Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Temperature is not affected" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

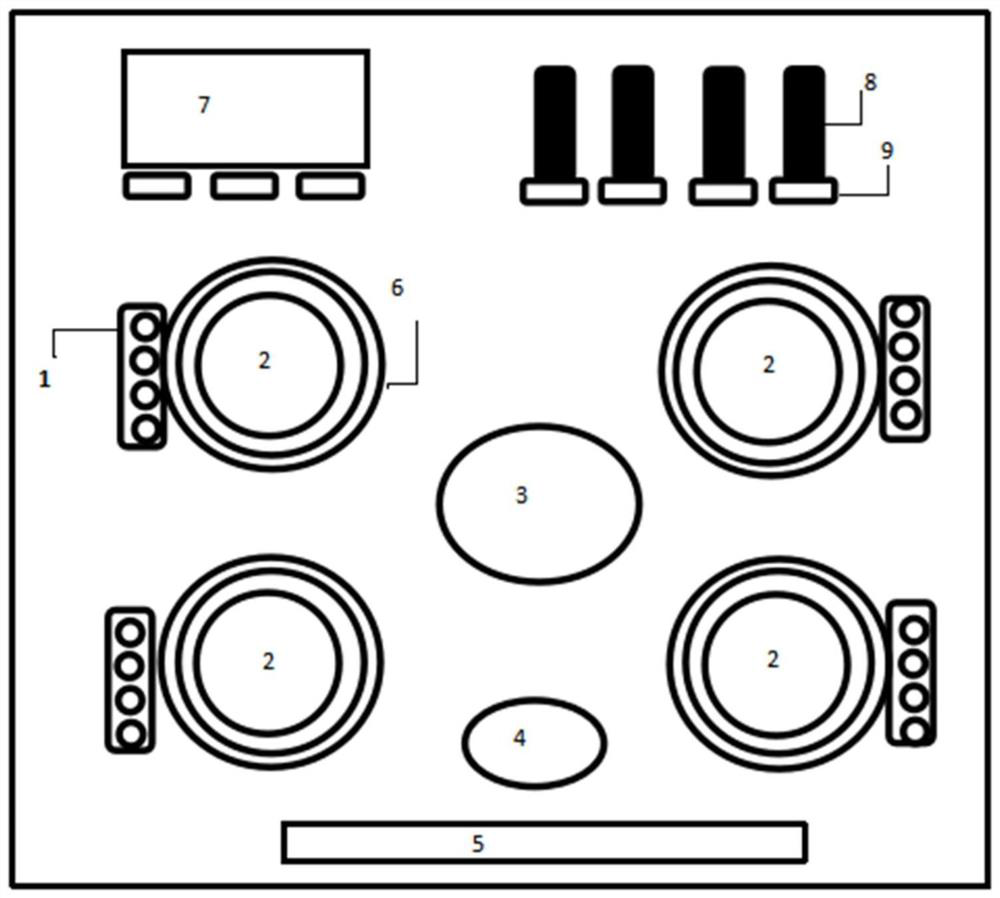

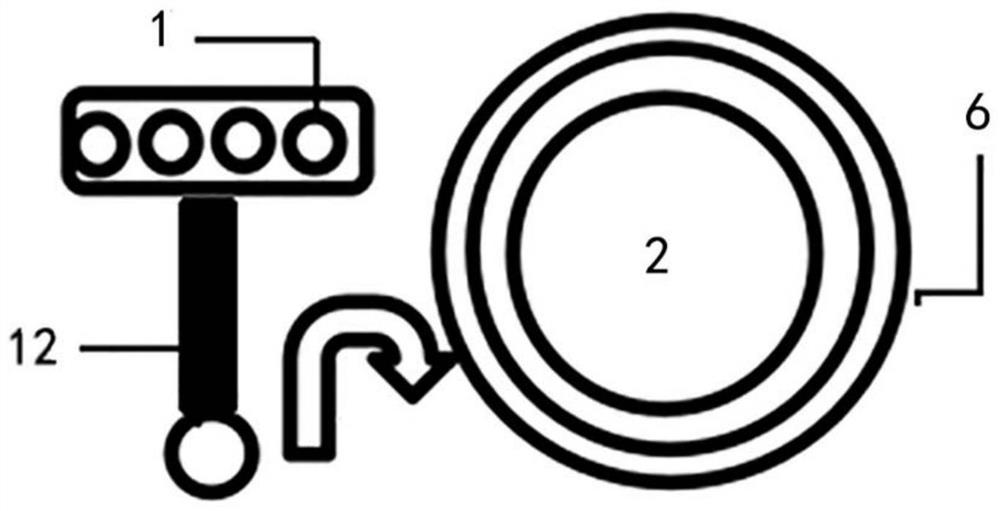

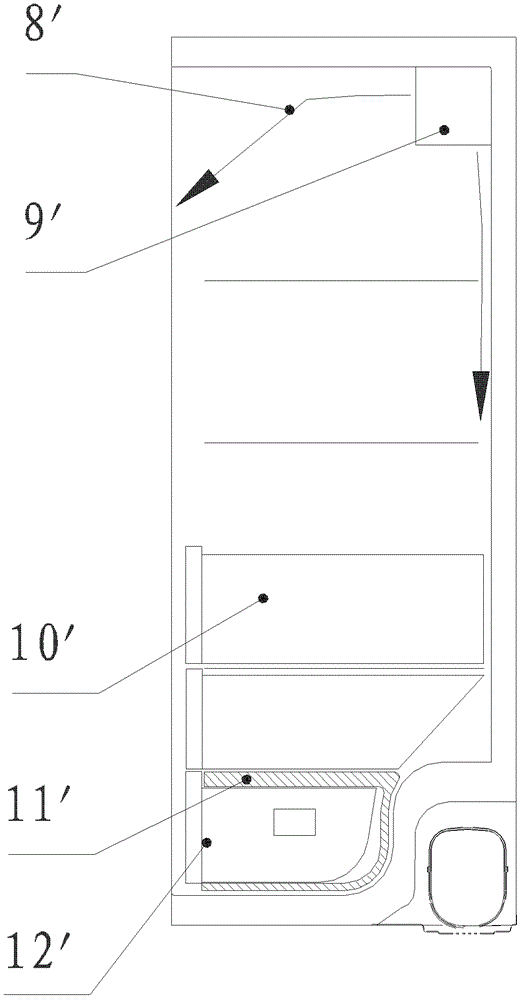

Refrigerator and method for controlling same

ActiveCN102538339ATemperature is not affectedMeet volume requirementsLighting and heating apparatusDomestic refrigeratorsEvaporatorEngineering

The invention provides a refrigerator and a method for controlling the same. The refrigerator comprises a freezing space, a refrigerating space, a temperature varying space, a compressor, a condenser, a freezing evaporator, a refrigerating evaporator, a freezing air channel, a refrigerating air channel, a temperature varying air channel, refrigerating fans and a refrigerating air door, wherein the outlet end of the freezing air channel is communicated with the freezing space; the outlet end of the refrigerating air channel is communicated with the refrigerating space; the temperature varying air channel is connected in parallel with the refrigerating air channel; the outlet end of the temperature varying air channel is communicated with the temperature varying space; the refrigerating fans are arranged between the refrigerating evaporator and the temperature varying air channel and between the refrigerating evaporator and the refrigerating air channel, and are used for blowing cold air which is generated by the refrigerating evaporator into the inlet end of the temperature varying air channel and the inlet end of the refrigerating air channel; and the refrigerating air door is arranged at the inlet end of the refrigerating air channel. By the refrigerator, temperatures of the freezing space, the refrigerating space and the temperature varying space can be controlled independently and are not interfered with one another.

Owner:HAIER GRP CORP +1

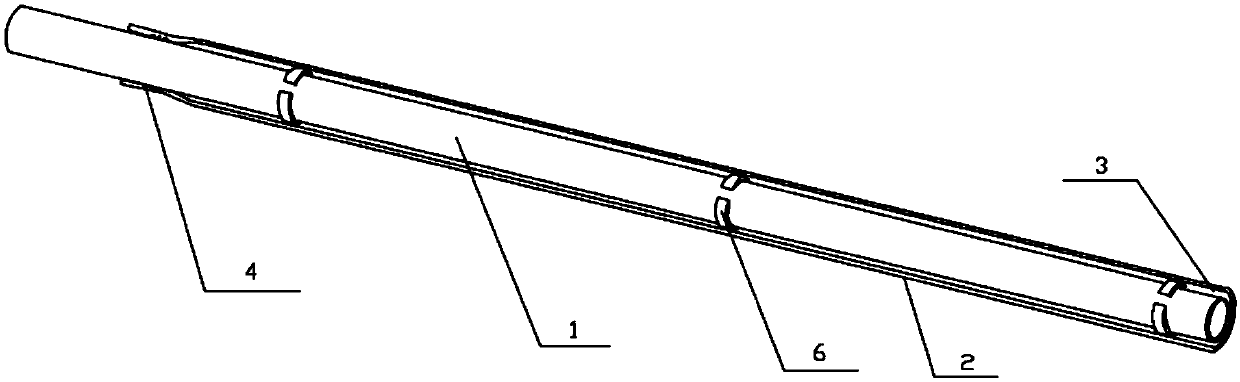

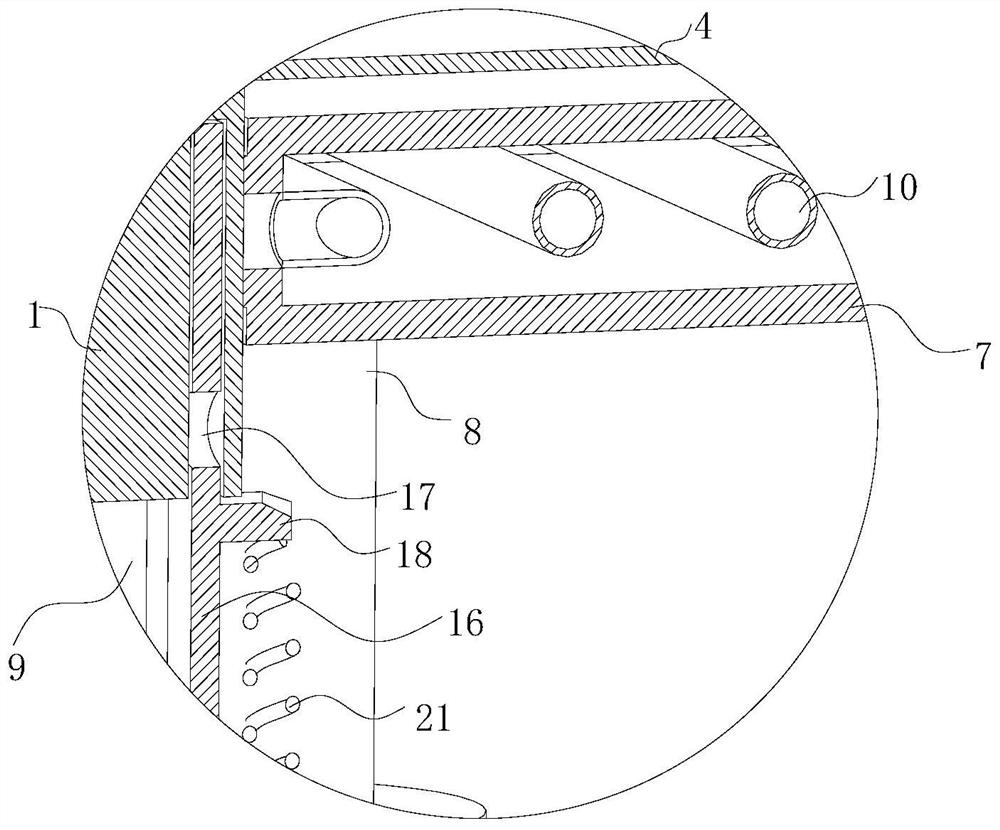

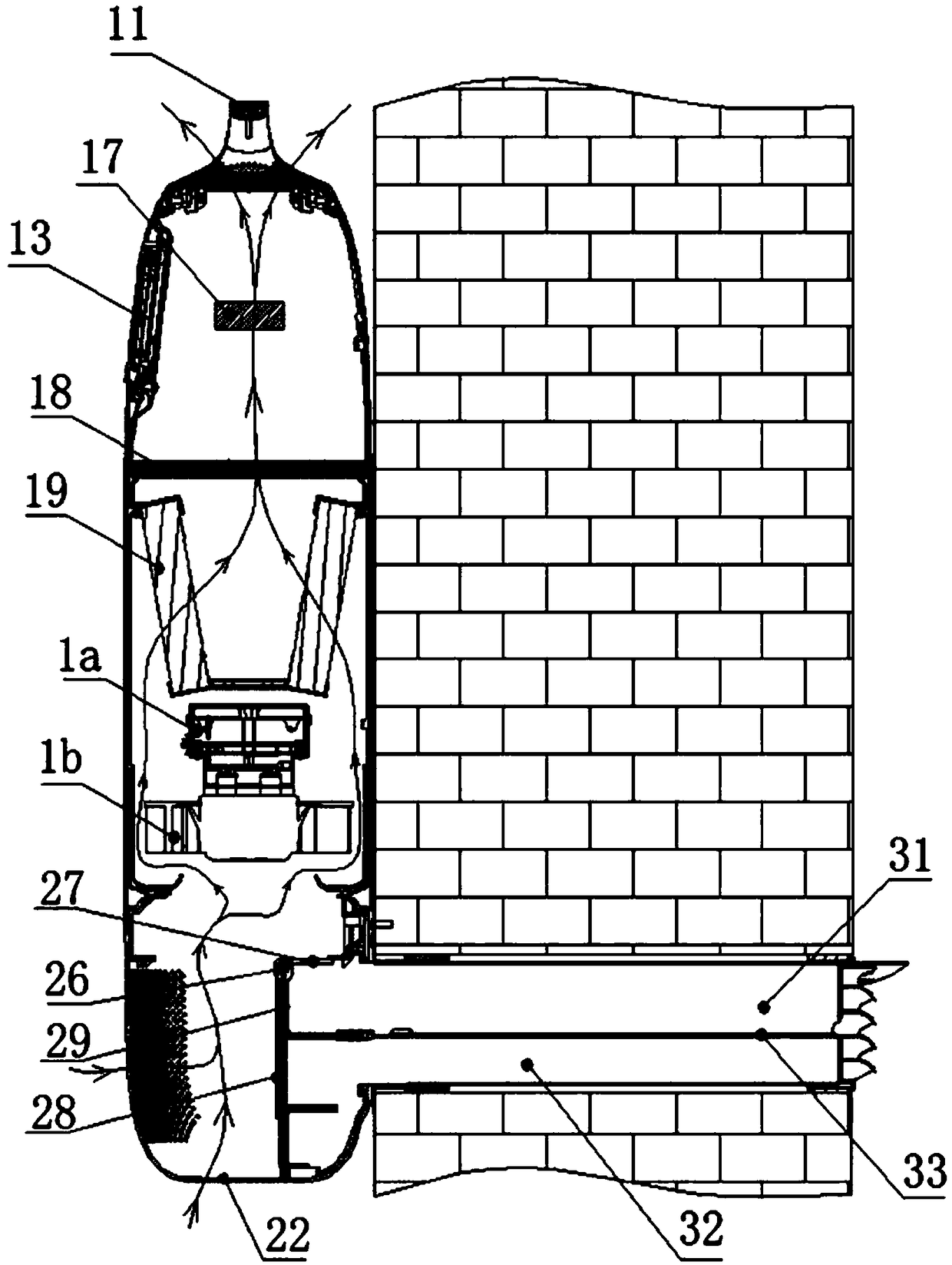

Super-long insulation steel-sleeved steel pipeline and machining process thereof

PendingCN109578752AImprove insulation effectImprove corrosion resistanceDrilling rodsFurnace typesPhase-change materialMachining process

The invention discloses a super-long insulation steel-sleeved steel pipeline and a machining process thereof. The pipeline has good insulation performance and corrosion resistance. An annular cavity of the pipeline is in a vacuum state, is internally provided with a support and is filled with phase change material. When underground energy is exploited through the super-long insulation steel-sleeved steel pipeline and outside temperature is lowered, the condition that temperature in a work steel pipe in the pipeline is not influenced can be kept effectively. Service life of the steel-sleeved steel pipeline is long, exploitation cost of petroleum and underground heat sources can be lowered greatly, and heat energy loss in exploitation is reduced.

