Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

65results about How to "The structure is simplified and reasonable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

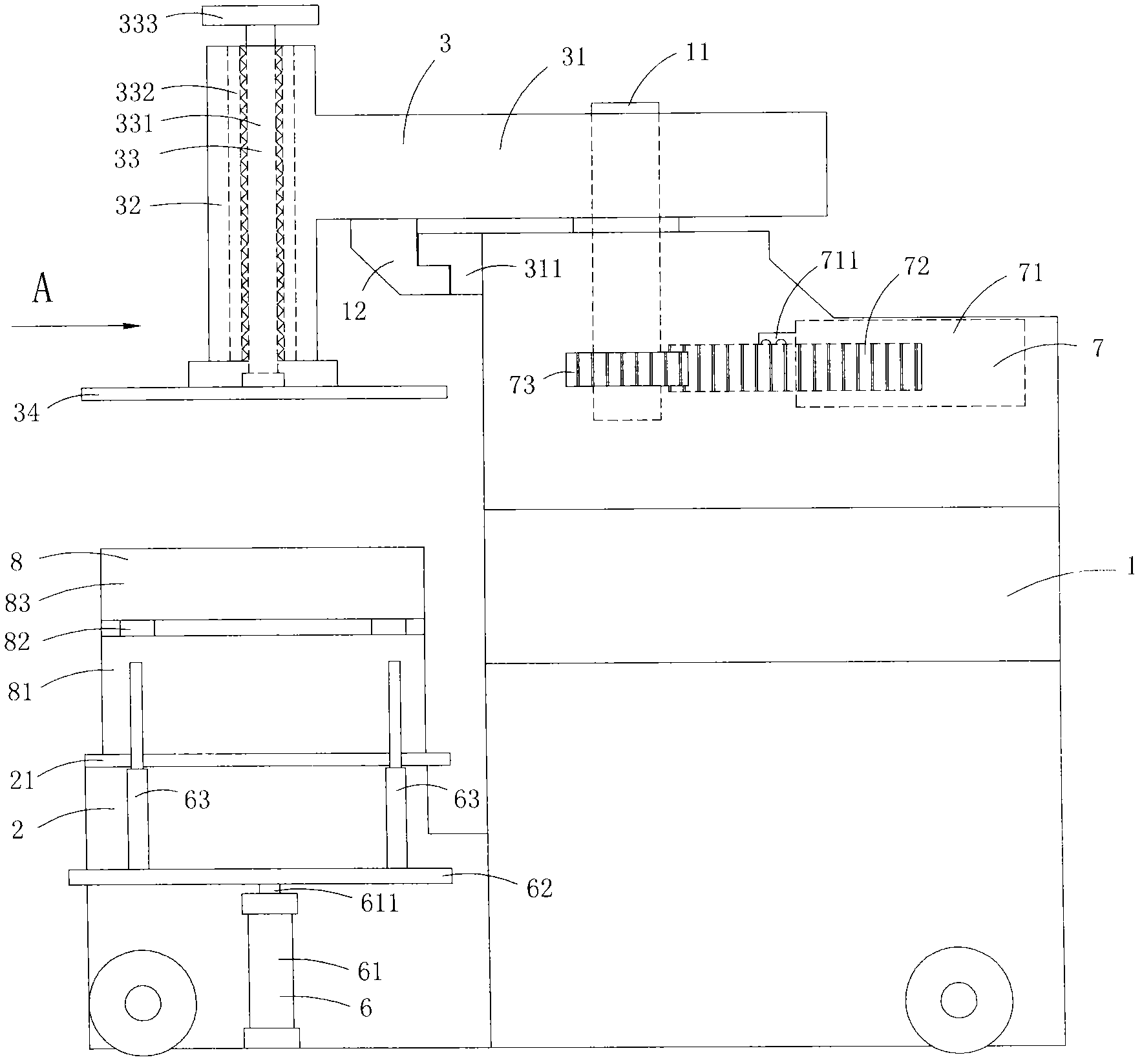

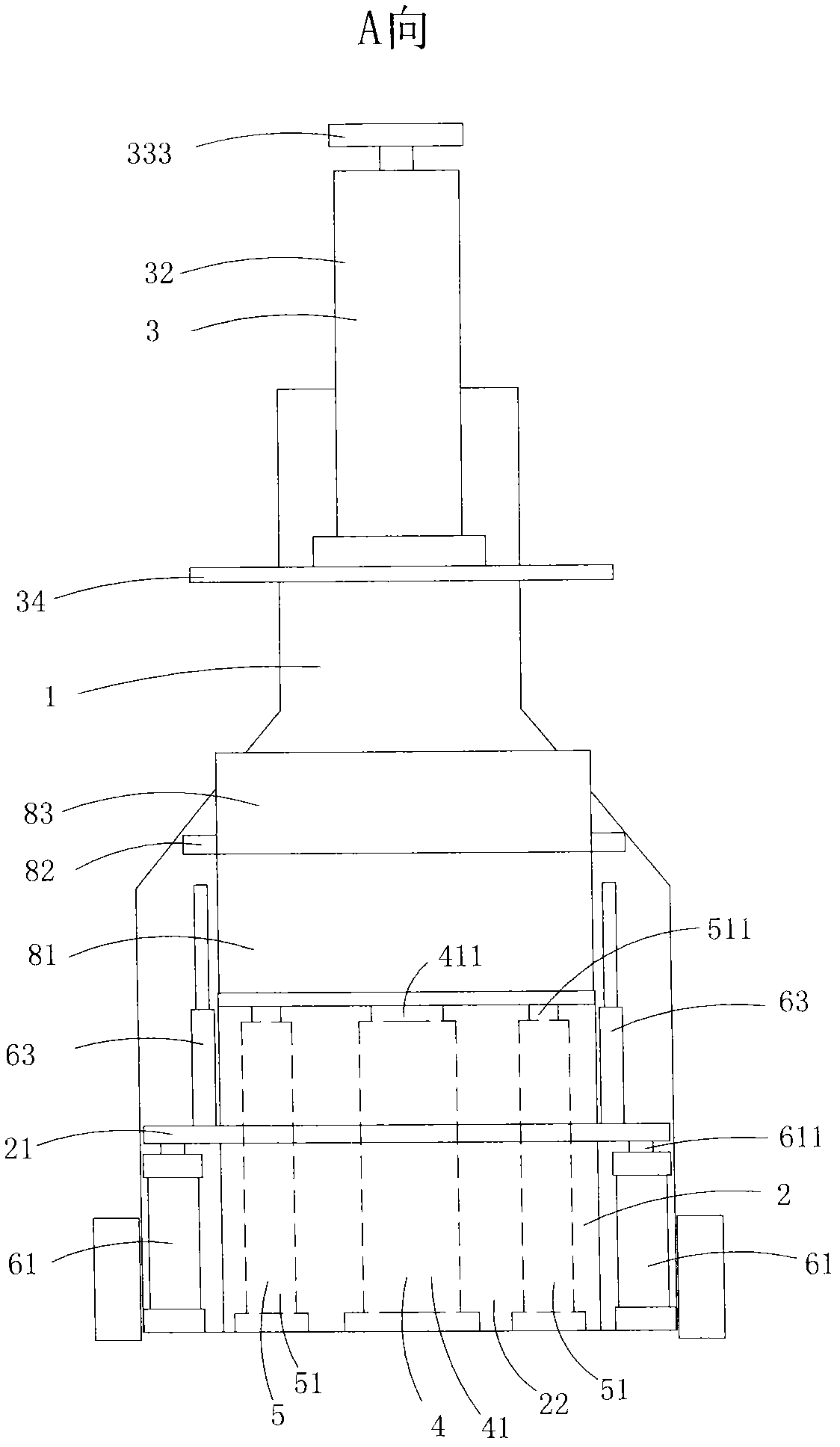

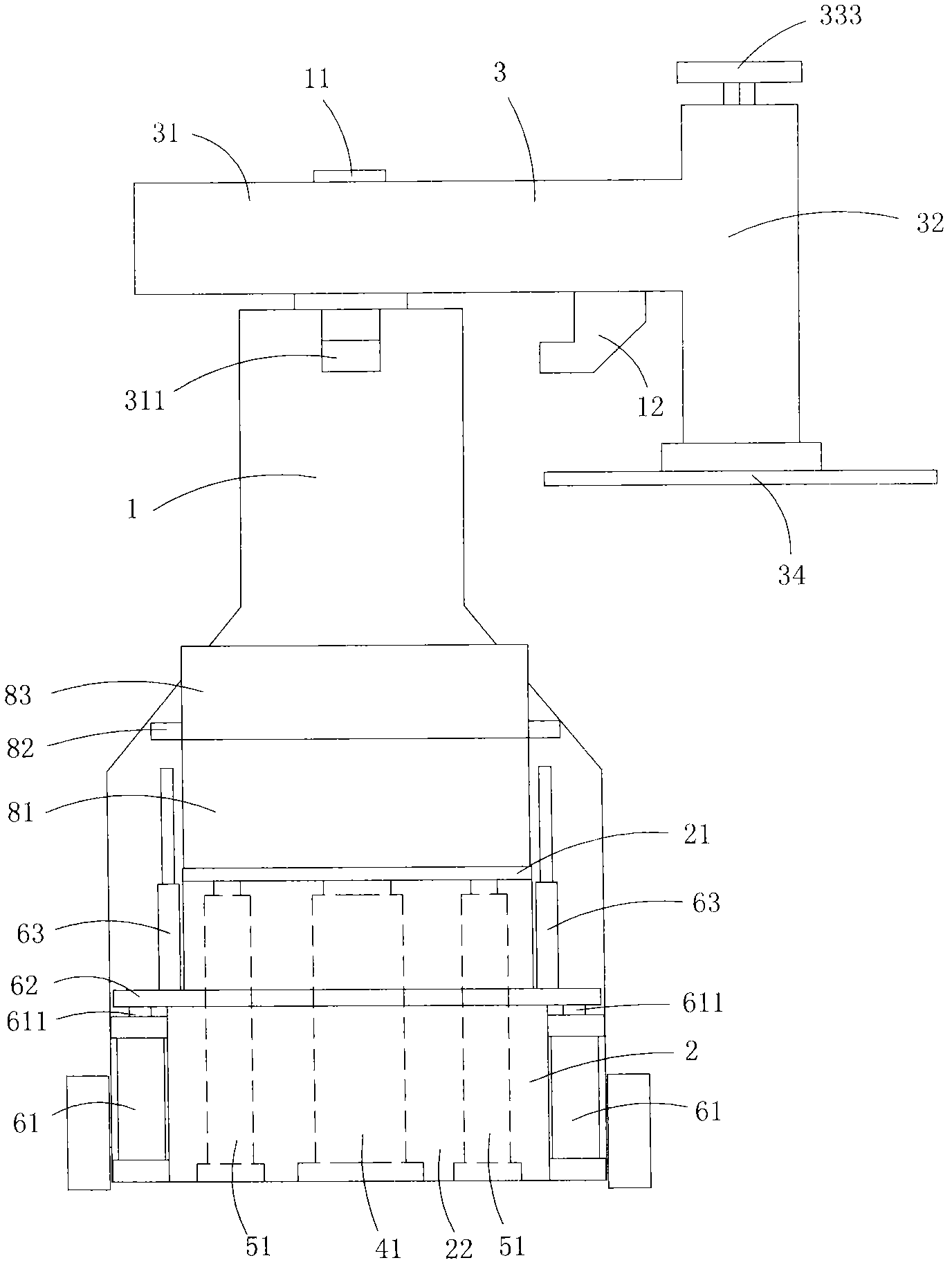

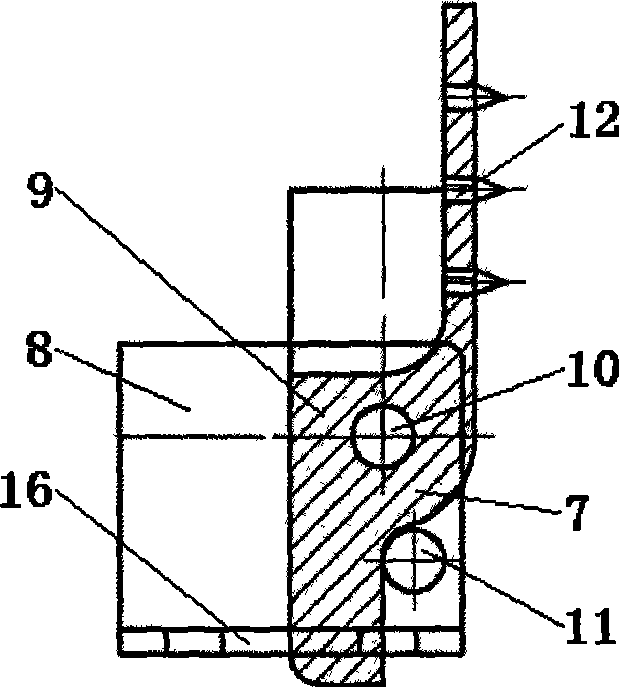

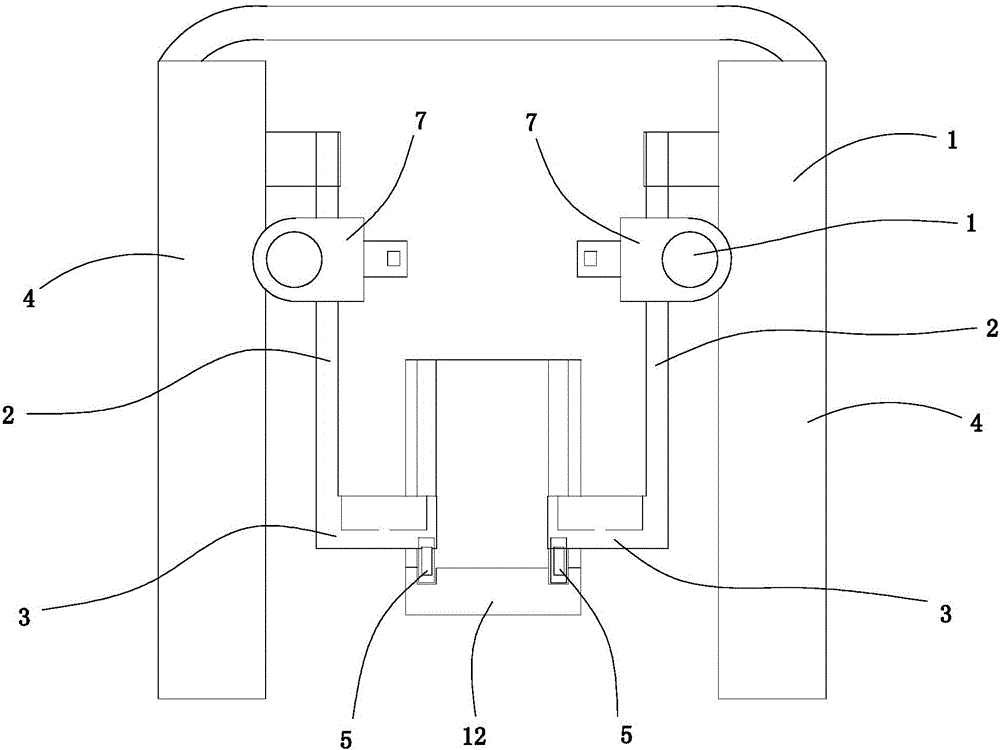

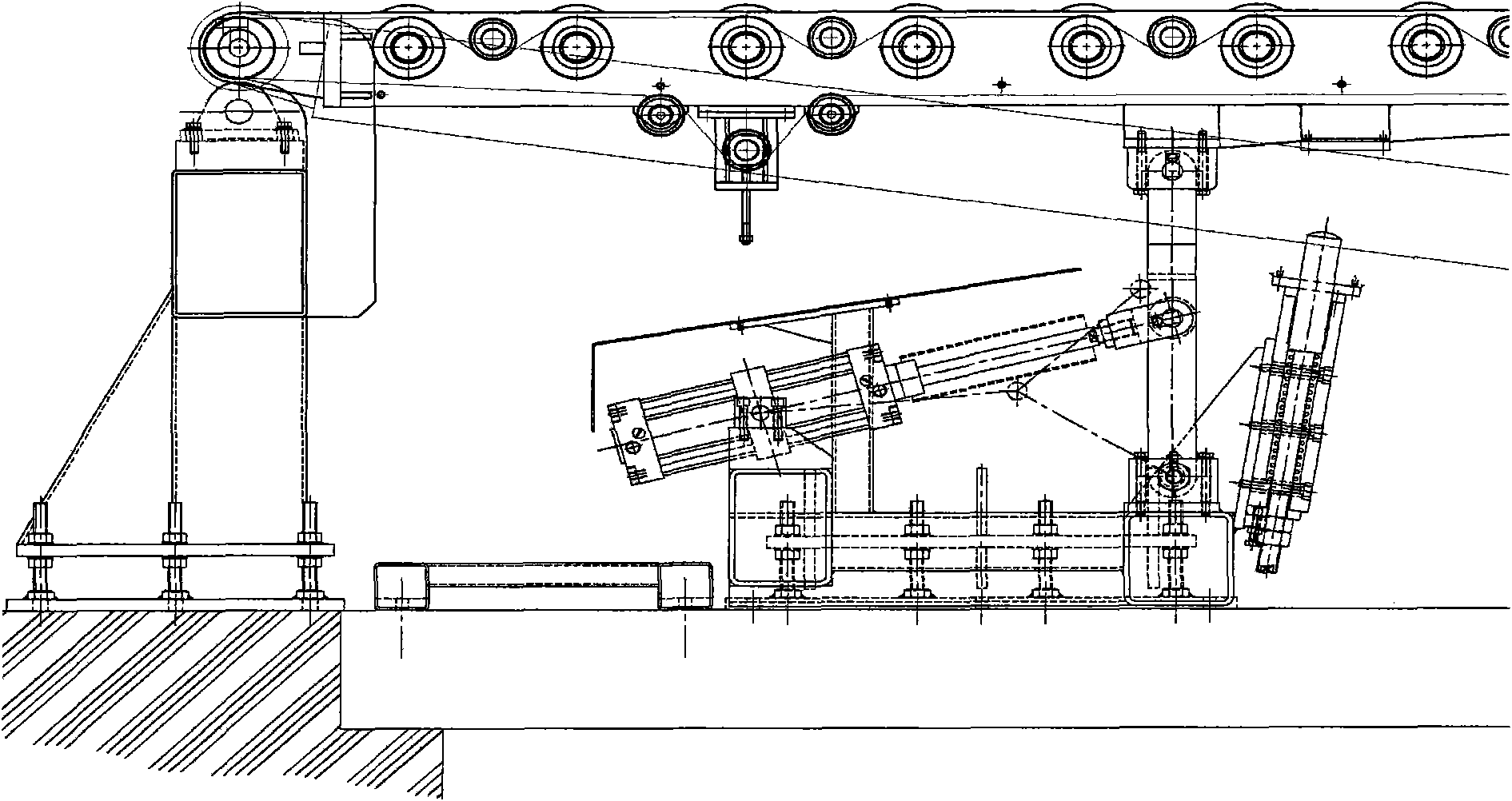

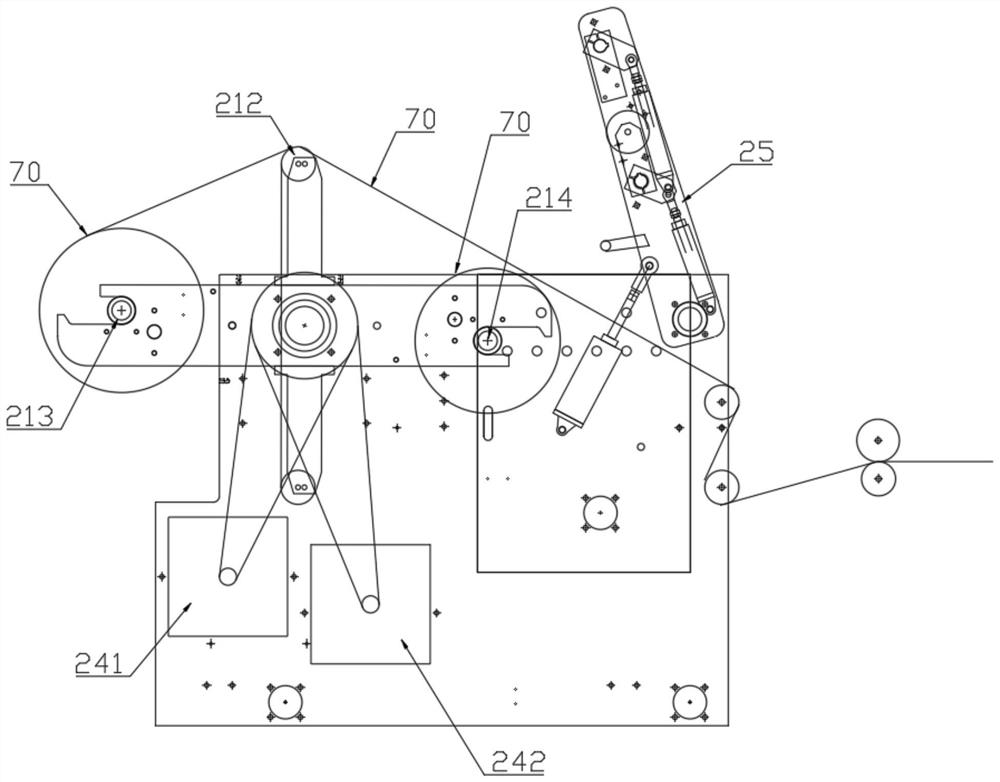

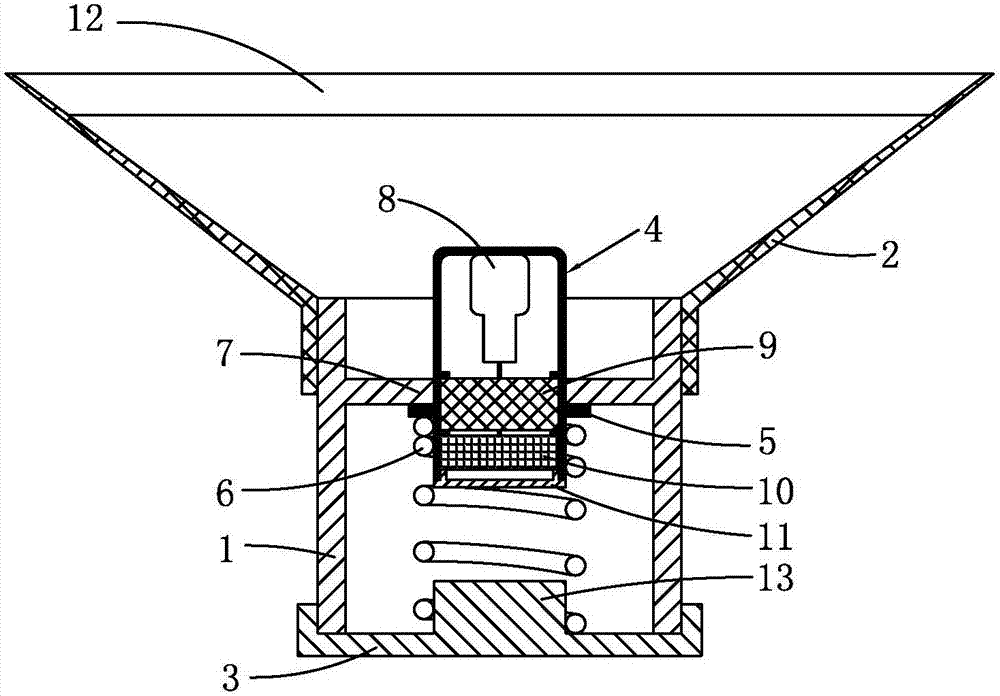

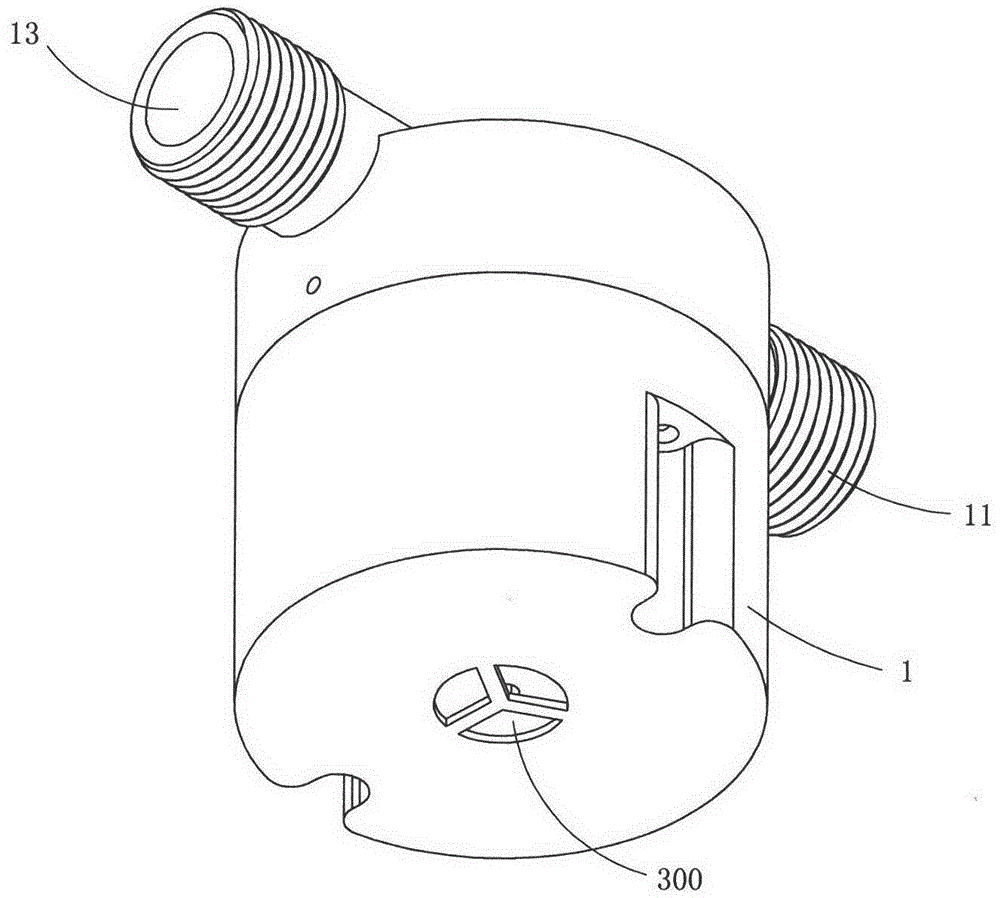

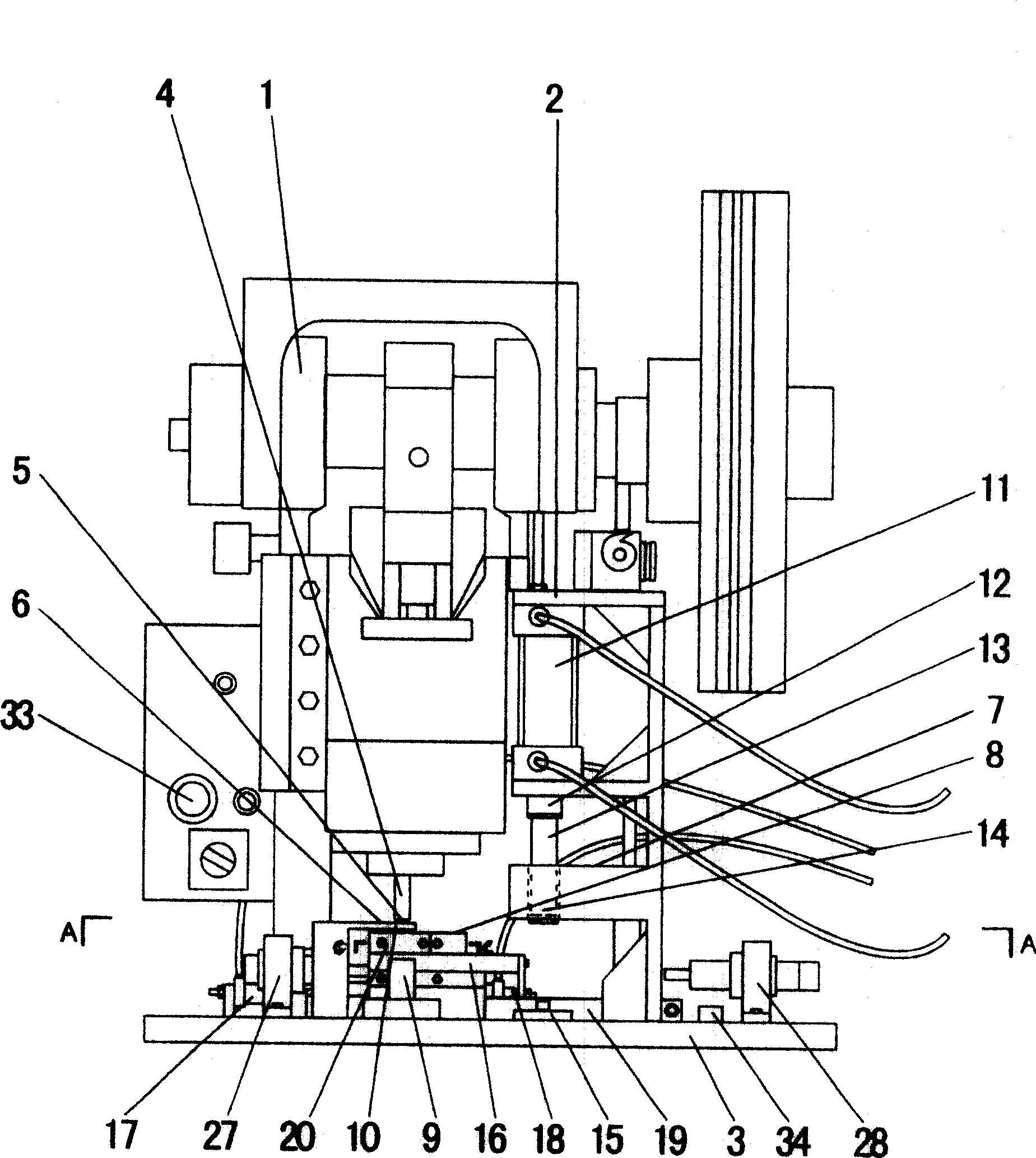

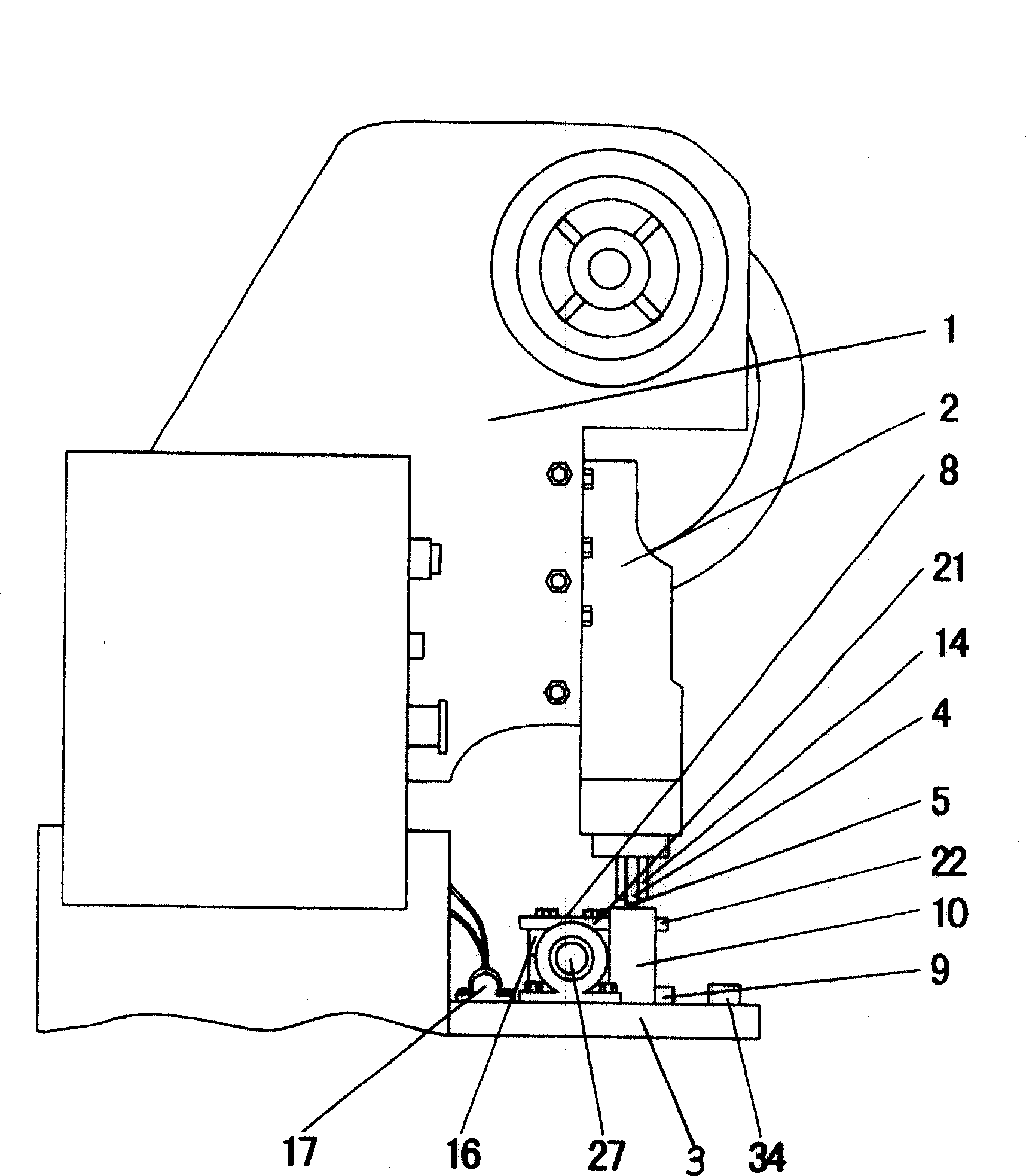

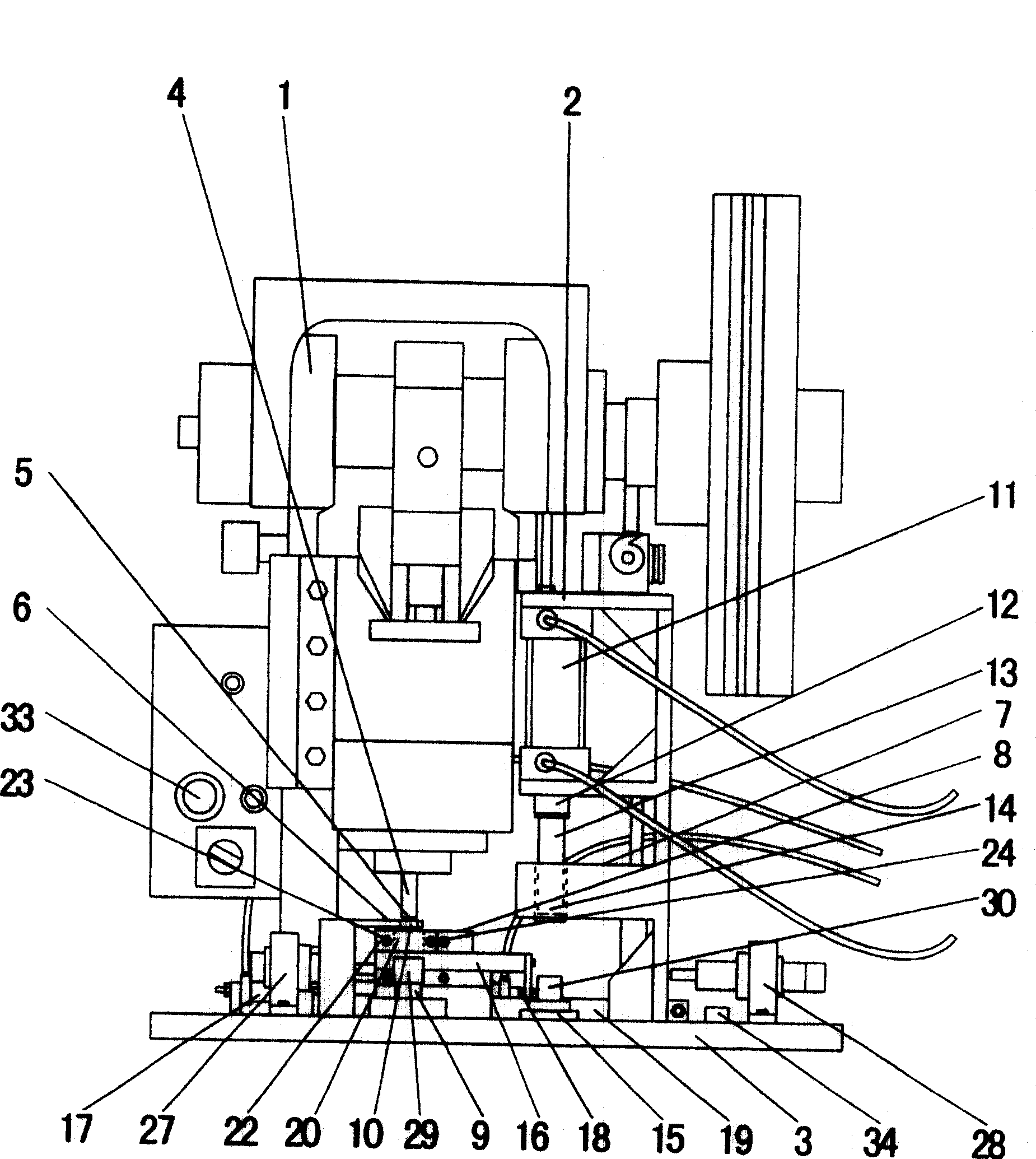

Molding machine

InactiveCN102059323AThe structure is simplified and reasonableLow costMoulding machinesRocker armMolding machine

The invention discloses a molding machine comprising a machine body, a work table, a rotary rocking arm, a shaking device, a sand press and a mold lifter. The work table is provided with a working plate and is horizontally arranged. The rotary rocking arm is provided with a pressing plate. The top of the machine body is provided with a rotary shaft, and the rotary rocking arm is fixedly arranged on the rotary shaft and can rotate along the rotation of the rotary shaft. The work table is arranged at one lateral end of the machine body, and the rotary rocking arm drives the pressing plate to be arranged just above the work table during the to-and-for rotation. The molding machine enables the pressing plate to horizontally rotate along the rotary rocking arm; when the molding machine adds sands into a sand tank or lifts the mold, the rotary rocking arm and the pressing plate rotate for the certain angle firstly to make the upper part of the sand tank without hampers, therefore, the pressing plate does not need to be arranged at a higher position; and when a jacking compaction operation is carried out, the pressing plate rotates above the work table and the sand tank.

