Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52 results about "Lime softening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lime softening, also known as Clark's process, is a type of water treatment used for water softening which uses the addition of limewater (calcium hydroxide) to remove hardness (calcium and magnesium) ions by precipitation. The process is also effective at removing a variety of microorganisms and dissolved organic matter by flocculation.

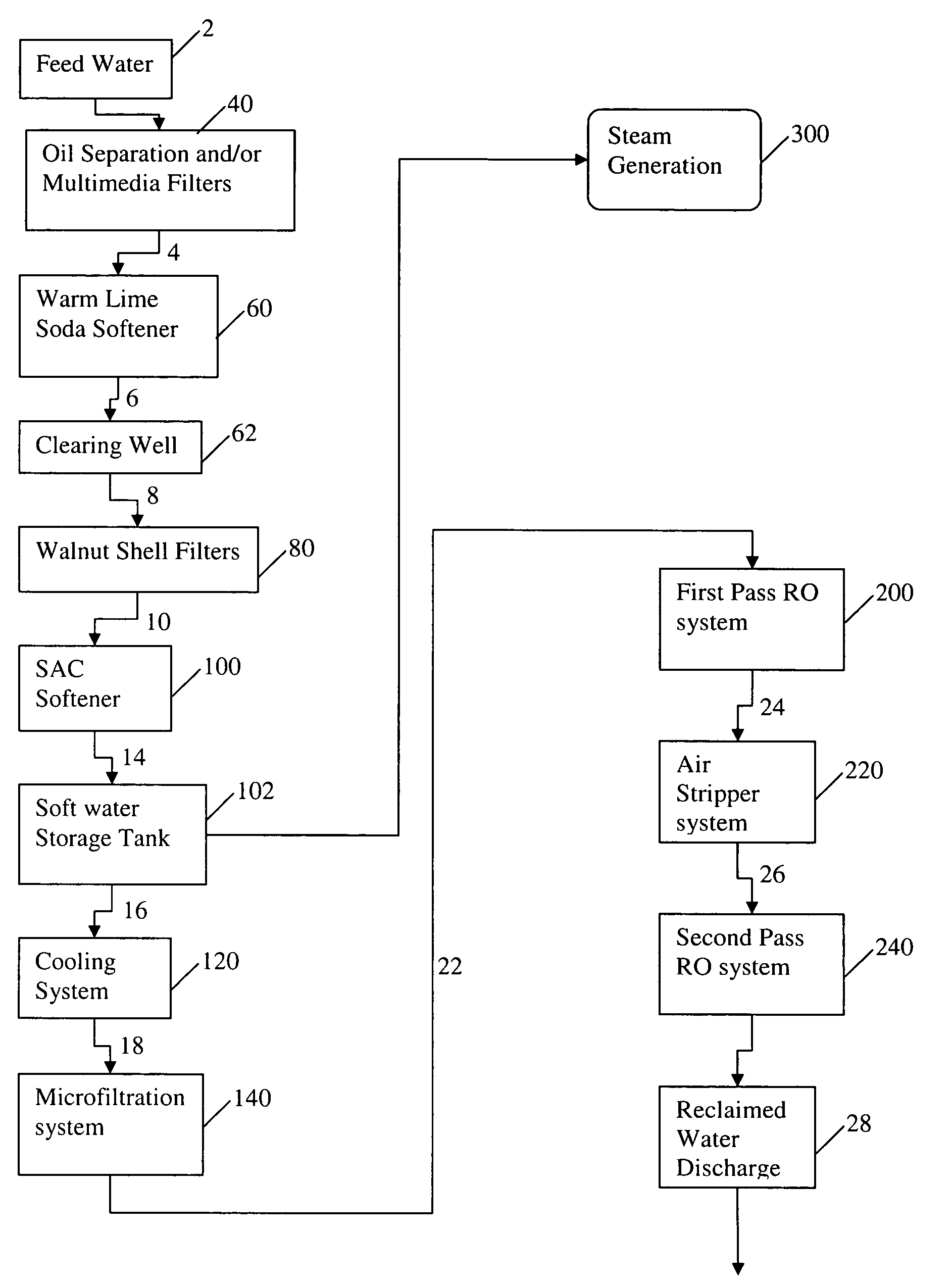

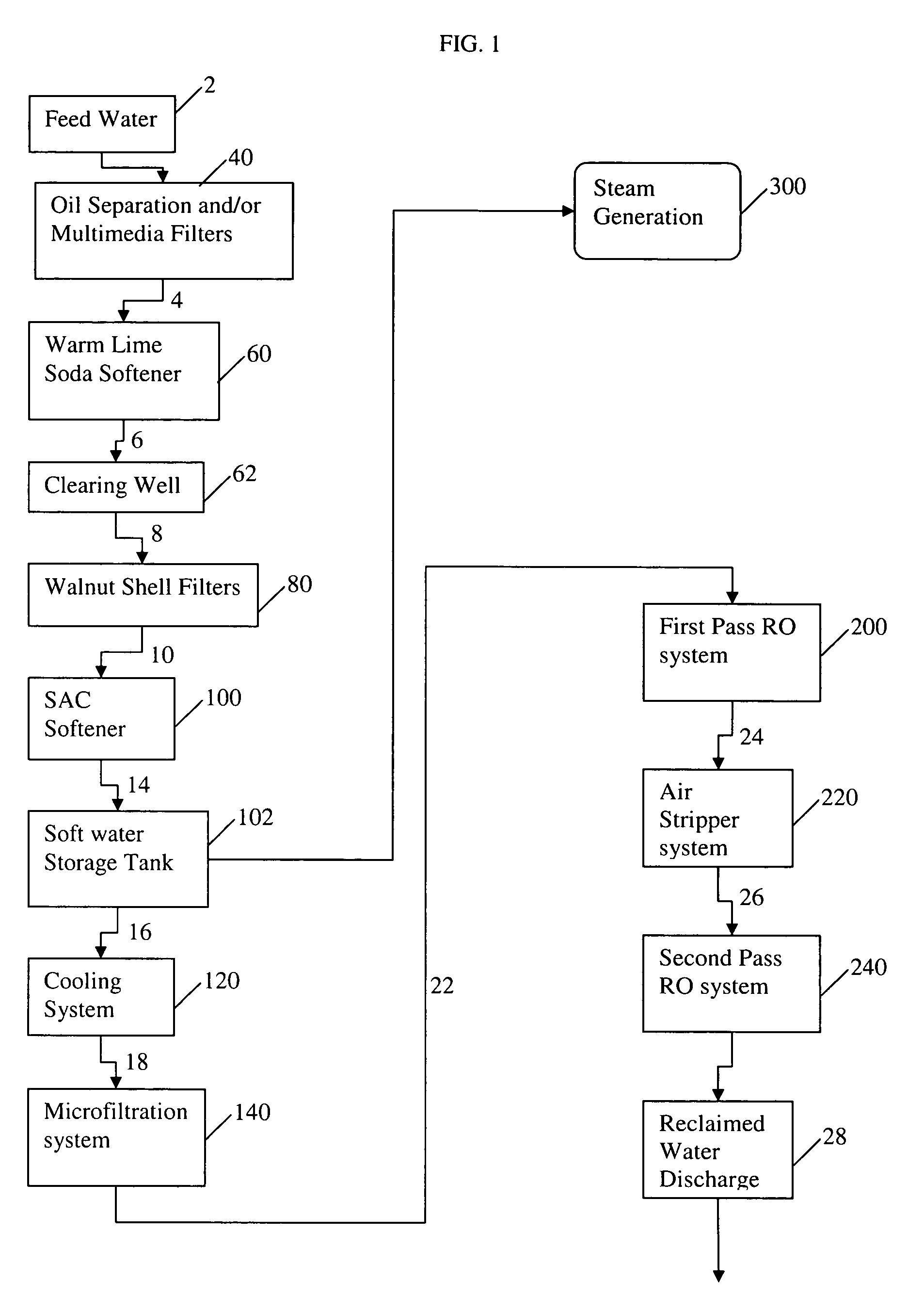

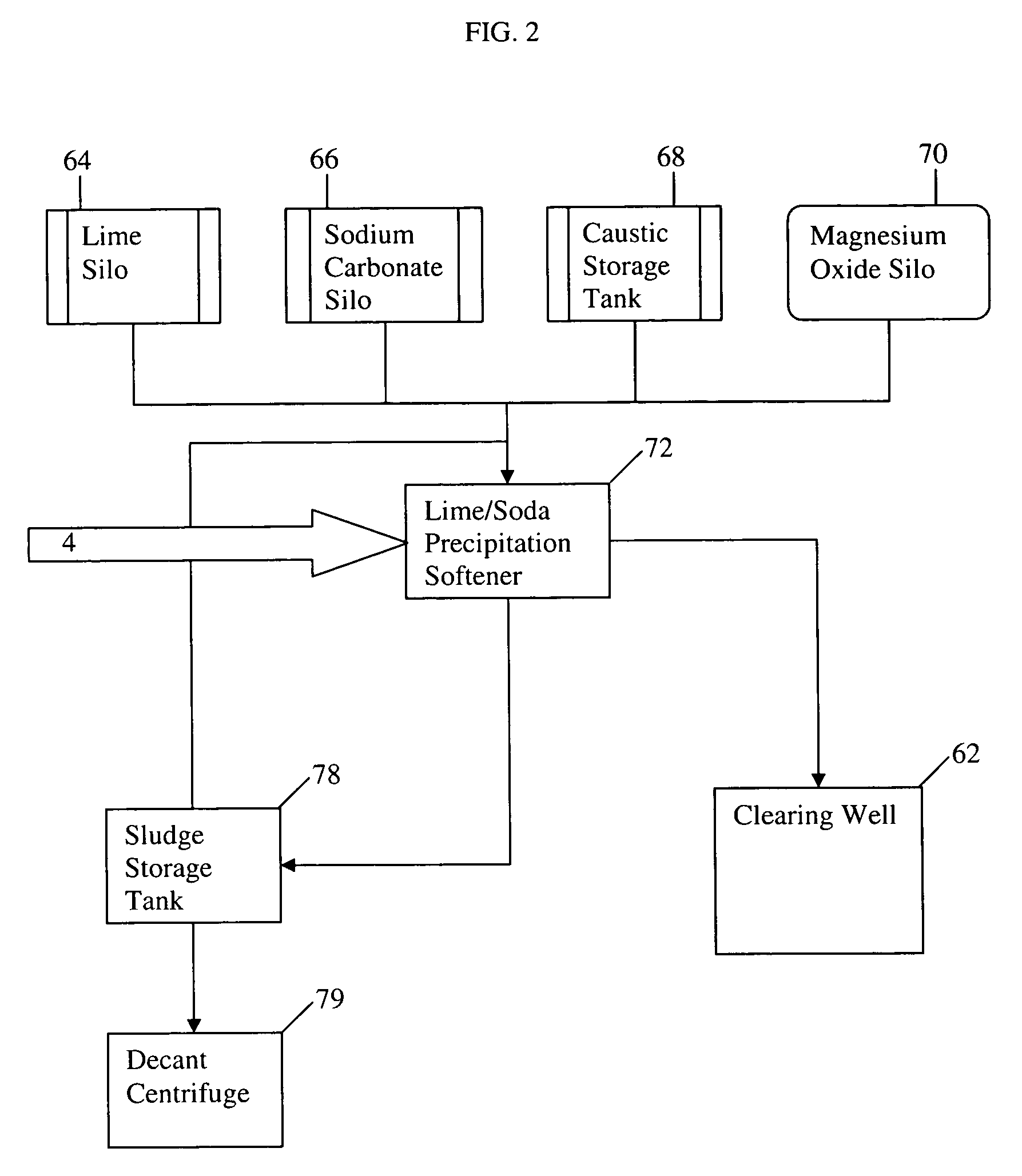

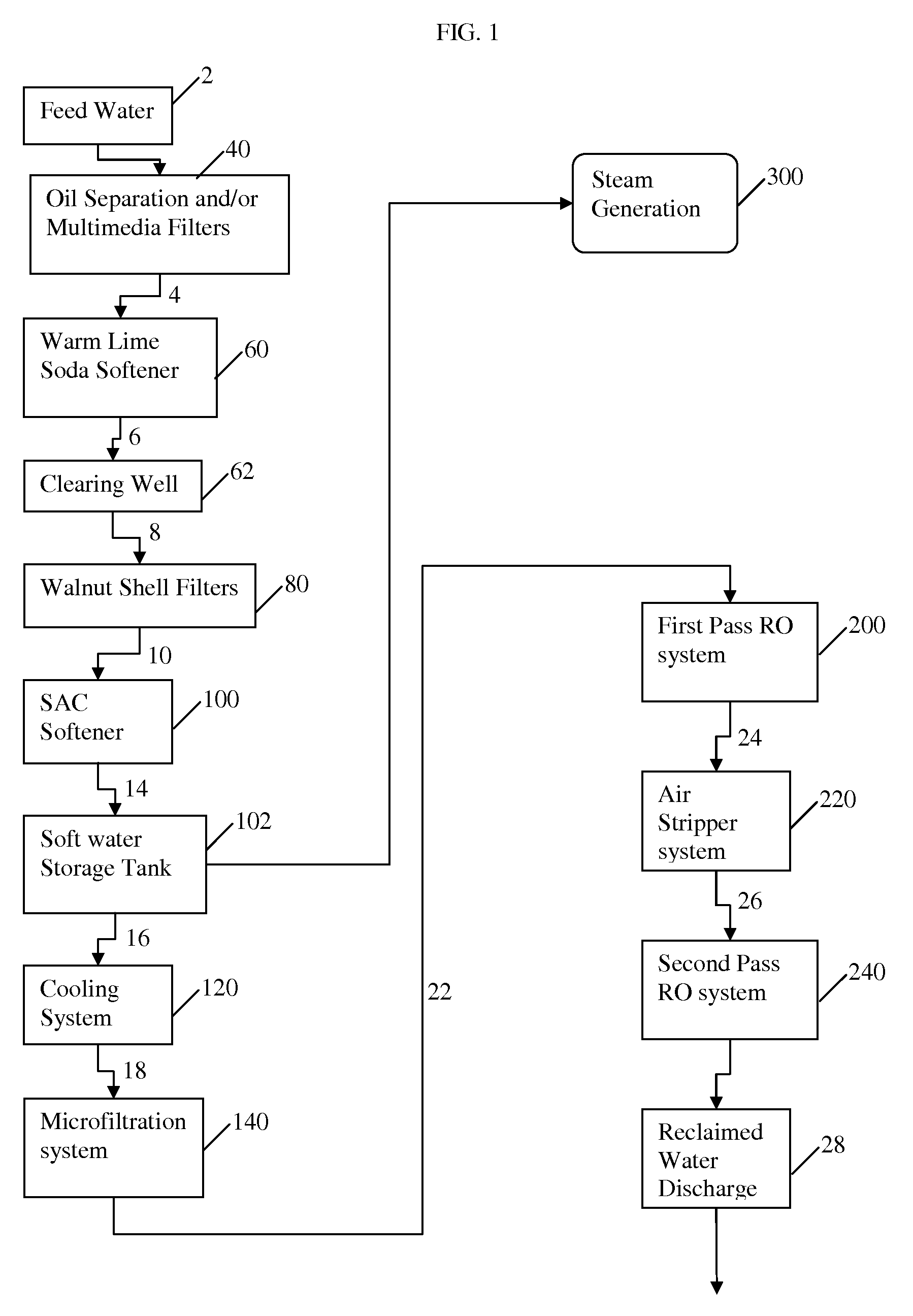

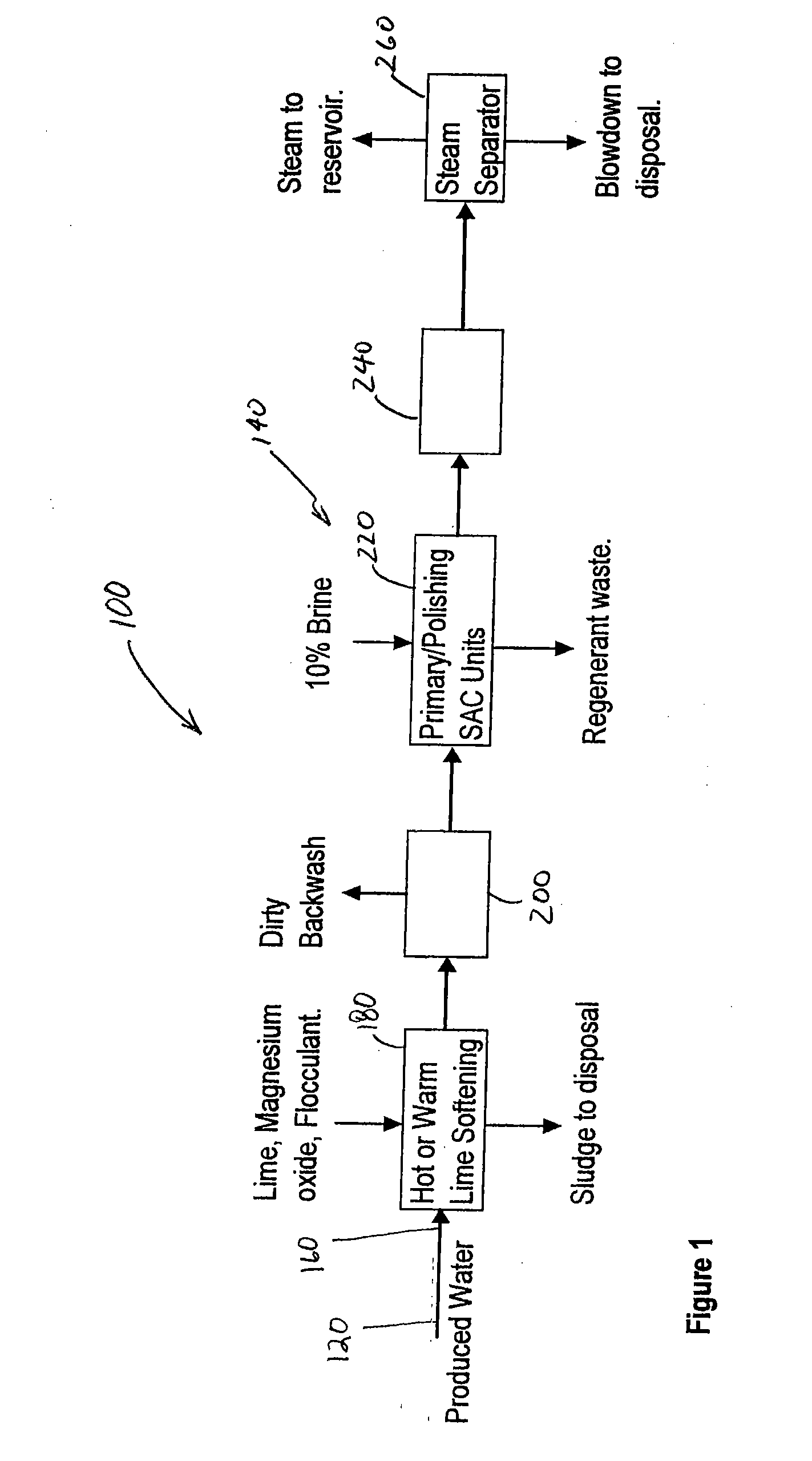

Water treatment process for oilfield produced water

ActiveUS7520993B1Minimize continued precipitationLiquid separation auxillary apparatusUsing liquid separation agentSludgeTreatments water