Owner:XINDA KECHUANG TANGSHAN PETROLEUM EQUIP CO LTD

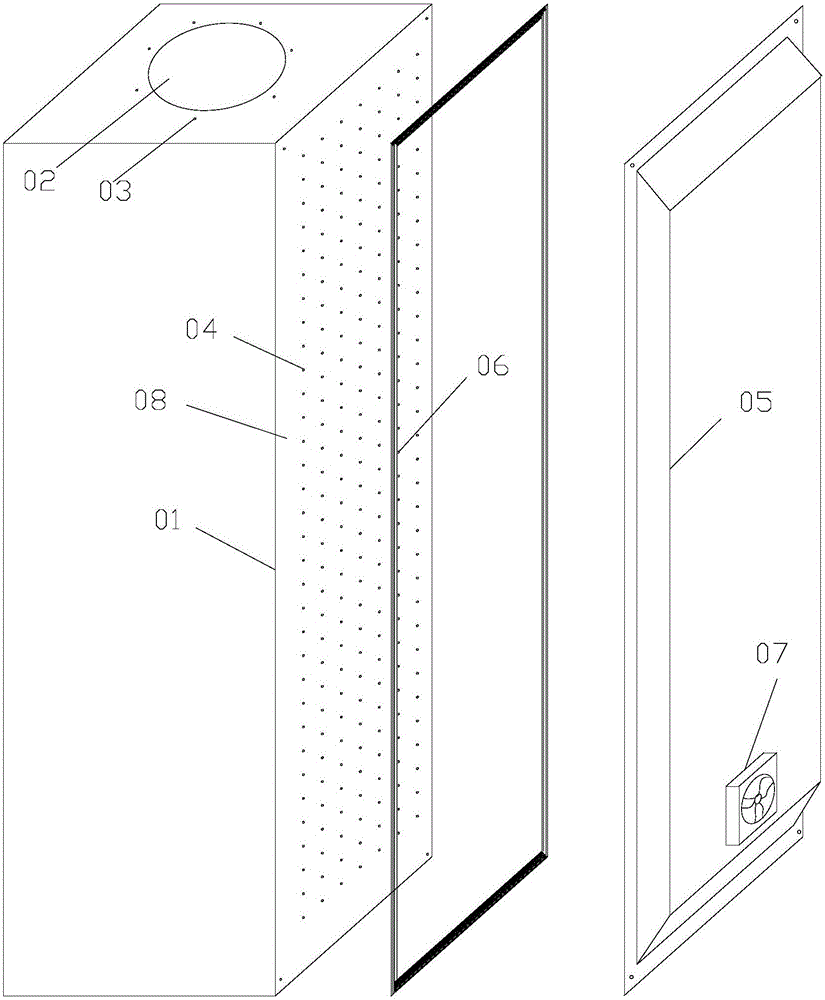

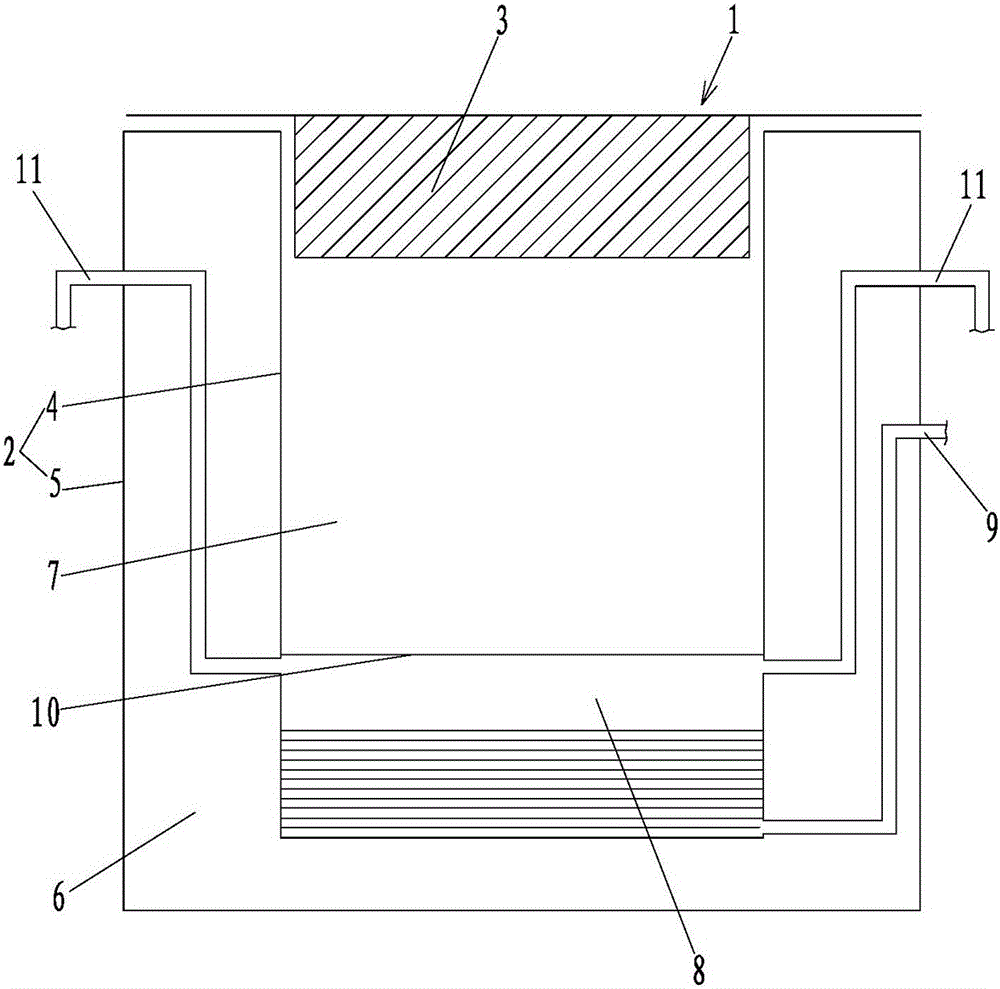

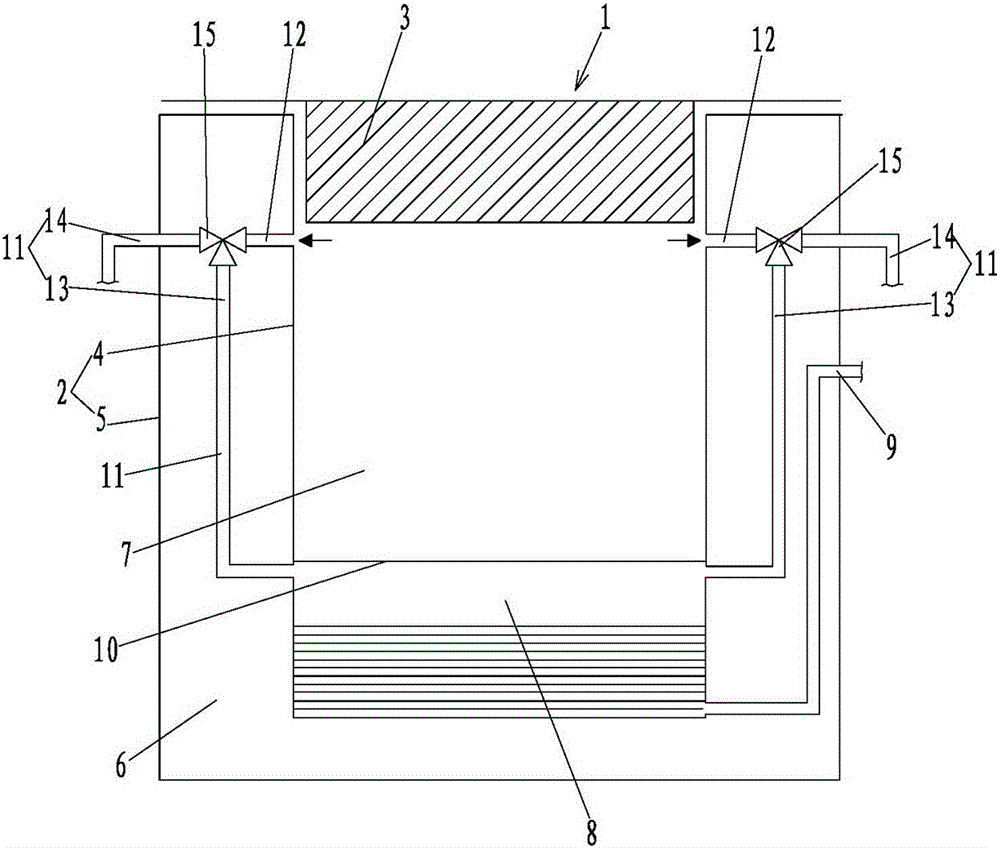

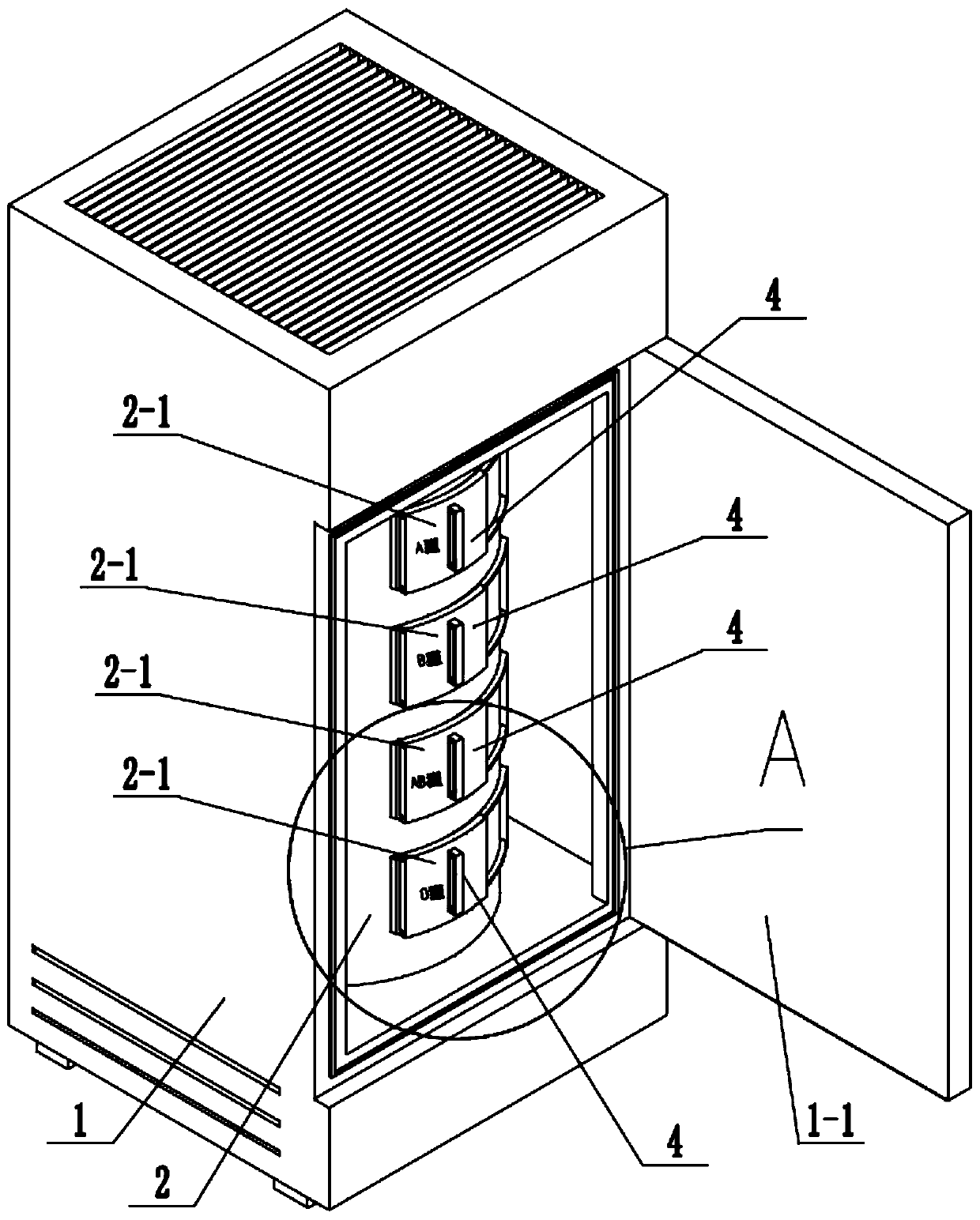

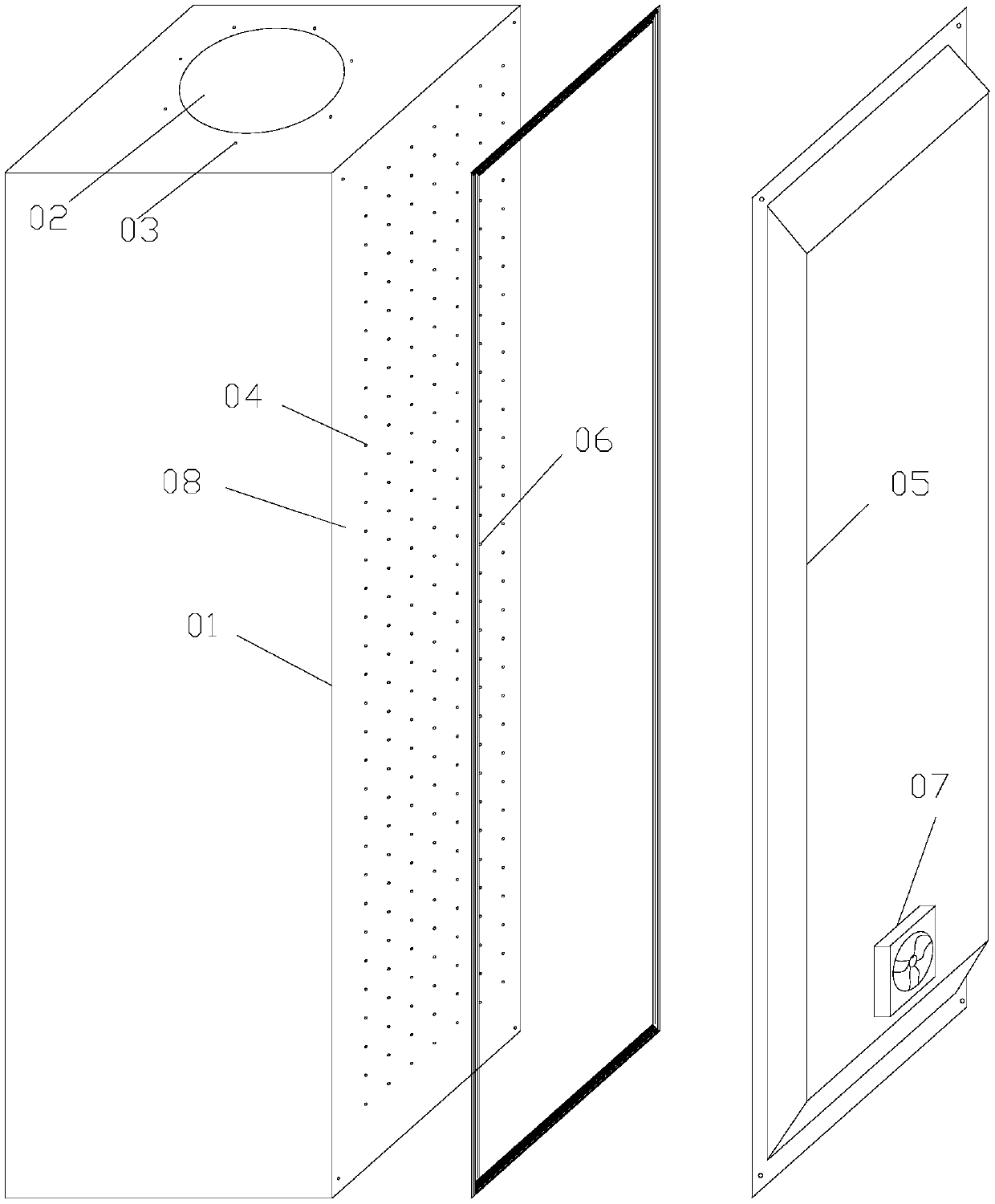

Power distribution cabinet as well as temperature control system and temperature control method of power distribution cabinet

ActiveCN106786057AImprove cooling effectTemperature controlTemperatue controlSubstation/switching arrangement cooling/ventilationTemperature controlBackplane

The invention discloses a power distribution cabinet. The power distribution cabinet comprises a cabinet body, wherein a ventilation hole is formed in the top of the cabinet body, and one circle of first mounting holes are formed in the periphery of the ventilation hole; dense screw holes are formed in a backing plate of the cabinet body, the back of the cabinet body is connected with a back cavity, and a frame type sealing strip is arranged between the backing plate and the back cavity; and a fan is arranged at the lower part of the back cavity. According to the power distribution cabinet disclosed by the invention, airflow is blown out from the back cavity and the screw holes in the backing plate when the fan rotates forwards and supplies the air inwards, and the blown-out wind is directly blown onto electrical components, so that the airflow can be pushed toward the ventilation hole in the top to be blown out, and heat dissipation effect is better. The invention also discloses a temperature control system and a temperature control method of the power distribution cabinet, when the temperature of the power distribution cabinet is lower than TA, the power distribution cabinet at higher temperature can carry out temperature compensation on the power distribution cabinet at low temperature through an air duct for preventing condensation, so that the temperature of the power distribution cabinet at the low temperature rises; and the temperature in the power distribution cabinet can be better controlled, so that the power distribution cabinet can meet temperature demand during operation, the use safety is improved, and the service lives of the electrical components are prolonged.

Owner:珠海盈源电气有限公司

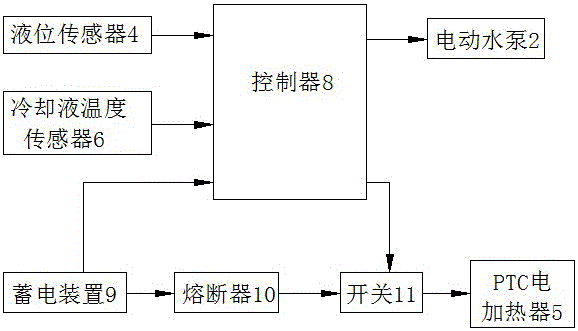

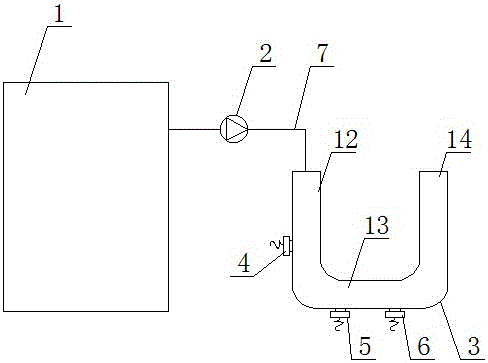

Automobile radiator with heating device

InactiveCN106014750AAvoid cold startEasy to repair and replaceMachines/enginesEngine startersElectric energyWater storage tank

The invention discloses an automobile radiator with a heating device, and belongs to the field of automobile radiators. The technical aim of heating cooling liquid of the automobile radiator through electric energy so as to achieve cold start and heating of an automobile is achieved. The automobile radiator structurally comprises an electrical storage device, a controller, a heating water storage tank, a PTC electric heater used for heating the cooling liquid, a cooling liquid temperature sensor used for detecting the temperature of the cooling liquid and a liquid level sensor used for detecting the liquid level of the cooling liquid. A water tank and the heating water storage tank of the automobile radiator communicate through a pipeline. An electric water pump is arranged on the pipeline. The PTC electric heater, the cooling liquid temperature sensor and the liquid level sensor are all arranged in the heating water storage tank. The electrical storage device, the PTC electric heater, the cooling liquid temperature sensor, the liquid level sensor and the electric water pump are all connected with the controller. The electrical storage device is connected with the PTC electric heater.

