Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Without lowering throughput" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

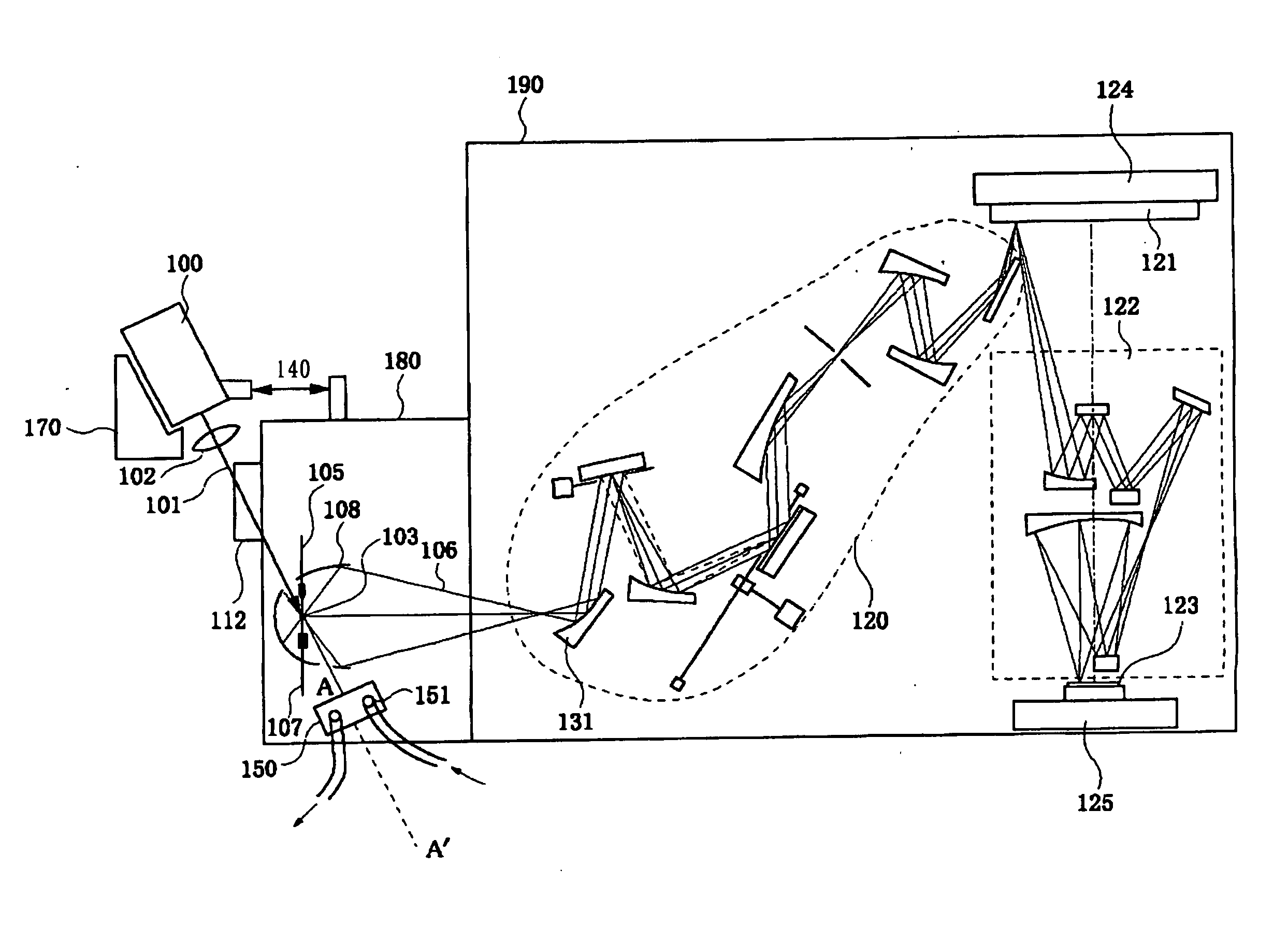

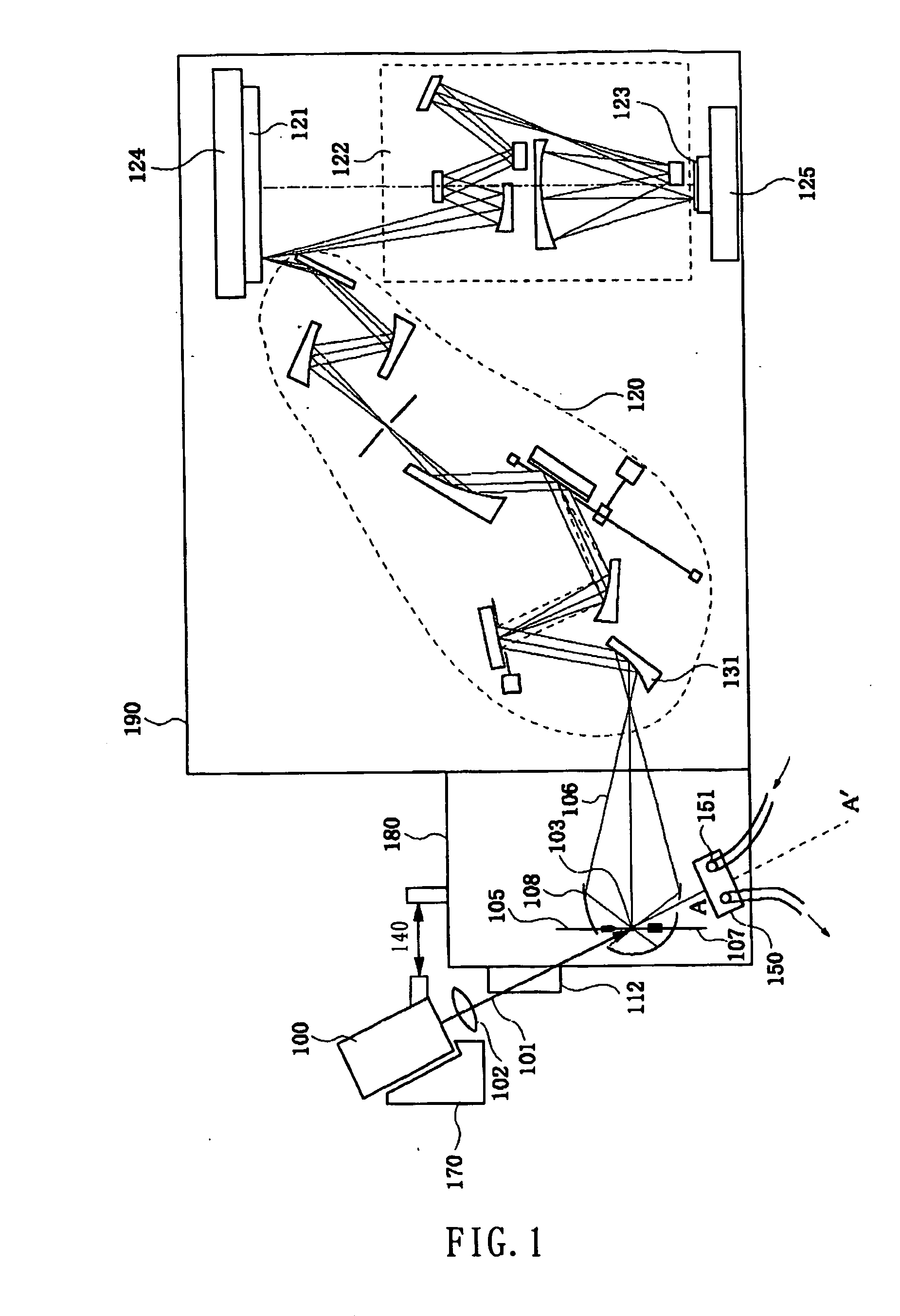

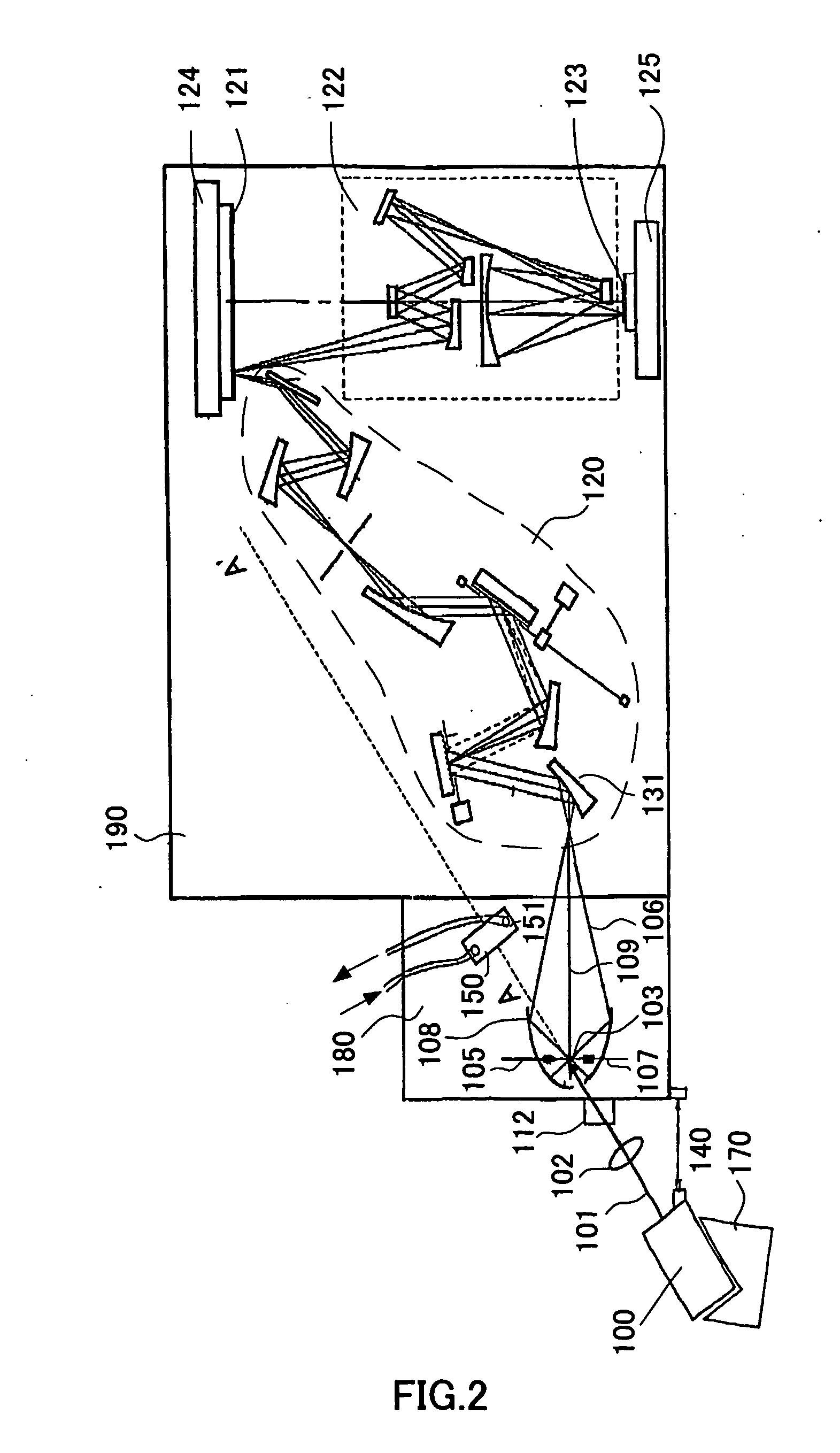

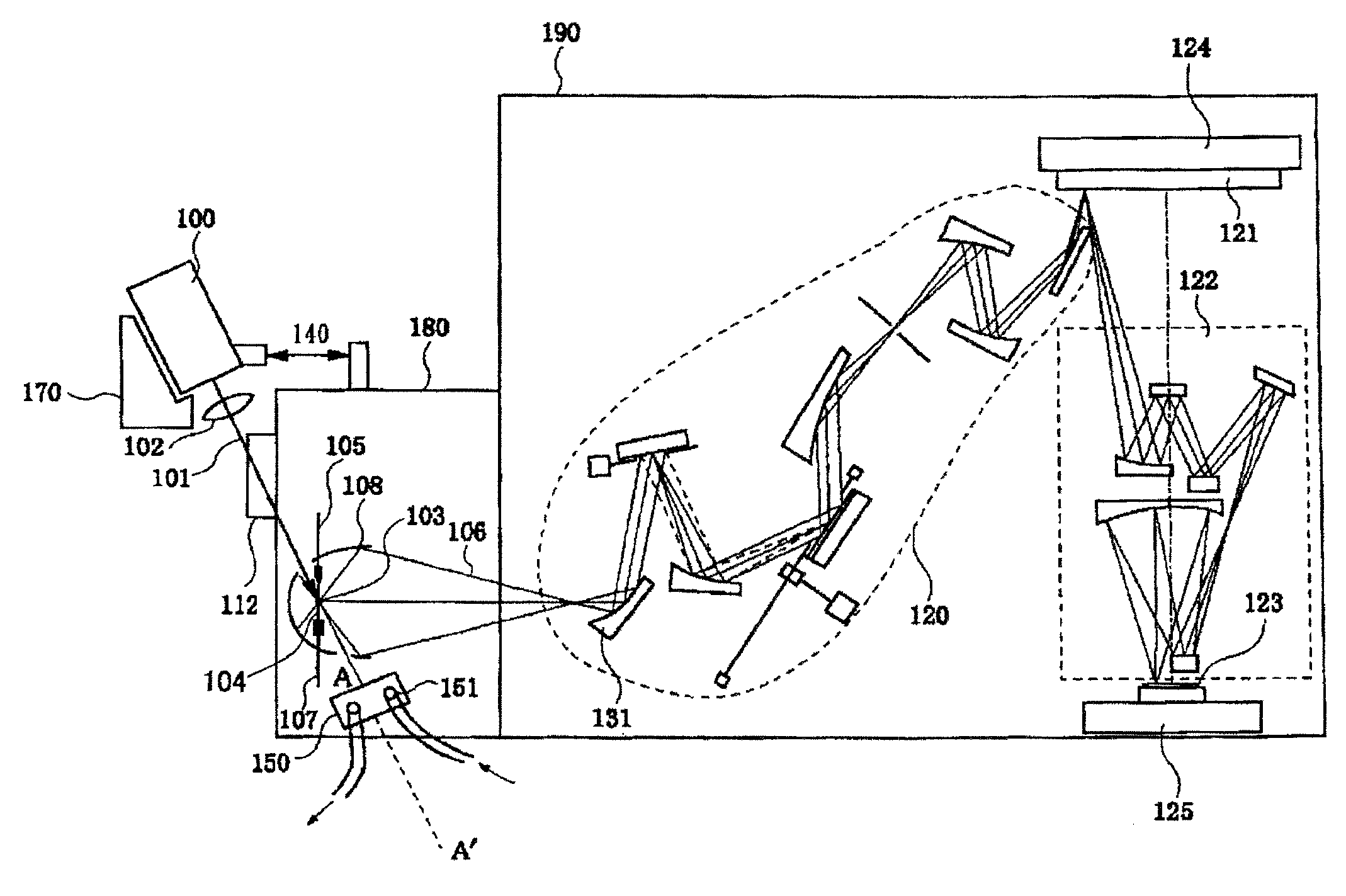

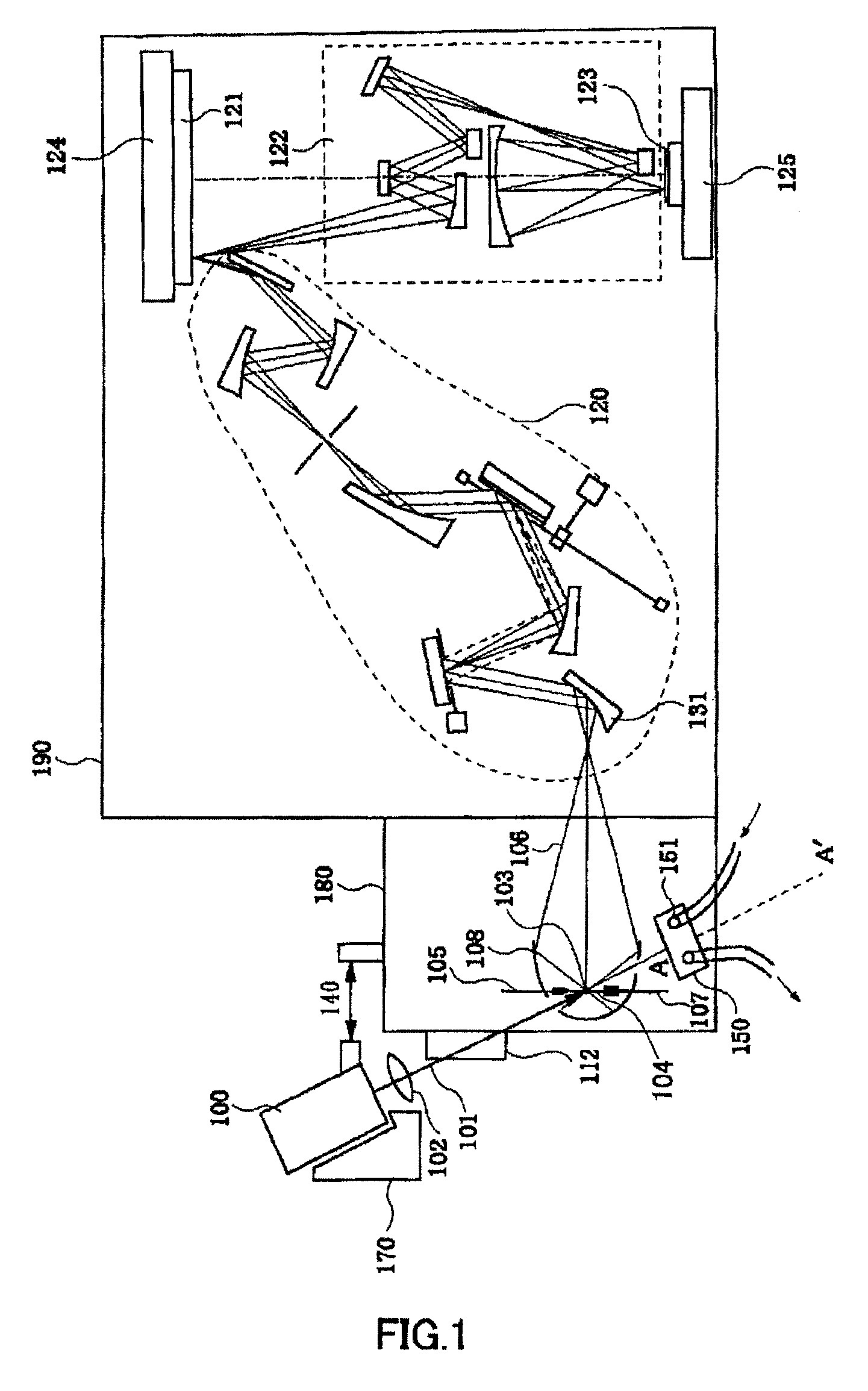

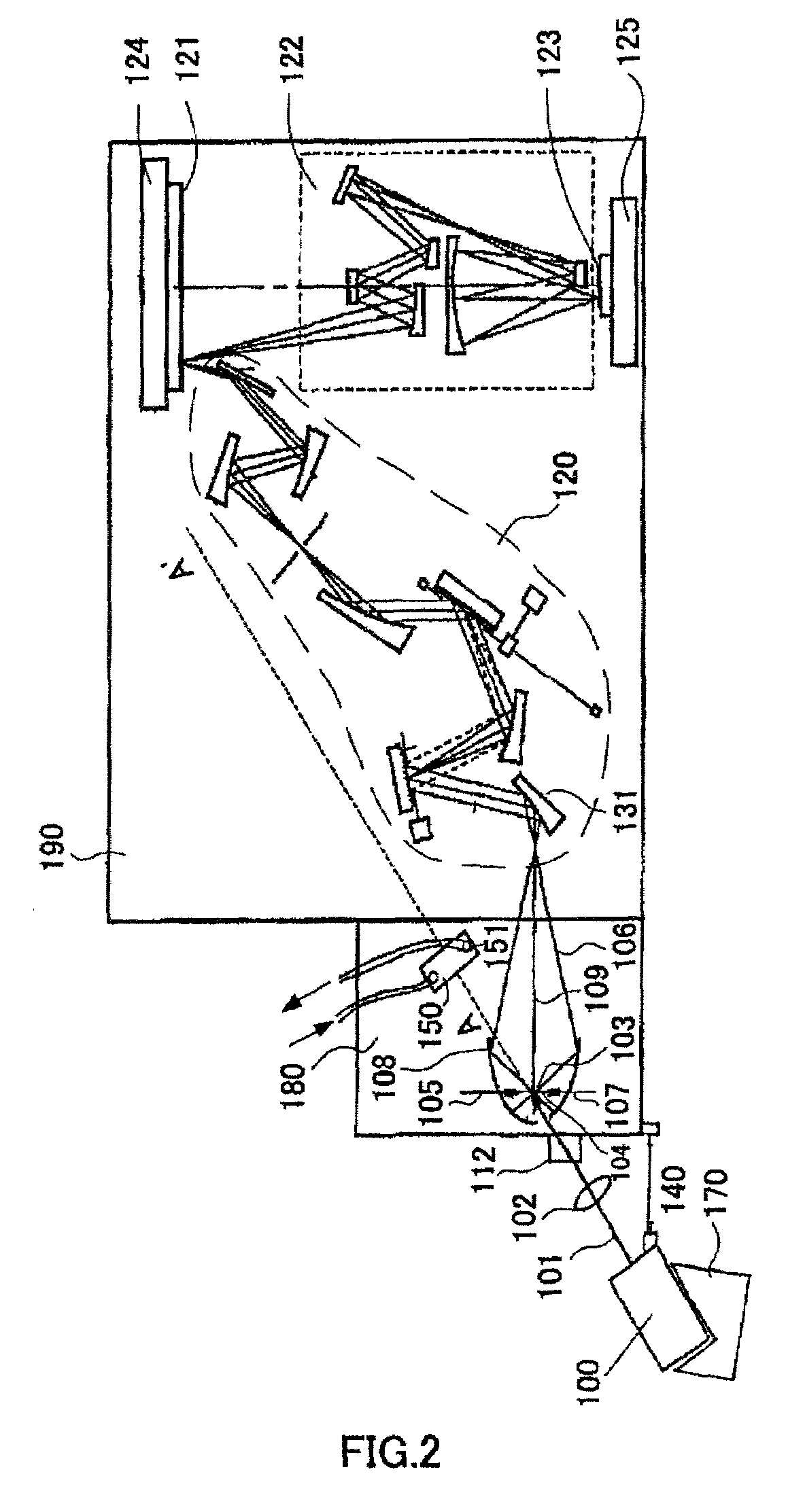

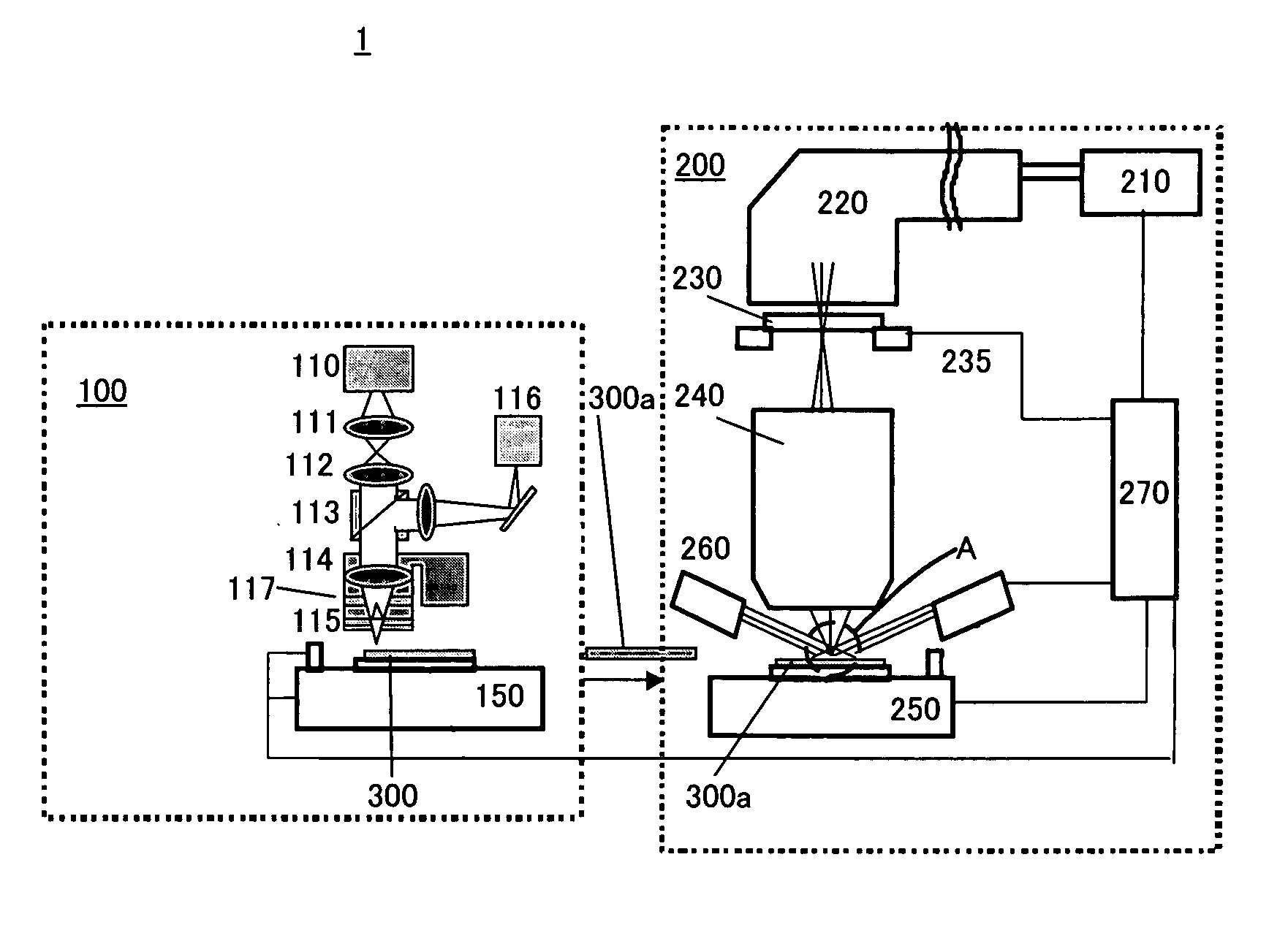

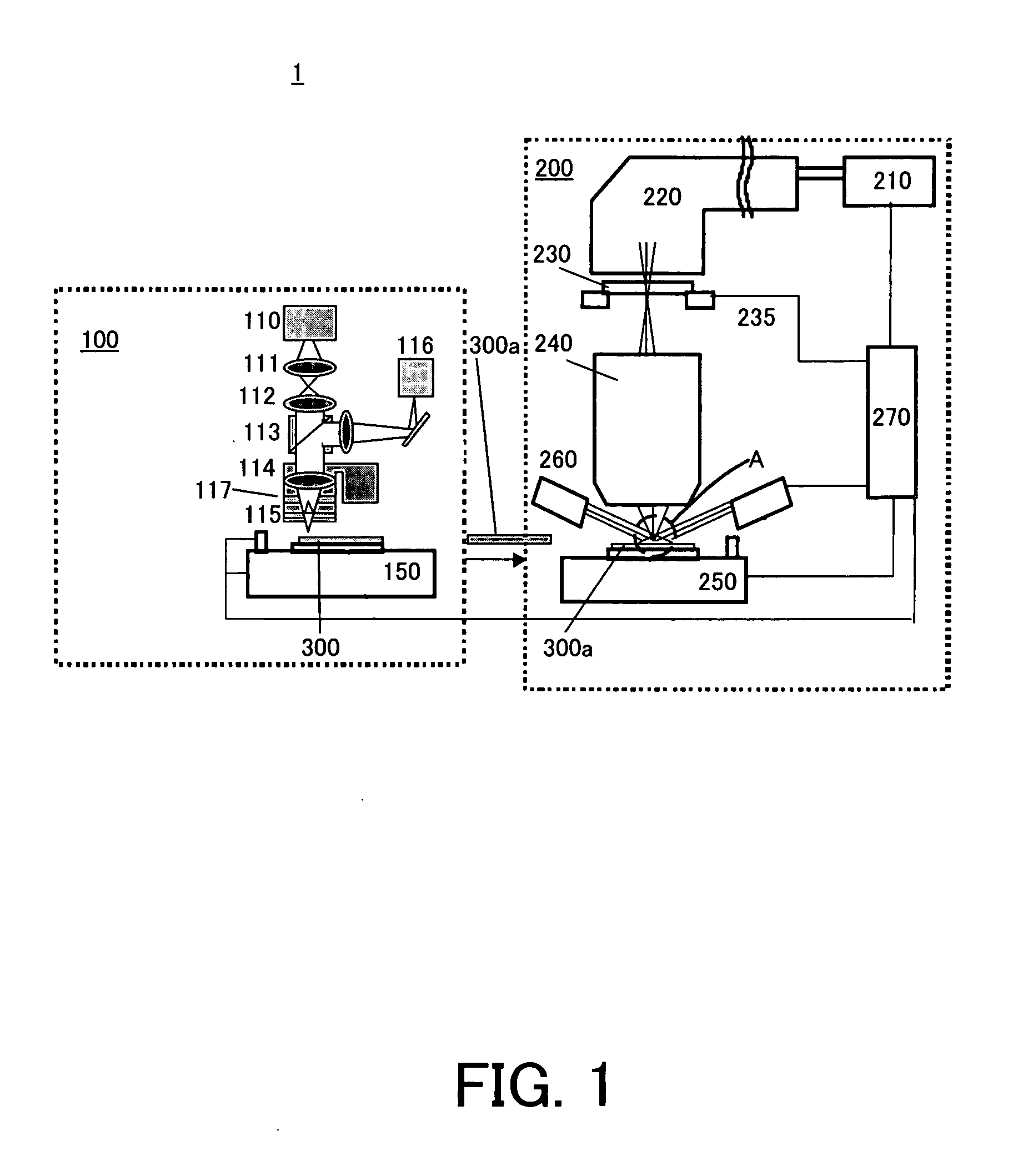

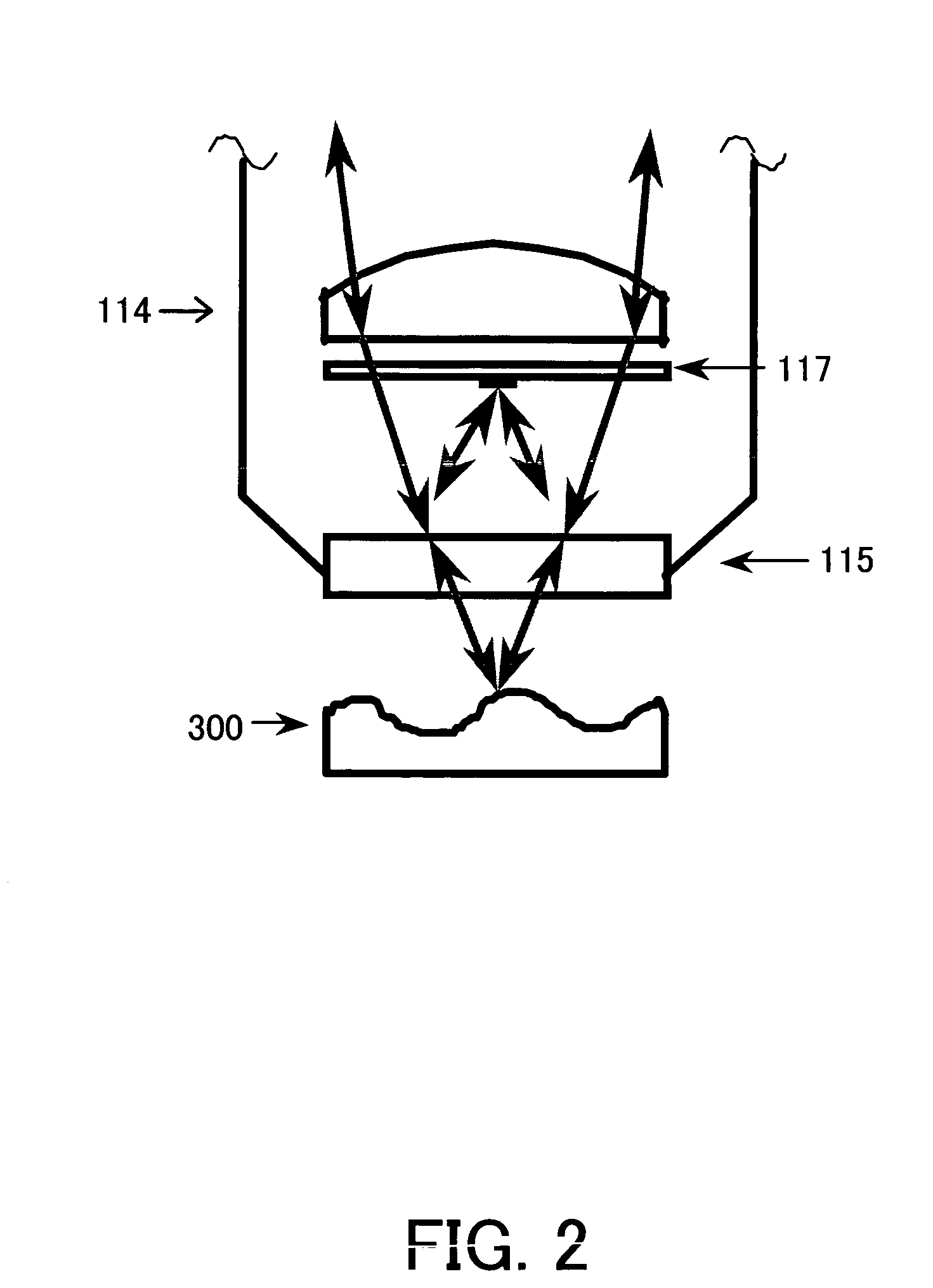

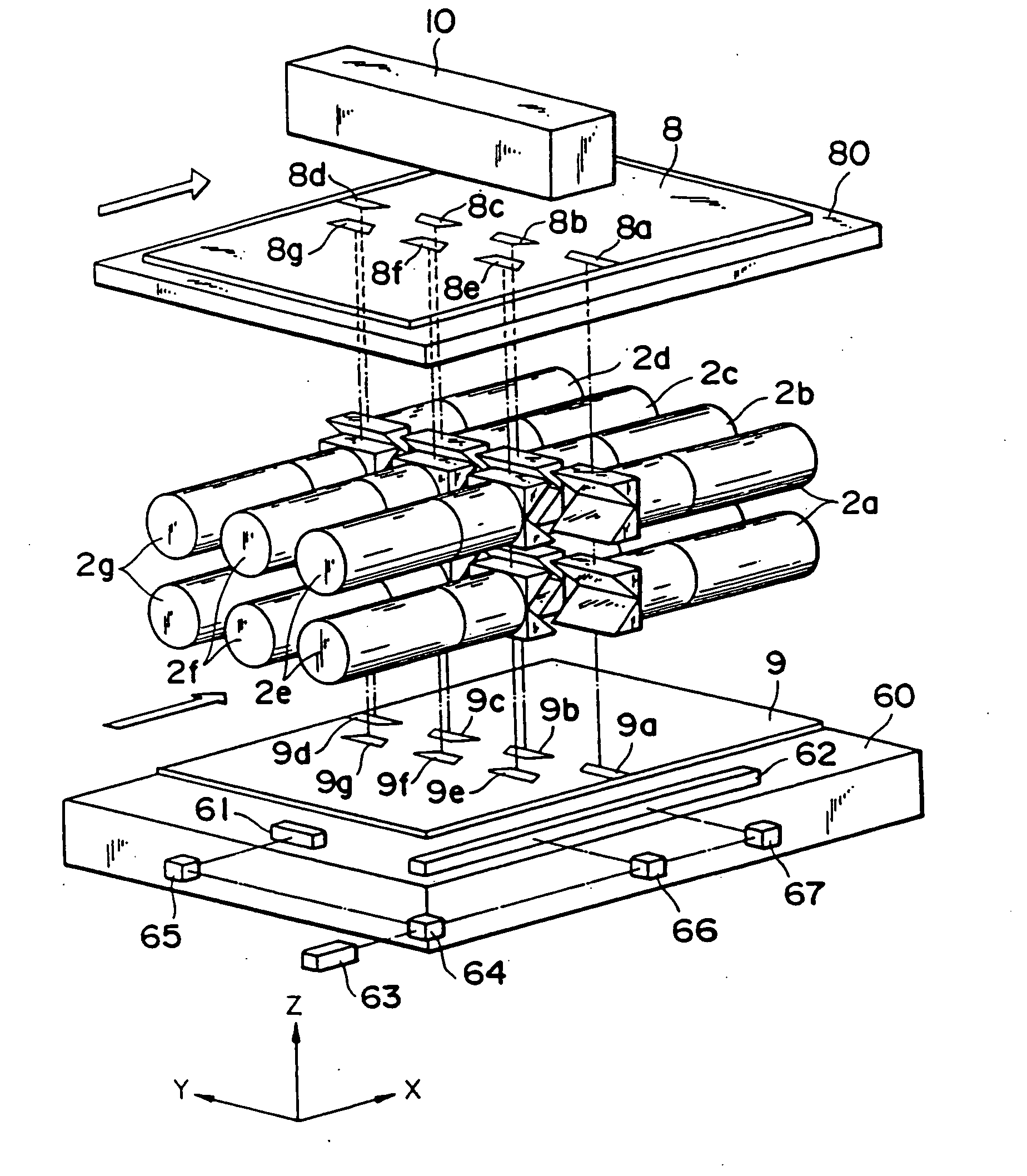

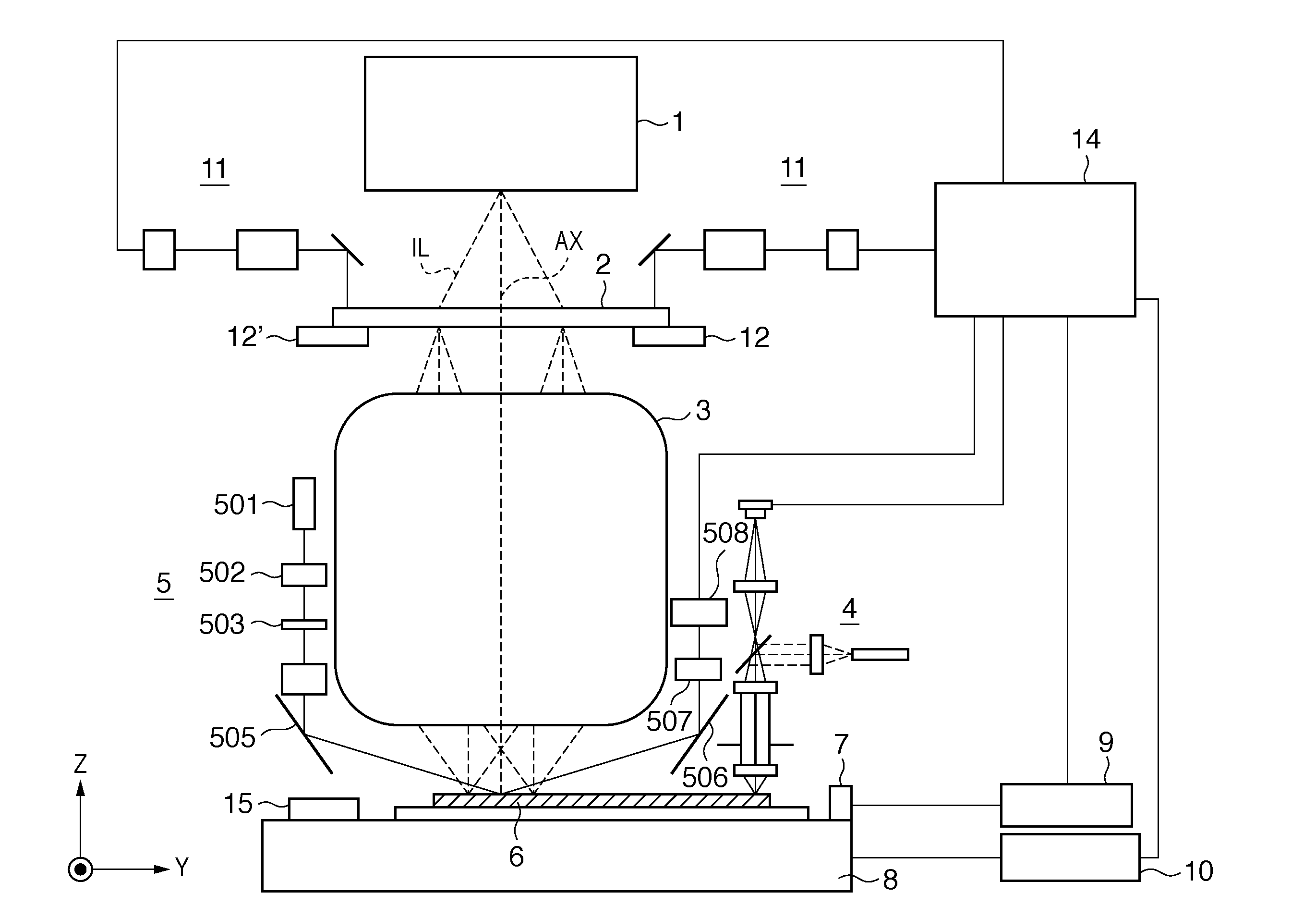

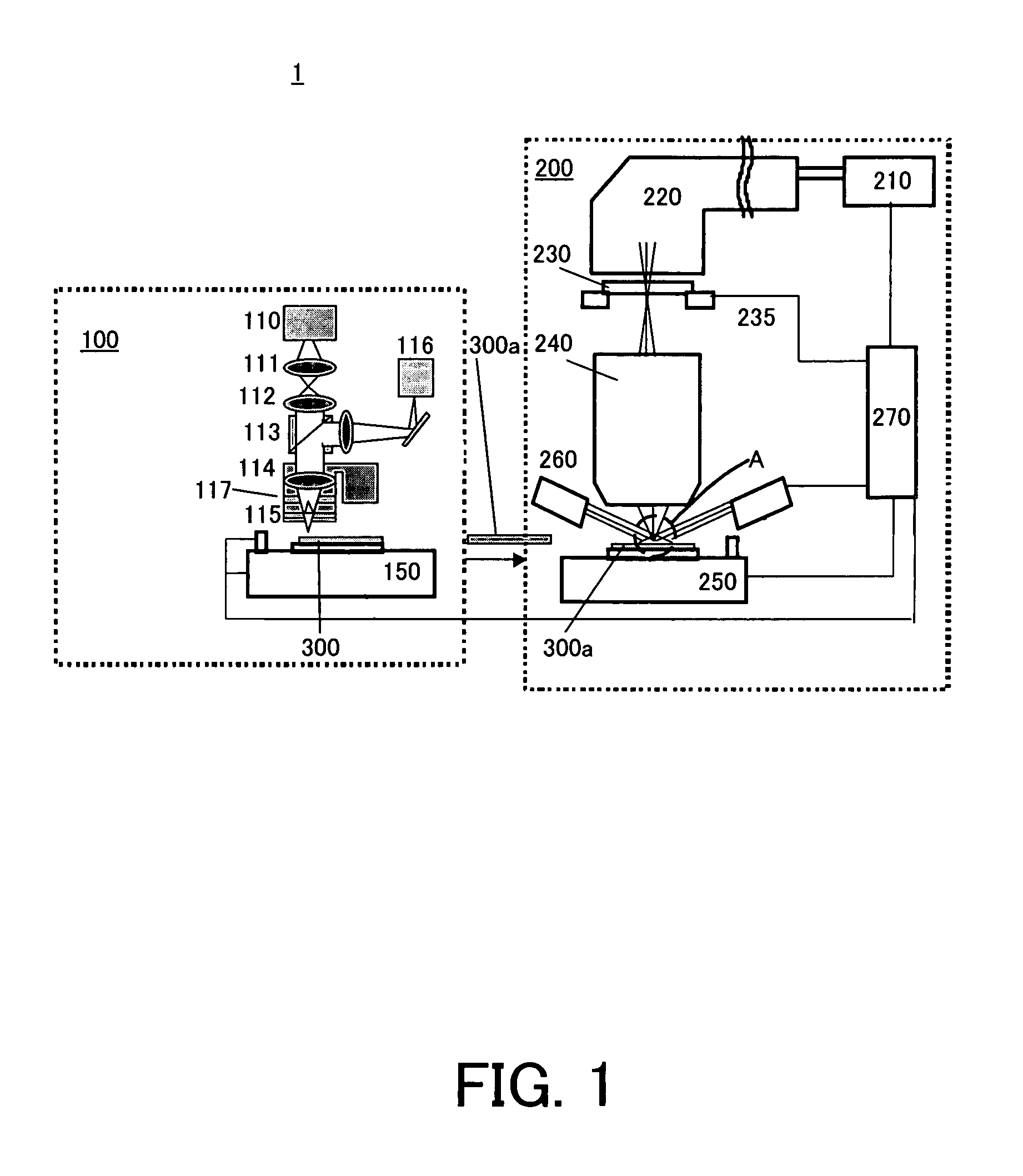

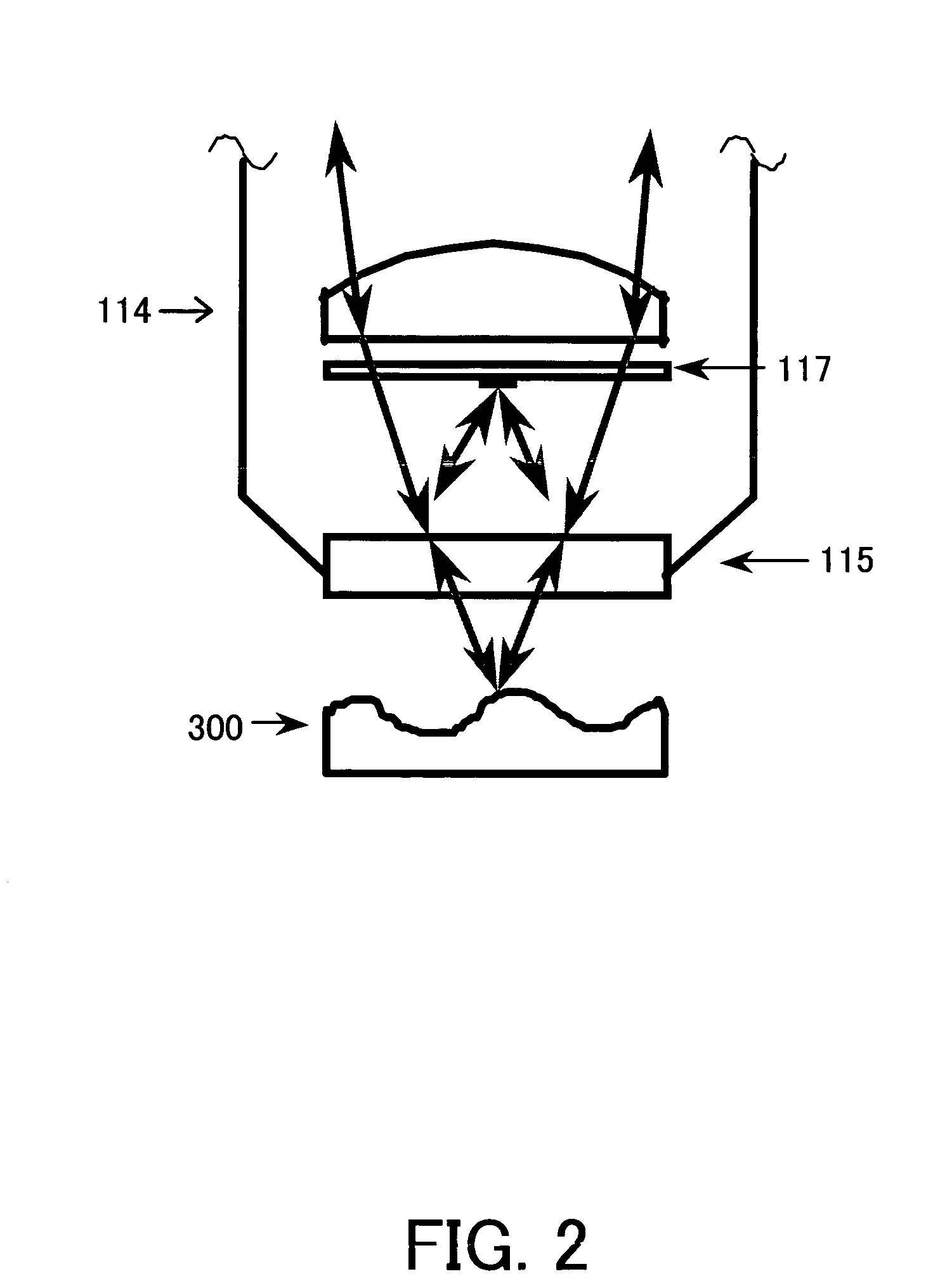

Exposure apparatus and device fabrication method using the same

InactiveUS20050225739A1Reduce throughputIncrease in sizeNanoinformaticsSemiconductor/solid-state device manufacturingProjection opticsOptical axis

An exposure apparatus that irradiates excitation laser onto a target, and generates from generated plasma a light source for generating illumination light of an extreme ultraviolet region or an X-ray region includes an illumination optical system that uses the illumination light to illuminate a catoptric reticle that forms a pattern to be transferred, the illumination optical system including a first mirror closest to the light source, an ellipsoidal mirror for condensing the illumination light in front of the first mirror in the illumination optical system, and a projection optical system that reduces and projects the pattern reflected on the reticle onto an object to be exposed, wherein light where an optical-axis direction of the excitation laser proceeds beyond a position that generates the plasma by the excitation laser does not interfere with components in the exposure apparatus including the illumination and projection optical systems, and the ellipsoidal mirror.

