Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32 results about "Human machine cooperation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A man-machine cooperation oriented real-time posture detection method for hand-held objects

ActiveCN109255813AThe test result is accurateImage enhancementImage analysisInteraction systemsColor image

The invention provides a man-machine cooperation oriented real-time posture detection method for hand-held objects, belonging to the technical field of a human-machine cooperation interaction system and the position and posture sensing of an industrial robot to a hand-held working object. The depth images of each part of the object to be detected are captured by a 3D stereoscopic camera, and the local point clouds are aligned and merged into a complete three-dimensional point cloud model of the object. Real-time RGB color images and depth images containing 3D point cloud information of the scene are obtained. The RGB image is segmented automatically to get the pixels representing the object in the image. The corresponding point cloud in the depth image is fused with the pixels to get the RGB-D image with color information of the object in the scene. Using ICP algorithm, the RGB-D image is matched with the complete 3D point cloud image of the object to obtain the position and posture ofthe hand-held object in the scene. The method overcomes the problem of obtaining the exact posture of the hand-held object at the current time, and can be used in a variety of scenes.

Owner:DALIAN UNIV OF TECH

Collision detection method for sensor-less type cooperative robot

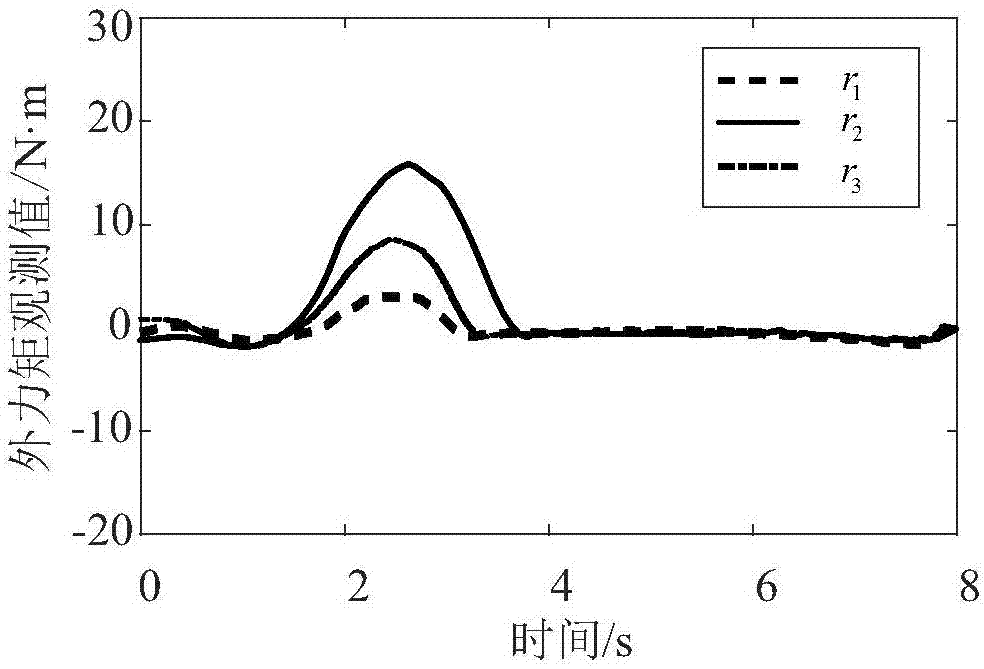

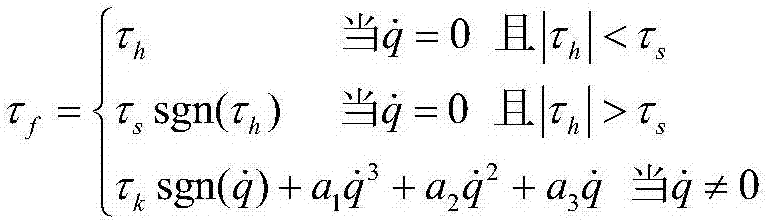

InactiveCN108000521ASecure CollaborationFlexible and convenient settingProgramme controlProgramme-controlled manipulatorMomentumCollision detection

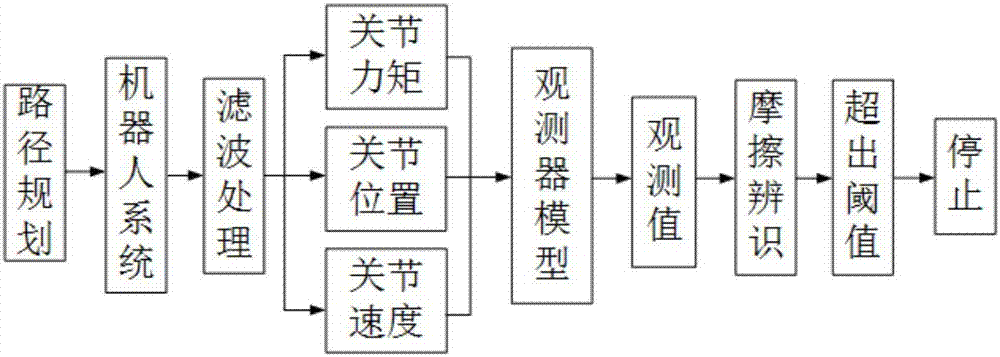

The invention discloses a collision detection method for a sensor-less type cooperative robot. Based on a method for constructing a joint external force moment observer of cooperative robot through generalized momentum, the real time observation of the moment of the external impact force and friction force applied to the joint is achieved. A joint friction moment model is solved through an observation value of the normal operation of a robot, so that the observation value is affected only by the impact force. The robot is considered to collide with others when the observation value exceeds thepreset threshold, and the robot stops running at once, so that the injury towards human in the process of human-machine cooperation is avoided. Without the need for installing an additional sensor outside the robot, and a joint driving moment, a joint position and a joint angle of the robot is got through a robot control system, so that the collision detection function is realized, the complexityof increasing robot structure and the increase of manufacturing cost are avoided. The sensitivity of the collision detection is changed by setting the threshold. Therefore, the safety of the human-machine cooperation is guaranteed.

Owner:TIANJIN UNIV

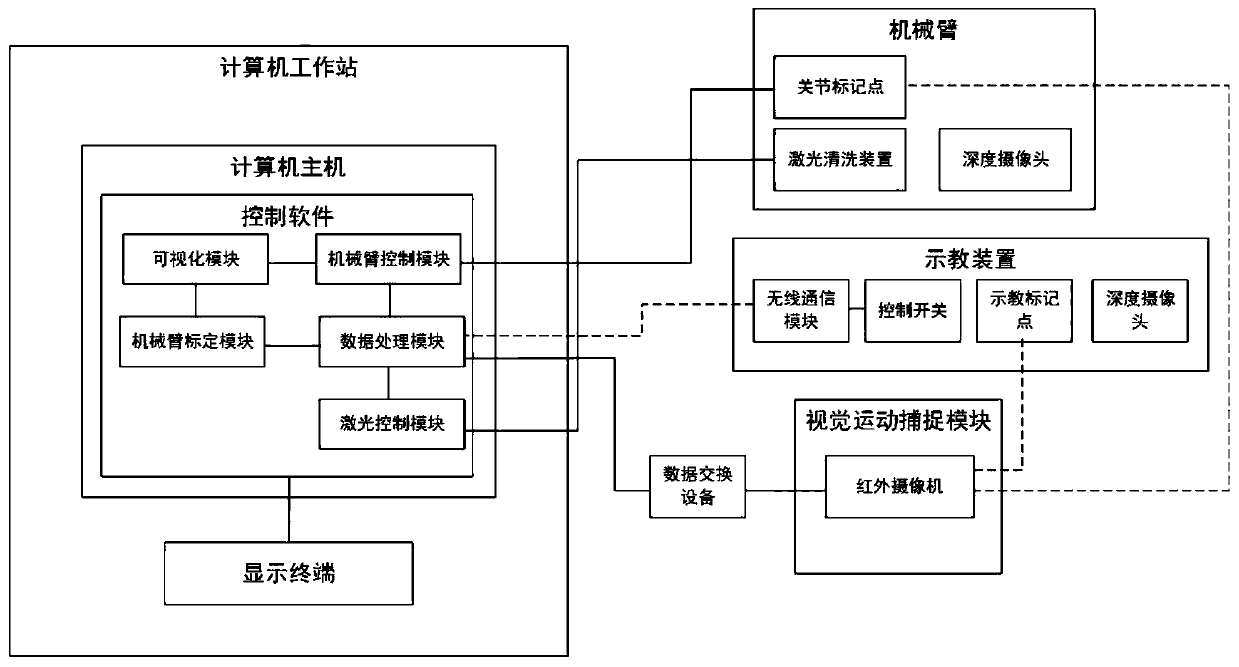

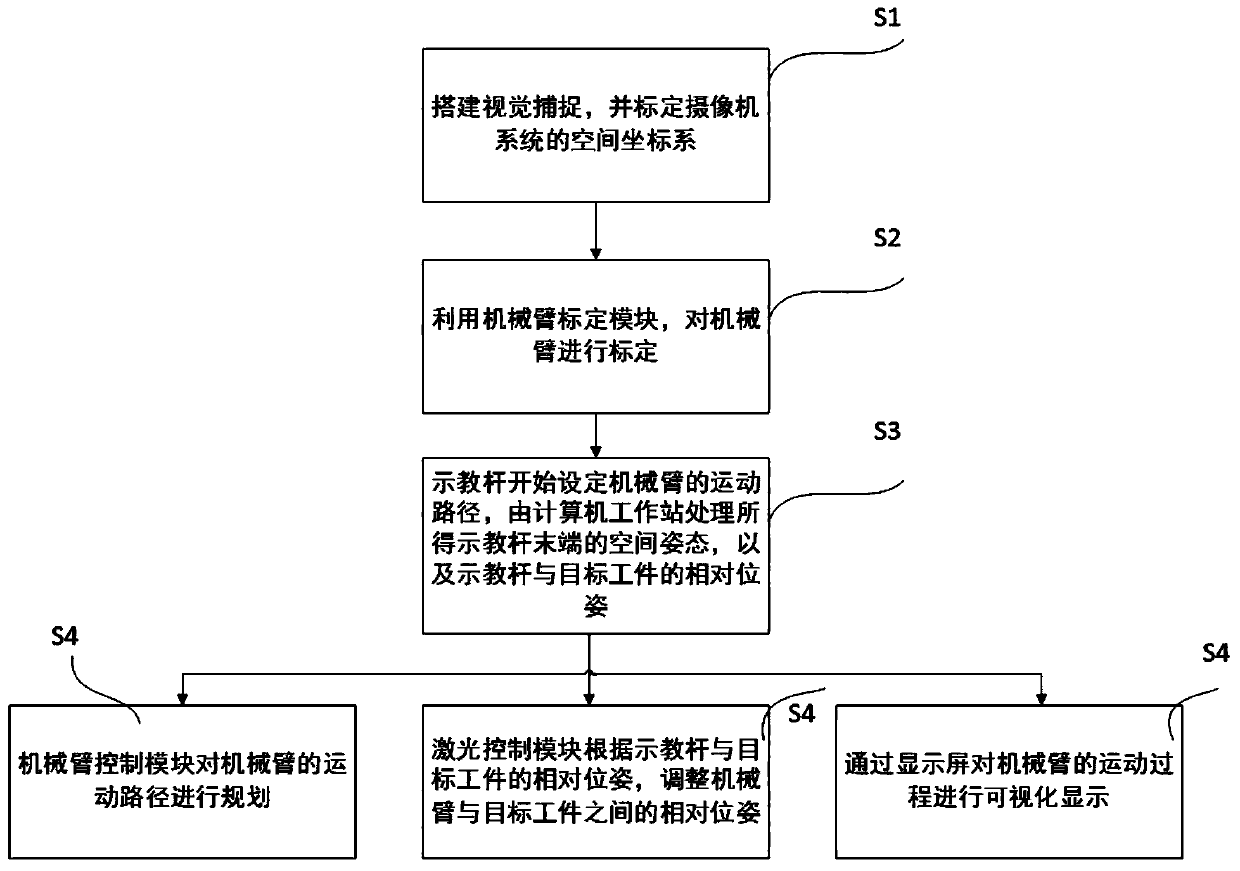

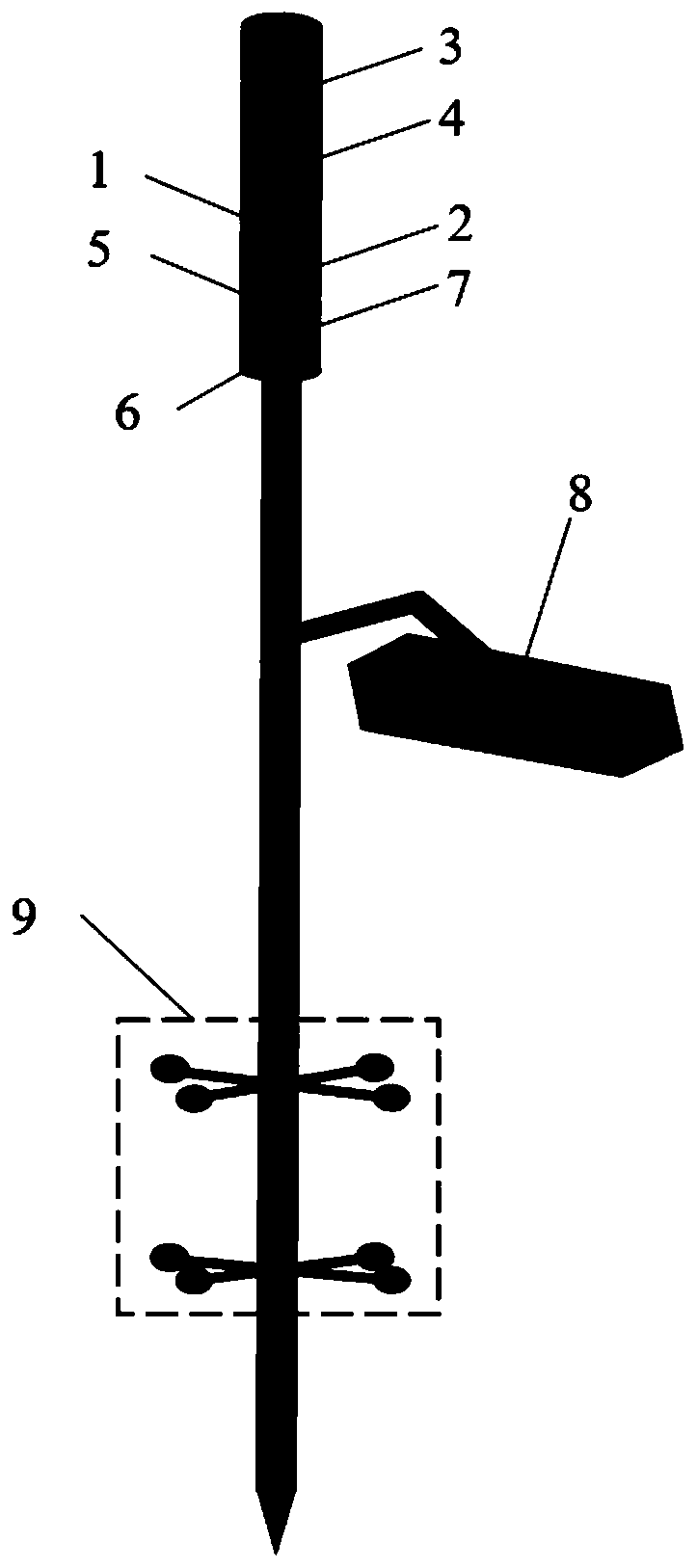

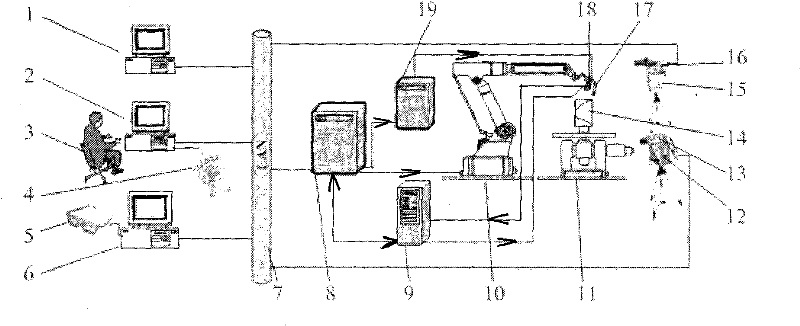

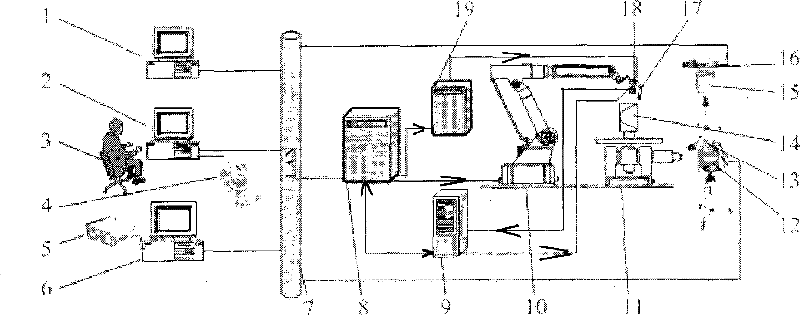

Robot laser cleaning path planning system and method based on computer vision

PendingCN110116116AImprove work efficiencyProgramme-controlled manipulatorCleaning processes and apparatusEngineeringAssembly line

The invention discloses a robot laser cleaning path planning system and method based on computer vision. The system comprises a vision motion capturing module, a computer work station, a mechanical arm, a laser cleaning device arranged at the tail end of the mechanical arm, a depth camera and a demonstration device. The demonstration method based on computer vision is adopted, a user finishes pathplanning through the demonstration device, and a robot is guided to conduct laser cleaning on a target workpiece in a human-machine cooperation manner. The method is applied to small workpiece assembly line work, and the work efficiency can be improved; and for to-be-machined large workpieces, the demonstration efficiency can be improved, meanwhile, the experience of people is sufficiently combined, and the problem that in the real complex environment, the error rate of an automatic vision recognition method is high is solved.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

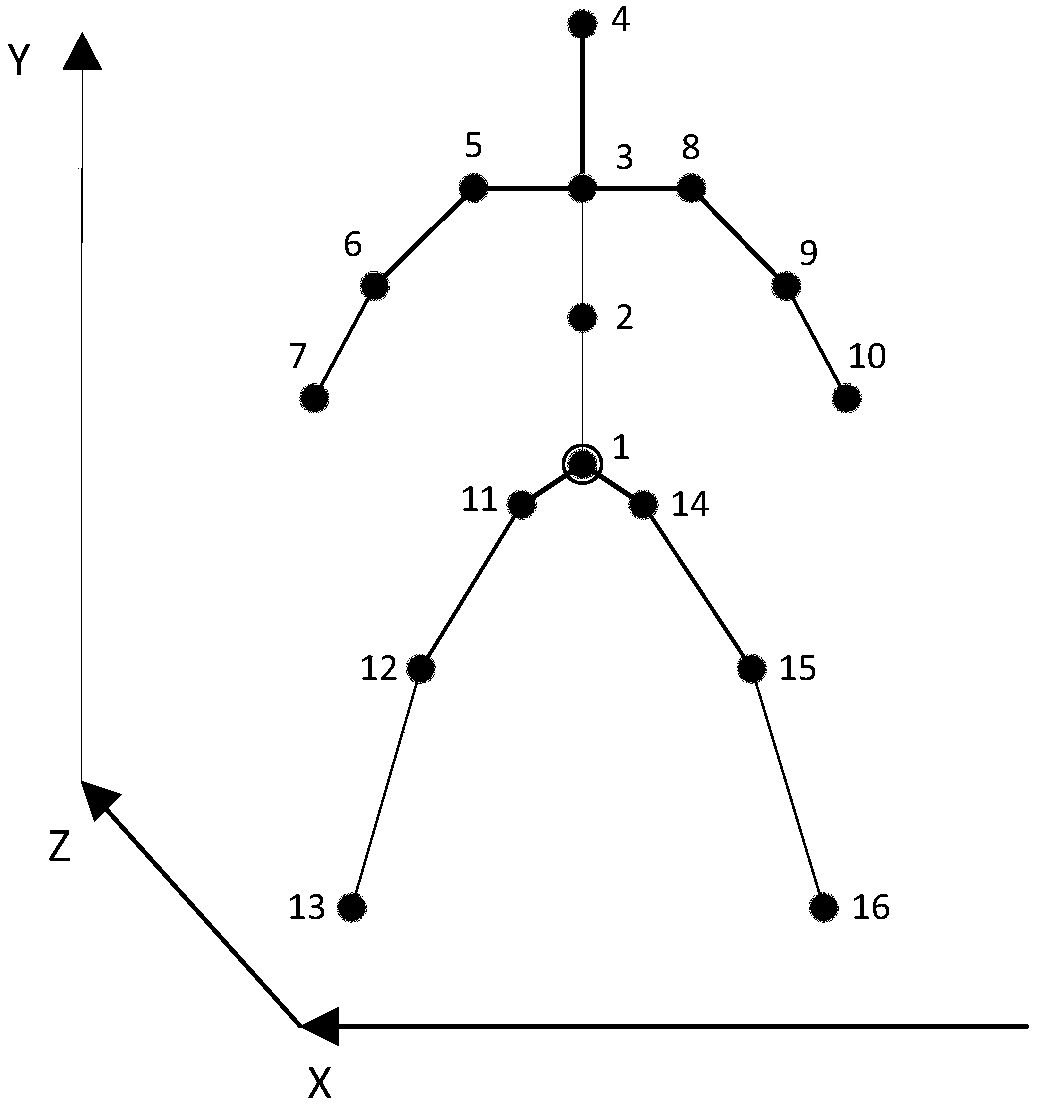

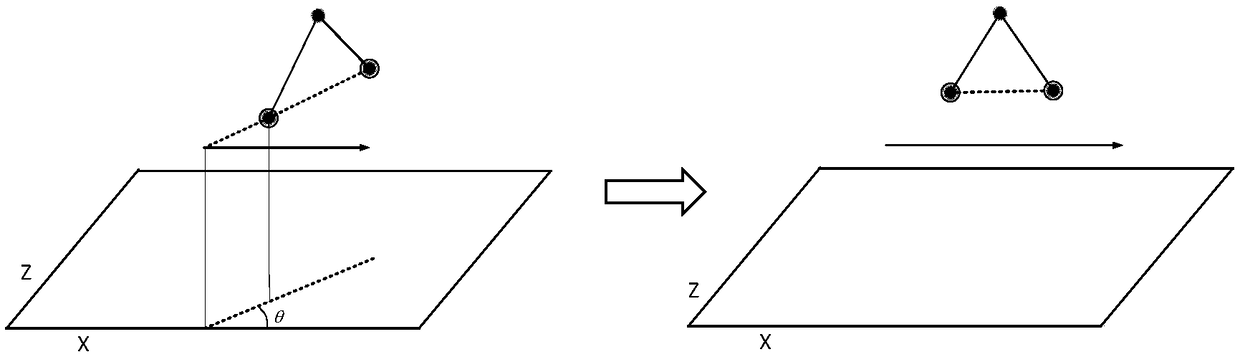

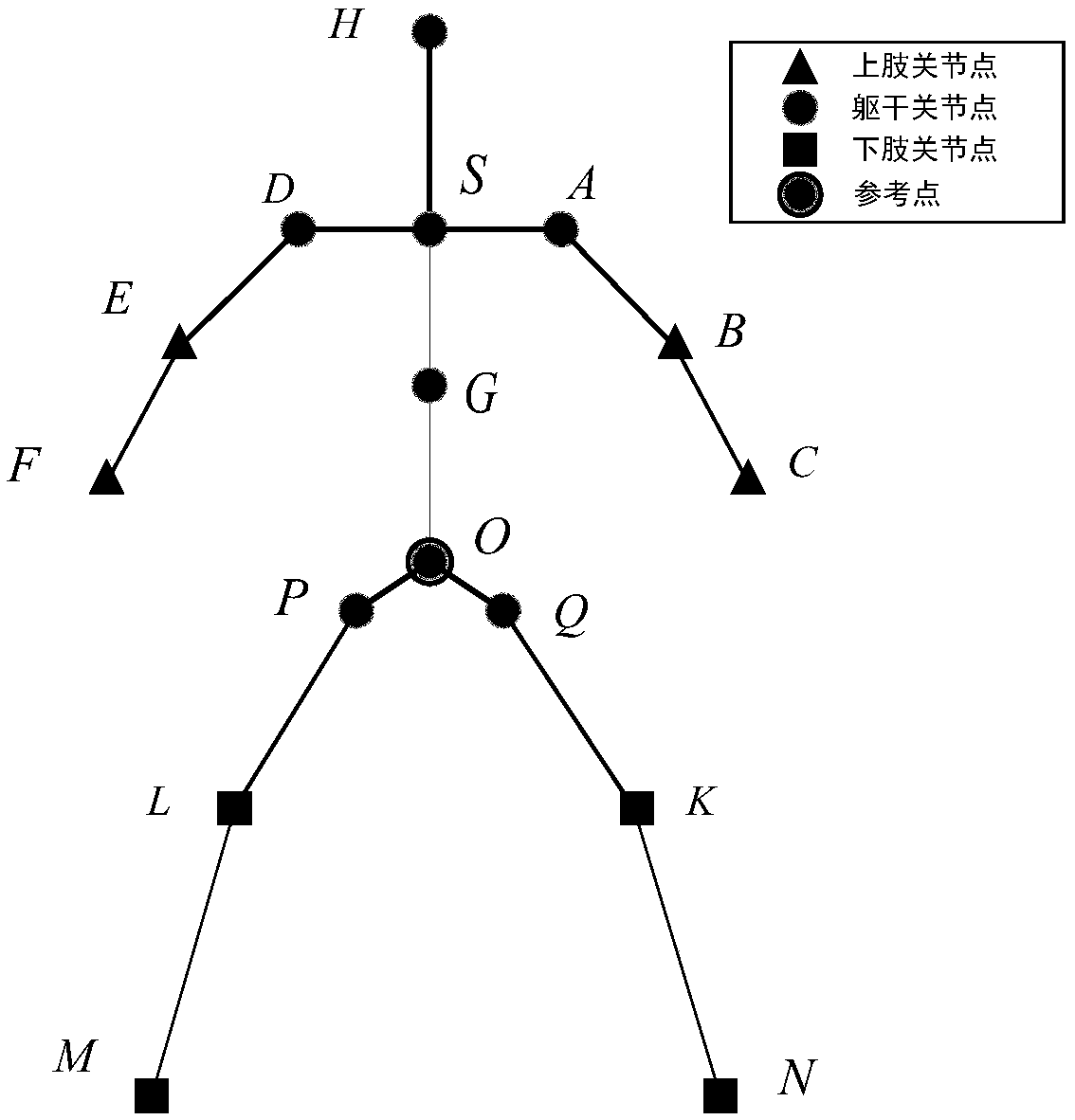

Motion recognition method based on segmented mannequin model applied in human-machine cooperation

