Nano-filtration and reverse osmosis concentrated solution reduction treatment system and method

A technology of reverse osmosis concentrate and treatment system, applied in the field of wastewater treatment, can solve the problems of high investment and high operating cost of the treatment system, and achieve the effects of low investment cost, high treatment efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

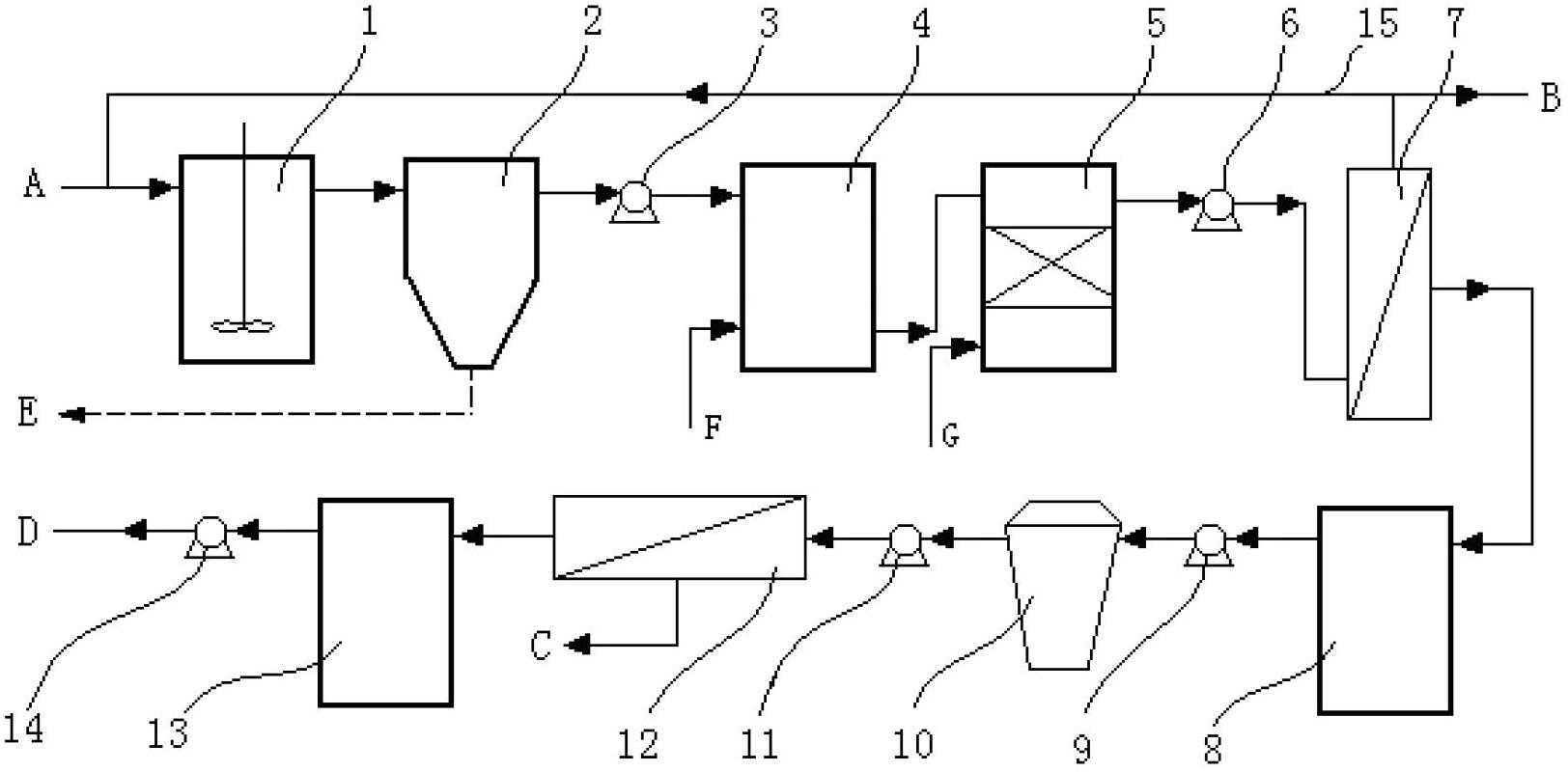

[0049] This embodiment provides a nanofiltration and reverse osmosis concentrated solution reduction treatment system for reducing the nanofiltration and reverse osmosis concentrated solution. The system includes:

[0050] Lime softening processor, ultrafiltration processor and reverse osmosis processor; wherein, the lime softening processor is connected with the ultrafiltration processor and the reverse osmosis processor in turn, and the ultrafiltration concentrated water outlet of the ultrafiltration processor is connected back to the In the coagulation sedimentation processor, the water outlet of the nanofiltration treatment area is connected with the recycling device. Wherein, the lime softening processor can be connected with the ultrafiltration processor through the sand filtration treatment area formed by sequentially connecting the sand filtration feed water pump 3, the sand filter 4 and the intermediate pool 5, so as to protect the ultrafiltration membrane in the ultra...

