Jacquard broach made of carbon fiber composite material and manufacturing method

A technology of composite materials and manufacturing methods, applied in jacquard machines, textiles, papermaking, textiles, etc., can solve the problems of jacquard machine broach structure complex, low broach service life, slow jacquard speed, etc., to achieve light weight and long service life Long, the effect of increasing the jacquard speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

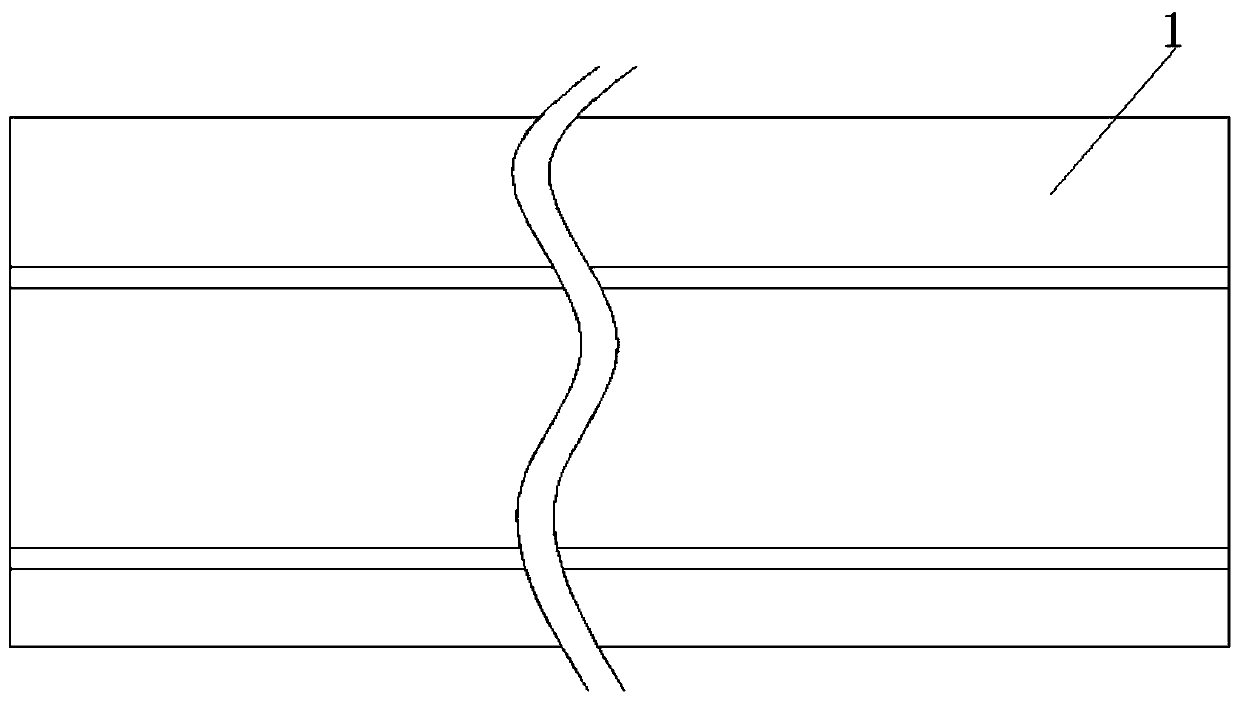

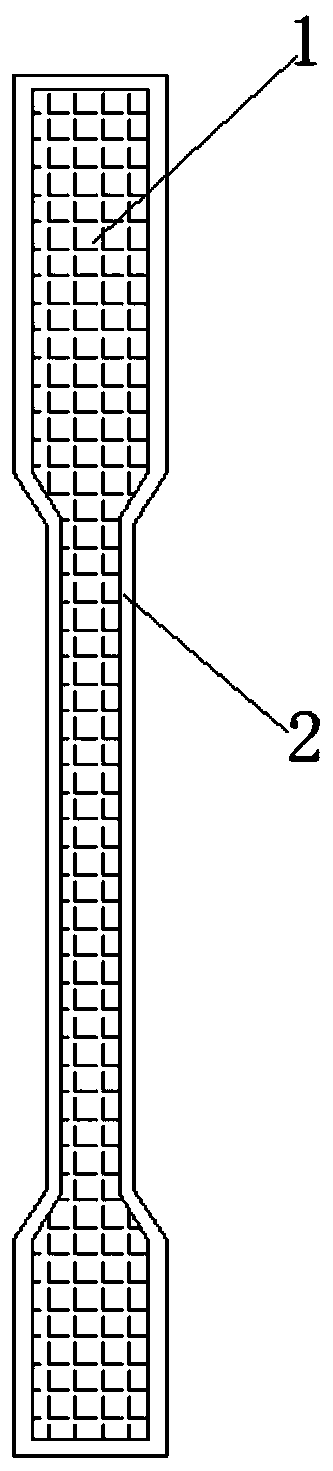

[0035] In Example 1, a method for manufacturing a broach of a carbon fiber composite material jacquard machine includes a pultrusion molding process of a broach body 1 and a broach assembly process;

[0036] The pultrusion molding process of the broach body 1 comprises the following steps:

[0037] S1. Weigh the following substances according to the weighing portion: 90kg of bisphenol A resin, 72kg of anhydride resin, and 1.5kg of internal mold release agent;

[0038] S2, add bisphenol A resin and acid anhydride resin into the resin tank and start stirring;

[0039] S3, adding the internal release agent into the resin tank and stirring, the stirring time is 8min, and the stirring temperature is 20°C;

[0040] S4. After the raw materials are stirred until the color becomes uniform and transparent, the stirring is completed to obtain the mixed resin;

[0041] S5. Composite carbon fiber and mixed resin. First, place the creel with carbon fiber symmetrically with respect to the ...

Embodiment 2

[0049] In Example 2, a method for manufacturing a jacquard broach made of carbon fiber composite materials, including a pultrusion forming process of a broach body 1 and a broach assembly process;

[0050]The pultrusion molding process of the broach body 1 comprises the following steps:

[0051] S1. Weigh the following substances according to the weighing portion: 100kg of bisphenol A resin, 80kg of anhydride resin, and 2kg of internal mold release agent;

[0052] S2, add bisphenol A resin and acid anhydride resin into the resin tank and start stirring;

[0053] S3. Add the internal release agent to the resin tank and stir for 10 minutes, and the stirring temperature is 30°C;

[0054] S4. After the raw materials are stirred until the color becomes uniform and transparent, the stirring is completed to obtain the mixed resin;

[0055] S5. Composite carbon fiber and mixed resin. First, place the creel with carbon fiber symmetrically with respect to the mold. The carbon filament...

Embodiment 3

[0063] In embodiment 3, a method for manufacturing a broach of a carbon fiber composite material jacquard machine includes a pultrusion molding process of a broach body 1 and a broach assembly process;

[0064] The pultrusion molding process of the broach body 1 comprises the following steps:

[0065] S1. Weigh the following substances according to the weighing portion: 110kg of bisphenol A resin, 88kg of anhydride resin, and 3kg of internal mold release agent;

[0066] S2, add bisphenol A resin and acid anhydride resin into the resin tank and start stirring;

[0067] S3. Add the internal release agent to the resin tank and stir for 15 minutes, and the stirring temperature is 50°C;

[0068] S4. After the raw materials are stirred until the color becomes uniform and transparent, the stirring is completed to obtain the mixed resin;

[0069] S5. Composite carbon fiber and mixed resin. First, place the creel with carbon fiber symmetrically with respect to the mold. The carbon fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pull | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com