The invention relates to a motion recognition method based on a segmented human body model applied in human-machine cooperation, which uses a Microsoft Kinect V2 sensor to collect human body bone information and obtain joint node coordinates. After preprocessing, the skeletal node sequence is mapped from four dimensions to three dimensions and stored as a point cloud sequence. The mannequin is divided into upper limb, lower limb and trunk. The Boolean eigenvectors and the relative positions of joints are extracted respectively. The key frames are extracted by the Boolean eigenvectors, and thetemplates are matched by the eigenvectors and the dynamic time warping algorithm (DTW algorithm). Finally, the recognition results of the three parts are combined to get the classification of the whole human motion. The present invention not only achieves the purpose of recognizing the whole movement of the human body, but also obtains the description of the movement of the upper limb, the torso and the lower limb of the human body, and can recognize the movement and the behavior of the human body in more detail and accurately, so as to help the robot under the cooperation of the human and themachine to carry out the subsequent task planning.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

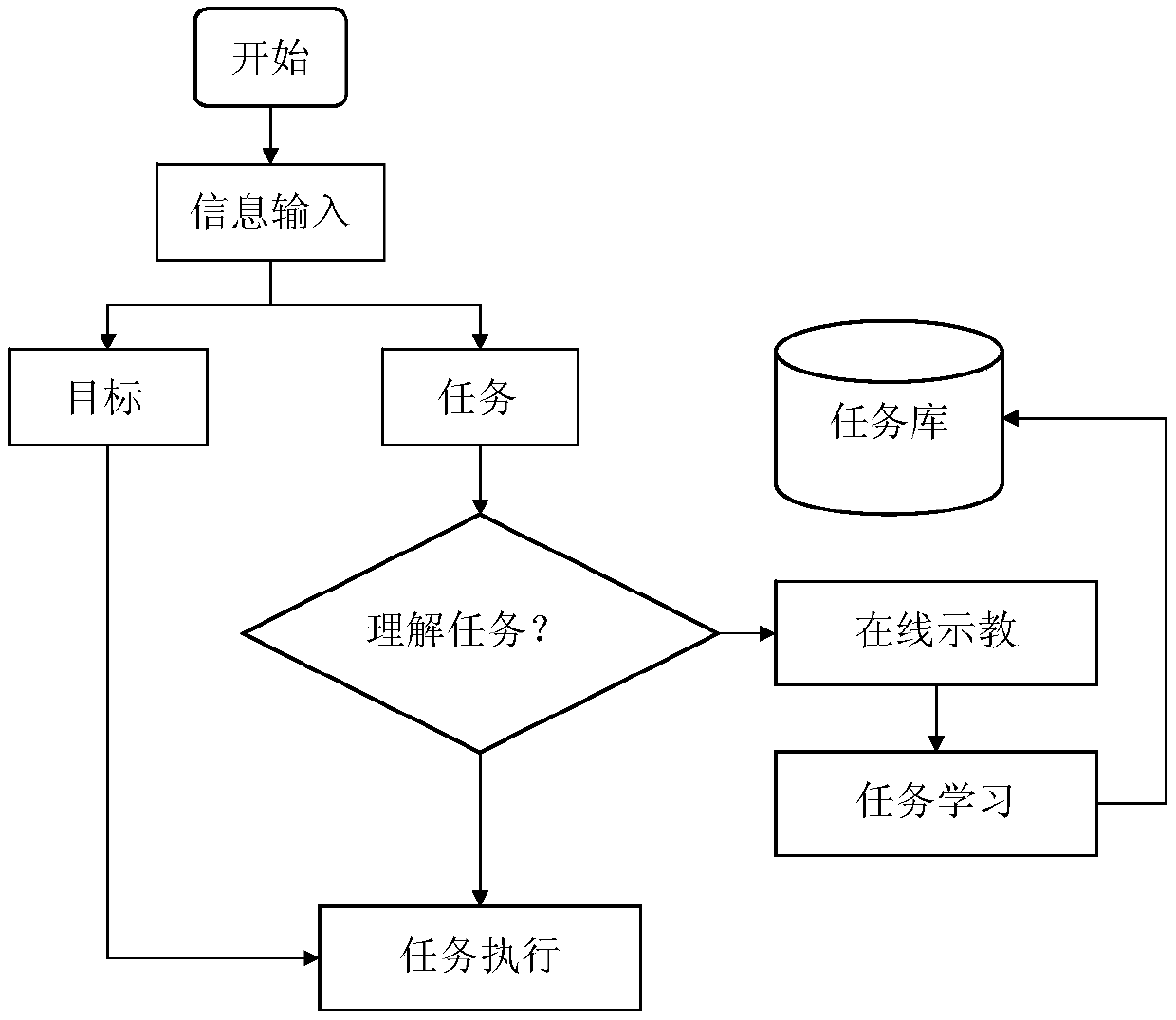

Robot self-directed learning method for human-machine cooperation

The invention provides a robot self-directed learning method for human-machine cooperation. The robot self-directed learning method for the human-machine cooperation comprises a target understanding method for the human-machine cooperation and a task learning algorithm; the self-directed learning method allows a robot to perceive a target rapidly with the help of humans and achieve the objective of mastering a new skill rapidly by simulating actions of humans. The self-directed learning method comprises the steps of (1) designing a deep learning method for the human-machine cooperation on thetarget understanding plane and introducing the experiential knowledge of humans; and (2) introducing evaluation and feedback of humans on the task learning plane to optimize and strengthen a learningalgorithm. According to the method, the robot can conduct self-learning and online learning effectively by combining real-time feedback and teaching of humans.

Owner:SOUTH CHINA UNIV OF TECH

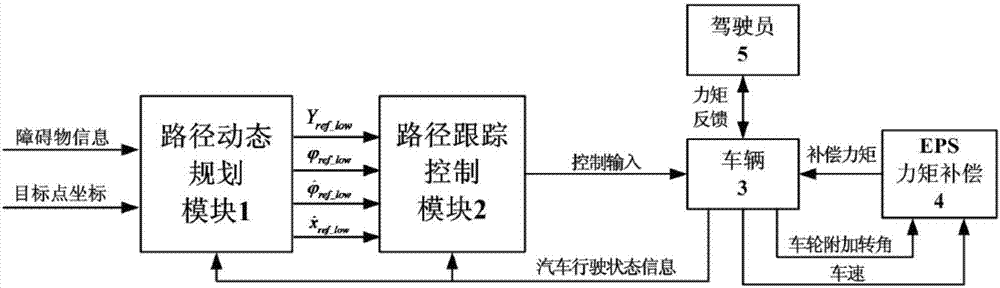

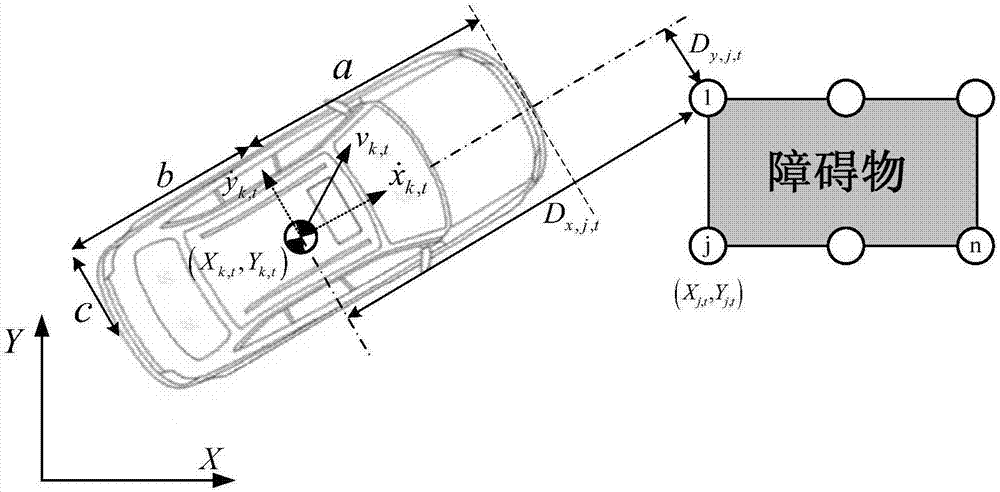

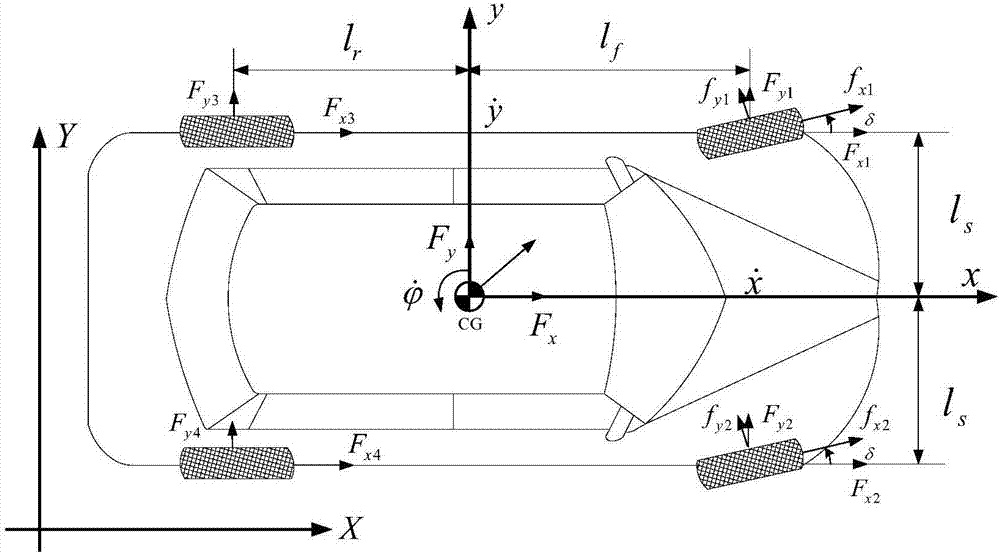

Automobile emergency collision avoidance hierarchical control method considering human-machine cooperation

InactiveCN107885932AImprove real-time performanceSolve real-timeGeometric CADElectrical steeringDynamic planningSteering wheel

The invention discloses an automobile emergency collision avoidance hierarchical control method considering human-machine cooperation and relates to the field of automobile assisted driving technology. According to the method, a lateral displacement reference value, a yaw angle reference value, a yaw velocity reference value and a longitudinal velocity reference value of a desired trajectory are obtained through real-time optimization through a path dynamic planning module according to barrier information, target point coordinates and automobile travel state information collected in real time,and the values are input into a path tracking control module; meanwhile, current automobile travel state information is collected through the path tracking control module, a front wheel rotating angle and slip rates of four wheels of an automobile are obtained through real-time optimization, and the automobile is controlled to realize collision avoidance; and in the collision avoidance control process, a compensation control moment is determined according to the velocity and a front wheel additional rotating angle through an EPS moment compensation module, the steering wheel sudden change moment is controlled to be within an ideal range, and automobile emergency collision avoidance with human-machine cooperation is realized. Through the method, path dynamic planning and real-time trackingduring emergency collision avoidance are realized, and safe optimal collision avoidance is realized.

Owner:CHANGCHUN UNIV OF TECH

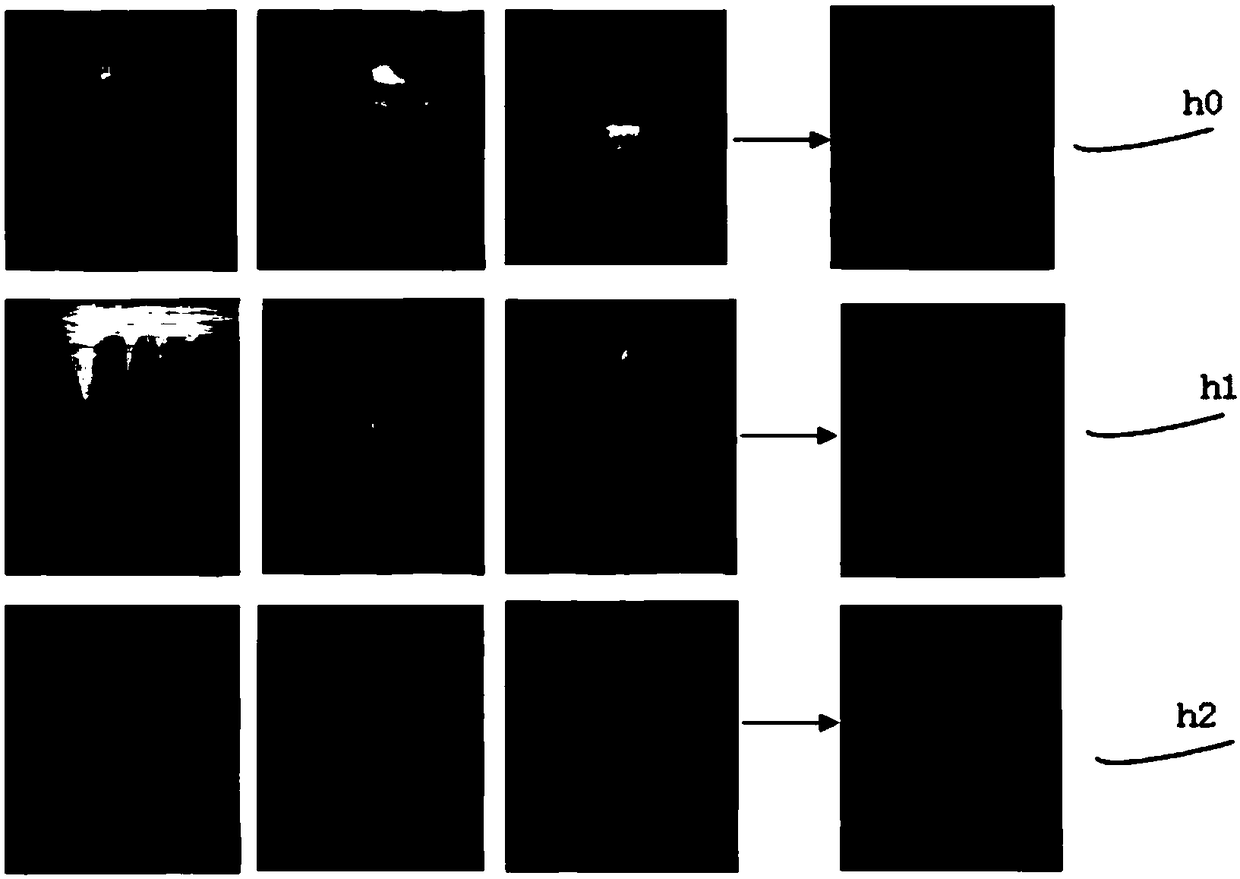

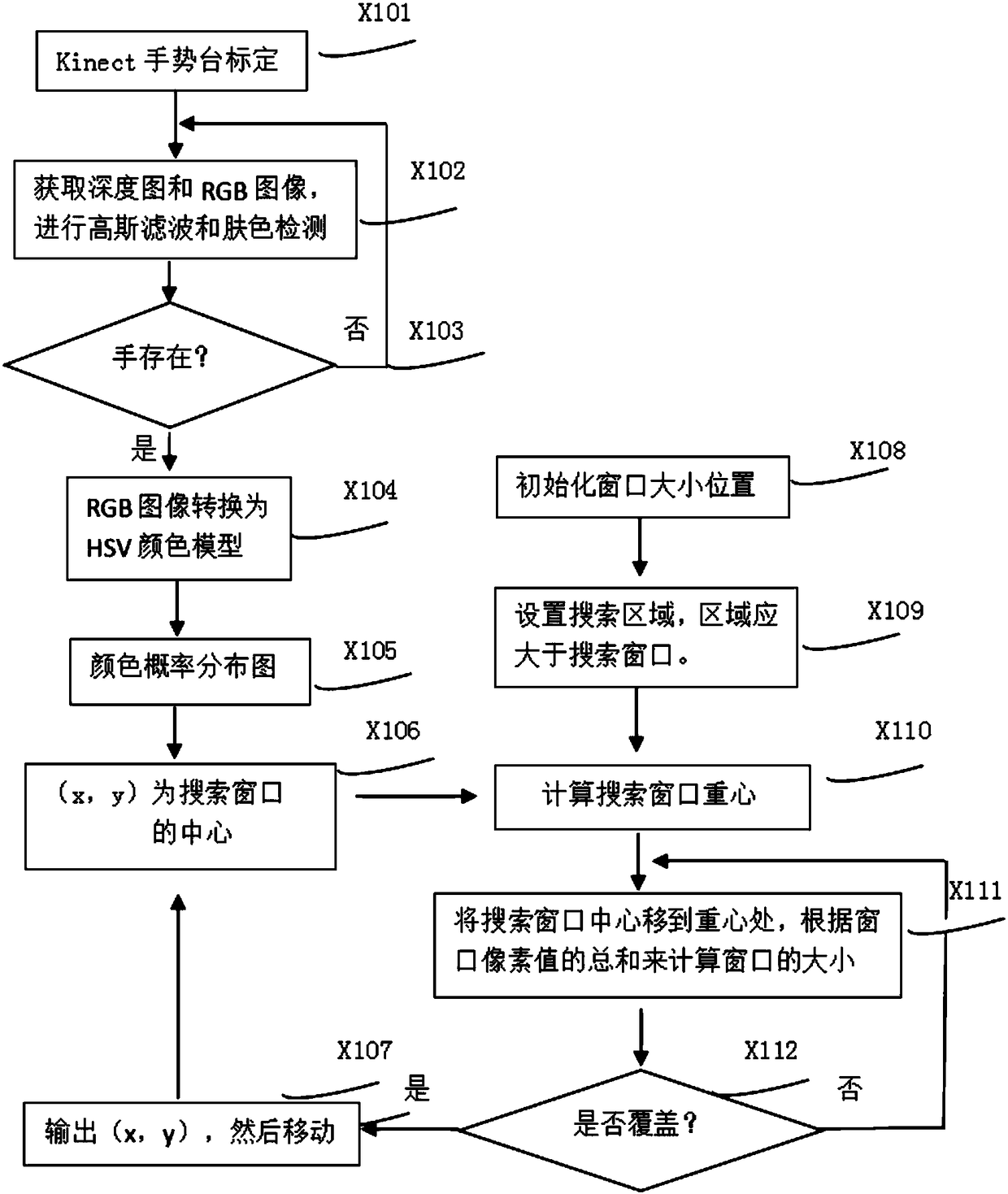

Human-machine cooperation system gesture recognition control method based on deep learning

ActiveCN108563995AHigh precisionFix security issuesInput/output for user-computer interactionCharacter and pattern recognitionPattern recognitionRemote computer

The invention discloses a human-machine cooperation system gesture recognition control method based on deep learning. The method comprises the following steps that: S1: tracking a gesture in real time, and obtaining the gesture image of an operator; S2: through a deep learning algorithm, automatically learning gesture image features, and identifying and classifying various postures of the same gesture; and S3: according to the recognized and classified gesture information, sending a corresponding preset robot control instruction. By use of the method, workpiece target collection is characterized in that a camera can be automatically selected according to workpiece characteristics for processing the workpiece characteristics, and then, the workpiece characteristics are transmitted to a processing side to finish communication configuration. The operator can carry out remote monitoring under a remote computer, in addition, various gestures of the same gesture action can be accurately identified and classified after the operator carries out replacement, and a true sense of human-machine cooperation is realized.

