Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

172 results about "Discharge location" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

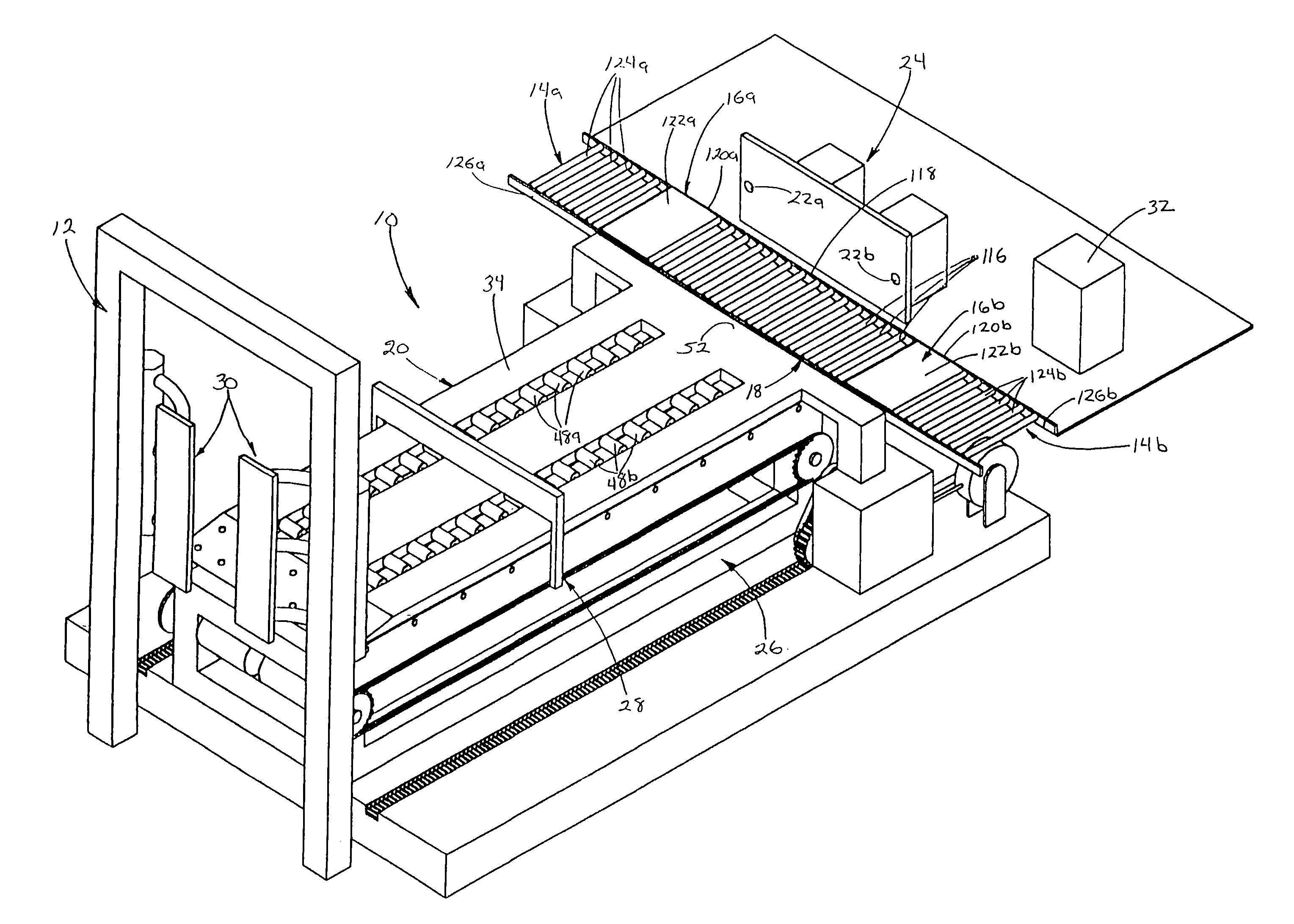

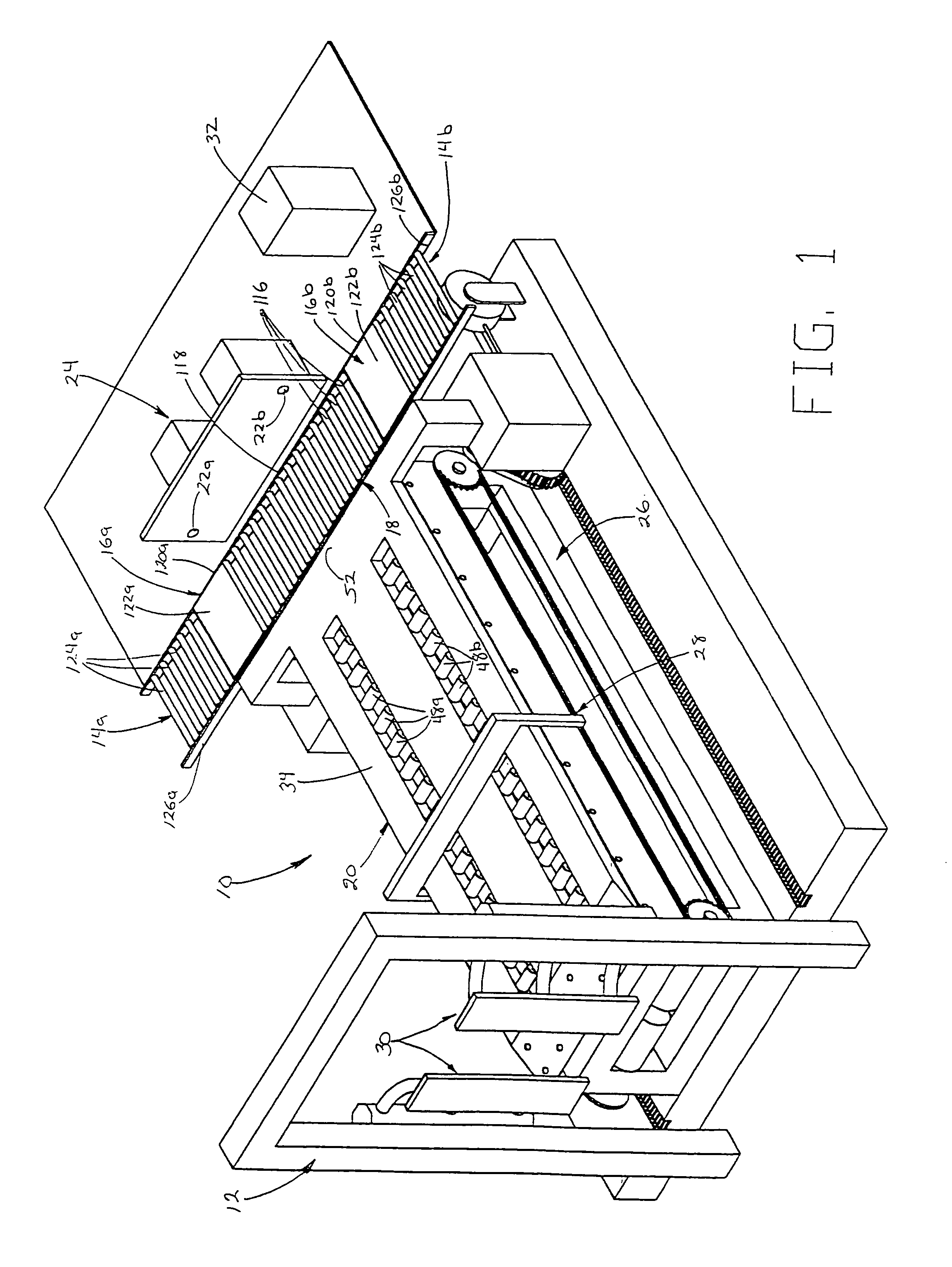

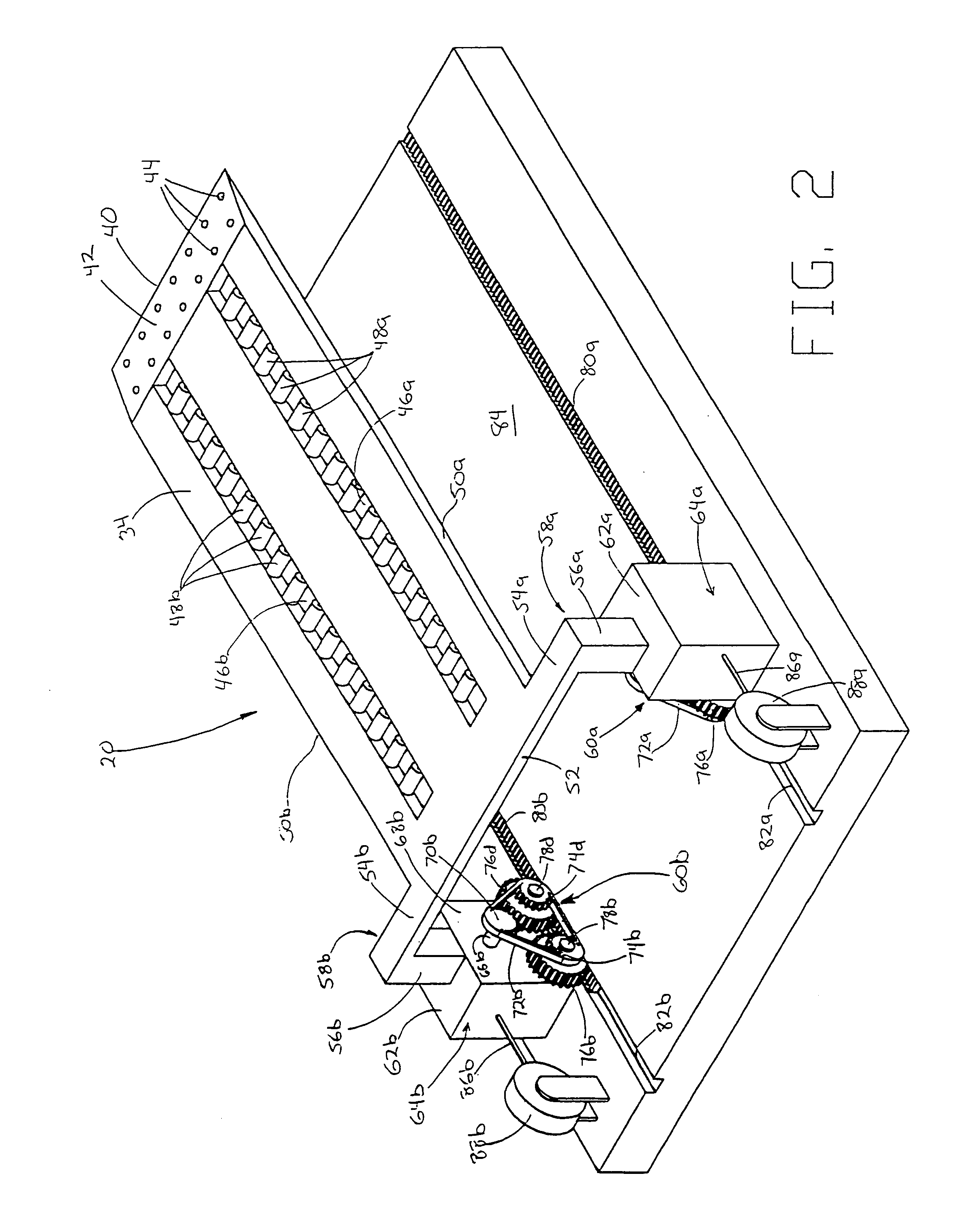

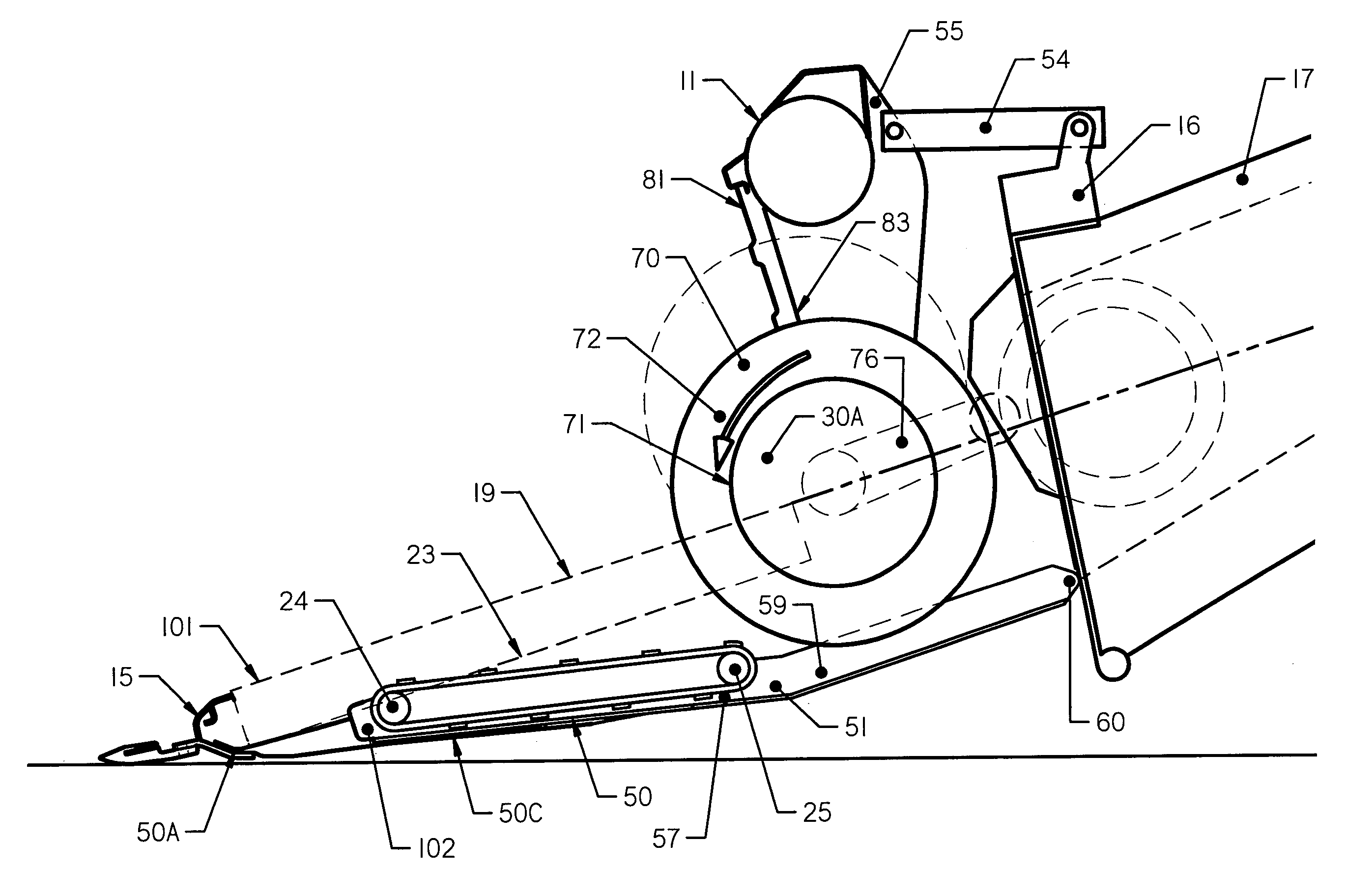

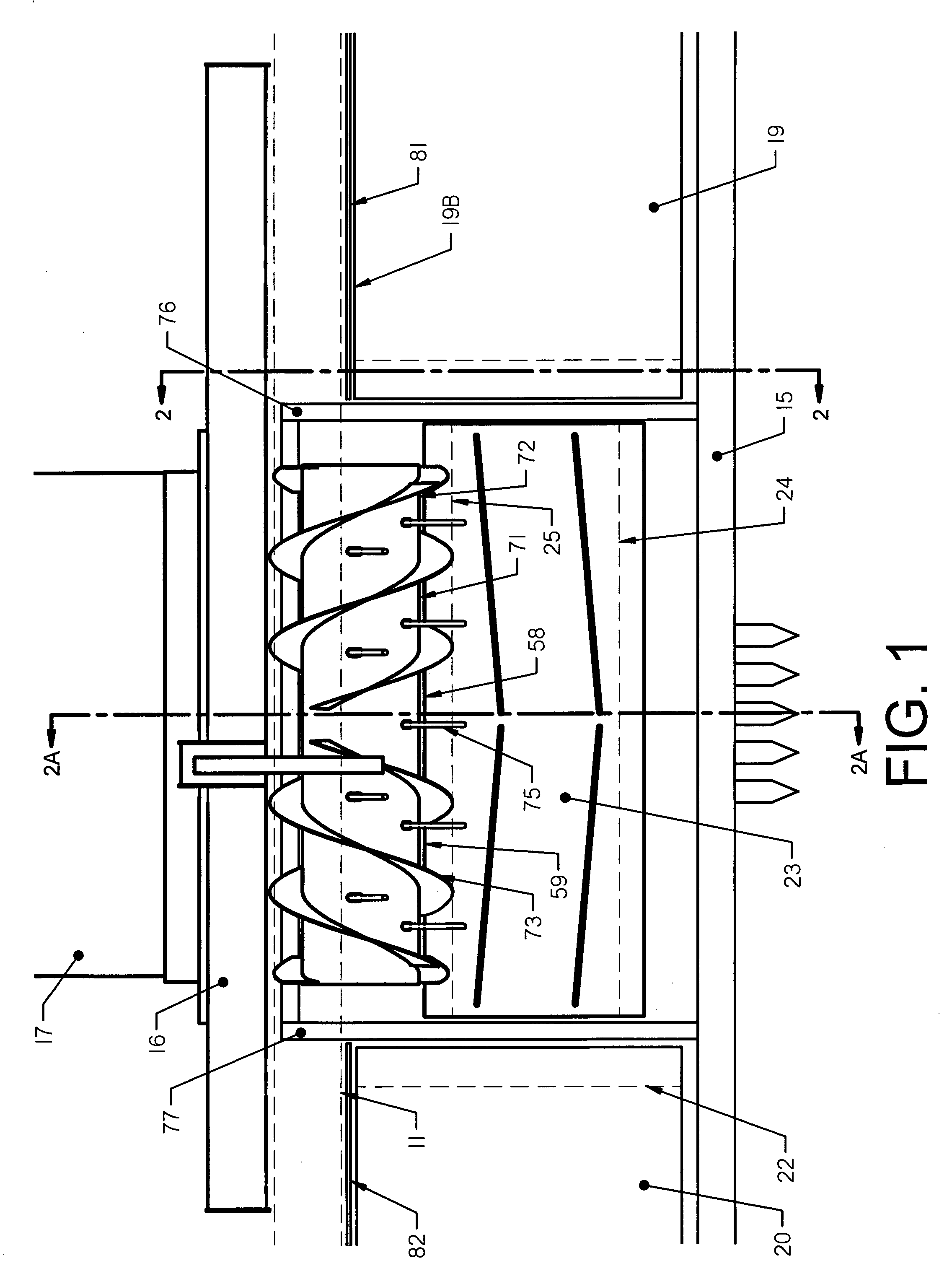

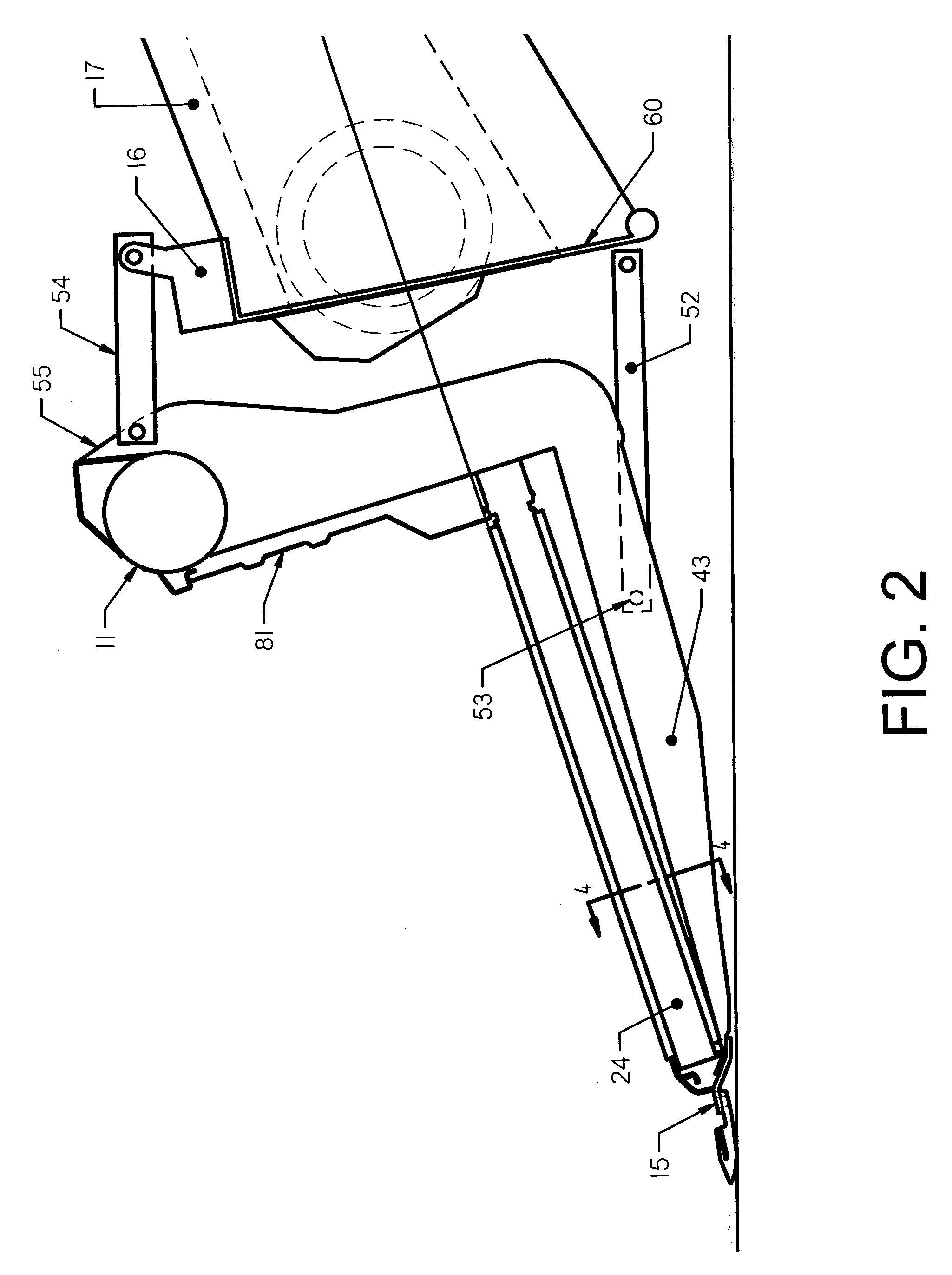

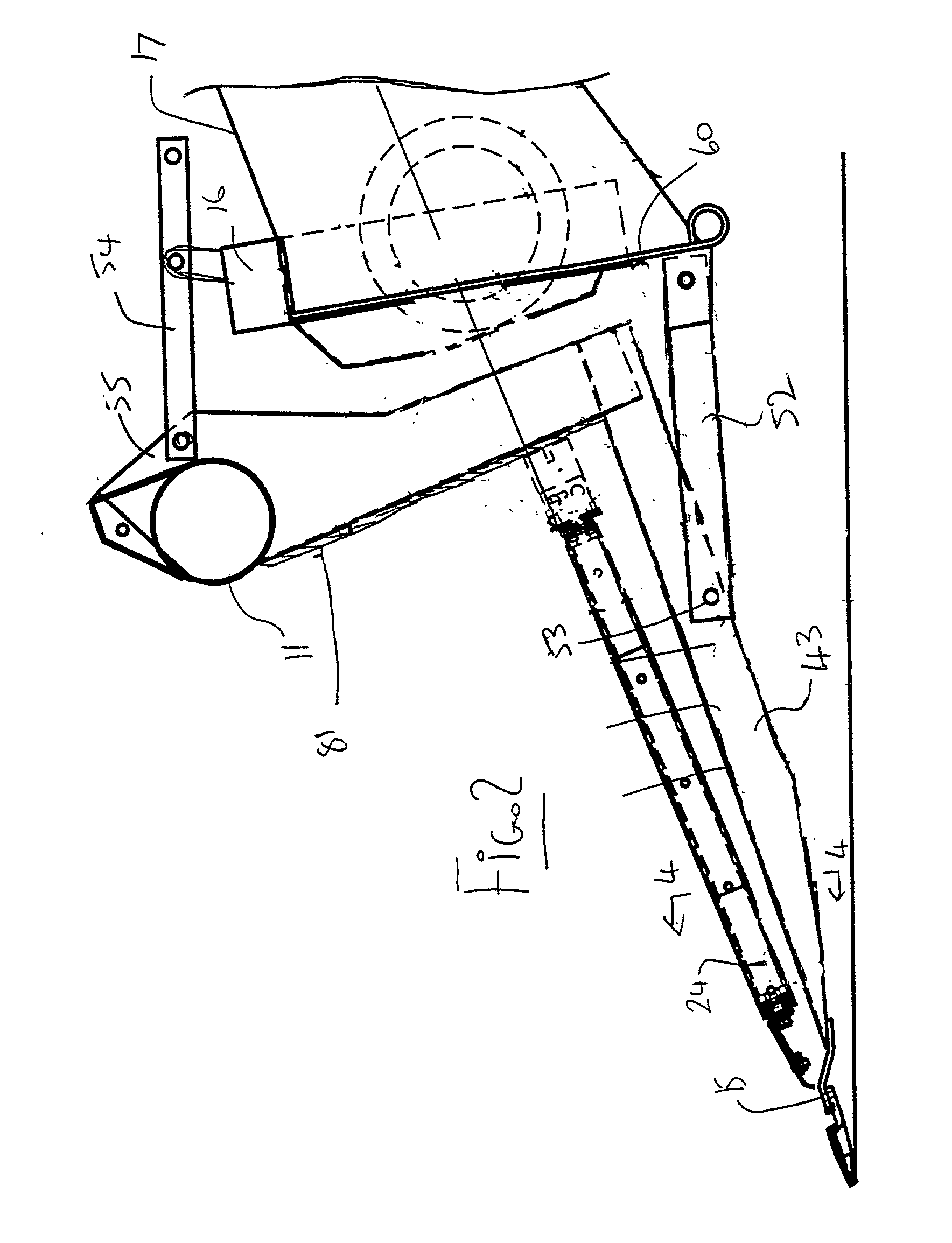

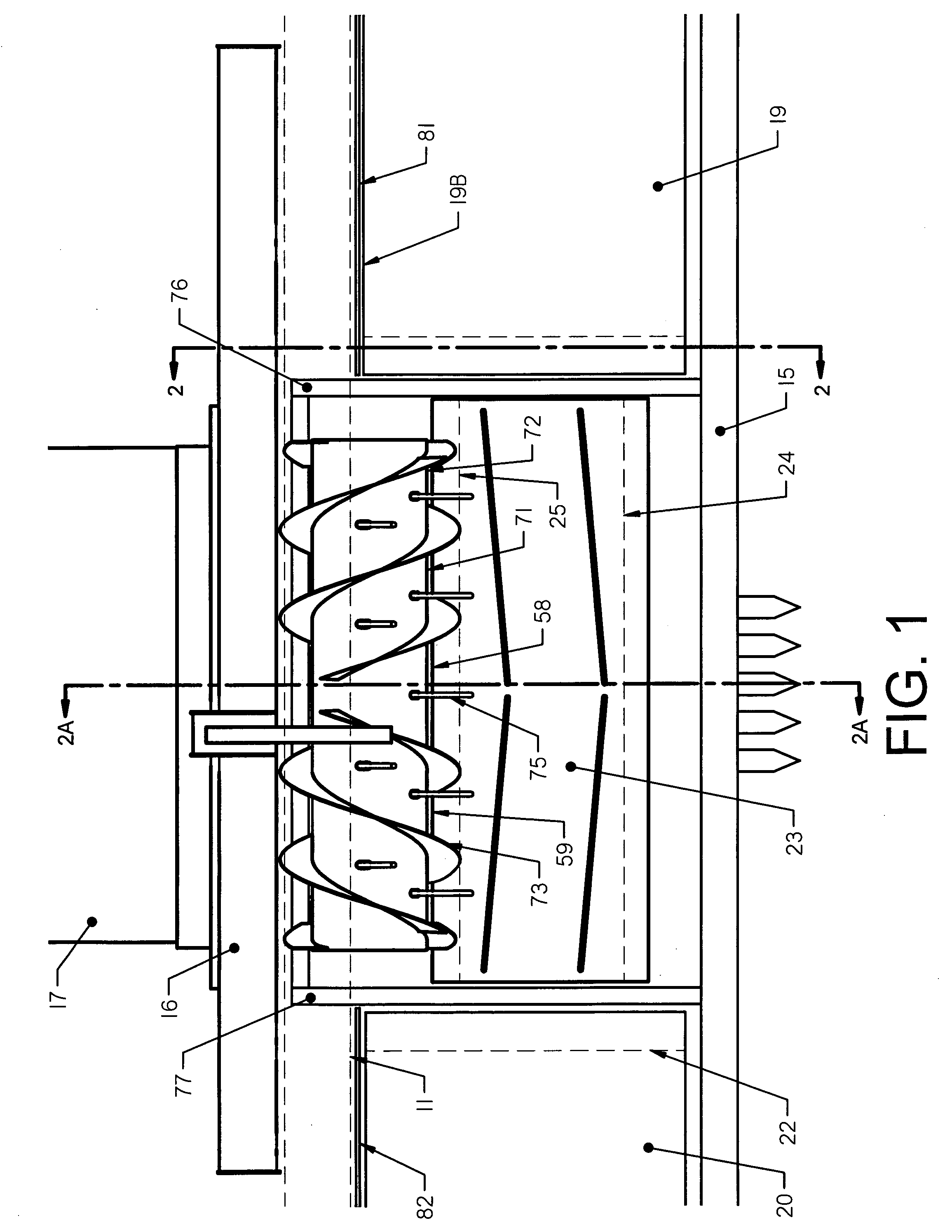

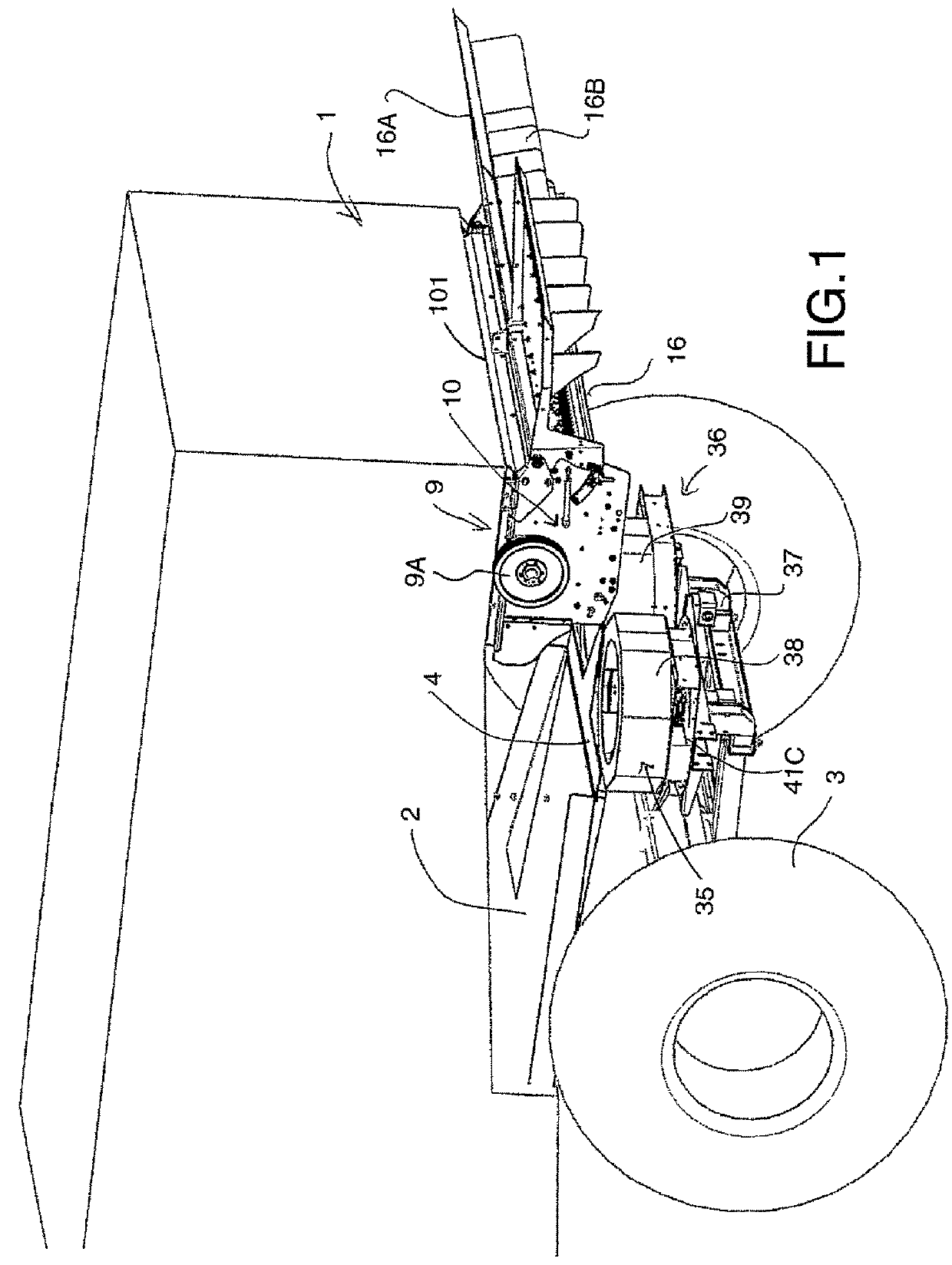

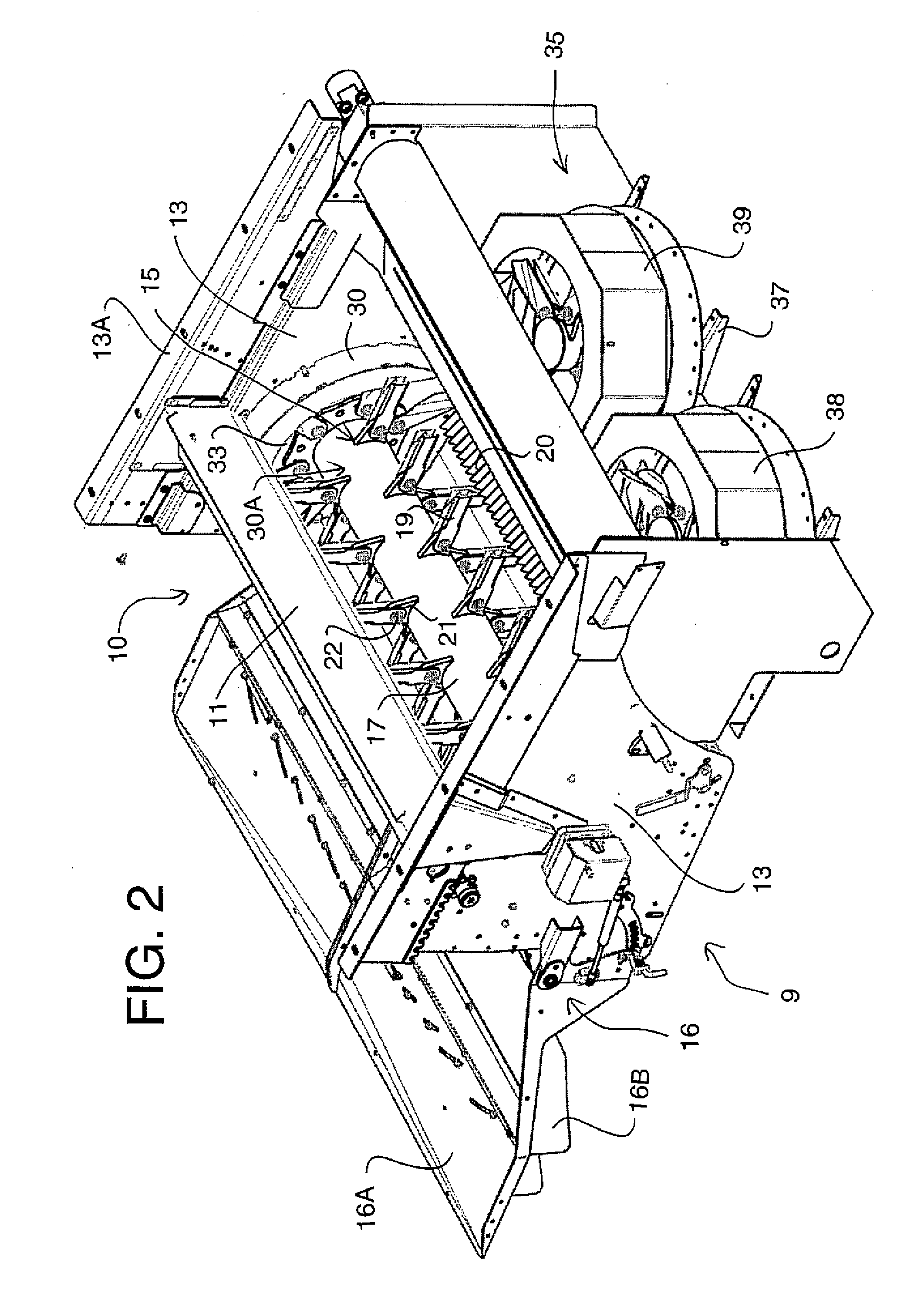

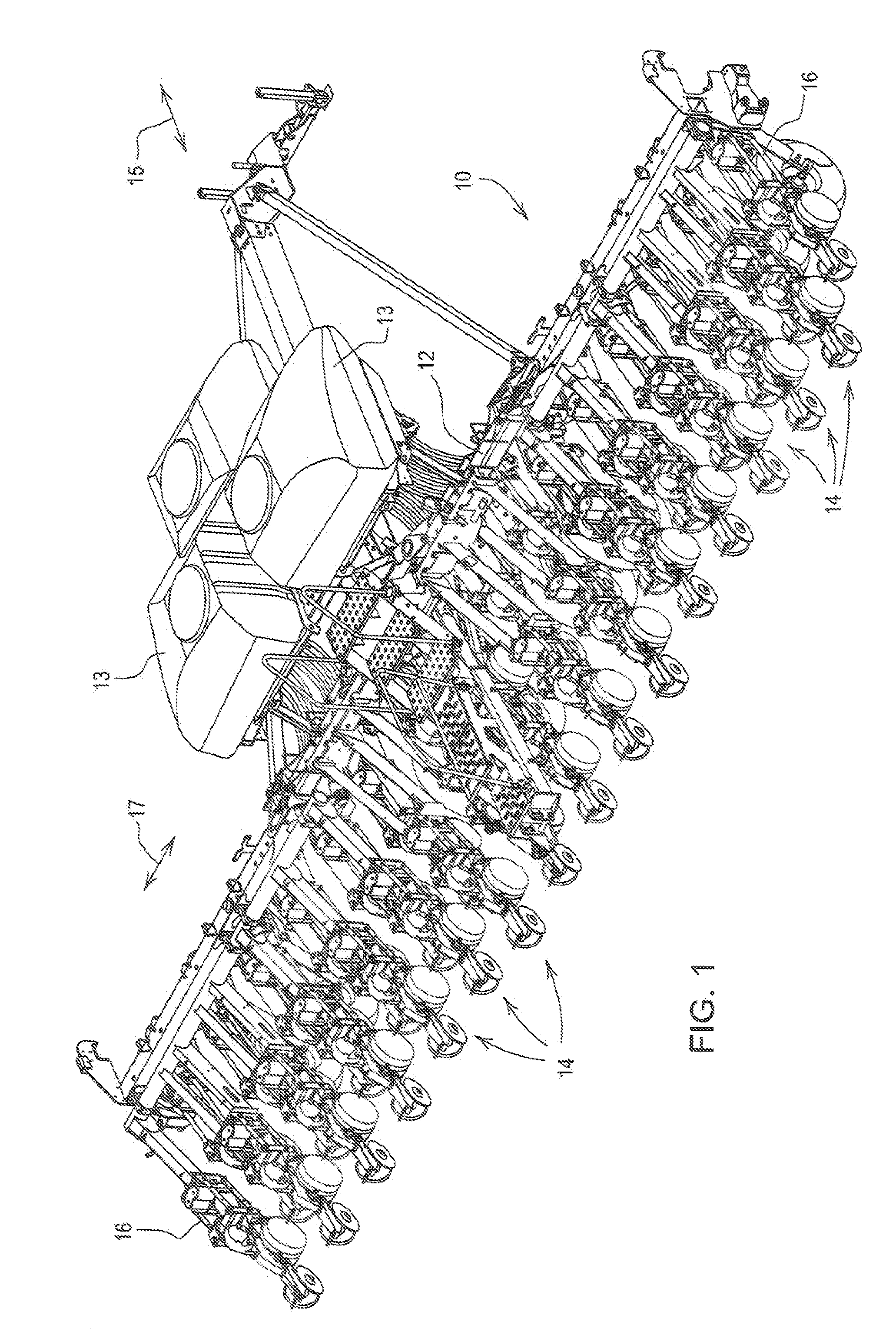

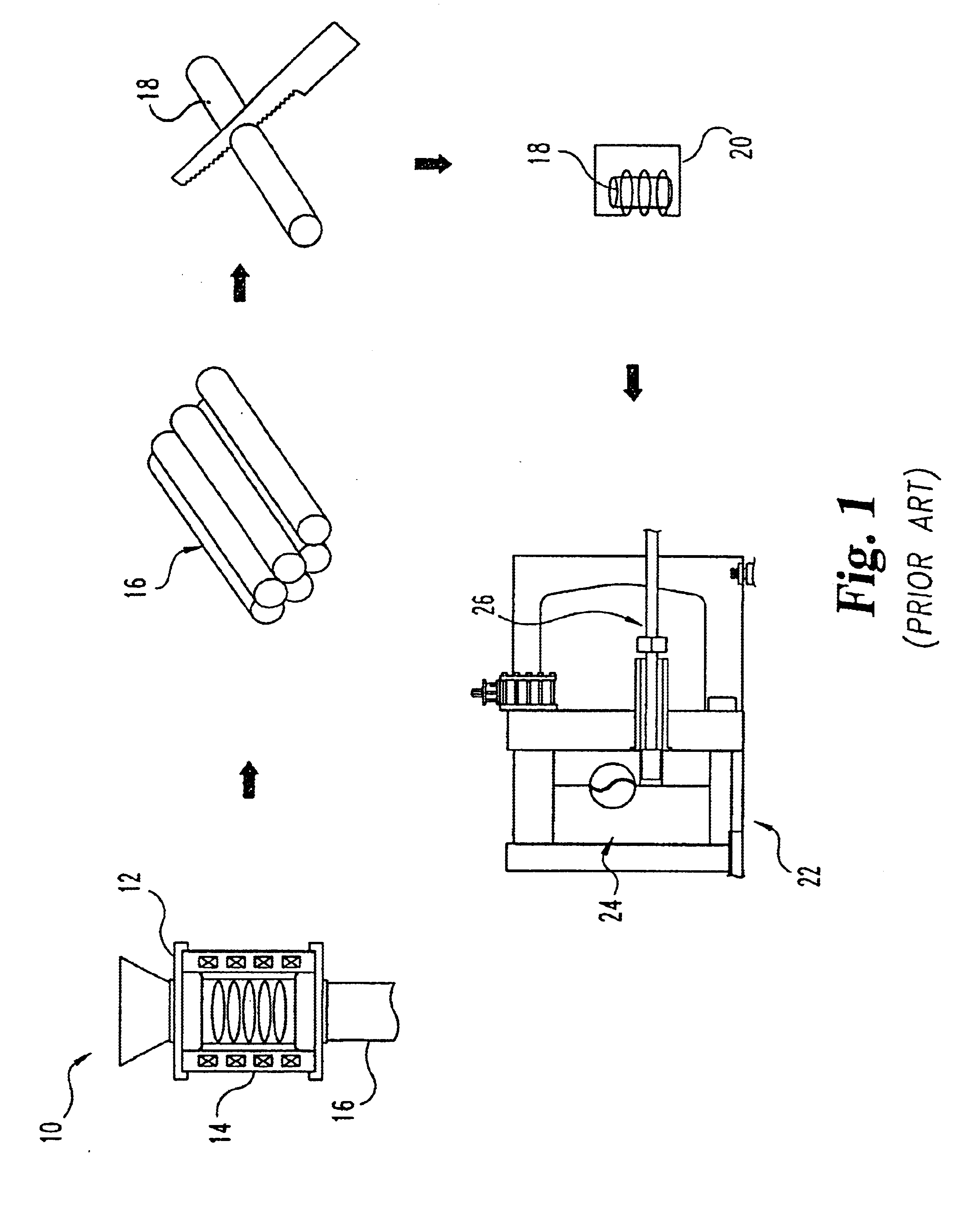

Automated warehousing and cargo loading system

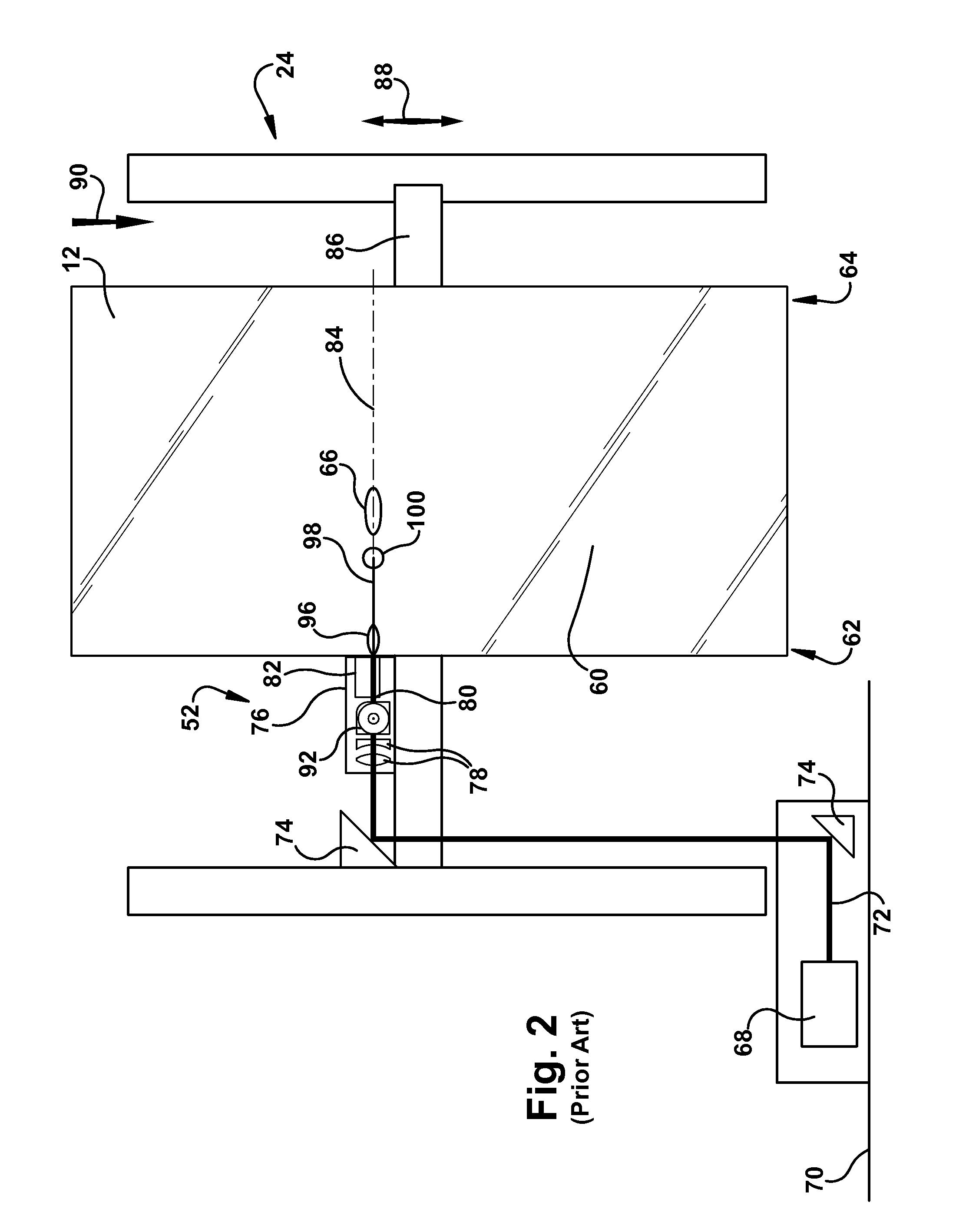

InactiveUS7695235B1Reduce operating costsImprove loading efficiencyLifting devicesRefuse transferringDischarge locationChassis

A warehousing system for palletized cargo, and an automated loading / unloading system for use with the same. The warehousing system includes a feed conveyer and a plurality of storage racks. A traveling conveyor carries the cargo from the feed conveyor to the individual racks, and from the racks to a loading / unloading conveyor which carries the cargo to the loading / unloading docks. The traveling conveyor rides on a wheeled chassis that is guided between the receiving and discharge locations on tracks. The storage racks are stackable in tiers, and the traveling conveyor has a deck that raises and lowers to be level therewith. The automated loading / unloading dock includes a rigid, extensible plate having an upper surface for supporting a load of palletized cargo, with a drive mechanism being mounted to the inner