Owner:山东文捷智能动力有限公司

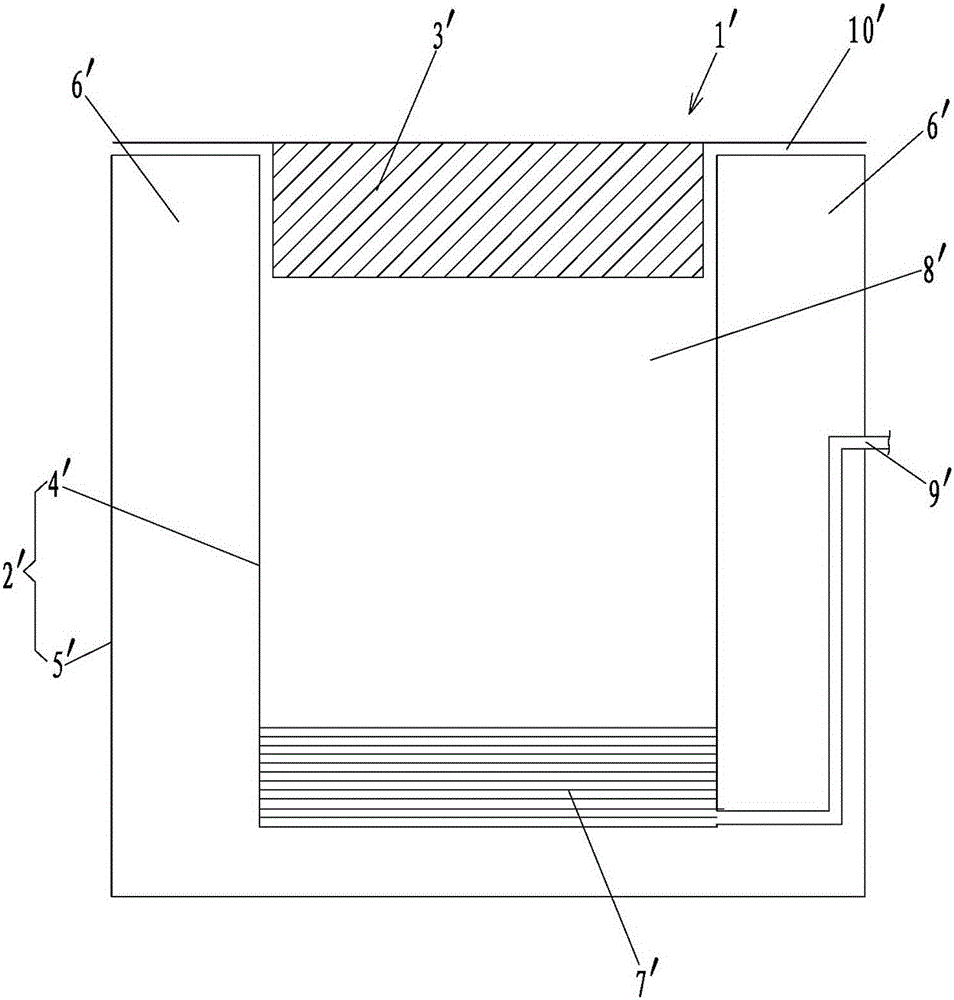

Constant low temperature storage system and method of removing dewar mist

ActiveCN106829202ATemperature is not affectedImprove efficiencyLiving organism packagingContainers preventing decayEngineeringService efficiency

A constant low temperature storage system and a method of removing dewar mist. The constant low temperature storage system comprises a dewar, at least one refrigerant inlet pipe, an airtight blocking device, at least one external vent pipe and at least one internal vent pipe,, wherein a sample storage room and a refrigerant room are arranged in the dewar; the inlet pipe is use for injecting a refrigerant from the dewar to the refrigerant room; the airtight blocking device is arranged between the sample storage room and the refrigerant room; the external vent pipe is used for venting gas in the refrigerant room out of the dewar; and the internal vent pipe is used for leading cool air in the refrigerant room into the sample storage room. The method of removing the dewar mist includes the steps that dry-filtered air is pressed from the external vent pipe and / or the refrigerant inlet pipe into the refrigerant room; and the gas flows from the internal vent pipe into the sample storage room to remove the mist and / or accelerate refrigeration of a sample after the gas foams in the refrigerant. The constant low temperature storage system and the method of removing the dewar mist can prevent a large quantity of cool air from entering the sample storage room in the process of adding the refrigerant and guarantees a constant storage temperature, and accordingly the service efficiency of the refrigerant is improved. Meanwhile, by pressing the dry-filtered air into the system, the mist in the sample storage room can be removed, and / or the sample can be refrigerated rapidly.

Owner:领航智飞管理咨询(北京)有限公司

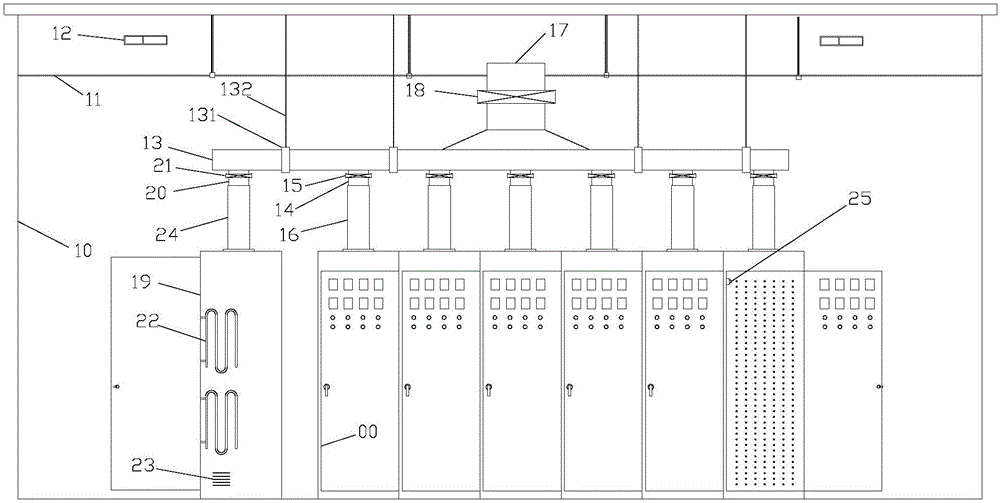

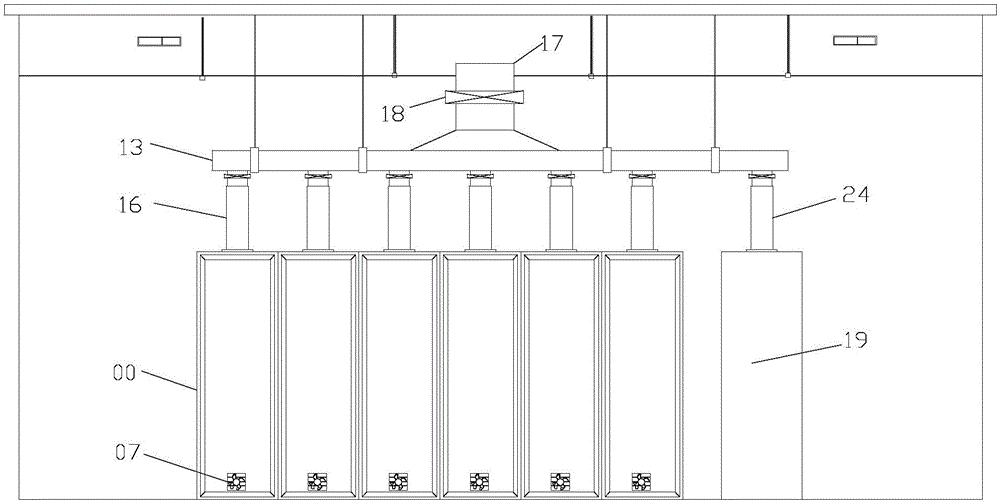

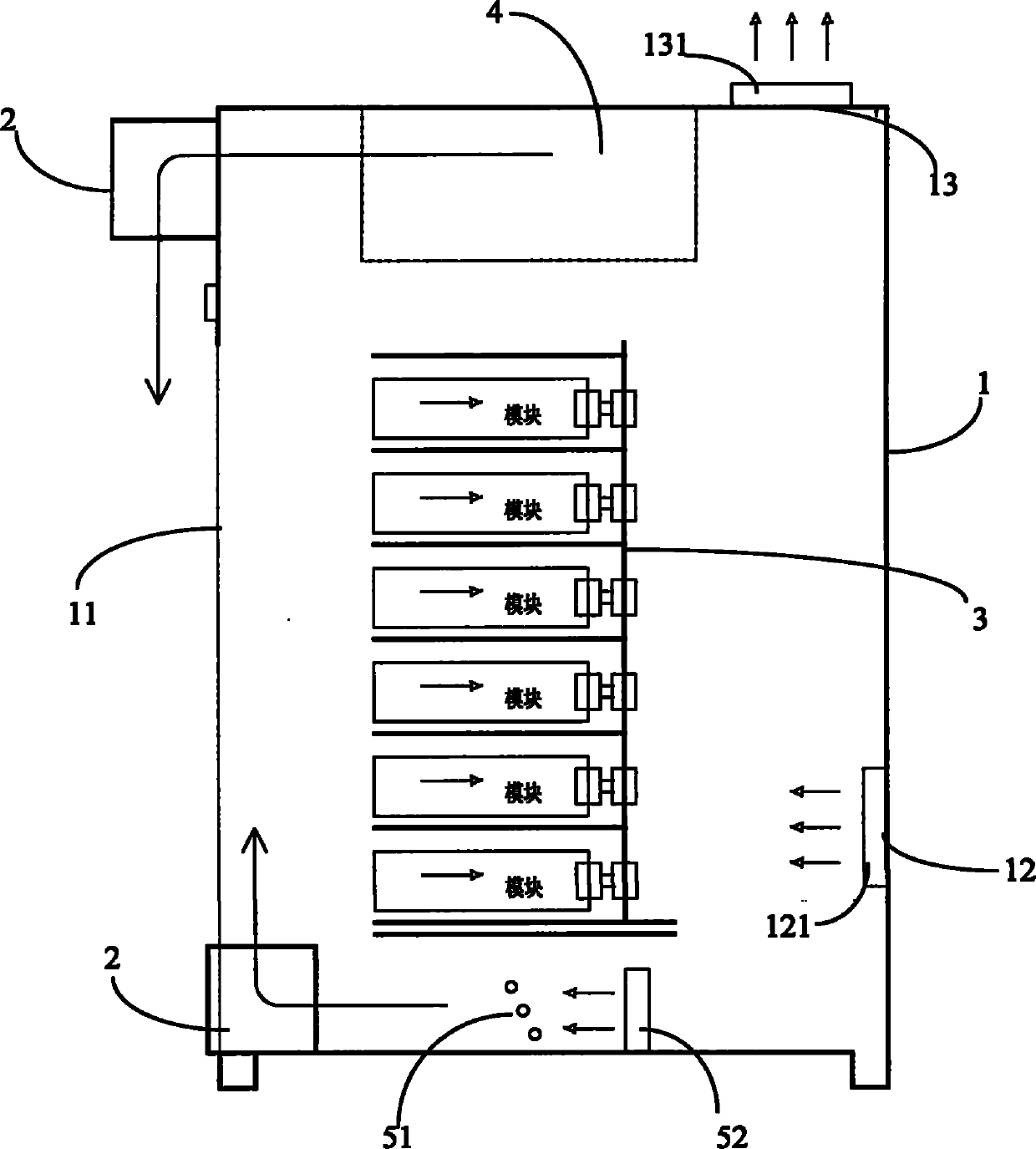

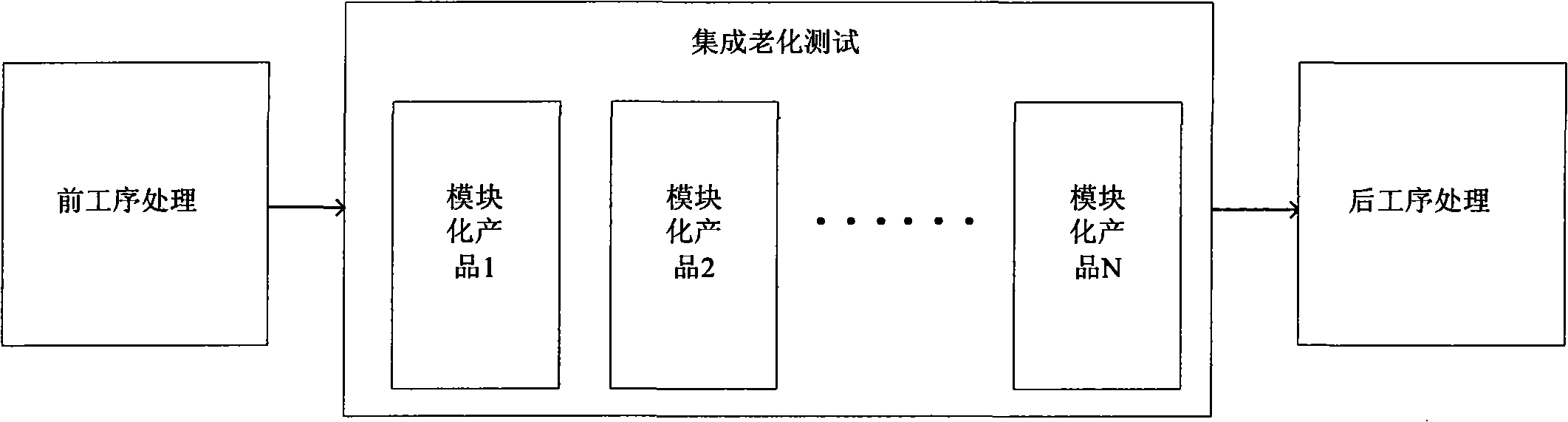

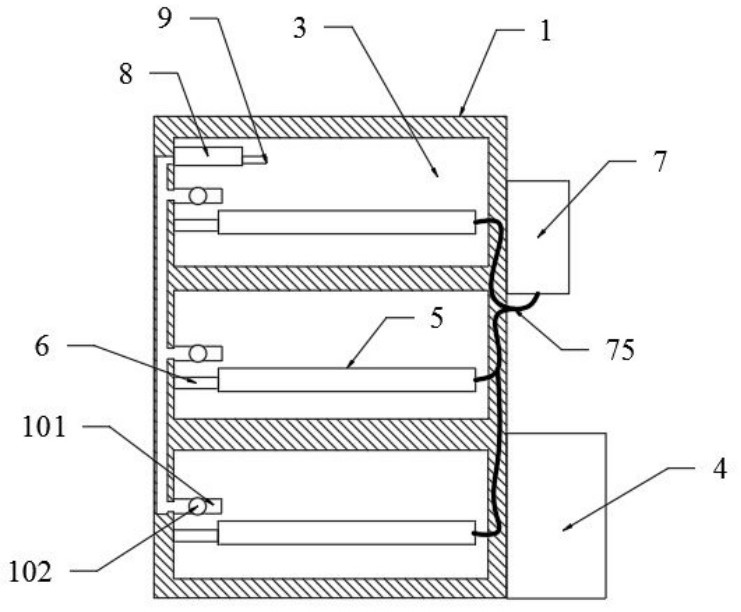

Consecutive aging test method

ActiveCN102087320ASave floor spaceOmit operabilityPower supply testingModular productSoftware engineering

The present invention relates to a consecutive aging test method, which is an integrated aging test for modularized products between whole-machine assembling process and packaging and delivery process. Wherein the consecutive aging test method comprises the following steps: inserting N modularized products into a test cabinet in turn, and carrying out the integration aging test; wherein N is a natural number and the above operation is a rounded down operation, T1 is the time for processing one modularized product by a pre-process of the integration aging test, and T2 is the time for the integration aging test. By integrating pre-aging test, aging test and post-aging test partly or fully; and making the time for rotating one modularized product by the integration aging test match with the time for processing one modularized product by the pre-process of the integration aging test, the method avoid the wait and accumulation of modularized products; not only realizes line production, but also avoid the large floor space occupation and manual operation caused by the flow line.