Owner:XIAN UNIV OF TECH

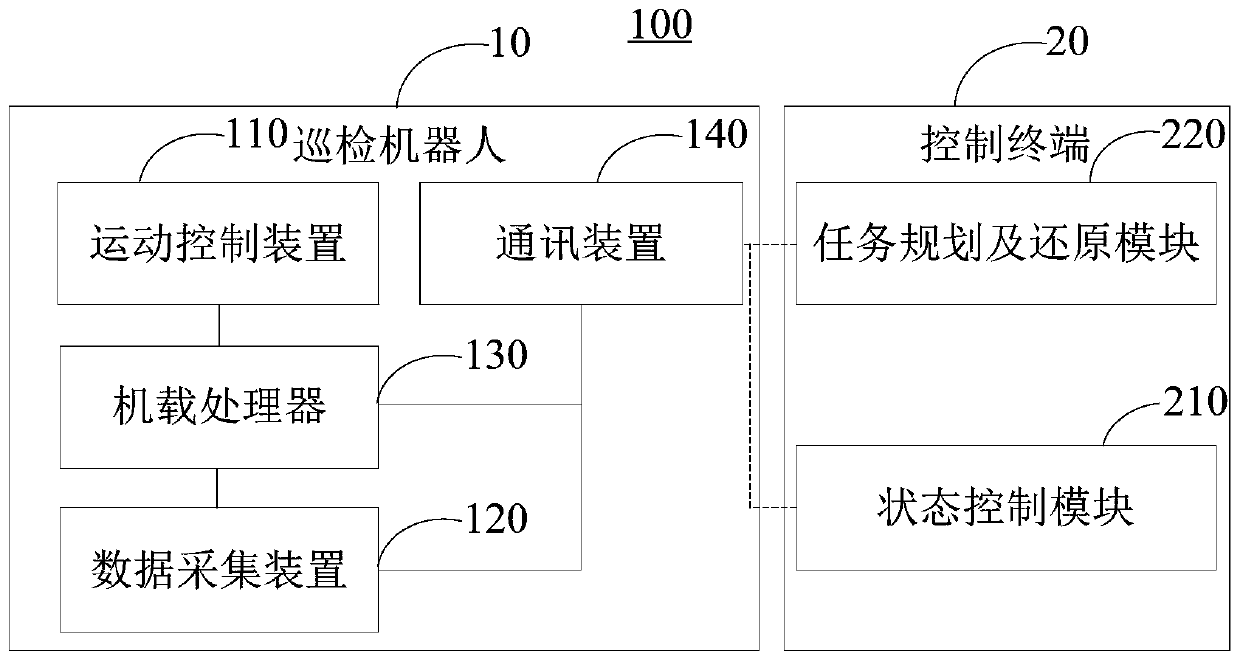

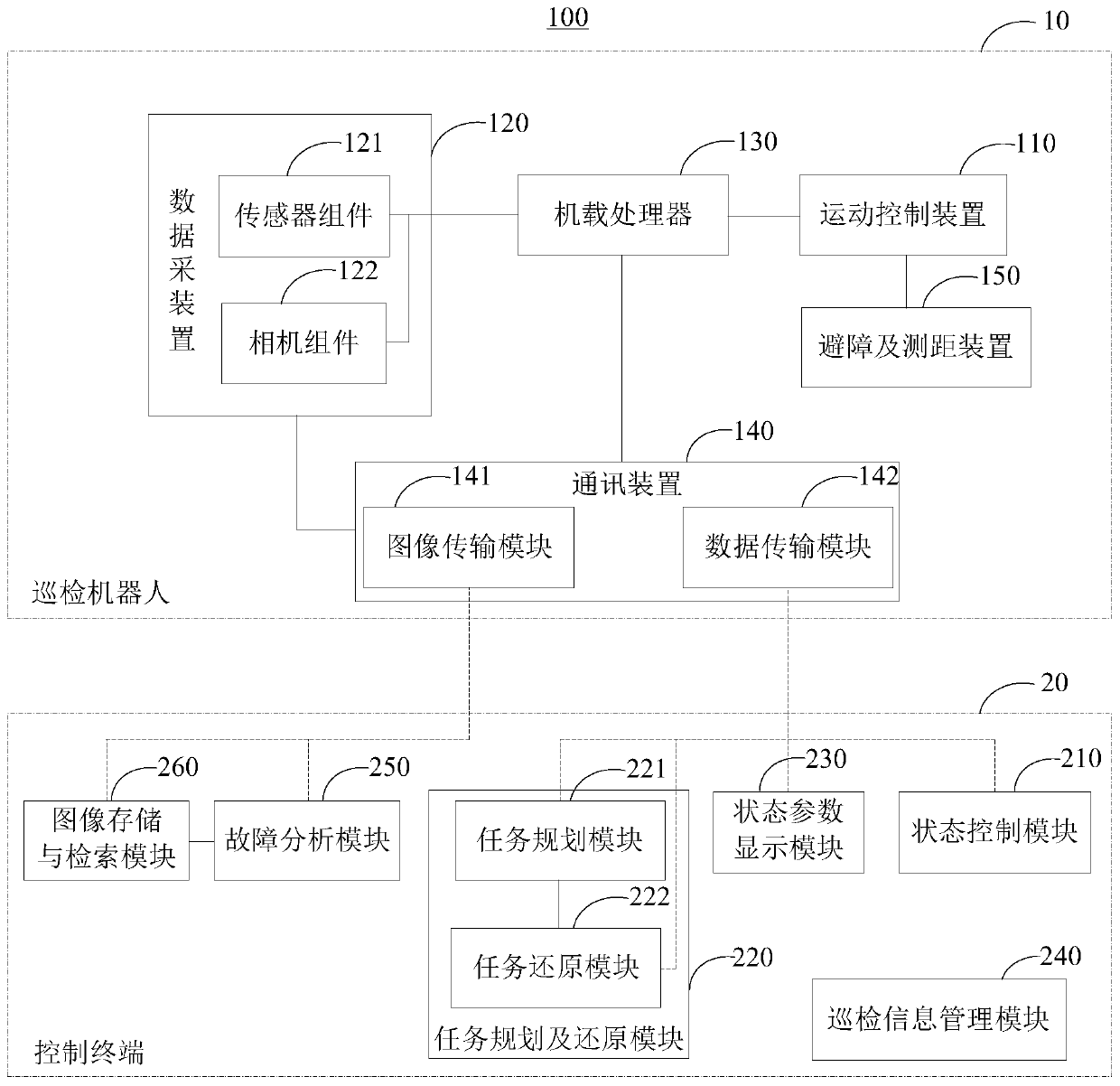

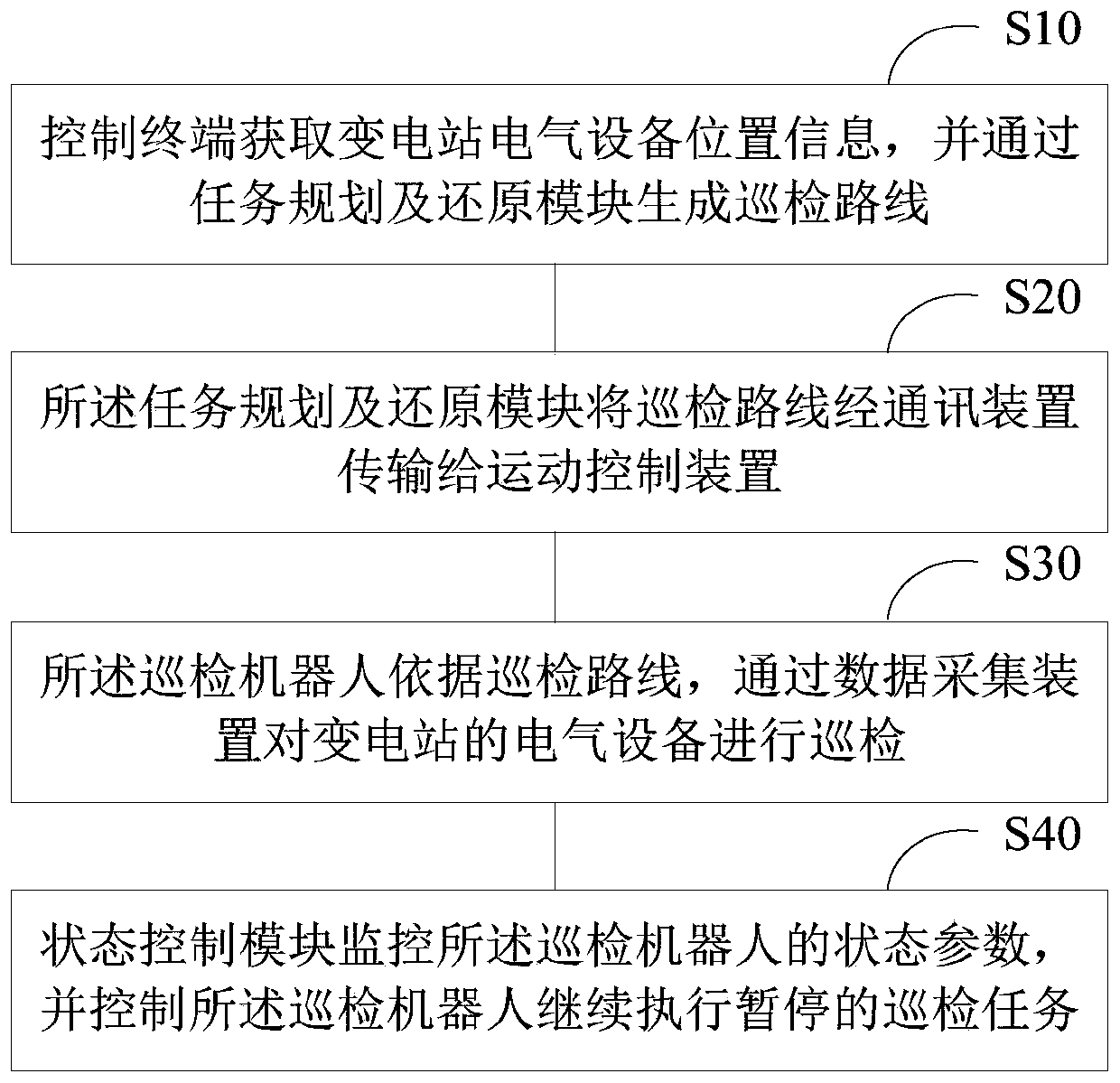

Substation inspection system

ActiveCN109921517AHigh degree of intelligenceRealize automatic identificationCircuit arrangementsSustainable buildingsSimulationData acquisition

The application relates to a substation inspection system comprising an inspection robot and a control terminal, wherein the inspection robot comprises a motion control device, a data acquisition device, an onboard processor and a communication device; and the control terminal comprises a state control module and a task planning and restoration module. The substation inspection system realizes high integration by setting the motion control device, the data acquisition device, the onboard processor, the communication device, the state control module and the task planning and restoration module.In addition, the substation inspection system can acquire the inspection data through the data acquisition device, and control the position and posture adjustment of the inspection robot according tothe processed data of the onboard processor. At the same time, through the state control module, manual start and stop and parameter adjustment control of the inspection robot can be realized, and the human-machine cooperation capability of the inspection robot is improved.

Owner:SHENZHEN POWER SUPPLY BUREAU

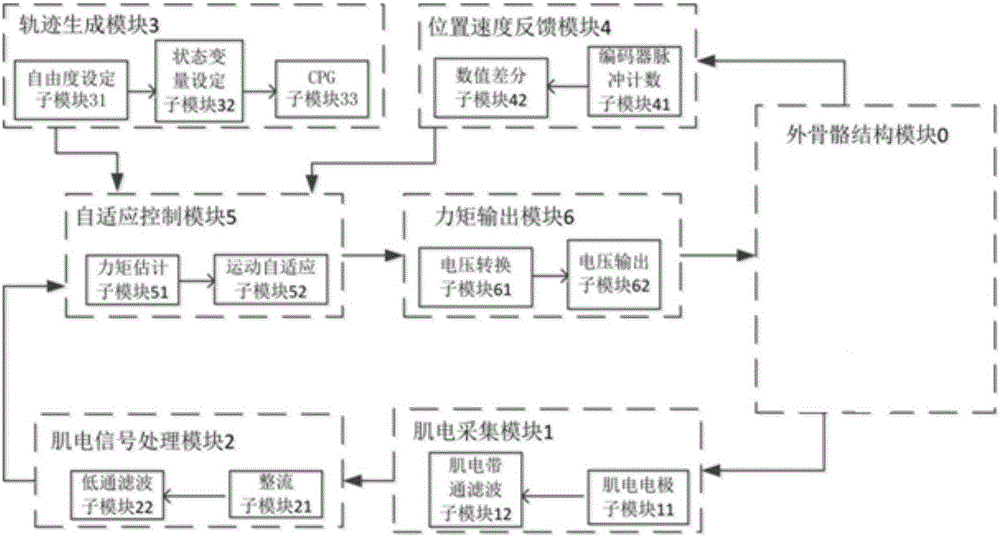

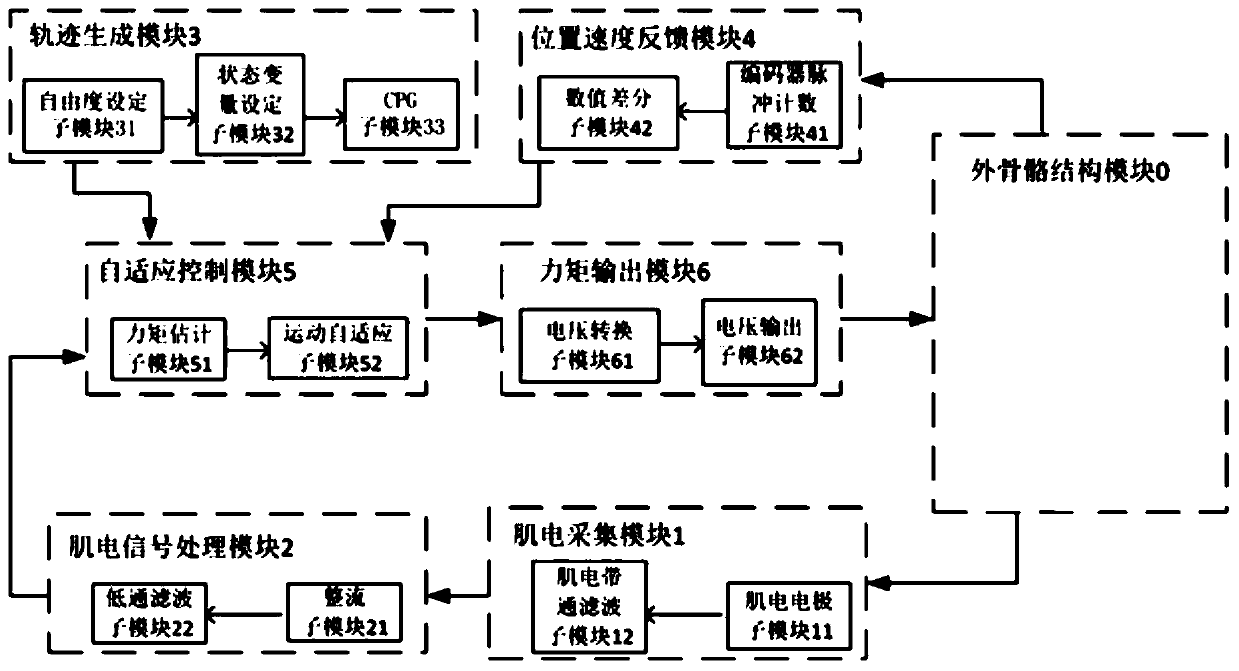

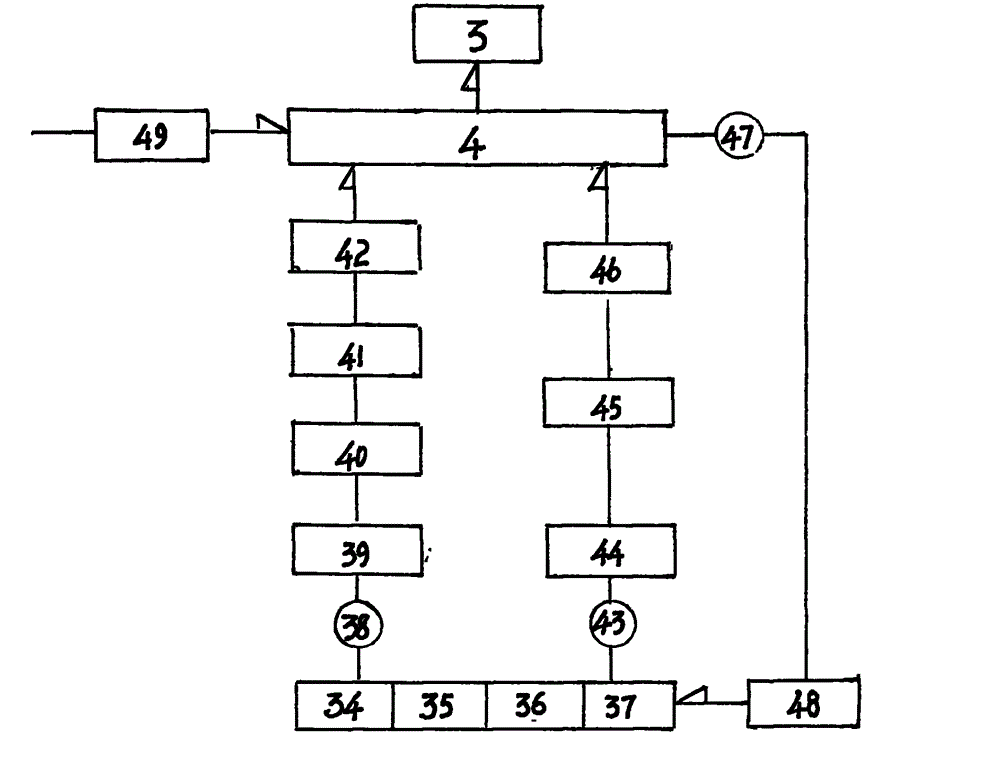

Lower extremity exoskeleton recovery system and method based on human-machine cooperation

ActiveCN106110587AIncrease engagementAchieving an Active Rehabilitation ModelGymnastic exercisingChiropractic devicesRecovery methodEngineering

The invention provides a lower extremity exoskeleton recovery system and a lower extremity exoskeleton recovery method based on human-machine cooperation. The system comprises an extremity structure module, an electromyographic signal acquisition module, an electromyographic signal processing module, a trace generation module, a position and speed feedback module, an adaptive control module and a motor torque output module, wherein the electromyographic signal acquisition module receives a signal from the extremity structure module and outputs the signal to the electromyographic signal processing module; the adaptive control module inputs a signal into the electromyographic signal processing module, the trace generation module and the position and speed feedback module, and outputs a signal to the motor torque output module; the position and speed feedback module acquires a signal from the electromyographic signal acquisition module; and the motor torque output module outputs a signal to the extremity structure module. The lower extremity exoskeleton recovery system is practicable; and due to a lower limb walking recovery training mode based on the human-machine cooperation, a paralyzed patient can be greatly encouraged to participate in the recovery training, and the recovery effect is expected to be enhanced.

Owner:SHANGHAI JIAO TONG UNIV

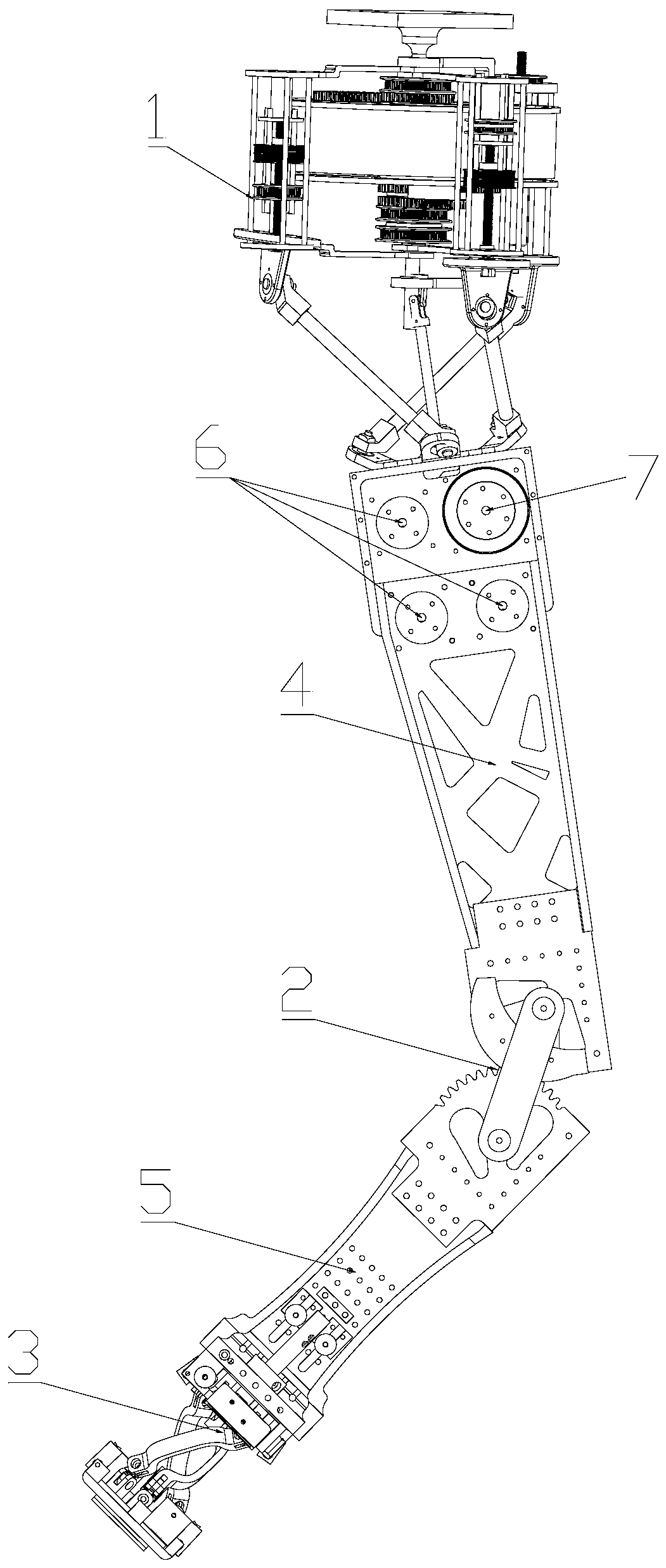

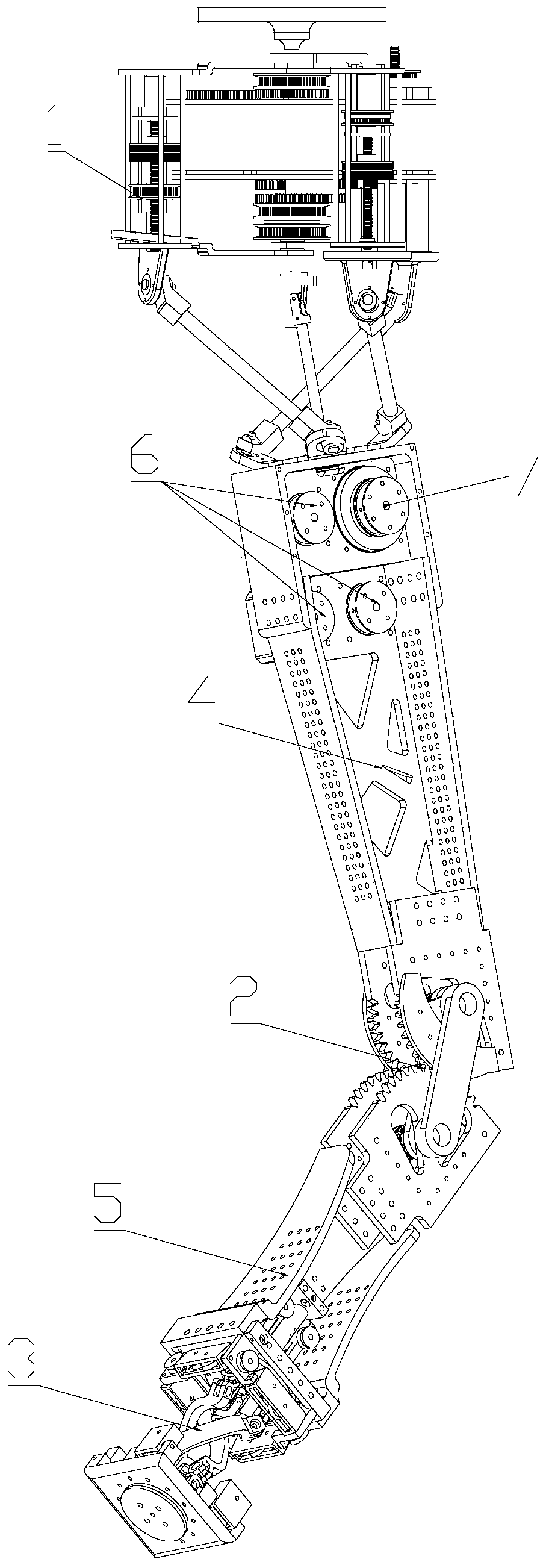

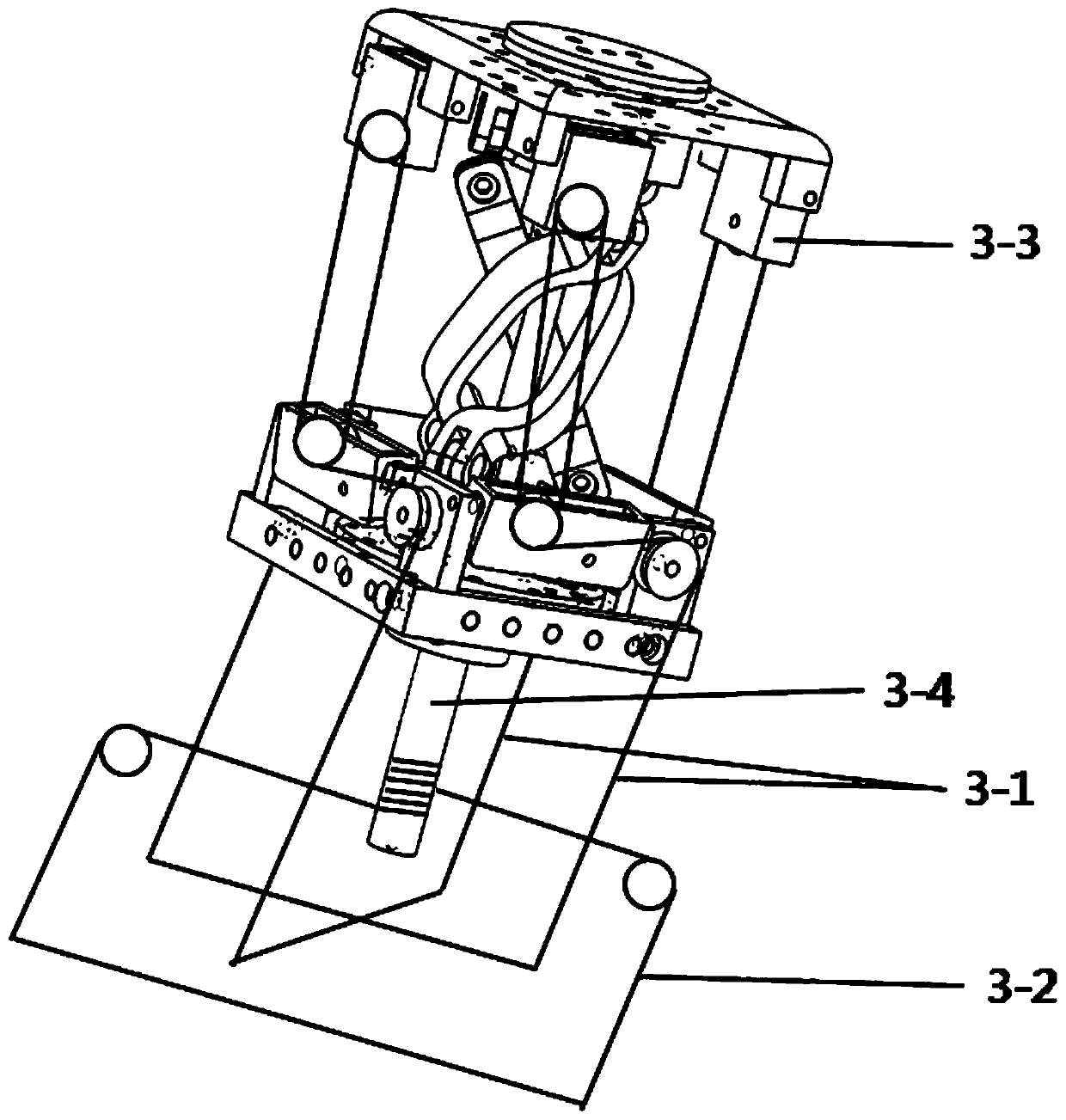

Human-machine cooperation oriented bionic lightweight mechanical arm

PendingCN110202559AGuaranteed symmetryIncrease stiffnessProgramme-controlled manipulatorEngineeringDrive motor

The invention discloses a human-machine cooperation oriented bionic lightweight mechanical arm comprising a first machine arm, a second machine arm, a wrist joint, an elbow joint and a shoulder joint.The first machine arm is arranged between the shoulder joint and the elbow joint, the second machine arm is arranged between the elbow joint and the wrist joint, the wrist joint is a three-degree-of-freedom motion pair, the wrist joint includes a two-degree-of-freedom parallel mechanism connected with a single-degree-of-freedom Hook hinge mechanism in series, the elbow joint is a single-degree-of-freedom rotational joint, and the shoulder joint is a three-degree-of-freedom parallel ball joint mechanism; and the mechanical arm further comprises an elbow joint drive motor and three wrist jointdrive motors, and the elbow joint drive motor arranged at the end, close to the shoulder joint, of the second machine arm and the wrist joint drive motors control the elbow joint and the wrist joint through rope drive transmission. By means of the mechanical arm, the collision inertia is reduced, and therefore the safety of human-computer interaction is improved.