end of the plate to translate it in and out of the transport vehicle. The plate carries a load of palletized cargo into or out of the transport vehicle en masse. For loading, restraining doors hold the loaded cargo within the interior of the vehicle as the extensible dock is withdrawn. When unloading, a paddle is deployed above the upper surface of the lock member and is translated towards its inner end so as to push the cargo onto the loading / unloading conveyor.

Owner:RALLIS JOHN H

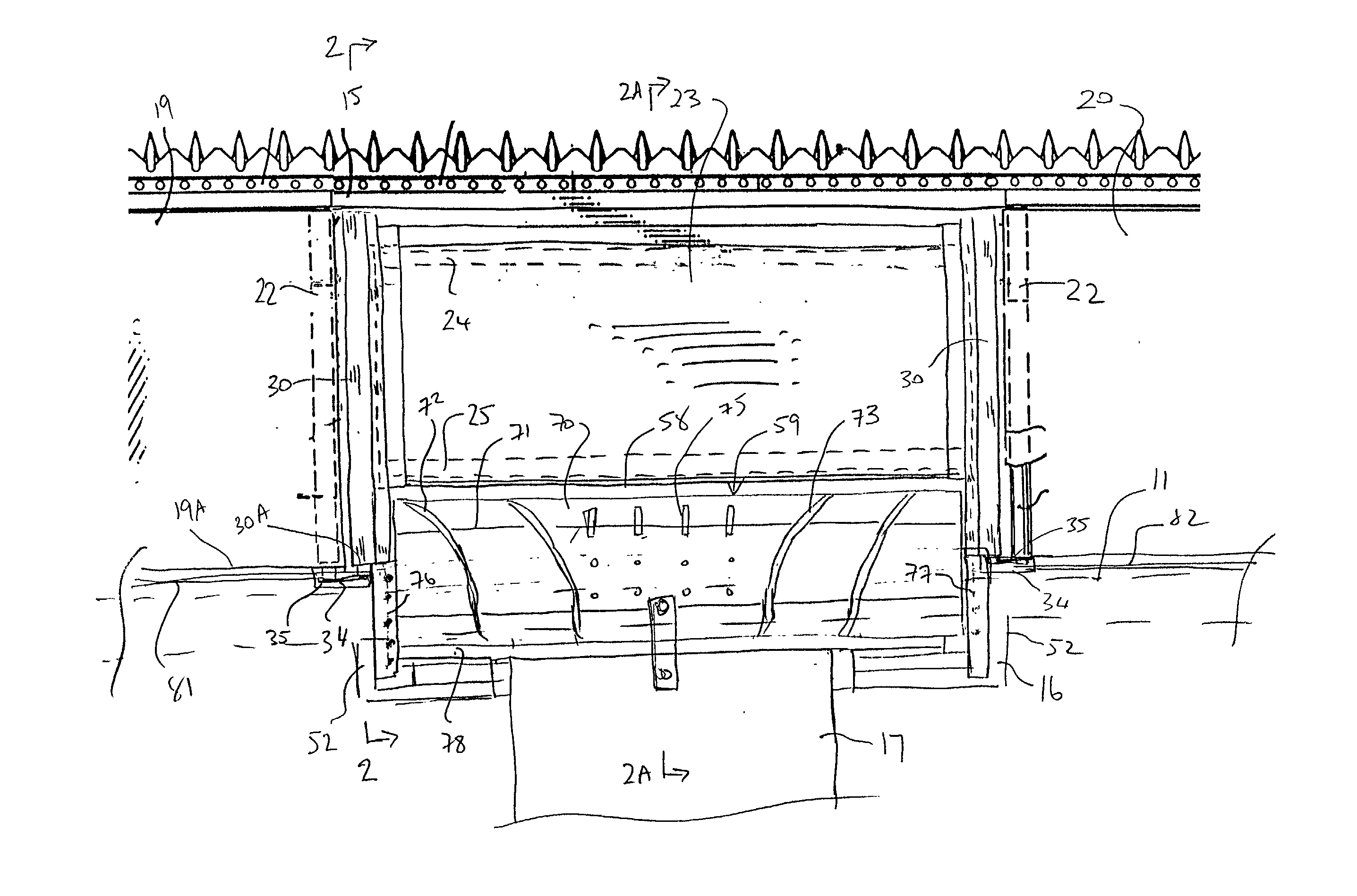

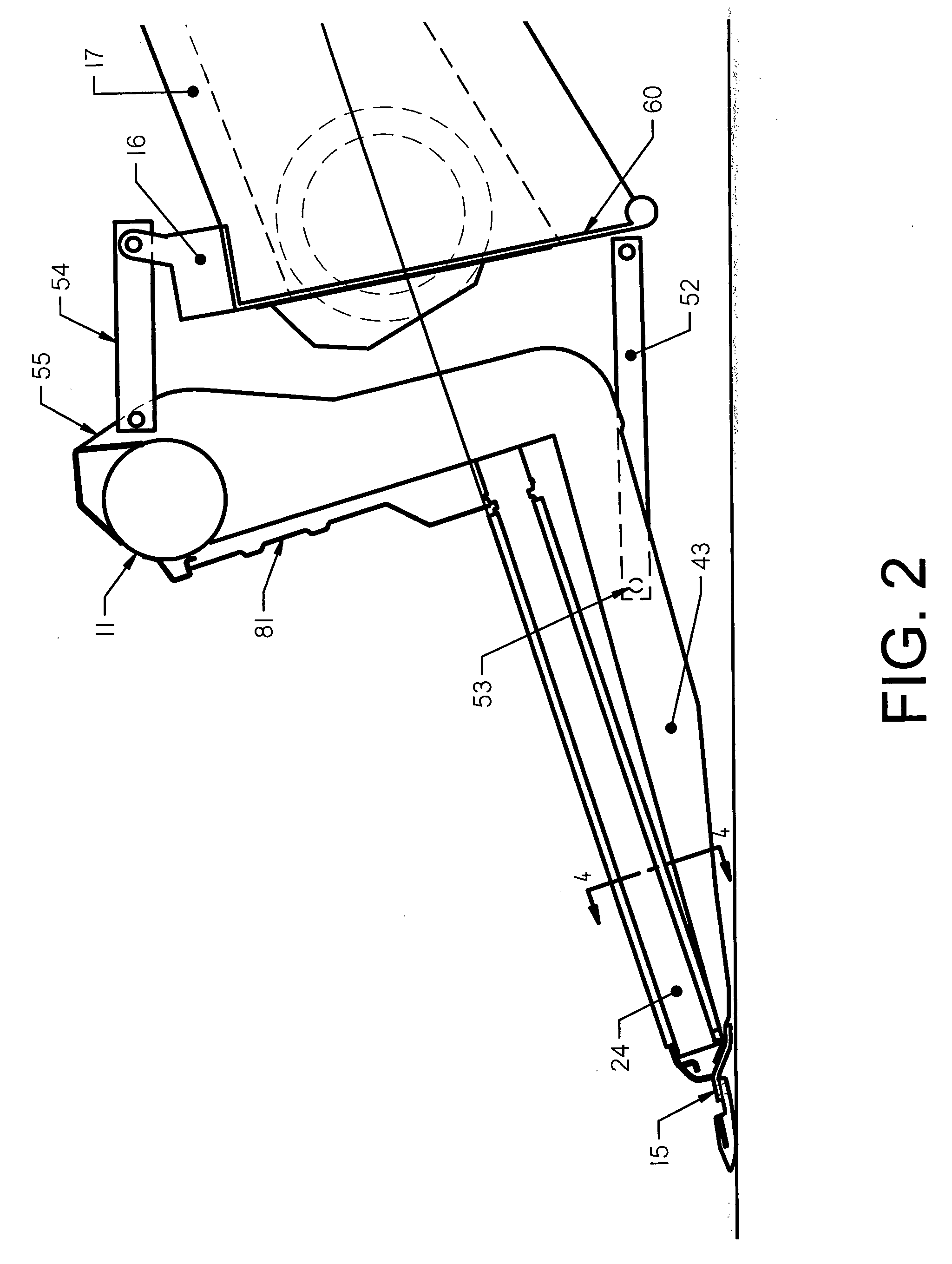

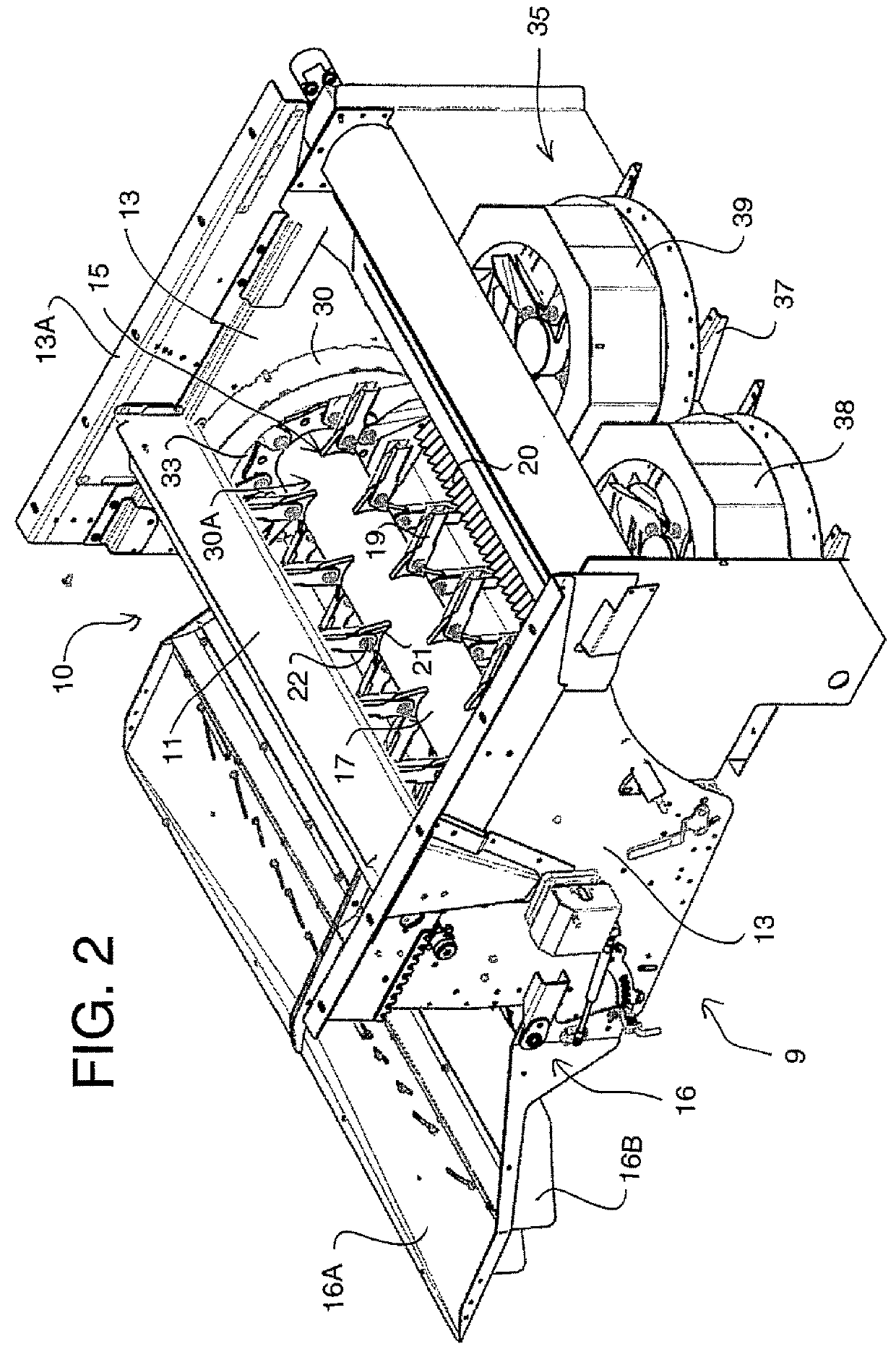

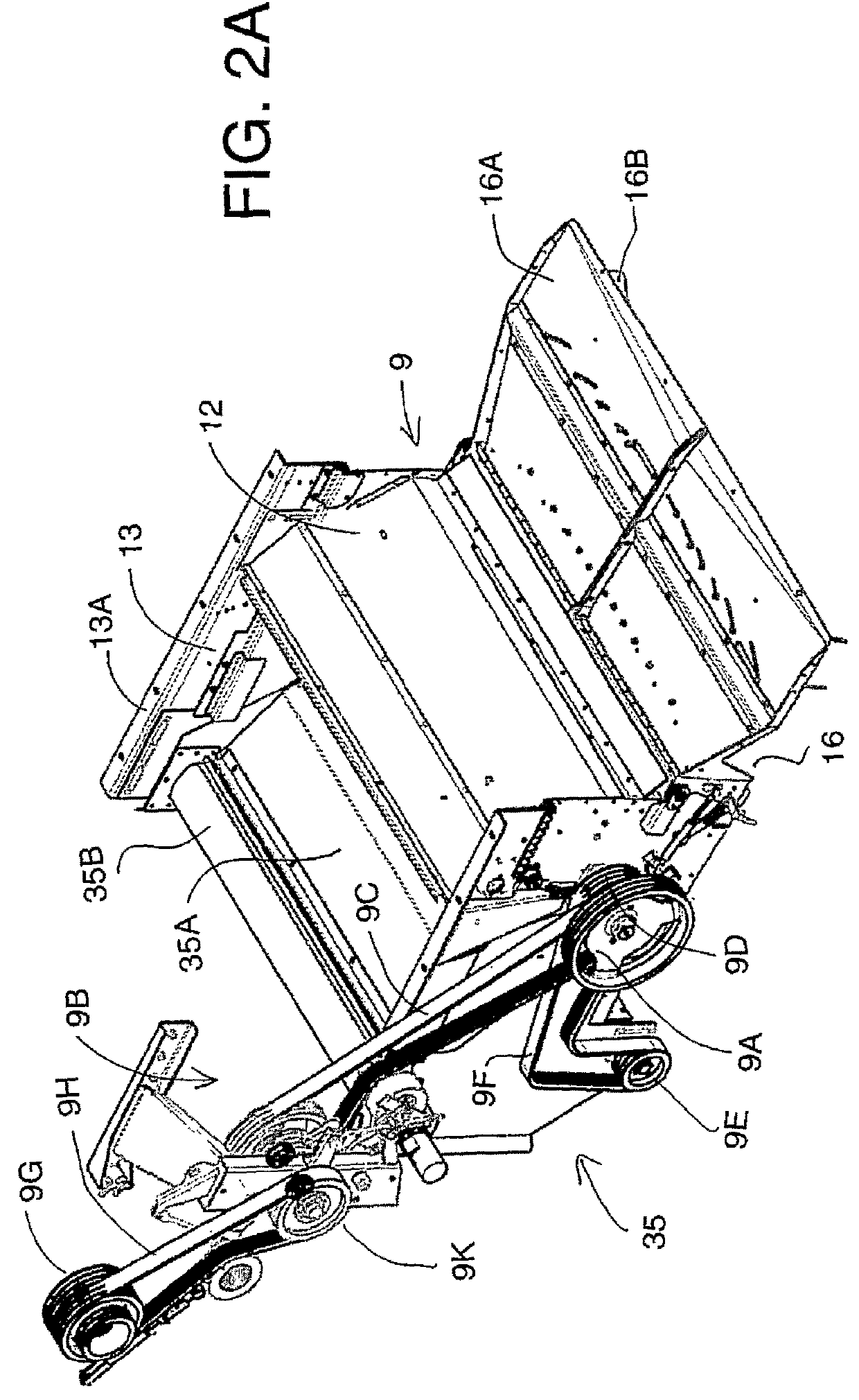

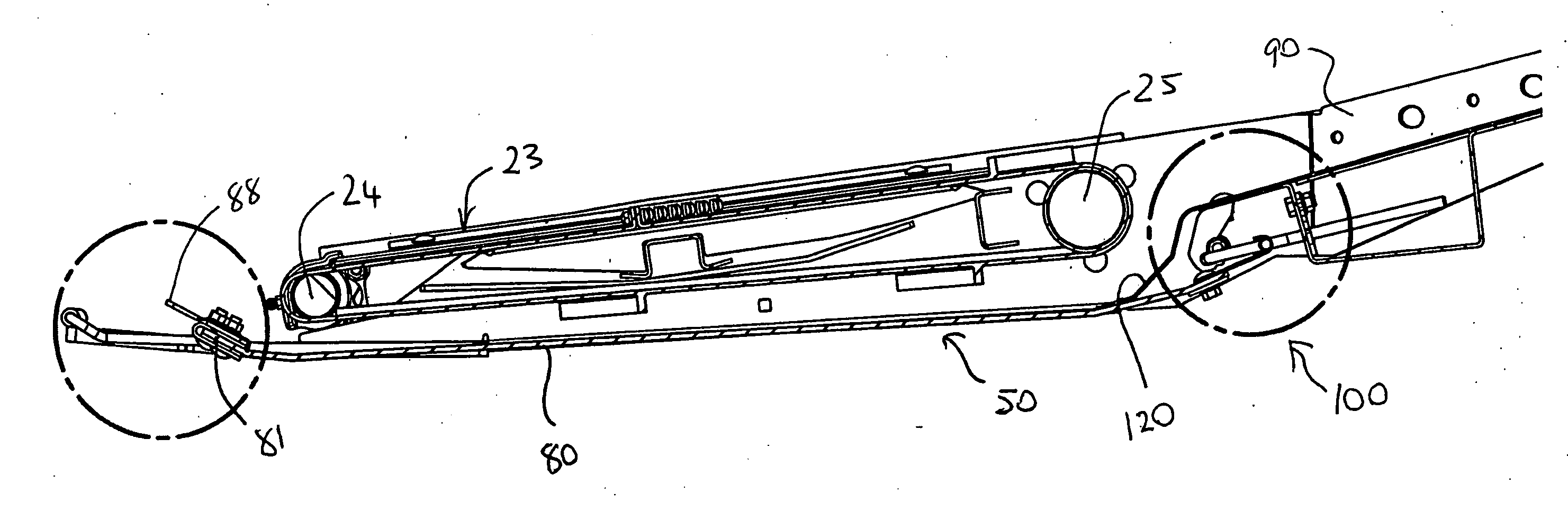

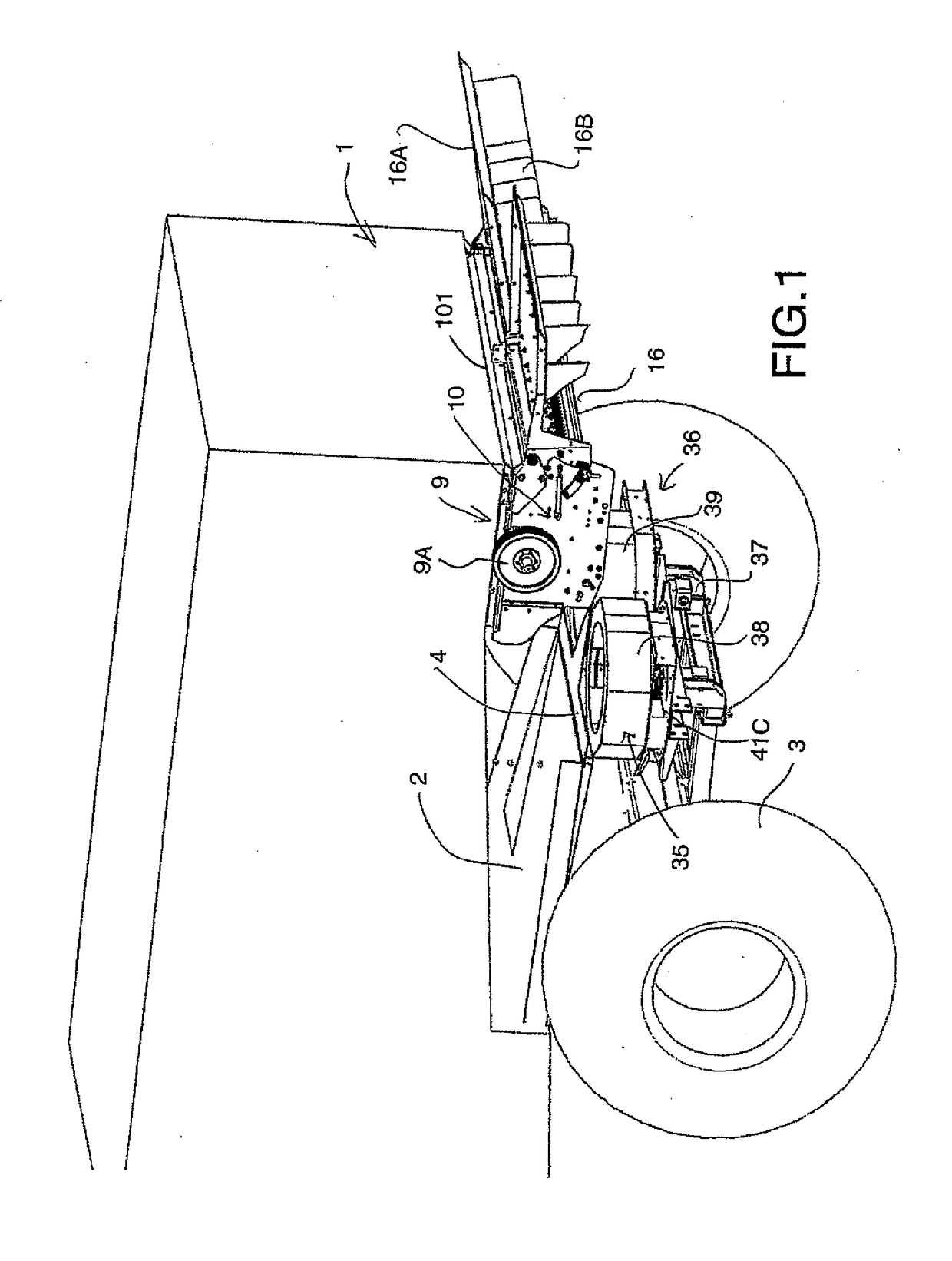

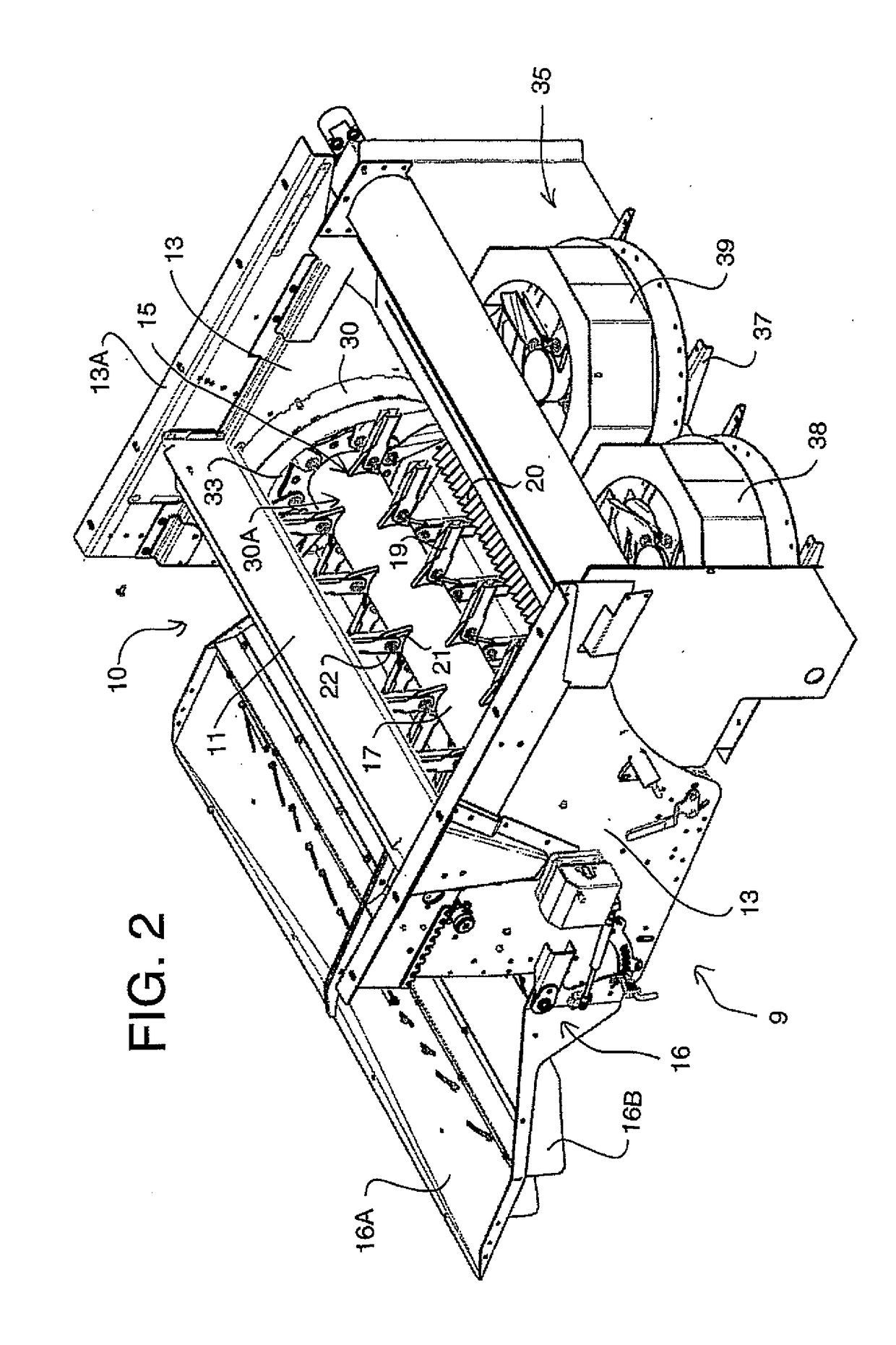

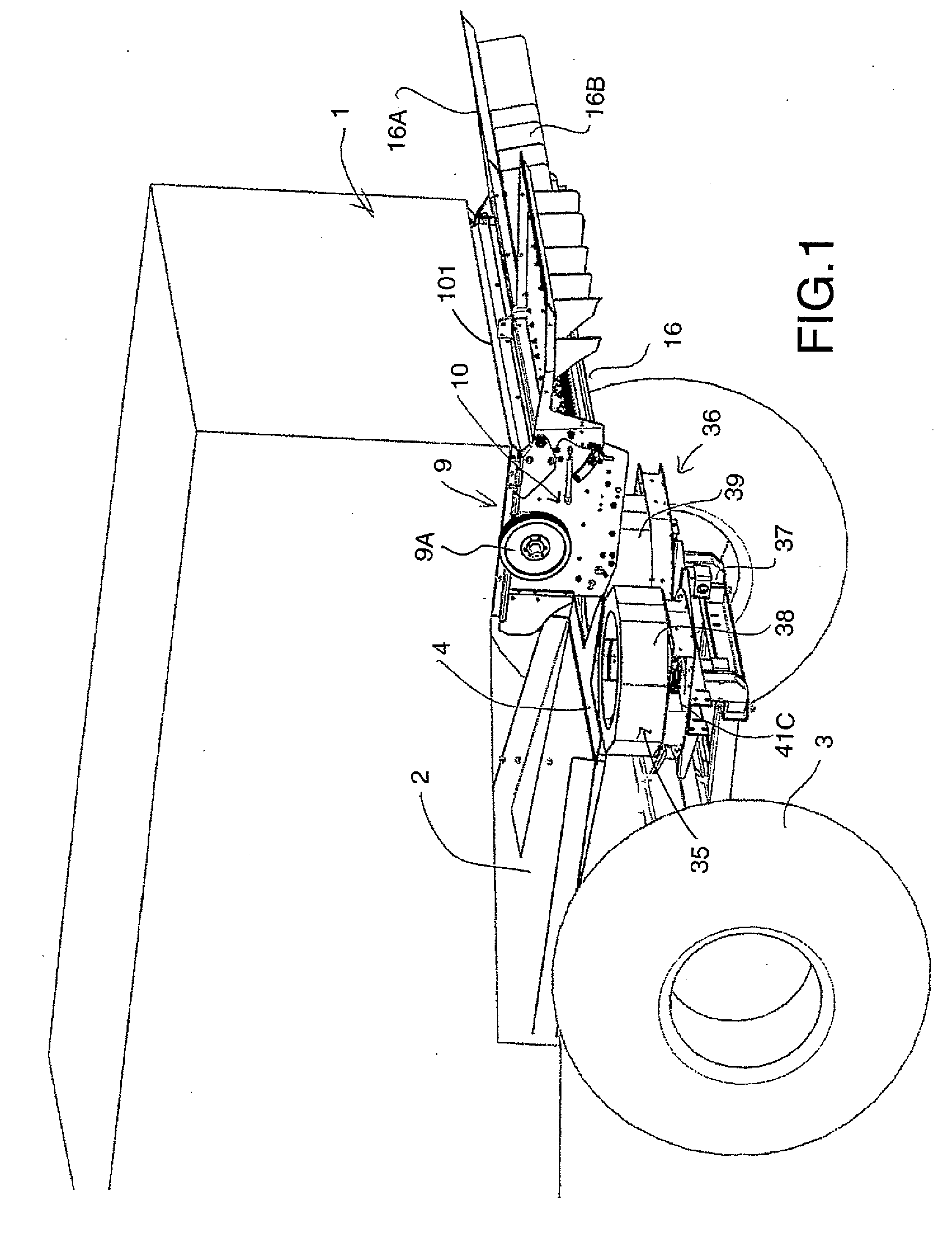

Crop feed arrangement for the header of a combine harvester

A draper header for a combine harvester includes two side drapers each running from an outer end guide roller at a first end of the header to an inner end guide roller adjacent the discharge location of the header and a central feed draper located at the discharge location and including a front guide roller just behind the cutter bar and running to a rear guide roller in front of the feeder house of the combine harvester. An auger is located between the discharge rollers with a front edge of the flight forward of the rear end of the discharge rollers to feed the material inwardly and underneath the auger to the inlet of the feeder house. A pan is located underneath the auger and is mounted on a common structure with the feed draper for common pivotal movement about a transverse horizontal axis.