Owner:CANON KK

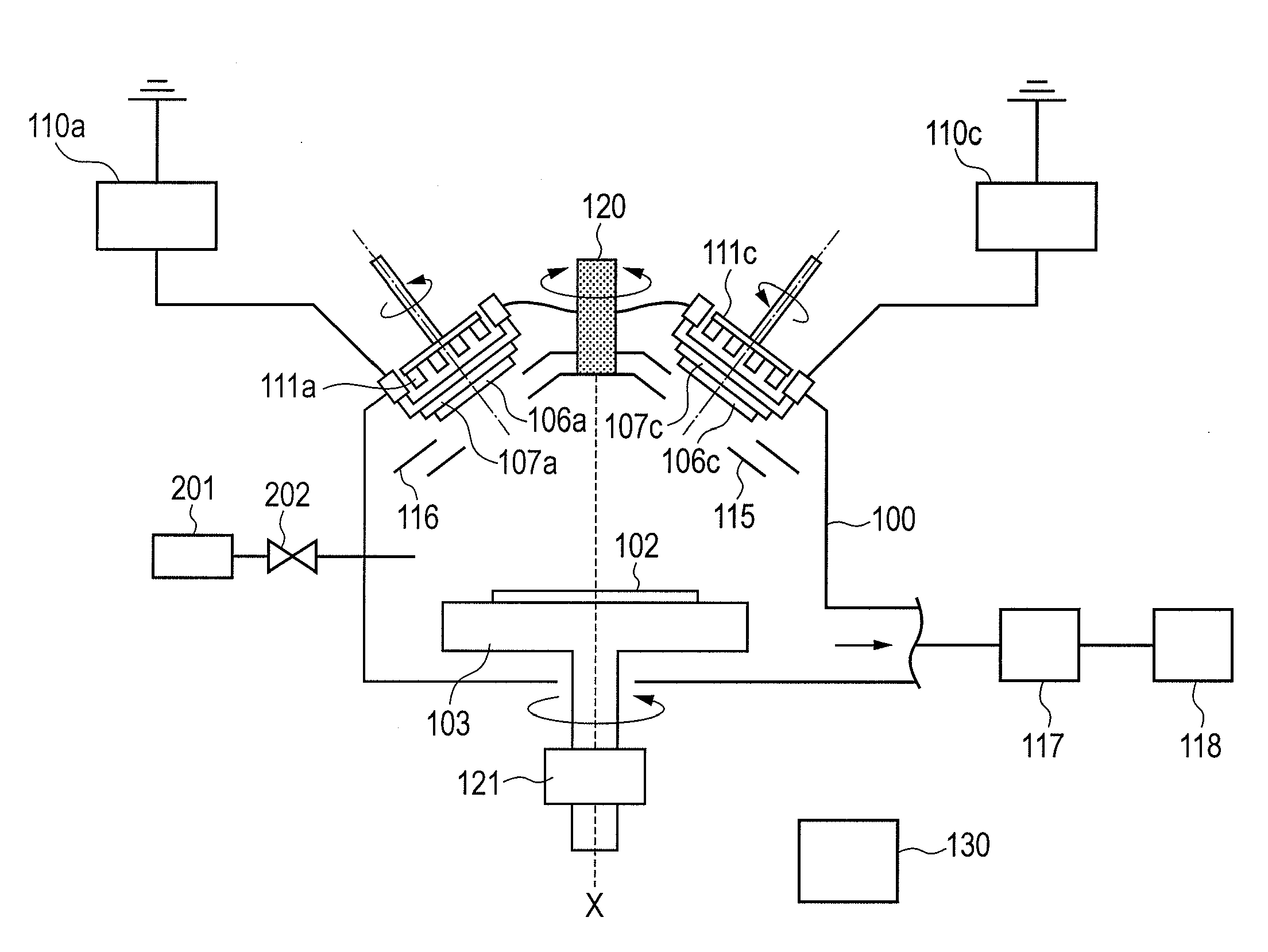

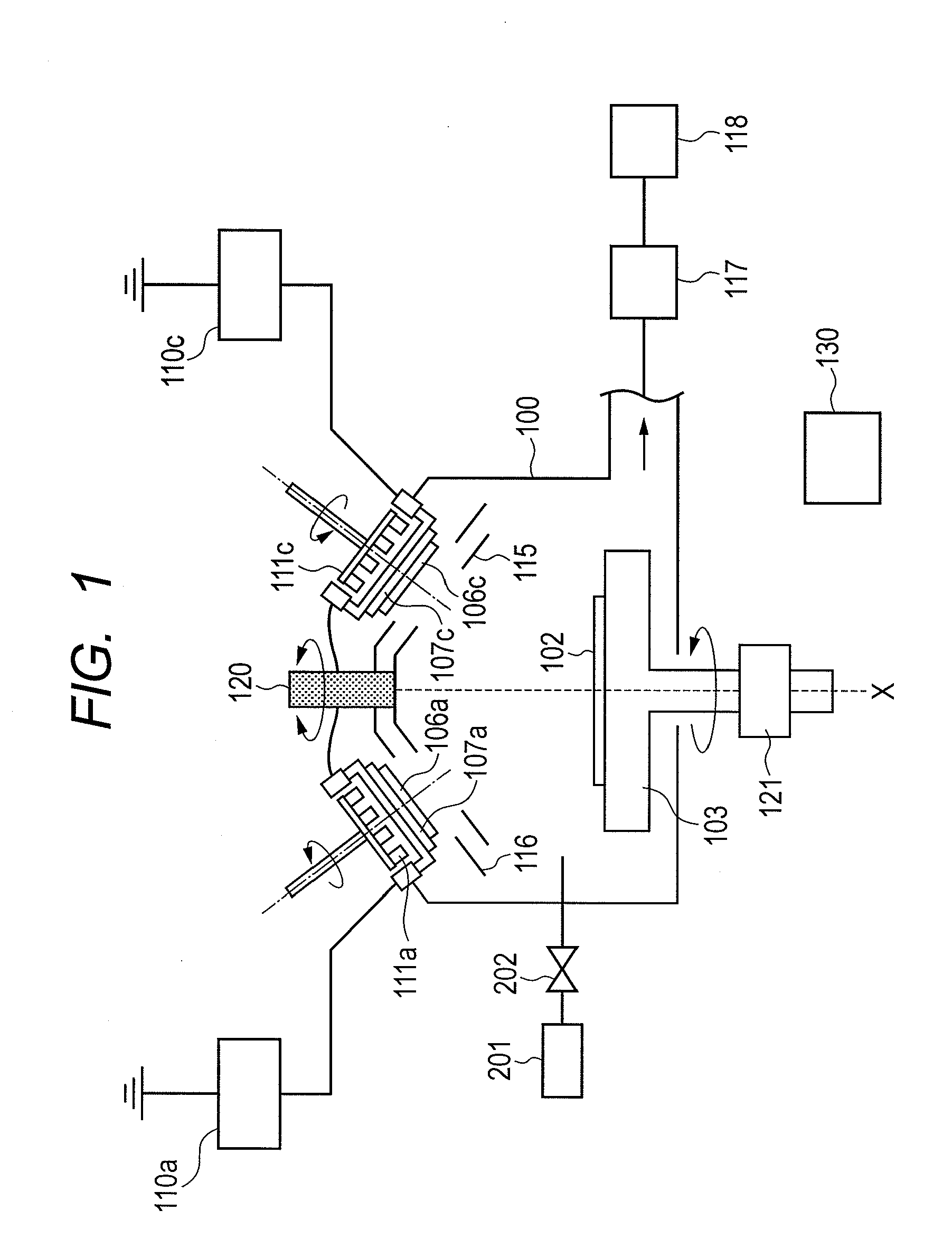

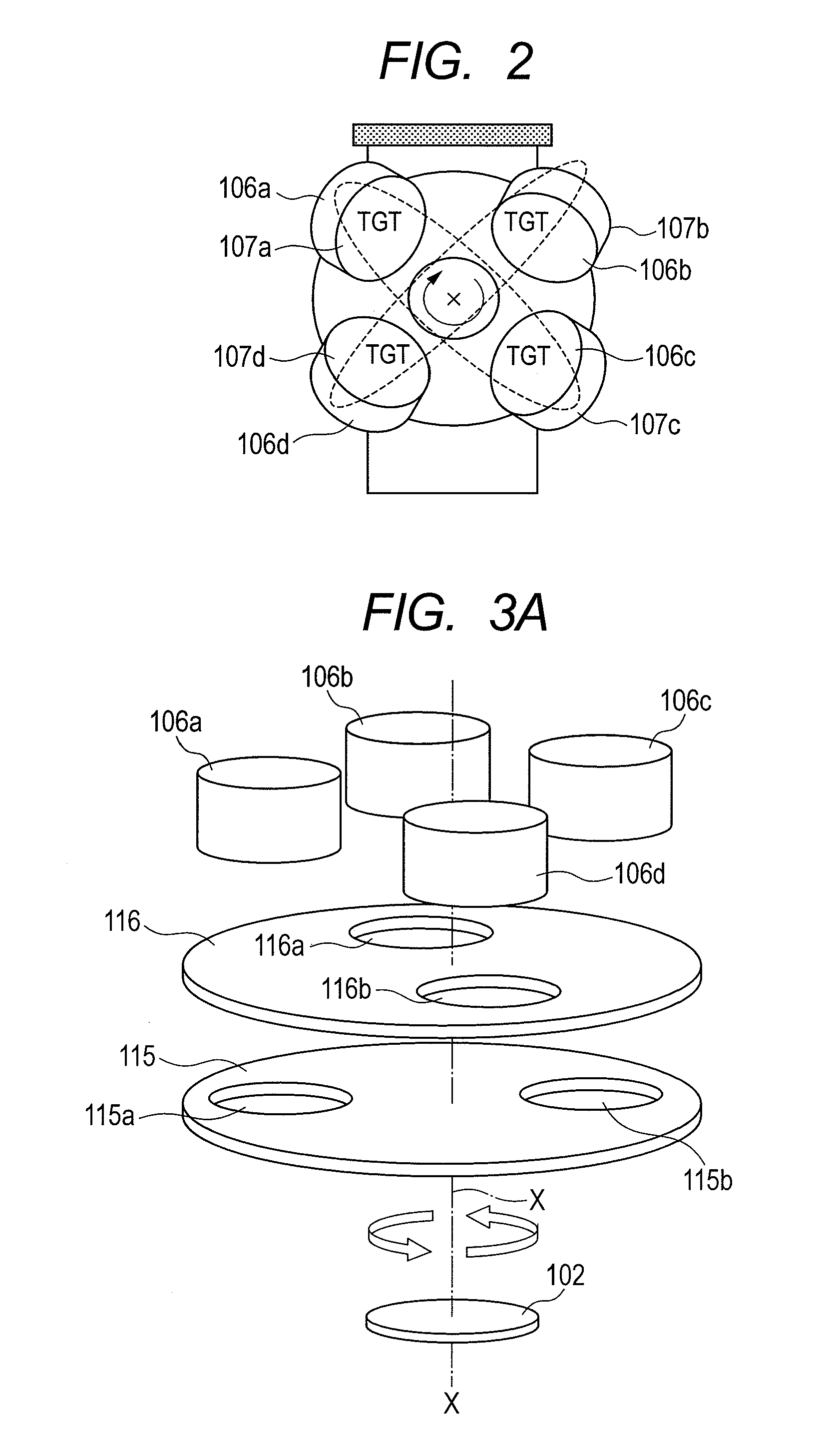

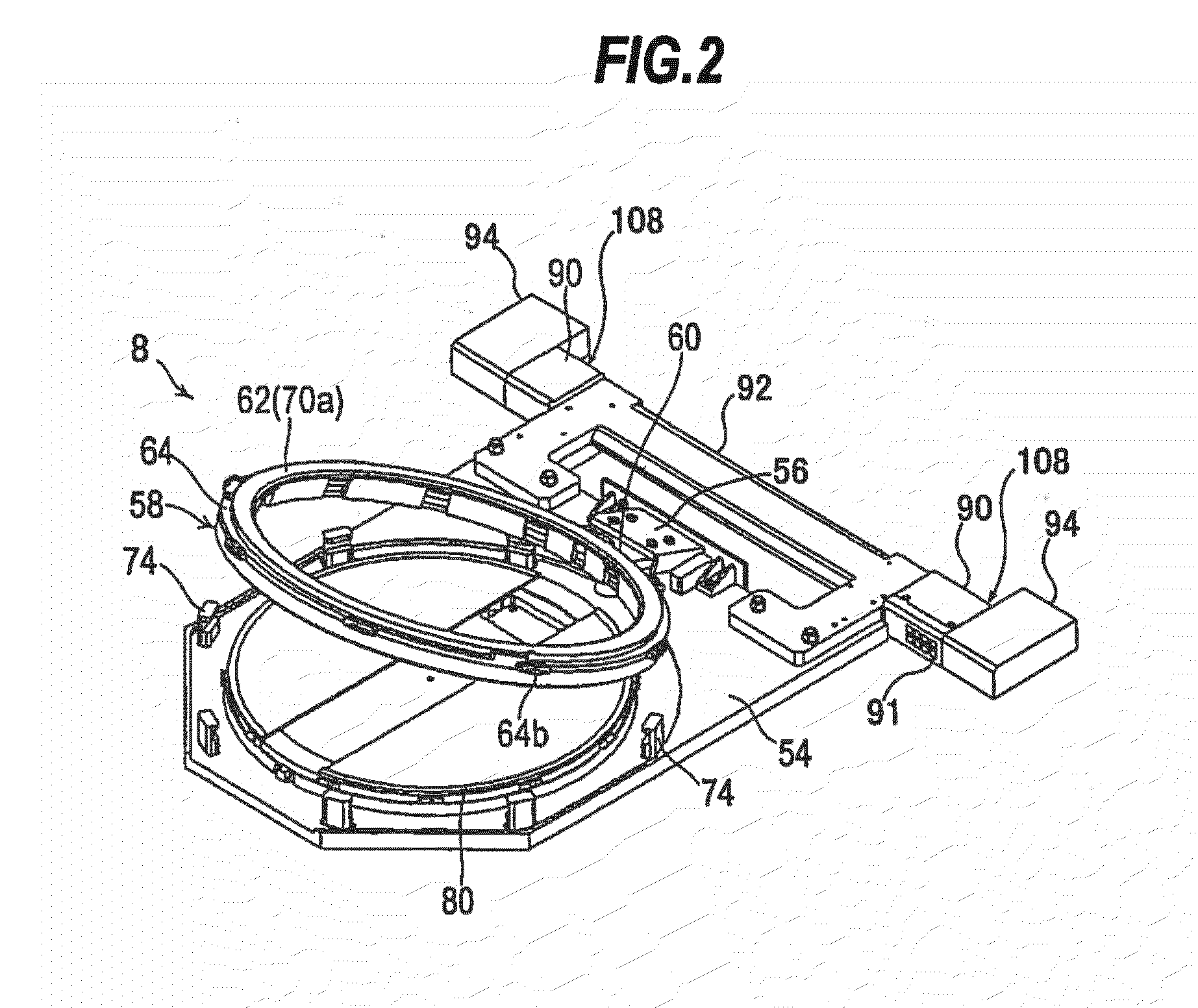

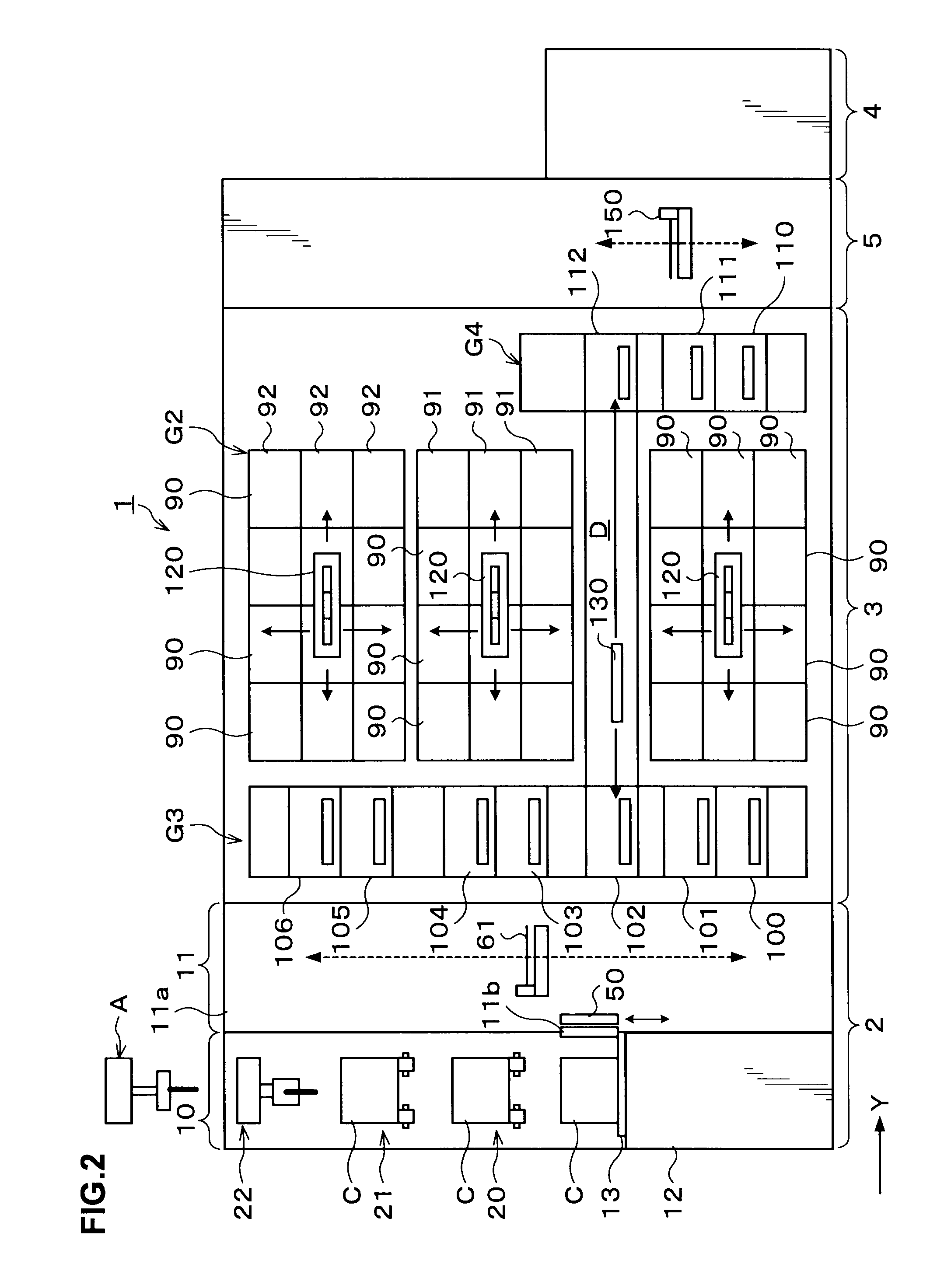

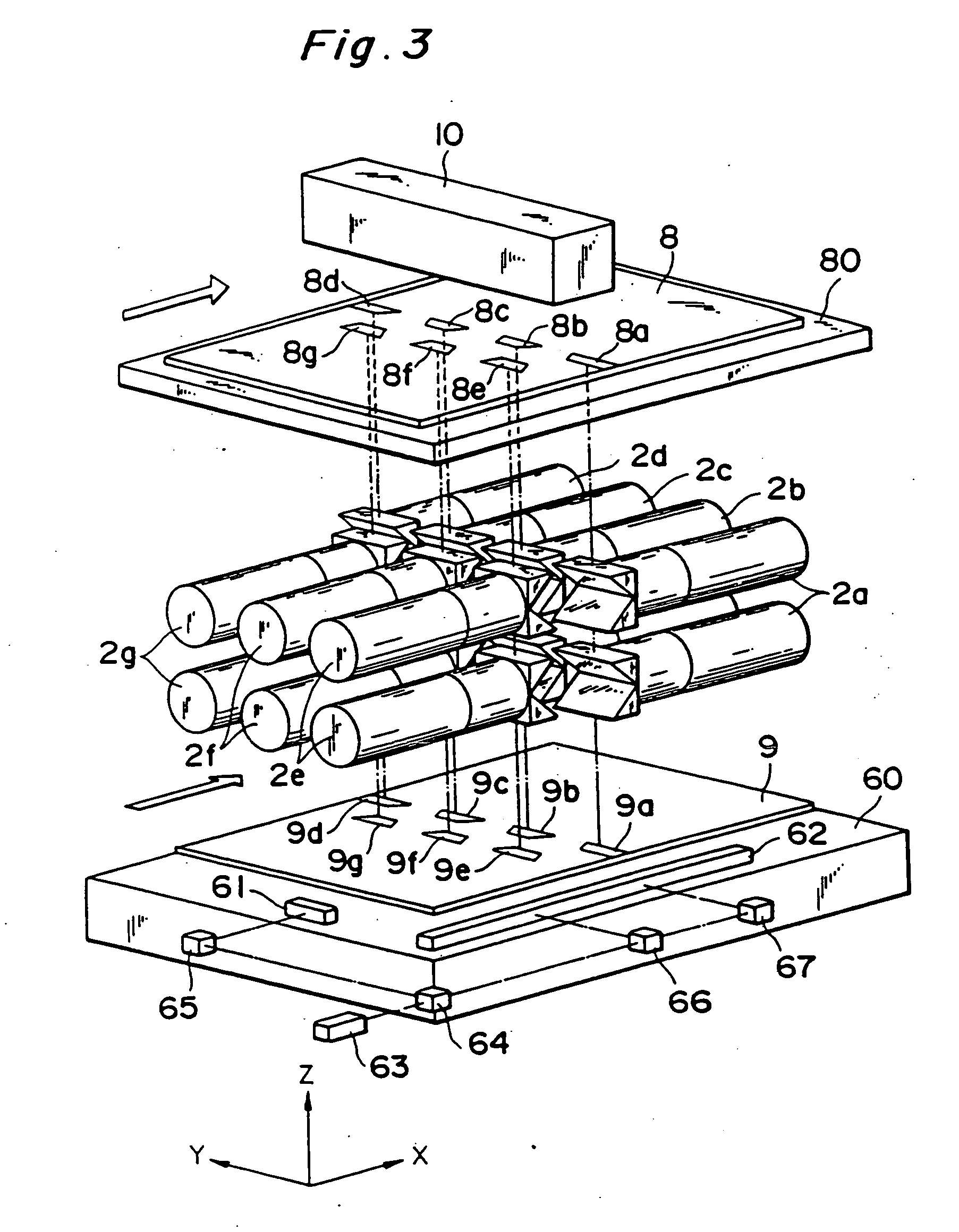

Sputtering apparatus and manufacturing method of electronic device

InactiveUS20120164354A1Efficiently laminate thin films in a short timeWithout lowering throughputSpark gapsLiquid surface applicatorsRotational axisEngineering

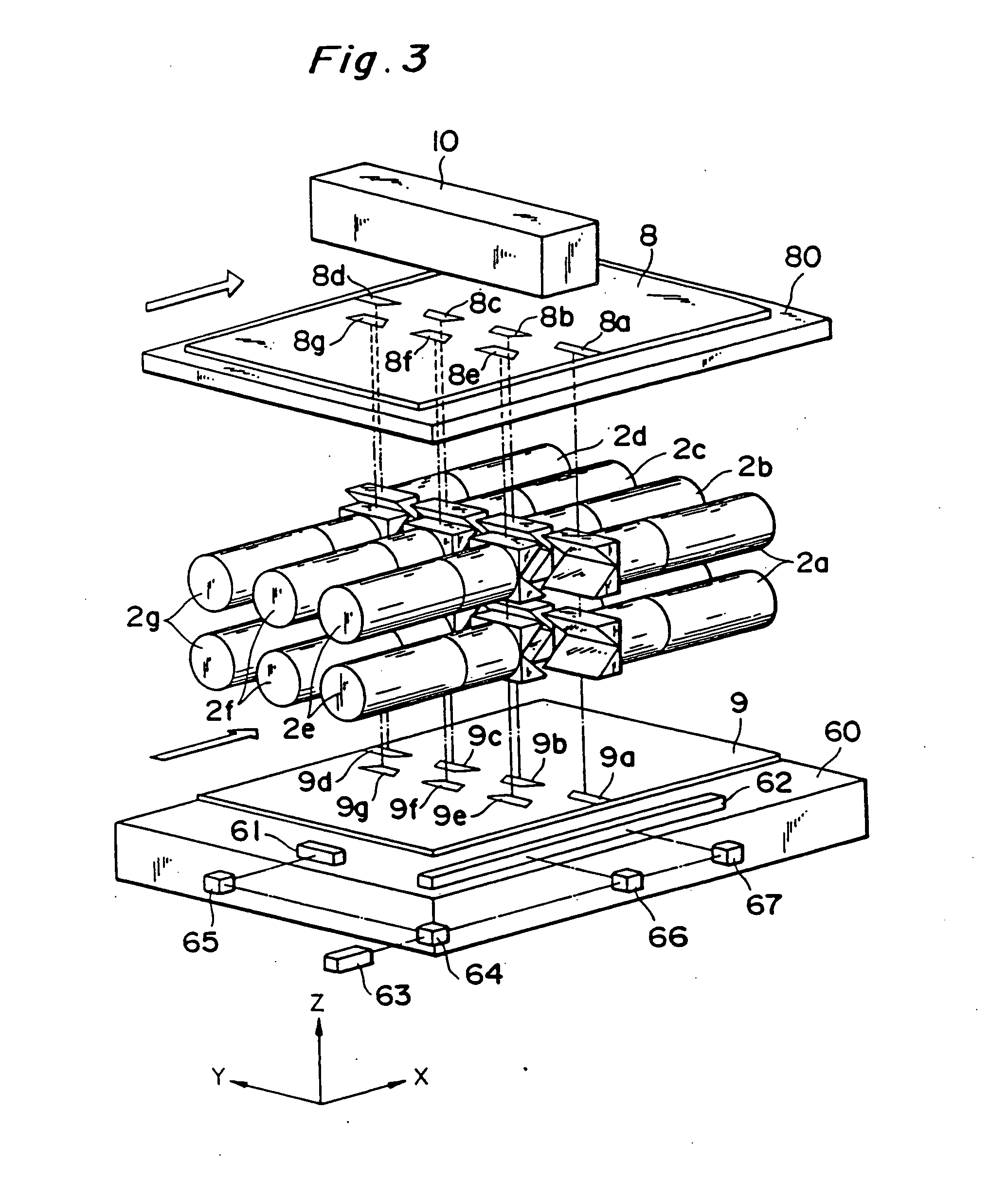

The present invention provides a sputtering apparatus that can efficiently laminate thin films in a short time without lowering throughputs, and a manufacturing method of an electronic device. The sputtering apparatus according to an embodiment of the present invention includes a rotatable substrate holder, four target holders obliquely arranged with respect to the substrate holder, and a first shutter and a second shutter that each are provided between the target holders and the substrate holder and have two holes arranged two-fold symmetrical with respect to a rotational axis X. Two of the four target holders are first group target holders arranged two-fold symmetrical with respect to the rotational axis X, and the other two target holders are second group target holders arranged between the first group target holders and two-fold symmetrical with respect to the rotational axis X.