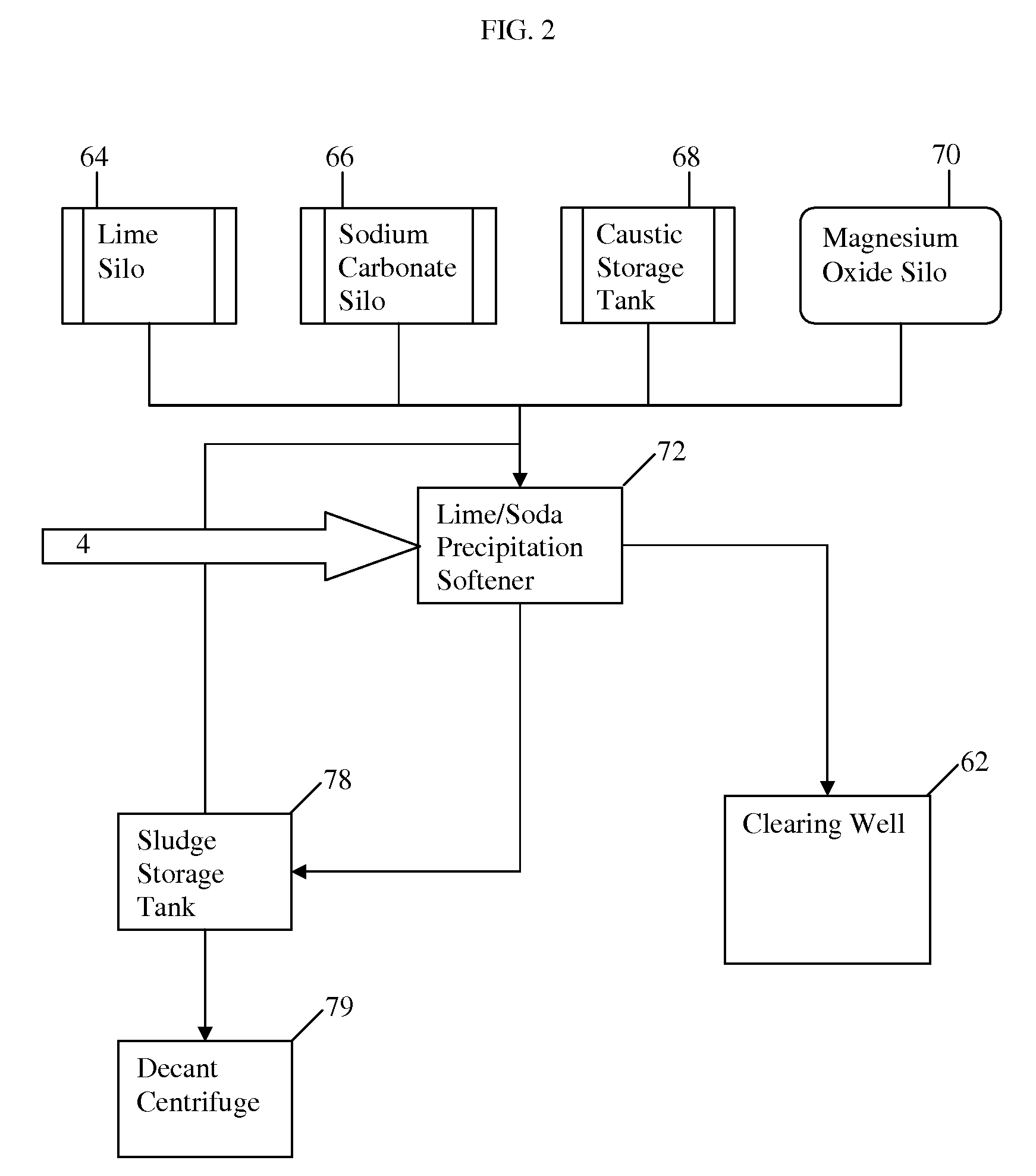

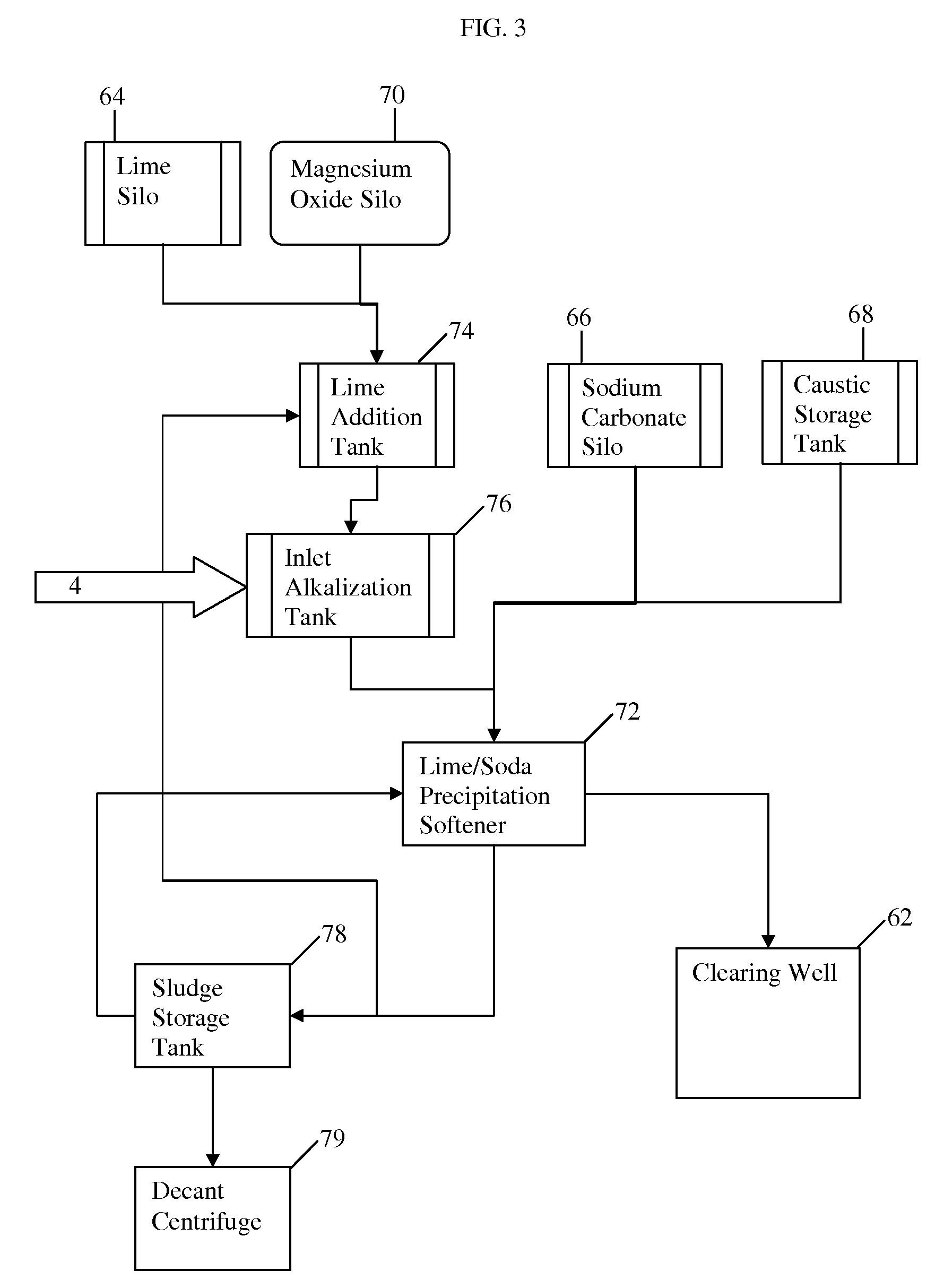

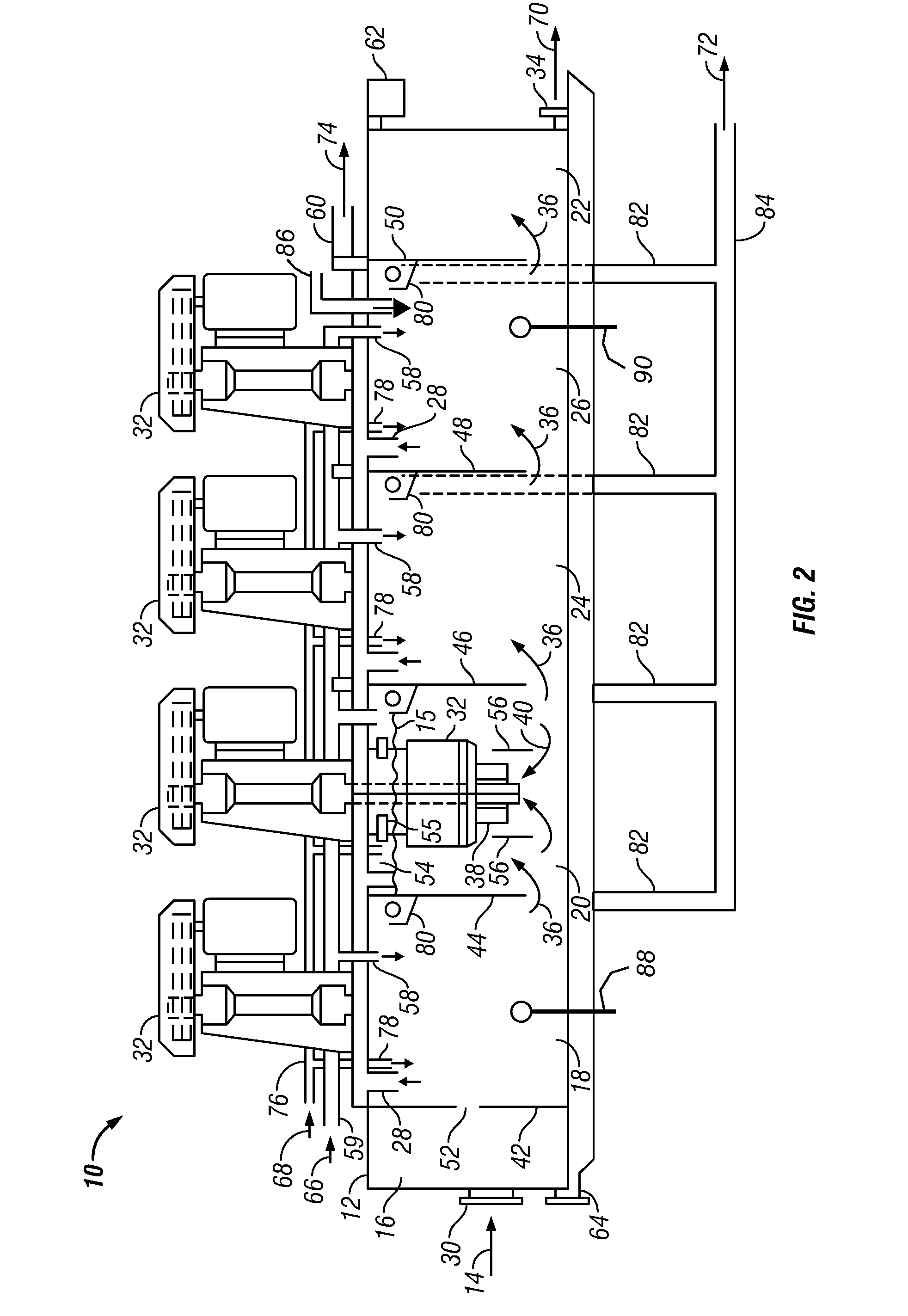

The invention relates to a method and system for treating an aqueous liquid containing dissolved minerals and dissolved hydrocarbons. Method steps and apparatus for treating a waste water feed stream are disclosed which utilize a warm lime softening system in fluid communication with the waste water feed stream, wherein sludge from the warm lime softening system is recycled to improve lime utilization and enhance silica and boron removal without the addition of an external source of magnesium. In addition, a microfiltration system and / or an air stripper system may be used in fluid communication with at least one reverse osmosis system to produce a treatment water that meets state and federal guidelines for surface discharge.

Owner:WATER & POWER TECH

Water treatment process for oilfield produced water

ActiveUS20090173692A1Minimize continued precipitationSolid sorbent liquid separationWater softeningSludgeTreatments water

The invention relates to a method and system for treating an aqueous liquid containing dissolved minerals and dissolved hydrocarbons. Method steps and apparatus for treating a waste water feed stream are disclosed which utilize a warm lime softening system in fluid communication with the waste water feed stream, wherein sludge from the warm lime softening system is recycled to improve lime utilization and enhance silica and boron removal without the addition of an external source of magnesium. In addition, a microfiltration system and / or an air stripper system may be used in fluid communication with at least one reverse osmosis system to produce a treatment water that meets state and federal guidelines for surface discharge.

Owner:WATER & POWER TECH

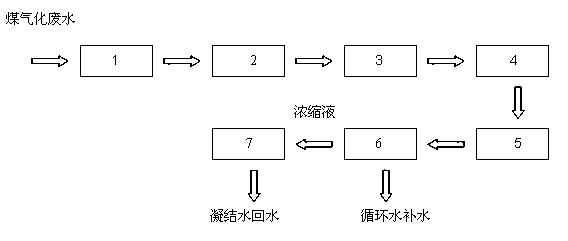

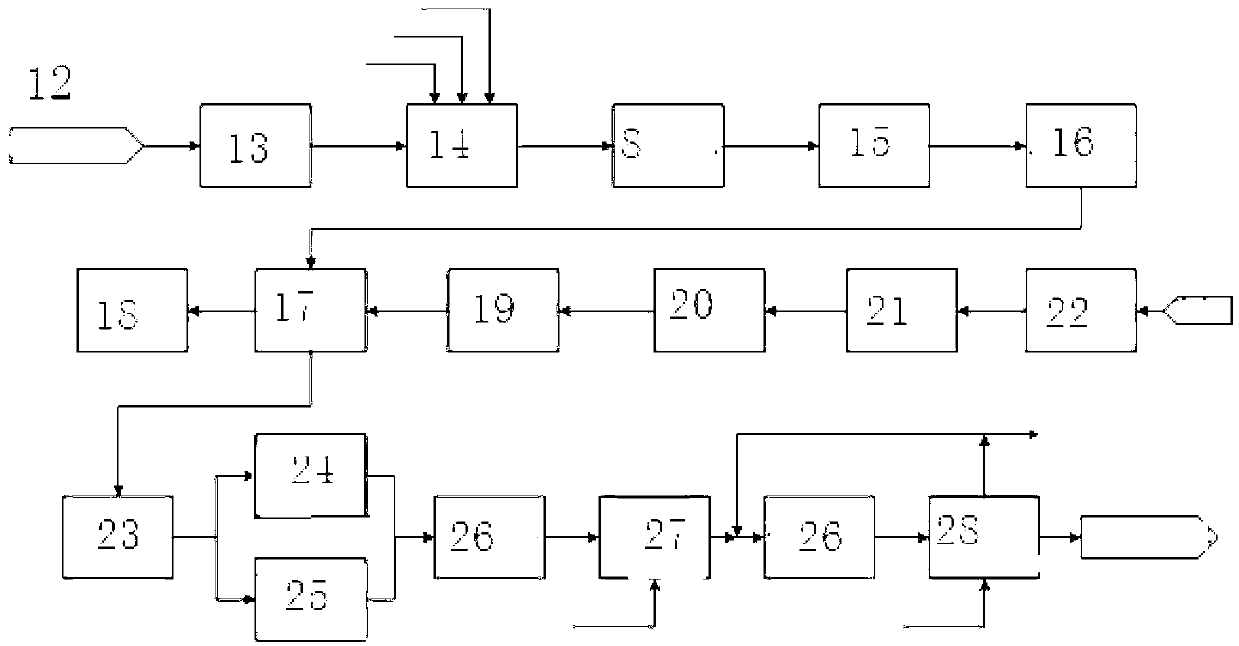

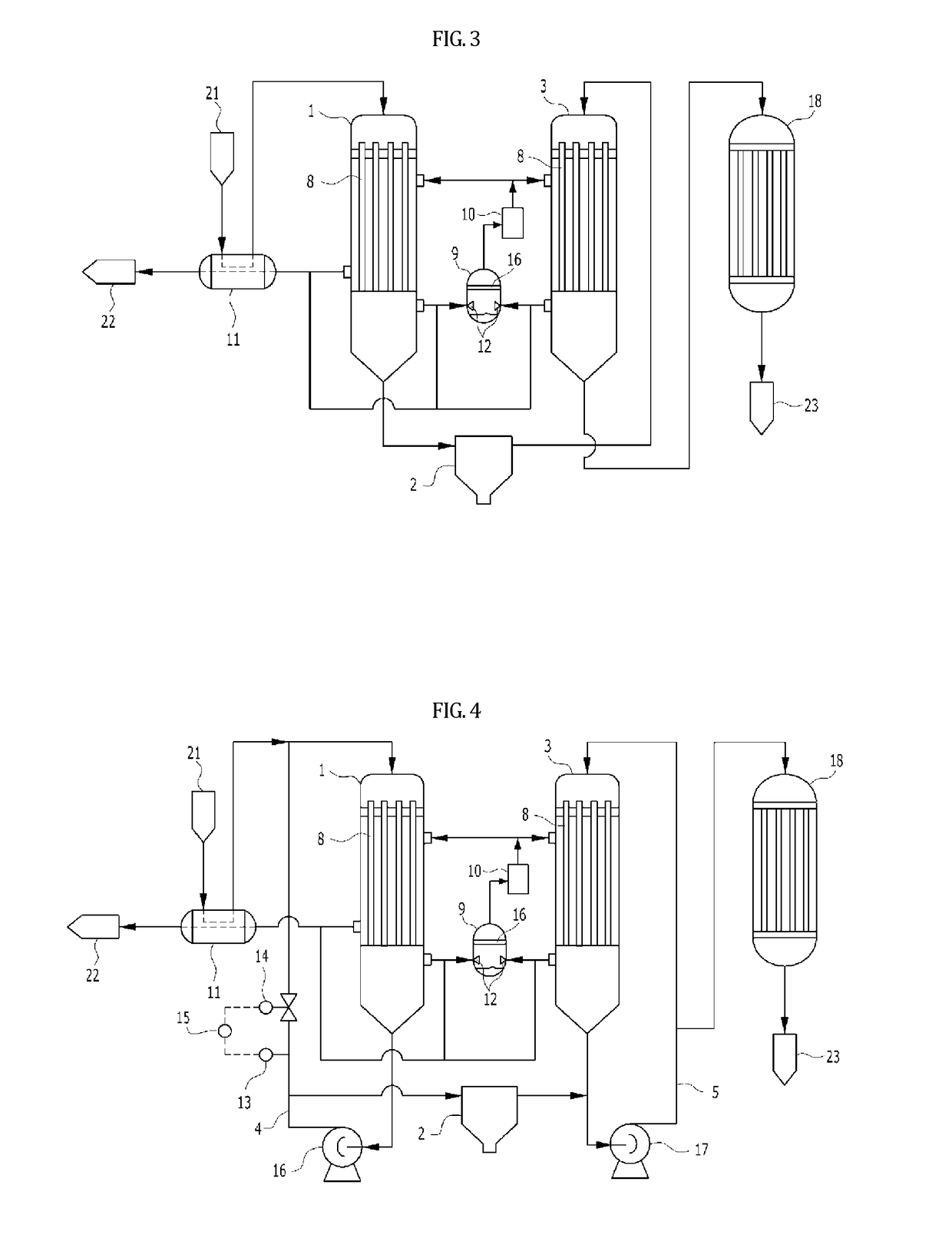

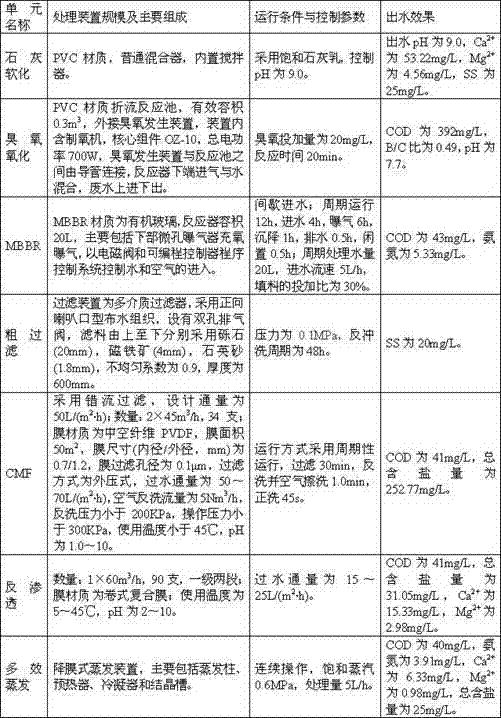

Method for treating coal gasification wastewater

ActiveCN103771650AReduce hardnessHigh removal rateWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentCoal gasification wastewaterFiltration

The invention discloses a method for treating coal gasification wastewater. The method comprises steps of: (1) lime softening by first adding lime milk to the coal gasification wastewater to conduct chemical precipitation on calcium salt and magnesium salt with the lime milk, standing the precipitation and filtering an supernatant; (2) ozone oxidation by sending the wastewater filtered in the step (1) into an ozone oxidation device for treatment; (3) MBBR treatment by sending the wastewater subjected to ozone oxidation into an MBBR for treatment; (4) coarse filtration; (5) continuous membrane filtration or ultrafiltration; (6) reverse osmosis; and (7) multi-effect evaporation by conducting multi-effect evaporation on the concentrate obtained by reverse osmosis treatment, and further crystallizing the concentrate obtained by multi-effect evaporation. The method of the invention can effectively remove the main pollutants such as COD, ammonia nitrogen and chroma in coal gasification wastewater, can also greatly reduce the salt content of the wastewater, ensure the efficient and long-term running of the double membranes, and achieve zero discharge of coal gasification wastewater.