Owner:李苏文

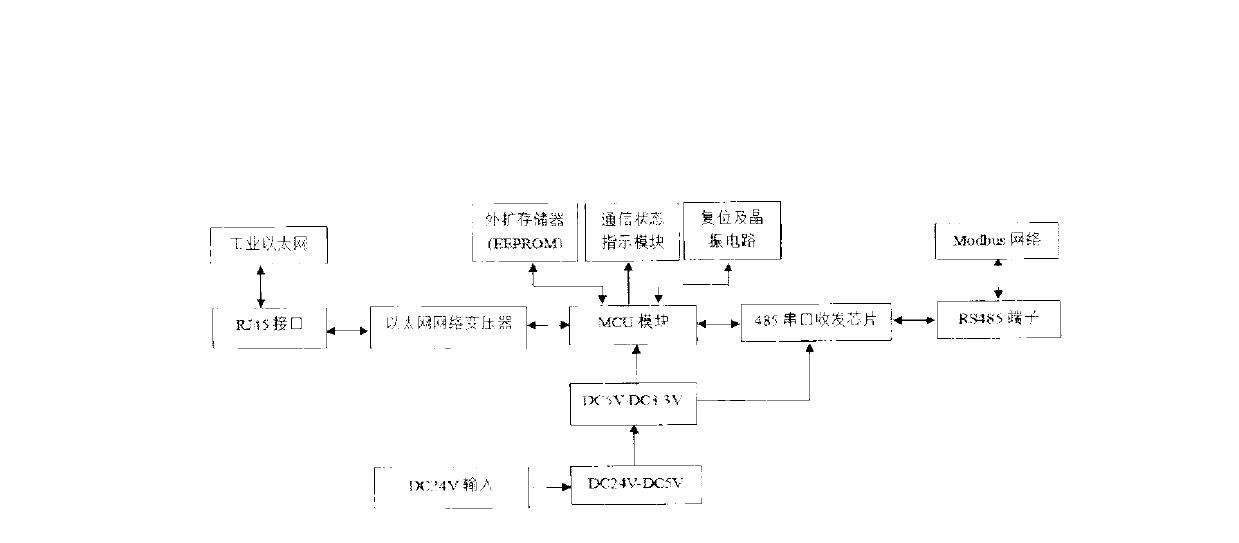

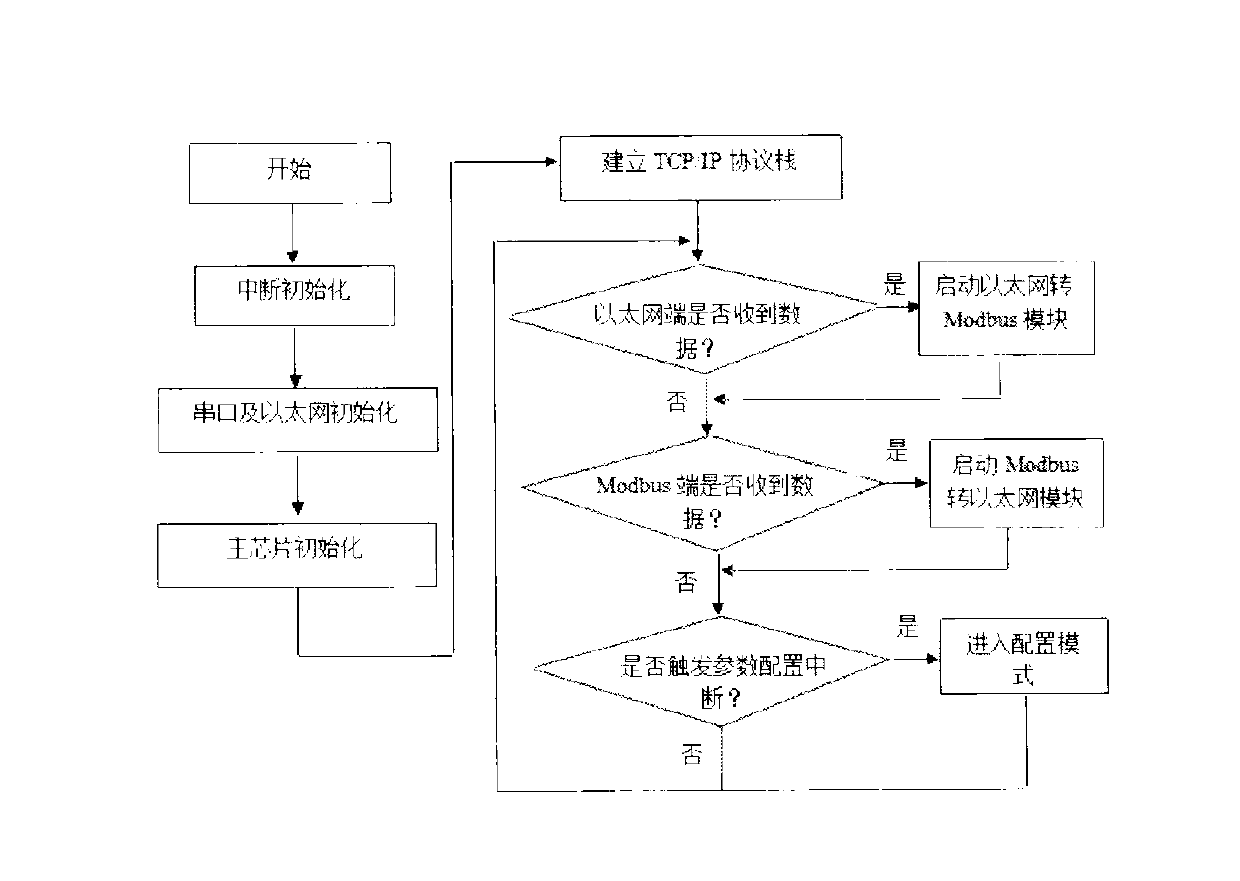

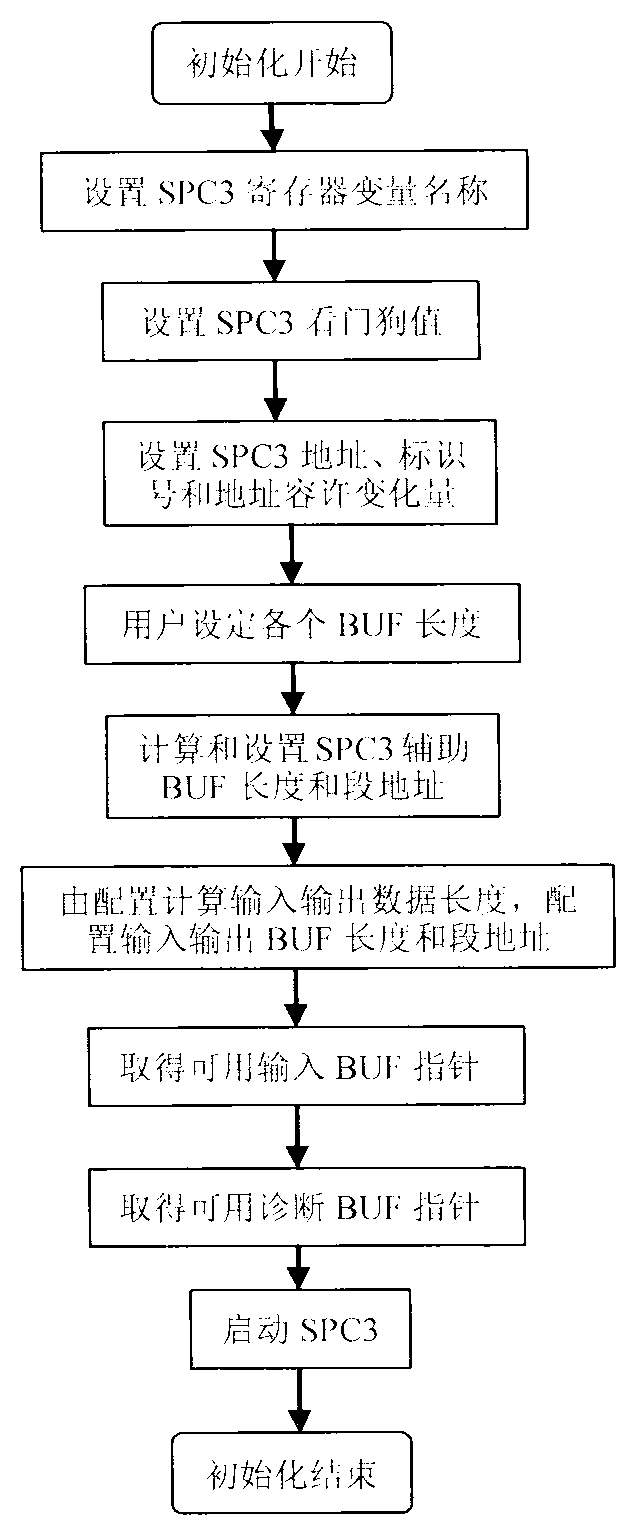

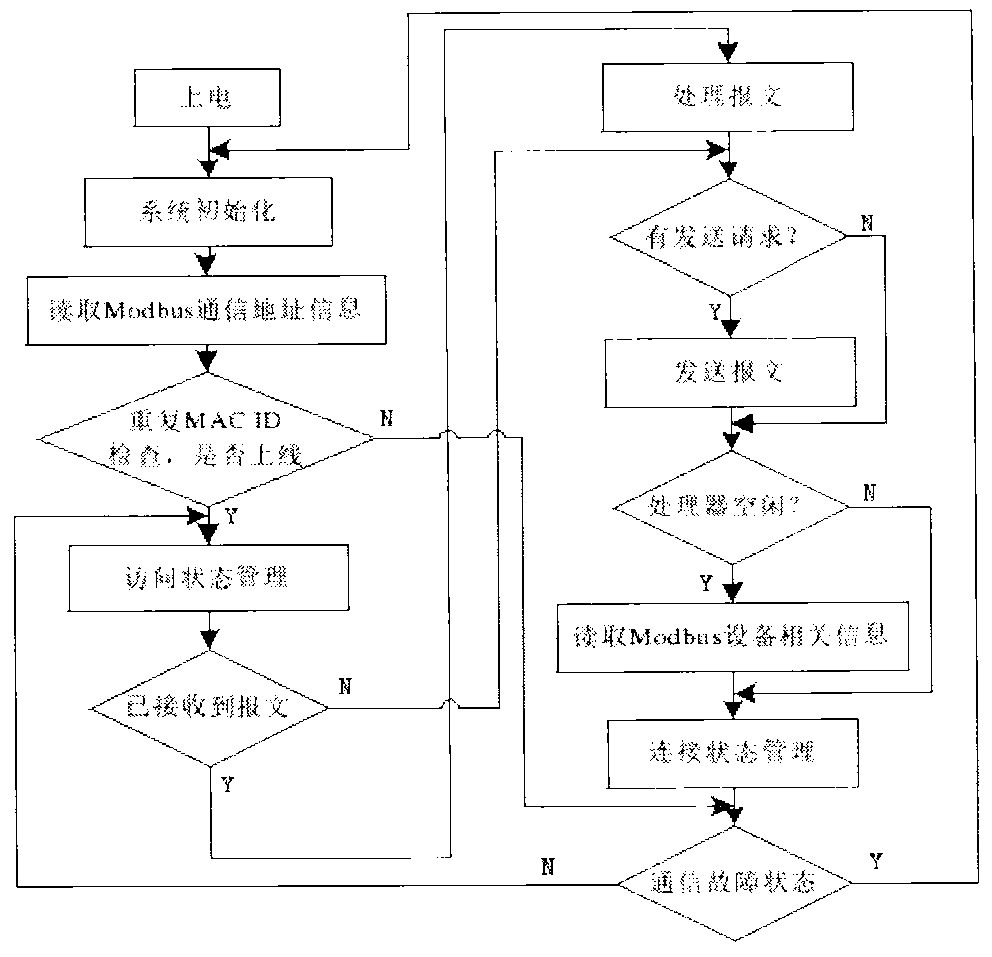

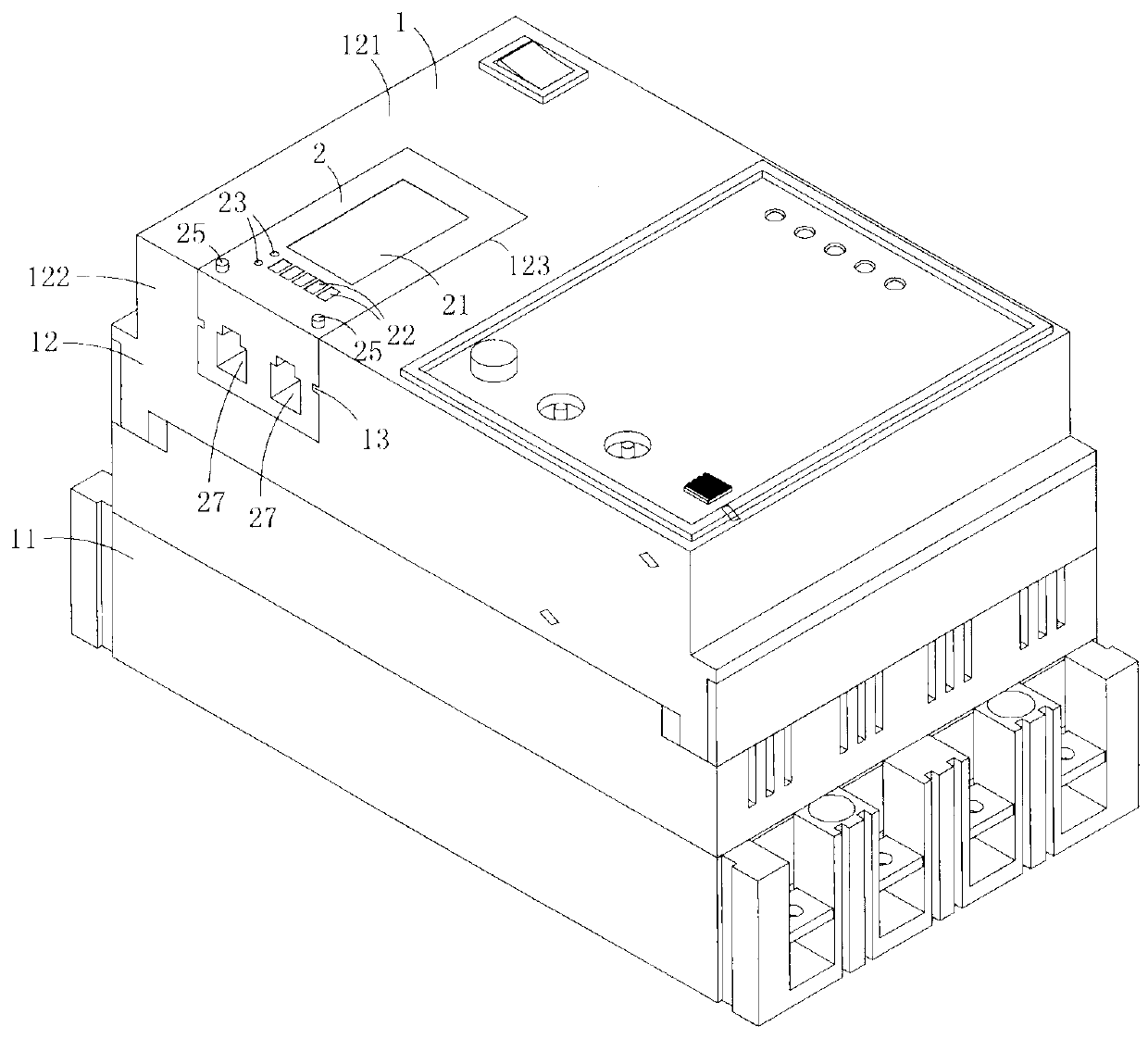

Protocol converting module and intelligent circuit breaker of Modbus and transmission control protocol (TCP)

ActiveCN103152236AThe structure is simplified and reasonableSmall footprintBus networksModbusTransformer

The invention discloses a protocol converting module and an intelligent circuit breaker of Modbus and a transmission control protocol (TCP). The protocol converting module comprises a microprogrammed control unit (MCU) module, an external expansion memory connected with the MCU module, a communication state identifying module, a reset and crystal oscillator circuit, an Ethernet network transformer, a 485 serial port receiving and sending chip, a direct current (DC) 5V - DC 3.3V direct current power converting module, a radio sonde (RS) 485 terminal connected with the 485 serial port receiving and sending chip, a RJ45 port connected with the Ethernet network transformer, and a DC 24V - DC 5V direct current power converting module connected with the DC 5V - DC 3.3V direct current power converting module. The intelligent circuit breaker comprises a plastic shell breaker body, a remote motion execution mechanism and protocol transmission modules mentioned above. The protocol converting module and the intelligent circuit breaker of the Modbus and the TCP enable a user to carry out real-time inspection and controlling of Modbus equipment through a TCP bus.

