Material channel for automatic mechanical processing system

A technology of mechanical processing and forehearth, applied in the direction of metal processing, etc., can solve the problems of the length of the forehearth and the large floor space, and achieve the effect of small floor space, easy grasping, and reduction of the length of the conveyor belt.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

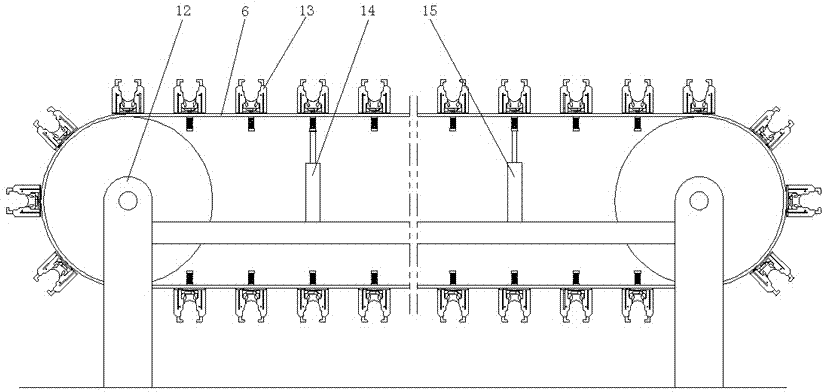

[0013] like figure 1 , 2 , shown in 3, the feedway of conveyer belt form is to be made up of frame 12 and endless conveyer belt 6, on endless conveyer belt, part is evenly installed with fixing manipulator 13, is installed at the loading and unloading position between conveyer belt up and down A jacking cylinder that loosens parts from a fixed arm.

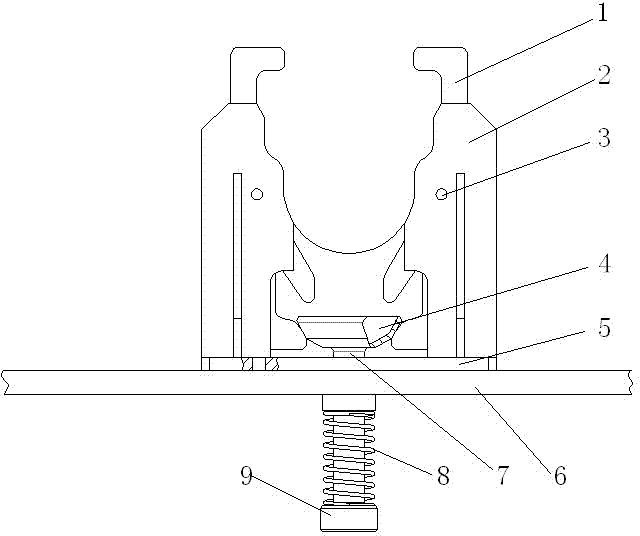

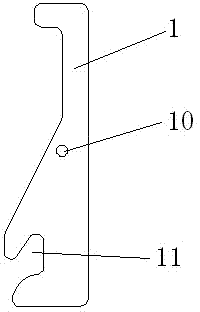

[0014] Parts fixing manipulator is evenly installed on the conveyer belt 6 on the feedway through the fixed base plate 5, and two U-shaped brackets 2 are fixedly installed on the fixed base plate front and back, between the two U-shaped brackets, relative to the U-shaped brackets. Two fingers 1 are arranged symmetrically on the left and right sides of the U-shaped groove, and the middle part of the two fingers is rotatably fixed on the U-shaped bracket by the pin shaft 3. The bowl-shaped top plate 4 at the upper end is composed of a compression spring 8 set on the guide shaft, wherein the guide shaft passes through the hole betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com