Owner:CHINA PETROLEUM & CHEM CORP +1

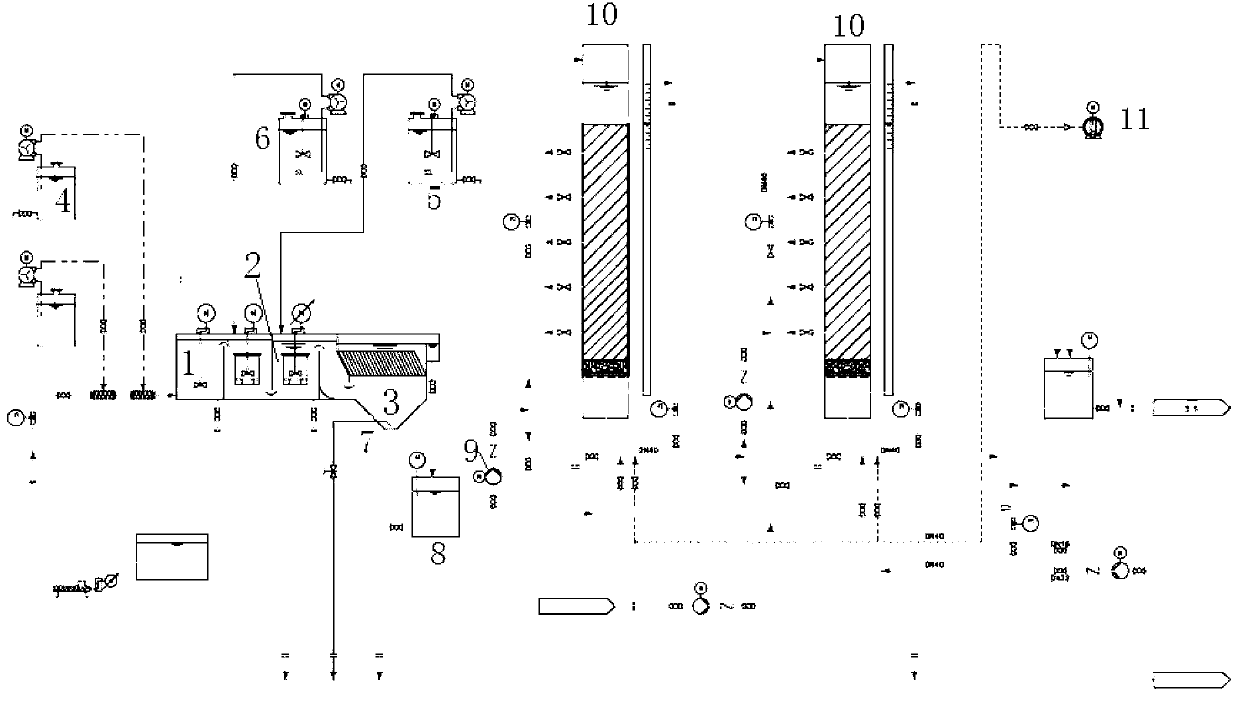

Treatment process and device for wastewater containing benzene

InactiveCN103102042AReduce reuse operating costsExtended operating cycleGeneral water supply conservationMultistage water/sewage treatmentMoving bedSuspended solids

The invention relates to a treatment process and device for wastewater containing benzene. The device comprises a pretreatment unit, an ozone oxidation unit, a biochemical treatment unit and a double-membrane advanced treatment unit which are sequentially connected. The treatment process comprises the steps of: firstly adding lime to the wastewater for softening the wastewater, then adding a coagulant for polyferric sulfate coagulation, adding a flocculating agent for flocculation, precipitating and clarifying, and then sending clear liquid into a sand filtering layer, wherein yielding water enters an ozone contact tank for ozone aeration and oxidation, carrying out biochemical treatment on the wastewater subjected to ozone oxidation by adopting a biological aerated filter treatment process and a moving bed biomembrane reactor so as to further degrade COD (Chemical Oxidant Demand), and carrying out ultra-filtration and reverse osmosis double-membrane treatment on the wastewater for desalination. According to the invention, through combination of the treatment units, the removal rate of CODcr with benzene rings in the fed water can be up to above 80%, and the removal rate of SS (Suspended Solids) is about 90%, and the removal rate of ammonia nitrogen is above 85% before fed water enters a RO (Reverse Osmosis) membrane. For a double-membrane system, the cleaning period is increased by 3-4 times, and the service life of the membrane is prolonged by 1-2 years.

Owner:ZHENGZHOU JIANGHE ENVIRONMENTAL PROTECTION TECH

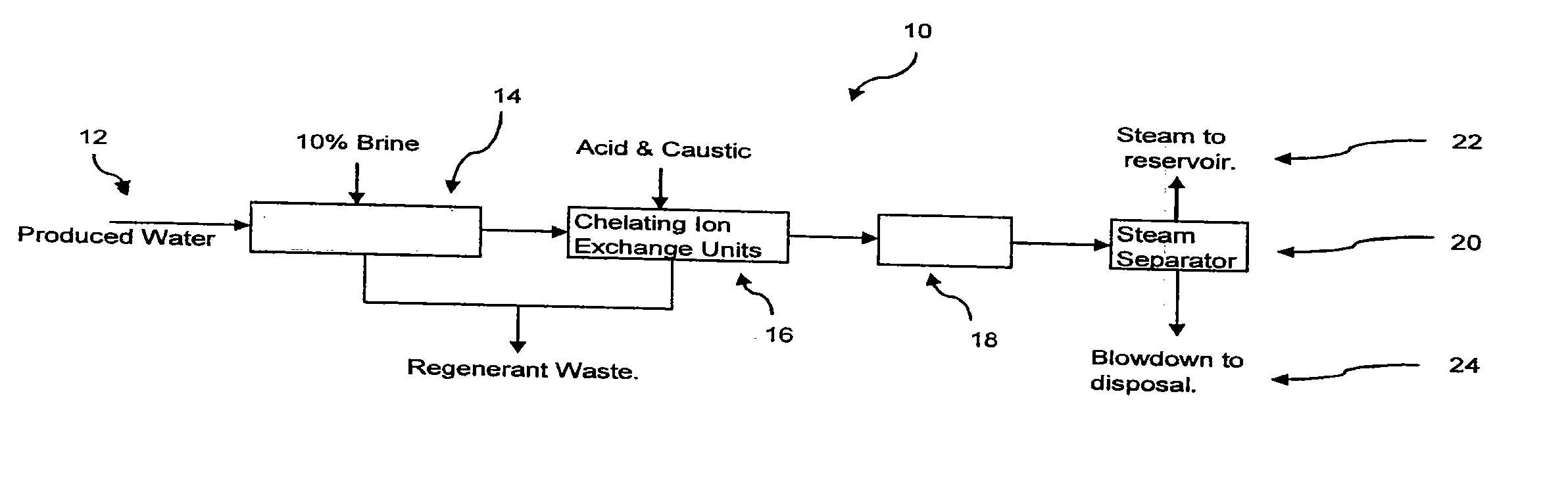

Method and apparatus for treating natural gas and oil well waste waters for removal of contaminants and dissolved solids

InactiveUS20150368137A1Reduce salt contentIncrease flexibilityWaste water treatment from quariesSludge treatmentFiltrationWastewater

A method for treating wastewater is disclosed. The method is useful in particular for treating wastewater that is generated from the process of drilling, hydraulic fracturing and / or cleaning a bore of an oil or natural gas well bore. The method may include performing cold lime softening of the wastewater to form waste salt floes, filtration of waste salt floes, ozonation of the filtrate from the filtration, and reverse osmosis of the filtrate to produce a purified permeate.

Owner:ADDLEMAN ENTERPRISES +1

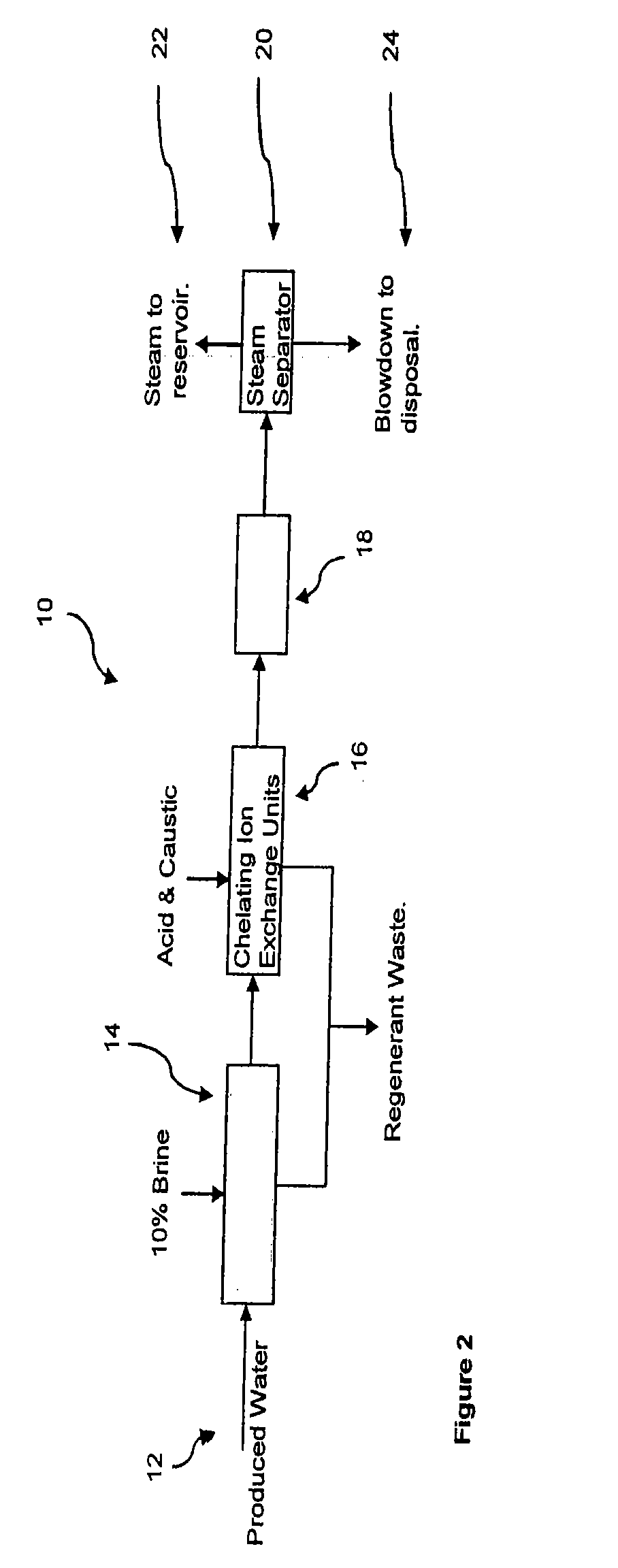

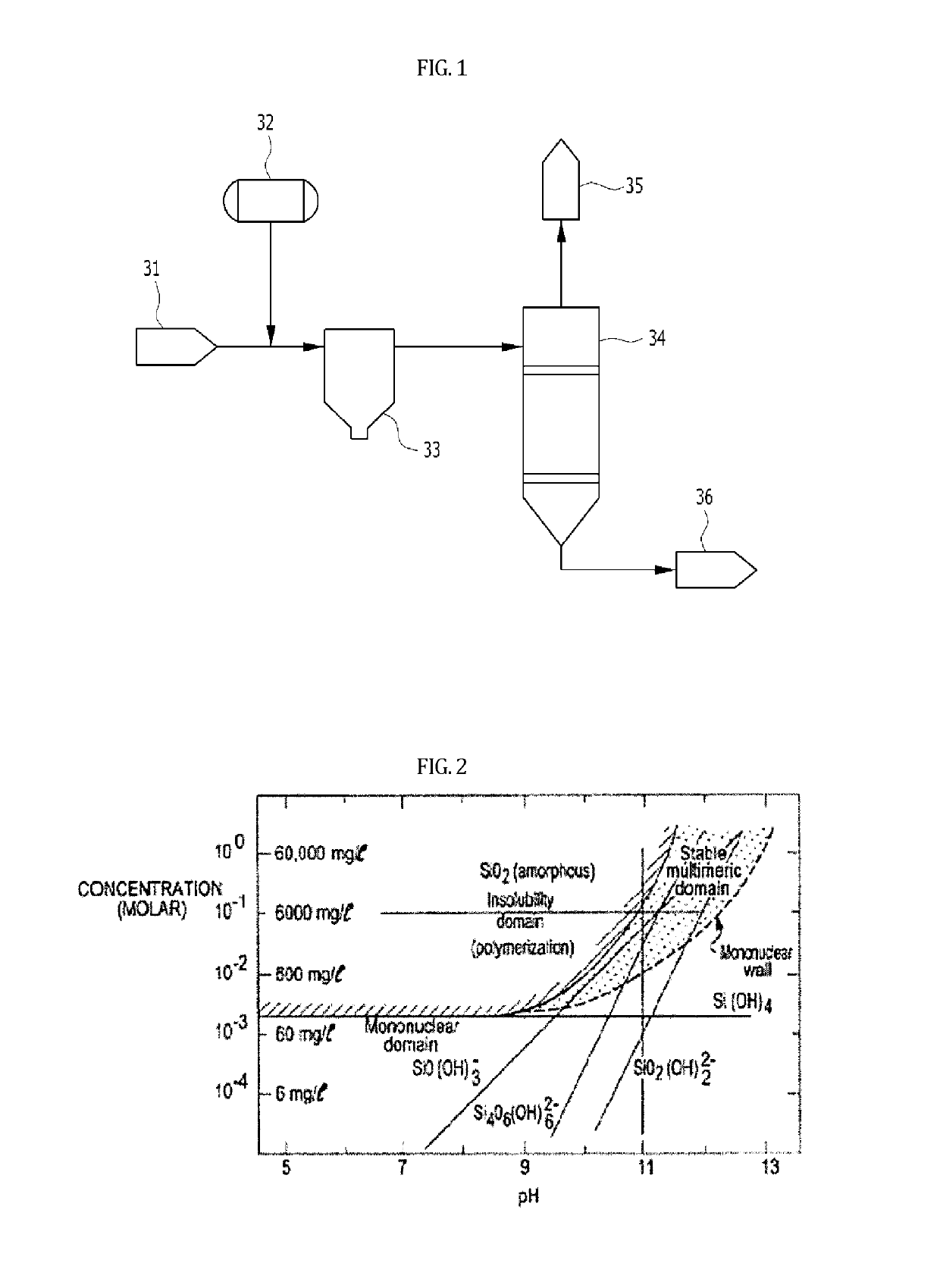

Method and apparatus for treating water to reduce boiler scale formation

InactiveUS20070095759A1Effective treatmentReduce the amount requiredWaste water treatment from quariesWater/sewage treatment by ion-exchangeOperational costsSilicon dioxide

A process for treating water to reduce silica based compound scaling in steam generation equipment is provided, including the step of subjecting water to a cation removal process to reduce the di- and trivalent cation concentration within the water to, most preferably, less than about 20 ppb prior to introducing the water into the steam generation equipment. This process eliminates the need for a lime softening stage and savings in capital and operating costs are realized.

