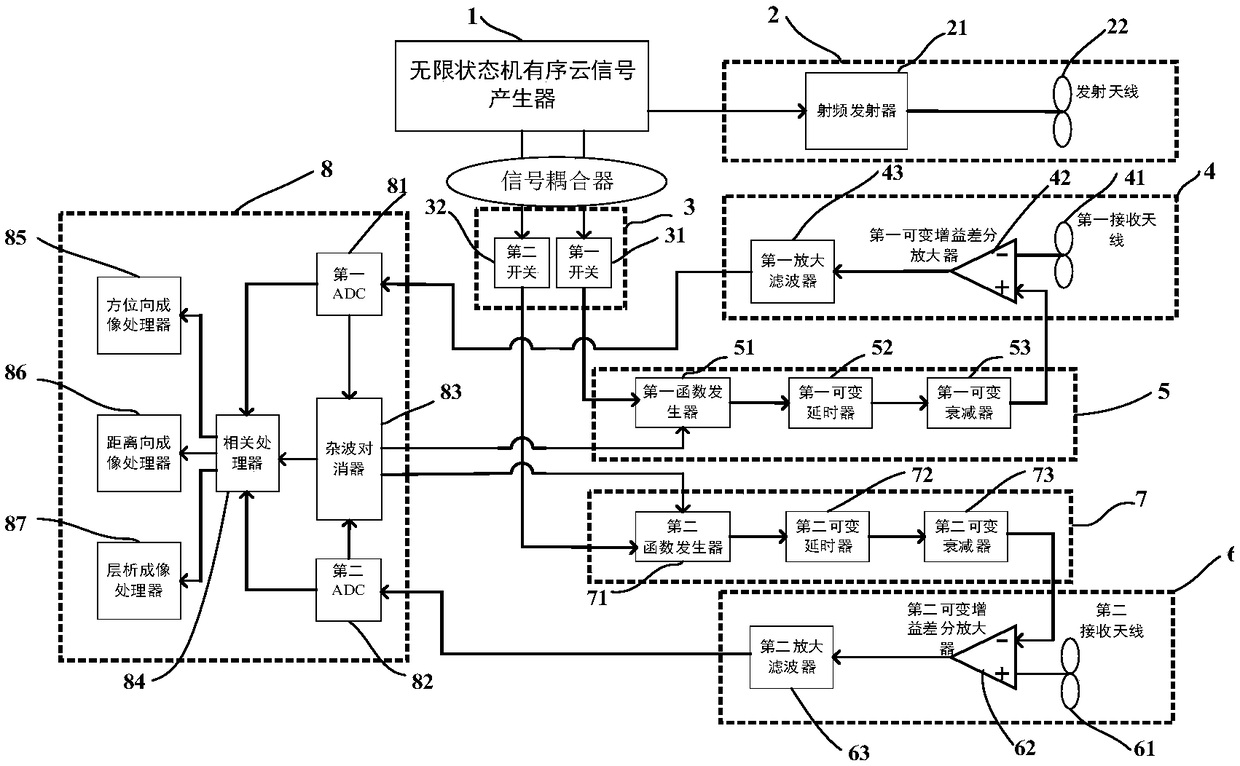

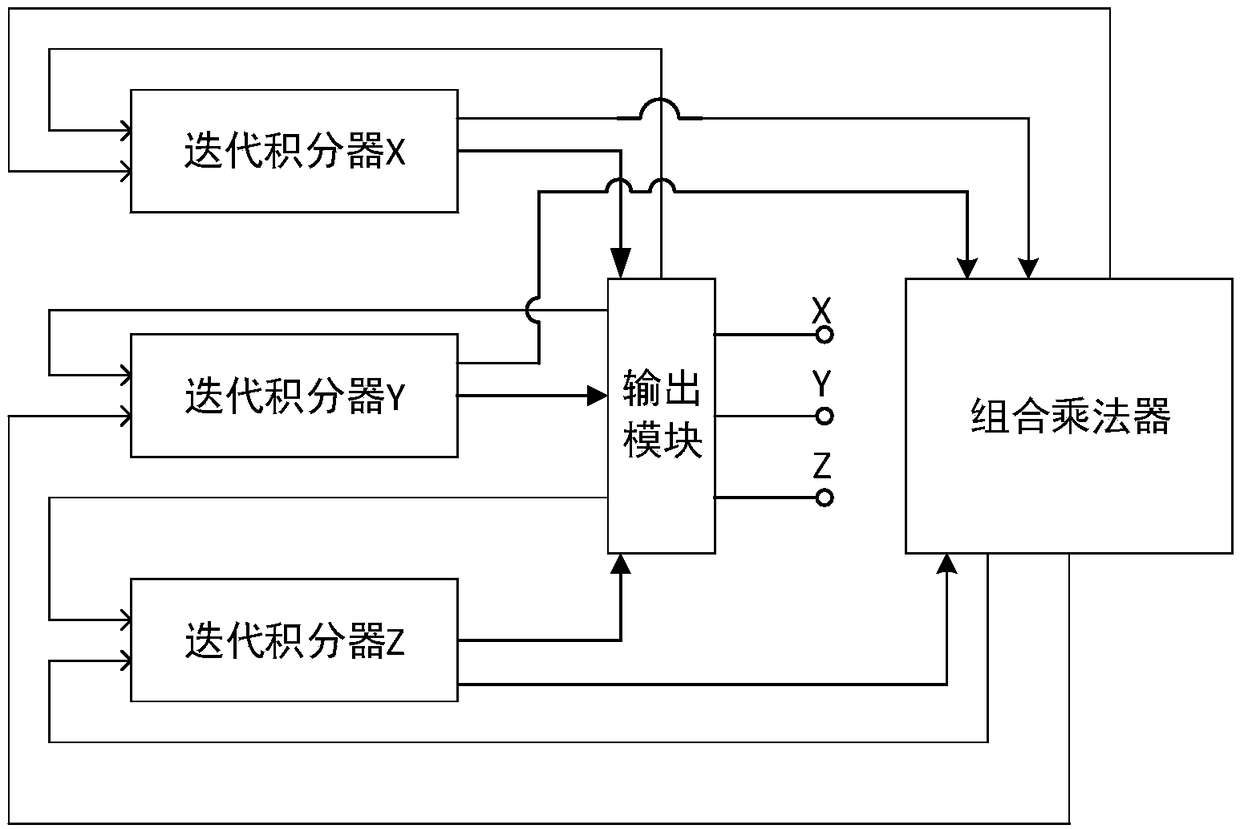

Tomographic scanning imager based on ordered cloud signals of infinite state machine

ActiveCN108646243AUnlimited Signal BandwidthNo temporal ambiguityRadio wave reradiation/reflectionImaging processingVirtual finite-state machine

The invention provides a tomographic scanning imager based on ordered cloud signals of an infinite state machine. The tomographic scanning imager comprises an infinite state machine ordered cloud signal generator (1),a signal coupler,a radio frequency transmitting module (2),a switch combination module (3),a receiving module and a relevant interference imaging processing module (8). The infinite state machine ordered cloud signal generator (1) is used for generating the first ordered cloud signals; the signal coupler is used for converting the first ordered cloud signals into the second ordered cloud signals; the radio frequency transmitting module (2) is used for receiving the first ordered cloud signals,converting the first ordered cloud signals into radio frequency and transmitting theradio frequency to the outside; the switch combination module (3) is used for controlling the operation time sequence of the receiving module and eliminating clutter of the ordered cloud signals; thereceiving module is used for performing delay and gain processing on the ordered cloud signals,and the processed signals are transmitted to the relevant interference imaging processing module (8). Therelevant interference imaging processing module (8) is used for completing tomographic imaging of a detection target.

Owner:王彩云 +1

Machining order sending method based on mechanical part drawing

InactiveCN110910025AMaster UtilizationReduce the need for errorsResourcesManufacturing computing systemsNumerical controlMachine

The invention discloses a machining order sending method based on a mechanical part drawing. The machining order sending method includes the steps: automatically identifying a part processing demand in an order from a part characteristic value module of a server; and carrying out matching with idle productivity of a numerical control machine tool accessed to the server so as to perform precise matching, thus reducing processing information error demands while mastering the utilization rate of the numerical control machine tool, guaranteeing that orders are not to be transferred to packets andhands in distribution, and furthest guaranteeing reasonable utilization of productivity of the processing machine tool. On one hand, the machining order sending method helps enterprises with machine tools to improve the effective utilization rate and the order receiving efficiency of equipment, and on the other hand, can improve the efficiency of finding machining machine tools by customers.