Owner:CANON ANELVA CORP

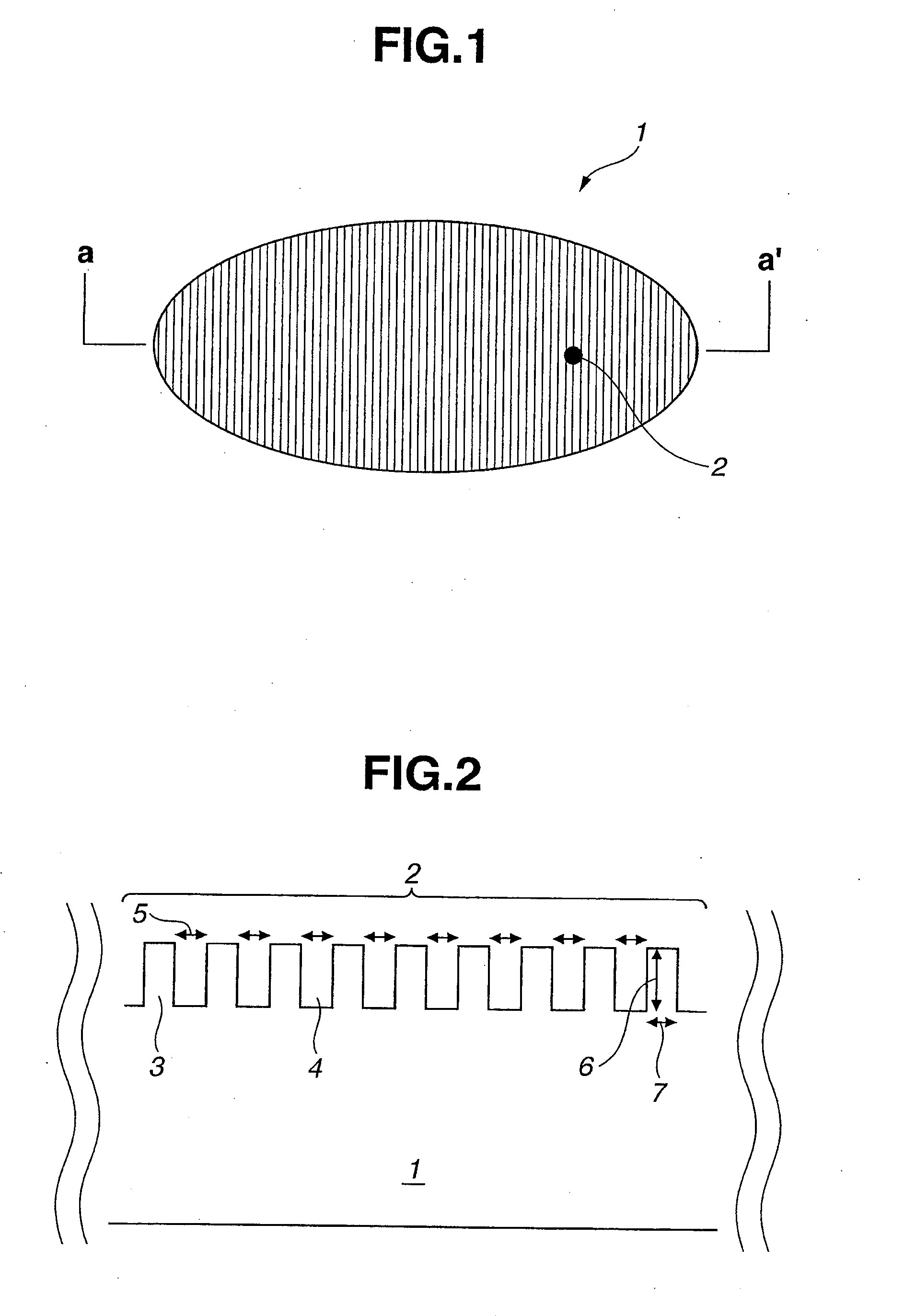

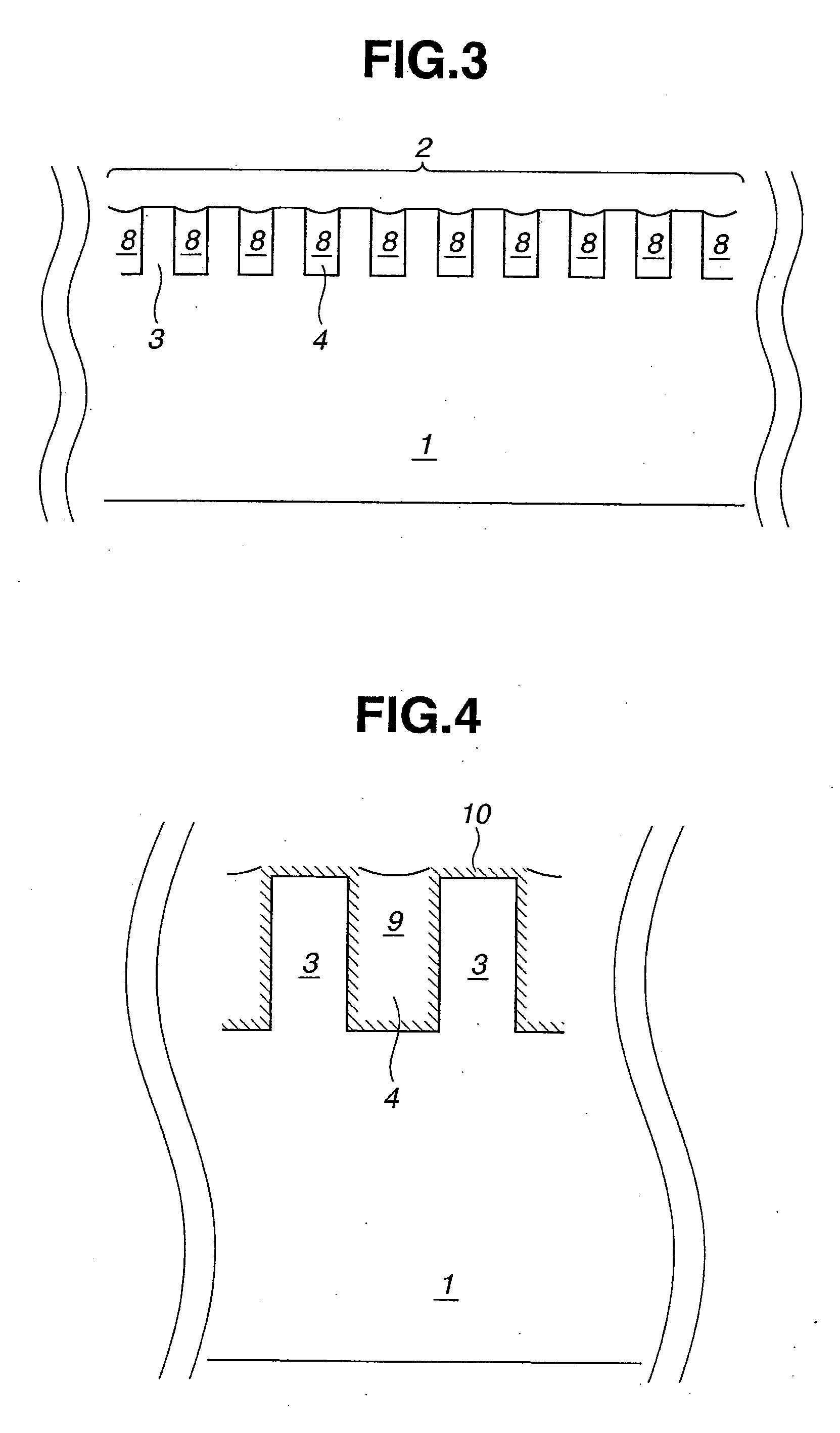

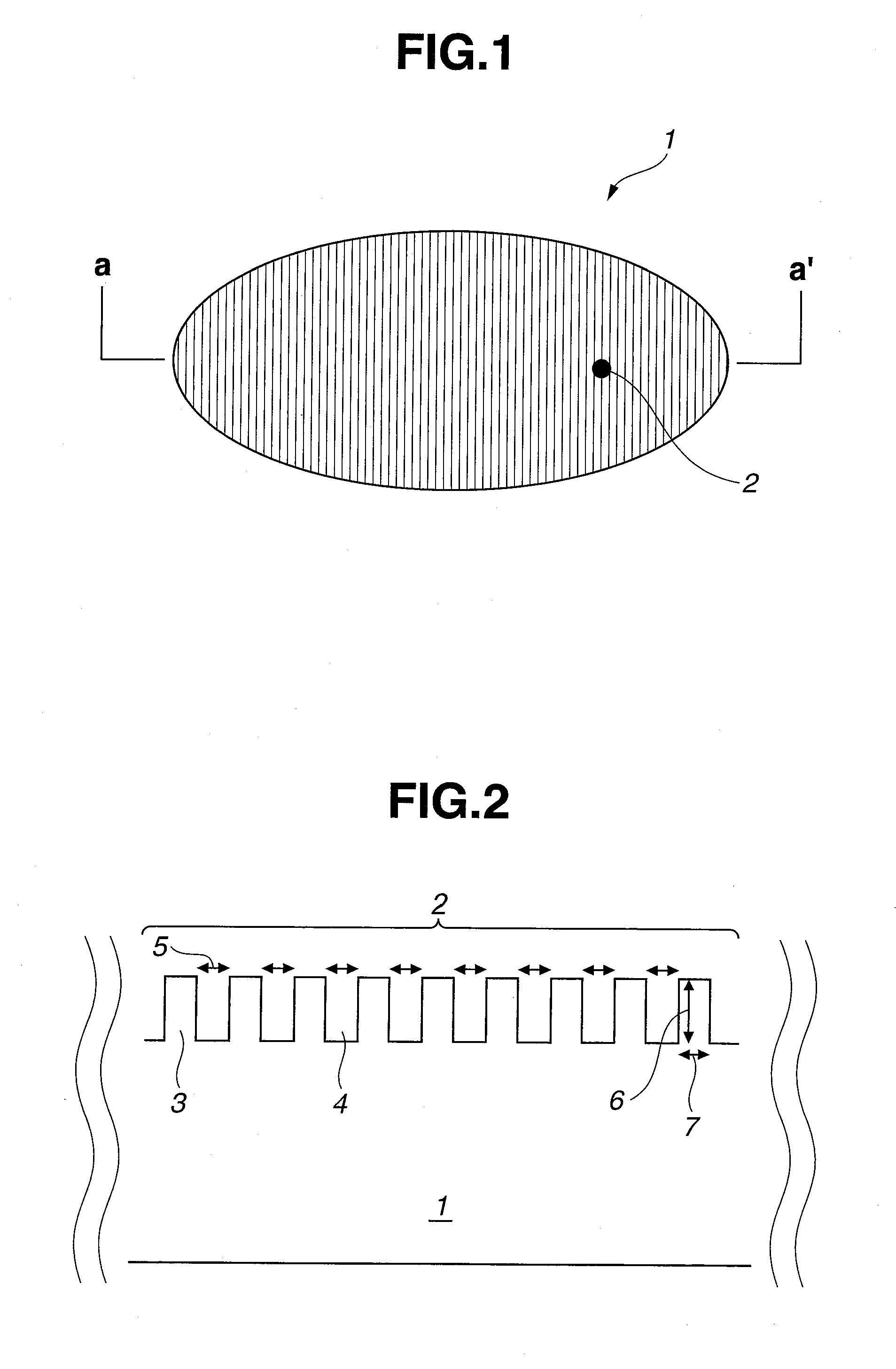

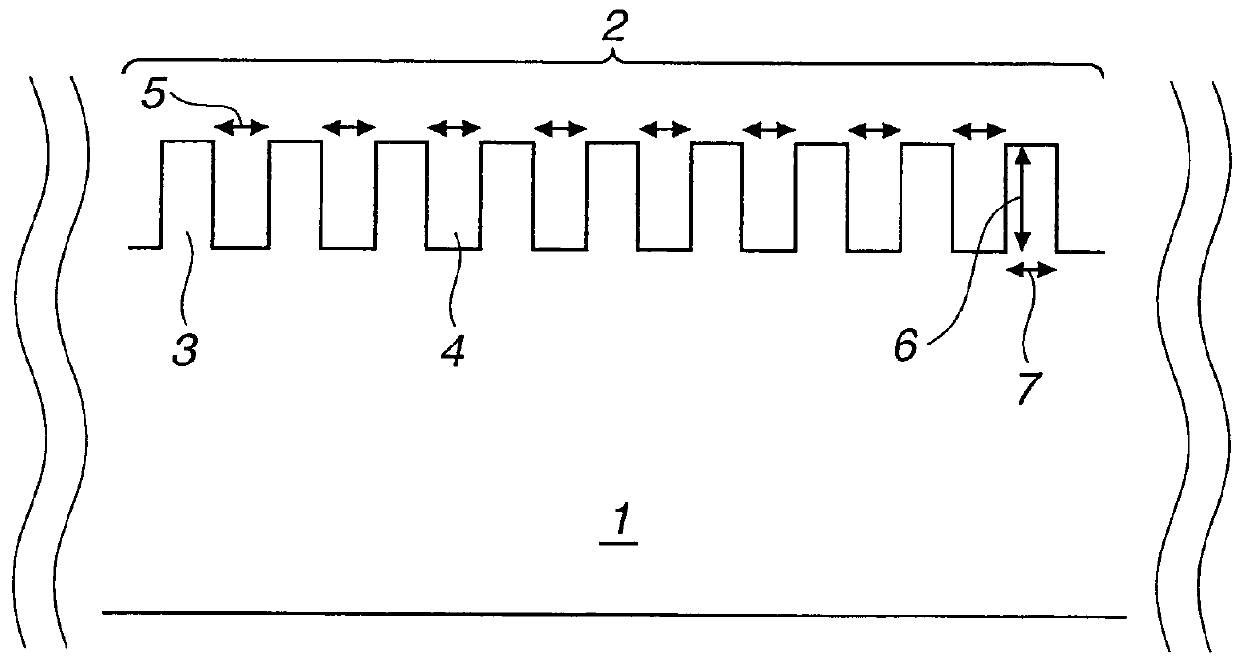

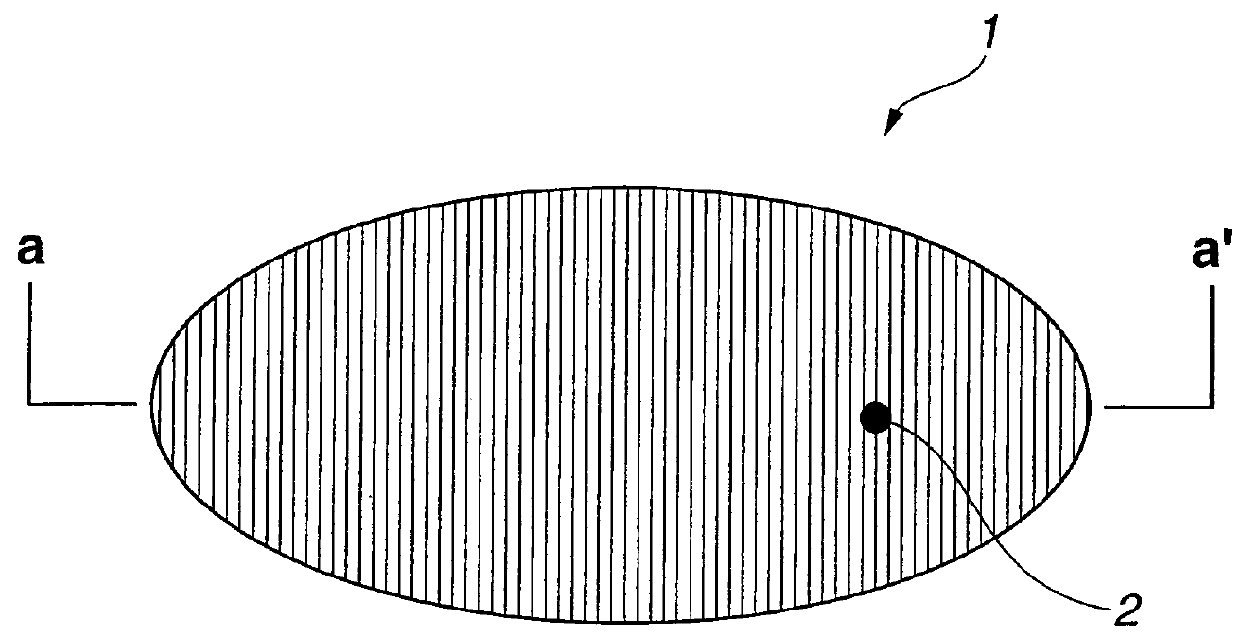

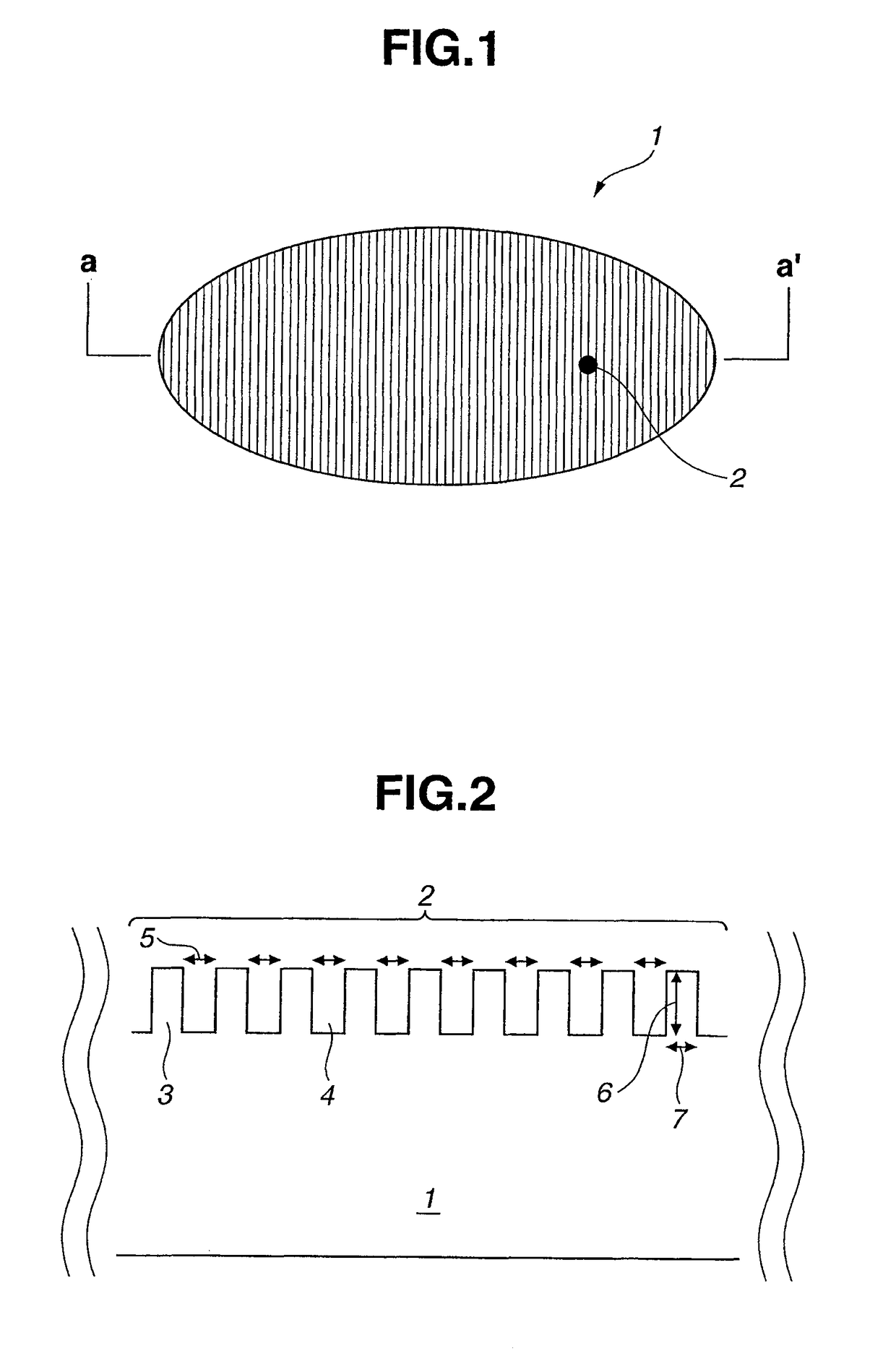

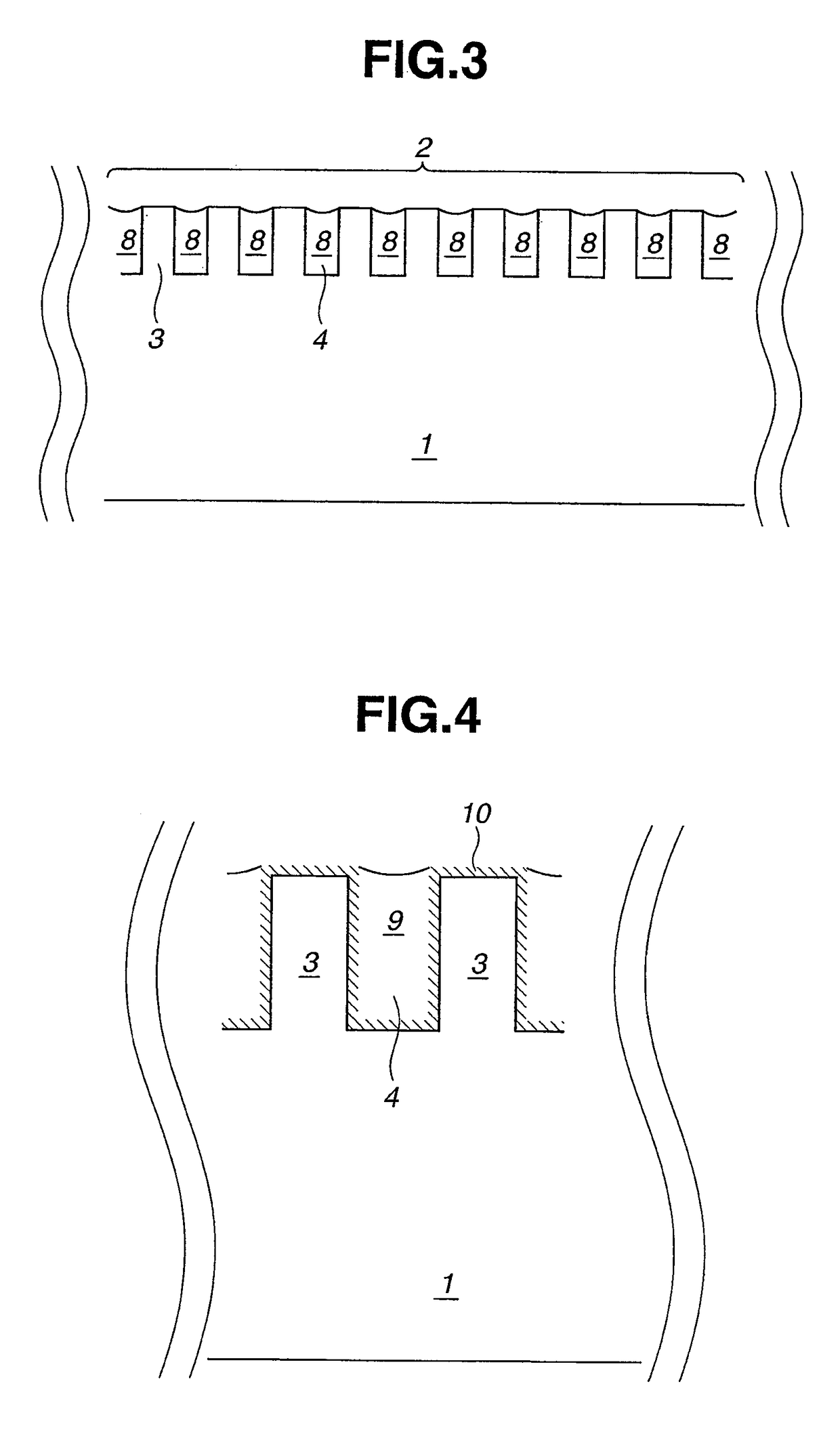

Liquid Chemical for Forming Protecting Film

ActiveUS20120017934A1Improve waterproof performanceReduce capillary forceNon-ionic surface-active compoundsOther chemical processesTrimethylsilyl trifluoromethanesulfonateCompound a

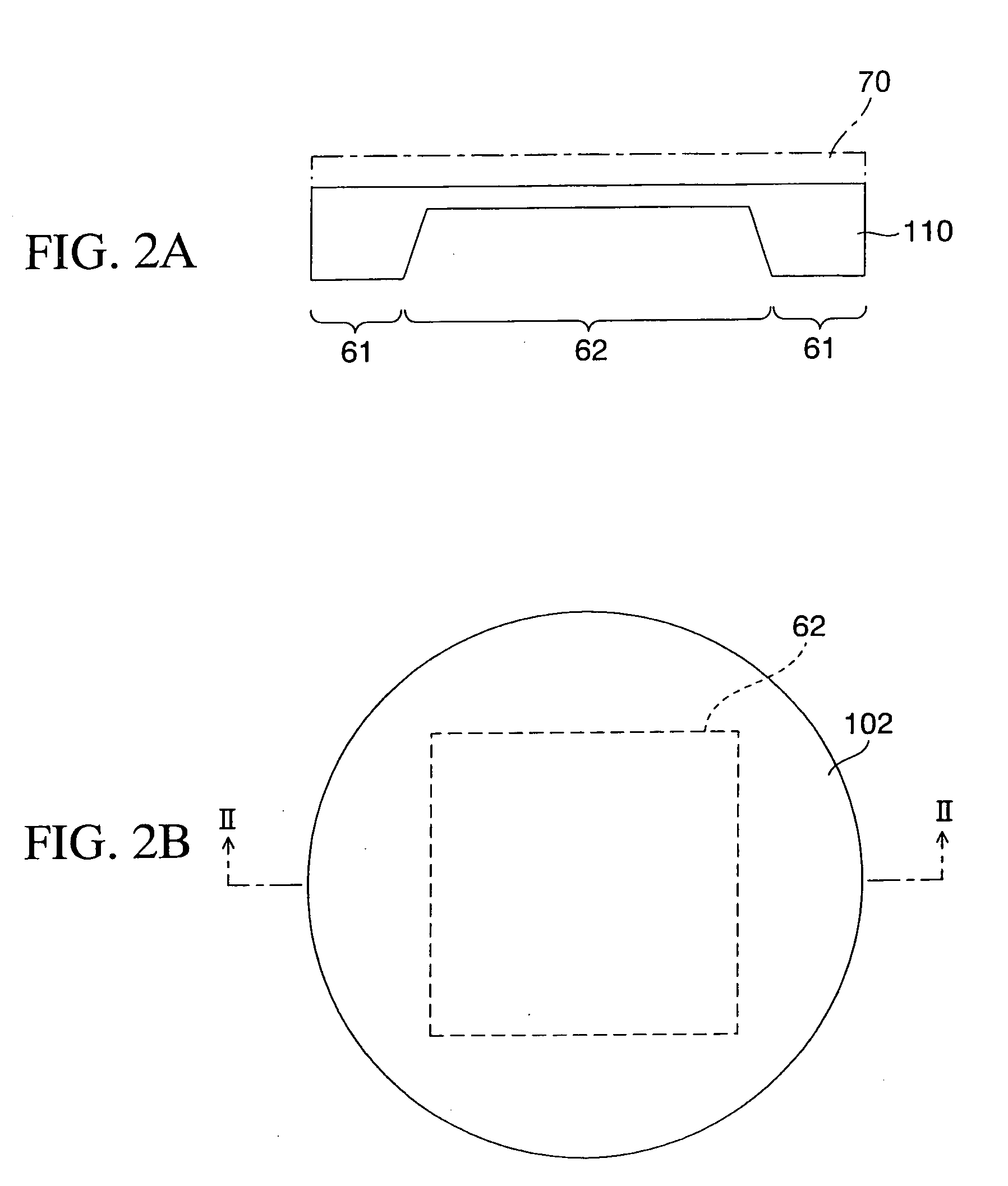

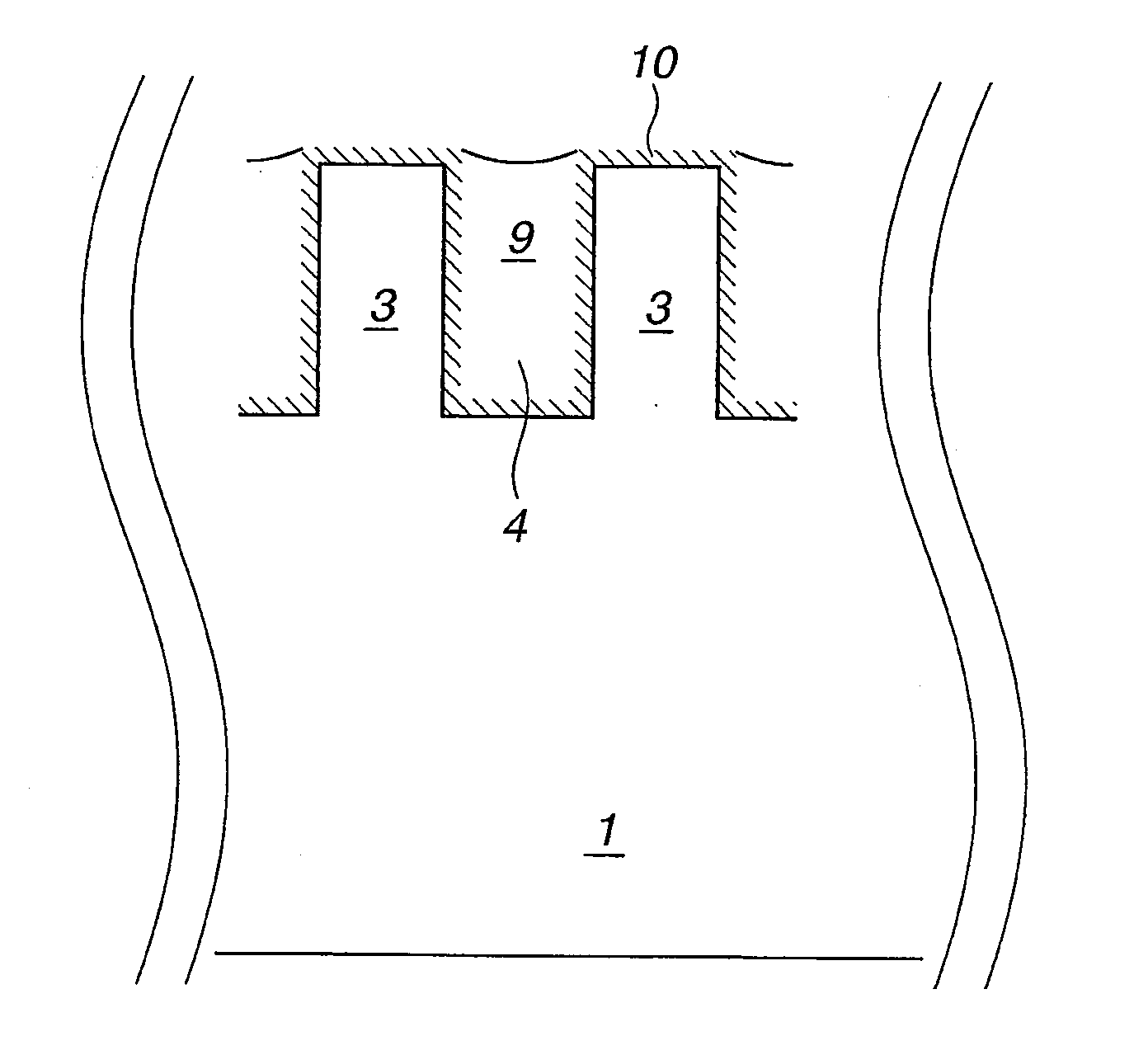

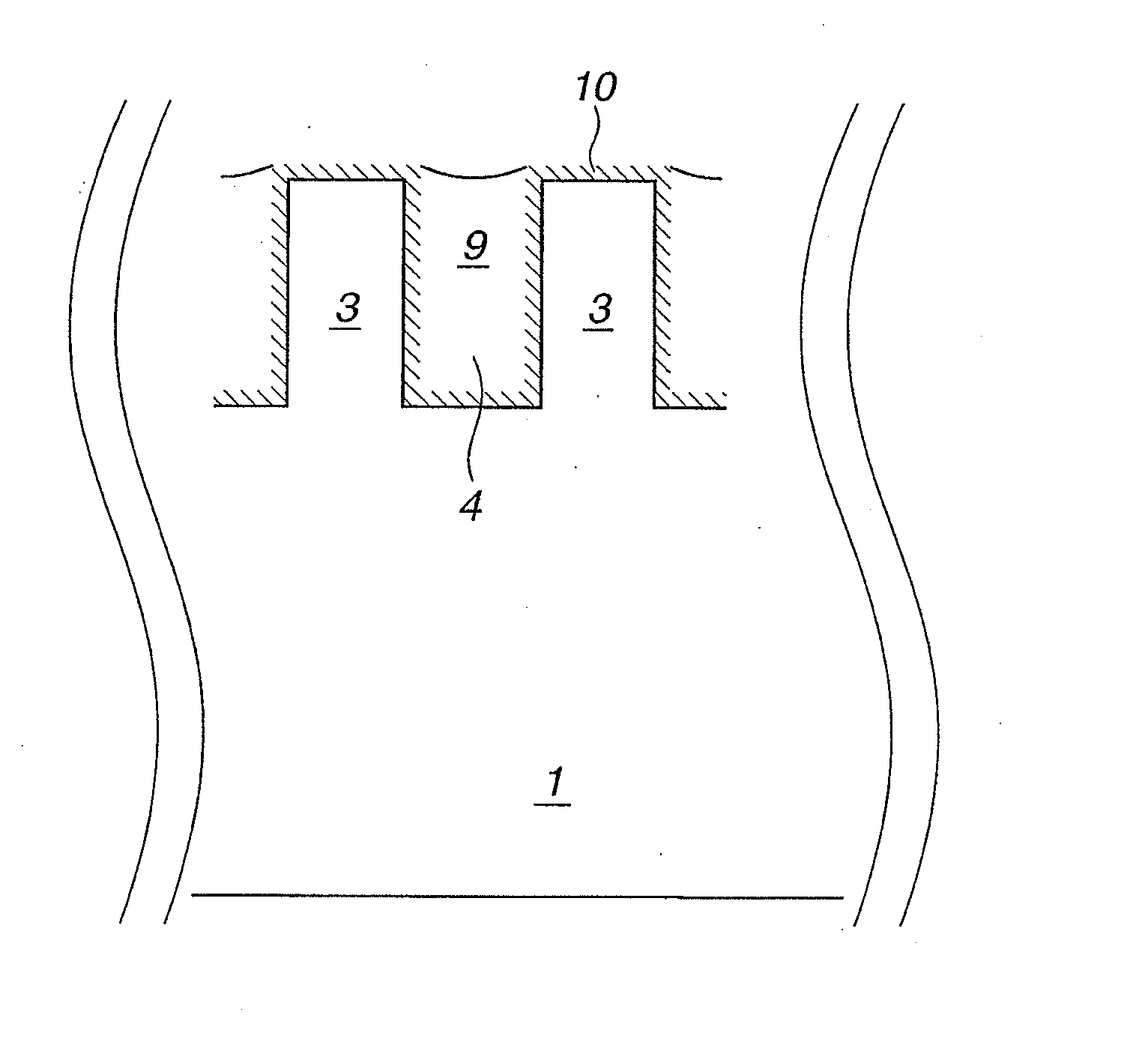

Disclosed is a liquid chemical for forming a water-repellent protecting film at least on a surface of a recessed portion of an uneven pattern at the time of cleaning a wafer having a finely uneven pattern at its surface and containing silicon at least a part of the uneven pattern. This liquid chemical contains a silicon compound A represented by the general formula: R1aSi(H)bX4-a-b and an acid A, the acid A being at least one selected from the group consisting of trimethylsilyl trifluoroactate, trimethylsilyl trifluoromethanesulfonate, dimethylsilyl trifluoroactate, dimethylsilyl trifluoromethanesulfonate, butyldimethylsilyl trifluoroactate, butyldimethylsilyl trifluoromethanesulfonate, hexyldimethylsilyl trifluoroacetate, hexyldimethylsilyl trifluoromethanesulfonate, octyldimethylsilyl trifluoroactate, octyldimethylsilyl trifluoromethanesulfonate, decyldimethylsilyl trifluoroacetate and decyldimethylsilyl trifluoromethanesulfonate.