Owner:VERTIV CORP

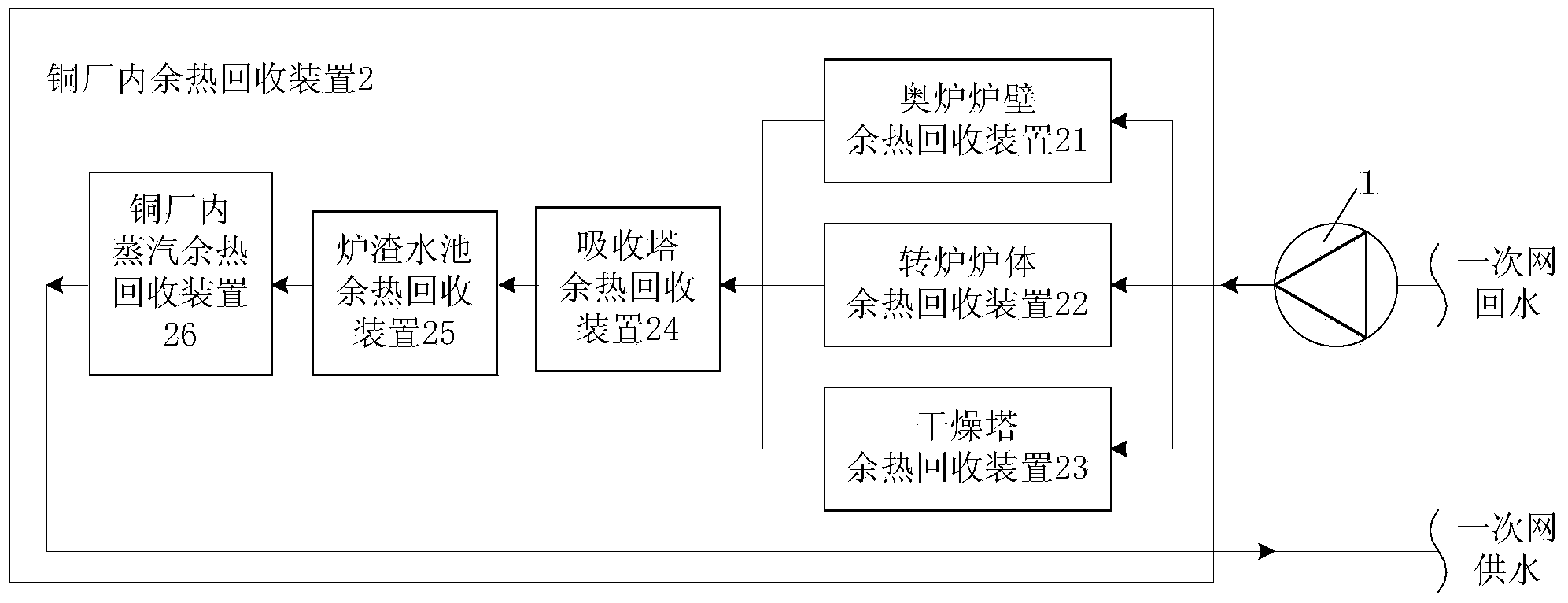

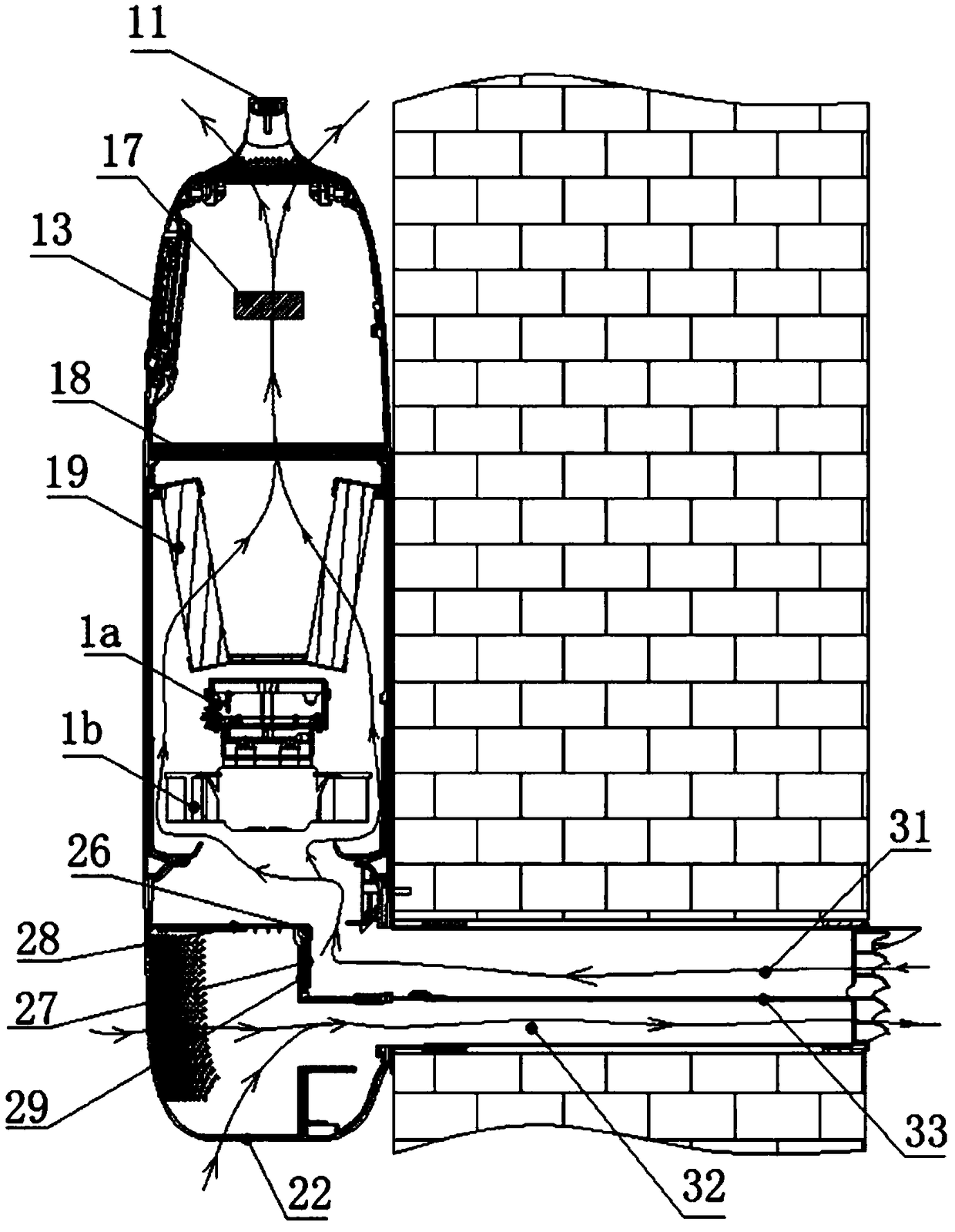

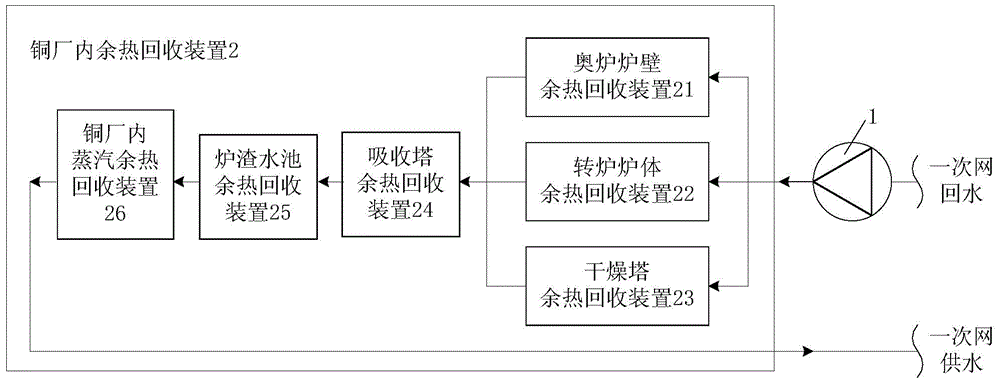

Copper plant low-grade waste heat recovery system for urban central heating

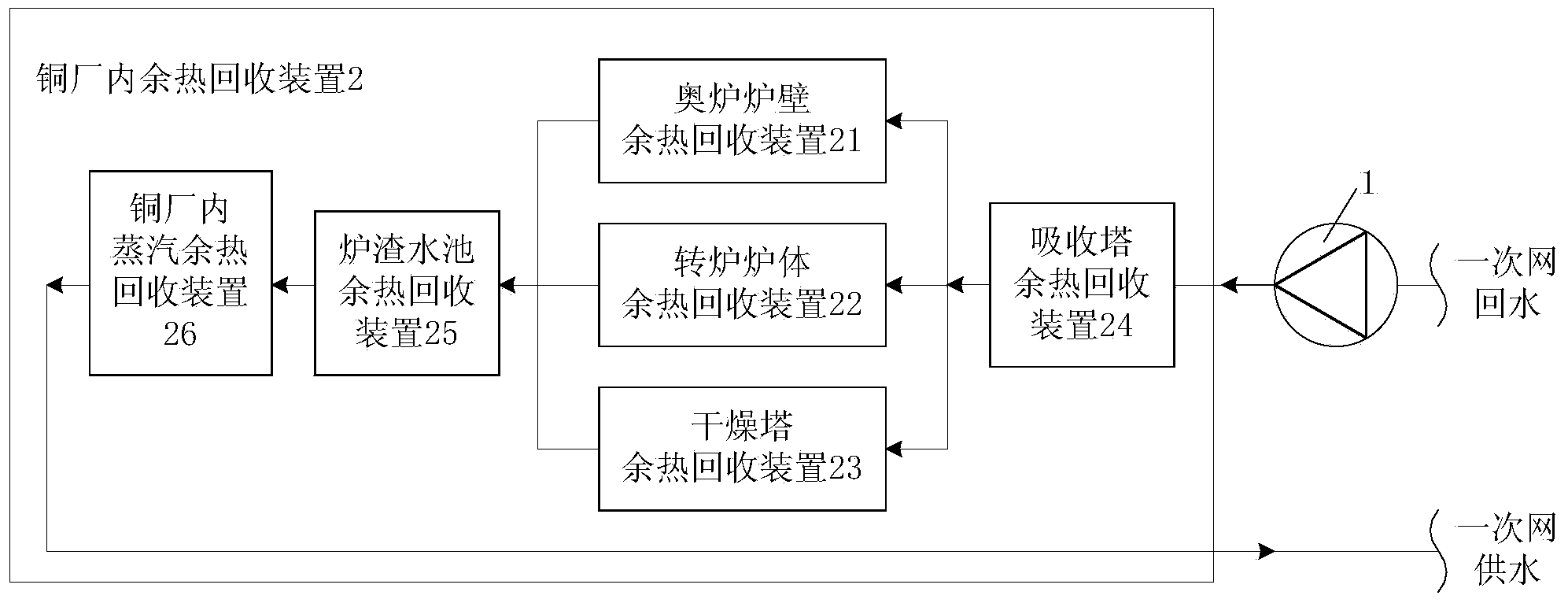

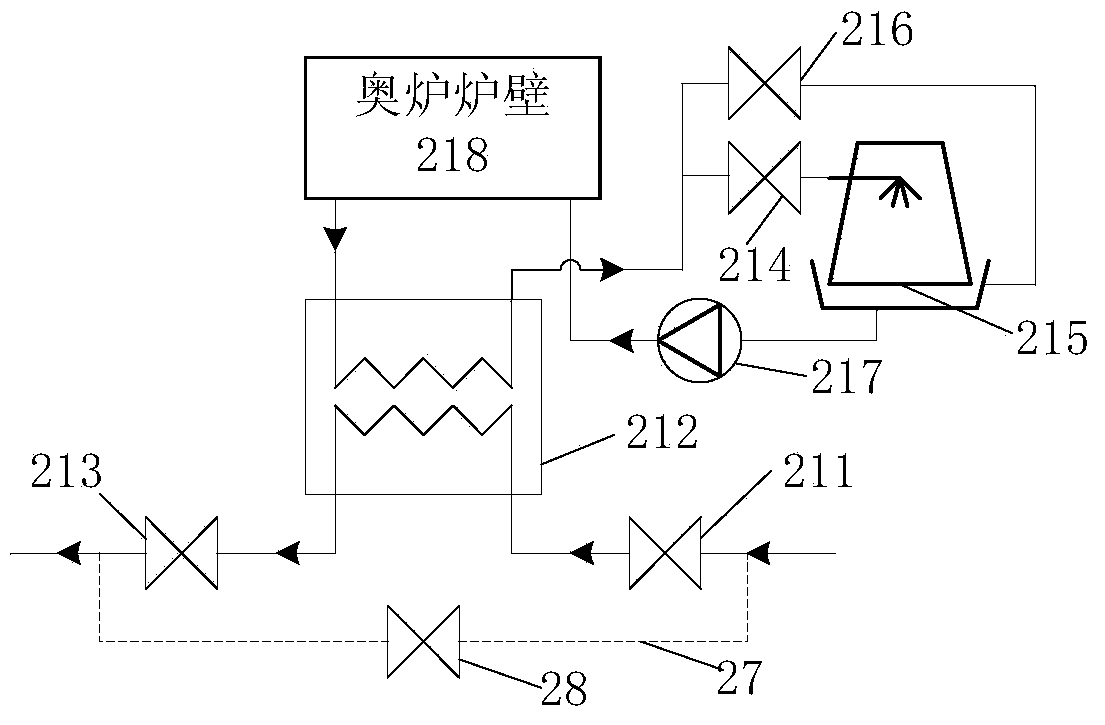

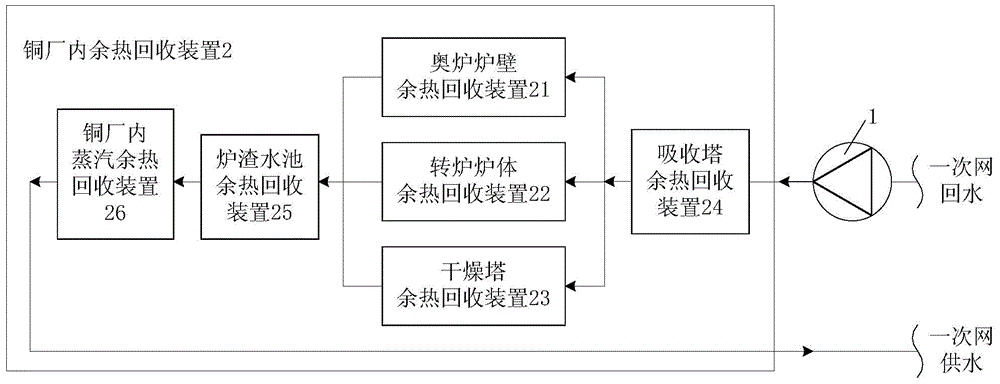

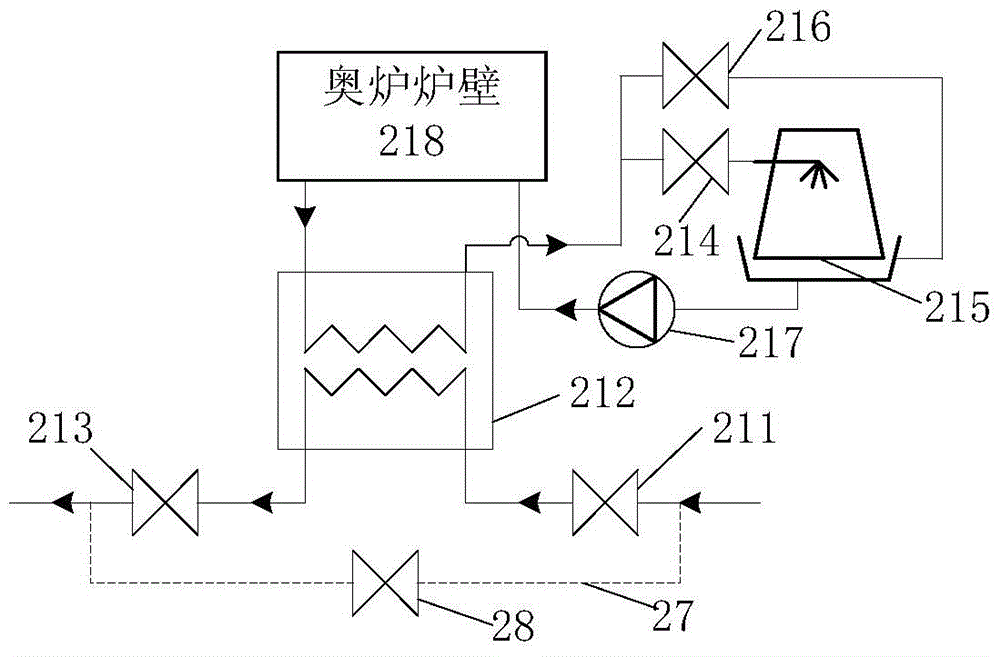

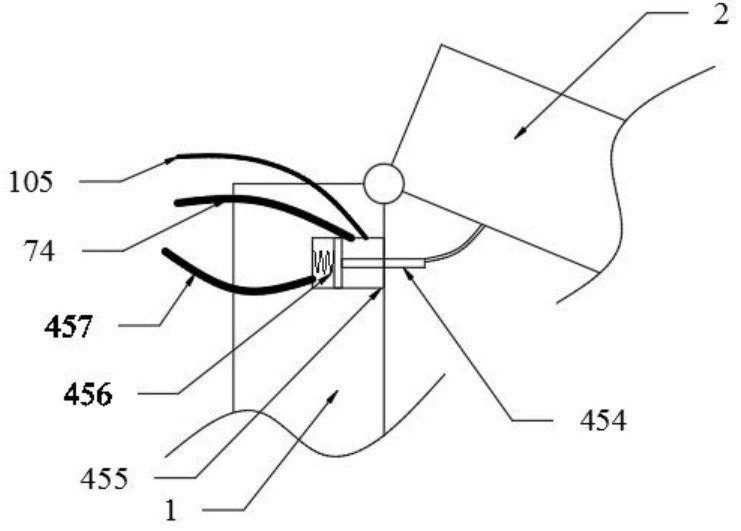

ActiveCN103868132AImprove waste heat recovery rateEase the shortageEnergy efficient heating/coolingEnergy industryWaste heat recovery unitSlag

The invention relates to a copper plant low-grade waste heat recovery system for urban central heating. The copper plant low-grade waste heat recovery system is characterized by comprising a primary network circulating pump and a copper plant waste heat recovery device, wherein primary network return water from a primary pipe network flows into the copper plant waste heat recovery device through the primary network circulating pump, the copper plant waste heat recovery device collects waste heat in a copper plant, the waste heat is used for heating the primary network return water, and after the temperature rises, the primary network return water is supplied to a user in the form of primary network water supply; the copper plant waste heat recovery device comprises an austenitic furnace wall waste heat recovery device, a converter body waste heat recovery device, a drying tower waste heat recovery device, an absorption tower waste heat recovery device, a slag pool waste heat recovery device and a copper plant steam waste heat recovery device, wherein the austenitic furnace wall waste heat recovery device, the converter body waste heat recovery device and the drying tower waste heat recovery device are arranged in parallel, and the absorption tower waste heat recovery device, the slag pool waste heat recovery device and the copper plant steam waste heat recovery device are connected in series with the three waste heat recovery devices which are connected in parallel. The copper plant low-grade waste heat recovery system can be widely applied to recovery of low-grade waste heat in the copper plant.