Owner:苏州安永数据科技有限公司

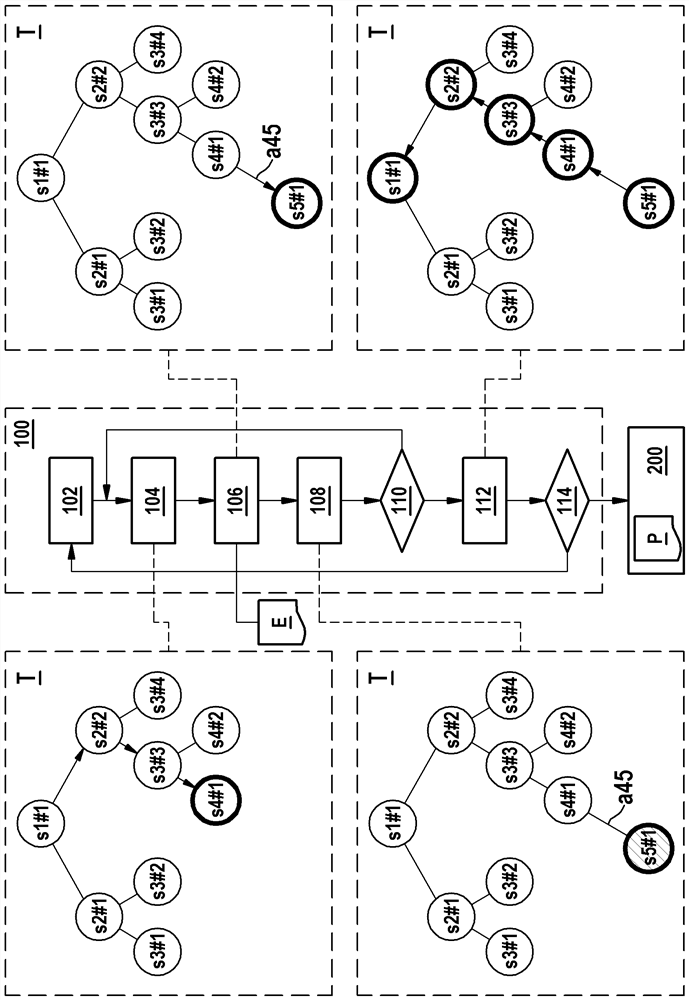

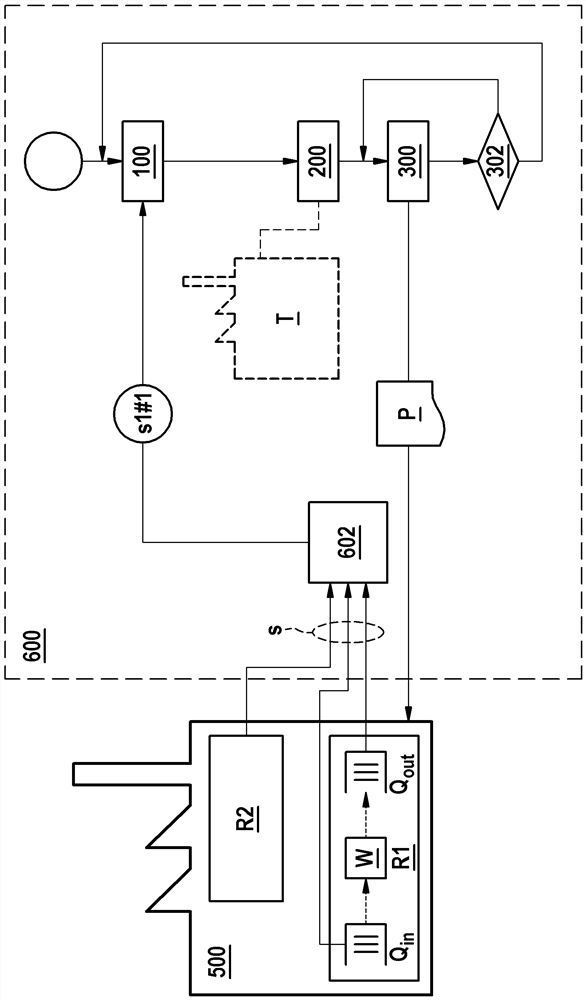

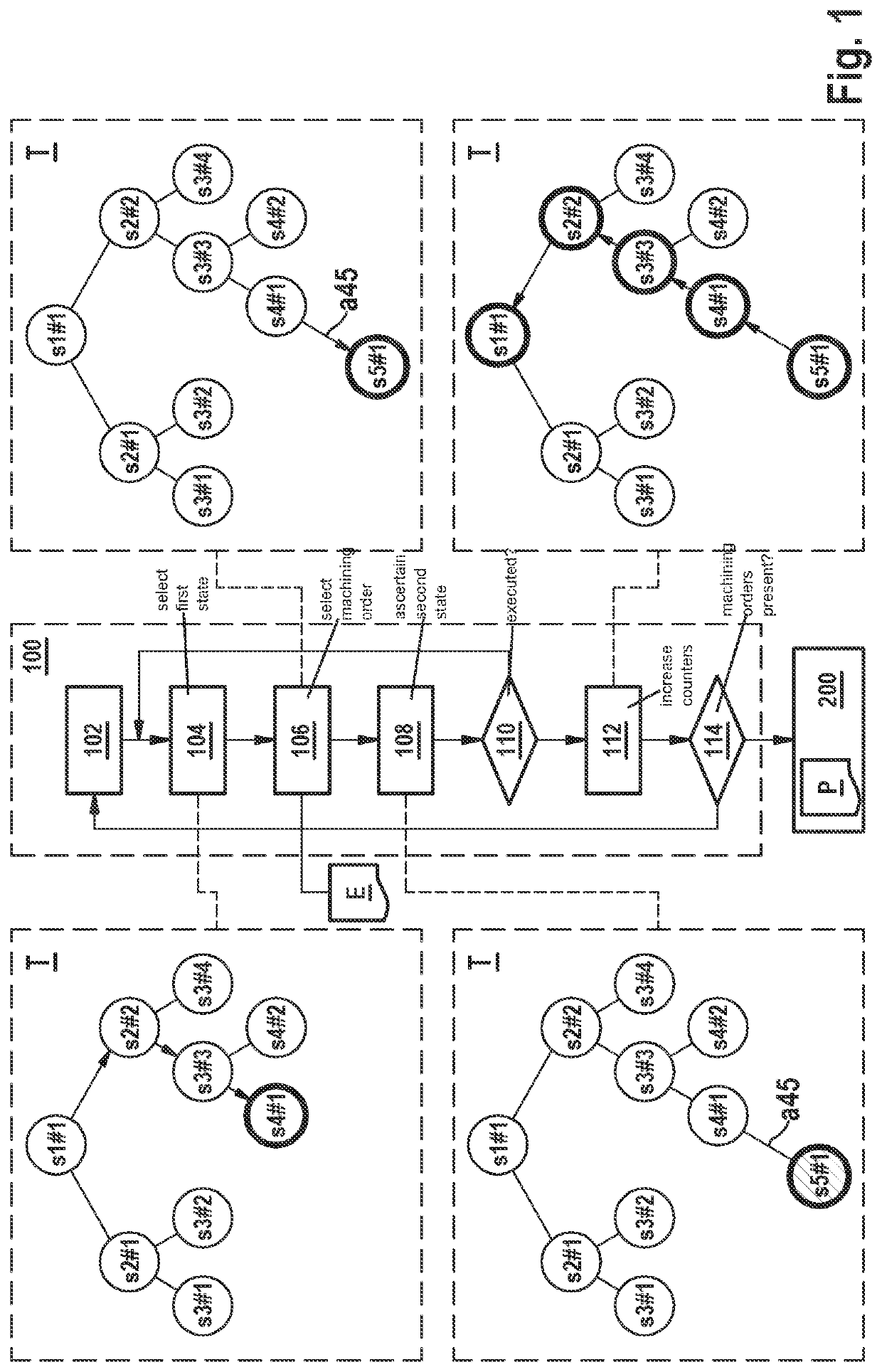

Method and device for an industrial system

PendingCN113919616AGood explainabilityHigh acceptanceProgramme controlDesign optimisation/simulationIndustrial systemsProcess engineering