Owner:SOUTH CHINA UNIV OF TECH

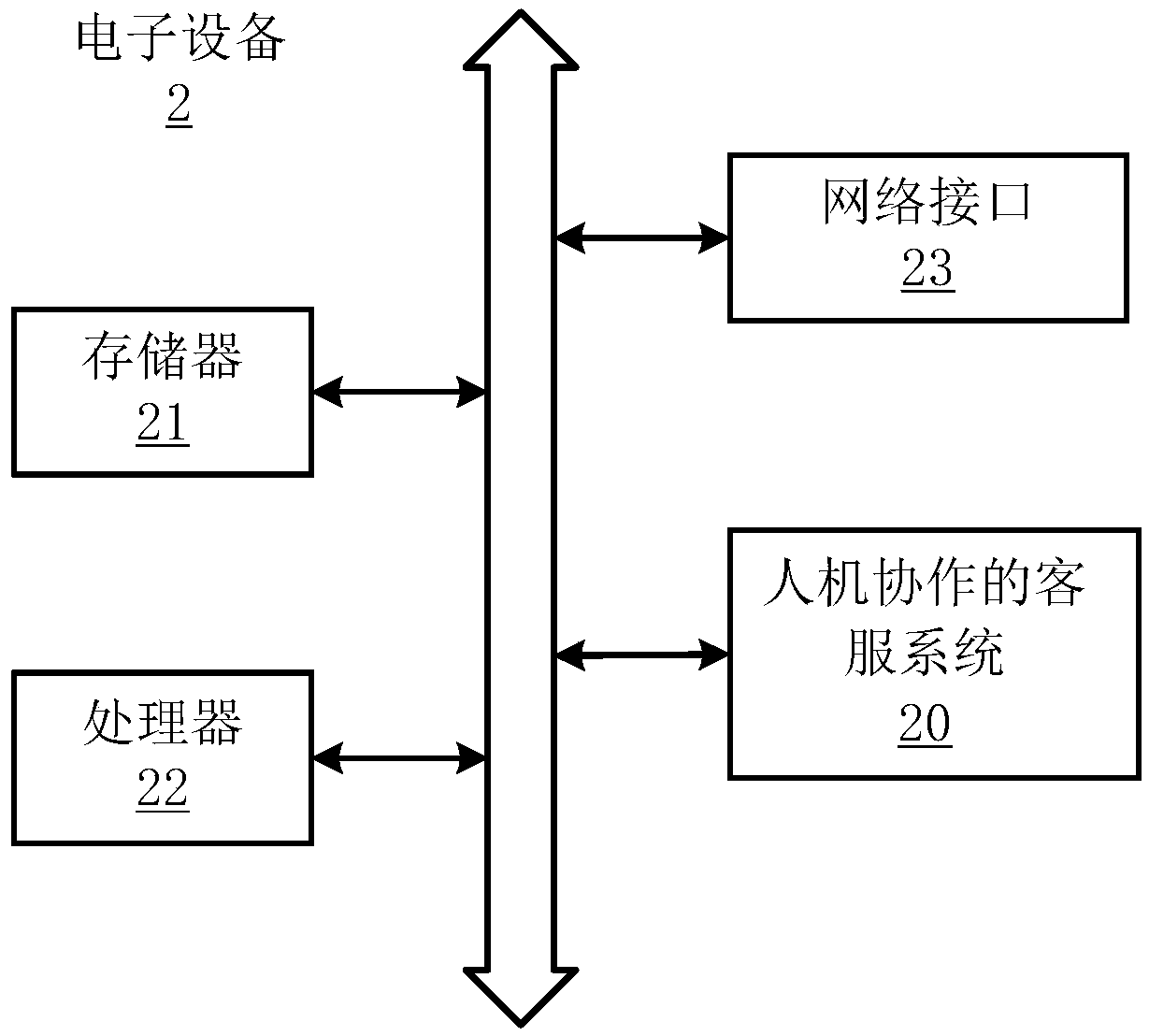

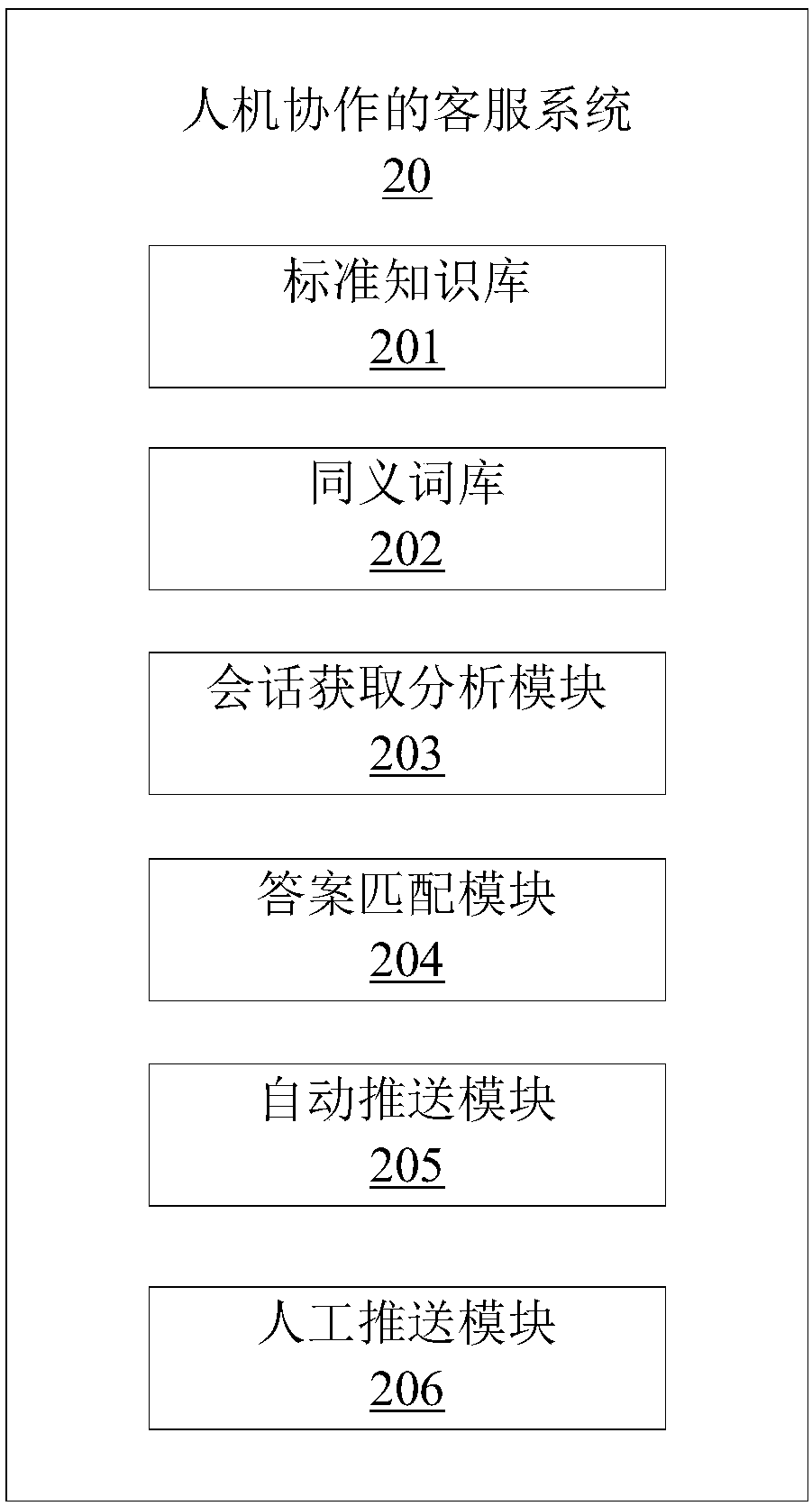

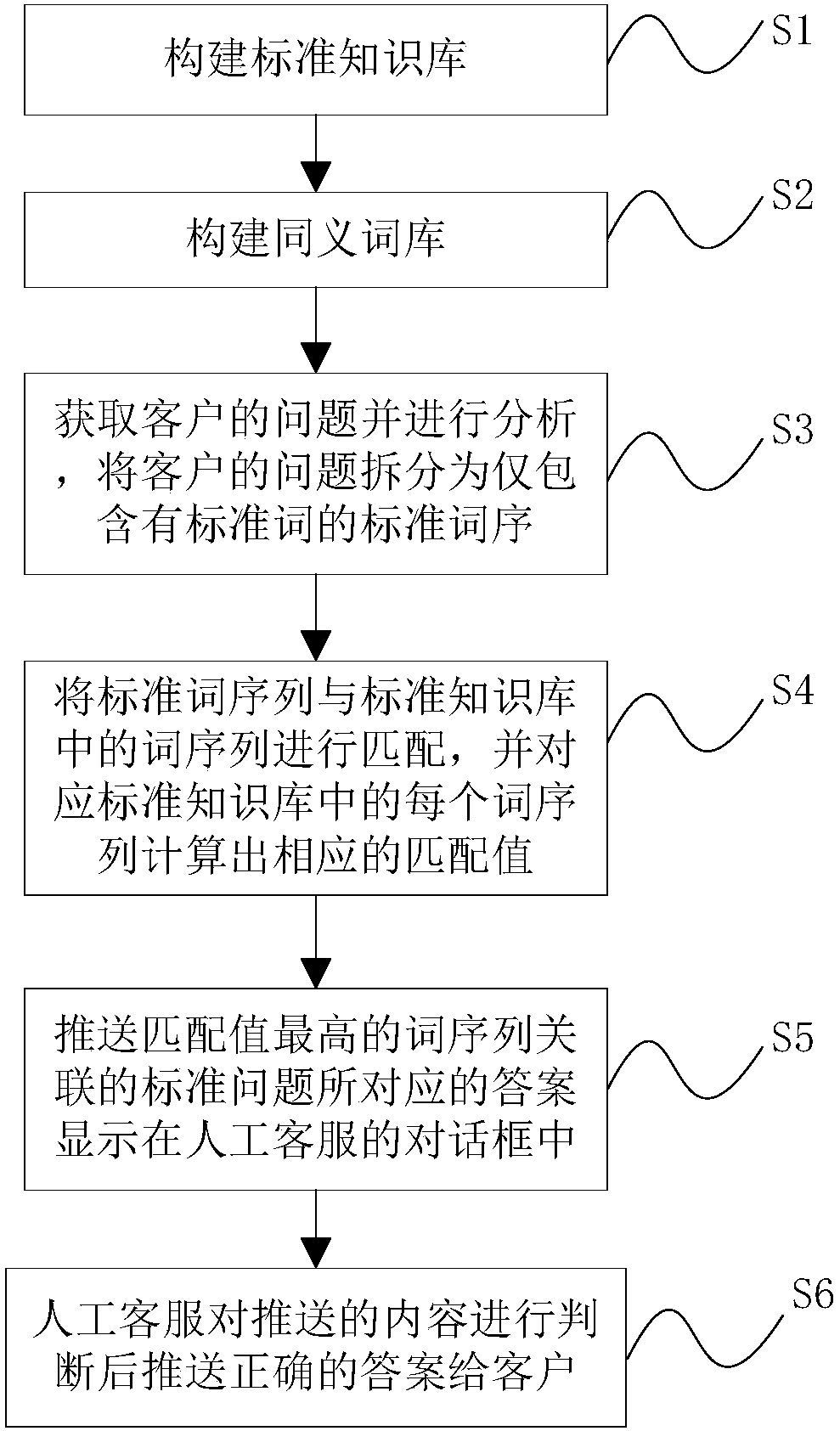

Customer service method for human-machine cooperation, electronic device and storage medium

ActiveCN107832291AReduce waiting timeImprove experienceSemantic analysisSpecial data processing applicationsLibrary scienceHuman machine cooperation

The invention discloses a customer service method for human-machine cooperation and belongs to the technical field of intelligent customer services. The method includes the following steps that 1, a standard knowledge base is built; 2, a synonym library is built; 3, a question of a customer is obtained and analyzed, and the customer's problem is divided into a standard word sequence only containing standard words; 4, word sequences in the standard word sequence and the standard knowledge base are matched, and a corresponding matching value is calculated according to each word sequence in the standard knowledge base; 5, an answer corresponding to the standard question associated with the word sequence highest in matching value is pushed and displayed in a dialog box of the manual customer service; 6, the manual customer service is used for judging the pushed content and pushing the correct answer to a customer. According the intelligent customer service, after the customer selects the manual customer service, the customer service interface does not directly exit, the intelligent customer service helps the manual customer service to obtain the matched answer, the answer is displayedin the dialog box of the manual customer service, and thus the time for the answer query and typing for the manual customer service is reduced.

Owner:PING AN TECH (SHENZHEN) CO LTD

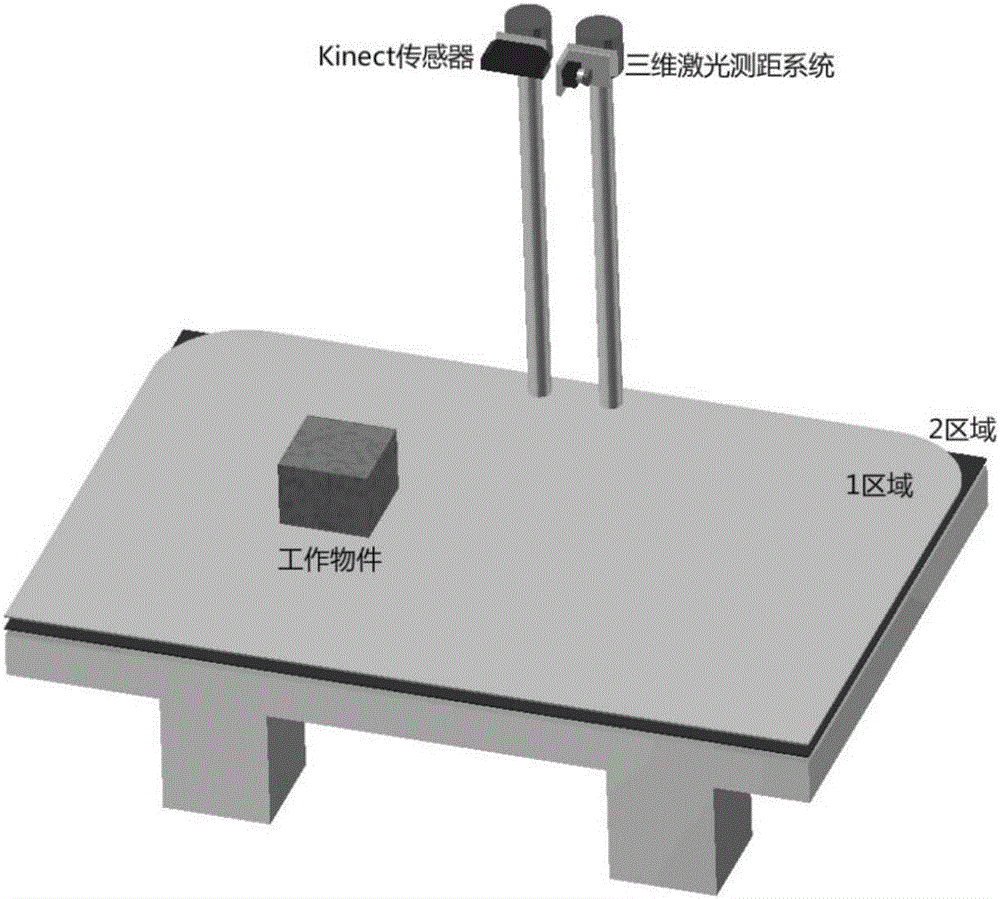

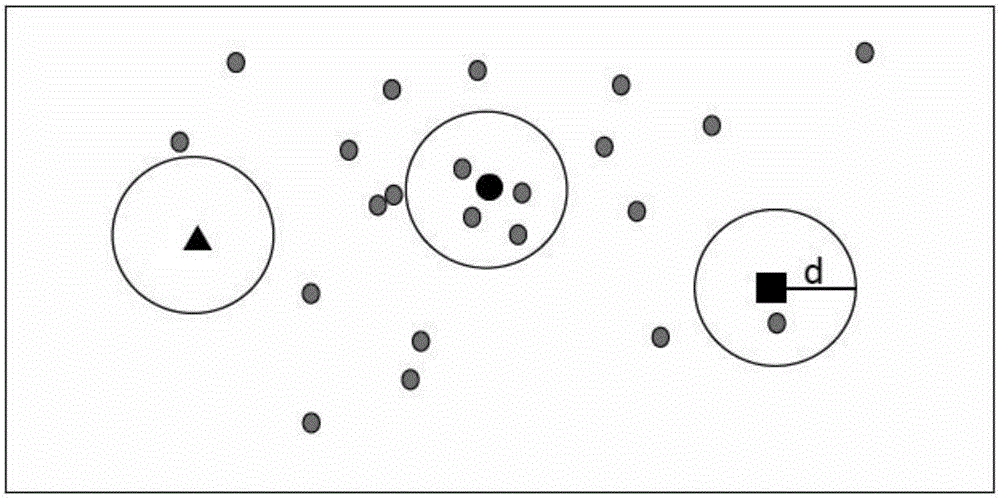

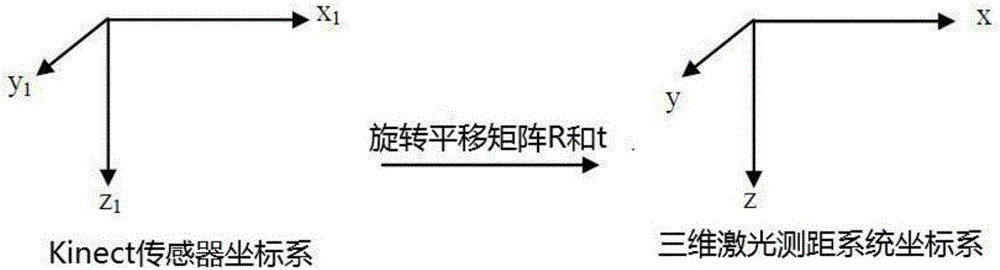

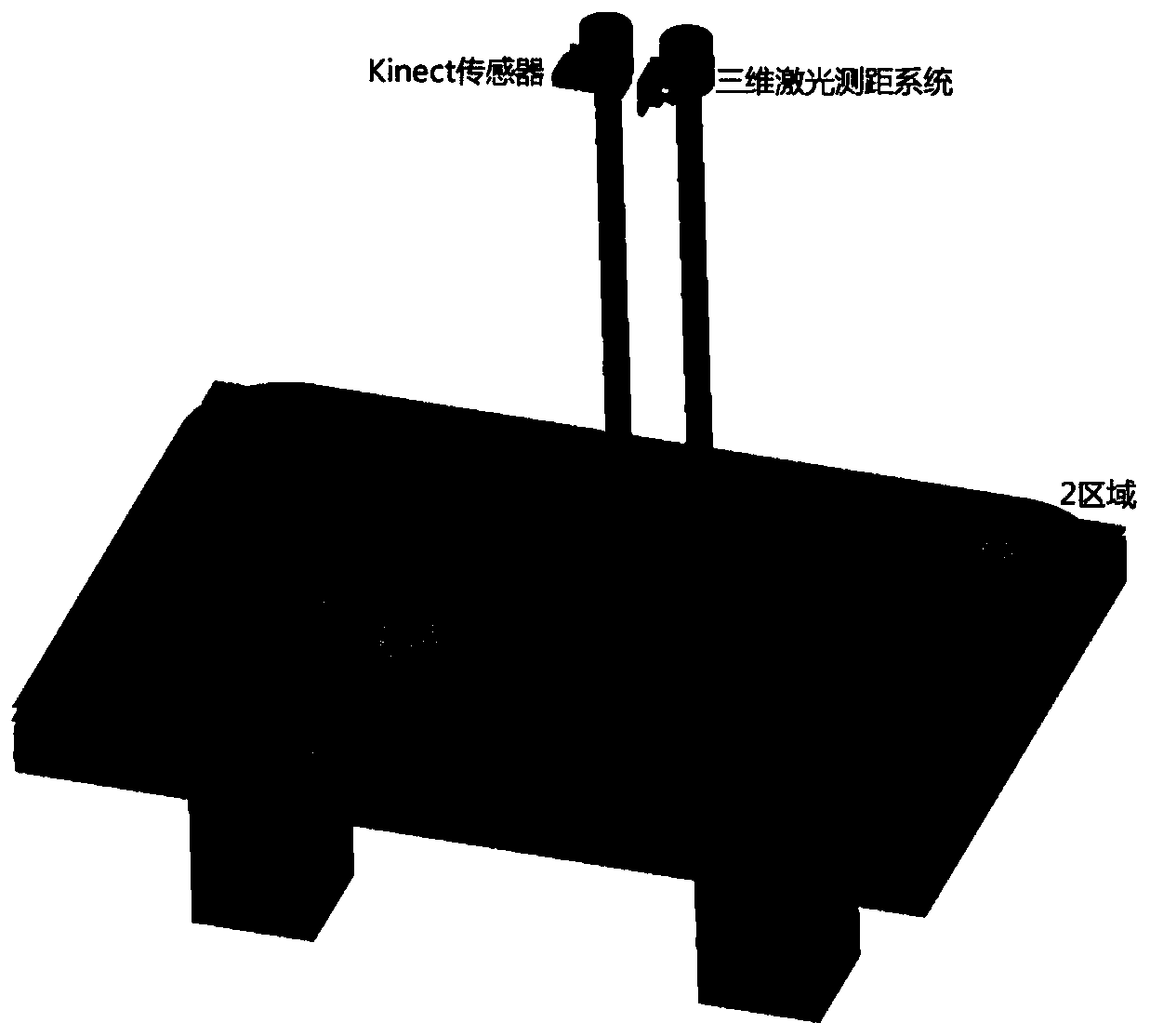

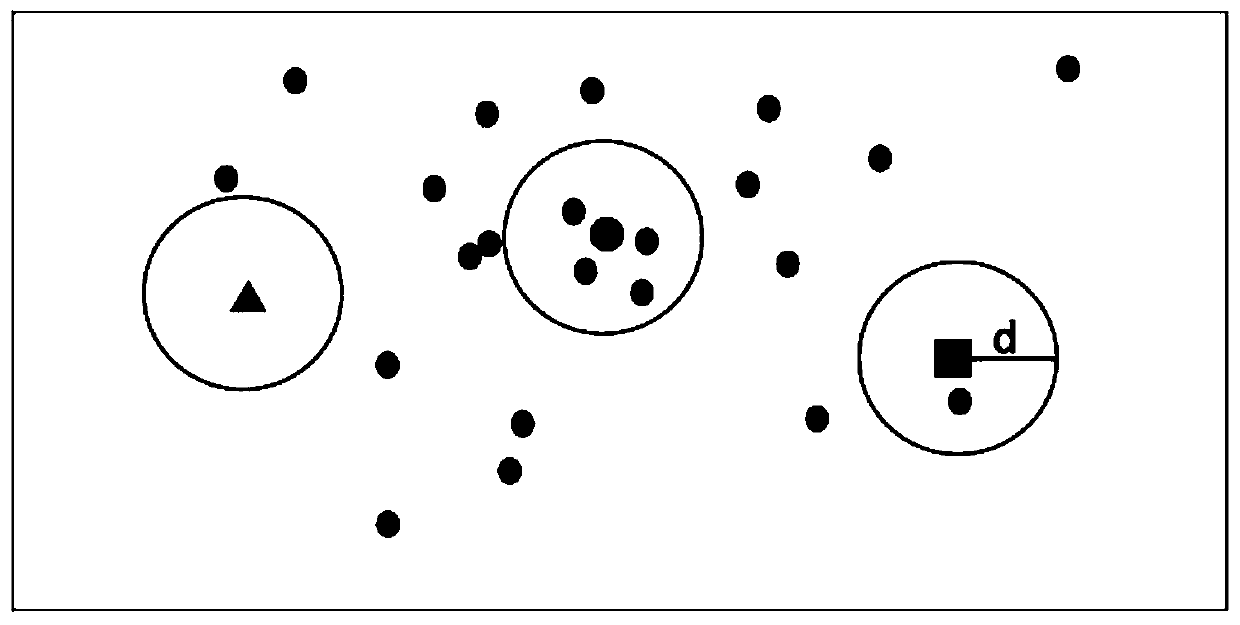

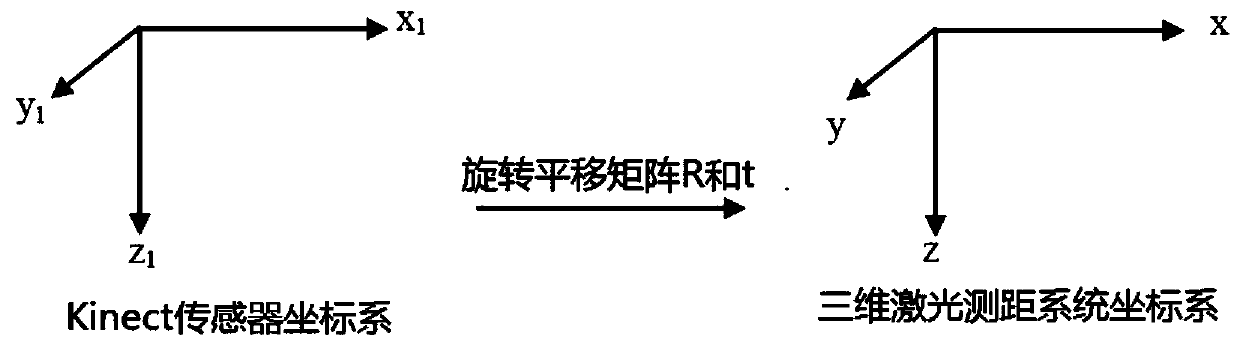

Workpiece position-pose on-line detection method based on cooperation of Kinect and three-dimensional lasers

ActiveCN106842216ASmall sizeAccurate locationUsing optical meansElectromagnetic wave reradiationLaser rangingInteraction systems

The invention discloses a workpiece position-pose on-line detection method based on the cooperation of a Kinect sensor and a three-dimensional laser distance measuring system, and is applied in the technical field of sensing workpiece positions and poses through human-machine cooperation and interaction systems and industrial robots. According to the method, cooperative work between the Kinect sensor and the three-dimensional laser distance measuring system is adopted to collect data; through three parts of preprocessing on obtained point clouds, associated calibration between the Kinect sensor and the three-dimensional laser distance measuring system and the on-line detection of the Kinect sensor and the three-dimensional laser distance measuring system, the problems are solved that the point clouds of the Kinect sensor are sparse, the data accuracy is insufficient and the accuracy and scanning speed of the three-dimensional laser distance measuring system have contradictory relations; the industrial robots can more efficiently and accurately acquire the accurate size information and position-pose information of workpieces, and the accuracy and working efficiency are improved. The method can be applied in the artificial intelligence fields of the understanding of the industrial robots on the working environment and the like.