Owner:TSINGHUA UNIV +1

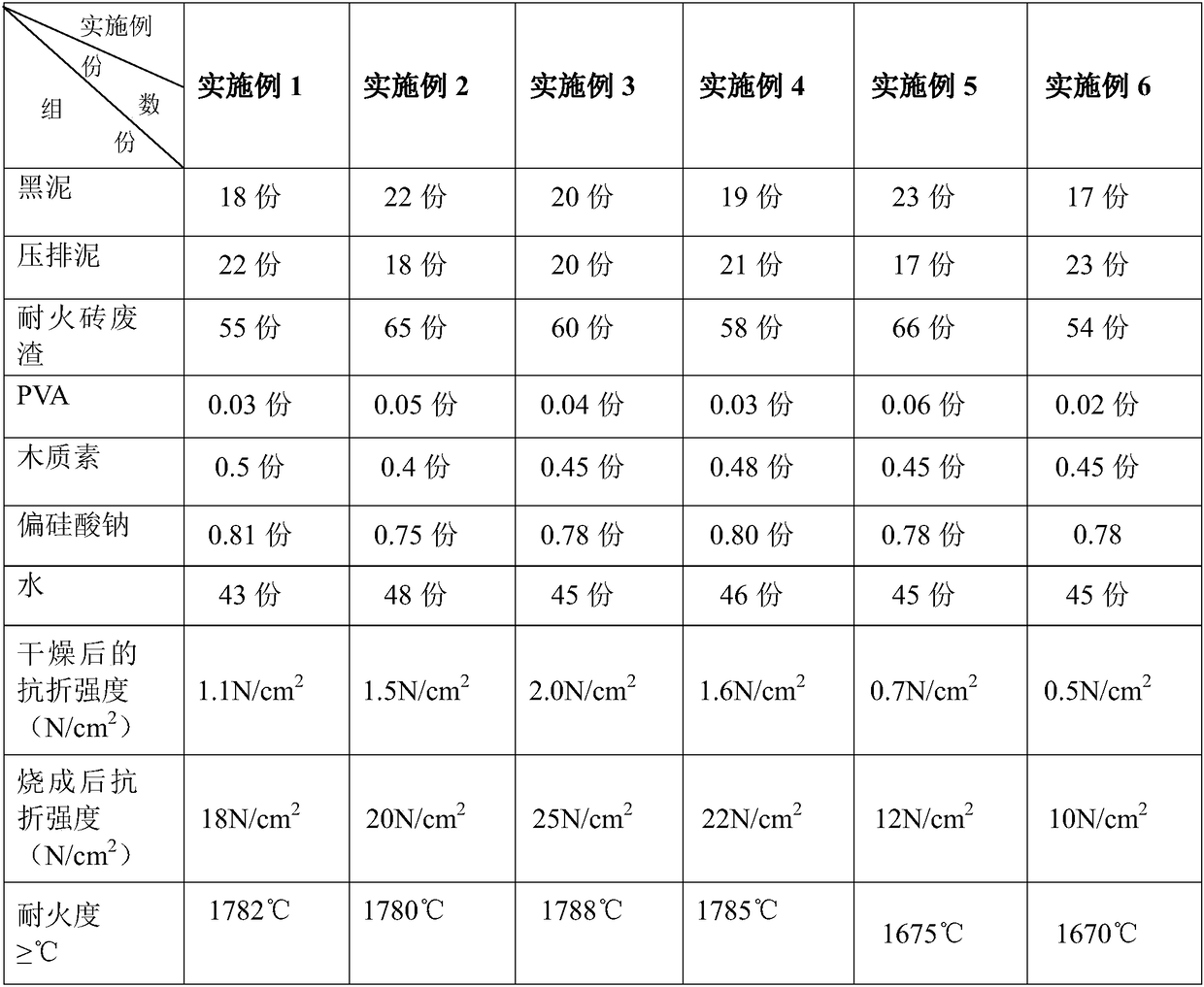

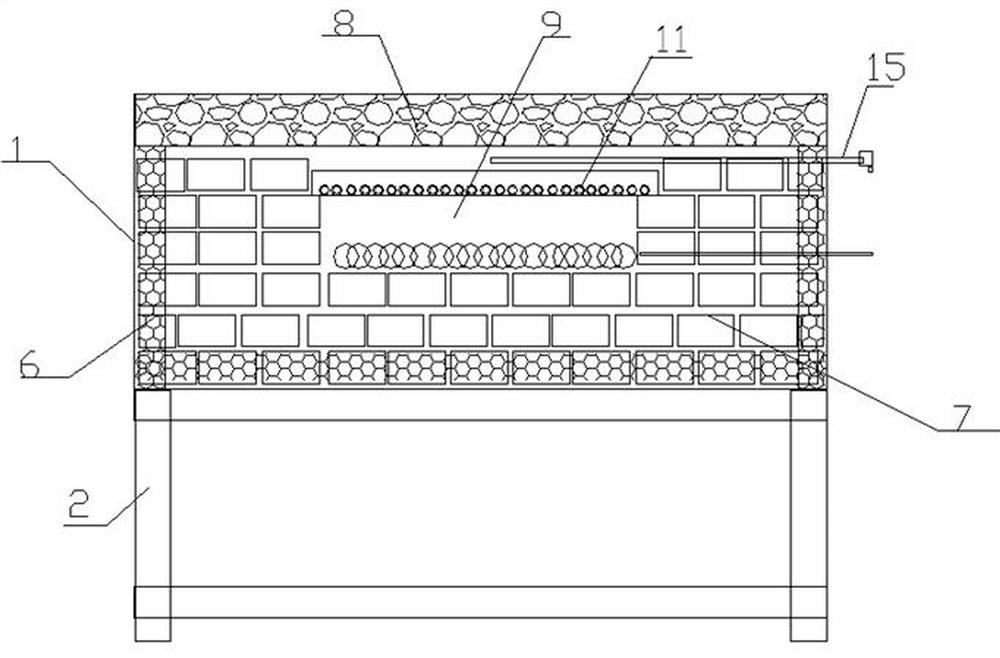

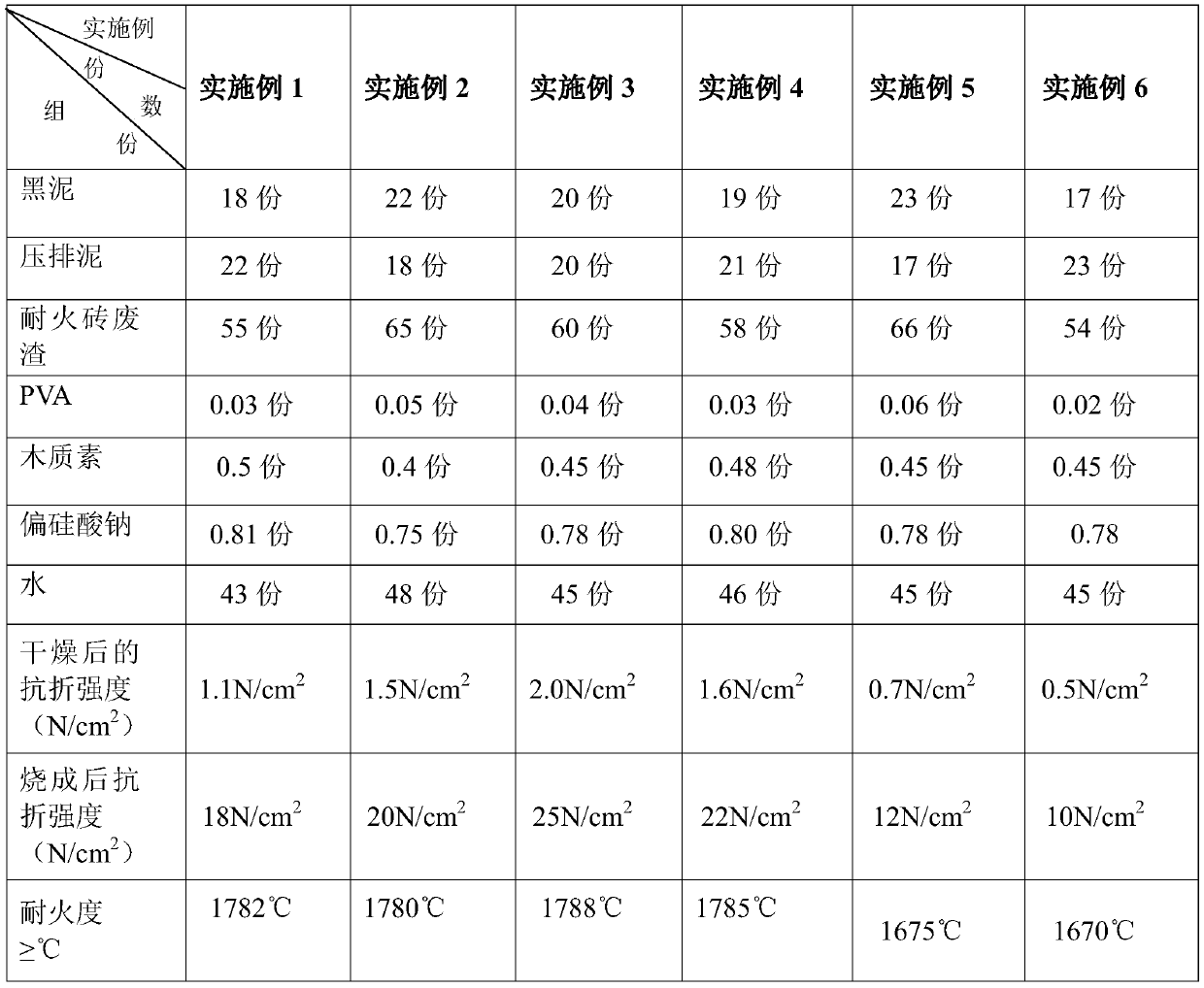

Low-cost preparation process of environment-friendly high-temperature brick and the high-temperature brick

ActiveCN108516847AEnergy saving and environmental protection in the preparation processHigh strengthCeramic materials productionClaywaresSodium metasilicateFire brick

A low-cost preparation process of an environment-friendly high-temperature brick and the high-temperature brick. The preparation process includes steps of: 1) mixing the raw materials including, by weight, 18-22 parts of black mud, 18-22 parts of pressure-discharged mud, 55-65 parts of waste residue of refractory bricks, 0.03-0.05 parts of PVA, 0.4-0.5 parts of lignin, 0.75-0.81 parts of sodium metasilicate and 43-48 parts of water, ball-milling the mixture to form slurry, and spray-drying the slurry to obtain a high-temperature brick powder material; 2) placing the high-temperature brick powder material in a pressing mould to press-shape the high-temperature brick powder material, and sintering the material in a kiln to obtain a finish product. The high-temperature brick not only has high-temperature fireproof effect but also is higher in strength, can be repeatedly used, is greatly reduced in preparation cost, is more environment-friendly and energy-saving, and has simple preparationprocess.

Owner:FOSHAN DONGPENG CERAMIC +2

Flash deposition apparatus

InactiveCN105088139AHigh material utilizationTemperature is not affectedVacuum evaporation coatingSputtering coatingEngineeringRadiation shield

A flash deposition apparatus includes a liquid delivery system configured to produce fine liquid droplets of an organic material, a heater configured to vaporize the fine liquid droplets to produce a vapor material to be directed to a substrate on which the organic material is deposited; and a radiation shield configured to shield the heater from the liquid delivery system.

Owner:AOYV NEW MATERIAL TECH (JIAXING)

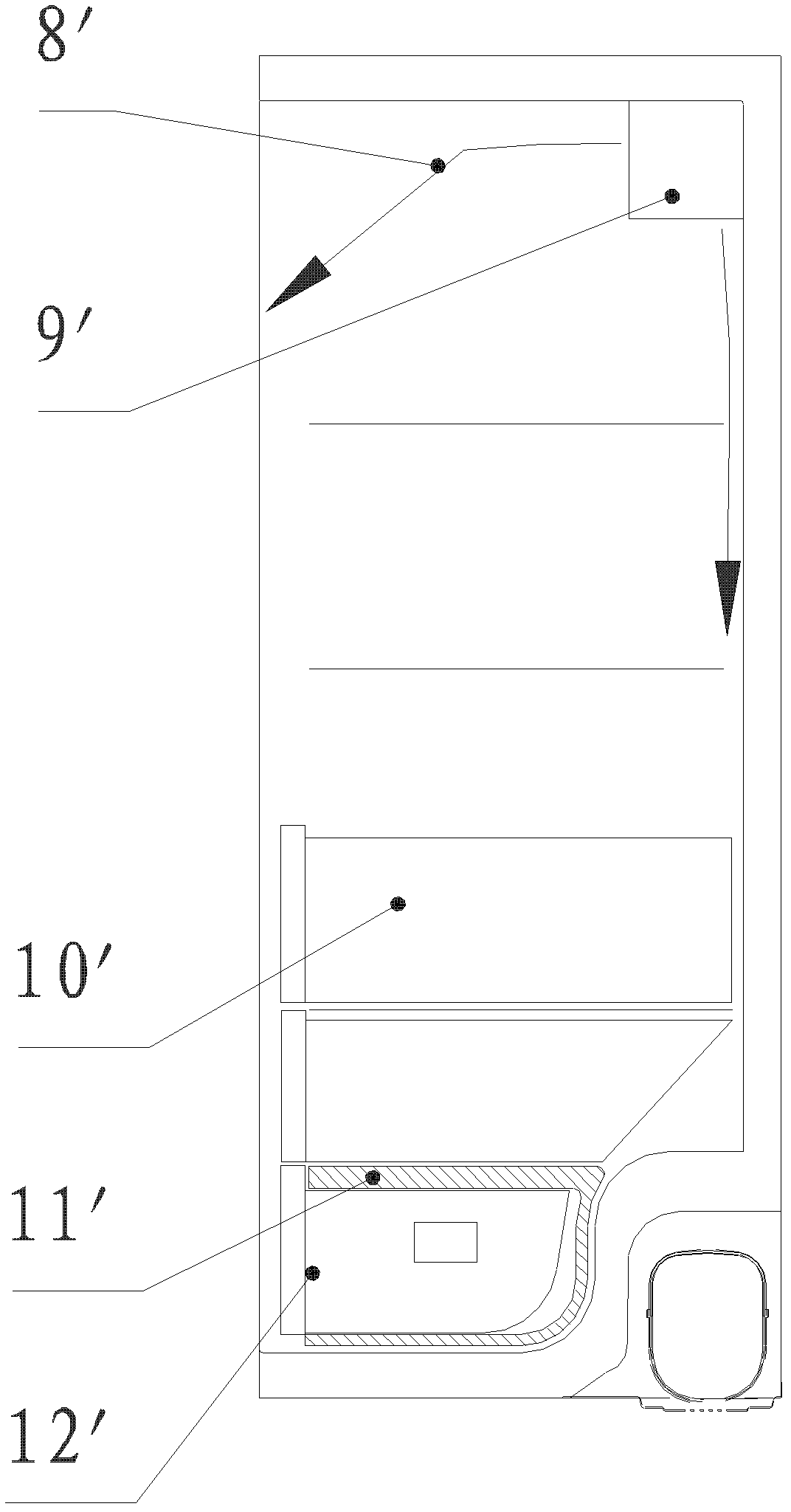

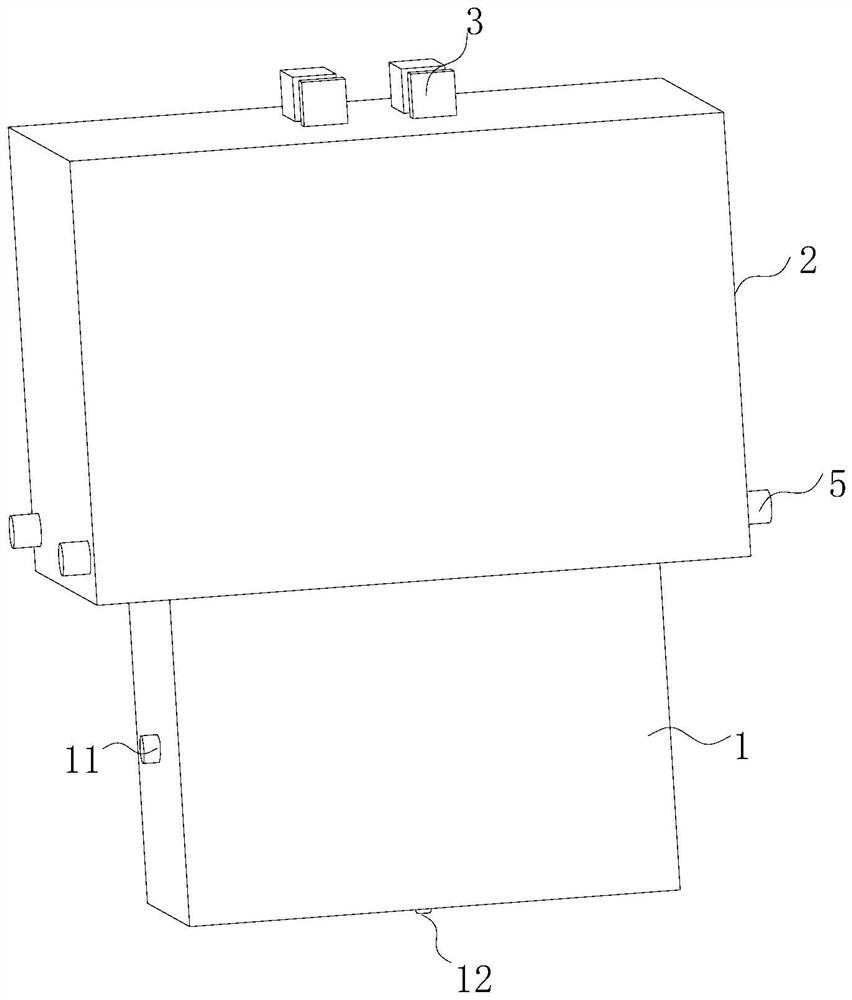

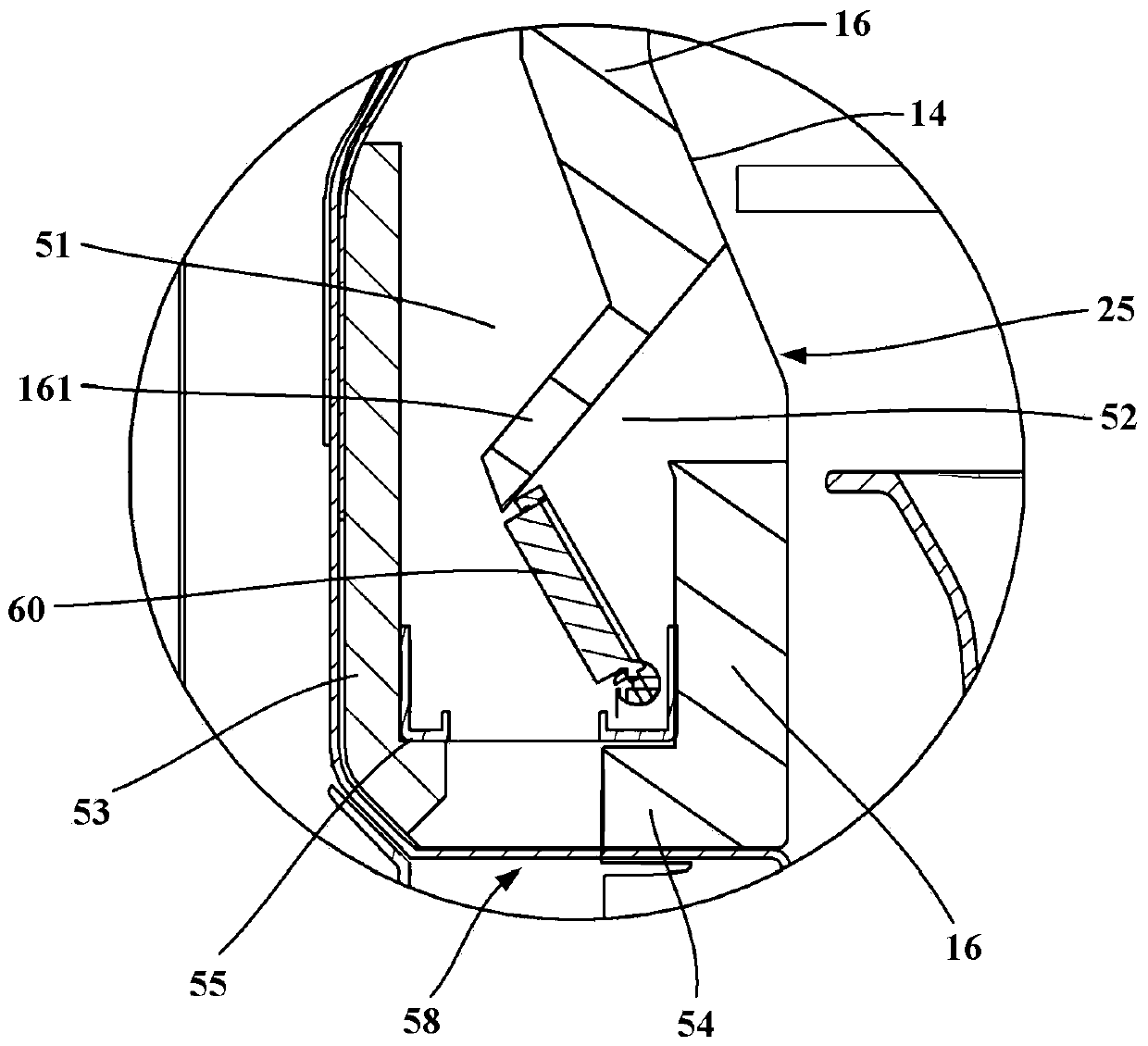

Special refrigerator for storing blood

InactiveCN109945580ATemperature is not affectedSatisfy the constant temperature requirement of blood storageLighting and heating apparatusDomestic refrigeratorsRefrigerator carBiomedical engineering