Owner:MACDON INDS

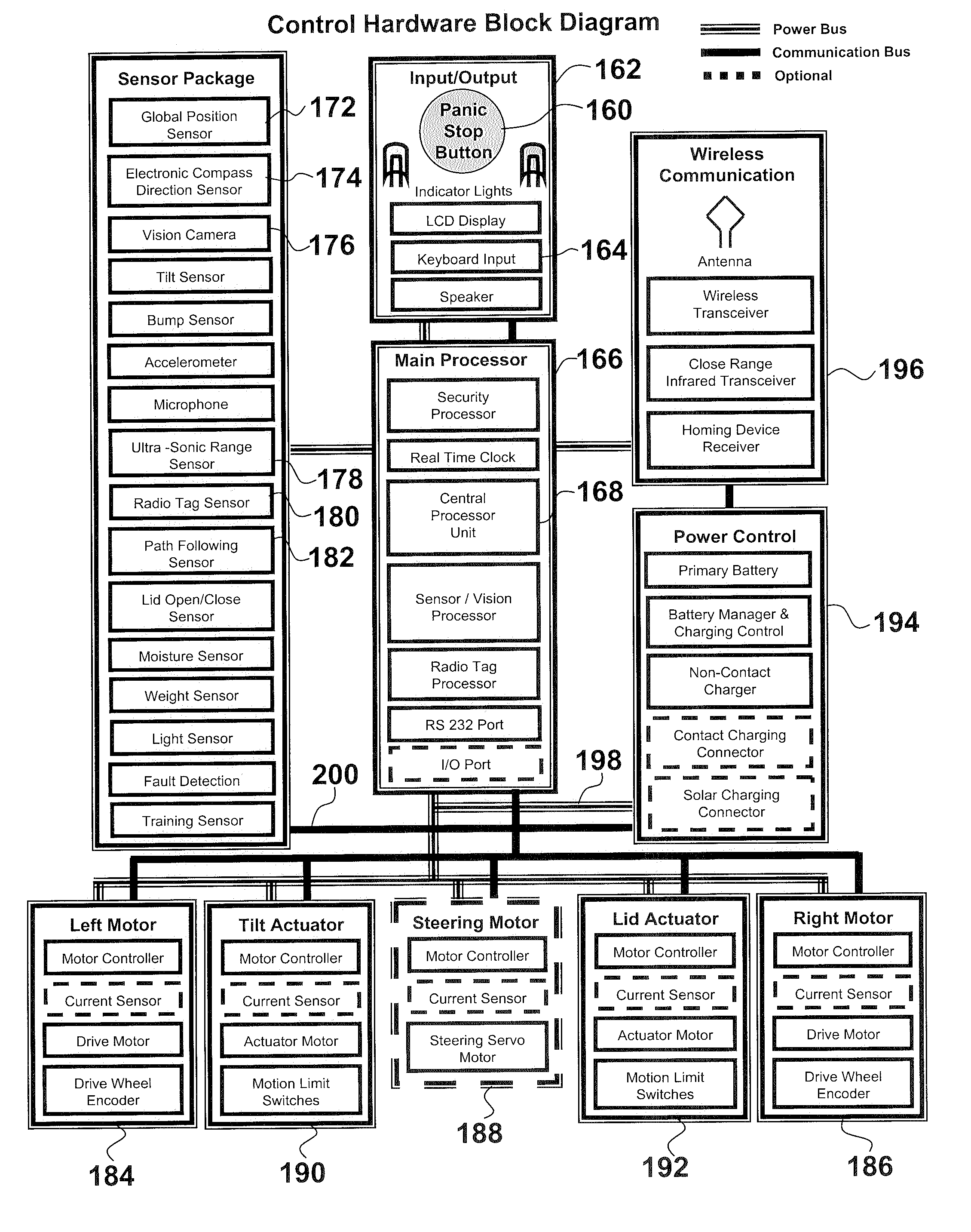

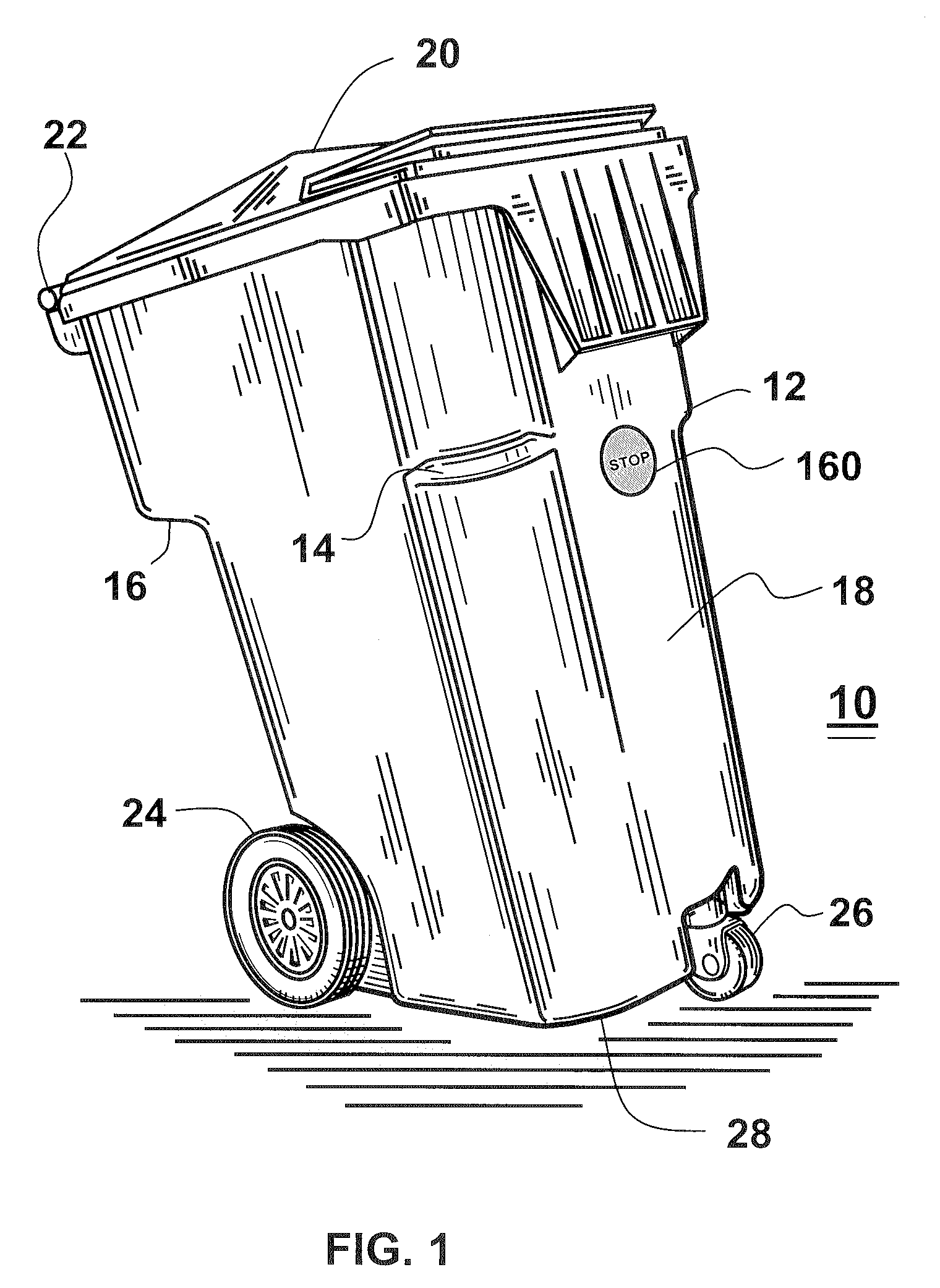

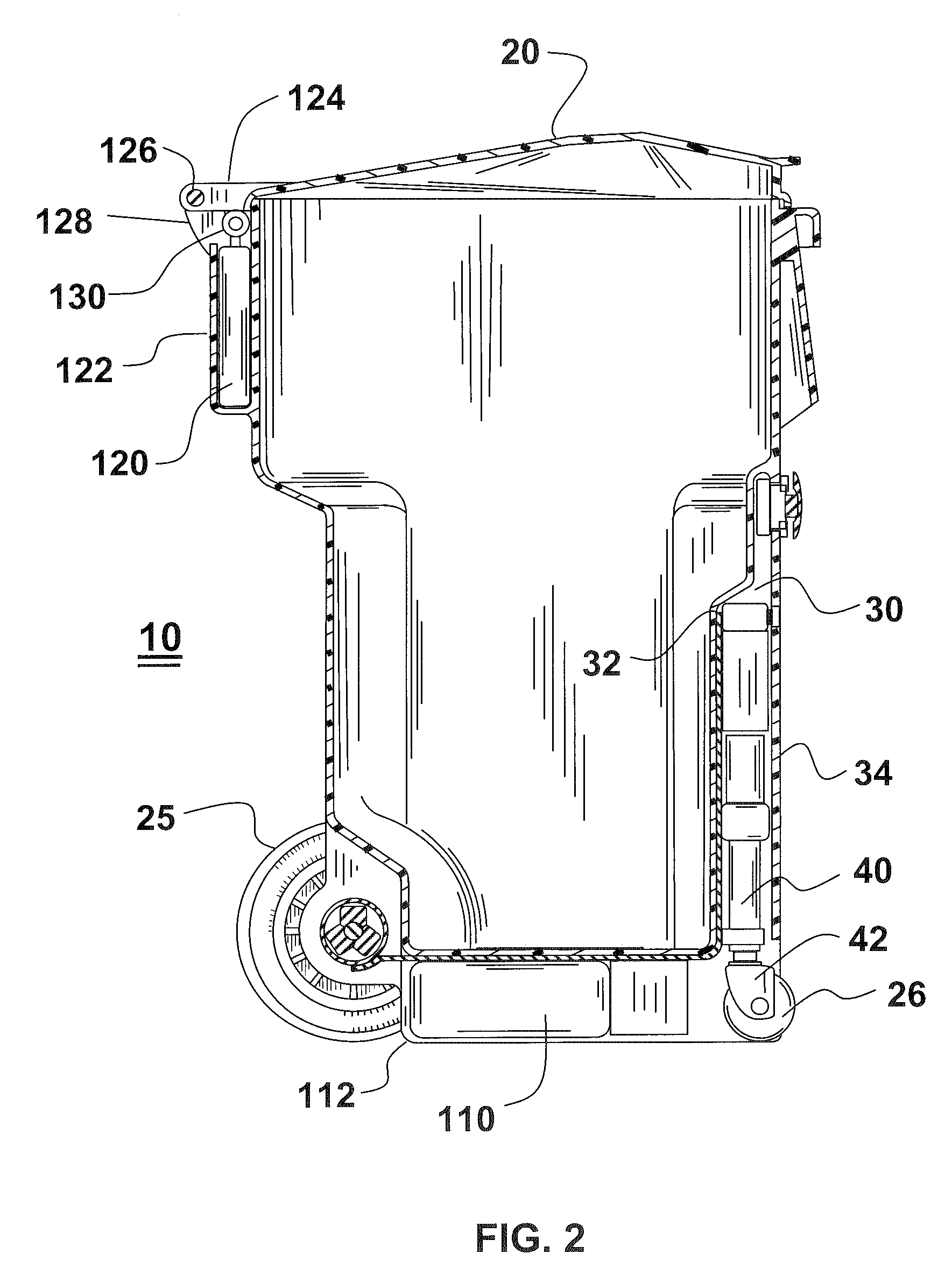

Automated self powered waste container

InactiveUS20080140253A1Increase the footprintReduce the possibilityRefuse receptaclesVehicle position/course/altitude controlDrive wheelSteering wheel

An automated self propelled refuse container travels from a parking or storage location to a refuse discharge location and return in response to a control unit cooperating with a tracking unit to control the direction of travel. Power is provided by an electric motor associated with each of two driving wheels rotating at the same rate and a third steering wheel provides stability and control over the direction of travel. The two driving wheels may rotate at a constant rate for straight line travel or charge direction, respectively, and a castering wheel provides stability and accommodates the direction of travel. Alternatively, a single wheel can provide both motive power and steering capability under control of a control unit responsive to the tracking unit and a pair of free wheeling wheels provide stability.

Owner:SONY CORP

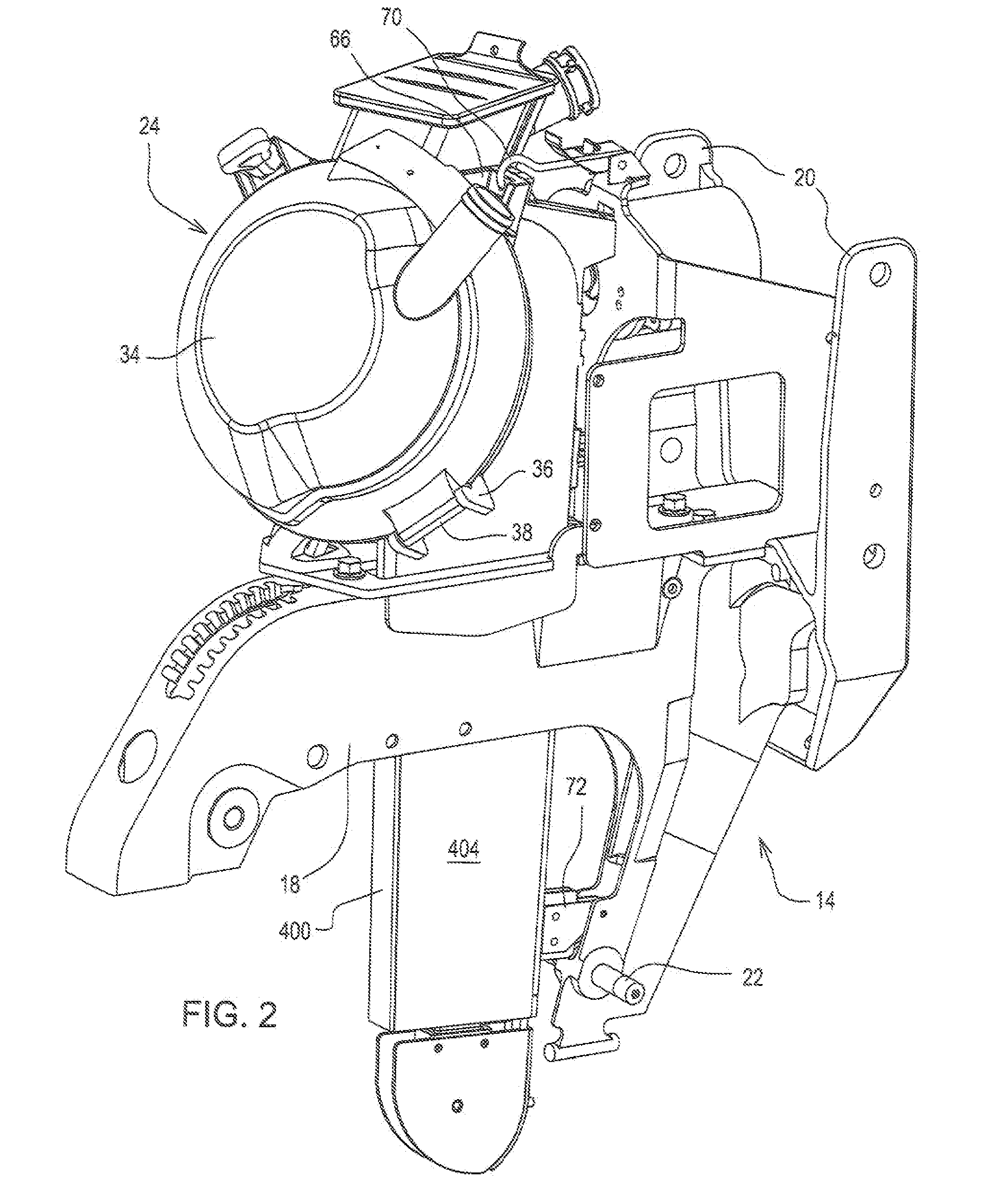

Crop stripper for the crop transport draper of a header

A draper header for a combine harvester includes two side drapers each running from an outer end guide roller at a first end of the header to an inner end guide roller adjacent the discharge location of the header and a central feed draper located at the discharge location and including a front guide roller just behind the cutter bar and running to a rear guide roller in front of the feeder house of the combine harvester. Each inner end guide roller is associated with a respective discharge roller immediately adjacent and parallel to it with a stripper blade in contact with the peripheral surface of the discharge roller so as to strip the crop from the peripheral surface along the full length of the roller. Each stripper blade is inclined downwardly and inwardly to a bottom edge closely adjacent the upper run of the feed draper. The stripper roller or in another arrangement the draper itself has rows of projections across the surface which pass through corresponding shaped recesses in the edge of the stripper blade so that the crop material is discharged onto the blade while the projections are shaped to prevent the crop from being driven into the recesses. An auger is located between the discharge rollers with a front edge of the flight forward of the rear end of the discharge rollers to feed the material inwardly and underneath the auger to the inlet of the feeder house.

Owner:MACDON INDS

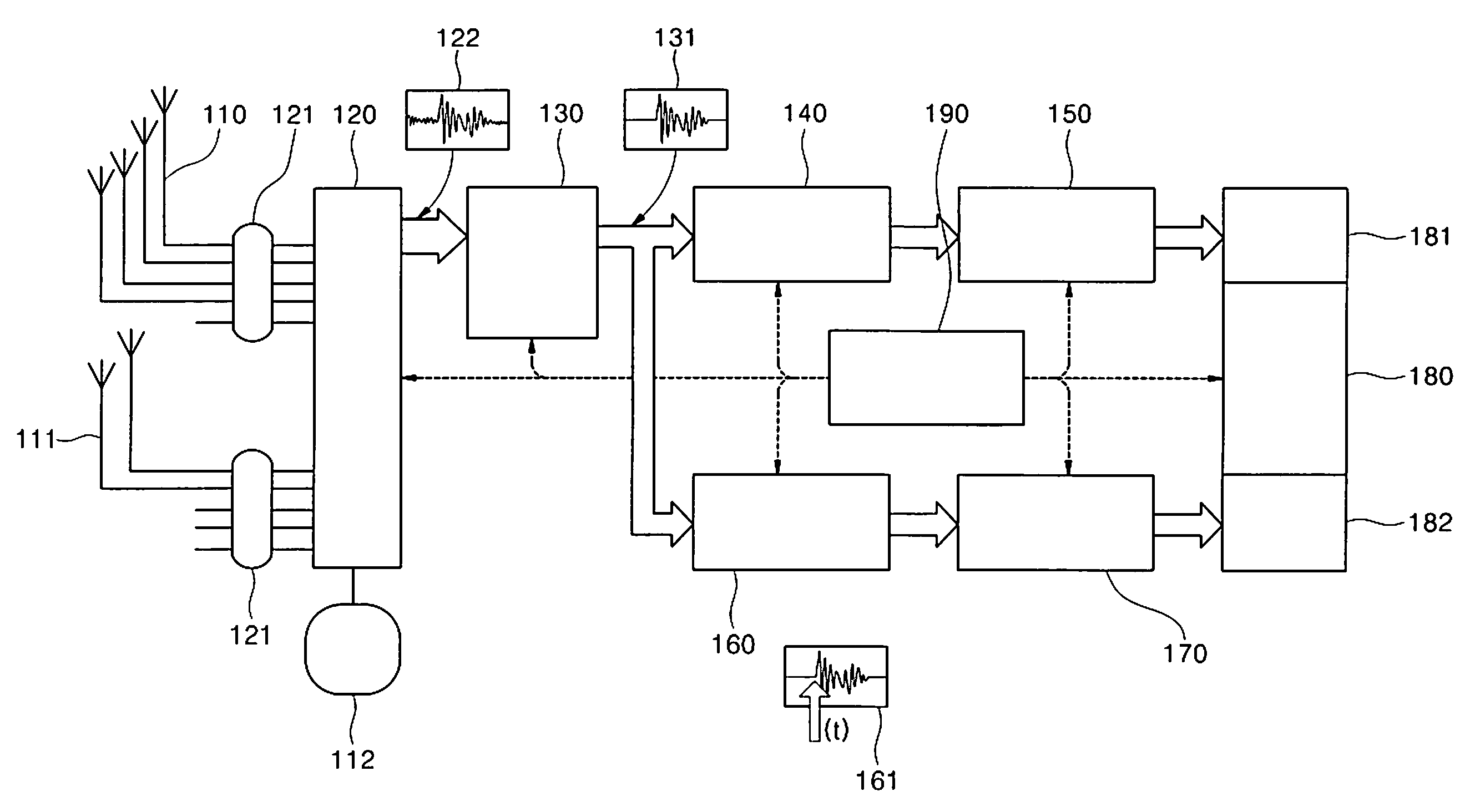

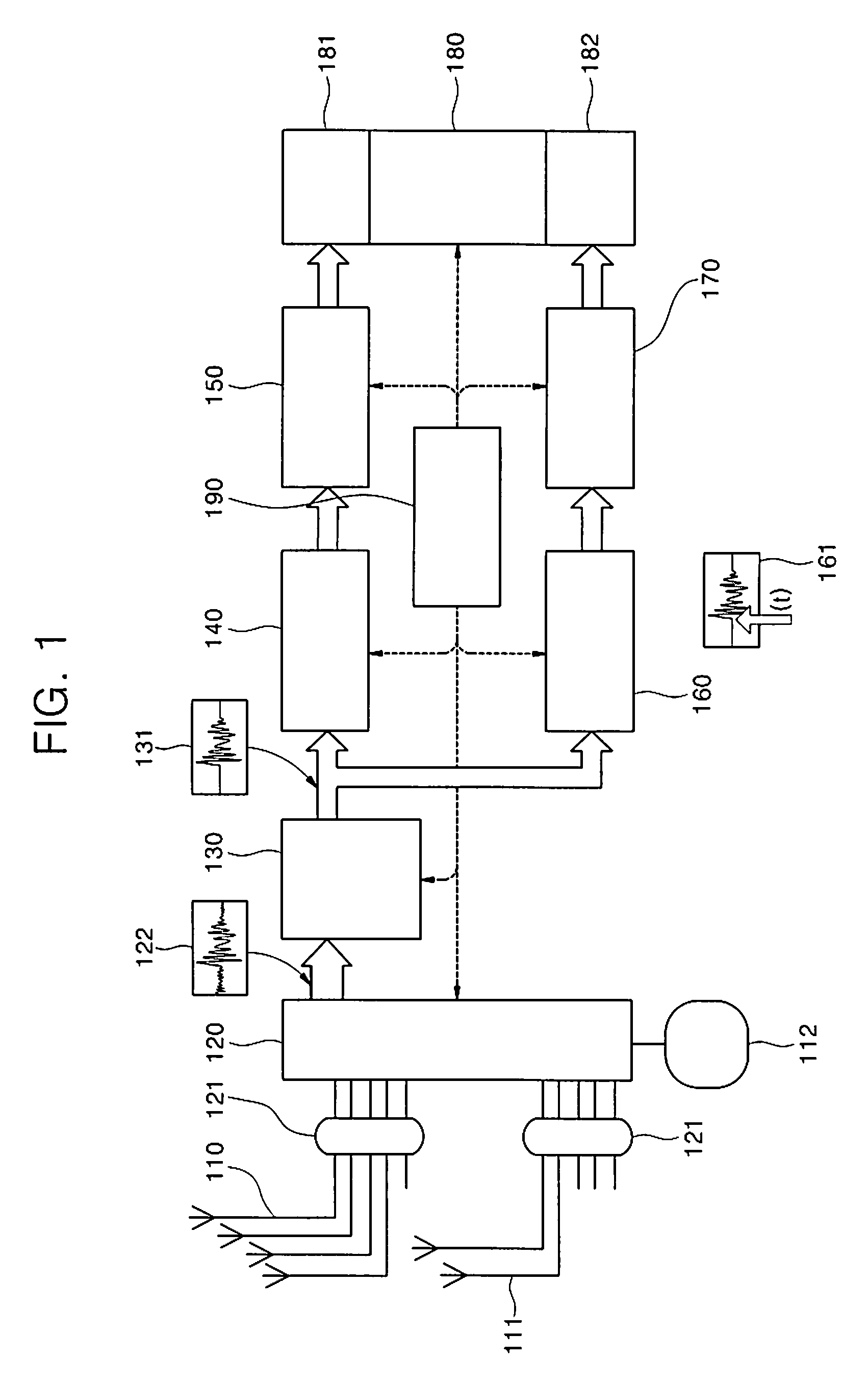

Uhf partial discharge and its location measuring device for high-voltage power devices

ActiveUS20100079148A1Easy to analyzeEliminate inconvenienceTesting dielectric strengthNoise figure or signal-to-noise ratio measurementMeasurement deviceArrival time

Disclosed is a UHF partial discharge and its location measuring device for high-voltage power devices. The measuring device includes a partial discharge sensor, an external noise sensor, an analogue-digital converter, a peak detector, a partial discharge signal processor, an arrival time detector, a discharge location processor, and a display unit.

Owner:KOREA ELECTRIC POWER CORP

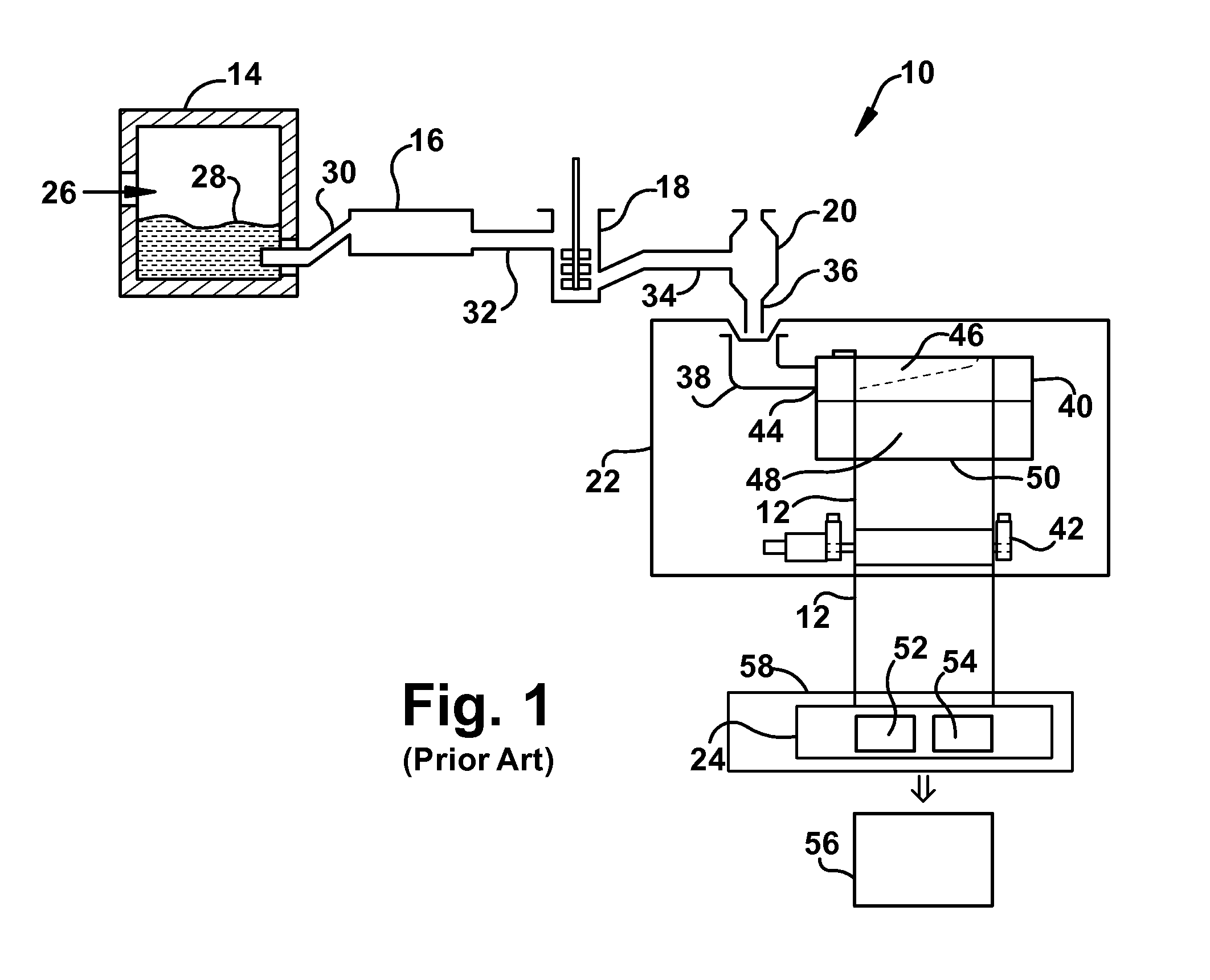

Preventing gas from occupying a spray nozzle used in a process of scoring a hot glass sheet

ActiveUS20100287991A1Improve spraying effectImprove performanceGlass drawing apparatusGlass forming apparatusSolubilityHigh energy

A spray nozzle is used in a process of quenching a hot glass sheet during a laser scoring process or other high energy glass heating process. The scoring is conducted by a high energy means such as a laser. The nozzle is located in proximity to the glass sheet, creating gas in liquid used to quench the glass located in the nozzle (e.g., water). The gas (e.g., air bubbles) is removed from the quenching liquid. Then, the spray nozzle is used to spray the quenching liquid onto the sheet at a location trailing laser scoring of the sheet, such as using a traveling anvil machine at the bottom of the draw. The spray nozzle (purge nozzle) has a purge opening and tubing leading to a discharge location. The purge nozzle can have a sloped passageway that pre-stages gas bubbles near the purge opening in the nozzle. The spray nozzle can include a cooling coil passing around the nozzle passageway that enables a coolant to travel along the coil. This cools the quenching liquid passing through the nozzle, and increases the solubility of bubbles in the quenching liquid in the nozzle. A gas filter can receive gas-rich quenching liquid from the pressurized quenching liquid source, remove gas from the liquid, and send gas-depleted quenching liquid to the spray nozzle.

Owner:CORNING INC

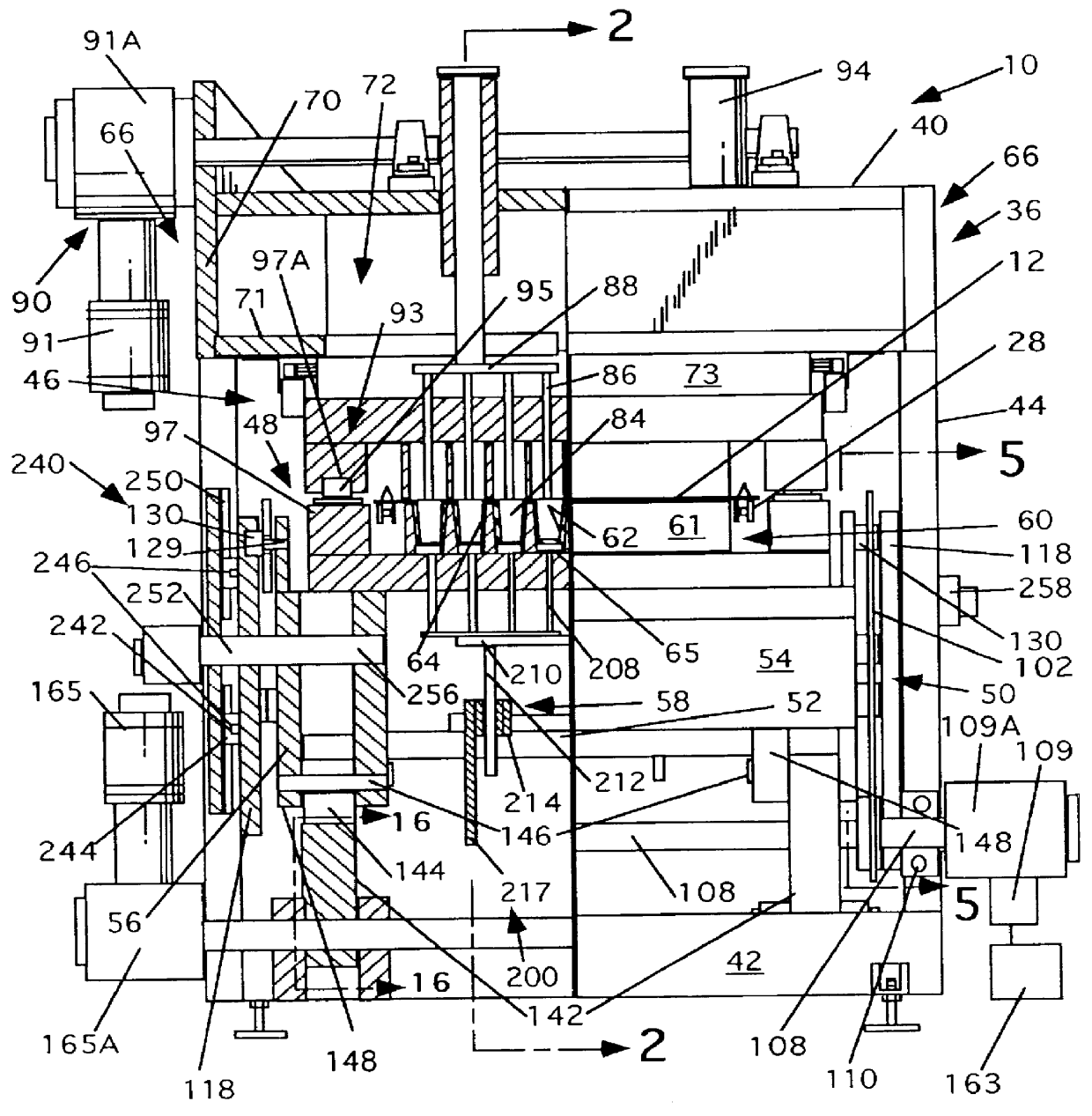

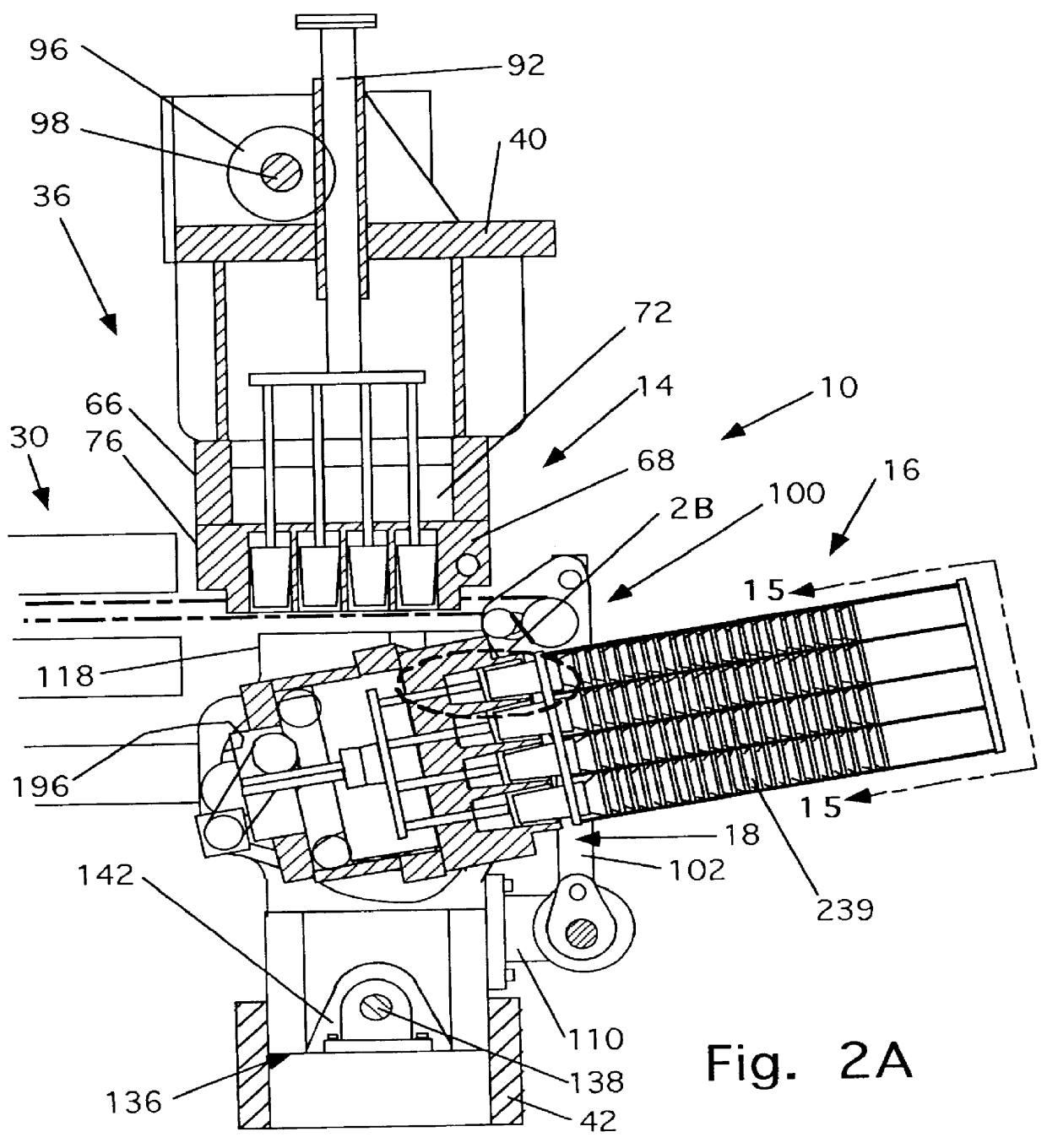

Differential pressure forming, trimming and stacking apparatus

Apparatus for forming articles in a thermoplastic sheet, severing the articles in the sheet, and stacking the articles in a stacking receiver. The apparatus includes upper and lower molds moveable between closed positions in which the molds engage opposite sides of the sheet to differentially pressure form a part in the thermoplastic sheet. The molds in which the article is formed are moved toward each from the closed positions to article trim positions to sever the article from the sheet. The lower mold is then moved linearly away from the sheet in a vertical direction and then transversely moved in a second linear transverse path of travel to a remote discharge location. Apparatus is provided for reorienting the mold between its orientation in the first linear path of travel and its orientation in the second path of travel.

Owner:BROWN MACHINE OF MICHIGAN

Angled fill ports and seal-off arrangement for patty-forming apparatus

ActiveUS20070098862A1Eliminates minimizesEfficient fillingConfectioneryMeat processingMolding machineEngineering

A food patty molding machine has a reciprocating mold plate. A moldable food product is pumped through a fill passage into cavities of the mold plate when the mold plate is in its fill position. A fill plate, interposed in the fill passage immediately adjacent the mold plate, has a multiplicity of fill orifices distributed in a predetermined pattern throughout an area aligned with the mold cavity when the mold plate is in its fill position. The fill orifices define paths through the fill plate, wherein the paths each have an inlet portion that is perpendicular to a fill side face of the mold plate that is connected to an outlet portion that is obliquely angled to a fill side face of the mold plate. A seal-off stripper plate is interposed in the fill passage immediately adjacent the face of the fill plate opposite the mold plate. The stripper plate is movable along a path transverse to the mold plate path between a fill location and a discharge location. The stripper plate has a multiplicity of fill openings aligned one-for-one with the fill orifices as extensions thereof when the stripper plate is in its fill location.

Owner:PROVISUR TECHNOLOGIES INC

Applicator wheel for filling cavities with metered amounts of particulate material

ActiveUS20070284012A1Efficient mannerEfficient and timelyLiquid fillingTobacco smoke filtersProcess functionEngineering

A machine and process function to fill cavities with metered amounts of particulate material. An applicator wheel includes a series of equally spaced apart peripheral pockets each having a perforated bottom wall, and a vacuum manifold inside the wheel includes a vacuum chamber for supplying vacuum to the perforated bottom walls of the pockets as the wheel rotates. Particulate material from a filling chamber of such material outside the wheel is withdrawn into the pockets by the vacuum chamber. A downstream vacuum relief on the vacuum manifold functions to discharge particulate material from the pockets into the cavities at a predetermined discharge location on the wheel. Adjustment structure is connected to rotatably adjust the position of the vacuum manifold within the applicator wheel to thereby advance or retard the discharge location depending upon the speed of the machine.

Owner:PHILIP MORRIS USA INC

Crop feed arrangement for the header of a combine harvester

A draper header for a combine harvester includes two side drapers each running from an outer end guide roller at a first end of the header to an inner end guide roller adjacent the discharge location of the header and a central feed draper located at the discharge location and including a front guide roller just behind the cutter bar and running to a rear guide roller in front of the feeder house of the combine harvester. An auger is located between the discharge rollers with a front edge of the flight forward of the rear end of the discharge rollers to feed the material inwardly and underneath the auger to the inlet of the feeder house. A pan is located underneath the auger and is mounted on a common structure with the feed draper for common pivotal movement about a transverse horizontal axis.

Owner:MACDON INDS

Preventing gas from occupying a spray nozzle used in a process of scoring a hot glass sheet

ActiveUS8132427B2Reduce solubilityAvoid occupyingGlass drawing apparatusGlass forming apparatusSolubilityHigh energy

A spray nozzle is used in a process of quenching a hot glass sheet during a laser scoring process or other high energy glass heating process. The scoring is conducted by a high energy means such as a laser. The nozzle is located in proximity to the glass sheet, creating gas in liquid used to quench the glass located in the nozzle (e.g., water). The gas (e.g., air bubbles) is removed from the quenching liquid. Then, the spray nozzle is used to spray the quenching liquid onto the sheet at a location trailing laser scoring of the sheet, such as using a traveling anvil machine at the bottom of the draw. The spray nozzle (purge nozzle) has a purge opening and tubing leading to a discharge location. The purge nozzle can have a sloped passageway that pre-stages gas bubbles near the purge opening in the nozzle. The spray nozzle can include a cooling coil passing around the nozzle passageway that enables a coolant to travel along the coil. This cools the quenching liquid passing through the nozzle, and increases the solubility of bubbles in the quenching liquid in the nozzle. A gas filter can receive gas-rich quenching liquid from the pressurized quenching liquid source, remove gas from the liquid, and send gas-depleted quenching liquid to the spray nozzle.

