Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

72results about How to "Troubleshoot Wiring Problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

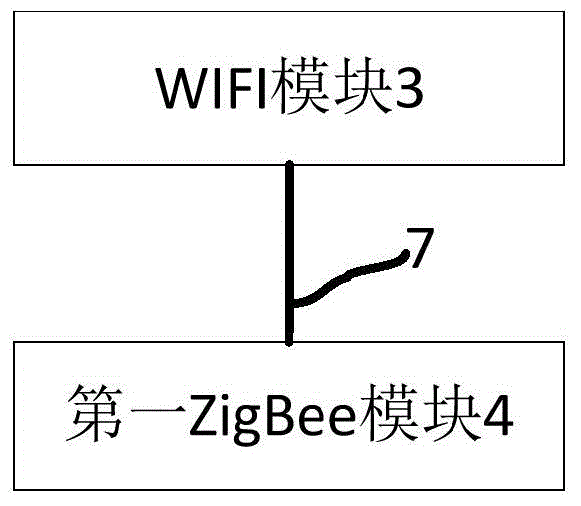

Intelligent lock monitoring system based on WeChat public platform and monitoring method of intelligent lock monitoring system

PendingCN105516352ADoes not affect power consumptionTroubleshoot Wiring ProblemsNetwork connectionsTerminal equipmentMonitoring system

The invention discloses an intelligent lock monitoring system based on a WeChat public platform and a monitoring method of the intelligent lock monitoring system. The intelligent lock monitoring system comprises an intelligent terminal device equipped with a WeChat client, a WeChat public platform server, a cloud server, an intelligent gateway and an intelligent lock, wherein the intelligent terminal device, the WeChat public platform server, the cloud server, the intelligent gateway and the intelligent lock are connected in sequence. A user can transmit a user instruction to the intelligent lock by using a WeChat public number of the intelligent terminal device; the user instruction reaches the intelligent lock through the cloud server and the intelligent gateway; the intelligent lock performs relative operation based on the user instruction; if the intelligent lock detects self state change, state information reaches the WeChat public number of the intelligent terminal device for displaying through the intelligent gateway, the cloud server and the WeChat public platform server. According to the technical scheme disclosed by the invention, the intelligent lock monitoring system is simple to operate, is conveniently controlled in real time and is safe and reliable, and an APP does not need to be installed independently.

Owner:广东海尔智能科技有限公司

Vehicle charging device used for stereo garage

InactiveCN105162211ATroubleshoot Wiring ProblemsEasy to installBatteries circuit arrangementsNon-rotary current collectorNew energyEngineering

The invention discloses a vehicle charging device used for a stereo garage. The vehicle charging device comprises a charging pile, a charging contact and a slide wire contact, wherein the charging pile and the charging contact are fixedly installed on a vehicle carrying plate, the slide wire contact is fixedly installed on the bottom part of a bearing beam corresponding to the vehicle carrying plate, and the slide wire contact is connected with a power supply through a first cable laid on the bearing beam; and the fixing position of the slide wire contact is corresponding to the up and down moving positions of the charging contact, the charging contact moves upwards along with the vehicle carrying plate and is inserted into the slide wire contact so as to be connected the power supply, and the charging pile is further connected with the power supply. By adopting the vehicle charging device, the lifting-sliding problem and the wiring problem of the simple lifting garage vehicle carrying plate are effectively solved, great convenience is provided for the charging of a new energy automobile on the stereo garage, the installation is simple, the maintenance cost is low, and the practicality is high.

Owner:北京大兆新元停车设备有限公司

Obstacle bypassing wiring method based on optimization of shortest wire length in large-sized integrated circuit design

InactiveCN103984789ATroubleshoot Wiring ProblemsReasonable wiringSpecial data processing applicationsParallel searchIntegrated circuit design

The invention relates to the technical field of the physical design of a large-sized integrated circuit, in particular to an obstacle bypassing wiring method based on the optimization of shortest wire length in the large-sized integrated circuit design. The method comprises the steps: establishing a wiring question map according to an escape map theory, marking top points, i.e., necessary points by adopting a multi-source parallel search method, establishing a feasible solution steiner tree on the basis of a necessary point set, and finally optimizing the feasible solution. The method is reasonable in wiring layout, the obtained wire length is short, and the wiring effect is good.

Owner:FUZHOU UNIV

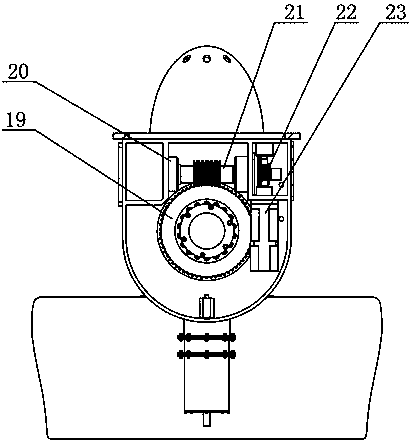

Full-rotating integrated propelling device

ActiveCN104015911ASolve the problem of insufficient reduction ratioTroubleshoot Wiring ProblemsPropulsion power plantsOutboard propulsion unitsOil pressureSignal lines

The invention relates to a full-rotating integrated propelling device which comprises a steering unit and a propelling unit. The steering unit and the propelling unit are connected with each other. The device is simple in structure and convenient to assemble and disassemble. The steering unit is arranged outside a boat, balance with external water pressure is kept through an oil pressure compensator, and high-pressure rotating dynamic sealing is achieved. Pressure in a motor shell body in the propelling unit and external water pressure are kept balanced through the motor oil pressure compensator so that the device can work in a water seepage environment at any depth. The problem that an existing turbine worm speed reducing mechanism is not sufficient in reduction ratio is solved through a first turbine worm speed reducing mechanism and a second turbine worm speed reducing mechanism, by arranging a sliding ring, a motor power line and a signal line can be connected with a boat body through sliding rings, and rotating wiring is achieved.

Owner:中国船舶重工集团公司第七〇二研究所

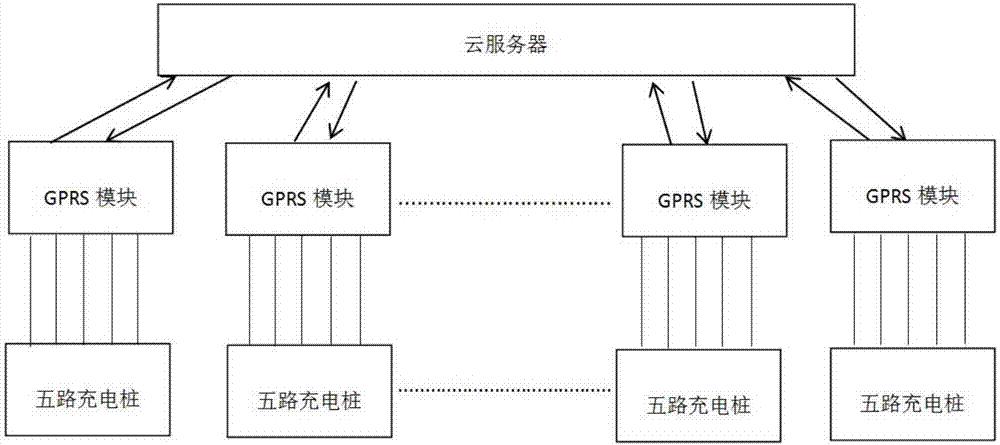

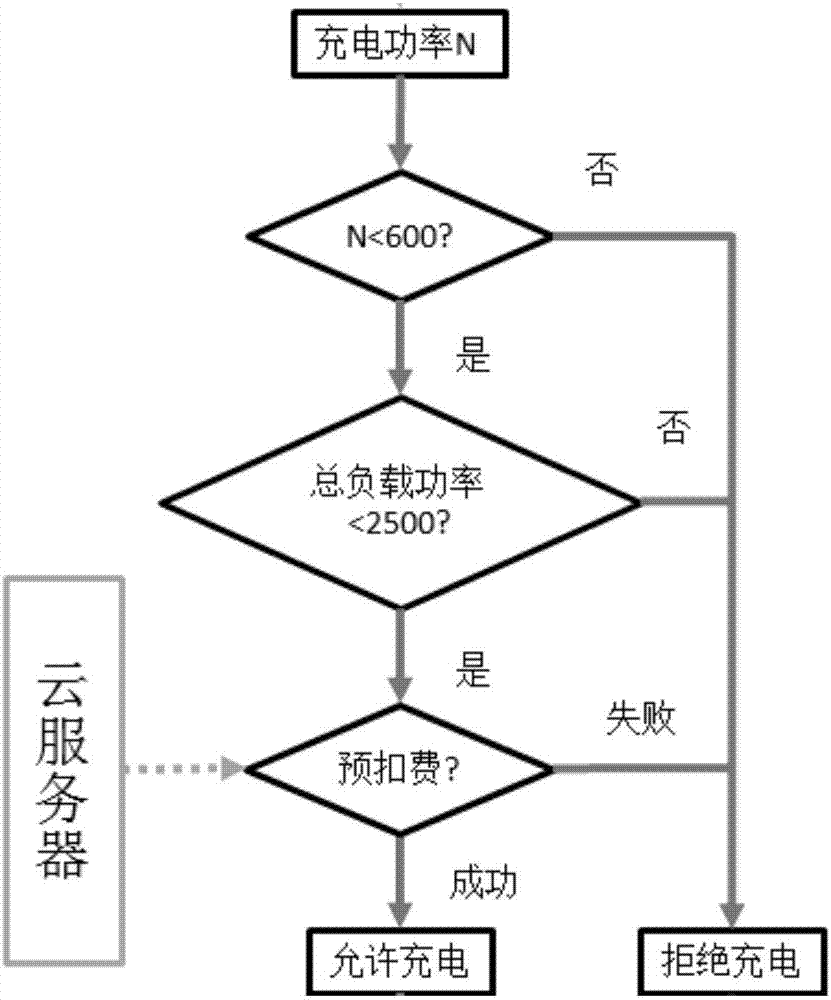

Electromobile charging pile using method based on WeChat payment

InactiveCN107221082AWill not harmExtended service lifePayment architectureElectric vehicle charging technologyPaymentComputer science

The invention discloses an electromobile charging pile using method based on WeChat payment. The method comprises the following steps: a1, creating a main account by a server; a2, completing mobile phone WeChat personal information binding by a user; a3, completing the pre-charging by the user; a4, finding out a charging pile corresponding to ID written on the mobile phone by the user; a5, using WeChat by the user; a6, recharging the user account; and a7, completing the charging. The method is capable of binding the WeChat account and the ID of the charging pile through a WeChat official account, performing the mobile side recharging to a recharge card through the official account by the user, eliminating the trouble of queuing up for recharging in the sales network, and realizing the recharging anytime anywhere which is not limited by the environment and time.