Embodiment 2

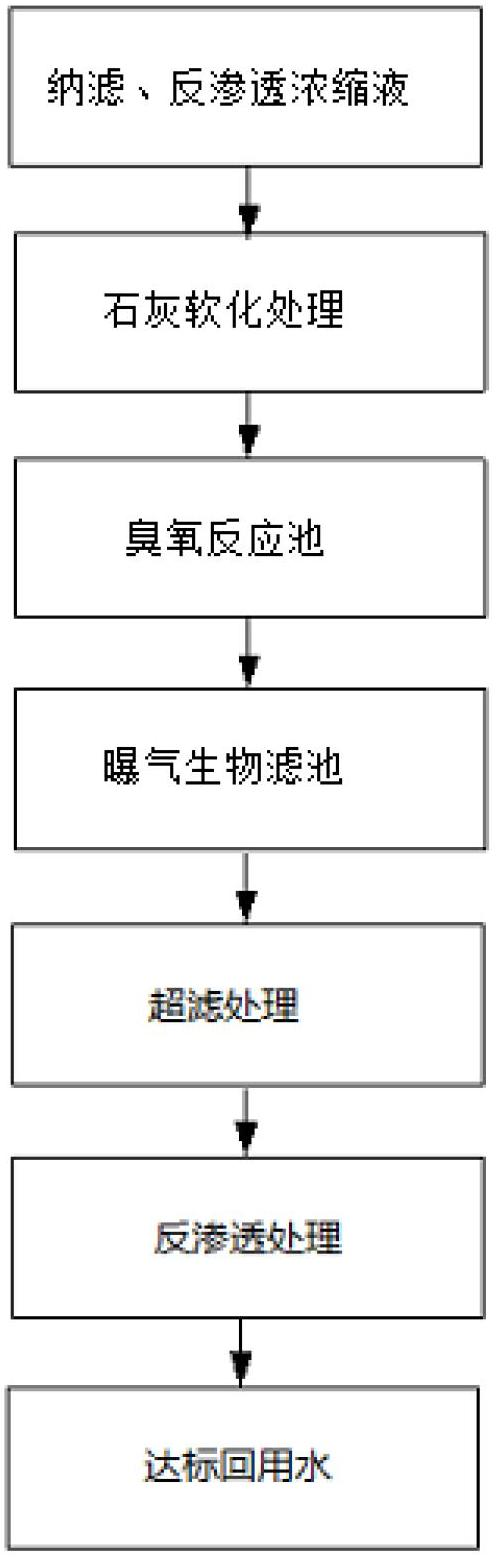

[0057] This embodiment provides a method for reducing the amount of nanofiltration and reverse osmosis concentrates by using the above-mentioned treatment system, such as figure 2 shown, including:

[0058] The nanofiltration and reverse osmosis concentrated solution is reduced as the treated wastewater and enters the lime softening treatment, and the effluent after lime softening treatment enters the ozone oxidation tank, aerated biological filter, and ultrafiltration UF treatment to remove suspended matter in the water through the ultrafiltration membrane matter, colloid and macromolecular organic matter, and then enter the reverse osmosis treatment to remove the hardness and salt in the water through the reverse osmosis membrane, and reuse the effluent after the reverse osmosis membrane treatment; among them, lime milk needs to be added in the lime softening treatment. The effluent after lime softening treatment can be treated by ozone oxidation and biological aerated filt...

Embodiment 3

[0064] This embodiment provides a treatment method for nanofiltration and reverse osmosis concentrates using the treatment system given in Example 1, using the treatment system as described in Example 1 to reduce the nanofiltration and reverse osmosis concentrates processing, the specific process is:

[0065] Nanofiltration and reverse osmosis concentrated liquid 280m3 / h enters the softening reaction tank and then enters the softening sedimentation tank after adding lime milk. The effluent of the softening sedimentation tank is used as effluent and then is lifted by the lift pump and then enters the ozone reaction tank and biological aerated filter. The effluent from the biological aerated filter enters the intermediate pool, and the effluent from the intermediate pool is lifted by the ultrafiltration feedwater pump as a lift pump before entering the ultrafiltration equipment. Equipment, 210m3 / h reverse osmosis product water reuse, 70m3 / h reverse osmosis concentrated water dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com