Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about How to "Solve the lack of penetration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Energy activated electrographic printing process

InactiveUS6887640B2Improved “ hand ” and controlled glossEasy to processMechanical recordingRecord information storageCross-linkCohesive strength

A process for printing images by means of an electrographic or electrostatic device using a toner that is cured by multiple applications of energy. The toner has energy-activated reactive components such as radiation-curable sites and reactive functional groups. An image is formed on a substrate by the toner without materially activating the reactive components. The reactive components are subsequently activated by applying a first energy source to adhere the image to the substrate by cross-linking and bonding the image permanently to the substrate, or by transferring the image to a second substrate. A second energy source is applied simultaneously with, or subsequently to, the first energy source, to promote cohesive strength of the image by cross-linking within the toner particles that form the image. The resulting image is permanently bonded to the substrate, yielding substantially enhanced image durability and fastnesses.

Owner:SAWGRASS SYST INC

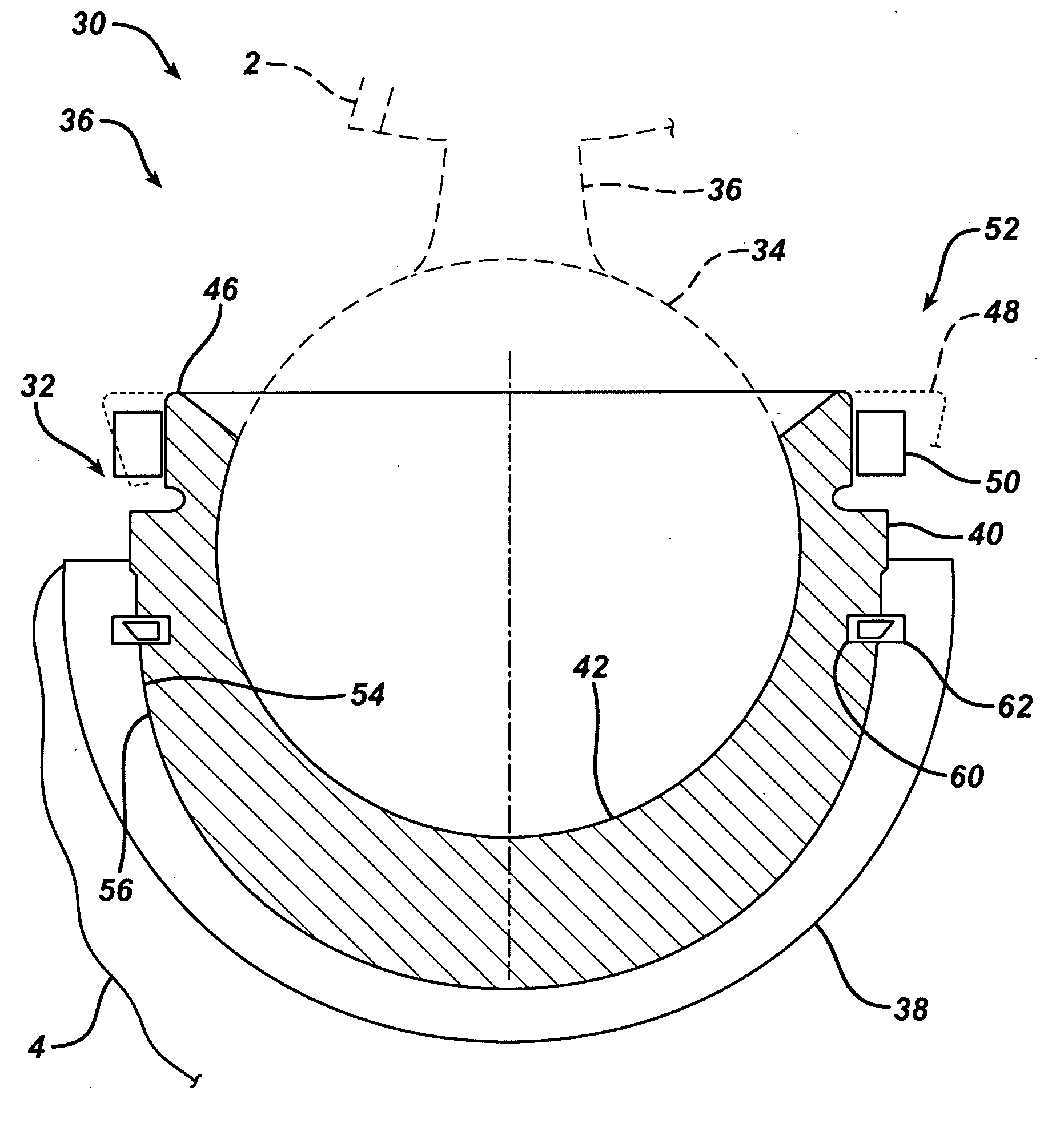

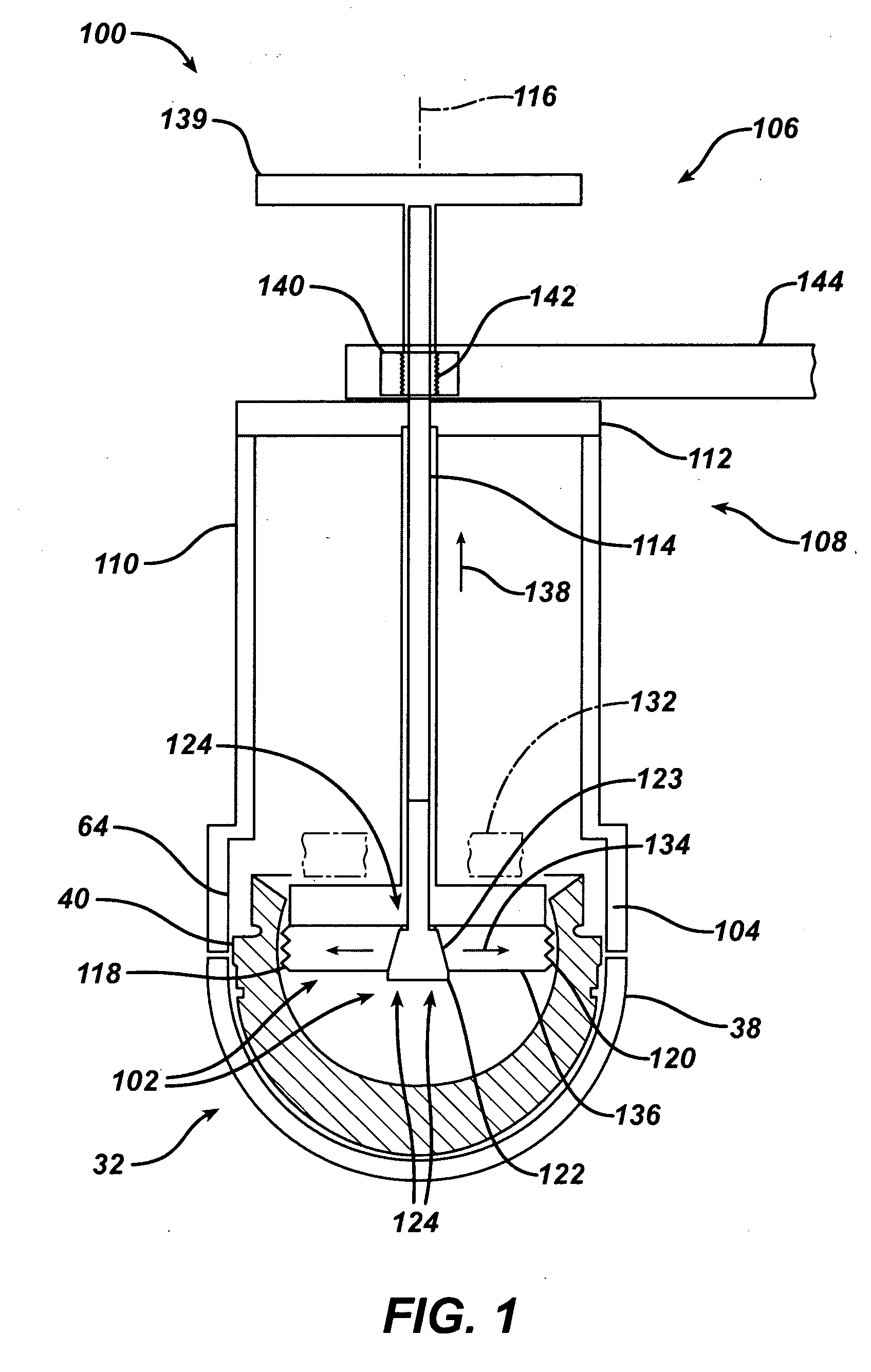

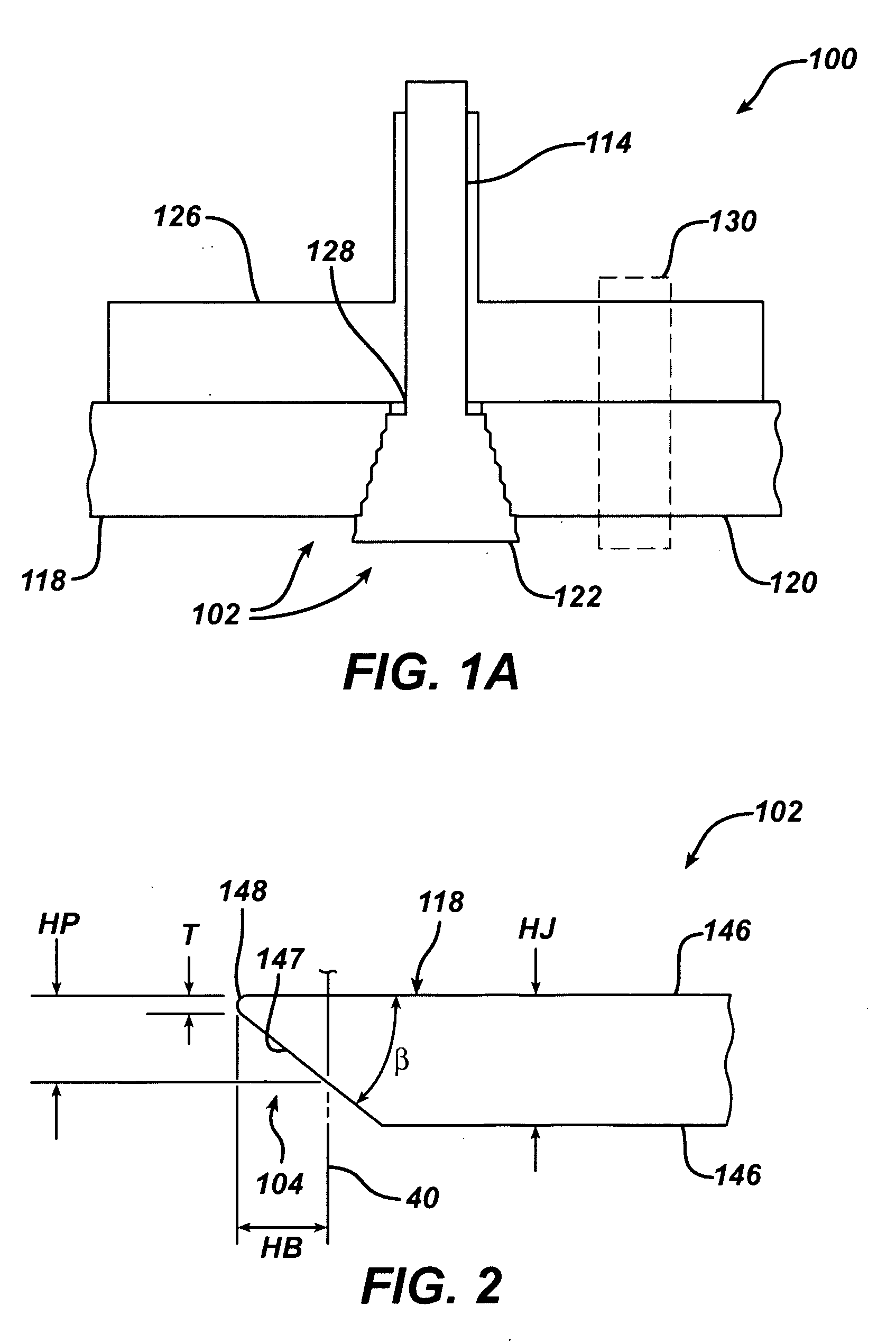

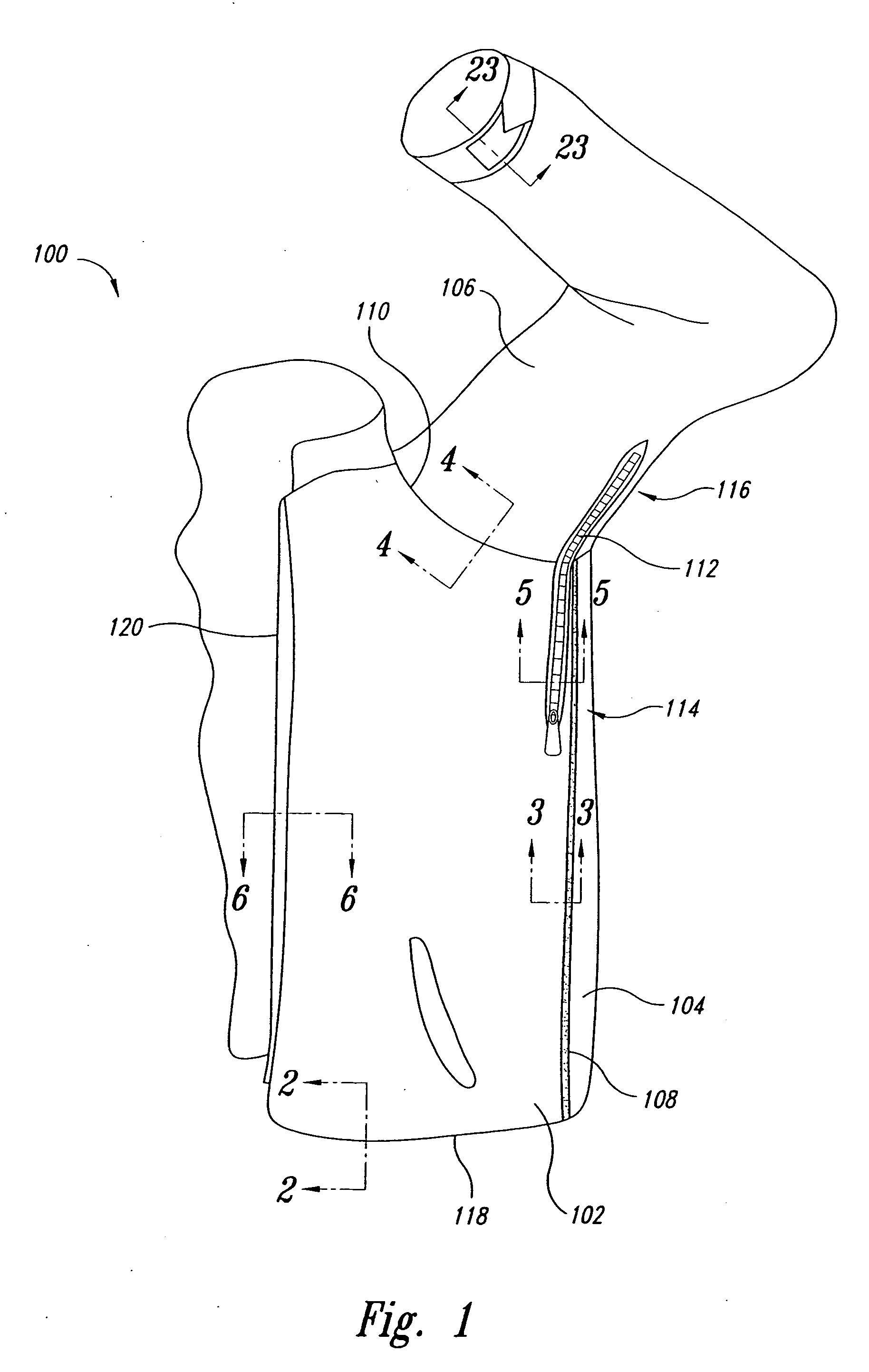

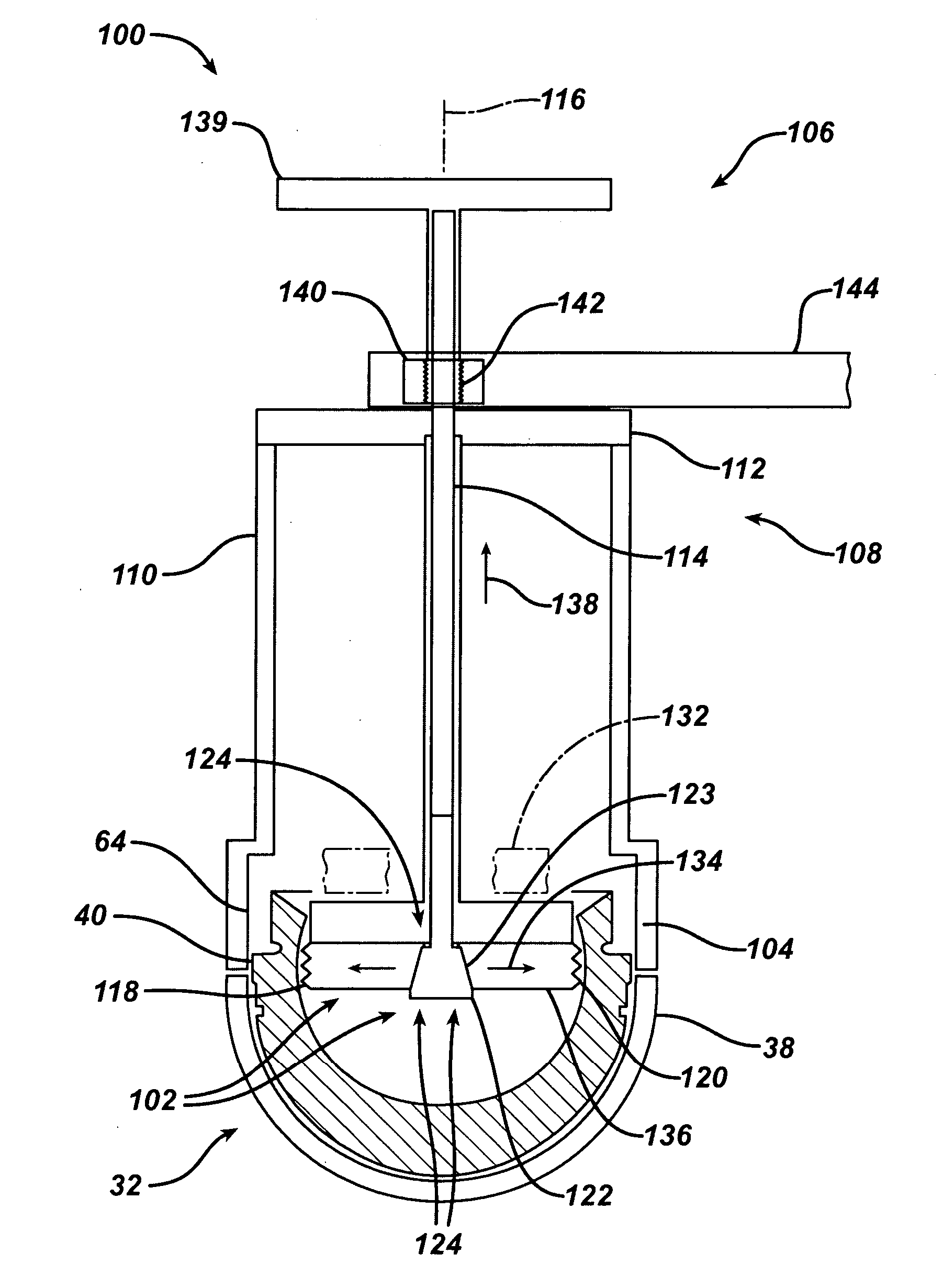

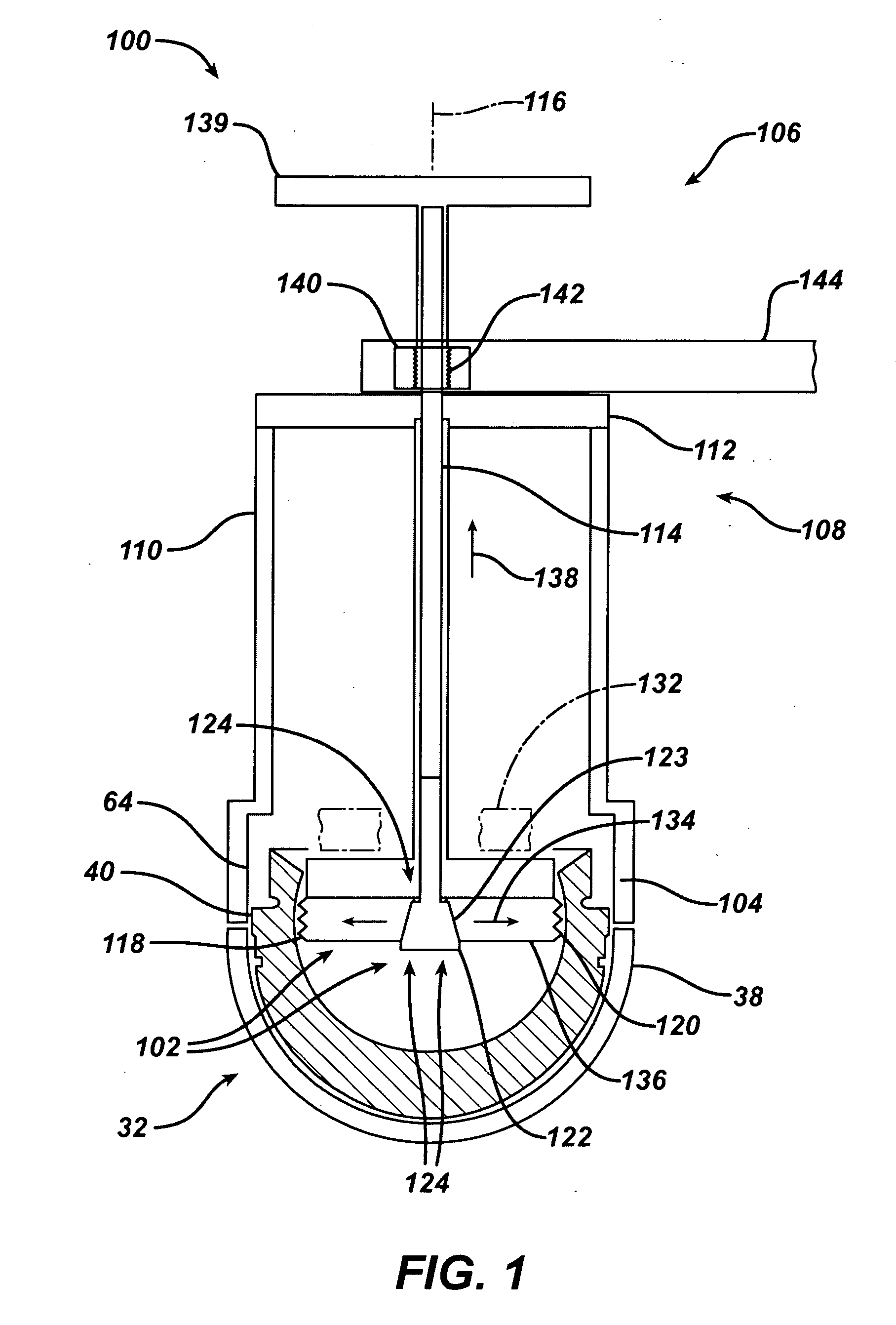

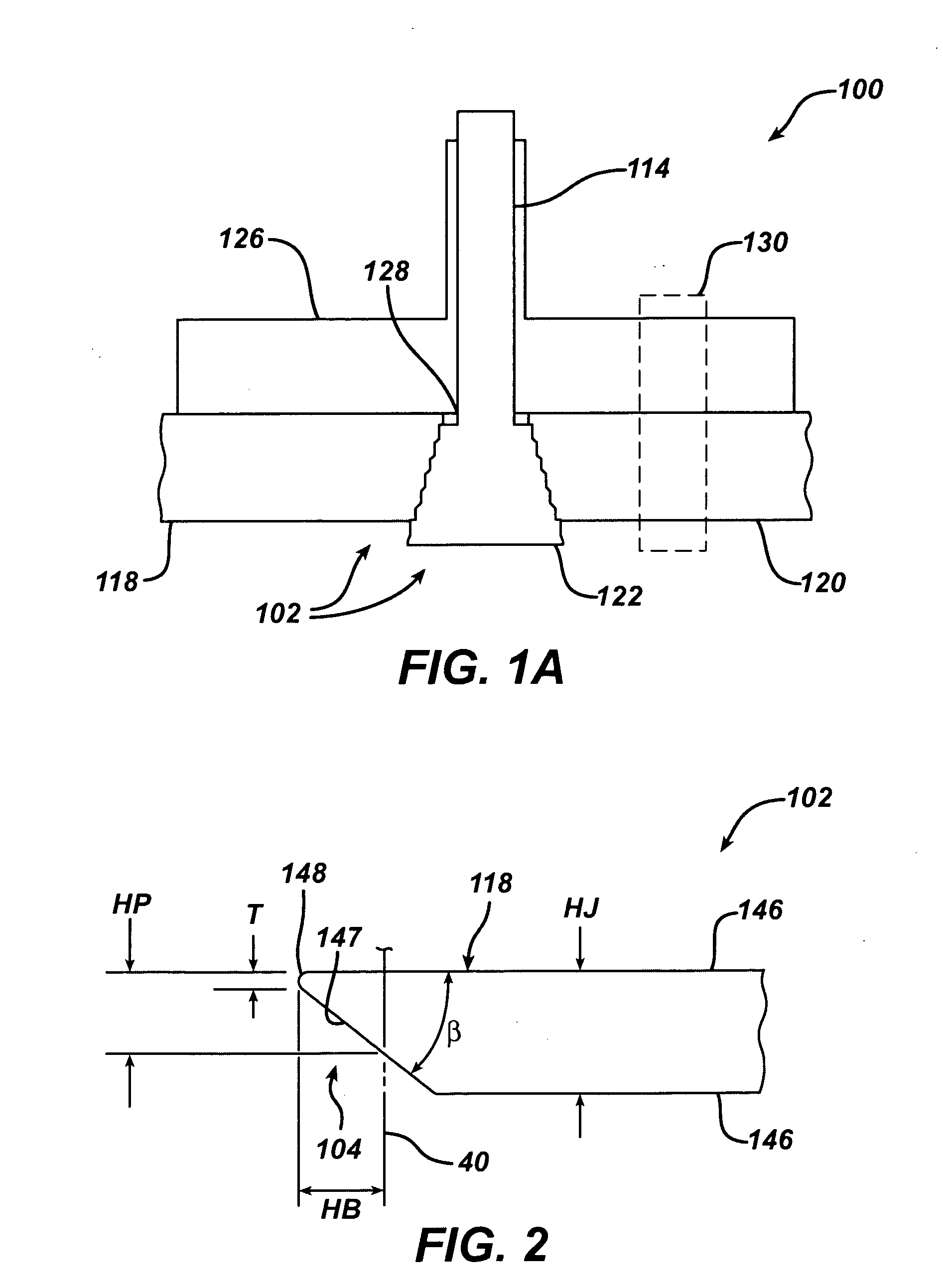

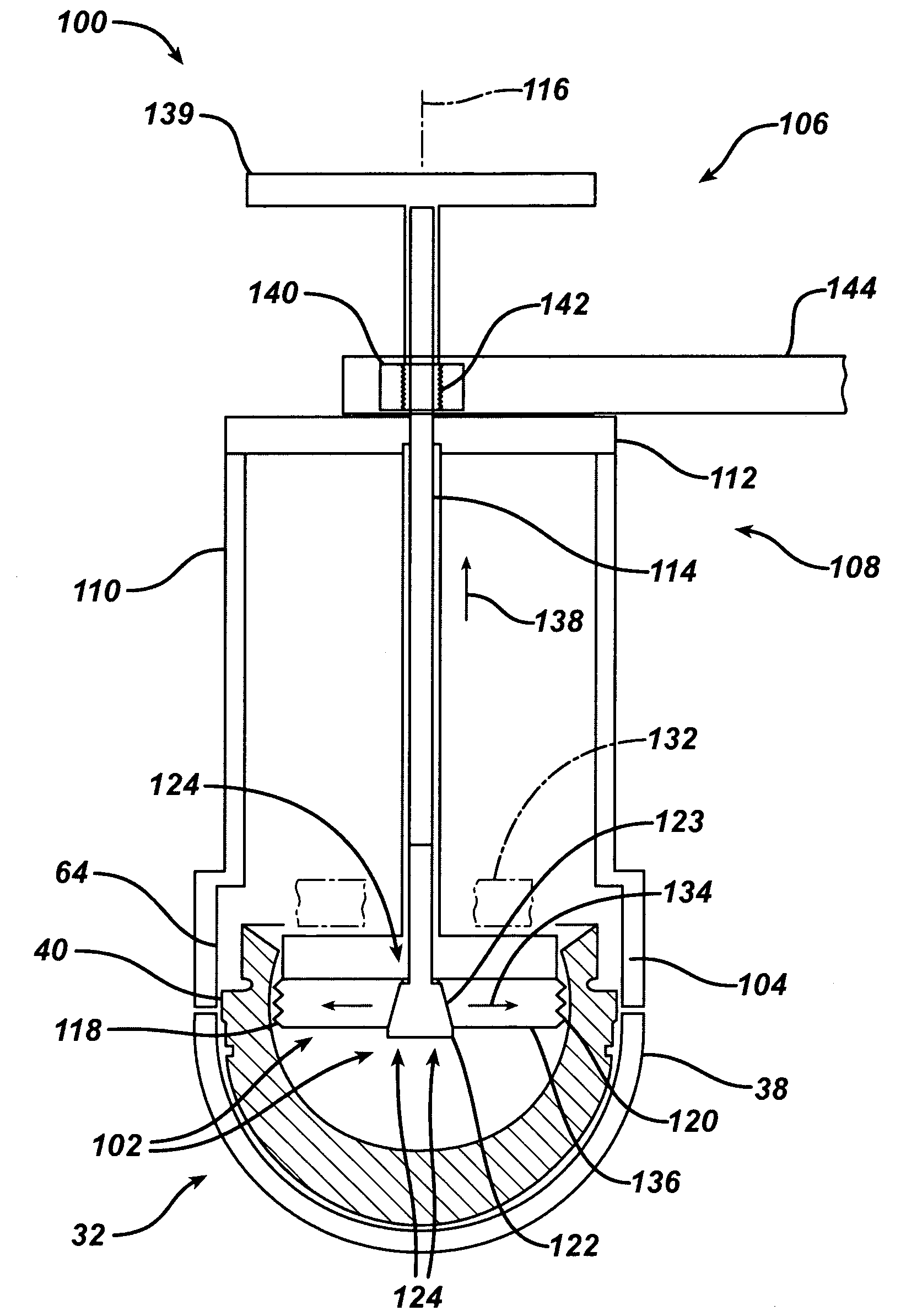

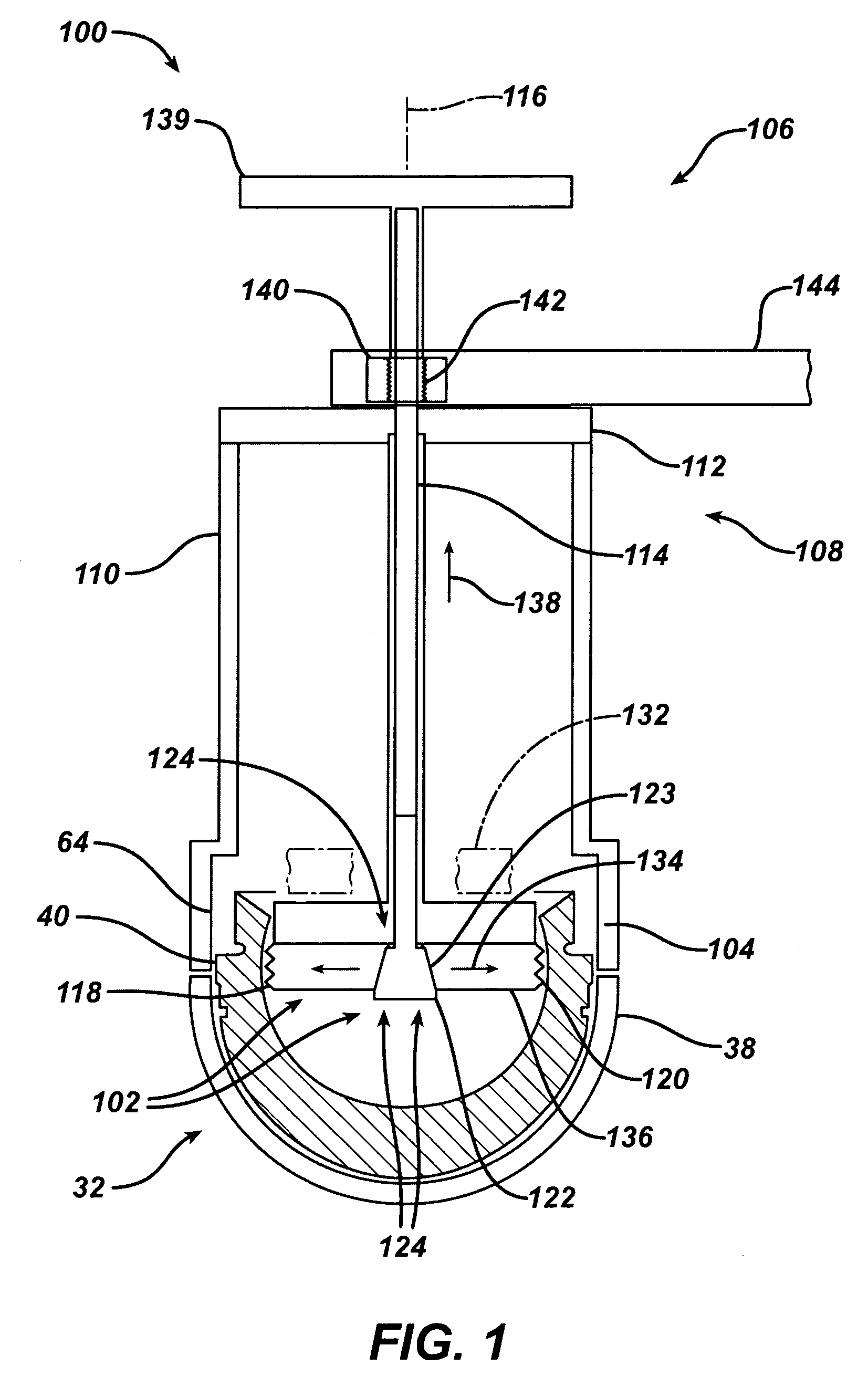

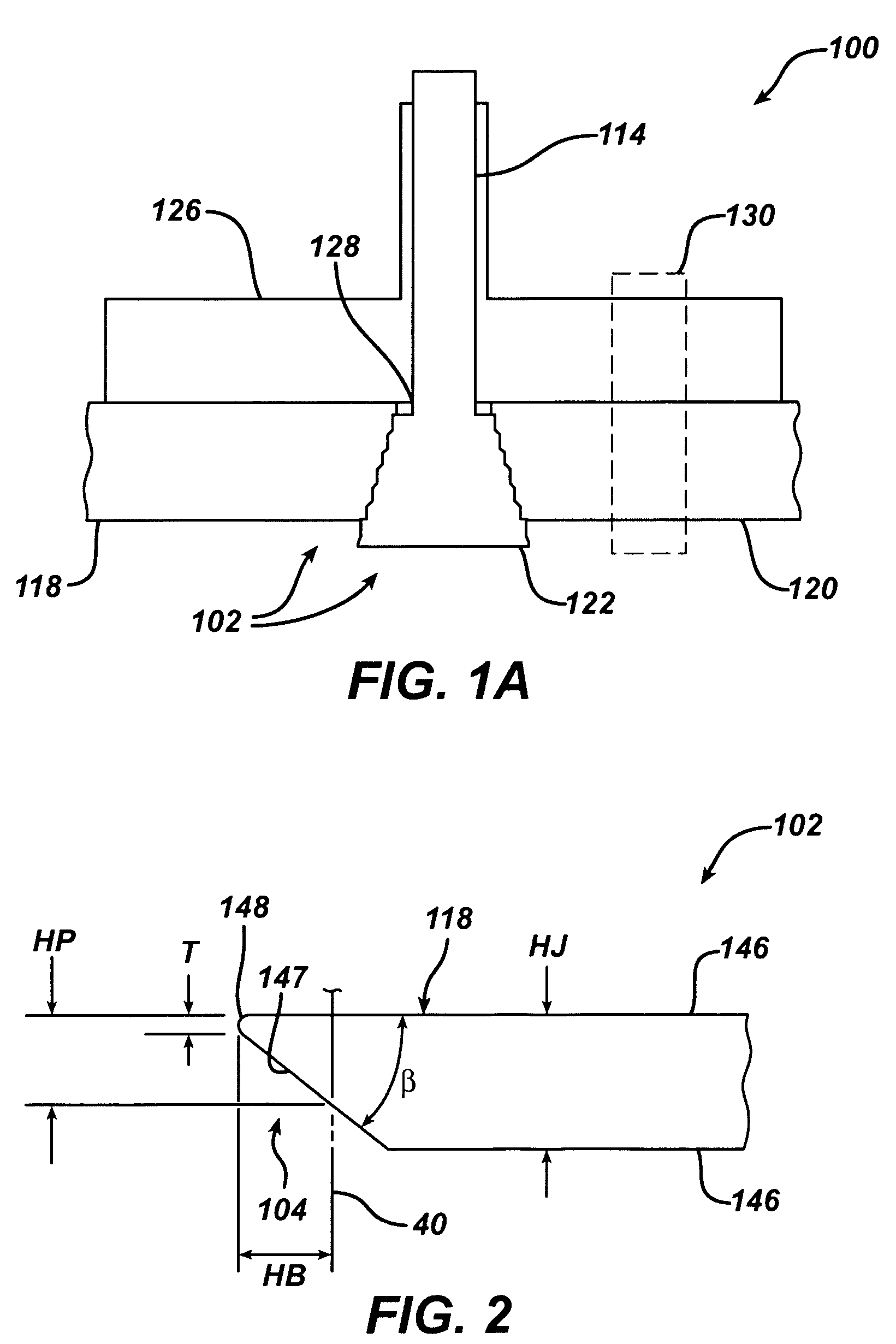

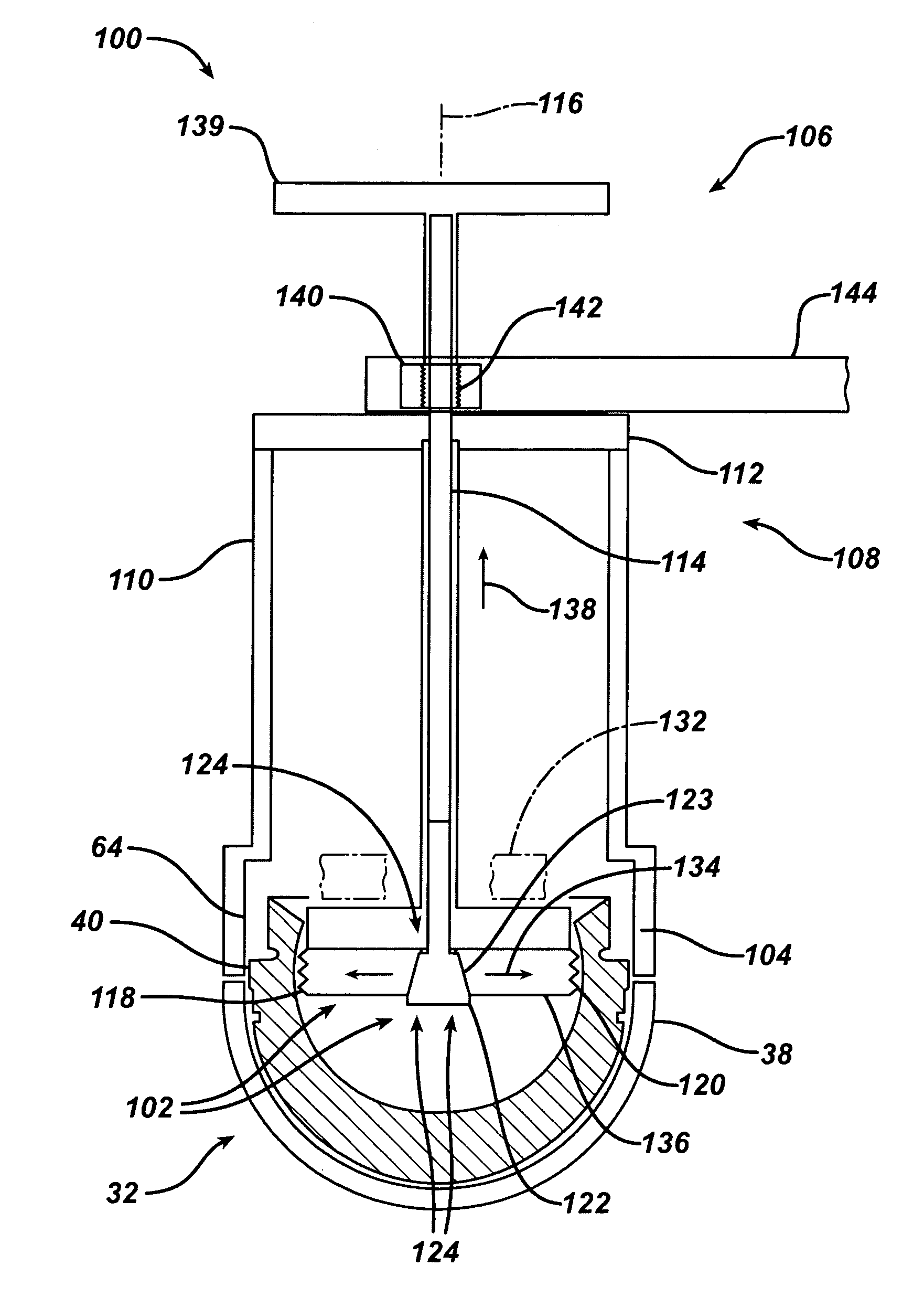

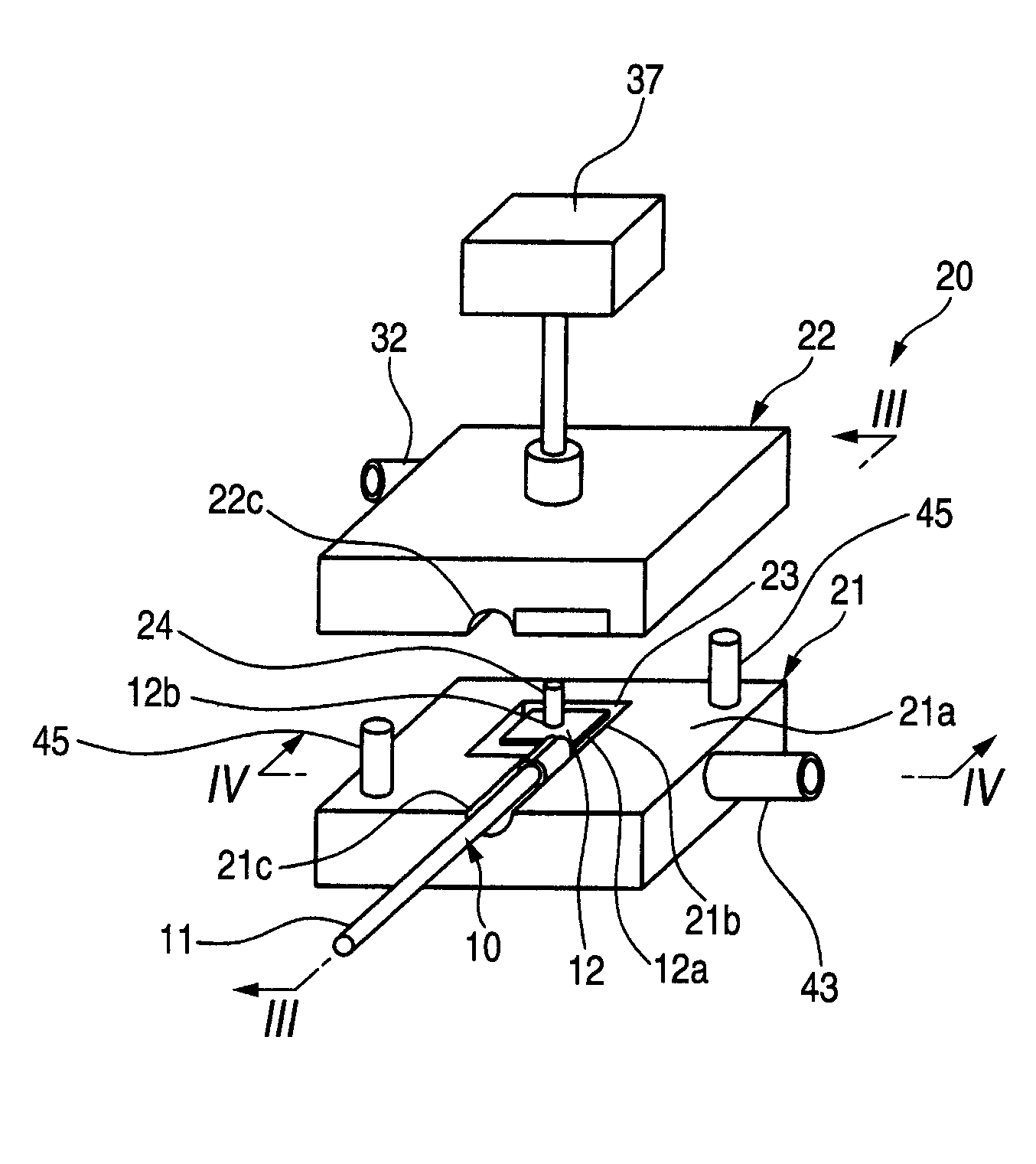

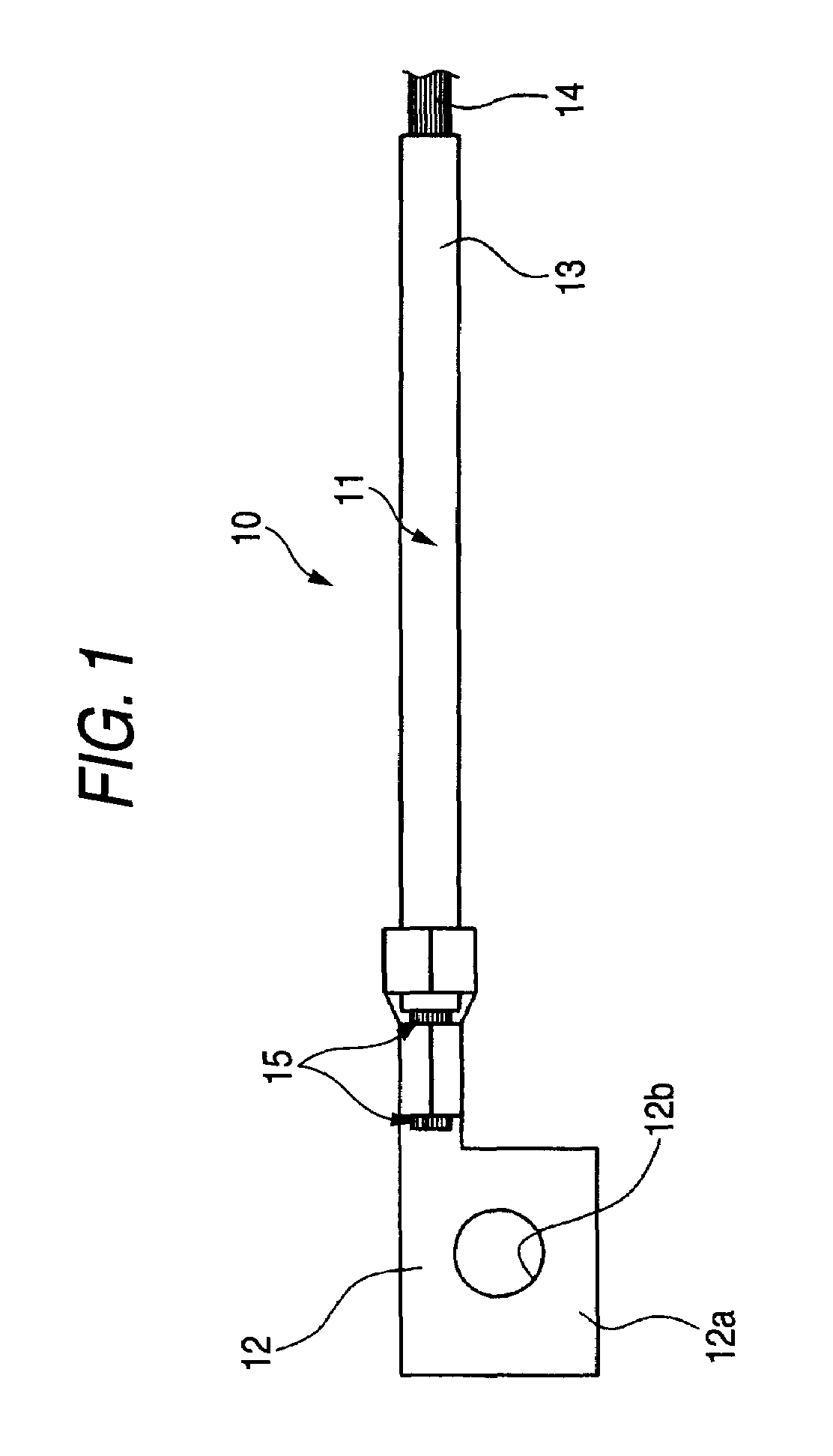

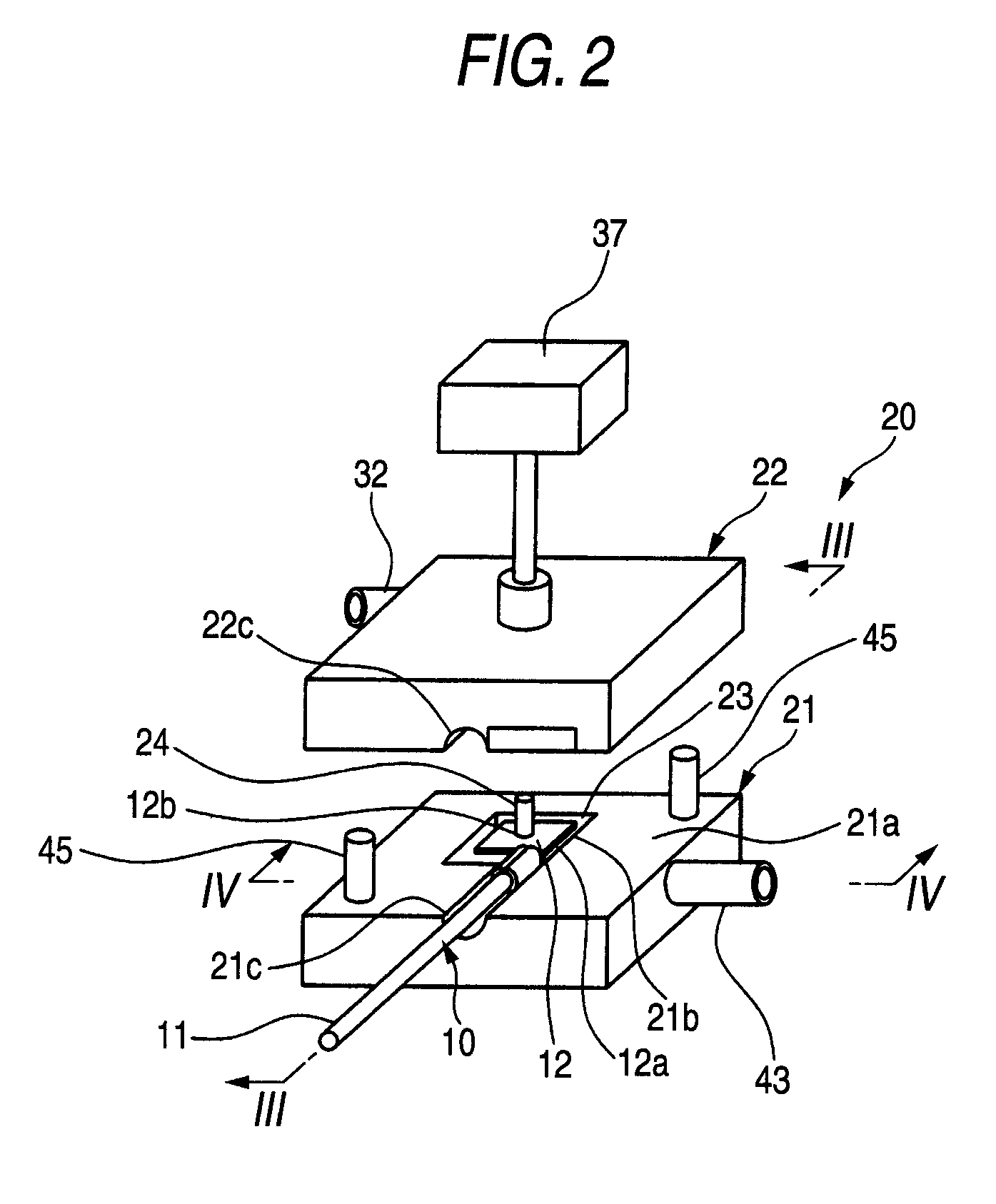

Expandable acetabular liner extraction device, cup assembly and associated method

ActiveUS20070005144A1Solve the lack of penetrationAbility to remove the liner without disabling of the locking mechanismJoint implantsFemoral headsAcetabular linerEngineering

An extraction device for removing a liner from an acetabular cup is provided. The extraction device includes a body and an actuator. The actuator is operably connected to the body. The extraction device also includes a jaw for cooperation with the liner. The jaw includes a portion of the jaw for penetrating into the