A low-cost, environment-friendly preparation process of heated brick and its heated brick

An environment-friendly and preparation technology, which is applied in the preparation technology of environment-friendly heated bricks and the field of heated bricks, can solve the problems of discontinuous production, difficult to recycle, and the aluminum content does not meet the requirements, and achieves the goal of manufacturing The process is environmentally friendly and energy-saving, conducive to repeated use, and the effect of simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] Embodiment group-a kind of preparation technology of low-cost environment-friendly band warm brick, comprises the steps:

[0023] (1) 18 parts of black mud, 22 parts of pressure discharge mud, 55 parts of refractory brick waste residue, 0.03 part of PVA, 0.5 part of lignin, 0.81 part of sodium metasilicate and 43 parts of water are mixed and ball milled in parts by weight Form a slurry and spray dry to obtain brick powder with temperature;

[0024] (2) After distributing warm brick powder in a pressing mold and pressing it into a kiln, the finished product can be obtained.

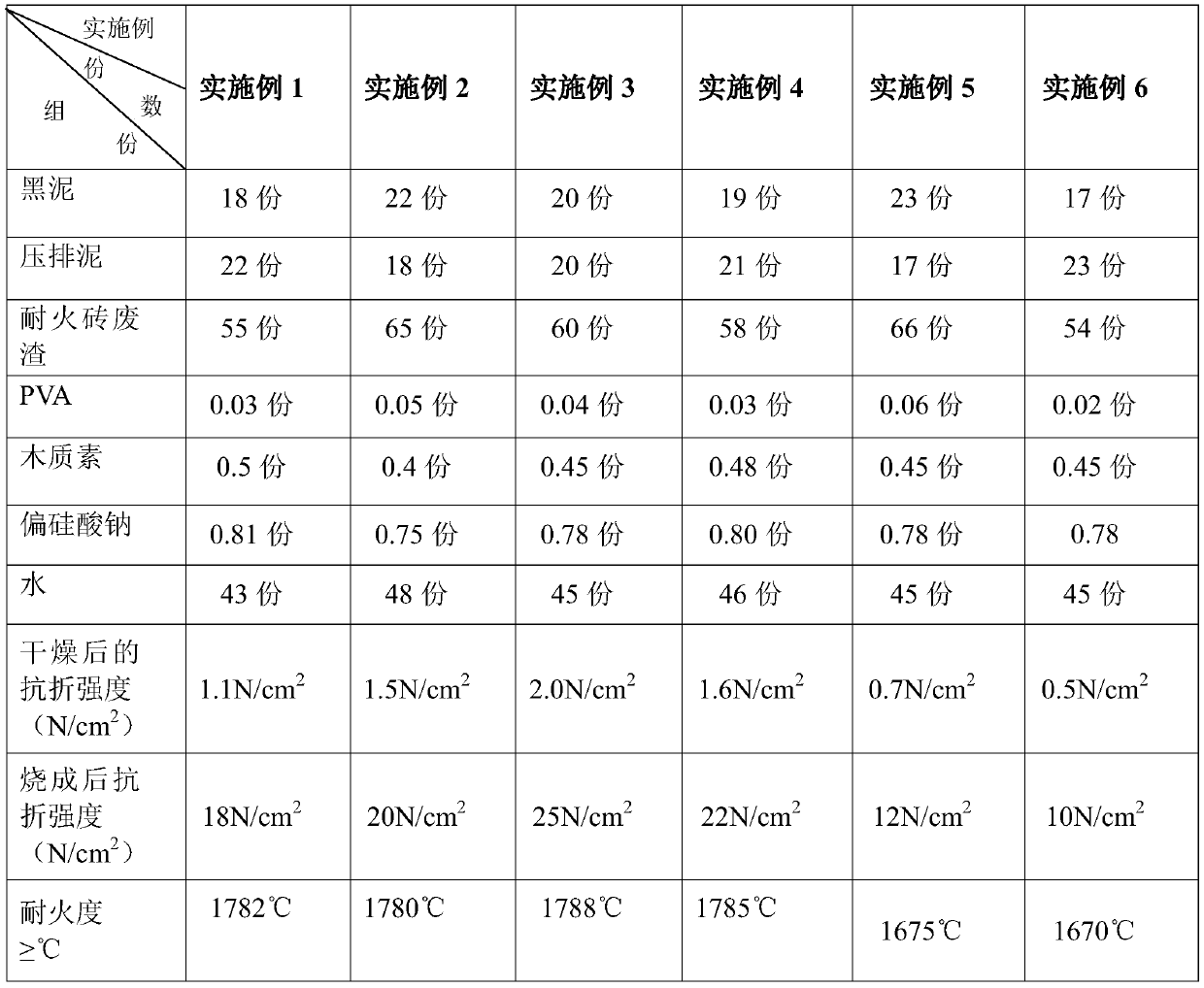

[0025] According to the above-mentioned preparation steps, and only change the proportioning ratio of each formula component of the slurry according to the parts by weight as shown in Table 1 below, obtain the corresponding finished brick with temperature, and test the green body performance of the finished brick with temperature obtained;

[0026] Table 1 Performance test of adobe products with di...

Embodiment 7-

[0029] Embodiment 7-a kind of low-cost environment-friendly preparation technology with warm brick, comprises the following steps:

[0030] (1) 20 parts of black mud, 20 parts of pressure and discharge mud, 60 parts of refractory brick waste residue, 0.04 part of PVA, 0.45 part of lignin, 0.78 part of sodium metasilicate and 45 parts of water are mixed and ball milled in parts by weight After 8 hours, a slurry is formed, the fineness modulus of the slurry is 0.58, the flow rate of the slurry is 30m / s, and the heated brick powder is obtained through spray drying;

[0031]Wherein, the particle size of the heated brick powder obtained by spray drying is controlled to be less than 1% on a 20-mesh sieve, 35-45% on a 40-mesh sieve, 80-90% on a 60-mesh sieve, and greater than 93% on a 100-mesh sieve. The sieve residue of each mesh is the cumulative value; the moisture content of the brick powder with temperature is controlled at 6.75%;

[0032] (2) Distribute the heated brick powder...

Embodiment 8-

[0033] Embodiment 8-a kind of low-cost environment-friendly preparation technology with warm brick, comprises the following steps:

[0034] (1) 20 parts of black mud, 20 parts of pressure and discharge mud, 60 parts of refractory brick waste residue, 0.04 part of PVA, 0.45 part of lignin, 0.78 part of sodium metasilicate and 45 parts of water are mixed and ball milled in parts by weight Form the slurry after 10 hours, the fineness modulus of the slurry is 1.16, the flow rate of the slurry is 50m / s, and the brick powder with temperature is obtained through spray drying;

[0035] Wherein, the particle size of the heated brick powder obtained by spray drying is controlled to be less than 1% on a 20-mesh sieve, 35-45% on a 40-mesh sieve, 80-90% on a 60-mesh sieve, and greater than 93% on a 100-mesh sieve. The sieve residue of each mesh is the cumulative value; the moisture content of the brick powder with temperature is controlled at 7.45%;

[0036] (2) Distribute the warm brick ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com