Owner:缪媛

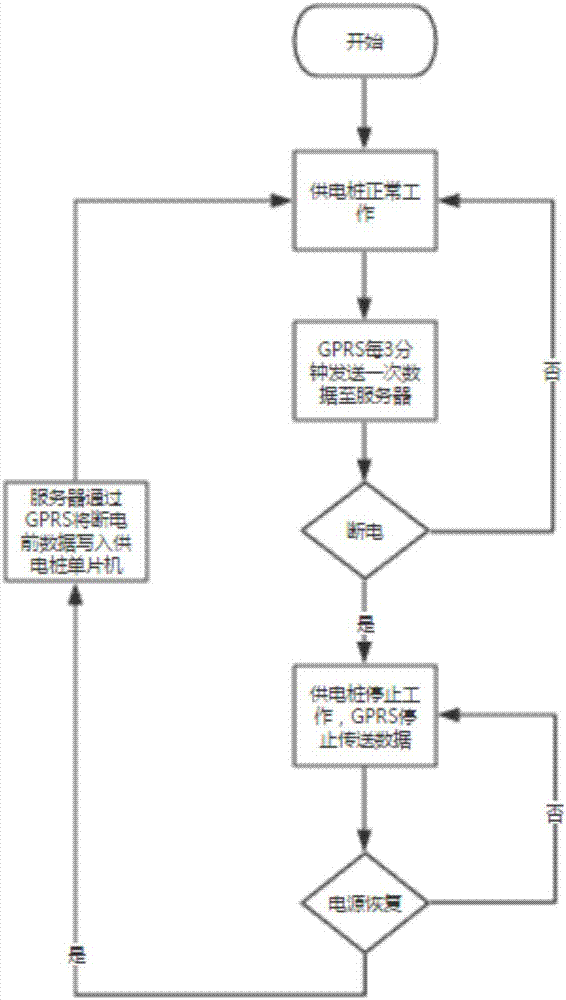

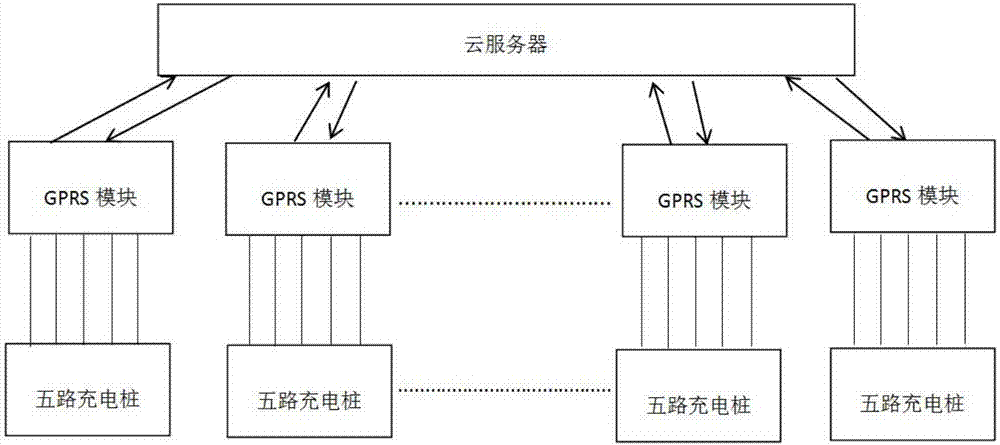

Charging using method for charging pile system with bluetooth interfaces

InactiveCN107458241AWill not harmExtended service lifeNear-field transmissionCharging stationsPublic networkBluetooth

The invention discloses a charging using method for a charging pile system with bluetooth interfaces. The charging pile system comprises a public network cloud terminal, a communication controller, charging piles, replays, electric quantity measuring chips and the bluetooth interfaces, 10-32 minimum charging units are connected to the main line of the communication controller in series, each minimum charging unit comprises the charging pile with eight output circuits, and the relay connected with the charging pile in series and the electric quantity measuring chip; and the communication controller is an LoRa internet of things base station. According to the charging using method for the charging pile system with the bluetooth interfaces, LoRa data transmission scheme is adopted, the LoRa internet of things base station is not only low in power consumption, but also wide in covering range, the problems of poor GPRS signals and ethernet wiring are avoided effectively, and the whole cost is lowered.

Owner:ZHEJIANG UNIV OF TECH

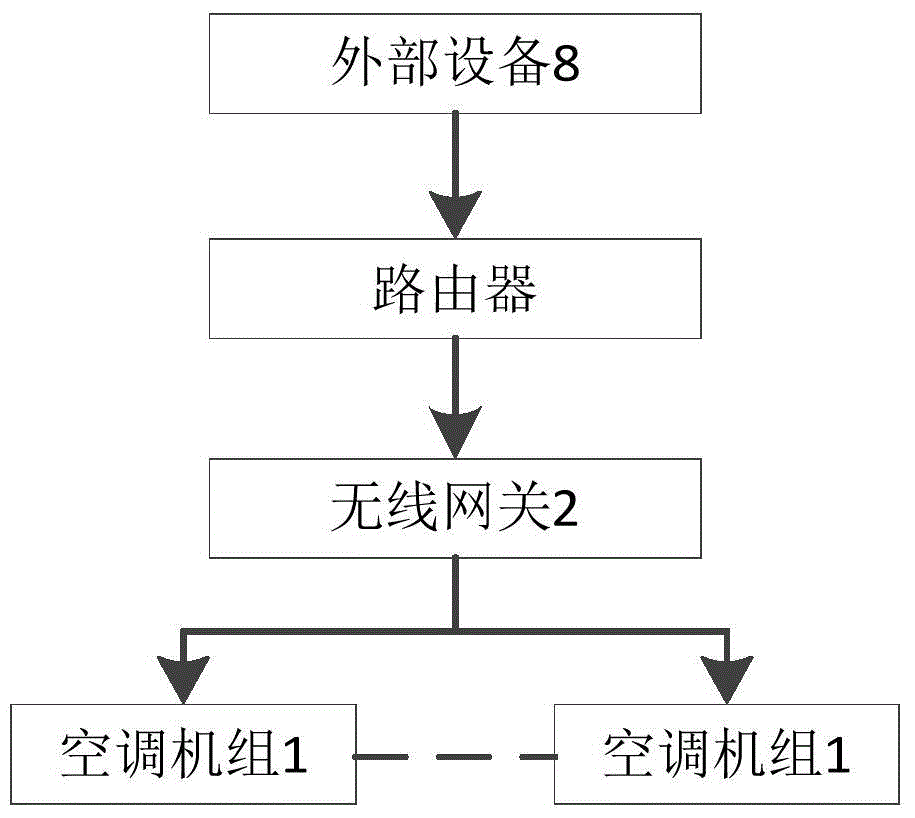

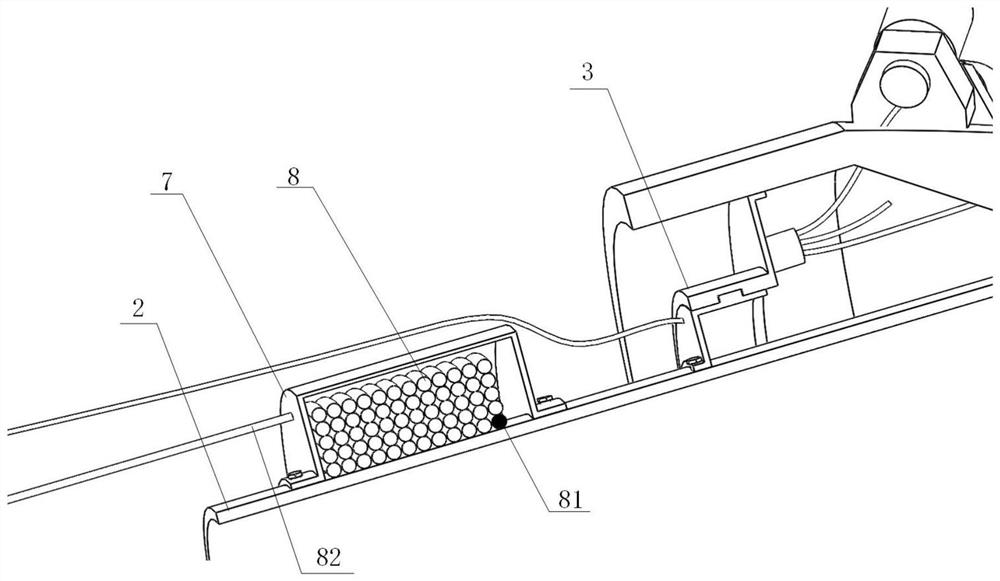

Air conditioning unit system and control method of air conditioning unit

InactiveCN105141671AEasy wiringDoes not spoil aestheticsNetwork topologiesTransmissionWired communicationRemote control

The invention discloses an air conditioning unit system and a control method of an air conditioning unit. The air conditioning unit system comprises multiple air conditioning units and a wireless gateway, wherein the wireless gateway is used for composing the multiple air conditioning units into a wireless local area network, so that the multiple air conditioning units communicate through the wireless local area network and / or the multiple air conditioning units are wirelessly connected with an external device through the wireless gateway. As the technical scheme is adopted, wire connection among air conditioners is simplified, the fussy wiring problem is avoided, manpower and material resources for wiring are saved, and the aesthetic sense of buildings also can be prevented from being destroyed; furthermore, as a wireless networking form is adopted, the aging problem of communication lines of wired communication does not exist, the maintaining difficulty of the air conditioning unit is reduced, and the remote control is realized conveniently.

