Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

104results about How to "Reduce turbulence intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

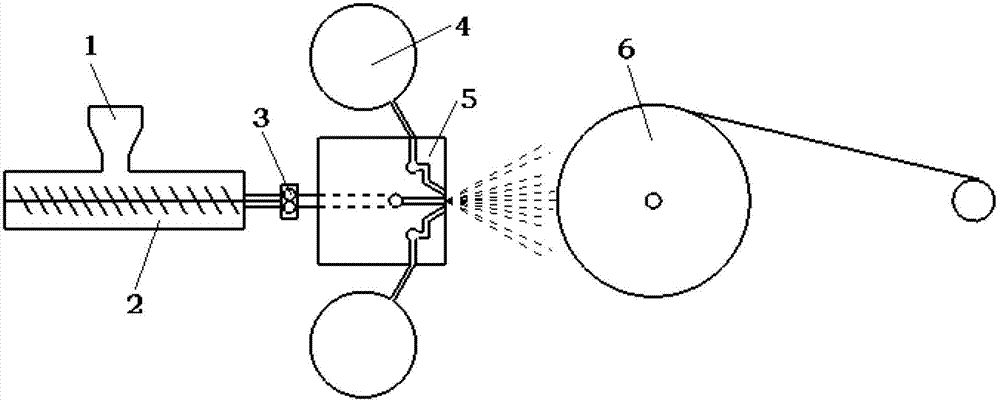

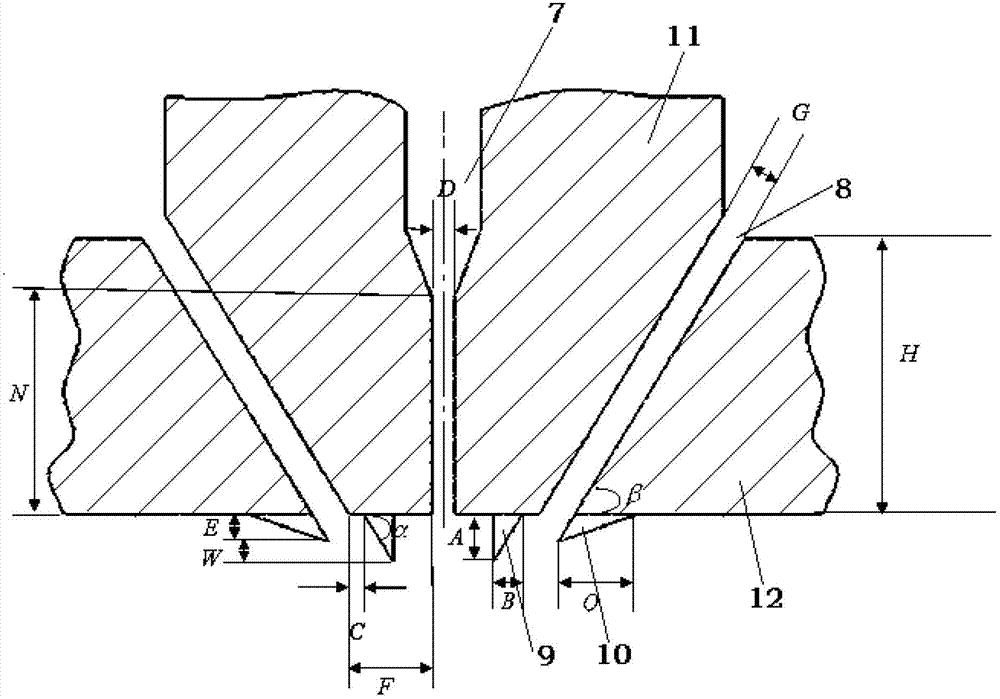