Owner:CORNING INC

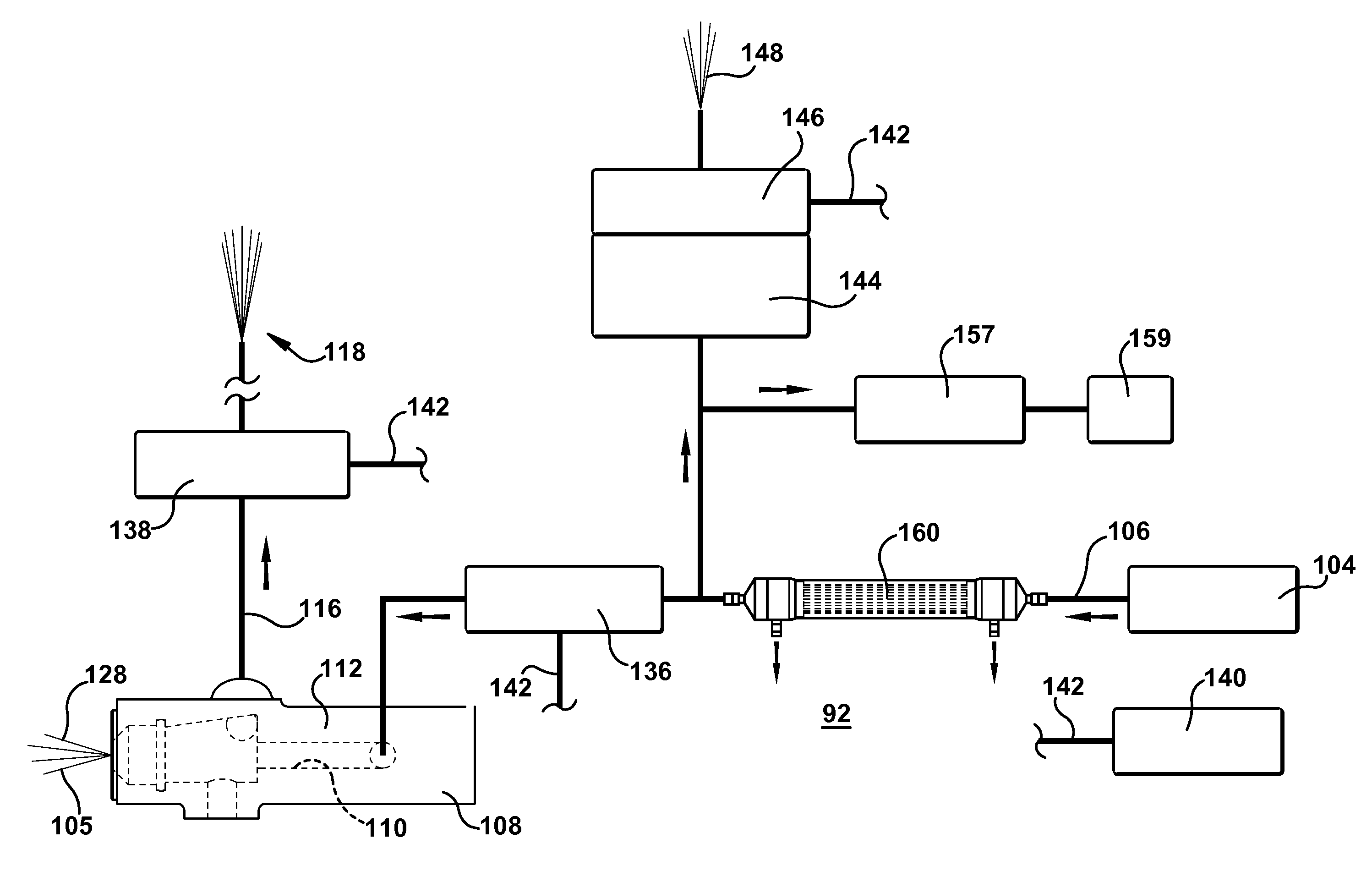

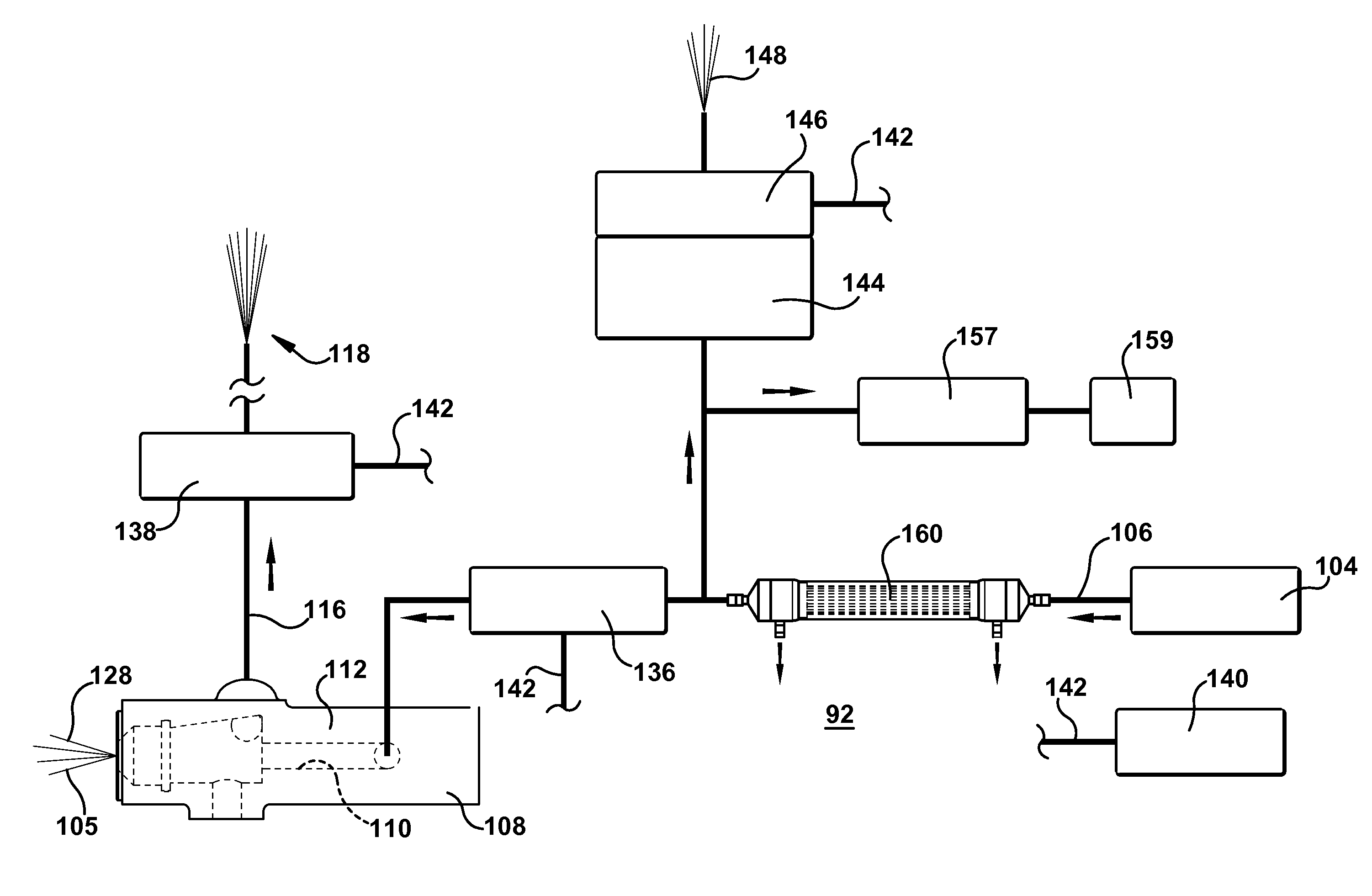

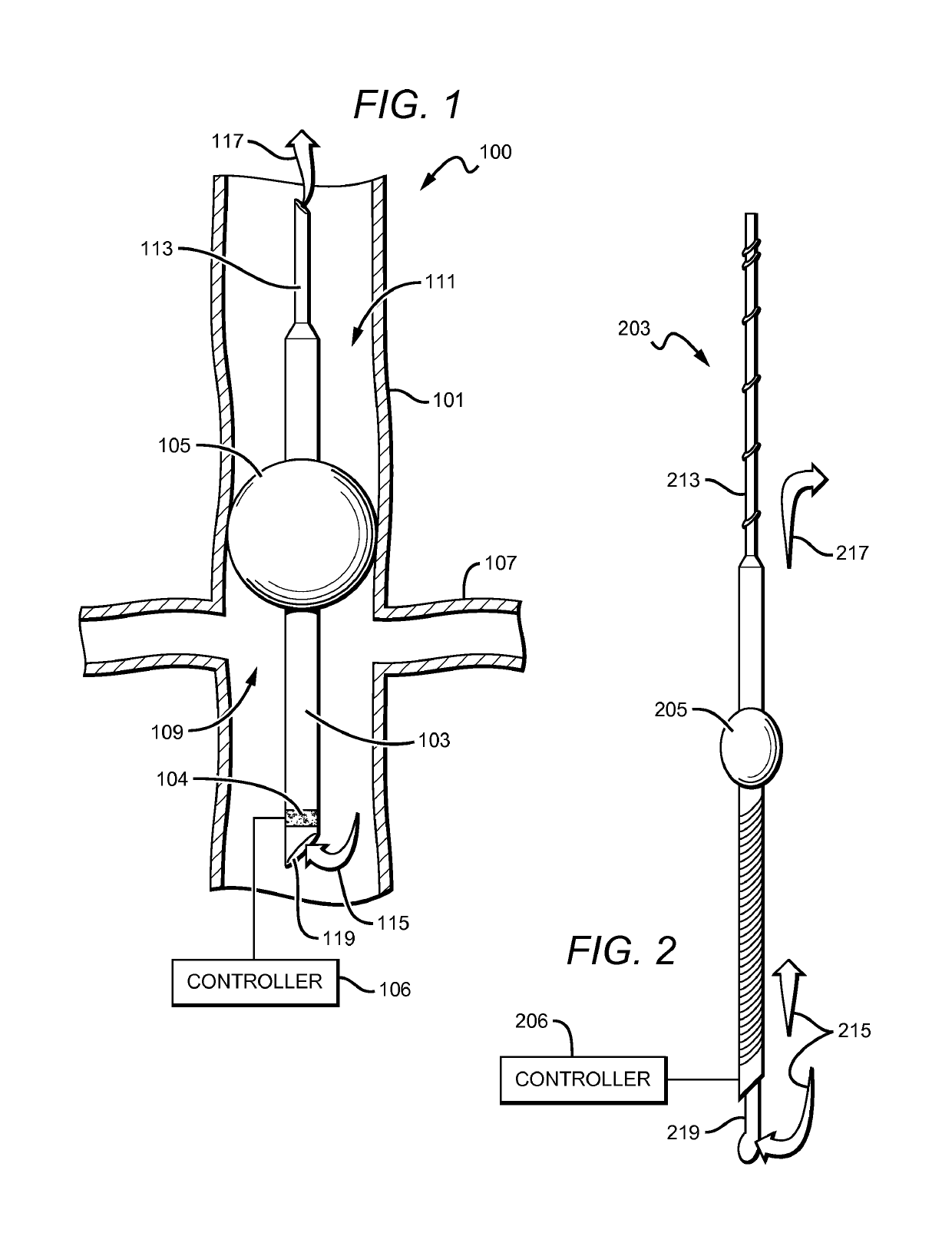

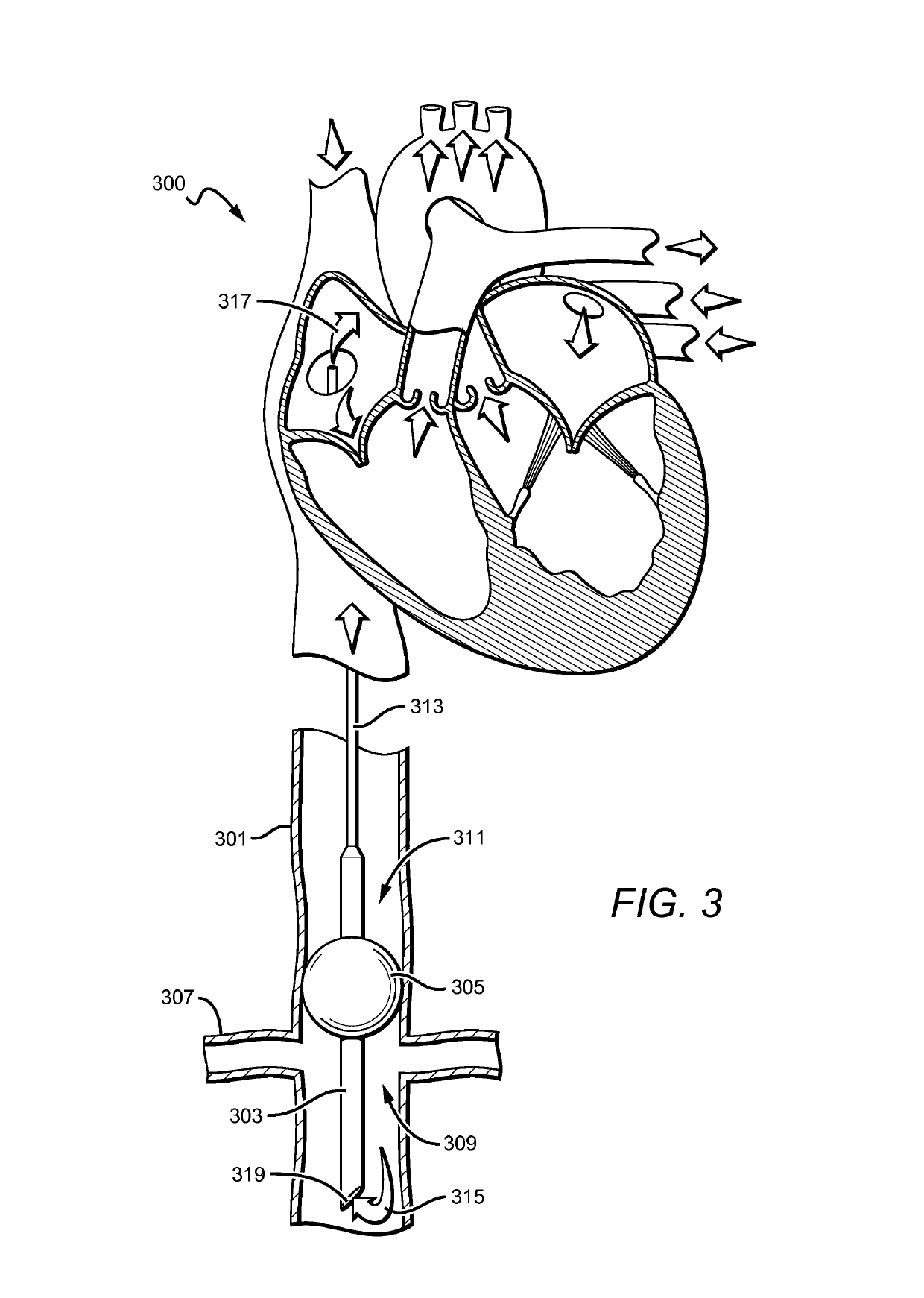

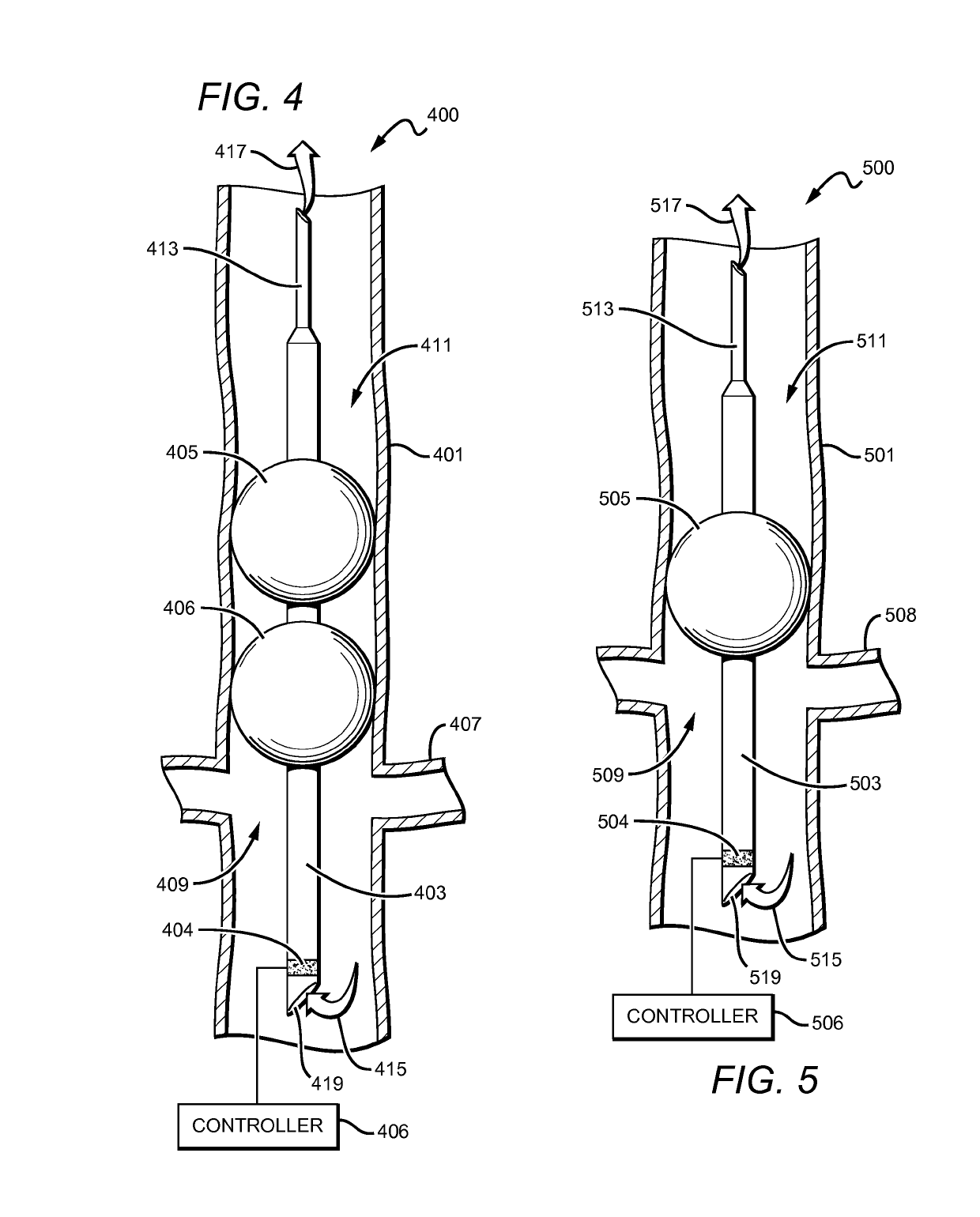

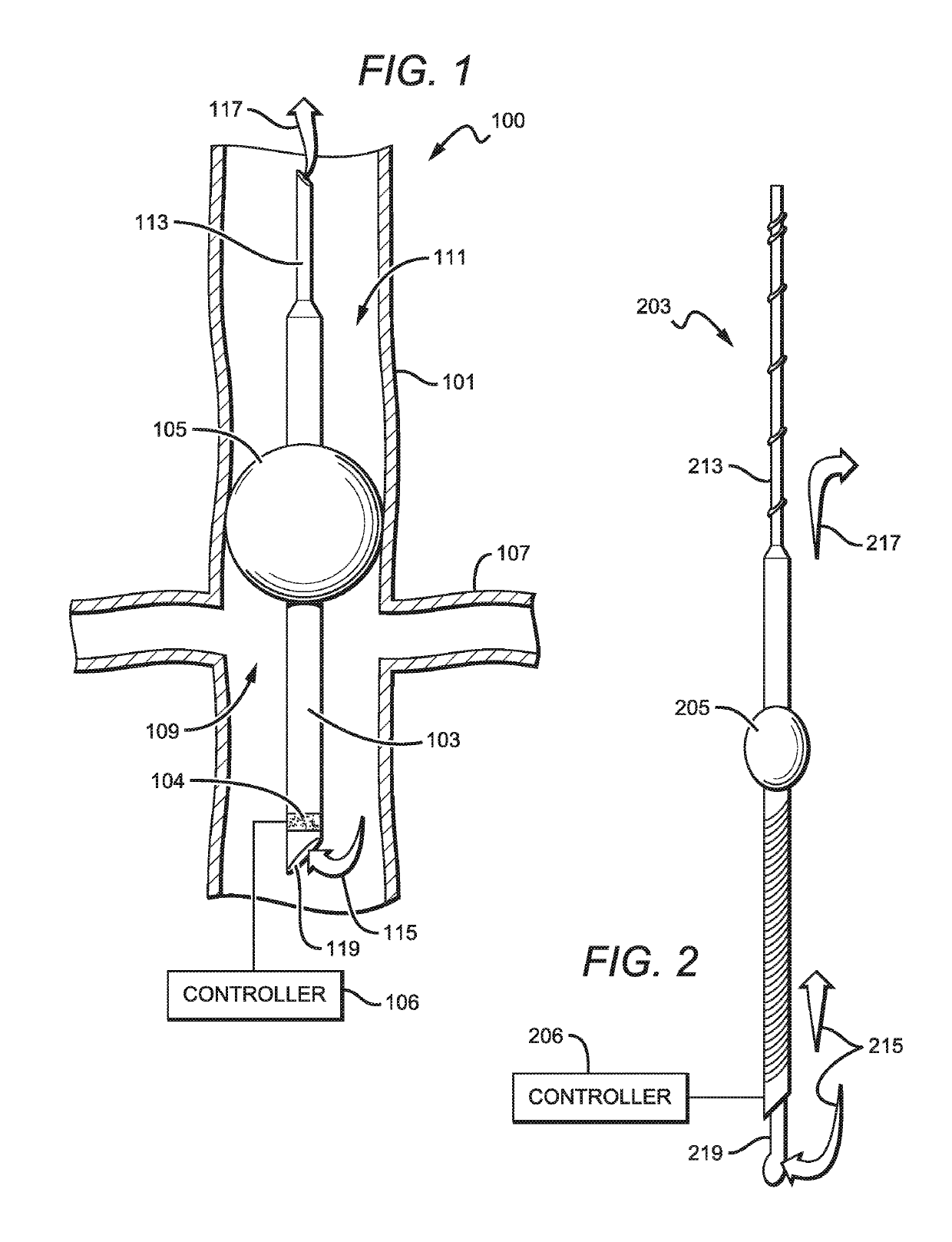

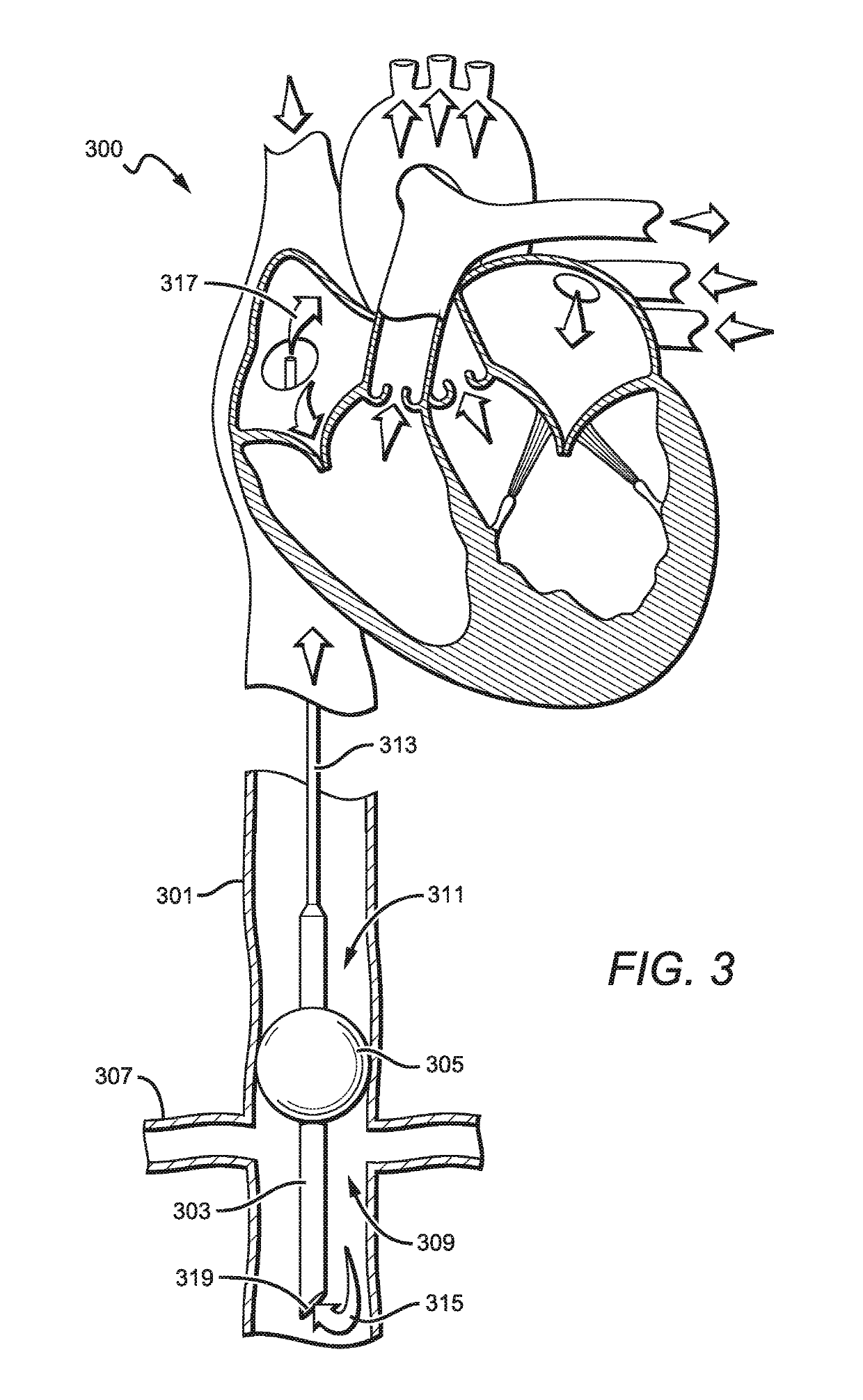

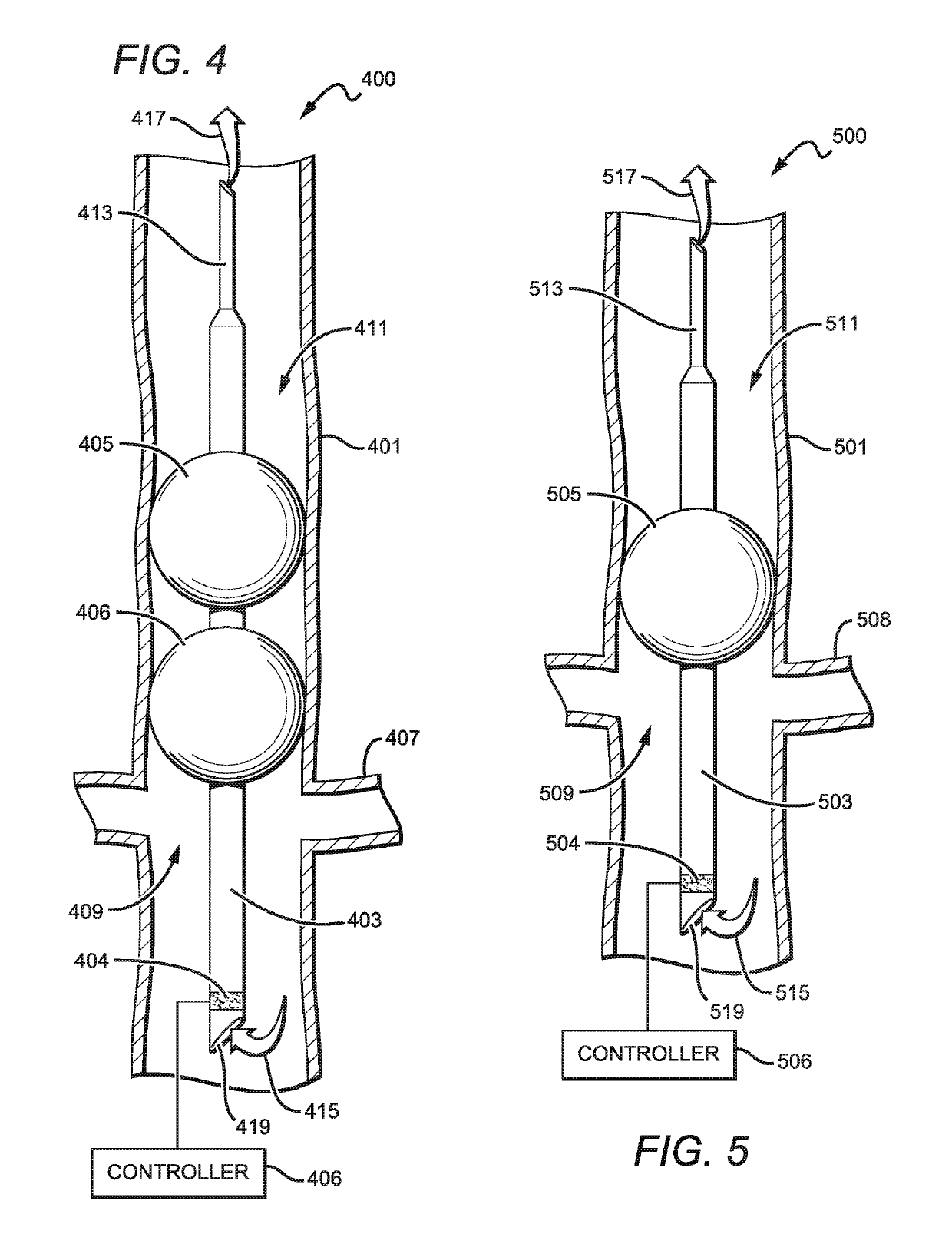

Catheter-based pump for improving organ function

InactiveUS10245363B1High gradientImprove organ functionBalloon catheterControl devicesVeinLine tubing

Apparatus, systems, and methods in which a catheter-based pump is used are disclosed. The catheter-based pump is placed within the inferior vena cava of a patient. The catheter-based pump has a variable obstructor, such as a balloon or some other artificial obstruction, which is sized and dimensioned to compartmentalize the inferior vena cava into an upstream region and a downstream region of the inferior vena cava. The catheter-based pump is configured to pump blood from the upstream region to a fluid line that discharges blood to a discharge location in the downstream region. Thus, a suitable pressure gradient across the organ is provided, which can benefit organ function.

Owner:ROWE STANTON J

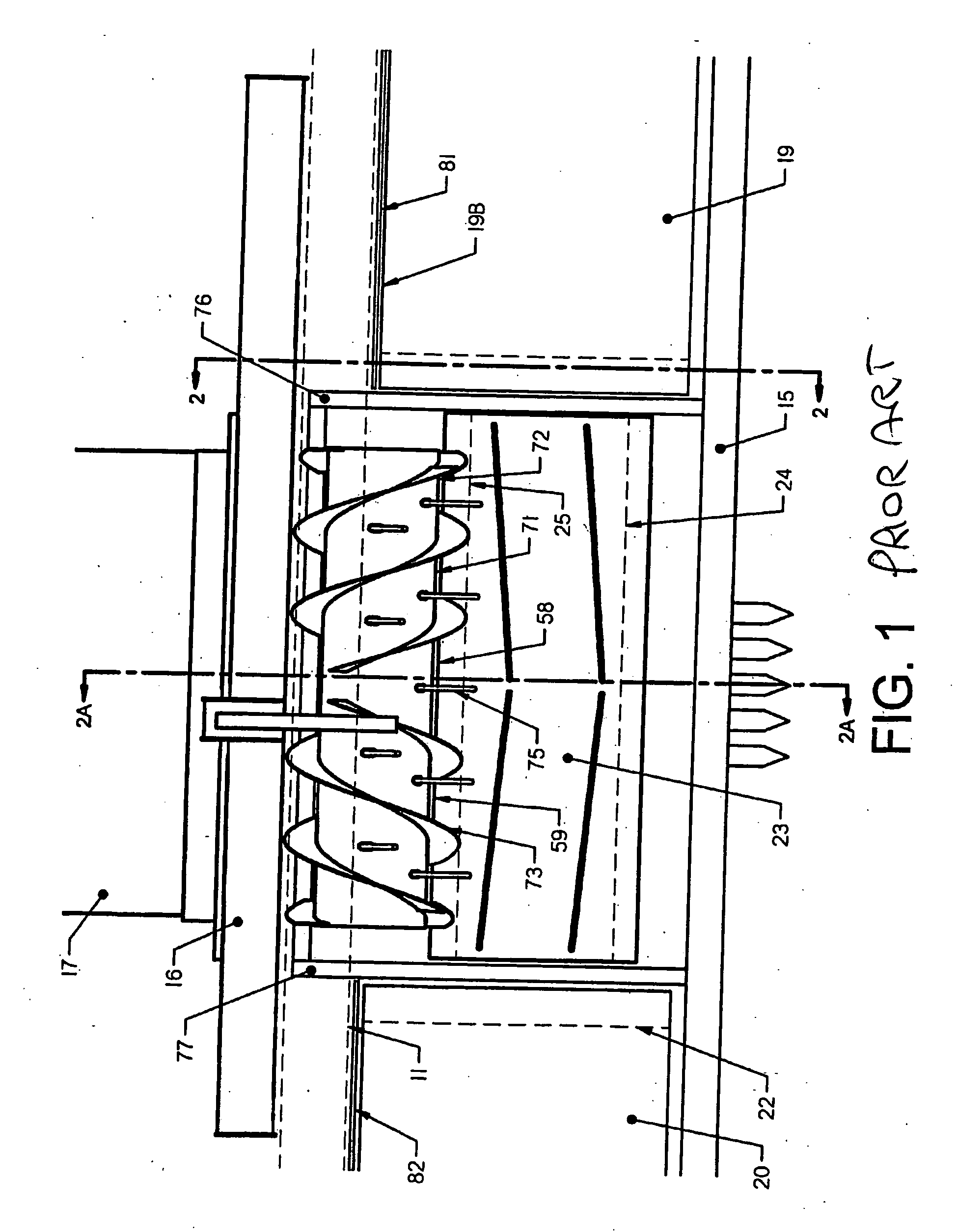

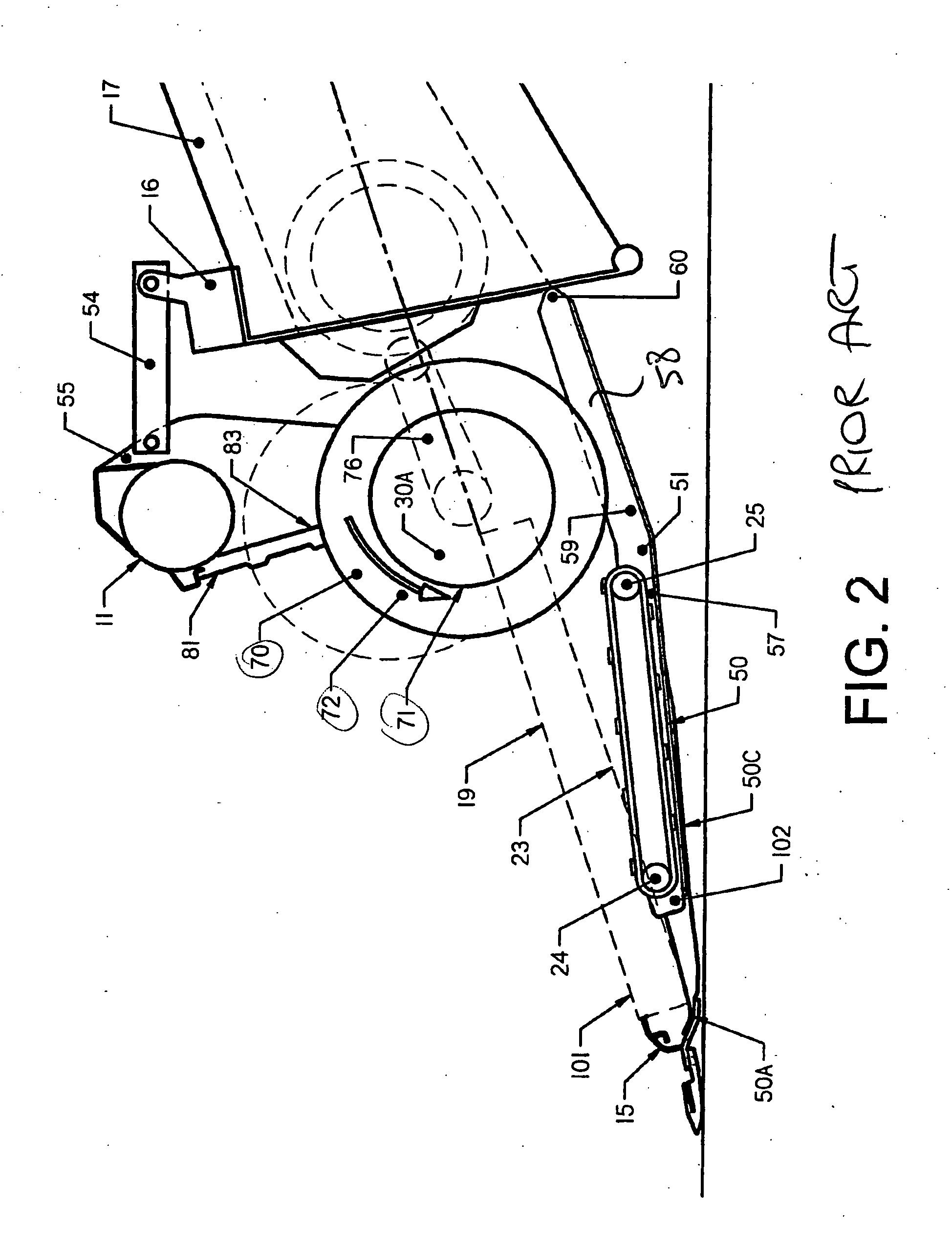

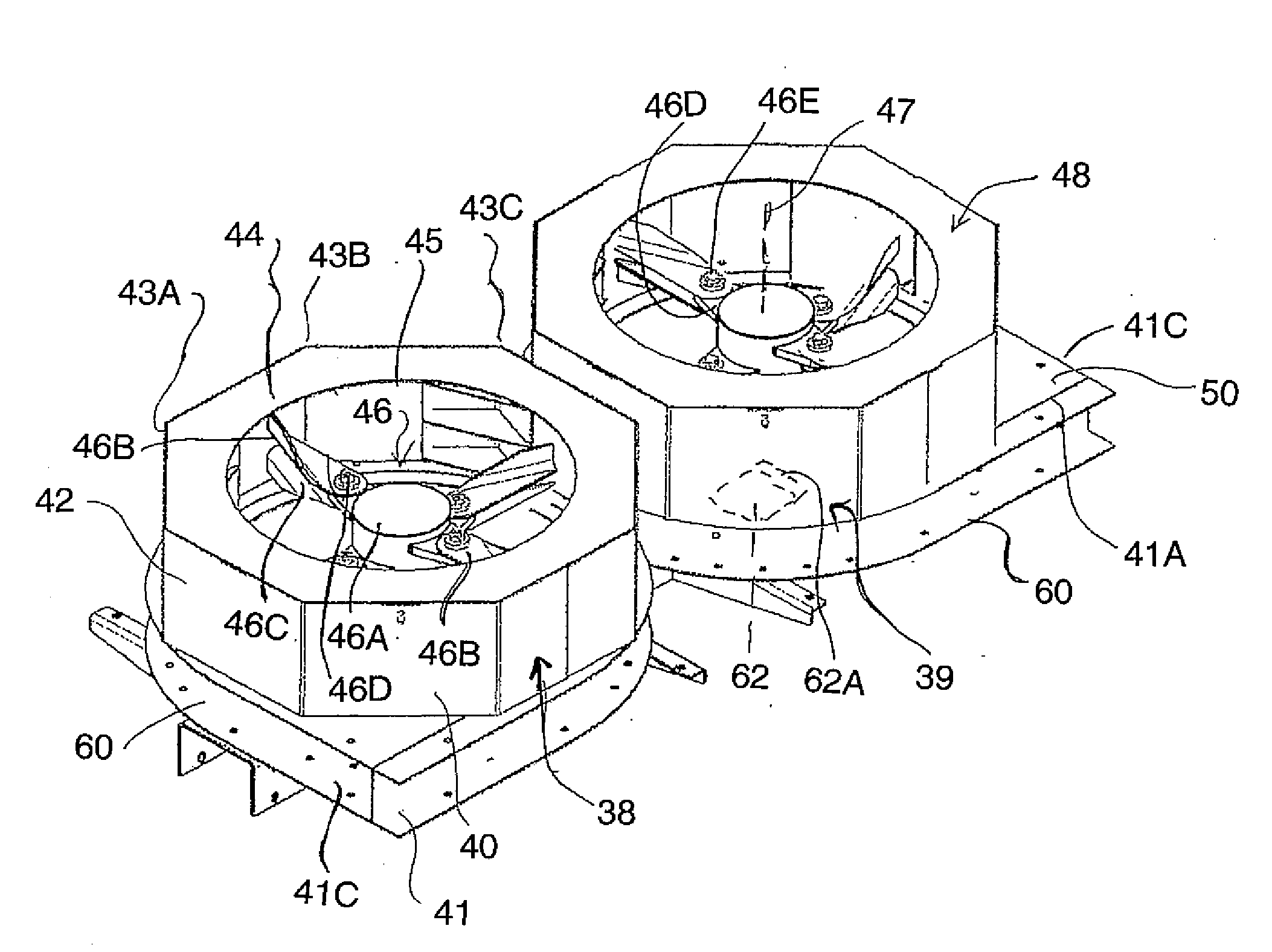

Weed seed destruction

Weed seeds are destroyed in the chaff from a combine harvester by repeated high speed impacts caused by a rotor mounted in one of a pair of side by side housings which accelerate the discarded seeds in a direction centrifugally away from the rotor onto a stator including angularly adjustable stator surfaces around the axis. Thus the discarded seeds rebound back and forth between the rotor and the stator to provide a plurality of impacts. The seeds are carried axially of the rotor by a controlled airstream so that they move to an axial discharge location where a discharge fan is mounted. The angle of the discharge around the rotor axis can be changed to direct the seeds to the side of the combine away from a straw chopper, towards the guide fins of the tailboard of the chopper, or into the housing of the straw chopper.