Owner:GREE ELECTRIC APPLIANCES INC

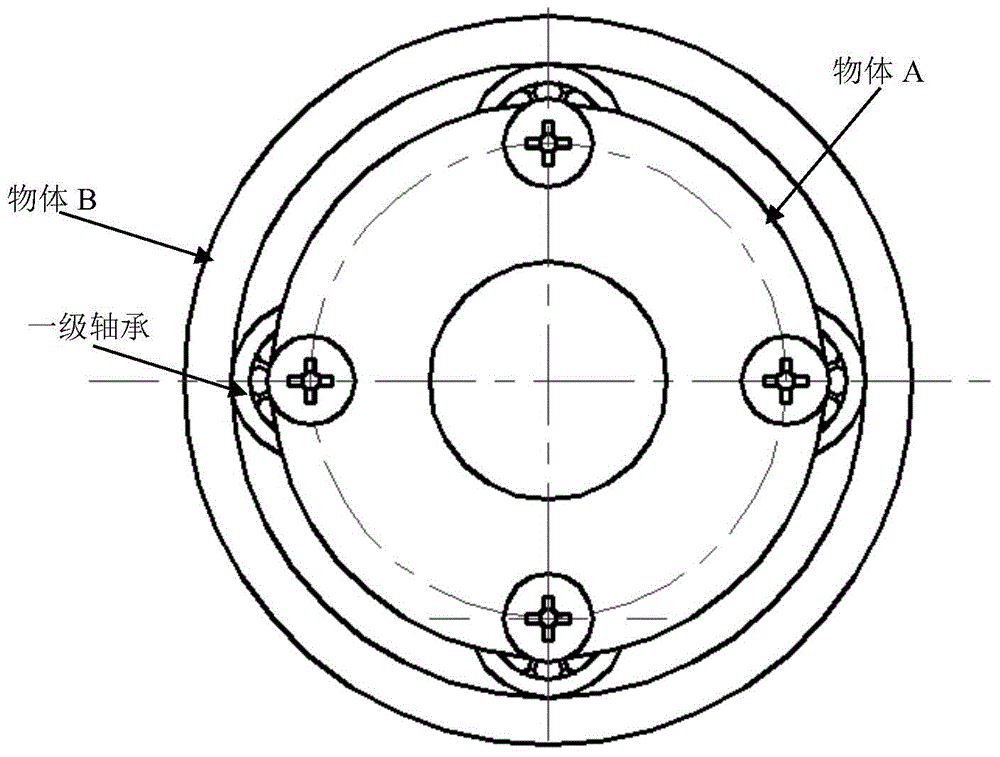

Force bearing device based on annularly-distributed multistage bearing

ActiveCN104454978AReduce volumeReduce weightRolling contact bearingsMechanical engineering technologyEngineering

The invention provides a force bearing device based on an annularly-distributed multistage bearing and belongs to the technical field of mechanical engineering. In the device, an M-class bearing comprises K (M-1)-class bearings and objects A' and B' which are connected with the M-class bearing and can rotate relative to each other, the object A' is taken as an inner ring of the M-class bearing, and the object B' is taken as an outer ring of the M-class bearing; the K (M-1)-class bearings are uniformly and annularly distributed between the outer ring and inner ring of the M-class bearing, the inner rings of the K (M-1)-class bearings are fixedly connected with the inner ring of the M-class bearing by virtue of studs, the outer rings of the K (M-1)-class bearings are contacted with the inside orbit of the outer ring of the M-class bearing, and K is an integer greater than 2, and M=2,3,.....N. By virtue of the force bearing device of the multistage bearing, the two objects which can rotate relative to each other are directly taken as the inner ring and the outer ring, the volume and weight of the whole force bearing device are greatly reduced, and the objects such as cables are distributed in the middle hollow part of the inner ring of the multistage bearing in a passing manner.

Owner:BEIJING KEYI TECH

Intelligent bolt monitoring system for fault detection of machine tool spindle transmission part

ActiveCN109333161AImprove operational efficiencyMonitor working statusMeasurement/indication equipmentsPattern perceptionMachine tool control

The invention discloses an intelligent bolt monitoring system for fault detection of a machine tool spindle transmission part. The intelligent bolt monitoring system includes a plurality of intelligent bolts installed in the key connection positions of the machine tool spindle transmission part, wireless transmission units, a signal receiving unit, a data processing unit, an alarm unit and a machine tool servo unit, wherein triaxial acceleration sensors for vibration signal acquisition are arranged in the intelligent bolts, and the wireless transmission units are arranged inside the intelligent bolts and send vibration signals; the signal receiving unit is located in a machine tool control system and used for receiving the vibration signals; the data processing unit is located in the machine tool control system, and calculates and analyzes the vibration signals; the alarm unit is electrically connected with the receiving data processing unit to issue an alarm; and the machine tool servo unit is electrically connected with the receiving data processing unit to control emergency shutdown of corresponding equipment. The intelligent bolt monitoring system for fault detection of the machine tool spindle transmission part has the following advantages and effects that the ubiquitous bolts on a machine tool are endowed with the perception function, the working status of the machine tool spindle transmission part can be effectively monitored, the quality of machined products is guaranteed to the maximum, the running efficiency of the machine tool is improved, and machine and personnel safety is guaranteed.

Owner:WENZHOU UNIVERSITY

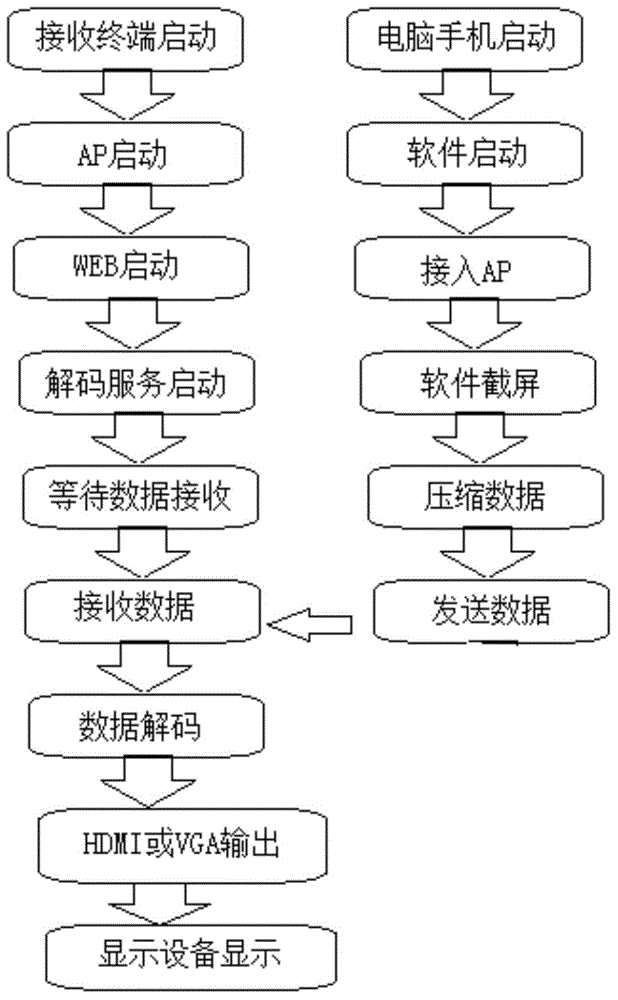

Wireless video transmission method

InactiveCN104618676ATroubleshoot Wiring ProblemsImprove experienceTelevision system detailsColor television detailsWeb serviceIp address

The invention discloses a wireless video transmission method. The wireless video transmission method includes following steps: 1) starting a receiving terminal, and starting an AP (access point) and a DHCP (dynamic host configuration protocol) service module of the receiving terminal and a decoder; 2) starting an upper computer, connecting the upper computer with the receiving terminal by connecting the upper computer into the AP of the receiving terminal through a WEB (world wide web) server, and obtaining an IP (internet protocol) address through the DHCP service module; 3) enabling upper computer software to start to capture a screen so as to obtain screen capturing data, transmitting coding data obtained by coding the screen capturing data to the receiving terminal, and generating data between the upper computer and the receiving terminal so as to obtain a data link; 4) decoding the coding data received by the receiving terminal through the decoder so as to obtain decoding data, and transmitting the decoding data to a display device through a HDMI (high definition multimedia interface) or a VGA (video graphics array) interface so as to display the decoding data. The wireless video transmission method sends a screen of a computer or a mobile phone to the receiving terminal through a wireless network in real time, converts the screen of the computer or the mobile phone into HDMI or VGA signals, transmits the HDMI or VGA signals to the display device for display, and thereby can effectively solve an HDMI or VGA wiring problem.

