Flash deposition apparatus

A deposition device and flash evaporation technology, applied in vacuum evaporation plating, ion implantation plating, gaseous chemical plating, etc., can solve the problems of uneven heating, low productivity of production equipment, waste of materials, etc., and achieve high material utilization rate , Improve the effect of thickness control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

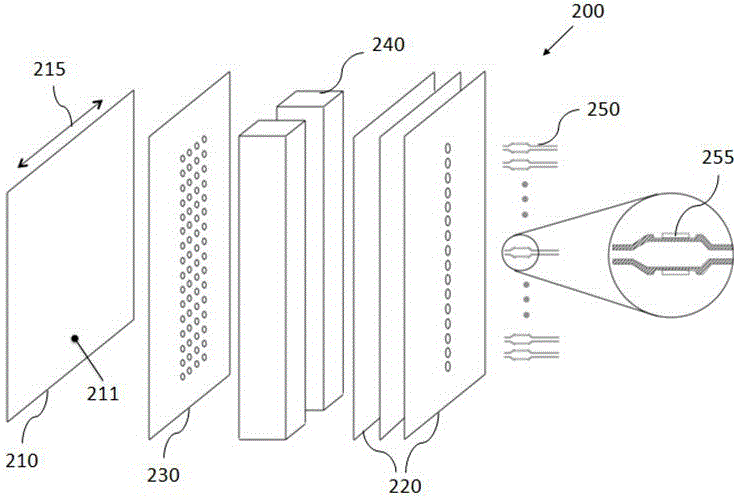

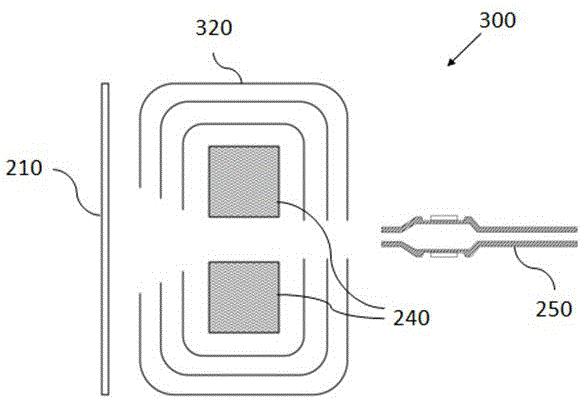

[0023] refer to figure 2 , the flash deposition apparatus 200 includes a substrate 210 , a shower head 230 , one or more evaporation heaters 240 , one or more radiation shields 220 , and a liquid material delivery device 250 . Each liquid material delivery device 250 can eject small liquid droplets with precise volume control and repeatability as required. The droplets pass through one or more apertures in the radiation shield 220 to the vicinity of the evaporation heater 240, where the droplets are evaporated to produce a vapor. The vapor generated by the evaporation heater 240 passes through the small holes on the shower head 230 having a plurality of small holes. The showerhead 230 ensures that the evaporated material reaches the substrate 210 evenly to form a thin film on the substrate 210 with a well-defined distribution and desired deposition uniformity. The film can be in liquid or solid phase, physically deposited or formed by chemical reaction. The substrate 210 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com