Owner:RENMIN ELECTRIC APPLIANCES GROUP

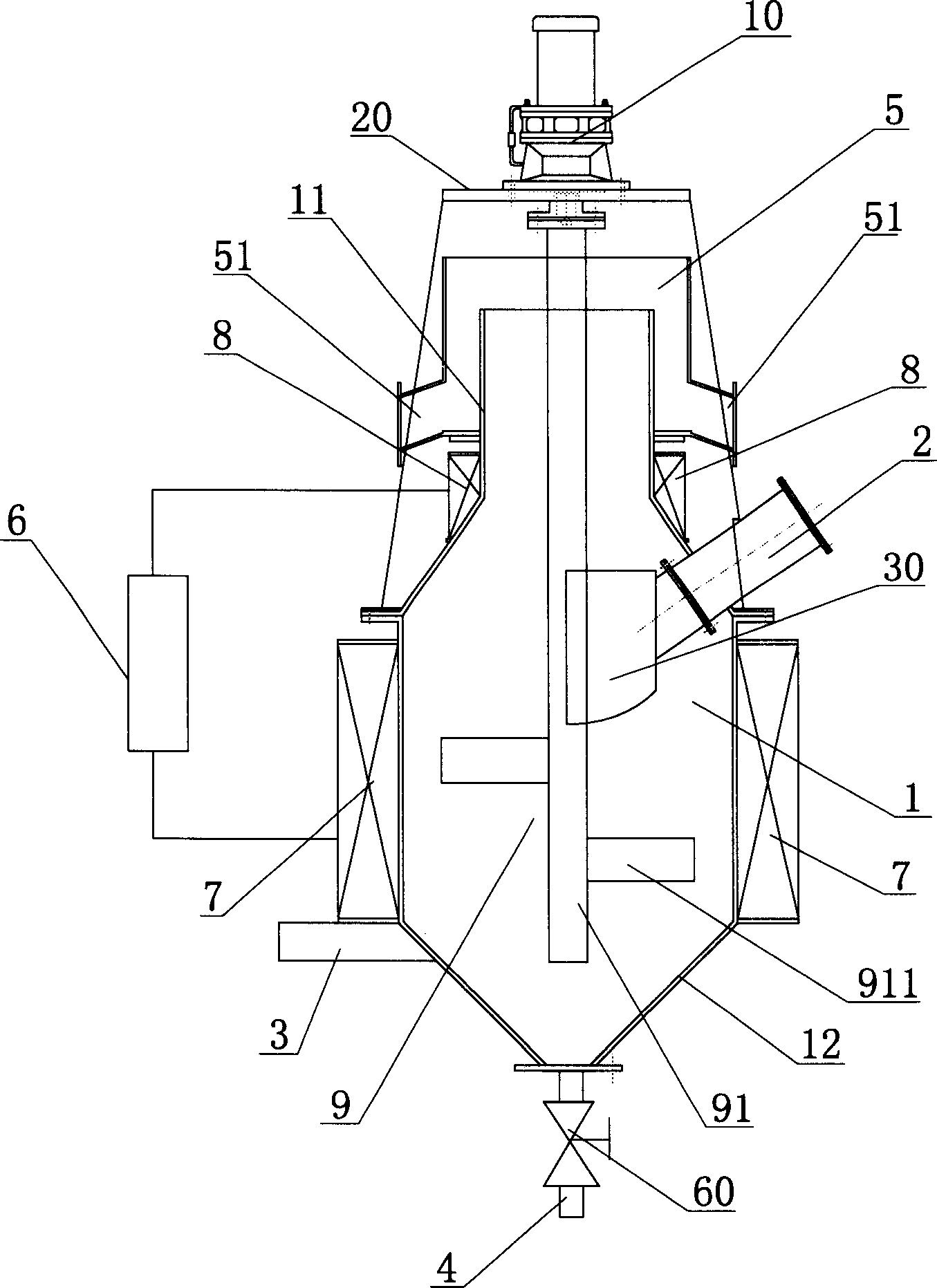

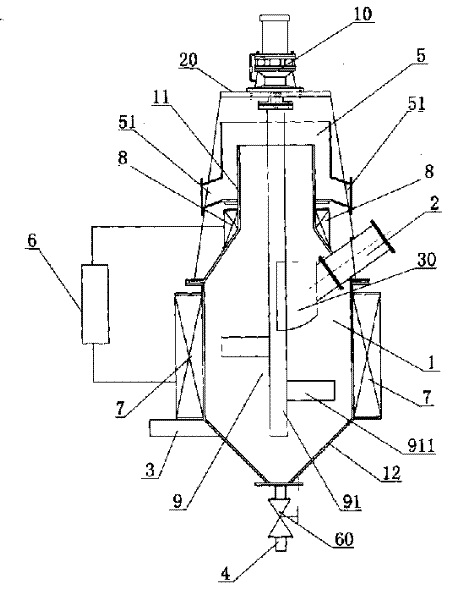

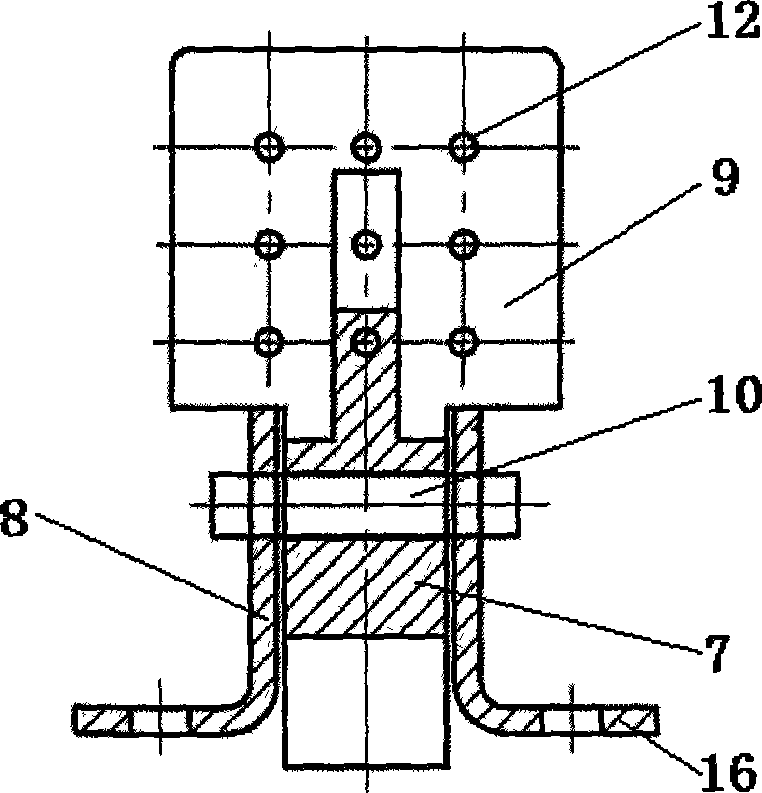

Vertable pulse vibration magnetic field magnetic separator

InactiveCN1428203ARaise the gradeHigh recovery rateMagnetic separationMagnetic separatorElectrical current

The vertical impulse vibration magnetic-field magnetic separator indudes cylindrical body, mineral feeding pipe, water feeding pipe, concentrate pipe, overflow tank body and excitation power supply, and is characterized by that on the external wall of lower portion of cylindrical body a magnetic field device for producing alternating magnetic field is set, it is connected with excitatino power supply for producing uniofrm alternating magnetic field passing through the cylindrical body. Said inventino adopts the vertical structure capable of producing alternating magnetic field to make magnetic separation, so that it effectively raise grade of separated concentrate and its recovery rate.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

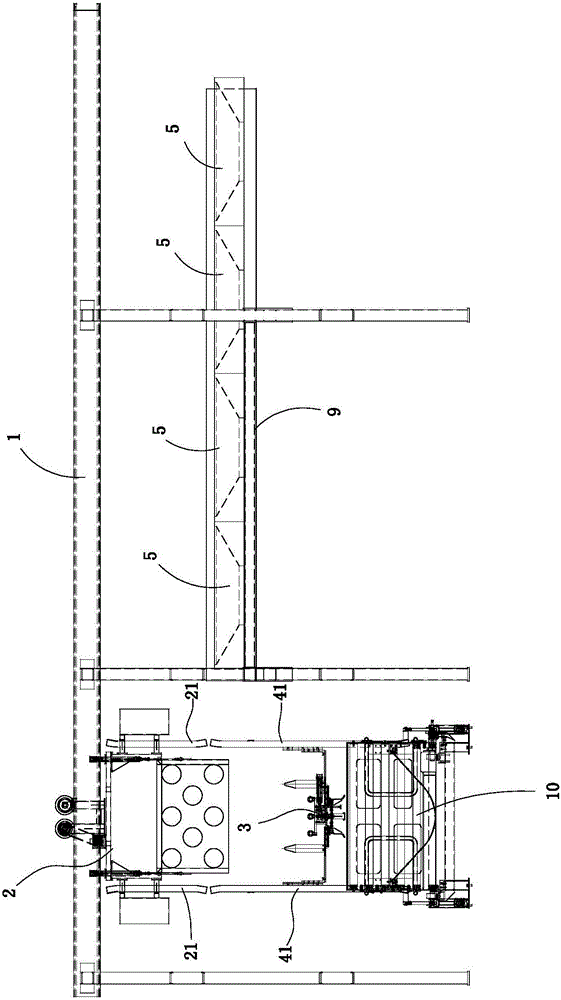

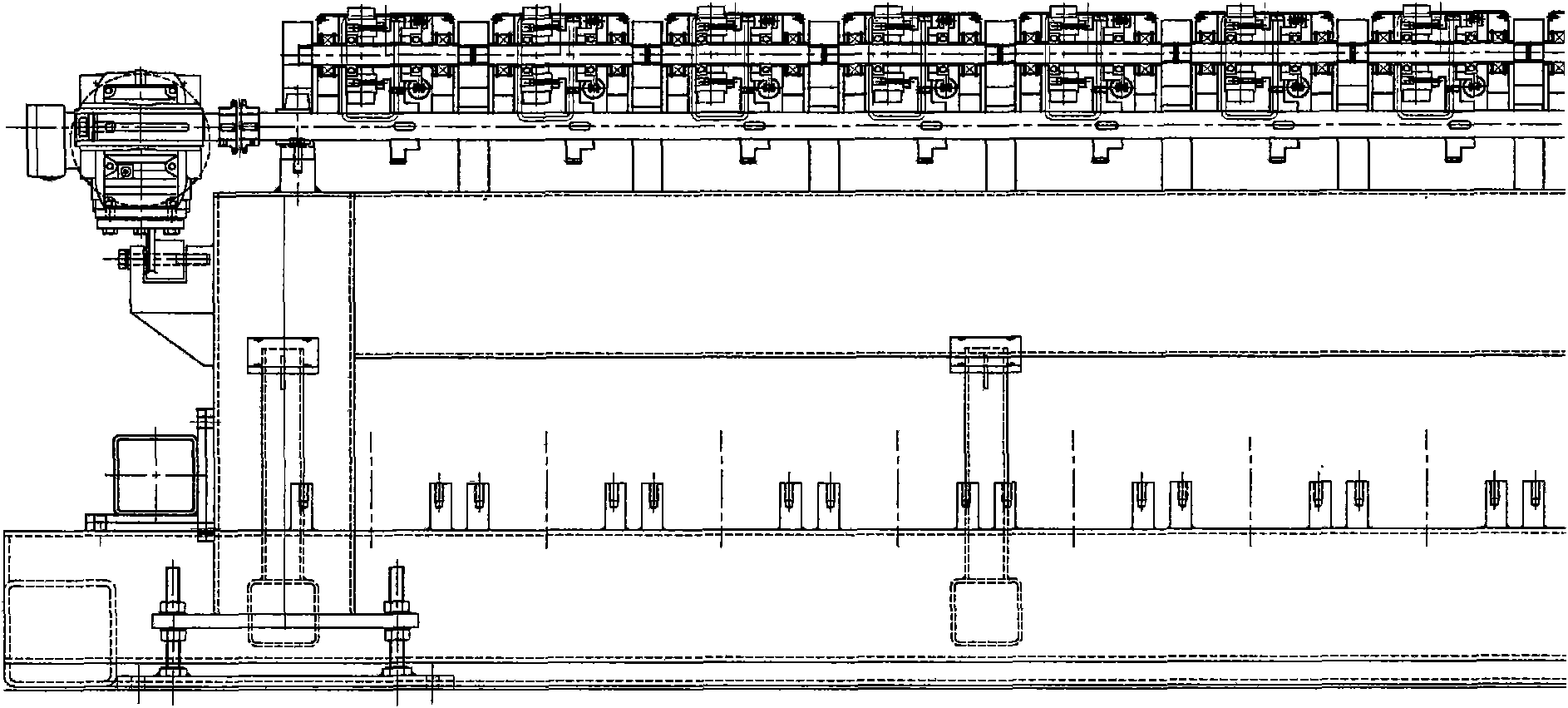

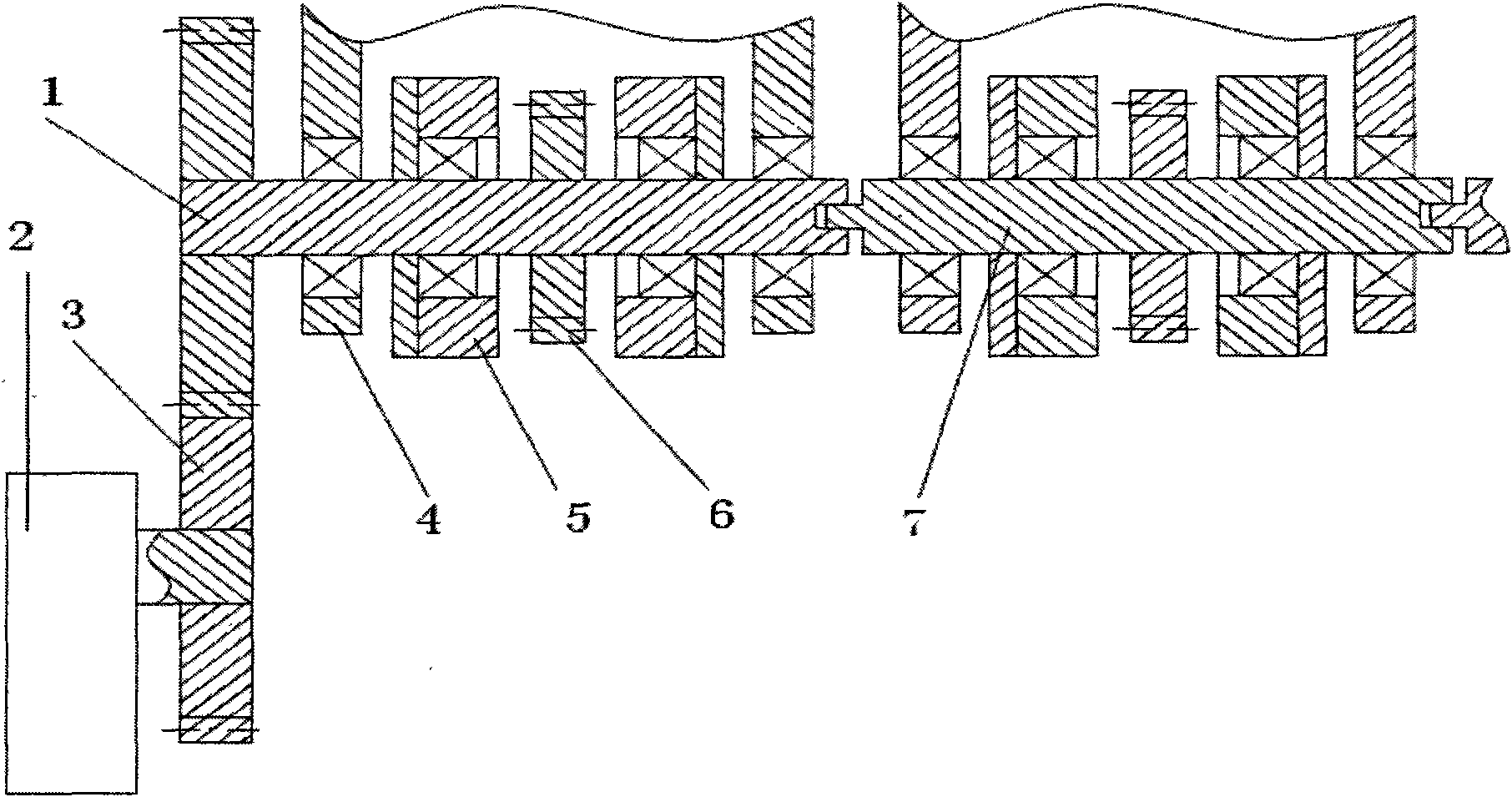

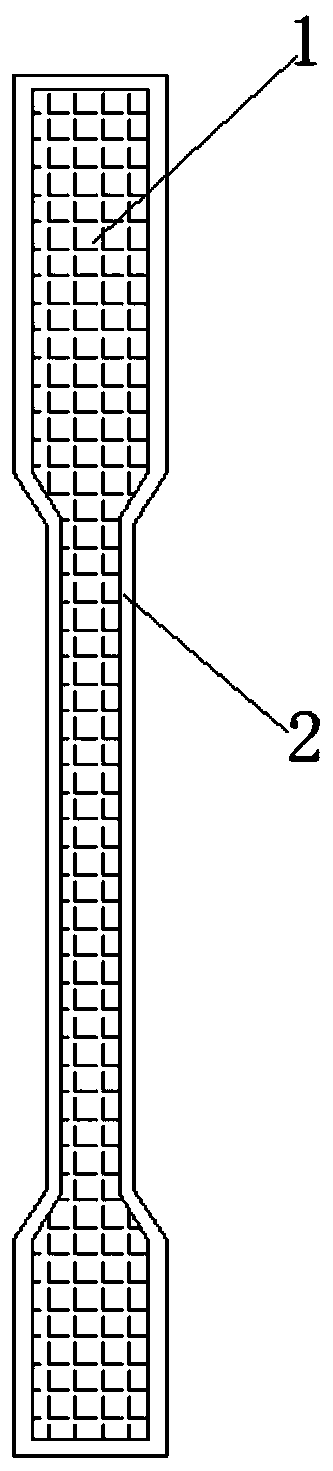

Feeding mechanism and operation method of timber processing machine

The invention discloses a feeding mechanism for wood processing machinery. The feeding mechanism (3) is provided with a chain feeding mechanism (4) which comprises a sprocket wheel (5) and a chain (6), wherein the moving direction of the chain (6) is the feeding direction of wood (2); the feeding mechanism is provided with a rushing board component (7) to be connected with the chain (6); and the rushing board component (7) is pushed from the end part of the wood (2). The invention also discloses an operation method for the feeding mechanism. With the technical proposal, the operation of the feeding mechanism can be more stable and reliable, the production efficiency for wood processing is improved, the continuous automatic production is realized under the condition of no outage and no withdrawal of the feeding mechanism, and the labor intensity for operator is reduced. The structure of the equipment is more reasonable and simpler, and the processing cost is reduced.

Owner:冯士祥

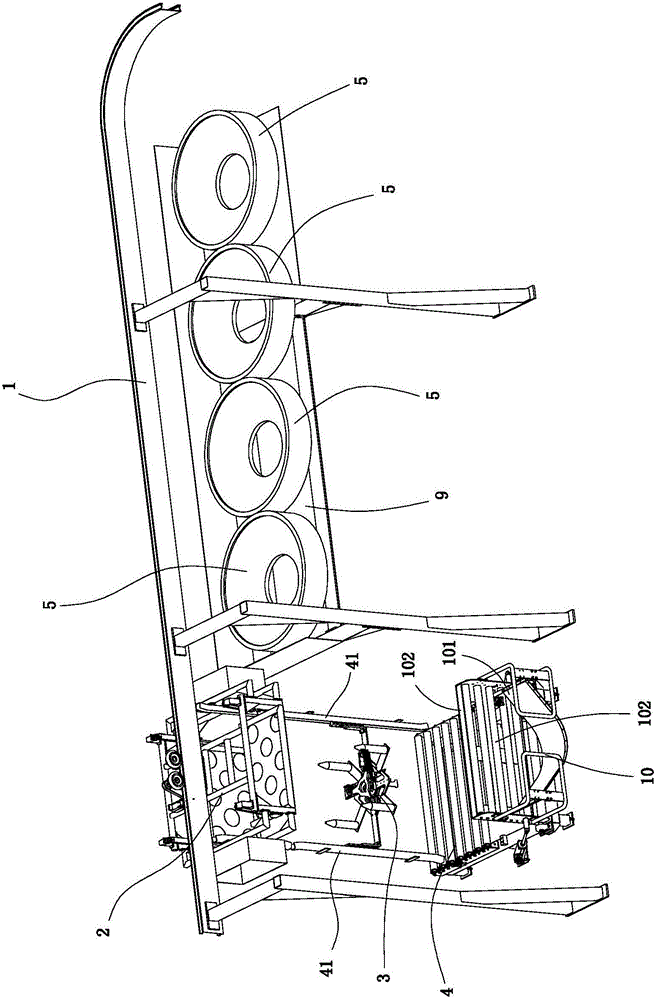

Rough tire transferring system

ActiveCN105947652AReduce interference effectsReasonable structureTyresConveyor partsVulcanizationTransfer system

The invention discloses a rough tire transferring system. The system comprises a transferring rail, the transferring rail is arranged in a suspended manner through a supporting frame, a transferring trolley is arranged on the transferring rail, a rough tire grabbing device is arranged on the transferring trolley, a supporting cross beam arranged in the arranging direction of the transferring rail is arranged at the position, away from the ground by a certain height, below the transferring rail, and rough tire trays are arranged on the supporting cross beam at intervals; and when the transferring system is practically applied, rough tires formed through a forming machine are grabbed by the rough tire grabbing device and are transferred to a vulcanization station through the transferring trolley, and a rail seeking trolley does not need to be used; when the system is used, the interference influence on ground operation can be effectively reduced; when the rough tire vulcanization speed is smaller than the rough tire forming speed or the rough tires need to be laid up for a certain time according to technological requirements, the rough tires are temporarily stored in the rough tire trays below the transferring rail, the system occupied area can be effectively reduced, and production efficiency is improved; and the system is simple and reasonable in structure and low in construction cost and has the good practicability.