Owner:CENT GLASS CO LTD

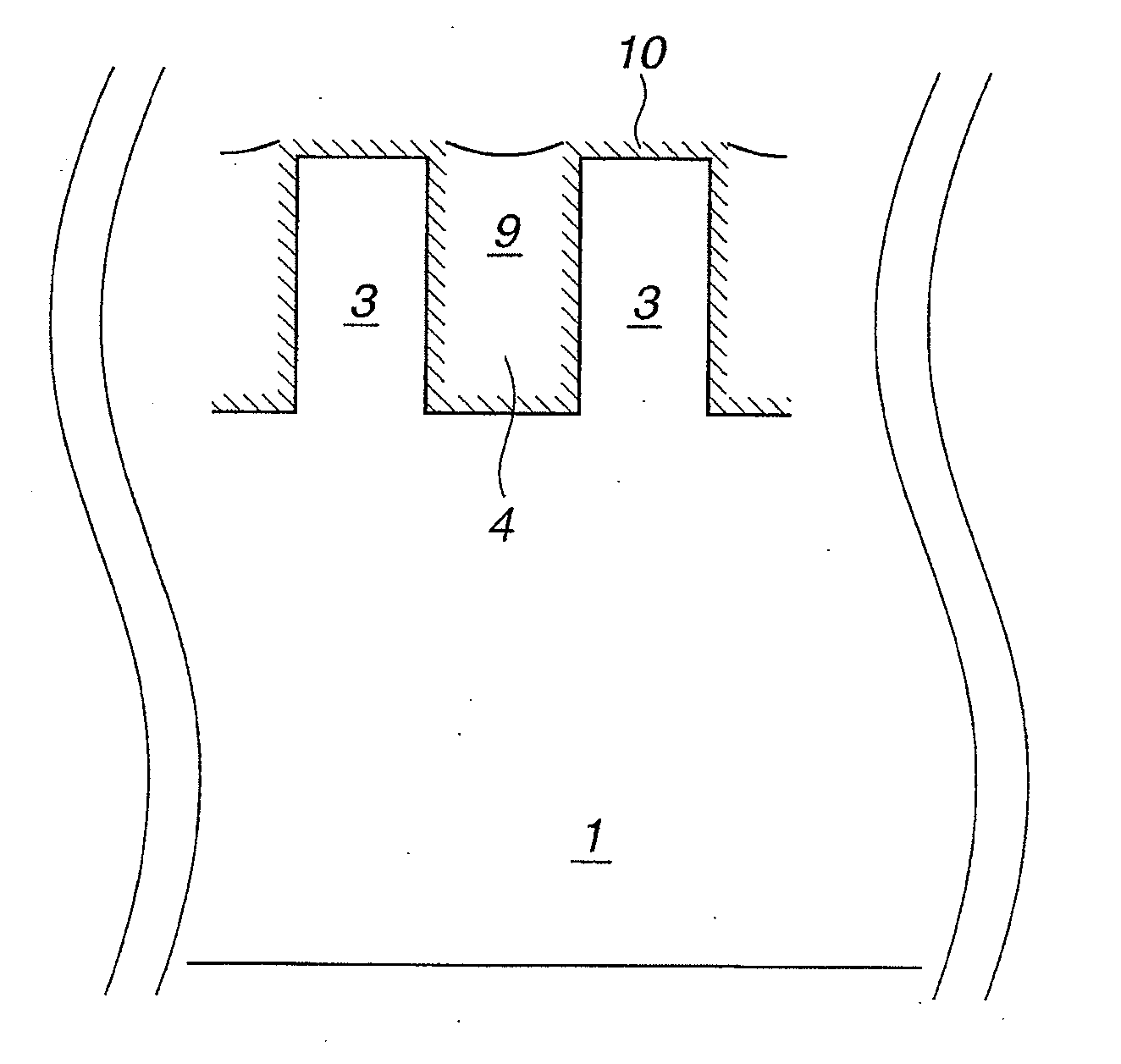

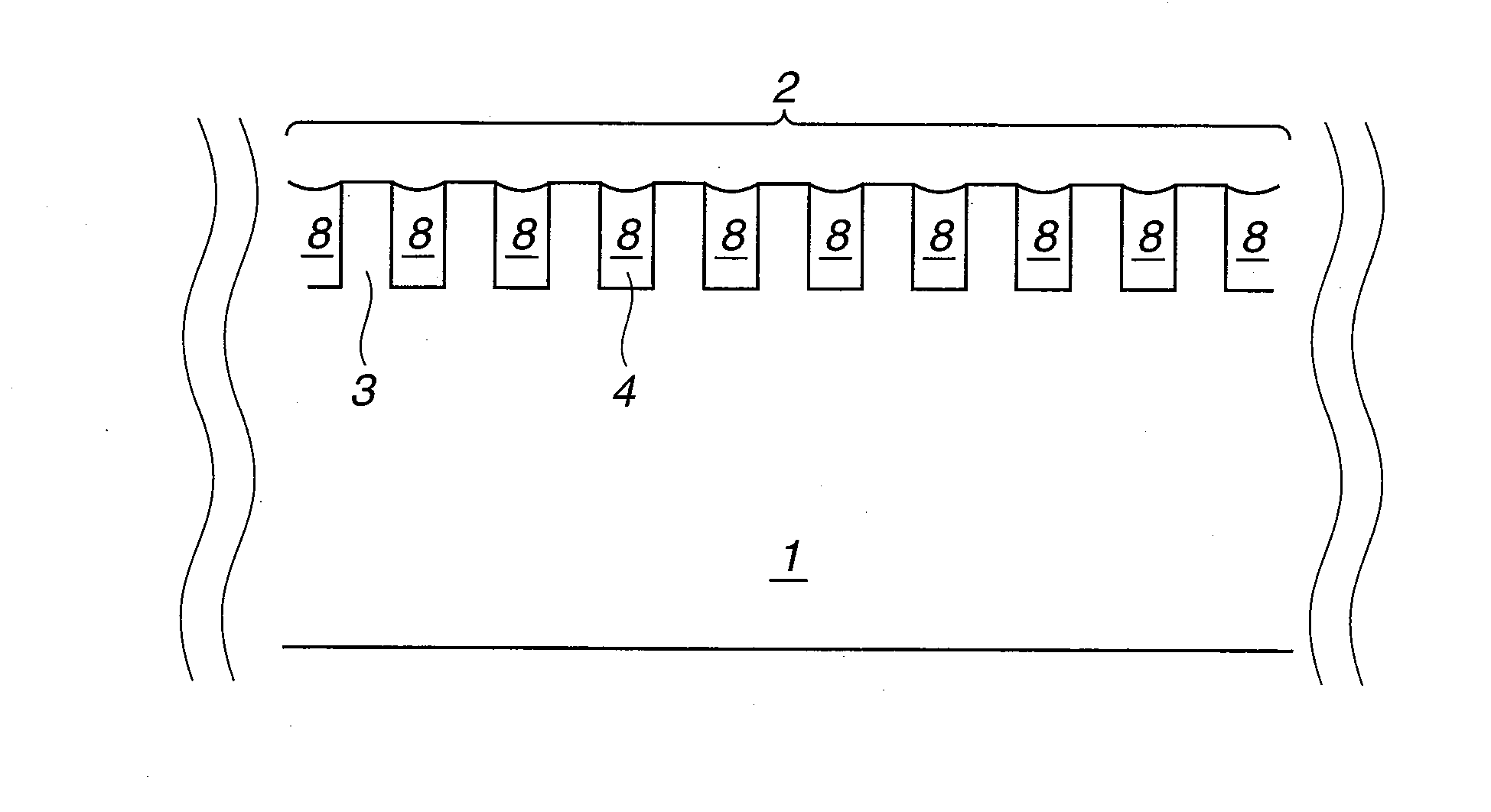

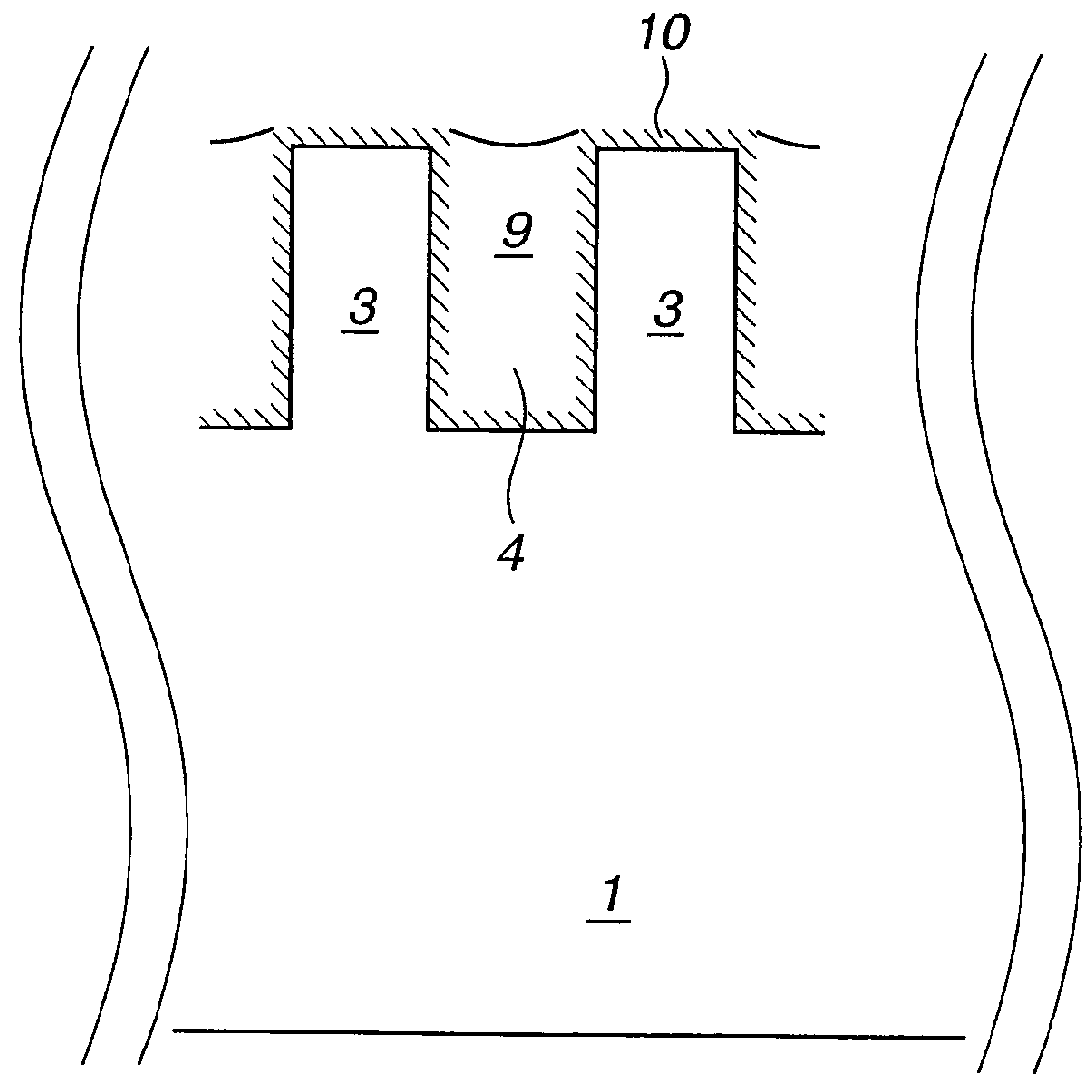

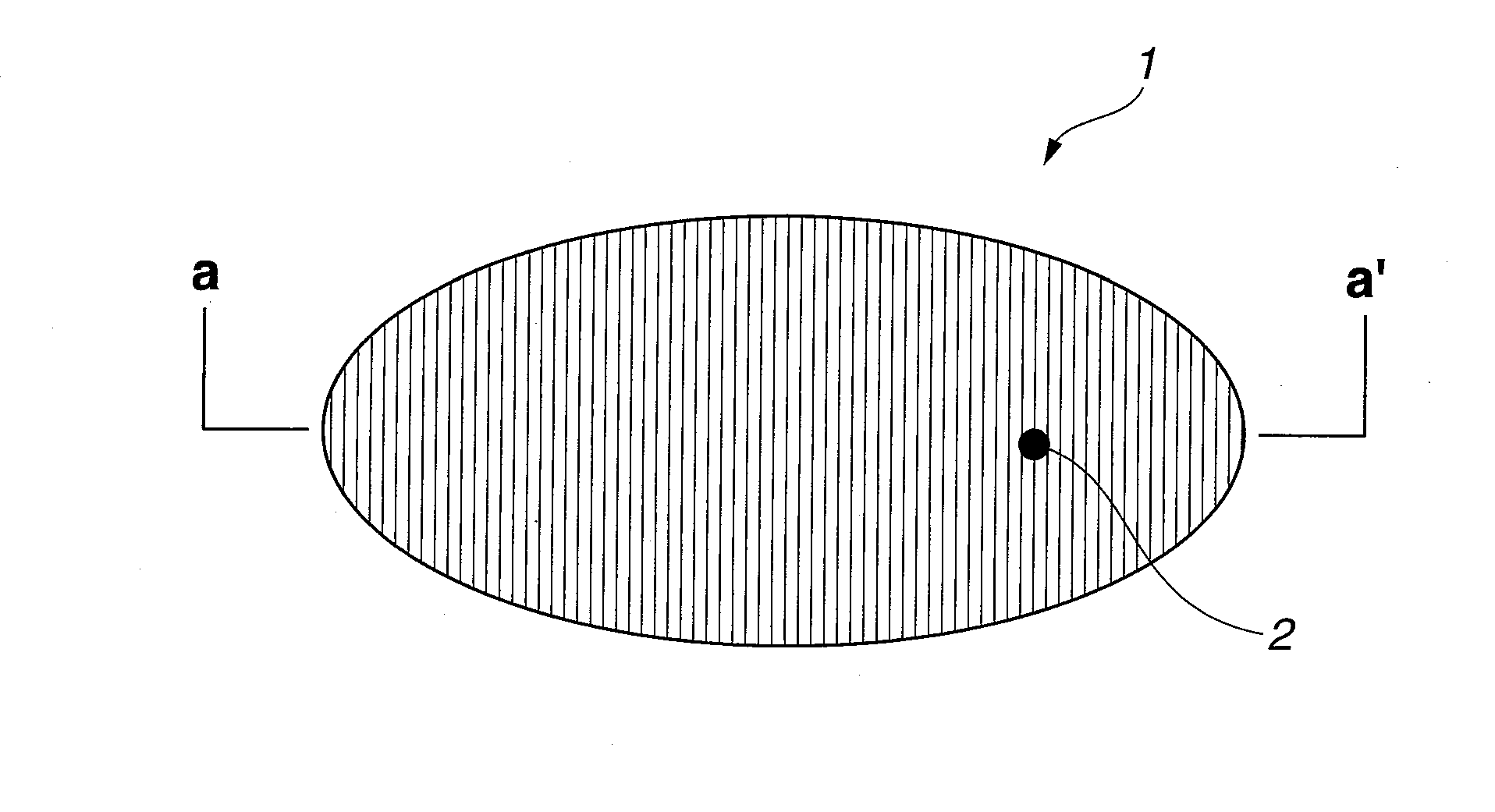

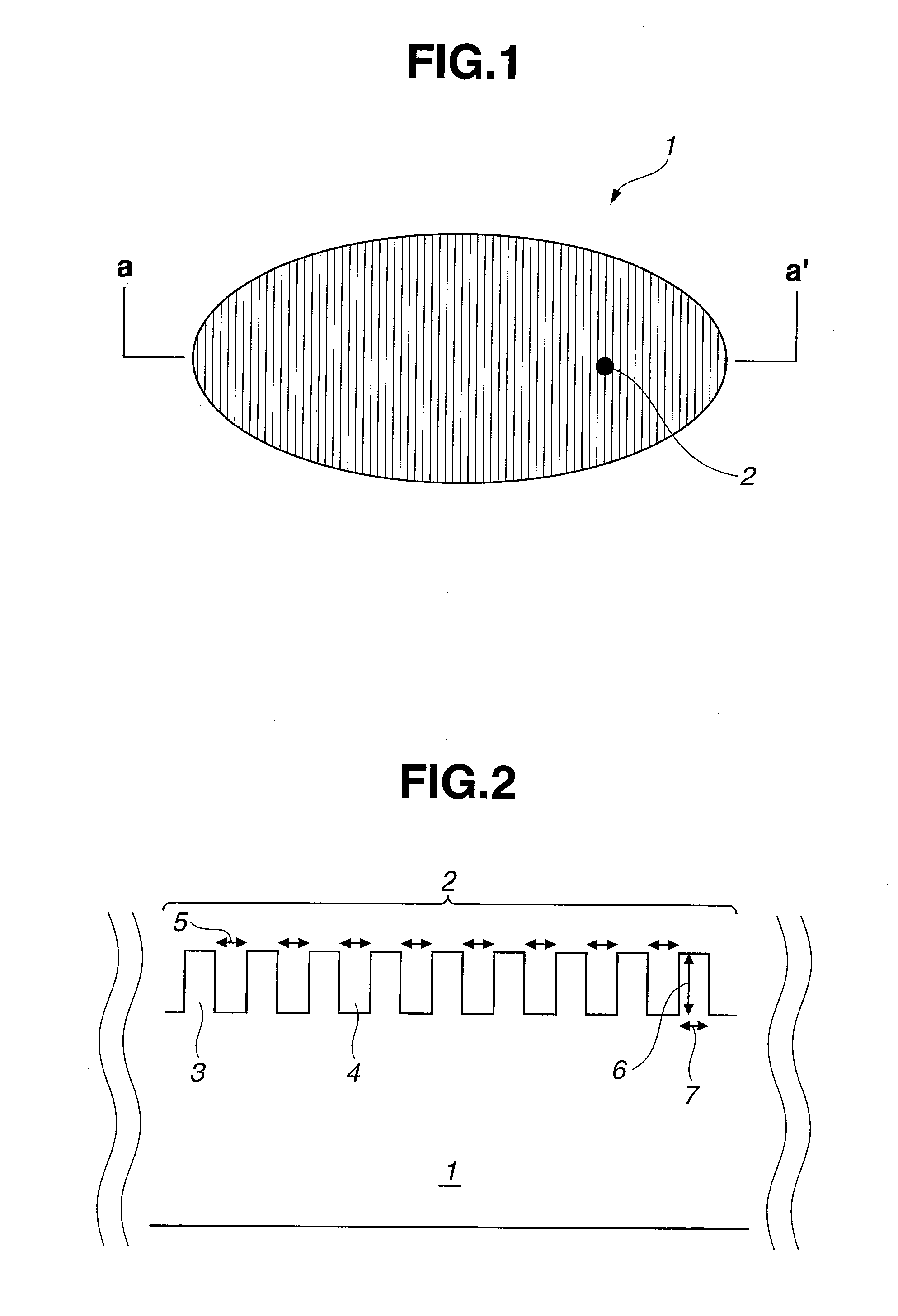

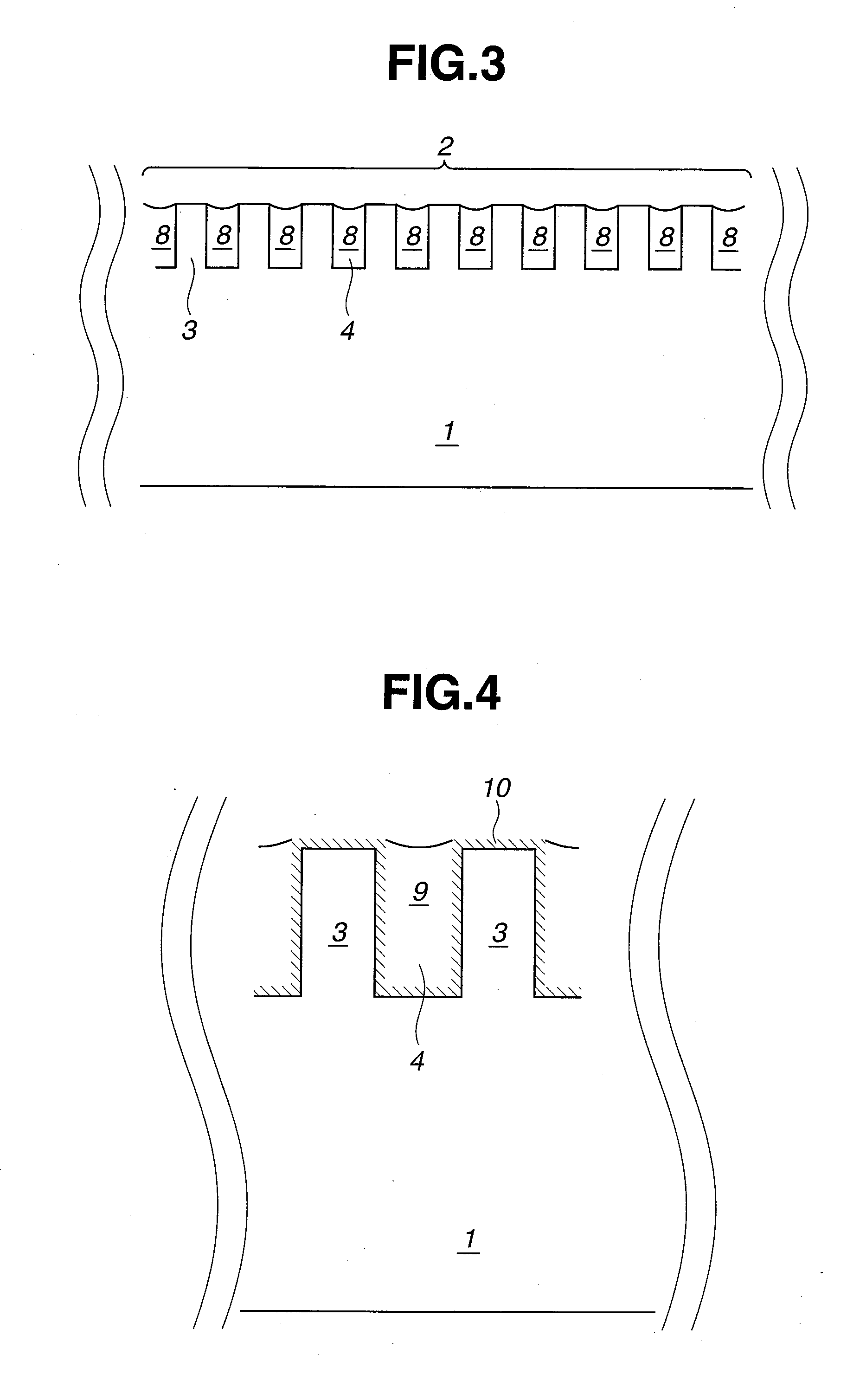

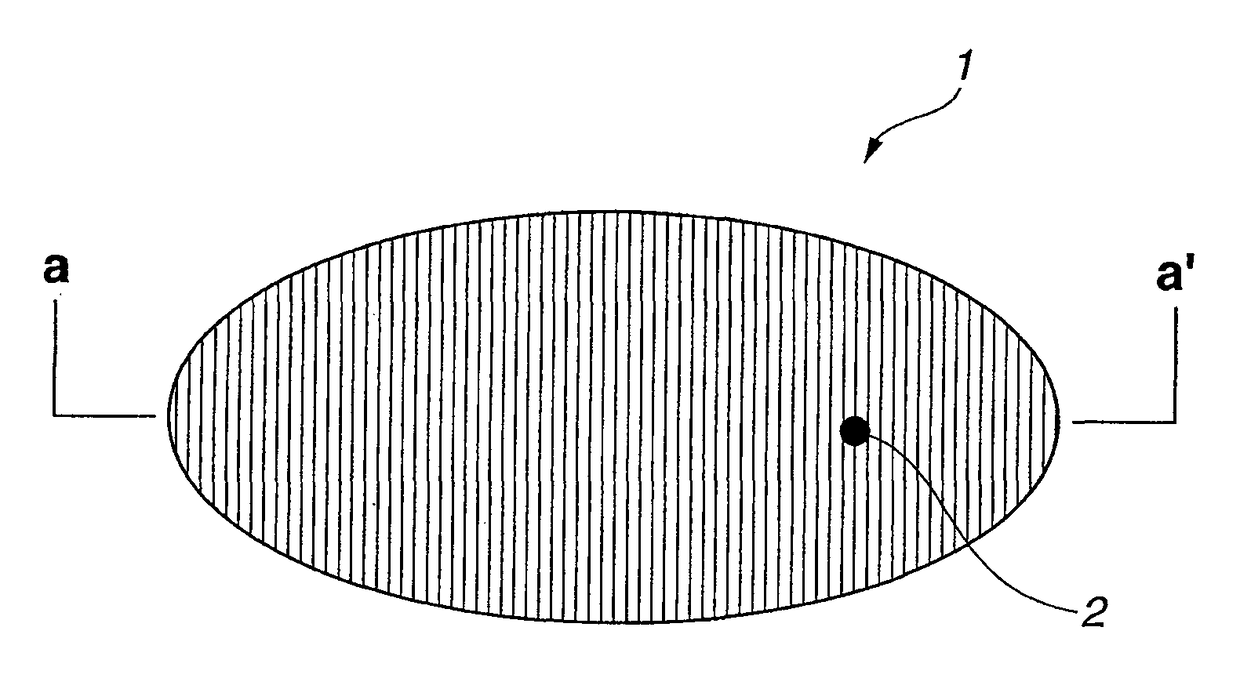

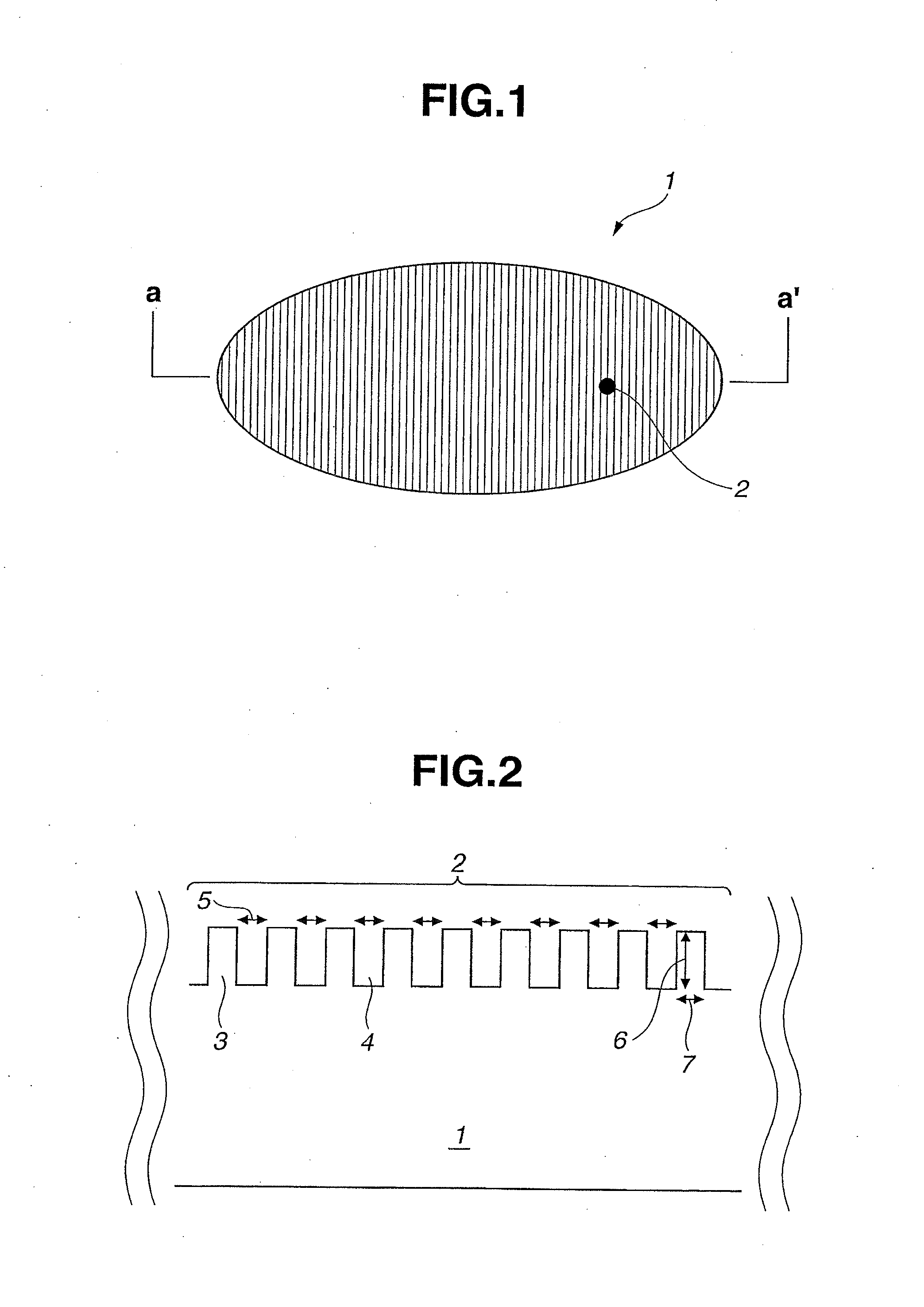

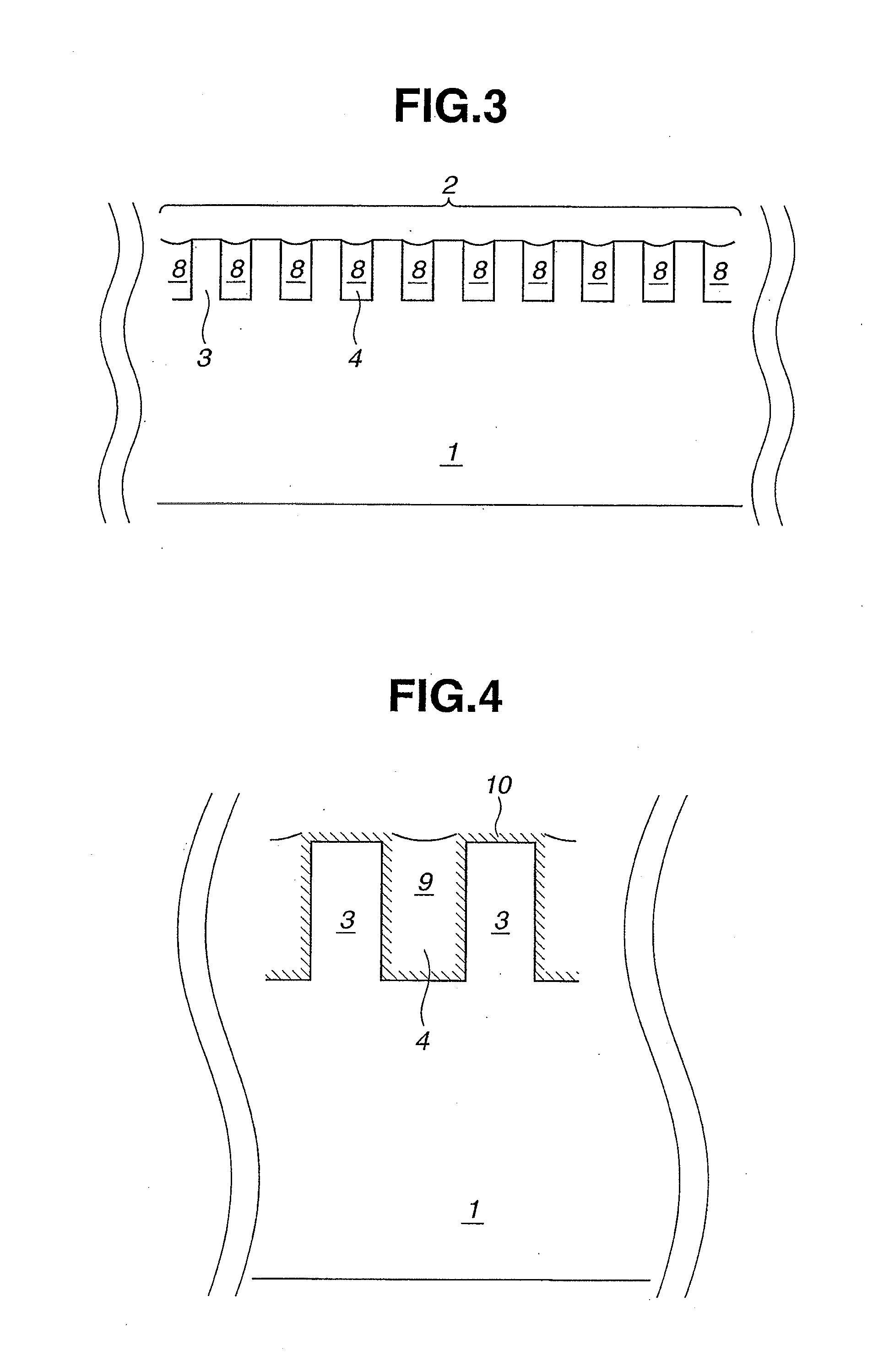

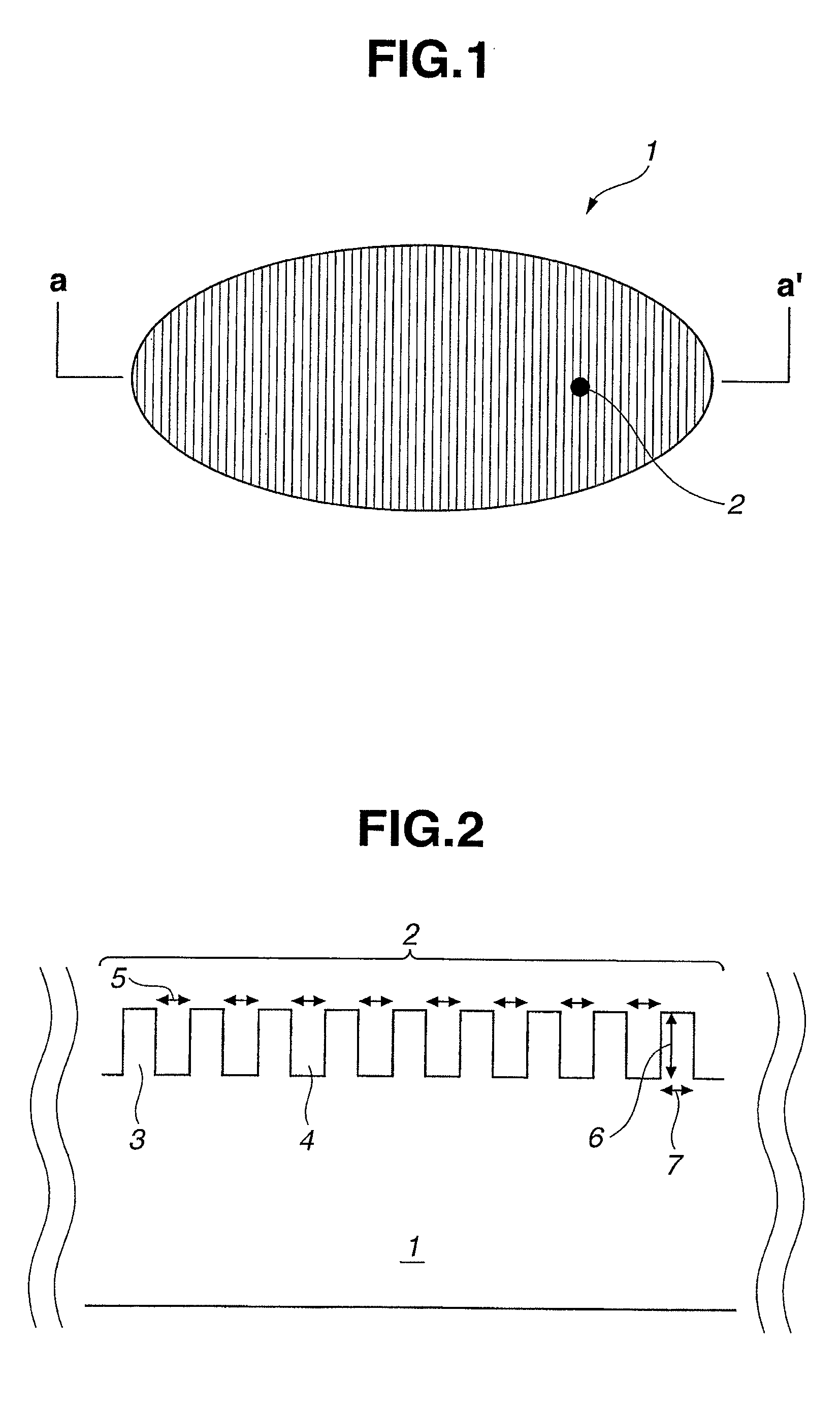

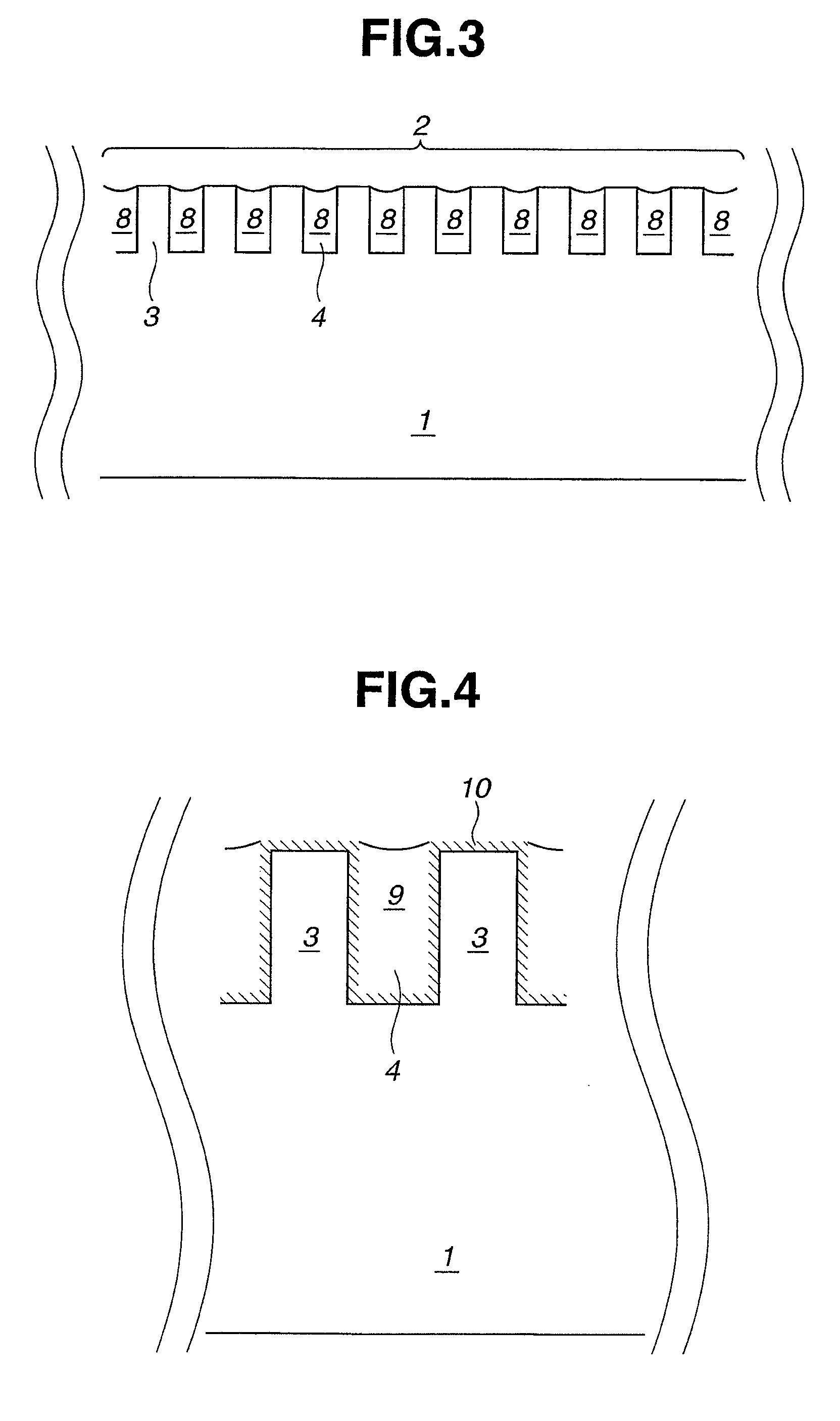

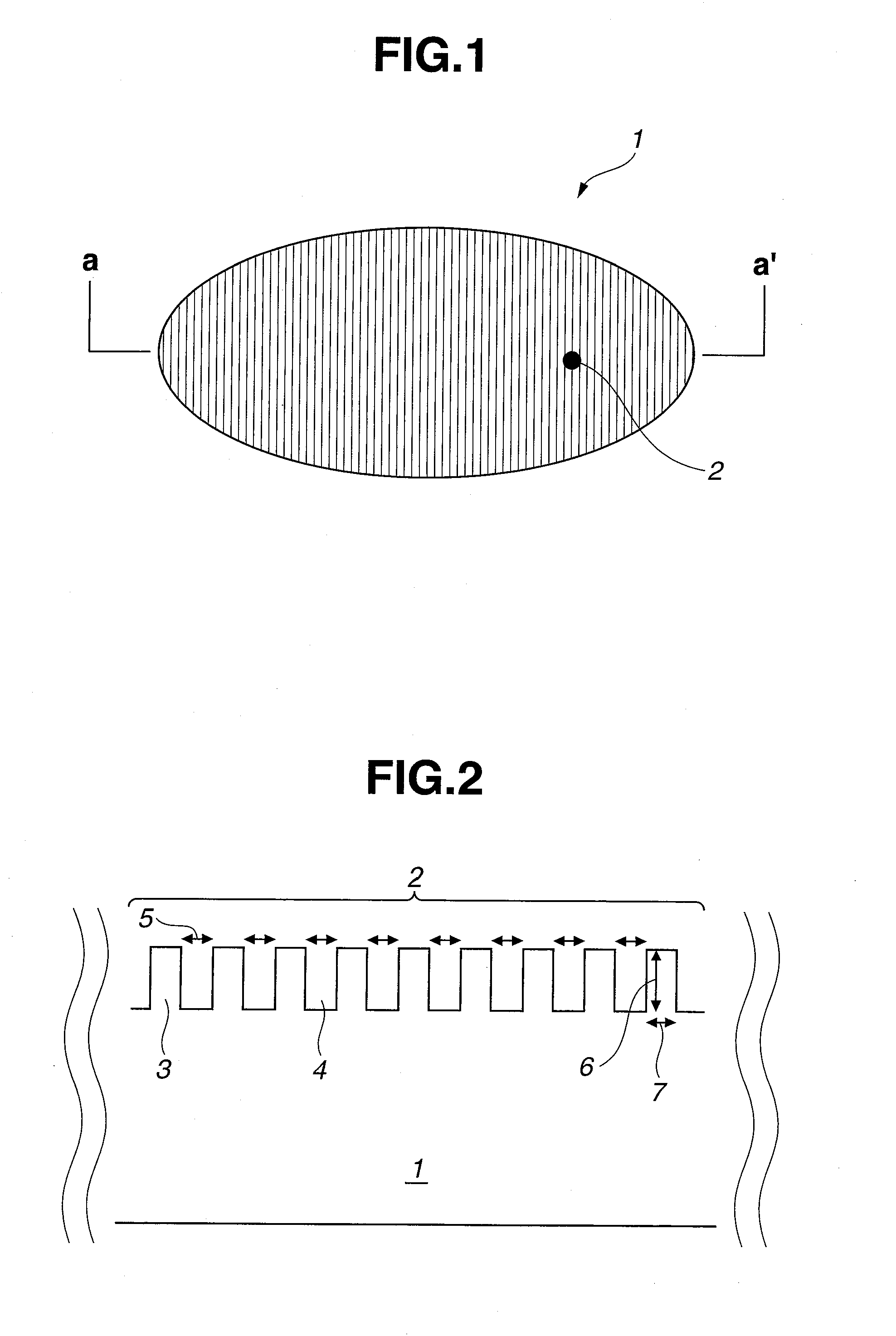

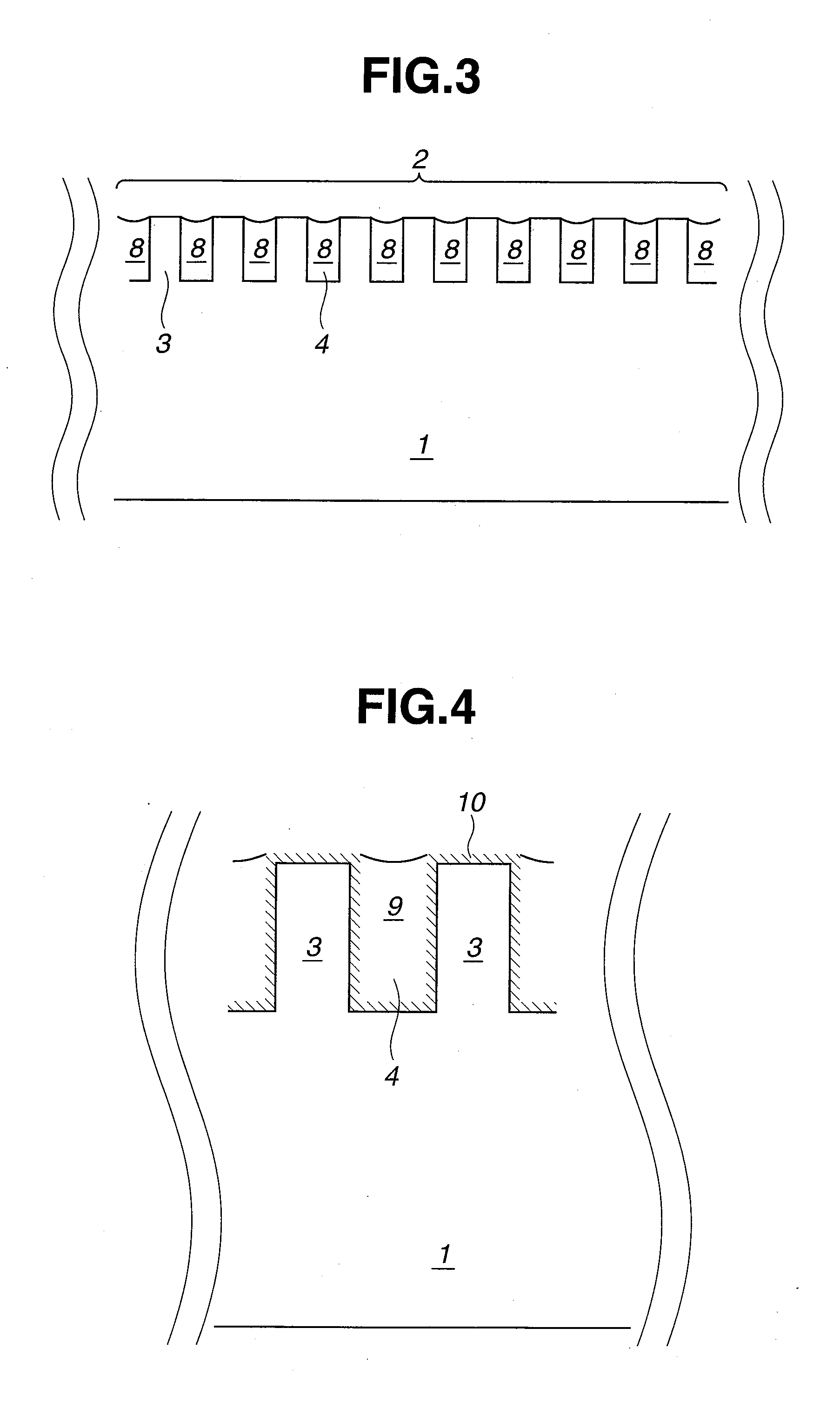

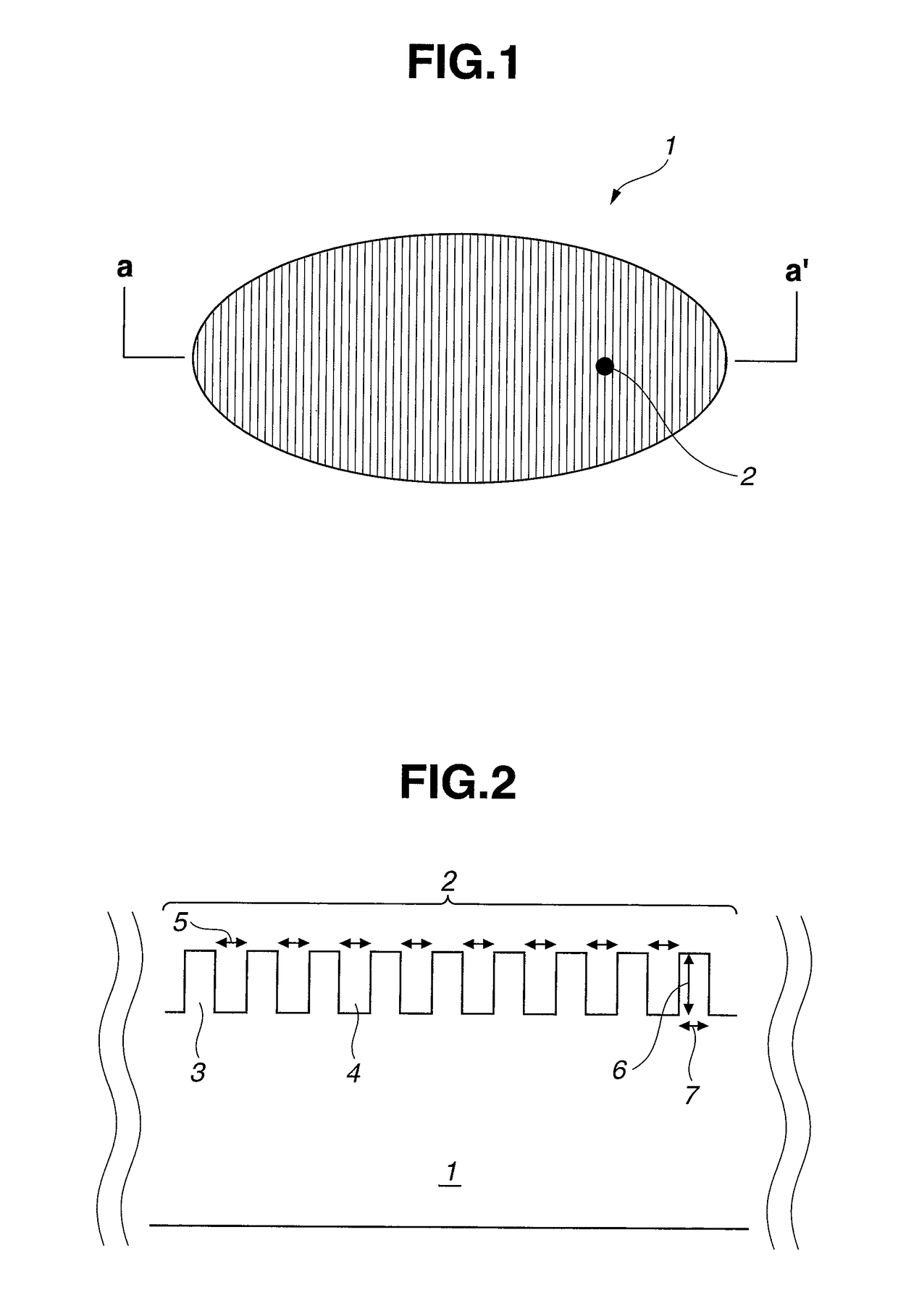

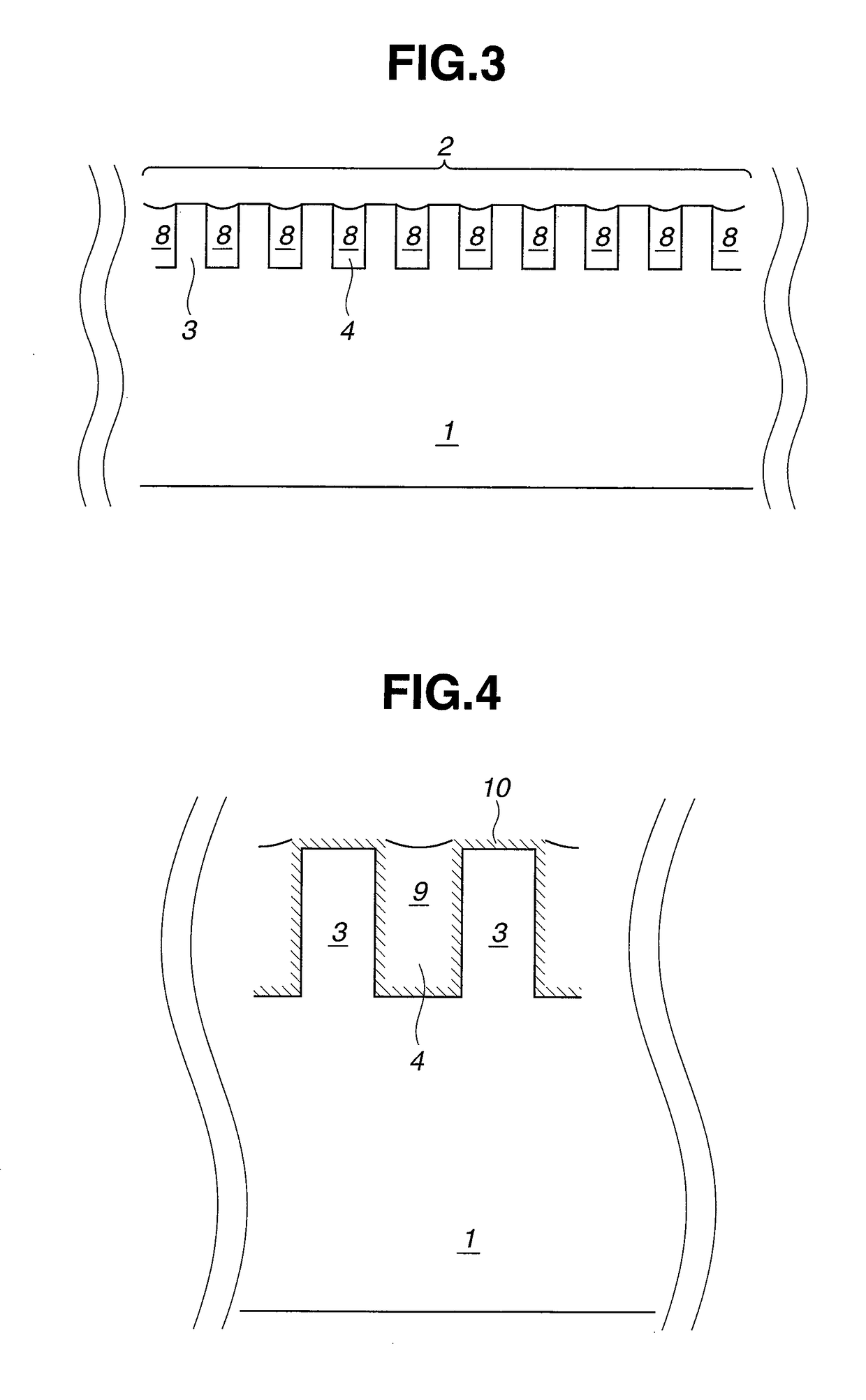

Electrostatic chuck and substrate fixing method using the same

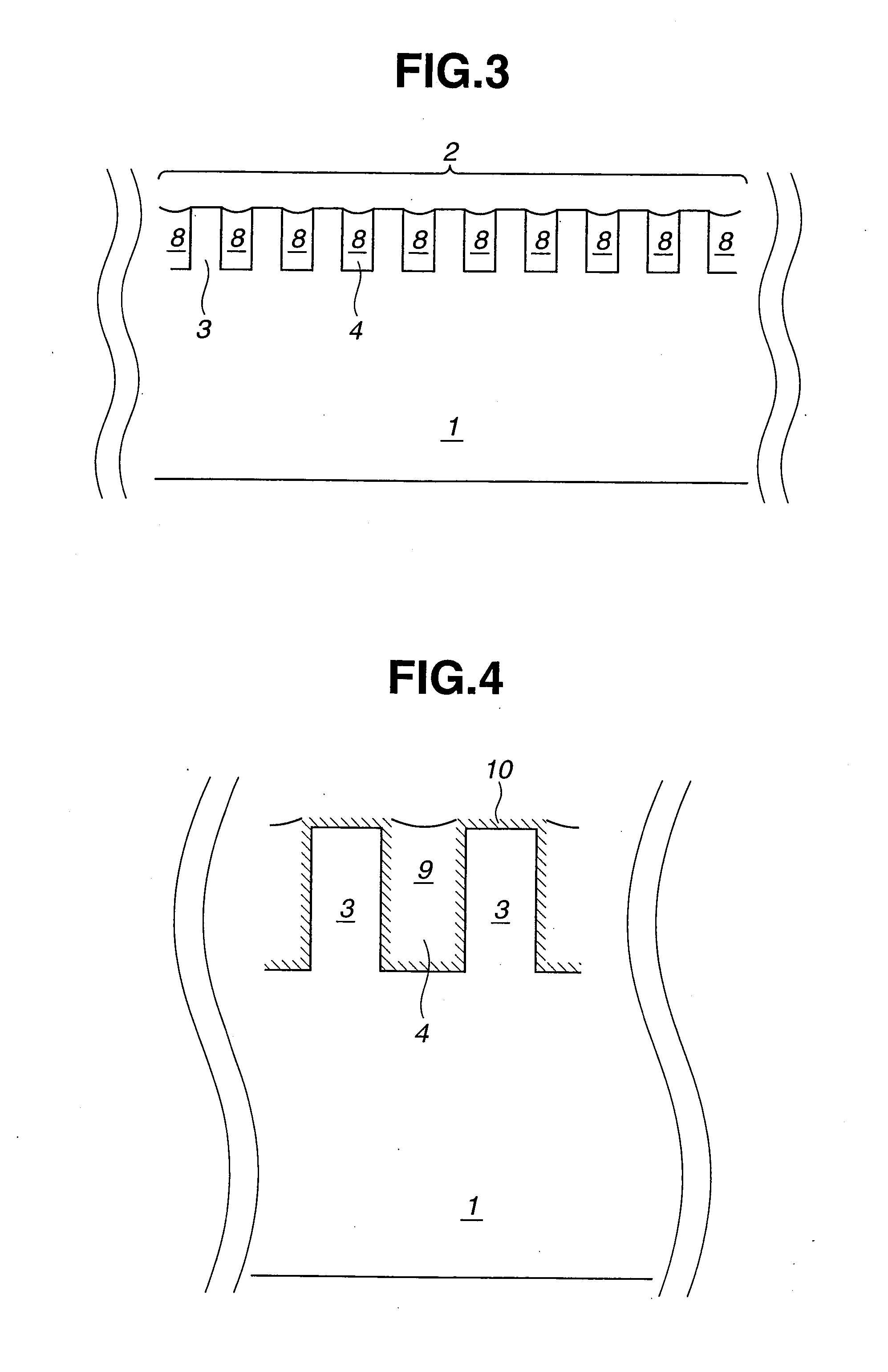

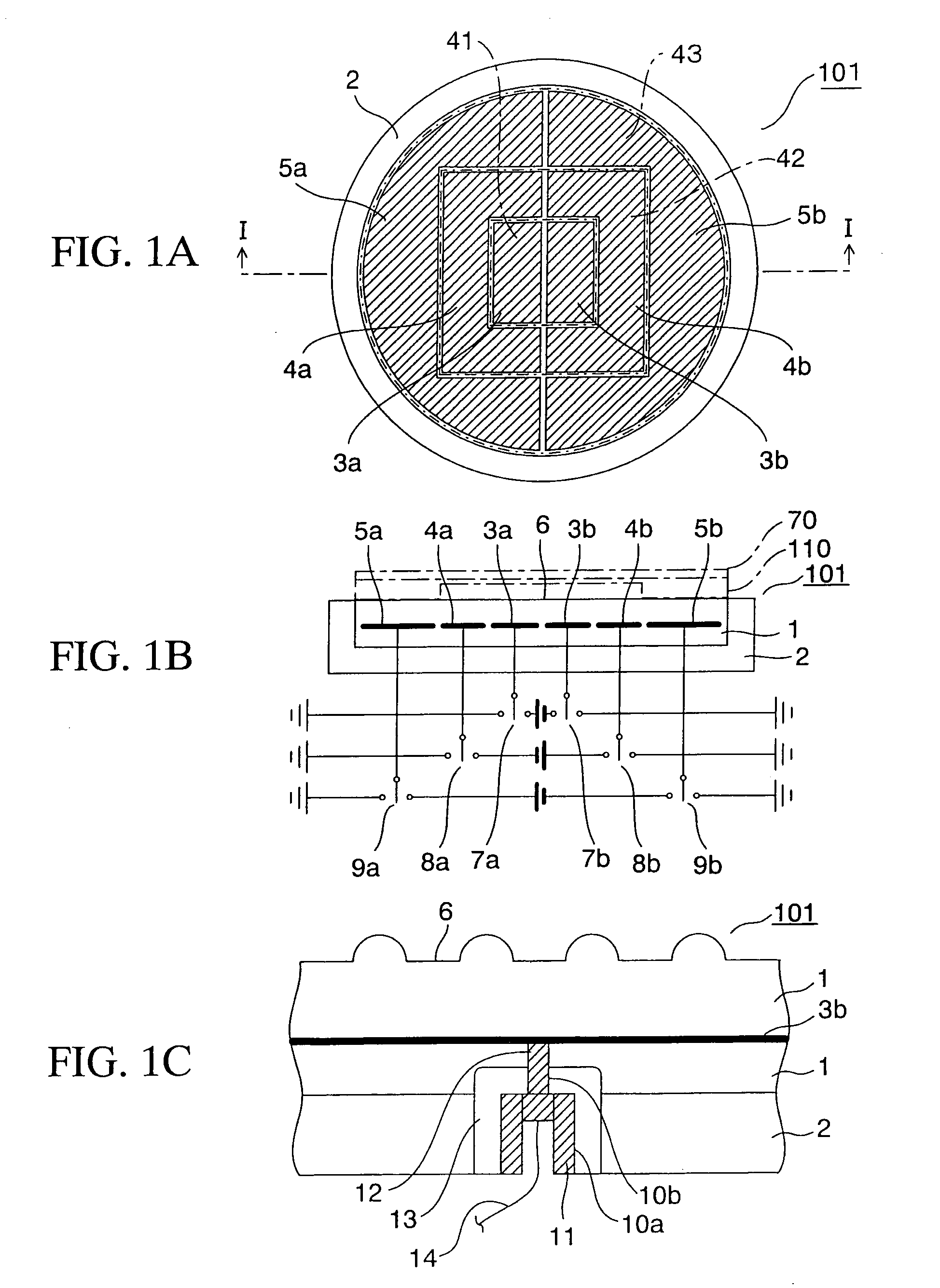

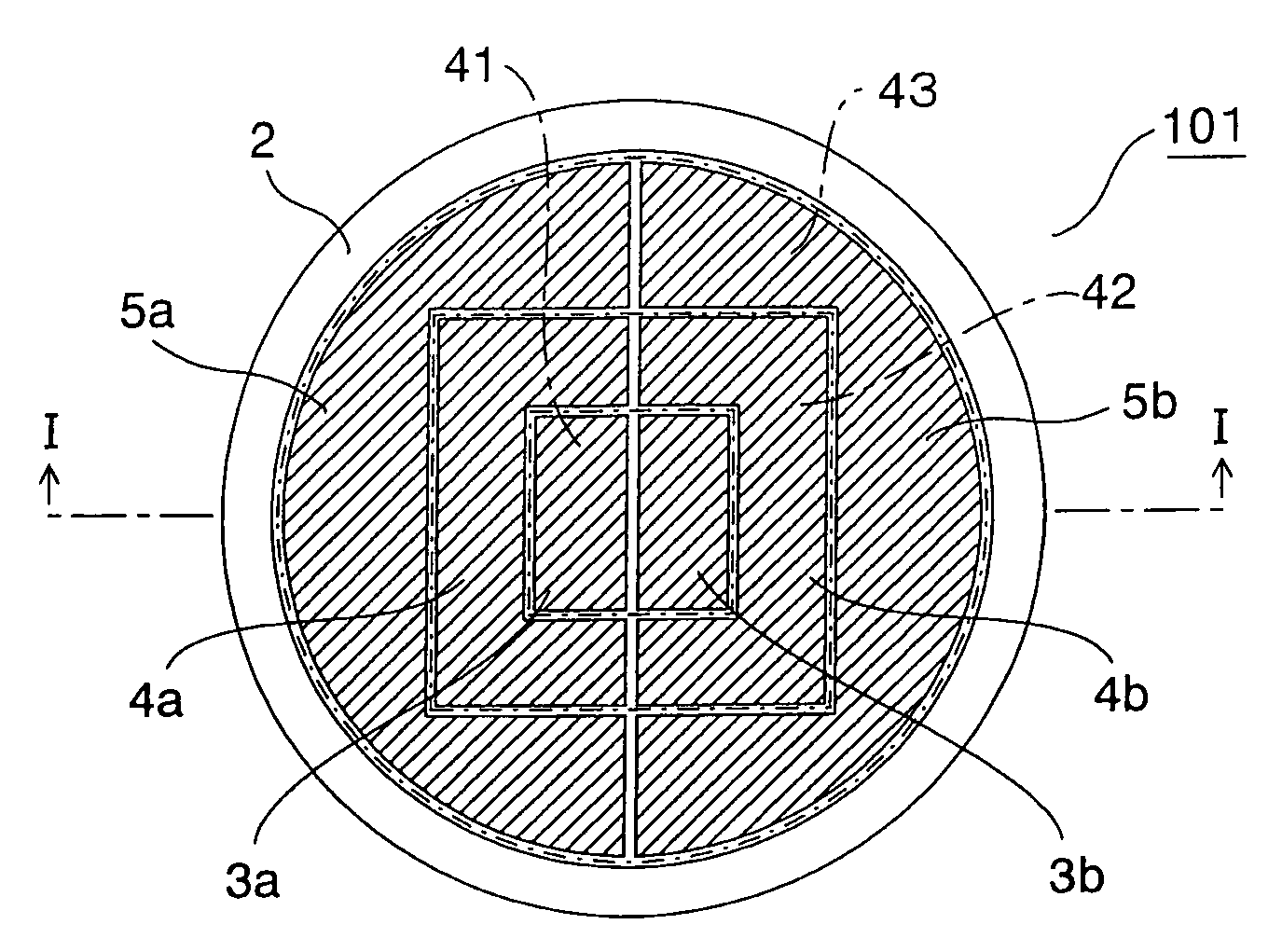

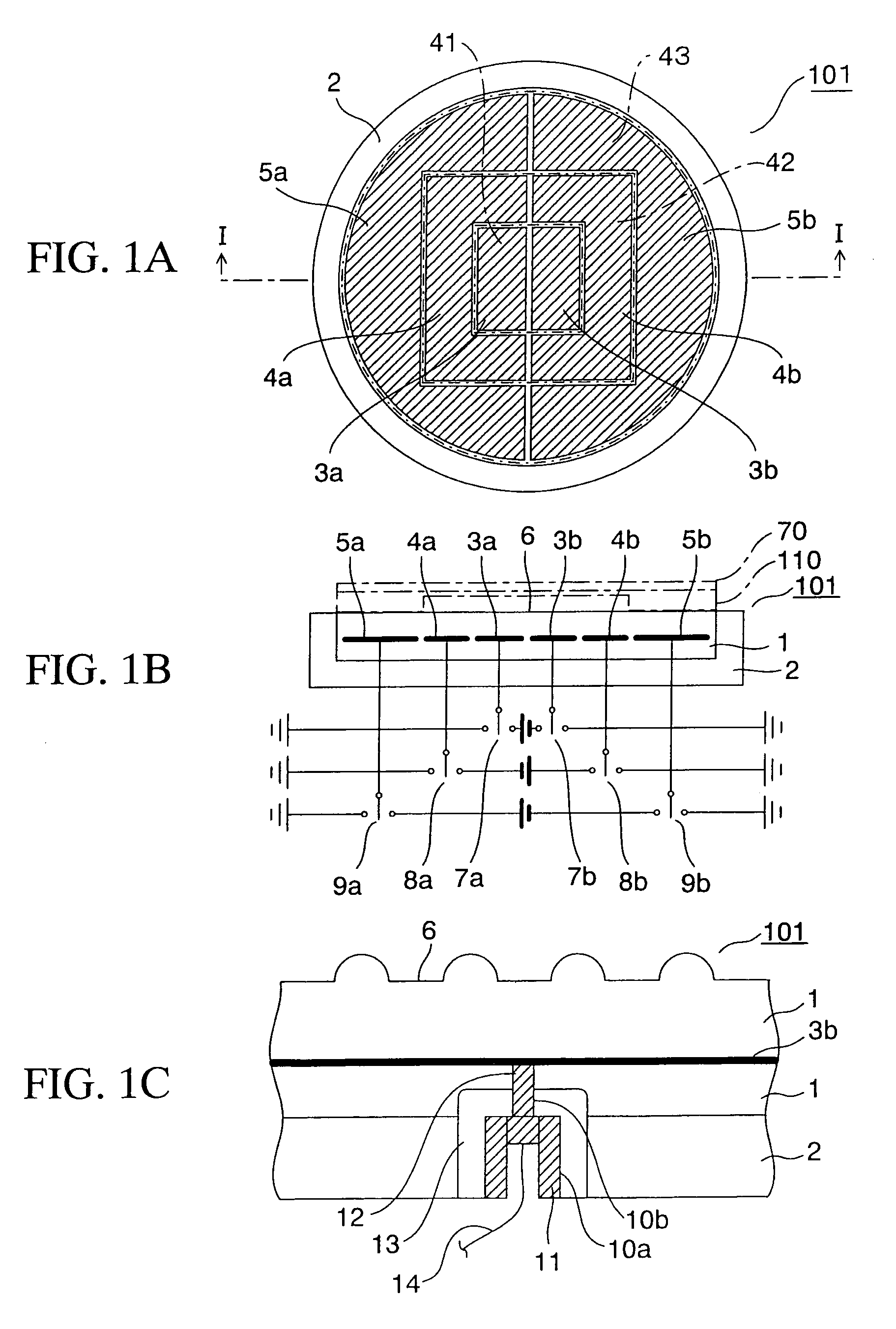

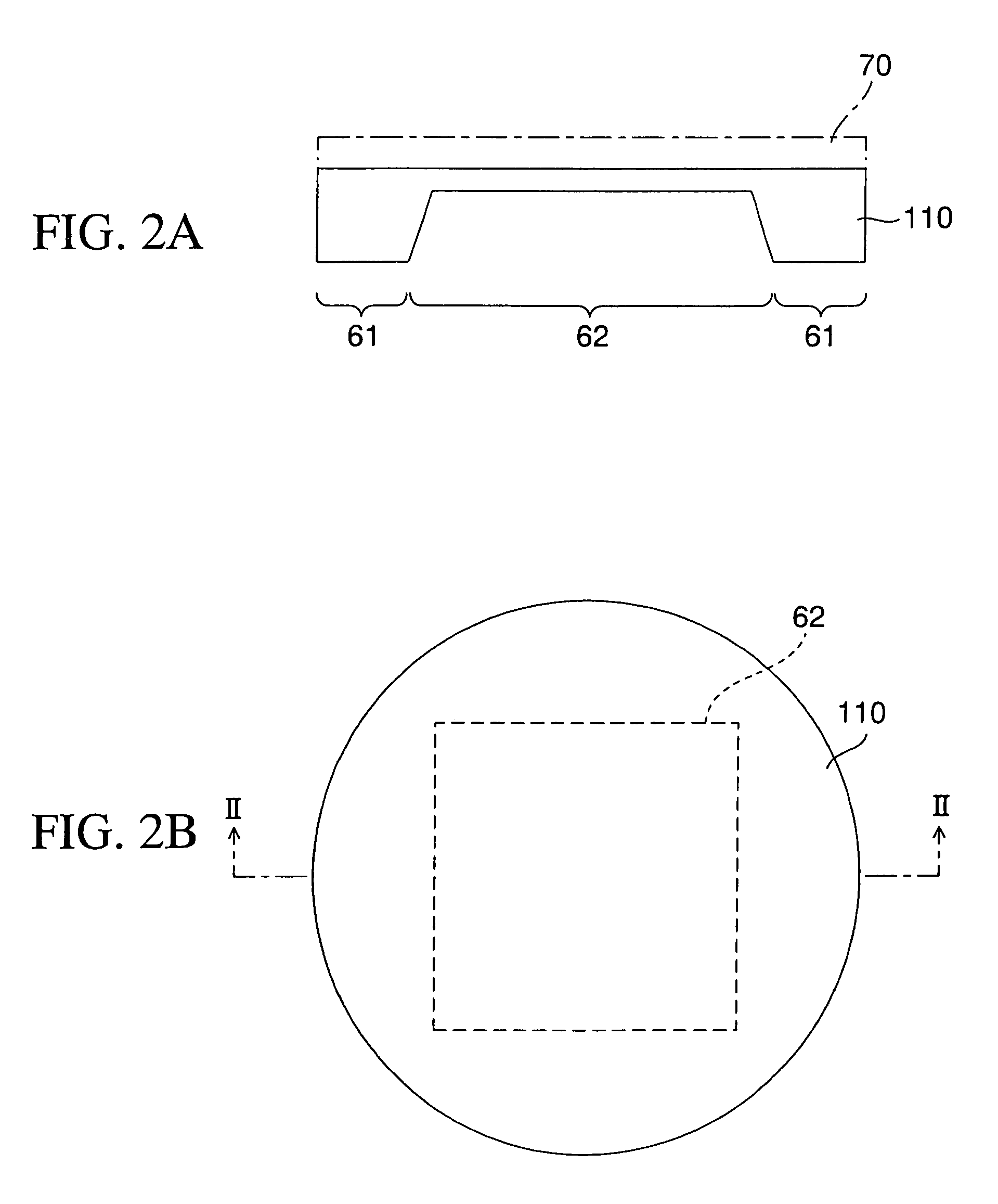

ActiveUS20050213279A1Accurate exposureGuaranteed flatnessSleeve/socket jointsElectric discharge tubesBiomedical engineeringVoltage

The electrostatic chuck 101 of the present invention, where pairs of electrodes 3a / 3b, 4a / 4b and 5a / 5b to which voltages are applied are embedded in the main body 1, and where a substrate 110 is placed and held on the surface of the main body 1, includes a first electrode group constituted of one pair or more of electrodes 3a / 3b arranged in a center region 41 inside the main body 1, and a second electrode group constituted of one pair or more of electrodes 4a / 4b and 5a / 5b arranged in outer peripheral portions 42 and 43 surrounding the center region 41.

Owner:ADVANTEST CORP

Chemical for Forming Protective Film

ActiveUS20130056023A1Excellent water-repellencyReduce wettabilityOther chemical processesSemiconductor/solid-state device manufacturingChemistryCompound (substance)

