A low-grade waste heat recovery system for copper plants used in urban central heating

A waste heat recovery system and central heating technology, which is applied in hot water central heating systems, heating systems, household heating, etc., can solve the problems of cooling water consumption and power consumption, and achieve saving production water and reducing fan power consumption , The effect of high recovery rate of waste heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

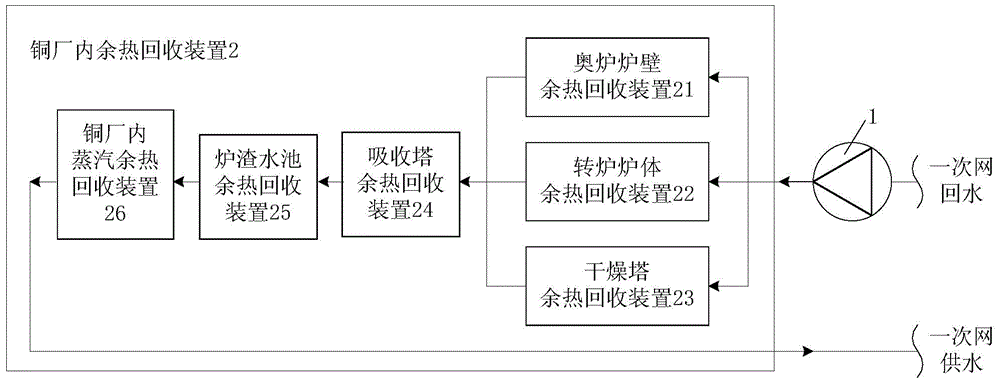

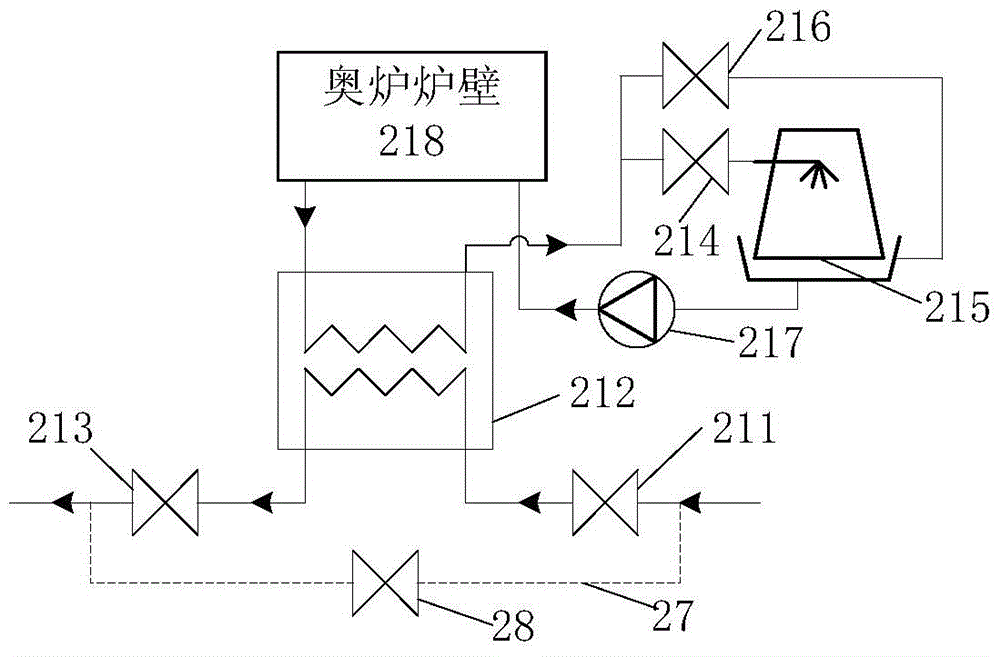

[0027] Embodiment 1: as figure 1 As shown, when the return water temperature of the primary network is low, that is, below 30°C, the principle of "cascaded heating" is implemented. First, the return water entering the copper plant is divided into the first to third shares of primary network return water in parallel, and the three shares The primary network return water flows into the Ao furnace wall waste heat recovery device 21, the converter body waste heat recovery device 22 and the drying tower waste heat recovery device 23; secondly, the three primary network return water are respectively connected with the Ao furnace wall, the converter body and the drying Three heat sources that generate lower-grade waste heat in the tower are used for heat exchange; again, the three strands of primary network water absorb the lower-grade waste heat and then merge into one stream to flow into the absorption tower waste heat recovery device 24 and the slag pool waste heat recovery device ...

Embodiment 2

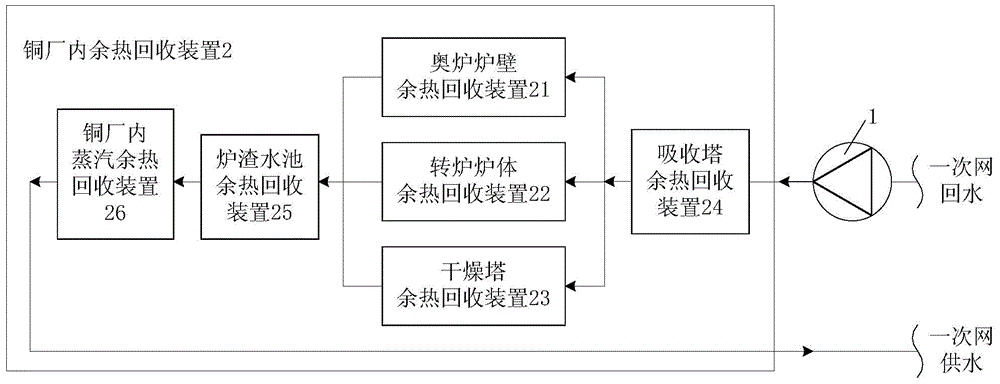

[0034] Example 2: When the return water temperature of the primary network is relatively high, that is, above 30°C, especially around 45°C, if figure 2 As shown, the principle of "step heating" is implemented. Firstly, the return water from the primary network entering the copper plant flows into the waste heat recovery device 24 of the absorption tower. The return water flows into the waste heat recovery device 21 of the furnace wall of the Austrian furnace, the waste heat recovery device 22 of the converter body and the waste heat recovery device 23 of the drying tower respectively, and absorbs the low-grade waste heat generated by the furnace wall 218 of the Austrian furnace, the furnace body of the converter and the drying tower 232 respectively and heat up; again, absorb the lower-grade waste heat and heat up the three primary network water into one stream into the slag pool waste heat recovery device 25, and absorb the higher-grade waste heat produced by the slag pool w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com