Owner:HAINING RUICHUANG MACHINERY TECH

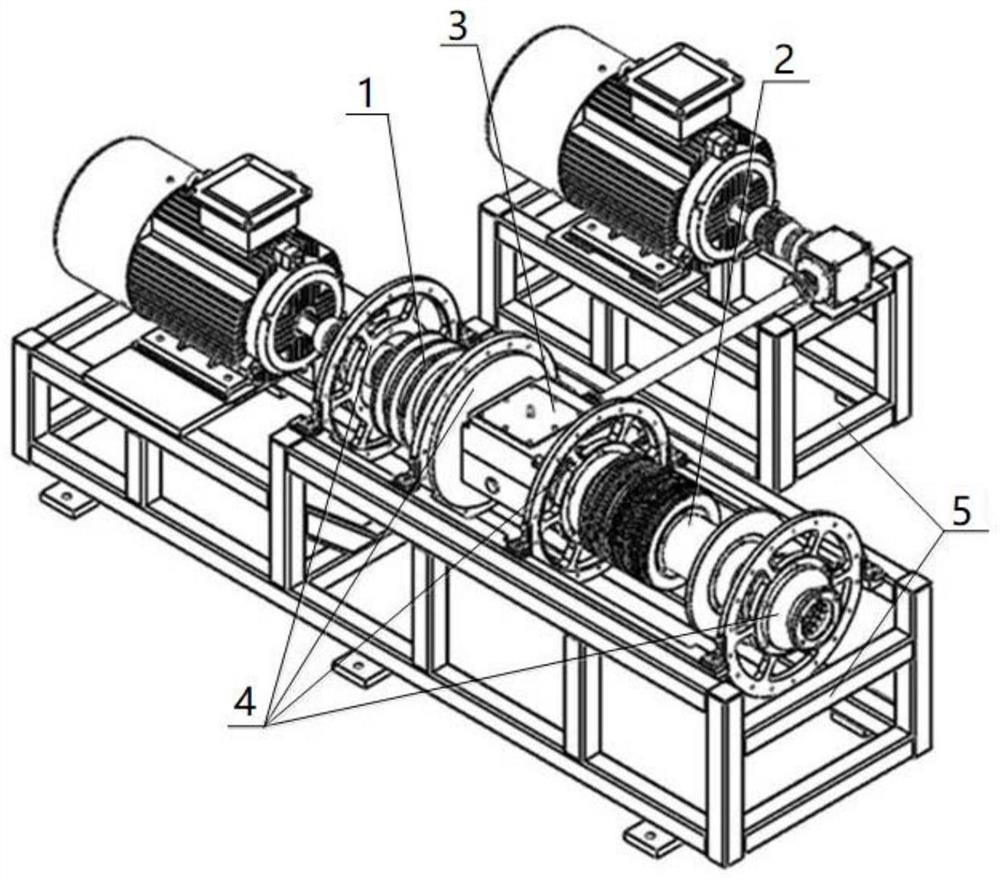

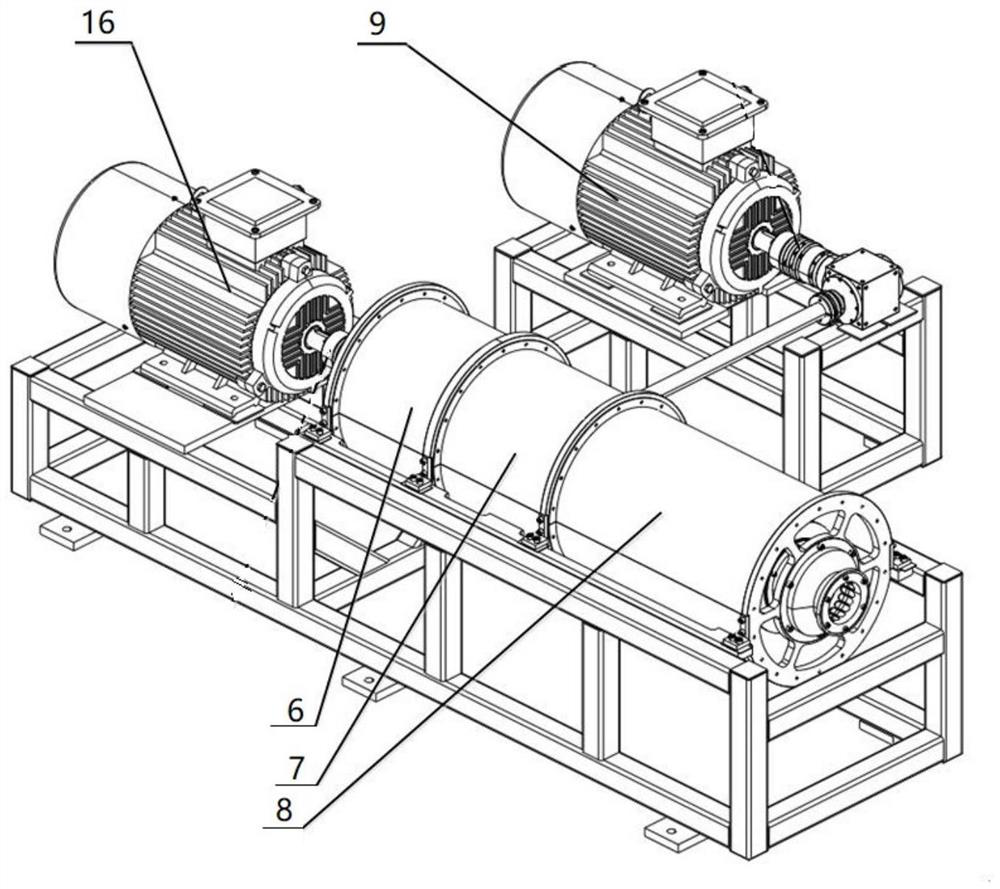

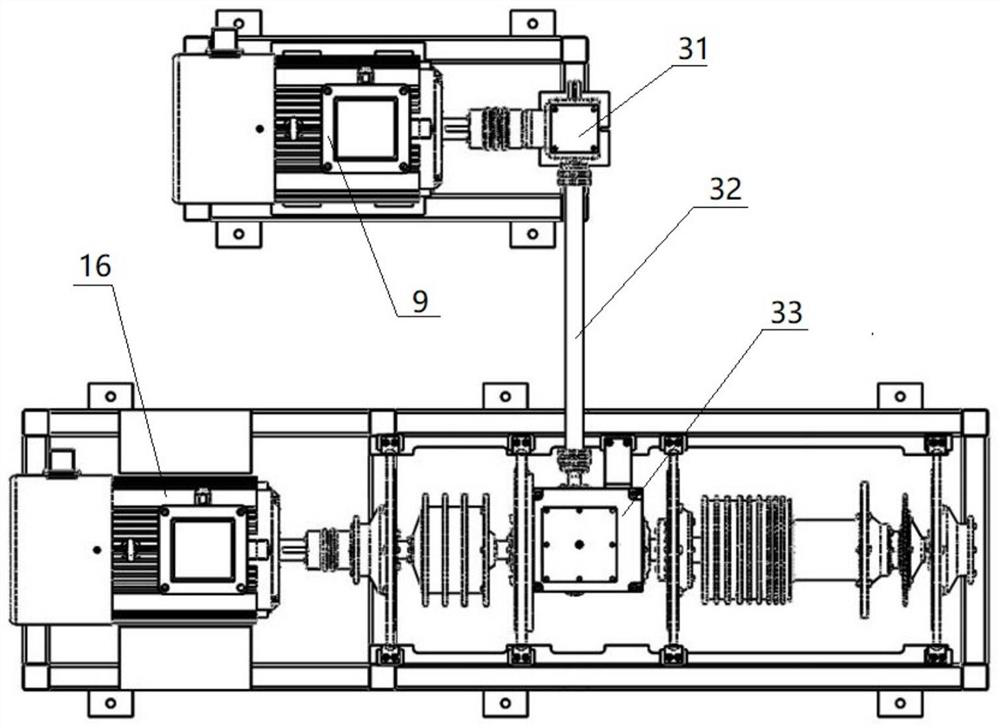

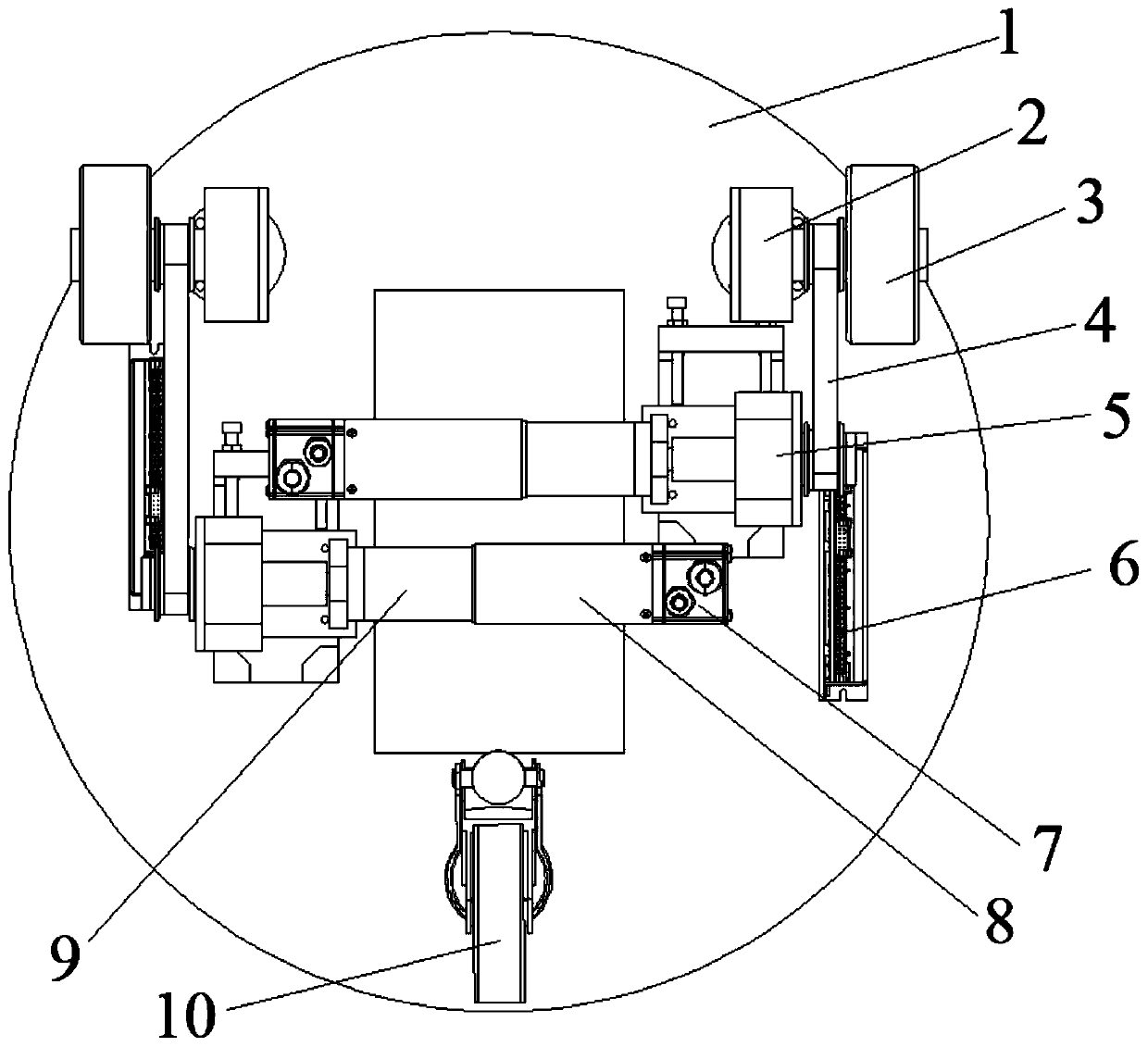

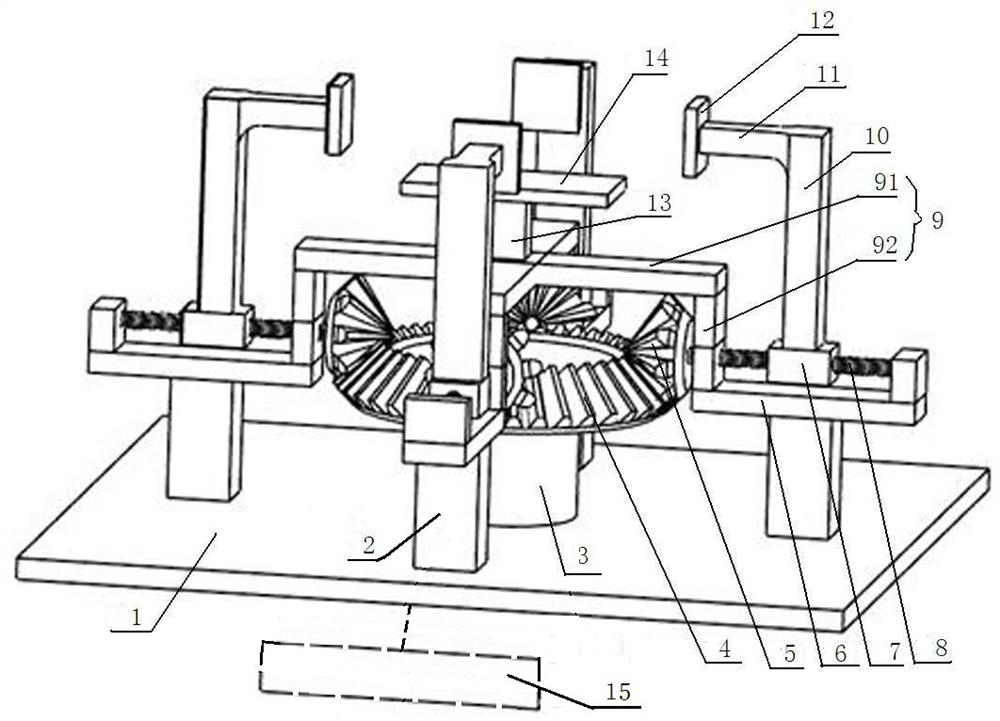

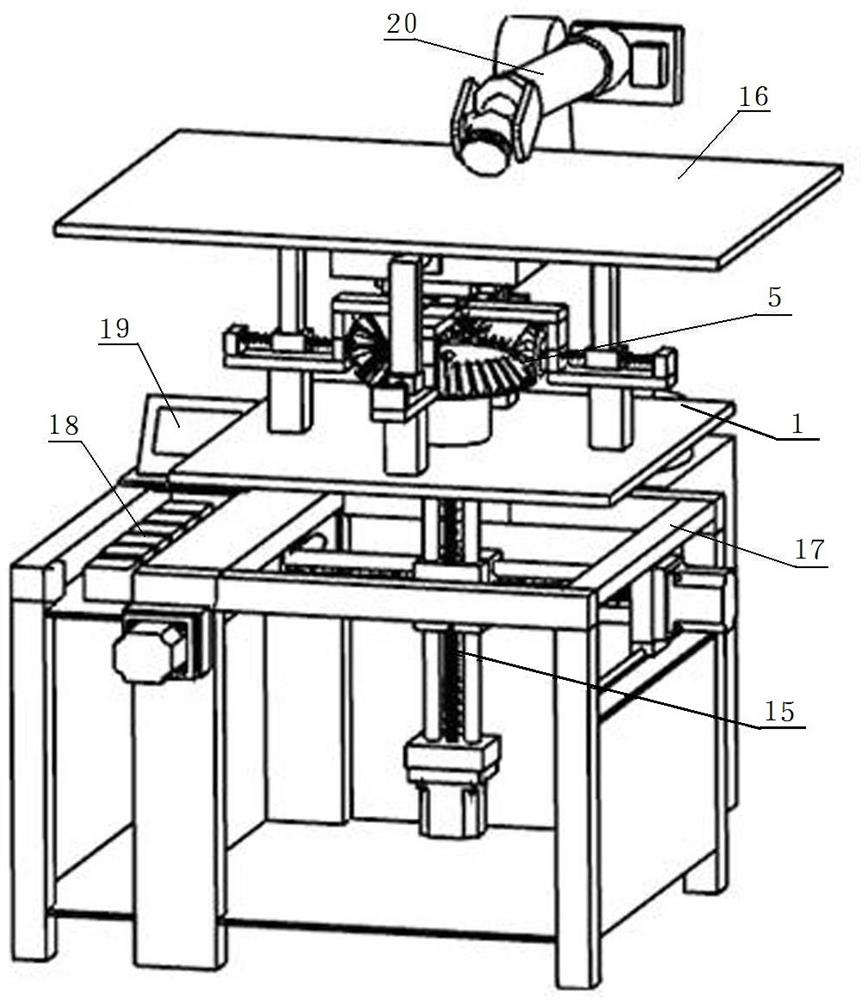

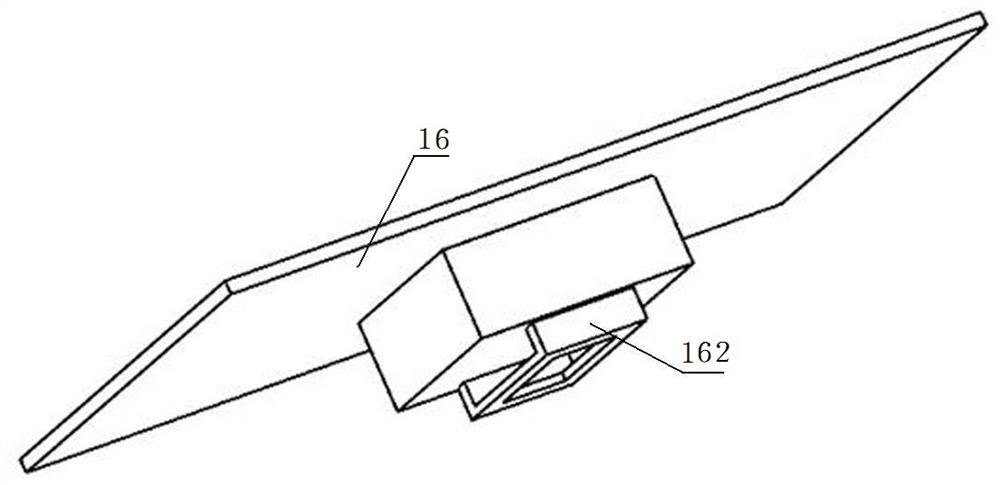

Aero-engine birotor-support-casing tester and testing method thereof

PendingCN112629840AReflect coupling characteristicsMeeting Vibration Research NeedsMachine part testingSubsonic/sonic/ultrasonic wave measurementEngine testingControl engineering

The invention belongs to the technical field of aero-engine testing and testing, and particularly relates to an aero-engine birotor-support-casing tester and a testing method thereof. The aero-engine birotor-support-casing tester comprises a low-pressure rotor, a central bevel gear system, a high-pressure rotor, a low-pressure casing, a middle casing and a high-pressure casing; the low-pressure rotor comprises a low-pressure turbine shaft, and the low-pressure turbine shaft penetrates through the central bevel gear system and is rotationally connected with the high-pressure rotor; and the low-pressure rotor is driven by a low-pressure driving motor, the central bevel gear system is connected with a high-pressure driving motor, and the high-pressure rotor is driven by the central bevel gear system. The structure is simplified and reasonable, the scale design with the fixed proportion (such as 2: 1) is adopted according to the real engine structure, and the four-stage fan disc and the nine-stage high-pressure disc are consistent with the real engine structure. Structures such as a squirrel cage, a conical shell, a bearing spoke plate and a flexible casing in a real machine are reserved, the structure and vibration of an engine rotor system can be truly simulated, and the whole machine vibration research requirement of an aero-engine is met.

Owner:韩清凯

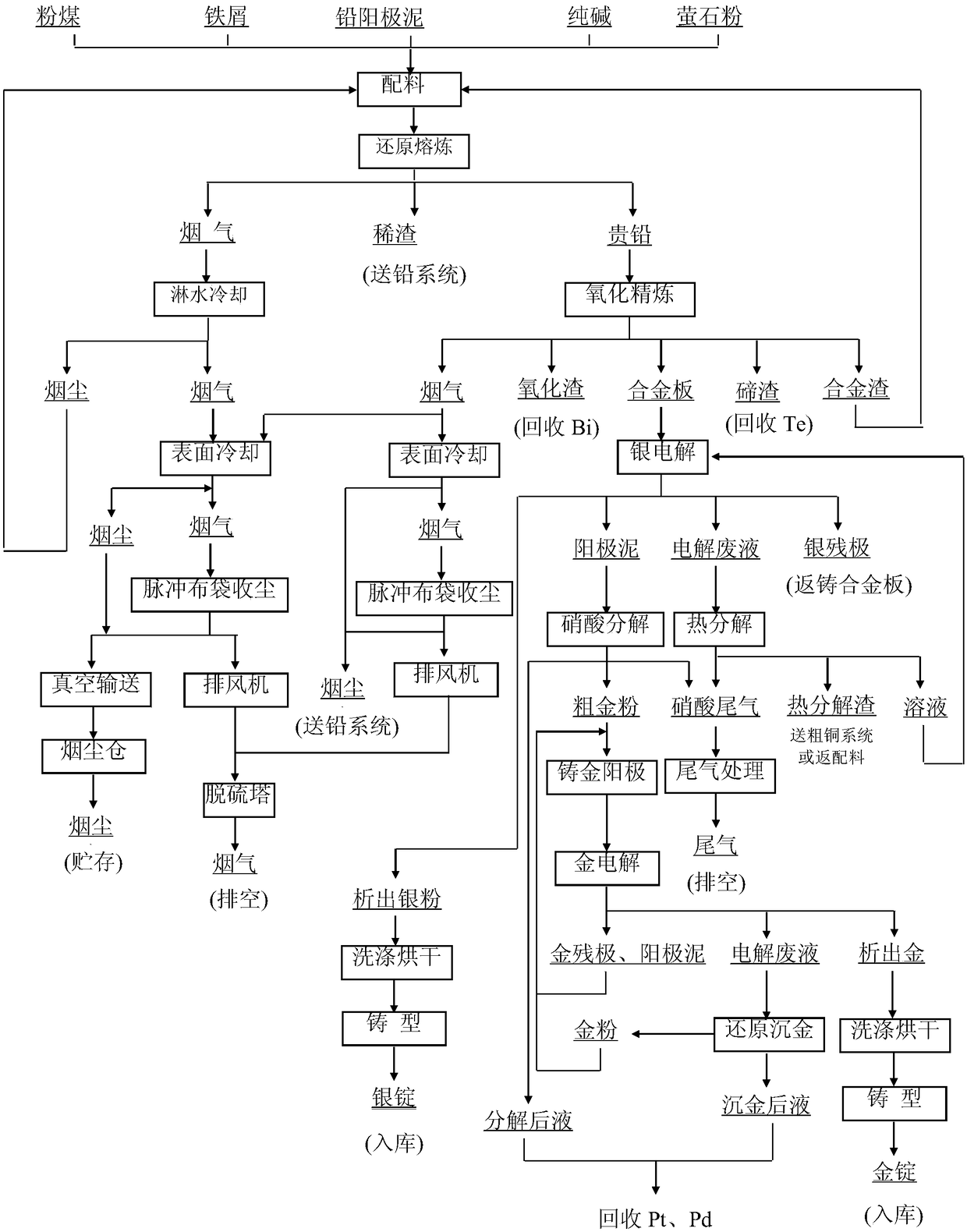

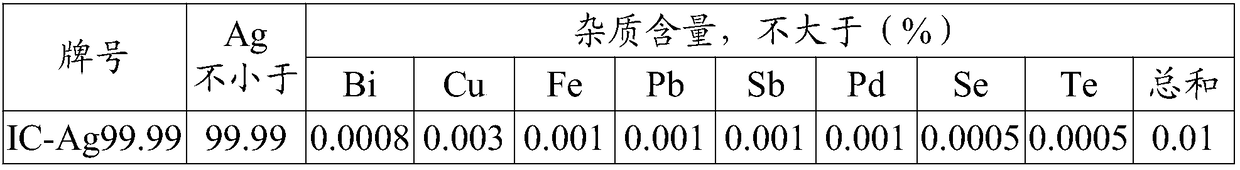

Dore silver electro-refining process

InactiveCN109023433ALess investmentThe structure is simplified and reasonableElectrolysis componentsProcess efficiency improvementSilver plateIngot

The invention discloses a dore silver electro-refining process. The dore silver electro-refining process includes the following steps of (1) preparation of a silver nitrate solution; (2) immersion silver reaction; (3) preparation of silver electrolyte; and (4) silver electro-refining. According to the dore silver electro-refining process, silver nitrate serves as the electrolyte, a dore silver alloy anode and a pure silver plate cathode are put in the silver nitrate electrolyte during electrolysis, after direct current is led in, silver and base metal impurities at the anode are dissolved, pure silver is separated out at the cathode, the pure silver is tested, washed to be neutral and dried in a spinning mode, and silver ingots are cast. On the premise that technical and economical indicators are identical with those of imported equipment, the structure is more simple and reasonable, operation is more convenient, and investment on equipment and accessories is greatly saved. Compared with a silver electrolytic cell with the same volume, the yield of an electrolytic cell in the dore silver electro-refining process is doubled or above compared with the common electrolytic cell. Therefore, the dore silver electro-refining process disclosed by the invention has good popularization and demonstration effect in the industry.

Owner:岷山环能高科股份公司

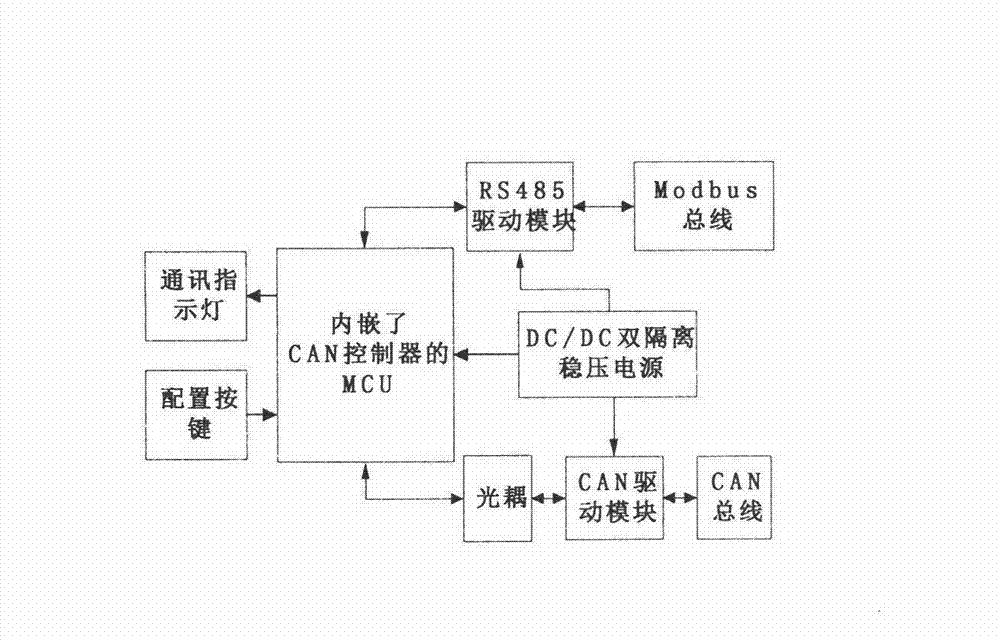

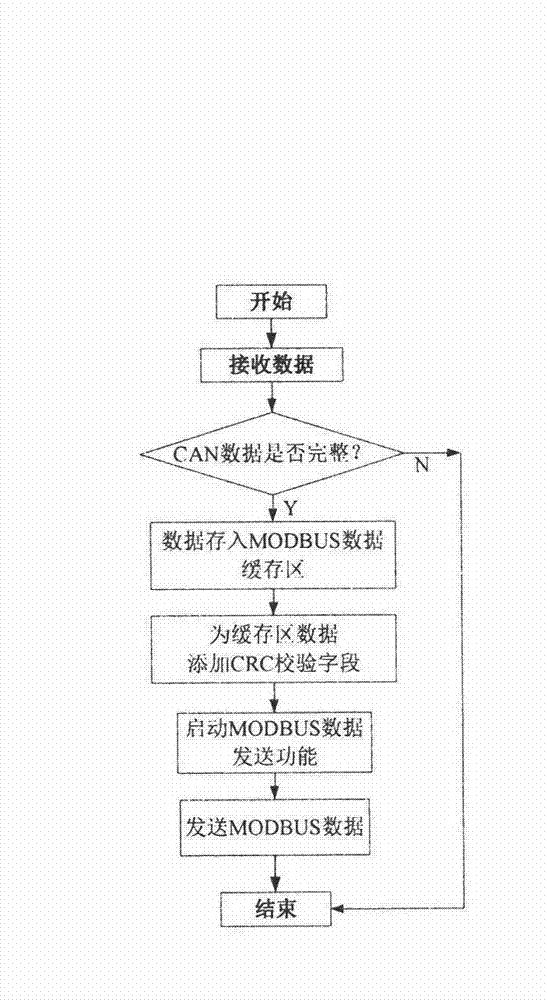

Protocol conversion module and intelligent circuit breaker of controller area network (Can) and Modbus

ActiveCN103092111AThe structure is simplified and reasonableSmall footprintProgramme controlComputer controlModbusCommunication interface

The invention discloses a protocol conversion module and an intelligent circuit breaker of a controller area network (Can) and a Modbus. The protocol conversion module comprises a microprogrammed control unit (MCU) center processing unit, a static random access memory (SRAM) storage unit which is connected with the MCU center processing unit, a dial-up switch, a Modbus communication interface, an indicating unit, a PROFIBUS interface chip, an isolated form RS 485 transceiver chip and a Can communication interface, wherein the isolated form RS 485 transceiver chip and the Can communication interface are sequentially connected with the PROFIBUS interface chip. The circuit breaker comprises a plastic shell circuit breaker body, a remote action actuator and the protocol conversion module. According to the protocol conversion module and the intelligent circuit breaker of the Can and the Modbus, a user can monitor and control Modbus equipment through a Can bus in real time.

