Molding machine

A molding machine and machine body technology, applied in the field of molding sand molding, can solve the problems of cumbersome adjustment operations, waste of materials, and high height, and achieve the effects of reducing costs, facilitating adjustment operations, and avoiding waste molds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

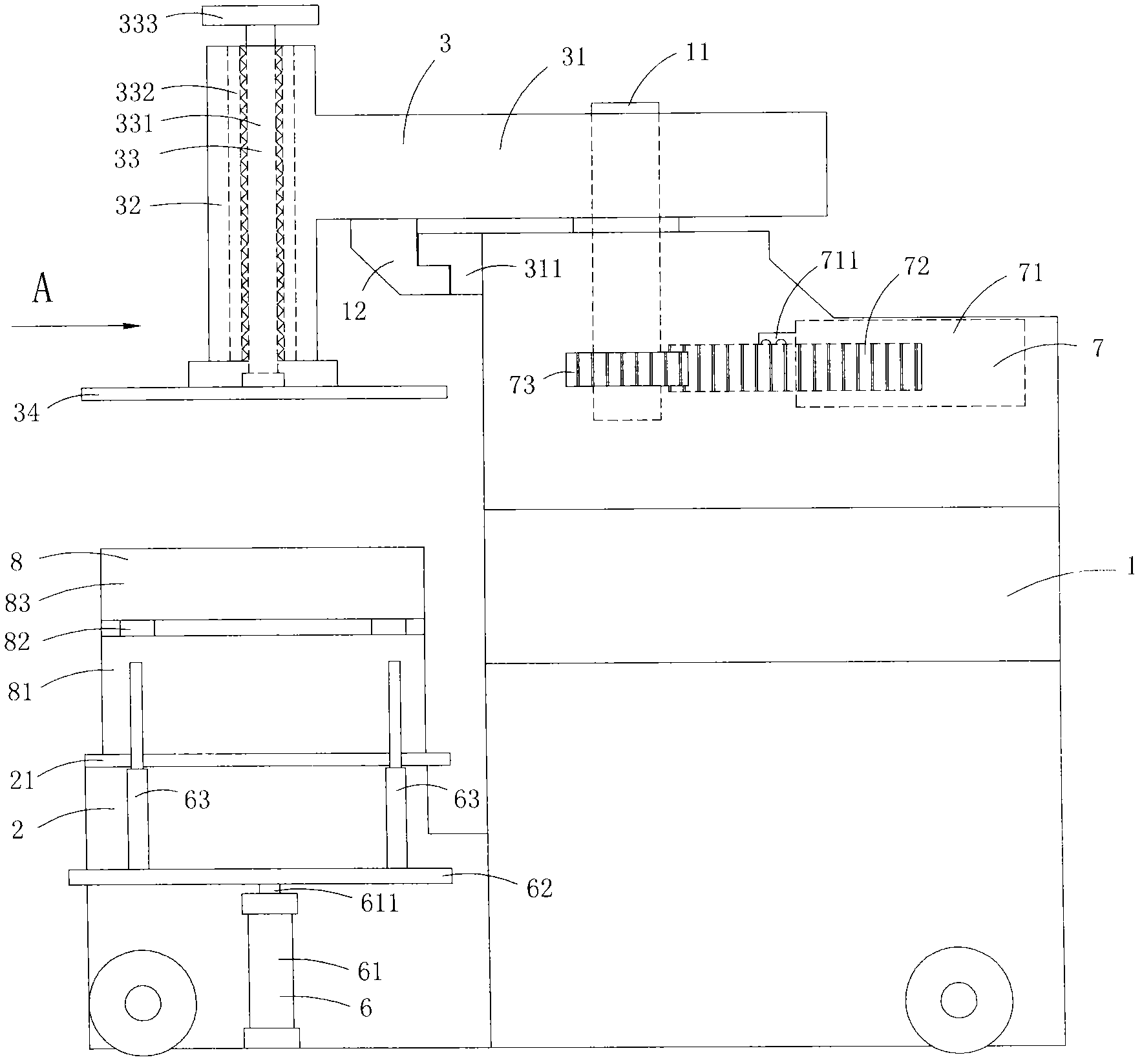

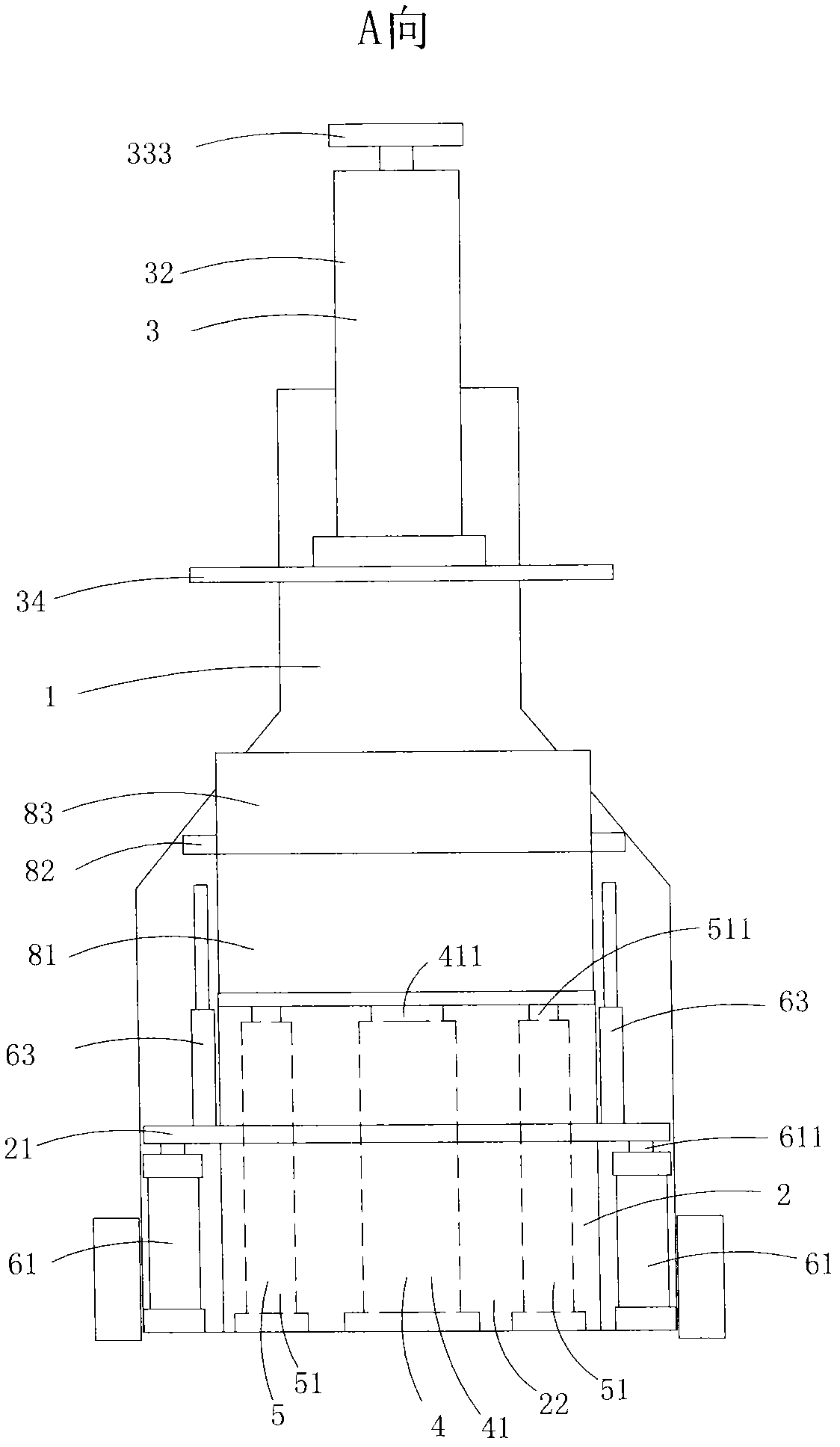

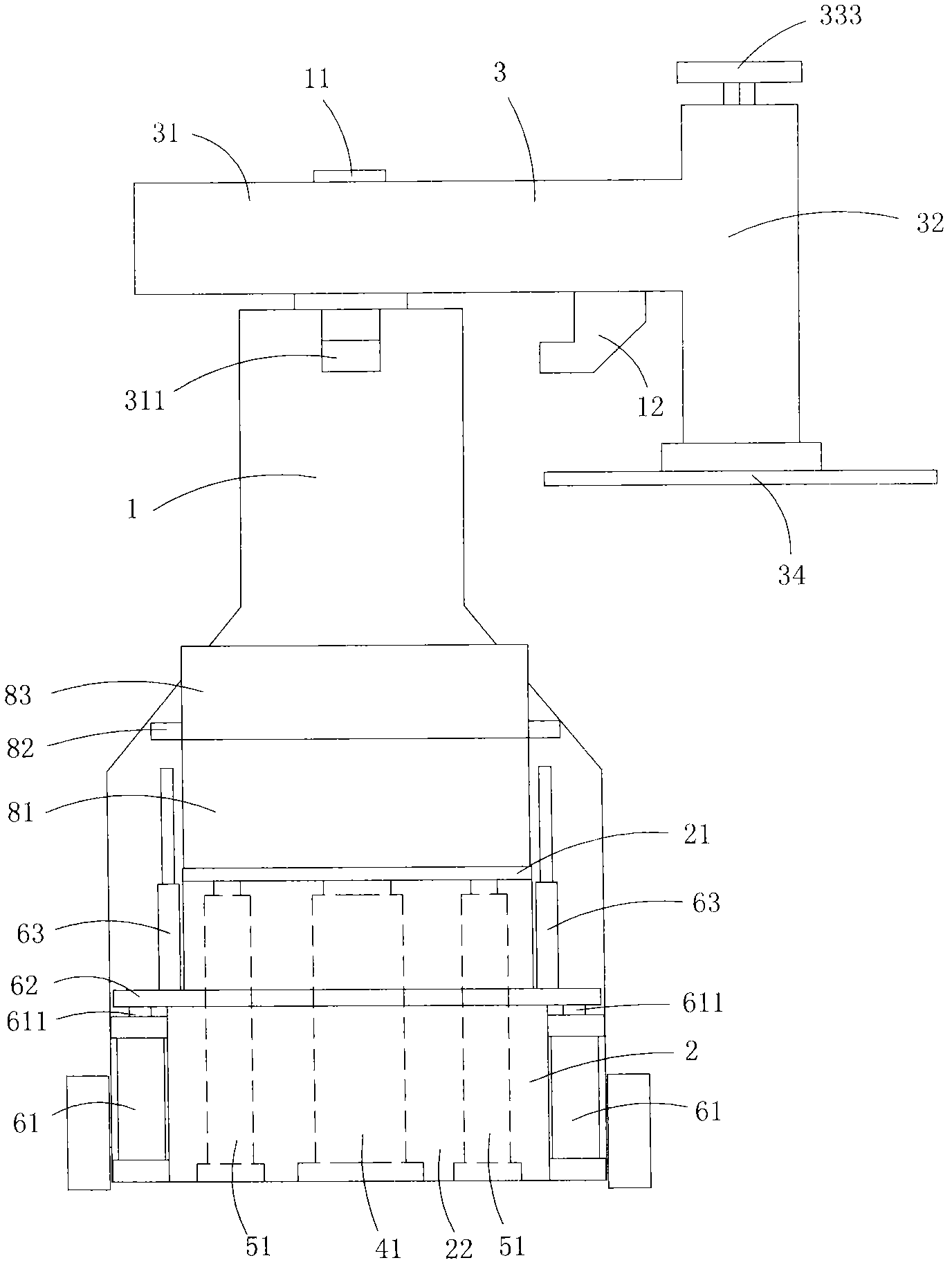

[0026] Figure 1 to Figure 5 A specific embodiment of the invention is shown in which figure 1 It is a schematic diagram of the structure of the invention; figure 2 for figure 1 A-direction view; image 3 for figure 2 A schematic diagram of a state after the rotating rocker arm and the pressing plate in the molding machine shown are rotated 90 degrees; Figure 4 for figure 2 A schematic diagram of the structure of the molding machine shown when the piston of the top pressure cylinder presses the sand box on the working plate to the pressure plate; Figure 5 for figure 2 Shown is a schematic diagram of the structure of the molding machine when the piston of the mold lifting cylinder lifts the upper mold box of the sand box.

[0027] This embodiment is a molding machine, see Figure 1 to Figure 5 , including a body 1, a workbench 2 provided with a working plate 21, a rotating rocker arm 3 provided with a pressing plate 34, a vibrating device 4, a sand pressing device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com