Owner:WORLEYPARSONS GROUP

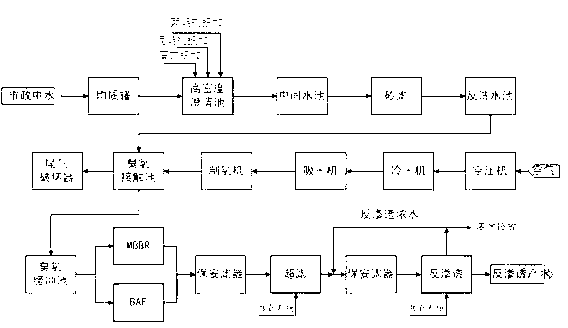

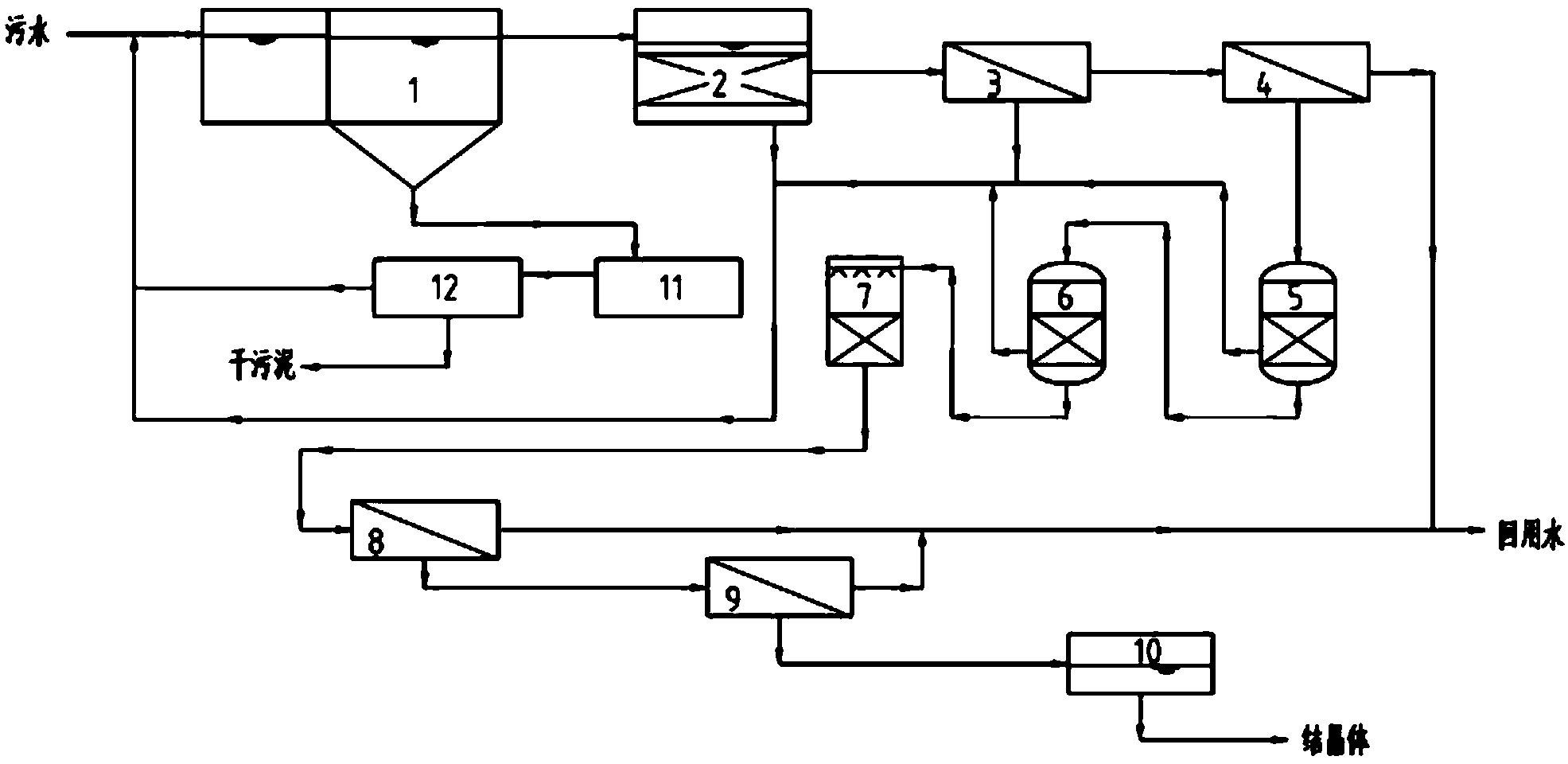

Reverse osmosis membrane treatment process for recycling industrial sewage and realizing zero release

InactiveCN104276711AImprove toleranceIncrease concentrated water ratioWater/sewage treatment by ion-exchangeWater/sewage treatment bu osmosis/dialysisProcess systemsWater source

The invention relates to a reverse osmosis membrane treatment process for recycling industrial sewage and realizing zero release. The reverse osmosis membrane treatment process is characterized by adopting a lime softening, alkaline-removing and clarifying tank, a filter tank, an ultrafiltration device and a primary reverse osmosis device as a first-stage concentrating and recycling system; adopting a weak acid type cation exchanger, a strong acid type cation exchanger, a carbon remover and a concentrated water reverse osmosis device as a second-stage concentrating and recycling system; adopting a concentrating reverse osmosis device as a third-stage concentrating and recycling system; adopting an evaporation crystallizer as a crystallizing and separating device for inorganic ions of the final concentrated liquid; and connecting the three systems in series to form the treatment process. The reverse osmosis membrane treatment process is especially suitable for reduction of industrial sewage and zero-release treatment projects of enterprises. The outlet water of the process system can be recycled as supplementing water for circulating and cooling water, a water source of boiler supplementing water and other purposes; the evaporation crystal substances can be used for a chemical raw material-brine; and other pollutants such as hard substances and suspended solids (SS) in the sewage are subjected to the solid-waste treatment in the form of dry sludge.

Owner:上海水合环境工程有限公司

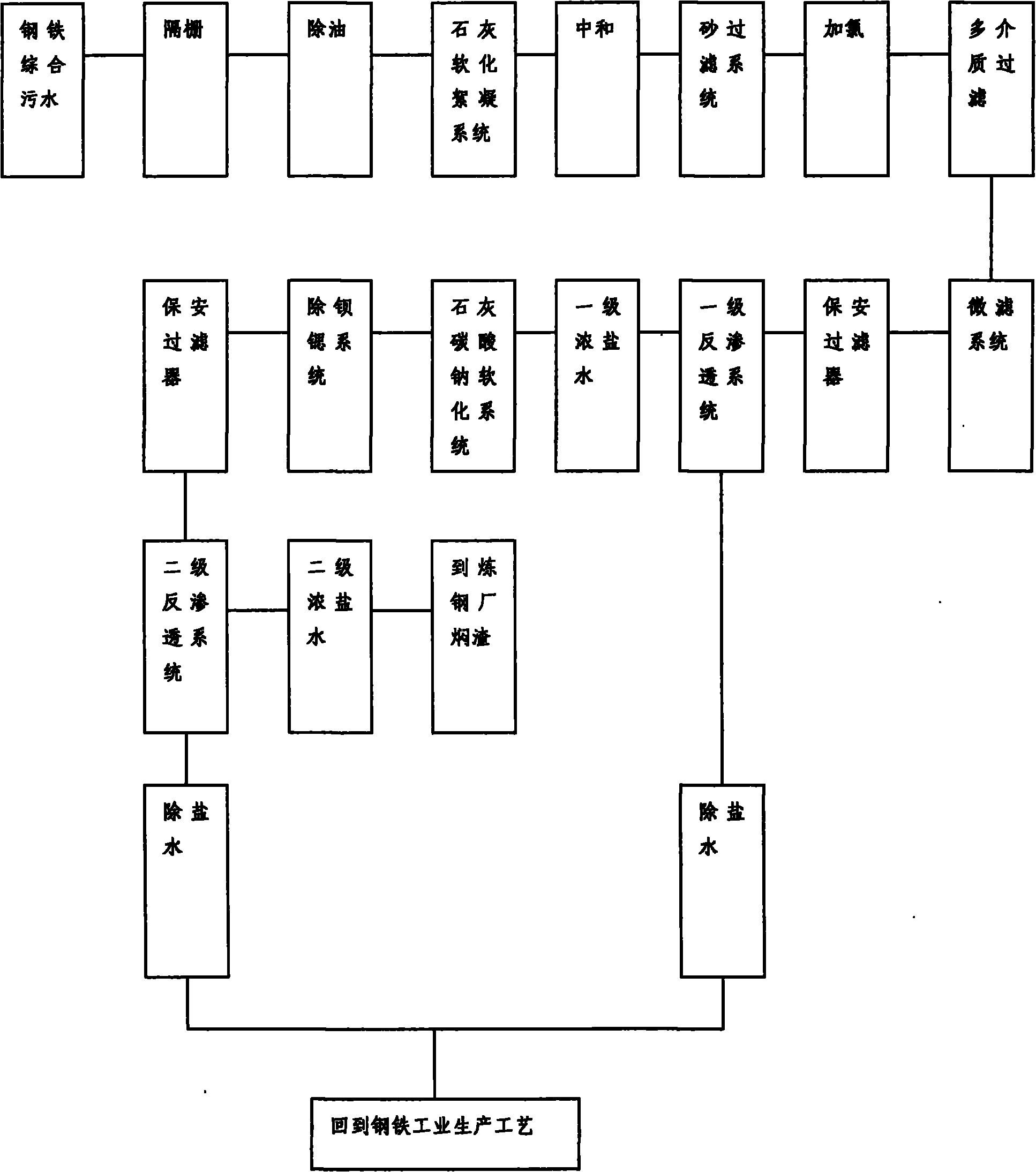

Method for comprehensive wastewater desalination and zero release in steel production

ActiveCN102030437AAvoid easy cloggingTo achieve the goal of zero pollutionGeneral water supply conservationWaste water treatment from metallurgical processSteelmakingFlocculation

The invention discloses a method for comprehensive wastewater desalination and zero release in steel production, belonging to the technical field of wastewater desalination and zero release. The method comprises the following steps of: introducing wastewater to a regulating pond through a fence, wherein the regulating pond is provided with a deoiling device; deoiling the wastewater; then introducing the wastewater into a lime softening flocculation precipitation system; enabling a supernatant to be subjected to neutralization, sand filtration, chlorination, multi-medium filtration and then introducing into a micro-filtration system, a cartridge filter and a primary reverse osmosis system; introducing primary reverse osmosis strong brine to a lime sodium carbonate softening system, the cartridge filter and a secondary reverse osmosis system; introducing secondary reverse osmosis strong brine for steelmaking and slag stewing so as to achieve zero release; and returning primary reverse osmosis demineralized water and secondary reverse osmosis demineralized water to the steel production process for application. The method has the advantages that a film is not blocked easily and the service life of equipment is long because the micro-filtration system, the primary reverse osmosis system, the resin softening system, the cartridge filter and the secondary reverse osmosis system are utilized. The primary reverse osmosis strong brine is introduced to the lime sodium carbonate softening system, the cartridge filter and the secondary reverse osmosis system; and the secondary reverse osmosis strong brine is introduced for steelmaking and slag stewing so as to achieve zero release of the wastewater.

Owner:BEIJING SHOUGANG CO LTD

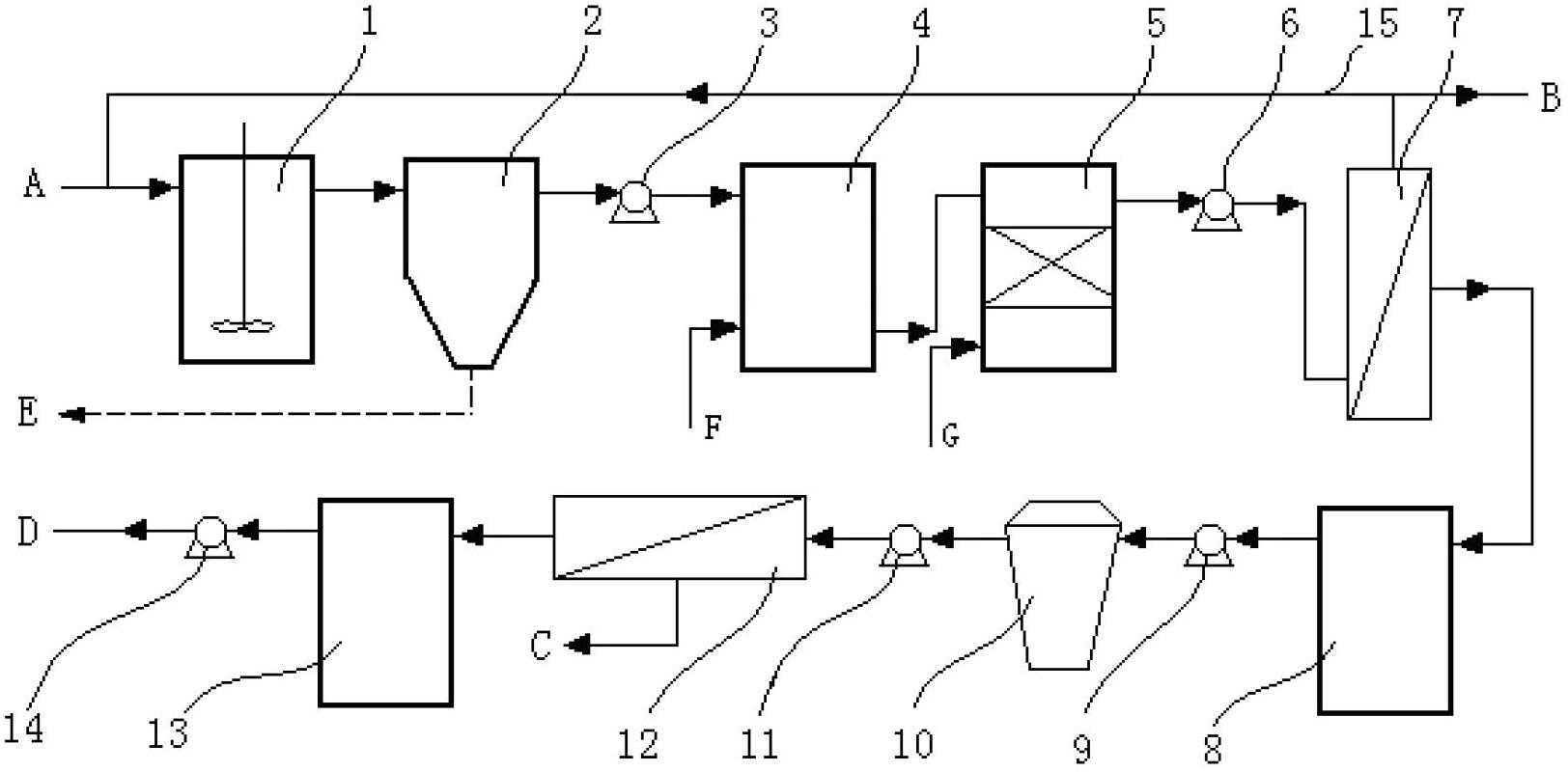

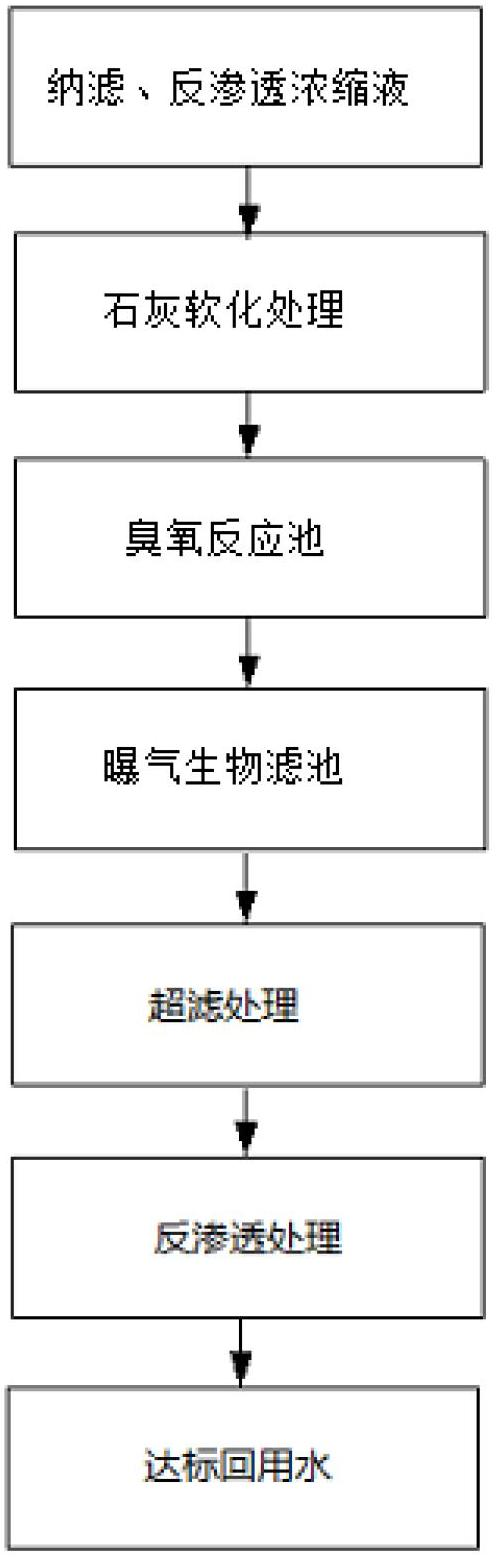

Nano-filtration and reverse osmosis concentrated solution reduction treatment system and method

InactiveCN102659291ALow costLow investment costWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentUF - UltrafiltrationLime softening

The invention discloses a nano-filtration and reverse osmosis concentrated solution reduction treatment system and method, and belongs to the field of wastewater treatment. The system comprises a lime softening treatment device, an ozone reactor, an aeration biofilter treatment device, an ultrafiltration treatment device and a reverse osmosis treatment device, wherein the lime softening treatment device is connected with the aeration biofilter treatment device, the ultrafiltration treatment device and the reverse osmosis treatment device sequentially; an ultrafiltration concentrate outlet of the ultrafiltration treatment device is connected back to a coagulating sedimentation treatment device; and the reverse osmosis treatment device is provided with a water outlet connected with an external recycling device. The treatment system can be used for nano-filtration and reverse osmosis concentrated solution reduction treatment with low cost, and has the advantages of low investment cost and high treatment efficiency.

Owner:BEIJING SOUND ENVIRONMENTAL ENG

Process for crushed coal pressurized gasification industrial wastewater deep processing and high recovery rate

InactiveCN105540971AImprove the operating environmentDegradation of suspended solidsGeneral water supply conservationTreatment involving filtrationWastewaterHardness

The invention relates to a process for crushed coal pressurized gasification industrial wastewater deep processing and high recovery rate. The process is characterized by feeding biochemical wastewater into a lime softening clarifier, adding lime and coagulant to enable the total hardness removal rate to be 50 percent or over 50 percent, sequentially passing through a multi-media filter, carrying out ultrafiltration and special resin adsorption, passing through a reverse osmosis device and a concentrated water processing device to produce fresh water, and recycling the fresh water for production. The process for crushed coal pressurized gasification industrial wastewater deep processing and high recovery rate has the advantages of low investment, low operation cost and high recovery rate.

Owner:SEDIN ENG

Method for treating reclaimed water reused as circulating cooling water of power plant

InactiveCN102701352AImprove removal efficiencyReduce moisture contentWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionTotal dissolved solidsRetention time

The invention provides a method for treating reclaimed water reused as circulating cooling water of a power plant. The method comprises the following steps of: 1, coal ash preprocessing stage: directly adding coal ash into second-level discharged water of a municipal sewage plant and mixing the coal ash with raw water; 2, lime softening stage: adding lime emulsion and a flocculant into the mixed solution of the coal ash and the raw water, obtained in the coal ash preprocessing stage, and stirring, wherein the retention time of the mixed solution is 2-3min in the lime softening stage; 3, flocculation stage: stirring and standing for 15-25min; and 4, settling stage: standing for 1.5-2.5h in the settling stage and then discharging for use. According to the method, the coal ash is used for adsorbing a part of organic substances in the reclaimed water, so that chemical agent cost is reduced, sludge dewatering is facilitated, and the stability of discharged water is good, and the turbidity removal rate, TDS (Total Dissolved Solids) removal rate and calcium hardness removal rate of water are greatly improved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Thermal power plant circulating water blow-down water electrodialysis desalination treatment system and method thereof

PendingCN111056676AHigh salt contentAvoid contamination riskSludge treatmentWater contaminantsSludgeWater production

The invention discloses a thermal power plant circulating water blow-down water electrodialysis desalination treatment system and a method thereof. An outlet of a circulating water blowdown pool is communicated with an inlet of the middle pool through a lime softening treatment system; an outlet of the middle pool is communicated with an inlet of a ceramic membrane ultrafiltration treatment system; wherein an outlet of the ceramic membrane ultrafiltration treatment system is communicated with an inlet of a ultrafiltration water production tank, an outlet of the ultrafiltration water productiontank is communicated with an inlet of the electrodialysis treatment system, a clear water outlet of the electrodialysis treatment system is communicated with an inlet of a fresh water tank, and a concentrated water outlet of the electrodialysis treatment system is communicated with an inlet of the concentrated water tank; and the sludge outlet of the lime softening treatment system and the wastewater outlet of the ceramic membrane ultrafiltration treatment system are connected with a waste treatment system. The system and the method have the advantages that the treatment and the recycling ofthe circulating water sewage of a thermal power plant can be realized, the operation cost is lower, and the economy is better.