Owner:RENMIN ELECTRIC APPLIANCES GROUP

Outdoor fitness equipment

ActiveCN106039636AAvoid security issuesSituations to avoid misoperationMovement coordination devicesCardiovascular exercising devicesLocking mechanismEngineering

The invention discloses outdoor fitness equipment. The outdoor fitness equipment comprises a rack, swing arms and pedals, wherein the rack comprises two stand columns vertically arranged and safety armrests fixed to the top ends of the two stand columns, the upper ends of the swing arms are hinged to the stand columns, the pedals are fixed to the lower ends of the swing arms, and the stand columns are provided with limiting mechanisms for limiting the amplitude of swing of the swing arms; each limiting mechanism comprises a limiting rod fixedly arranged on the corresponding stand column, blocking components are arranged at the two ends of each limiting rod, the swing of each swing arm is limited between the two corresponding blocking components, and the distance between the two blocking components on the corresponding limiting rod is adjustable; a locking mechanism for locking the corresponding swing arm is arranged in the middle of the corresponding limiting rod. When the outdoor fitness equipment is used, a citizen can adjust the amplitude of swing according to the self demands, and the swing arms can be locked when the outdoor fitness equipment is not used, so that the potential safety hazards caused by the random swing of the swing arms are eliminated, and finally, the safe exercising purpose is achieved.

Owner:JIAXING VOCATIONAL TECHN COLLEGE

Protocol conversion module and intelligent circuit breaker of Profibus and Modbus

InactiveCN103135483AThe structure is simplified and reasonableSmall footprintProgramme controlComputer controlCommunication interfaceModbus

The invention discloses a protocol conversion module and an intelligent circuit breaker of Profibus and Modbus. The protocol conversion module comprises a microprogrammed control unit (MCU) central processing unit, a static random access memory (SRAM) storage unit, a toggle switch, a Modbus communication interface, an indicating unit, a PROFIUBS interface chip, an isolation type RS485 sending-receiving chip and a Profibus communication interface, wherein the SRAM storage unit, the toggle switch, the Modbus communication interface, the indicating unit and the PROFIUBS interface chip are connected with the MCU central processing unit, and the isolation type RS485 sending-receiving chip and the Profibus communication interface are connected with the PROFIUBS interface chip in sequence. The intelligent circuit breaker comprises a moulded case circuit breaker body, a remote movement executing mechanism and the protocol conversion module. The protocol conversion module and the intelligent circuit breaker can enable users to monitor and control Modbus equipment through a Profibus bus in real time.

Owner:RENMIN ELECTRIC APPLIANCES GROUP

Sealing ring processing equipment

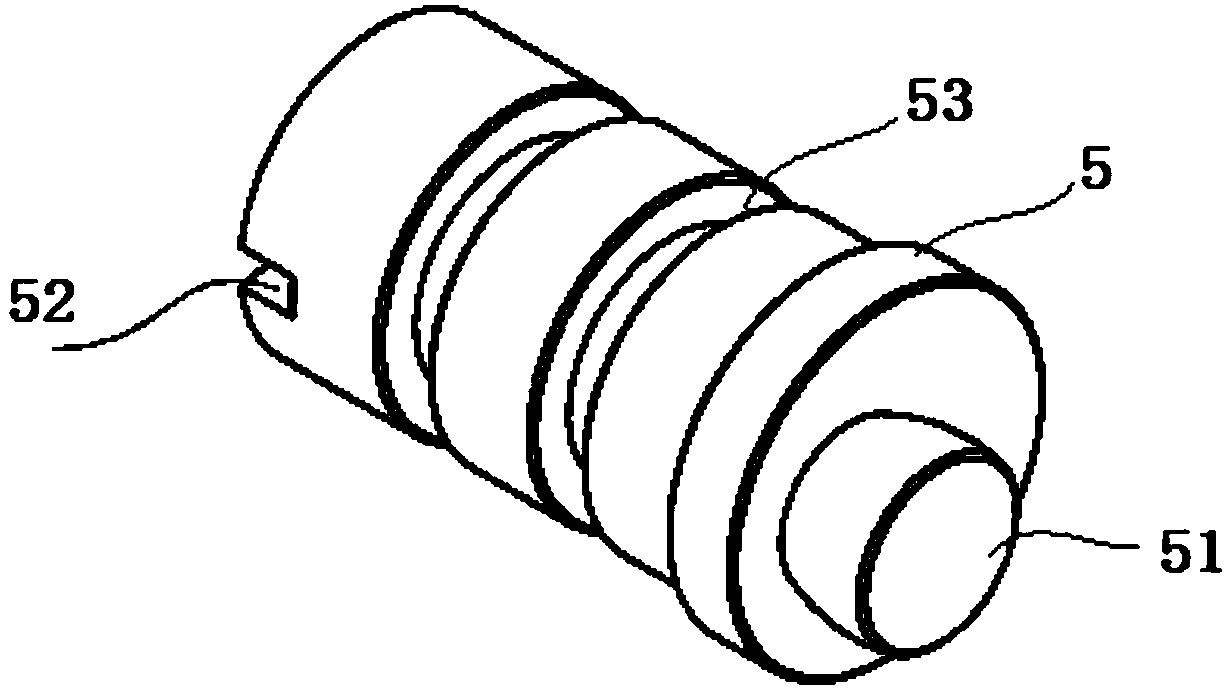

InactiveCN105364184AGuaranteed machining accuracyGuaranteed all-round machiningPositioning apparatusMetal-working holdersDrive shaftDrive motor

The invention discloses sealing ring processing equipment which comprises a rack, a workpiece positioning device and a cutting device, wherein the workpiece positioning device comprises a positioning seat, a second driving device, a driving shaft and a mobile lock rod, and a first spring is arranged at the lower part of the driving shaft in an inner chamber; a propping component capable of moving up and down is arranged at the upper end of the positioning seat, and the inner end of the propping component is propped against the upper end surface of the driving shaft; a push oblique plane suitable for pushing the mobile lock rod to move outwards is formed on the side surface of the driving shaft, and the mobile lock rod is sleeved with a second spring suitable for providing inward elastic force for the mobile lock rod; the outer surface of the positioning seat is a cylindrical surface suitably sleeved with a sealing ring to be processed, and a support ring surface suitable for supporting the inner edge of the corresponding end surface on the sealing ring is formed at the bottom end of the positioning seat; the cutting device comprises a cutting seat, a first driving device, a cutting tool, a feed screw and a driving motor. The structure of the sealing ring processing equipment is reasonable and simplified, and the precision of the sealing ring processed by the sealing ring processing equipment is ensured.

Owner:HAINING JIUJIU RUBBER & PLASTIC

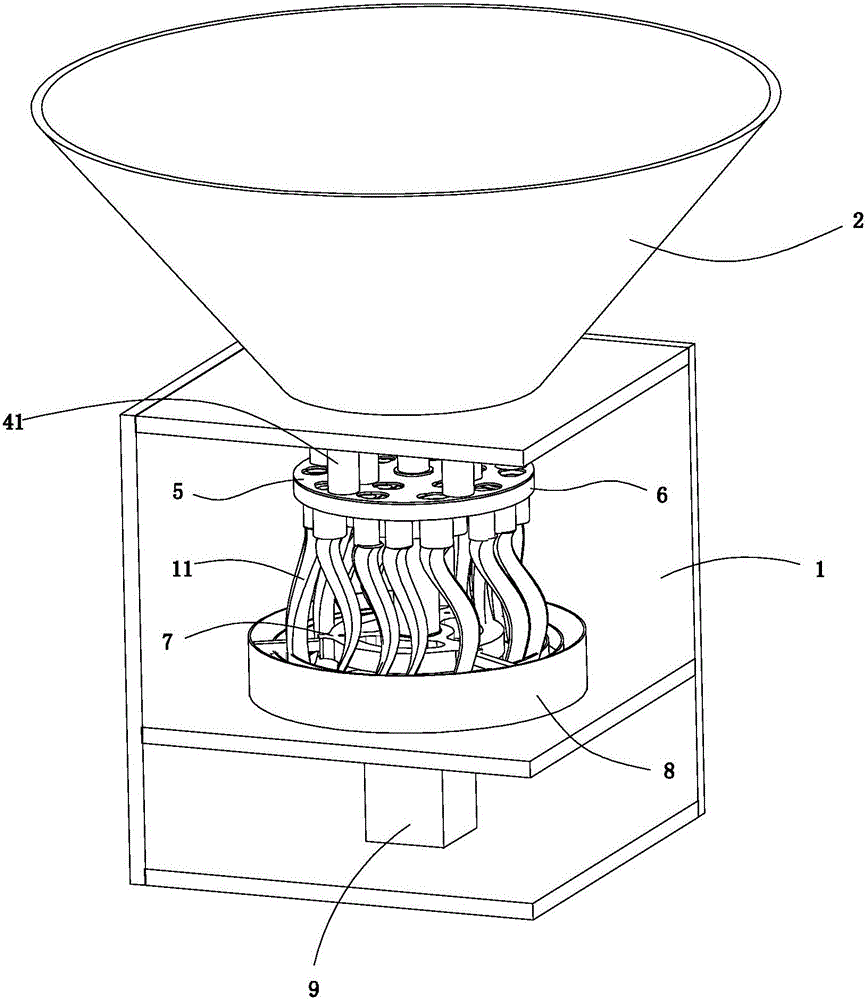

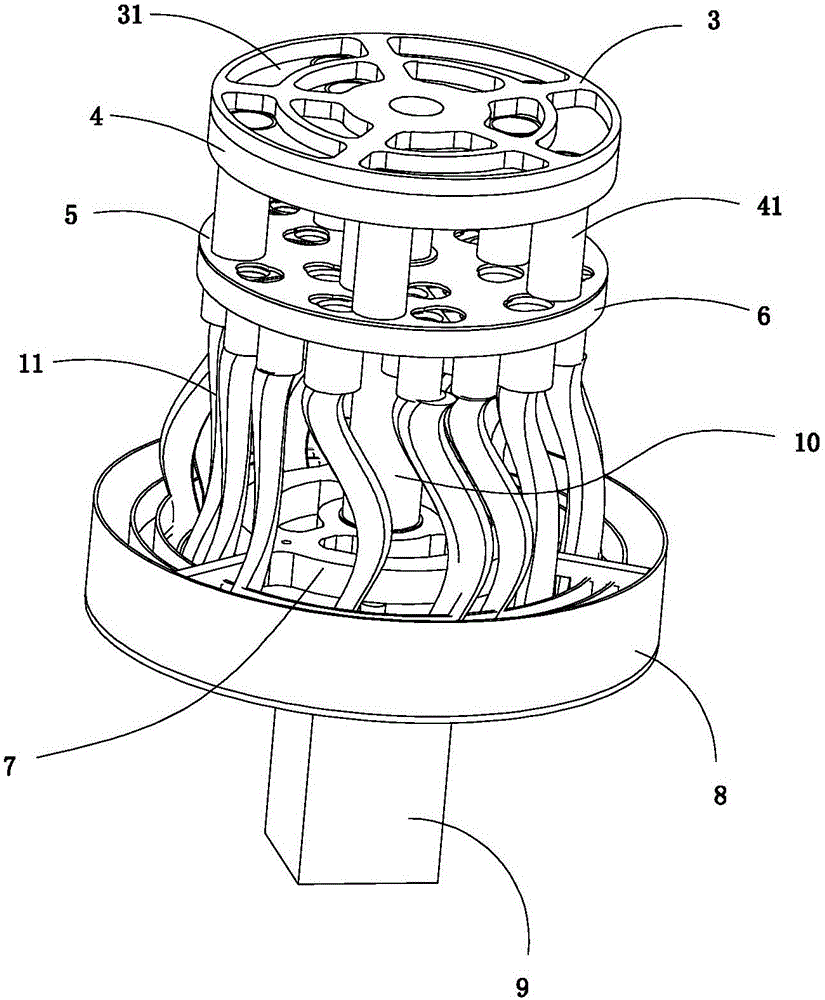

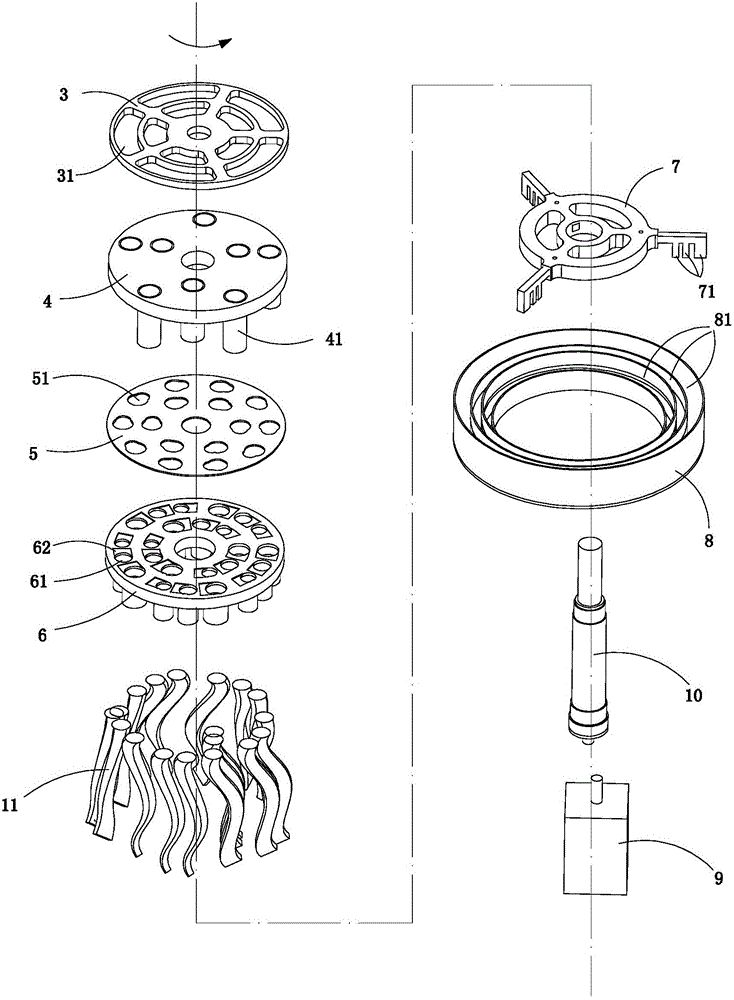

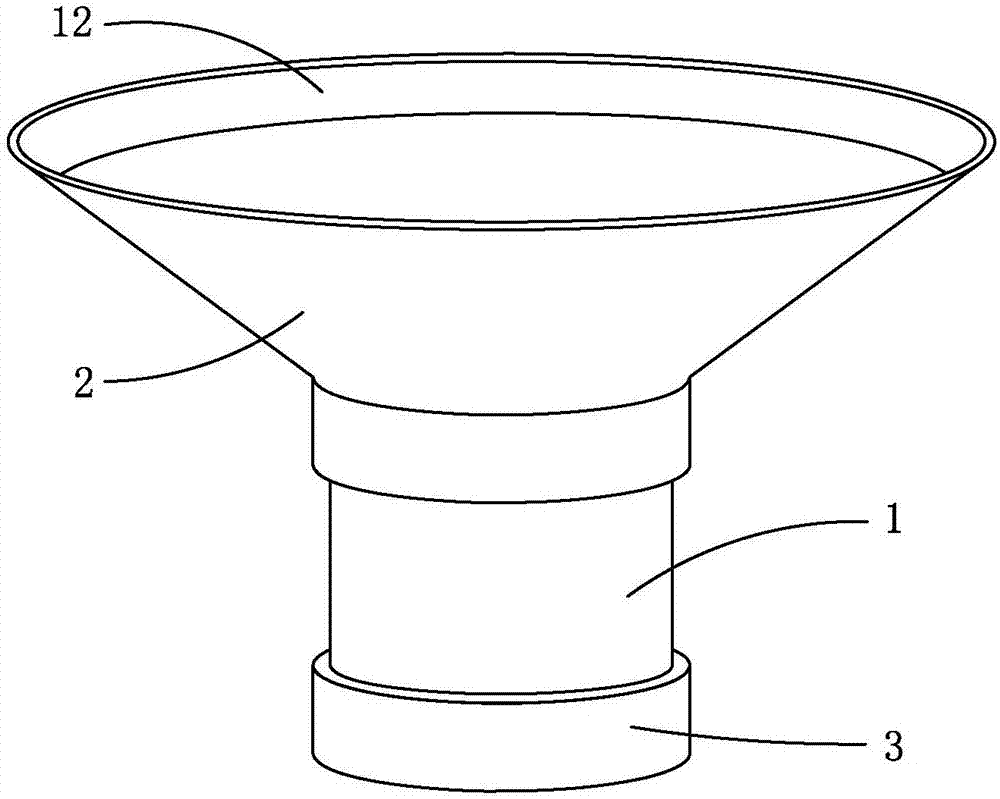

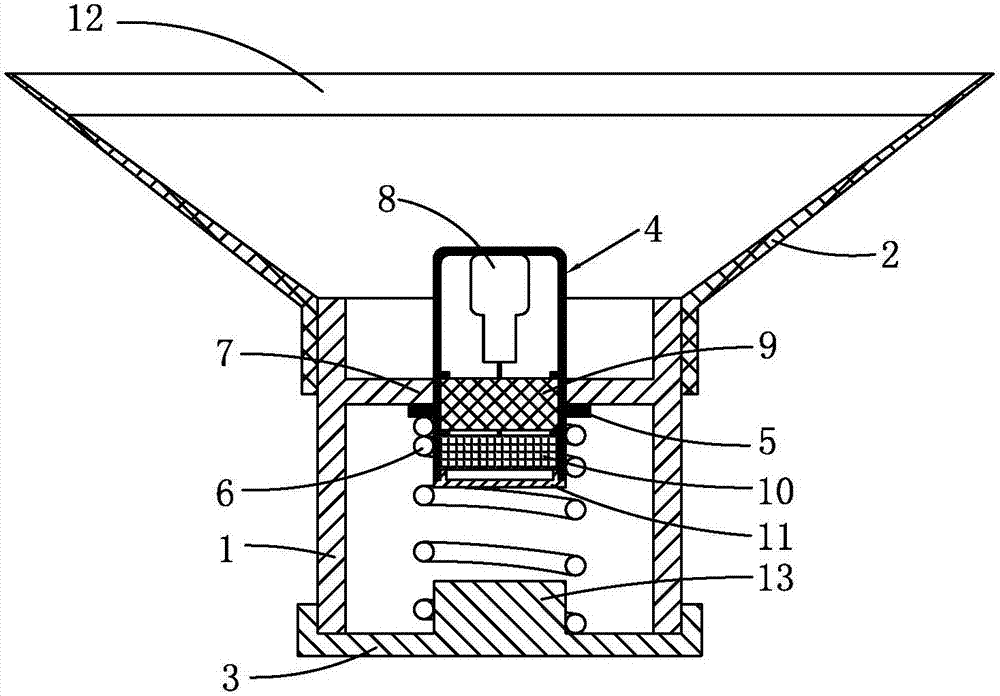

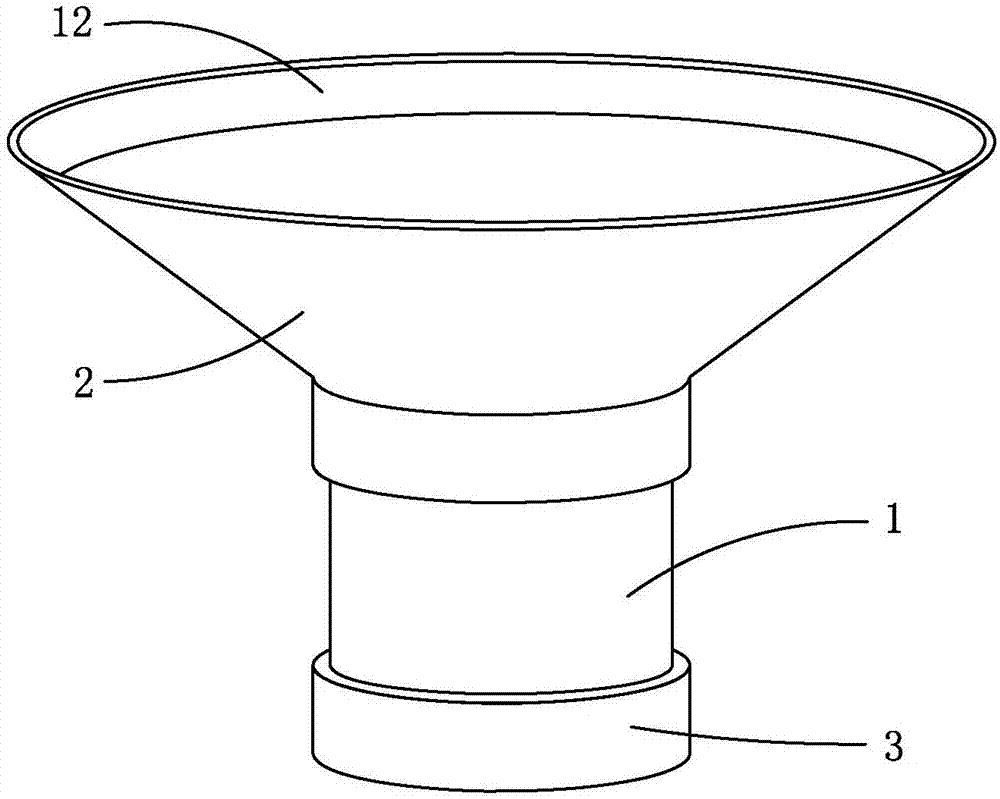

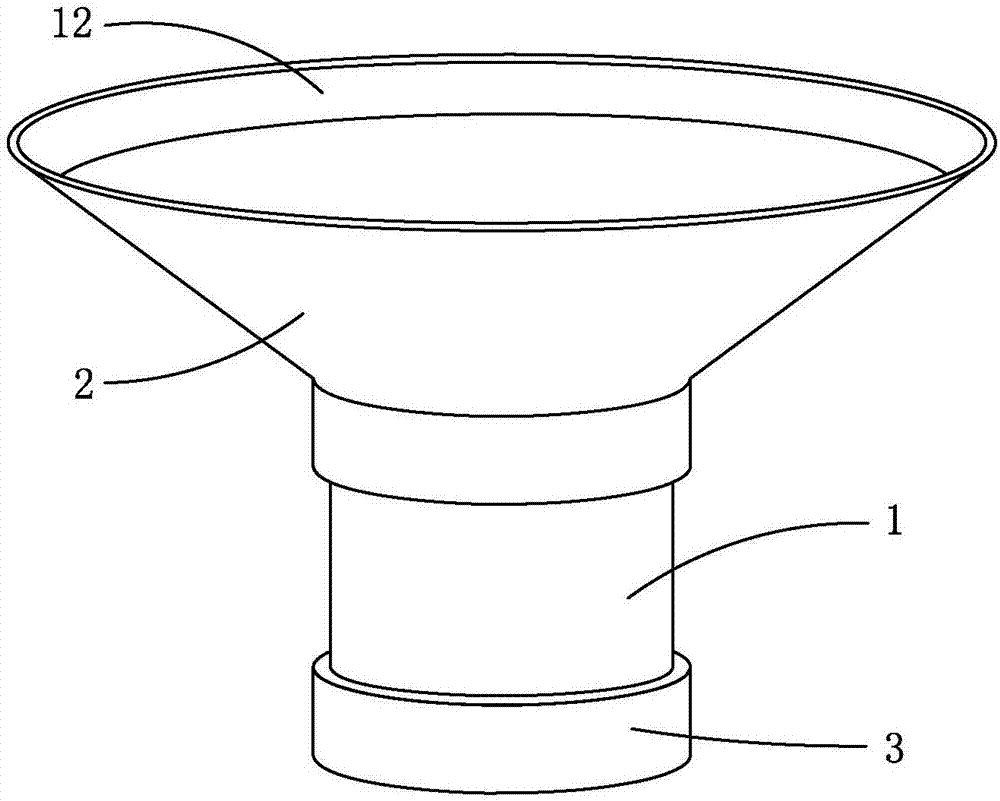

Coin sorter

ActiveCN105913542AThe structure is simplified and reasonableEasy to useCoin/paper handlersEngineeringElectric motor

The invention discloses a coin sorter. A machine shell is provided with a coin inlet funnel, a coin pushing disc, a coin guiding disc, a screening disc, a classification disc, a coin sweeping wheel and a coin blocking ring that are all orderly arranged from top to bottom coaxially; a main shaft which is driven by an electric motor to rotate is arranged on axis positions of the coin pushing disc, the coin guiding disc, the screening disc, the classification disc, the coin sweeping wheel and the coin blocking ring in a penetrating manner; the main shaft drives the coin pushing disc, the screening disc and the coin sweeping wheel to rotate synchronously; the coin guiding disc, the classification disc and the coin blocking ring are fixed and cannot rotate along with the main shaft; the coin pushing disc is provided with a coin pass hole through which coins can pass, the coin guiding disc is provided with coin falling tubes, the screening disc is provided with coin inlet holes, the classification disc is provided with coin separating holes, side parts of all the coin separating holes are connected with a coin guiding grooves, the coin blocking ring is provided with annular accommodating chambers, lower ends of all the coin separating holes are connected with coin guiding tubes, the coin sweeping wheel are provided with coin sweeping teeth, bottom parts of all the annular accommodating chambers are provided with coin falling holes, and lower parts of the coin falling holes are connected with the coin falling tubes. The coin sorter disclosed in the invention is simple and reasonable in structure, low in manufacture cost, and low in sorting error rate.

Owner:JIAXING VOCATIONAL TECHN COLLEGE

Buoyancy type automatic control valve

InactiveCN102095016AGuaranteed service lifeHigh sensitivityOperating means/releasing devices for valvesAutomatic controlWater channel

The invention discloses a buoyancy type automatic control valve. The buoyancy type automatic control valve comprises a valve body, a floater, a driving piece, a seal plug and a diaphragm type valve plug assembly; the diaphragm type valve plug assembly comprises a pressure relieving piece, and a seal film arranged on the pressure relieving piece; the valve body comprises a water inlet passage, a pressure regulation chamber and a water outlet passage; a water inlet pipe communicated with the water inlet passage and an water outlet pipe communicated with the water outlet passage are arranged in the pressure regulation chamber; a pressure regulation cavity is formed between one end of the pressure regulation chamber near the floater and the diaphragm type valve plug assembly; a water diversion hole communicated with the pressure regulation cavity and the water inlet passage is formed on the pressure relieving piece; a pressure regulation hole is formed at one end of the pressure regulation chamber near the floater; and the floater drives the seal plug to block up or separate from the pressure regulation hole through the driving piece in the reciprocating process. Water channel in the valve body can be automatically connected or disconnected according to the change of water level in a water storage container without power supply so as to realize automatically supplying water or cutting off the water supply; moreover the buoyancy type automatic control valve has a reasonable and simplified structure and high sensitivity, can guarantee the service life of a floating ball, and is not easily damaged.

Owner:陈银环

Piano keyboard coupling type glass slice board falling device

The invention relates to a piano keyboard coupling type glass slice board falling device, in particular to a glass slice board falling device which comprises a stander, a swing arm mechanism, a lifting mechanism and an electric motor transmission mechanism; wherein the lifting mechanism consists of an air cylinder, a crank and a buffering device; the glass slice board falling device is characterized in that each swing arm is provided with an independent transmission shaft and a pair of bearing seats, and each unit transmission shaft is fixed with a sprocket wheel which is sheathed and jointed with the swing arm; the swing arm is separately connected with the lifting mechanism to form a glass piece falling unit; the first unit transmission shaft is meshed with an output gear of the electric transmission mechanism, and the right end of the first unit transmission shaft is provided with a groove vertical to a shaft axis, left shaft ends of the unit transmission shafts are provided with the same boss, and right shaft ends are provided with grooves; bosses of the adjacent unit transmission shafts are sheathed and jointed with the grooves. The device has the advantages that compared with the prior art, a long shaft and a plurality of pairs of gears can be omitted, the structure is simplified and reasonable, and the structure cost is reduced.

