Super-long insulation steel-sleeved steel pipeline and machining process thereof

A processing technology, a technology of steel sleeve steel, applied in the direction of protecting pipelines, casings, and insulation through heat insulation, can solve problems such as high mining costs, shortened service life of pipelines, and reduced insulation effects, and achieve good insulation performance and corrosion resistance Performance, long service life, and the effect of ensuring thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

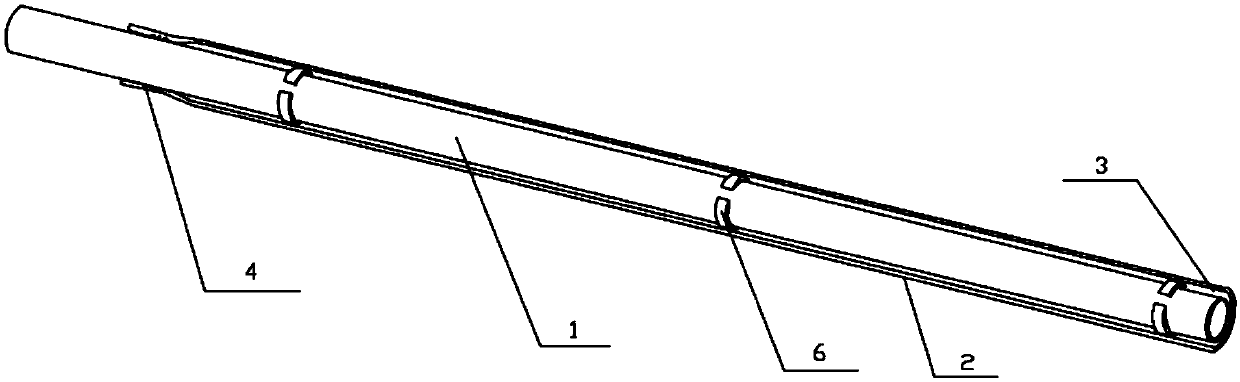

[0054] Stainless steel is selected as the steel used for the working steel pipe, and the weight percentages of its main components are as follows: C 0.019%, Si 0.49%, Mn 1.25%, P 0.022%, S 0.00005%, Ni 5.16%, Cr 22.46%, N 0.163%, Cu0. 003%, Mo 3.07%, and the rest are Fe and unavoidable impurities. Titanium alloy TA18 alloy is selected as the jacket steel pipe, and the weight percentages of its main components are as follows: Al 3.5%, V 1.5%-3.0%, Fe 0.25%, C 0.05 %, N 0.05%, H0.015%, O 0.12%, and the rest are Ti and unavoidable impurities. Utilize the above-mentioned steel material that selects (wherein two kinds of steel material lengths are 1000 meters) prepare 1000 meters of thermal insulation steel sheathed steel pipes, its structure is as follows figure 1 As shown, the specific preparation process is as follows:

[0055] (1) The steel plate used in the working steel pipe is cleaned on the surface, specifically by using a surfactant (preferably sodium dodecylbenzene sulfo...

Embodiment 2

[0061] Titanium alloy TA18 is selected as the material for making working steel pipes. The weight percentages of its main components are as follows: Al2.0%, V 1.5%, Fe 0.25%, C 0.05%, N 0.05%, H 0.015%, O 0.12%, and the rest are Ti and unavoidable impurities. Carbon steel is selected as the material for making outer jacket steel pipes, and the weight percentages of its main components are as follows: C 0.11%, Si0.22%, Mn 1.44%, P 0.008%, S 0.001%, Cr 0.58%, Ni 0.14%, Cu 0.24% , Mo 0.15%, the rest is Fe and unavoidable impurities. Utilize the above-mentioned steel material that selects (wherein two kinds of steel material lengths are 3000 meters) preparation length is the insulation steel sheath steel pipeline of 3000 meters, and its structure is as follows figure 2 As shown, the specific preparation process of the pipeline is as follows:

[0062](1) The steel plate used in the working steel pipe is cleaned on the surface, specifically by using a surfactant (preferably sodiu...

Embodiment 3

[0068] Carbon steel is selected as the material for making working steel pipes, and the weight percentages of its main components are as follows: C 0.11%, Si0.24%, Mn 1.5%, P 0.012%, S 0.001%, Cr 0.58%, Ni 0.14%, Cu 0.24% , Mo 0.16%, the rest is Fe and unavoidable impurities. Stainless steel is selected as the material for making the jacket steel pipe, and the weight percentages of its main components are as follows: C 0.020%, Si 0.50%, Mn 1.26%, P 0.022%, S 0.00005%, Ni 5.17%, Cr22.52%, N 0.163%, Cu 0.006%, Mo 3.07%-3.09%, the rest is Fe and unavoidable impurities. Utilize the above-mentioned steel material that selects (wherein two kinds of steel material lengths are 5000 meters) preparation length is the insulation steel sheathed steel pipeline of 5000 meters, the preparation process of this pipeline is as follows:

[0069] (1) The steel plate used in the working steel pipe is cleaned on the surface, specifically by using a surfactant (preferably sodium dodecylbenzene sulf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com