Owner:TRITANA INTPROP LTD

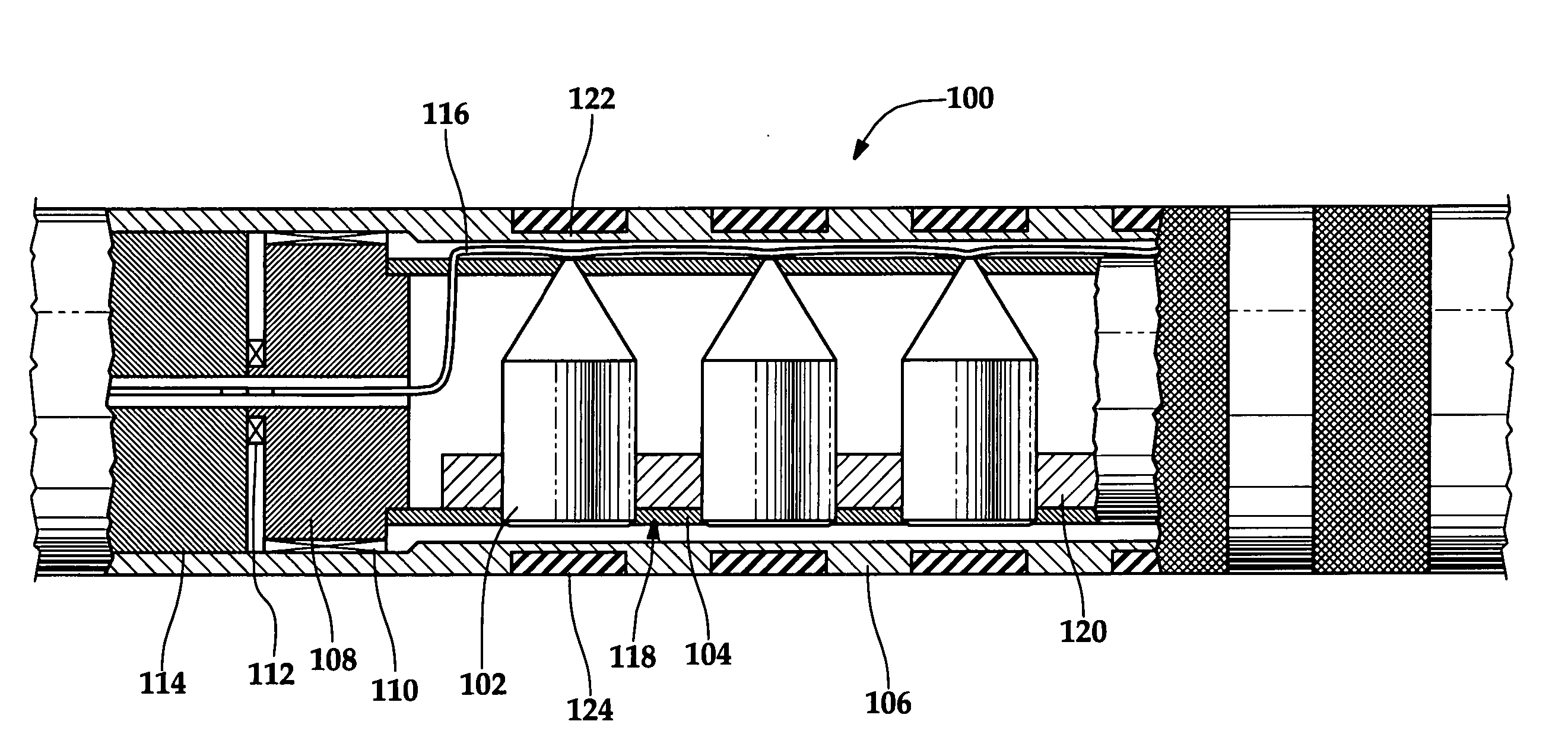

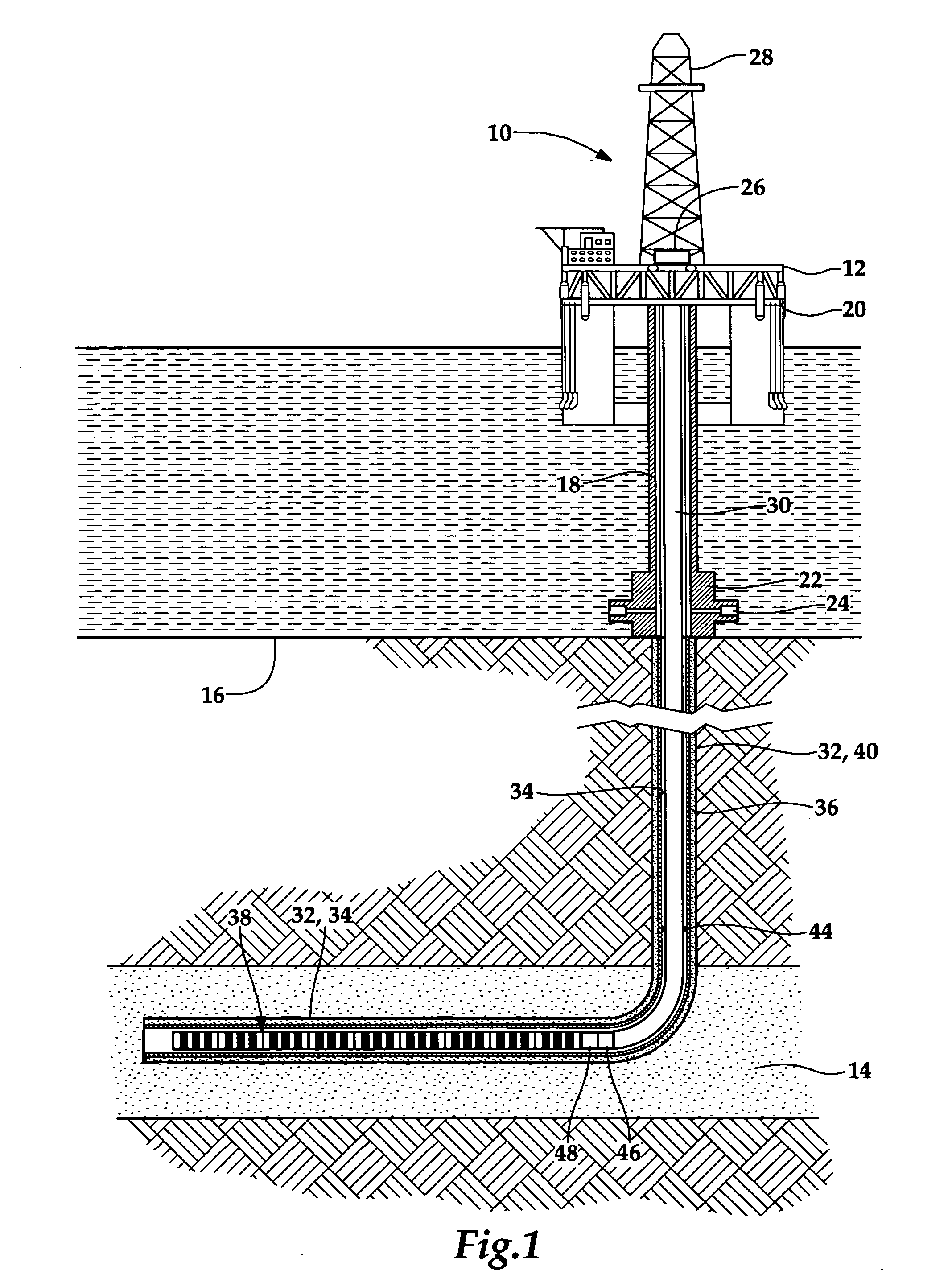

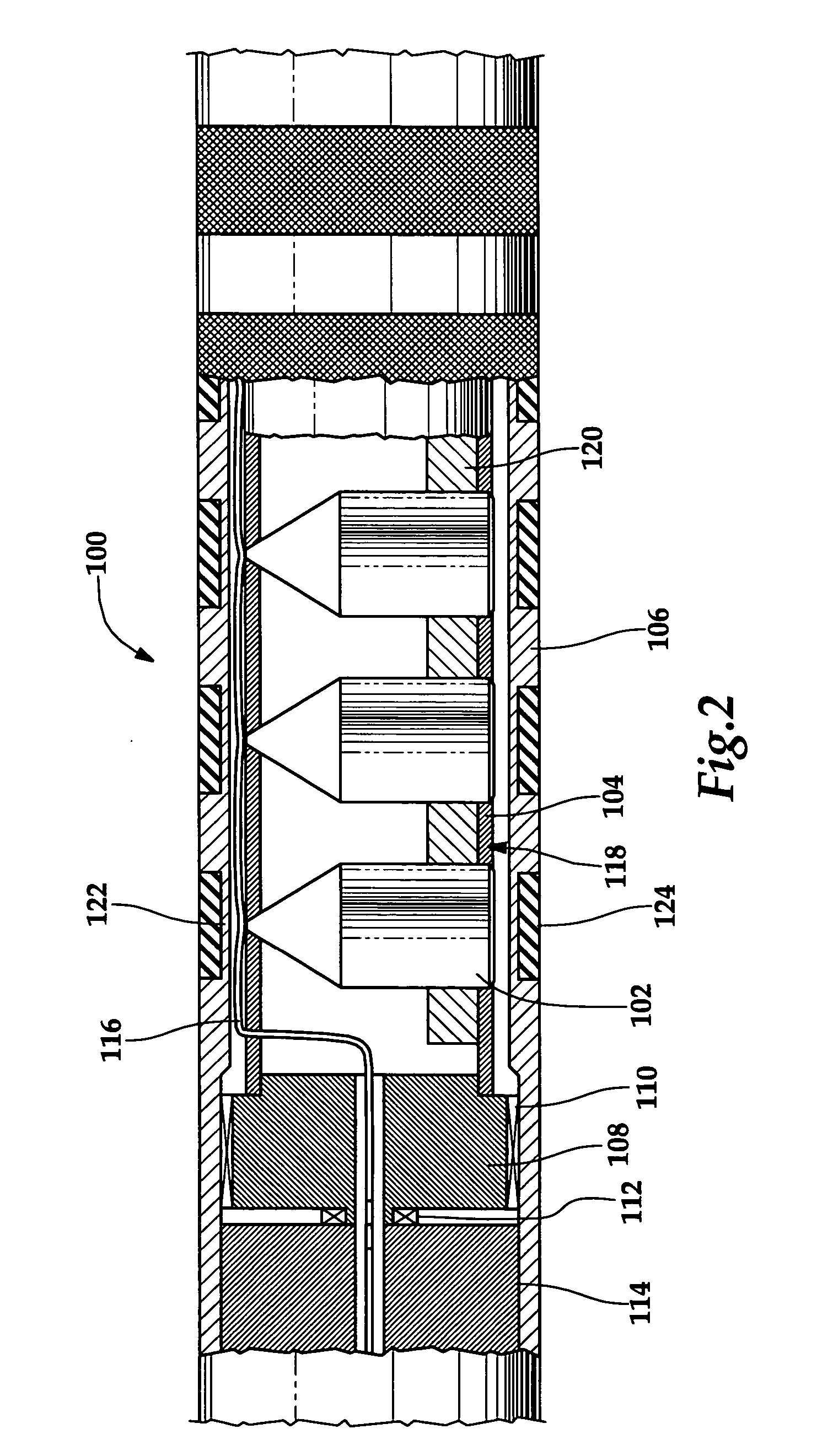

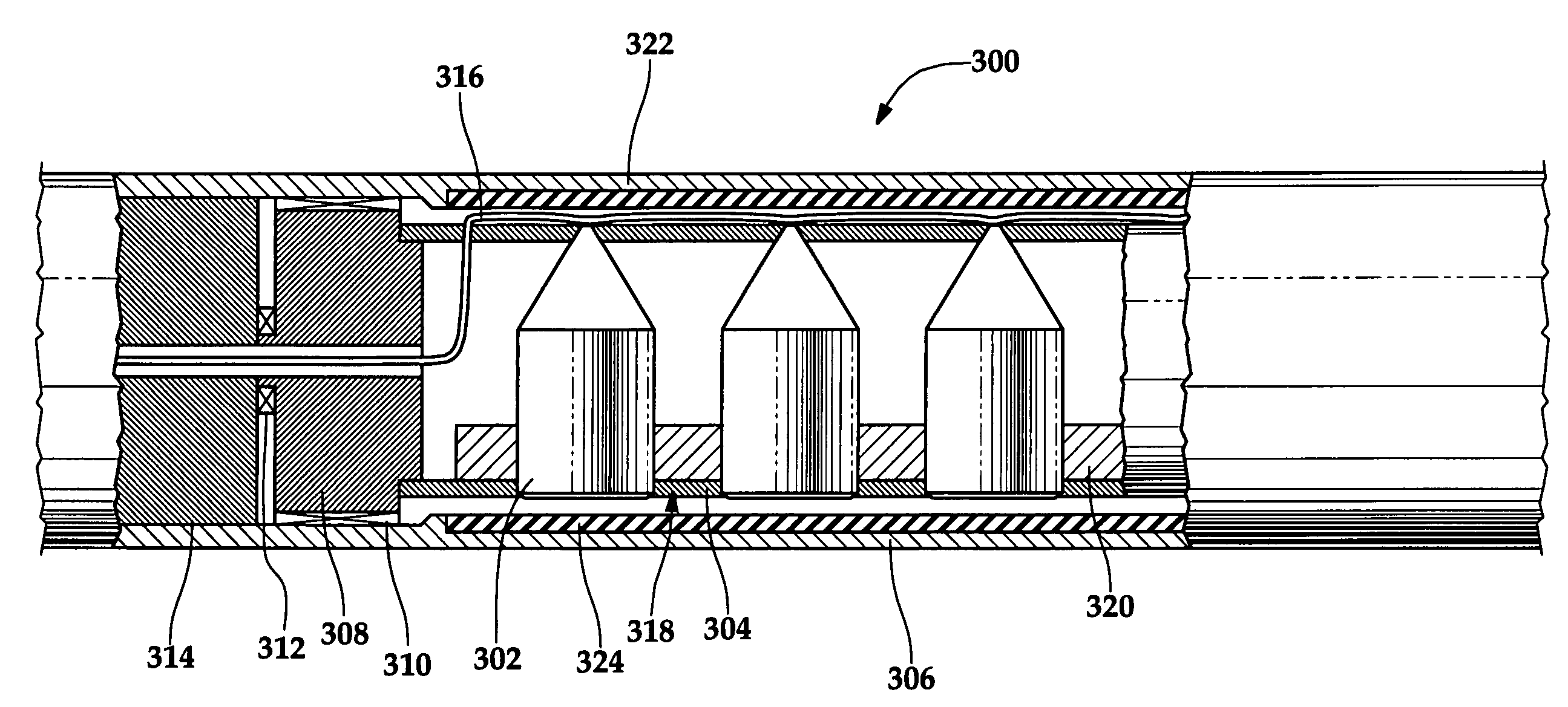

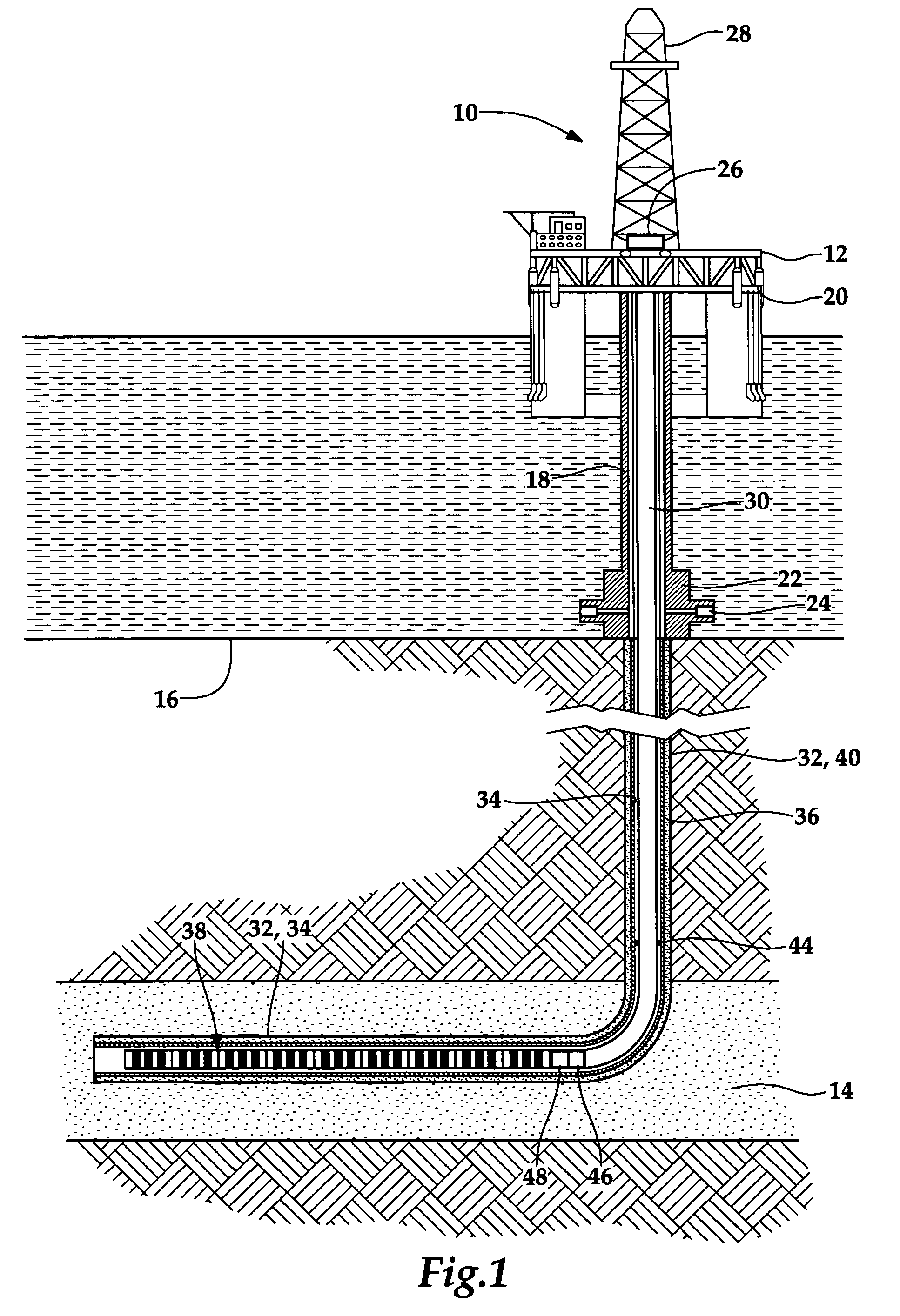

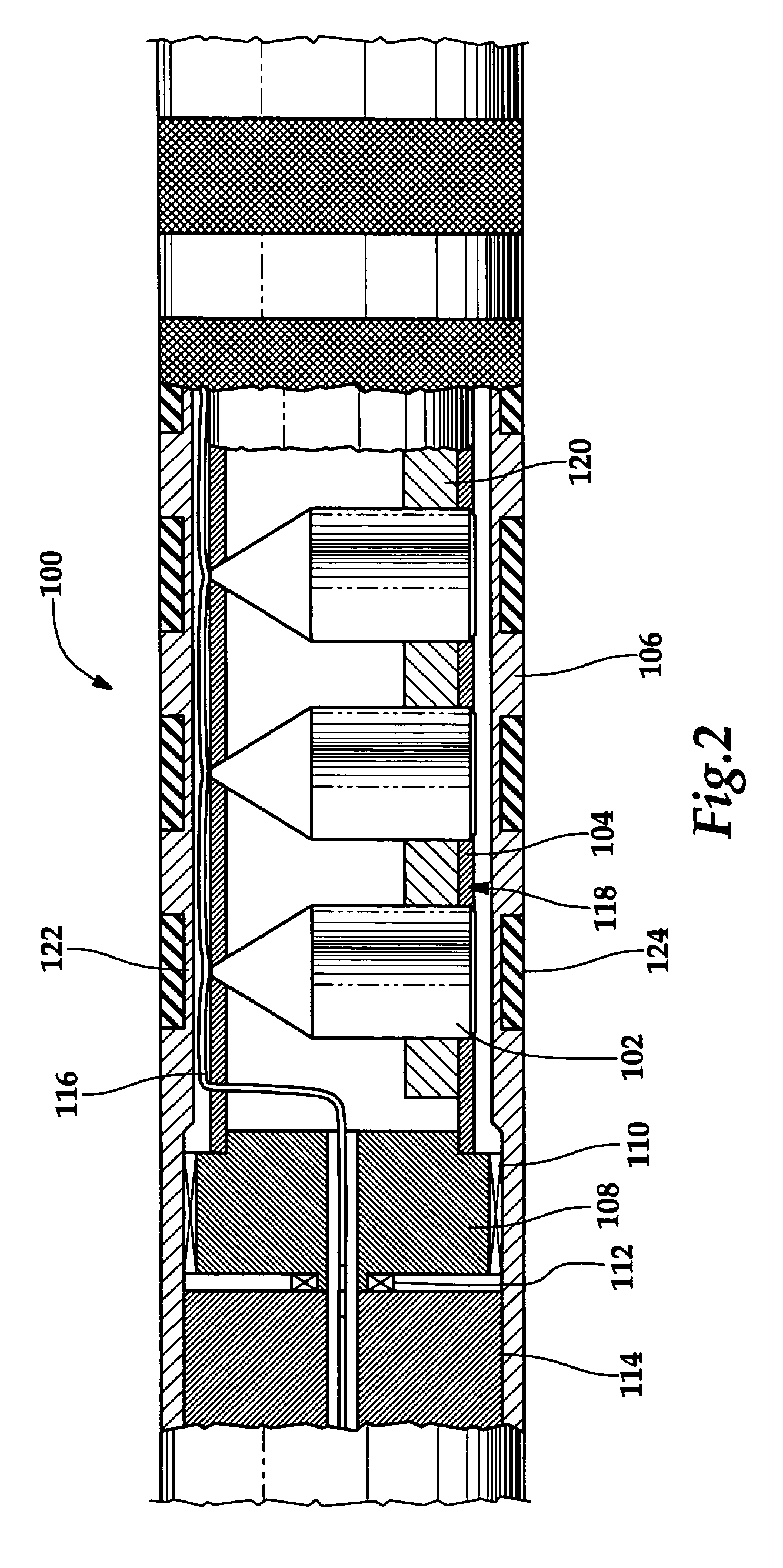

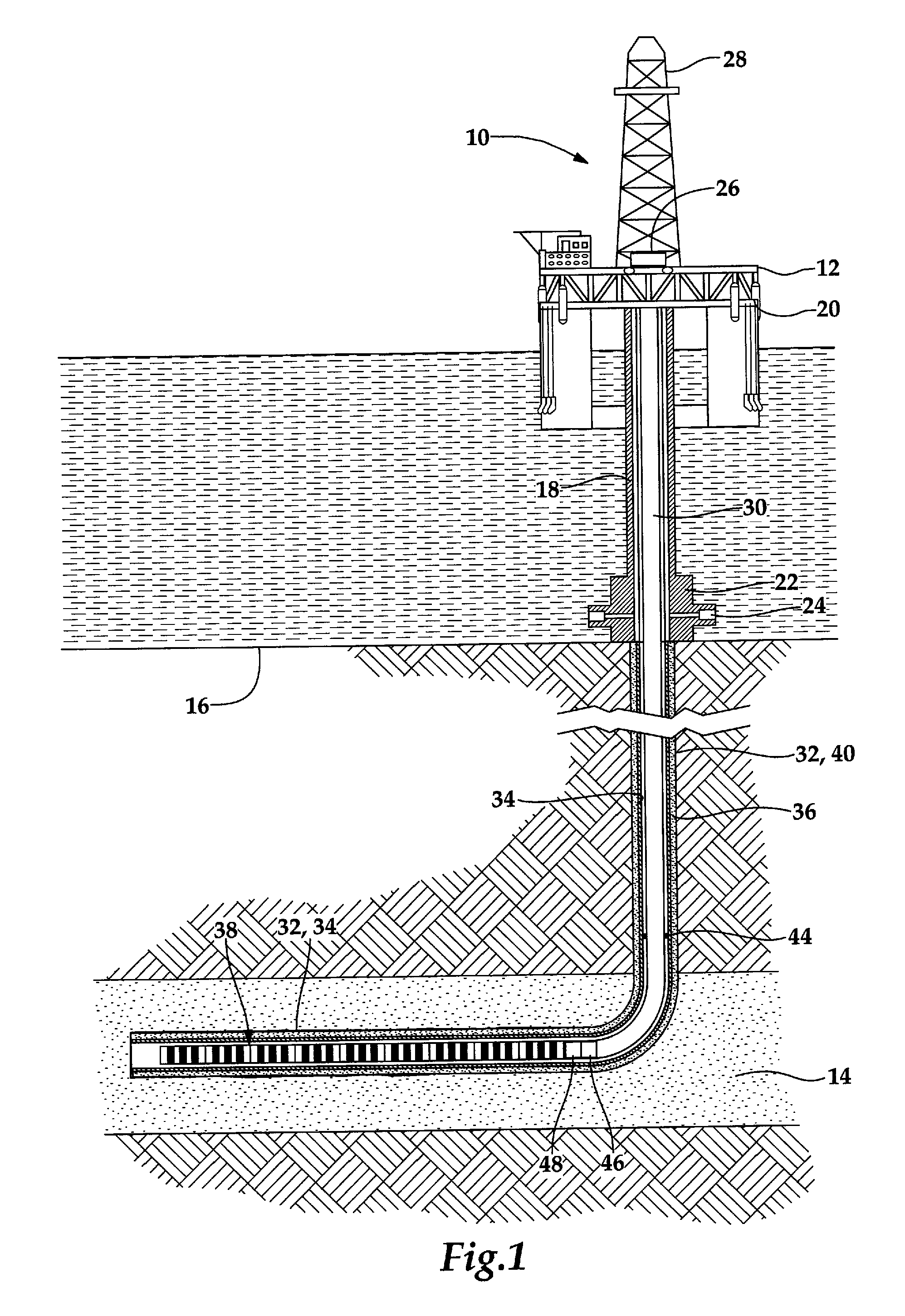

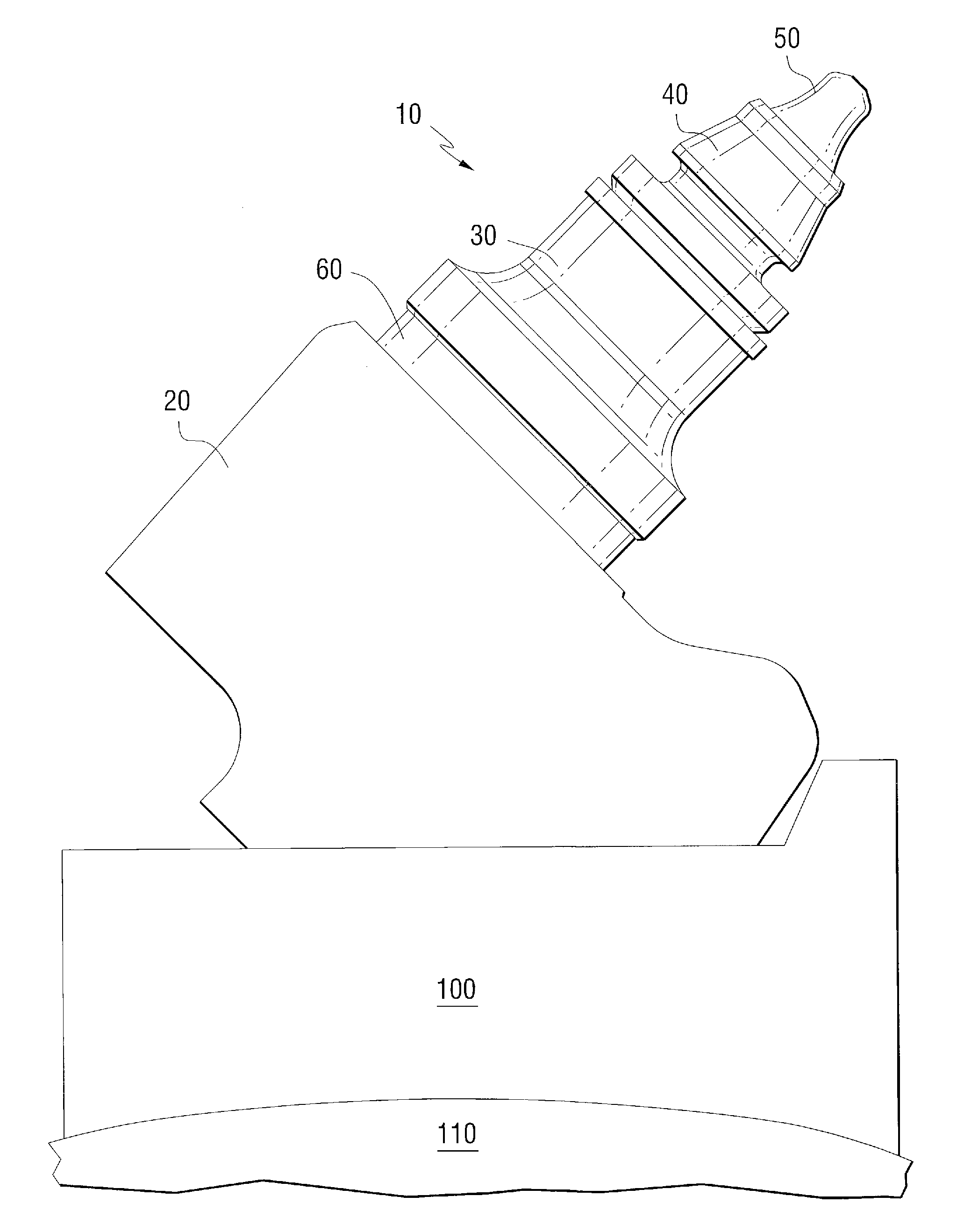

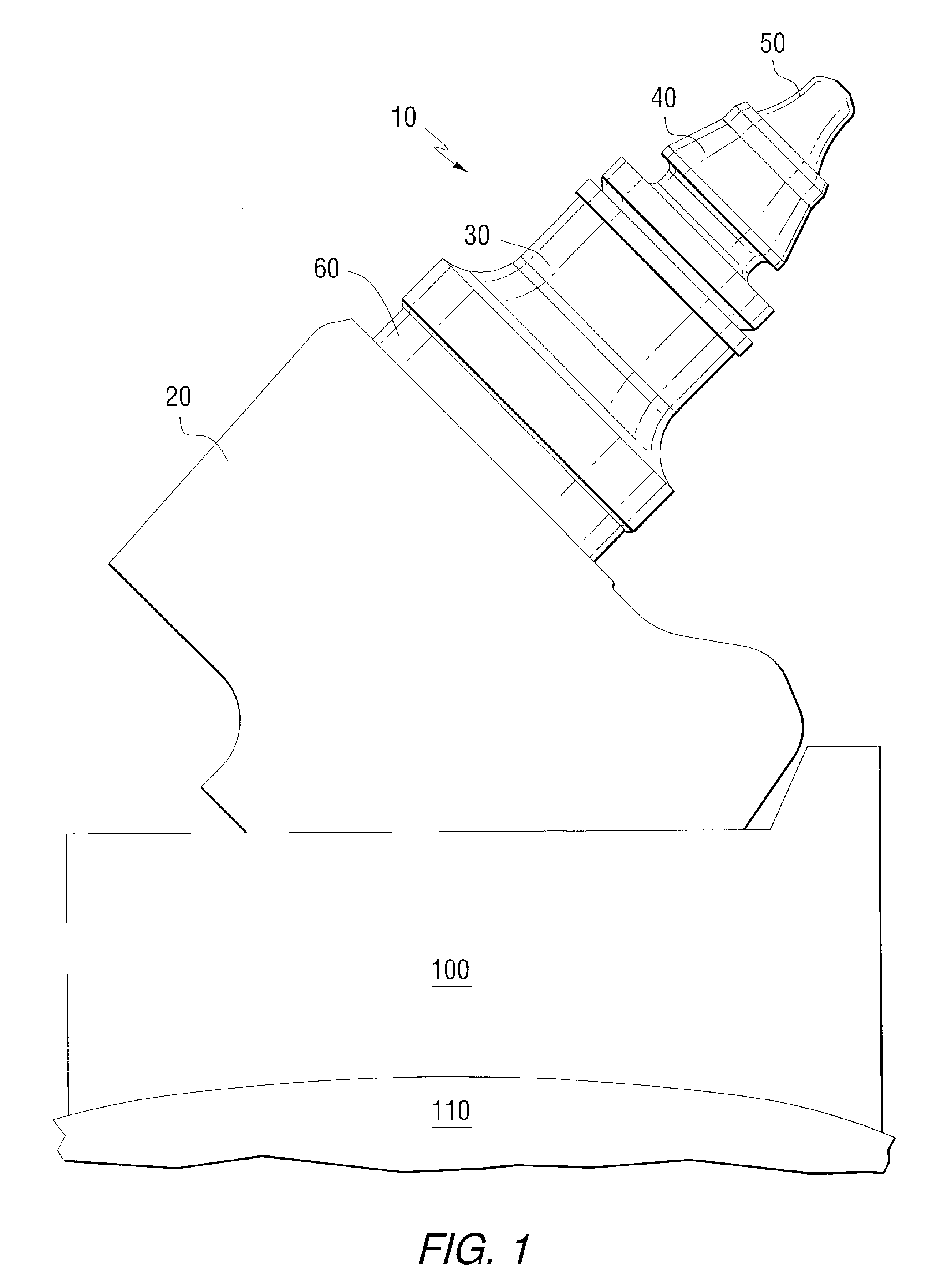

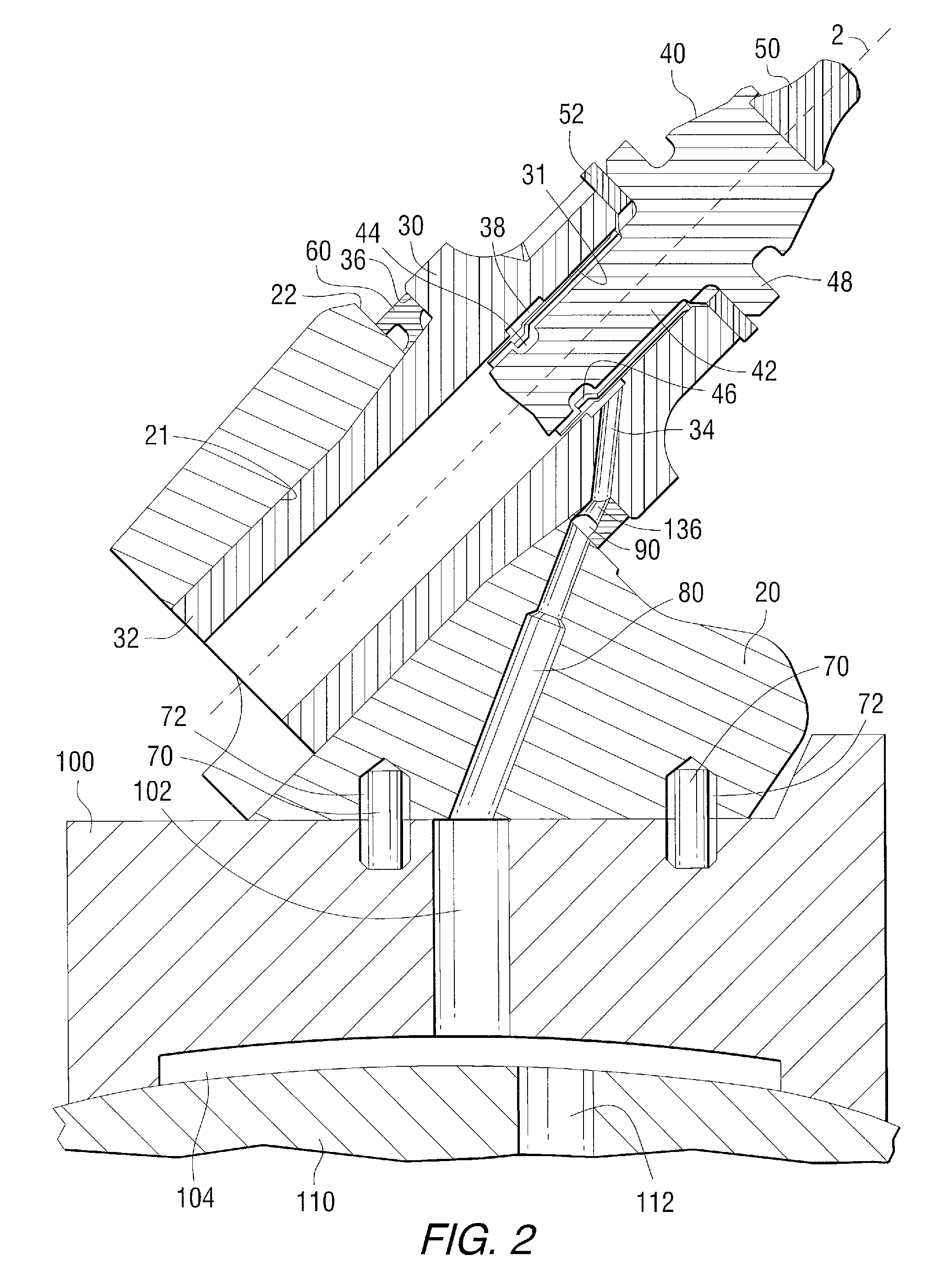

Debris retention perforating apparatus and method for use of same

A perforating apparatus (100) includes a plurality of shaped charges (102) each having an initiation end and a discharge end. A detonating cord (116) is operably coupled to the initiation ends of the shaped charges (102). A carrier (106) contains the shaped charges (102). The carrier (106) includes at least one discharge location corresponding to the discharge ends of the shaped charges (102) when the perforating apparatus (100) is in its operable position. The discharge location has first and second material layers (122, 124) wherein the second material layer (124) exhibits resilient recovery such that an opening created by a jet formed from detonating one of the shaped charges (102) in the second material layer (124) is smaller than an opening created by the jet in the first material layer (122), thereby retaining debris in the perforating apparatus (100) with the second material layer (124).