Owner:FUYAO GLASS IND GROUP CO LTD

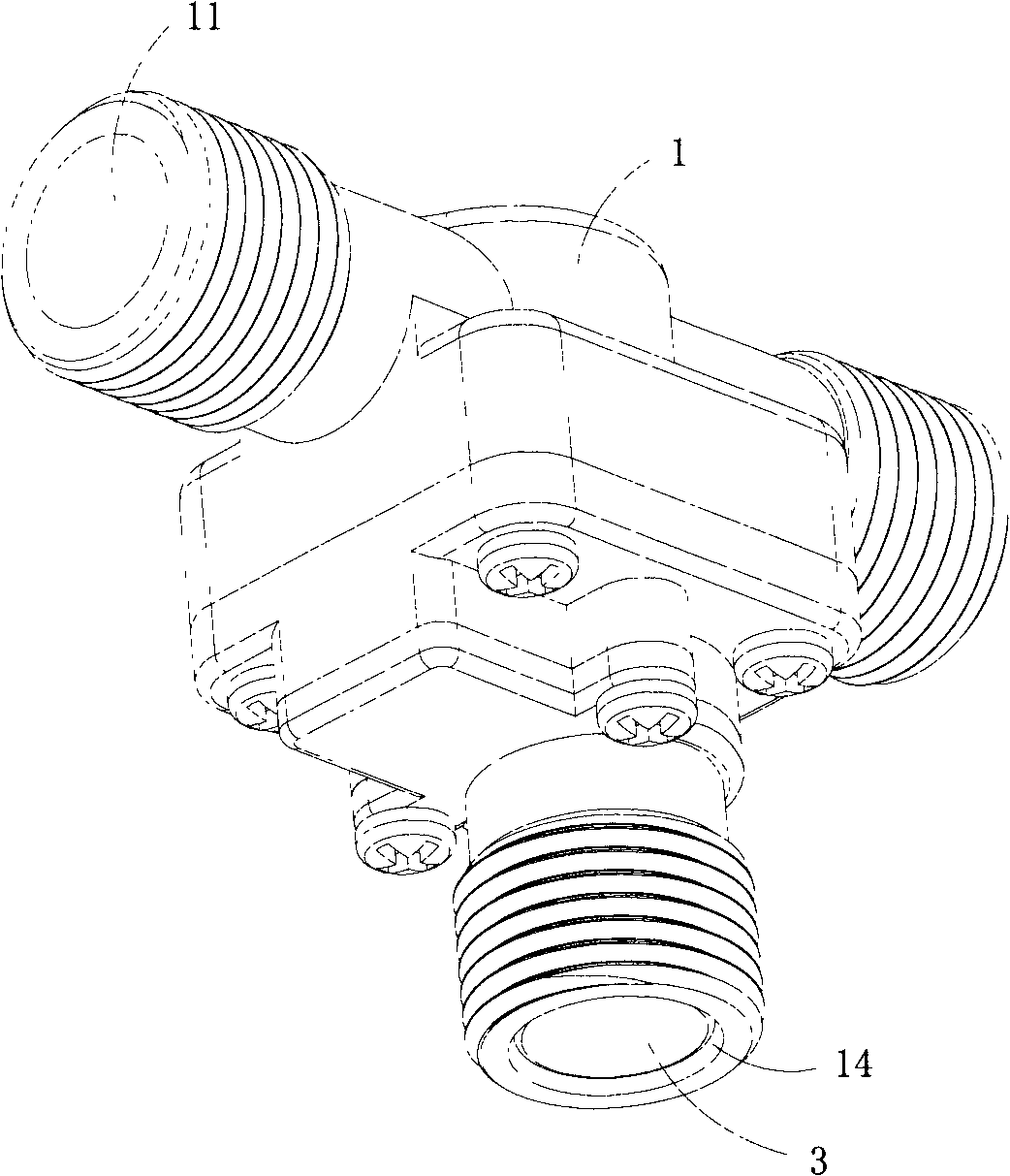

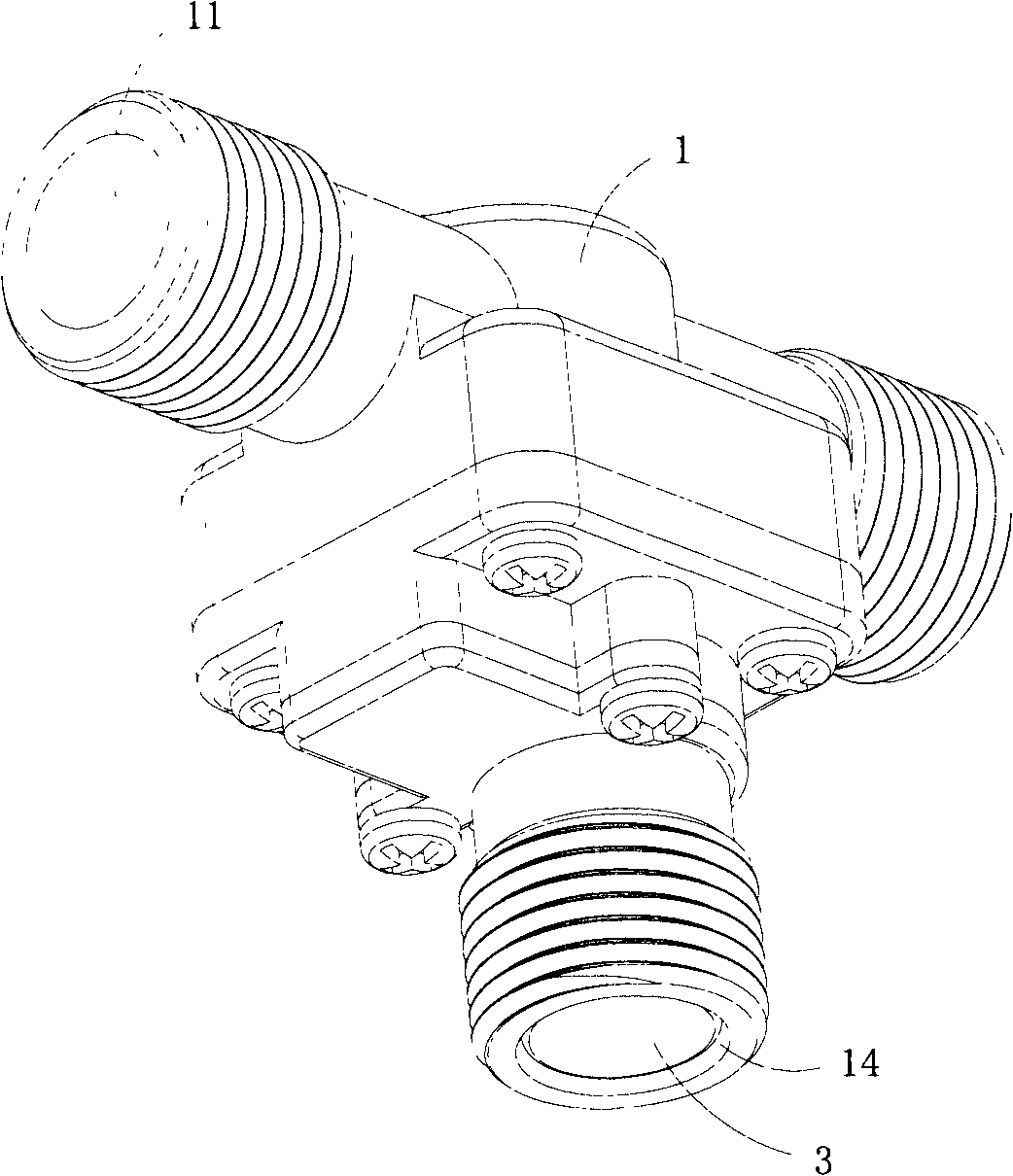

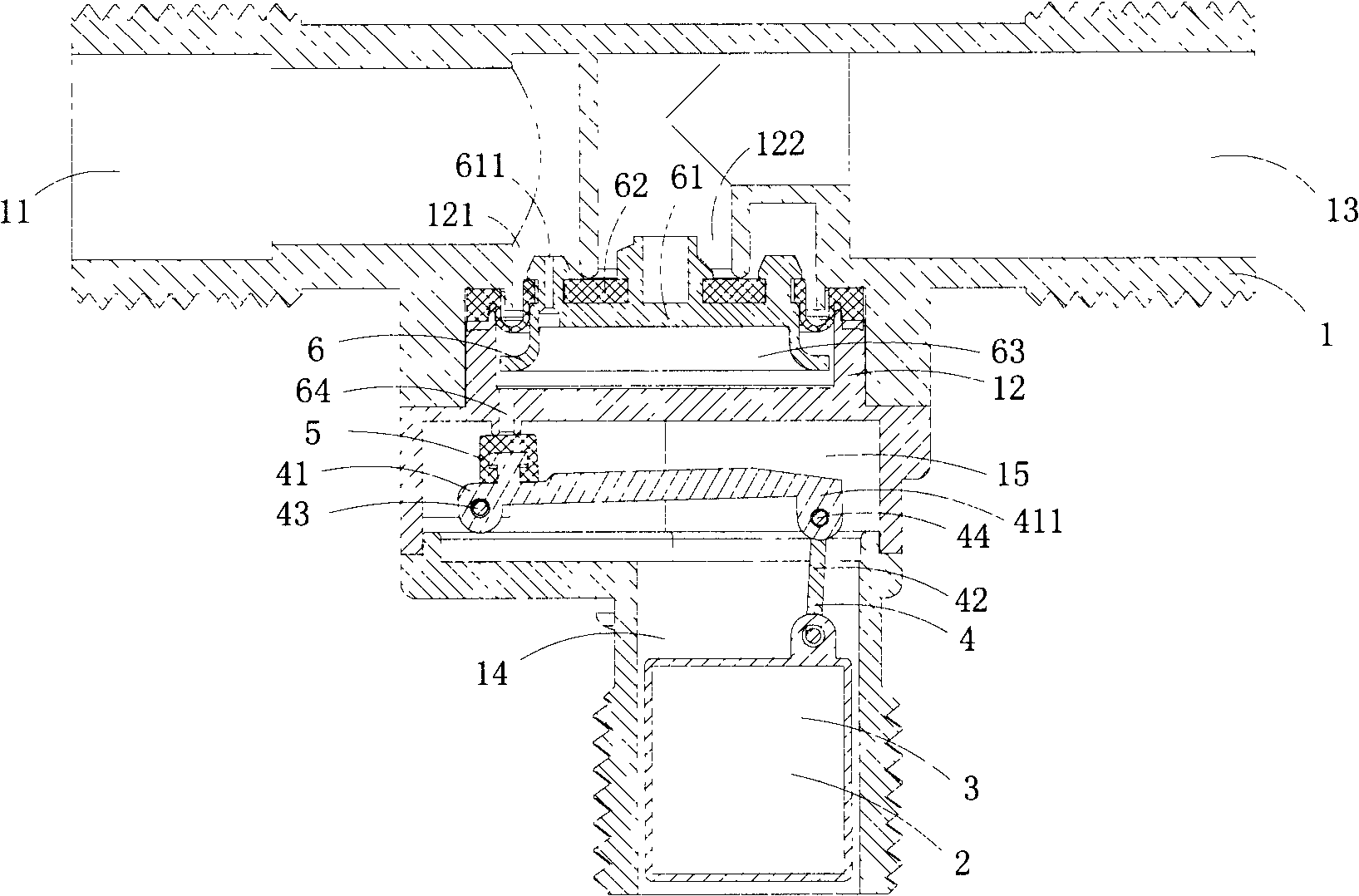

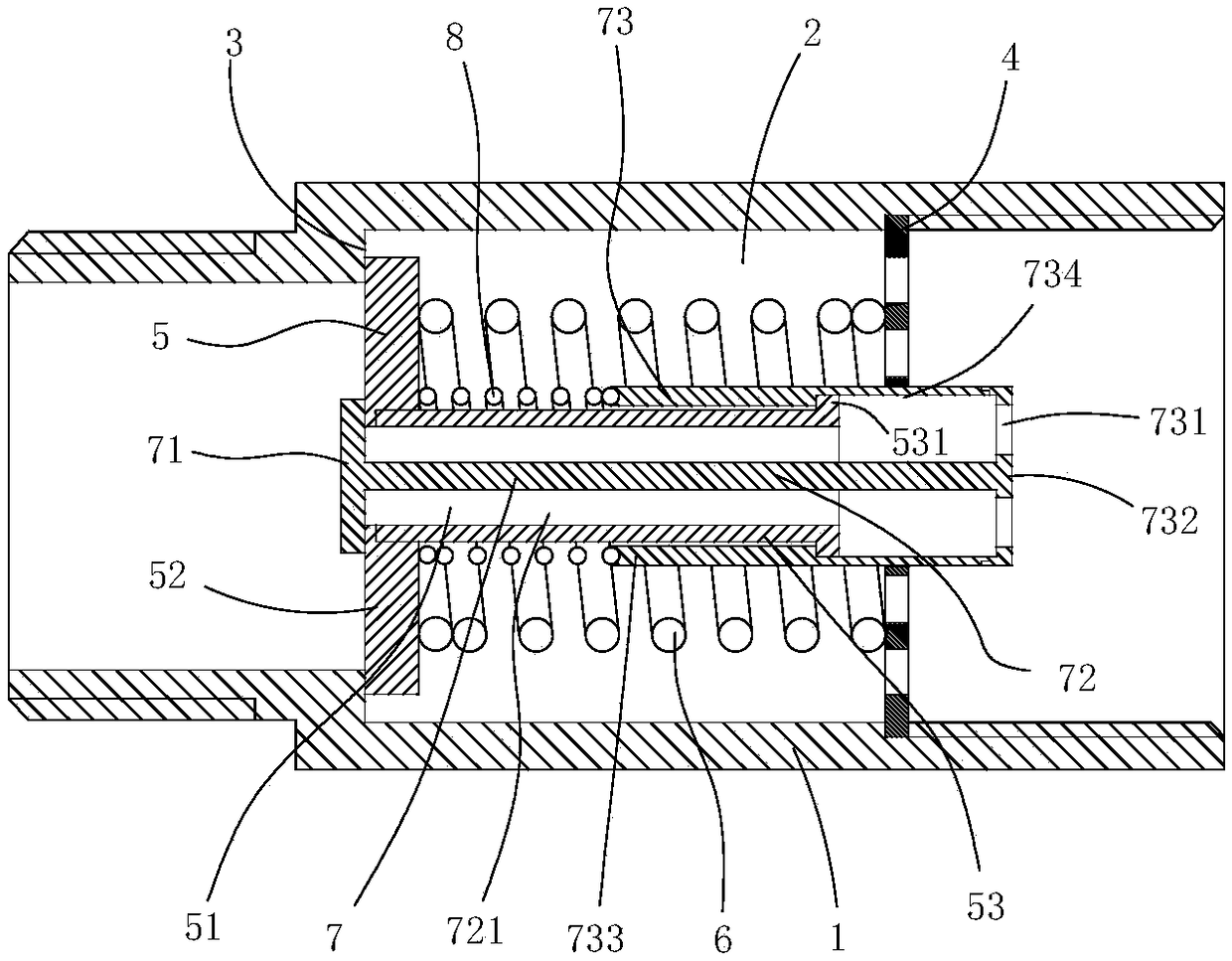

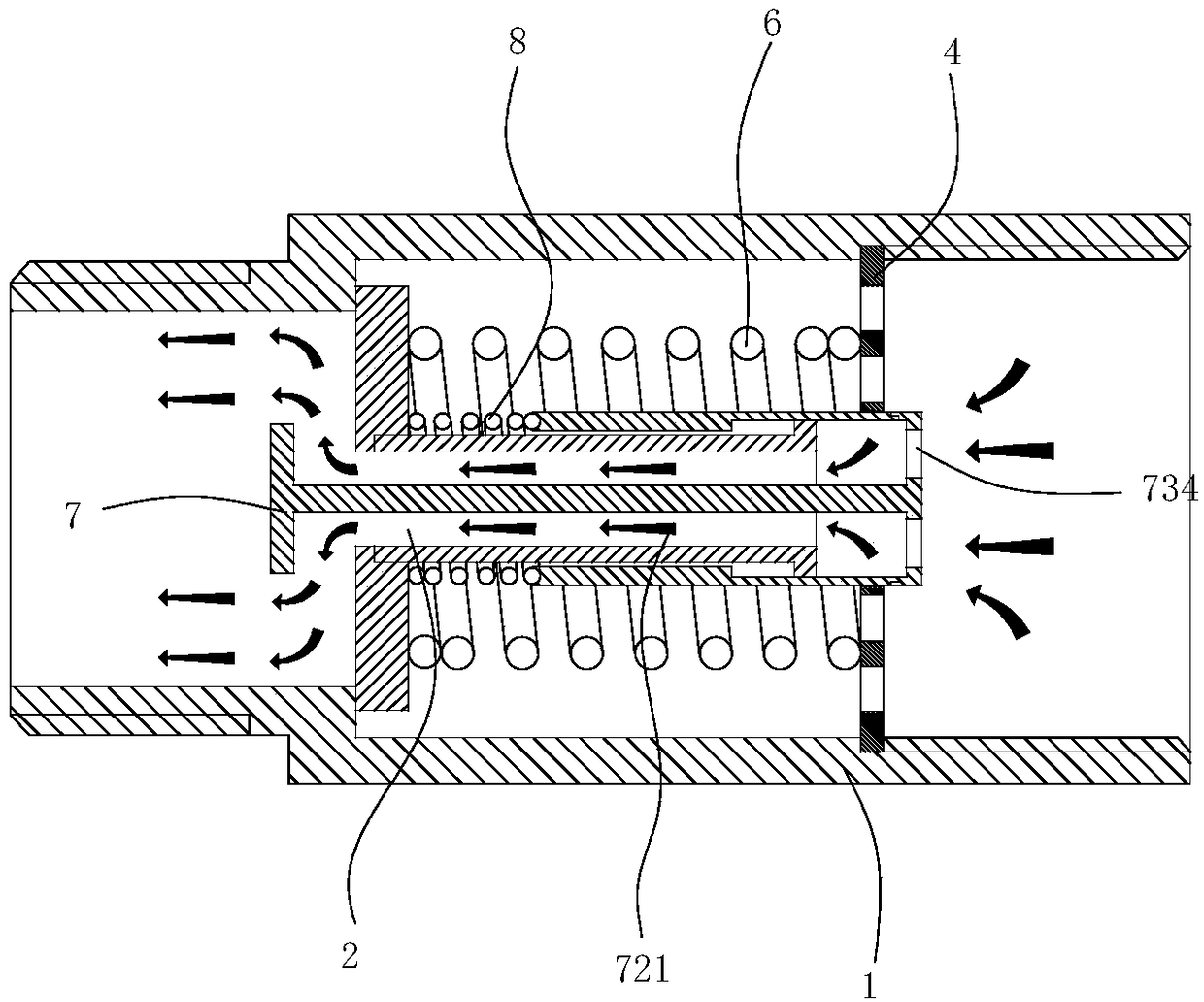

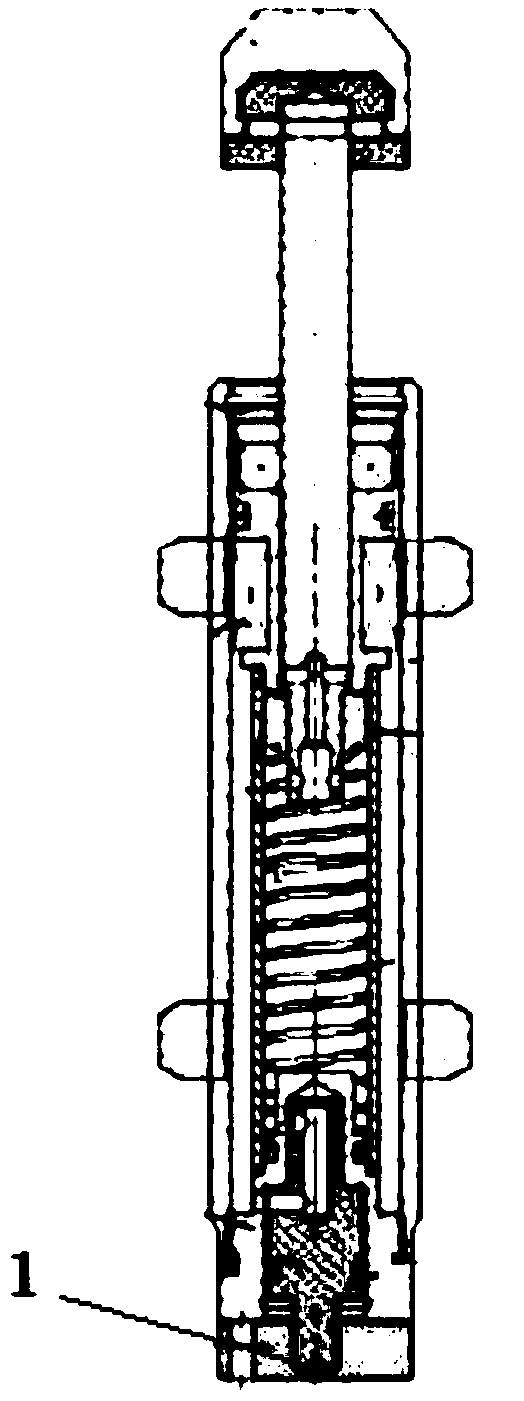

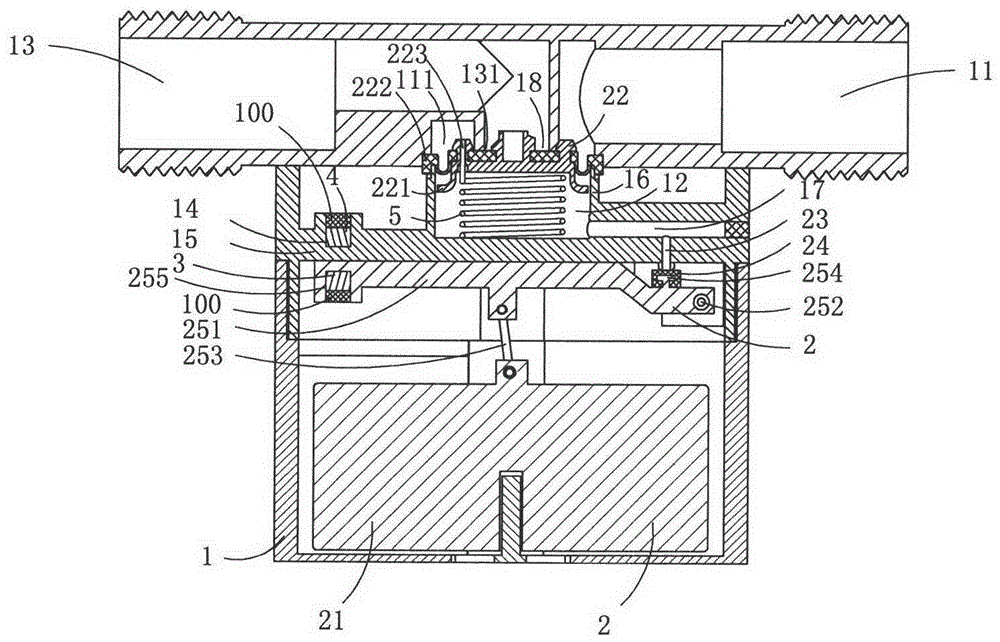

One-way valve with built-in decompression function

PendingCN108131473AThe structure is simplified and reasonablePrevent backflowCheck valvesEqualizing valvesEngineeringWater tanks

The invention discloses a one-way valve with a built-in decompression function. The one-way valve comprises a valve body; the valve body is internally provided with a fluid channel in the axial direction; annular sealing faces and spring seats are fixed in the fluid channel at intervals; a first valve element assembly is arranged between the annular sealing faces and the spring seats in the fluidchannel; the first valve element assembly comprises first valve elements and first springs; the first valve elements contact with the annular sealing faces under the action of the first springs in a sealing mode; decompression holes are formed on the first valve elements in the axial direction in a penetrating mode; the valve body is also internally provided with a second valve element assembliesused for plugging the decompression holes; the second valve element assembly comprises a second valve element and second springs; the second valve element seals the decompression holes under the action of the second springs; and the opening direction of the second valve element is opposite to that of the first valve elements. The one-way valve with the built-in decompression function is suitable to be installed at a water inlet of a water heater tank; when the water heater water tank supplies water normally, the one-way valve can guide a pipeline; and when the pressure of the water heater tankis too high, and the one-way valve can reflow pressure.