Disclosed is a liquid chemical for forming a water repellent protective film on a wafer that has at its surface a finely uneven pattern and contains silicon element at least at a part of the uneven pattern, the water repellent protective film being formed at least on surfaces of recessed portions of the uneven pattern at the time of cleaning the wafer. The liquid chemical contains: a silicon compound (A) represented by the general formula R1aSi(H)b(X)4−a−b and an acid; or a silicon compound (C) represented by the general formula R7gSi(H)h(CH3)w(Z)4−g−h−w and a base that contains no more than 35 mass % of water. The total amount of water in the liquid chemical is no greater than 1000 mass ppm relative to the total amount of the liquid chemical. The liquid chemical can improve a cleaning step that easily induces pattern collapse.

Owner:CENT GLASS CO LTD

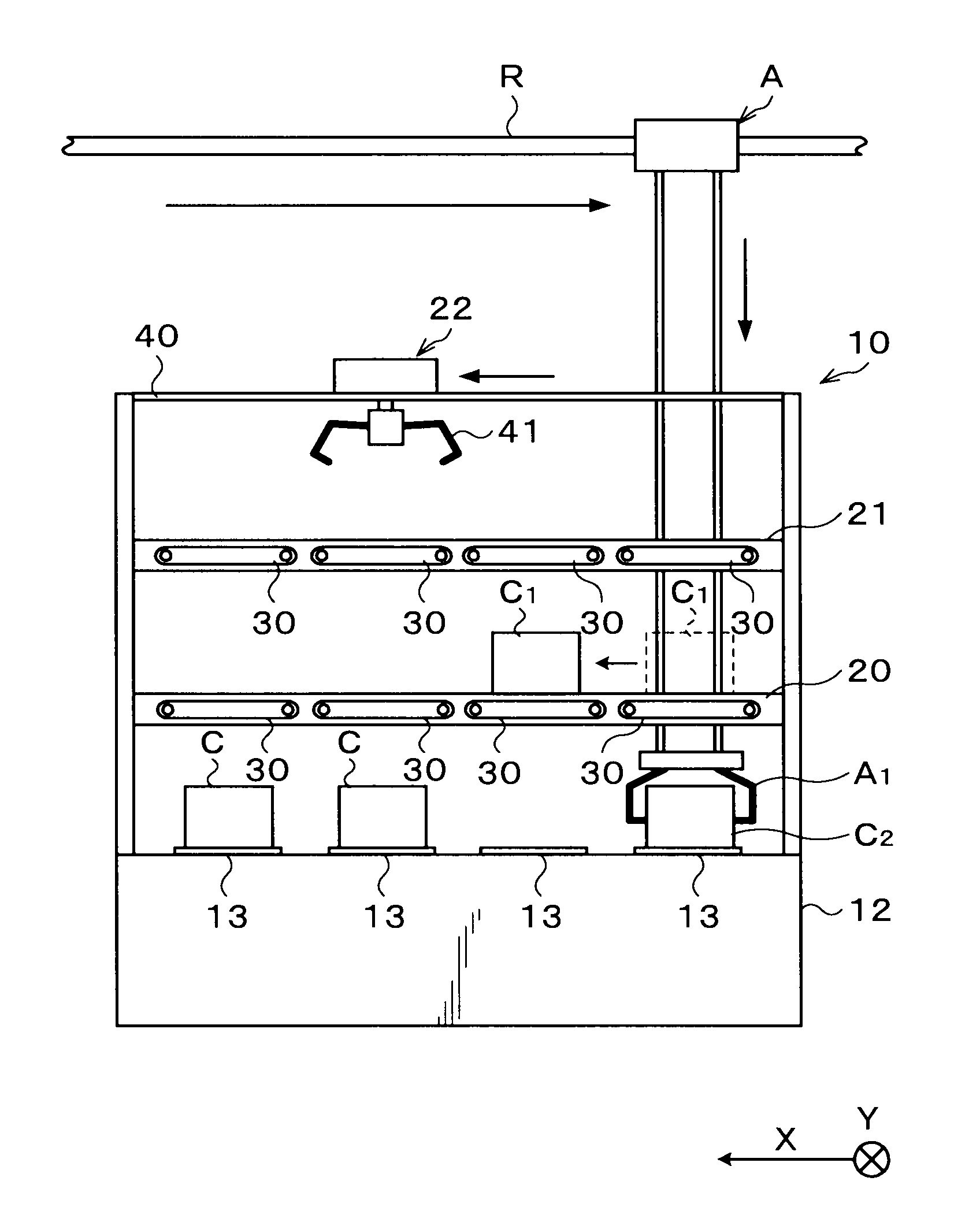

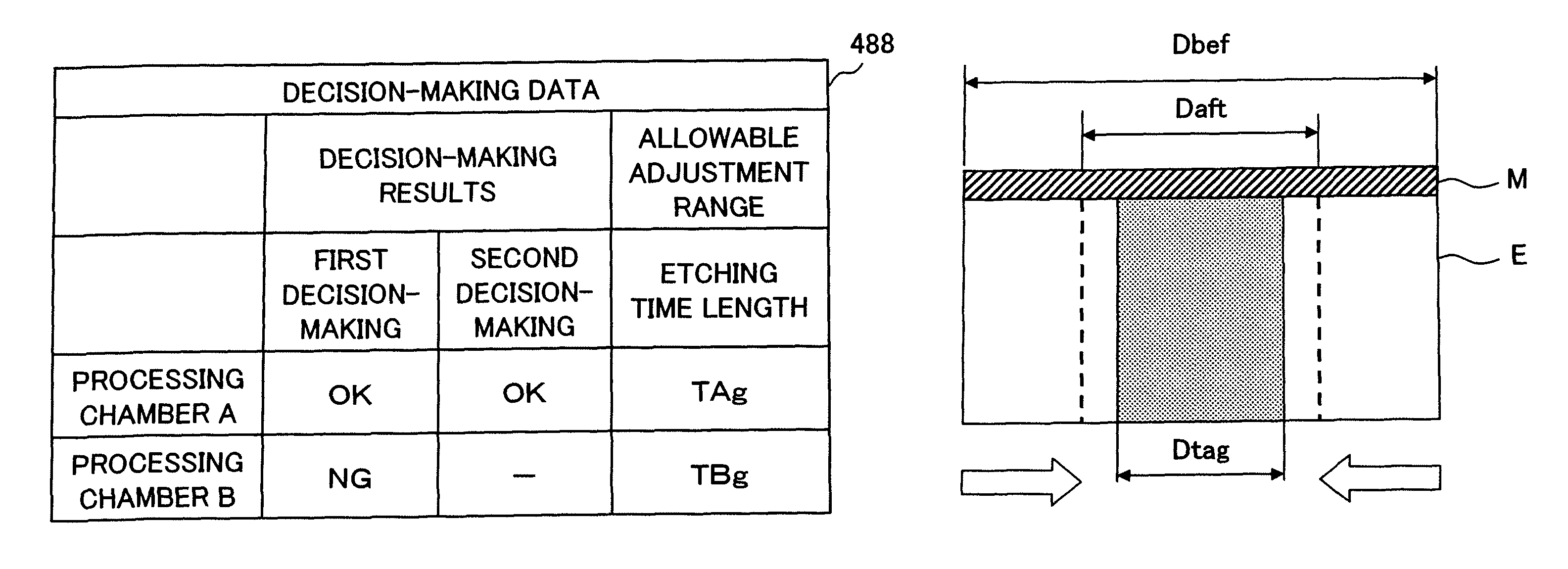

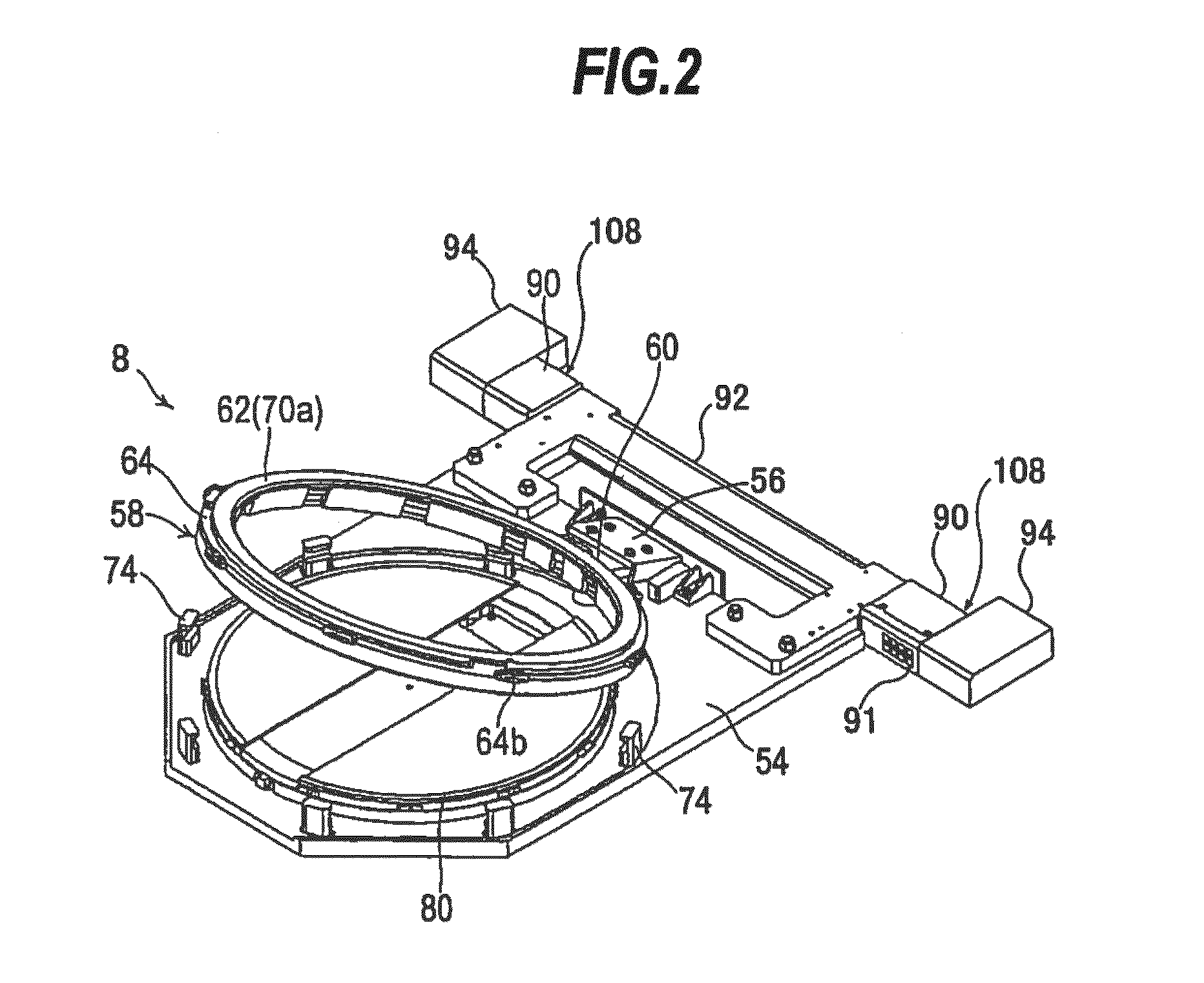

Plating apparatus and plating method

ActiveUS20140295093A1Without lowering throughputCellsLiquid surface applicatorsMechanical engineeringElectroplating

A plating apparatus includes a processing bath configured to store a processing liquid therein, a transporter configured to immerse a substrate holder, holding a substrate, in the processing liquid, raise the substrate holder out of the processing bath, and transport the substrate holder in a horizontal direction, and a gas flow generator configured to generate a clean gas flow forward of the substrate with respect to a direction in which the substrate holder is transported. The transporter moves the gas flow generator together with the substrate holder in the horizontal direction while transporting the substrate holder in the horizontal direction.