Owner:SHENZHEN MANYOUNG TECH

Mine tunneling robot environment monitoring device and method

ActiveCN112901159ATroubleshoot Wiring ProblemsEnables resistance measurementsTesting machinesSlitting machinesCurrent sensorEngineering

The invention discloses a mine tunneling robot environment monitoring device. The device is composed of a current excitation source, a telescopic protection cylinder, an electric rotating device, auxiliary cutting teeth, a cutting head entity, a transmission shaft, an optical fiber ring protection shell, an optical fiber ring, an optical fiber current sensor control unit and a recycling electrode. According to the device, auxiliary current Ie and monitoring current Id are emitted into the coal seam, the auxiliary current Ie extrudes the monitoring current Id due to the fact that the auxiliary current Ie and the monitoring current Id are homologous currents and are incompatible, and the monitoring current Id is gathered to conduct environment monitoring on the front coal seam. A part of current emitted by a cutting head entity flows into a coal seam as monitoring current Id, a part of current flows through a transmission shaft and a telescopic part of the heading machine as backflow current If, the backflow current If is measured by an optical fiber ring, when the heading machine advances forwards and encounters abnormal geologic bodies such as water inrush and mud inrush, namely, the resistance of the coal seam is changed, the measured backflow current If can change, and the monitoring current Id and the backflow current If are monitored. Therefore, the front geological condition can be detected in real time.

Owner:CHINA UNIV OF MINING & TECH

Flexible configurable vehicle access control system

InactiveCN109345647ATroubleshoot Wiring ProblemsReasonable and convenient access controlTicket-issuing apparatusRoad vehicles traffic controlControl areaControl system

The invention discloses an elastic configurable vehicle access control system, which comprises: a plurality of gates to be configured for performing vehicle access rules to control vehicle access; a control mechanism, which is respectively connected with the to-be-configured gate and the server, acquires the vehicle access rules of the server, configures the to-be-configured gates according to thevehicle entry and exit rules of the server, and converts the vehicle entry and exit rules into control signals for controlling the opening and closing of the gates to be configured; the server configures the vehicle access rules of the traffic control area to be configured in real time according to the real-time scene of the vehicle entering and exiting, and sends the vehicle access rules to thecontrol mechanism, performs the vehicle access rules to control the vehicle access by synchronously controlling the to-be-configured gates through the control mechanism. The system realizes the flexible setting of the gates of the parking lot, and solves the problem that the vehicle traveling efficiency of the parking lot in the prior art is difficult to solve in the peak time of the vehicle entering or exiting or in an emergency situation, and can also be applied to different parking lots.

Owner:苏州爱开客信息技术有限公司

Intelligent verification system of main transformer oil temperature and winding temperature controller

InactiveCN102654770AImplement smart checksConvenient pre-test maintenance and useElectric testing/monitoringElectric power systemData acquisition

The invention relates to an intelligent verification system of a main transformer oil temperature and winding temperature controller, relating to the technical field of verification of a temperature controller of a power supply system. The intelligent verification system comprises an industrial control main machine, data acquisition heads, standard temperature slots and tested temperature controllers; the USB interface of the industrial control main machine is expanded into at least four RS232 interfaces to be connected with at least four standard temperature slots, one end of a data acquisition head is connected with the industrial control main machine through one RS 232 interface, and the other end of the data acquisition head is connected with the tested temperature controller; a sensor of the tested temperature controller is inserted into a standard temperature slot; the industrial control main machine is internally provided with a low-power wireless data transmission module and can transmit field detection data to a background monitoring system in real time; and the intelligent verification system is provided with four independent running detection channels and can simultaneously detect four temperature controllers. Through the intelligent verification system of the main transformer oil temperature and winding temperature controller, disclosed by the invention, the intelligent verification of the temperature controller is realized, and the verification technical level and the detection efficiency of the temperature controller are improved.

Owner:CHENGDU POWER BUREAU +1

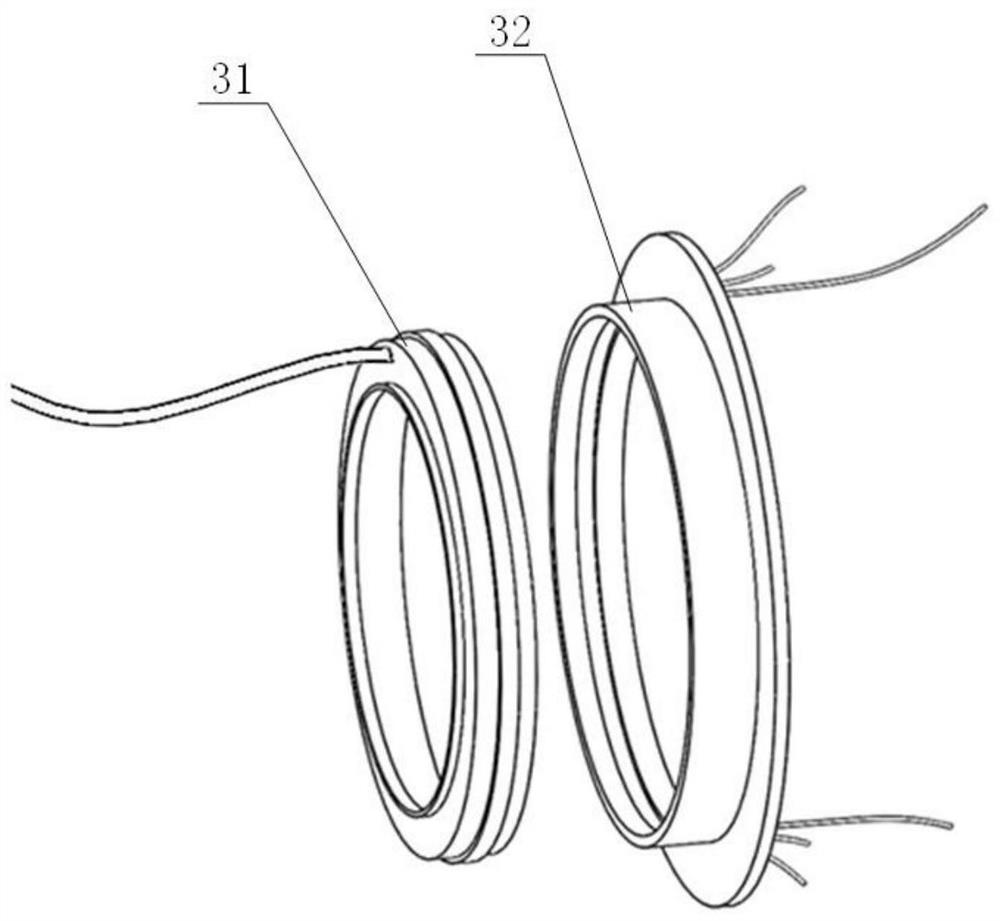

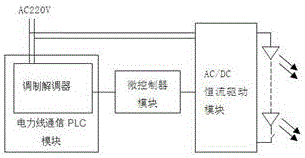

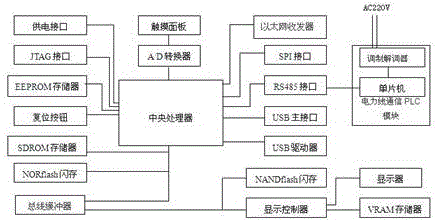

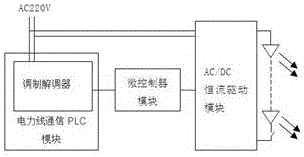

Multi-network integration remote-communication searchlighting system

InactiveCN106211428AProne to electromagnetic interferenceEasy to interceptPower distribution line transmissionElectroluminescent light sourcesSignal processing circuitsCarrier signal

The invention discloses a multi-network integration remote-communication searchlighting system. The multi-network integration remote-communication searchlighting system comprises a searchlighting system, an optical detector, a plurality of network appliances, a central processing unit, a receiving antenna, a signal processing circuit, a power supply circuit, and an LED lamp field-programmable gate array circuit, wherein the power supply circuit is connected with the central processing unit and the field-programmable gate array circuit separately; and a solar cell panel, a voltage-stabilizing circuit, a power supply controller and a direct current power supply circuit are arranged in the power supply circuit; the optical detector is used for converting network signals into LED optical signals; and the plurality of network appliances are provided with corresponding optical detection modules which are used for receiving the LED optical signals. A home network system based on visible light communication can simplify the communication light source wiring, and integrates a visible light communication technology and a power line carrier communication technology with an existing home network.

Owner:SUZHOU TIANQING ELECTRONICS COMM

Device for producing a product by means of injection molding, and method

The invention relates to a molding device (1) for producing a product (12) by means of injection molding. The molding device (1) comprises a central mold part (2), which can be rotated about a rotational axis (9) and which comprises at least one inner mold half (4a-4d) arranged on the central mold part (2), and at least one outer mold half (5a, 5b), which interacts with the inner mold half (4a-4d)in order to form cavities in a closed configuration of the molding device (1) and which is arranged in a movable manner relative to the inner mold half (4a-4d) in a first direction (x). Furthermore,at least one first connector element (8) arranged on the central mold part (2) and at least one second connector element (10) arranged on the outer mold half (10) are provided, said second connector element (10) being operatively connected to the first connector element (8) at least in a closed configuration of the molding device (1).