Owner:ZHEJIANG SHENTAI SOLAR ENERGY

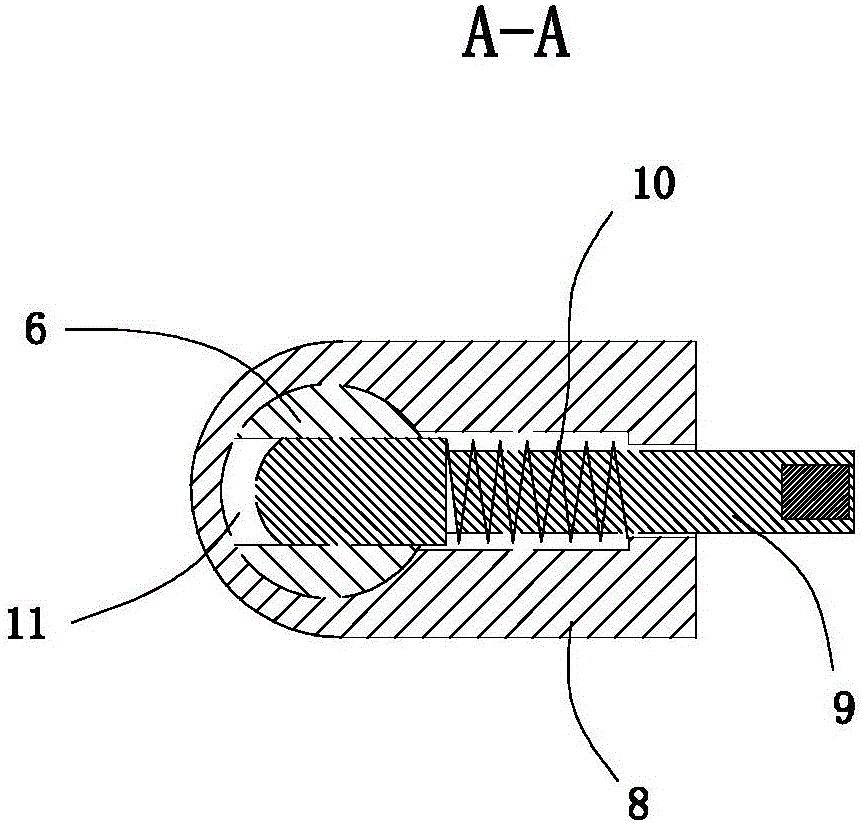

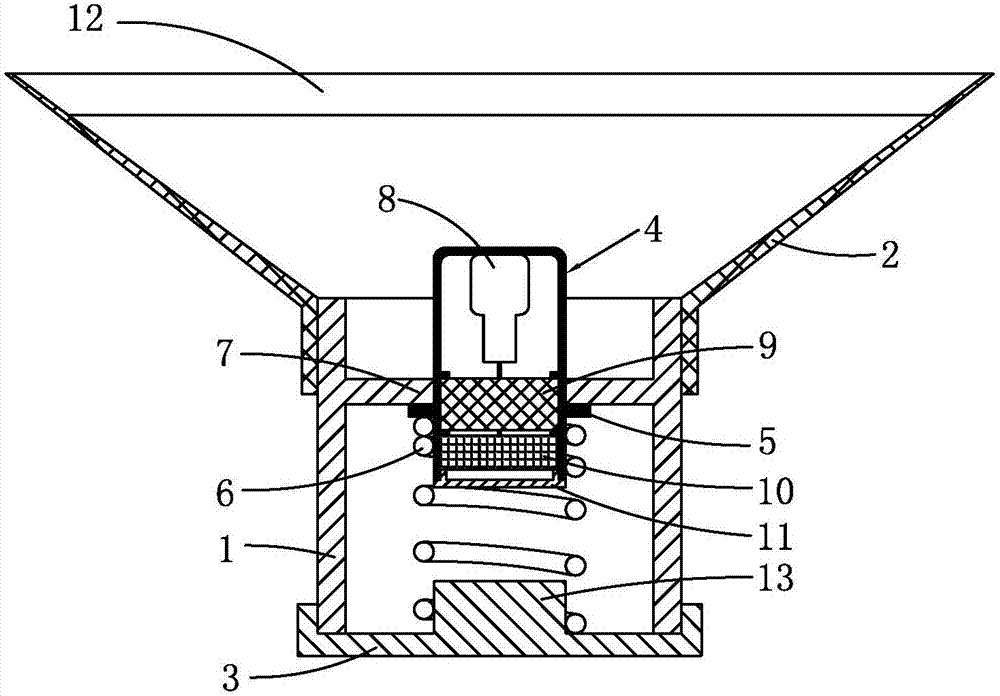

Wireless sensor

InactiveCN107014503AReliable contactEasy to installThermometer detailsMeasurement apparatus componentsLine sensorWireless transmission

The invention discloses a wireless sensor comprising a sleeve. The front end of the sleeve is connected with an absorbing plate; and the rear end of the sleeve is connected with an end cover. A sensor body is arranged in the sleeve; and a limit protrusion protrudes from the outer wall of the sensor body. A spring sleeves the sensor body; and one end of the spring is abutted against the limit protrusion and the other end of the spring is abutted against the end cover. The inner wall of the sleeve protrudes to form a limit step; and the limit protrusion is abutted against the limit step under the effect of the spring. A front probe of the sensor body passes through the limit step and extends out of the bottom of the absorbing plate. The sensor body consists of a wireless transmitting circuit and a battery; and the front probe and a wireless transmitting circuit board are connected. When being installed, the wireless sensor is absorbed to the surface of a to-be-measured object by the absorbing plate; and under the effect of the spring, the sensor body is in contact with the to-be-measured object reliably all the time. Therefore, installation becomes convenient. The sensor body uses the wireless transmitting circuit board to realize wireless transmission of front probe detection signals; and the usage becomes convenient and flexible.

Owner:成都灯岛科技有限公司

Side adjustment oil buffer

PendingCN107606033AChanging the problem of blind spots in the field of visionAccurate alignment adjustmentSpringsLiquid based dampersPulp and paper industryCylinder block

The invention discloses a side adjustment oil buffer. The side adjustment oil buffer comprises a cylinder body component, a buffer component arranged in the cylinder body component, an adjustment component and a liquid accommodated in the cylinder body component, and is characterized in that the cylinder body component comprises an outer cylinder and an inner cylinder arranged in the outer cylinder, wherein an end cap is arranged at one end of the outer cylinder; a bushing is arranged at the other end of the outer cylinder; the inner end of the inner cylinder is propped against the end cap; the outer end of the inner cylinder is propped against the bushing; the adjustment component comprises an adjustment bolt and an adjustment sleeve arranged on the outer wall of the inner cylinder; the adjustment bolt is inserted into the outer cylinder in the radial direction; an eccentric lug boss on the adjustment bolt is clamped with the adjustment sleeve; an adjustment hole is formed in the adjustment sleeve; a throttling hole is formed in the inner cylinder; the eccentric lug boss rotates to enable the adjustment sleeve to be displaced; and the adjustment hole can relatively adjust the cross section of the throttling hole. A visual dead zone is avoided during adjustment of a throttling area.

Owner:C JAC IND CO LTD

Chemiluminescence immunoassay instrument washing system with uniformly-mixing function

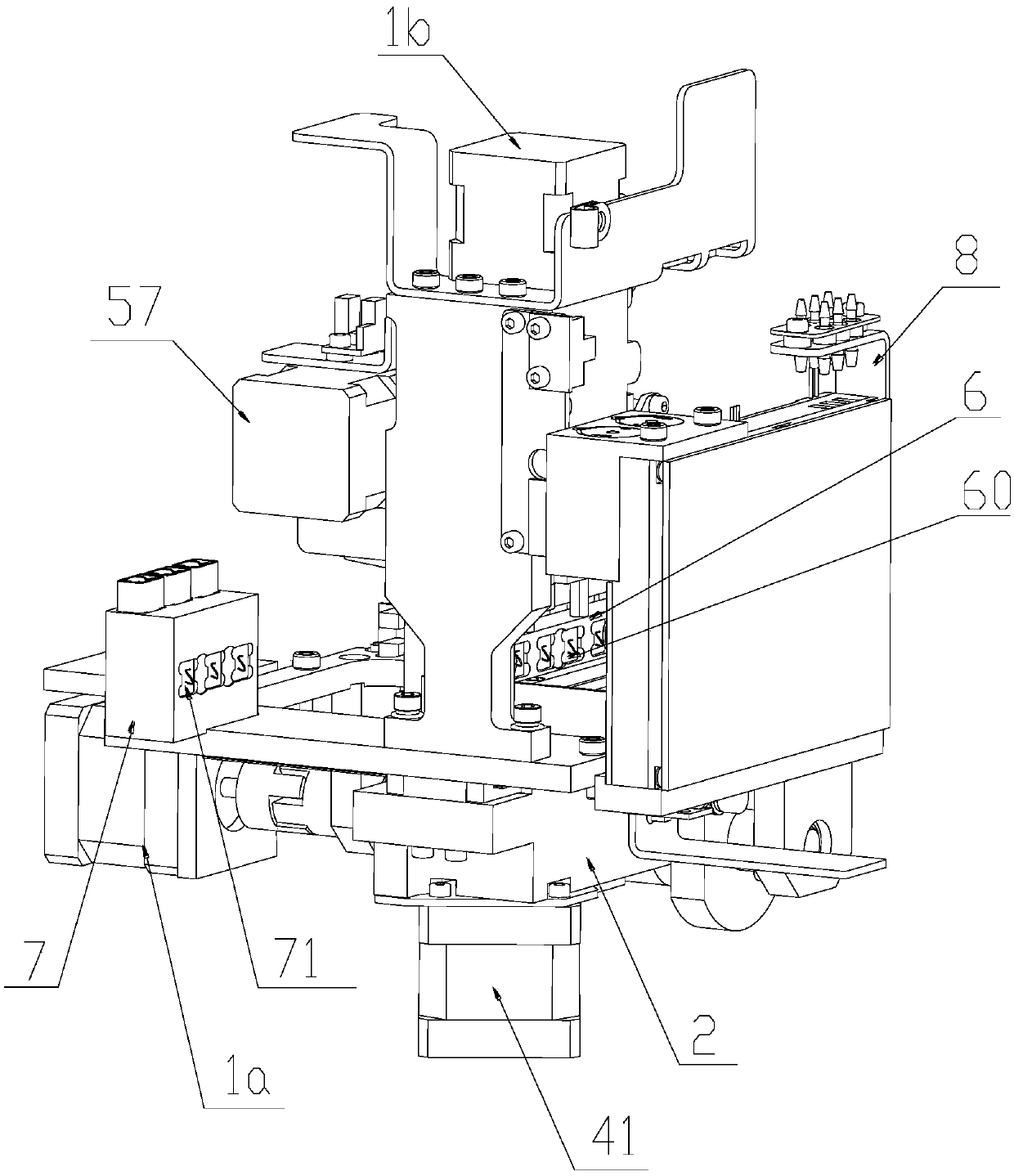

PendingCN109675889ASimple structureShorten wash in and out timesHollow article cleaningPuncturingInstrumentation

The invention discloses a chemiluminescence immunoassay instrument washing system with a uniformly-mixing function. The chemiluminescence immunoassay instrument washing system with the uniformly-mixing function comprises a base plate, and a uniformly-mixing base slidably arranged on the base plate, a washing cup holder, a uniformly-mixing assembly, and a washing head, wherein the uniformly-mixingbase has the a clamping position, a material filling position and a washing position in the slide stroke of the uniformly-mixing base; the washing cup holder is fixedly arranged on the uniformly-mixing base, and provided with washing holes distributed in the length direction; the uniformly-mixing assembly is fixedly arranged on the uniformly-mixing base, and used for enabling the washing cup holder to carry out horizontal reciprocating swinging, and carrying out uniformly-mixing on solutions in reaction cups in the washing holes; the washing head is movably arranged on the base plate, and capable of carrying out lifting movement relative to the base plate, and washing needle groups forming one-to-one correspondence with the washing holes and at least one substrate filling needle are arranged on the washing head. A washing mechanism and a uniformly-mixing mechanism are cooperated, and the functions of pre-adsorption and cup puncturing prevention are added, so that the washing effect andthe substrate uniformly-mixing effect are greatly improved, reduction for space occupation and gripper running times is benefited, the detection efficiency is increased, and the running safety and reliability are improved; and meanwhile, realization for the micro development of the instrument is benefited.

Owner:CHONGQING KEYSMILE BIOLOGICAL TECH CO LTD

Embossing machine

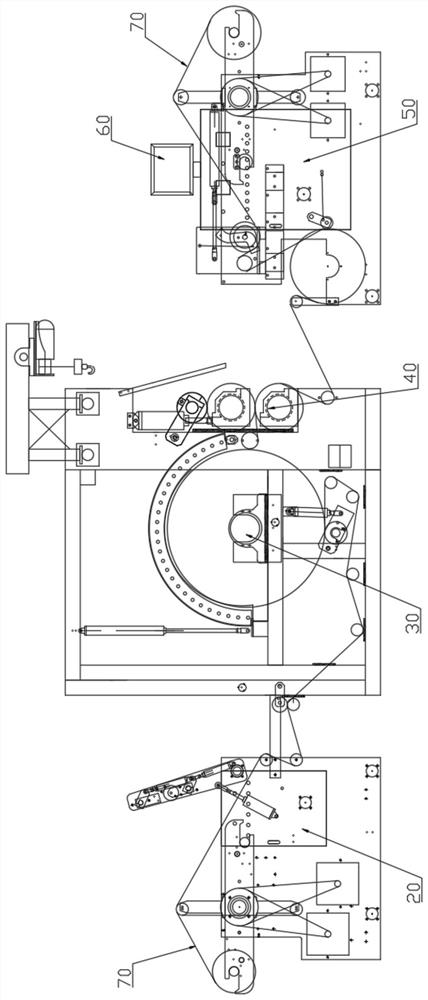

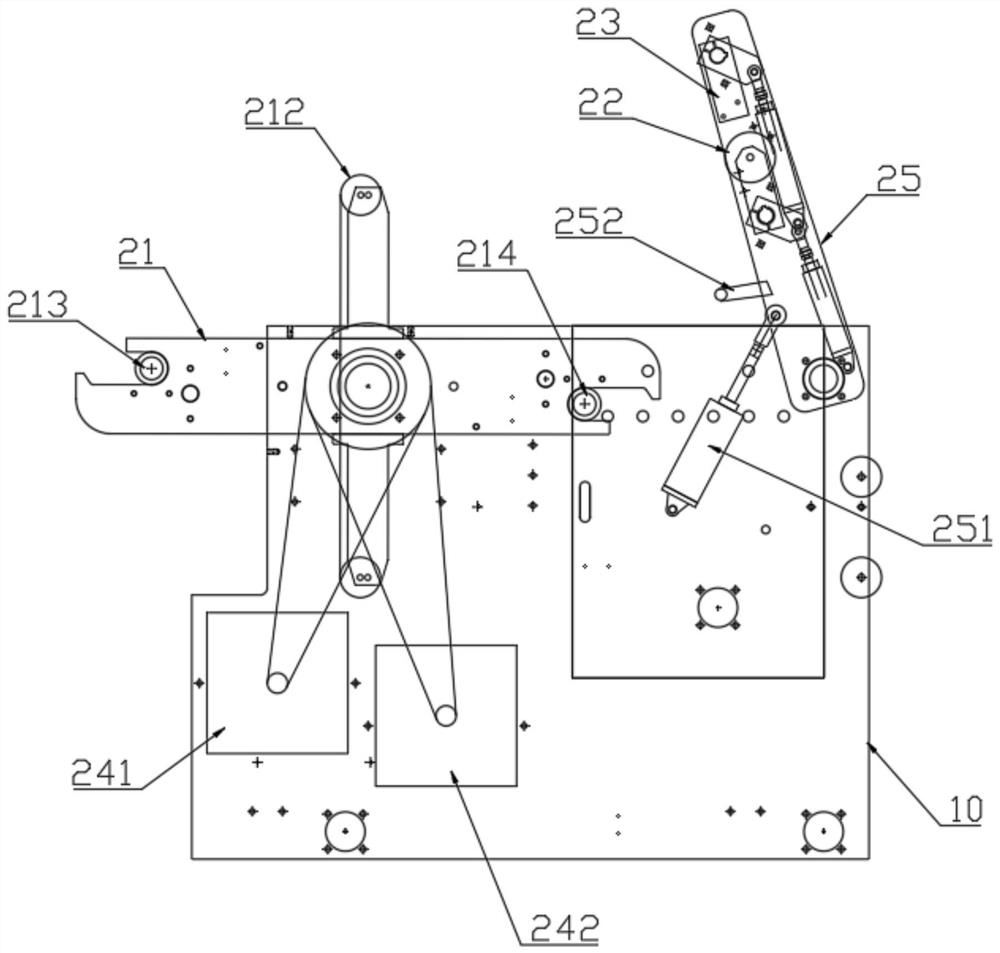

InactiveCN113119527AAchieve embossingRealize intelligent operationBag making operationsFinal product manufactureAssembly disassemblyEngineering

The invention relates to an embossing machine. The embossing machine comprises a support, a double-station roller feeding mechanism, a heating device, an embossing device and a double-station roller receiving mechanism. By arranging a feeding bearing frame and a receiving bearing frame, double-station work of the feeding mechanism and the receiving mechanism can be achieved, switching of coiled materials can be achieved without stopping the machine for feeding or receiving, the working efficiency of the machine is greatly improved, the structure is ingenious, intelligent operation of switching of the coiled materials is achieved, and manpower and material resources are saved; and the double-station roller feeding mechanism, the heating device, the embossing device and the double-station roller receiving mechanism can be independently installed and arranged, assembly, disassembly or maintenance and replacement are convenient, and transportation is convenient.

Owner:中山市中伟机械设备有限公司

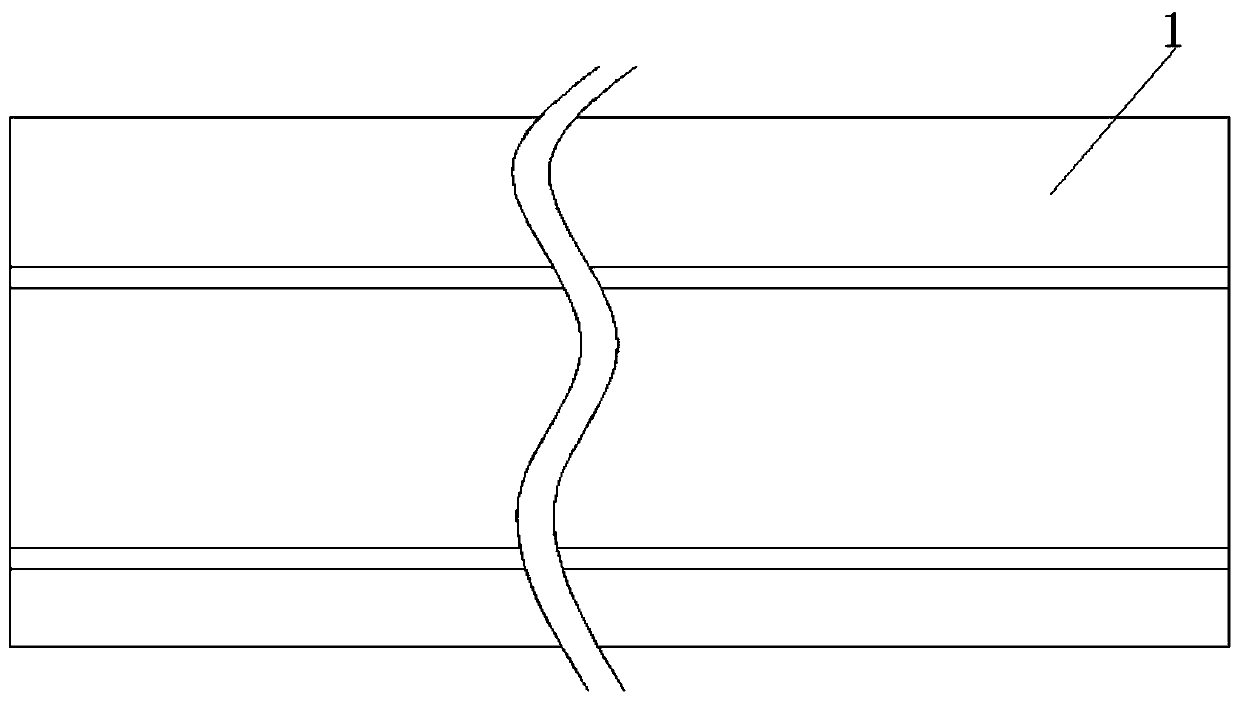

Jacquard broach made of carbon fiber composite material and manufacturing method

The invention relates to the technical field of jacquard broaches, in particular to a jacquard broach made of carbon fiber composite material. The broach comprises a broach body, the outer side of thebroach body is covered with an aluminum alloy wear-resistant layer, and the broach body is made of the carbon fiber composite material. The jacquard broach made of the carbon fiber composite materialcomprises the jacquard broach body made of the carbon fiber composite material and the aluminum alloy wear-resistant layer, the carbon fiber broach adopts pultrusion forming, so that the weight is lighter, the strength is higher, the jacquard weaving speed of a jacquard can be effectively improved, and the production efficiency is improved.

Owner:常州神鹰碳塑复合材料有限公司

Sensor

InactiveCN106932000AReliable contactEasy to installThermometer detailsMeasurement apparatus componentsPetroleum engineering

Owner:成都灯岛科技有限公司

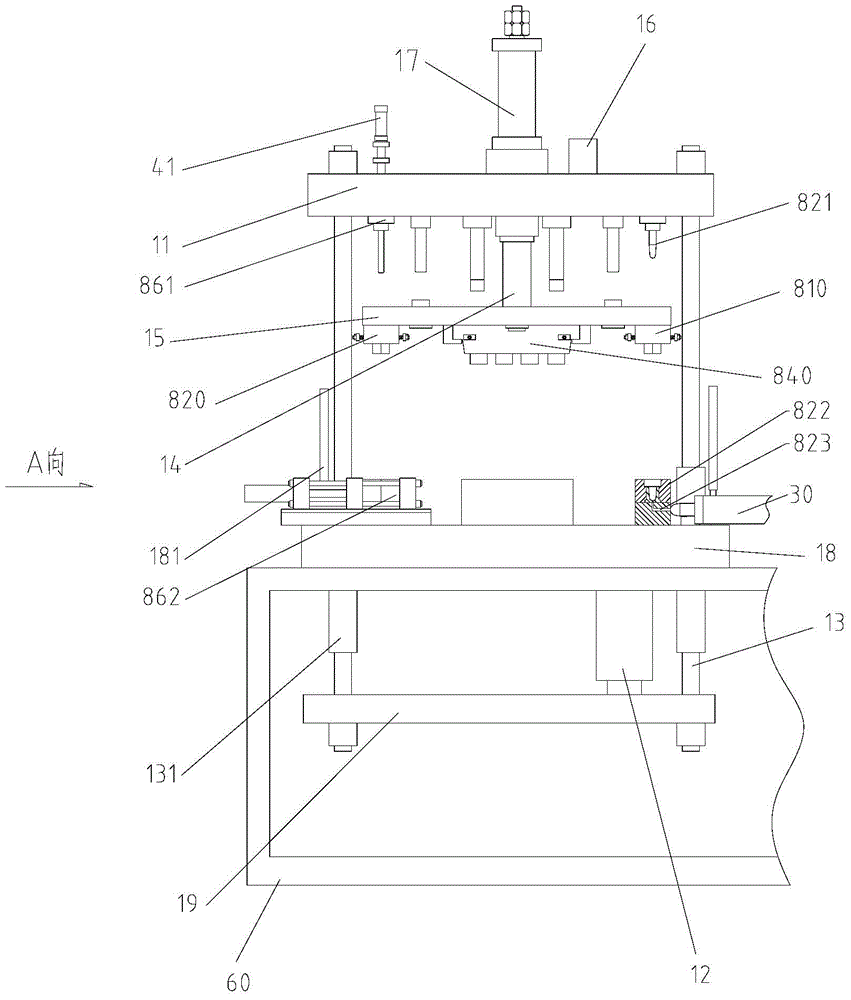

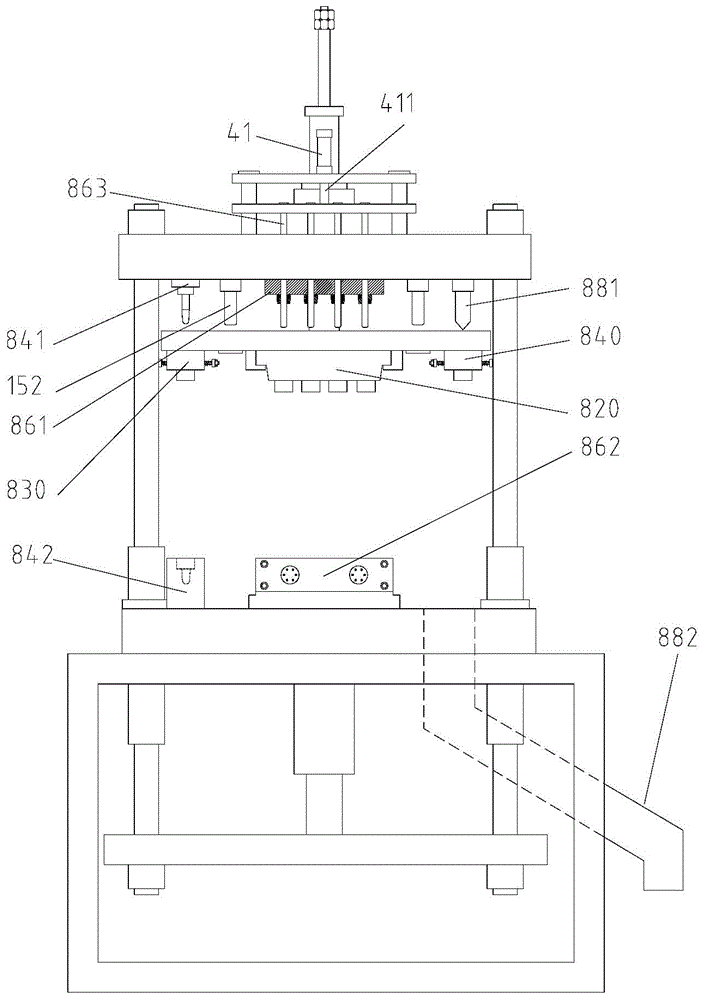

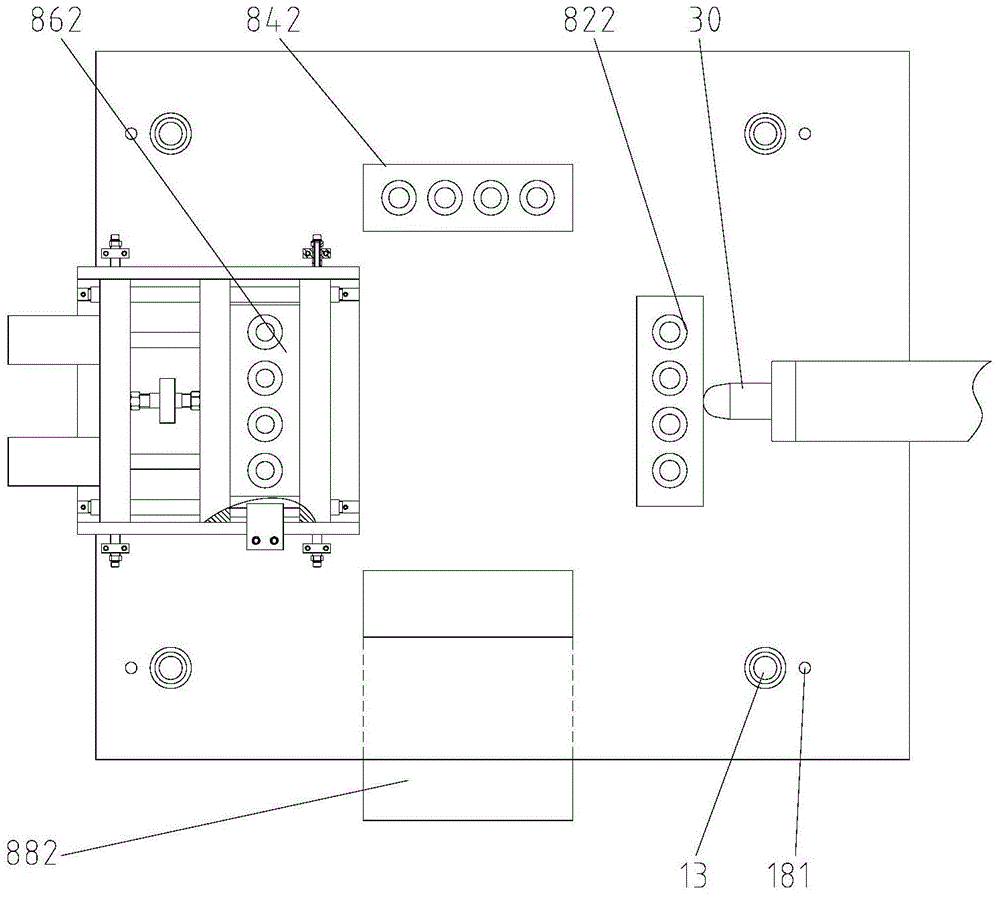

Multi-station rotary forming machine

The invention provides a multi-station rotary forming machine. The multi-station rotary forming machine comprises a main machine as well as an injection mold set and a stretch blow molding mold set which are arranged on the main machine. The main machine comprises a rack (60). A workbench panel (18) is fixed to the rack and connected with a lower mold plate (19) through a mold locking oil cylinder (12). The lower mold plate is connected with an upper mold plate (11) through a guide column (13). A rotary disk (15) is arranged below the upper mold plate and connected with a rotary driving mechanism (16). The injection mold set mainly comprises an injection opening mold set (810), a core mold set (821) and a female mold set (822). The injection opening mold set is fixedly arranged on the lower surface of the rotary disk and corresponds to the core mold set and the female mold set in position. The core mold set is directly and fixedly arranged on the lower end surface of the upper mold plate. A downward pushing oil cylinder (17) is arranged above the upper mold plate. A piston rod (171) of the downward pushing oil cylinder is connected with the rotary disk (15). According to the multi-station rotary forming machine, the structure is simplified and reasonable, operation action is stable, energy consumption is reduced, the requirements for the diversity of products are met, and the production efficiency is high.