Owner:DALIAN UNIV OF TECH

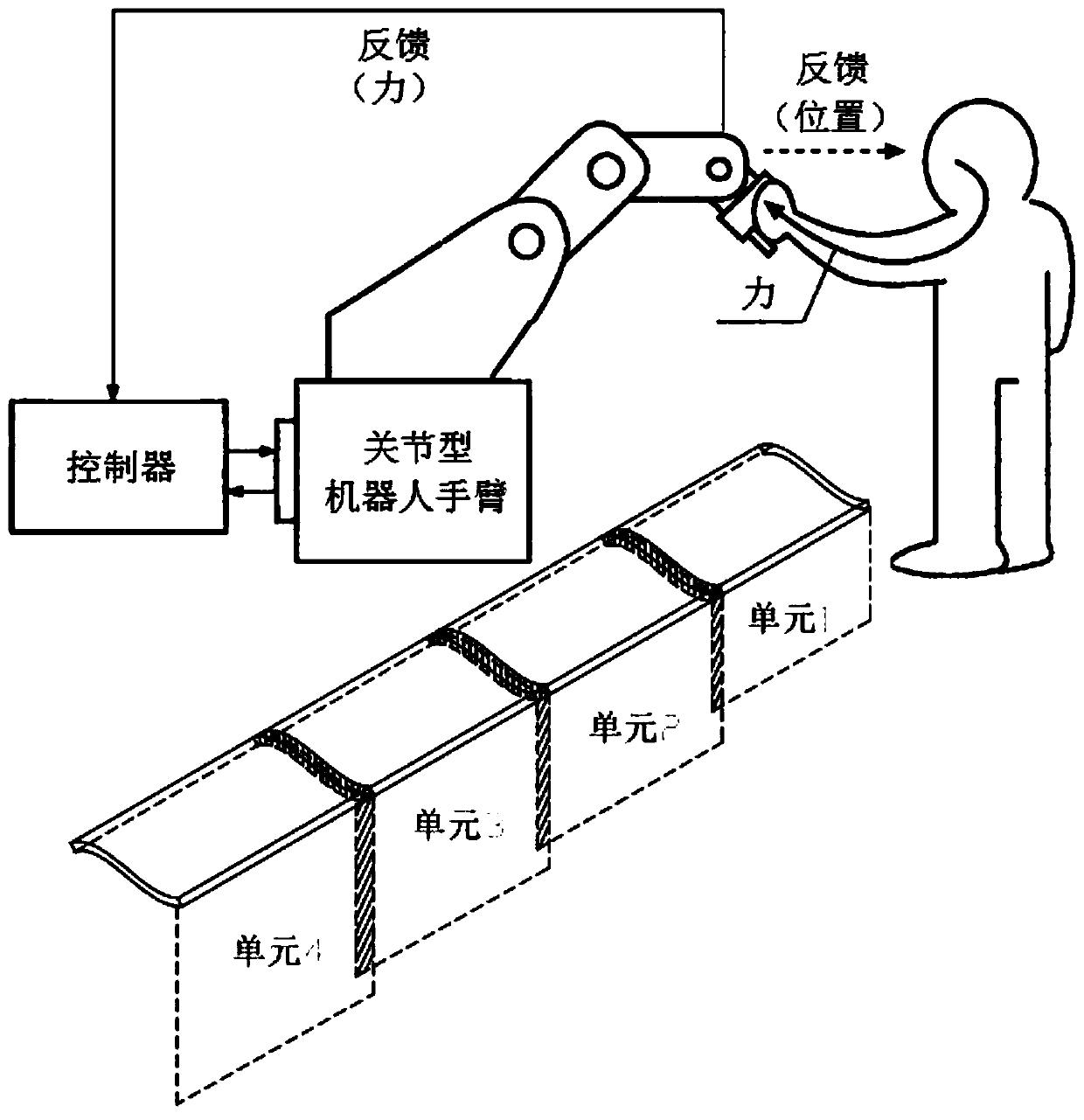

Robot auxiliary operation system and robot auxiliary operation method

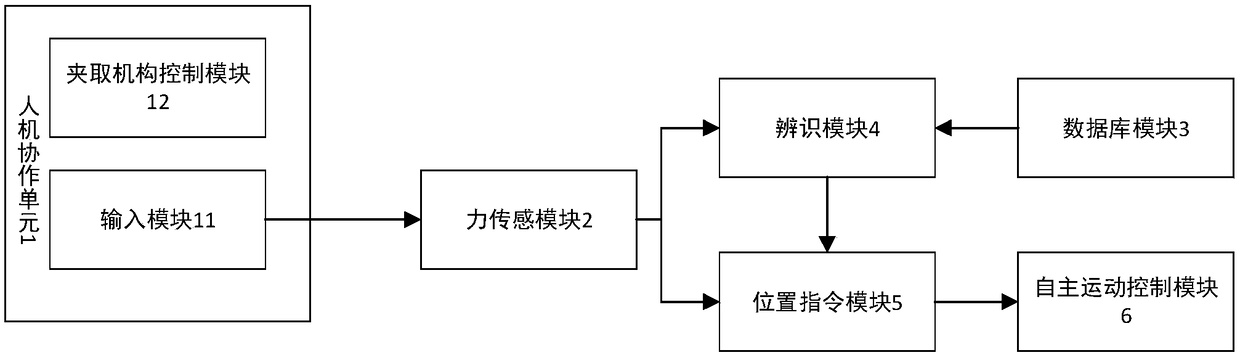

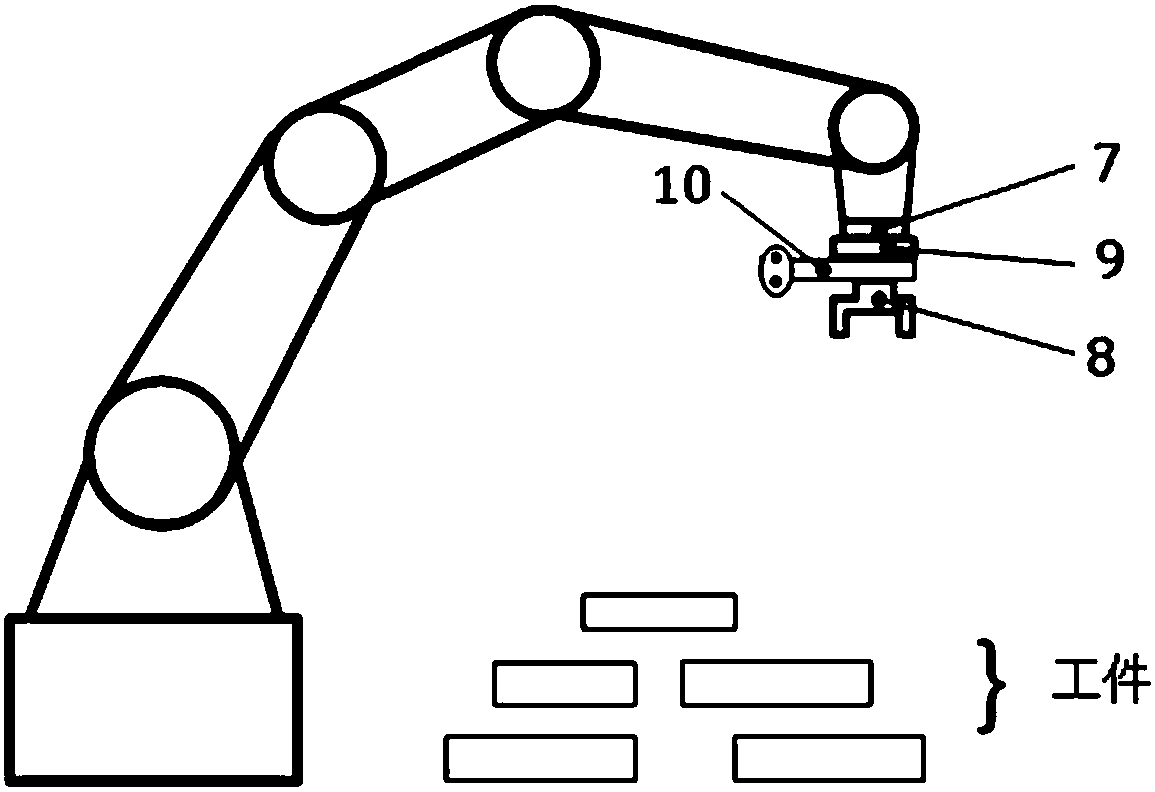

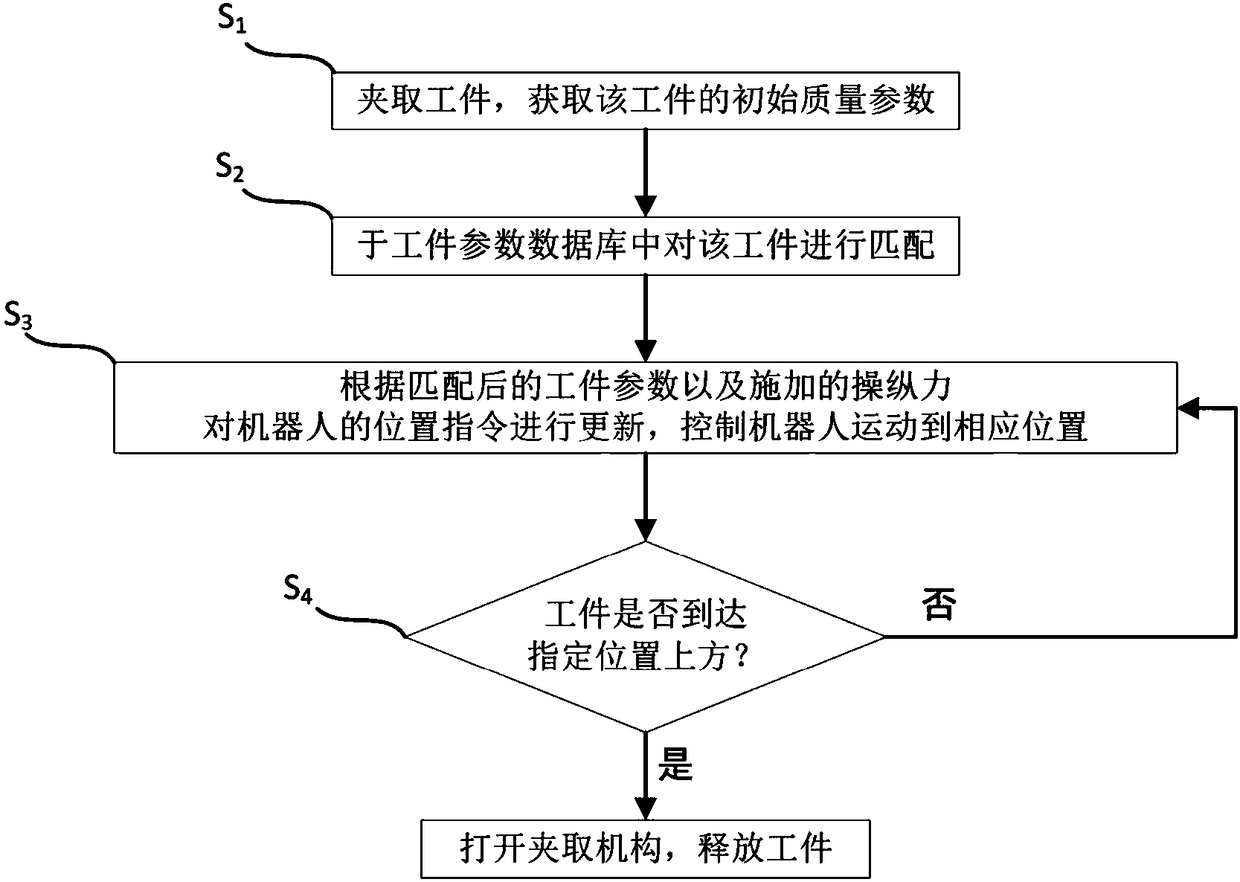

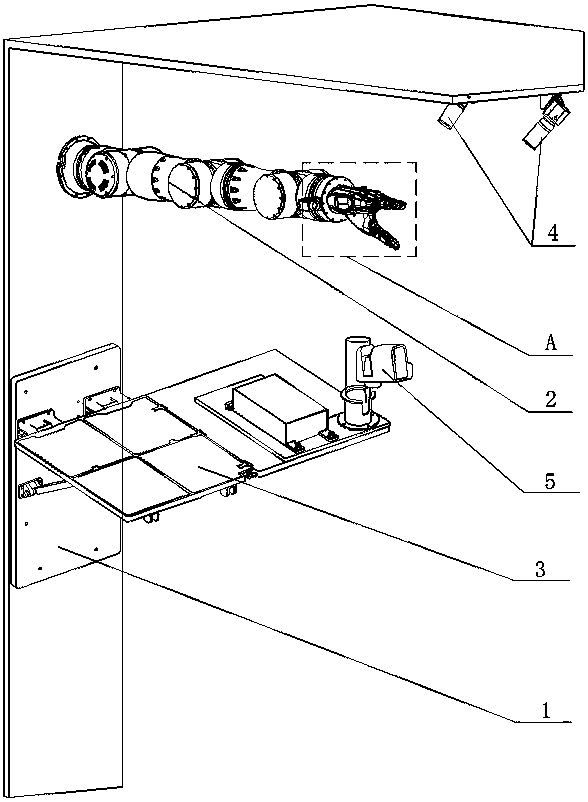

ActiveCN108466290AImprove work efficiencyReduce labor intensityProgramme-controlled manipulatorConveyor partsStress conditionsComputer module

The invention provides a robot auxiliary operation system and a robot auxiliary operation method and relates to the technical field of automatic production. The robot auxiliary operation system comprises a human-machine cooperation operating unit used for inputting operating force to the tail end of a robot flange, a force sensing module arranged at the tail end of the robot flange and used for acquiring the stress condition of the tail end of the robot flange, a database module used for storing standard mechanical parameters of all workpieces, an identification module used for identifying mechanical parameters of clamped workpieces and matching the mechanical parameters of the clamped workpieces with stored workpiece standard mechanical parameters, a position command module used for updating position commands and an autokinetic movement control module used for controlling a robot to move according to the position commands. The robot auxiliary operation system allows the robot to control different qualities of workpieces without changing programming parameters by establishing a workpiece mechanical parameter database, and the use convenience is greatly improved.

Owner:SUZHOU LINGHOU ROBOT

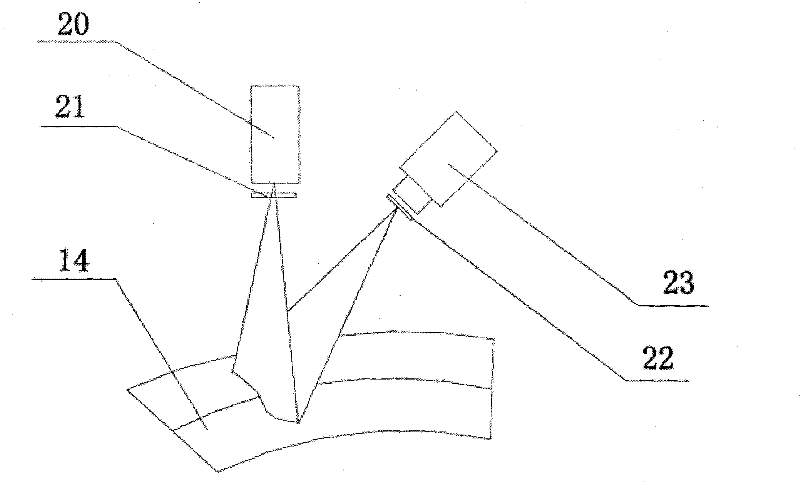

Operation method for unscrewing screws with human-machine cooperation by utilizing space manipulator operation system

ActiveCN108161940AReduce work intensityImprove operation success rateProgramme-controlled manipulatorOperational systemEngineering

The invention provides an operation method for unscrewing screws with human-machine cooperation by utilizing a space manipulator operation system, and belongs to the technical field of space manipulator operation. The problems that an existing robot cannot be aligned with and insert screws, and screwing operation is hard to complete are solved. The operation method comprises two work links, wherein the first link is that an astronaut holding an electric hand drill demonstrates screwing at the position of an operated screw, and the second link is that a manipulator autonomously hold the electric hand drill to screw the operated screw. The astronaut demonstrates screwing at the operation position of the operated screw off-line, the astronaut holds the electric hand drill and places the electric hand drill at the position of the operated screw, and a global camera measures the position of the electric hand drill. The manipulator autonomously holds the electric hand drill to screw the screw, the global camera measures the posture of the electric hand drill, the manipulator is driven to move in real time through visual, and the manipulator submissively controls the electric hand drill in the process that the electric hand drill is inserted into the screw. The problems of electric tool holding posture control, precise aligning of the operated screw and submissive control over the manipulator in the operating process are solved.

Owner:HARBIN INST OF TECH

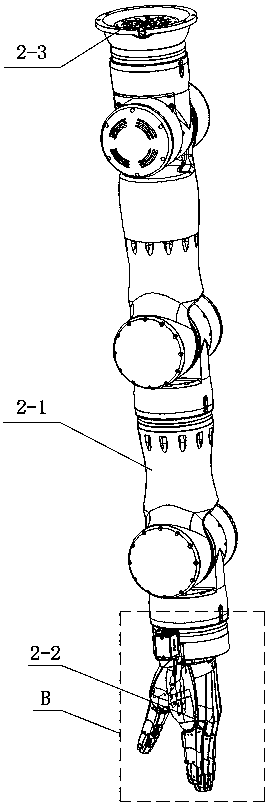

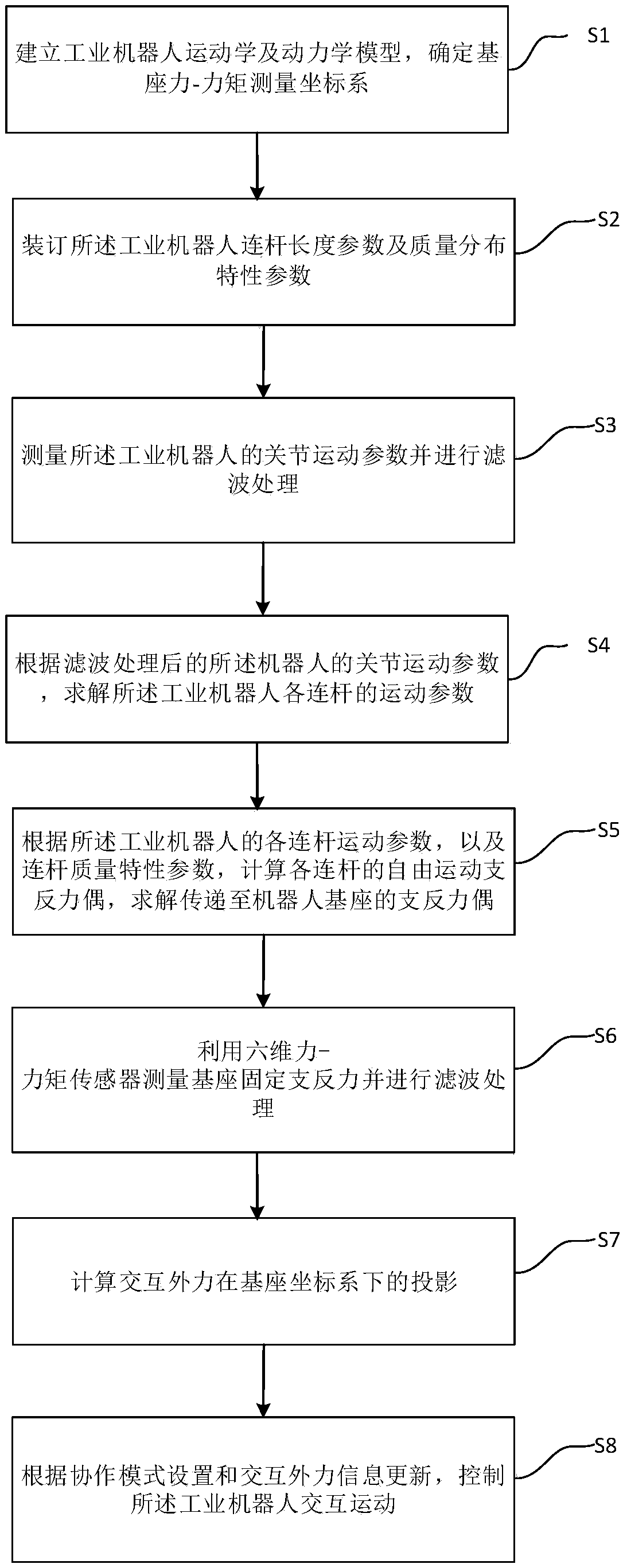

Industrial robot collaborative interaction method and system

ActiveCN108453740AAchieving Collaborative Interaction CapabilitiesEnsure safetyProgramme-controlled manipulatorKinematicsDynamic models

The invention provides an industrial robot collaborative interaction method and system. The industrial robot collaborative interaction method comprises the following steps that an industrial robot kinematics and dynamics model is established, and a base force-torque measuring coordinate system is determined; length parameters and mass distribution characteristic parameters of connecting rods of anindustrial robot are bound; joint motion parameters of the industrial robot are measured, and filtering processing is carried out; according to the joint motion parameters of the robot, motion parameters of all the connecting rods of the industrial robot are solved; according to the motion parameters of all the connecting rods of the industrial robot and the mass characteristic parameters of theconnecting rods of the industrial robot, the free motion reaction couple of all the connecting rods are calculated, and the reaction couple which is transmitted to a robot base is solved; the fixed reaction of the base is measured, and filtering processing is carried out; the projection of the interaction external force under the coordinate system of the base is calculated; and the interaction motion of the industrial robot is controlled. The method and the system can be applied to all the robots with series structures, and through three sub modes set in the method, the basic interaction capability requirement in the human-machine cooperation process can be met on the premise of ensuring the human-machine safety.

