Rapid Pneumatic Bulging Method for Hot Metal Sheet

A technology of metal sheet and metal slab, which is applied in the field of sheet metal parts forming, can solve the problems of inability to realize the precision and rapid prototyping of thin-walled parts of complex metal sheet metal parts, and the inability to guarantee the deformation of the blank, so as to achieve gas pressure maintenance and pressure difference distribution controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

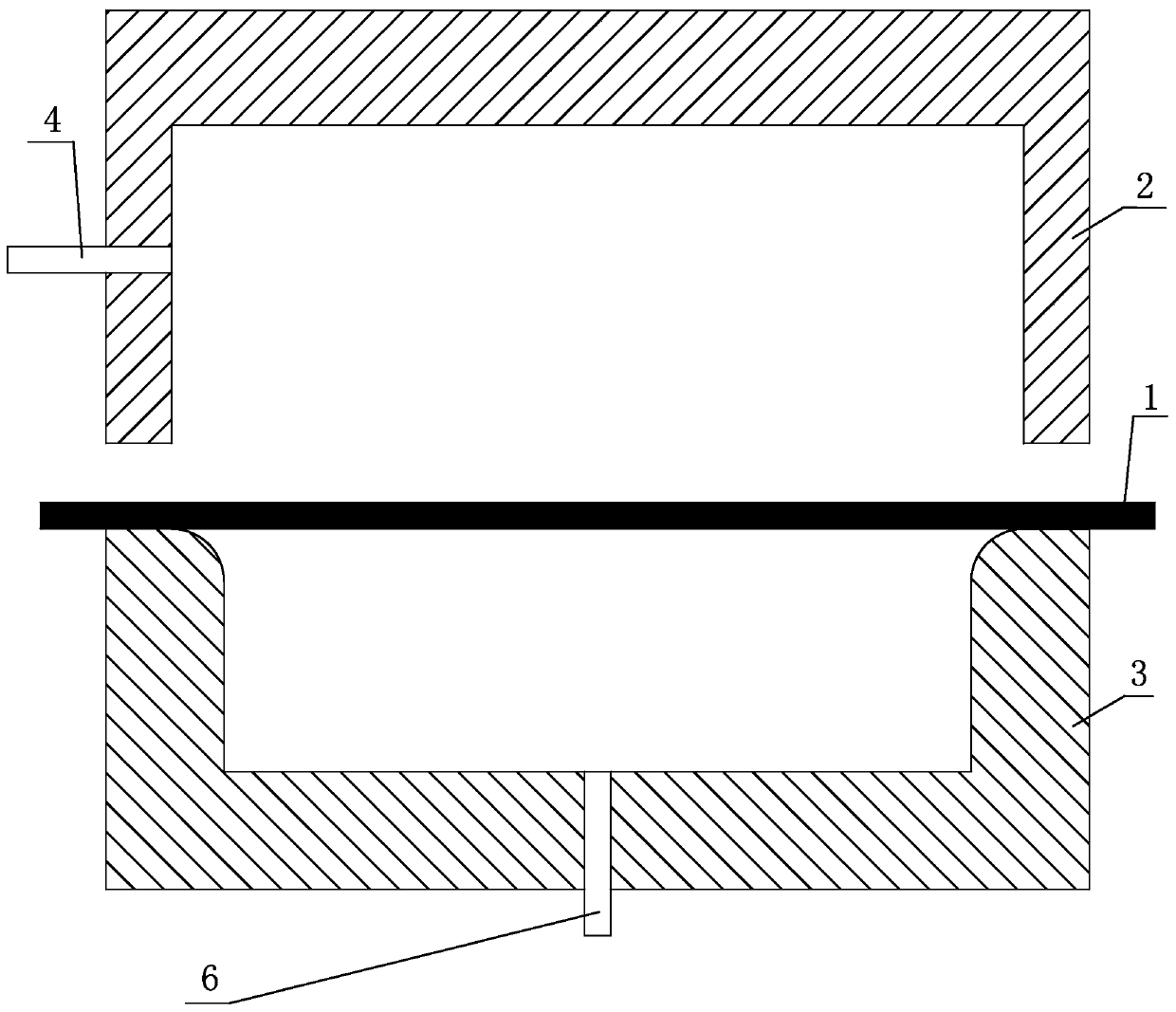

[0049] Specific implementation mode one: see Figure 5-Figure 8 and Figure 10 Illustrates that the rapid gas bulging method of the hot metal sheet material is realized according to the following steps:

[0050] Step 1, placing the metal slab 1 to be formed on the forming mold 3, closing the sealing mold 2 to form a closed cavity on the upper and lower surfaces of the metal slab 1;

[0051] Step 2: filling the upper and lower airtight cavities formed by the upper air hole 4 and the lower air hole 5 into the upper and lower airtight cavities formed by the metal slab 1 and the sealing mold 2, and the metal slab 1 and the forming mold 3 respectively;

[0052] Step 3, heating the metal slab 1 to a preset forming temperature condition;

[0053] Step 4, quickly release the high-pressure gas in the airtight cavity formed by the metal slab 1 and the forming die 3 by the vent hole 6, so that the high pressure gas in the airtight cavity formed by the metal slab 1 and the sealing mold ...

specific Embodiment approach 2

[0060] Specific implementation mode two: see Figure 5-Figure 8 , Figure 10 , Figure 12-Figure 14 Note that the difference between this embodiment and the specific embodiment 1 is that in step 3, the heating method of the metal slab is limited, such as external preheating of the mold, steel plate contact heating, mold radiation heating, etc., and the metal slab is isothermal and non-isothermal, specifically : In step one, the sealing mold 2 and forming mold 3 that are adopted are all in a hot state, and its temperature is T 2 . The predetermined forming temperature of metal slab 1 is T 0 . The sheet metal blank 1 is preheated to a temperature T before being placed in the sealing mold 3 and the forming mold 2 1 . When T 1 less than T 0 , then T 2 > T 0 , to use the mold to reheat the metal slab 1 to reach the predetermined forming temperature T 0 . When the original metal slab 1 is larger in size and far away from the mold cavity, a hot steel plate 7 can be placed...

specific Embodiment approach 3

[0062] Specific implementation mode three: see Figure 5-Figure 8 , Figure 10 and Figure 15-Figure 17 Note that the difference between this embodiment and the specific embodiment 1 or 2 is that the arrangement of the vent holes is limited, and different arrangements are adopted for different parts, specifically: in step 4, there are A plurality of vent holes 6 are unevenly distributed, vent hole one 6-1 is located on the left side of the cavity, vent hole two 6-2 and vent hole three 6-3 are located on the right side of the cavity.

[0063] In this embodiment, when the airtight cavity of the forming die 3 is a complex asymmetric structure, by reasonably setting the number and positions of the vent holes 6, the airtight cavity formed by the metal slab 1 and the forming die 3 can be The high-pressure gas is quickly released to normal pressure at almost the same speed, so that an approximately uniform pressure difference can be quickly formed on the upper surface and the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com