Owner:EBARA CORP

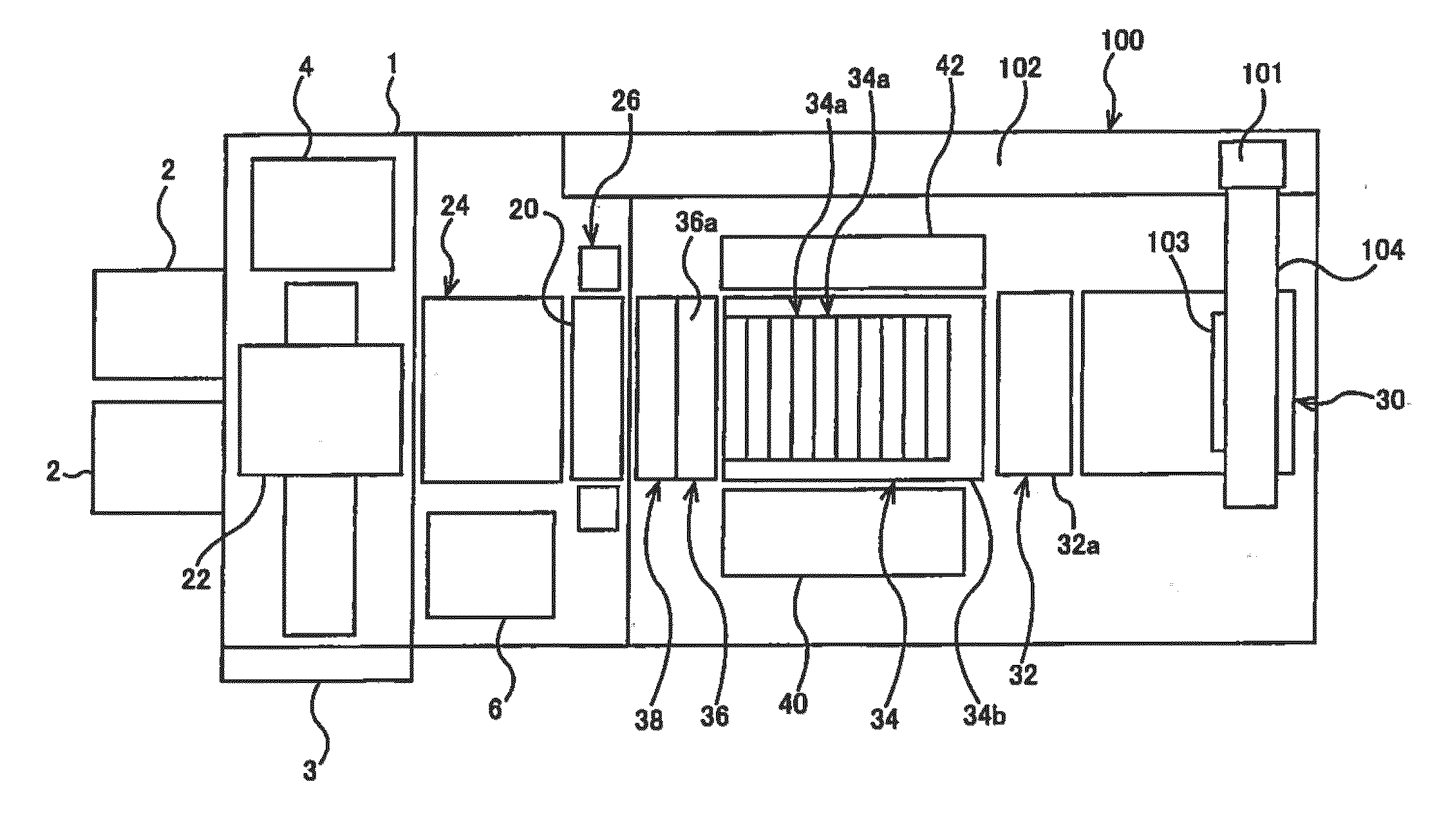

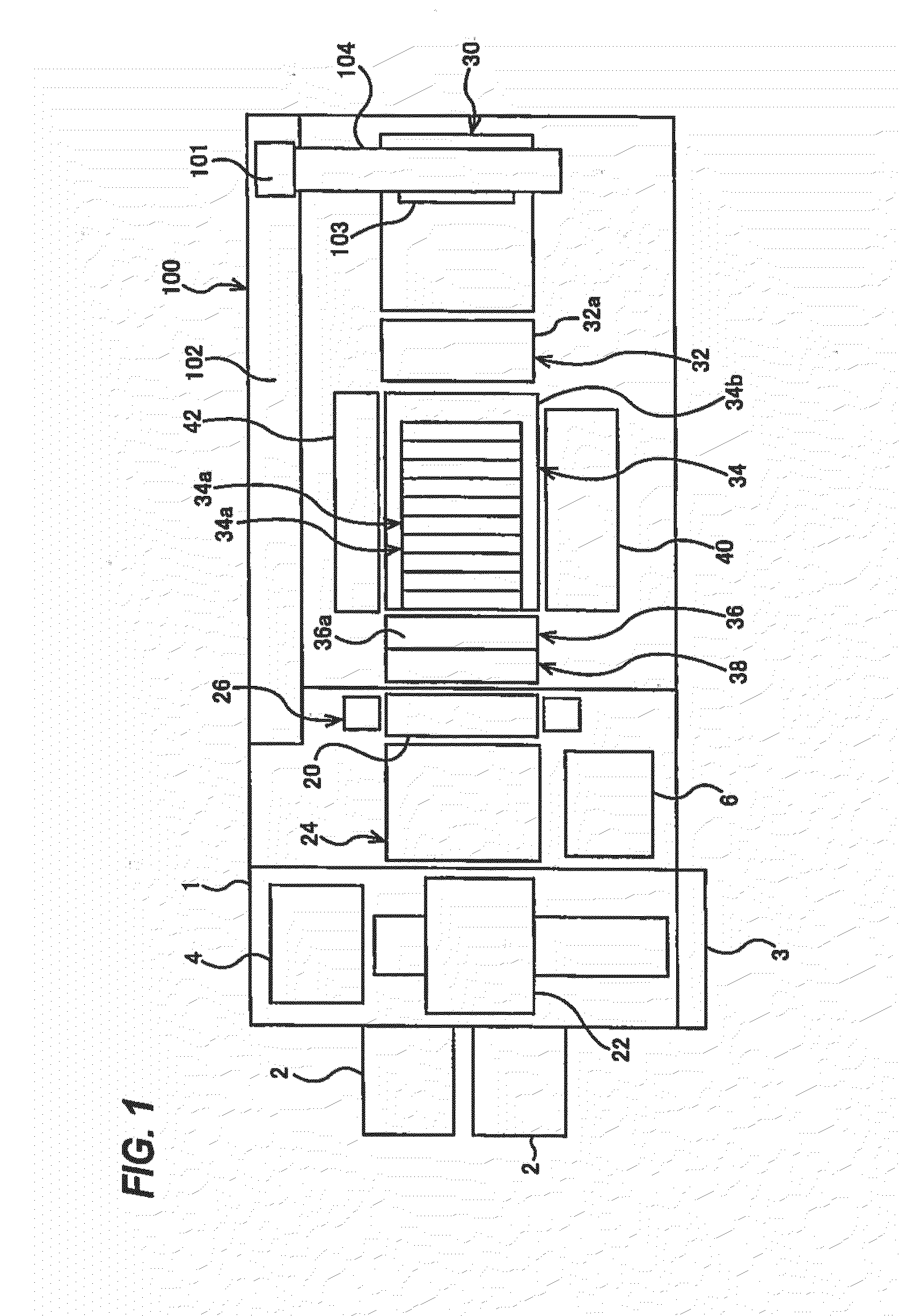

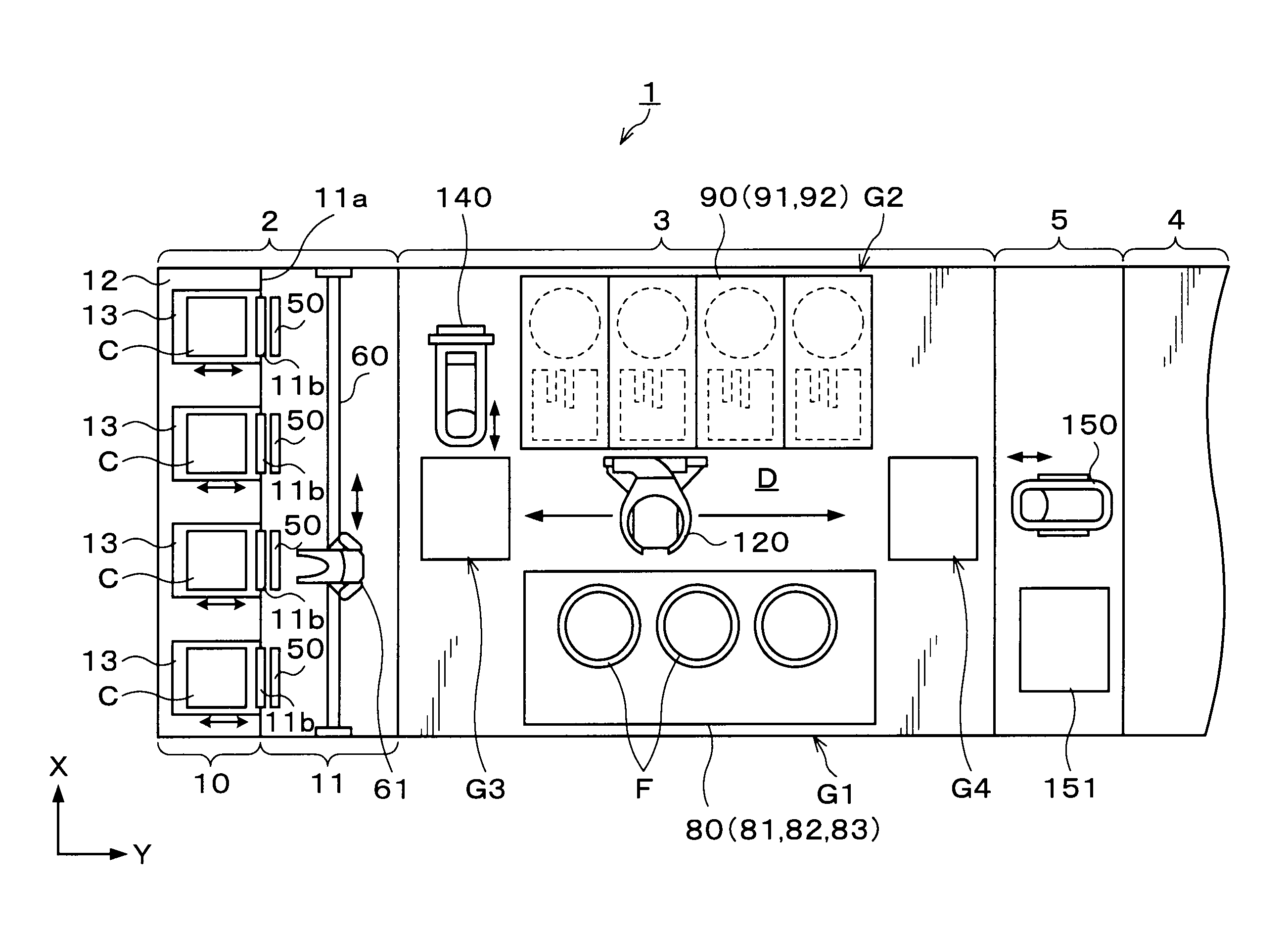

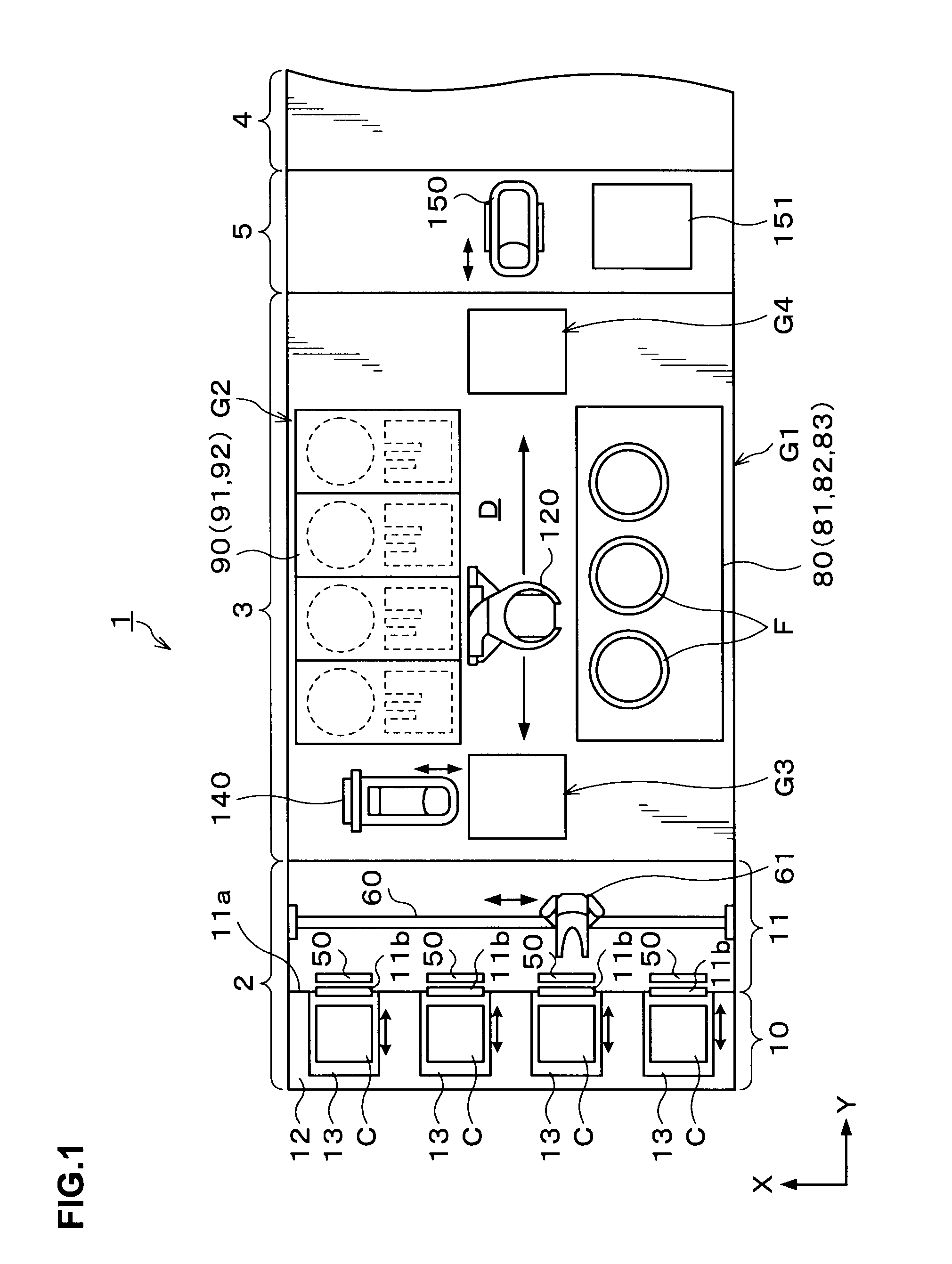

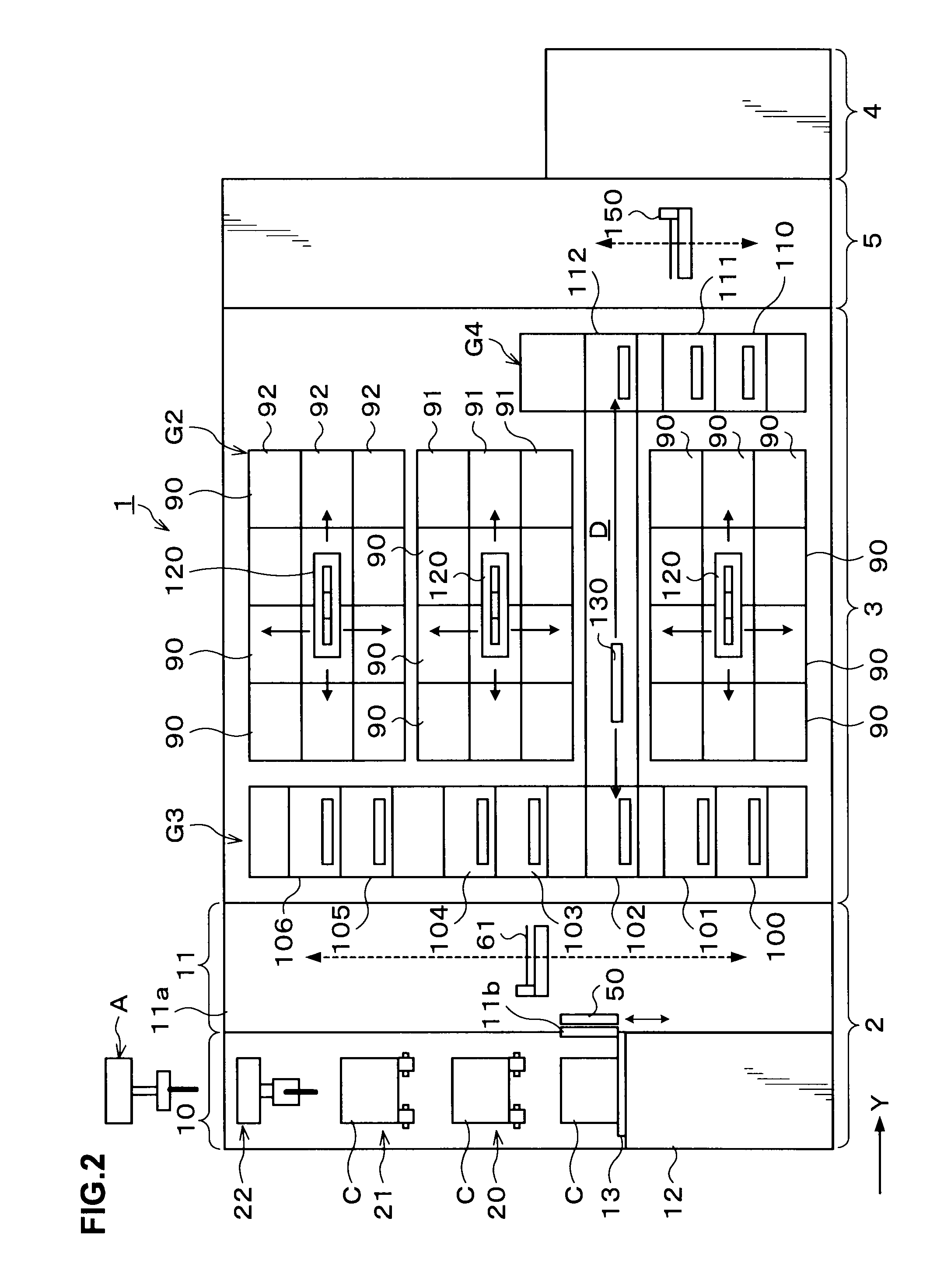

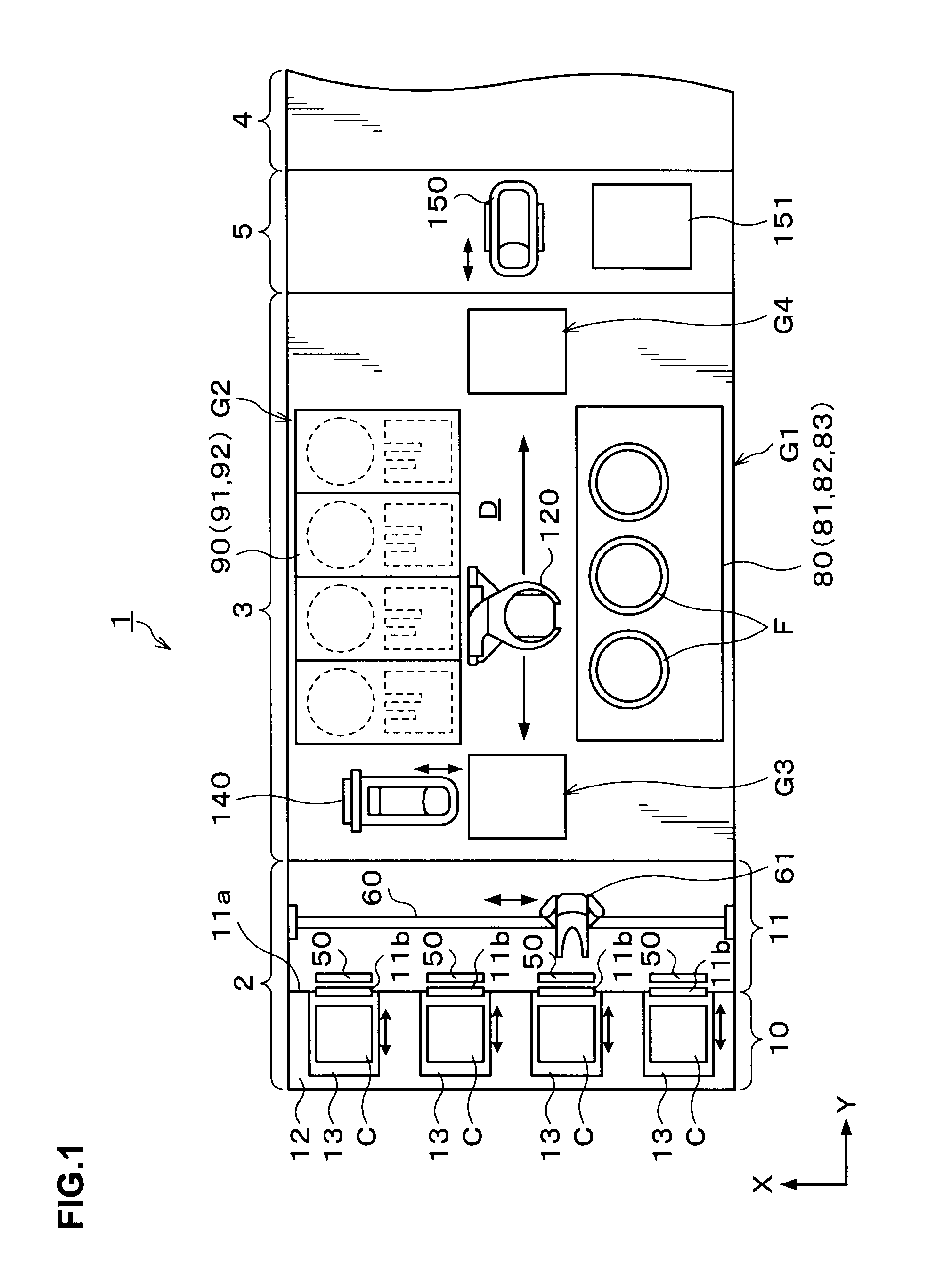

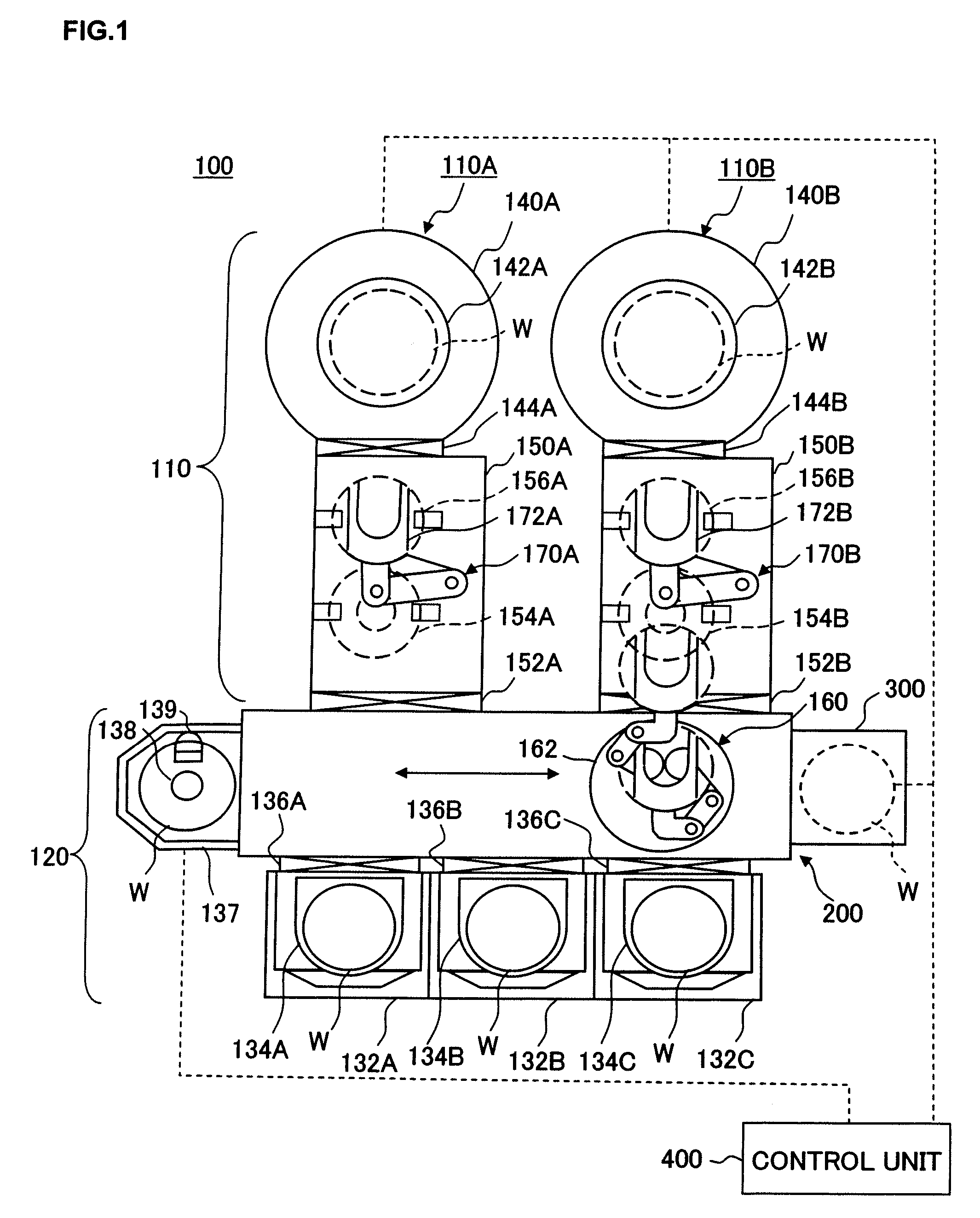

Substrate treatment apparatus

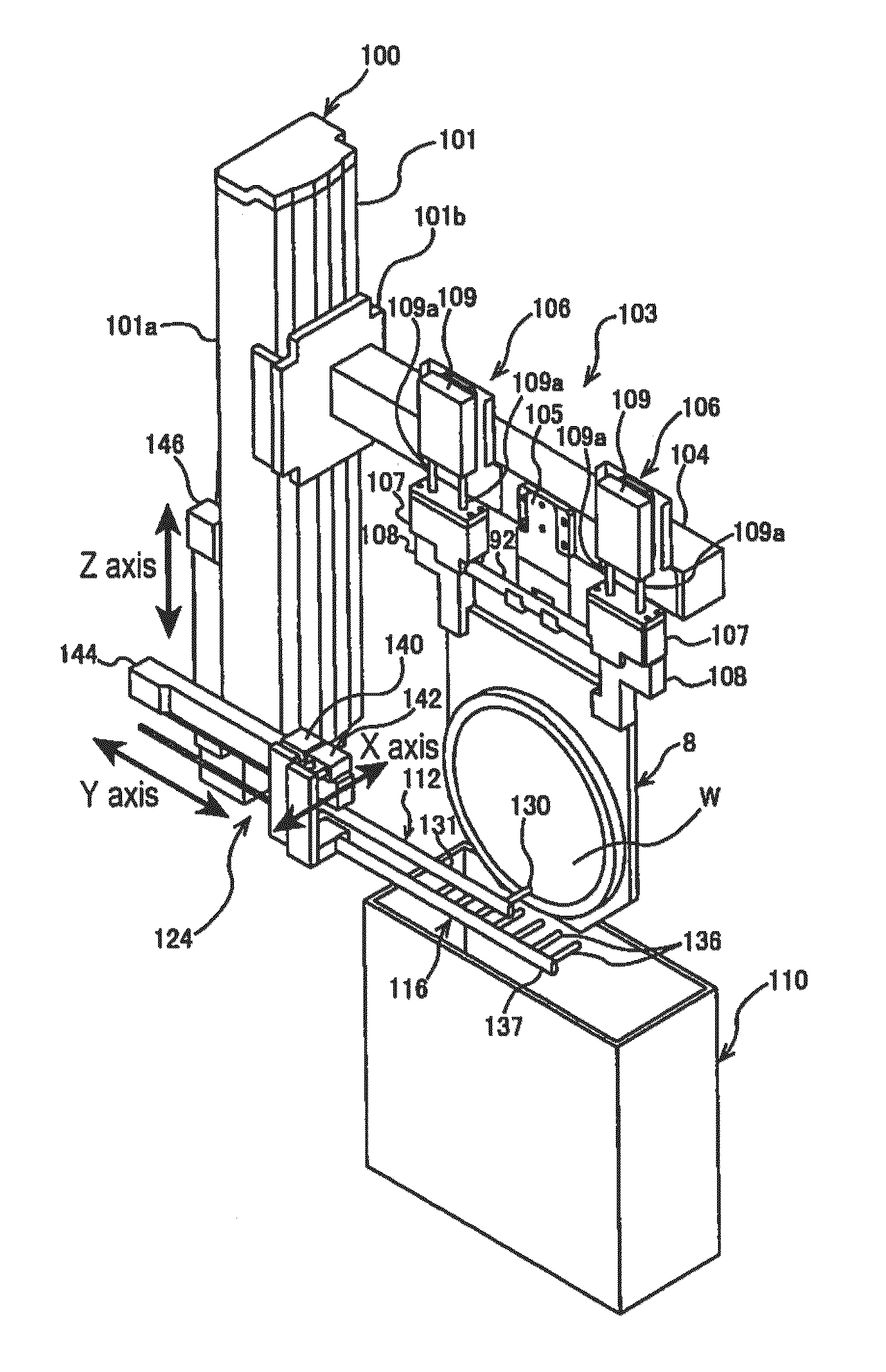

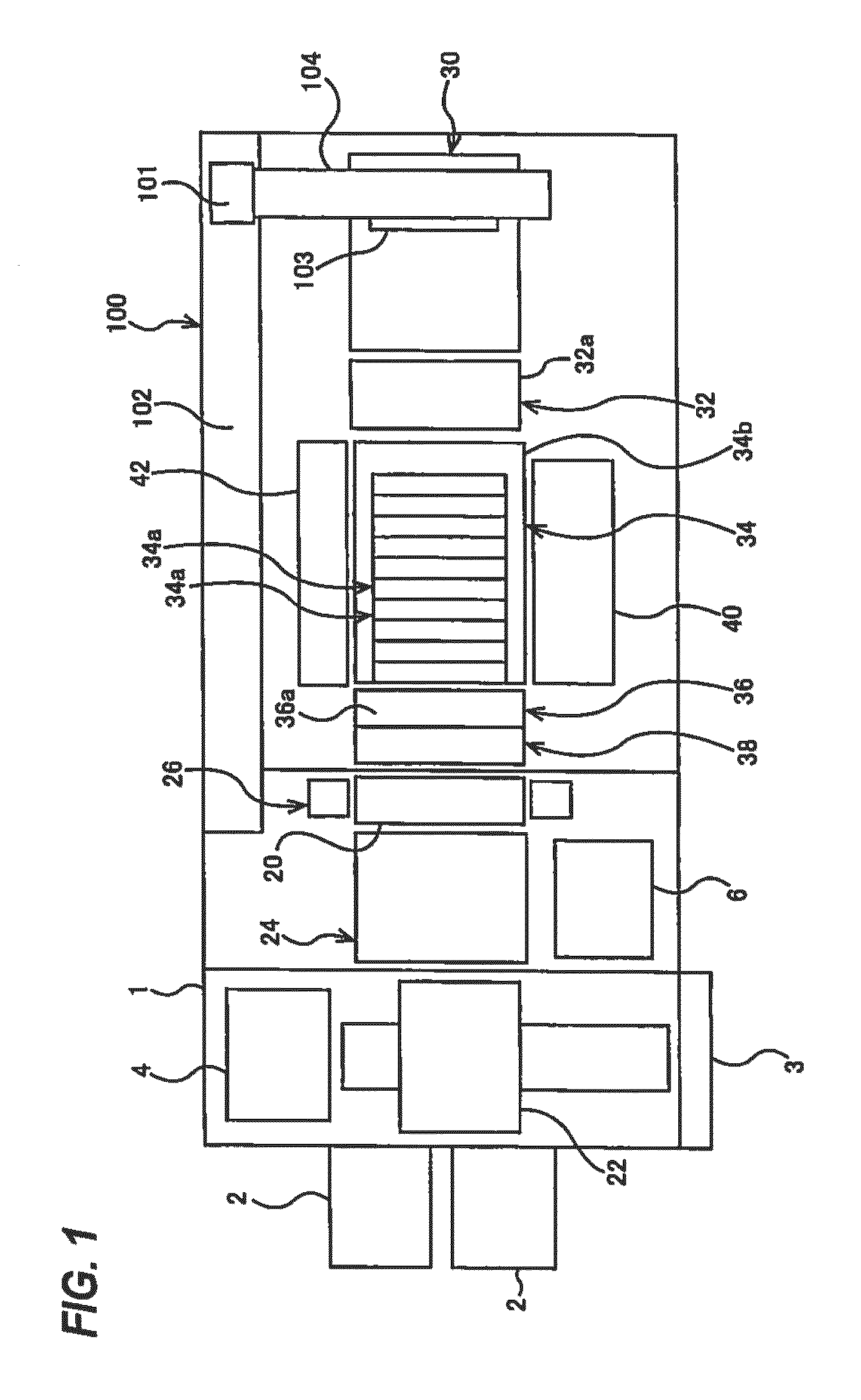

ActiveUS20090081009A1Reduce throughputWithout lowering throughputSemiconductor/solid-state device manufacturingConveyor partsMagnetic tapeEngineering

A substrate treatment apparatus is disclosed. The substrate treatment apparatus includes: a cassette loading portion on which a cassette for containing a substrate is loaded when the cassette is carried to / from outside of the substrate treatment apparatus; a substrate treatment portion for performing a treatment on the substrate; a substrate carrying portion for carrying the substrate in the cassette loaded on the cassette loading portion to the substrate treatment portion, and carrying the substrate that has been subjected to the treatment by the substrate treatment portion to the cassette on the cassette loading portion; a vacant cassette loading portion on which the cassette caused to be vacant by carrying the substrate to the substrate treatment portion is temporarily loaded; and a vacant cassette transfer mechanism for transferring the vacant cassette between the vacant cassette loading portion and the cassette loading portion.

Owner:TOKYO ELECTRON LTD

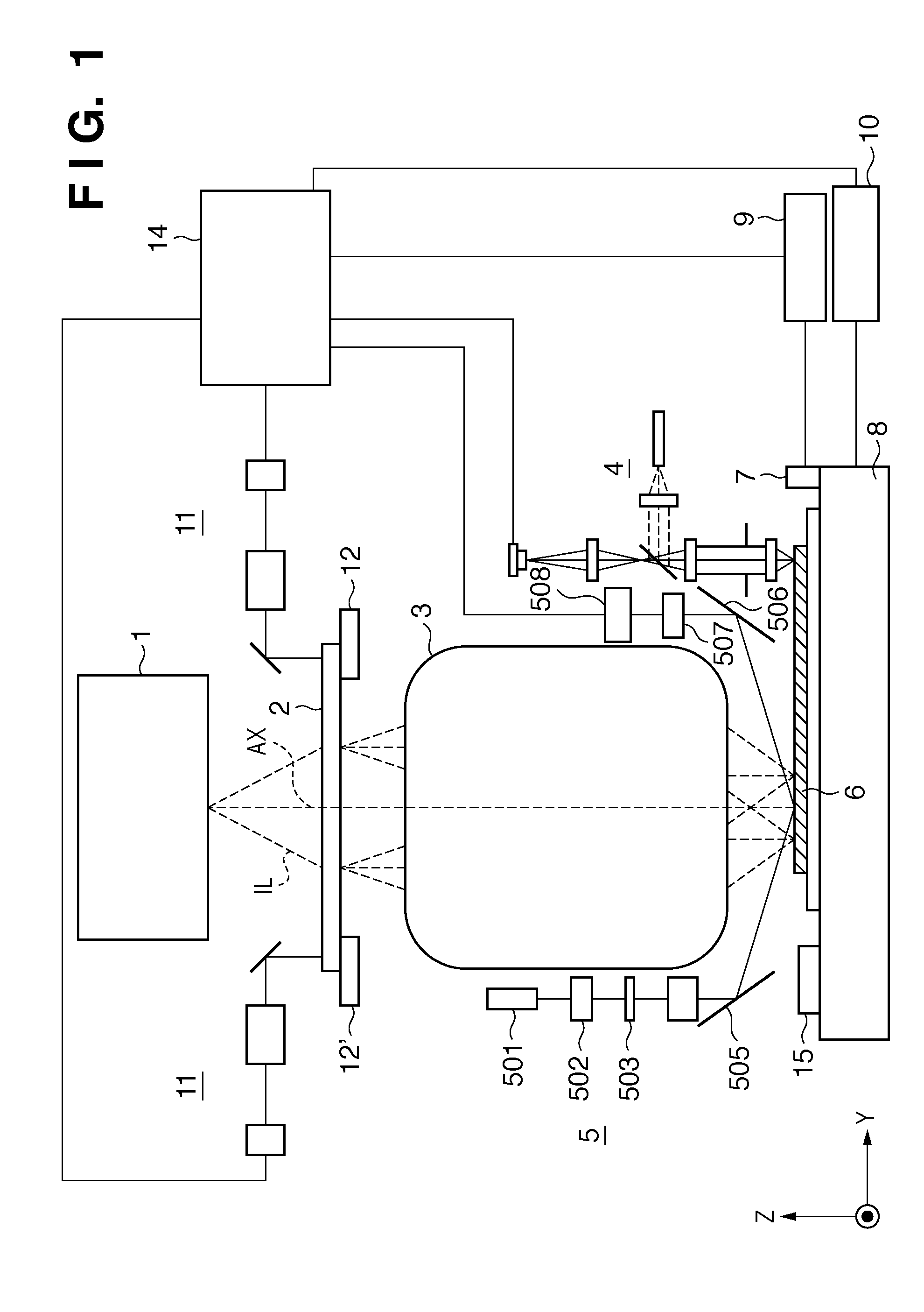

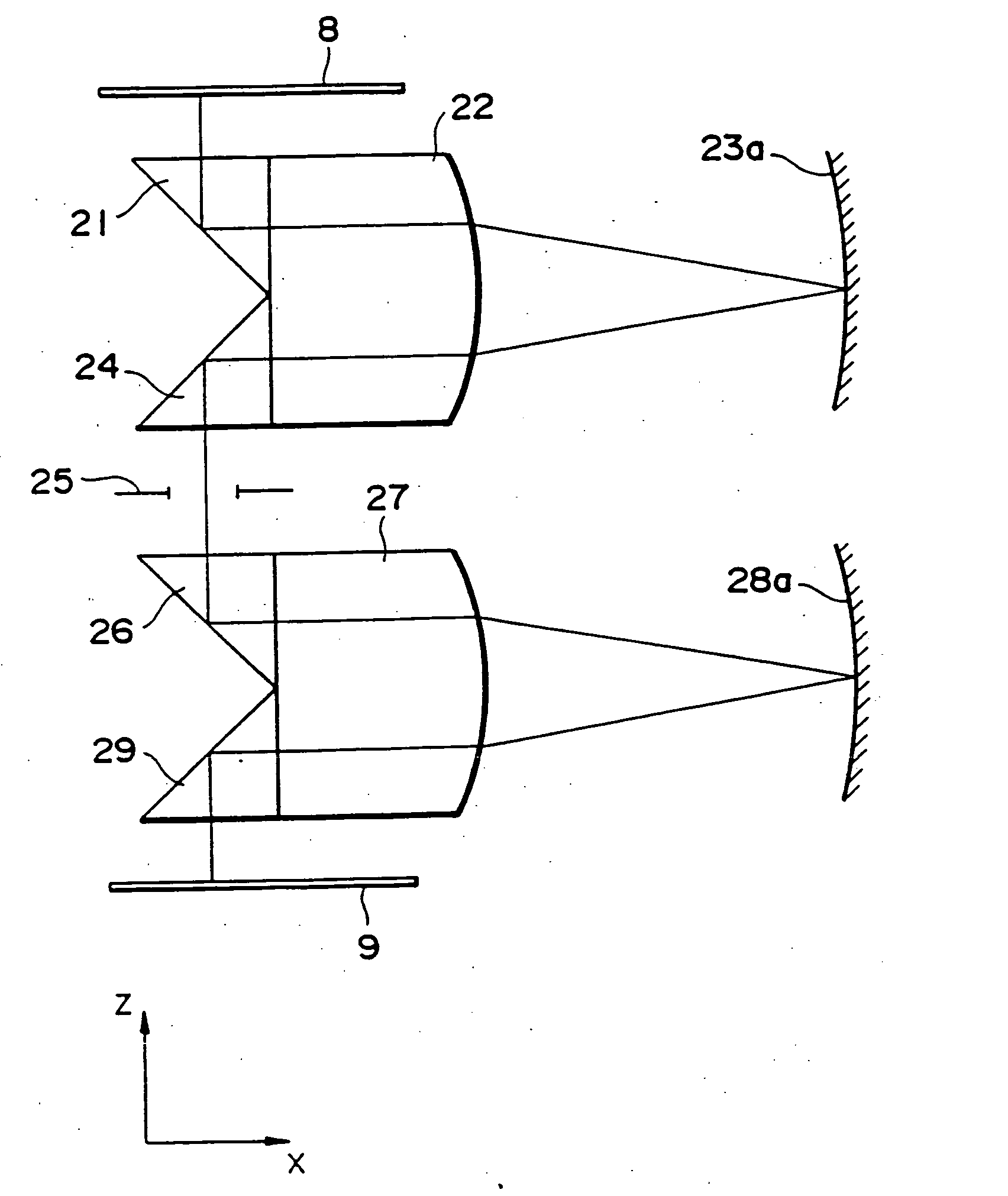

Exposure apparatus and device fabrication method using the same

InactiveUS7274435B2Without lowering throughputIncreases its cover angleNanoinformaticsSemiconductor/solid-state device manufacturingOptical axisX-ray

An exposure apparatus that irradiates excitation laser onto a target, and generates from generated plasma a light source for generating illumination light of an extreme ultraviolet region or an X-ray region includes an illumination optical system that uses the illumination light to illuminate a catoptric reticle that forms a pattern to be transferred, the illumination optical system including a first mirror closest to the light source, an ellipsoidal mirror for condensing the illumination light in front of the first mirror in the illumination optical system, and a projection optical system that reduces and projects the pattern reflected on the reticle onto an object to be exposed, wherein light where an optical-axis direction of the excitation laser proceeds beyond a position that generates the plasma by the excitation laser does not interfere with components in the exposure apparatus including the illumination and projection optical systems, and the ellipsoidal mirror.

Owner:CANON KK

Liquid Chemical for Forming Protecting Film

ActiveUS20120174945A1Improve waterproof performancePreventing pattern collapseOther chemical processesDetergent mixture composition preparationTectorial membraneCompound (substance)

Disclosed is a liquid chemical for forming a water-repellent protecting film. The liquid chemical contains an agent for forming a water-repellent protecting film, and a solvent. The agent is for provided to form a water-repellent protecting film on a wafer after a cleaning step for the wafer and before a drying step for the wafer, the wafer having at its surface an uneven pattern and containing at least one kind element of titanium, tungsten, aluminum, copper, tin, tantalum and ruthenium at surfaces of recessed portions of the uneven pattern, the water-repellent protecting film being formed at least on the surfaces of the recessed portions. The liquid chemical is characterized in that the agent for forming a water-repellent protecting film is a compound represented by the following general formula [1].