Owner:HALLIBURTON ENERGY SERVICES INC

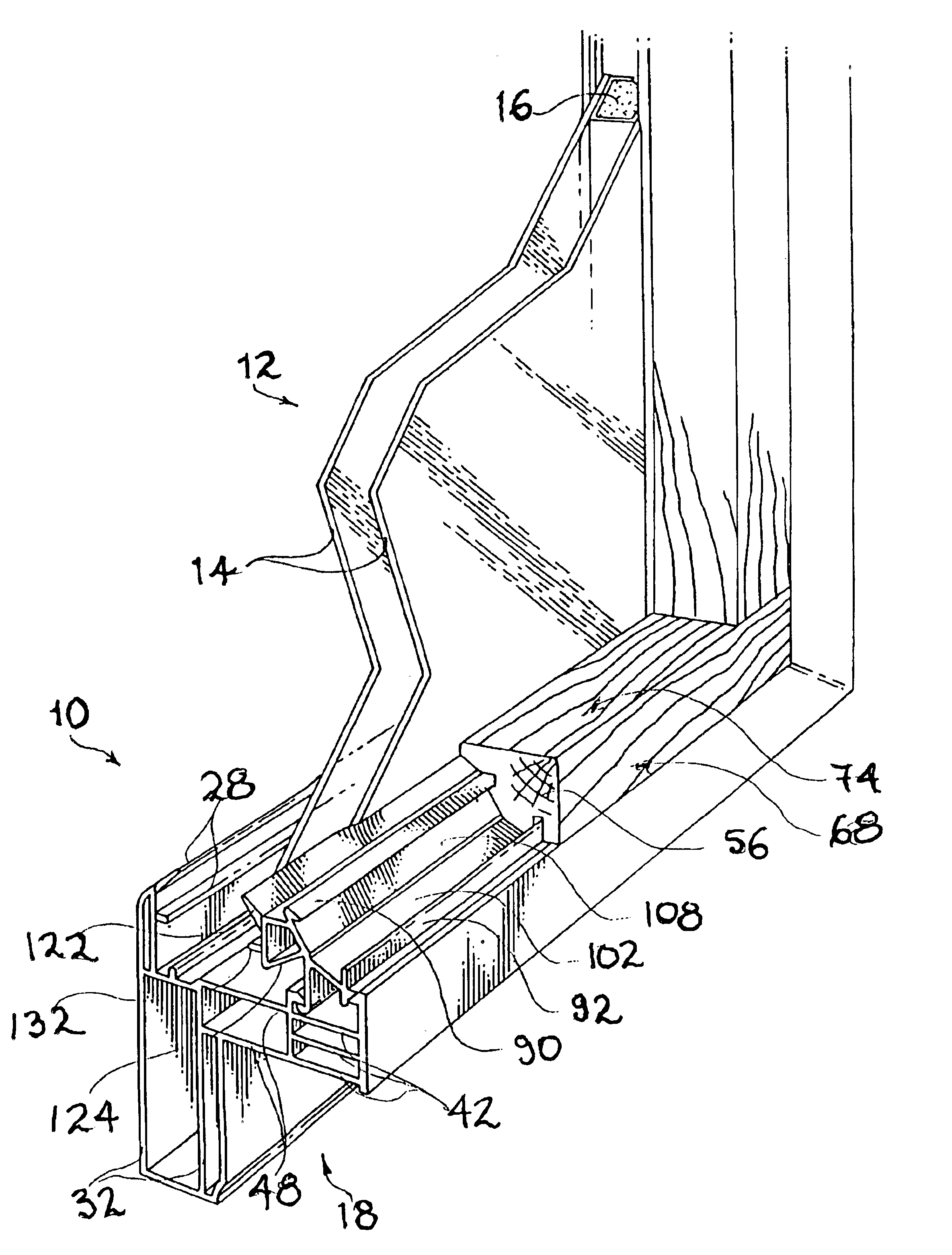

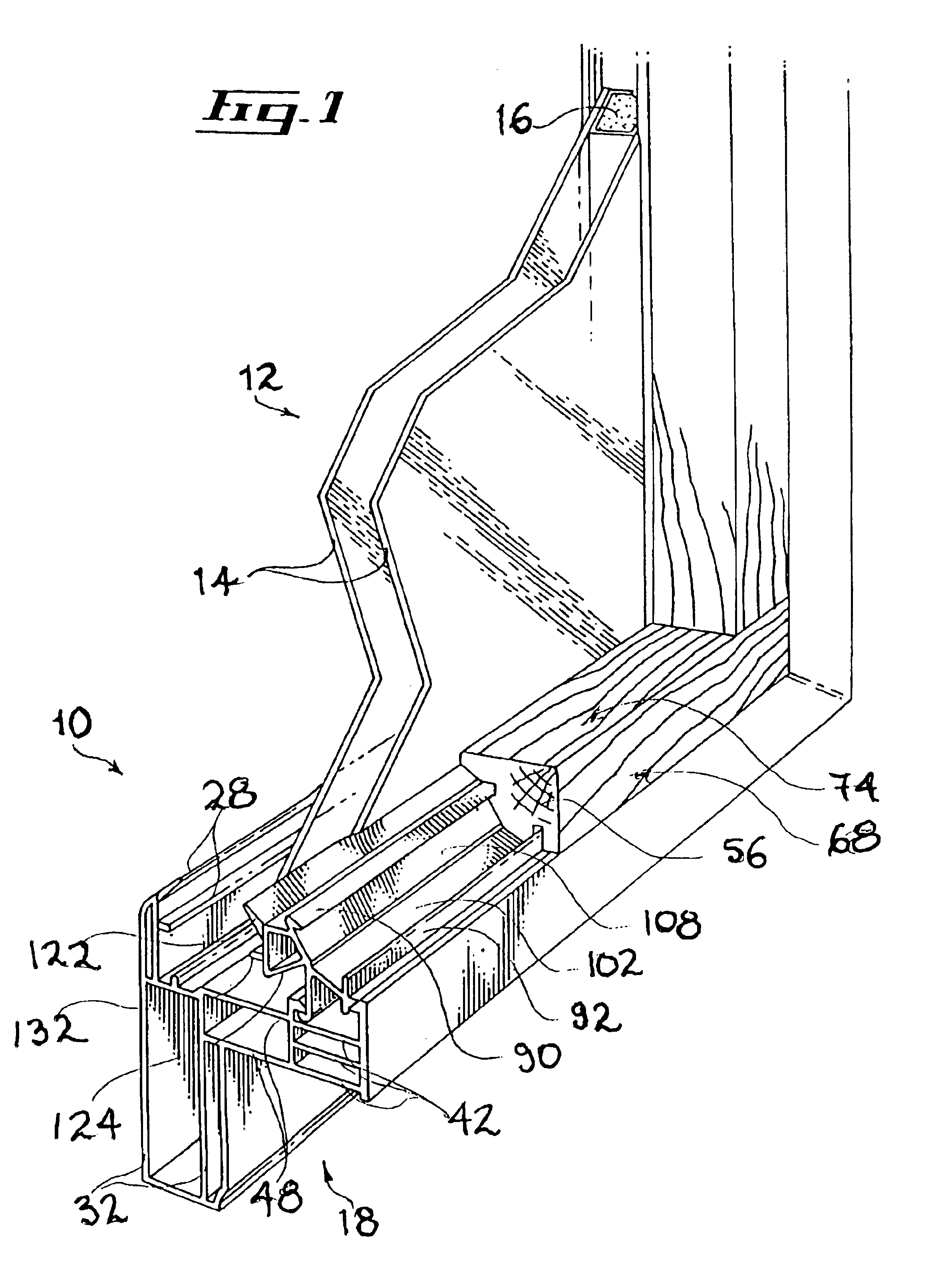

Condensation evacuating window sill

InactiveUS6848225B2Inhibit deteriorationImprove aestheticsFixed grillesCondensed water drain-offWindow sillEngineering

A condensation evacuating sill for evacuating condensate having formed on an inner surface of a window pane includes a molding strip and an attachment extrusion for attaching the molding strip to the window frame. The attachment extrusion includes an extrusion-to-molding attachment section for attaching the molding attachment surface to the attachment extrusion and an extrusion-to-frame attachment section for attaching the attachment extrusion to the window frame. The attachment extrusion is configured and sized for attaching the molding strip to the window frame so that the molding inner edge is spaced relative to the inner surface by a pane-to-molding spacing allowing the condensate to flow therethrough without contacting the molding strip. The attachment extrusion further includes flow guiding components for guiding the flow of condensate from the pane-to-molding spacing to a discharge location located away from the attachment extrusion.

Owner:LAPIERRE NORMAND

Crop feed arrangement for the header of a combine harvester

A draper header for a combine harvester includes two side drapers each running from an outer end guide roller at a first end of the header to an inner end guide roller adjacent the discharge location of the header and a central feed draper located at the discharge location and including a front guide roller just behind the cutter bar and running to a rear guide roller in front of the feeder house of the combine harvester. An auger is located between the discharge rollers with a front edge of the flight forward of the rear end of the discharge rollers to feed the material inwardly and underneath the auger to the inlet of the feeder house. A pan member is located underneath the feed draper and is formed of a flexible polyethylene sheet which is tensioned between its front and rear edges by a front mounting strip which is spring mounted for up and down movement and a rear latch which can be released to allow the rear edge to be lowered.

Owner:MACDON INDS

Weed Seed Destruction

ActiveUS20180070534A1Less potentEasily removable annual replacementMowersThreshersCombine harvesterWeed

Weed seeds are destroyed in the chaff from a combine harvester by repeated high speed impacts caused by a rotor mounted in one of a pair of side by side housings which accelerate the discarded seeds in a direction centrifugally away from the rotor onto a stator including angularly adjustable stator surfaces around the axis. Thus the discarded seeds rebound back and forth between the rotor and the stator to provide a plurality of impacts. The seeds are carried axially of the rotor by a controlled airstream so that they move to an axial discharge location where a discharge fan is mounted. The angle of the discharge around the rotor axis can be changed to direct the seeds to the side of the combine away from a straw chopper, towards the guide fins of the tailboard of the chopper, or into the housing of the straw chopper.

Owner:TRITANA INTPROP LTD

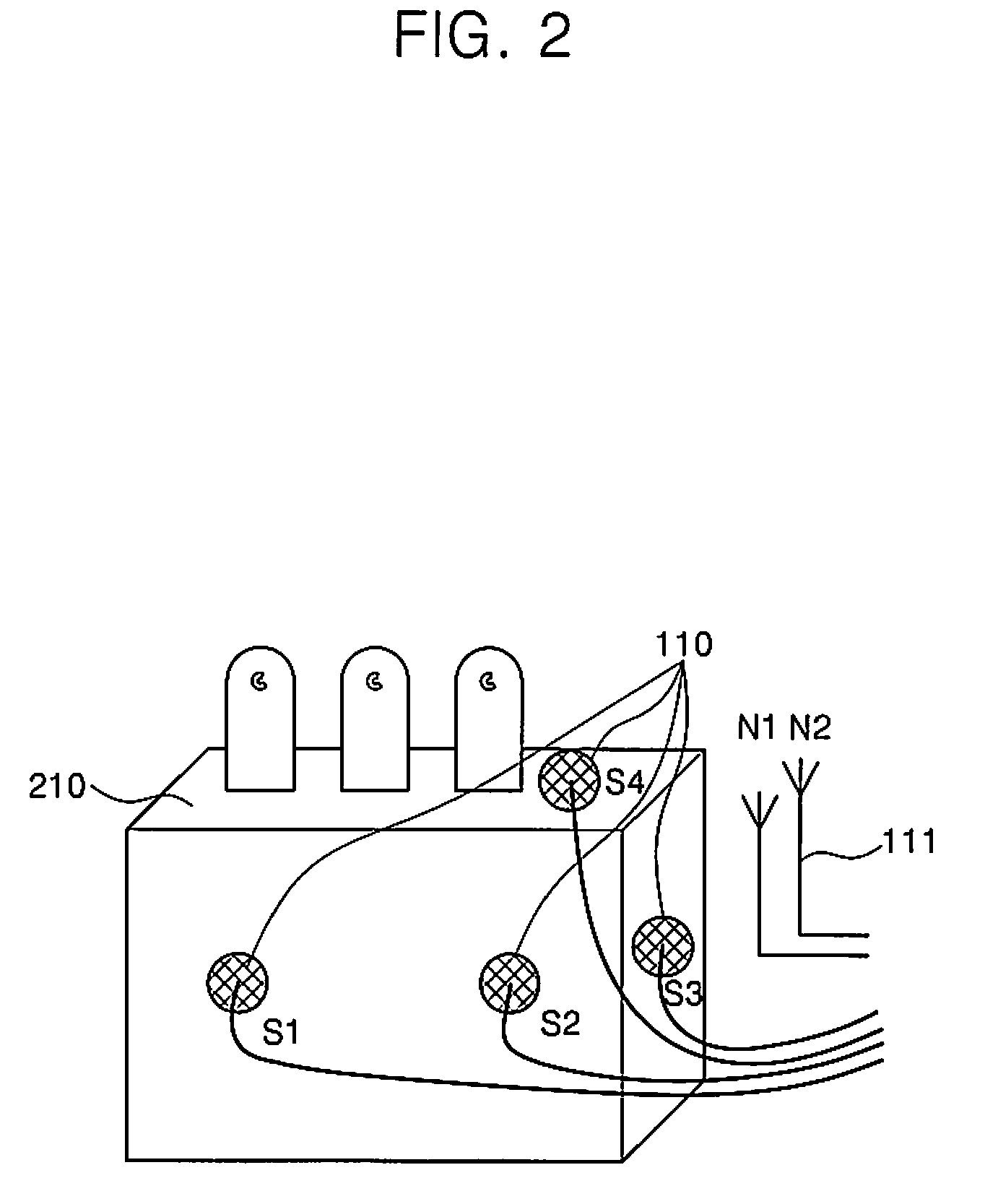

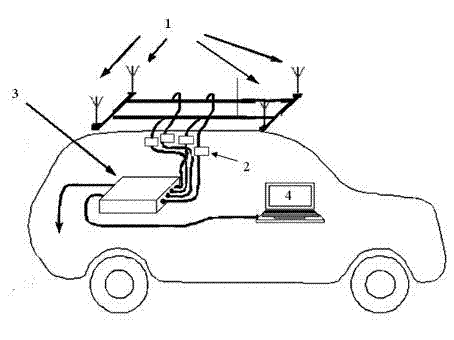

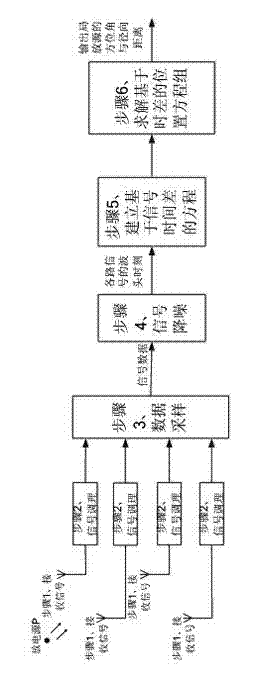

Vehicle-mounted local discharge locating system for mobile substation and locating method thereof

InactiveCN102866334AImprove reliabilityImprove the level of intelligenceTesting dielectric strengthSignal conditioning circuitsRadio frequency

The invention discloses a vehicle-mounted local discharge locating system for a mobile substation and a locating method of the vehicle-mounted local discharge locating system. Four radio frequency electromagnetic wave sensors are arranged on an automobile for receiving electromagnetic wave signals sent out from local discharge points, a signal conditioning circuit is used for amplifying and filtering the received signals, and a high-speed data sampling unit is used for synchronously collecting 4 paths of output signals and outputting the data to a data processing and analyzing unit so as to establish an equation set according to starting times when four radio frequency omnidirectional sensors receive ultrahigh frequency signals radiated by the same discharge source calculated in real time and on the basis of time differences of the four paths of received signals, solve direction angles and radial distances of the discharge signals and locate the discharge parts. According to the invention, all high-voltage equipment in the substation can be detected and located for local discharge, the cost for detecting the local discharge of the equipment can be greatly reduced, defects can be found out as soon as possible during patrol and inspection of the substation equipment, and accidents and interruption maintenance time can be reduced, so that the operation reliability and the intellectualization level of the substation can be improved and increased.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +2

Debris retention perforating apparatus and method for use of same

A perforating apparatus (100) includes a plurality of shaped charges (102) each having an initiation end and a discharge end. A detonating cord (116) is operably coupled to the initiation ends of the shaped charges (102). A carrier (106) contains the shaped charges (102). The carrier (106) includes at least one discharge location corresponding to the discharge ends of the shaped charges (102) when the perforating apparatus (100) is in its operable position. The discharge location has first and second material layers (122, 124) wherein the second material layer (124) exhibits resilient recovery such that an opening created by a jet formed from detonating one of the shaped charges (102) in the second material layer (124) is smaller than an opening created by the jet in the first material layer (122), thereby retaining debris in the perforating apparatus (100) with the second material layer (124).

Owner:HALLIBURTON ENERGY SERVICES INC

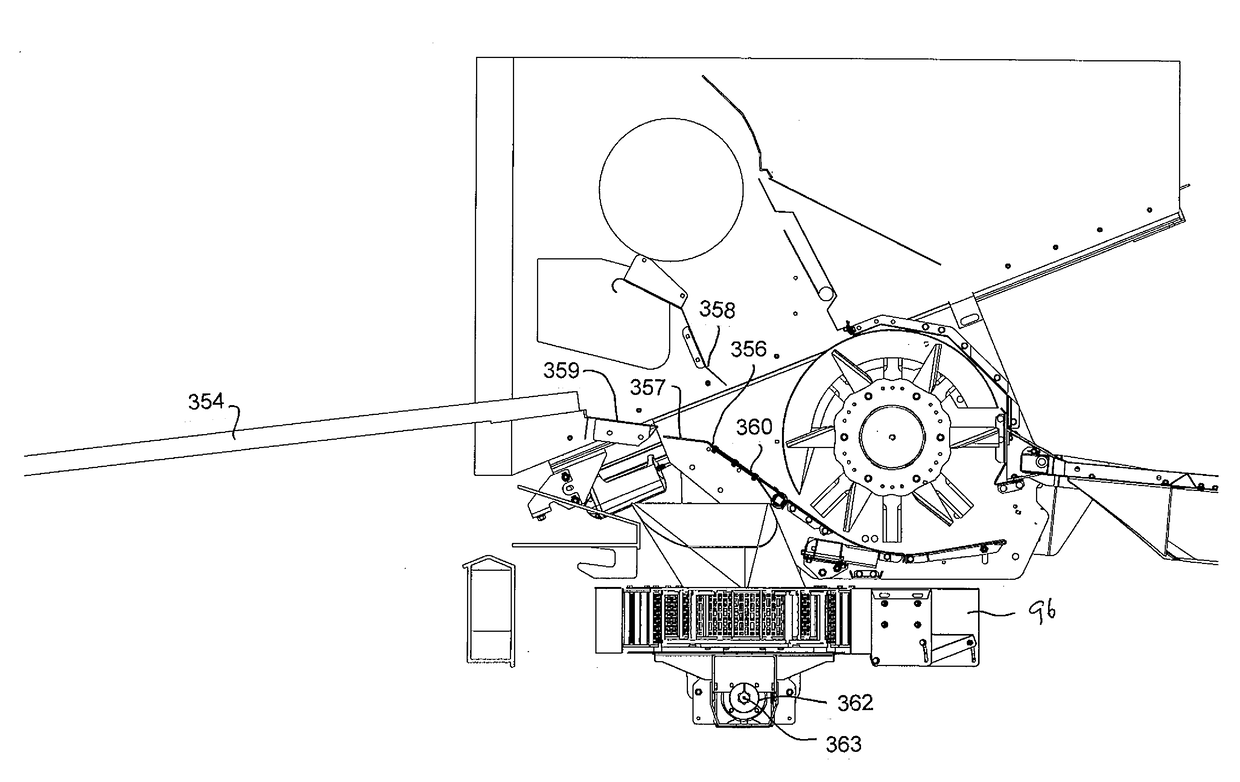

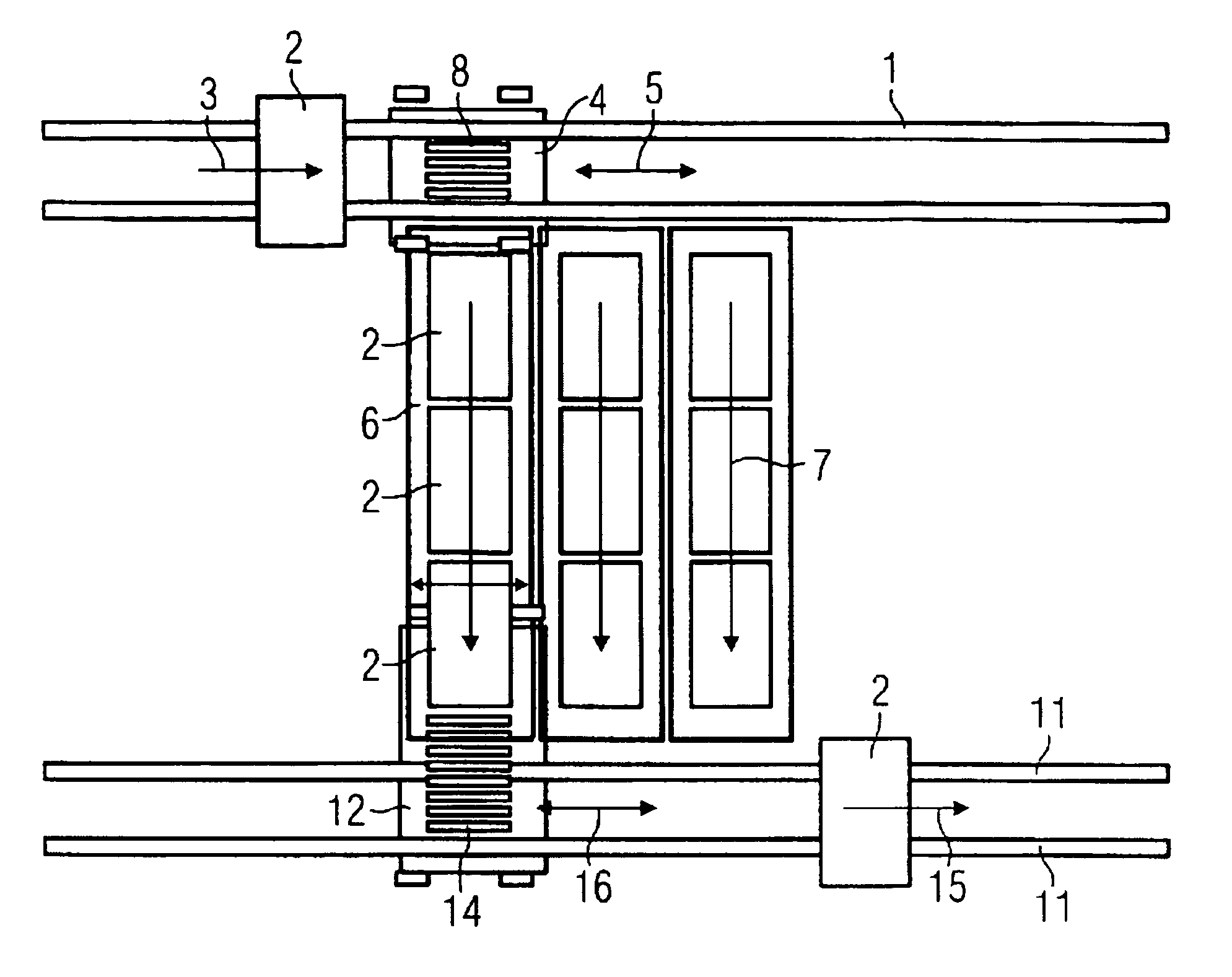

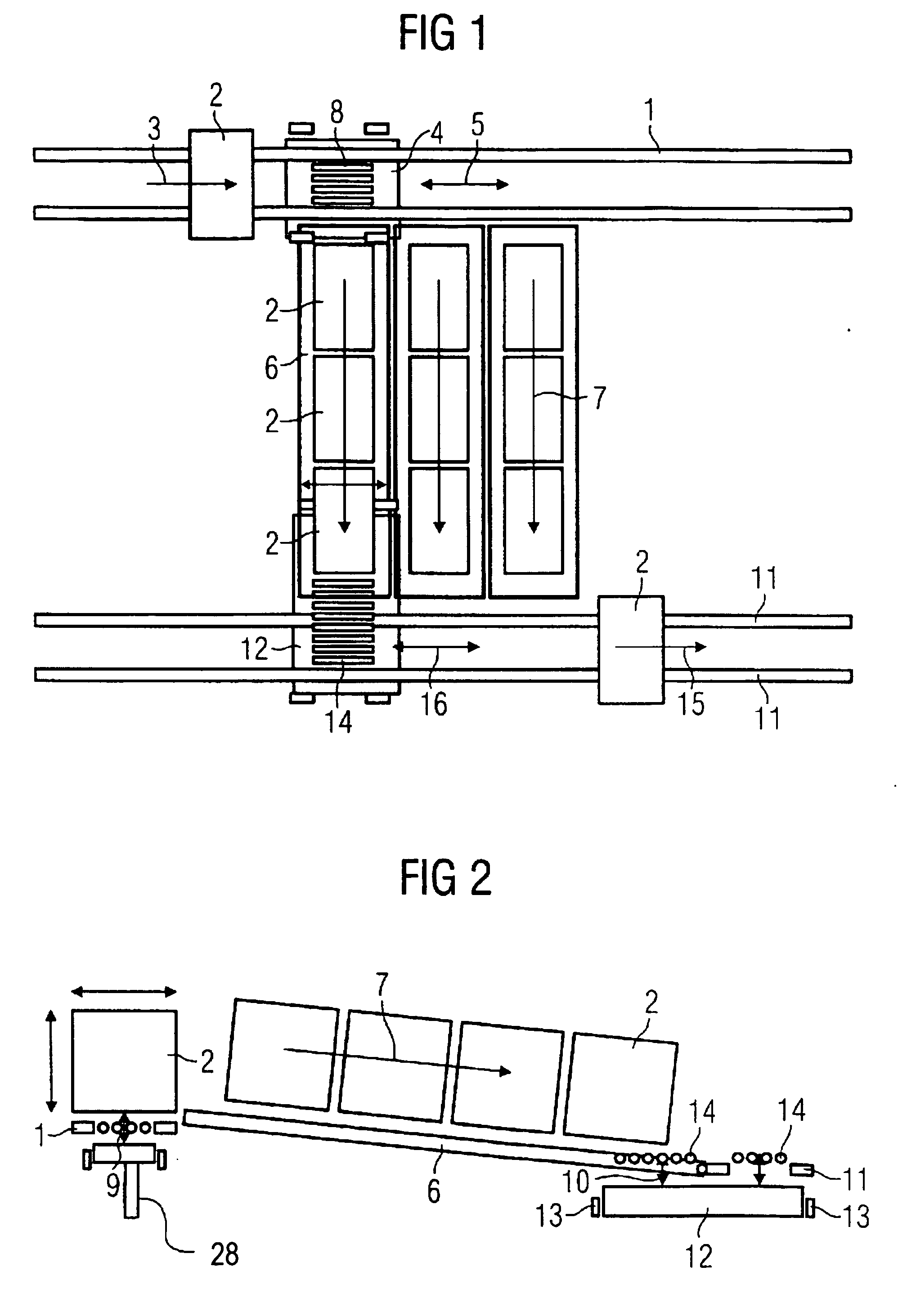

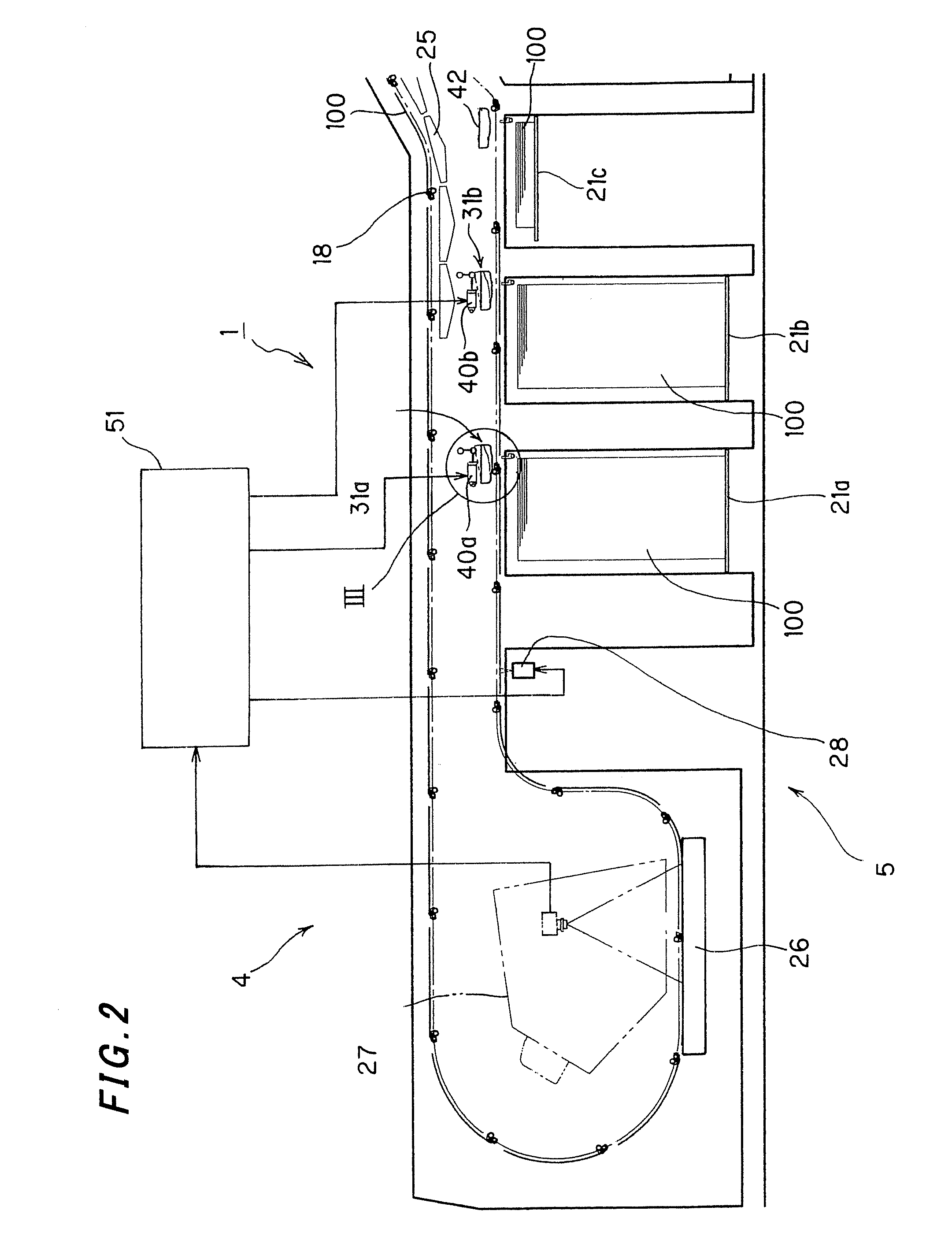

Apparatus for charging and removing load carriers or piece goods

InactiveUS20060070847A1Raise and low transferConsiderable cost advantageStorage devicesConveyor partsEngineeringDischarge location

The invention relates to an apparatus for charging and / or removing load carriers or piece goods onto or from buffer sections, such as sloping roller tracks or continuous channels, by means of a transfer apparatus for picking up in each case one load carrier or item of piece goods from a conveyor track and discharging it to a fixed buffer section, or for accepting a load carrier or item of piece goods from a buffer section in order to pass it on to a fixed discharge location. In order to achieve the object of providing an economic, simple and functional charging and / or removal apparatus, it is proposed to construct the transfer apparatus as a mobile carriage which can be positioned below the transport plane of the conveyor track or the buffer section and has a transfer element arranged thereon, and to configure the mobile carriage such that it can be moved transversely with respect to the buffer sections into positions in which it corresponds with one of the buffer sections in each case.

Owner:SIEMENS AG

Weed Seed Destruction

Weed seeds are destroyed in the chaff from a combine harvester by repeated high speed impacts caused by a rotor mounted in one of a pair of side by side housings which accelerate the discarded seeds in a direction centrifugally away from the rotor onto a stator including angularly adjustable stator surfaces around the axis. Thus the discarded seeds rebound back and forth between the rotor and the stator to provide a plurality of impacts. The seeds are carried axially of the rotor by a controlled airstream so that they move to an axial discharge location where a discharge fan is mounted. The angle of the discharge around the rotor axis can be changed to direct the seeds to the side of the combine away from a straw chopper, towards the guide fins of the tailboard of the chopper, or into the housing of the straw chopper.

Owner:TRITANA INTPROP LTD

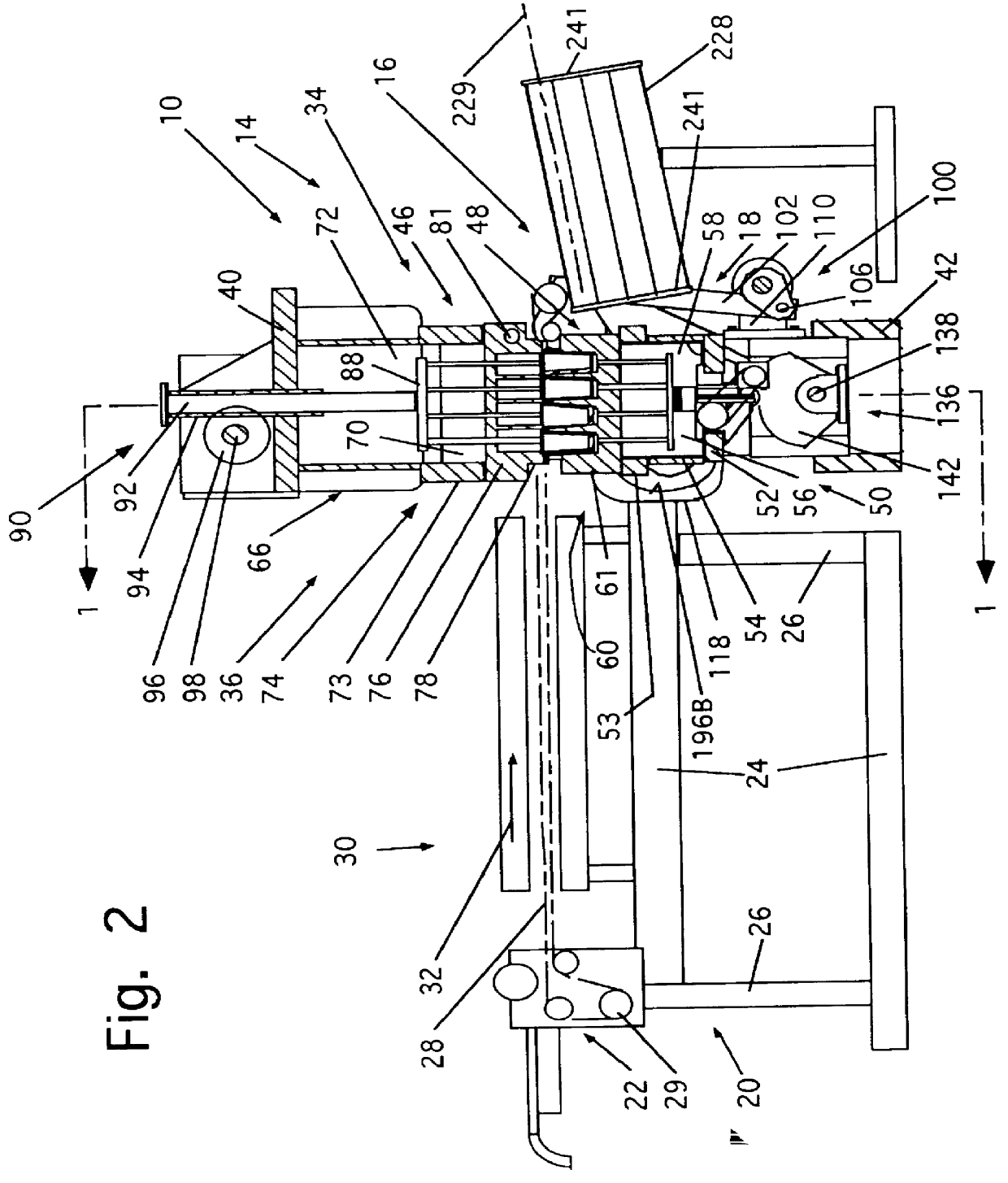

Planting unit for a seeding machine having a seed meter with a downwardly facing metering member and a seed delivery system

A planting unit for a seeding machine having a seed meter with a metering member. The metering member has a sidewall with inner and outer surfaces and apertures extending through the sidewall. The metering member is adapted to adhere seed to the apertures to sequentially move seed to a release position at which the inner surface of the sidewall is facing downward such the seed is hanging beneath the sidewall. A mechanical seed delivery system takes seed from the metering member at the release portion and controls movement, of seed from the seed meter to a discharge location adjacent a seed furrow formed in soil beneath the seeding machine.

Owner:DEERE & CO

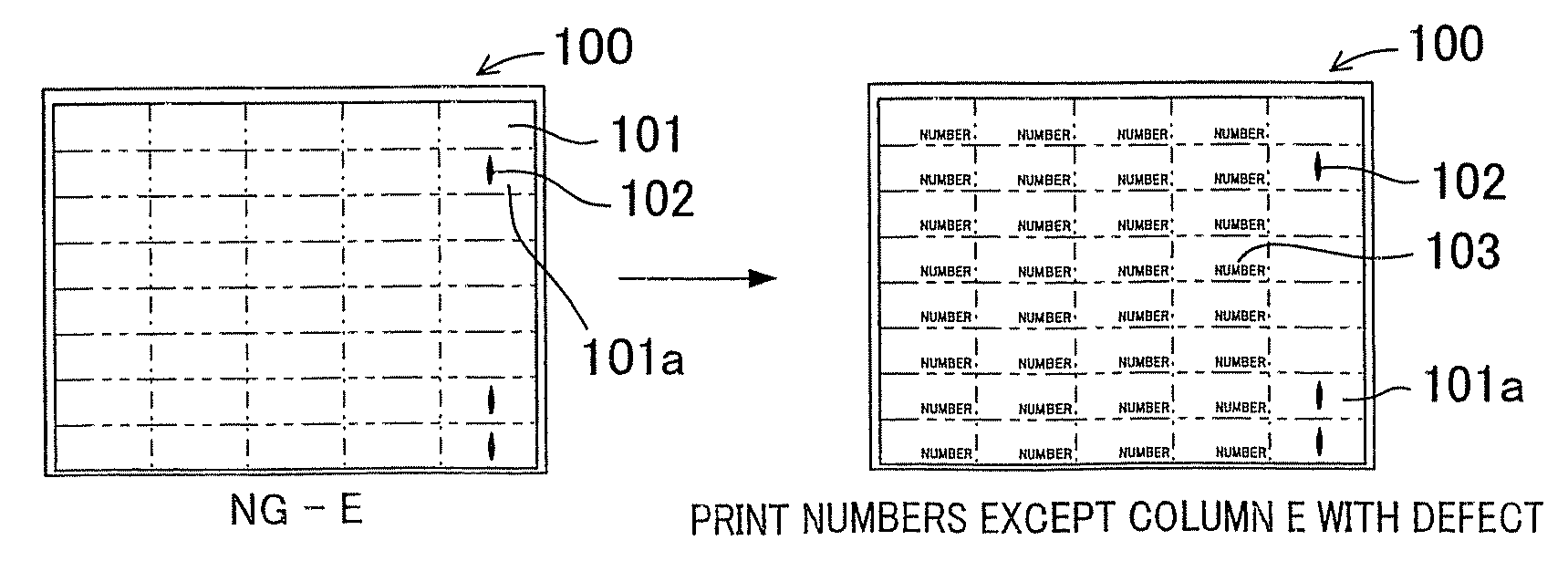

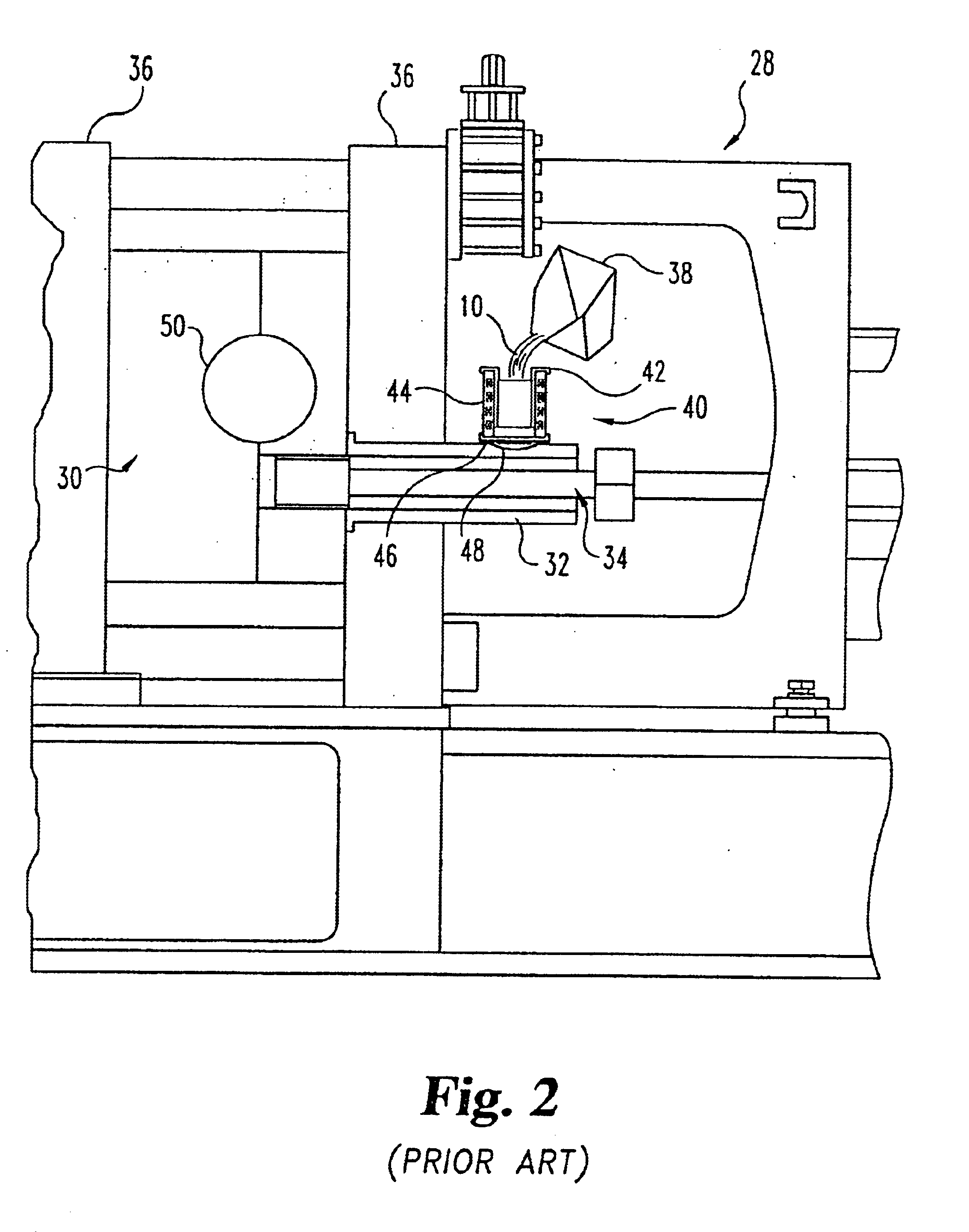

Sheet sorting method and apparatus

InactiveUS20070175912A1Reduce in quantityReduce manpowerRegistering devicesCoin-freed apparatus detailsPaper sheetDischarge location

Disclosed is a sheet sorting method in which, on paper sheets each with a plurality of identical patterns printed thereon side by side in a longitudinal direction and in a lateral direction, a quality of the patterns thereof is inspected; in a case where the quality of the patterns on the sheets in all of groups into which the plurality of patterns are grouped is determined to be non-defective, these paper sheets are discharged to non-defective sheet discharge locations; in a case where a defect is determined to exist among the patterns in only one of the groups on each of the sheets, these paper sheets are discharged to single-column defective discharge locations (single-group defective sheet discharge locations); and in a case where defects are determined to exist among the patterns in a plurality of groups on each of the sheets, these paper sheets are discharged to plural-group defective discharge locations.

