Circuit board-based multi-leaf collimator motor lead fixing structure

A multi-leaf collimator and circuit board technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of accuracy and reliability affecting motor movement, poor wiring workmanship, signal interference, etc., and improve detection accuracy. and control stability, structural design and circuit design optimization, and the effect of improving accuracy and anti-interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] A circuit board-based multi-leaf collimator motor lead wire fixing structure designed by the present invention is further described in conjunction with the accompanying drawings and embodiments as follows:

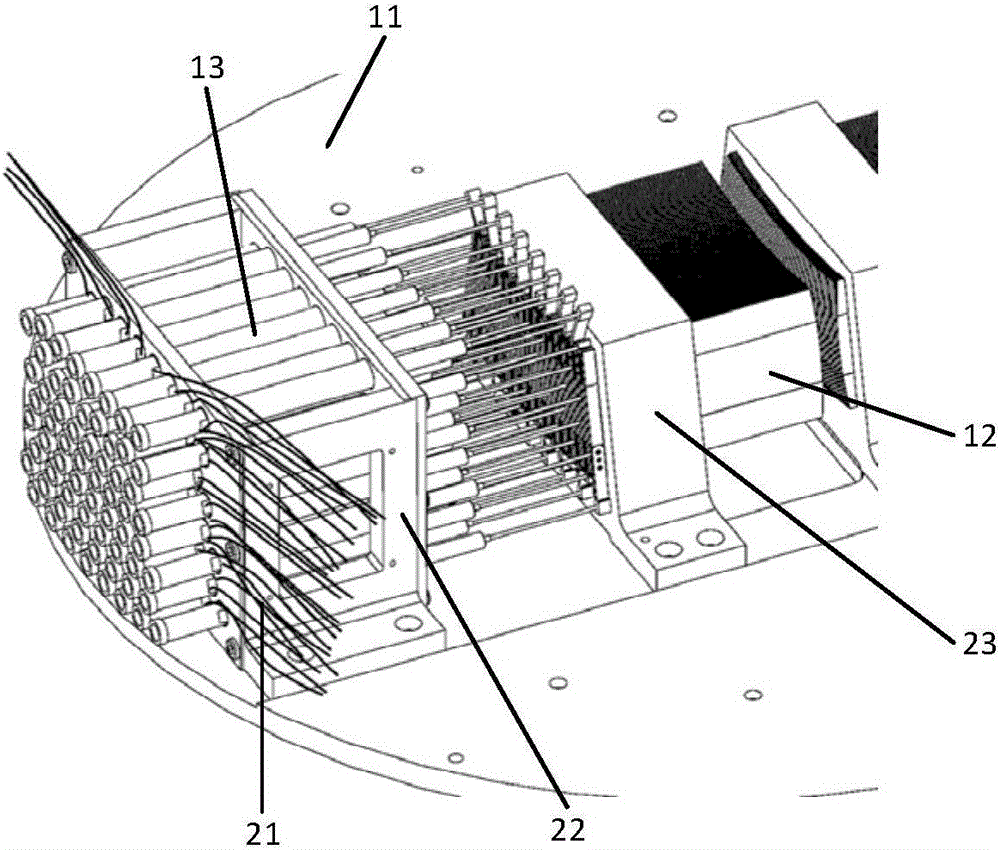

[0032] The circuit board-based multi-leaf collimator motor lead wire fixing structure of the present invention is as follows Figure 4 As shown, wherein the multi-leaf collimator has the same structure as the traditional multi-leaf collimator, including a frame 11, a tungsten alloy blade assembly 12 installed on the frame, and a driving micro-motor array 13 connected with the tungsten alloy blade group 12, Motor array support 22; The lead wire 21 of every miniature motor (as figure 2 shown) and lead structure. The difference lies in that the motor lead wire structure of the present invention is different from that of the traditional multi-leaf collimator motor lead wire structure. The motor lead wire structure of the multi-leaf collimator of the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com