liner. The jaw is operably connected to the actuator. The actuator is adapted to cooperate with the jaw to provide a first position for the jaw spaced from the liner and a second position for the jaw in contact with the liner.

Owner:DEPUY PROD INC

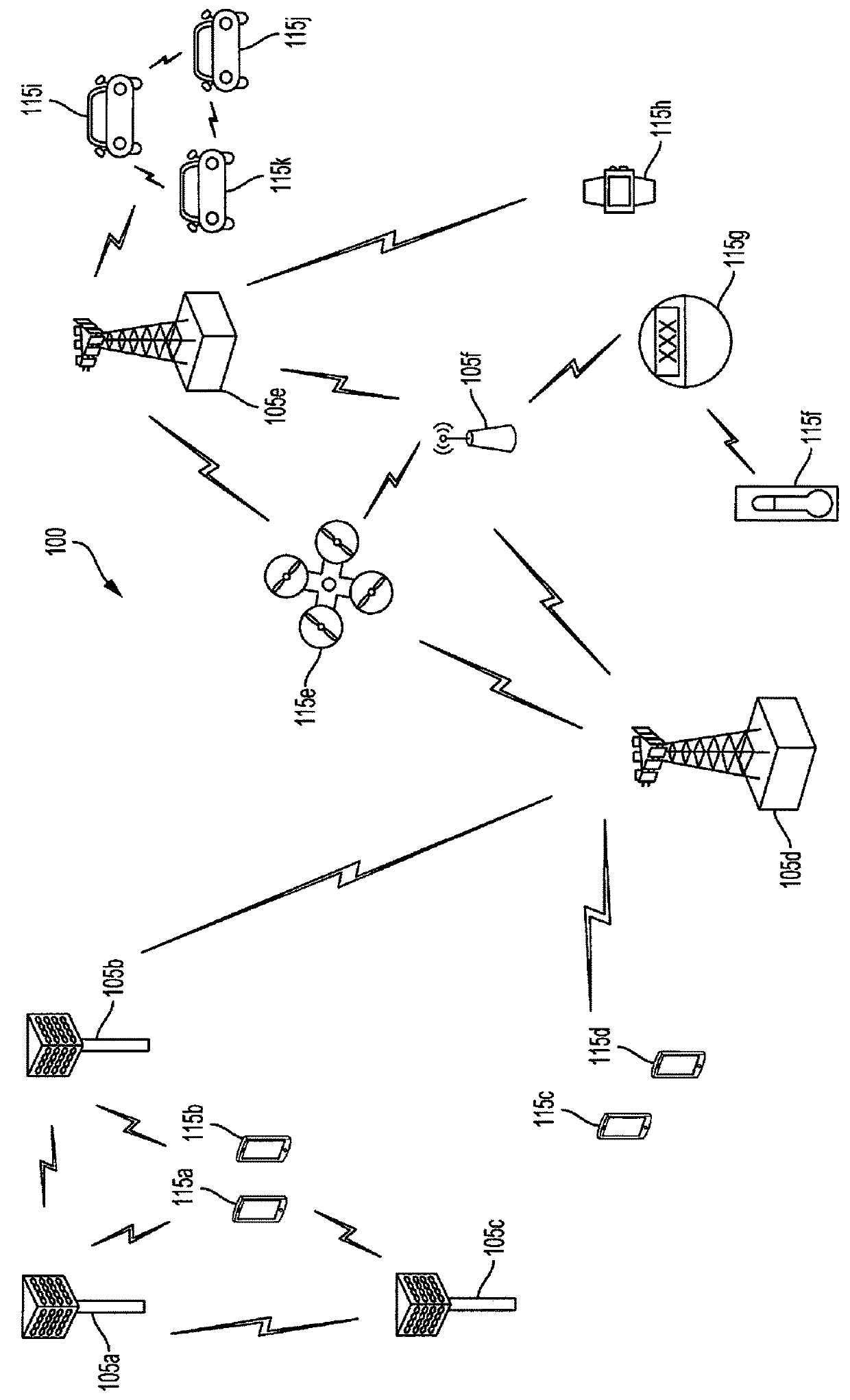

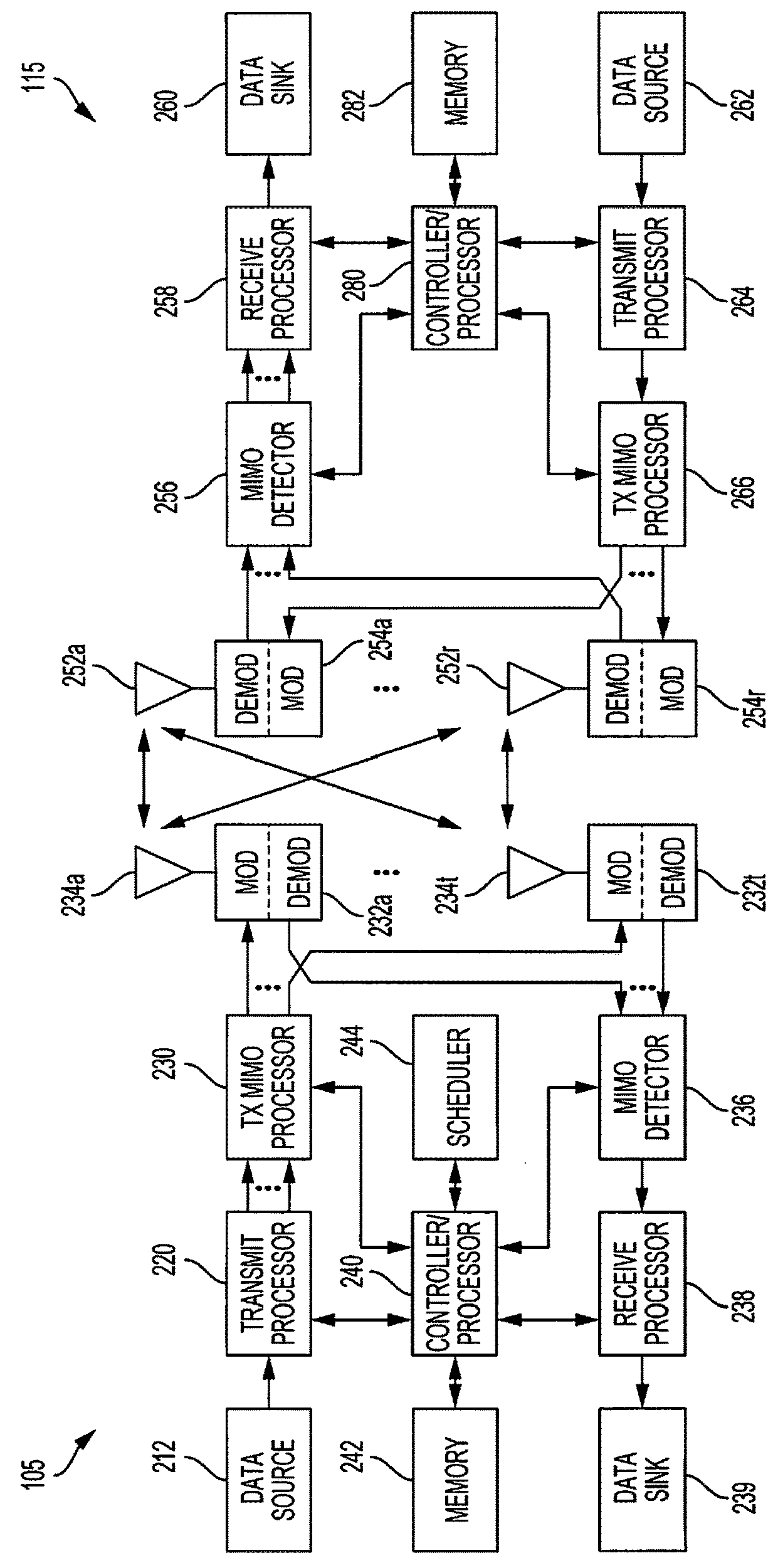

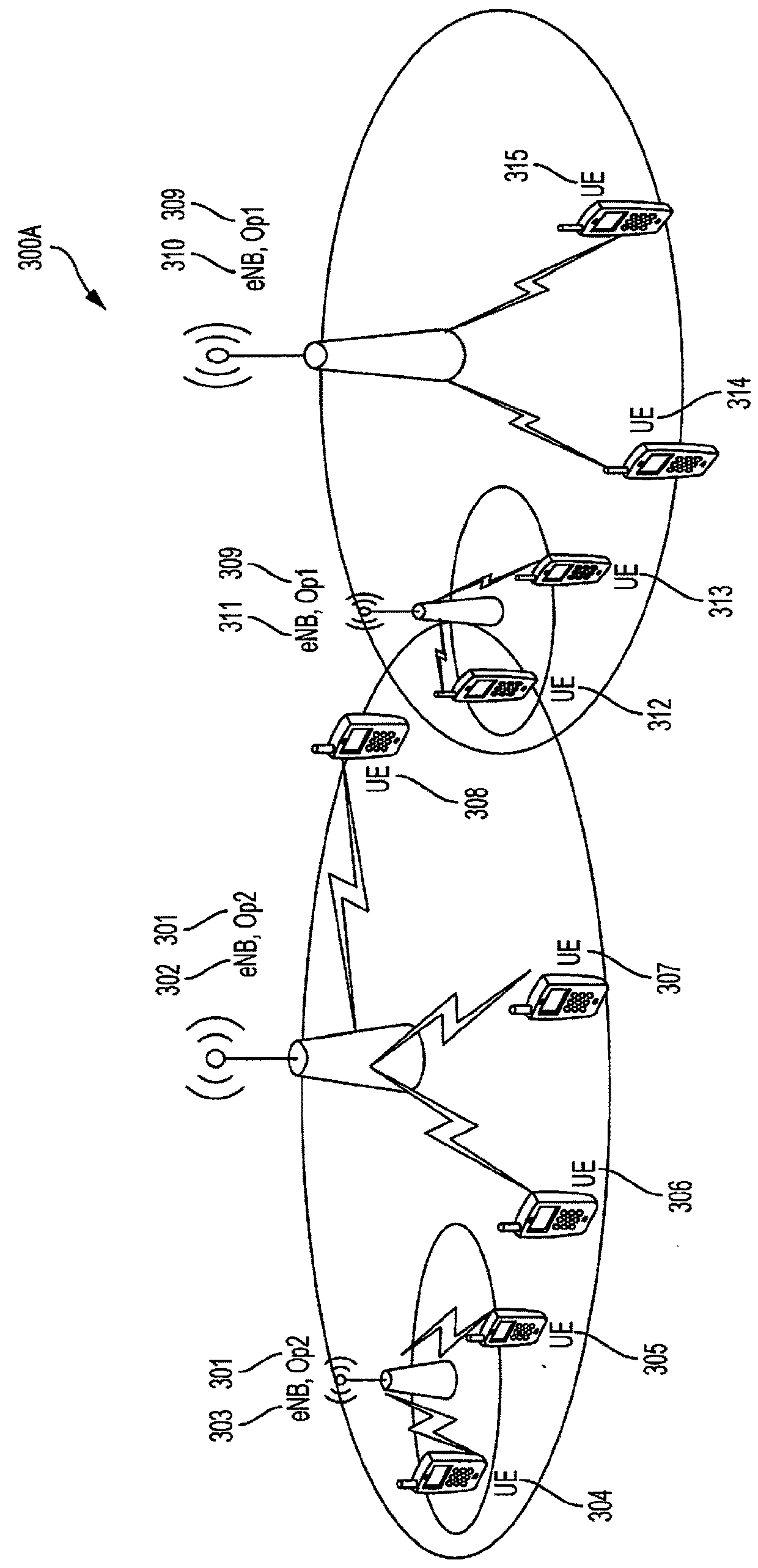

Channel reservation signals for new radio interference management

ActiveUS20180167848A1Reducing access contentionReduce overheadNetwork traffic/resource managementNetwork planningPriority callInterference management

Channel reservation systems and methods are disclosed herein, which schedule transmissions on a shared radio medium that is shared by a plurality of licensed network operators. In embodiments, priority access is pre-assigned to the network and the method determines whether to send a transmission based at least on the transmitter's priority class as compared to another transmitter's priority class and to which transmitter the time slot of a signal is dedicated. In embodiments, priority access may not be preassigned to the network and pre-grants may be used in conjunction with CR-Ts and CR-Rs to determine whether a transmitter transmits.