Owner:XIAN TPRI WATER & ENVIRONMENTAL PROTECTION +1

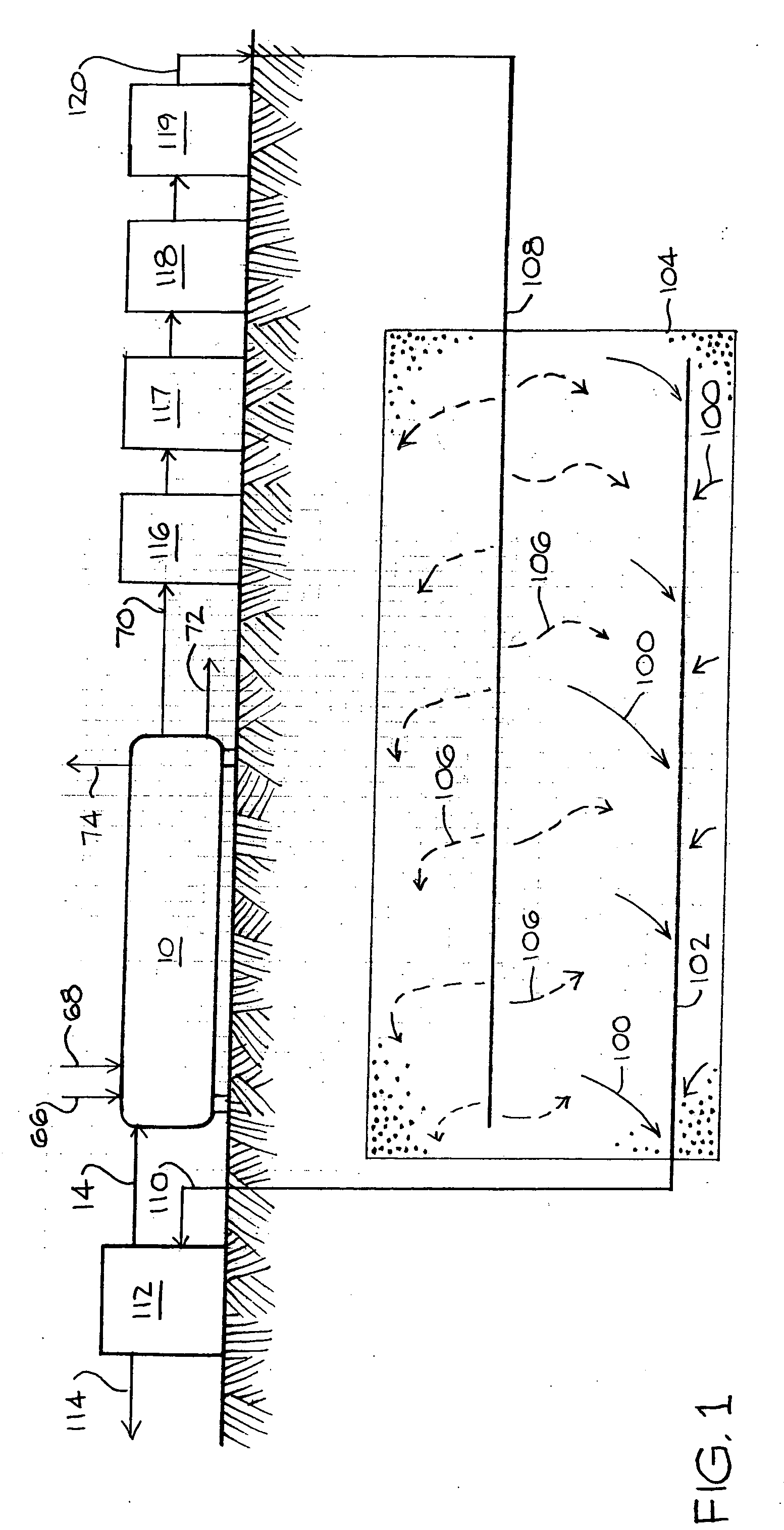

Mechanical Flotation Device for Reduction of Oil, Alkalinity and Undesirable Gases

InactiveUS20090014368A1Reduce gasReduce alkaline specie contentLiquid degasificationLiquid hydrocarbon mixture productionAlkalinityEnvironmental engineering

A mechanical vessel may effectively and simultaneously displace a first undesired gas from within water with a second desired gas, and remove at least one alkaline species and oily matter from the water. The vessel raises the pH of the water and reduces the lime requirement for subsequent lime softening. The vessel receives the water containing the first gas and passes the water through a series of gasification chambers. Each gasification chamber may have a mechanism that ingests and mixes a second gas into the water thereby physically displacing at least a portion of the first gas into a vapor space at the top of each gasification chamber from which it is subsequently removed. There is an absence of communication between the vapor spaces of adjacent chambers. An acid is added to remove the alkaline species, where the first gas is an optional by-product that is also removed.

Owner:CAMERSON INT CORP

Mine shaft sewage treatment process

InactiveCN110467288ALower pHReduce hardnessWaste water treatment from quariesSludge treatmentDisinfectantFiltration

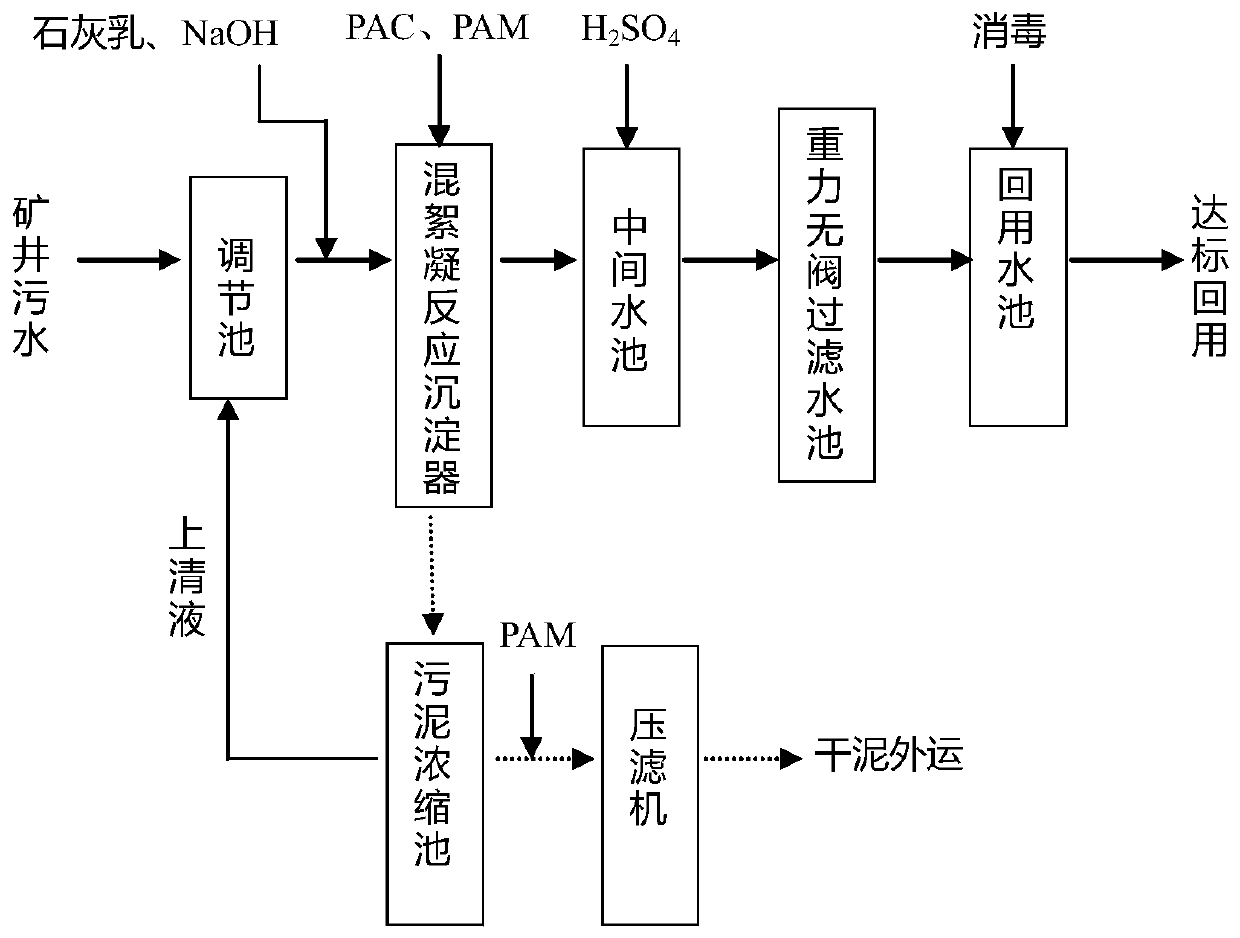

The invention discloses a mine shaft sewage treatment process, and relates to the technical field of sewage treatment. The mine shaft sewage treatment process comprises that mine shaft sewage enters aregulating pool, and is subjected to water amount and water quality regulating; the regulated mine shaft sewage enters a flocculation reaction precipitator, sodium hydroxide is added to adjust the pHvalue of the mine shaft sewage, lime milk is added, and hardness reducing treatment is performed by using a lime softening method; PAC and PAM are added, flocculation precipitation treatment is performed, and finally solid-liquid separation is performed; the supernatant after the solid-liquid separation is lifted to the high-position water box of a gravity valve-free filtering water pool by a pump through a middle pool, and is filtered, the effluent enters a reuse water pool, a disinfectant is added, and disinfection treatment is performed; and the sludge after the solid-liquid separation isdischarged into a sludge concentration pool, PAM is added, flocculation precipitation is performed, the supernatant refluxes to the regulating pool, the sludge is sucked to a filter press by a sludgepump, and is dewatered, and the dried sludge is externally transported. According to the present invention, by using the treatment process of coagulation, precipitation and filtration, the turbidity,the hardness and the chrominance in mine shaft wastewater can be effectively reduced.

Owner:安徽环境科技集团股份有限公司

Device and method for treating waste residues of circulating make-up water by reutilizing lime softening method of power plant

ActiveCN103011462AImprove desulfurization efficiencyHigh environmental valueMultistage water/sewage treatmentWater sourceEnvironmental engineering

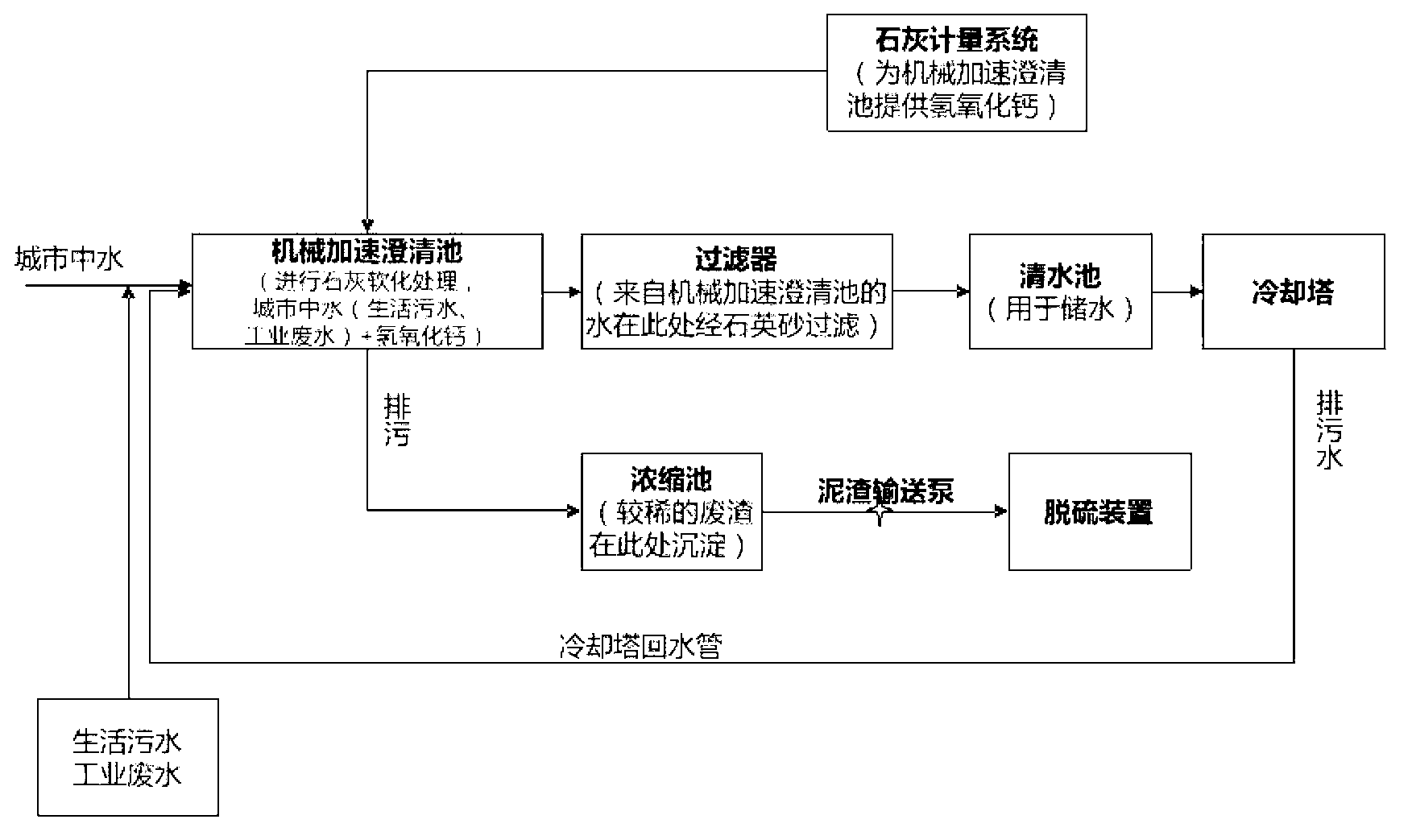

The invention provides a method for treating waste residues of circulating make-up water by reutilizing a lime softening method of a power plant. The method comprises the following steps of: a), mixing a circulating make-up water source with a pH value regulating agent for regulating the pH value of the circulating make-up water source to 9.9-10.3 on the condition of not adding a flocculant and a coagulant aid; and b), stewing the mixed solution with the pH value of 9.9-10.3 obtained in the step a) and using the obtained filter residue as a desulfurizing agent. According to the method provided by the invention, the flocculant and the coagulant aid are not added while the circulating make-up water is treated by the lime softening method, and the treated water also satisfies the water standard of the circulating make-up water; the obtained filter residue can form into dry solid gypsum, so that high desulfurizing efficiency can be achieved; and moreover, according to the method provided by the invention, the pH value of the circulating make-up water source is regulated to 9.9-10.3 by adopting the pH value regulating agent, so that the obtained filter residue can directly serve as the desulfurizing agent and has high desulfurizing efficiency.