Owner:ROKAE SHANDONG INTELLIGENT TECH CO LTD

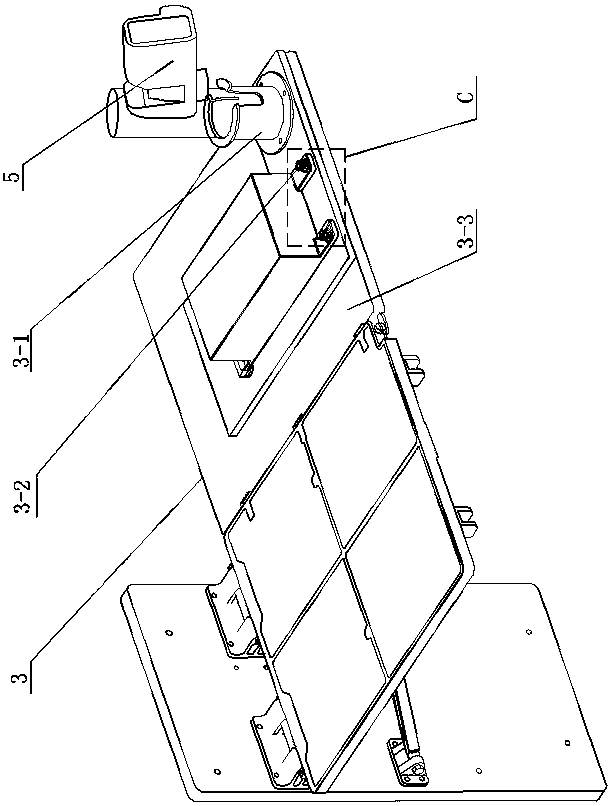

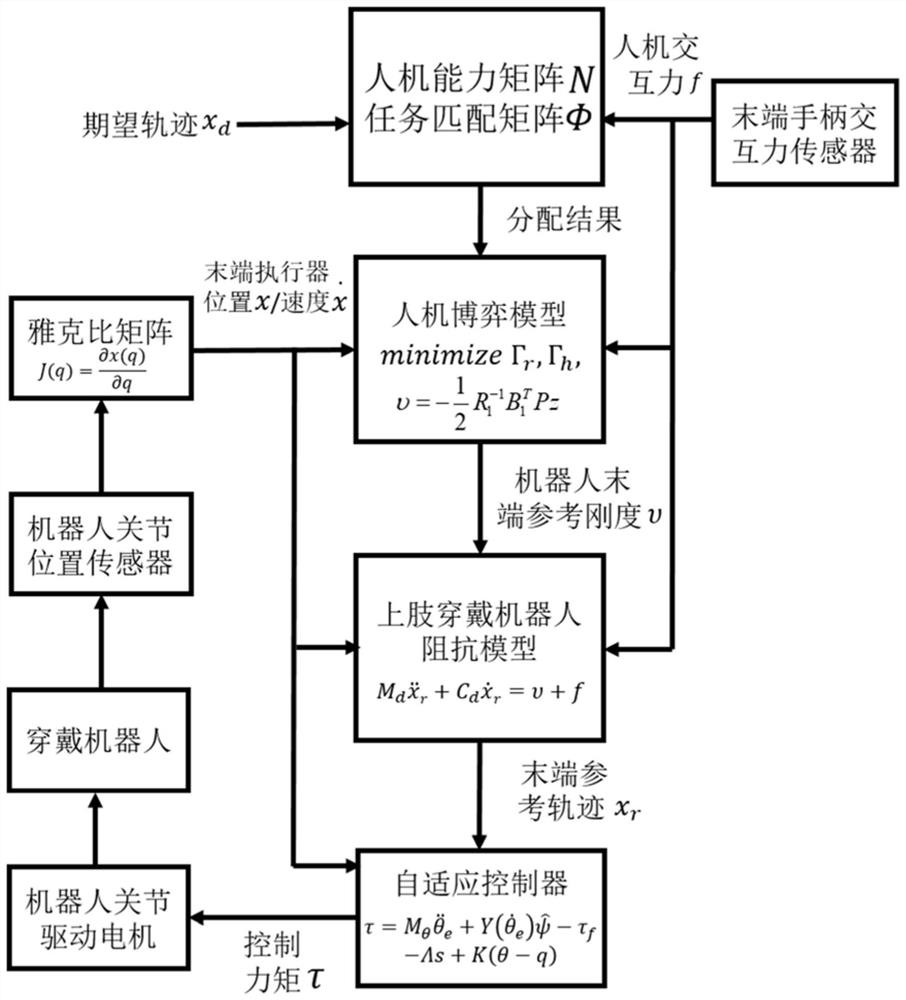

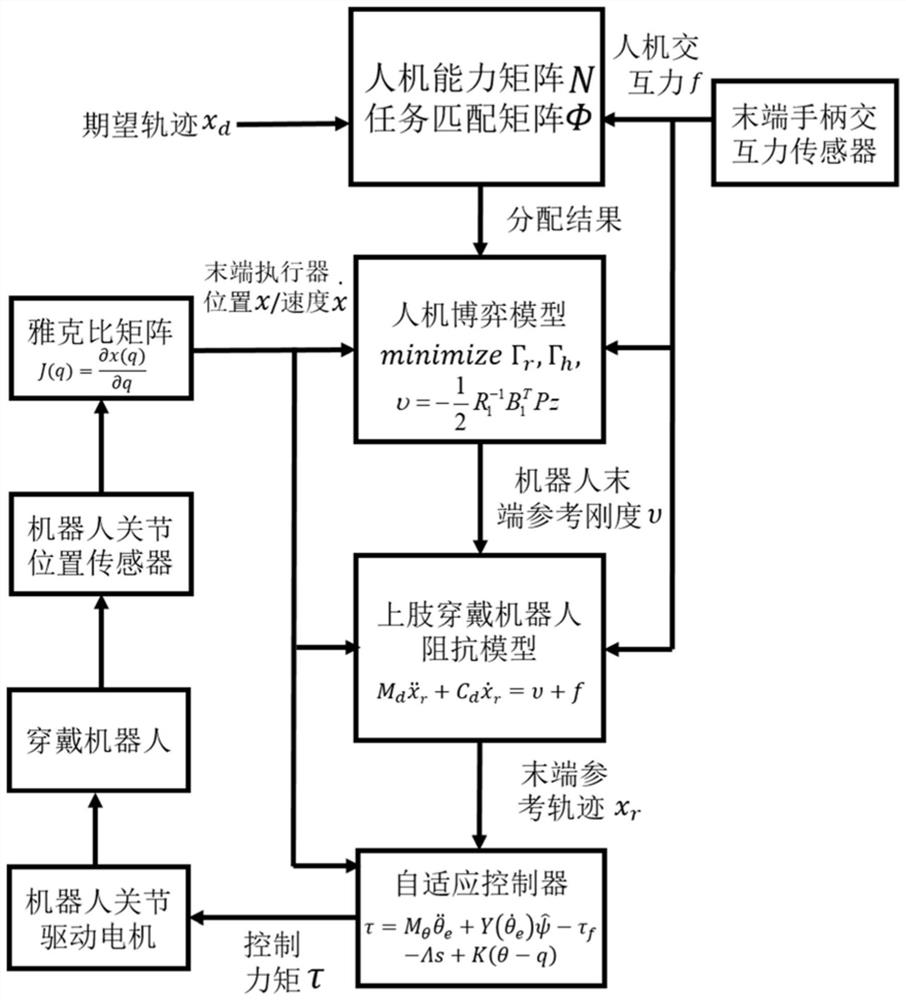

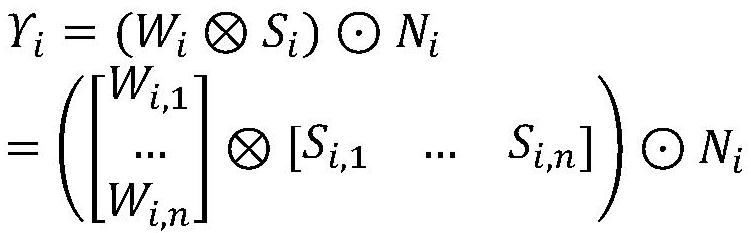

Upper limb wearable robot oriented man-machine game control method and system

ActiveCN112247962ASatisfy control scenariosSolve the singularityProgramme-controlled manipulatorPhysical medicine and rehabilitationMathematical model

The invention provides an upper limb wearable robot oriented man-machine game control method and system. The method comprises the following steps of decomposing a complex or multi-process task jointlycompleted by a user and a robot into a plurality of basic tasks, and establishing a man-machine capability matrix and a task matching matrix, which aim at each basic task, to perform task allocation;and inputting a result of the task allocation into a man-machine zero-sum or non-zero-sum play mathematical model based on a game theory, calculating the optimal rigidity, which is matched at a man-machine tail end, of the robot, then calculating a reference trajectory of the tail end of the robot by a robot impedance model, and finally outputting control moment by an adaptive controller to realize tracking the reference trajectory. By using the control method of the upper limb wearable robot, which is provided in the invention, the better compliance control can be achieved under the situation of man-machine cooperation; the movement intention of the user is perceived; and the input force of the user is minimized.

Owner:UNIV OF SCI & TECH OF CHINA

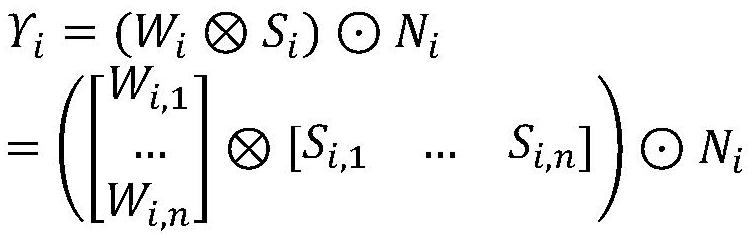

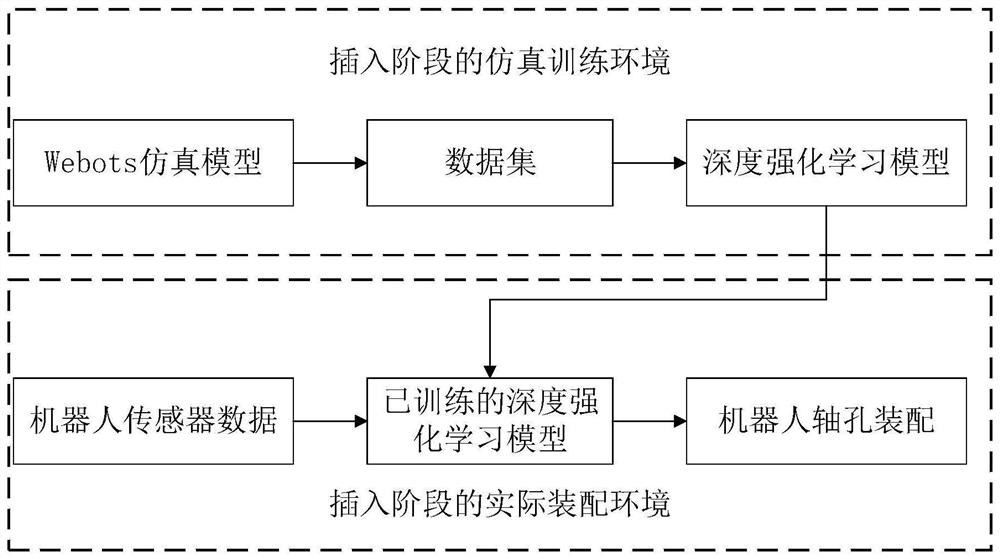

Nuclear operation and maintenance robot shaft hole assembling method based on man-machine cooperation

InactiveCN112192614AGuaranteed safe operationReduce radiation doseMetal working apparatusManipulatorMachineIndustrial engineering

The invention provides a nuclear operation and maintenance robot shaft hole assembling method based on man-machine cooperation, and belongs to the technical field of industrial robots. A slave end mechanical arm is controlled by a master end mechanical arm to rotate a pin in a gap area of the center of a hole; the pin at the tail end of the slave end mechanical arm makes contact with a plane wherethe hole is located, and adjusting is carried out on the pose of the pin through data returned by a torque sensor in real time; and pose information of the pin and information of the torque sensor are acquired, and the pin is pushed to be inserted into the hole by utilizing a depth deterministic strategy gradient network of continuous action, and then nuclear operation and maintenance robot shafthole assembly based on man-machine cooperation is finished. In order to reduce the radiation dosage borne by operation and maintenance personnel and improve the operation and maintenance efficiency,robot intelligence and human intelligence are fully combined through the method; the reliability of the operation process is enhanced by utilizing experience knowledge of people, and it is guaranteedthat the risk is controllable; and meanwhile, the robot autonomously acts in a local area by utilizing an artificial intelligence algorithm.

Owner:SOUTHWEAT UNIV OF SCI & TECH +1

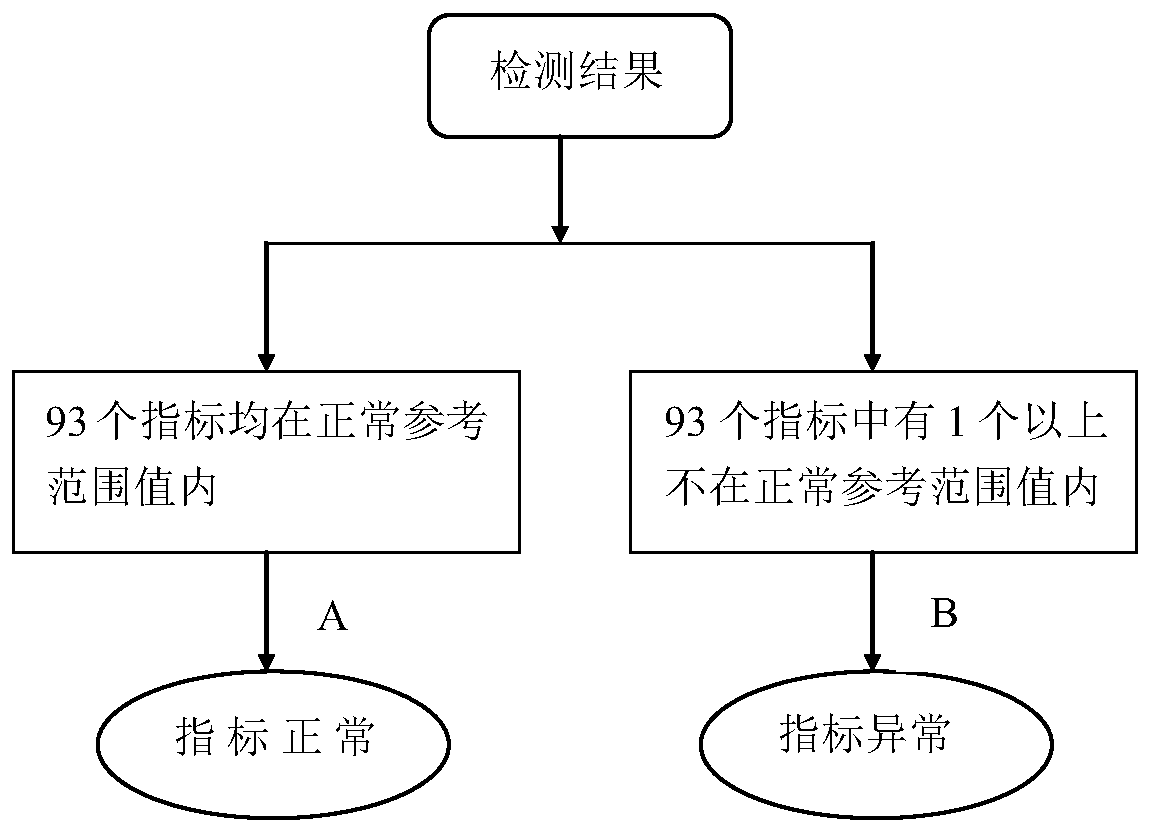

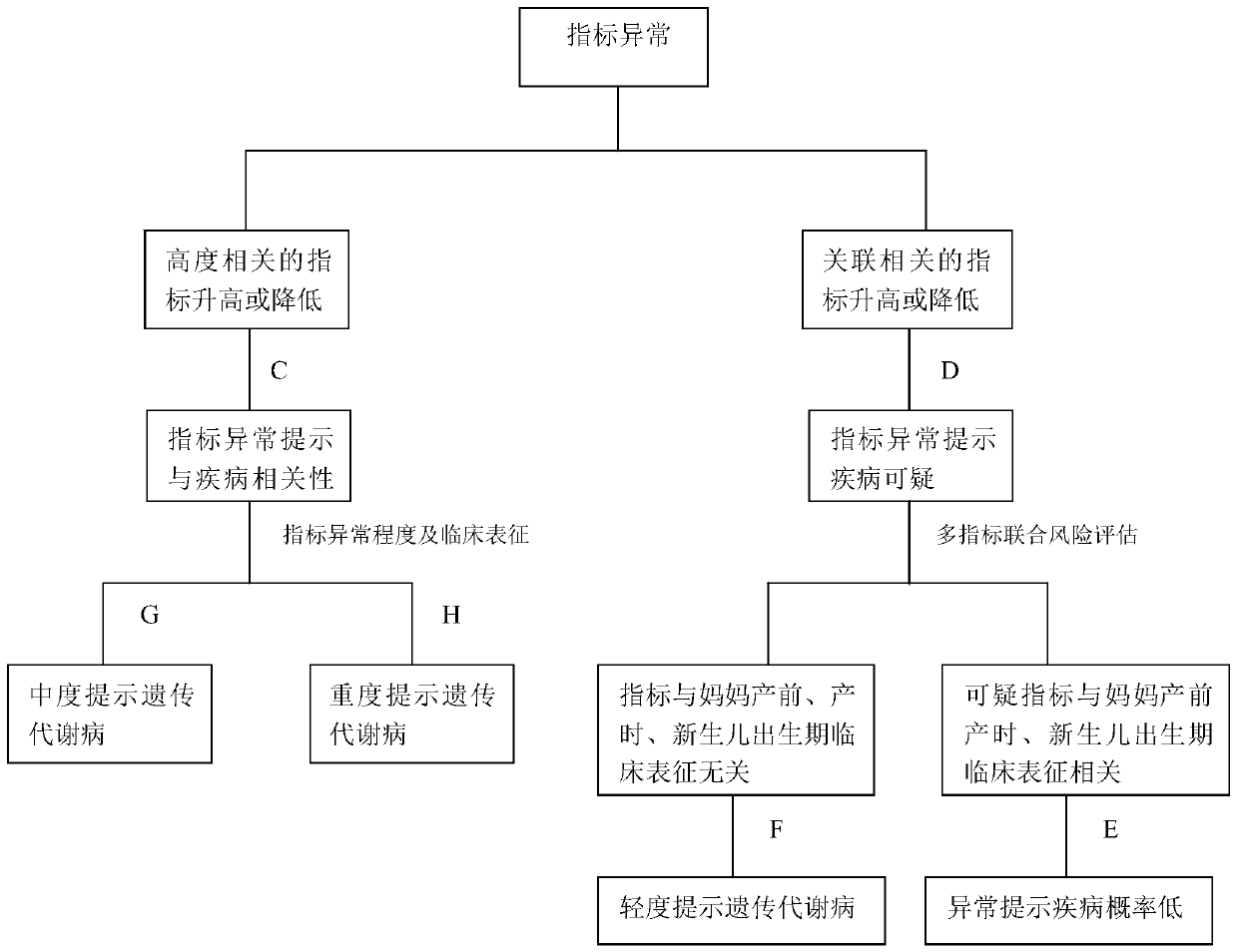

Method, device and system for detecting and analyzing inherited metabolic diseases of newborns

PendingCN110322963AAccurate readingRealization of interpretationMedical automated diagnosisLaboratory analysis dataRetrospective analysisWork flow

The invention provides a method, device and system for detecting and analyzing inherited metabolic diseases of newborns. An interpretation mode which combines a computer system, a disease database anda doctor is originally created; the tandem mass spectrometry detection result of the inherited metabolic diseases of newborns can be interpreted more quickly and accurately, and an accurate conclusion can be given; the comprehensive datamation of the whole working process is realized; therefore, the interpretation process can be traced back more easily and can be repeatedly compared and researched in the later period, and the situation that retrospective analysis cannot be carried out due to forgetting in the later period of manual interpretation can be greatly avoided. The system adopts a man-machine cooperation mode to realize higher degree of automation, the investment of labor cost is greatly reduced, and with the increase of data volume and the continuous optimization of the system,the tandem mass spectrometry detection result interpretation of the inherited metabolic diseases of newborns is even possible to realize the artificial intelligence interpretation of a computer.

Owner:成都新基因格生物科技有限公司

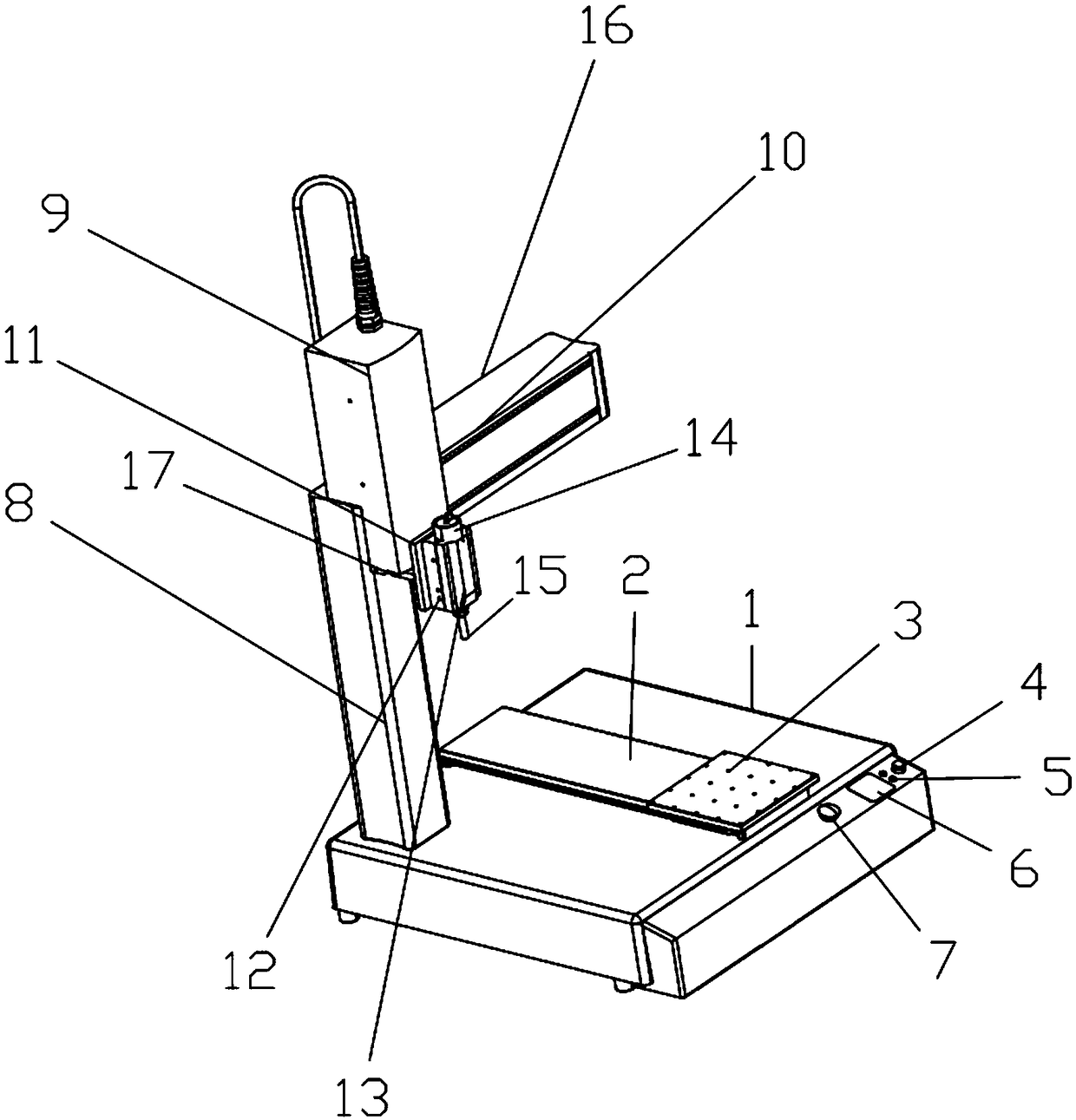

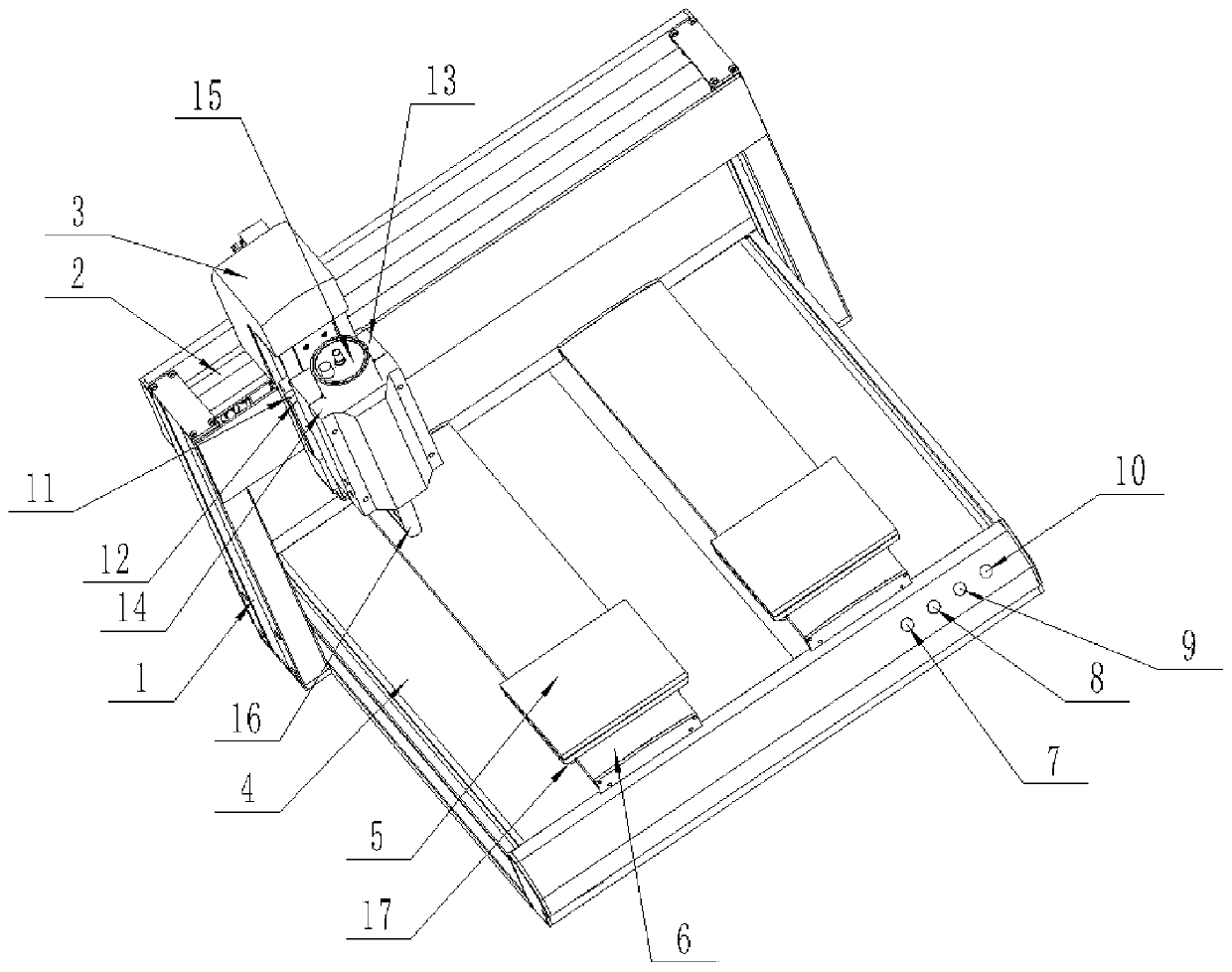

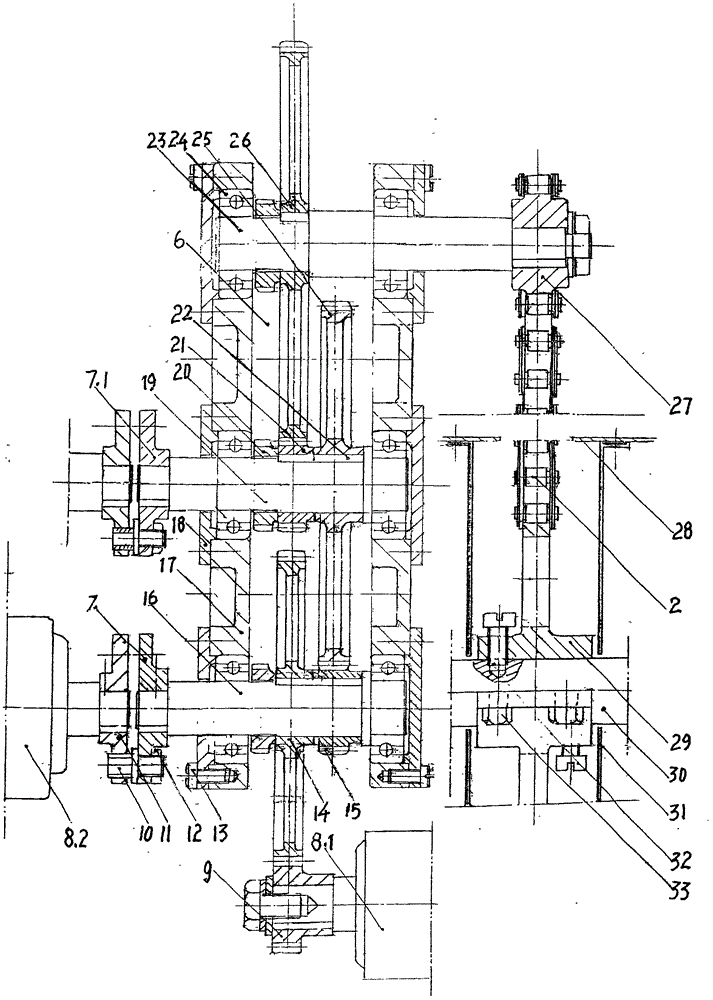

Three-axis ultrasonic welding device

InactiveCN109352163AEnhance the imageQuality assuranceWelding/cutting auxillary devicesAuxillary welding devicesMachine partsUltrasonic welding

The invention discloses a three-axis ultrasonic welding device. The device comprises a base (1), a support frame (8), a cantilever (16) and a welding device, wherein the support frame (8) is fixedly connected to the base (1), the cantilever (16) is fixedly connected to the support frame (8), the welding device is connected with the cantilever (16), a Y axis (2) is arranged on the base, and a workbench (3) is connected to the Y axis (2) in a sliding mode. The device has the greatest advantages that the machining efficiency and the machining quality are greatly increased in a human-machine cooperation mode, and especially for a product of which one part can be machined in different positions, the effects of one-time clamping and multi-time machining can be realized; compared with a traditional manual machining mode, the machining efficiency can be improved, the quality and stability of the to-be-machined part can be guaranteed, and a good effect is achieved on the increase of the corporate image and the enterprise competitiveness.