The invention discloses a special refrigerator for storing blood. The special refrigerator for storing the blood comprises a refrigerator body, wherein the refrigerator body is provided with a refrigerator door. The special refrigerator for storing the blood is characterized in that a blood storage cylinder is fixedly arranged in the refrigerator body; at least four blood storage trays are rotatably arranged in the blood storage cylinder and are distributed at intervals from bottom to top; blood bag pick-and-place ports are formed in the side wall of the blood storage cylinder; the quantity ofthe blood bag pick-and-place ports is the same as the quantity of the blood storage trays; the positions of the blood bag pick-and-place ports and the blood storage trays are in one-to-one correspondence; sealing doors for opening and closing the blood bag pick-and-place ports are arranged on the blood storage cylinder; the quantity of the sealing doors is the same as the quantity of the blood bag pick-and-place ports; the sealing doors and the blood bag pick-and-place ports are matched in a one-to-one correspondence way; multiple radial clapboards are fixedly arranged on the upper surfaces of the blood storage trays and are uniformly distributed along the circumferential direction; and a blood bag placement space is formed between each two adjacent radial clapboards. According to the special refrigerator for storing the blood provided by the invention, when a blood bag is picked and placed, the occurrence of the phenomenon that bacteria are carried into the refrigerator body so as tocontact a blood bag can be reduced; and after the refrigerator door is opened, the temperature fluctuation of the blood bag is small, and the blood bag is sanitary and can be picked in a way of firstly placing and firstly discharging.

Owner:AFFILIATED YONGCHUAN HOSPITAL OF CHONGQING MEDICAL UNIV

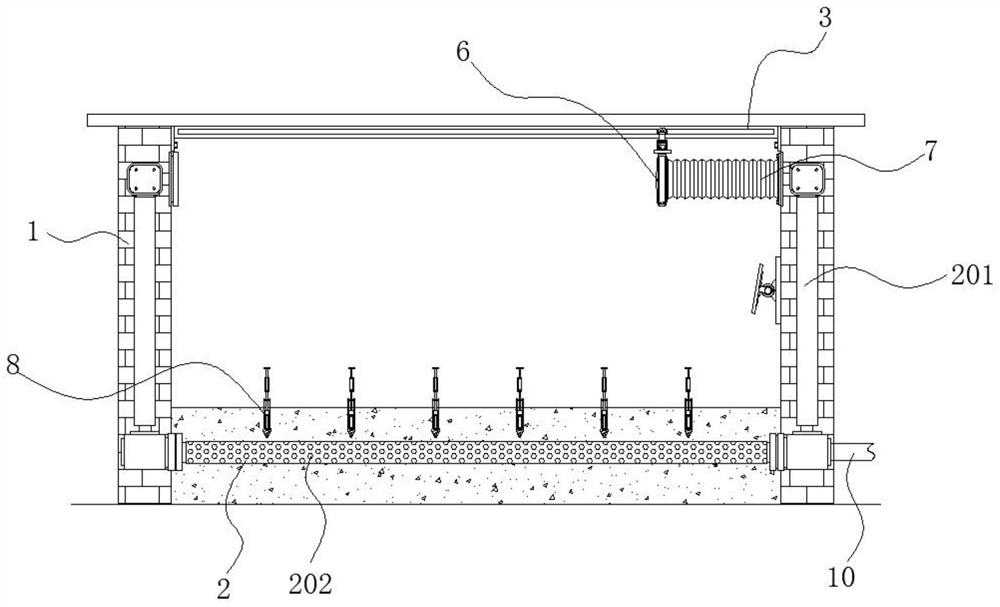

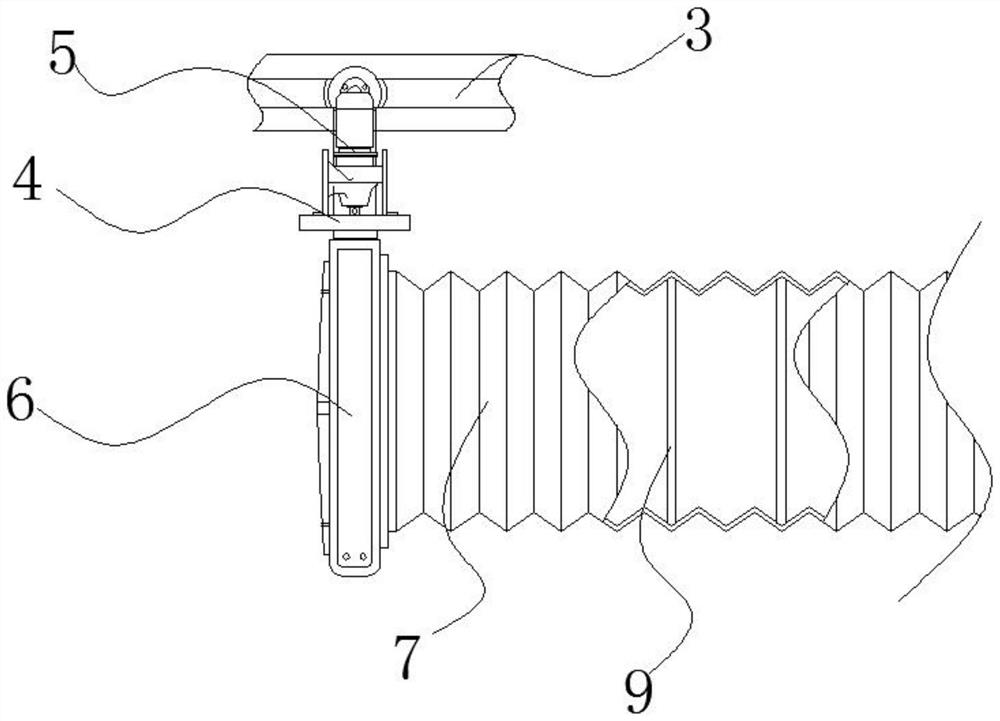

System equipment for adjusting temperature in soil and temperature in greenhouse

ActiveCN113207505ASuitable temperatureTemperature is not affectedThermometer detailsClimate change adaptationSoil scienceGreenhouse

The invention discloses system equipment for adjusting temperature in soil and temperature in a greenhouse, and relates to the technical field of greenhouses. The system equipment specifically comprises a greenhouse body, a temperature sensor assembly and a ventilation pipeline; the greenhouse body is used for creating an adaptive growth temperature environment for plants; the ventilation pipeline is buried in soil in the greenhouse body; and the temperature sensor assembly is located above the ventilation pipeline. According to the system equipment for adjusting the temperature in soil and the temperature in the greenhouse, based on the principle that the temperature in the soil is lower than the earth surface temperature, the temperature in the greenhouse and air in the soil in the greenhouse are mutually replaced, the temperature in the greenhouse is suitable, the comfort degree of a human body is improved, meanwhile, it is guaranteed that the soil temperature is not affected, plants can grow healthily, moreover, the soil temperature can be adjusted by monitoring the temperature in the soil and cooperatively heating or not heating the water body, and meanwhile, the water body can flow out to humidify the soil by pressurizing the water body, so that sufficient water required by plant growth is ensured.

Owner:宋骐骏

Consecutive aging test method

ActiveCN102087320BTemperature is not affectedAvoid high temperaturePower supply testingModular productSoftware engineering

The present invention relates to a consecutive aging test method, which is an integrated aging test for modularized products between whole-machine assembling process and packaging and delivery process. Wherein the consecutive aging test method comprises the following steps: inserting N modularized products into a test cabinet in turn, and carrying out the integration aging test; wherein N is a natural number and the above operation is a rounded down operation, T1 is the time for processing one modularized product by a pre-process of the integration aging test, and T2 is the time for the integration aging test. By integrating pre-aging test, aging test and post-aging test partly or fully; and making the time for rotating one modularized product by the integration aging test match with the time for processing one modularized product by the pre-process of the integration aging test, the method avoid the wait and accumulation of modularized products; not only realizes line production, but also avoid the large floor space occupation and manual operation caused by the flow line.

Owner:VERTIV CORP

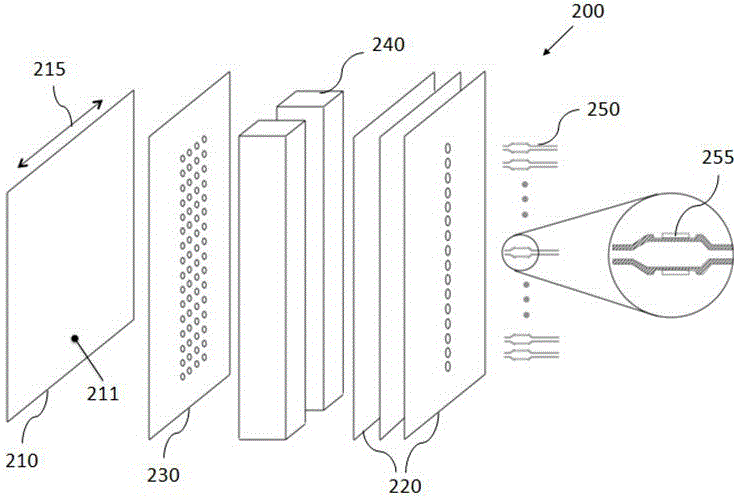

A fast-cooling dual-laser printing device

ActiveCN113400640BImprove molding efficiencyDoes not affect temperatureAdditive manufacturing apparatusAdditive manufacturing with solidsThermal insulationMechanical engineering

The invention discloses a rapid-cooling dual-laser printing device in the field of intelligent manufacturing, which includes a working cavity installed on a frame, an insulating cavity is arranged above the working cavity, and a laser head is arranged on the top of the insulating cavity. A powder bed is provided at the bottom, and a powder spreading mechanism for laying powder on the powder bed and a heating mechanism for heating the heat preservation chamber are arranged inside the heat preservation chamber; a support plate for placing workpieces is arranged in the working chamber, The support plate is fixedly installed on the lifting mechanism, and the support plate slides up and down along the inner wall of the working cavity; a cooling mechanism is arranged in the working cavity, and the cooling mechanism is used to cool down the molded area of the workpiece during workpiece processing. The invention can quickly cool down the molded area of the workpiece while the equipment is printing the workpiece, and does not affect the temperature of the unmolded area of the workpiece, and does not cause the powder to fly, so that the workpiece can be cooled synchronously when printing is completed, and the molding efficiency of the workpiece is improved. .

Owner:山东创瑞激光科技有限公司

A fresh air air purifier

ActiveCN106322521BPrevent dumpingEasy to moveMechanical apparatusSpace heating and ventilation safety systemsEngineeringComposite filter

The invention relates to a purifier and provides a fresh air purifier. The fresh air purifier comprises a purification module, a fresh air module, a fresh air pipe module, a composite filter net, HEPA filter nets, a motor and a centrifugal fan; the purification module is arranged on the fresh air module; the fresh air pipe module communicates with the fresh air module; supporting columns and an upper contact are arranged at the bottom of the purification module; supporting seats corresponding to the supporting columns and a lower contact corresponding to the upper contact are arranged at the upper part of the fresh air module; and the composite filter net, the HEPA filter nets, the motor and the centrifugal fan are arranged in the purification module. The purification module of the fresh air purifier can be taken down easily and used alone and can be moved conveniently and rapidly, and purification space can be changed at will.

Owner:CHENGDU GUIGU ENVIRONMENTAL TECH

A temperature control method for a power distribution cabinet

ActiveCN106786057BReduce the temperatureImprove cooling effectTemperatue controlSubstation/switching arrangement cooling/ventilationTemperature controlEngineering

The invention discloses a power distribution cabinet. The power distribution cabinet comprises a cabinet body, wherein a ventilation hole is formed in the top of the cabinet body, and one circle of first mounting holes are formed in the periphery of the ventilation hole; dense screw holes are formed in a backing plate of the cabinet body, the back of the cabinet body is connected with a back cavity, and a frame type sealing strip is arranged between the backing plate and the back cavity; and a fan is arranged at the lower part of the back cavity. According to the power distribution cabinet disclosed by the invention, airflow is blown out from the back cavity and the screw holes in the backing plate when the fan rotates forwards and supplies the air inwards, and the blown-out wind is directly blown onto electrical components, so that the airflow can be pushed toward the ventilation hole in the top to be blown out, and heat dissipation effect is better. The invention also discloses a temperature control system and a temperature control method of the power distribution cabinet, when the temperature of the power distribution cabinet is lower than TA, the power distribution cabinet at higher temperature can carry out temperature compensation on the power distribution cabinet at low temperature through an air duct for preventing condensation, so that the temperature of the power distribution cabinet at the low temperature rises; and the temperature in the power distribution cabinet can be better controlled, so that the power distribution cabinet can meet temperature demand during operation, the use safety is improved, and the service lives of the electrical components are prolonged.

Owner:珠海盈源电气有限公司

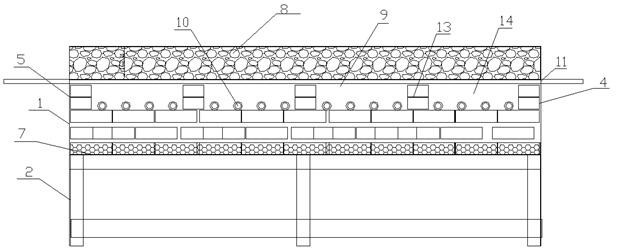

Heat treatment furnace for heat treatment of steel wire

ActiveCN110343845BInexpensive materialsLow priceFurnace typesHeat treatment process controlFiberBrick

The invention discloses a heat treatment furnace for steel wire heat treatment, and relates to the technical field of steel wire production. The heat treatment furnace comprises a furnace body shell,a steel wire inlet and a steel wire outlet, a ceramic fiber plate is adopted as the lining for the structure of the furnace body, a light brick is laid on the ceramic limiting plate, the material price of the heat treatment furnace is low, so that the price of the finally built heat treatment furnace can be effectively reduced; in terms of energy consumption, the power distribution cabinet controls on-off and heating temperature of a plurality of sets of heating resistance wires, so that the energy consumption of the heating resistance wire can be effectively controlled; and furthermore, the structure of a heating cavity of the heat treatment furnace can be effectively controlled, the heat preservation and the heat insulation of the heating cavity can be effectively realized under the limitation of the light brick and a heat insulation material, the heat in the heating cavity can be well controlled, and the problem that the energy consumption is increased due to the fact that heat is leaked is avoided.