Owner:CHINA RESOURCES POWER HENAN SHOUYANGSHAN

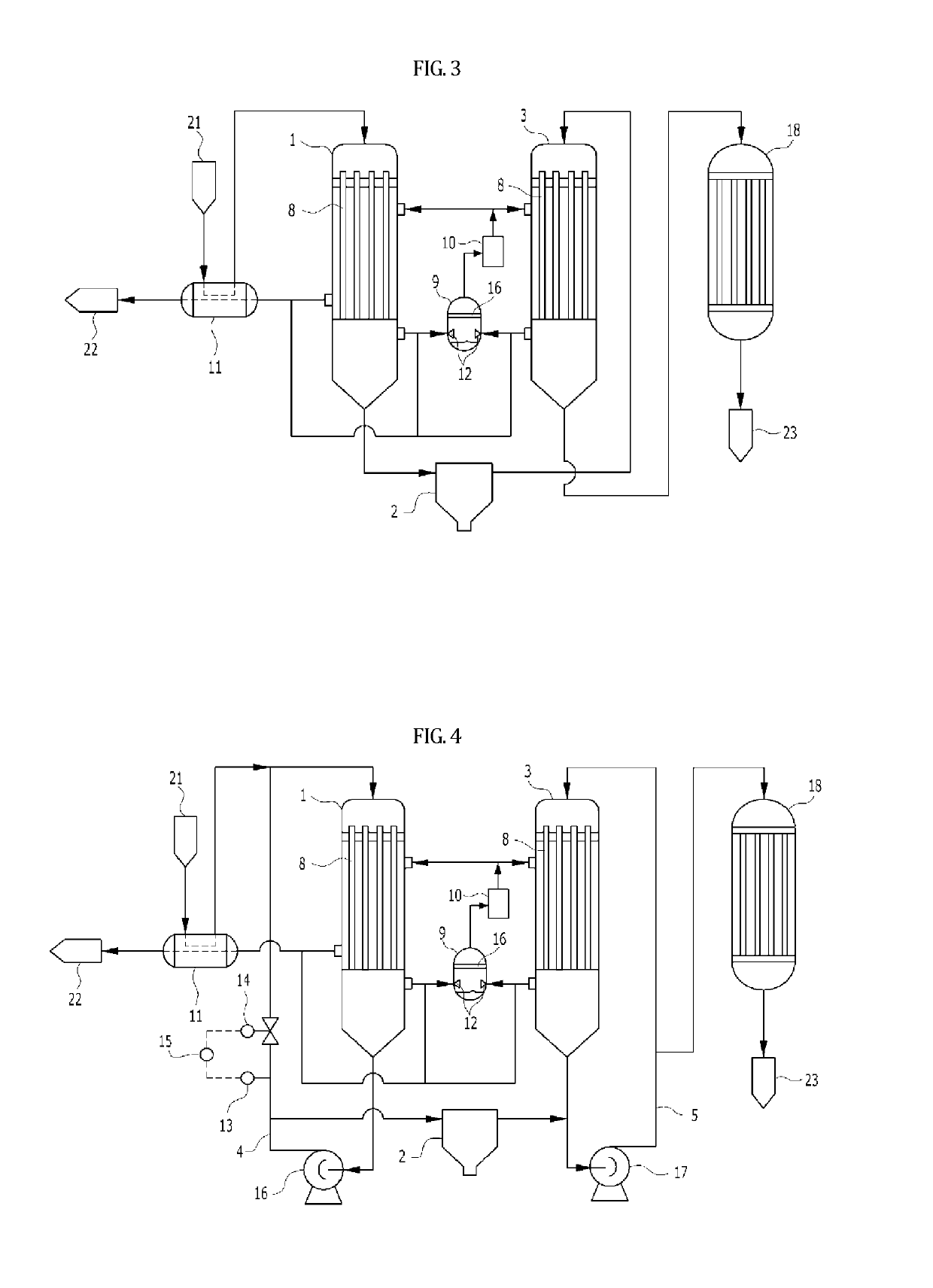

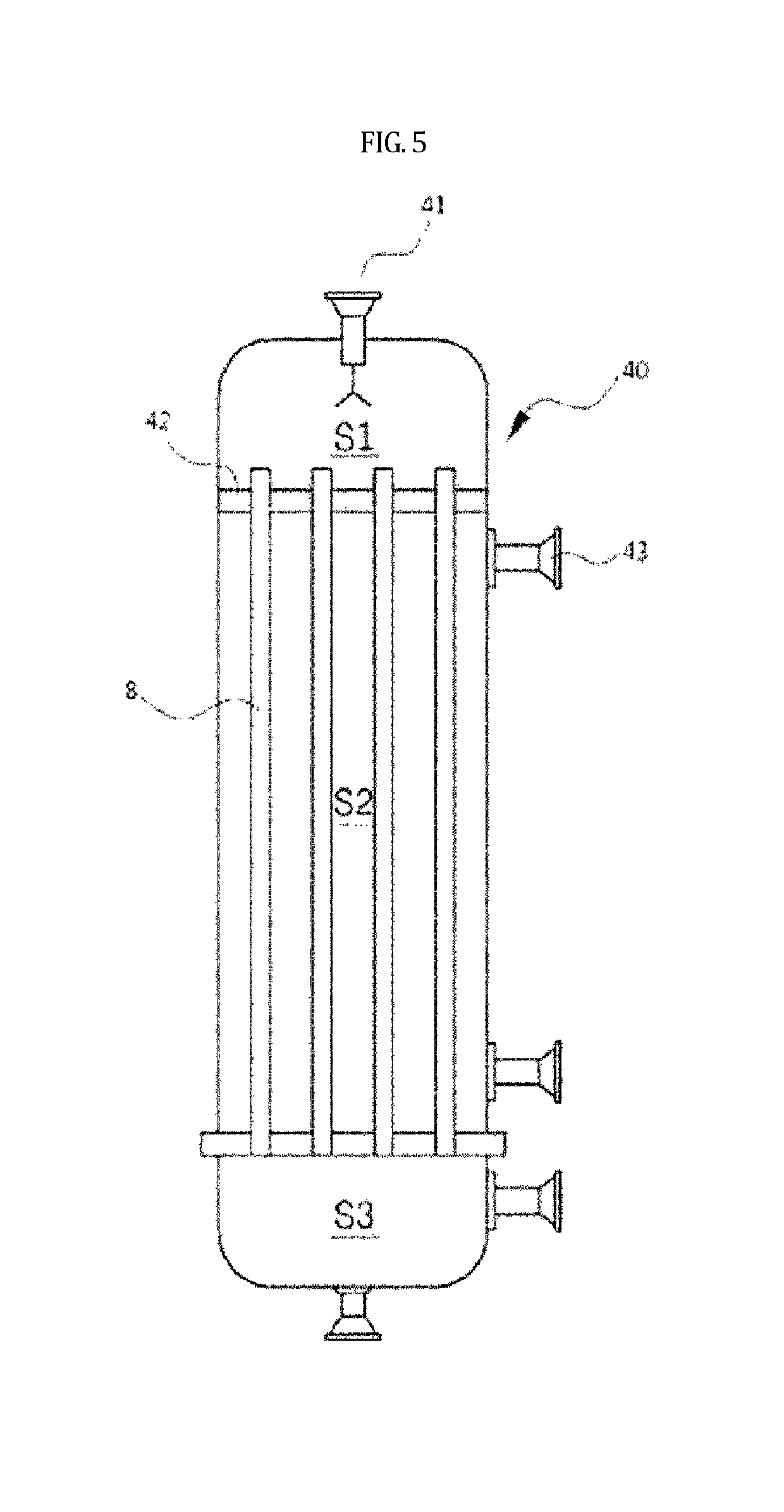

Apparatus for evaporative concentration of water to be treated, which uses hot lime softening, and method for evaporative concentration of water using the same

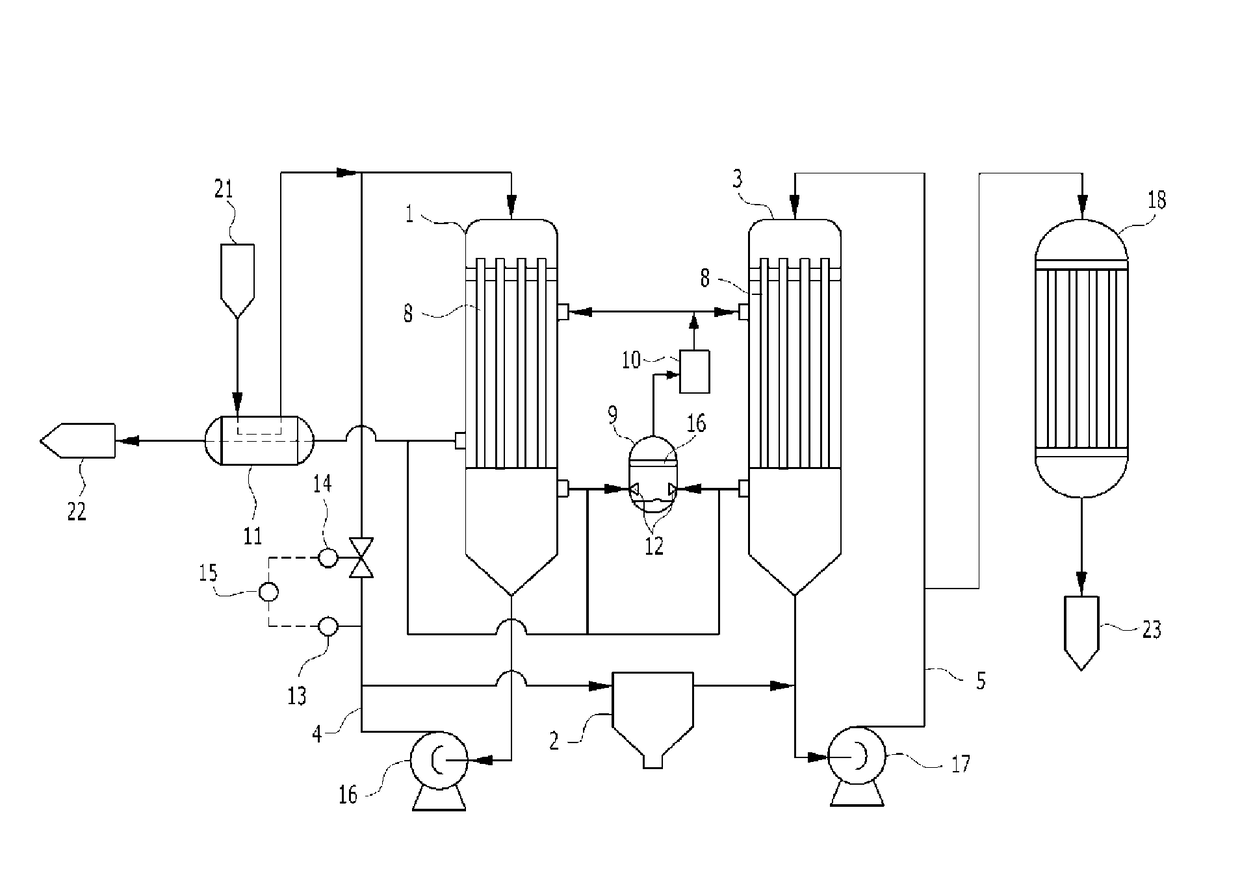

ActiveUS20170088452A1Improve abilitiesInhibition is effectiveWater/sewage treatment by centrifugal separationEvaporation with vapour compressionWater useHardness

An apparatus for evaporative concentration of water, containing hardness-causing substances, to be treated using hot lime softening, includes: a first evaporator configured to form first concentrated water from the water to be treated by evaporatively concentrating the water by first heat exchange with hot steam; a hot lime softener configured to precipitate and to separate hardness-causing substances contained in the first concentrated water from at least a portion of the first concentrated water from the first evaporator by reaction with lime and configured to remove the hardness-causing substances from the first concentrated water; and a second evaporator configured to form second concentrated water by further evaporatively concentrating at least a portion of the first concentrated water that passed through the hot lime softener by second heat exchange with hot steam.

Owner:DOOSAN HEAVY IND & CONSTR CO LTD

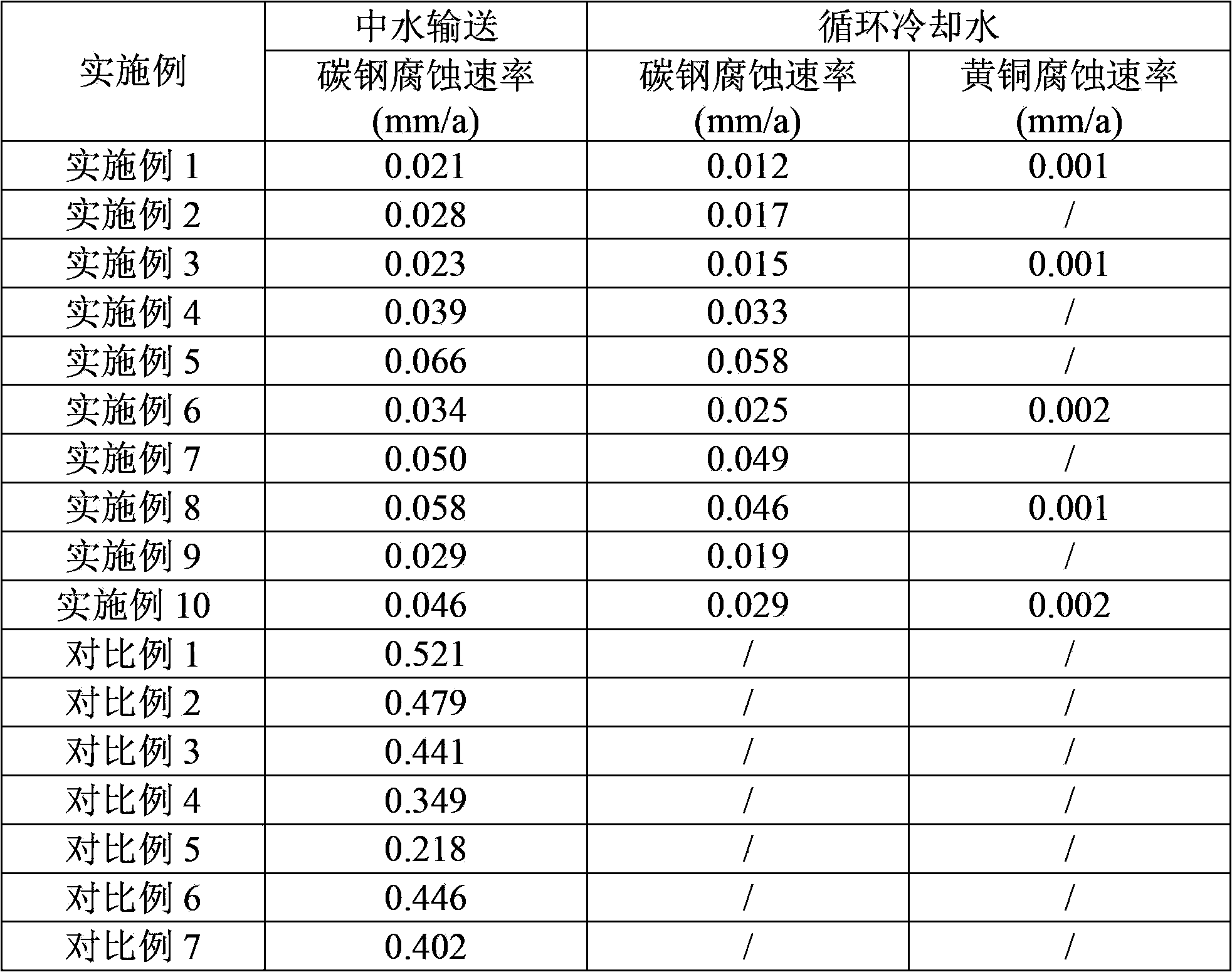

Method for recycling reclaimed water in circulating cooling water system

ActiveCN103803717AEnsure safetyReduce difficultyTreatment using complexing/solubilising chemicalsEutrophicationReclaimed water

The invention discloses a method for recycling reclaimed water in a circulating cooling water system. The method is characterized by comprising the following steps: (1) adding lime to the reclaimed water to carry out softening treatment and then carrying out solid-liquid separation; (2) adding silicates as corrosion inhibitors to the reclaimed water obtained after solid-liquid separation in the step (1); (3) adding the reclaimed water to which the silicates are added in the step (2) to circulating cooling water of the circulating cooling water system as replenished water of circulating cooling water; (4) adding polymer scale inhibitors and dispersants to the circulating cooling water to which the reclaimed water is added in the step (3). By adopting the method, non-phosphorus operation can be achieved in the whole process from reclaimed water transport to circulating cooling water system operation, thus avoiding the risk of water body eutrophication caused by circulating water pollution discharge and effectively reducing corrosion of transport pipelines caused by the reclaimed water.

Owner:CHINA PETROLEUM & CHEM CORP +1

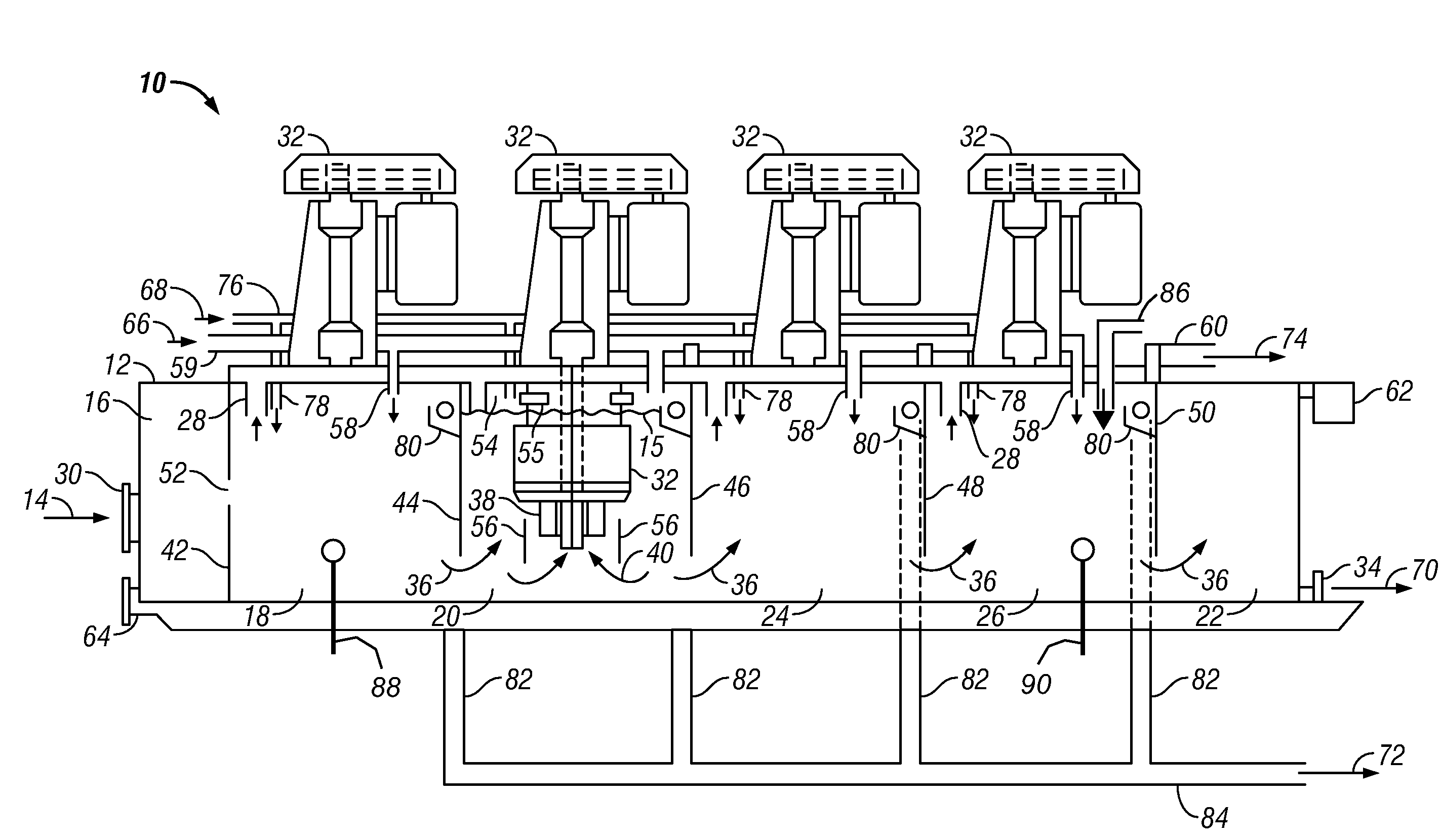

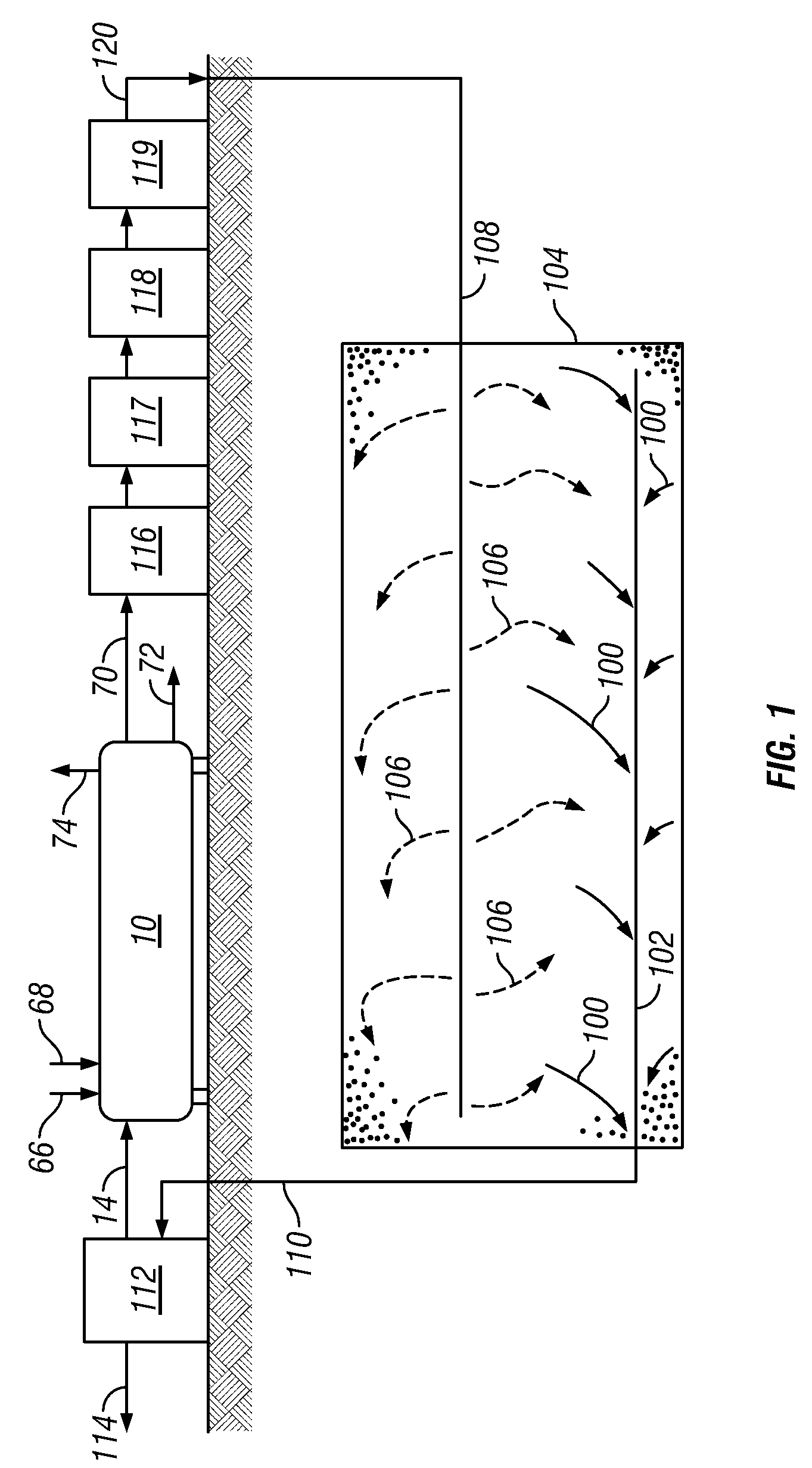

Mechanical flotation device for reduction of oil, alkalinity and undesirable gases

InactiveUS20060231504A1Reduce gasReduce alkaline specie contentLiquid degasificationSettling tanks feed/dischargeAlkalinityEnvironmental engineering

A mechanical vessel may effectively and simultaneously displace a first undesired gas from within water with a second desired gas, and remove at least one alkaline species and oily matter from the water. The vessel raises the pH of the water and reduces the lime requirement for subsequent lime softening. The vessel receives the water containing the first gas and passes the water through a series of gasification chambers. Each gasification chamber may have a mechanism that ingests and mixes a second gas into the water thereby physically displacing at least a portion of the first gas into a vapor space at the top of each gasification chamber from which it is subsequently removed. There is an absence of communication between the vapor spaces of adjacent chambers. An acid is added to remove the alkaline species, where the first gas is an optional by-product that is also removed.