Owner:SBT ULTRASONIC TECH CO LTD

Human-machine cooperation full-automatic ultrasonic welding equipment

InactiveCN110355460AInhibition releaseSimple structureWelding/cutting auxillary devicesAuxillary welding devicesUltrasonic weldingMan machine

The invention discloses human-machine cooperation full-automatic ultrasonic welding equipment. The human-machine cooperation full-automatic ultrasonic welding equipment comprises a supporting seat, anX-axis assembly, a Z-axis assembly, a base, a product positioning jig, a Y-axis assembly, a fixing plate, a cover plate, a clamp bottom plate, a clamp cover plate, an ultrasonic welder, a welding head, a sliding seat and the like. The human-machine cooperation full-automatic ultrasonic welding equipment has the advantages of the reasonable and simple structure, low production cost, convenient installation and complete functions; little heat is generated in the process of machining plastics, and toxic gases can be effectively prevented from being released; and the production efficiency can beimproved byadopting a double-Y-axis design by the equipment.

Owner:SBT ULTRASONIC TECH CO LTD

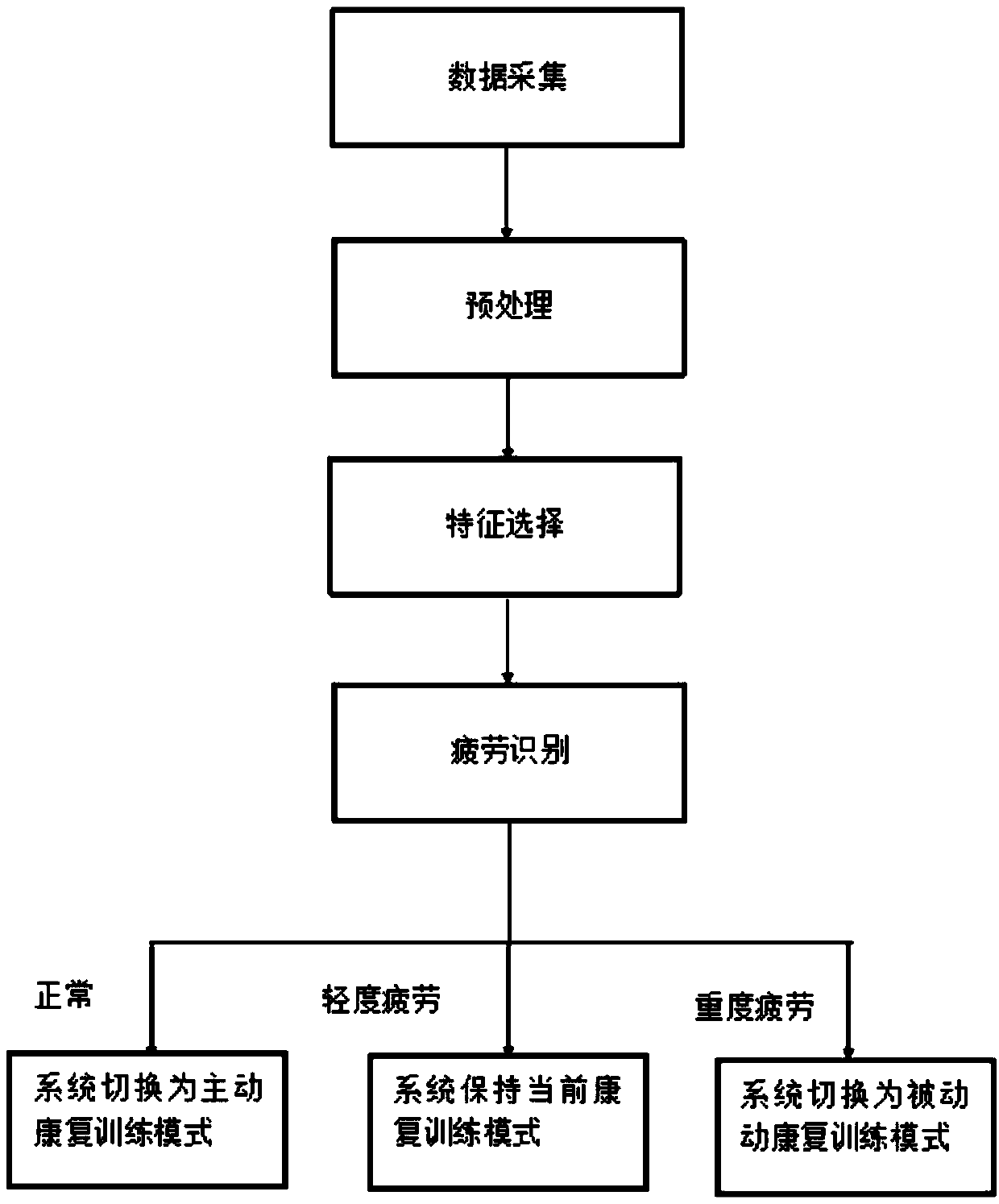

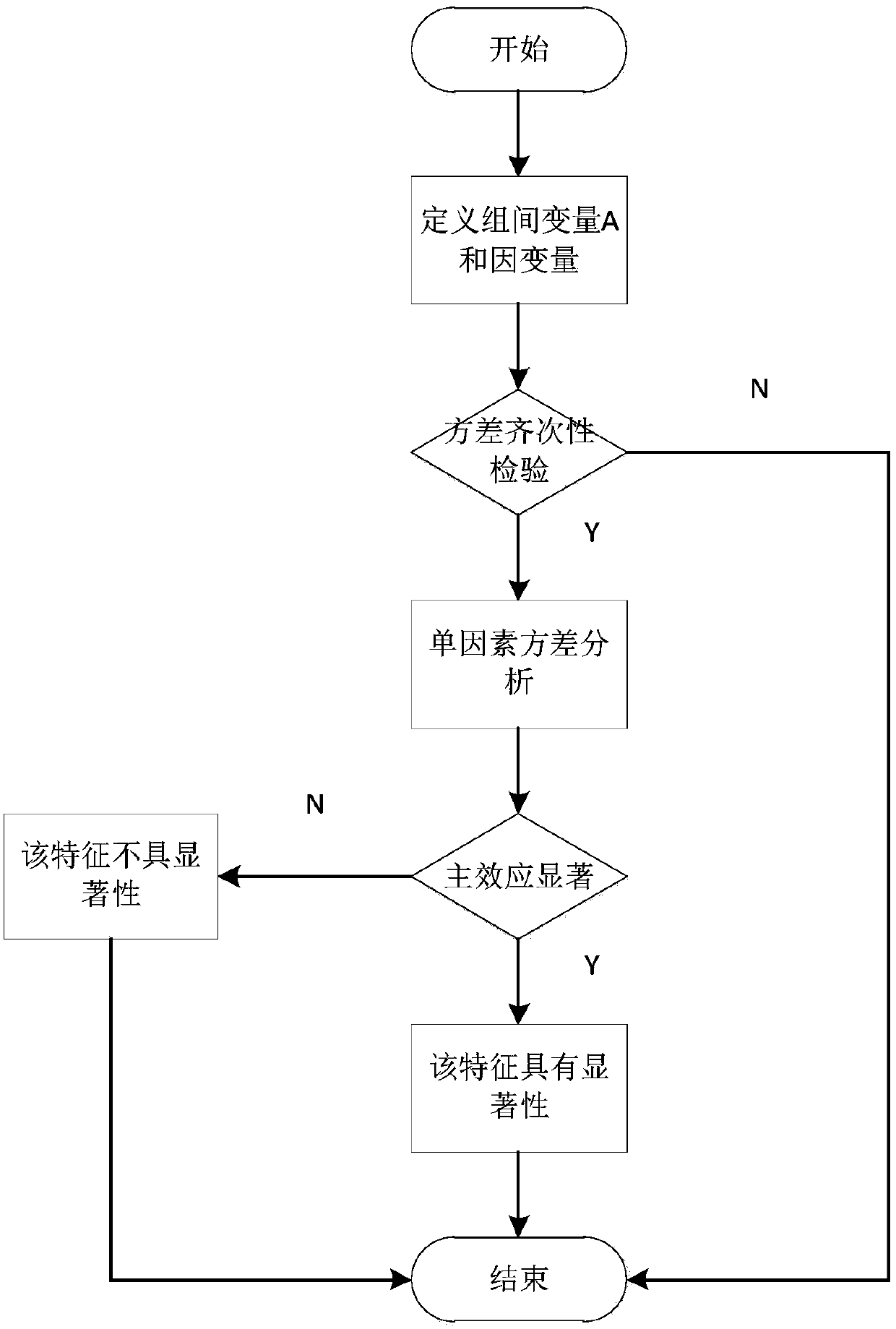

Robot-assisted rehabilitation human-machine cooperation training method based on fatigue sensing

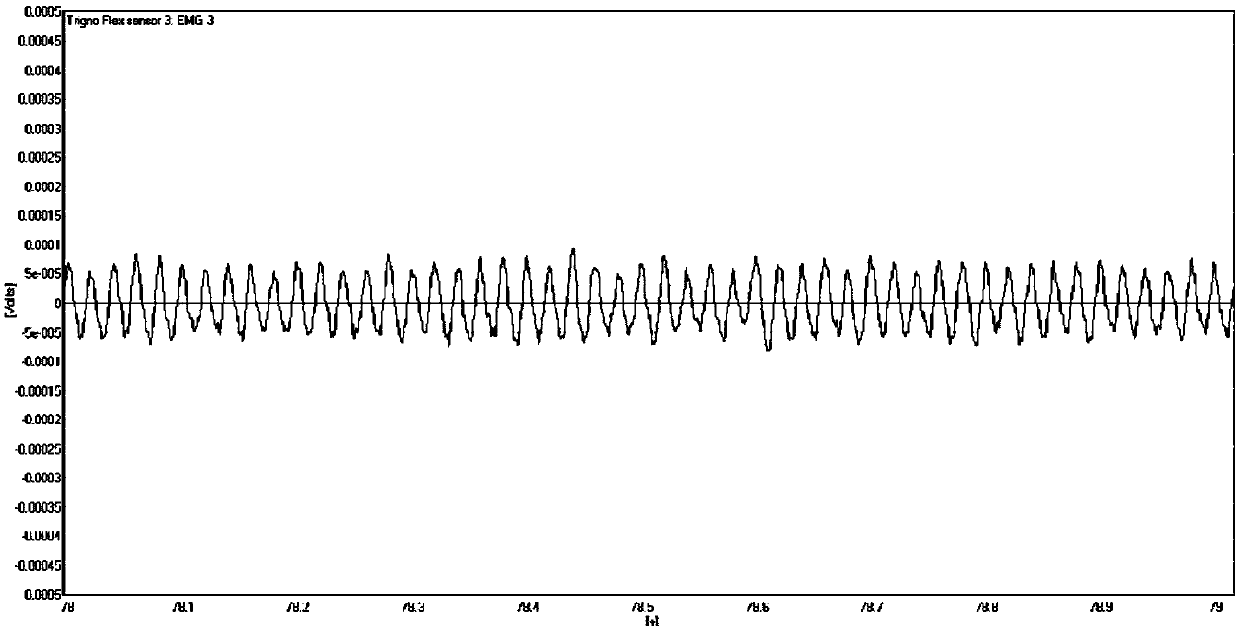

InactiveCN109645962AAvoid secondary damageApplicable to a wide range of groupsDiagnostic recording/measuringSensorsPhysical medicine and rehabilitationOver training

The invention discloses a robot-assisted rehabilitation human-machine cooperation training method based on fatigue sensing. The method comprises the following steps that myoelectricity data of an affected side of a patient is collected in a normal state and in a fatigue state respectively; the collected myoelectricity data is subjected to feature selection; according to different myoelectricity signals in the normal and fatigue states, whether the patient is in the fatigue state or not is accurately judged; through a judged result, rehabilitation training modes are intelligent switched. By means of the robot-assisted rehabilitation human-machine cooperation training method, the fatigue of the apoplectic patient can be sensed in the rehabilitation training process, in the active rehabilitation training process of the patient, the fatigue state of the patient can be detected, after it is detected that the patient is in the fatigue state, active training is intelligently switched into passive training, and therefore, secondary injury brought by over training of the patient is avoided.

Owner:NANJING UNIV OF POSTS & TELECOMM

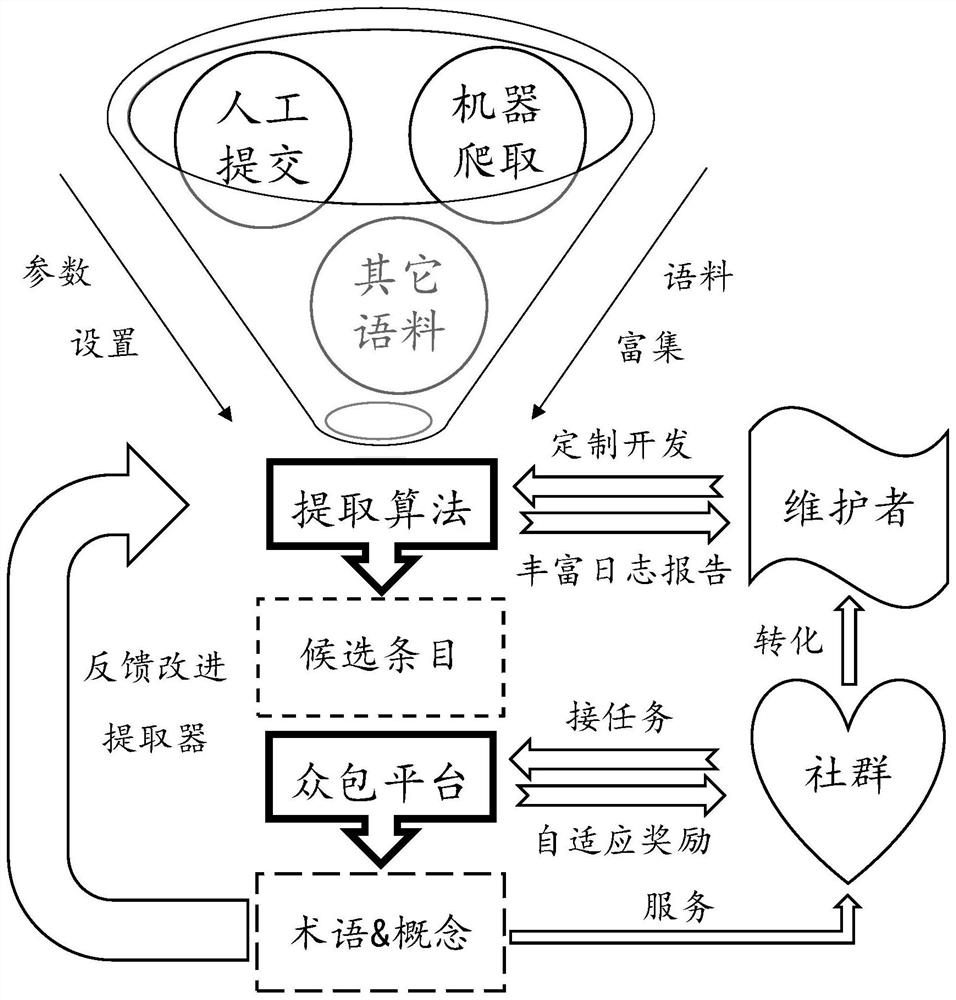

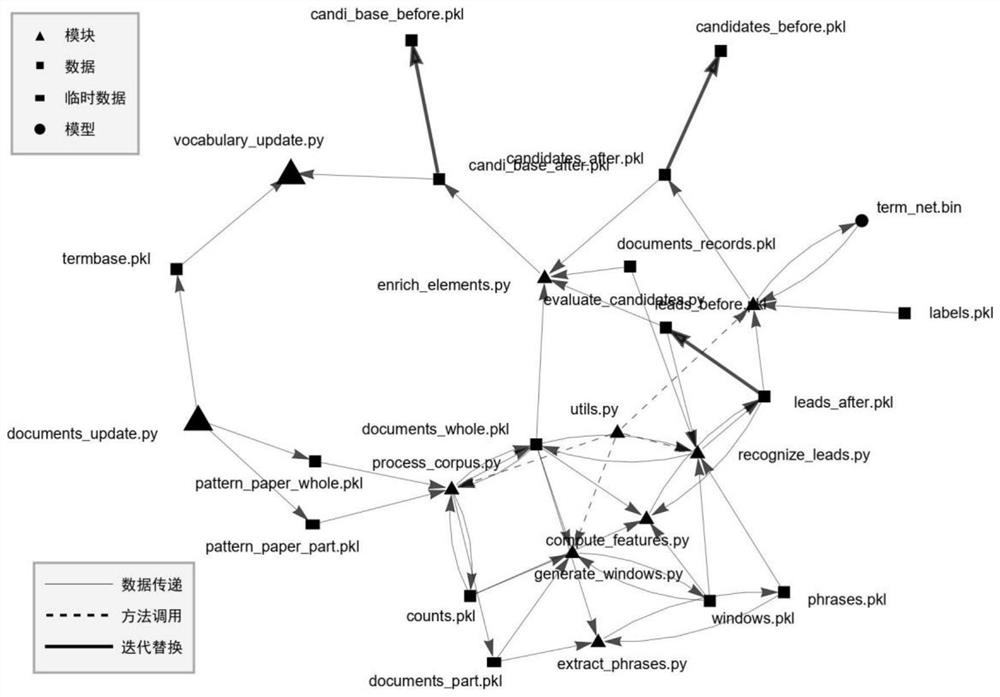

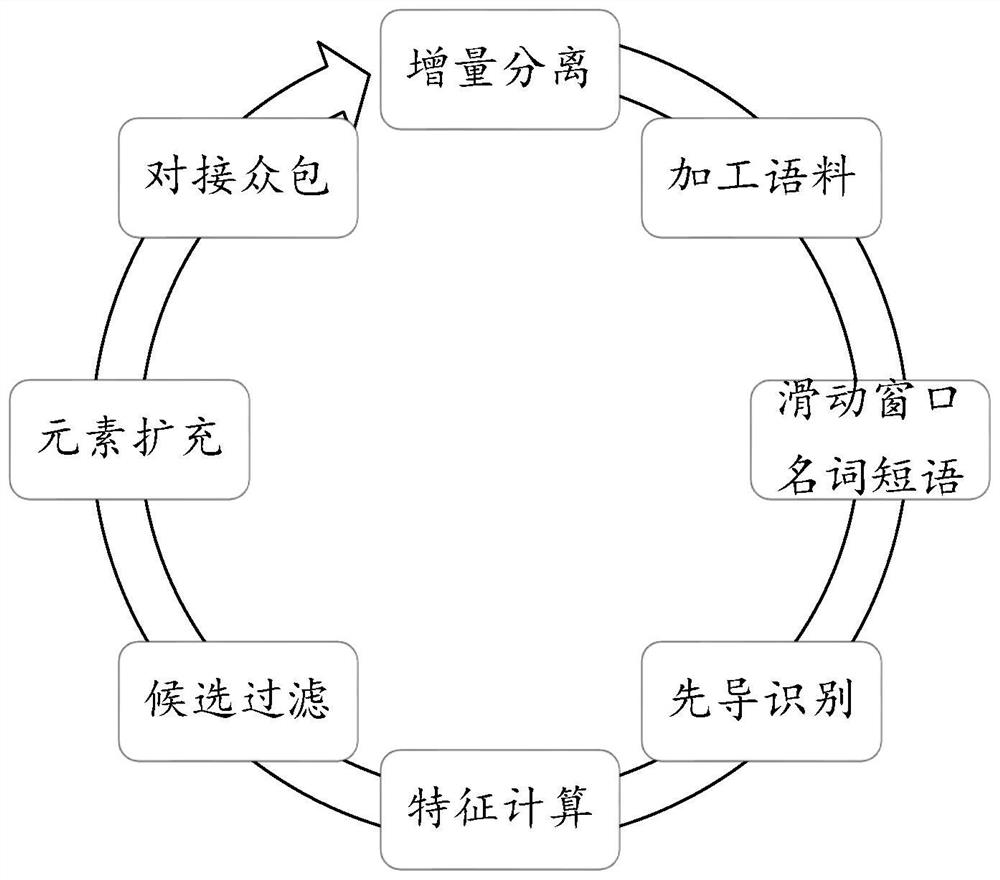

Man-machine cooperation system and method for dynamically maintaining high-quality science and technology concept library

PendingCN114462602AReduce maintenance costsIncrease diversityNatural language data processingKnowledge representationMan machineEngineering

The invention discloses a man-machine cooperation system for dynamically maintaining a high-quality science and technology concept library, and designs a complete science and technology concept library maintenance framework based on incremental operation and man-machine cooperation on the basis of an automatic term extraction (ATE) algorithm TERMATE with excellent performance and aiming at the contradiction and pain point of fast science and technology concept updating and long time consumption of an excellent algorithm. And finally, an online closed-loop corpus utilization system is realized on the basis. In the system, a customized extraction algorithm is used for carrying out organic integrated ATE on inrush corpora so as to enrich term candidates and report logs; the crowdsourcing platform for collecting crowdsourcing confirms and perfects the candidates to obtain terms and concepts and perform self-adaptive settlement rewards; the acknowledged candidate will in turn gain ATE performance. The whole system is named as ConceptEST or the most concept, machine intelligence and group intelligence are seamlessly integrated, high-quality science and technology knowledge is enriched, and field term and concept management is facilitated, so that concerned field changes can be followed with low cost and high efficiency, and convenience is brought to field practitioners.