Owner:KOMORI CORP

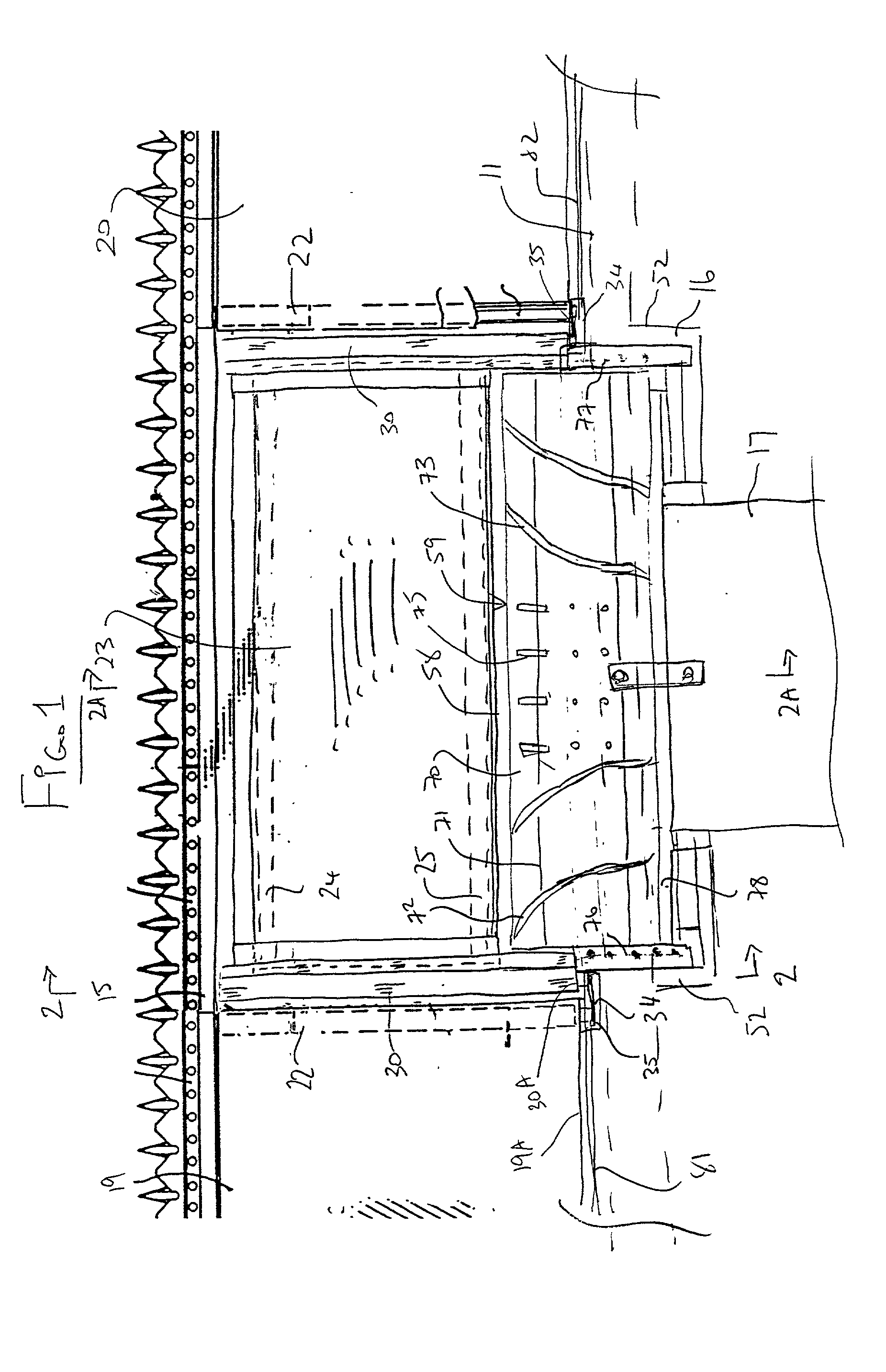

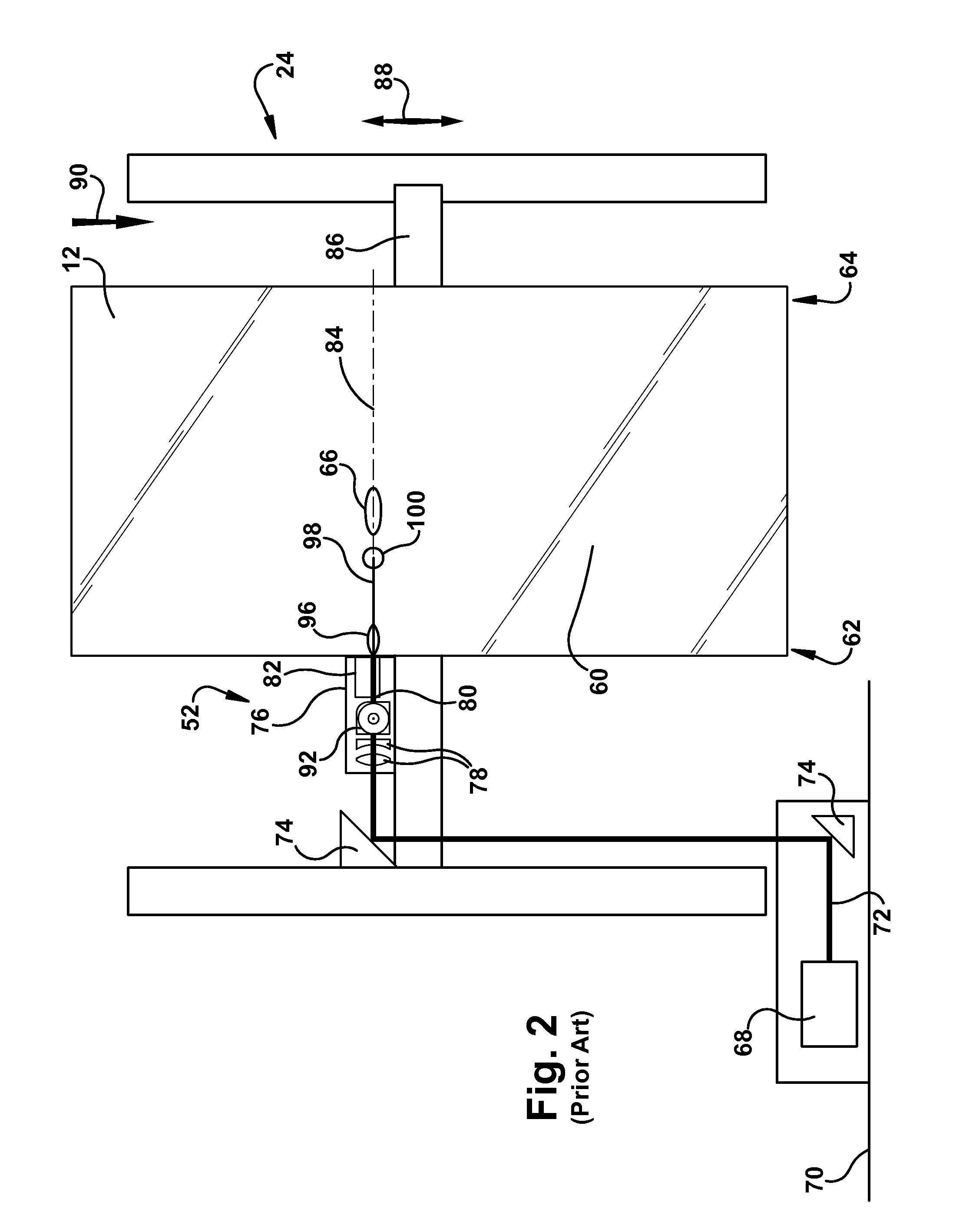

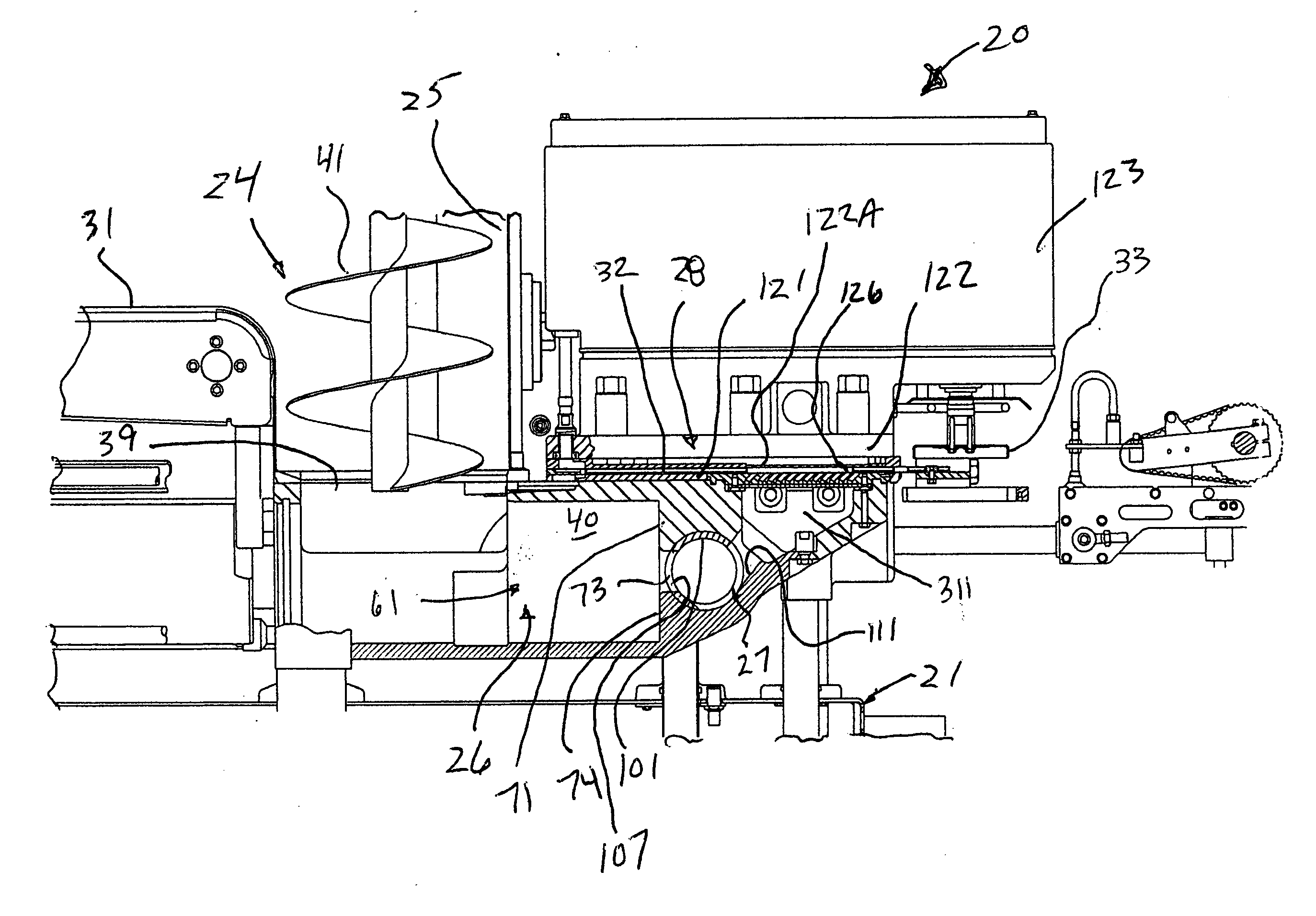

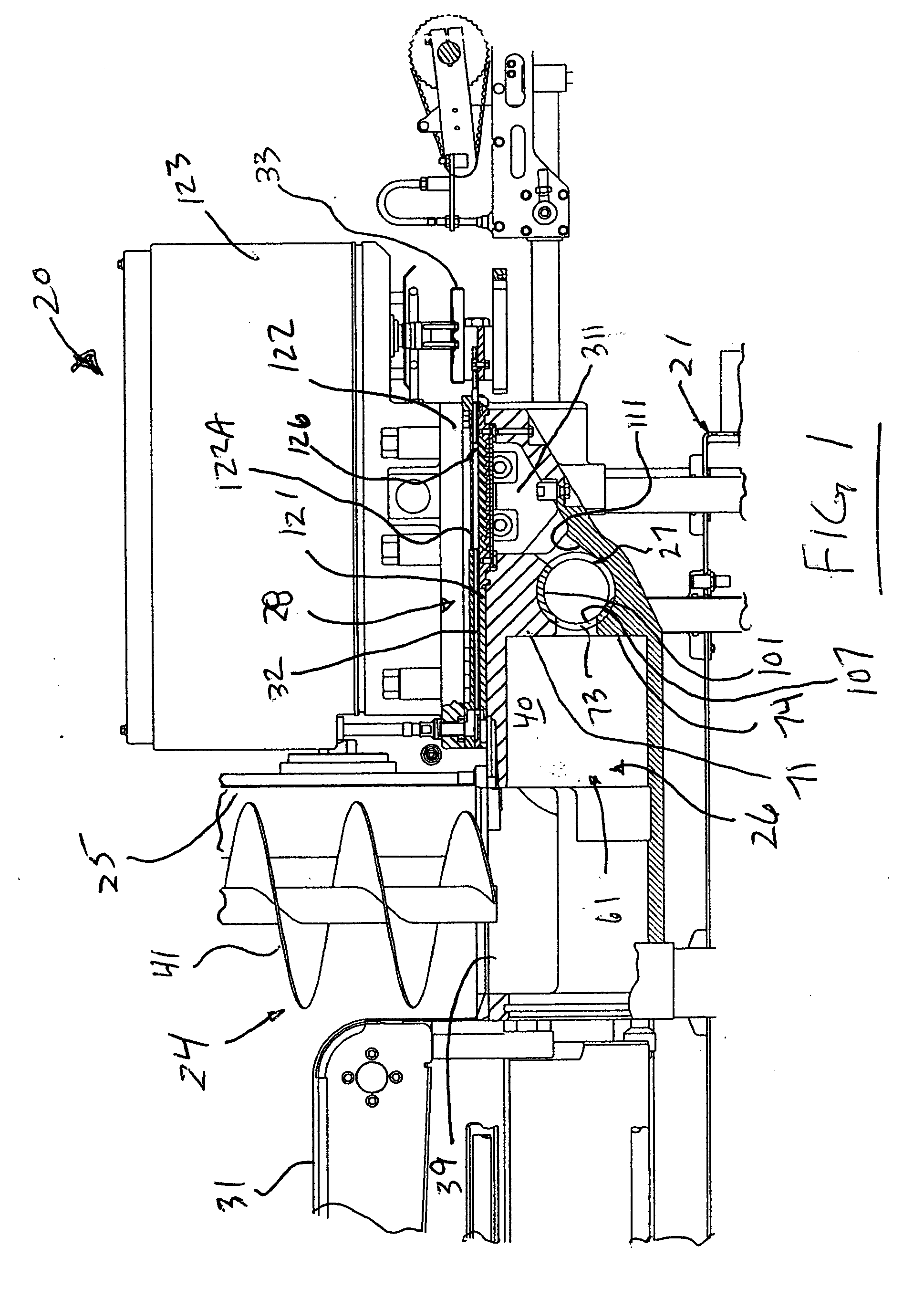

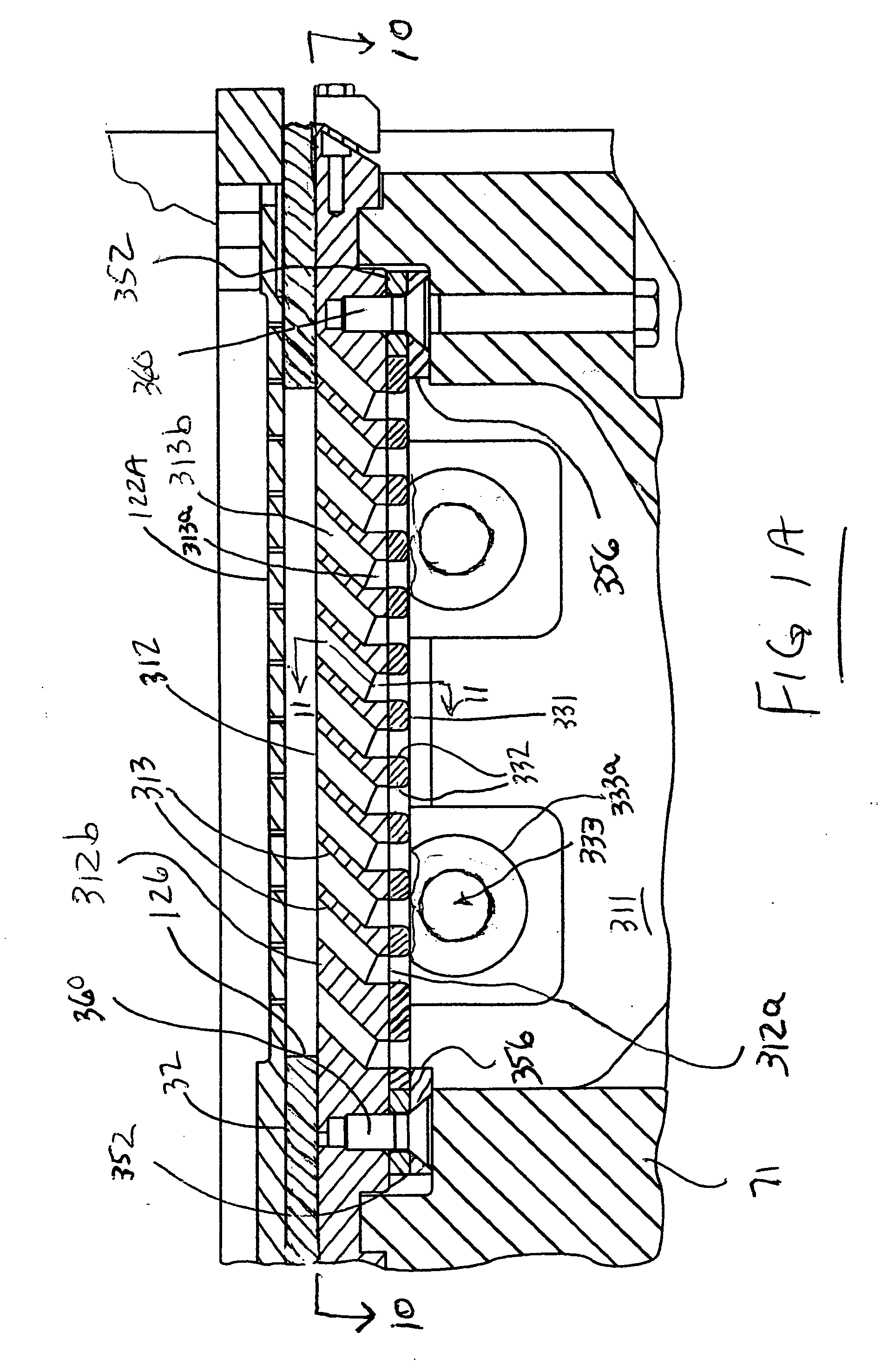

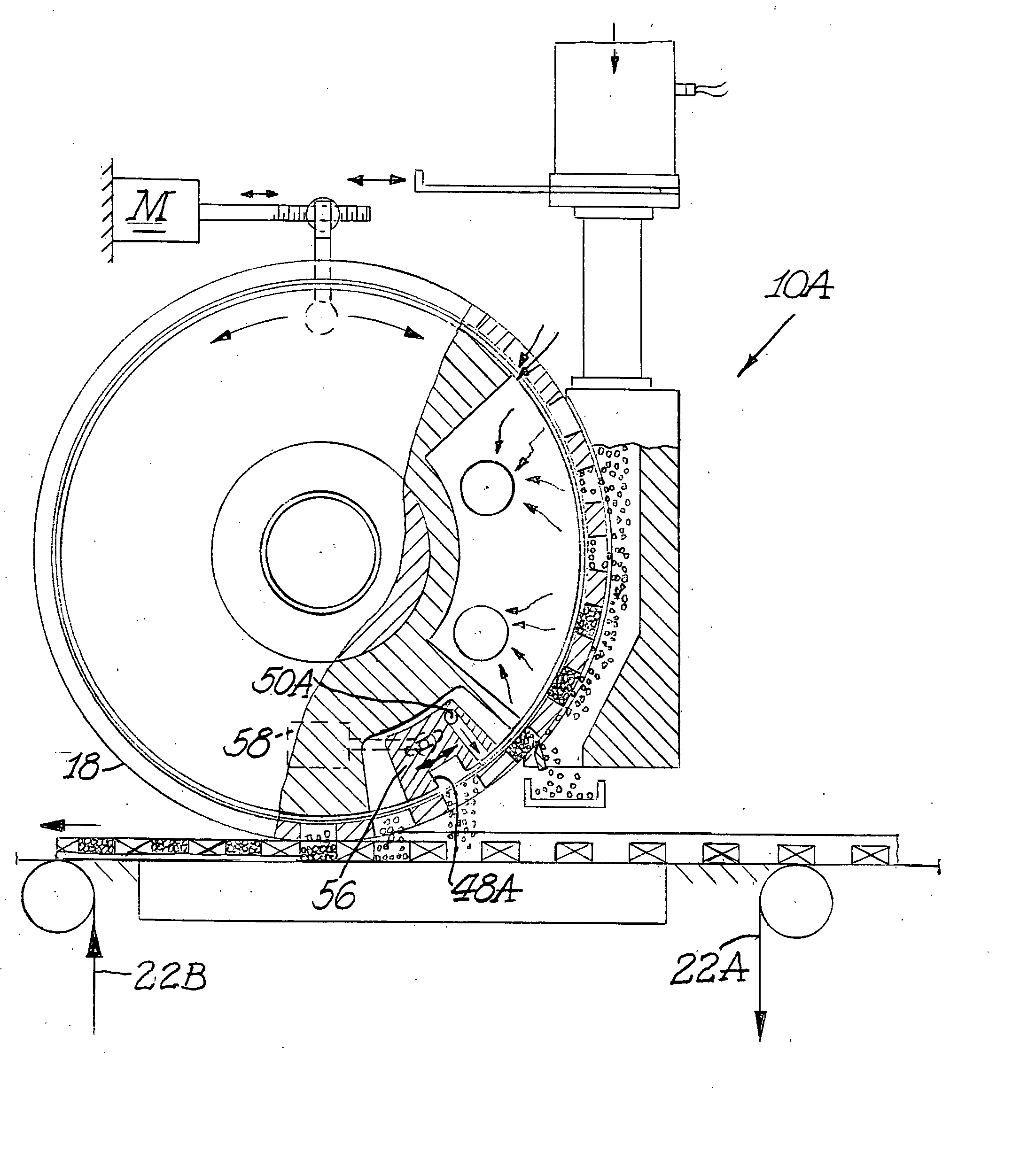

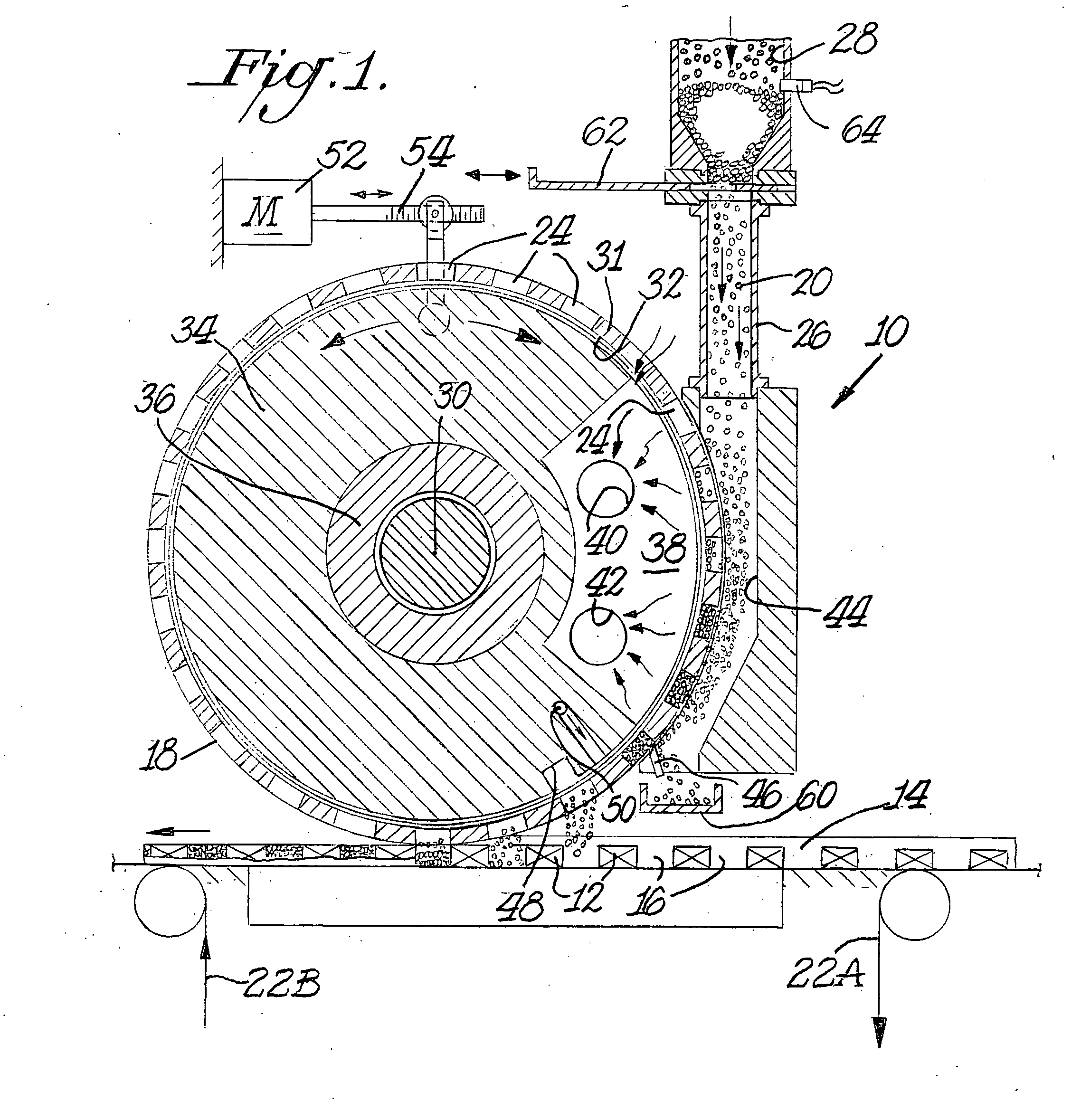

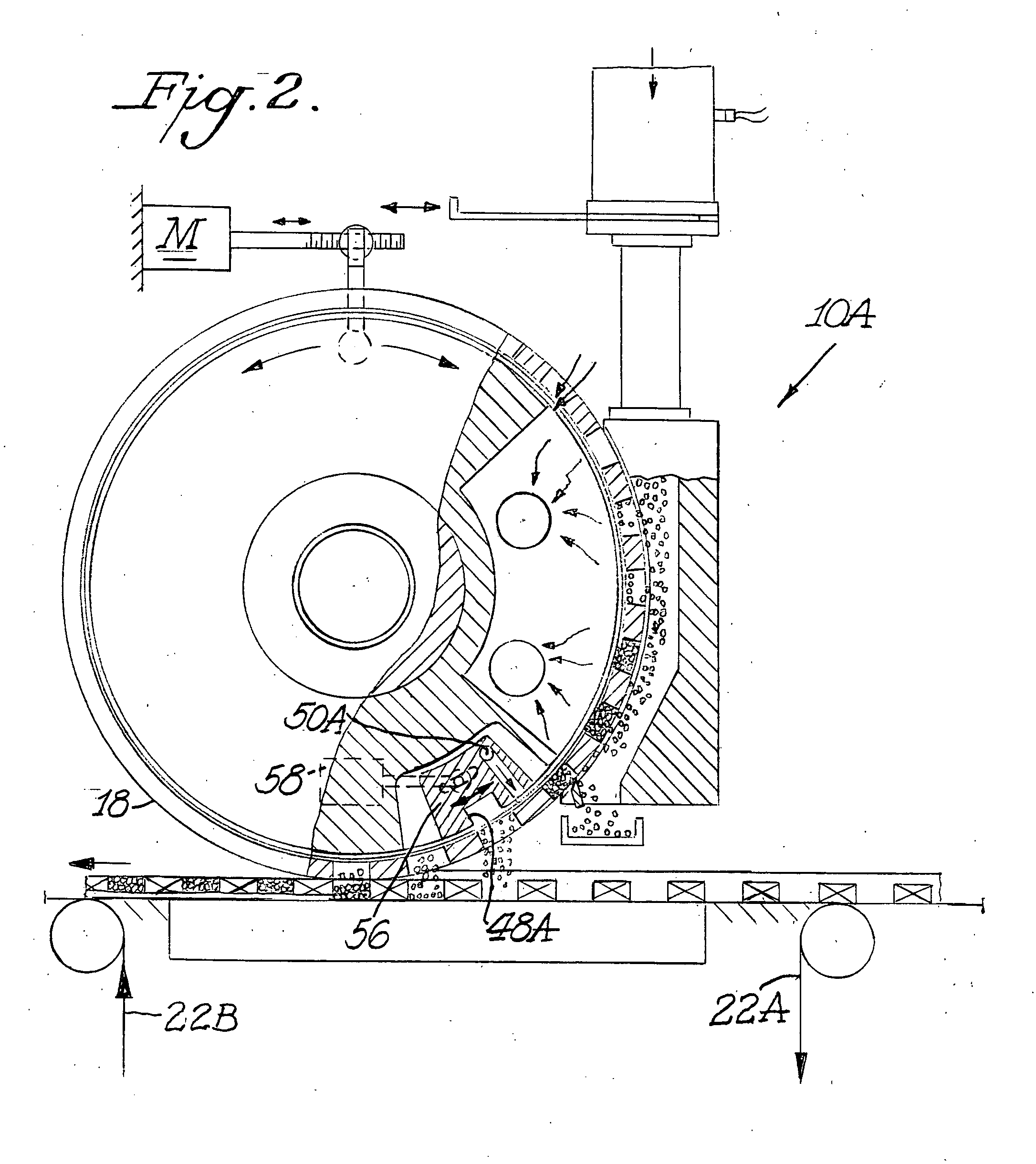

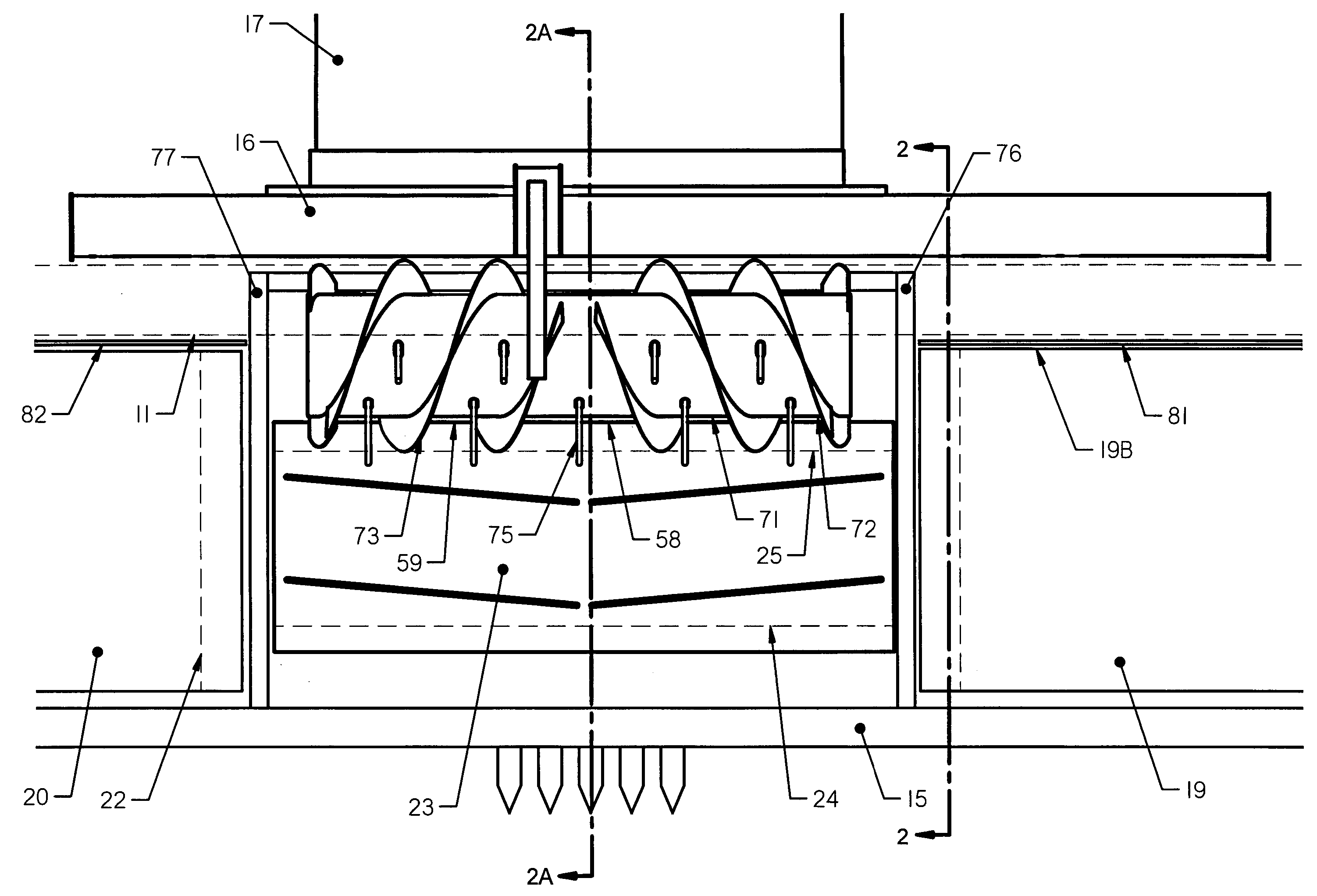

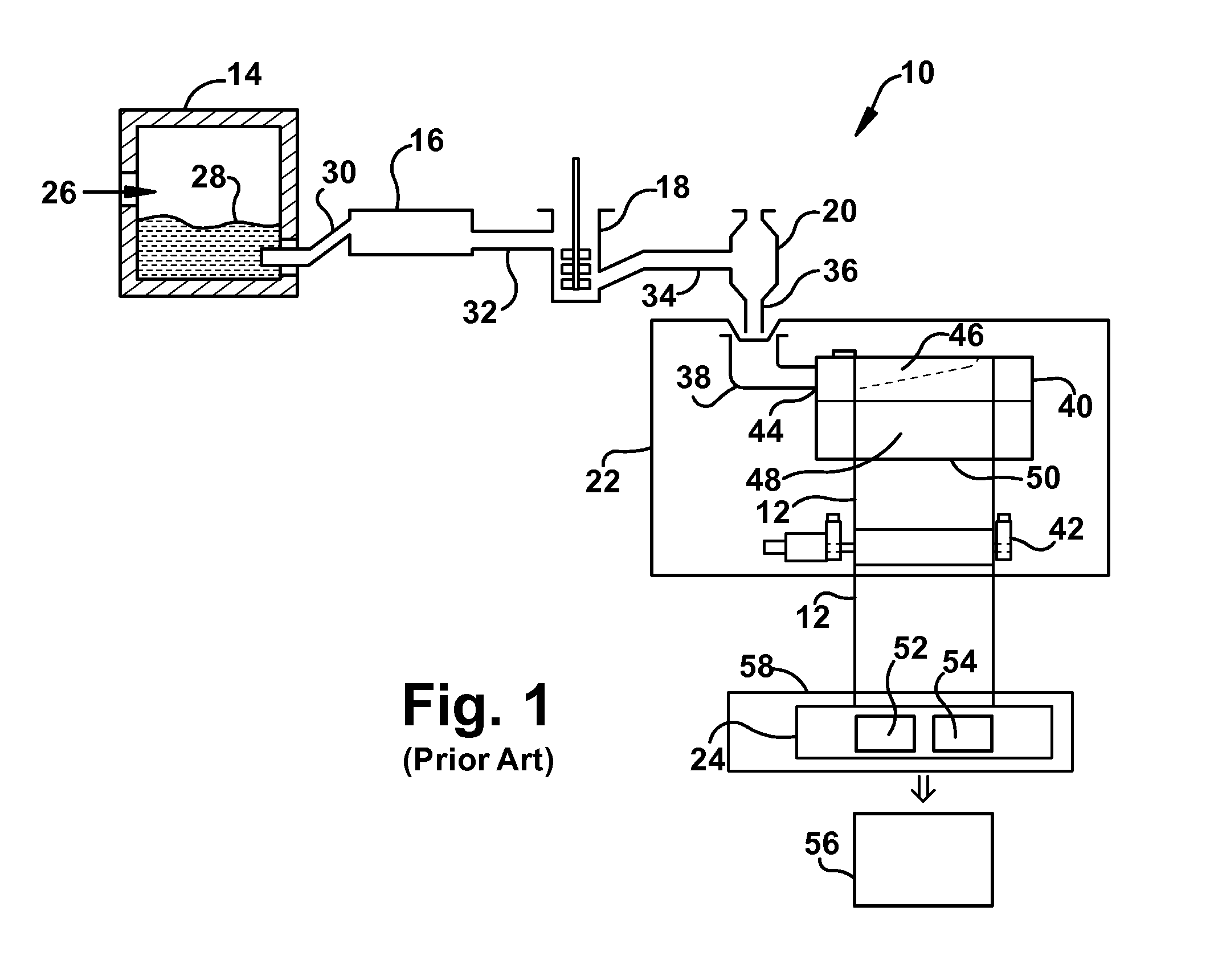

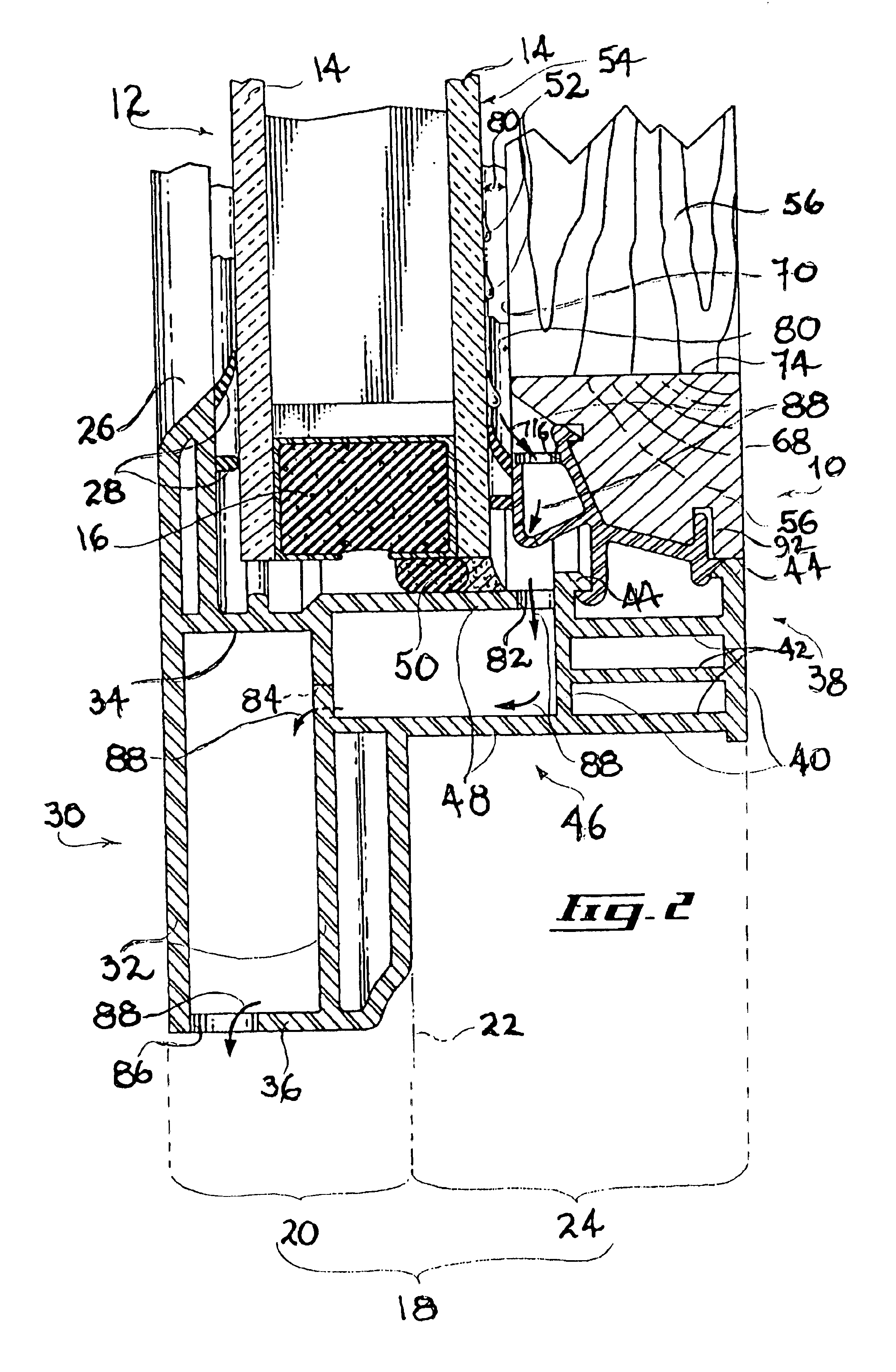

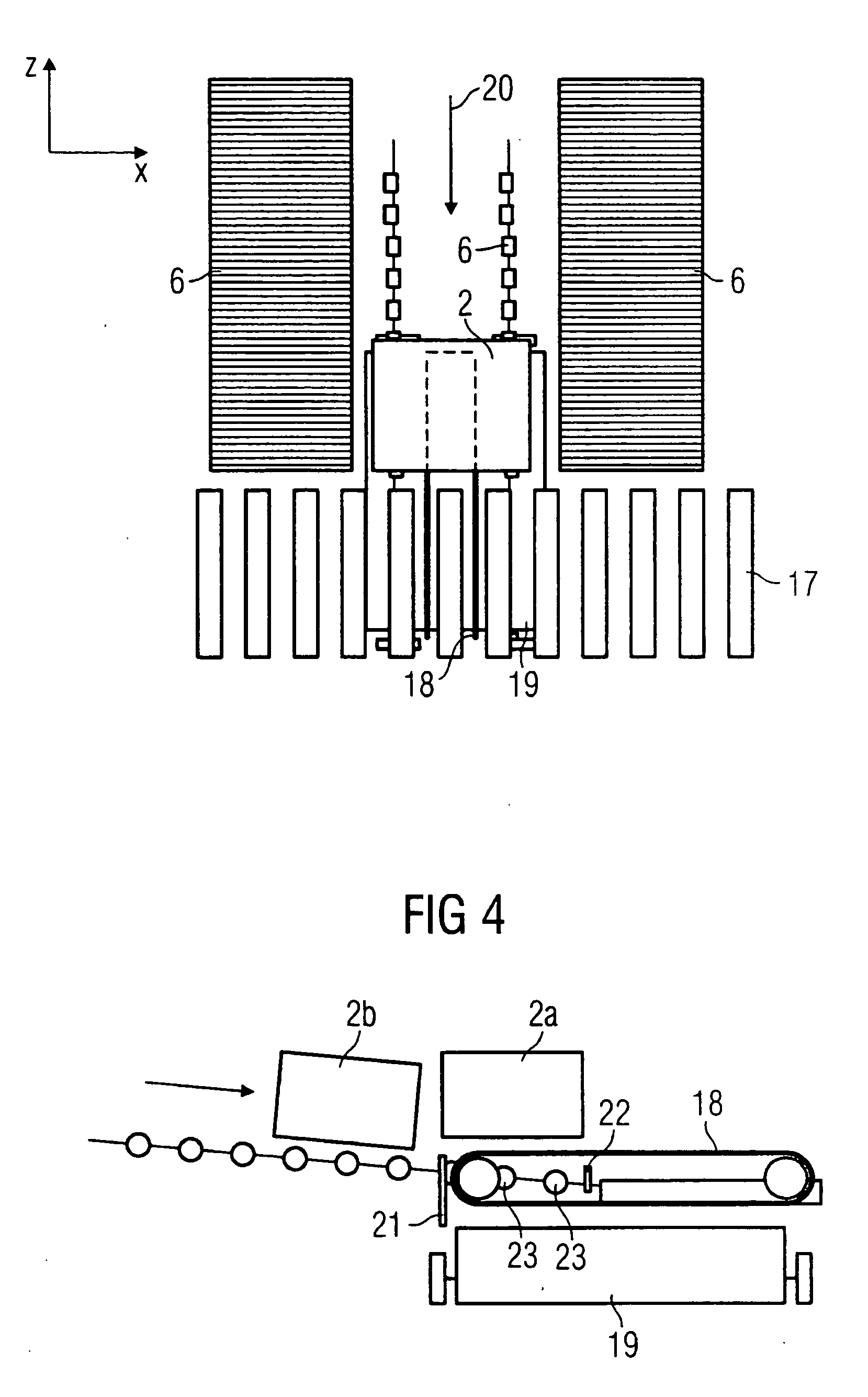

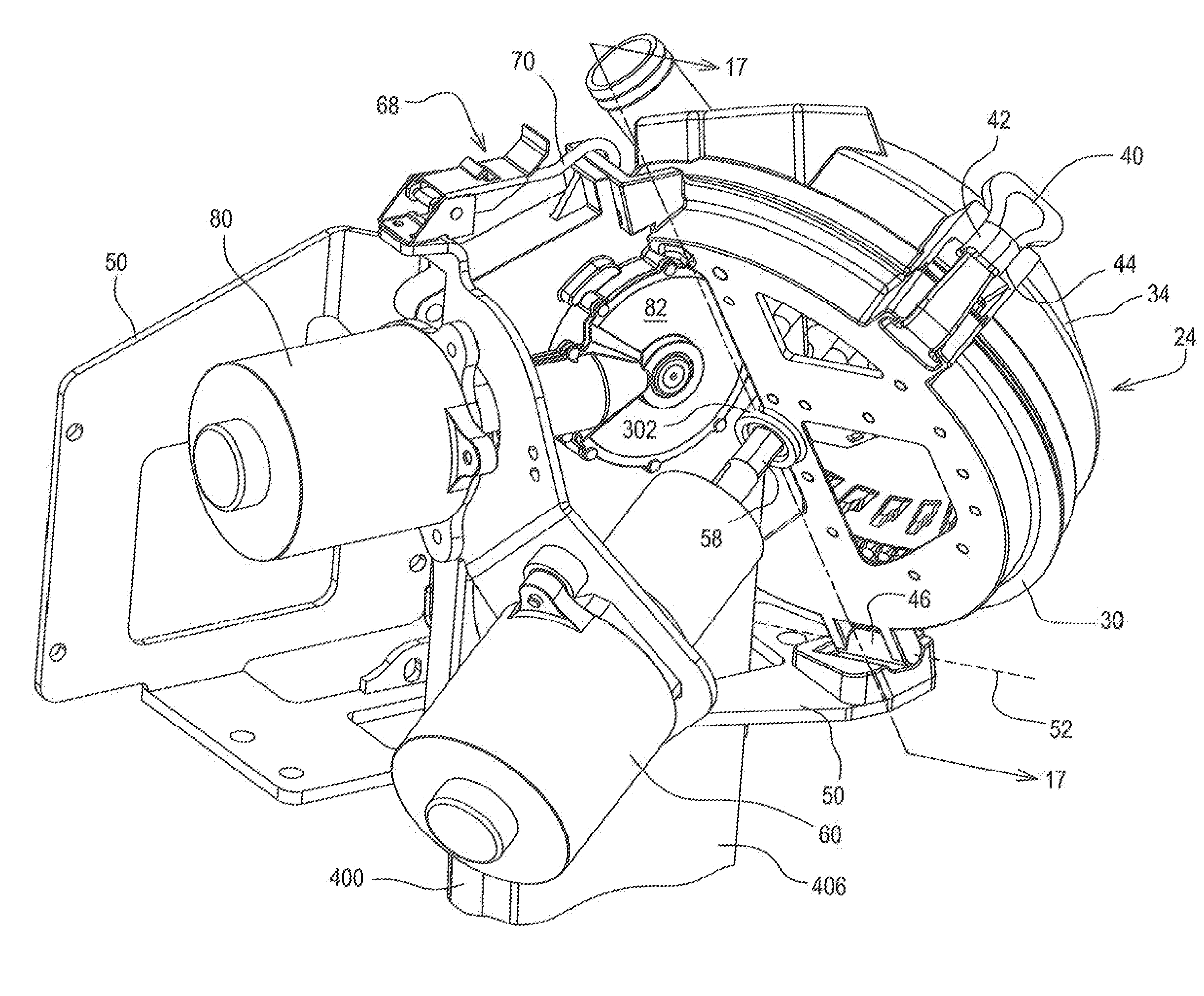

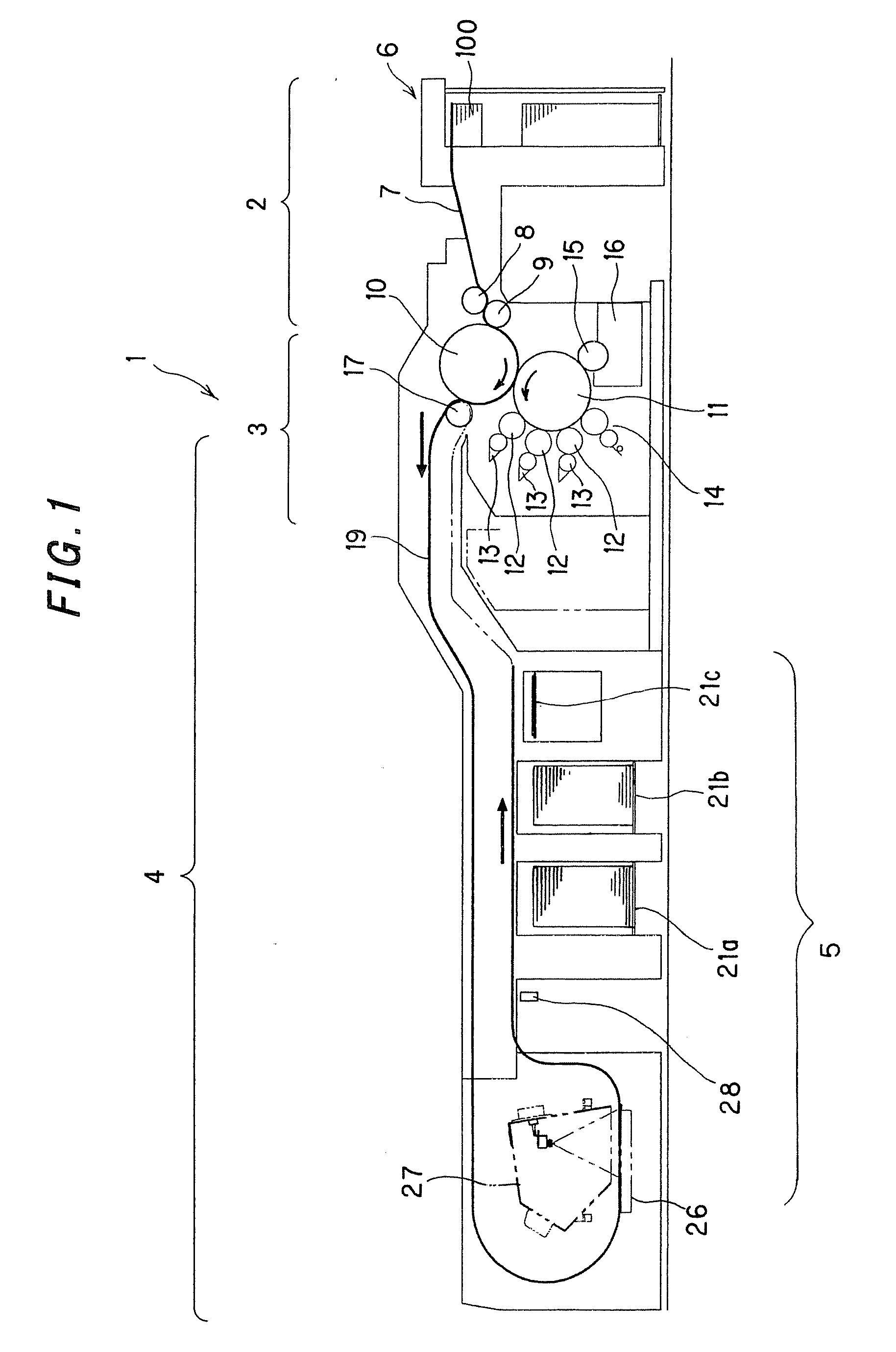

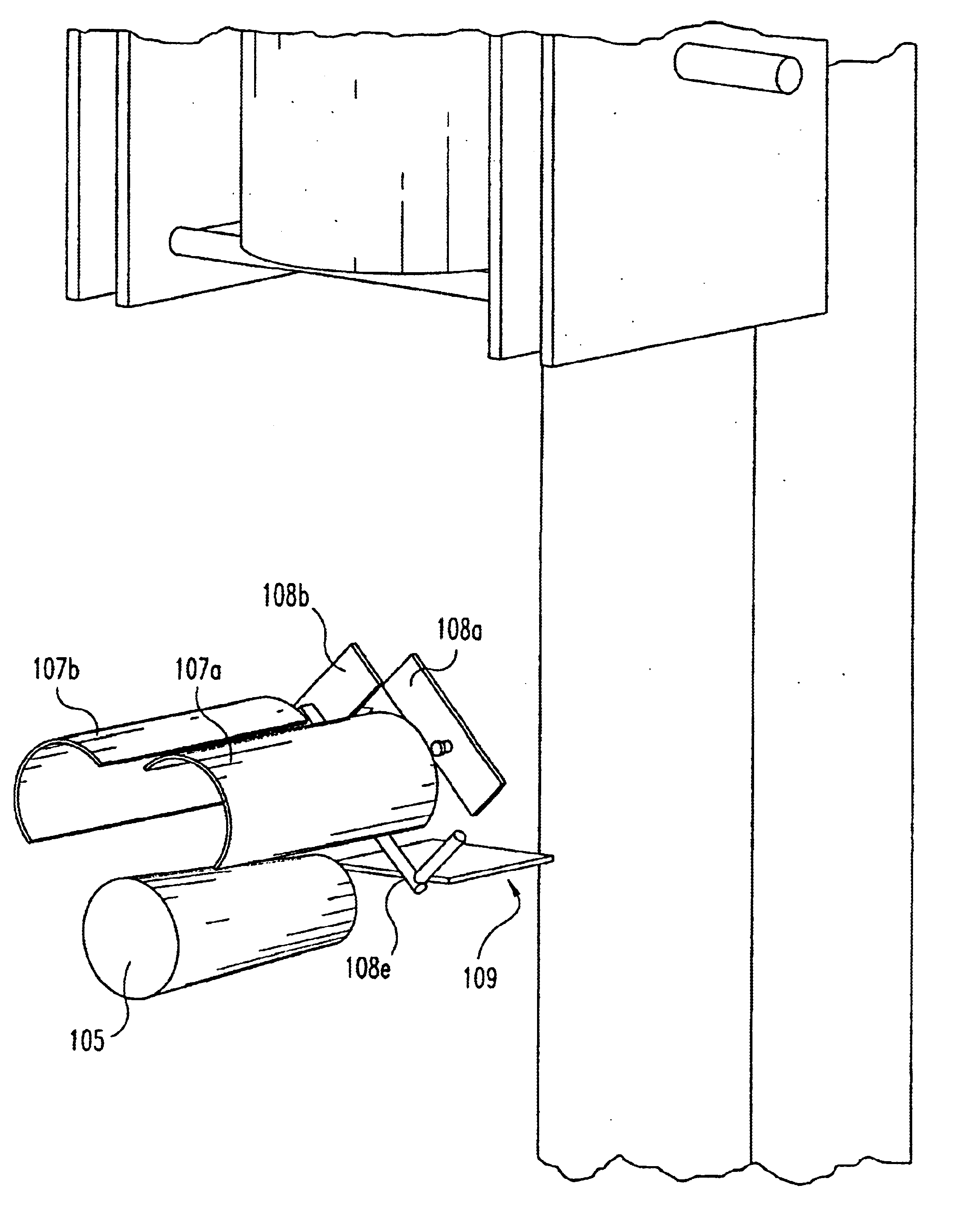

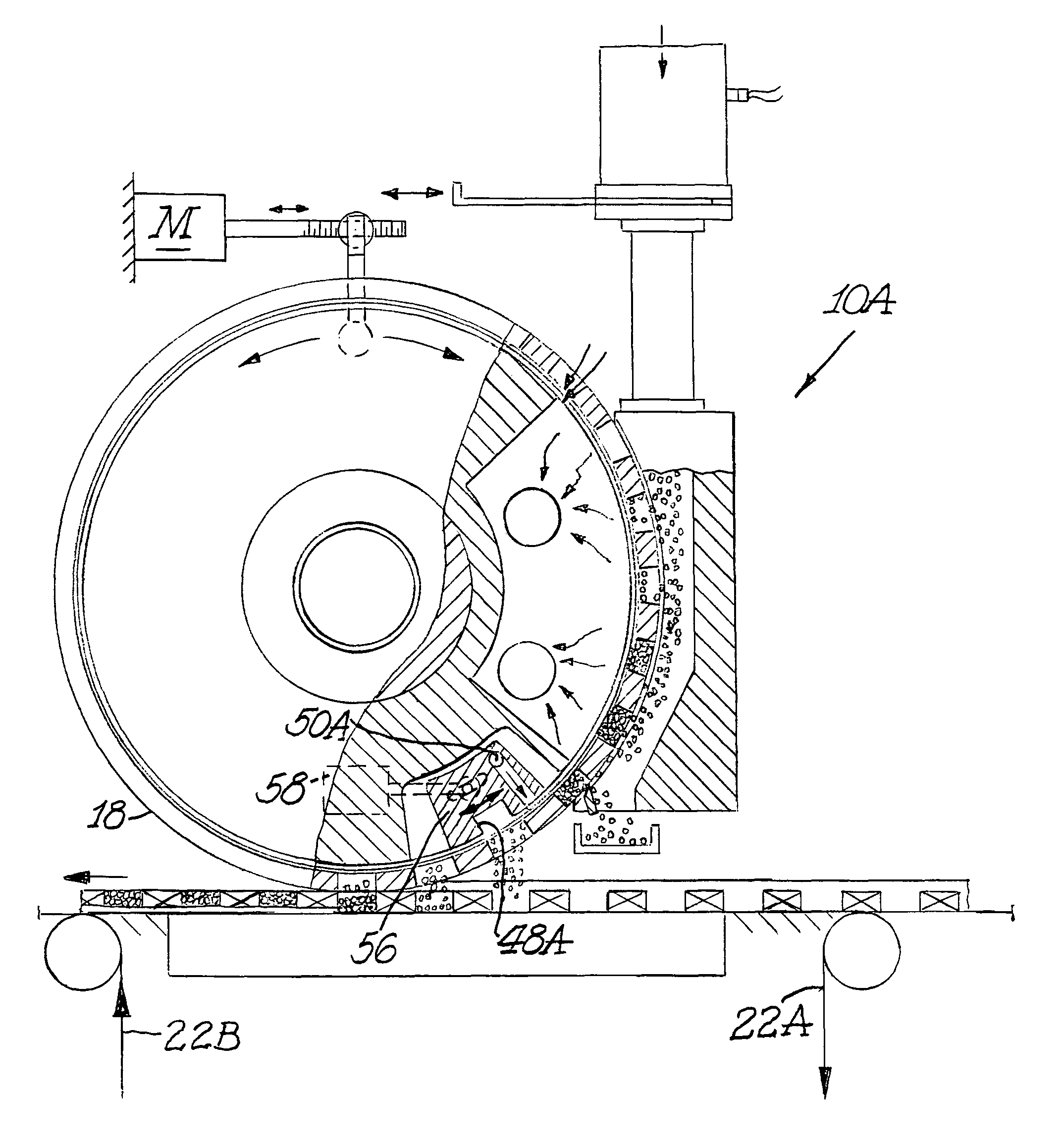

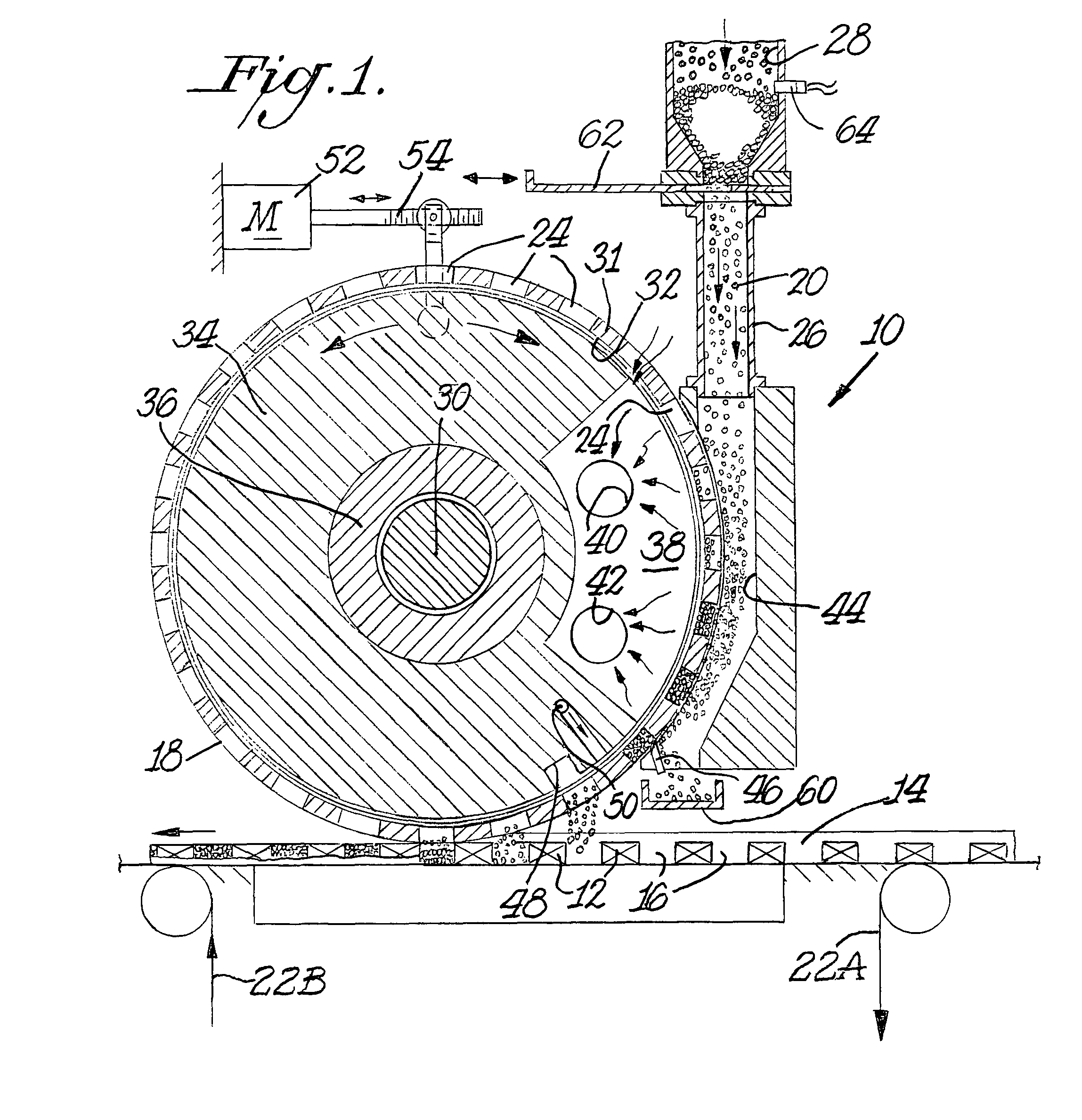

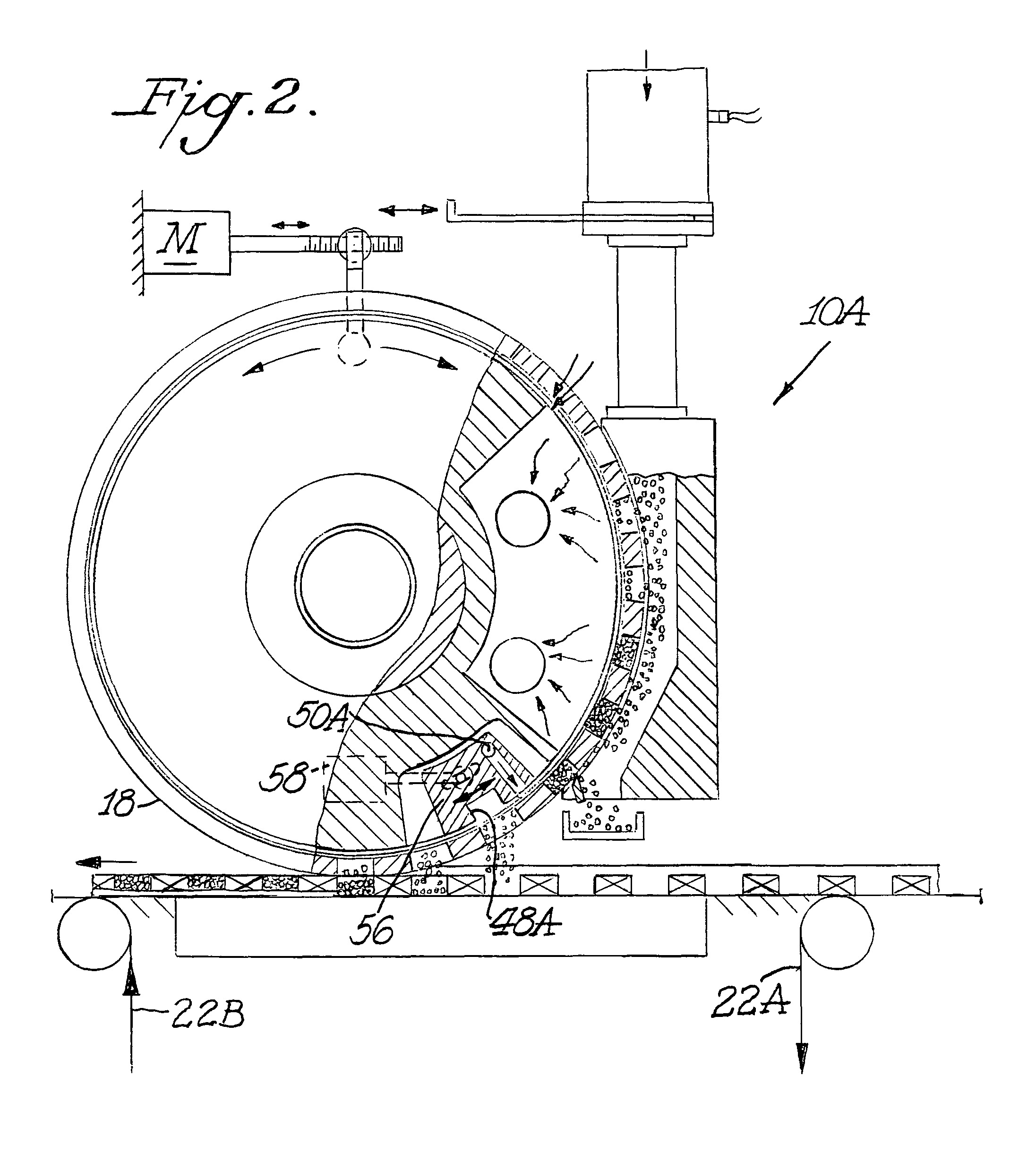

Apparatus for and method of producing on-demand semi-solid material for castings

A method of producing on-demand, semi-solid material for a casting process includes the steps of first heating a metal alloy until it reaches a molten state and maintaining that molten state within a desired temperature range. The next step is to ladle out a portion of the molten alloy and transfer it into a processing vessel. In one arrangement the vessel is configured with its own cooling arrangement so as to begin the solidification process for the molten alloy. In another embodiment, a thermal jacket is used to facilitate the cooling of the vessel and accordingly the cooling of the molten alloy. The next step is to apply an electromagnetic field to the molten alloy in order to create a stirring action which results in a desired flow pattern of the molten alloy within the vessel. The electromagnetic stirring begins as soon as the molten alloy is placed in the vessel and continues while the cooling continues in order to create a slurry billet of the desired metallurgical composition. The final step is to discharge the slurry billet from the vessel directly into a shot sleeve of a casting machine. The apparatus related to the described method includes a vessel which is constructed and arranged for receipt of the molten alloy. A robotic arm is provided in one embodiment for moving the vessel into a stator and then from the stator to the discharge location. In another embodiment, pneumatic cylinders are used in cooperation with structural linkages to effect movement of the vessel first into the stator and then from the stator to the discharge location. Suitable cooling arrangements for the vessel include cooling lines within the vessel, the passage of cooling air between the stator and the vessel, and the use of a thermal jacket.

Owner:HANJOO METAL

Method for Retaining Debris in a Perforating Apparatus

A perforating apparatus (100) includes a plurality of shaped charges (102) each having an initiation end and a discharge end. A detonating cord (116) is operably coupled to the initiation ends of the shaped charges (102). A carrier (106) contains the shaped charges (102). The carrier (106) includes at least one discharge location corresponding to the discharge ends of the shaped charges (102) when the perforating apparatus (100) is in its operable position. The discharge location has first and second material layers (122, 124) wherein the second material layer (124) exhibits resilient recovery such that an opening created by a jet formed from detonating one of the shaped charges (102) in the second material layer (124) is smaller than an opening created by the jet in the first material layer (122), thereby retaining debris in the perforating apparatus (100) with the second material layer (124).

Owner:HALLIBURTON ENERGY SERVICES INC

Cutting tool with water injection to the cutting bit shank

InactiveUS20100052406A1Facilitate free rotationWear is promotedSlitting machinesMaintainance and safety accessoriesFree rotationEngineering

A cutting tool assembly mounted on a rotating drum and having a base block, a wear sleeve and a cutting bit wherein a seal is located between the base block and wear sleeve is disclosed. A fluid passage spans from the rotating drum to a discharge location between the wear sleeve and the shank of the cutting bit. The fluid lubricates the shank of the cutting bit and bore of the wear sleeve allowing the cutting bit to rotate freely within the wear sleeve. Rotation of the cutting bit promotes even wear and long life of the bit.

Owner:KENNAMETAL INC

Catheter-based pump for improving organ function

InactiveUS20190167878A1Improve kidney functionImprove liver functionControl devicesMedical devicesVeinOrgan function