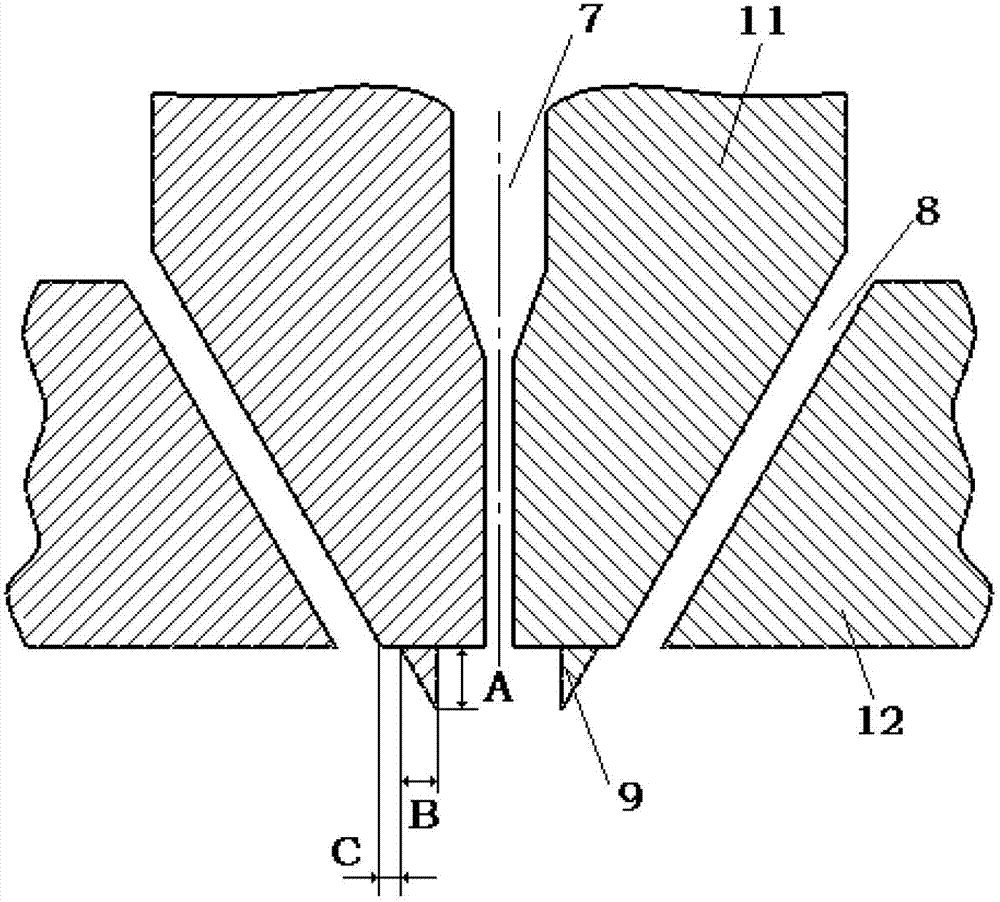

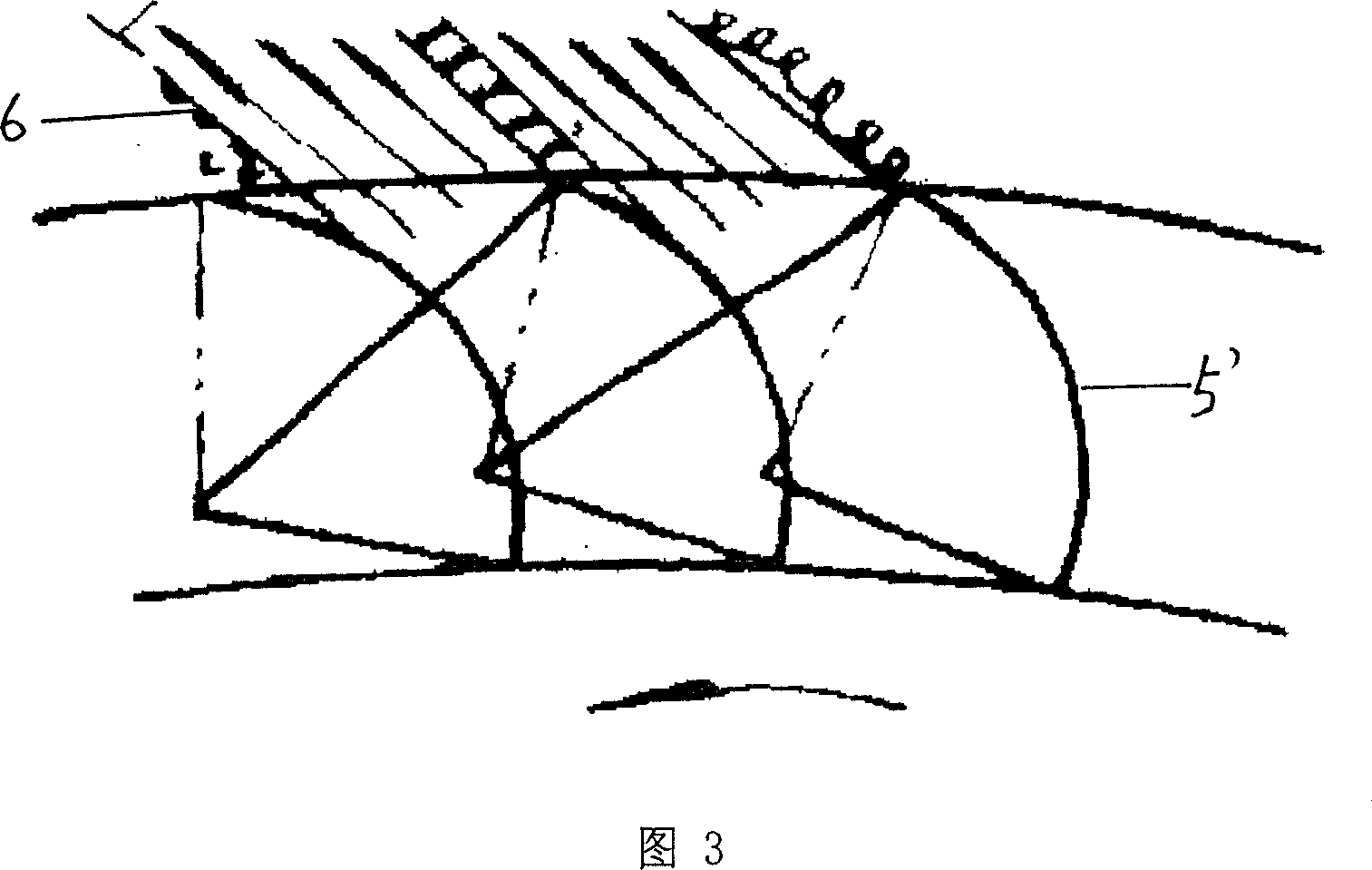