Owner:QUALCOMM INC

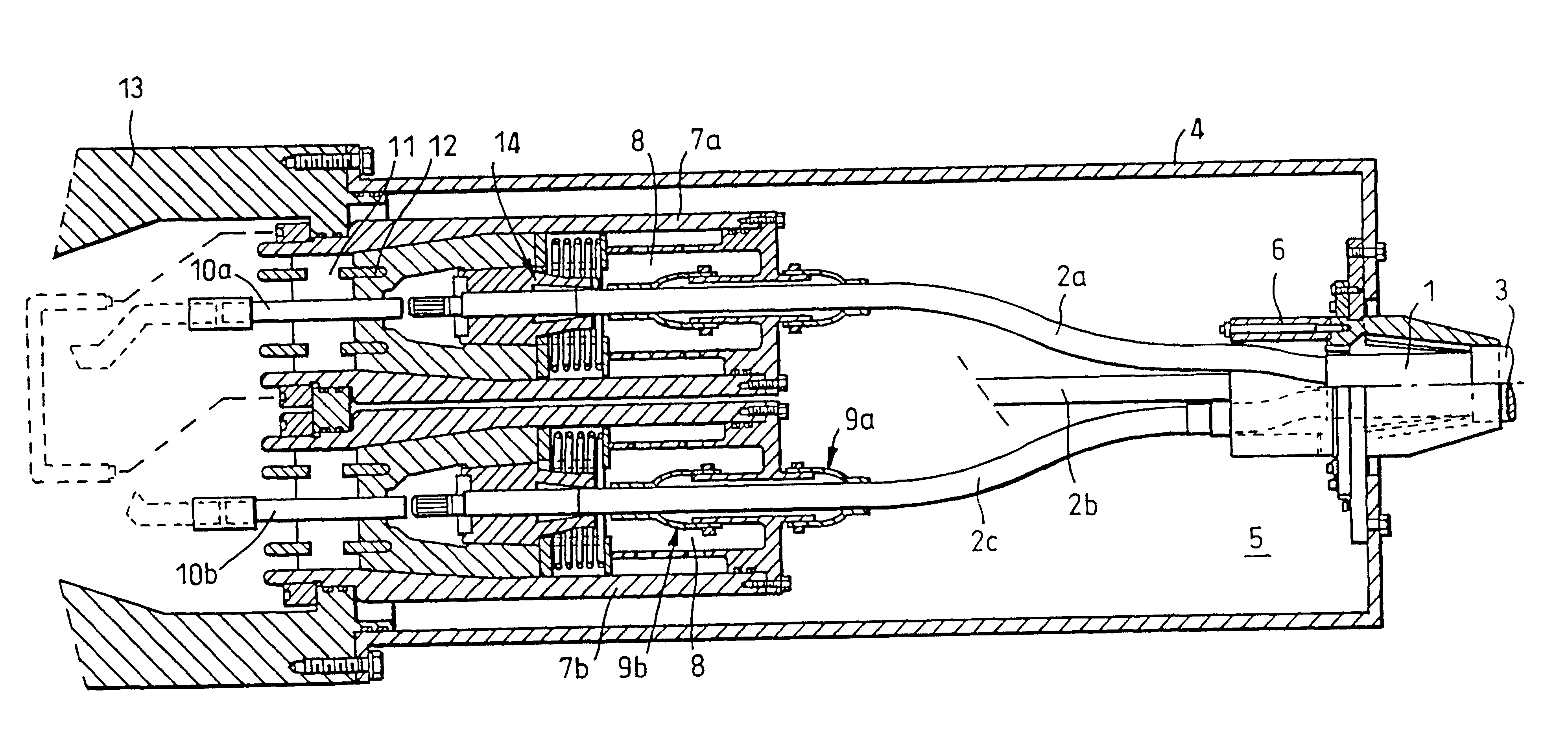

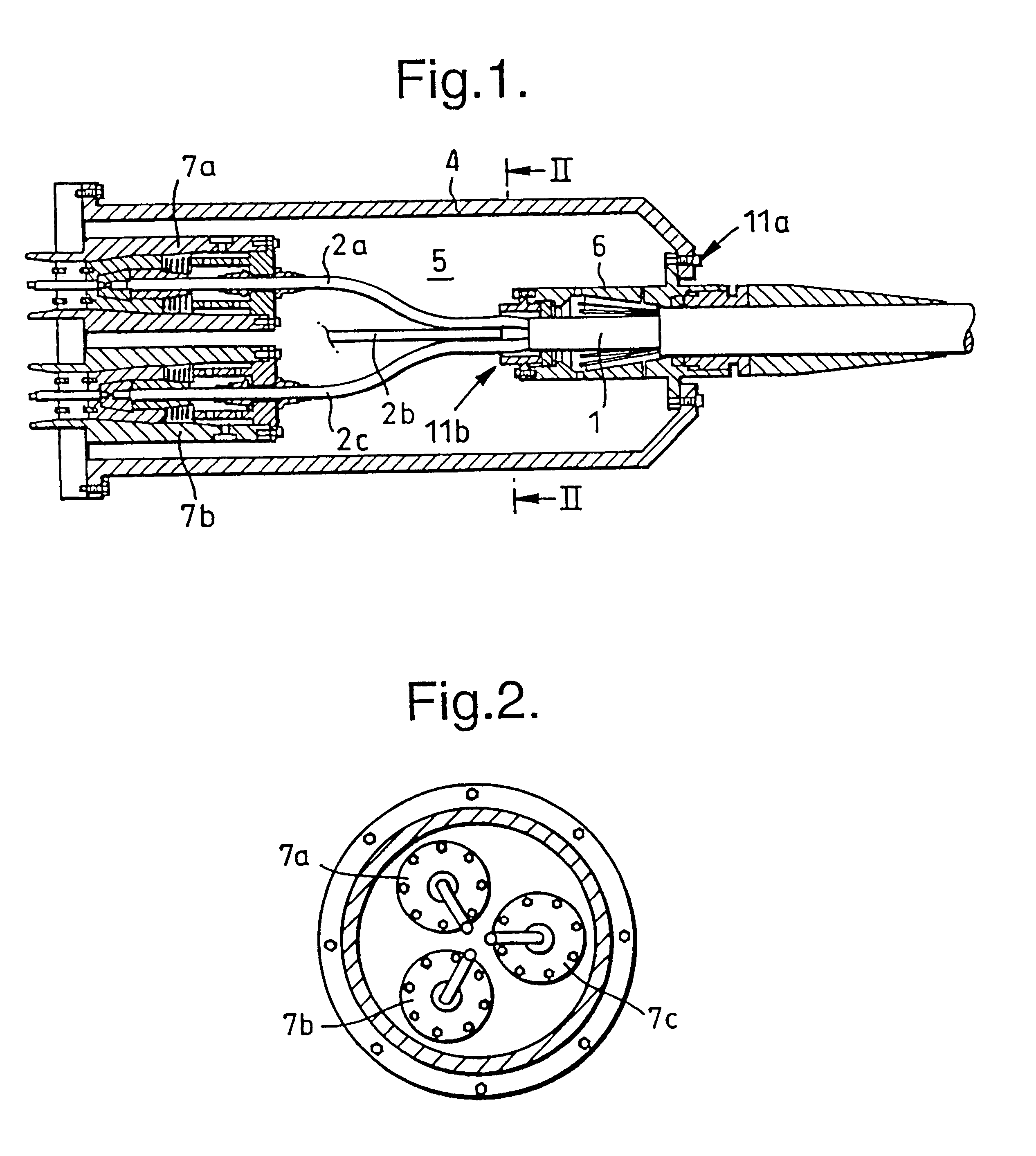

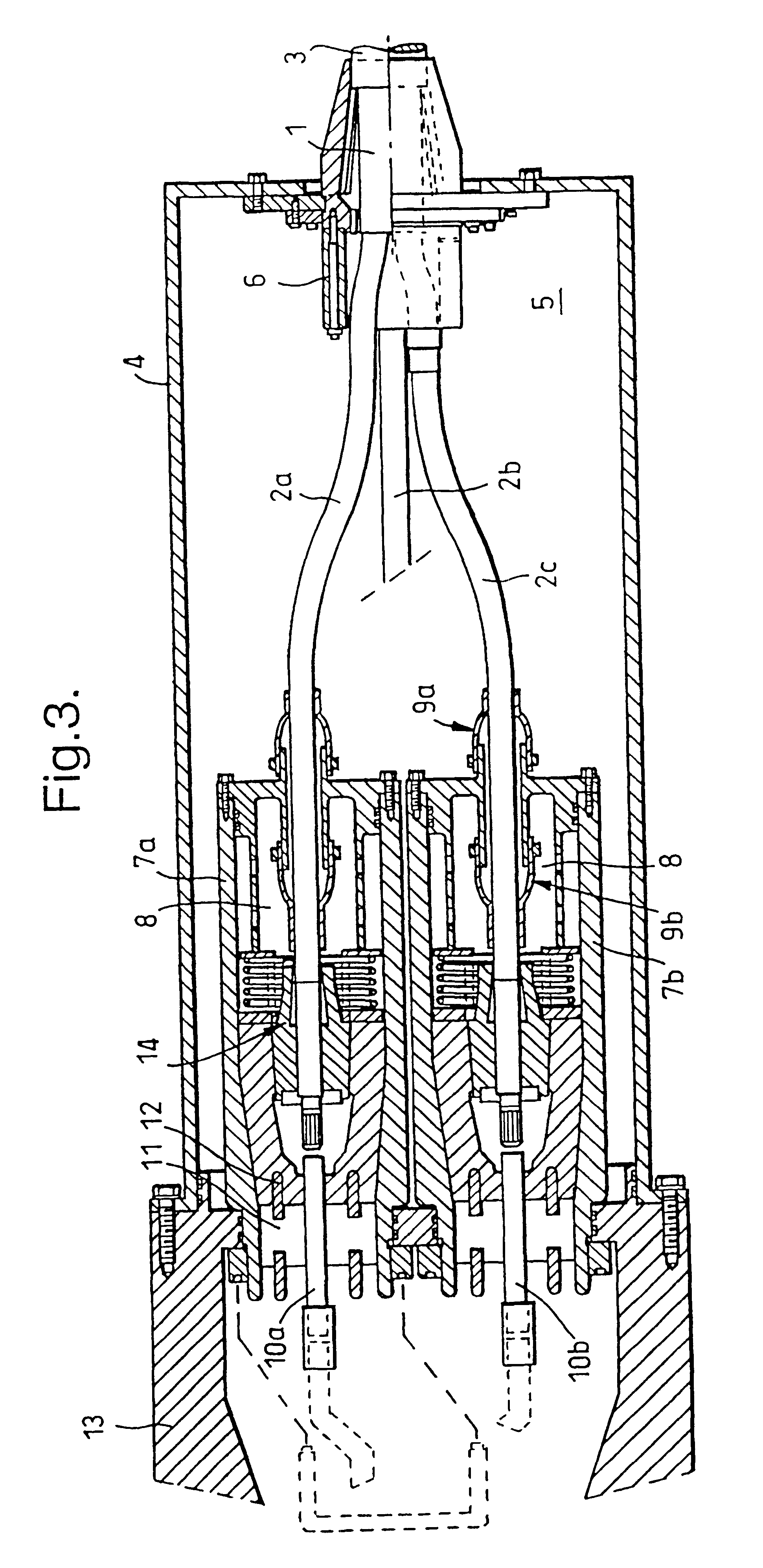

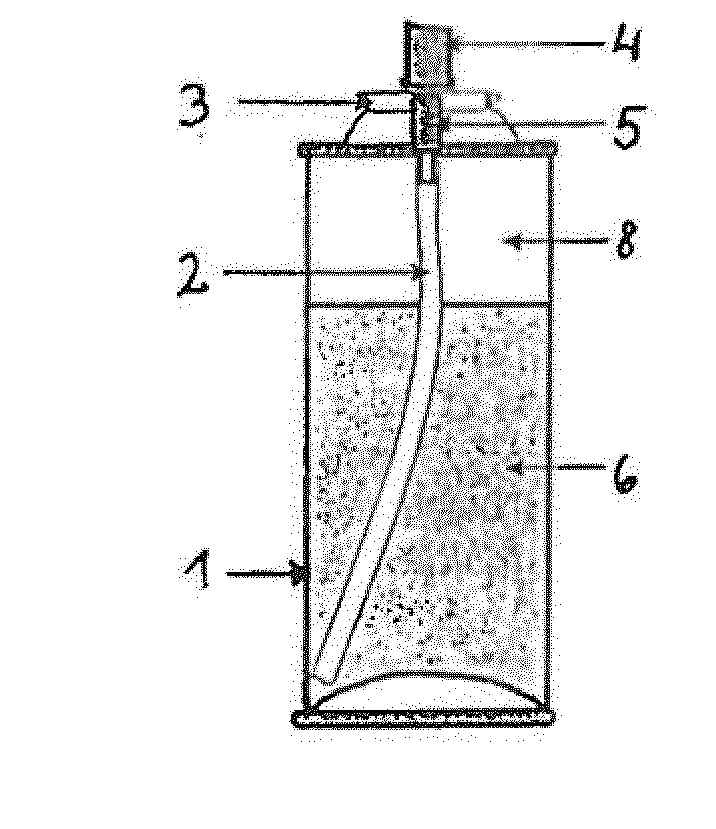

Arrangement in terminating a cable

InactiveUS6364677B1Avoid Insufficient SealingSolve the lack of penetrationCable junctionsCable fittings in presence of gas/oilPower cableElectrical conductor

The present invention relates to a device for terminating cables (1), particularly for underwater termination of high voltage power cable and for conducting high voltage conductors in an electrical underwater apparatus, with the purpose of providing a liquid and water tight termination, at the same time as it provides pressure relief for vital components. According to this it is suggested that: each high voltage conductor (phase) (2a, 2b, 2c) is terminated in a separate, liquid filled and pressure compensated interior chamber (7a, 7b, 7c); conduction of the high voltage conductor from each interior chamber into attached electrical apparatus is carried out by means of a solid electrical conductor (10a, 10b, 10c), said conductor being fixed in an insulation material (11) which is liquid and gas tight, the solid electrical conductor and insulation material forming a gas and liquid tight barrier between the cable conductor and attached apparatus, and all interior chambers (7a, 7b, 7c) are adapted to a common, liquid filled and pressure compensated outer chamber (4).

Owner:VETCO GRAY SCANDINAVIA

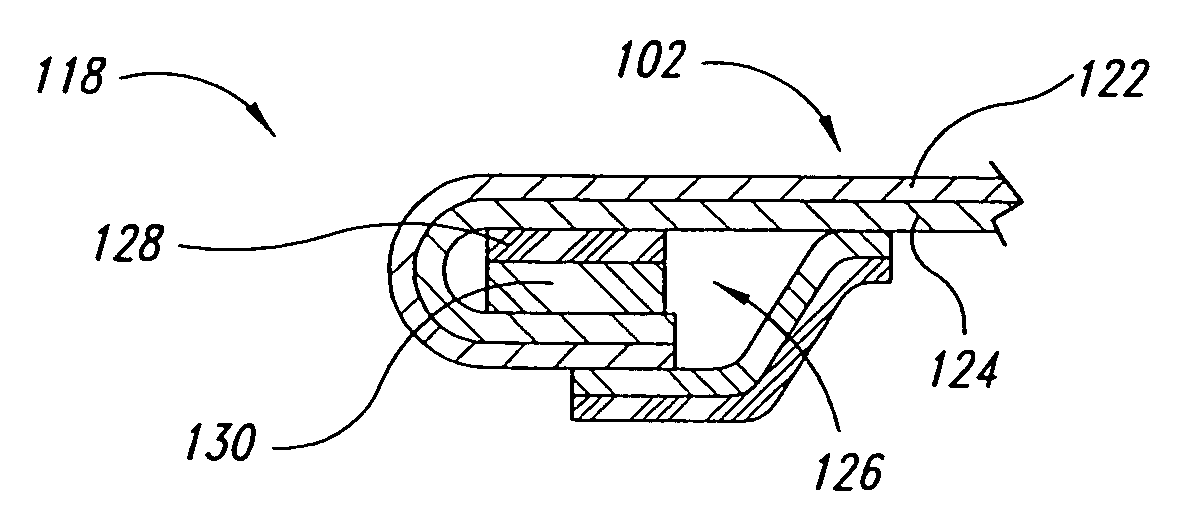

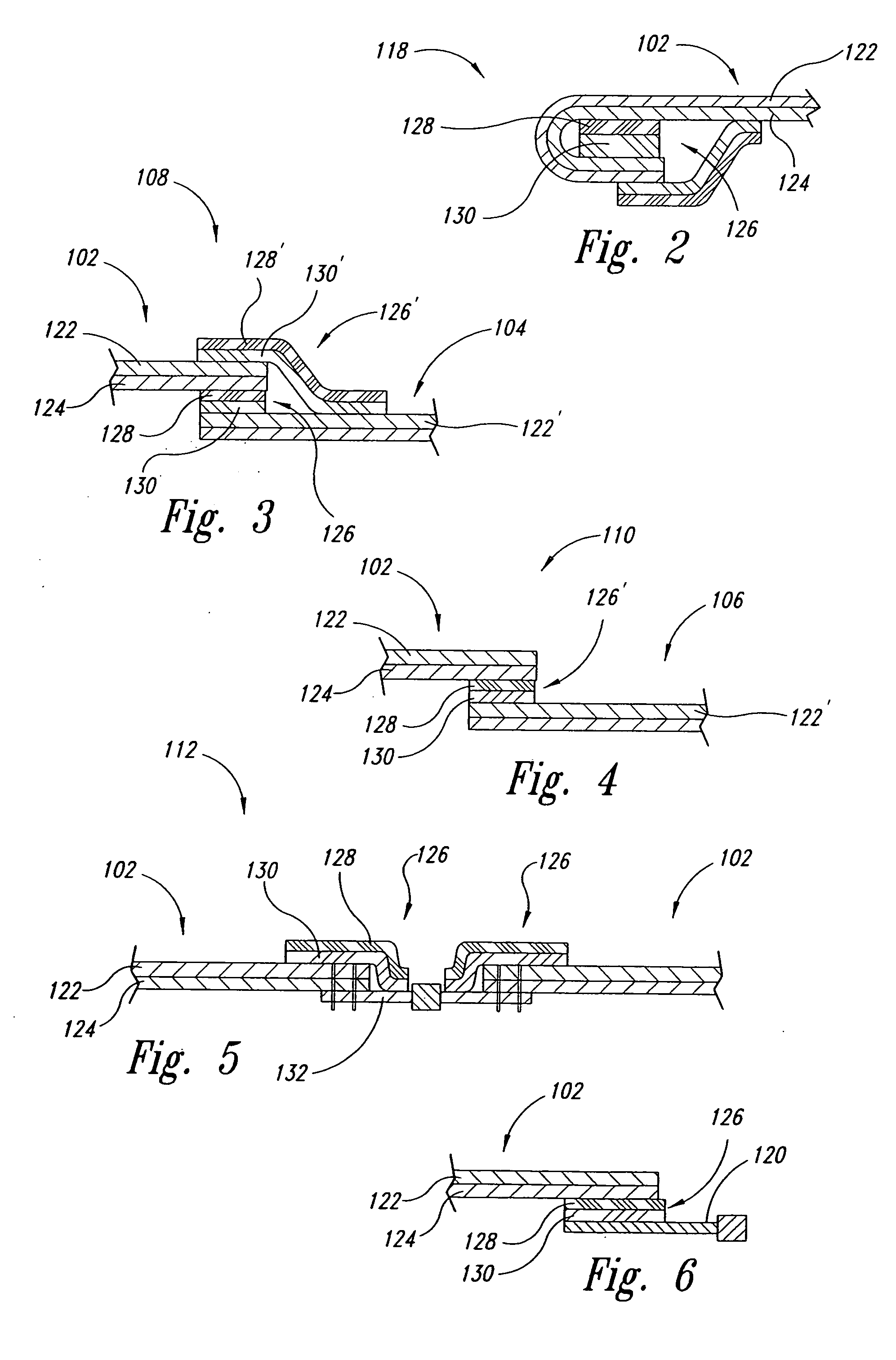

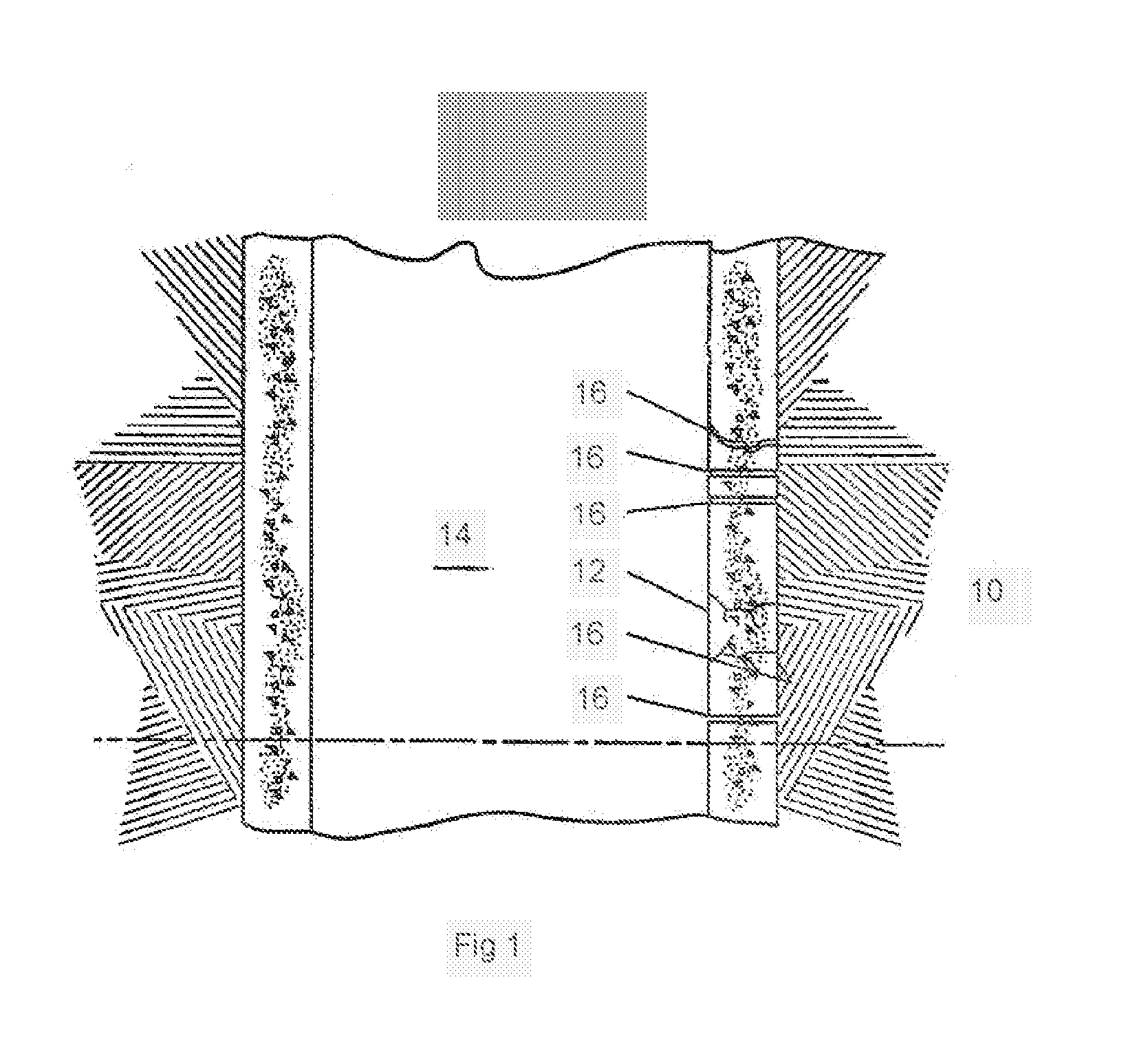

Hems, edges, patches and seams for durable, water repellant woven fabric, and methods for making the same

Edges, hems, patches and seams for woven fabric that has been treated for water repellency, and methods for making the same, are shown and described. In one particular embodiment of the invention, for example, a lapped seam between two pieces of water repellent fabric has an outer material at least partially overlapping an inner material, and a laminate strip positioned between the overlapping portions of the materials. The outer and inner materials, which are both oriented in the same direction, have an exterior layer of woven fabric that has been treated with water repellent and / or stain repellent chemicals, and an inner layer comprising a polymer membrane, such as polyurethane. The laminate strip has a bottom portion in contact with the outer layer of the inner material. The bottom portion has a low melt point, high flow rate adhesive system of one or more layers that penetrates and surrounds the fibers in the woven fiber of the outer layer of the inner piece of material. The laminate strip also has a top layer in contact with the inner layer of the outer piece of material. The top layer of the laminate is a thin, elastic, highly abrasion resistant material with a strong bonding affinity for polyurethane. The layers of the laminate strip bond to the adjacent layers of the overlapped material to create a strong lap seam.

Owner:FOWLER

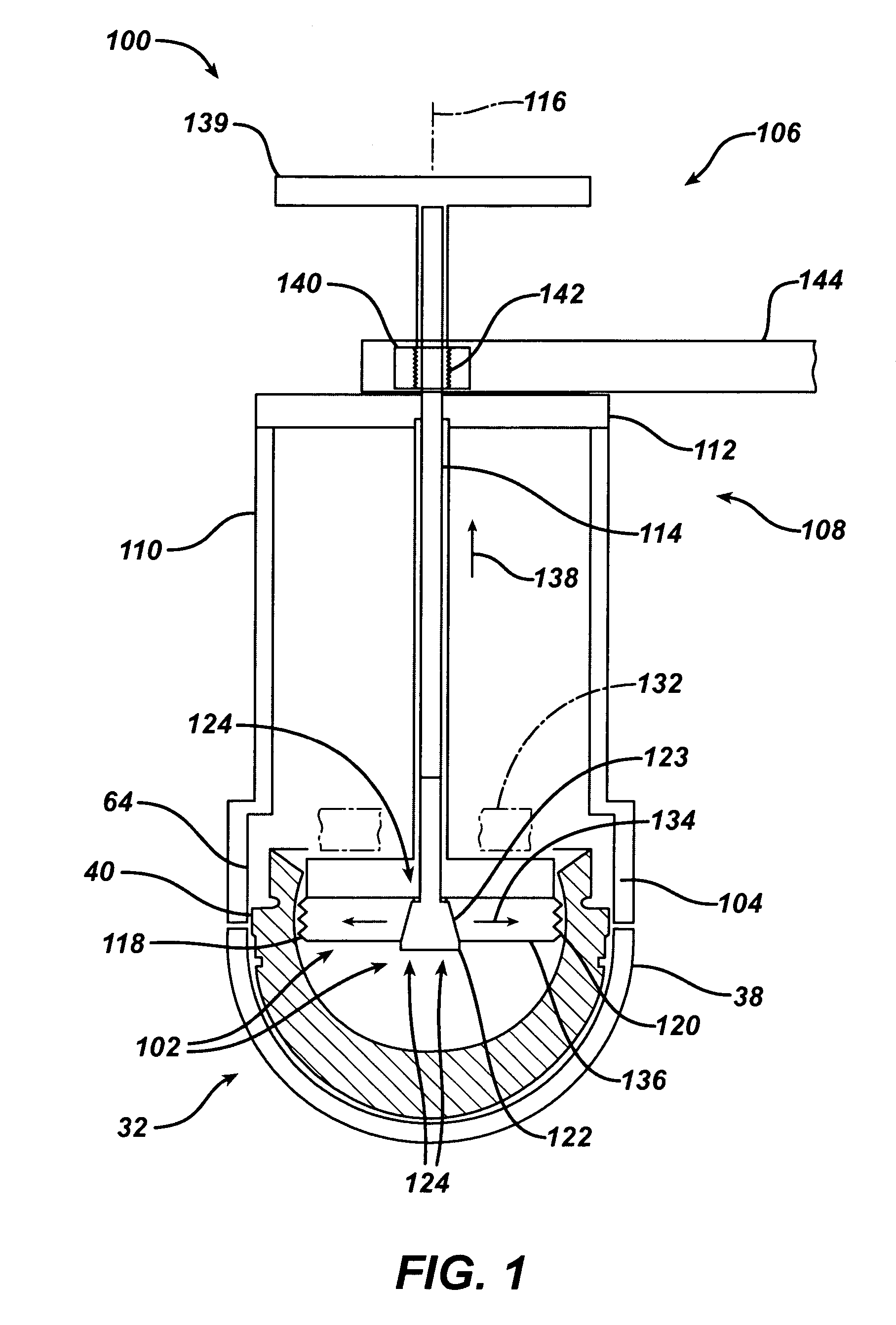

Acetabular liner extraction device, kit and associated method

ActiveUS20070010825A1Solve the lack of penetrationAbility to remove the liner without disabling of the locking mechanismJoint implantsAcetabular cupsEngineeringAcetabular liner

An extraction device for removing a liner from an acetabular cup is provided. The extraction device includes a jaw and a handle. The jaw is for cooperation with the liner and including a portion of the jaw for penetrating into the liner. The handle is operably associated with the jaw and is adapted for gripping the extraction device.