Owner:CENT GLASS CO LTD

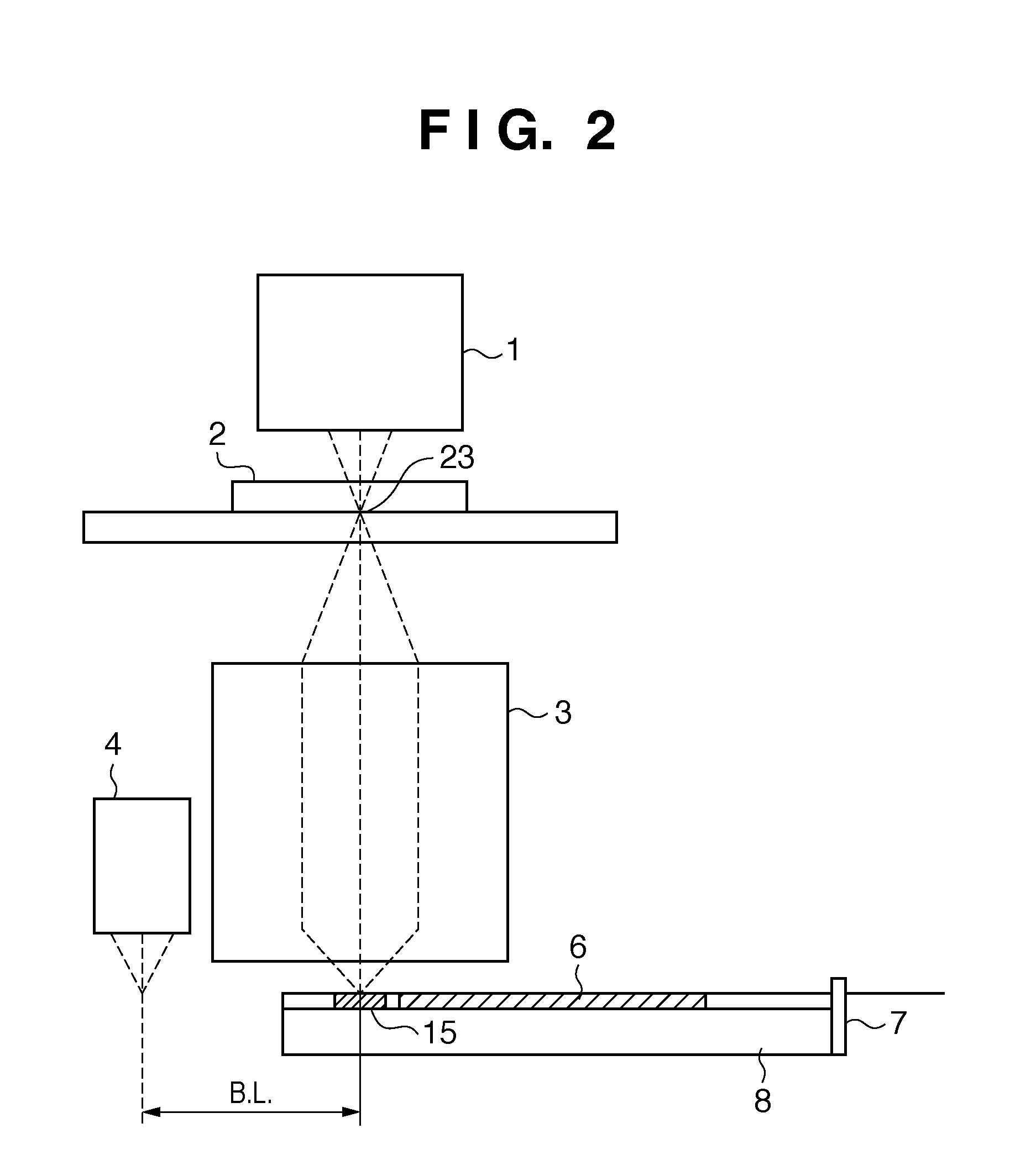

Exposure method and apparatus

InactiveUS20050128454A1Accurate focusReduce throughputSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusMeasurement pointReticle

An exposure method for exposing a pattern on a reticle onto plural shots on an object, includes the steps of measuring flatness information of each of the plural shots on the object, identifying a shot as a specific shot among the plural shots, the specific shot having flatness that is measured in the measuring step and outside a predetermined range, obtaining positional information by measuring plural measurement points on the object, the obtaining step obtaining more detailed positional information of the specific shot identified by the identifying step than that of a non-specific shot that is not the specific shot, and controlling at least one of a position and a tilt of the object using the positional information obtained by the obtaining step.

Owner:CANON KK

Substrate treatment apparatus

InactiveUS8043039B2Reduce throughputWithout lowering throughputSemiconductor/solid-state device manufacturingConveyor partsMagnetic tapeEngineering

A substrate treatment apparatus is disclosed. The substrate treatment apparatus includes: a cassette loading portion on which a cassette for containing a substrate is loaded when the cassette is carried to / from outside of the substrate treatment apparatus; a substrate treatment portion for performing a treatment on the substrate; a substrate carrying portion for carrying the substrate in the cassette loaded on the cassette loading portion to the substrate treatment portion, and carrying the substrate that has been subjected to the treatment by the substrate treatment portion to the cassette on the cassette loading portion; a vacant cassette loading portion on which the cassette caused to be vacant by carrying the substrate to the substrate treatment portion is temporarily loaded; and a vacant cassette transfer mechanism for transferring the vacant cassette between the vacant cassette loading portion and the cassette loading portion.

Owner:TOKYO ELECTRON LTD

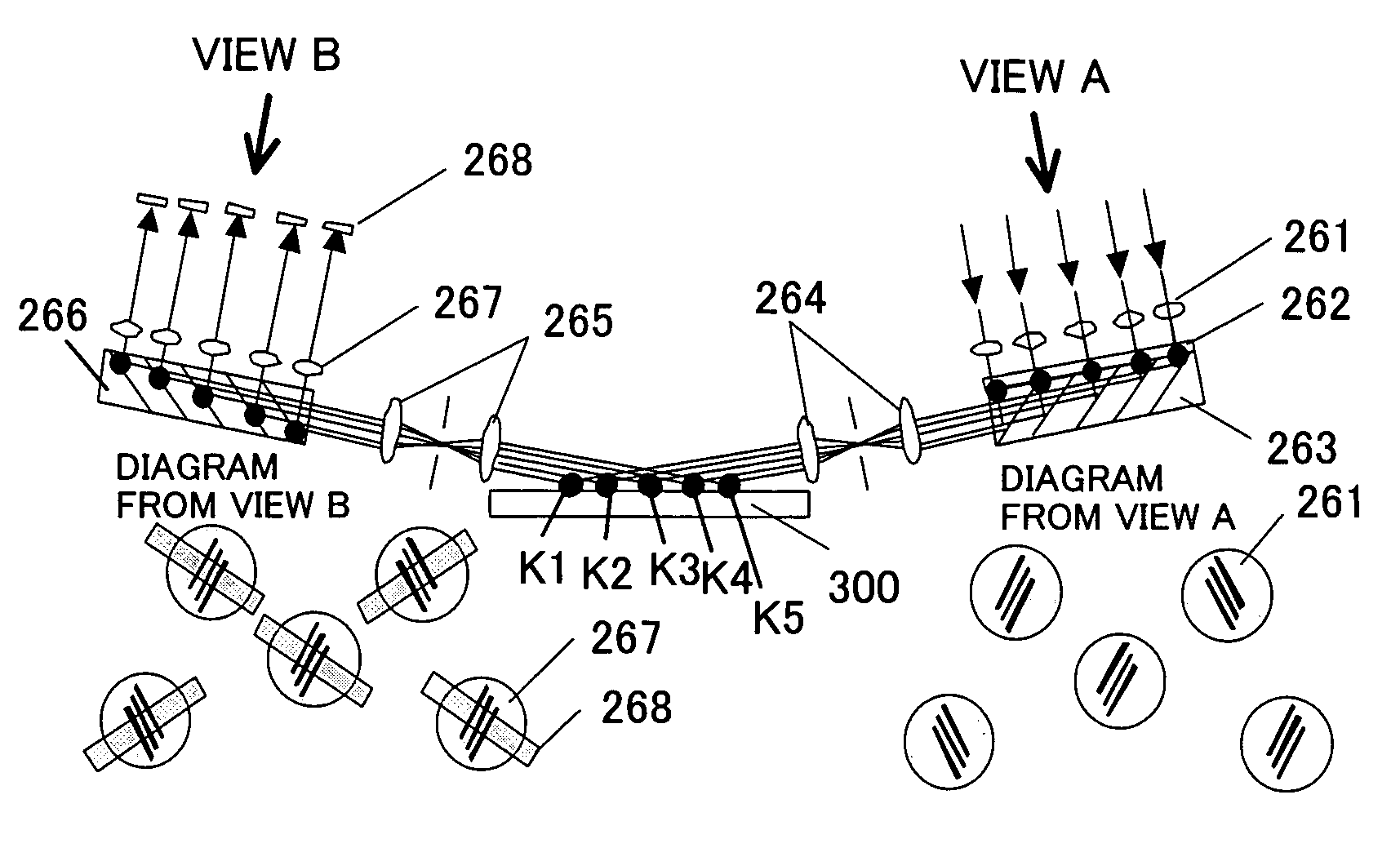

Exposure apparatus, optical projection apparatus and a method for adjusting the optical projection apparatus

InactiveUS20050012917A1Improve imaging effectReduce throughputPhotomechanical exposure apparatusMicrolithography exposure apparatusOptical pathWaveplate

A scanning projection exposure apparatus transfers a pattern of a mask onto a photosensitive substrate while moving the photosensitive substrate along a scanning direction. The scanning projection exposure apparatus can include an illumination optical system optically connected to a light source, and a projection optical system arranged in an optical path between the mask and the substrate. The illumination optical system illuminates the mask with linearly polarized light whose polarization direction extends along one of the scanning direction and a direction perpendicular to the scanning direction, without losses in quantity of light. The illumination optical system of the scanning projection exposure apparatus also can include a wave plate which is rotatable about a traveling direction of the light.

Owner:NIKON CORP

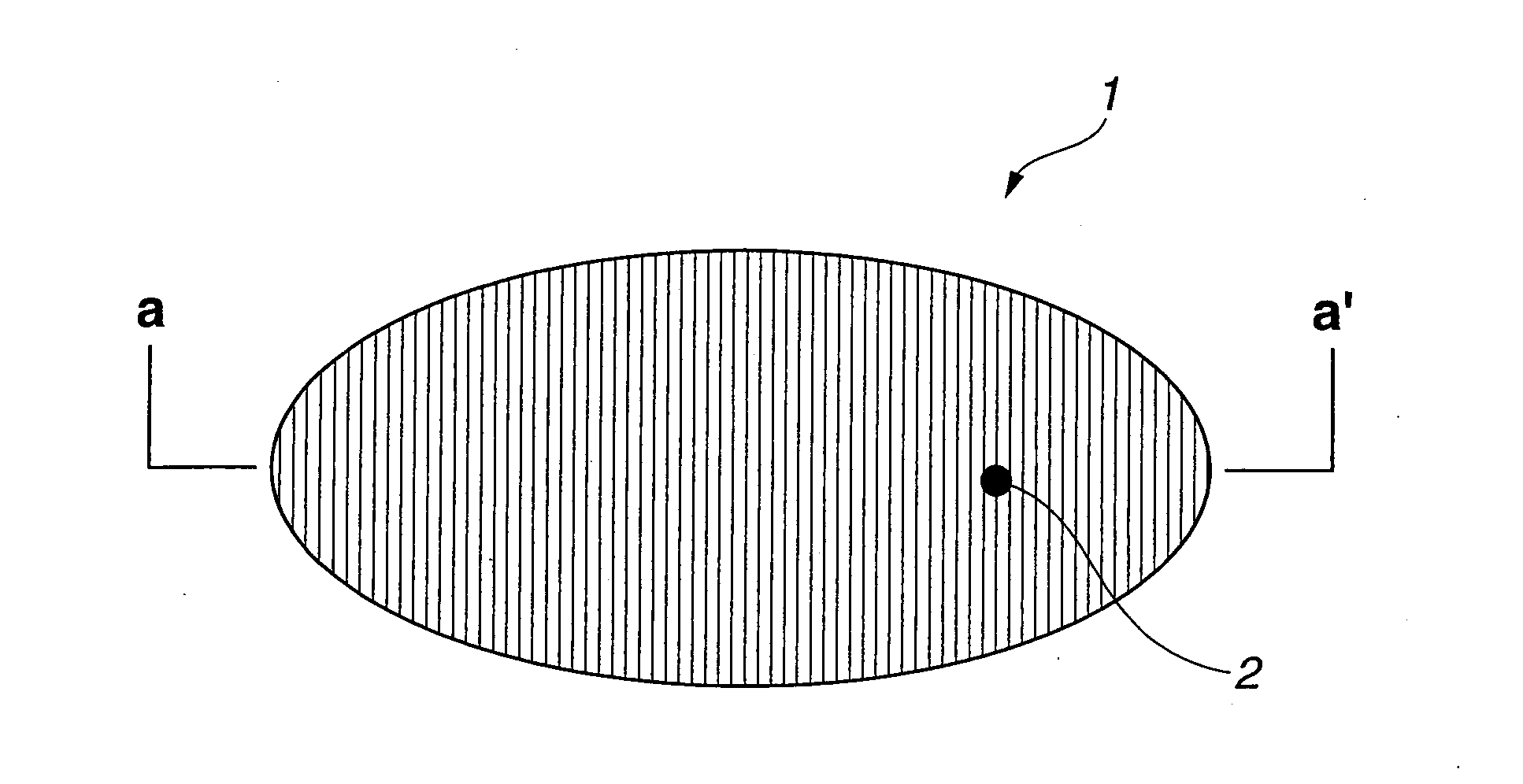

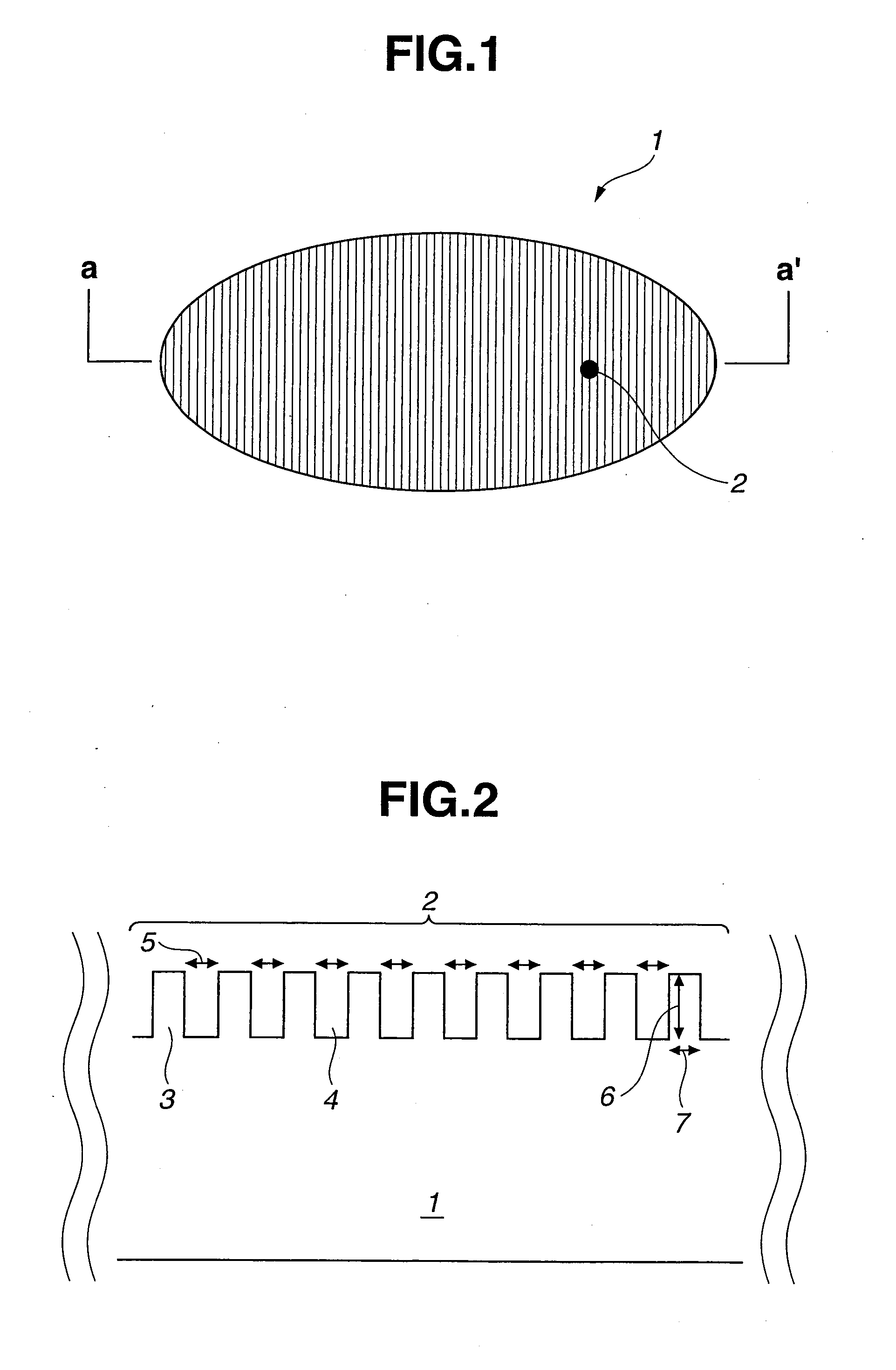

Electrostatic chuck and substrate fixing method using the same

ActiveUS7394640B2Without lowering throughputImprove flatnessSleeve/socket jointsElectric discharge tubesBiomedical engineeringVoltage

The electrostatic chuck 101 where pairs of electrodes 3a / 3b, 4a / 4b and 5a / 5b to which voltages are applied are embedded in the main body 1, and where a substrate 110 is placed and held on the surface of the main body 1, includes a first electrode group constituted of one pair or more of electrodes 3a / 3b arranged in a center region 41 inside the main body 1, and a second electrode group constituted of one pair or more of electrodes 4a / 4b and 5a / 5b arranged in outer peripheral portions 42 and 43 surrounding the center region 41.

Owner:ADVANTEST CORP

Exposure apparatus and method of manufacturing device

InactiveUS20090310106A1Reduce throughputHigh-accuracy exposurePhotomechanical apparatusOriginals for photomechanical treatmentEngineeringReticle

An exposure apparatus which transfers a pattern of a reticle onto a substrate via a projection optical system comprises a controller configured to correct an image of the pattern, formed on the substrate, in accordance with a shape of the reticle in a standby state until an exposure operation starts.

Owner:CANON KK

Liquid Chemical for Forming Protective Film

InactiveUS20150270123A1Improve waterproof performanceSufficient water repellencyNon-macromolecular adhesive additivesNon-macromolecular organic additionTectorial membraneRuthenium

A liquid chemical for forming a water-repellent protective film, containing: a water-repellent protective film forming agent for forming a water-repellent protective film on a wafer having at its surface an uneven pattern and containing at least one kind of element selected from titanium, tungsten, aluminum, copper, tin, tantalum and ruthenium at surfaces of recessed portions of the uneven pattern, the protective film being formed at least on the surfaces of the recessed portions by retaining the liquid chemical at least on the recessed portions of the wafer before a rinsing treatment step of rinsing the wafer surface with a rinsing liquid consisting only of a protic polar solvent or a rinsing liquid containing a protic polar solvent as the principal component; and a solvent. The water-repellent protective film forming agent is at least one kind of compound represented by the following general formulas [1] to [3].

Owner:CENT GLASS CO LTD

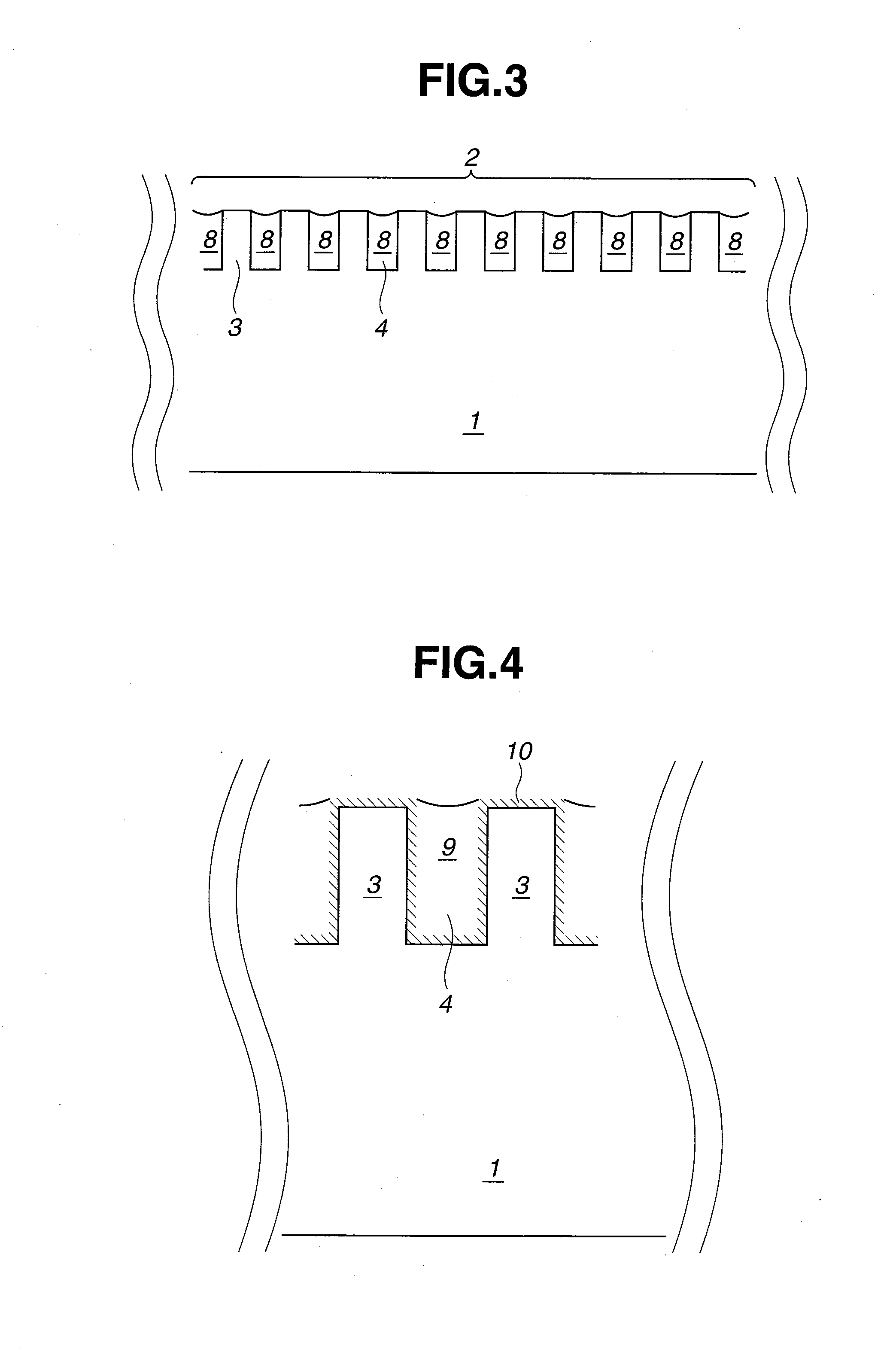

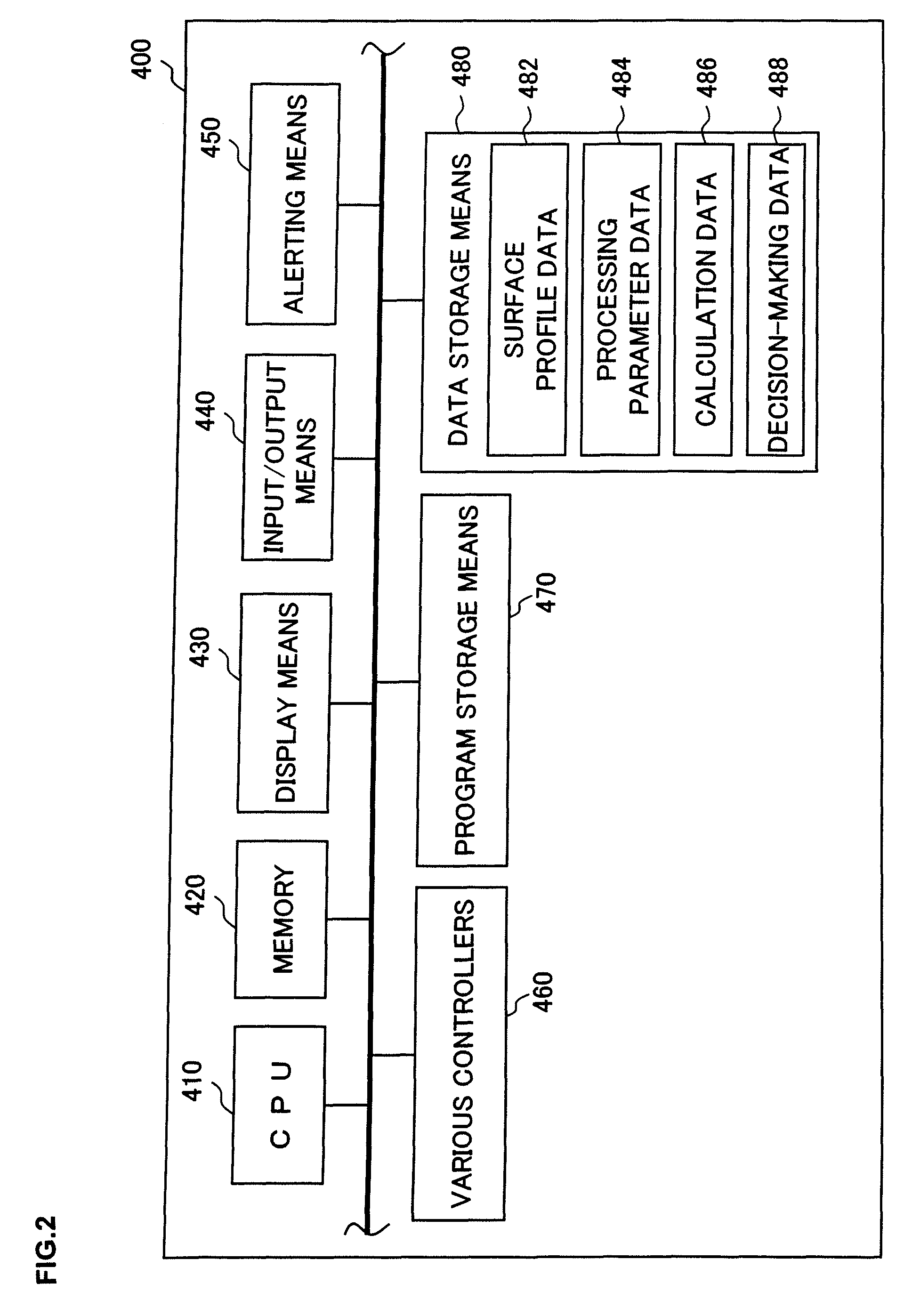

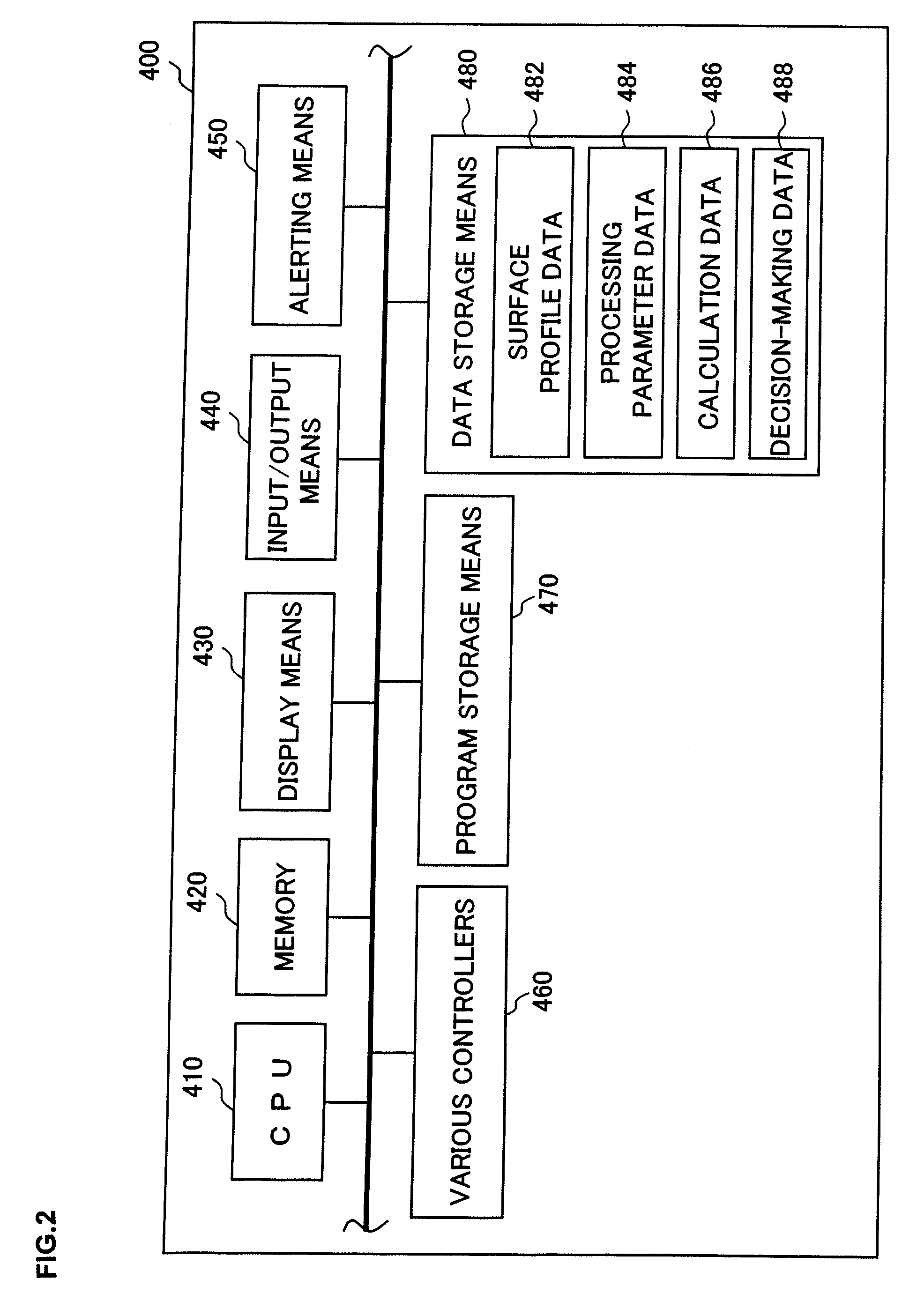

Substrate processing method and storage medium having program stored therein

ActiveUS7774082B2Eliminating superfluous transferImprove accuracyNuclear monitoringDigital computer detailsEntry pointParallel computing

First feedforward calculation is executed when a preprocessing surface profile is measured and a processing chamber with its processing parameter value having been obtained through the first feedforward calculation judged to be within an allowable range is determined. Wafer transfer is executed only in conjunction with a processing chamber having a processing parameter value judged to be within the allowable range, and the wafer is carried to the entry point of the processing chamber. Then, second feedforward calculation is executed by reflecting the results of feedback calculation executed based upon the most recent processing having been executed in the particular processing chamber and wafer processing is executed in the processing chamber based upon the processing parameter value calculated in the second feedforward calculation.

Owner:TOKYO ELECTRON LTD

Liquid chemical for forming protecting film

ActiveUS9228120B2Improve waterproof performanceReduce capillary forceOrganic detergent compounding agentsNon-ionic surface-active compoundsTrimethylsilyl trifluoromethanesulfonateCompound a

Disclosed is a liquid chemical for forming a water-repellent protecting film at least on a surface of a recessed portion of an uneven pattern at the time of cleaning a wafer having a finely uneven pattern at its surface and containing silicon at least a part of the uneven pattern. This liquid chemical contains a silicon compound A represented by the general formula: R1aSi(H)bX4-a-b and an acid A, the acid A being at least one selected from the group consisting of trimethylsilyl trifluoroactate, trimethylsilyl trifluoromethanesulfonate, dimethylsilyl trifluoroactate, dimethylsilyl trifluoromethanesulfonate, butyldimethylsilyl trifluoroactate, butyldimethylsilyl trifluoromethanesulfonate, hexyldimethylsilyl trifluoroacetate, hexyldimethylsilyl trifluoromethanesulfonate, octyldimethylsilyl trifluoroactate, octyldimethylsilyl trifluoromethanesulfonate, decyldimethylsilyl trifluoroacetate and decyldimethylsilyl trifluoromethanesulfonate.

Owner:CENT GLASS CO LTD

Substrate processing method and storage medium having program stored therein

ActiveUS20080091290A1Desired level of throughputHigh adjustment accuracyNuclear monitoringDigital computer detailsEntry pointParallel computing

First feedforward calculation is executed when a preprocessing surface profile is measured and a processing chamber with its processing parameter value having been obtained through the first feedforward calculation judged to be within an allowable range is determined. Wafer transfer is executed only in conjunction with a processing chamber having a processing parameter value judged to be within the allowable range, and the wafer is carried to the entry point of the processing chamber. Then, second feedforward calculation is executed by reflecting the results of feedback calculation executed based upon the most recent processing having been executed in the particular processing chamber and wafer processing is executed in the processing chamber based upon the processing parameter value calculated in the second feedforward calculation.

Owner:TOKYO ELECTRON LTD

Water-Repellent Protective Film, and Chemical Solution for Forming Protective Film

ActiveUS20150179433A1Improve waterproof performancePreventing pattern collapseOther chemical processesNon-surface-active detergent compositionsTectorial membraneChemical solution

A surface treatment was conducted by using a liquid chemical containing a water-repellent protective film forming agent represented by the following general formula [1], subsequent to a step of cleaning a metal-based wafer and prior to a step of drying the wafer.(R1 represents a C1-C18 monovalent hydrocarbon group the hydrogen elements of which may partially or entirely be replaced with a fluorine element(s). R2 mutually independently represents a monovalent organic group having a C1-C18 hydrocarbon group the hydrogen elements of which may partially or entirely be replaced with a fluorine element(s). “a” is an integer of from 0 to 2.)

Owner:CENT GLASS CO LTD

Chemical for forming protective film

ActiveUS9691603B2Reduce capillary forceWithout lowering throughputOther chemical processesElectrostatic cleaningTectorial membraneCompound (substance)

Disclosed is a liquid chemical for forming a water repellent protective film on a wafer that has at its surface a finely uneven pattern and contains silicon element at least at a part of the uneven pattern, the water repellent protective film being formed at least on surfaces of recessed portions of the uneven pattern at the time of cleaning the wafer. The liquid chemical contains: a silicon compound (A) represented by the general formula R1aSi(H)b(X)4−a−b and an acid; or a silicon compound (C) represented by the general formula R7gSi(H)h(CH3)w(Z)4−g−h−w and a base that contains no more than 35 mass % of water. The total amount of water in the liquid chemical is no greater than 1000 mass ppm relative to the total amount of the liquid chemical. The liquid chemical can improve a cleaning step that easily induces pattern collapse.