Owner:柳州市精业机器有限公司

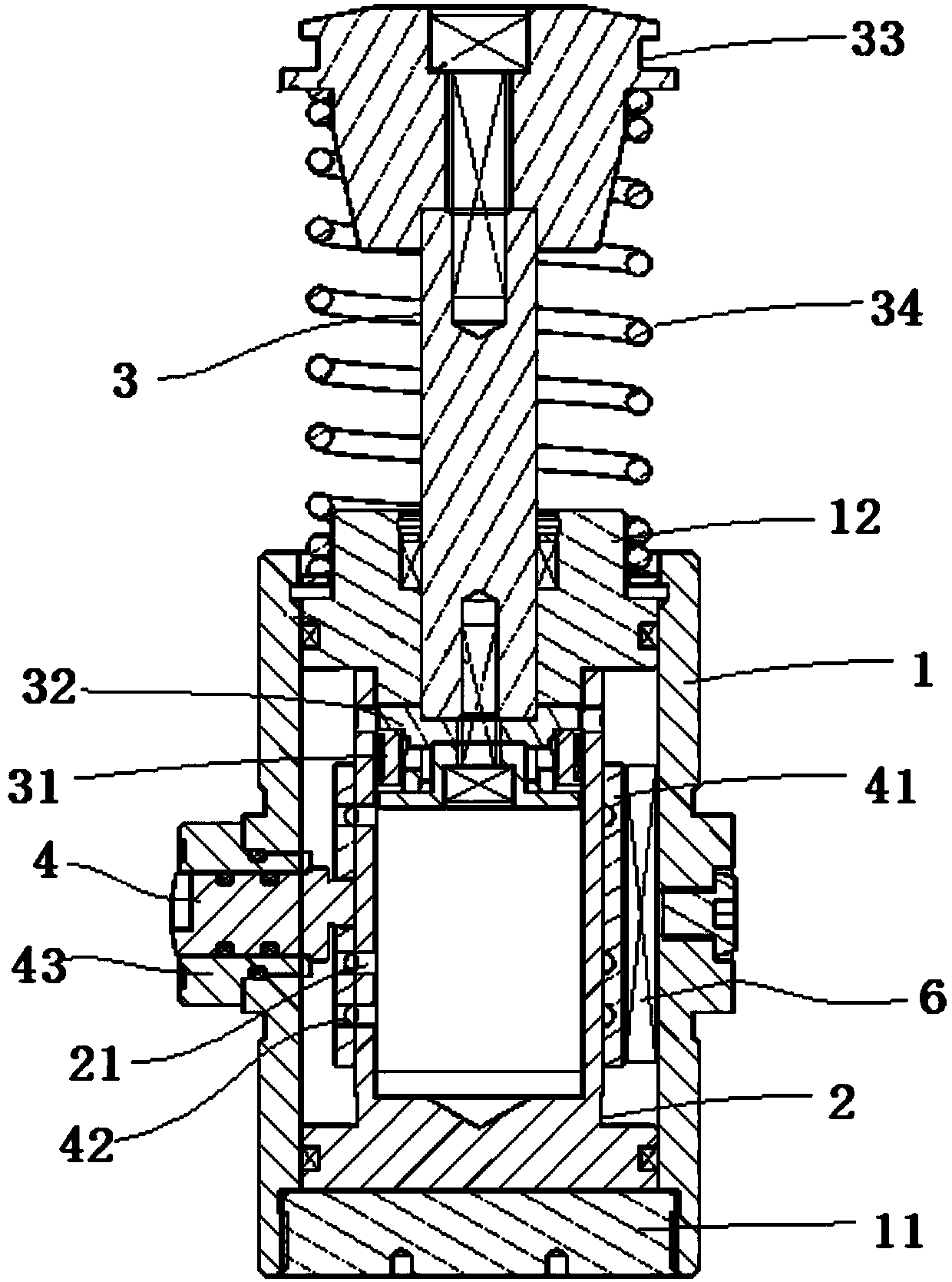

Buoyancy automatic control valve

ActiveCN102537493BGuaranteed service lifeHigh sensitivityOperating means/releasing devices for valvesValve housingsInlet channelAutomatic control

The invention discloses a buoyancy-type automatic control valve which comprises a valve body and a buoyancy-type on / off component, wherein the buoyancy-type on / off component comprises a floater for providing buoyancy, a pressure regulating chamber, a diaphragm-type valve core component, a pressure relieving channel, a seal plug, a linkage element, wherein the pressure regulating chamber is arranged above a control chamber; the diaphragm-type valve core component is arranged in the pressure regulating chamber and is used for separating the water inlet of a water outlet channel and the water outlet of a water inlet channel; the pressure relieving channel is used for communicating the pressure regulating chamber with the external environment; the seal plug is used for sealing and blocking a pressure relieving channel; the linkage element is used for linking the floater and the seal plug; the linkage element comprises a lever, a rotary shaft positioned at one end of the lever and a transmission element arranged at the middle part of the lever; the rotary shaft is arranged on the valve body; the seal plug is arranged on the lever and is positioned between the rotary shaft and the transmission element; and the transmission element drives the lever to rotate along the rotary shaft under the driving of the floater, and further drives the seal plug to perform the action of sealing and blocking the pressure relieving channel or opening the pressure relieving channel. The buoyancy-type automatic control valve provided by the invention is reasonable and compact in structure, has higher flexibility, and is difficult to damage.

Owner:佛山市顺德区中江节能电子有限公司

Temperature sensor

Owner:成都灯岛科技有限公司

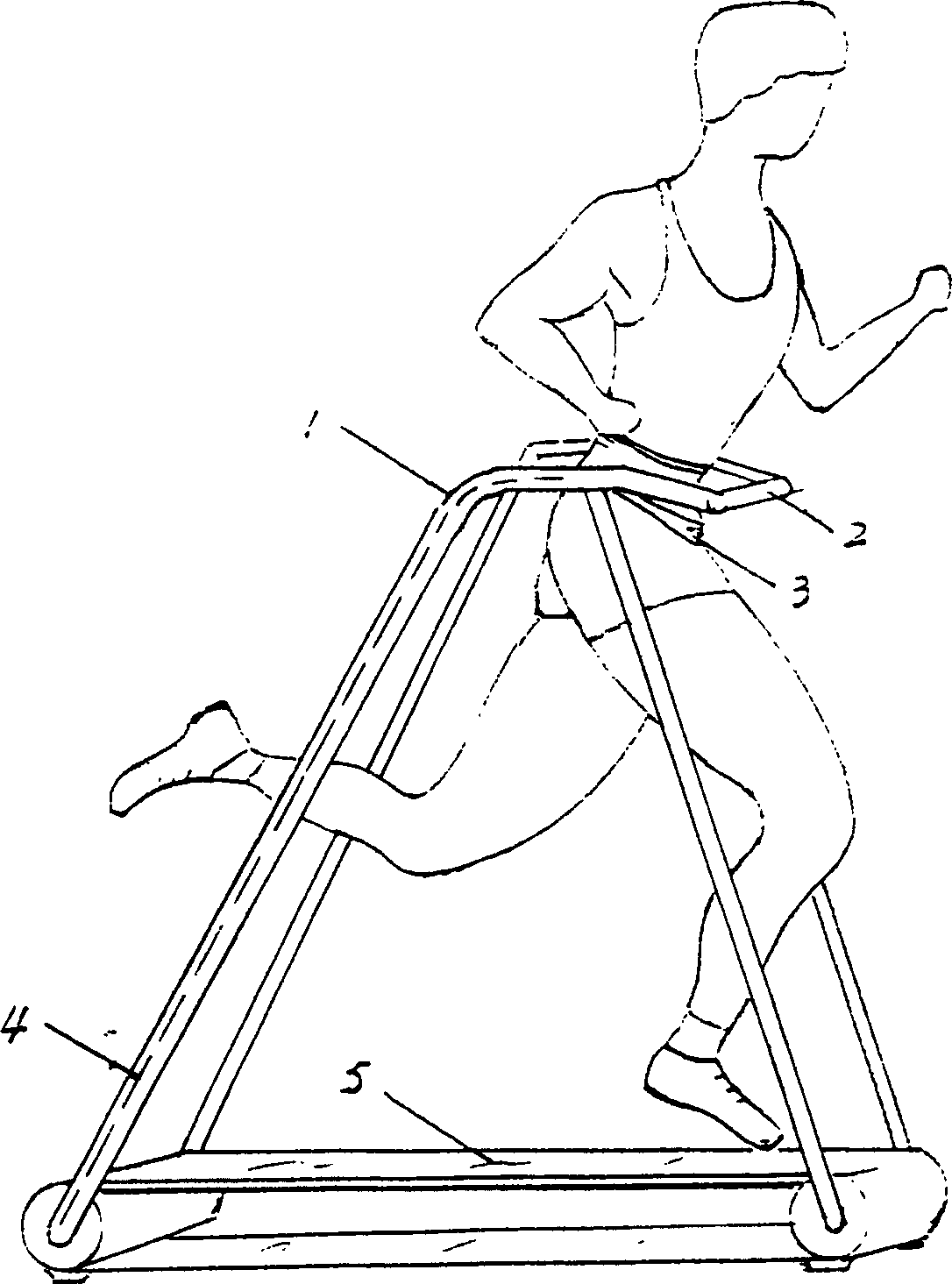

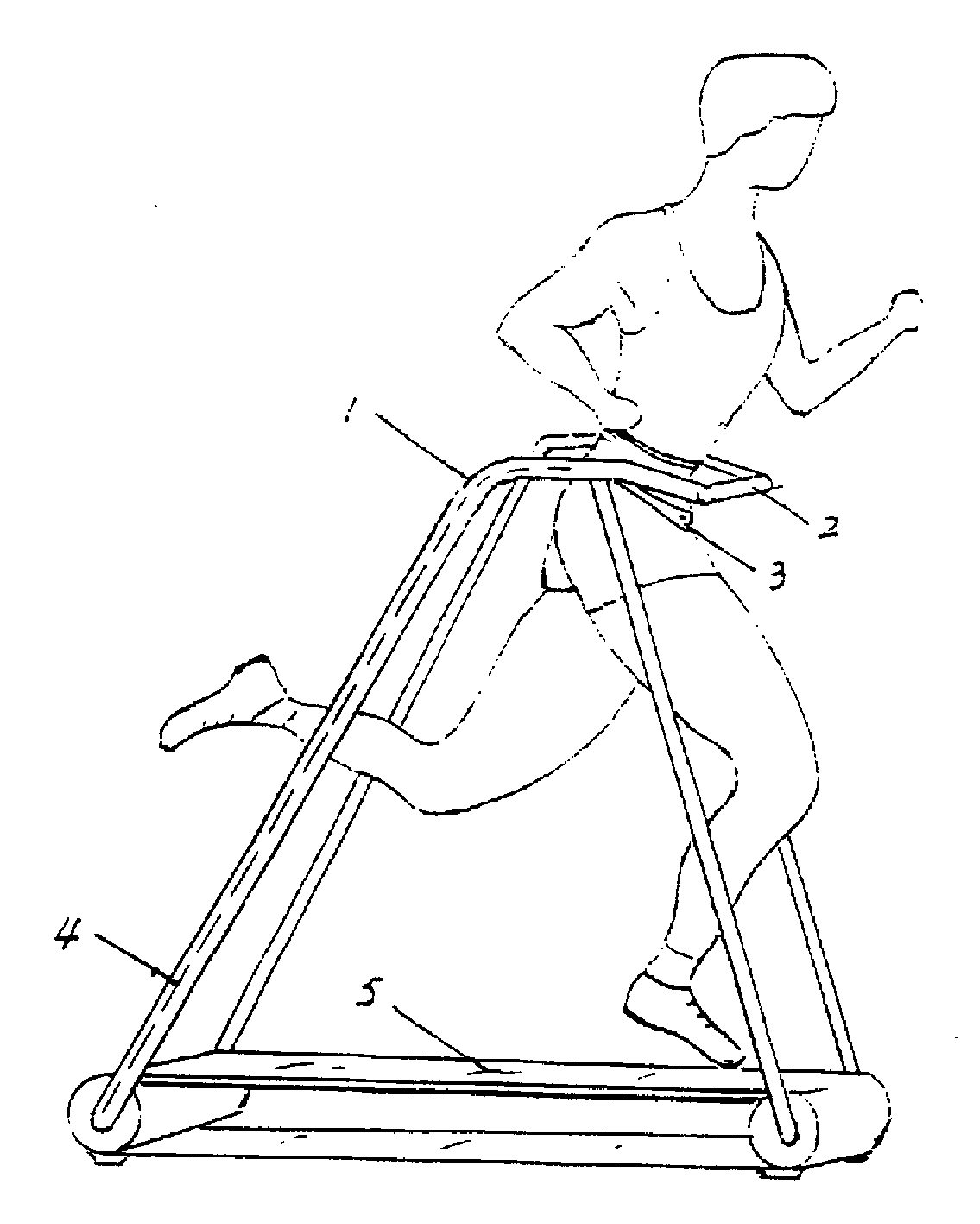

Traction-type automatic speed-regulating walking-running machine

InactiveCN1218759CPlay the role of anti-fallEasy to masterMovement coordination devicesCardiovascular exercising devicesEngineeringRunway

The traction automatic speed-regulating walking and running machine is characterized by that it has an electric runway identical to that of general electric running machine, its front portion has no the devices of handrail, etc. and its two sides are equipped with foldable support respectively, a stretch band is cross-connected between upper ends of two supports, said stretch band is connected with the speed-regulating device of the electric runway by a traction rope. When it is used, firstly the hip is wrapped by said stretch band, and when the person starts to walk or run, the stretch band can be controlled tightly. The traction force can be transferred into the speed-regulating device by traction rope to start electric runway, when the walking or running speed is changed.

Owner:高锡庚

Differential drive mobile robot platform

InactiveCN111452883ASolving Tension ProblemsThe structure is simplified and reasonableElectric propulsion mountingVehiclesDrive wheelControl engineering

The invention belongs to the field of robots, and particularly relates to a differential drive mobile robot platform, which is based on a wheel type moving mechanism, and is characterized by comprising a bottom plate and two driving wheels arranged at the bottom of the bottom plate, and the two driving wheels are each controlled and driven by a driving mechanism and transmission mechanism group. Athree-wheel structure is adopted, differential driving is achieved through the two driving wheels, one universal wheel is used for balancing and steering, the structure is more reasonable and simplerthan that of four wheels, the cost is saved, and advancing, retreating and steering of different radiuses of the moving mechanism are achieved by controlling the rotating speeds of the two motors; meanwhile, the tensioning mechanism is arranged, so that the tensioning problem of a synchronous belt is simply and skillfully solved, the space is saved, and the transmission efficiency is improved.

Owner:CHANGZHOU INST OF DALIAN UNIV OF TECH

Protocol conversion module and intelligent circuit breaker of Devicenet and Modbus

InactiveCN103135484AThe structure is simplified and reasonableSmall footprintProgramme controlComputer controlMicrocontrollerMicrocomputer

The invention discloses a protocol conversion module and an intelligent circuit breaker of Devicenet and Modbus. The protocol conversion module comprises a controller area network (CAN) bus transceiver, an optocoupler, a CAN controller, a single chip microcomputer, a Modbus bus transceiver, an address and Baud rate setting toggle switch and a network state indicating lamp, wherein the address and Baud rate setting toggle switch and the network state indicating lamp are connected with the single chip microcomputer. The intelligent circuit breaker comprises a moulded case circuit breaker body, a remote movement executing mechanism and the protocol conversion module. The protocol conversion module and the intelligent circuit breaker can enable users to monitor and control Modbus equipment through a Devicenet bus in real time.

Owner:RENMIN ELECTRIC APPLIANCES GROUP

Anti-collision control method of fixture

ActiveCN110052857BHigh anti-collision sensitivityMake sure it's intactGrinding drivesPositioning apparatusMachine buildingControl engineering

The invention discloses an anti-collision control method of a clamp, and belongs to the technical field of mechanical manufacturing. The method adopts a multidirectional anti-collision clamp, the clamp comprises a transverse anti-collision sensor arranged between a chuck supporting column and a chuck of the clamp and a vertical anti-collision sensor arranged between the middle of a support of theclamp and a mounting plate of the object to be clamped; a driving device is arranged at the bottom end of the mounting bottom plate of the clamp; the anti-collision control method comprises the following steps that when the external collision signals sensed by the vertical anti-collision sensor and / or the transverse anti-collision sensor in real time exceeds a preset value range in the controller,the controller controls the driving device to drive the clamping object to move towards the direction of unloading collision force after the received external collision signals are judged and processed. According to the anti-collision control method, the problems of equipment damage and product precision influence caused by collision of a clamping object or an operation platform or a robot of anexisting clamp can be solved.

Owner:广西现代职业技术学院

Three-in-one press sleeving machine tool of sleeving lock

InactiveCN100460141CLow proficiency dependencyThe structure is simplified and reasonableOther manufacturing equipments/toolsPunch pressEngineering

A 3-in-1 machine-tool for punching holes and trademark on lock casing and riveting the casing with lock body is composed of punch machine, punching platform on punch machine, punch head, the hole and trademark punching unit with female die and unloading barrier, the casing-lock body riveting unit with cylinder, piston rod and punch head for riveting, and the casing clamping and work position transferring unit with the slide blocks for clamping casings. Its advantages are high speed and high precision.

Owner:吴鋆

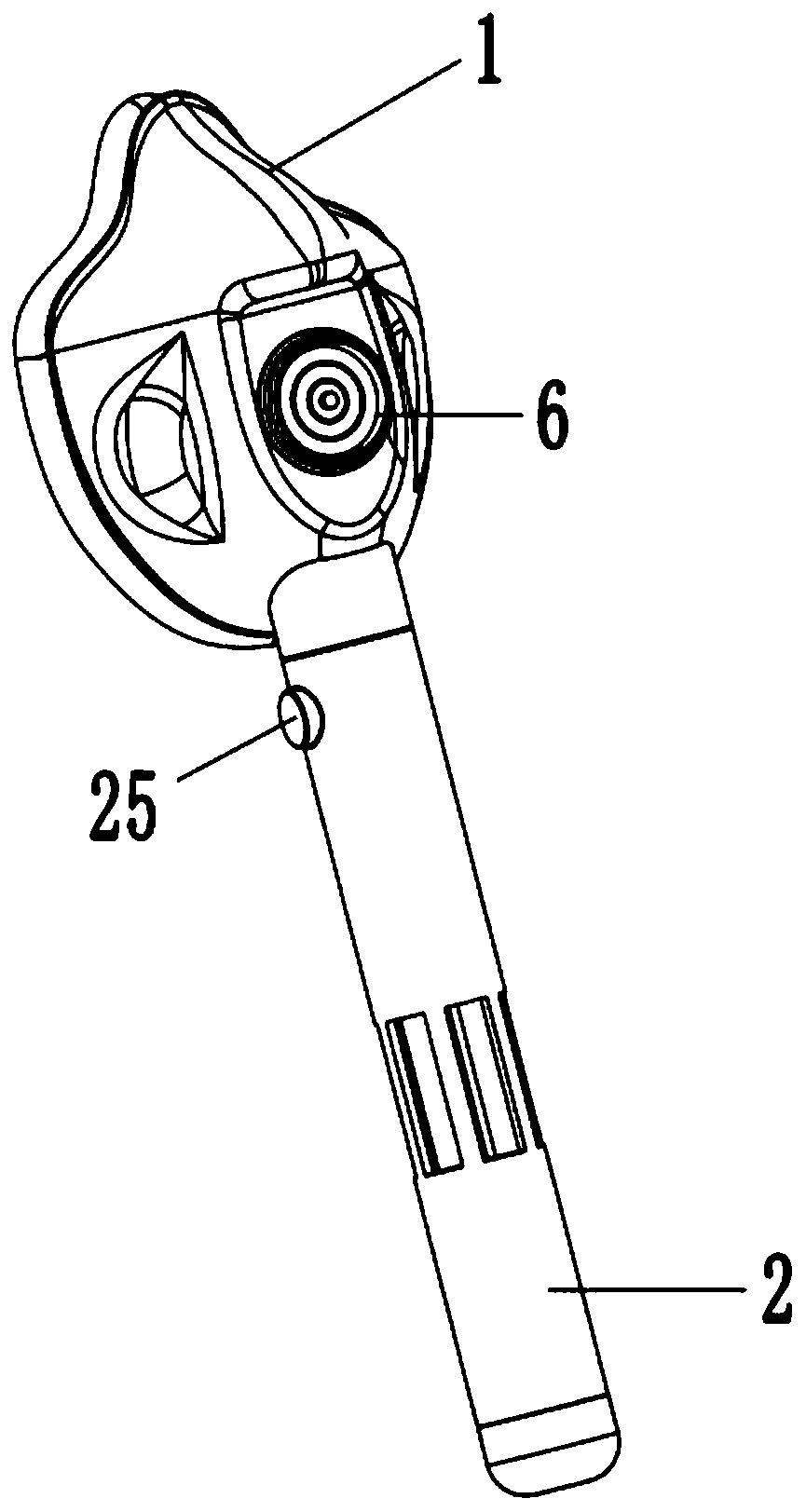

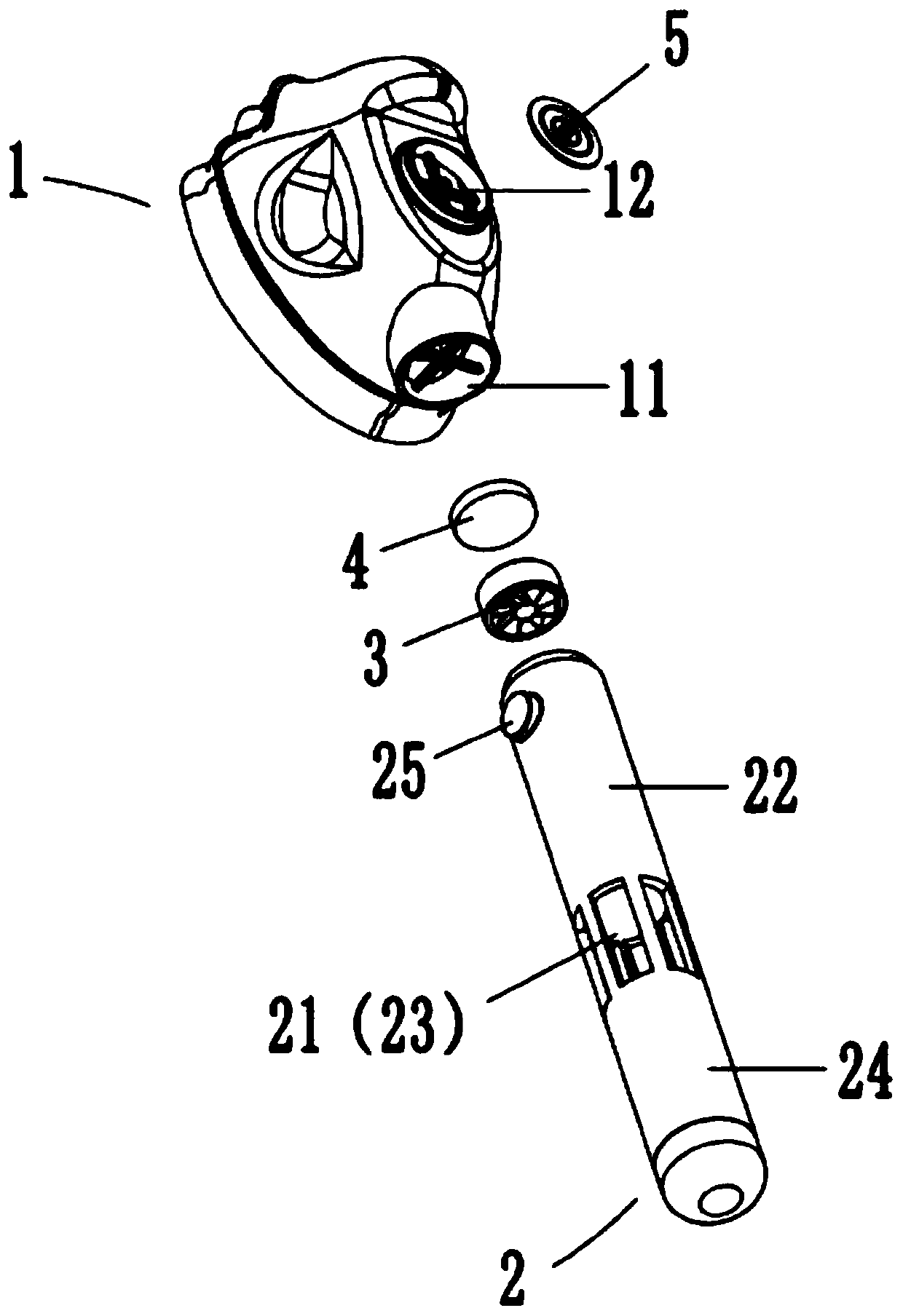

Handheld pressurizing mask

PendingCN109876319AThe structure is simplified and reasonableFew partsBreathing masksFire rescueEngineeringOxygen

The invention relates to a handheld pressurizing mask. A mask body and a pressurizing assembly are included. The mask body is provided with a pressurizing hole. The pressurizing assembly comprises a handheld piece, a draught fan and a power supply device. The handheld piece and the mask body are connected. The handheld piece is provided with an air inlet, and an air circulation passageway is arranged in the handheld piece. One end of the air circulation passageway communicates with the pressurizing hole, and the other end of the air circulation passageway communicates with the air inlet. The draught fan is fixedly arranged in the air circulation passageway. The power supply device is arranged on the handheld piece. The power supply device is electrically connected with the draught fan. Thehandheld pressurizing mask can simulate the barometric pressure of the low-altitude areas, oxygen inflation treatment is conducted on personnel with altitude stress, meanwhile, the structure is reasonable and is simplified, components are reduced, and usage and operation are convenient.

Owner:王福洪

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com