Device and method for treating waste residues of circulating make-up water by reutilizing lime softening method of power plant

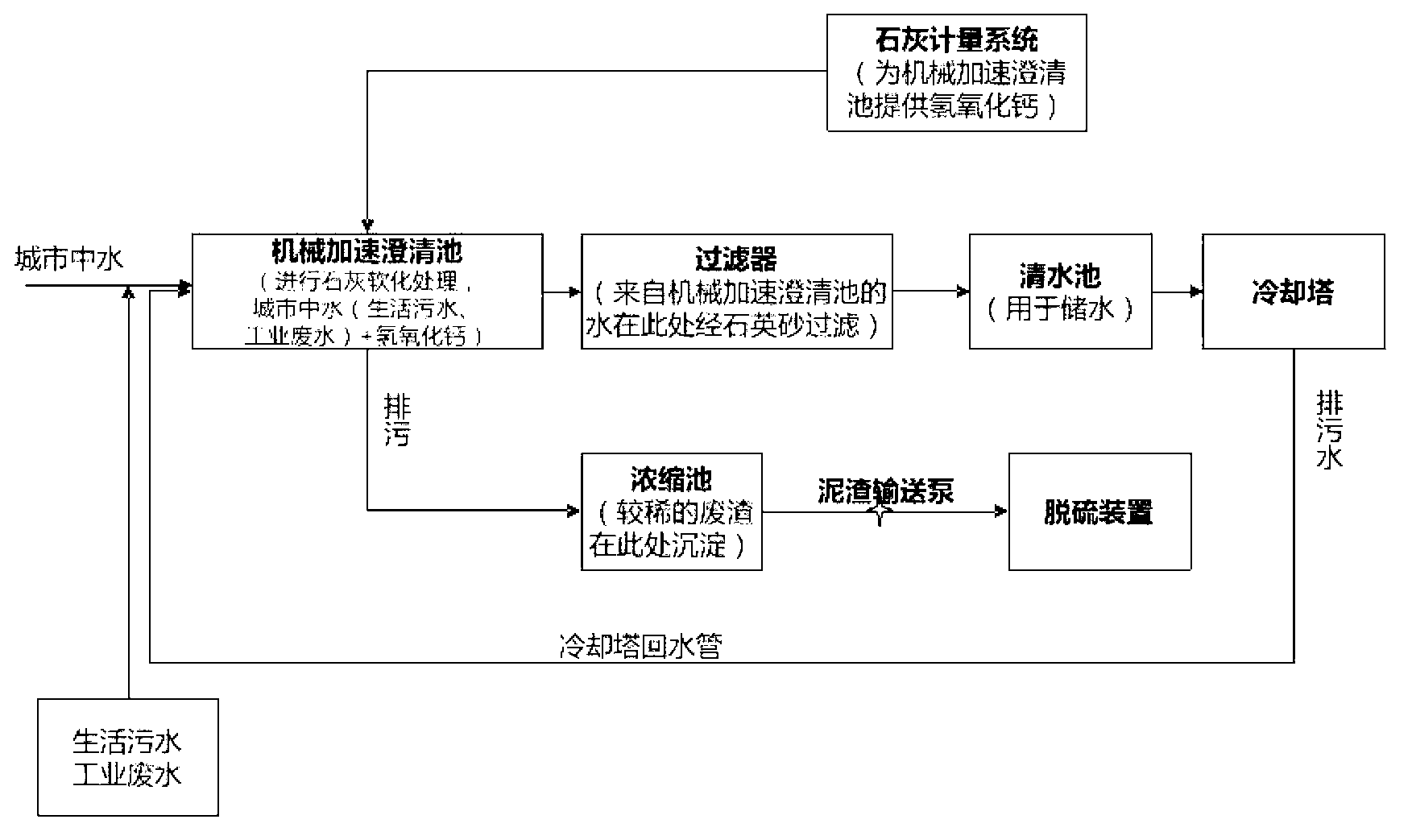

A lime softening and processing cycle technology, applied in the field of waste residue devices, can solve problems such as waste of calcium carbonate resources, and achieve the effects of high environmental protection value, avoiding waste of resources and high desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Inject urban reclaimed water into the mechanically accelerated clarifier with an injection volume of 600m 3 / h. At a temperature of 12°C and without flocculants and coagulants, calcium hydroxide is added to the mechanical acceleration clarifier through the lime metering system, and the amount of calcium hydroxide added with a purity of 85% per hour is 172Kg; after adding calcium hydroxide At the same time, use the pH meter to monitor the pH value of the solution in the mechanical accelerated clarification tank in real time. When the solution in the tank is greater than 10.3, reduce the addition of calcium hydroxide, mix it evenly and let it stand to complete the softening treatment of urban reclaimed water;

[0071] The softened water in the mechanically accelerated clarifier is discharged into the filter, and the sludge is discharged into the concentration tank through the sewage outlet, and settles for 4 hours to obtain waste residue;

[0072] The waste slag obtained ...

Embodiment 2

[0083] Inject domestic sewage into the mechanical accelerated clarification tank with an injection volume of 1300m 3 / h. At a temperature of 24°C and without flocculants and coagulants, calcium hydroxide is added to the mechanically accelerated clarifier through the lime metering system, and the amount of calcium hydroxide added with a purity of 85% per hour is 350Kg; after adding calcium hydroxide At the same time, use the pH meter to monitor the pH value of the solution in the mechanical accelerated clarification tank in real time. When the pH value of the solution in the tank is 10.3, stop adding calcium hydroxide, mix it evenly and let it stand to complete the softening treatment of urban reclaimed water;

[0084] The softened water in the mechanically accelerated clarifier is discharged into the filter, and the sludge is discharged into the concentration tank through the sewage outlet, and settles for 4 hours to obtain waste residue;

[0085] The waste slag obtained is t...

Embodiment 3

[0090] Inject the cooling tower sewage into the mechanical acceleration clarification tank, the injection volume is 1000m 3 / h. At a temperature of 15°C and without flocculants and coagulants, calcium hydroxide is added to the mechanical acceleration clarifier through the lime metering system, and the amount of calcium hydroxide added with a purity of 90% per hour is 200Kg; At the same time, the pH meter is used to monitor the pH value of the solution in the mechanical acceleration clarification tank in real time. When the pH value of the solution in the tank is 10.0, stop adding calcium hydroxide, mix well and let stand to complete the softening treatment of urban reclaimed water;

[0091] The softened water in the mechanically accelerated clarifier is discharged into the filter, and the sludge is discharged into the concentration tank through the sewage outlet, and settled for 5 hours to obtain waste residue;

[0092] The waste slag obtained is transported to the desulfuriz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com