Owner:CENT GLASS CO LTD

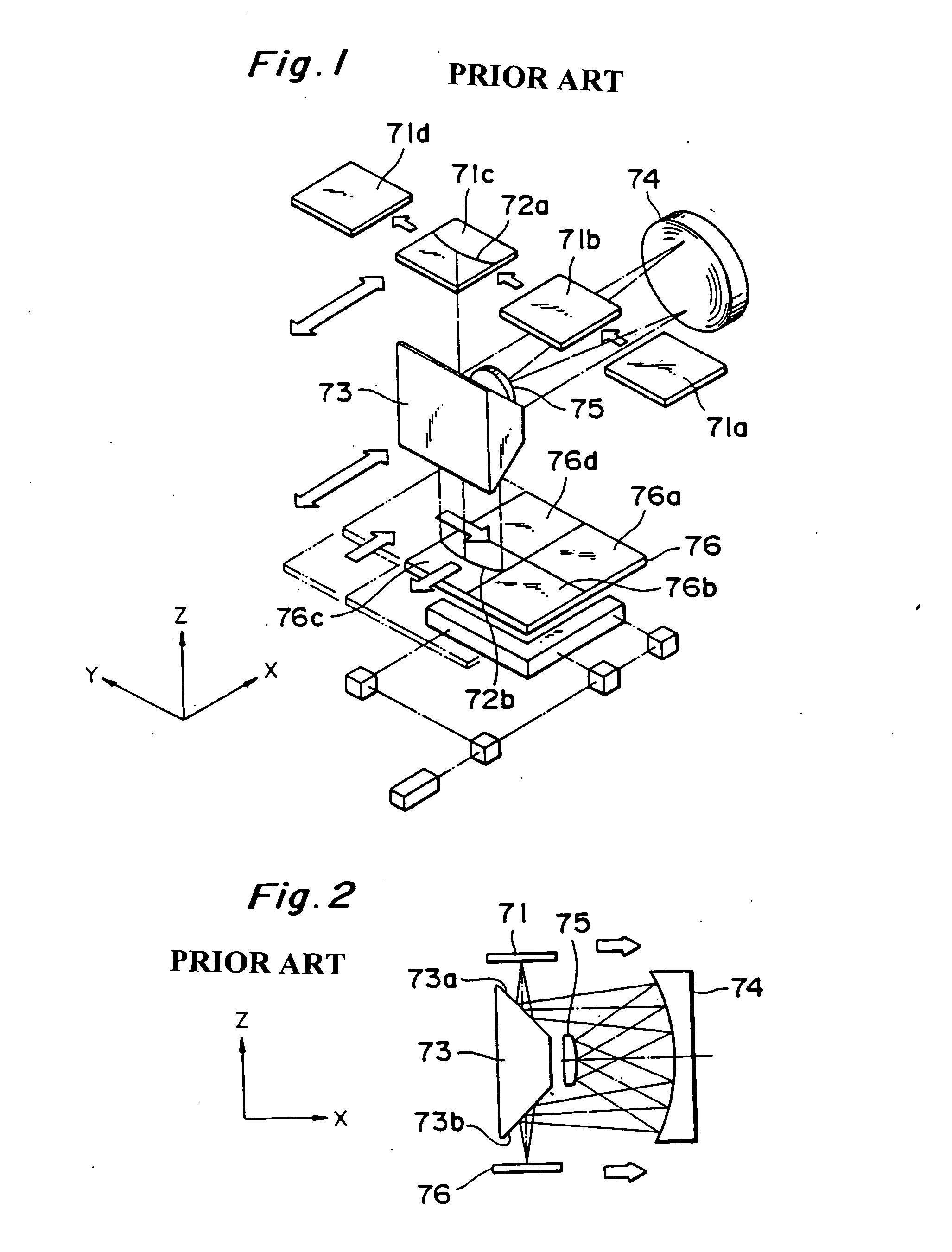

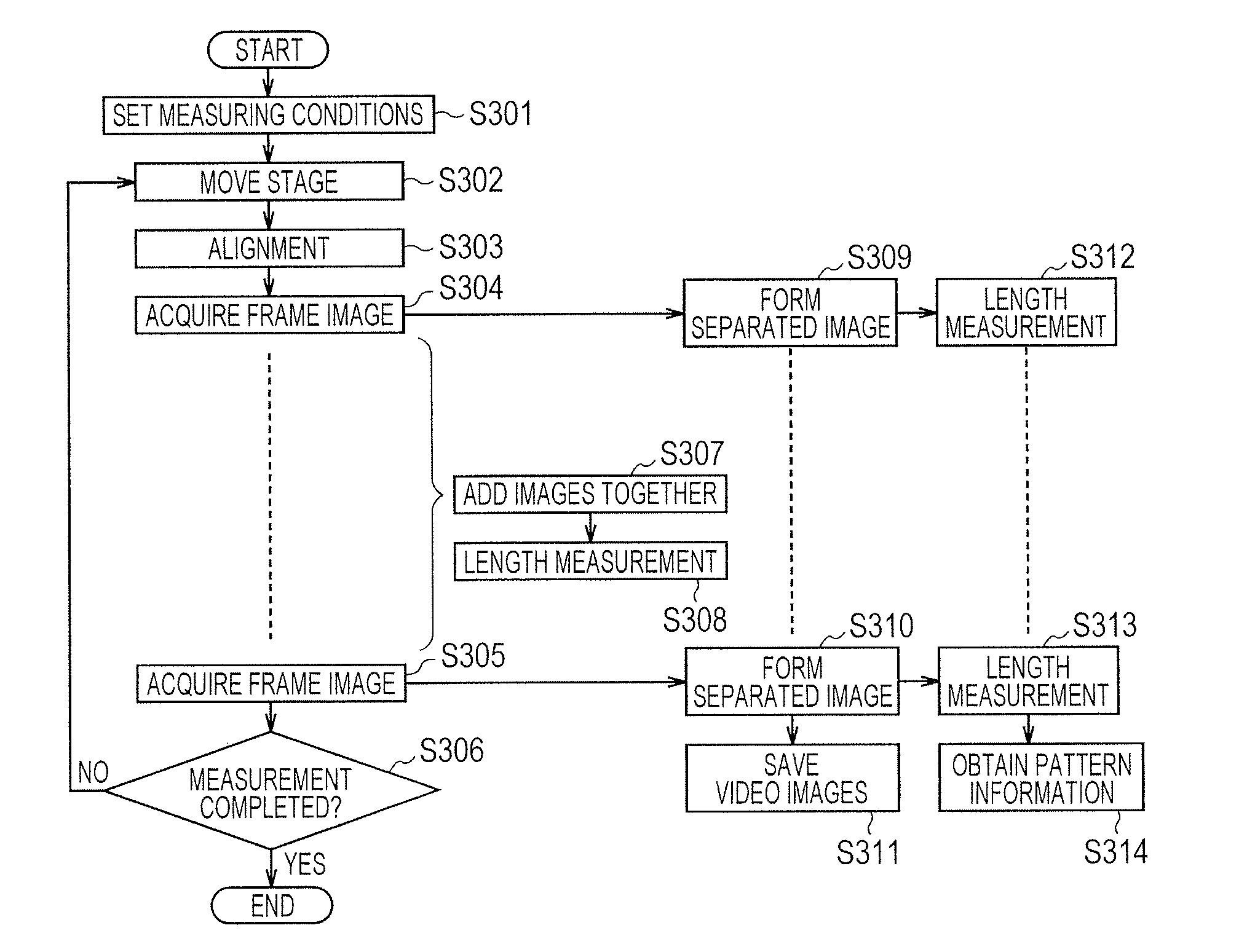

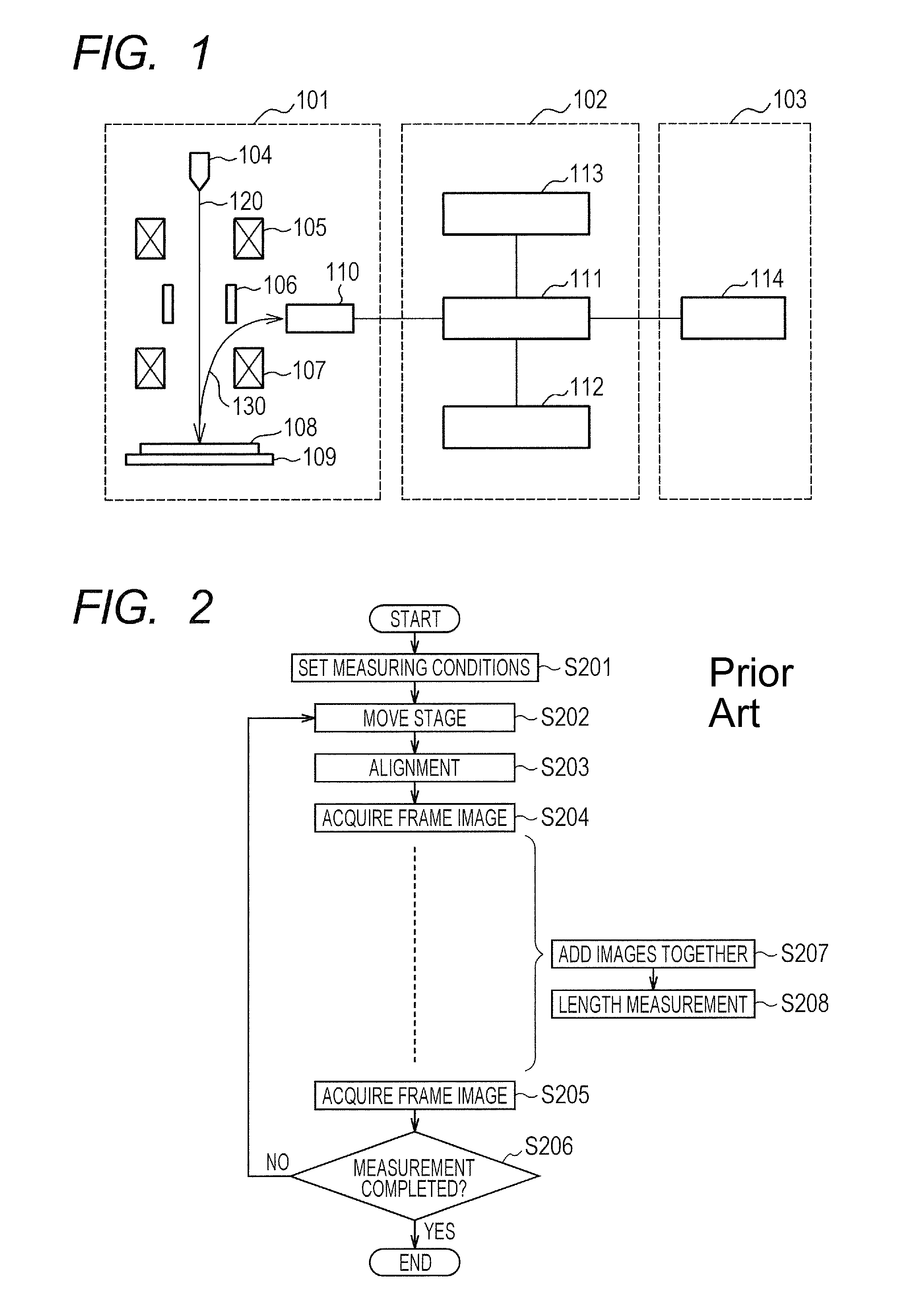

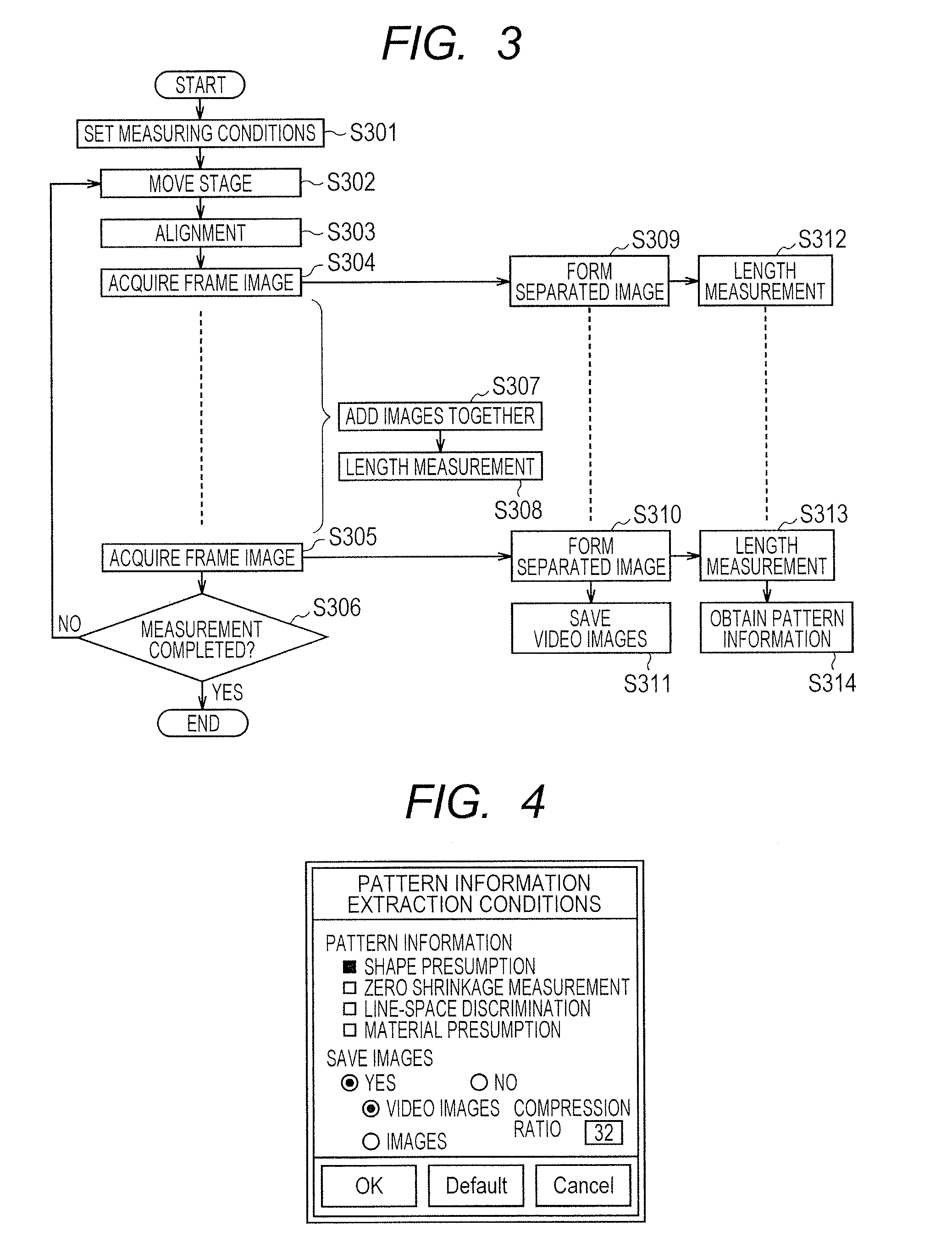

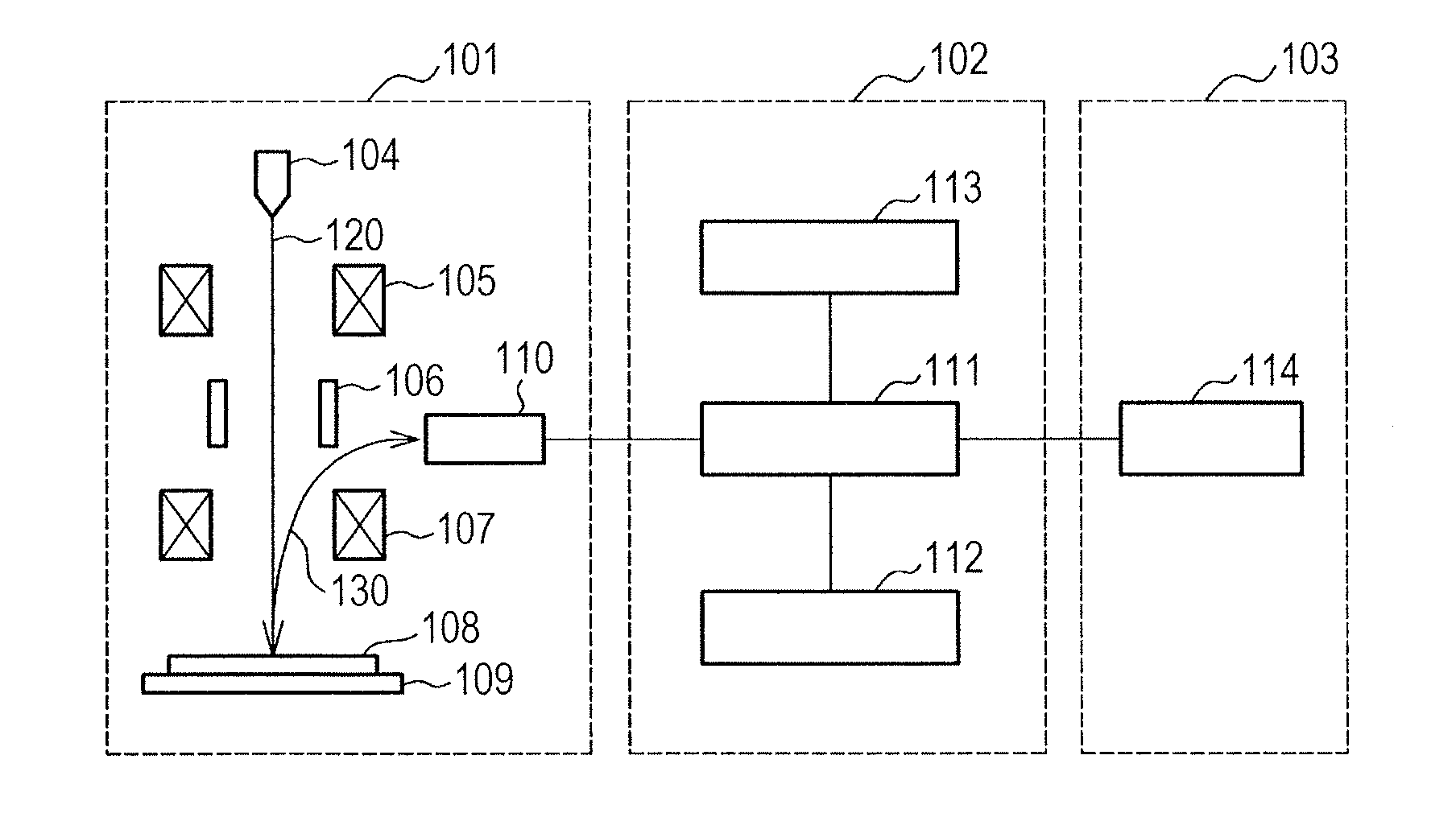

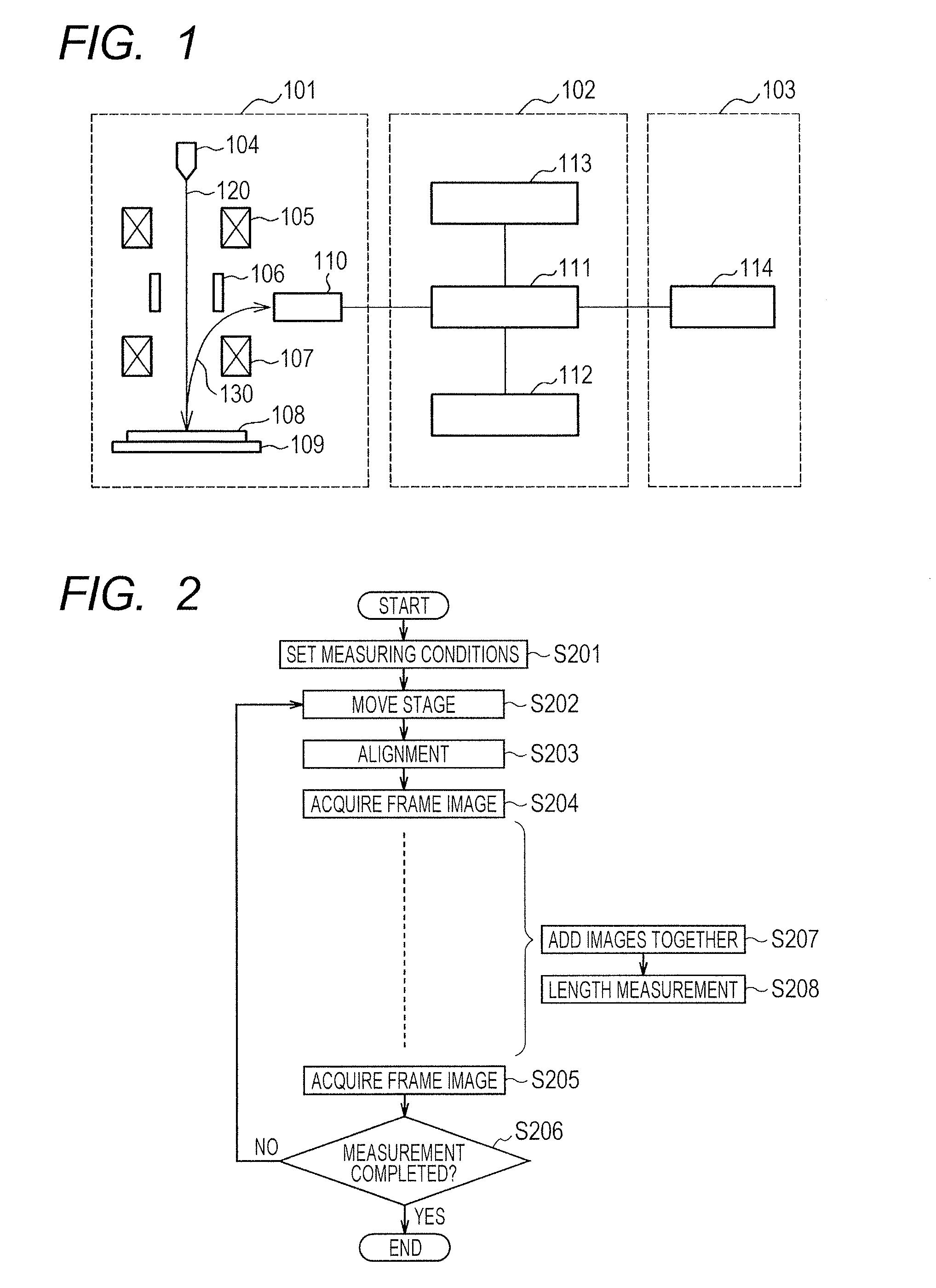

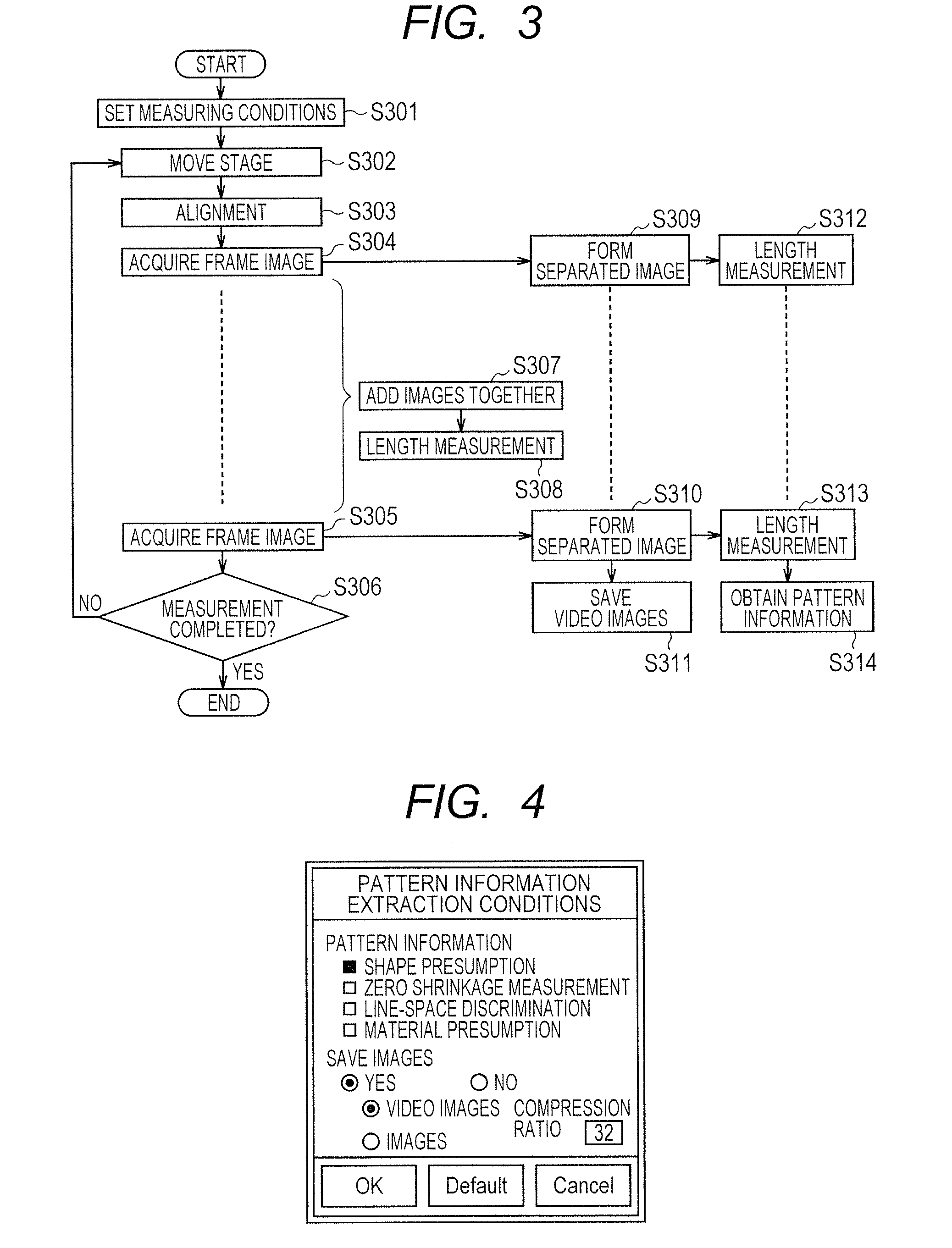

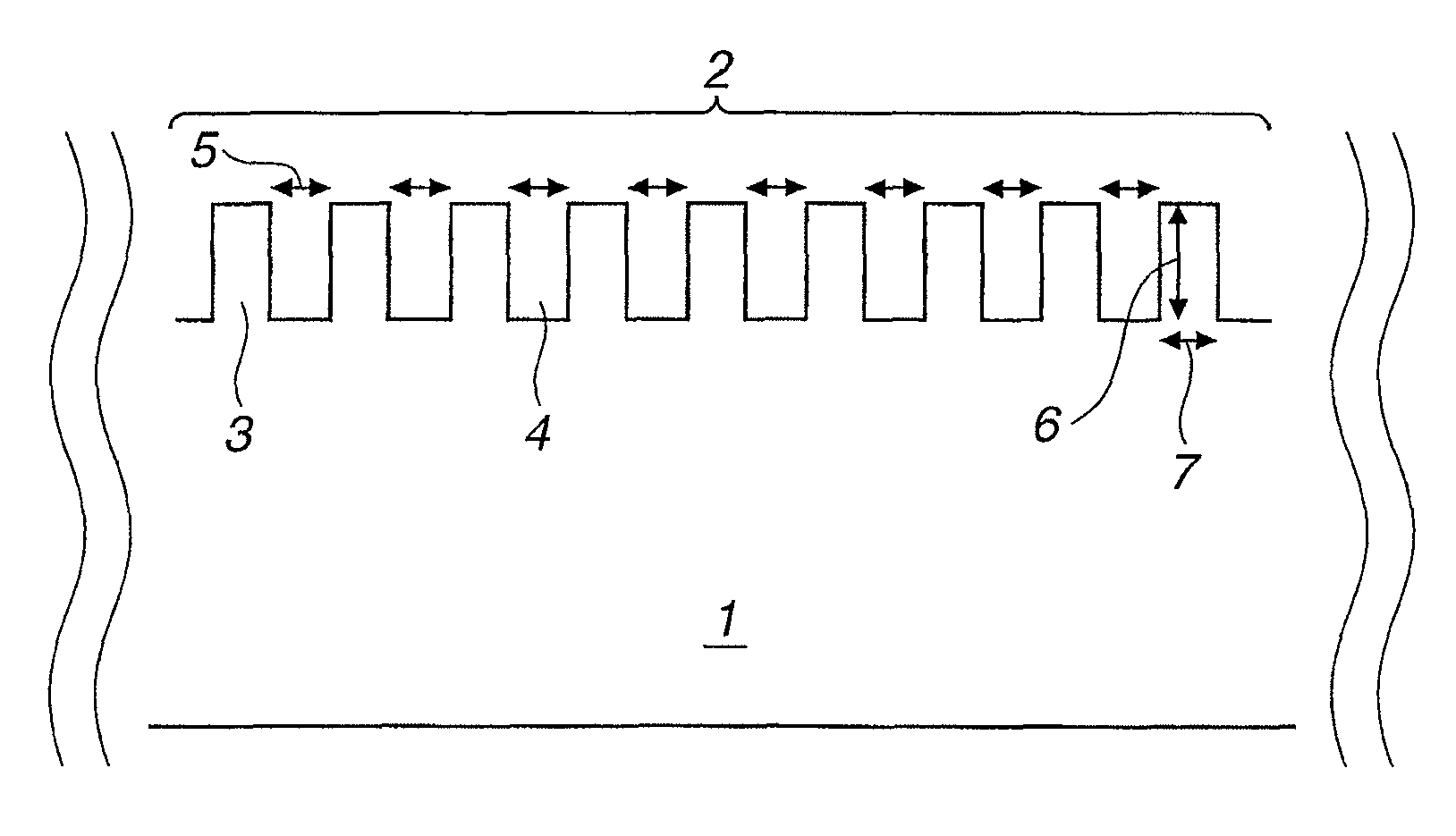

Charged particle beam microscope

ActiveUS9261360B2Without lowering throughputElectric discharge tubesColor television detailsDimension measurementParticle physics

Disclosed is a charged particle beam microscope which can obtain information about pattern materials and stereostructure without lowering throughput of pattern dimension measurement. To achieve this, the charged particle beam microscope acquires a plurality of frame images by scanning the field of view of the sample (S304, 305), adds the images together (S307), computes the dimensions of the pattern formed on the sample (308) and at the same time acquires pattern information (314) using components of a frame image, such as a single frame image or subframe image, as a separated image (309, 310).

Owner:HITACHI HIGH-TECH CORP

Liquid Chemical for Forming Protective Film, and Cleaning Method for Wafer Surface

InactiveUS20130104931A1Improve production yieldAdditional cleaning stepSemiconductor/solid-state device manufacturingChemical vapor deposition coatingTectorial membraneCleaning methods

Disclosed is a liquid chemical for forming a water repellent protective film at least on surfaces of recessed portions of a metal-based wafer, the liquid chemical for forming a water repellent protective film being characterized by comprising a surfactant which has an HLB value of 0.001-10 according to Griffin's method and includes a hydrophobic moiety having a C6-C18 hydrocarbon group and water, and characterized in that the concentration of the surfactant in the liquid chemical is not smaller than 0.00001 mass % and not larger than the saturated concentration relative to 100 mass % of the total amount of the liquid chemical. This liquid chemical can improve a cleaning step which tends to induce a metal-based wafer to cause a pattern collapse.

Owner:CENT GLASS CO LTD

Exposure apparatus, optical projection apparatus and a method for adjusting the optical projection apparatus

InactiveUS20050185162A1Without lowering throughputImprove imaging effectPhotomechanical exposure apparatusMicrolithography exposure apparatusPhysicsOptics

An exposure apparatus includes a plurality of projection optical systems and a substrate stage. Each of the plurality of projection optical systems forms an exposure field on the substrate. The substrate stage holds the substrate and moves in at least a scanning direction extending in a straight line. The plurality of exposure fields are arranged along a direction crossing the scanning direction. The plurality of projection optical systems and the substrate relatively move during an exposure field forming operation along the scanning direction.

Owner:NIKON CORP

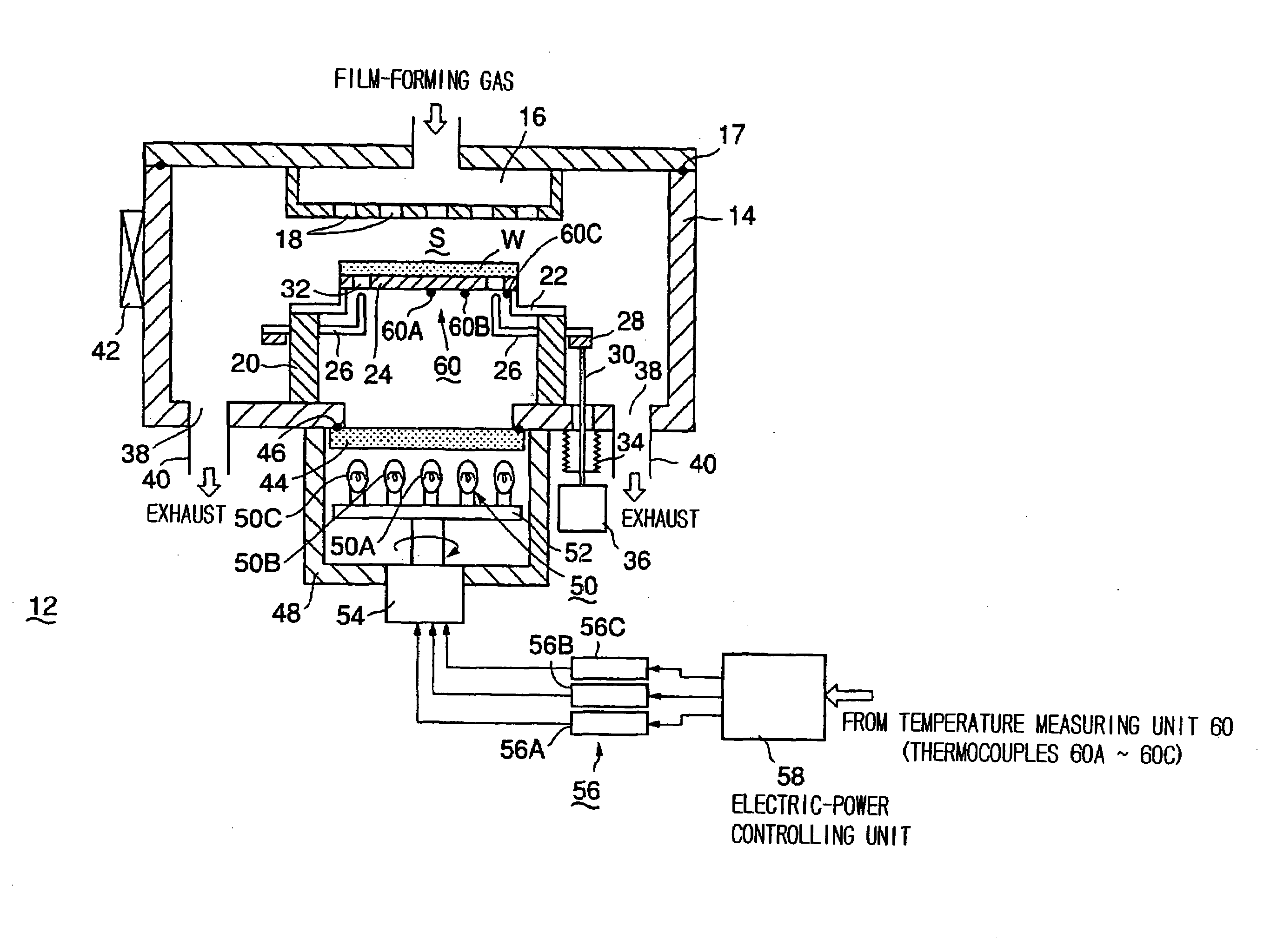

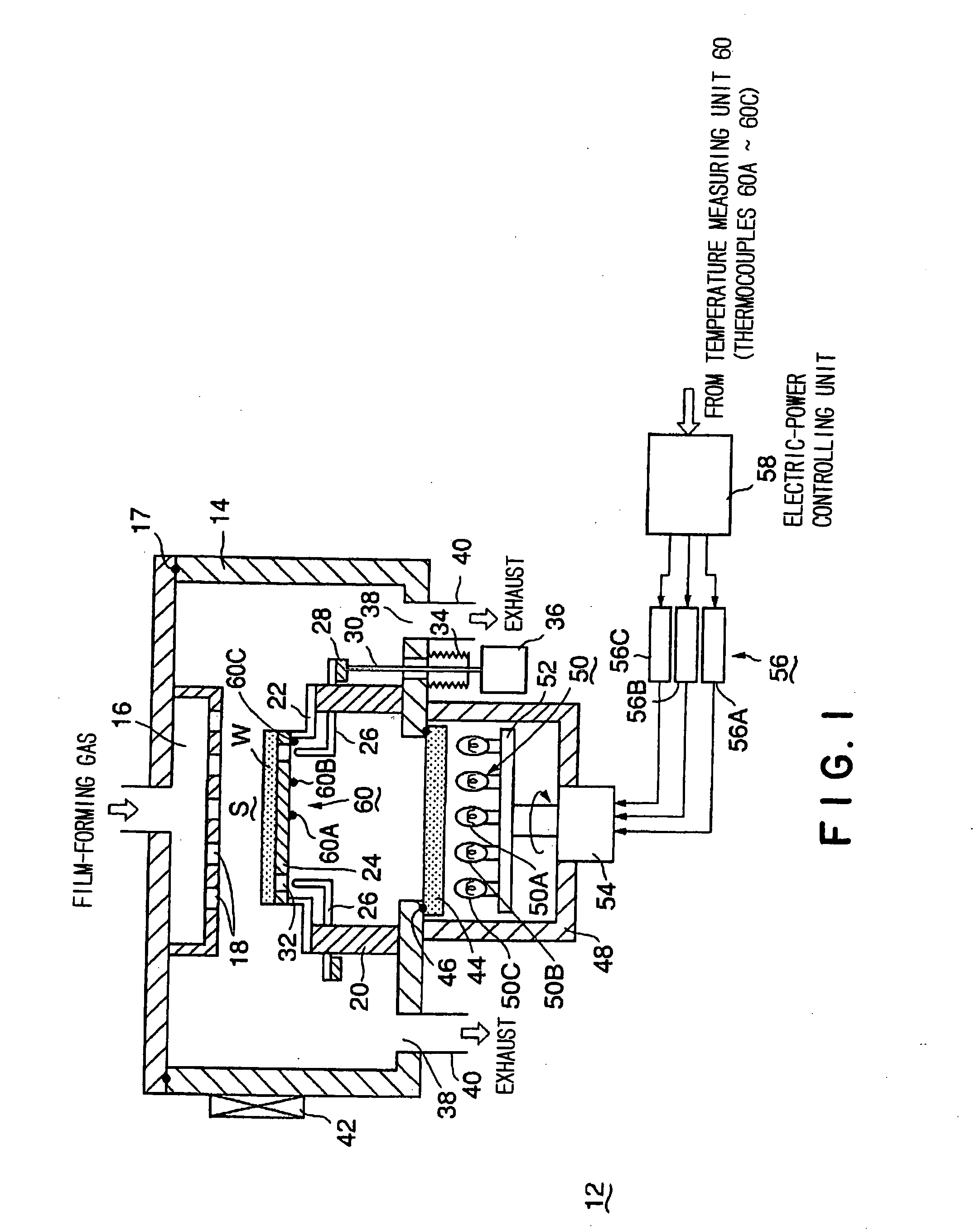

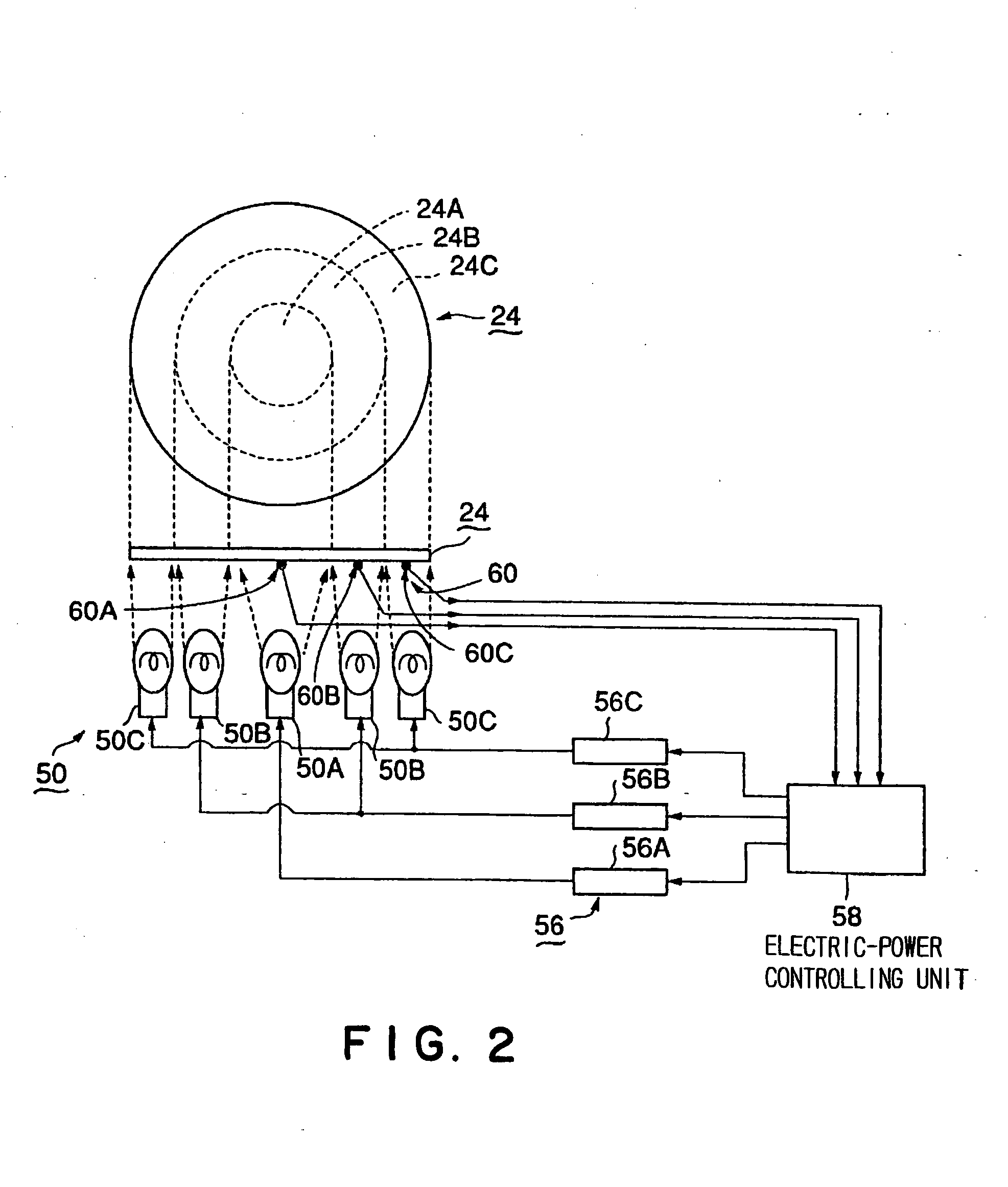

Single wafer processing unit

InactiveUS20080280048A1Film-stress becomes so greatPromote generationPretreated surfacesSemiconductor/solid-state device manufacturingEngineeringSingle crystal

This invention relates to a thermal processing method including: a placing step of placing an object to be processed onto a stage arranged in a processing container that can be vacuumed; and a heating step of heating the object to be processed to a predetermined temperature. The object to be processed is heated under a state in which a temperature distribution is maintained in such a manner that a temperature at a central portion of the object to be processed is high while a temperature at a peripheral portion of the object to be processed is low, during at least a part of the heating step.

Owner:KASAI SHIGERU +1

Plating apparatus and plating method

A plating apparatus includes a processing bath configured to store a processing liquid therein, a transporter configured to immerse a substrate holder, holding a substrate, in the processing liquid, raise the substrate holder out of the processing bath, and transport the substrate holder in a horizontal direction, and a gas flow generator configured to generate a clean gas flow forward of the substrate with respect to a direction in which the substrate holder is transported. The transporter moves the gas flow generator together with the substrate holder in the horizontal direction while transporting the substrate holder in the horizontal direction.

Owner:EBARA CORP

Charged Particle Beam Microscope

ActiveUS20120327213A1Reduce throughputWithout lowering throughputElectric discharge tubesColor television detailsDimension measurementParticle physics

Disclosed is a charged particle beam microscope which can obtain information about pattern materials and stereostructure without lowering throughput of pattern dimension measurement. To achieve this, the charged particle beam microscope acquires a plurality of frame images by scanning the field of view of the sample (S304, 305), adds the images together (S307), computes the dimensions of the pattern formed on the sample (308) and at the same time acquires pattern information (314) using components of a frame image, such as a single frame image or subframe image, as a separated image (309, 310).

Owner:HITACHI HIGH-TECH CORP

Liquid chemical for forming water repellent protecting film, and process for cleaning wafers using the same

ActiveUS9349582B2Improve waterproof performanceWithout lowering throughputOrganic detergent compounding agentsOther chemical processesCompound (substance)Ruthenium

A liquid chemical for forming a water repellent protecting film on a wafer having at its surface an uneven pattern and containing at least one kind of element selected from the group consisting of titanium, tungsten, aluminum, copper, tin, tantalum and ruthenium at surfaces of recessed portions of the uneven pattern, the water repellent protecting film being formed at least on the surfaces of the recessed portions. The liquid chemical is characterized by including: a water repellent protecting film forming agent; and water, and characterized in that the water repellent protecting film forming agent is at least one selected from compounds represented by the following general formula [1] and salt compounds thereof and that the concentration of the water relative to the total quantity of a solvent contained in the liquid chemical is not smaller than 50 mass %.

Owner:CENT GLASS CO LTD

Exposure method and apparatus

InactiveUS7106419B2Without lowering throughputSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusMeasurement pointReticle

An exposure method for exposing a pattern on a reticle onto plural shots on an object, includes the steps of measuring flatness information of each of the plural shots on the object, identifying a shot as a specific shot among the plural shots, the specific shot having flatness that is measured in the measuring step and outside a predetermined range, obtaining positional information by measuring plural measurement points on the object, the obtaining step obtaining more detailed positional information of the specific shot identified by the identifying step than that of a non-specific shot that is not the specific shot, and controlling at least one of a position and a tilt of the object using the positional information obtained by the obtaining step.

Owner:CANON KK

Liquid Chemical for Forming Protecting Film

ActiveUS20140373870A1Improve waterproof performanceWithout lowering throughputOther chemical processesDetergent mixture composition preparationTectorial membraneRuthenium

Disclosed is a liquid chemical for forming a water-repellent protecting film. The liquid chemical contains an agent for forming a water-repellent protecting film, and a solvent. The agent is for provided to form a water-repellent protecting film on a wafer after a cleaning step for the wafer and before a drying step for the wafer, the wafer having at its surface an uneven pattern and containing at least one kind element of titanium, tungsten, aluminum, copper, tin, tantalum and ruthenium at surfaces of recessed portions of the uneven pattern, the water-repellent protecting film being formed at least on the surfaces of the recessed portions. The liquid chemical is characterized in that the agent for forming a water-repellent protecting film is a compound represented by the following general formula [1].

Owner:CENT GLASS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com