Owner:FOBOHA GERMANY

Intelligent fog and haze removing system based on multi-network fusion telecommunication

InactiveCN106179747AProne to electromagnetic interferenceEasy to interceptComputer controlElectric supply techniquesParticulatesSignal processing circuits

The invention discloses an intelligent fog and haze removing system based on multi-network fusion telecommunication. The intelligent fog and haze removing system comprises an intelligent street lamp, a light detector, a plurality of network appliances, a central processing unit, a receiving antenna, a signal processing circuit, a power circuit, and an LED lamp field programmable gate array circuit, wherein the power circuit is connected with both the central processing unit and the LED lamp field programmable gate array circuit; and a solar panel, a voltage stabilizing circuit, a power controller and a direct current power supply circuit are arranged in the power circuit. According to the intelligent fog and haze removing system, a lighting lamp is covered with transparent protecting covers and can be protected from damage; meanwhile, an atomizing structure is arranged below the lighting lamp, and water in a water tank can be pumped by a silent pump to the atomizing structure; after the pumped water is atomized and the atomized water is sprayed out, the air humidity can be increased; and meanwhile, solid particles in air can be adsorbed by utilizing the atomized water, so that coagulation and precipitation of the solid particles can be achieved, and the content of the solid particles can be effectively reduced.

Owner:SUZHOU TIANQING ELECTRONICS COMM

Vehicle entering and exiting cloud management system based on group policy

InactiveCN106981118ALow costAvoid training learningIndividual entry/exit registersWireless commuication servicesParking areaGroup Policy

The invention provides a vehicle entering and exiting cloud management system based on a group policy. The vehicle entering and exiting cloud management system comprises base stations and a server, wherein the base stations are connected with an entrance and exit passage gate for controlling the parking place, and are used for controlling to open and close the entrance and exit passage gate; each base station is equipped with a unique equipment identification code, and is in communication with the server in a wireless way; the server is in communication with the base stations to obtain information, the base stations are paired according to the equipment identification codes of the base stations, and an execution rule is set for the paired base stations, and is distributed to the corresponding base station. The vehicle entering and exiting cloud management system has the advantage by grouping the parking area, the centralized parking lot, the parking lot entrance and exit, and the base stations, the vehicle entrance and exit passage gate of the whole parking area is controlled, the cost is automatically settled for vehicle users, and the parking cost can be effectively managed.

Owner:苏州爱开客信息技术有限公司

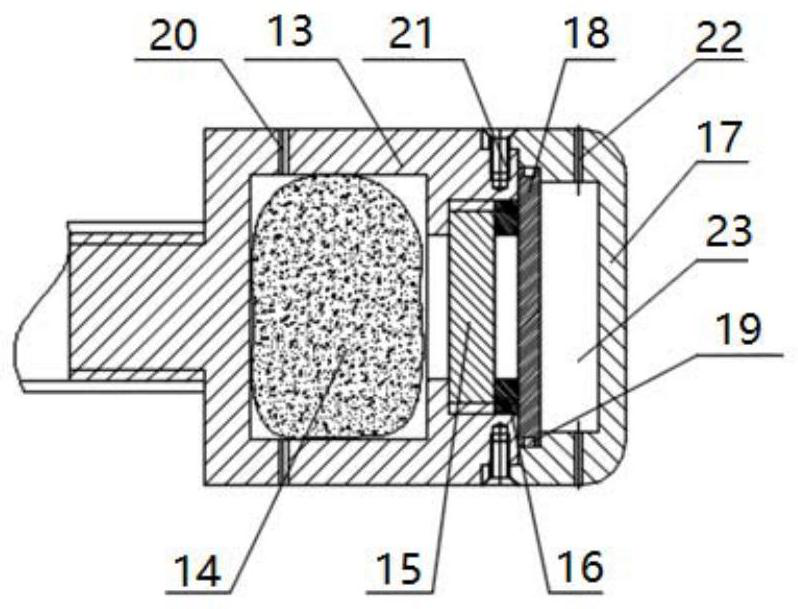

Ignition device suitable for end combustion grain and assembling method

The invention discloses an ignition device suitable for an end combustion grain and an assembling method, and belongs to a solid rocket engine technology. The device comprises an ignition powder box (1), an ignition wire (2), a covering sleeve (3), the grain (4) and a top cover (5), after the grain (4) is glued to the ignition power box (1), the ignition power box (1) is taken as the head of the ignition device; the covering sleeve (3) covers the grain (4), after the top cover (5) is glued to the covering sleeve (3), the top cover (5) is taken as the tail of the ignition device; a groove is formed in the outer surface of the covering sleeve (3), and the ignition wire (2) is installed in the groove; and a through hole is formed in the top cover (5), one end of the ignition lead (2) is connected with the ignition powder box (1), and the other end of the ignition wire (2) penetrates out through a through hole in the top cover (5).

Owner:SHANGHAI XINLI POWER EQUIP RES INST

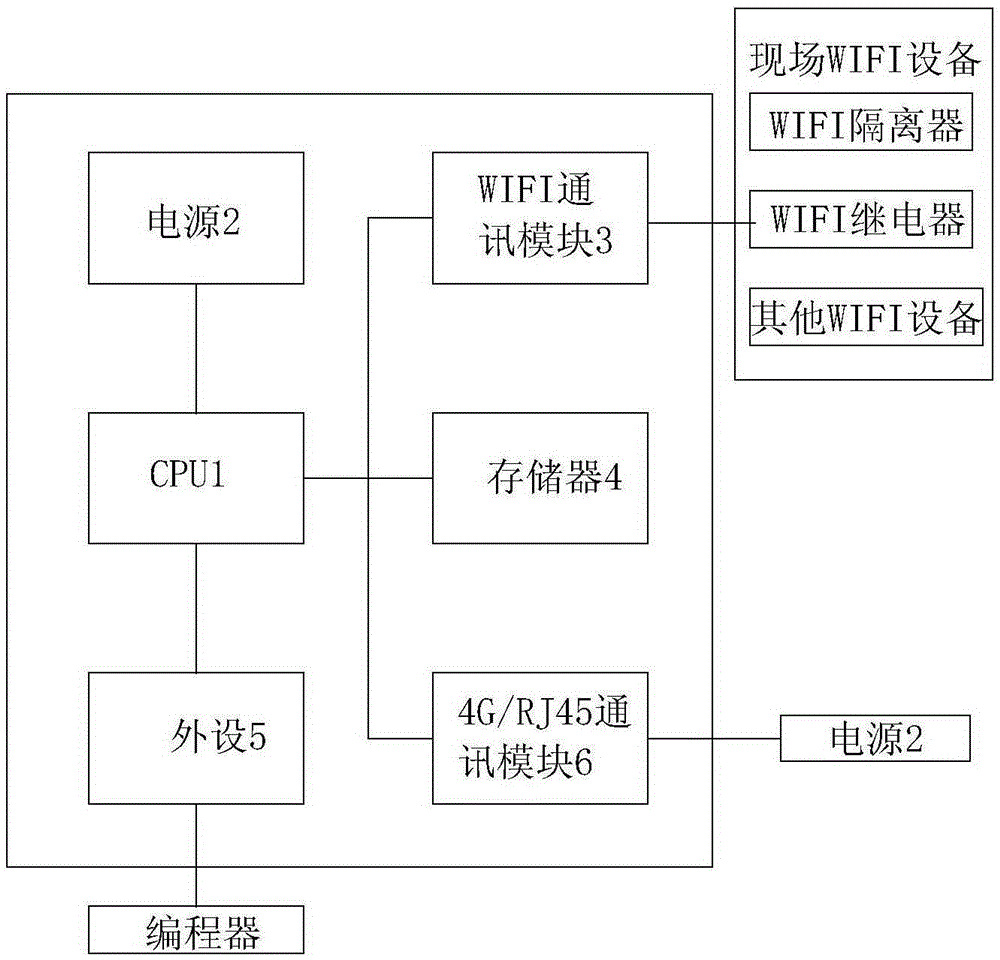

WIFI data acquisition module for cloud service automation

InactiveCN105261170ASatisfy data operationMeet logic controlTransmission systemsTransmissionData acquisitionComputer module

The invention discloses a WIFI data acquisition module for cloud service automation and relates to the technical field of electronic information. The WIFI data acquisition module comprises a CPU, a power supply, a WIFI communication module, a memory, peripheral equipment and a 4G / RJ45 communication module, the power supply is connected to the CPU, the CPU is connected to the peripheral equipment, and the CPU is respectively connected to the WIFI communication module, the memory and the 4G / RJ45 communication module by buses. The WIFI data acquisition module solves the problem of high wiring complexity, simplifies a system maintenance process, is compatible with an old system and realizes cloud service automation.