Apparatus, systems, and methods in which a catheter-based pump is used are disclosed. The catheter-based pump is placed within the inferior vena cava of a patient. The catheter-based pump has a variable obstructor, such as a balloon or some other artificial obstruction, which is sized and dimensioned to compartmentalize the inferior vena cava into an upstream region and a downstream region of the inferior vena cava. The catheter-based pump is configured to pump blood from the upstream region to a fluid line that discharges blood to a discharge location in the downstream region. Thus, a suitable pressure gradient across the organ is provided, which can benefit organ function.

Owner:ROWE STANTON J

Applicator wheel for filling cavities with metered amounts of particulate material

A machine and process function to fill cavities with metered amounts of particulate material. An applicator wheel includes a series of equally spaced apart peripheral pockets each having a perforated bottom wall, and a vacuum manifold inside the wheel includes a vacuum chamber for supplying vacuum to the perforated bottom walls of the pockets as the wheel rotates. Particulate material from a filling chamber of such material outside the wheel is withdrawn into the pockets by the vacuum chamber. A downstream vacuum relief on the vacuum manifold functions to discharge particulate material from the pockets into the cavities at a predetermined discharge location on the wheel. Adjustment structure is connected to rotatably adjust the position of the vacuum manifold within the applicator wheel to thereby advance or retard the discharge location depending upon the speed of the machine.

Owner:PHILIP MORRIS USA INC

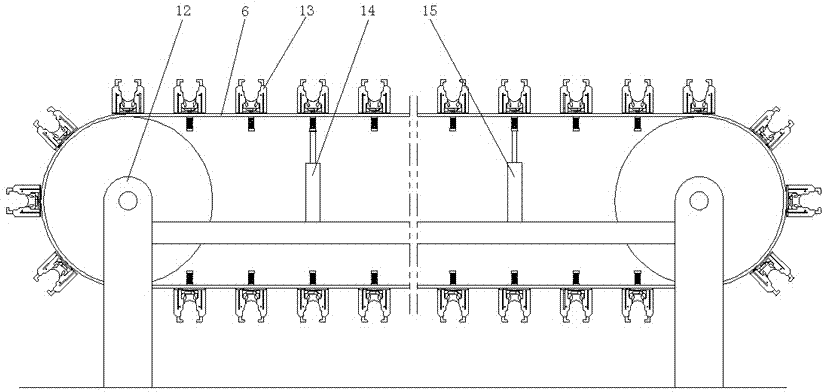

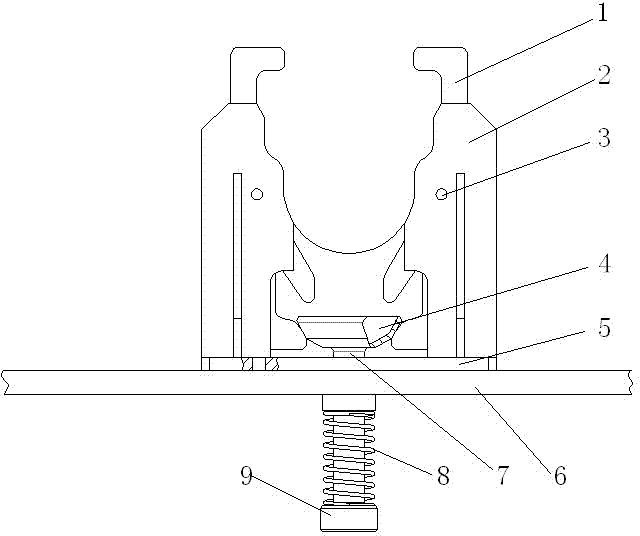

Material channel for automatic mechanical processing system

InactiveCN103028999AShorten the lengthAchieve releaseMetal working apparatusTransmission beltEngineering

The invention relates to a material channel for an automatic mechanical processing system. The material channel comprises a transmission belt type material channel formed by a frame and a transmission belt on the frame. The material channel is characterized in that manipulators for fixing parts are arranged on the annular transmission belt; and a parts fixing manipulator which is used for loosening the manipulators for fixing the parts and jacking the parts on the material channel of a cylinder is arranged between the charging and discharging positions of the annular transmission belt. According to the technical scheme, the to-be processed parts can be fixed on the material channel, so that the to-be parts can be placed on the whole transmission belt; under the condition of conveying the same parts, the length of the transmission belt can be reduced by one half; and the material channel has the characteristics of being simple in structure, convenient to use, small in occupied area and suitable for the automatic mechanical processing system.

Owner:宁夏巨能机器人股份有限公司

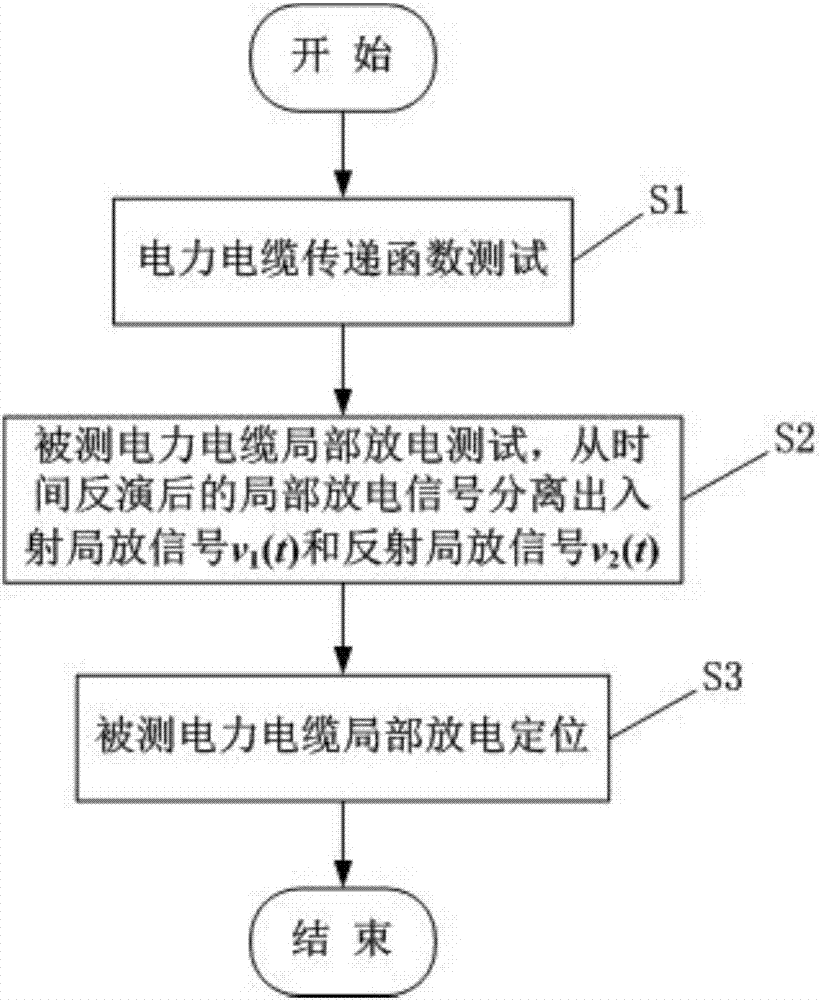

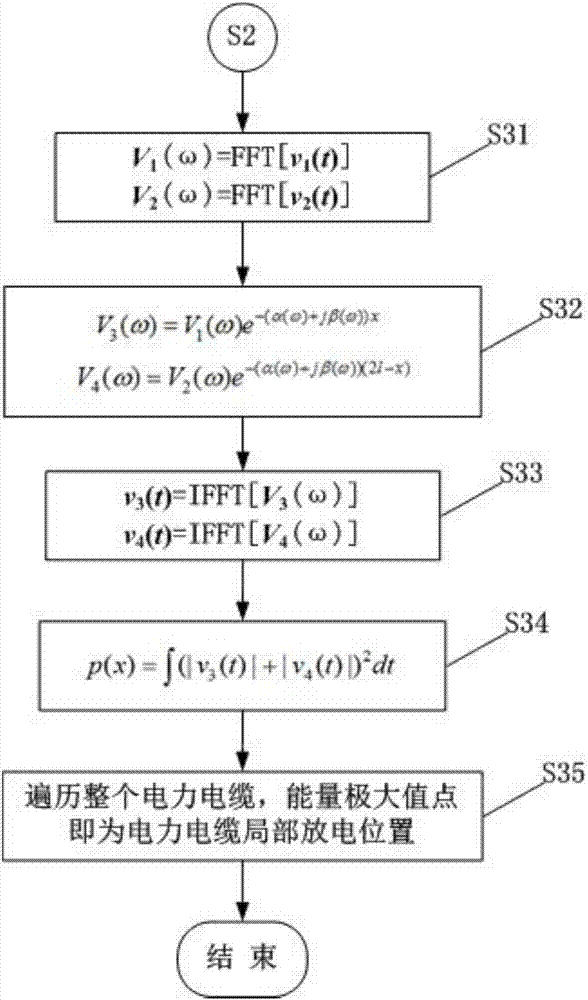

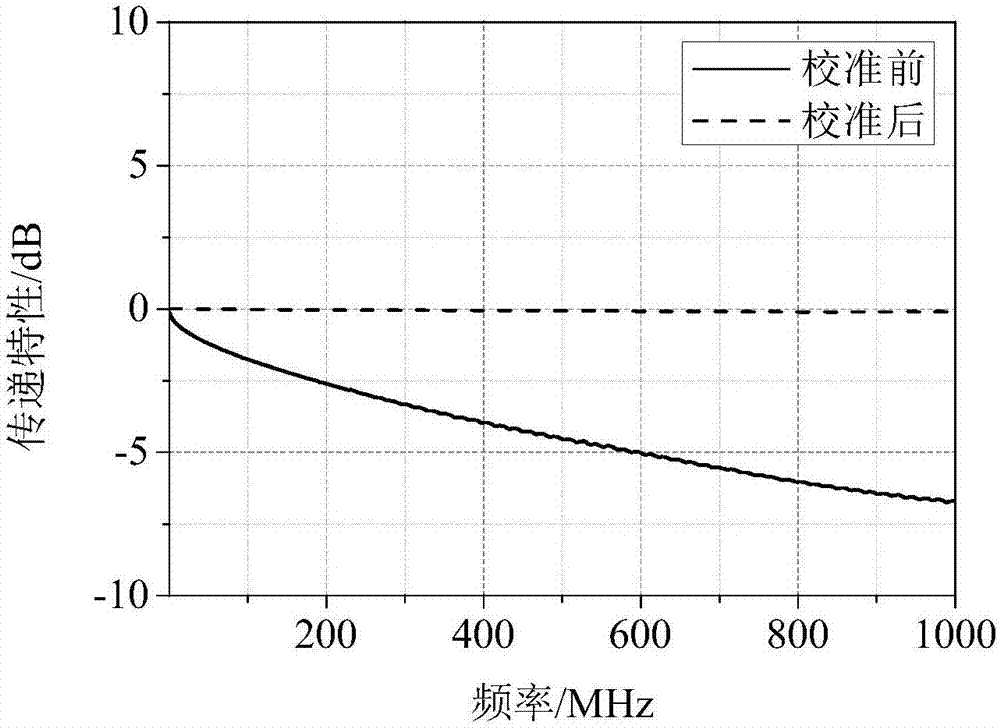

Power cable partial discharge positioning method based on time reversal

ActiveCN107390100AImproving the accuracy of partial discharge locationReduce the impact of partial discharge location accuracyTesting dielectric strengthUltrasound attenuationPower cable

The invention discloses a power cable partial discharge positioning method based on time reversal. The method comprises the following steps: to begin with, carrying out transfer function test on a detected power cable, and finding attenuation constant and phase constant of the power cable according to a transfer function obtained after test; carrying out partial discharge test on the detected power cable to obtain an incident partial discharge signal and a reflection partial discharge signal; and then, carrying out correction on the incident partial discharge signal and the reflection partial discharge signal by utilizing the attenuation constant and the phase constant, and obtaining an overall power cable location-energy spectrogram according to the corrected incident partial discharge signal and the reflection partial discharge signal, the energy maximum point in the spectrogram being the partial discharge position of the power cable. The method does not need to estimate delay of the partial discharge signal and enables the influence of phase speed and frequency-dependent characteristics of the power cable on power cable discharge location being taken into consideration, thereby improving location accuracy of partial discharge of the power cable.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com