Owner:DEPUY PROD INC

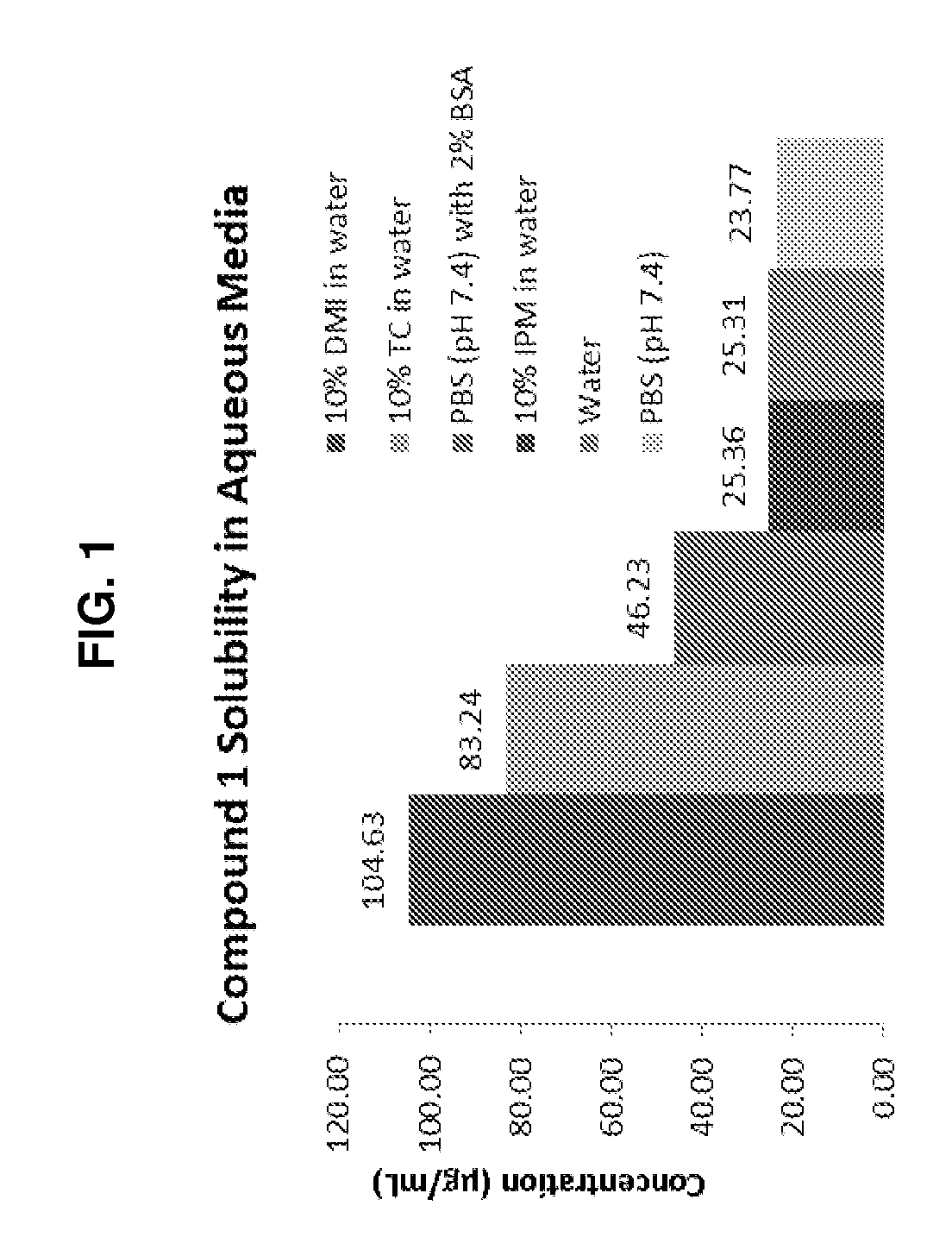

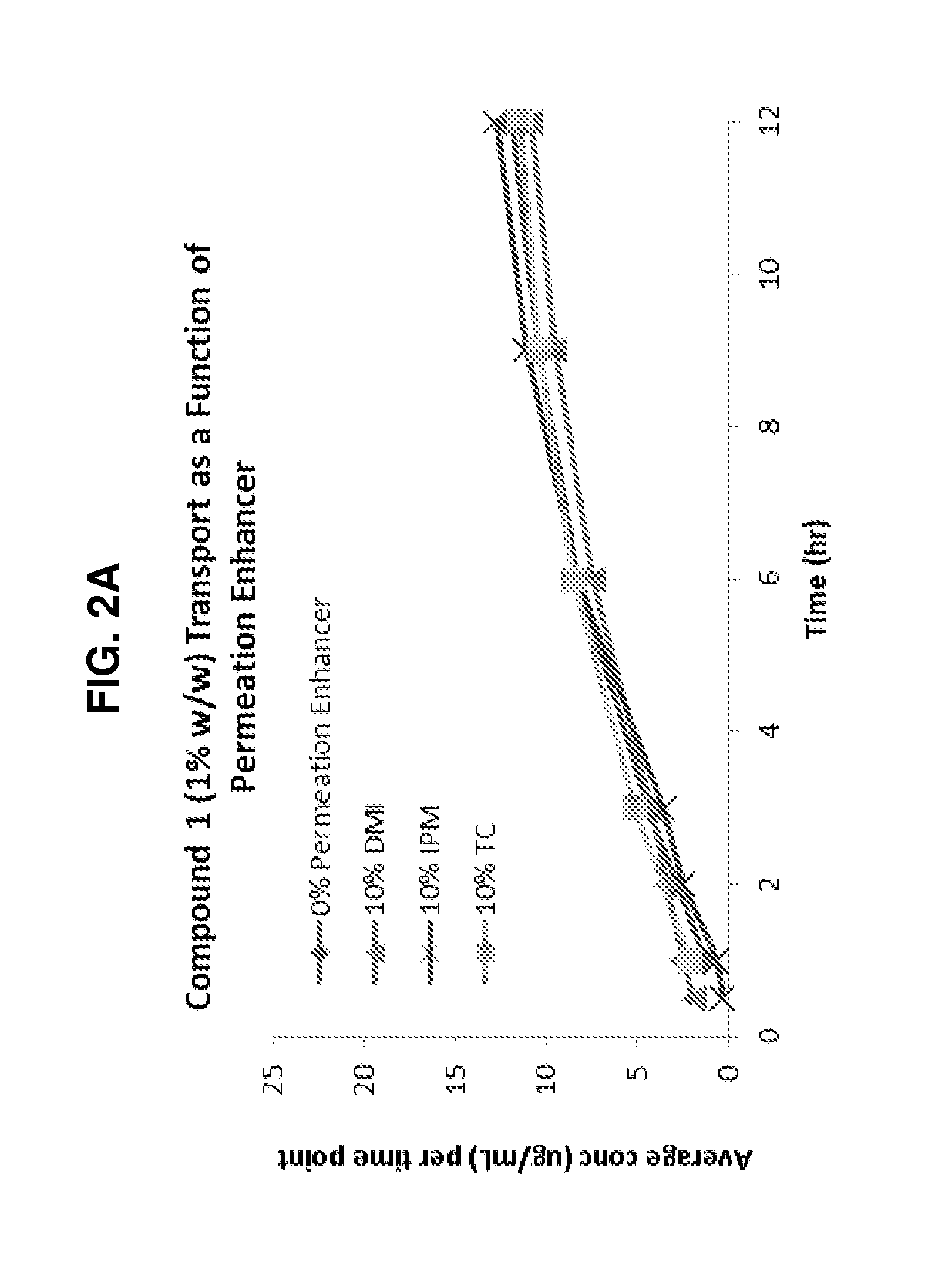

Topical formulation

InactiveUS20170266289A1Penetrate the skin more sufficientlyMore effective skin barrier penetrationCosmetic preparationsAerosol deliveryMedicineHeat sensitive

The invention described herein provides topical formulations that can be prepared at ambient temperature without the need for any heating step during preparation. Thus the formulations are particularly suitable for cosmetic and pharmaceutical active ingredients that are relatively heat sensitive. The invention also provides methods for preparing the same.

Owner:ABBVIE INC

Expandable acetabular liner extraction device, cup assembly and associated method

ActiveUS7927376B2Solve the lack of penetrationAbility to remove the liner without disabling of the locking mechanismJoint implantsFemoral headsAcetabular linerEngineering

An extraction device for removing a liner from an acetabular cup is provided. The extraction device includes a body and an actuator. The actuator is operably connected to the body. The extraction device also includes a jaw for cooperation with the liner. The jaw includes a portion of the jaw for penetrating into the liner. The jaw is operably connected to the actuator. The actuator is adapted to cooperate with the jaw to provide a first position for the jaw spaced from the liner and a second position for the jaw in contact with the liner.

Owner:DEPUY PROD INC

Energy activated electrographic printing process

InactiveUS20030165766A1Improve performanceImprove propertiesMechanical recordingRecord information storageCross-linkCohesive strength

A process for printing images by means of an electrographic or electrostatic device using a toner that is cured by multiple applications of energy. The toner has energy-activated reactive components such as radiation-curable sites and reactive functional groups. An image is formed on a substrate by the toner without materially activating the reactive components. The reactive components are subsequently activated by applying a first energy source to adhere the image to the substrate by cross-linking and bonding the image permanently to the substrate, or by transferring the image to a second substrate. A second energy source is applied simultaneously with, or subsequently to, the first energy source, to promote cohesive strength of the image by cross-linking within the toner particles that form the image. The resulting image is permanently bonded to the substrate, yielding substantially enhanced image durability and fastnesses.

Owner:SAWGRASS SYST INC

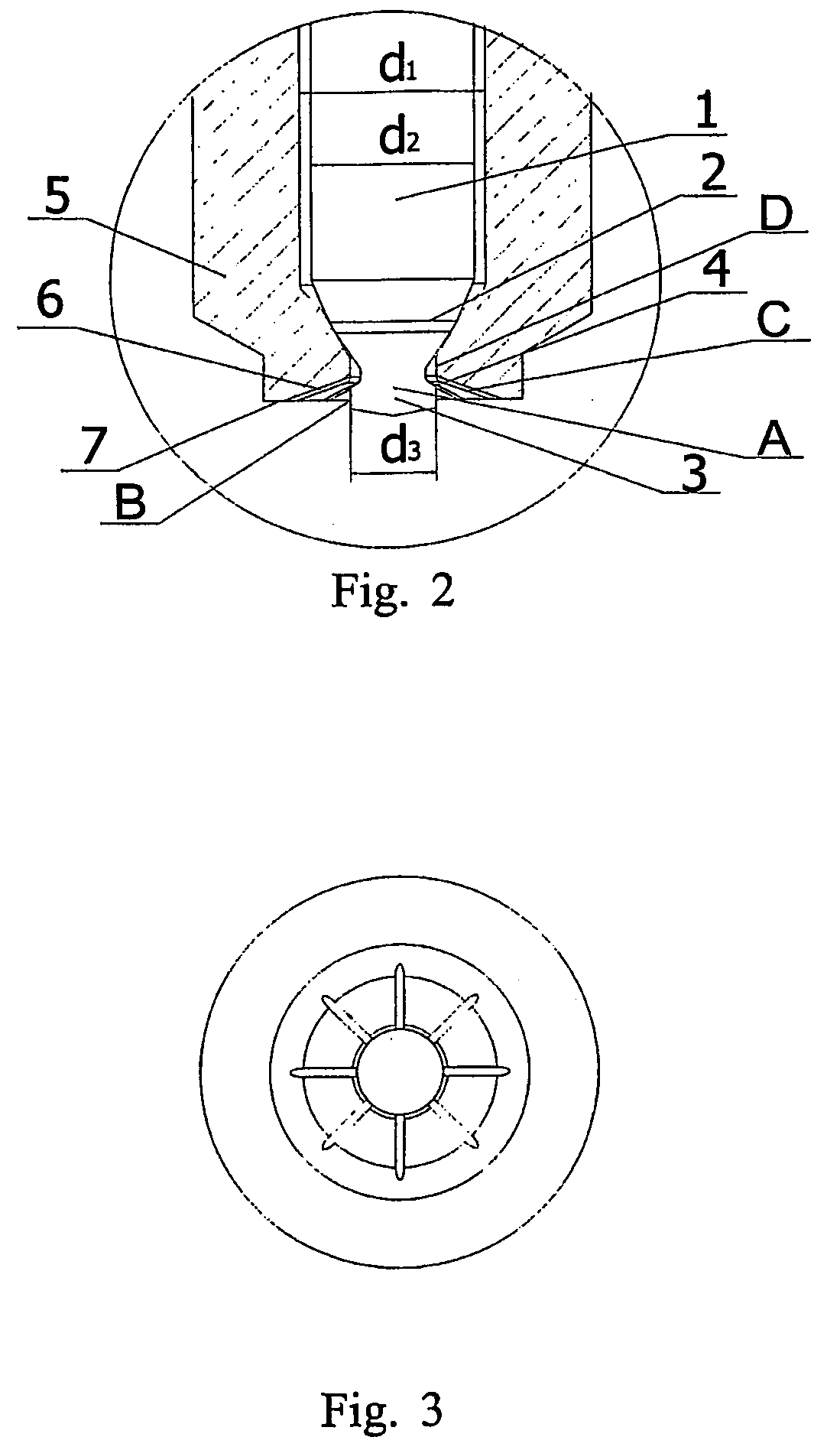

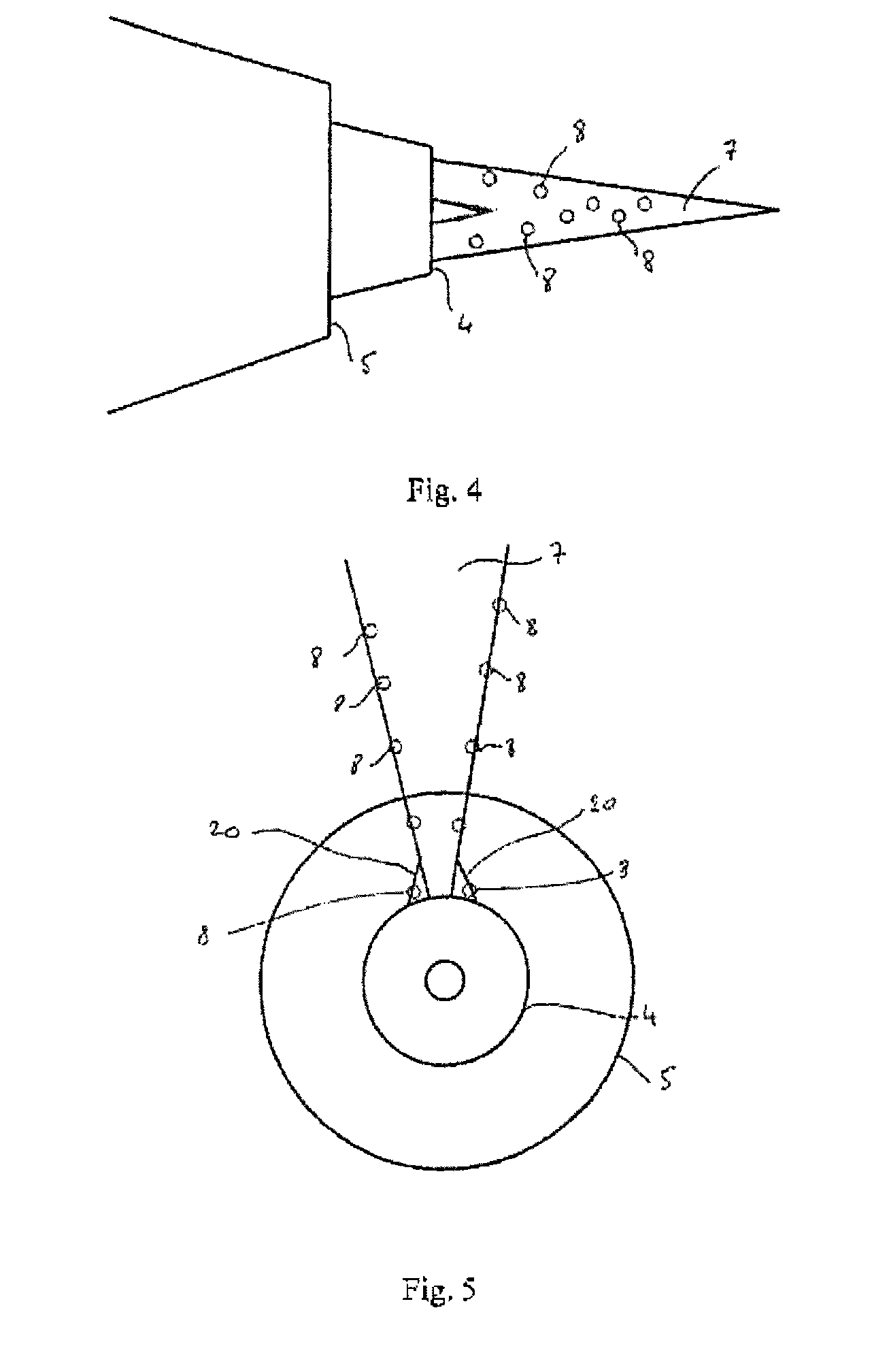

Mixed-Mode Fuel Injector with a Variable Orifice

InactiveUS20080245902A1Reduce total pressure lossPromote atomizationFuel injection apparatusMachines/enginesGasolineEngineering

The invention disclosed a mixed-mode fuel injector with micro-variable-circular-orifice (MVCO), which is a fuel injection device for internal combustion engines, either diesel or gasoline engines. The fuel injector is a high-accuracy couple of components comprising a needle valve (1) and a nozzle body (5). Said needle valve is movable back and forth and received in said nozzle body to provide an opening position for fuel injection and a biased closing position. Said nozzle body has multiple-micro-channels (6) on the inner conical surface (C) close to the tip of the nozzle body. The injector has a MVCO (4) comprising a micro-variable-circular aperture and multiple-micro-channels, and has means of generating variable mixed-mode sprays of conical and multi-jet shapes, with a major homogeneous conical spray at low to medium injection loads.

Owner:HOU DEYANG +1

Biodegradable ether dry cleaning solvent

InactiveUS7008458B2Good physical propertiesMinimizes or eliminates the shrinkage of woolen garmentsSoftening compositionsDetergent mixture composition preparationSolvent compositionDipropylene glycol

Compositions for dry-cleaning garments containing dipropylene glycol tertiary-butyl ether (DPTB), water, and at least one other solvent selected from cyclic siloxanes and glycol ethers other than DPTB suitable for use as dry-cleaning solvents, wherein the water is present at a level of about 10% by weight or less.

Owner:RYNEX HLDG

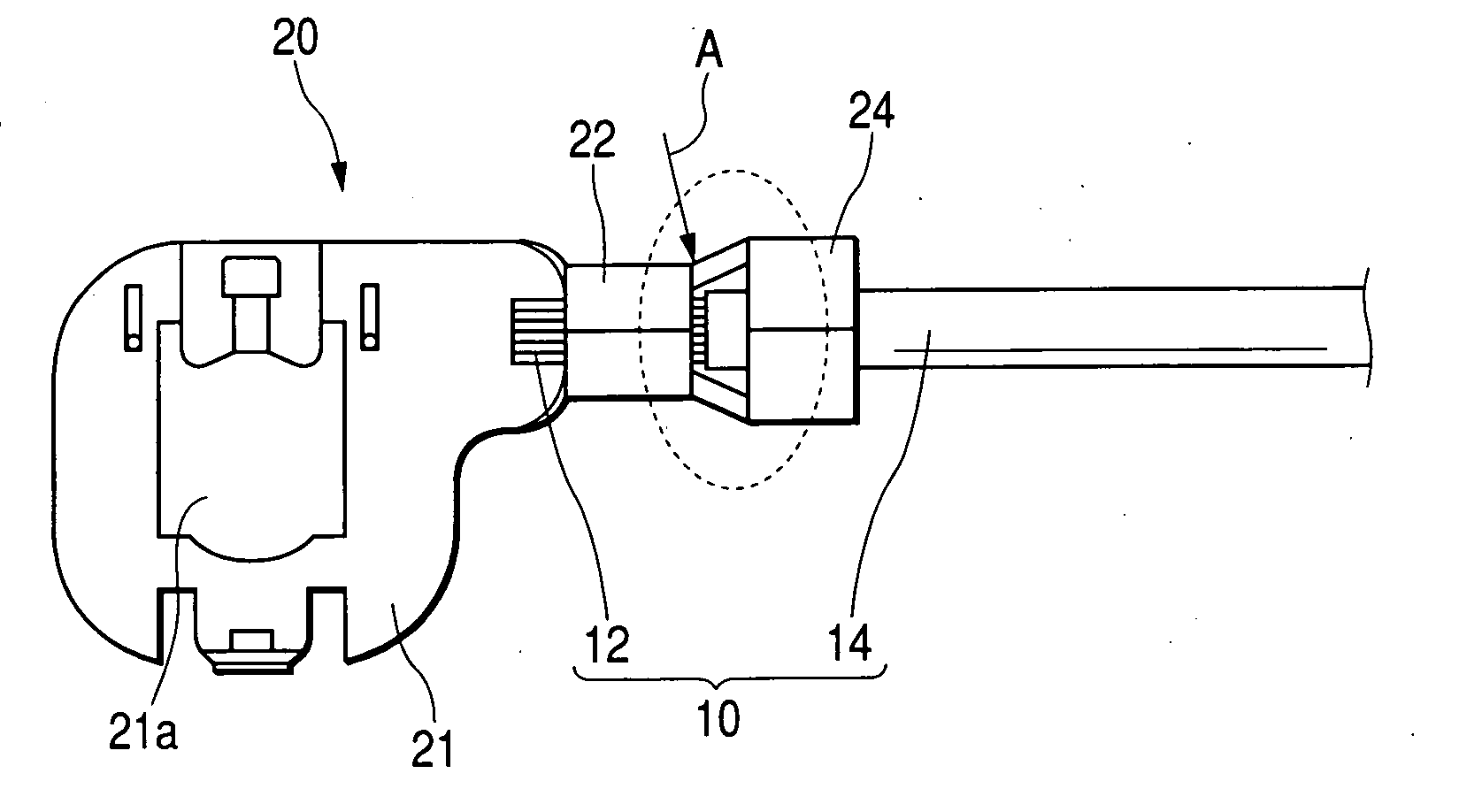

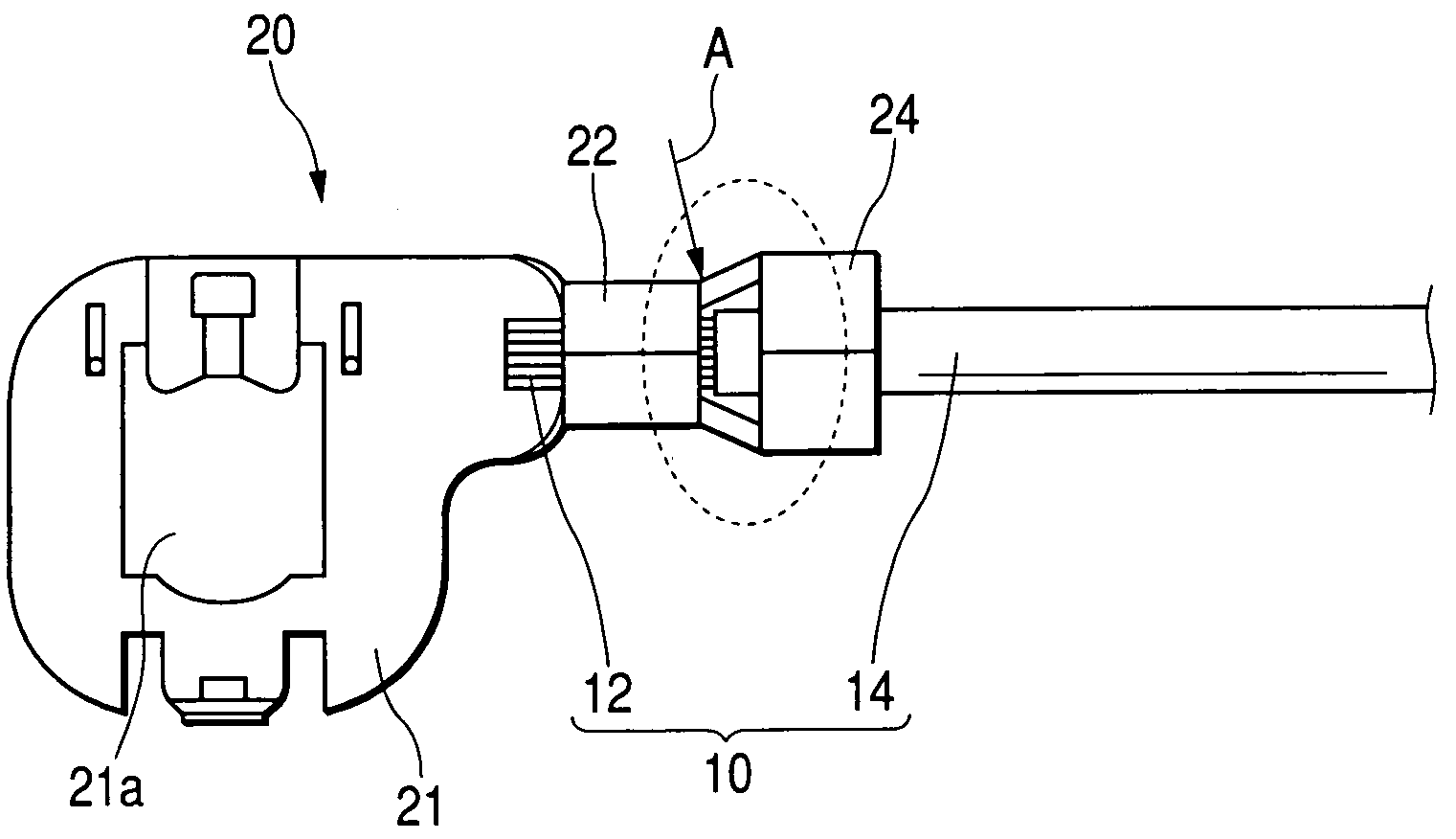

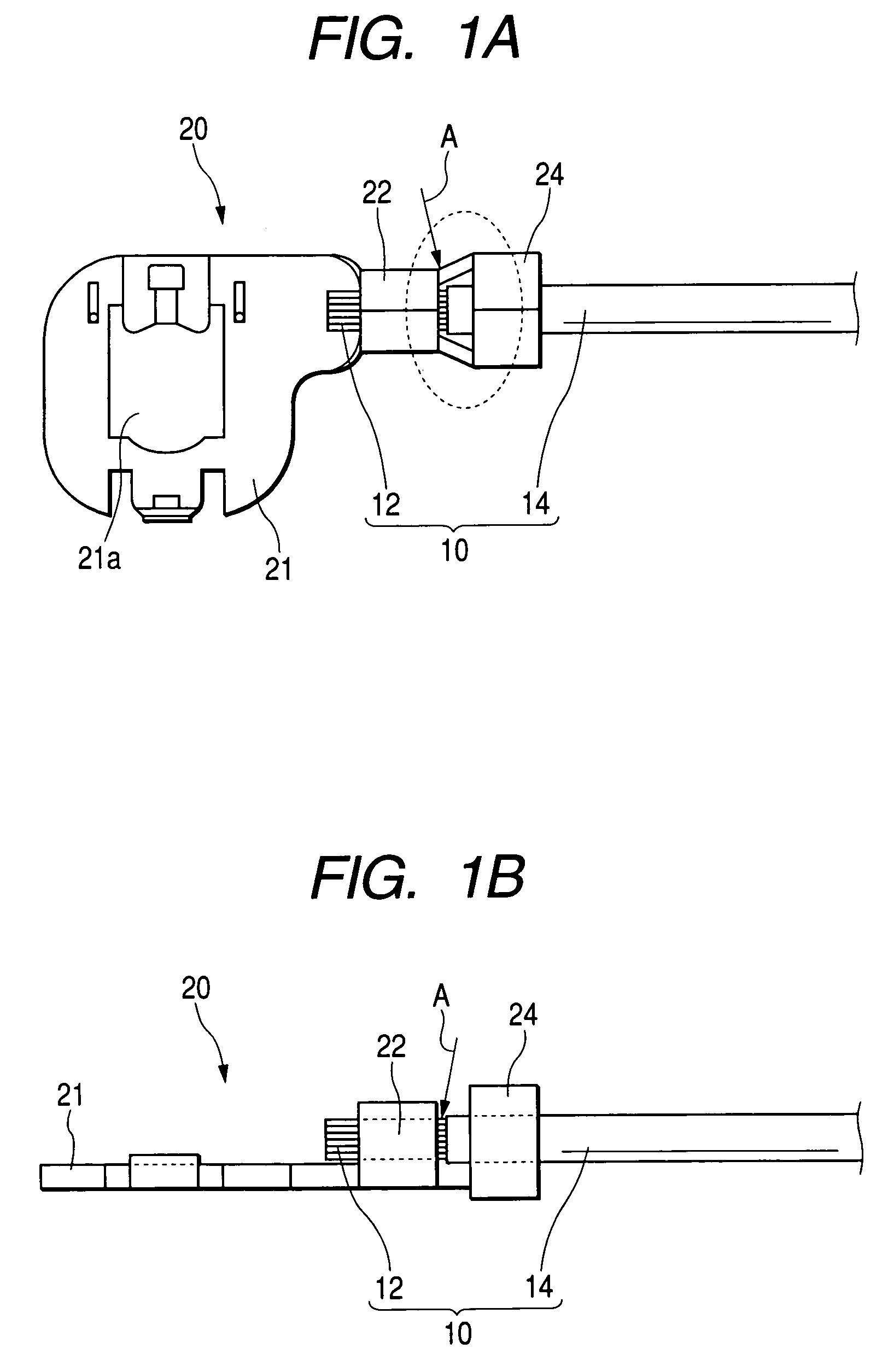

Earthing electric wire and water-stopping method therefor

ActiveUS20040238200A1Reduce pressureReliable treatmentLine/current collector detailsInsulated cablesElectrical conductorElectric wire

An earthing electric wire including a conductor; and a coating material outside of the conductor, wherein a water-stopping agent having a flowability is located between the conductor and the coating material on an earthing connection terminal side of the earthing electric wire for connecting a circuit mounted on a vehicle with the earth.