Owner:宝惠自动化科技(上海)有限公司

Solar intelligent louver

PendingCN110424877AChange statusRealize power generationLight protection screensSpecial door/window arrangementsMotor driveEngineering

The invention discloses a solar intelligent louver. The solar intelligent louver comprises a frame, and a plurality of parallel and linked fan blades arranged in the frame. The solar intelligent louver is characterized in that a control unit, an energy storage module, a motor driving module and a stepping motor are further arranged on the frame, an output shaft of the stepping motor is connected with a rotary shaft of the fan blades, and the stepping motor is used for driving the fan blades to rotate; the control unit is connected with the stepping motor through the motor driving module, and used for controlling the stepping motor to work, and the energy storage module is connected with the control unit and the stepping motor and supplies power to the control unit and the stepping motor; and the fan blades are solar battery pieces, and connected with the energy storage module. According to the solar intelligent louver, on the basis of guaranteeing a shading function, a rain blocking function and the like, power generation is achieved, external power supply is not needed, and the problem of wiring caused by external power supply is avoided. Meanwhile, due to the fact that linkage design is adopted by connection of all the fan blades, the fan blades at the top end are changed through the rotating angle of the stepping motor, and the state and angle of the whole louver can be changed.

Owner:FOSHAN POLYTECHNIC

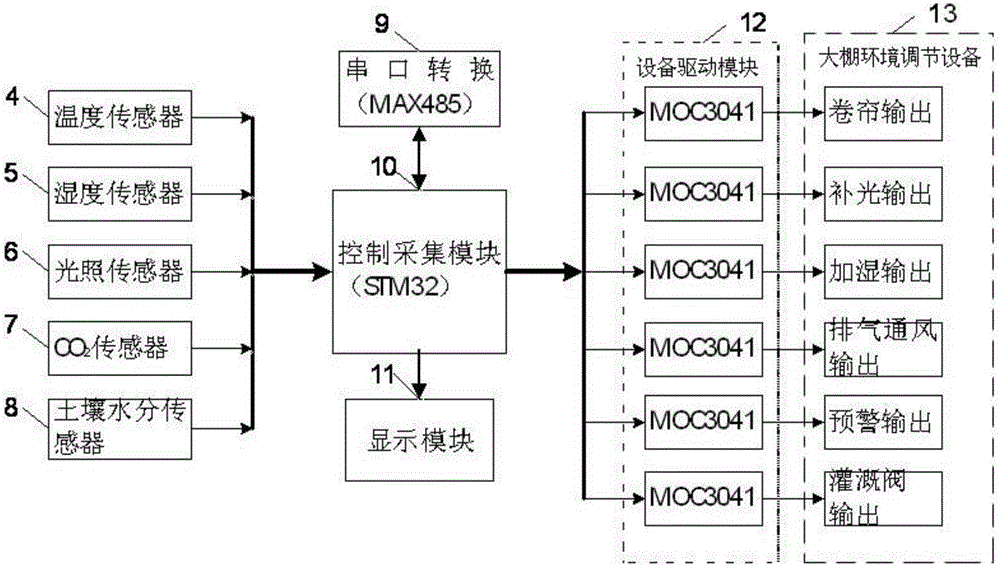

Environmental monitoring system for facility strawberry cultivation

InactiveCN106527550ATroubleshoot Wiring ProblemsImprove reliabilitySimultaneous control of multiple variablesMonitoring dataEngineering

The invention discloses an environmental monitoring system for facility strawberry cultivation. The environment monitoring system includes a monitoring center, a GPRS communication module and a plurality of facility strawberry environmental parameter acquisition and control nodes, each facility greenhouse for strawberry cultivation is internally provided with the facility strawberry environmental parameter acquisition and control nodes providing environmental monitoring services, the facility strawberry environmental parameter acquisition and control nodes transmit monitoring data to a monitoring center through the GPRS communication module, and the monitoring center sends control instructions to the facility strawberry environmental parameter acquisition and control nodes according to the monitoring data. The environmental monitoring system for facility strawberry cultivation provided by the invention adopts a node facility concept and applies a GPRS communication technology to directly send environmental data to a Web side, thereby avoiding the complicated wiring problem, and adopts a control system combining field control with remote Web control, thereby improving reliability and stability of the system.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Industrial Internet of Things data acquisition and transmission device

InactiveCN113473263ATroubleshoot Wiring ProblemsEasy data collectionAntenna supports/mountingsParticular environment based servicesTelecommunicationsAcquisition apparatus

The invention relates to the technical field of industrial Internet of Things data, in particular to an industrial Internet of Things data acquisition and transmission device. The equipment comprises transmission control equipment, acquisition equipment and control equipment, a partition plate II is mounted in the transmission control equipment through a bolt; a controller is mounted at the top of the partition plate II through a bolt; a third partition plate is installed in the transmission control equipment through bolts, a circuit board is installed at the top of the third partition plate through bolts, a main control chip is welded to the top of the circuit board, and a first wireless communication chip is welded to the top of the circuit board. The beneficial effect of the invention is that the wireless communication connection is adopted to avoid the wiring problem between the transmission control device and the acquisition device. The device can transmit data acquired by the industrial Internet of Things, Internet of Things data acquisition and transmission can be conveniently carried out on industrial control equipment, and Internet of Things data acquisition and transmission can be comprehensively carried out on the industry. Therefore, the communication stability of data acquisition and transmission of the industrial Internet of Things is improved.

Owner:深圳市玄羽科技有限公司

Wireless command guidance rocket projectile for 40mm rocket tube

PendingCN111981917ASolve the problem of anti-high chamber pressureTroubleshoot Wiring ProblemsSelf-propelled projectilesGuidance controlControl system

The invention provides a wireless command guidance rocket projectile for a 40mm rocket tube. An execution mechanism, a wireless command receiving device, an on-projectile control module and a beacon module are additionally arranged, and peripheral equipment is a ground launching control device; the execution mechanism is arranged in a nose fairing of a rocket projectile, the beacon module is arranged at the tail of the rocket projectile, an uncontrolled counterweight beacon or a controlled infrared beacon is adopted, and a universal mechanical interface is arranged on the beacon module and iscapable of being switched between the two beacons; in the uncontrolled mode, the uncontrolled counterweight beacon works, and a guidance control system on the rocket projectile does not work and fliesin an uncontrolled manner; and in the controlled mode, the controlled infrared beacon works and infrared signals are emitted, the wireless command receiving device is in wireless communication with the on-projectile control module, the on-projectile control module forms a control command to be transmitted to the execution mechanism, and the rocket projectile is controlled to fly until a target isdestroyed. According to the wireless command guidance rocket projectile for the 40mm rocket tube, not only the hit precision of near-range engagement is guaranteed, but also the firepower hitting range of the 40mm rocket tube on static and moving targets is greatly improved.

Owner:北京恒星箭翔科技有限公司

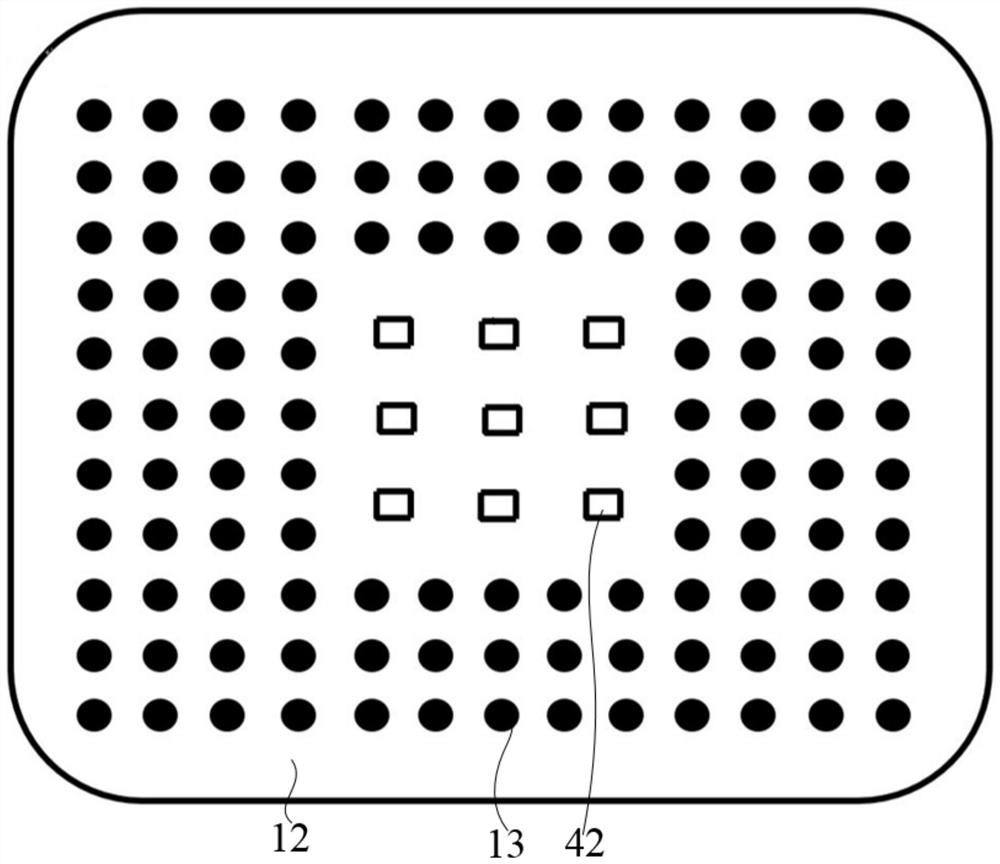

Circuit board-based multi-leaf collimator motor lead fixing structure

ActiveCN105703526AImprove detection accuracyImprove control stabilitySupports/enclosures/casingsMulti leaf collimatorEngineering

The invention relates to a circuit board-based multi-leaf collimator motor lead fixing structure, which belongs to the technical field of mechanical structure design. The multi-leaf collimator motor lead structure adopts two fixed circuit boards; each fixed circuit board comprises a lead fixing hole, a rotor reservation hole and a lead pad arranged on the fixed circuit board, a Hall signal conversion circuit, a peripheral cable interface and a fixing mounting hole arranged on the circuit board and a connection lead; the two fixed circuit boards are vertically fixed at two ends of a rack respectively, and each micro DC motor rotor, a motor power lead and a motor signal output lead tail end are respectively welded on the lead pad on the periphery of the lead fixing hole; and the fixed circuit board is fixed behind a motor frame via the fixing mounting hole, and after the motor power lead and the signal output lead are connected to the Hall signal conversion circuit via the connection lead of the circuit board, the leads are then connected onto the peripheral cable interface. The structure of the invention improves the anti-interference performance of the sensor signal and the sensor precision.