Owner:PETRECO INT

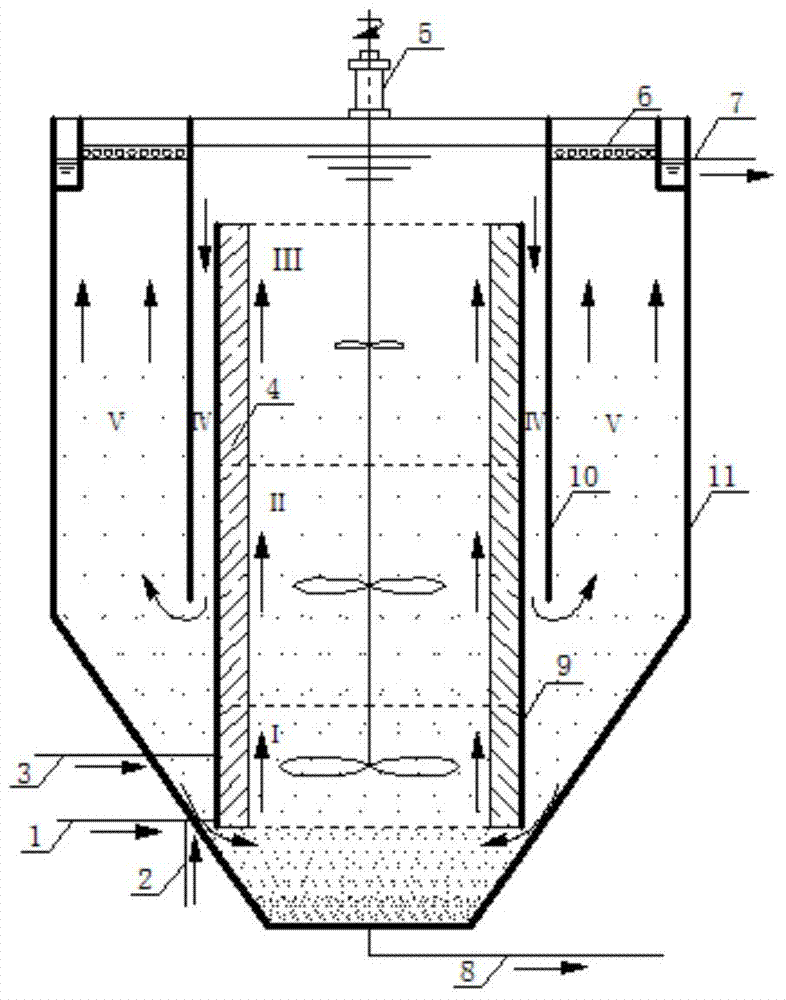

Efficient hardness removal method and device applicable to underground water

ActiveCN103922450AReduce dosageReduce consumptionWater/sewage treatment by flocculation/precipitationSludgeWater flow

The invention discloses efficient hardness removal method and device applicable to underground water, belonging to the field of water treatment technologies. The device is divided into a reaction zone, a diversion zone IV and a settling zone V from the inside to outside; a pitched blade type stirrer is arranged at the very center of the device and penetrates through the whole reaction zone; three groups of paddles are arranged on a rotation shaft of the stirrer from the bottom to top; the reaction zone is divided into three reaction control zones I, II and III from the bottom to top; the speed gradients G of the three zones are decreased in sequence; and four baffle plates are uniformly fixed on the inner wall of the reaction zone. The reaction process comprises the steps of respectively importing raw water and lime milk into the lower part of the reaction zone I through a water inlet pipe and a CaO addition pipe, importing a flocculating agent into the upper part of the reaction zone I through a flocculating agent addition pipe, ensuring the elevation f the water flow and the backflow process of the settling through the elevation function of the pitched blade type stirrer, completing the coagulation process during the lime softening process, and draining the clean water from a catch basin via a water outlet, wherein the precipitates are increased gradually along the long-time running of the reaction device, so that the part of the precipitates need to be discharged through a sludge removal emptying pipe at regular intervals.

Owner:BEIJING UNIV OF TECH

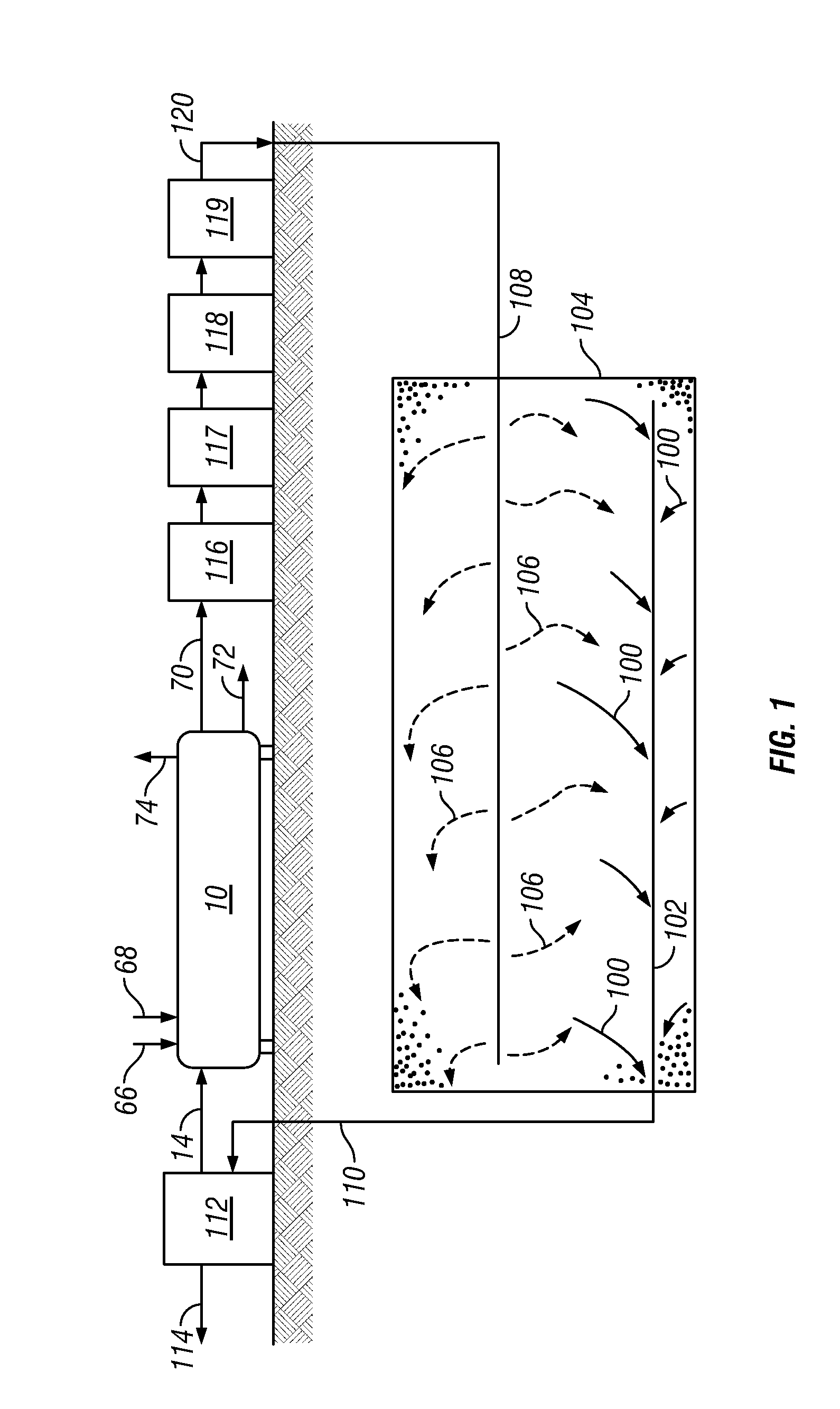

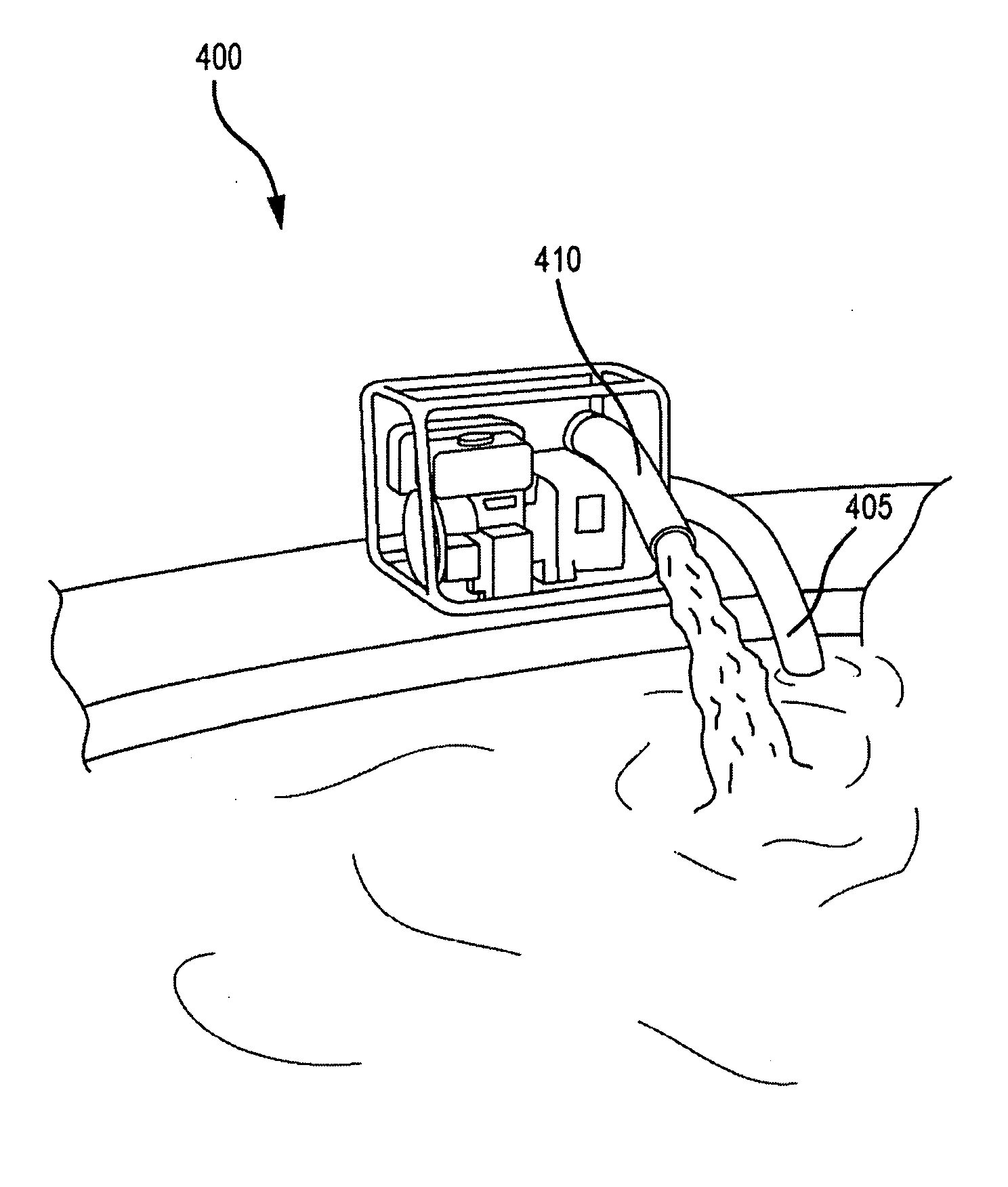

Mobile system and method for mineral hardness management

InactiveUS20080067131A1Reduce needIon-exchanger regenerationScale removal and water softeningParticulatesFiltration

The disclosed systems and methods for maintenance of an enclosed body of water generally include mobile systems and / or methods for removal of mineral hardness and other particulate impurities via lime softening filtration. Chemicals are added to a body of water containing unwanted mineral hardness (or other particulate impurities) and mixed to assist dispersion. The chemicals react with the hardness minerals making them insoluble. The resulting precipitate falls out of solution to the bottom of the body of water for subsequent removal via filtration. This eliminates or otherwise reduces the need for draining water and / or adding new water to a body of water to maintain proper mineral hardness balance and / or concentration of other particulate impurities.

Owner:RAYNE DEALERSHIP CORP

Process and system for treating power plant wastewater

InactiveCN107162259AReduce hardnessReduce turbidityGeneral water supply conservationSpecific water treatment objectivesSoftened waterTurbidity

The application provides a process and method for treating power plant wastewater. The process comprises the following steps: S1, performing lime softening on wastewater; S2, filtering the wastewater softened with lime to obtain filtrate; S3, performing sodium bed softening on the filtrate to obtain softened water; and S4, performing efficient reverse osmosis treatment on the softened water to obtain primary demineralized water. According to the method, the power plant wastewater is subjected to lime softening and sodium bed softening processes, Ca<2+>, Mg<2+> and other ions can be removed, hardness of wastewater can be reduced, and turbidity in water is reduced since wastewater is filtered, so that wastewater treated by the treatment process can reach the water quality index of primary demineralized water, and partial water can be utilized in households and production, and the aim of changing wastewater into available water can be achieved. Furthermore, the recycling rate of wastewater is improved to 90 percent by adopting efficient reverse osmosis treatment, the recycling rate of wastewater can be greatly improved, fresh water usage can be reduced, and the water resource can be saved.

Owner:CHINA SHENHUA ENERGY CO LTD +1

Mechanical flotation device for reduction of oil, alkalinity and undesirable gases

InactiveUS7416661B2Reduce gas and alkaline specie contentLiquid degasificationSettling tanks feed/dischargeEnvironmental engineeringLime softening

A mechanical vessel may effectively and simultaneously displace a first undesired gas from within water with a second desired gas, and remove at least one alkaline species and oily matter from the water. The vessel raises the pH of the water and reduces the lime requirement for subsequent lime softening. The vessel receives the water containing the first gas and passes the water through a series of gasification chambers. Each gasification chamber may have a mechanism that ingests and mixes a second gas into the water thereby physically displacing at least a portion of the first gas into a vapor space at the top of each gasification chamber from which it is subsequently removed. There is an absence of communication between the vapor spaces of adjacent chambers. An acid is added to remove the alkaline species, where the first gas is an optional by-product that is also removed.

Owner:PETRECO INT

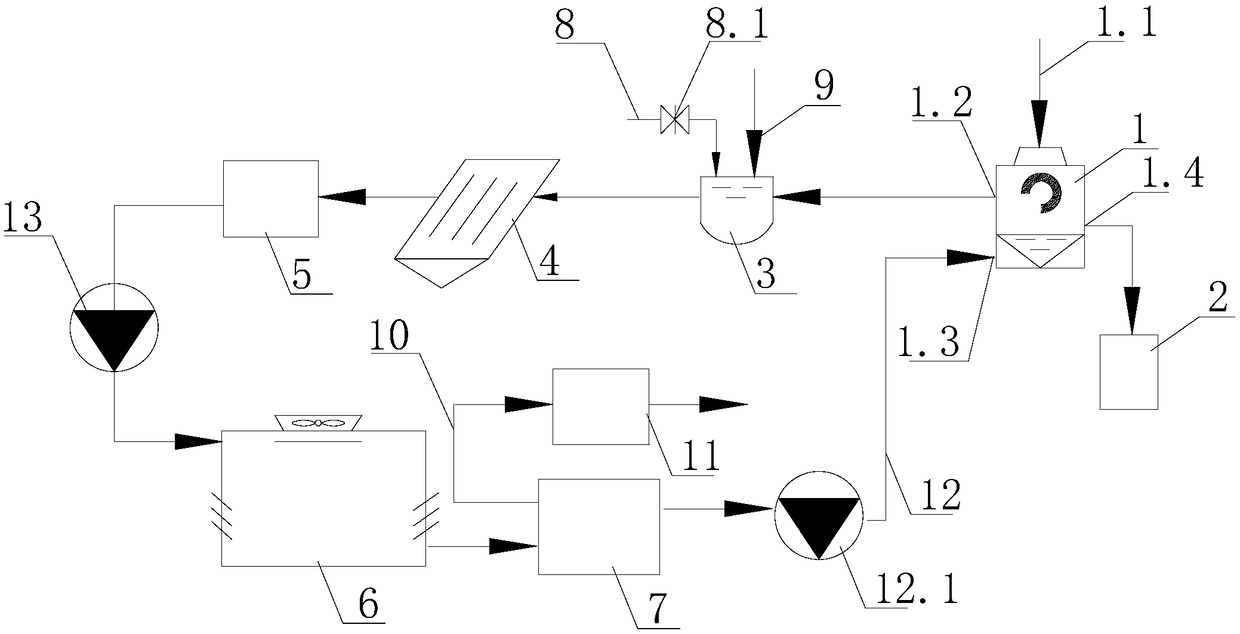

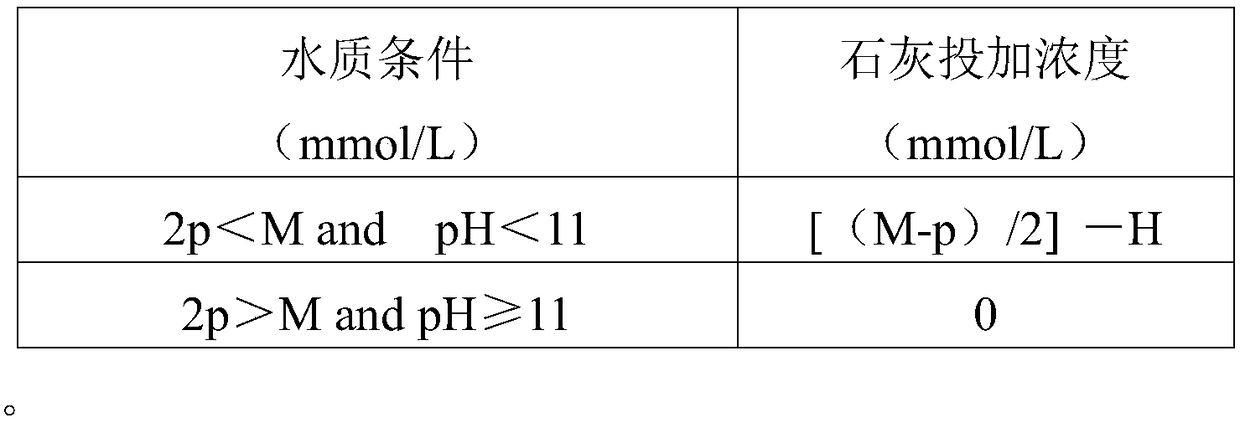

Ammonia nitrogen wastewater treatment method and ammonia nitrogen wastewater treatment system for wet dust collection blast furnace gas system

InactiveCN108793549AReduce the concentration of ammonia nitrogen in sewageReduce concentrationWater treatment parameter controlWater contaminantsCooling towerWater quality

The invention discloses an ammonia nitrogen wastewater treatment method and an ammonia nitrogen wastewater treatment system for a wet dust collection blast furnace gas system. The method realizes ammonia nitrogen wastewater treatment by six steps of detection of water quality conditions; lime softening; settling and separating; air stripping; blowoff, sewage discharge and decyanation treatment ofblast furnace gas. The system comprises a circumferential seam scrubbing tower, wherein a blast furnace gas inlet pipe is arranged at the top of the circumferential seam scrubbing tower; a scrubbing water return port and a scrubbing water inlet are formed in the side wall of the circumferential seam scrubbing tower from top to bottom; the side wall of the circumferential seam scrubbing tower is provided with a gas outlet; a gas utilizing system is connected to the gas outlet; a return water elevated flow slot, a settling pond, a hot water pool, a cooling tower and a cold water pool are sequentially connected to the scrubbing water return port through a pipeline; the cold water pool is connected with the scrubbing water inlet through a circular water supply pipe. According to the ammonia nitrogen wastewater treatment method and the ammonia nitrogen wastewater treatment system disclosed by the invention, the wastewater amount is reduced by using an evaporative cooling principle, and no water treatment structure or increase of energy consumption for water treatment is needed; the ammonia nitrogen wastewater treatment method and the ammonia nitrogen wastewater treatment system have thecharacteristics of less investment, low cost, reliable operation and the like.

