Side adjustment oil buffer

A technology of hydraulic buffers and adjustment components, which is applied to shock absorbers, shock absorbers, liquid shock absorbers, etc., can solve the problems of relatively complex structure, high processing difficulty, blind area of scale vision, etc., and achieves reasonable structure simplification, Easy to assemble and accurate alignment adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

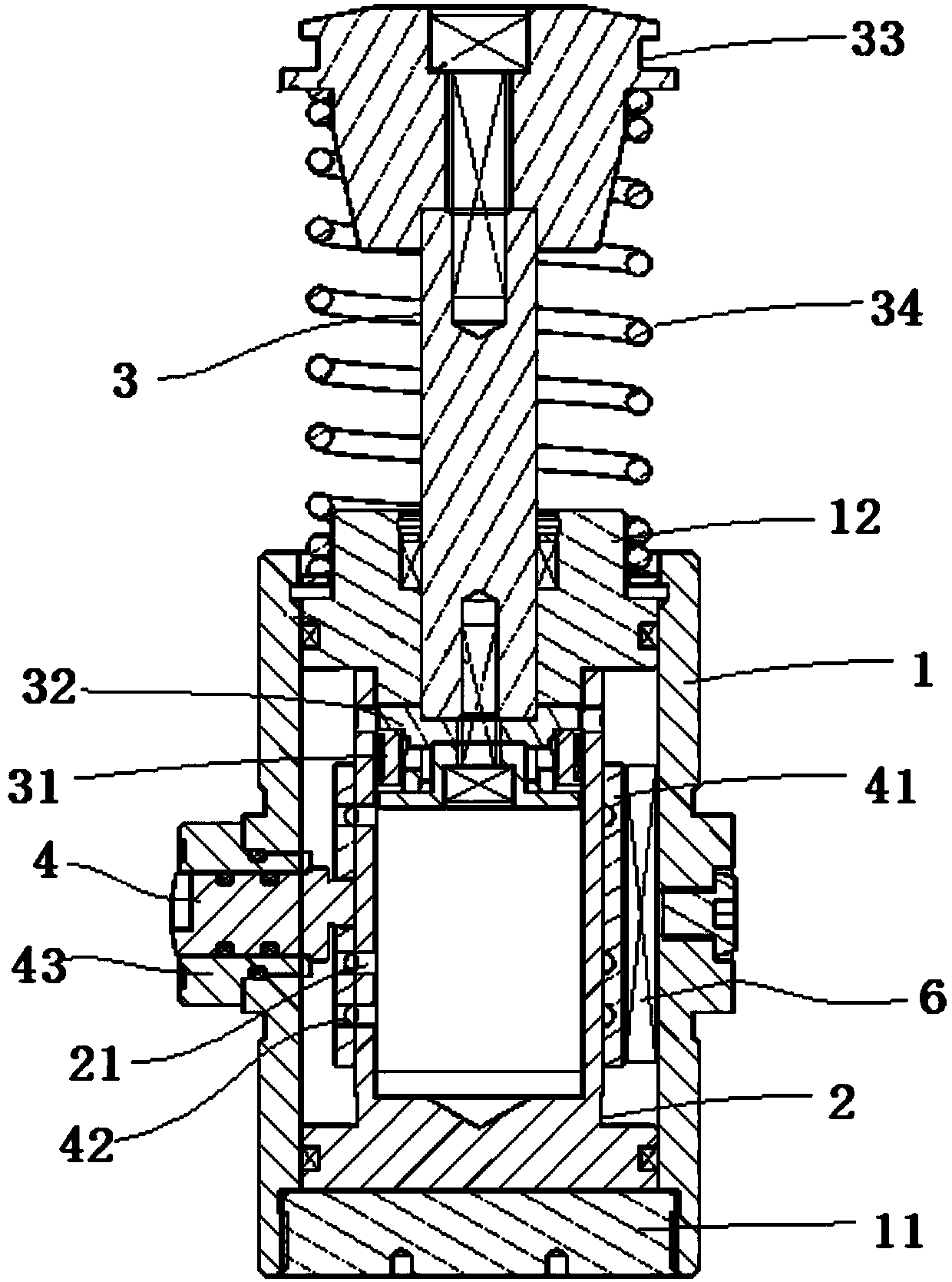

[0019] refer to Figure 2-3 As shown, this embodiment is a side-adjustable hydraulic buffer, including a cylinder assembly, a buffer assembly located in the cylinder assembly, an adjustment assembly, and a liquid contained in the cylinder assembly. The liquid is hydraulic Oil. The cylinder body assembly includes an outer cylinder 1 and an inner cylinder 2 arranged in the outer cylinder 1 and axially consistent with it. One end of the outer cylinder 1 is detachably fixed with an end cover 11 , and the other end of the outer cylinder 1 is detachably fixed with a bushing 12 . The inner end of the inner cylinder 2 abuts against the end cover 11 , the outer end of the inner cylinder 2 abuts against the bushing 12 , and a buffer cavity is formed between the inner cylinder 2 and the outer cylinder 1 .

[0020] The buffer assembly includes a piston rod 3 inserted into the inner cylinder 2 through the bushing 12 , and a piston 31 arranged at the inner end of the piston rod 3 . A pis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com