Owner:集智学园(北京)科技有限公司

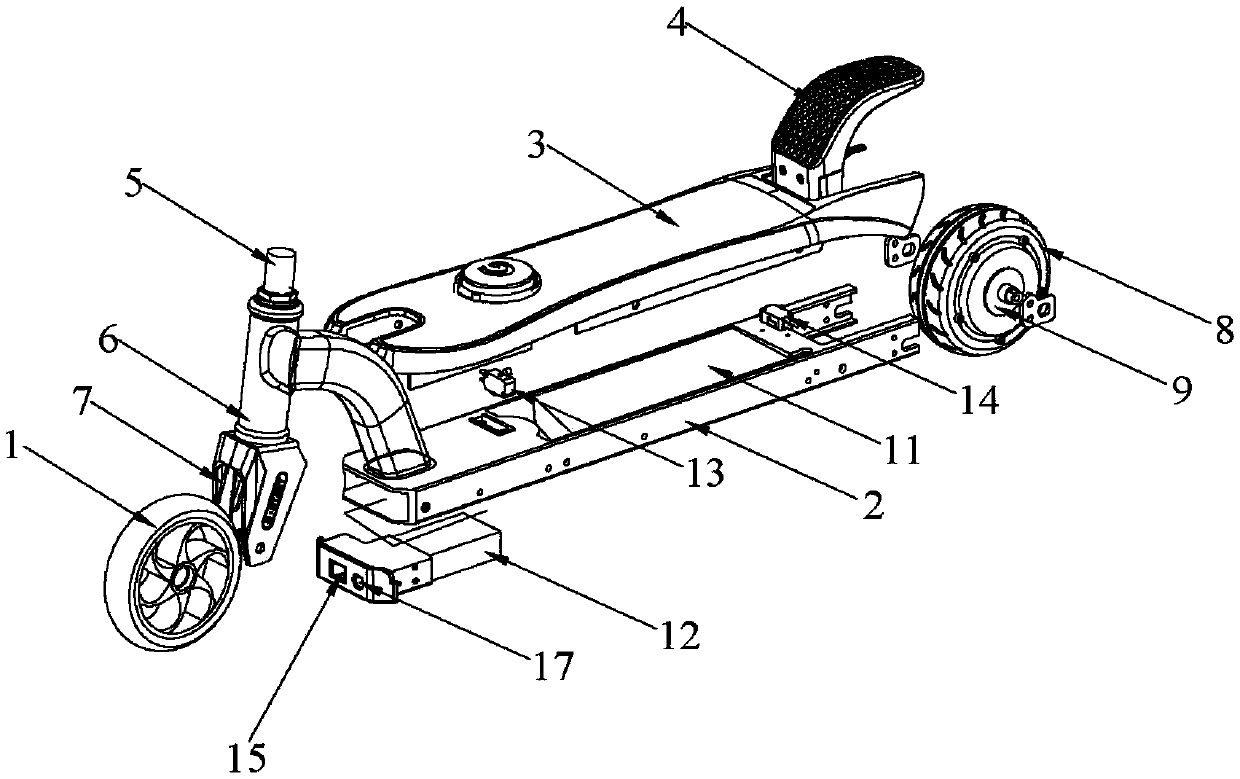

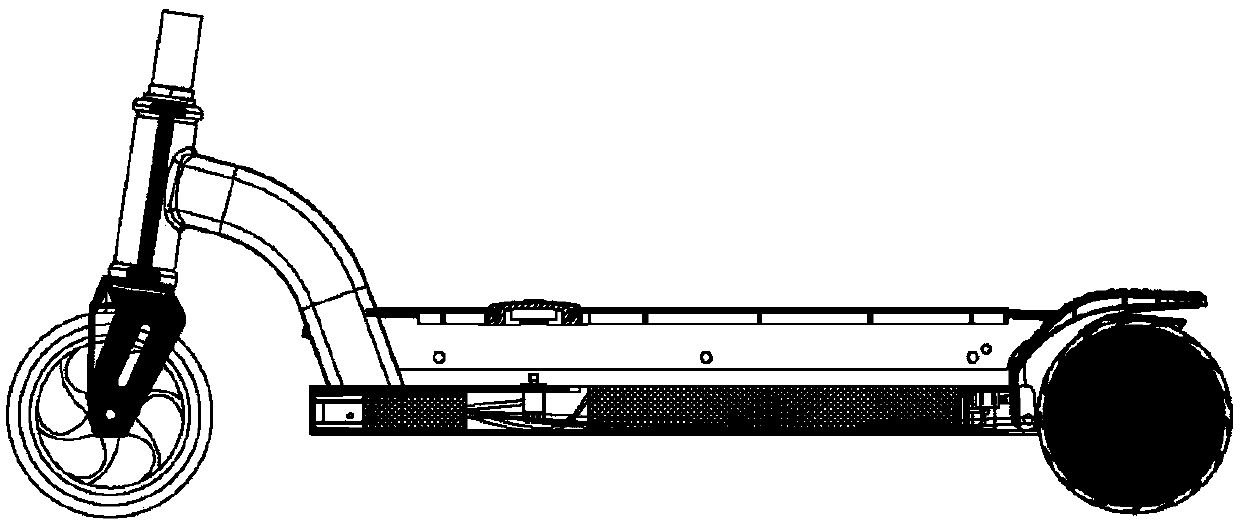

Sliding electric bicycle

PendingCN109665049ASpeed up the boot processImprove efficiencyMotorcyclesRider propulsionControl switchHuman machine cooperation

The invention discloses a sliding electric bicycle. The sliding electric bicycle comprises a sliding bicycle body consisting of a front wheel rack, a front wheel device, a pedal rack, a pedal, a rearwheel device and a brake device, wherein the front wheel rack comprises a rudder lever, a bicycle head tube, and a front wheel fork, the front wheel device is connected onto the front wheel fork, thefront of the pedal rack is connected with the bicycle head tube, the back of the pedal rack is connected with the rear wheel device, the top of the pedal rack supports and connects with the pedal, thefront of the brake device is connected with the rear end of the pedal, the rear section of the brake device covers above the rear wheel device, the rear wheel device comprises a rear wheel and a wheel core motor and is connected and fixed on the rear wheel rack through the wheel core motor, the sliding bicycle body is further provided with a battery device and a sense control switch device that are connected electrically, the sense control switch device comprises a controller and a sensor arranged below the pedal, the controller is provided with a monitor and an electric appliance, the sensecontrol switch device further comprises a brake switch arranged at the corresponding position of the brake device, and the controller is further provided with a general switch controlling the batterydevice to supply power. The sliding electric bicycle can be driven intelligently through human-machine cooperation, can be started and stopped efficiently, and can be better controlled.

Owner:柳建曙

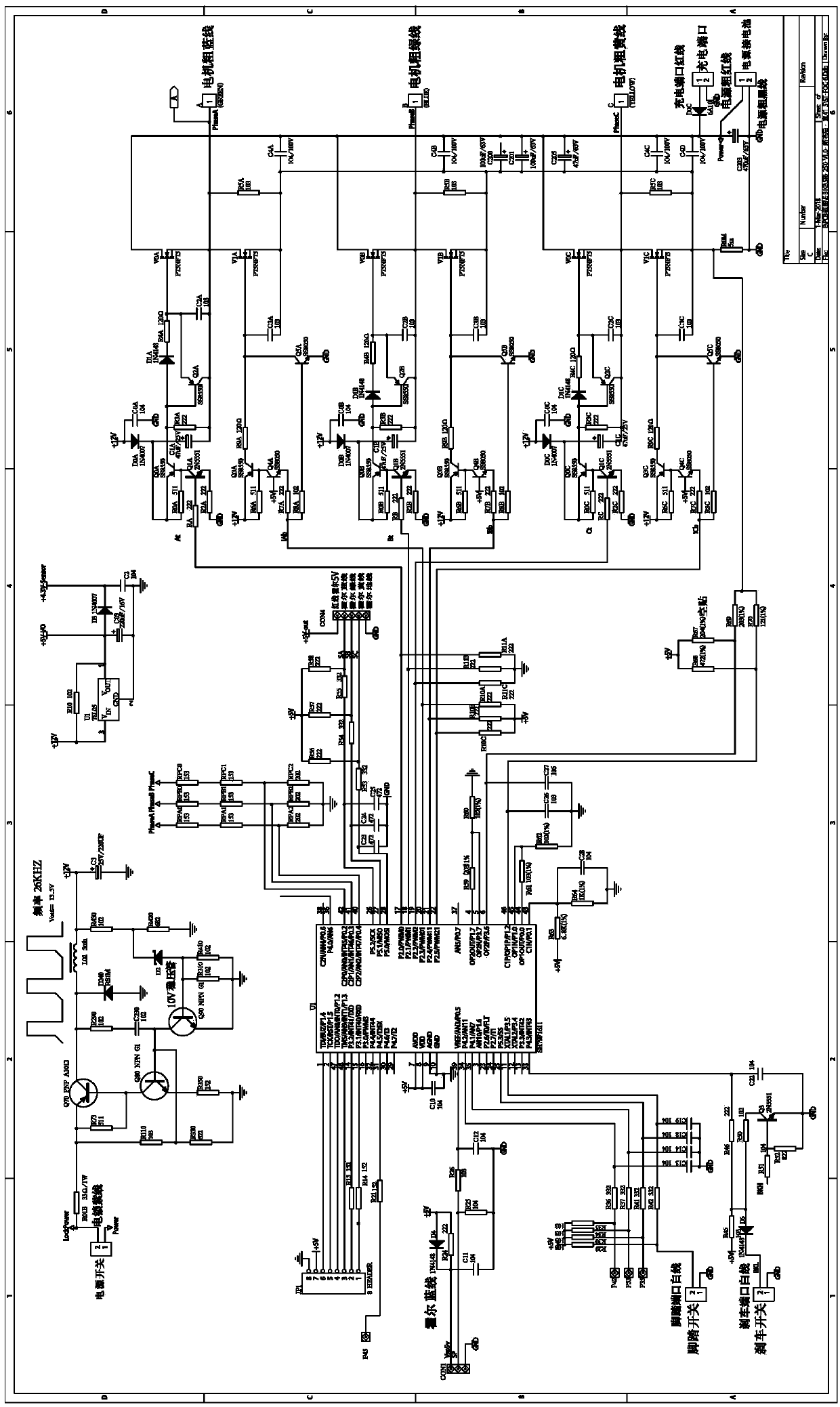

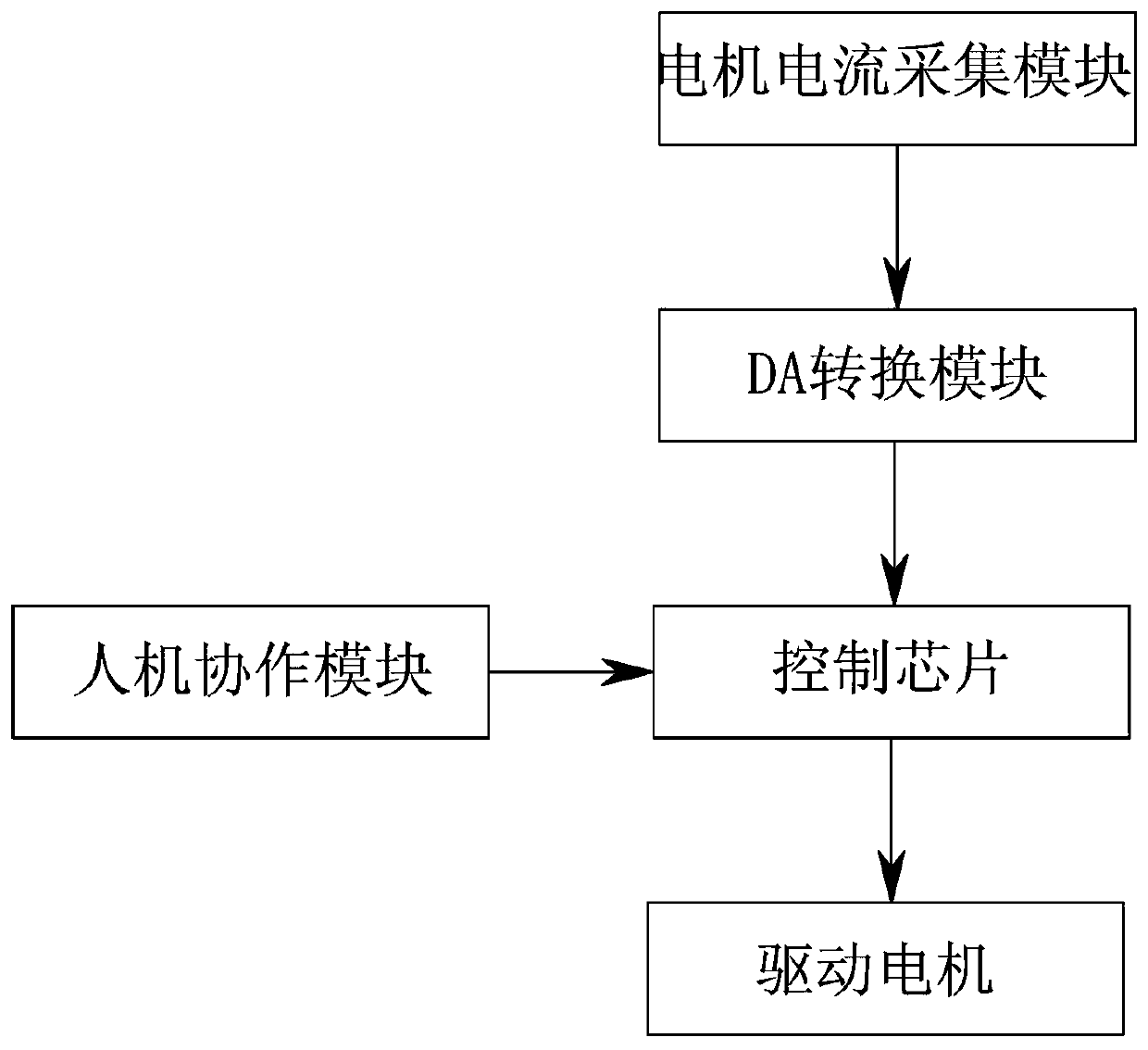

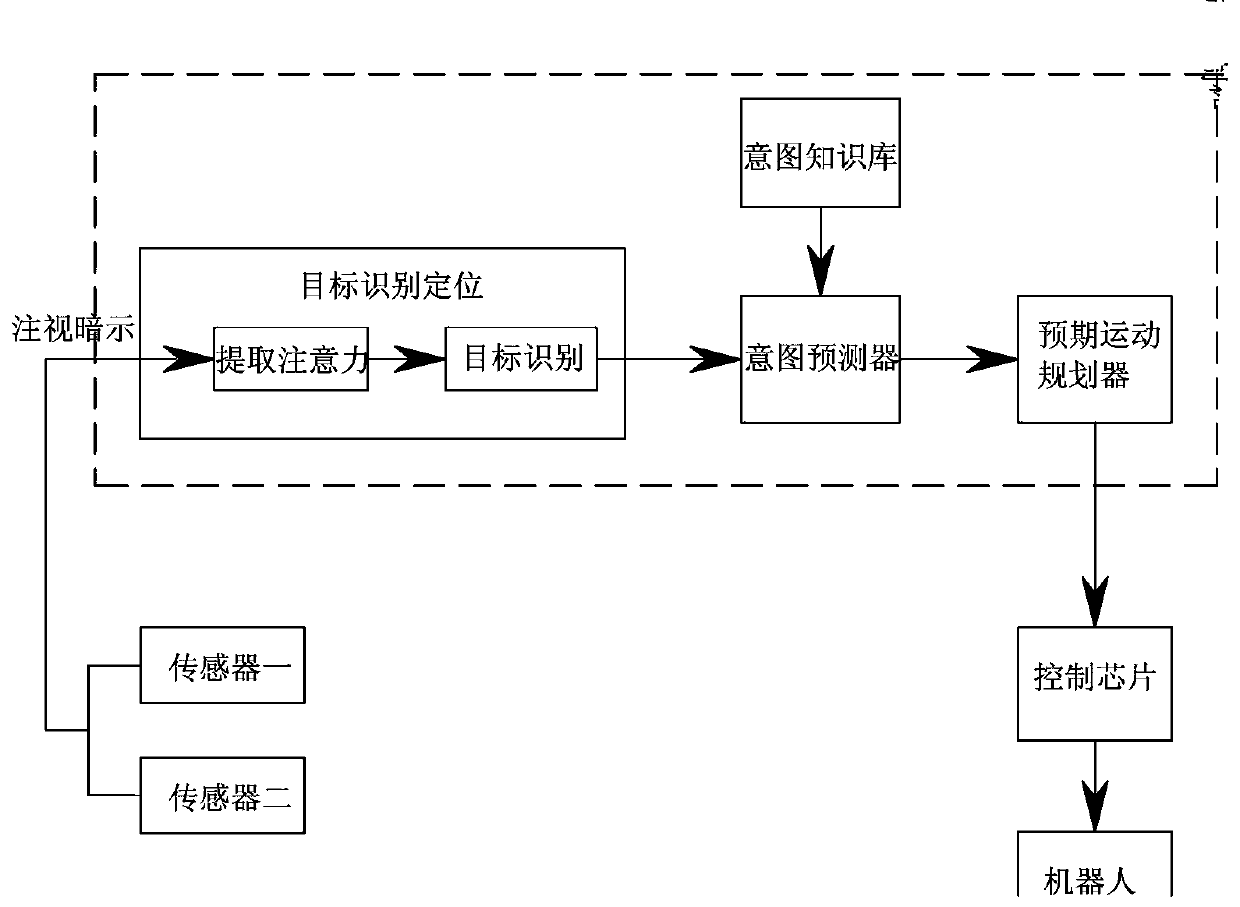

Man-machine cooperation industrial robot drive-control integrated system

ActiveCN110497408AImprove securityHigh precisionProgramme-controlled manipulatorTotal factory controlElectric machineryMan machine

The invention discloses a man-machine cooperation industrial robot drive-control integrated system. The man-machine cooperation industrial robot drive-control integrated system comprises a motor current collecting module, a DA conversion module, a control chip, a driving motor and a man-machine cooperation module. The output end of the motor current collecting module is electrically connected withthe input end of the DA conversion module, and the output end of the DA conversion module and the output end of the human-computer cooperation module are electrically connected with the input end ofthe control chip, and the output end of the control chip is electrically connected with the input end of the driving motor. The man-machine cooperation module comprises a sensor 1, a sensor 2, a target recognition positioning module, an intention predictor, an intention knowledge base and an expected motion planner. The invention improves the safety of robot through setting the motor current collecting module, the DA conversion module, the control chip, the driving motor and the man-machine cooperation module, and can realized the human-machine cooperation; and the operator can work with an industrial robot, and can drag the robot for teaching.

Owner:SHENZHEN HUAZHONG NUMERICAL CONTROL

Lower limb exoskeleton rehabilitation system and method based on human-machine cooperation

ActiveCN106110587BIncrease engagementAchieving an Active Rehabilitation ModelGymnastic exercisingChiropractic devicesRecovery methodEngineering

The invention provides a lower extremity exoskeleton recovery system and a lower extremity exoskeleton recovery method based on human-machine cooperation. The system comprises an extremity structure module, an electromyographic signal acquisition module, an electromyographic signal processing module, a trace generation module, a position and speed feedback module, an adaptive control module and a motor torque output module, wherein the electromyographic signal acquisition module receives a signal from the extremity structure module and outputs the signal to the electromyographic signal processing module; the adaptive control module inputs a signal into the electromyographic signal processing module, the trace generation module and the position and speed feedback module, and outputs a signal to the motor torque output module; the position and speed feedback module acquires a signal from the electromyographic signal acquisition module; and the motor torque output module outputs a signal to the extremity structure module. The lower extremity exoskeleton recovery system is practicable; and due to a lower limb walking recovery training mode based on the human-machine cooperation, a paralyzed patient can be greatly encouraged to participate in the recovery training, and the recovery effect is expected to be enhanced.

Owner:SHANGHAI JIAO TONG UNIV

Man-machine game control method and system for upper limb wearable robot

ActiveCN112247962BSatisfy control scenariosSolve the singularityProgramme-controlled manipulatorMathematical modelUser input

The present invention provides a man-machine game control method and system for an upper-limb wearable robot, which decomposes the complex or multi-process tasks jointly completed by the user and the robot into a plurality of basic tasks, and establishes the human-machine capability matrix and Task matching matrix for task assignment. Input the results of task assignment into the man-machine zero-sum or non-zero-sum game mathematical model based on game theory, calculate the optimal stiffness of the robot at the end of the man-machine match, and then calculate the reference trajectory of the robot end through the robot impedance model, and finally The control torque is output by the adaptive controller to realize the reference trajectory tracking. The control method of the upper limb wearable robot of the present invention can realize better compliant control in the context of human-machine cooperation, sense the user's movement intention, and minimize the user's input force.

Owner:UNIV OF SCI & TECH OF CHINA

A Method of Cleaning and Grinding Large Castings Based on Human-Machine Collaboration

ActiveCN108789026BOvercome limitationsSolve the difficulties faced by manual workProgramme-controlled manipulatorGrinding machinesMan machineHuman machine cooperation

The invention discloses a heavy casting cleaning and polishing method based on man-machine collaboration. The heavy casting cleaning and polishing method is characterized in that a heavy casting is divided into a plurality of units to be polished; the size of each unit is less than a working range of an adopted robot; two adjacent units are overlapped slightly; and after the robot polishes one unit, the heavy casting is moved or the robot polishes the adjacent unit, and so on, till the polishing of the entire heavy casting is completed. The heavy casting cleaning and polishing method overcomesdilemma confronted by manual operation and avoids limitation from a programming mode adopted by an industrial robot. By establishing a robot demonstration platform for trajectory emulation and on-site operation testing, the results show that a demonstration system is stable in performance and accurate in trajectory tracking and has a favorable demonstration function, and a novel solution is provided for heavy casting cleaning and polishing.

Owner:WUHAN TEXTILE UNIV

An online detection method of workpiece pose based on kinect and 3D laser cooperation

ActiveCN106842216BSmall sizeAccurate locationUsing optical meansElectromagnetic wave reradiationInteraction systemsLaser ranging

The invention discloses a workpiece position-pose on-line detection method based on the cooperation of a Kinect sensor and a three-dimensional laser distance measuring system, and is applied in the technical field of sensing workpiece positions and poses through human-machine cooperation and interaction systems and industrial robots. According to the method, cooperative work between the Kinect sensor and the three-dimensional laser distance measuring system is adopted to collect data; through three parts of preprocessing on obtained point clouds, associated calibration between the Kinect sensor and the three-dimensional laser distance measuring system and the on-line detection of the Kinect sensor and the three-dimensional laser distance measuring system, the problems are solved that the point clouds of the Kinect sensor are sparse, the data accuracy is insufficient and the accuracy and scanning speed of the three-dimensional laser distance measuring system have contradictory relations; the industrial robots can more efficiently and accurately acquire the accurate size information and position-pose information of workpieces, and the accuracy and working efficiency are improved. The method can be applied in the artificial intelligence fields of the understanding of the industrial robots on the working environment and the like.

Owner:DALIAN UNIV OF TECH

Robot remote control welding system and method used for remote welding

InactiveCN101791750BVersatilityReduce workloadWelding/cutting auxillary devicesAuxillary welding devicesHuman–machine interfaceWelding power supply

The invention relates to a robot remote control welding system and a method used for remote welding, which relate to a robot remote control welding system and a method. The invention has the goal of solving the problems that in the existing remote control welding process, the real-time requirement of the welding process is high, the adaptability of the autonomous control remote control welding is low, the visual feedback of the remote welding is poor, and the system universality on welding tasks is low. The system has the technical scheme that a center monitoring human-machine interface is connected with a robot controller, and the robot controller is respectively connected with a laser visual controller, a robot and a welding power supply. The method has the technical scheme that a binocular camera transmits a welding environment image to a three-dimensional visual display, operators obtain the deep information of the remote end environment and guide a welding gun to move to the welding seam starting position, and four work modes: the direct control work mode, the remote control teaching work mode, the laser visual display tracking work mode or the human-machine cooperation sharing control work mode can be respectively adopted for completing the remote control welding. The invention is used for robot remote control welding.

Owner:HARBIN INST OF TECH

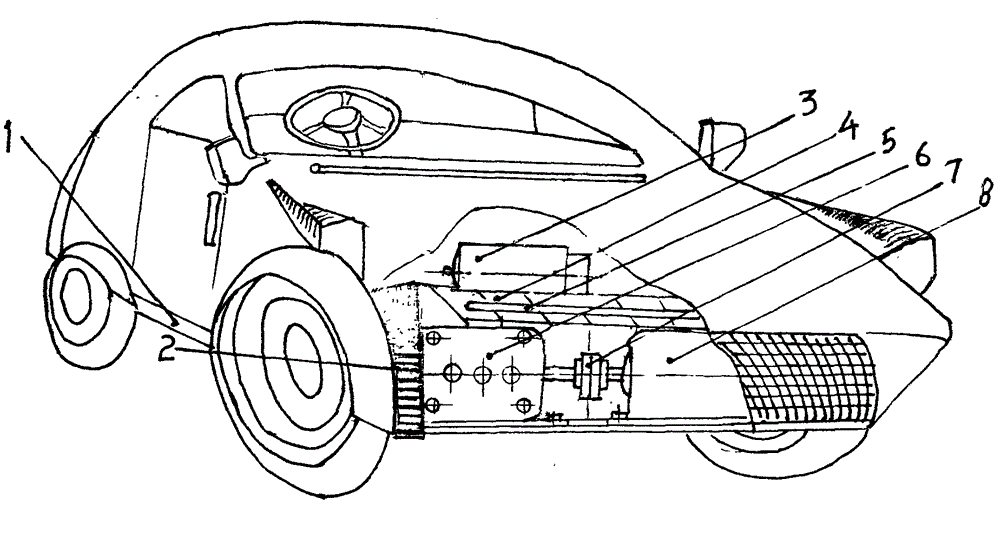

Innovative intelligently-controlled electromobile capable of self-producing and self-supplying electricity

The invention discloses an innovative intelligently-controlled electromobile capable of self-producing and self-supplying electricity. The electromobile is characterized in that the electricity can be self-produced and self-supplied, and the electromobile is intelligently controlled. A power source of the electromobile is arranged on a drive wheel shaft on one side below a chassis, wherein a large chain wheel is fixed on the drive wheel shaft; the large chain wheel is in linkage transmission with a small chain wheel on a drive gear shaft of a speed changing box arranged in an electromobile head; the speed changing box links two generators and is provided with a generator connecting plate; when the electromobile starts, the two generators subjected to speed changing rotates at high speed to generate strong current, and the current is automatically input into a storage battery after being subjected to inversion, voltage transformation and voltage stabilization through an intelligent control center, so that the electromobile can be charged and discharged synchronously during running, and the running distance is increased; the intelligent control center is formed by aggregating a plurality of groups of digital inputs and outputs, a plurality of groups of analog inputs and outputs, transmission software, advanced RISK machine (ARM) processor, a digital signal processor (DSP) motor controller, a liquid crystal display (LCD), global distribution system (GDS) navigation, controller area network (CAN) bus control and the like and public high technologies, so that various functions of the electromobile is intelligently controlled, human-machine cooperation is realized; and therefore, the electromobile is really innovative.

Owner:赵全文 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com