Owner:武汉钢铁有限公司

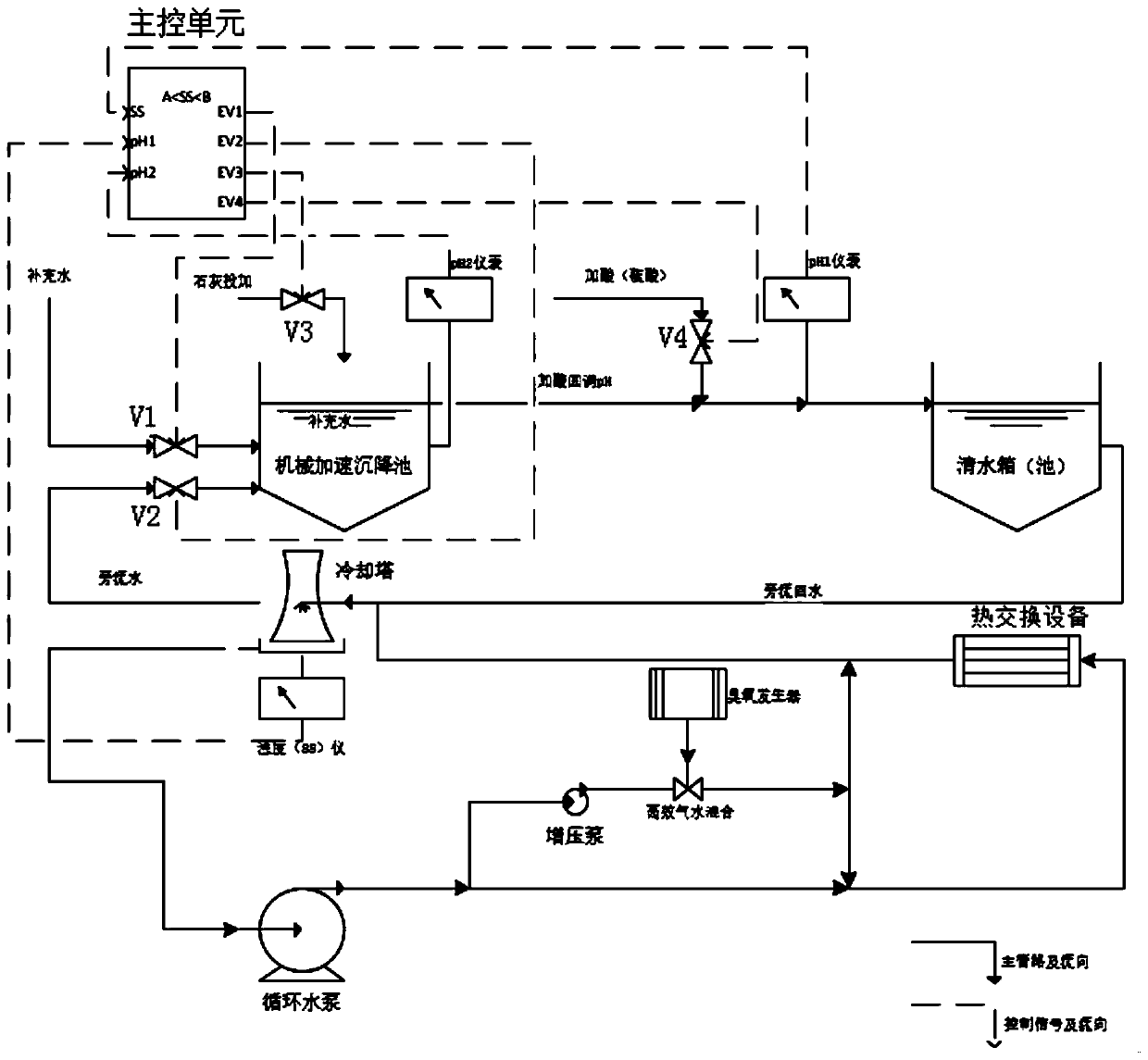

System and device for treating circulating cooling water by using lime softening and ozone

PendingCN110759523AReduce chemical leachImprove effectivenessWater softeningMultistage water/sewage treatmentCooling towerAutomatic control

The invention relates to a system for treating circulating cooling water by using lime softening and ozone. The system includes a lime softening treatment system, a circulating cooling water system using an ozone treatment technology, and a control system; the lime softening treatment system is sequentially provided with a mechanically accelerated sedimentation tank, a water collection tank and acooling tower, and a second automatic valve is arranged between the cooling tower and the mechanically accelerated sedimentation tank; the mechanically accelerated sedimentation tank communicates witha supplementary water source through a first automatic valve; a lime addition channel of the mechanically accelerated sedimentation tank is provided with a third automatic valve; an acid addition channel of the lime softening treatment system is provided with a fourth automatic control valve; and a first pH monitor is arranged in the mechanically accelerated sedimentation tank, and a second pH monitor is arranged at the rear end of the fourth automatic control valve. The system can reduce chemical precipitates caused by a high concentration multiple, circulating cooling water by-pass emergency treatment and supplementary water treatment can be automatically performed by monitoring water quality indexes, and the efficiency and economy of the operation of the system can be improved by controlling a lime addition process.

Owner:上海铱钶环保科技有限公司

Apparatus for evaporative concentration of water to be treated, which uses hot lime softening, and method for evaporative concentration of water using the same

ActiveUS10294137B2Improve abilitiesInhibition is effectiveWater/sewage treatment by centrifugal separationEvaporation with vapour compressionWater useHardness

An apparatus for evaporative concentration of water, containing hardness-causing substances, to be treated using hot lime softening, includes: a first evaporator configured to form first concentrated water from the water to be treated by evaporatively concentrating the water by first heat exchange with hot steam; a hot lime softener configured to precipitate and to separate hardness-causing substances contained in the first concentrated water from at least a portion of the first concentrated water from the first evaporator by reaction with lime and configured to remove the hardness-causing substances from the first concentrated water; and a second evaporator configured to form second concentrated water by further evaporatively concentrating at least a portion of the first concentrated water that passed through the hot lime softener by second heat exchange with hot steam.

Owner:DOOSAN HEAVY IND & CONSTR CO LTD

A kind of treatment method of coal gasification wastewater

ActiveCN103771650BReduce hardnessHigh removal rateWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentCoal gasification wastewaterFiltration

The invention discloses a method for treating coal gasification wastewater. The method comprises steps of: (1) lime softening by first adding lime milk to the coal gasification wastewater to conduct chemical precipitation on calcium salt and magnesium salt with the lime milk, standing the precipitation and filtering an supernatant; (2) ozone oxidation by sending the wastewater filtered in the step (1) into an ozone oxidation device for treatment; (3) MBBR treatment by sending the wastewater subjected to ozone oxidation into an MBBR for treatment; (4) coarse filtration; (5) continuous membrane filtration or ultrafiltration; (6) reverse osmosis; and (7) multi-effect evaporation by conducting multi-effect evaporation on the concentrate obtained by reverse osmosis treatment, and further crystallizing the concentrate obtained by multi-effect evaporation. The method of the invention can effectively remove the main pollutants such as COD, ammonia nitrogen and chroma in coal gasification wastewater, can also greatly reduce the salt content of the wastewater, ensure the efficient and long-term running of the double membranes, and achieve zero discharge of coal gasification wastewater.

Owner:CHINA PETROLEUM & CHEM CORP +1

Mechanical flotation device for reduction of oil, alkalinity and undesirable gases

InactiveUS8173016B2Reduce gas and alkaline specie contentLiquid degasificationLiquid hydrocarbon mixture productionAlkalinityProduct gas

Owner:CAMERSON INT CORP

Method for treating reclaimed water reused as circulating cooling water of power plant

InactiveCN102701352BImprove removal efficiencyReduce moisture contentWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionTotal dissolved solidsRetention time

The invention provides a method for treating reclaimed water reused as circulating cooling water of a power plant. The method comprises the following steps of: 1, coal ash preprocessing stage: directly adding coal ash into second-level discharged water of a municipal sewage plant and mixing the coal ash with raw water; 2, lime softening stage: adding lime emulsion and a flocculant into the mixed solution of the coal ash and the raw water, obtained in the coal ash preprocessing stage, and stirring, wherein the retention time of the mixed solution is 2-3min in the lime softening stage; 3, flocculation stage: stirring and standing for 15-25min; and 4, settling stage: standing for 1.5-2.5h in the settling stage and then discharging for use. According to the method, the coal ash is used for adsorbing a part of organic substances in the reclaimed water, so that chemical agent cost is reduced, sludge dewatering is facilitated, and the stability of discharged water is good, and the turbidity removal rate, TDS (Total Dissolved Solids) removal rate and calcium hardness removal rate of water are greatly improved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

System for mineral hardness management

The disclosed systems and methods for maintenance of an enclosed body of water generally include mobile systems and / or methods for removal of mineral hardness and other particulate impurities via lime softening filtration. Chemicals are added to a body of water containing unwanted mineral hardness (or other particulate impurities) and mixed to assist dispersion. The chemicals react with the hardness minerals making them insoluble. The resulting precipitate falls out of solution to the bottom of the body of water for subsequent removal via filtration. This eliminates or otherwise reduces the need for draining water and / or adding new water to a body of water to maintain proper mineral hardness balance and / or concentration of other particulate impurities.

Owner:RAYNE DEALERSHIP CORP

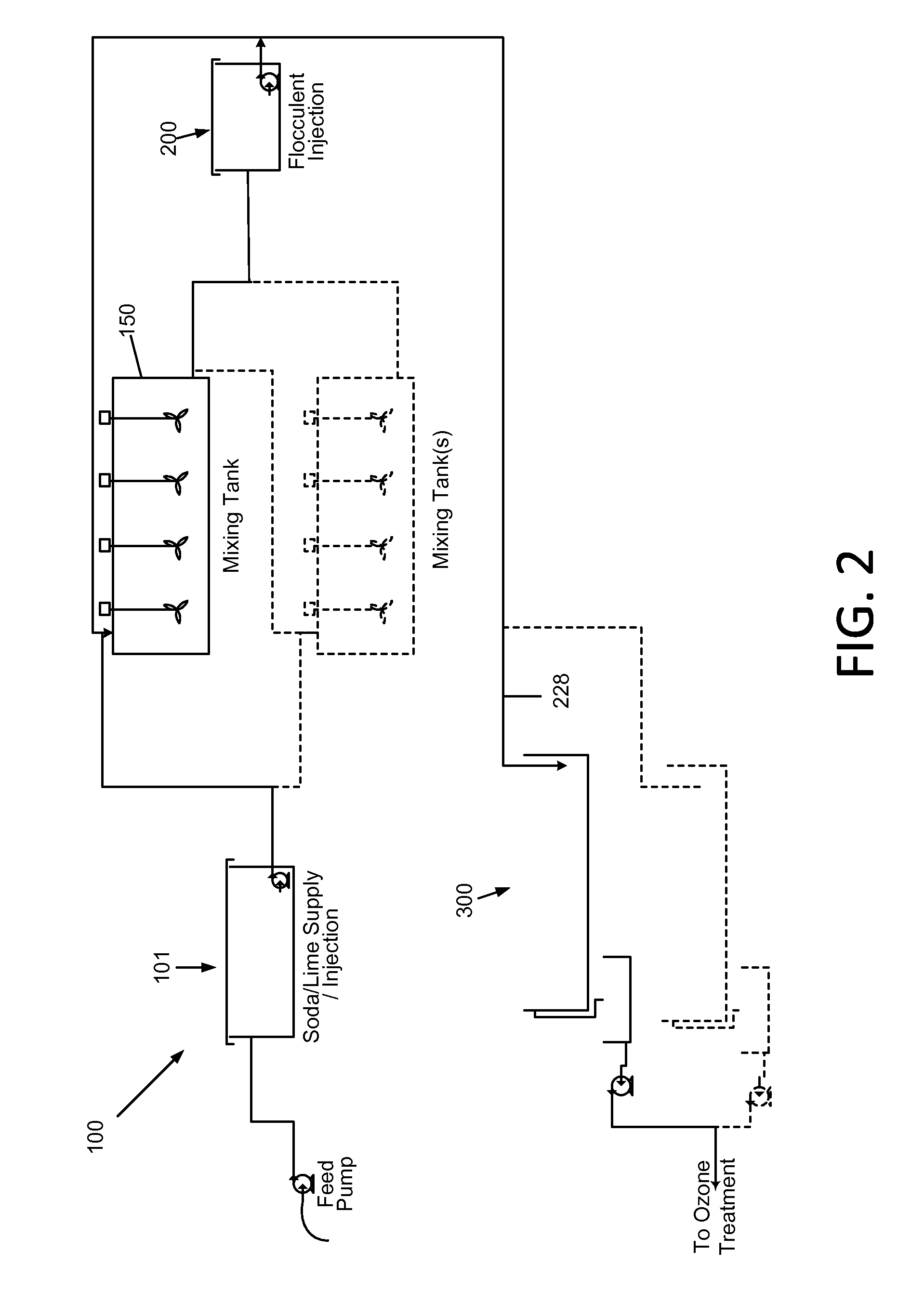

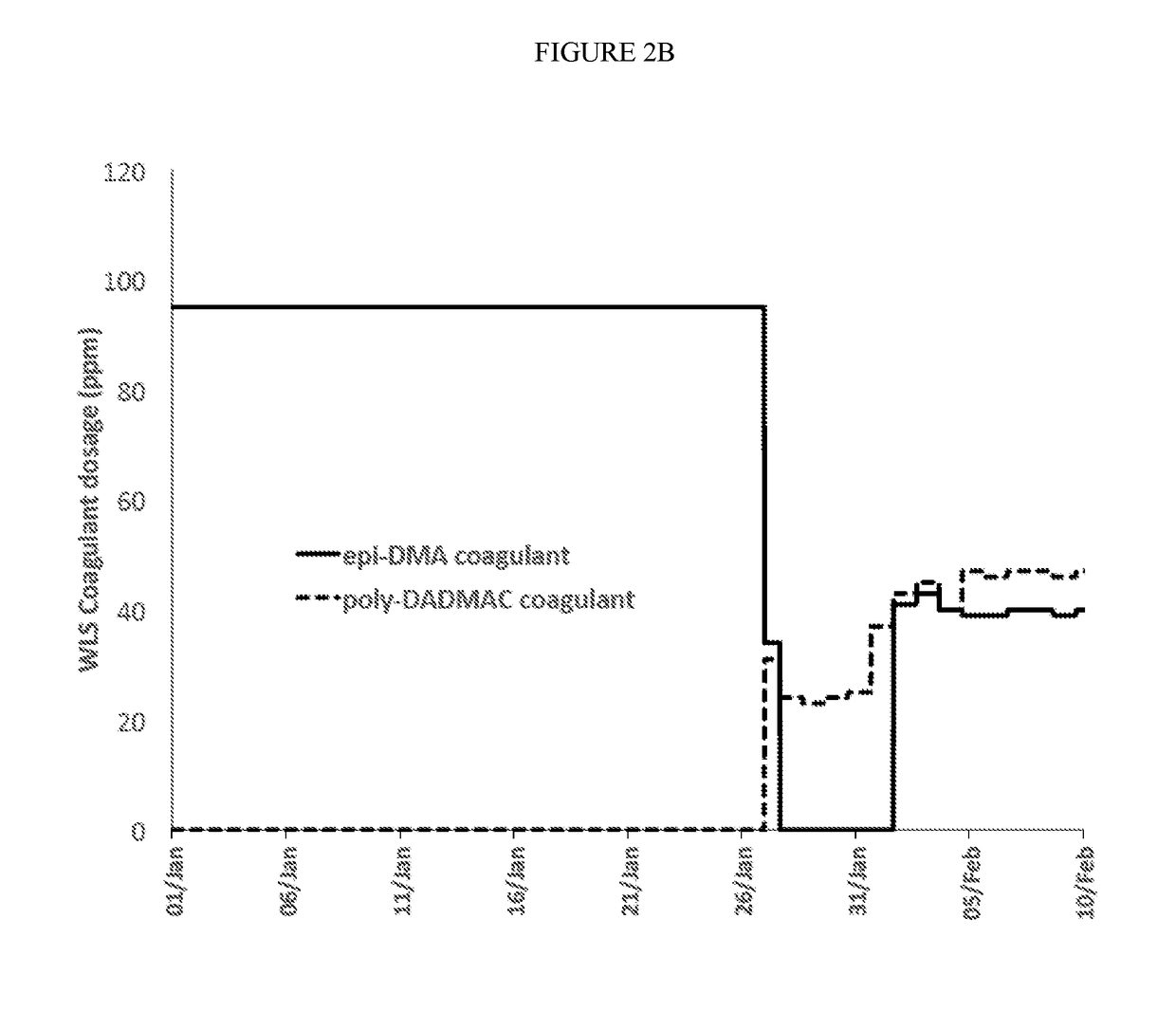

Coagulant Blend In SAGD Water Treatment

ActiveUS20190084848A1High molecular weightReduce charge densityWaste water treatment from quariesWater contaminantsWater treatment systemHandling system

Described herein is a coagulant blend for use in SAGD water treatment systems. Specifically, a blend of high charge density polyamine and low charge density poly(diallylmethyl ammonium chloride (poly-DADMAC) is used in the warm lime softening treatment process to coagulate and flocculate solids.

Owner:CONOCOPHILLIPS CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com