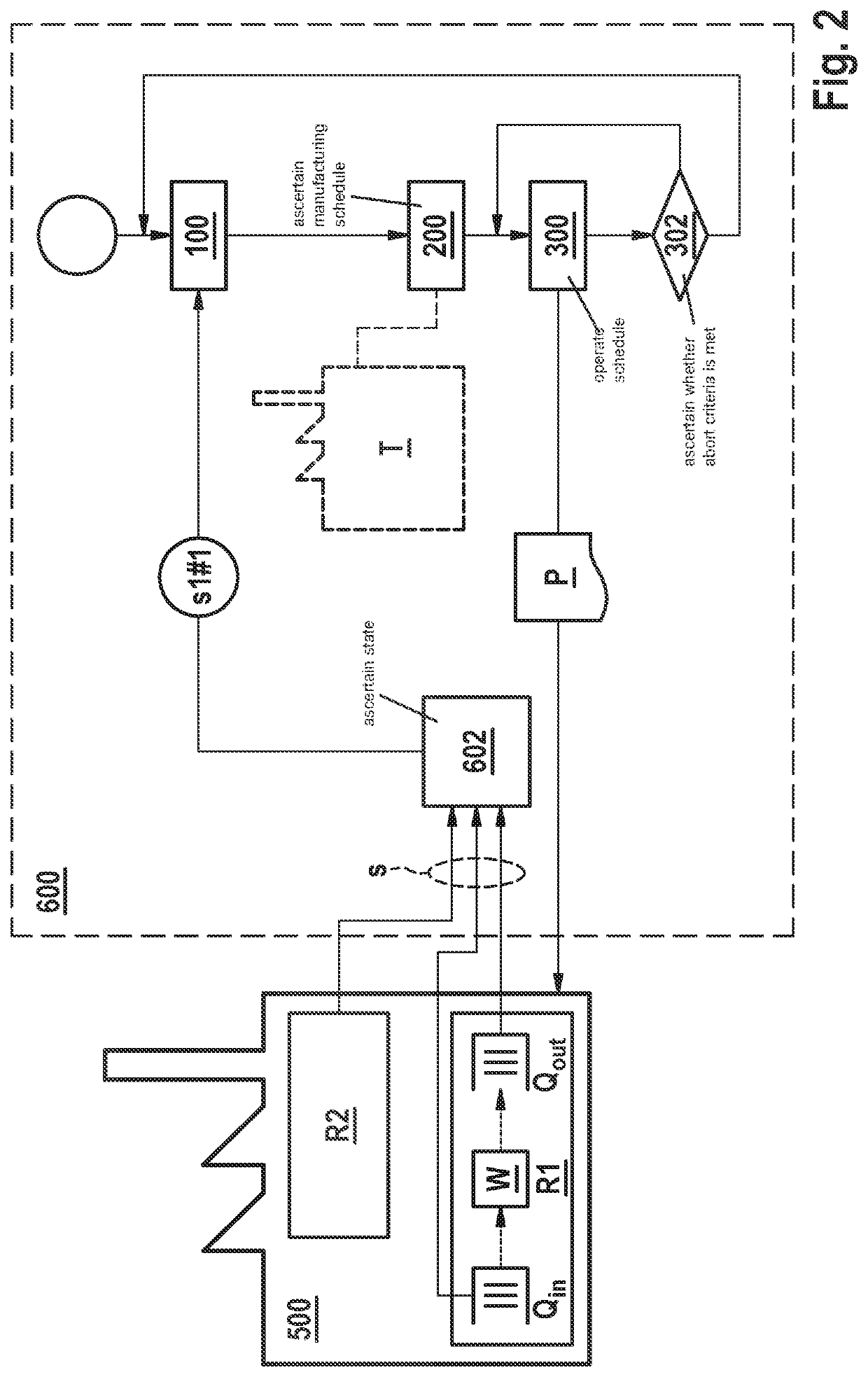

A method for an industrial system. The method includes: ascertaining 100 a representation T of the industrial system, the ascertainment of the representation T including: selecting 104 a first state s4#1 of the representation T, selecting 106, based on the first state s4#1, at least one machining order a45 from a plurality of machining orders as a function of the first state of the representation and as a function of at least one previously ascertained recommendation E, and ascertaining a second state s5#1 as a subsequent state of the first state via a simulation of the second state as a function of the at least one selected machining order a45 and as a function of the first state s4#1; and ascertaining 200 a manufacturing schedule P for the industrial system as a function of the ascertained representation T.

