Vertable pulse vibration magnetic field magnetic separator

A pulse vibration and magnetic separator technology, applied in the field of magnetic separators, can solve the problems of high production cost, high separation space, and complex structure, and achieve the effects of low production cost, improved concentrate grade, and simplified and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

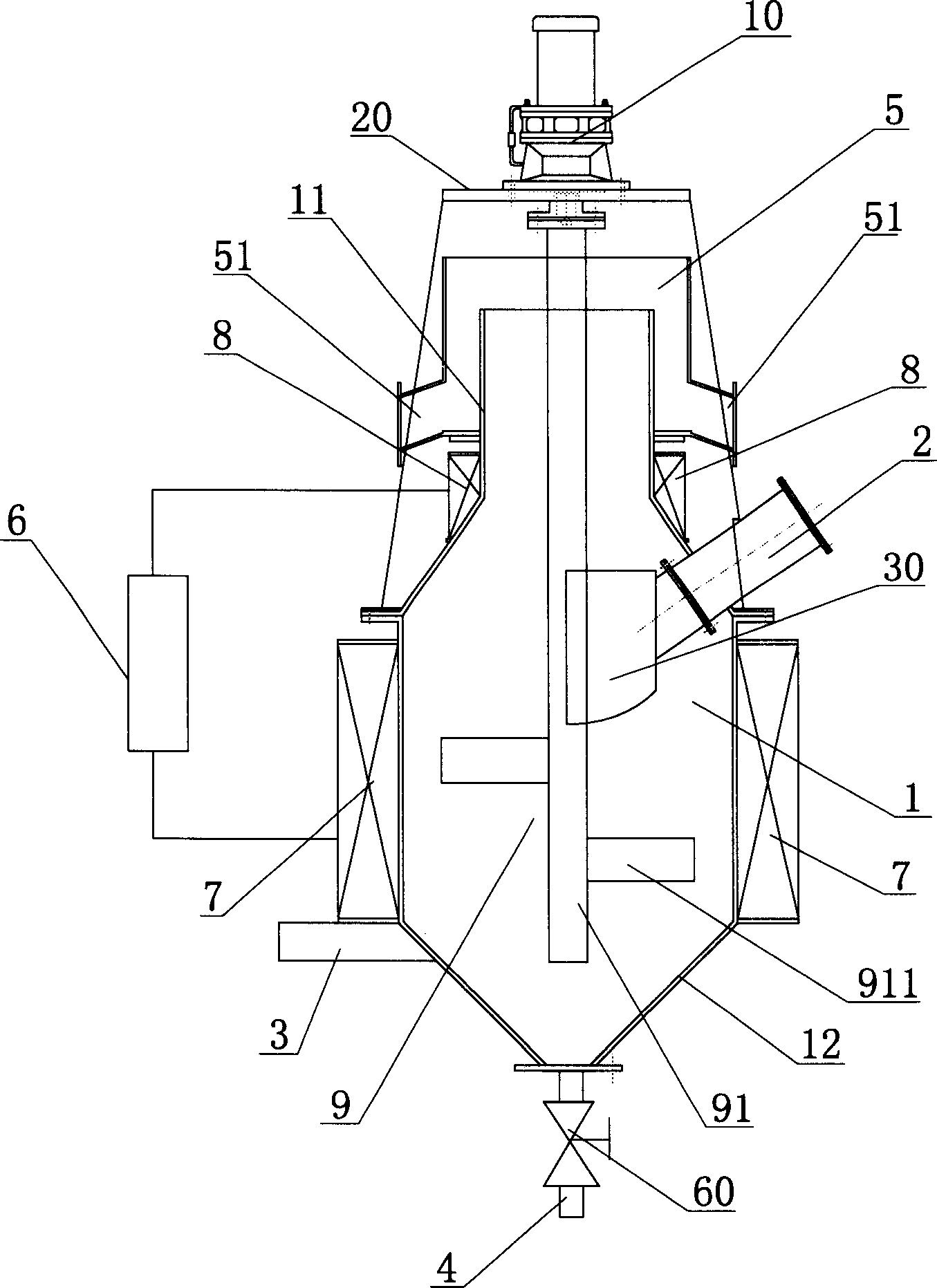

[0016] Such as figure 1 As shown, the present invention comprises cylinder body 1, ore supply pipe 2, water supply pipe 3, concentrate pipe 4, overflow tank body 5 and excitation power supply 6, adopts stable magnetic field as working magnetic field in order to solve existing magnetic separator, and magnetic field The gradient is high, there are problems such as low concentrate grade, high height, complex structure, and high production cost. A magnetic field device 7 for generating an alternating magnetic field is provided on the outer wall of the lower part of the cylinder body 1. 6 phases are connected to generate a uniform alternating magnetic field that runs through the cylinder 1, and the magnetic field device 7 is installed on the cylindrical outer wall of the lower part of the cylinder 1. At the same time, in order to improve the recovery rate and separation efficiency of magnetic concentrate and reduce the loss of concentrate, some of the strong magnetic particles ente...

Embodiment 2

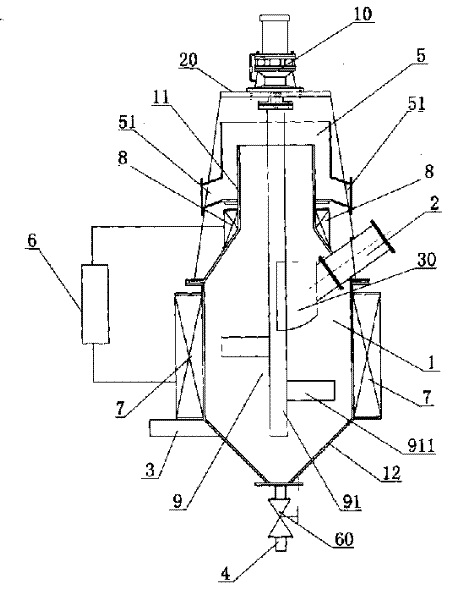

[0018] Such as figure 2 As shown, this embodiment includes a cylinder body 1, a magnetic field device, an ore supply pipe 2, a water supply pipe 3, a concentrate pipe 4, an overflow tank body 5 and an excitation power supply 6. In order to make the present invention applicable to occasions with a large amount of ore pulp , to provide a strong stirring shear force for sorting, to avoid the problem that the separation effect is not good only by the stirring shear force provided by tangential water supply. The difference between this embodiment and Embodiment 1 is: the cylinder body 1 A stirring device 9 is provided, which includes a stirring rod 91 with a stirring blade 911, the upper part of the stirring rod 91 is supported in the bearing seat 10, and the bearing seat 10 is installed on the support plate 20 on the upper part of the cylinder body 1, and is installed on the The upper and lower stirring blades 911 on the stirring rod 91 are misplaced to strengthen the separation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com