Owner:江苏高同装备有限公司

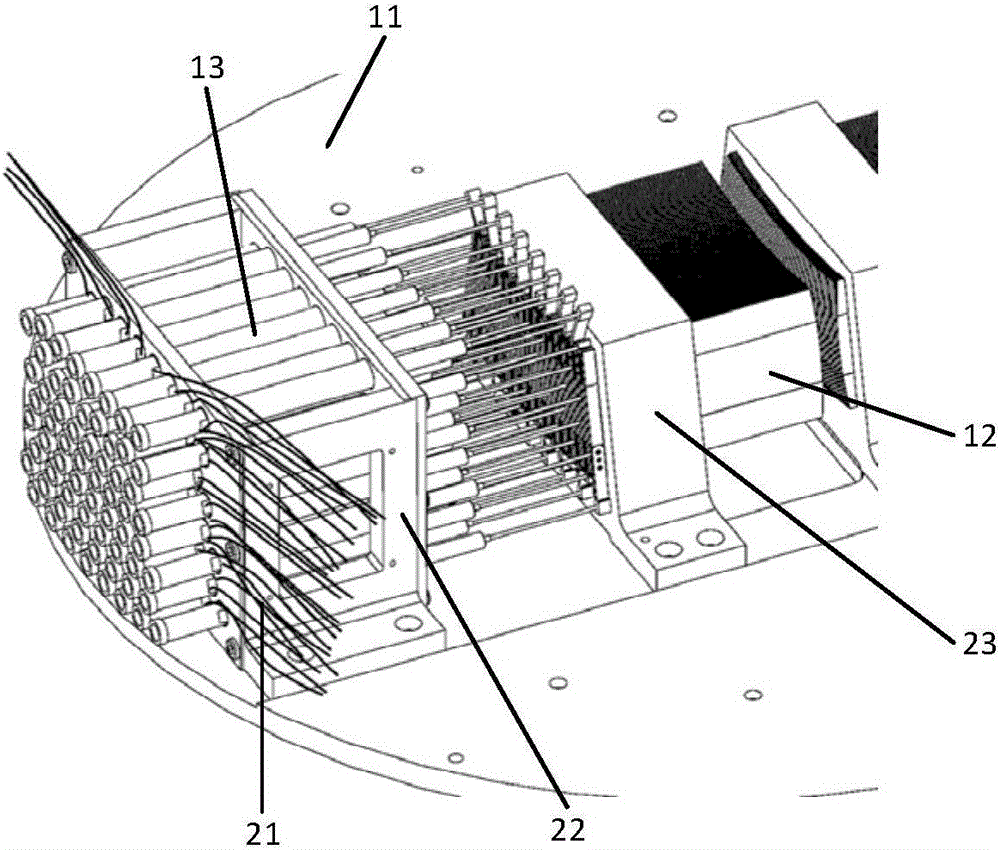

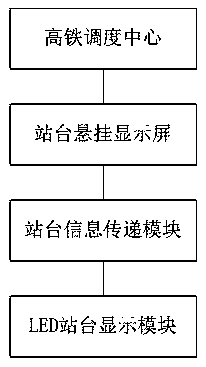

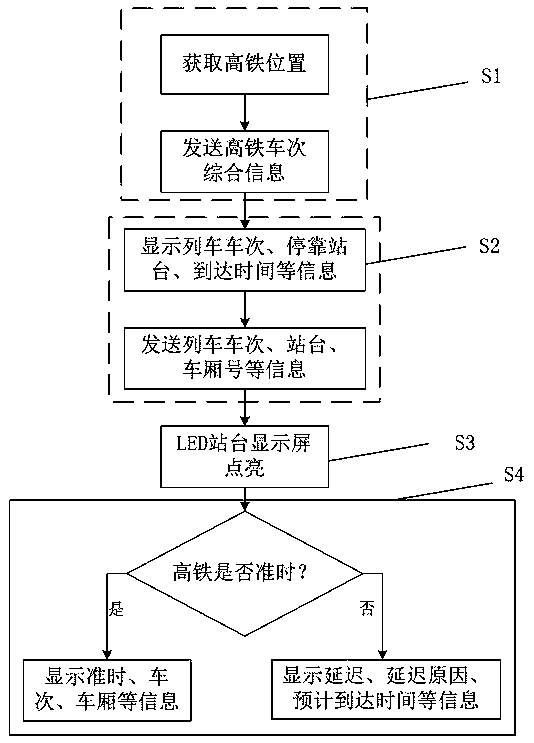

High-speed rail station LED electronic indication system device and guidance method thereof

InactiveCN111294727ATroubleshoot platform wiring issuesConvenient guidance serviceParticular environment based servicesRailway componentsAutomotive engineeringReal-time computing

The invention relates to the technical field of traffic guidance, in particular to a high-speed rail station LED electronic indication system device and a guidance method thereof, and the high-speed rail station LED electronic indication system device comprises a high-speed rail dispatching center, a station suspension display screen, a station information transmission module and an LED station display module. The high-speed rail dispatching center obtains the position of the high-speed rail through positioning, and when the distance between the position of the dispatching center and the position of the high-speed rail is smaller than a certain distance or the high-speed rail decelerates to a certain speed, the dispatching center sends high-speed rail train number comprehensive informationto the platform suspension display screen; the platform suspension display screen displays the information such as the train number, the stop platform and the arrival time acquired from the dispatching center; information on the platform hanging display screen is integrated into data which is transmitted to the LED platform display module by the platform information transmission module; and the LED platform display module displays information such as the number of high-speed trains and the number of carriages.

Owner:JIANGSU UNIV OF SCI & TECH

Real-time humidity monitoring and alarming device for terminal box

PendingCN107909776AReduce construction costsEasy maintenanceTransmission systemsMaterial analysis by electric/magnetic meansAnalog to digital conversionEngineering

The invention discloses a real-time humidity monitoring and alarming device for a terminal box. The real-time humidity monitoring and alarming device comprises at least one sensor capable of sensing an external humidity value, an analog-to-digital conversion module connected with the sensor, a control system connected with the analog-to-digital conversion module, a display module connected with the control system, a display connected to the display module, and a wireless transmission module connected to the control system. The real-time humidity monitoring and alarming device uses the humiditysensor to monitor the humidity inside the terminal box in real time and connect the humidity sensor with a host computer through a wireless network. A worker can know the humidity value in the terminal box in a machine room. When the humidity increases, the real-time humidity monitoring and alarming device can promptly send an abnormal signal to the host computer in order to ask a maintainer to perform inspection and maintenance, thereby shortening a maintenance interval and improving efficiency.

Owner:STATE GRID HEBEI ELECTRIC POWER CO LTD

Chip and mainboard

PendingCN112382624AHighly integratedReduce areaDigital data processing detailsSemiconductor/solid-state device detailsEmbedded systemPrinted circuit board

The invention provides a chip and a mainboard. The chip comprises a packaging substrate with a first surface and a second surface which are opposite to each other, and at least one memory bare chip arranged on the first surface of the packaging substrate. The first surface of the packaging substrate is provided with a central processing unit bare chip, and the central processing unit bare chip iselectrically connected with each memory bare chip in the at least one memory bare chip so as to write data into each memory bare chip or read data from each memory bare chip. The second surface of thepackaging substrate is provided with pins used for being electrically connected with the printed circuit board, and the central processor bare chip is further electrically connected with the pins onthe second surface. The central processing unit bare chip and the at least one memory bare chip are packaged on the packaging substrate, and each memory bare chip is electrically connected with the central processing unit bare chip, so that the central processing unit bare chip and the memory bare chip on the packaging substrate can work, the integration degree of the chip and the mainboard is improved. The area of a printed circuit board of a mainboard can be reduced, system design is simplified, and system reliability is improved.