Owner:ROBERT BOSCH GMBH

Method and device for an industrial system

PendingUS20220011748A1Reduce weightHigh simulationProgramme controlData processing applicationsIndustrial systemsManufacturing planning

A method for an industrial system. The method includes: ascertaining a representation of the industrial system, the ascertainment of the representation including: selecting a first state of the representation, selecting, based on the first state, at least one machining order from a plurality of machining orders as a function of the first state of the representation and as a function of at least one previously ascertained recommendation, and ascertaining a second state as a subsequent state of the first state via a simulation of the second state as a function of the at least one selected machining order and as a function of the first state; and ascertaining a manufacturing schedule for the industrial system as a function of the ascertained representation.

Owner:ROBERT BOSCH GMBH

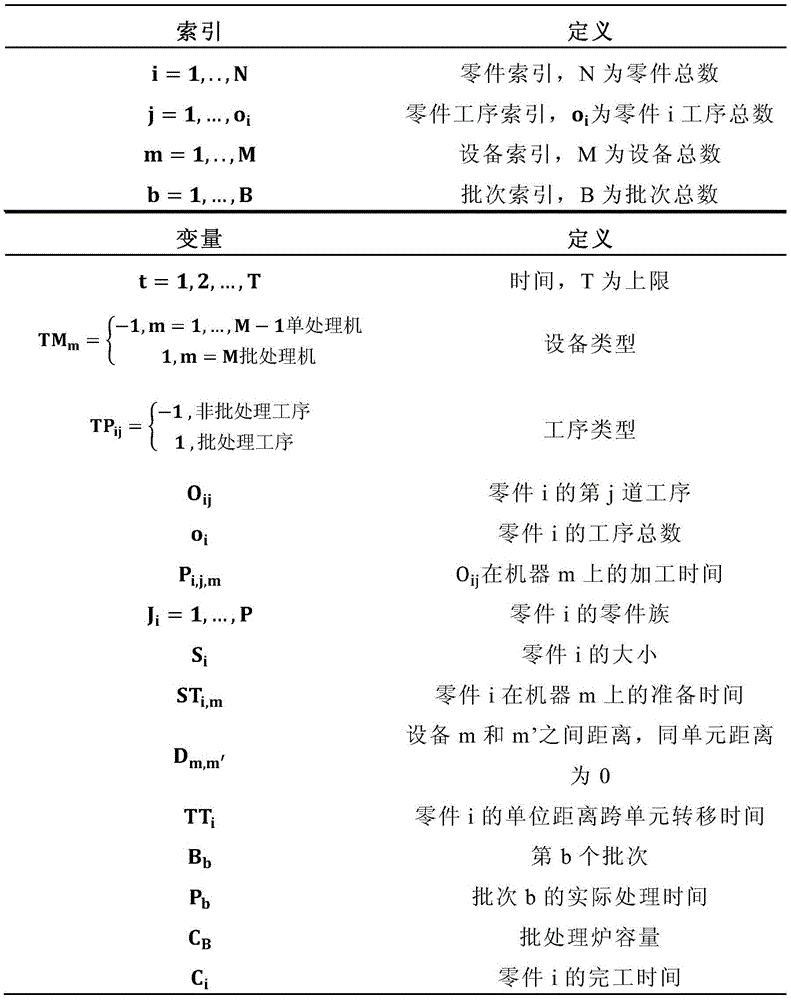

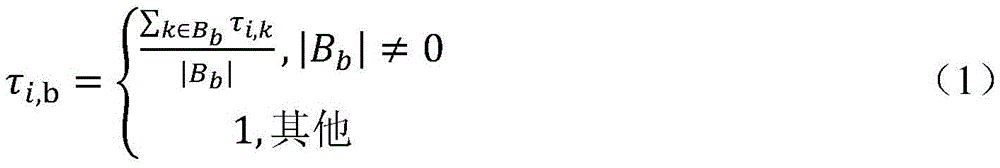

A Cross-job Unit Scheduling Method with Batch Processor

InactiveCN102938102BSolve the cross-unit scheduling problemGuaranteed operating efficiencyResourcesCell schedulingBatch machine

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com