Owner:四川圣德钢缆有限公司

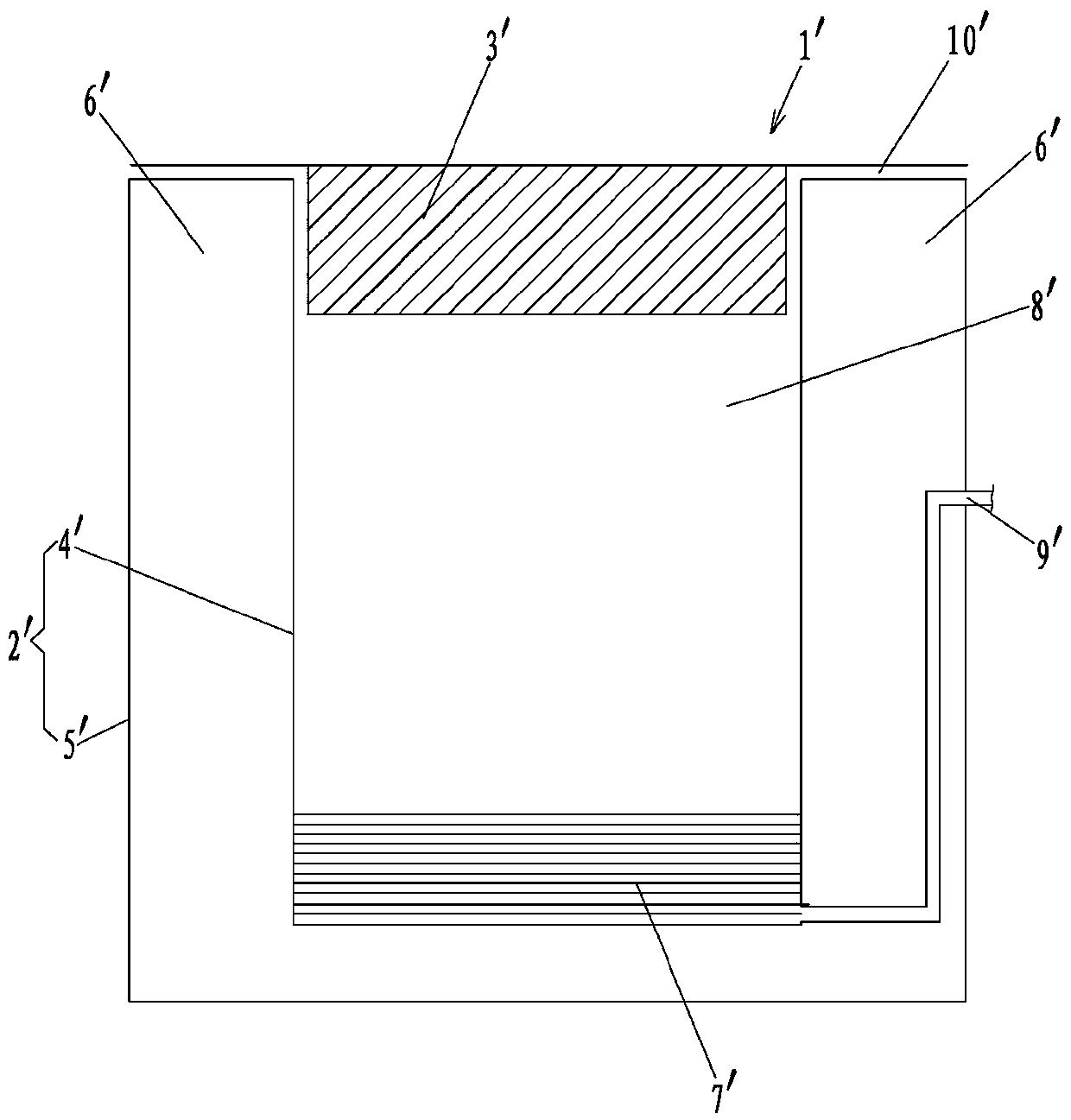

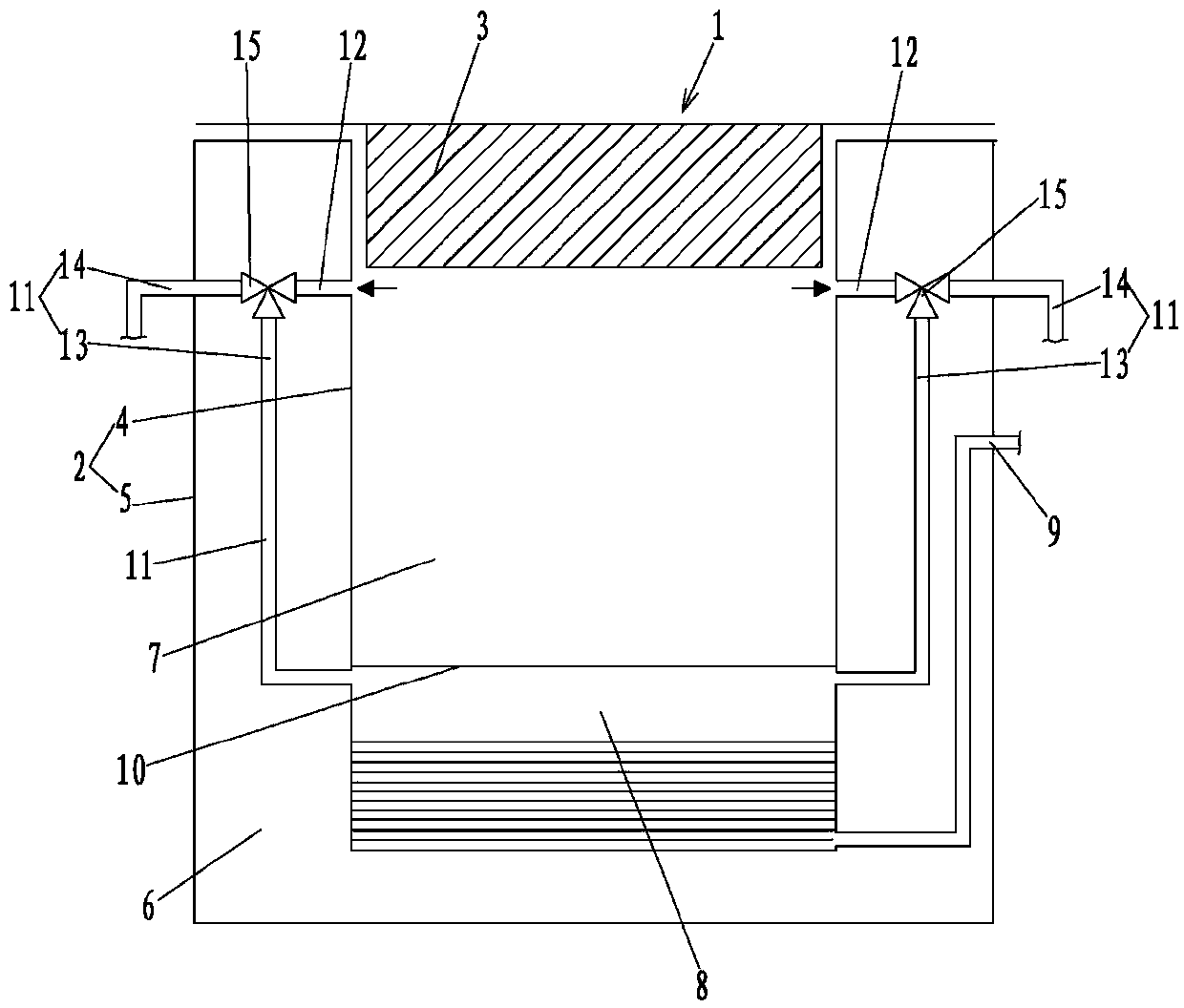

Constant-temperature and constant-humidity cell incubator

ActiveCN112980687AStable temperatureTemperature is not affectedBioreactor/fermenter combinationsBiological substance pretreatmentsMechanical engineeringExhaust pipe

The invention discloses a constant-temperature and constant-humidity cell incubator. The incubator comprises an incubator body, an incubator door, chambers, a water heating mechanism, humidifying discs, supporting rods, a humidity maintaining mechanism, a CO2 generator, a first exhaust pipe and a CO2 concentration maintaining mechanism, wherein one side of the incubator body is movably connected with the incubator door; the three chambers with the same volume are arranged in the incubator body; the water heating mechanism is arranged in the side wall of the incubator body; each chamber is provided with the humidifying disc; the middle of each chamber is fixedly connected with one end of the corresponding supporting rod; the other end of each supporting rod is fixedly connected with the corresponding humidifying disc; each humidifying disc is a cube with an opening in one face; the humidity maintaining mechanism is arranged in the incubator body; the CO2 generator is arranged in the incubator body; one end of the first exhaust pipe is fixedly connected with the CO2 generator; the end, away from the CO2 generator, of the first exhaust pipe is arranged at the upper end of the incubator body; the CO2 concentration maintaining mechanism is arranged in the incubator body; and the incubator door is made of transparent materials and coated with shading materials. The cell incubator is scientific, reasonable, simple in structure, economic and practical.

Owner:广州维柏生物科技有限公司

Constant low temperature storage system and method for removing Dewar fog

ActiveCN106829202BTemperature is not affectedImprove efficiencyLiving organism packagingContainers preventing decayEngineeringService efficiency

A constant low temperature storage system and a method of removing dewar mist. The constant low temperature storage system comprises a dewar, at least one refrigerant inlet pipe, an airtight blocking device, at least one external vent pipe and at least one internal vent pipe,, wherein a sample storage room and a refrigerant room are arranged in the dewar; the inlet pipe is use for injecting a refrigerant from the dewar to the refrigerant room; the airtight blocking device is arranged between the sample storage room and the refrigerant room; the external vent pipe is used for venting gas in the refrigerant room out of the dewar; and the internal vent pipe is used for leading cool air in the refrigerant room into the sample storage room. The method of removing the dewar mist includes the steps that dry-filtered air is pressed from the external vent pipe and / or the refrigerant inlet pipe into the refrigerant room; and the gas flows from the internal vent pipe into the sample storage room to remove the mist and / or accelerate refrigeration of a sample after the gas foams in the refrigerant. The constant low temperature storage system and the method of removing the dewar mist can prevent a large quantity of cool air from entering the sample storage room in the process of adding the refrigerant and guarantees a constant storage temperature, and accordingly the service efficiency of the refrigerant is improved. Meanwhile, by pressing the dry-filtered air into the system, the mist in the sample storage room can be removed, and / or the sample can be refrigerated rapidly.

Owner:领航智飞管理咨询(北京)有限公司

A low-grade waste heat recovery system for copper plants used in urban central heating

ActiveCN103868132BImprove waste heat recovery rateEase the shortageEnergy efficient heating/coolingEnergy industryWaste heat recovery unitSlag

Owner:TSINGHUA UNIV +1

Constant temperature and humidity cell incubator

ActiveCN112980687BStable temperatureTemperature is not affectedBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringMechanical engineering

The invention discloses a constant temperature and humidity cell culture box. The incubator of the present invention includes a box body, a box door, a chamber, a water heating mechanism, a humidifying plate, a support rod, a humidity maintaining mechanism, and a CO 2 Generator, No. 1 Exhaust Pipe and CO 2 Concentration maintenance mechanism, one side of the box body is movably connected to the box door, there are three chambers with equal volume inside the box body, a water heating mechanism is installed in the side wall of the box body, each chamber is equipped with a humidifying plate, and the middle of each chamber Both ends are fixedly connected to one end of the support rod, and the other end of the support rod is fixedly connected to the humidification plate. The humidification plate is a cube with an opening on one side. The inside of the box is equipped with a humidity maintaining mechanism. 2 Generator, one end of No. 1 exhaust pipe is fixedly connected to CO 2 Generator, No. 1 exhaust pipe away from CO 2 One end of the generator is placed on the upper end of the box, and the inside of the box is equipped with a CO 2 Concentration maintaining mechanism, the box door is made of transparent material, and the box door is coated with light-shielding material. The invention is scientific and reasonable, simple in structure, and economical.

Owner:广州维柏生物科技有限公司

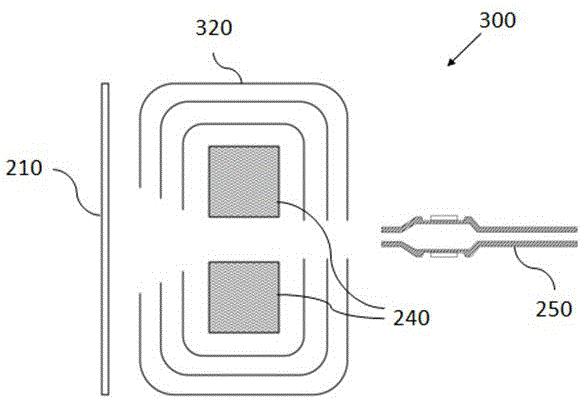

Rapid Pneumatic Bulging Method for Hot Metal Sheet

ActiveCN107297412BThe inflation process is independently controllableNo bulging deformationShaping toolsHeat exchange apparatusMetal sheetAtmospheric pressure

Provided is a method for quick forming of a hot metal sheet. The method relates to a technology for forming a metal sheet part, and solves the problem that the existing hot metal sheet forming technology cannot ensure that a blank is deformed under reasonable temperature and pressure conditions, thereby failing to realize precise and quick forming of a complex metal sheet part, especially a thin-walled part. The method mainly includes the following steps: step one, placing a metal sheet blank to be formed on a forming mold; step two, introducing high-pressure gases with equal pressures simultaneously into upper and lower enclosed cavities respectively formed by the metal sheet blank and the sealing mold, and the metal sheet blank and the forming mold; step three, heating the metal sheet blank to a preset forming temperature condition; step four, quickly releasing the high-pressure gas from the cavity formed by the metal sheet blank and the forming mold, such that the metal sheet blank bulges; and step five, discharging the gas from the cavity formed by the metal sheet blank and the sealing mold, and opening the mold to obtain a formed metal sheet part. The present invention is used for manufacturing a metal sheet part.

Owner:HARBIN INST OF TECH

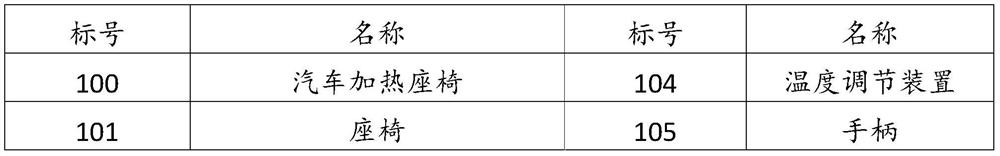

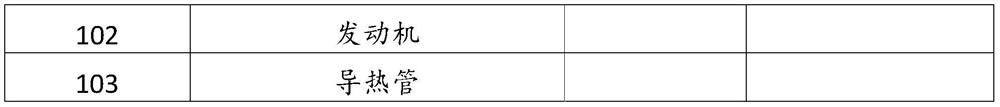

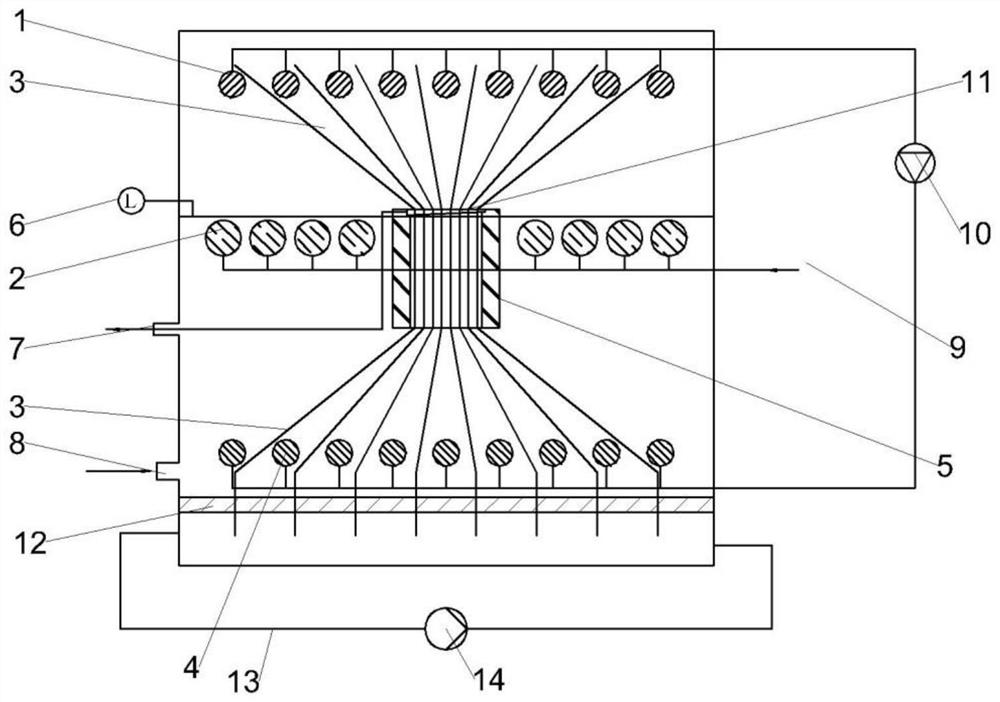

Automobile heating seat

InactiveCN112389290ATemperature is not affectedNo fogging phenomenonSeat heating/ventillating devicesInternal combustion piston enginesEngineeringAir temperature

The invention discloses an automobile heating seat. The automobile heating seat comprises a seat body, a heating device and a temperature adjusting device. A mounting cavity is formed in the bottom ofthe seat; the heating device comprises a heat conduction pipe, the heat conduction pipe is movably arranged in the mounting cavity in the vertical direction, and the heat conduction pipe is used forbeing communicated with an expansion kettle of the engine; and the temperature adjusting device is connected with the heat conduction pipe and used for adjusting the relative distance between the heatconduction pipe and the bottom of the seat. The direct transmission heating function is achieved, and low-temperature gas in the whole cab does not need to be heated; the air temperature at the windshield is not affected, the fogging phenomenon is avoided, and the driving visual field is better; and all parts for realizing the process of heating low-temperature gas by high-temperature liquid in the heat conversion of the fan heater are saved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Distillation type seawater desalination system

InactiveCN113735210AHighly stableTemperature is not affectedGeneral water supply conservationSeawater treatmentEnvironmental engineeringMetal sheet

The invention relates to the field of seawater desalination, in particular to a distillation type seawater desalination system which comprises a shell, an evaporation pipe arranged in the middle of the shell, a plurality of metal sheets arranged in the shell, a heat preservation part is adopted to sleeve on the outer sides of the middles of the plurality of metal sheets, and intervals are reserved between the plurality of metal sheets; the interval between the two ends of adjacent metal sheets is larger than the interval between the middle parts of the adjacent metal sheets; heat exchange parts are arranged at the two ends of the metal sheets, a fresh water collecting part is arranged at the top of the heat preservation part and is communicated with the outer side of the shell, a seawater inlet is formed in the side wall of the bottom of the shell, and a liquid level monitoring part is arranged on the side wall of the shell. The efficiency of seawater desalination by a distillation method can be improved.

Owner:恩拓必(临沂)能源发展有限责任公司

Rapid cooling type double-laser printing equipment

ActiveCN113400640AImprove molding efficiencyDoes not affect temperatureAdditive manufacturing apparatusAdditive manufacturing with solidsHeat conservationMechanical engineering

The invention discloses rapid cooling type double-laser printing equipment in the field of intelligent manufacturing. The rapid cooling type double-laser printing equipment comprises a working cavity mounted on a rack, a heat preservation cavity is arranged above the working cavity, a laser head is arranged at the top end of the heat preservation cavity, a powder bed is arranged at the bottom end of the heat preservation cavity, and a powder spreading mechanism used for spreading powder on the powder bed and a heating mechanism used for heating the interior of the heat preservation cavity are arranged in the heat preservation cavity. A supporting plate used for containing a workpiece is arranged in the working cavity, the supporting plate is fixedly mounted on a lifting mechanism, and the supporting plate slides up and down along the inner wall of the working cavity. A cooling mechanism is arranged in the working cavity and used for cooling the formed area of the workpiece when the workpiece is machined. According to the equipment, the formed area of the workpiece can be rapidly cooled while the equipment prints the workpiece, the temperature of the non-formed area of the workpiece is not affected, powder cannot fly, cooling can be synchronously completed when the workpiece is printed, and the forming efficiency of the workpiece is improved.