Owner:HYGON INFORMATION TECH CO LTD

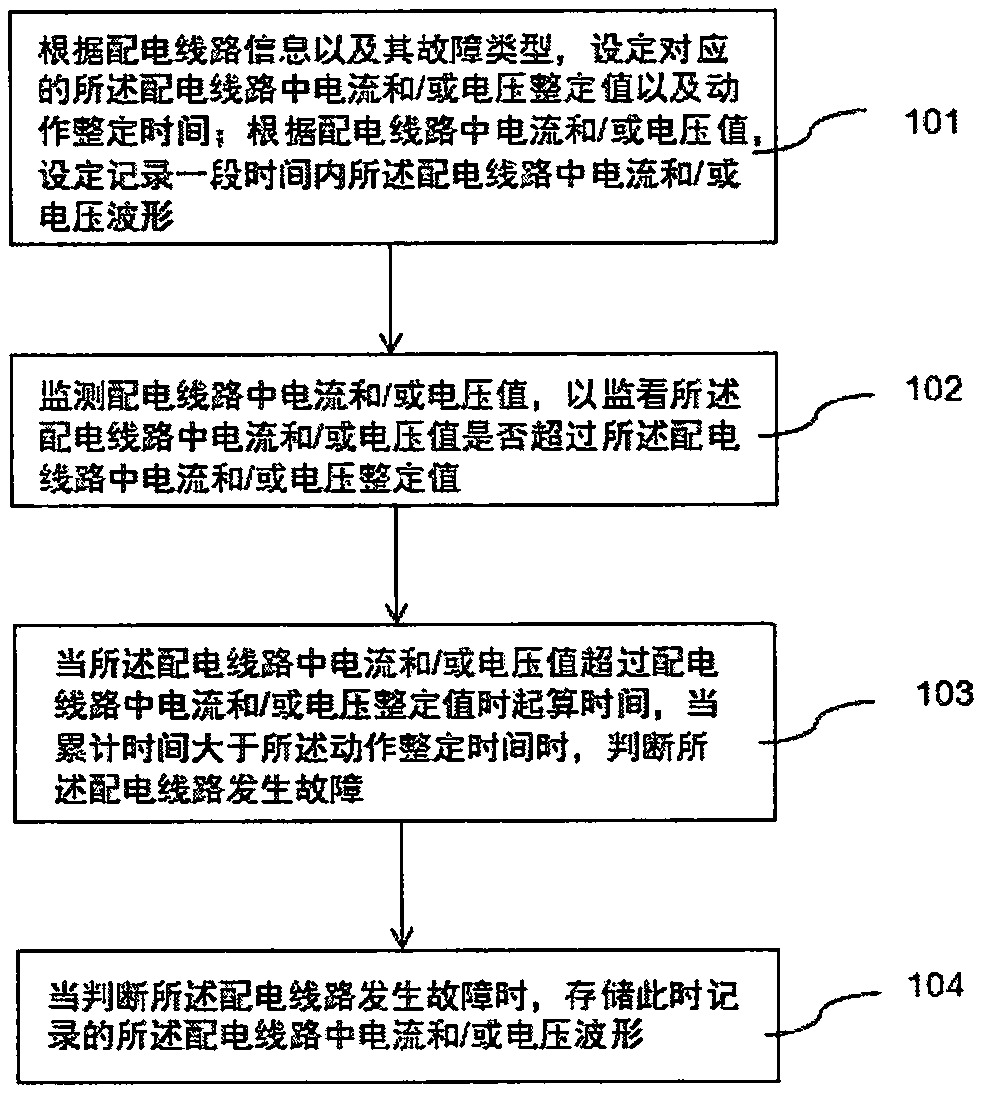

Fault recording method and system of power distribution line

PendingCN110412416ATroubleshoot wiring problemsReduce security risksFault location by conductor typesEngineeringSetting time

The invention provides a fault recording method and system of a power distribution line. The method comprises that corresponding current and / or voltage setting values and action setting time in the power distribution line are set according to power distribution line information and a fault type thereof; a waveform for recording the current and / or voltage of the power distribution line in a periodis set according to current and / or voltage values; the current and / or voltage values in the power distribution line are monitored to monitor that whether the current and / or voltage values exceed the current and / or voltage setting values; timing is carried out the moment that the current and / or voltage values exceed the current and / or voltage setting values, and it is determined that a fault occursin the power distribution line when accumulated time is greater than the motion setting time; and when it is determined that the fault occurs in the power distribution line, the recorded current and / or voltage waveform in the power distribution line is stored.

Owner:天津市中力神盾电子科技有限公司

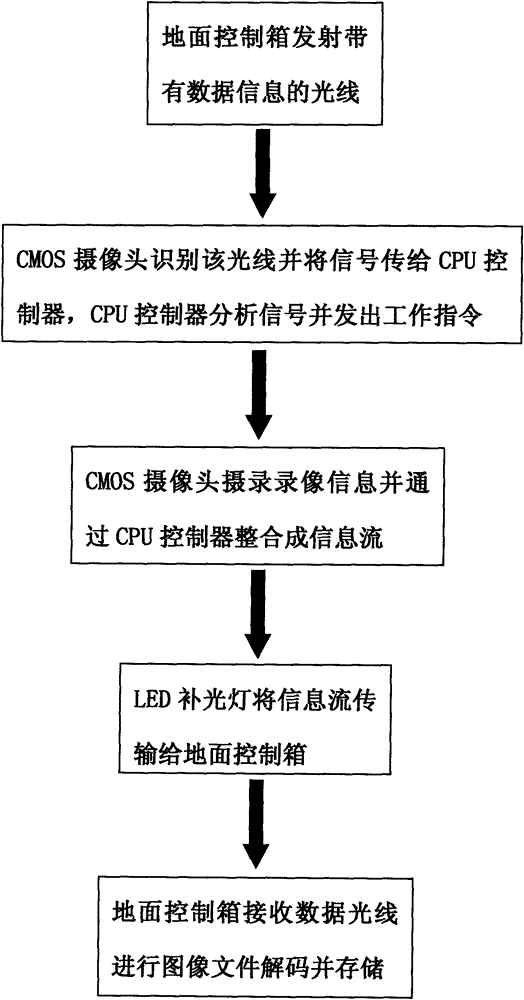

Novel vidicon system based on LED light-compensating lamp

InactiveCN104469175AEliminate the transfer stepTroubleshoot Wiring ProblemsTelevision system detailsColor television detailsCable transmissionData information

The invention relates to a novel vidicon system based on an LED light-compensating lamp. The system comprises a ground control box and a vidicon, wherein the ground control box is used for emitting light rays with data information to the vidicon and receiving the light rays sent by the vidicon for image file decoding and storage; the vidicon further comprises a rear-end control device, a transmission device and a front-end photo and video device. A CPU controller integrates the video recording information to information flows and transmits the information flows to the ground control box through the LED light-compensating lamp, the new technology is fused for function expansion of internal components, the cable transmission step is omitted, the cost is lowered, the working efficiency is improved, wiring of a monitoring photo and video vidicon at night is achieved, and the novel vidicon system based on the LED light-compensating lamp is suitable for multiple cameras for control and data transmission and suitable for large-scale popularization.

Owner:NINGBO HUMMINGBIRD OPTOELECTRONICS

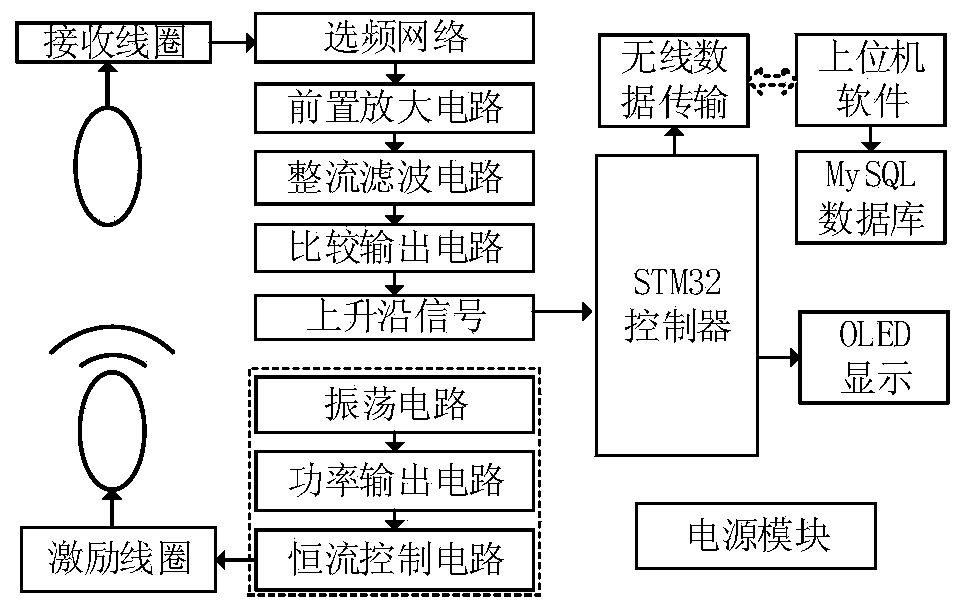

Pipeline vehicle instantaneous velocity measurement system based on electromagnetic method

InactiveCN110068701ASolve the speed deficiencyImprove accuracyDevices using time traversedComputer moduleElectromagnetic shielding

The invention provides a pipeline vehicle instantaneous velocity measurement system based on an electromagnetic method. The system comprises an exciting coil located on the pipeline, and a pair of detection coils, a core controller, an electromagnetic signal production circuit, an electromagnetic signal receiving conditioning circuit, a wireless data transmission module and a PC processing end which are arranged on the pipeline vehicle; the electromagnetic signal production circuit can produce AC with an constant effective value, so that the exciting coil can produce changed electromagnetic signals; the detection coil receives the electromagnetic signals and transmits the electromagnetic signals to the conditioning circuit, and then transmits to the core controller; the core controller performs computation according to the time difference of receiving two electromagnetic signals so as to obtain the pipeline vehicle instantaneous velocity data; the pipeline vehicle instantaneous velocity data is transmitted to the PC processing end to store through a wireless data transmission module. The defect that the photoelectric method cannot measure the pipeline vehicle velocity in a non-transparent pipeline is solved, and the measurement system can be used as a mature pipeline vehicle instantaneous velocity measurement system to be popularized and applied.

Owner:TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com