Owner:AUTONETWORKS TECH LTD +2

Earthing electric wire and water-stopping method therefor

ActiveUS7238884B2Improve powerEasy to operateLine/current collector detailsInsulated cablesElectrical conductorElectric wire

An earthing electric wire including a conductor; and a coating material outside of the conductor, wherein a water-stopping agent having a flowability is located between the conductor and the coating material on an earthing connection terminal side of the earthing electric wire for connecting a circuit mounted on a vehicle with the earth.

Owner:AUTONETWORKS TECH LTD +2

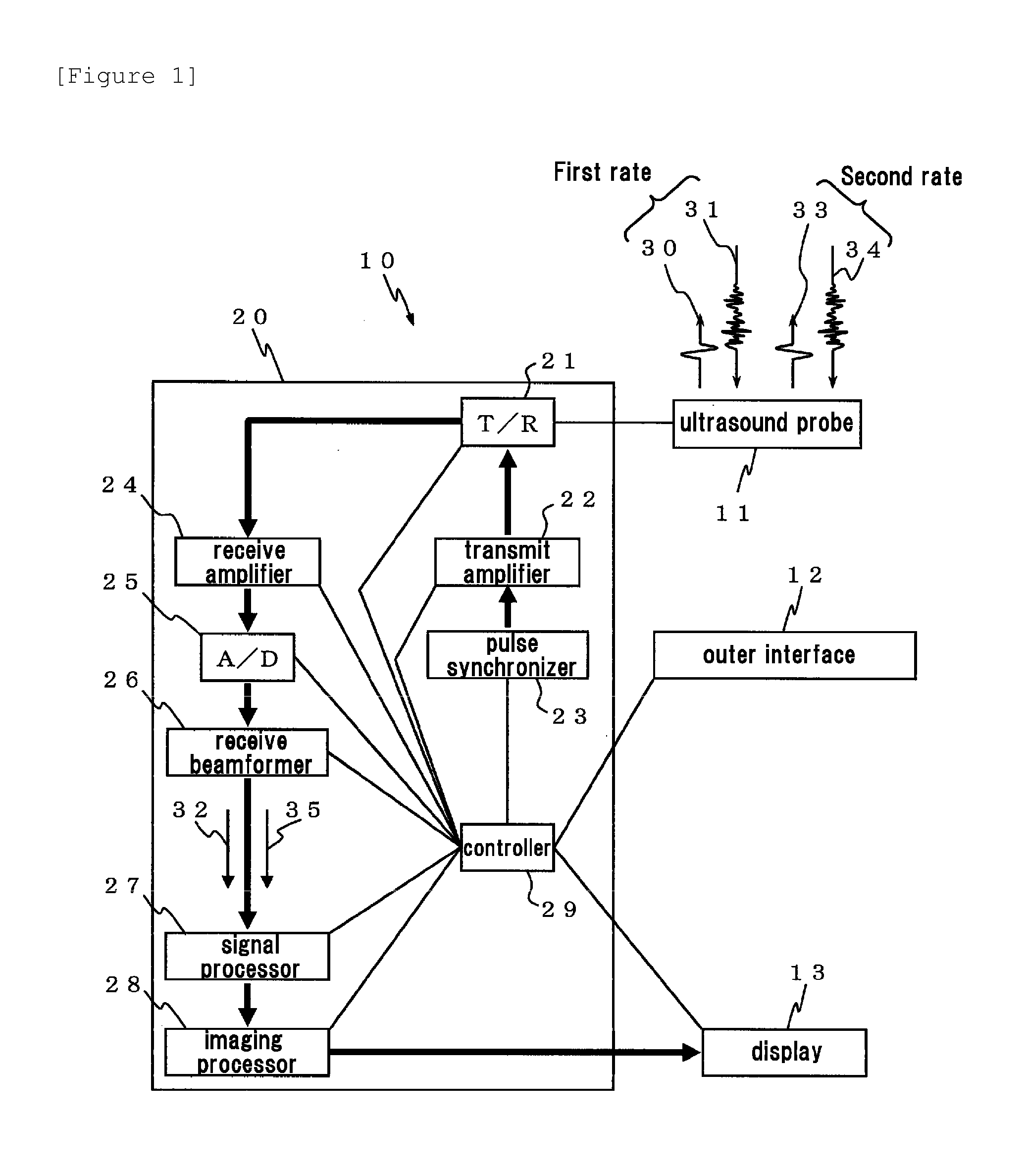

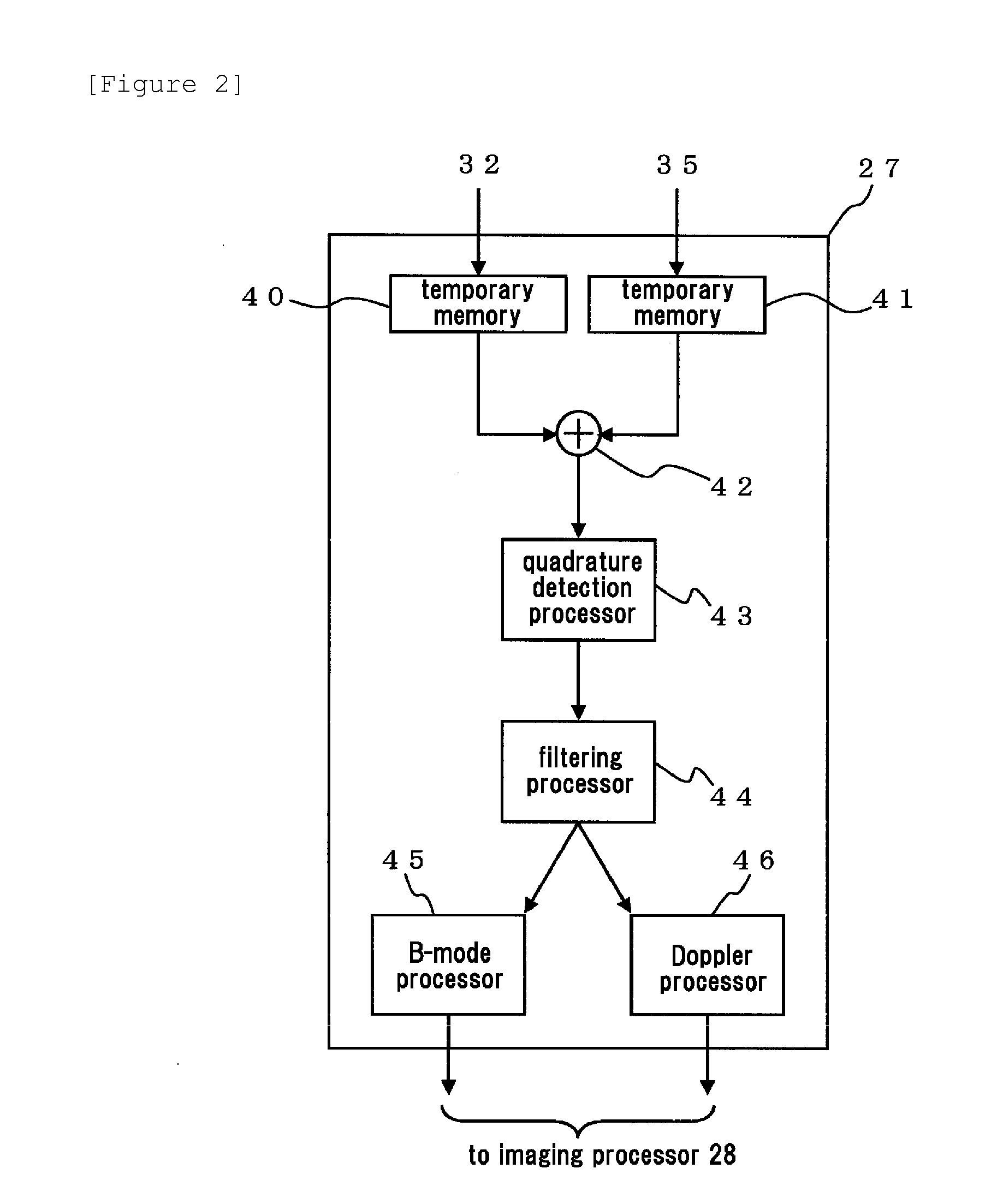

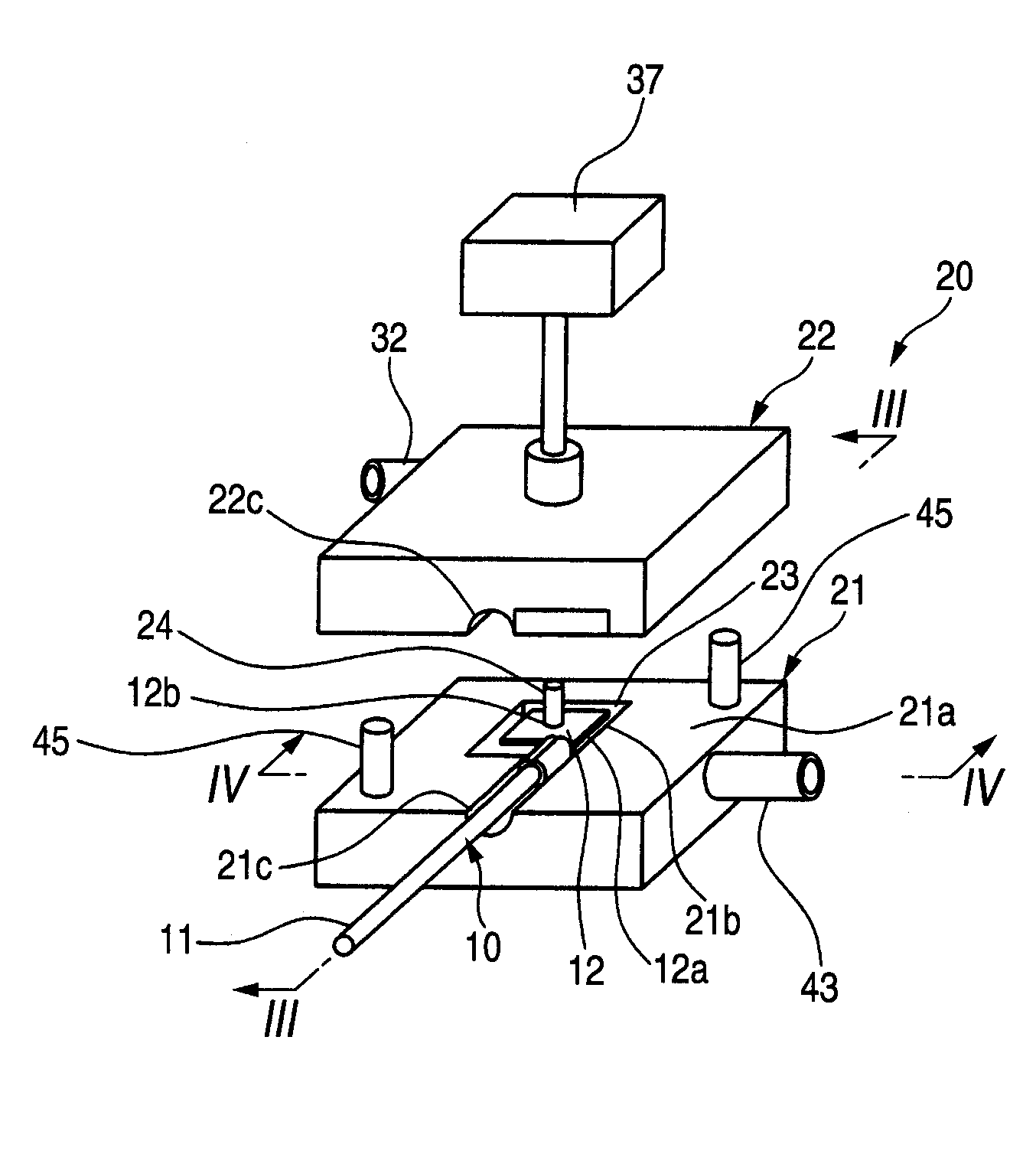

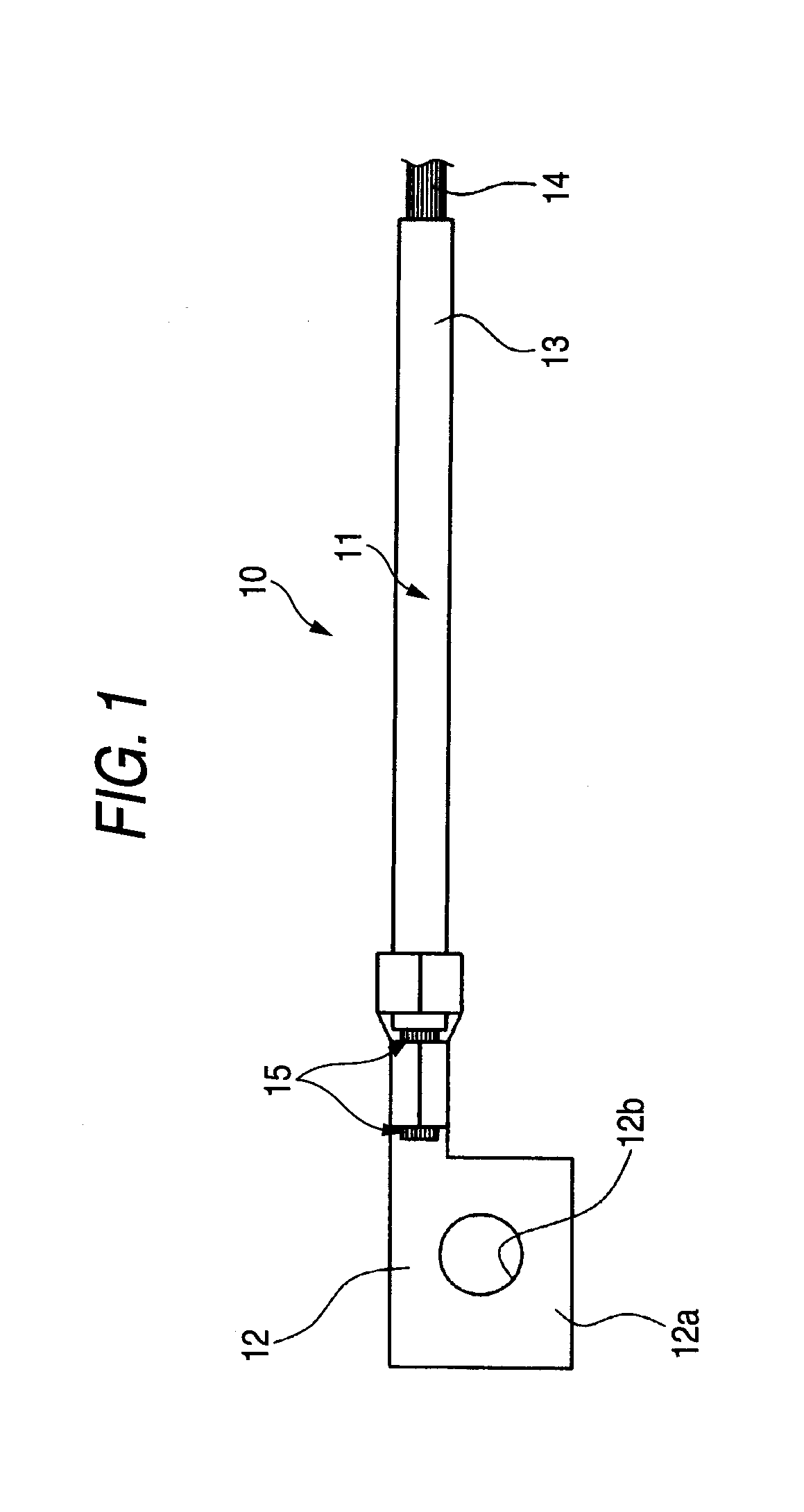

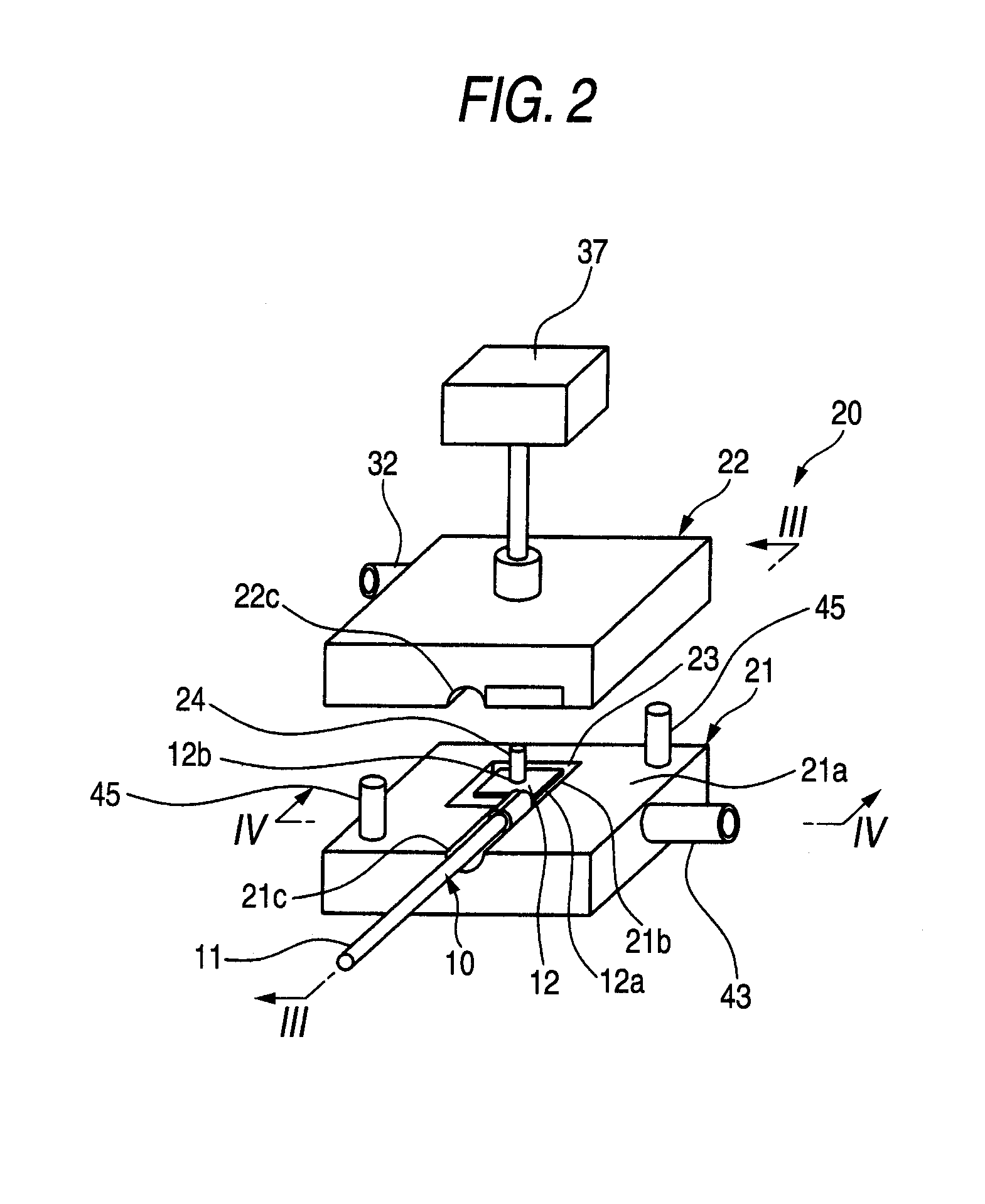

Ultrasound imaging device

ActiveUS20100168575A1Solve the lack of penetrationImprove efficiencyUltrasonic/sonic/infrasonic diagnosticsReconstruction from projectionLower limitUltrasound imaging

An ultrasound imaging device, which can extract nonlinear components efficiently and improve the ultrasound penetration, is provided.The receiving means has a given reception band 74, and the lower limit frequency of the reception band 74 is the first frequency f1. The frequency band of the ultrasound wave transmitted by the transmitting means is set as the first frequency f1 or higher and 3 times of the first frequency f1 or lower (f1−3f1). When the ultrasound wave in such band is transmitted, the low-frequency harmonic component 72 of the nonlinear component may have higher frequency than the first frequency f1 and therefore can be received by the receiving means. Also, as most of the high-frequency harmonic components 73 can be generated in the reception band 74, most of the high-frequency harmonic components 73 can be received.

Owner:FUJIFILM HEALTHCARE CORP

Ceramic support capable of supporting catalyst, catalyst-ceramic body and processes for producing same

InactiveUS20060178265A1Improve permeabilityEfficient use ofMetal/metal-oxides/metal-hydroxide catalystsCeramicwareVapor liquidMetal catalyst

A needle-shaped ceramic body having as its base material a cordierite porous body having a high specific surface area and superior thermal shock resistance, and a needle-shaped catalyst-ceramic body are provided. The present invention relates to a needle-shaped ceramic body having as its base material a needle-shaped cordierite in which the tips thereof are rounded, a needle-shaped catalyst-ceramic body loaded with a catalyst, and a method of production of a ceramic body in which a portion of a raw material (fluoride) gasified by a reaction between raw materials is grown into a needle like shape on the metal catalyst (Fe), wherein the tips of needle-shaped particles are rounded, using a vapor-liquid-solid (VLS) reaction, in a raw material burning process. A honeycomb structure composed of the needle-shaped ceramic for supporting a catalyst is provided, in which decreases in specific surface area caused by sintering can be inhibited, and it enables early catalyst activation due to the low thermal capacity, and has low pressure loss.