Owner:山东创瑞激光科技有限公司

Corrosion liquid medicine spraying device and method for improving wafer liquid medicine corrosion uniformity

PendingCN114582754AImprove liquidityTemperature is not affectedFinal product manufactureSemiconductor/solid-state device manufacturingWaferingElectric machine

The invention provides a corrosive liquid medicine spraying device and a method for improving the liquid medicine corrosion uniformity of a wafer. The device comprises a machine table control system, and the machine table control system is connected with a wafer box module, a robot module, a plurality of corrosion modules and a chemical supply module. The method for improving the wafer liquid medicine corrosion uniformity comprises the steps that corrosion liquid medicine in a liquid medicine storage tank is heated to a set temperature and set time, and wafers are conveyed to a horizontal suction cup of each corrosion module one by one through a robot module; starting a rotating motor, and starting the nozzle to carry out pre-corrosion operation; the rotating speed of the rotating motor is reduced, and the nozzle is started to carry out second corrosion operation, so that the whole wafer is paved with the liquid medicine; stopping the nozzle, keeping the rotating speed of the rotating motor at 10-50rpm, and continuing to corrode for 10-20 minutes; after corrosion is completed, a nozzle loaded with water is started for water spraying operation; repeating the previous steps for 2-3 times; and collecting the corrosion waste liquid and the water washing liquid generated in the previous process, and introducing into a liquid medicine treatment platform for treatment.

Owner:广州市众拓光电科技有限公司

High-performance epoxy insulating part local overheating defect simulation system and method

PendingCN113985221AWill not affect the electric field withstandDoes not affect the electric fieldTesting dielectric strengthTemperature controlTest sample

The invention belongs to the technical field of high-voltage tests and discloses a high-performance epoxy insulator local overheating defect simulation system and method. The system comprises a heating module and a temperature control module, wherein the temperature heating module is arranged in a reserved opening in the middle of an insulating support, a grounding copper sheet is arranged at an upper end of the heating module, and an epoxy insulating part to be tested is arranged at an upper end of the grounding copper sheet; the temperature control module comprises an adjustable direct-current voltage source, a temperature sensor and a temperature digital display meter, the adjustable direct-current voltage source and the temperature sensor are respectively connected with the heating module, and the temperature digital display meter is connected with the temperature sensor. The system is advantaged in that the temperature control device is installed on a lower surface of the grounding copper sheet, the electric field borne by the sample is not affected, meanwhile, the temperature control device is isolated from the high-voltage part, and therefore the temperature control device can work safely and normally, the power is adjusted manually, the temperature of the point is controlled, and the temperature of other parts of the tested sample is not affected; and simulation of the local overheating defect of the epoxy insulating part is completed.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD +1

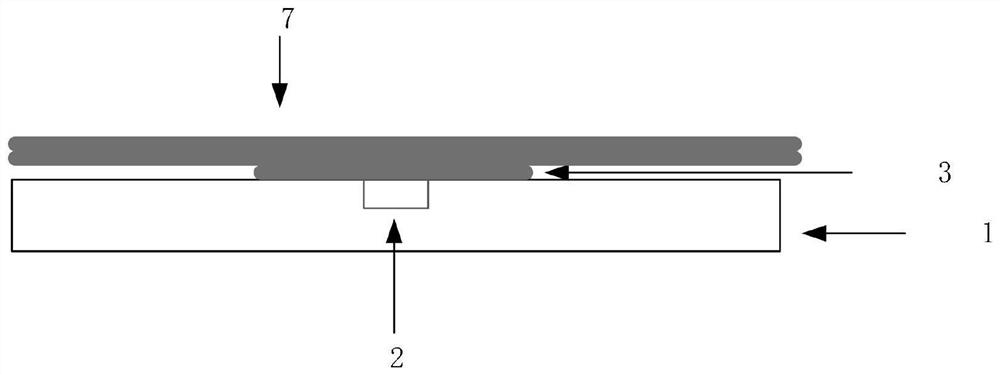

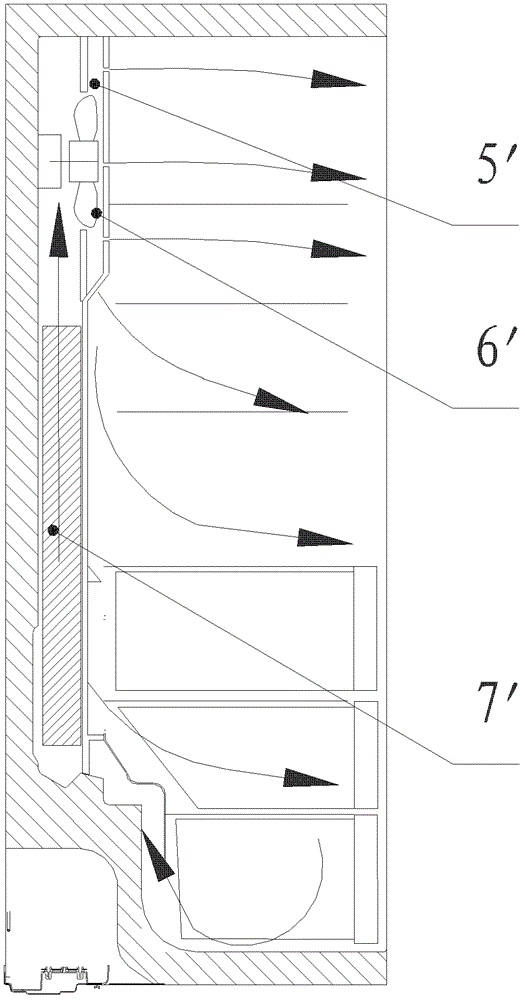

refrigerator

ActiveCN105180560BReduce manufacturing costTemperature is not affectedLighting and heating apparatusDomestic refrigeratorsCold airEngineering

The invention provides a refrigerator. The refrigerator comprises a refrigeration inner container, an evaporator and a cold air supply channel. A refrigeration chamber and a temperature variation chamber independent of the refrigeration chamber are defined in the refrigeration inner container. The evaporator is used for cooling air flowing through the evaporator. The cold air supply channel is used for conveying the air cooled by the evaporator to the refrigeration chamber and the temperature variation chamber. The cold air supply channel is provided with a cold air inlet, a refrigeration air outlet section and a temperature variation air outlet section. The air cooled by the evaporator flows in through the cold air inlet, the refrigeration air outlet section is connected with the cold air inlet and a refrigeration air inlet of the refrigeration chamber, and the temperature variation air outlet section is connected with the cold air inlet and a temperature variation air inlet of the temperature variation chamber. The refrigerator further comprises an air door. The air door is arranged at the cold air inlet in a pivoting manner and can pivot by different angles relative to the plane where the cold air inlet is located so as to close or open a flow path between the cold air inlet and the refrigeration air outlet section and a flow path between the cold air inlet and the temperature variation air outlet section. The refrigeration air outlet section and the temperature variation air outlet section are communicated with the same cold air inlet, air supply to the refrigeration chamber and the temperature variation chamber can be controlled by arranging only one air door, and therefore the production cost is lowered.

Owner:HAIER SMART HOME CO LTD

A low-cost, environment-friendly preparation process of heated brick and its heated brick

ActiveCN108516847BEnergy saving and environmental protection in the preparation processHigh strengthCeramic materials productionClaywaresSodium metasilicateFire brick

A low-cost preparation process of an environment-friendly high-temperature brick and the high-temperature brick. The preparation process includes steps of: 1) mixing the raw materials including, by weight, 18-22 parts of black mud, 18-22 parts of pressure-discharged mud, 55-65 parts of waste residue of refractory bricks, 0.03-0.05 parts of PVA, 0.4-0.5 parts of lignin, 0.75-0.81 parts of sodium metasilicate and 43-48 parts of water, ball-milling the mixture to form slurry, and spray-drying the slurry to obtain a high-temperature brick powder material; 2) placing the high-temperature brick powder material in a pressing mould to press-shape the high-temperature brick powder material, and sintering the material in a kiln to obtain a finish product. The high-temperature brick not only has high-temperature fireproof effect but also is higher in strength, can be repeatedly used, is greatly reduced in preparation cost, is more environment-friendly and energy-saving, and has simple preparationprocess.

Owner:FOSHAN DONGPENG CERAMIC +2

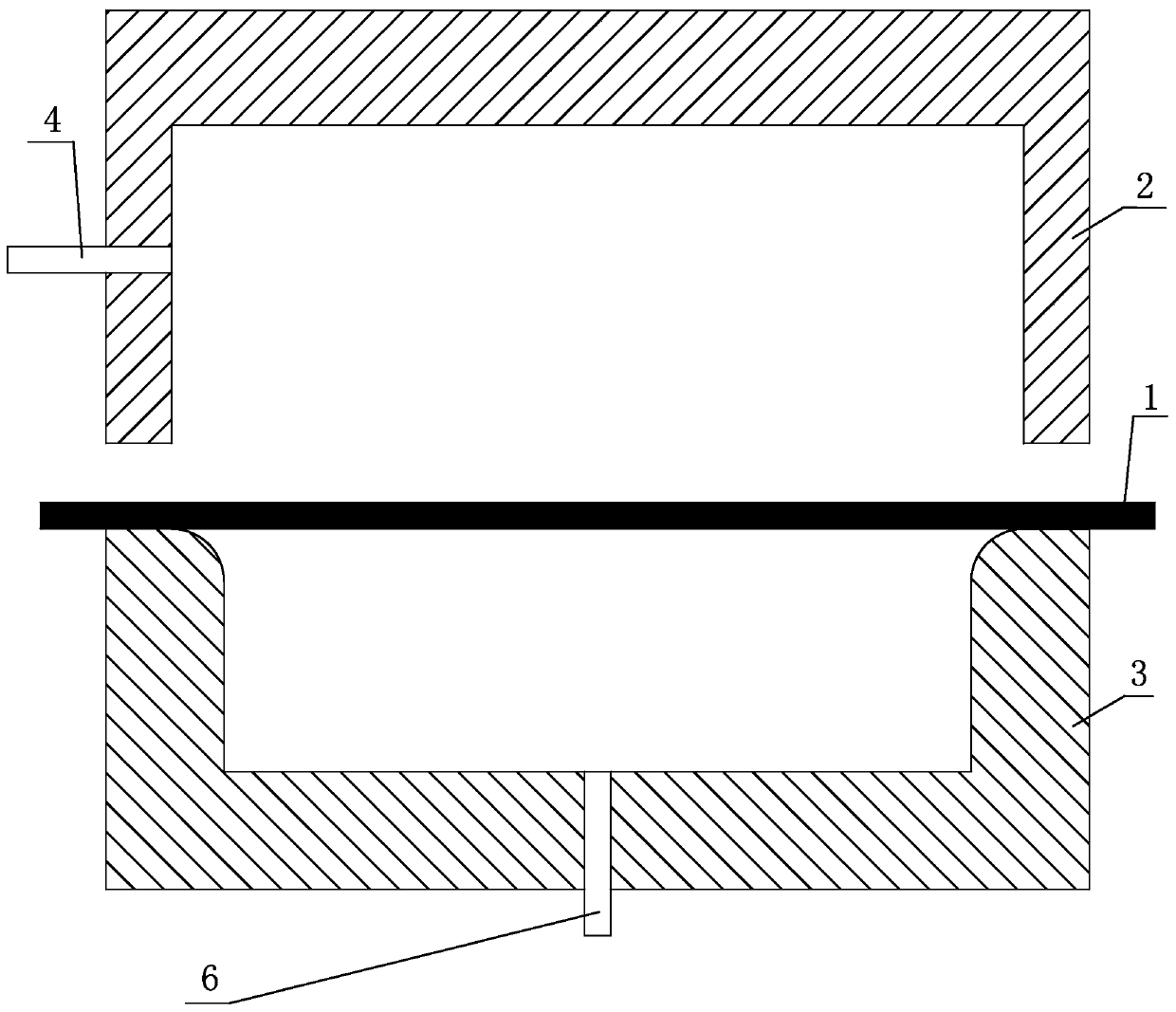

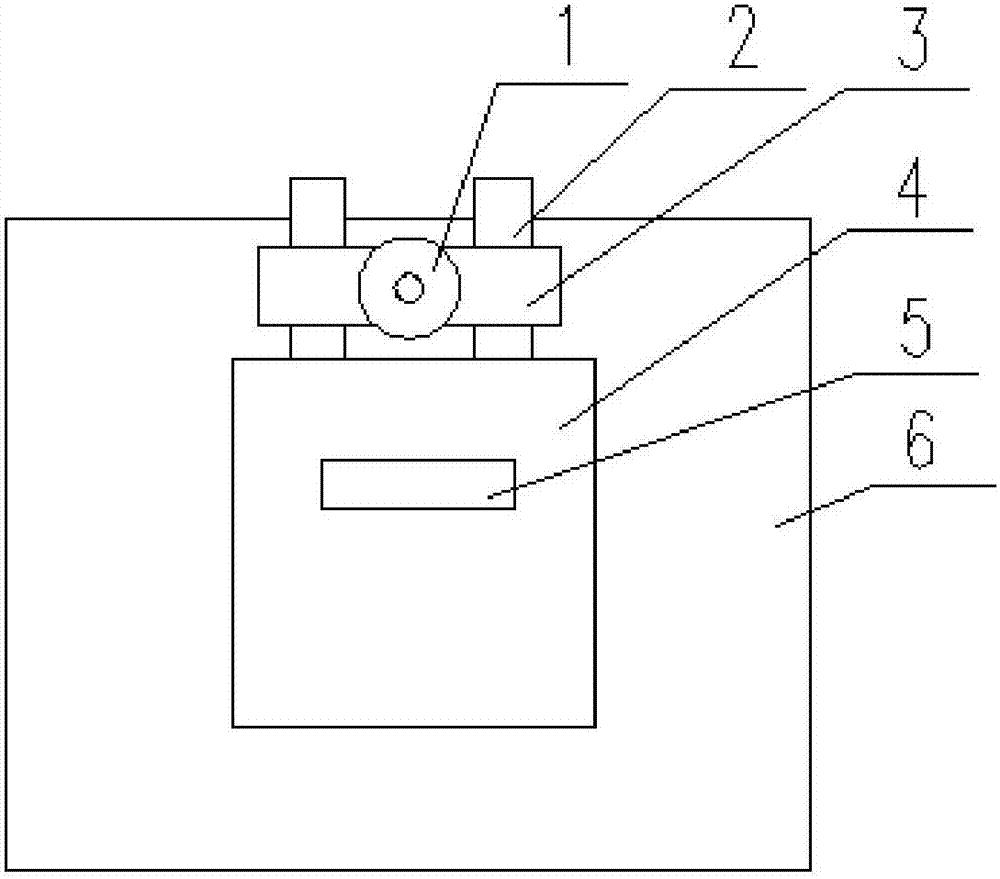

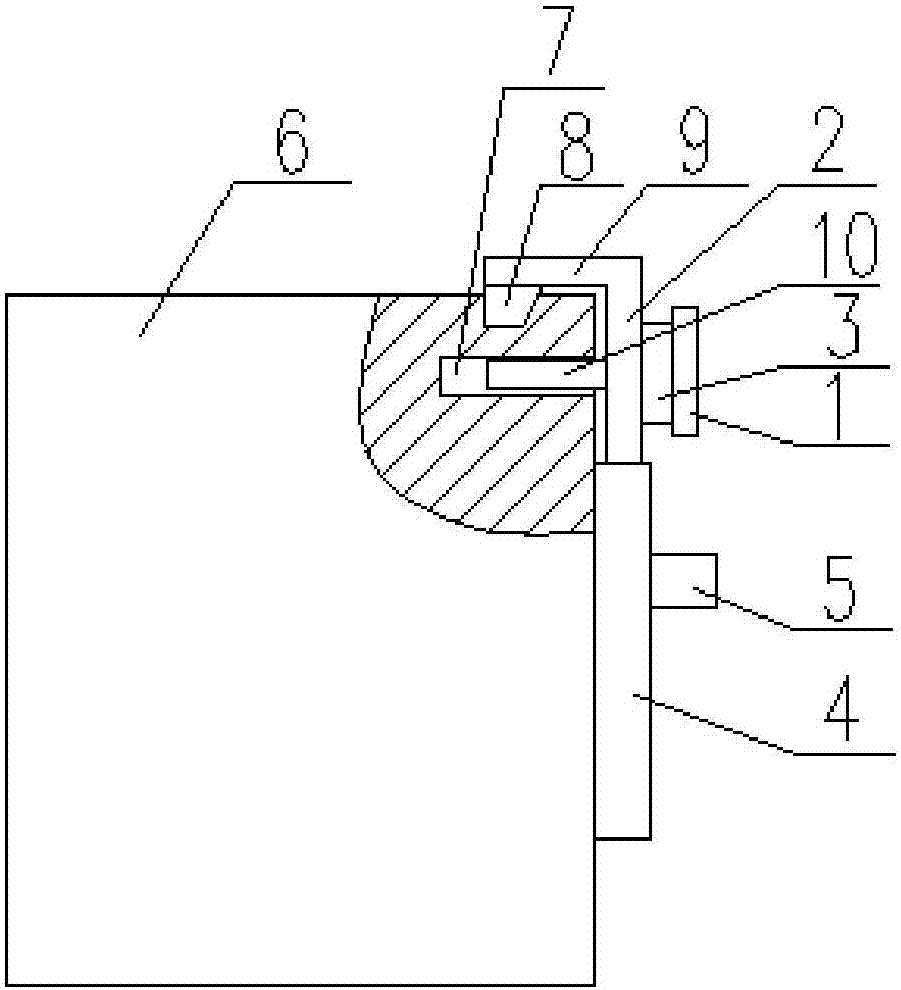

Sealing device for improving sealing property for high-temperature furnace

ActiveCN107356102ATemperature is not affectedImprove sealingMuffle furnacesRetort furnacesEngineeringMechanical engineering

The invention discloses a sealing device for improving sealing property for a high-temperature furnace. The sealing device comprises a door body arranged on a case body in an opening and closing way. The lower end of the door body is connected with the case body via a rotating shaft; the upper end of the door body is buckled to the upper end of the case body via buckling members; the upper end of the case body is provided with a groove cooperated with the buckling members; a locking member is arranged between the two buckling members; the locking member and the case body are locked in a screwing way via a thread; and a handle is arranged outside the door body. Compared with the prior art, great sealing effect can be achieved, and temperature inside the furnace cannot be affected.

Owner:天津北亚检测技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com