Owner:DENSO CORP +1

Water stopping method, wire harness processed by the method and water stopping apparatus

InactiveUS20080185169A1Solve problemsGood stopping effectConfectioneryInsulated cablesMechanical engineeringCable harness

Owner:YAZAKI CORP

Hems, edges, patches and seams for durable, water repellant woven fabric, and methods for making the same

Edges, hems, patches and seams for woven fabric that has been treated for water repellency, and methods for making the same, are shown and described. In one particular embodiment of the invention, for example, a lapped seam between two pieces of water repellent fabric has an outer material at least partially overlapping an inner material, and a laminate strip positioned between the overlapping portions of the materials. The outer and inner materials, which are both oriented in the same direction, have an exterior layer of woven fabric that has been treated with water repellent and / or stain repellent chemicals, and an inner layer comprising a polymer membrane, such as polyurethane. The laminate strip has a bottom portion in contact with the outer layer of the inner material. The bottom portion has a low melt point, high flow rate adhesive system of one or more layers that penetrates and surrounds the fibers in the woven fiber of the outer layer of the inner piece of material. The laminate strip also has a top layer in contact with the inner layer of the outer piece of material. The top layer of the laminate is a thin, elastic, highly abrasion resistant material with a strong bonding affinity for polyurethane. The layers of the laminate strip bond to the adjacent layers of the overlapped material to create a strong lap seam.

Owner:FOWLER

Acetabular liner extraction device, kit and associated method

ActiveUS7785331B2Solve the lack of penetrationAbility to remove the liner without disabling of the locking mechanismJoint implantsAcetabular cupsAcetabular linerEngineering

An extraction device for removing a liner from an acetabular cup is provided. The extraction device includes a jaw and a handle. The jaw is for cooperation with the liner and including a portion of the jaw for penetrating into the liner. The handle is operably associated with the jaw and is adapted for gripping the extraction device.

Owner:DEPUY PROD INC

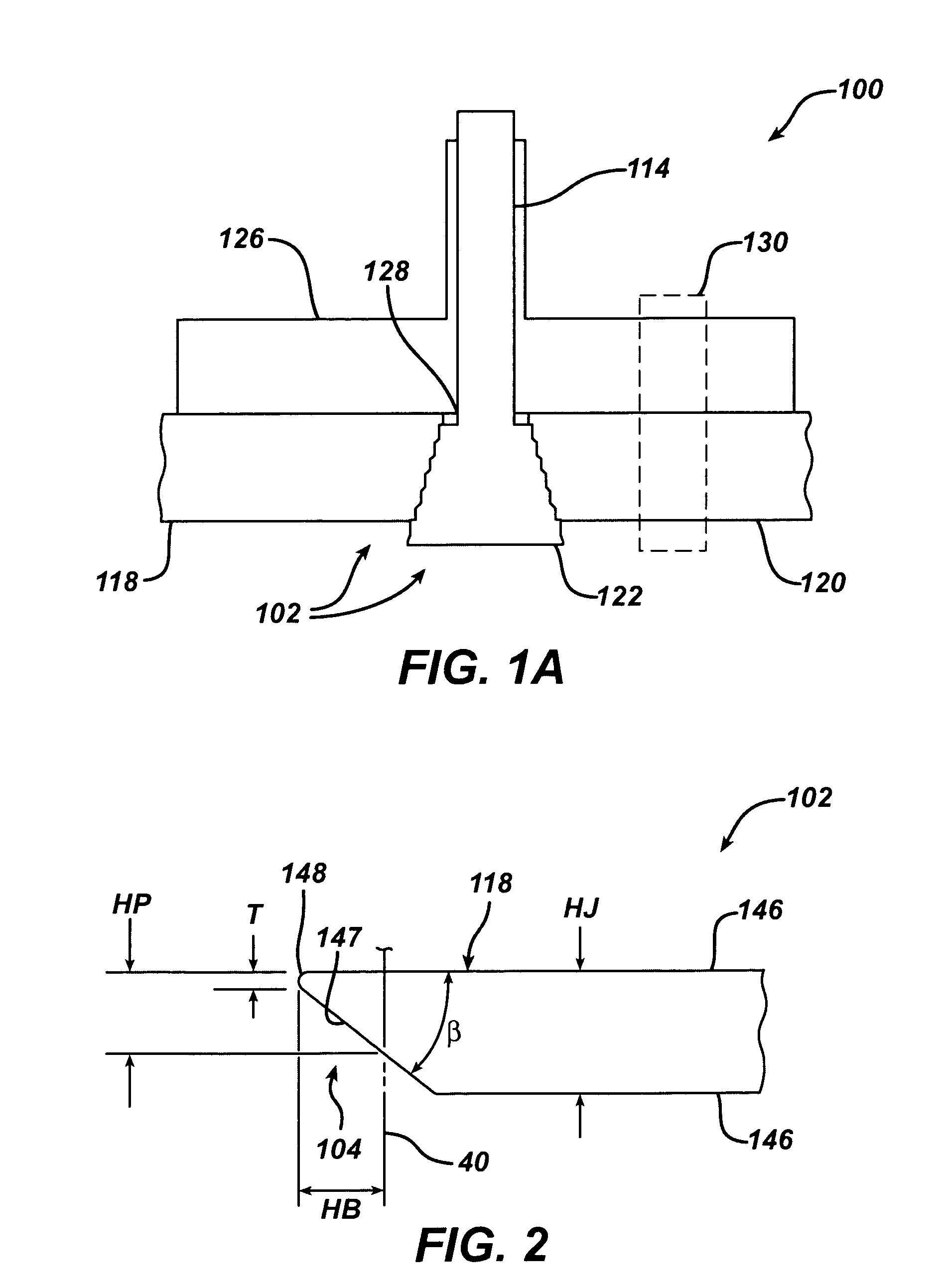

Fuel injection nozzle having multiple injection holes

InactiveUS7201334B2Solve the lack of penetrationCombustion enginesSpray nozzlesMultiple injectionEngineering

A fuel injection nozzle includes: an injection outlet having a plurality of injection holes. Each injection hole has an injection hole diameter defined as D, an outlet port and a center axis. The center axes of the injection holes cross at a cross point with a cross angle. A cross point distance between each outlet port of the injection holes and the cross point is defined as X. The cross angle of the center axes of the injection holes is defined as θ. The cross point distance X is in a range between 10 D and 100 D, and the cross angle θ is in a range between 1° and 10°.

Owner:DENSO CORP

Fuel injection nozzle having multiple injection holes

InactiveUS20070039587A1Solve the lack of penetrationCombustion enginesSpray nozzlesMultiple injectionEngineering

A fuel injection nozzle includes: an injection outlet having a plurality of injection holes. Each injection hole has an injection hole diameter defined as D, an outlet port and a center axis. The center axes of the injection holes cross at a cross point with a cross angle. A cross point distance between each outlet port of the injection holes and the cross point is defined as X. The cross angle of the center axes of the injection holes is defined as θ. The cross point distance X is in a range between 10D and 100D, and the cross angle θ is in a range between 1° and 10°.

Owner:DENSO CORP

Water stopping method, wire harness processed by the water stopping method and water stopping apparatus

InactiveUS7669324B2Good stopping effectSolve the lack of penetrationConfectioneryInsulated cablesEngineeringMechanical engineering

Owner:YAZAKI CORP

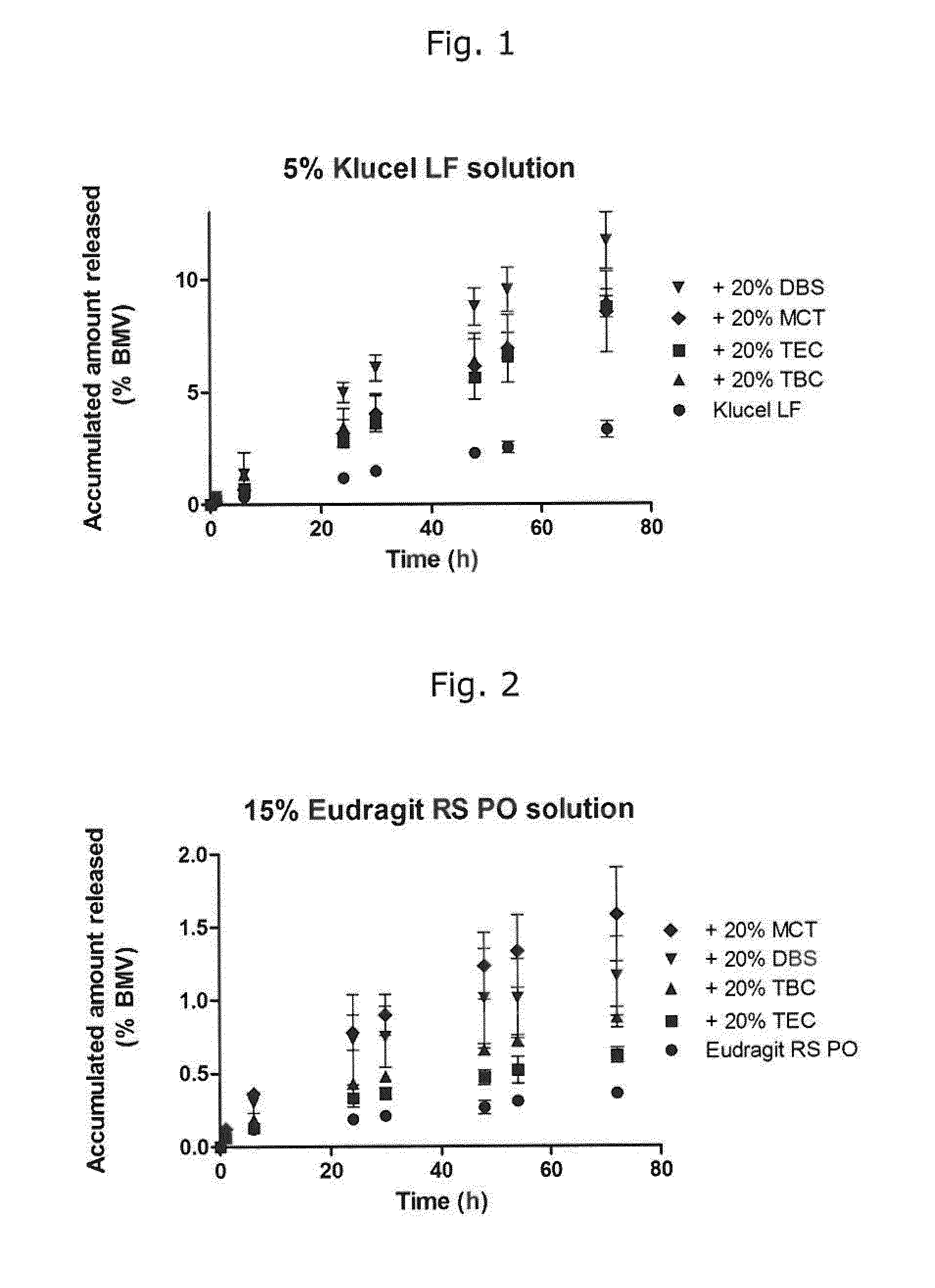

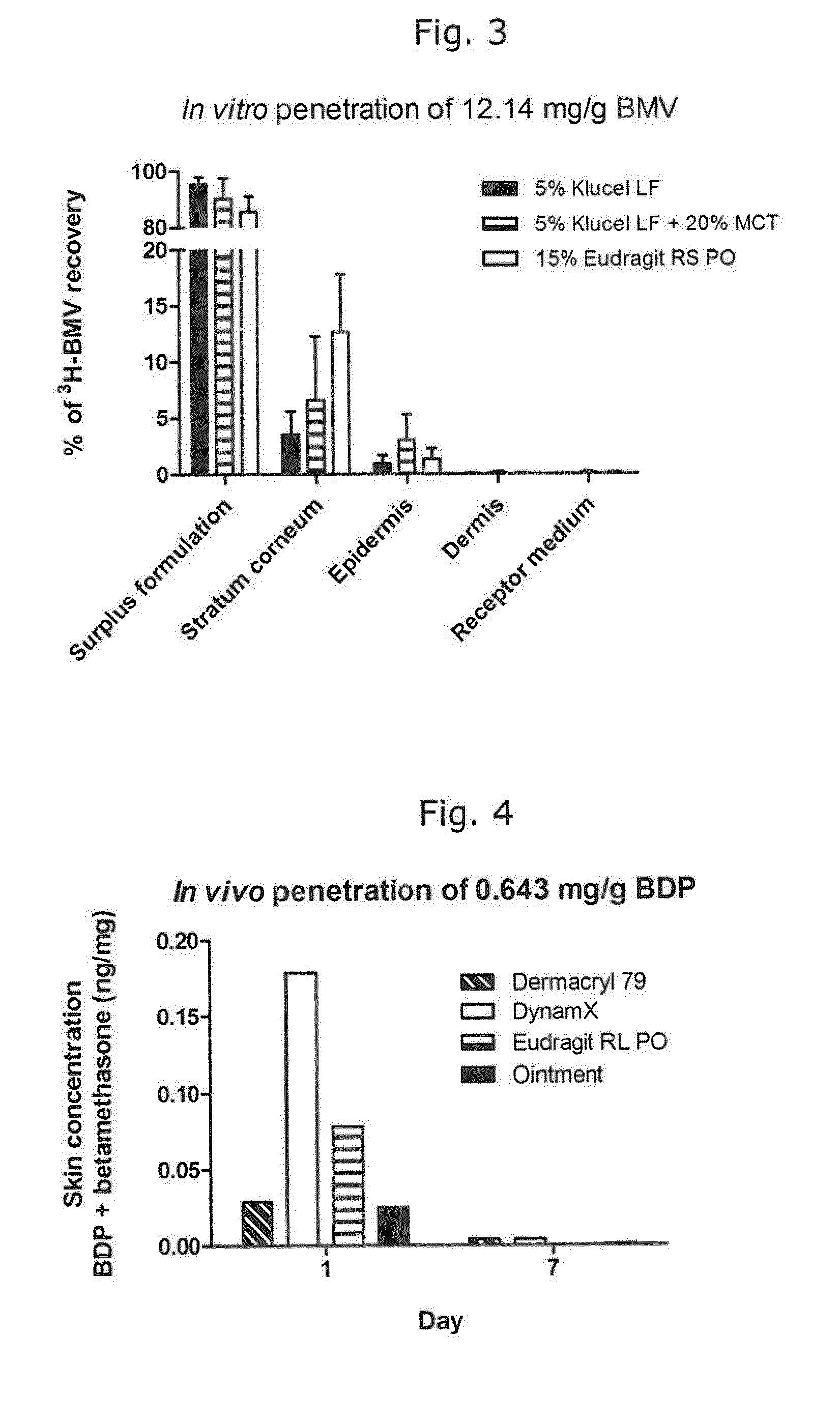

Topical composition comprising a film-forming polymer for delivering an active ingredient to skin

InactiveUS20150157729A1Improve permeabilityFacilitated releaseOrganic active ingredientsAntipyreticAlkaneChemical composition

A sprayable film-forming pharmaceutical composition for dermal application comprises at least one therapeutically active ingredient dissolved in a pharmaceutically acceptable propellant selected from the group consisting of dimethyl ether, diethyl ether and methylethylether, and a mixture of dimethyl ether, diethylether and methylethyl ether, and a second propellant selected from C3-5 alkanes, hydrofluoroalkanes, hydrochloroalkanes, fluoroalkanes and chlorofluoroalkanes, the propellant being present in an amount of 50-99.5% w / w of the composition, the composition further comprising a film-forming polymer, a plasticizer and an oily release-enhancing agent.

Owner:LEO PHARMA AS

Method of limiting permeability of a matrix to limit liquid and gas inflow

ActiveUS20150167269A1Prevent flocculationPrevent early coagulation and setting of surface compositionProtective foundationFoundation repairEngineeringVoids in mineral aggregate

A method of limiting or reducing permeability of a matrix to liquid or gas flow is described. The method includes limiting inflow of water and / or gas into passages such as cavities, fissures, voids and the like, encountered in formations such as geological formations. The method includes steps of measuring one or more parameters relating to the matrix and selecting one or more components of a multi-component sealing composition with reference to the measured parameters. The selected components are introduced into the passage where it is set or coagulated to form a seal. Method is also described whereby the passage is sealed with a sealing composition comprising a grout component and a grout curing agent. A portion of the grout component is mixed with a portion of grout curing agent, the ratio of each being selected with reference to the measured parameters. The combined grout / curing agent are introduced into the passage where rate of curing or setting is controlled by modifying the ratio.

Owner:RELBORGN +1

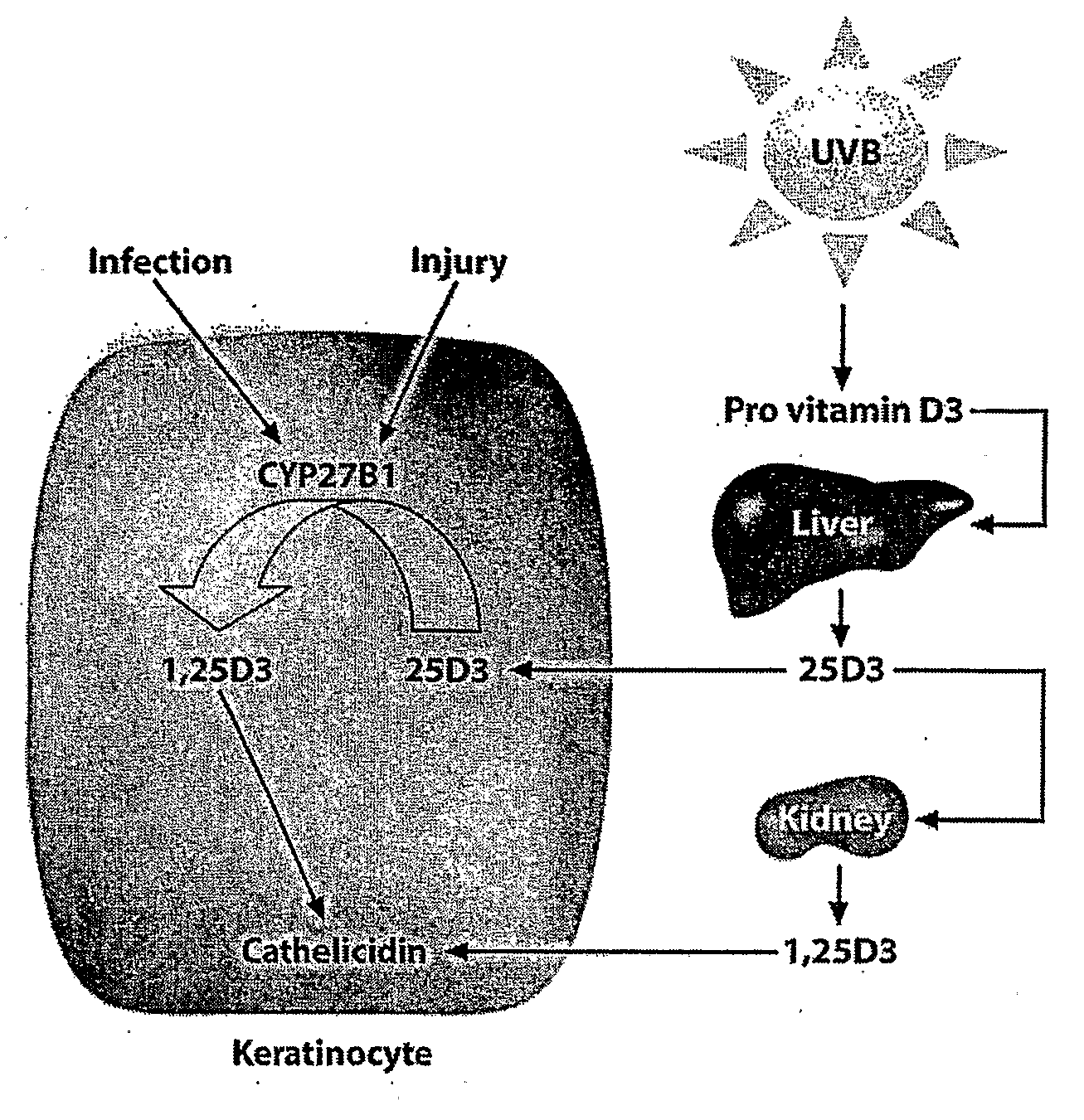

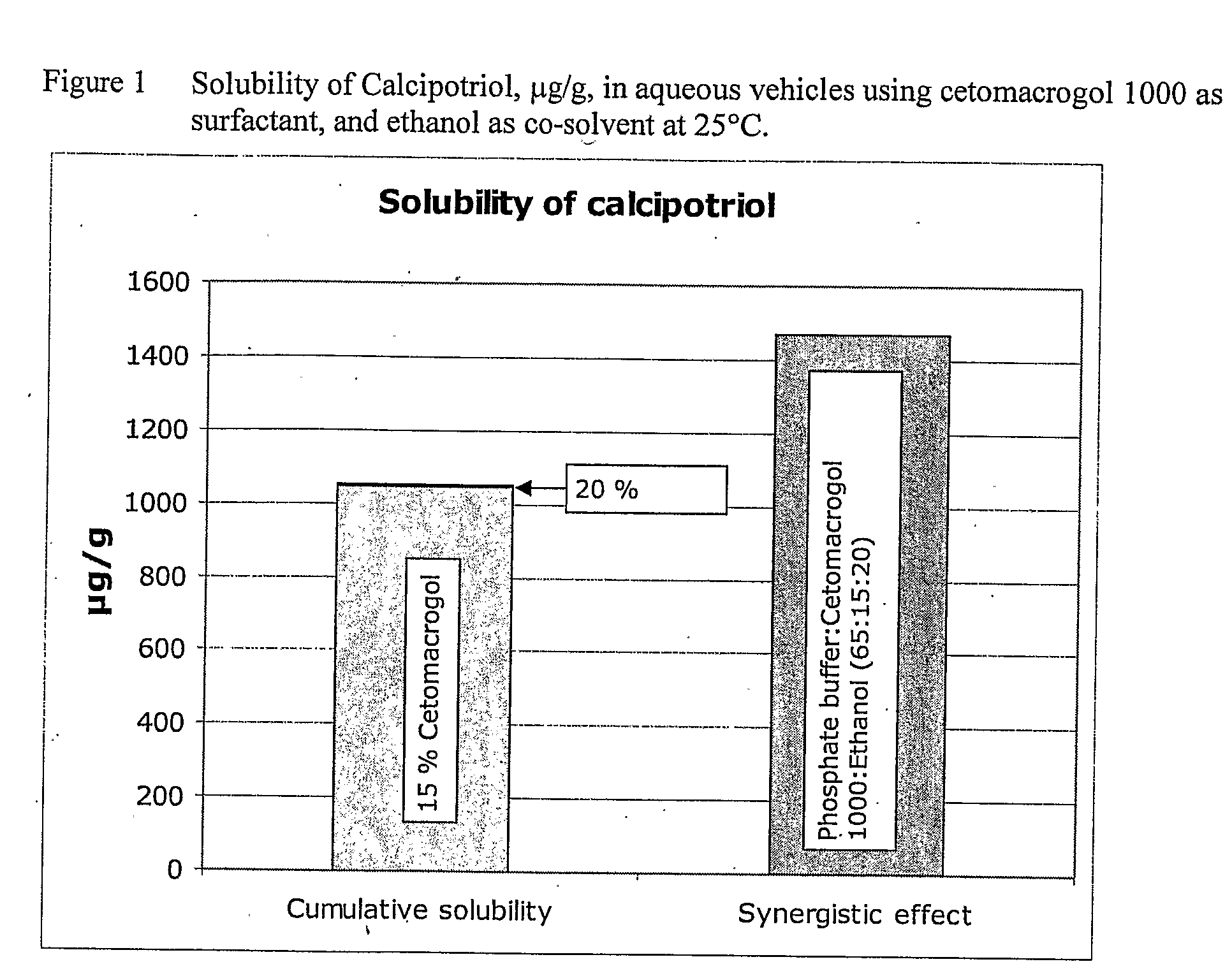

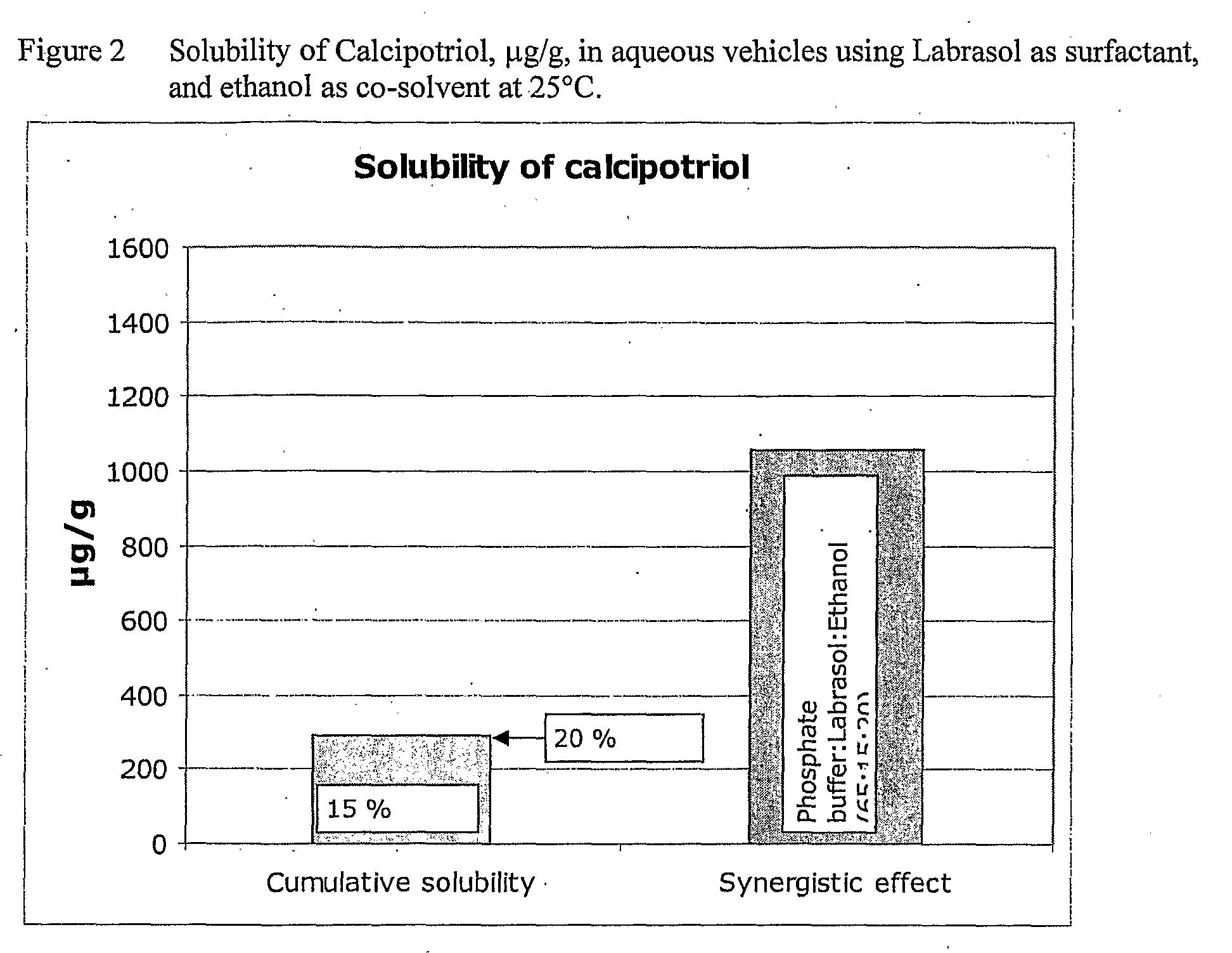

Pharmaceutical composition comprising vitamin d analogue and cosolvent-surfactant mixture

InactiveUS20130005680A1Effective barrierAdministration is quite complicatedOrganic active ingredientsBiocideOil emulsionWater in oil emulsion

A topical pharmaceutical composition which is an oil-in-water-oil emulsion comprising a vitamin D derivative or analogue dissolved in a mixture of a non-ionic surfactant and a lower alkanol. The topical pharmaceutical composition may be used in the treatment of dermal conditions, such as psoriasis.

Owner:LEO PHARMA AS

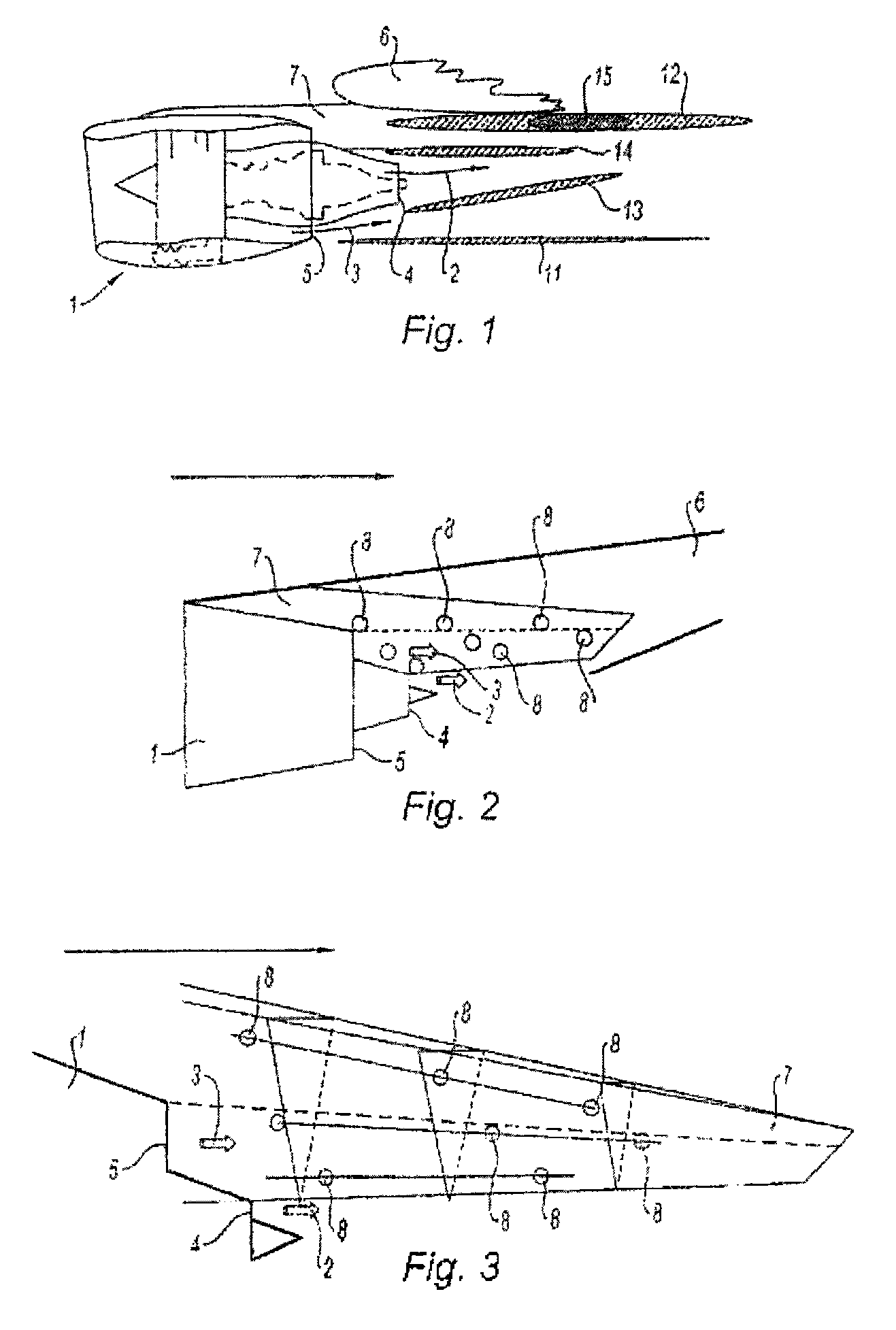

Device for reducing noise from jet-pylon interactions on jet engines

ActiveUS8991749B2Reduce turbulence intensityReduce noisePower plant exhaust arrangementsJet type power plantsJet engineSpray nozzle

An aircraft pylon for mounting a dual-flow or triple-flow jet engine, the pylon including an upper surface for connection to the aircraft, two side flanks, and a flange on the lower portion of the pylon. The pylon further includes at least one portion that extends downstream from the cold flow nozzle of the jet engine and lies in the cold flow and, on the portion thereof extending into the cold flow beyond the nozzle, at least one opening, positioned on one of the flanks of the pylon, by which an air stream is injected into or drawn from the gas flow that flows along the flanks of the pylon.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Hot press cushioning material

InactiveUS20150246498A1Effectively suppress fiber fraying, fluffingSolve the lack of penetrationGlass/slag layered productsWoven fabricsCushioningFiber

A hot press cushioning material includes: a base material layer being in a form of a plate and containing fibers, and a penetrated portion made of a heat resistant elastic material and formed by causing the heat resistant elastic material to penetrate the base material layer inward from the outer end face thereof. The penetration depth of the penetrated portion as a distance from the outer end face of the base material layer is in the range of 0.1 mm to 10.0 mm, both inclusive.

Owner:YAMAUCHI CORP

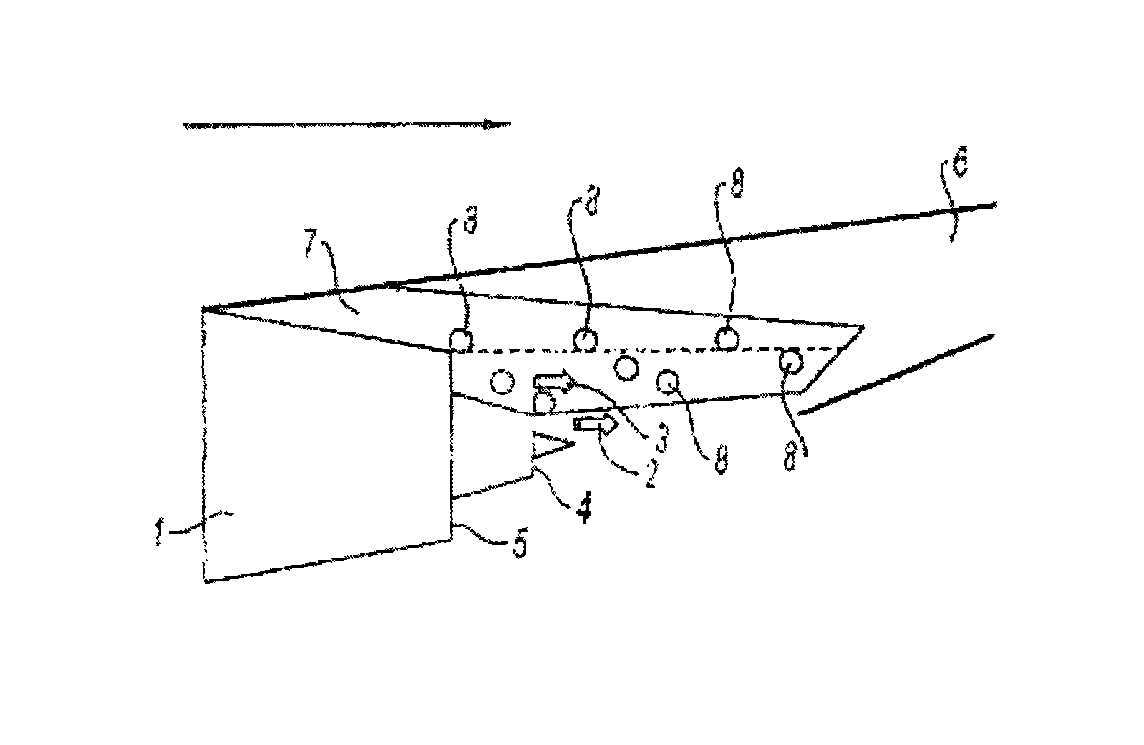

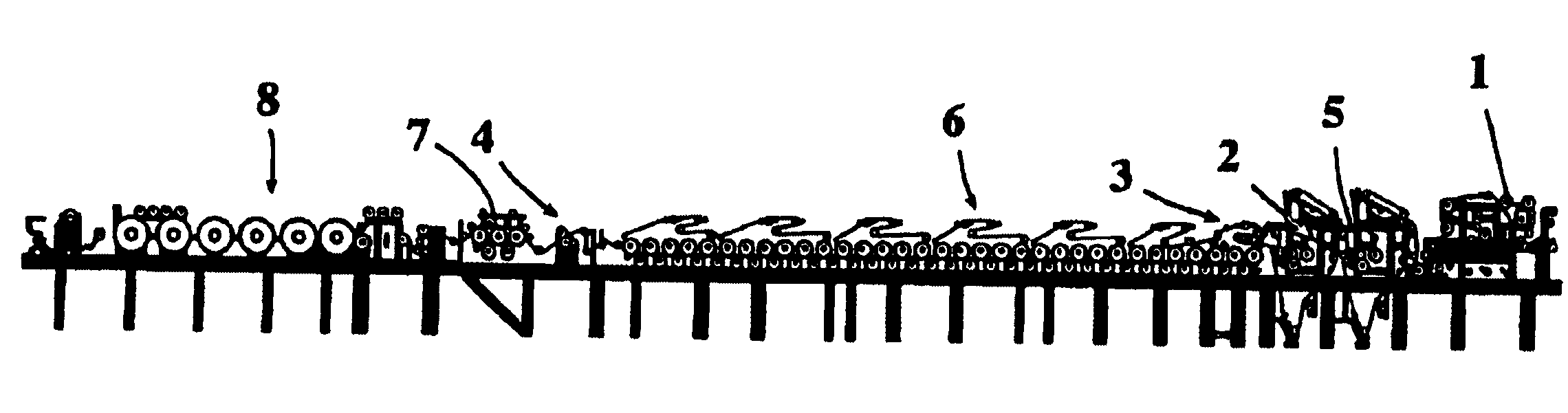

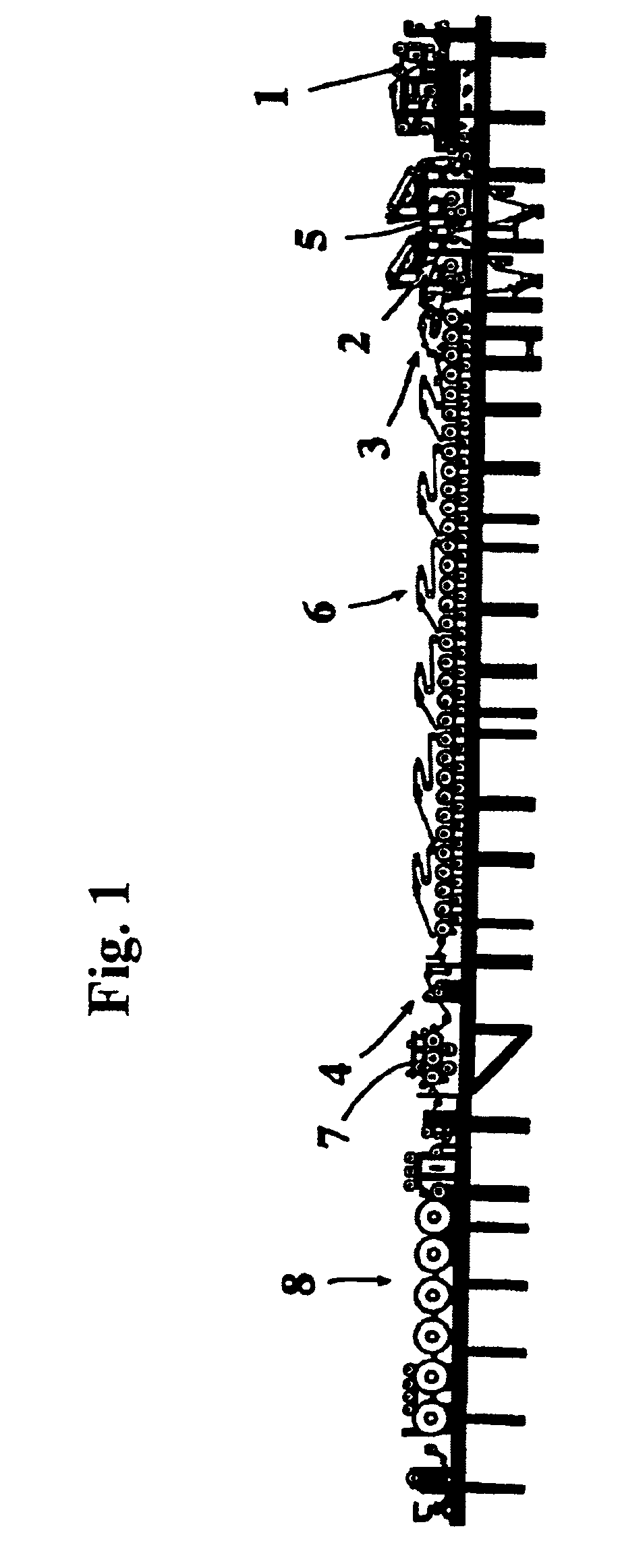

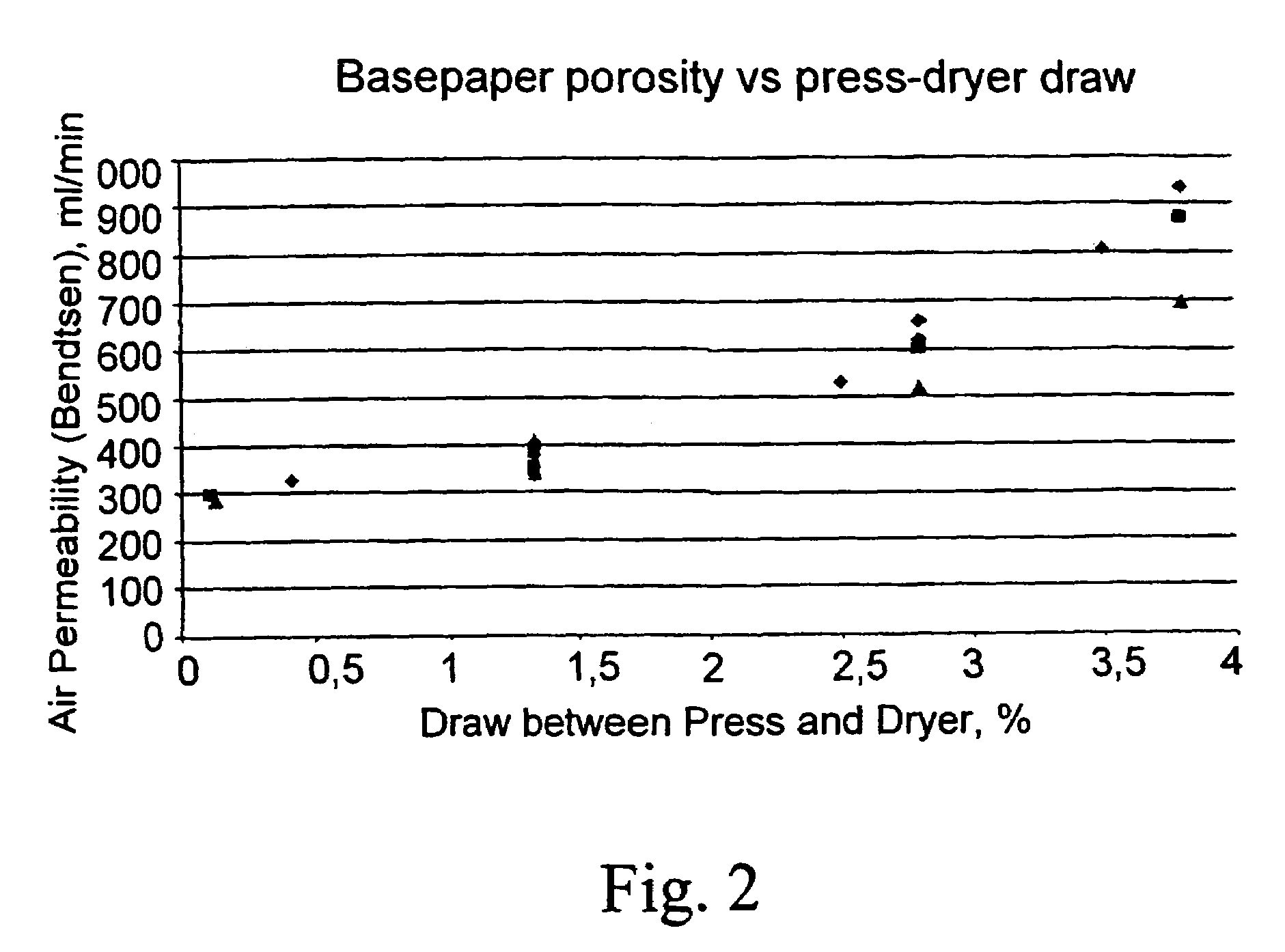

Method and apparatus for producing sized paper of board

InactiveUS7045036B2Significant benefitReduce needNatural cellulose pulp/paperSpecial paperPaper sheetEngineering

A method and assembly is disclosed for manufacturing a sized web of paper or paperboard, the method comprising the steps of first forming the web at a headbox (1) from a stock comprising at least water and fiber, then pressing the web for water drainage, and finally drying the web by heating. Size furnish is added to the web so that at least a portion of the overall amount of size is added to the web prior to initiating the drying of the web by heating, and at least a portion of the overall amount of size is applied to the web after initiating the drying of the web.

Owner:VALMET TECHNOLOGIES INC

Porous valve metal thin film, method for production thereof and thin film capacitor

ActiveUS8300386B2High densityIncrease surface areaLiquid electrolytic capacitorsVacuum evaporation coatingPore diameterNiobium alloy

A porous valve metal thin film, a method for the production thereof, and a thin film capacitor utilizing the thin film as an anode. The porous valve metal thin film has an integral continuous structure that includes the valve metal, an outside surface, and micropores connected to the outside surface. The thin film has a surface area that is at least double a surface area of the outside surface if the outside surface of the thin film were flat. The valve metal is niobium, tantalum, a niobium alloy or a tantalum alloy and has a particle diameter within a range of 10 nm to 1 μm. The micropores have pore diameters within a range of 10 nm to 1 μm.

Owner:SUMITOMO METAL MINING CO LTD

Topical composition comprising an ingenol derivative and a surfactant-cosolvent mixture

InactiveUS20140343141A1Good chemical stabilityImprove stabilityBiocideAnimal repellantsPolyoxyethylene castor oilSucrose

A topical composition for cutaneous application which is a water-in-oil emulsion comprises an oily phase comprising (a) an ingenol derivative in dissolved form; (b) at least one non-ionic surfactant selected from the group consisting of polyoxyl glycerides, polyoxyethylene castor oil derivatives, polyoxyethylene alkyl ethers, polysorbates, or a mixture of acrylamide acryloyldimethyl taurate copolymer, isohexadecane and polysorbate 80, sterols, fatty alcohols, fatty acid phosphonates, mono- or diglycol esters, mono- di- or polyglyceryl esters, mono-, di- or plyglucose esters, sucrose esters or sorbitan esters, the non-ionic surfactant being present in an amount of from about 0.5% by weight to about 10% by weight of the composition; (c) a solvent for the ingenol derivative; and an aqueous phase buffered to a pH of 2.6-3.7.

Owner:LEO LAB

Anti-explosion foam spray fire extinguishing system

The invention discloses an anti-explosion foam spray fire extinguishing system. The system comprises a fire pump set, a liquid storage tank, a foam proportional mixer, a liquid supply pipe network, horizontal pipelines, pressure telescopic pipes and water mist nozzles. By adopting a telescopic hidden arrangement mode, the reliability of the fire extinguishing system is remarkably improved. By adopting a multi-stage sealing structure, the pressure telescopic pipes solve the problems of easiness in liquid leakage, misoperation, immobility, small applicable pressure range and the like. The multi-section pressure telescopic pipes are adopted, the water mist nozzles can spray water mist close to a fire object, and the problems that an existing water mist nozzle is short in range, insufficient in penetrating force and prone to being influenced by environment wind and fire plume are solved. The fire extinguishing system disclosed by the invention has explosion-proof, dustproof and high-temperature-resistant functions, is safe, reliable, high in fire extinguishing efficiency, long in spraying time, convenient to install and use, small in influence on a protected object, and suitable for extinguishing a fire of a charged oil-immersed transformer; and the technical problem of fire extinguishing of a large oil-immersed transformer is effectively solved, and the system can be used for transporting the oil-immersed transformer and also newly building the oil-immersed transformer.

Owner:应急管理部天津消防研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com