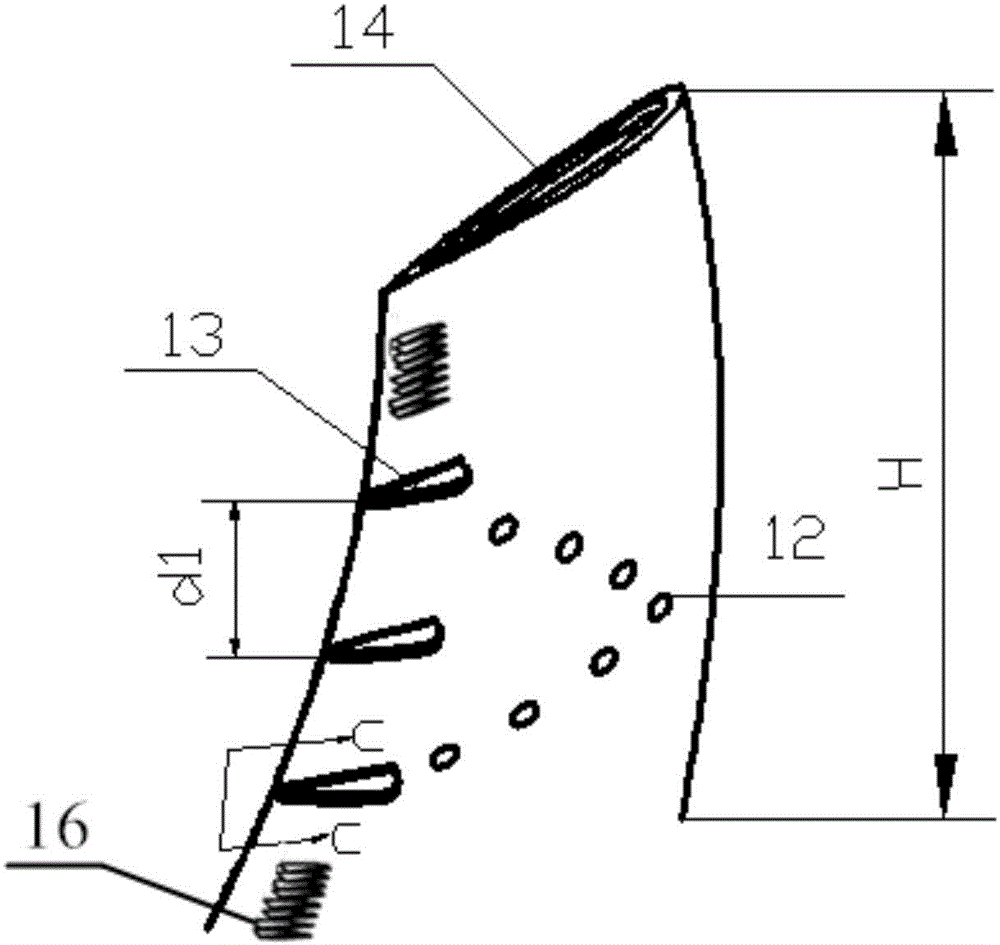

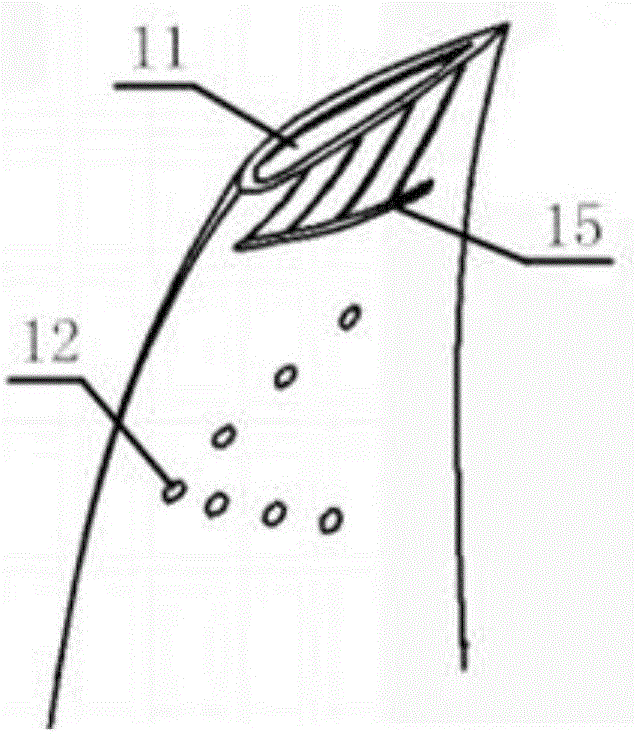

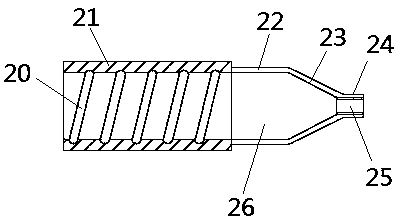

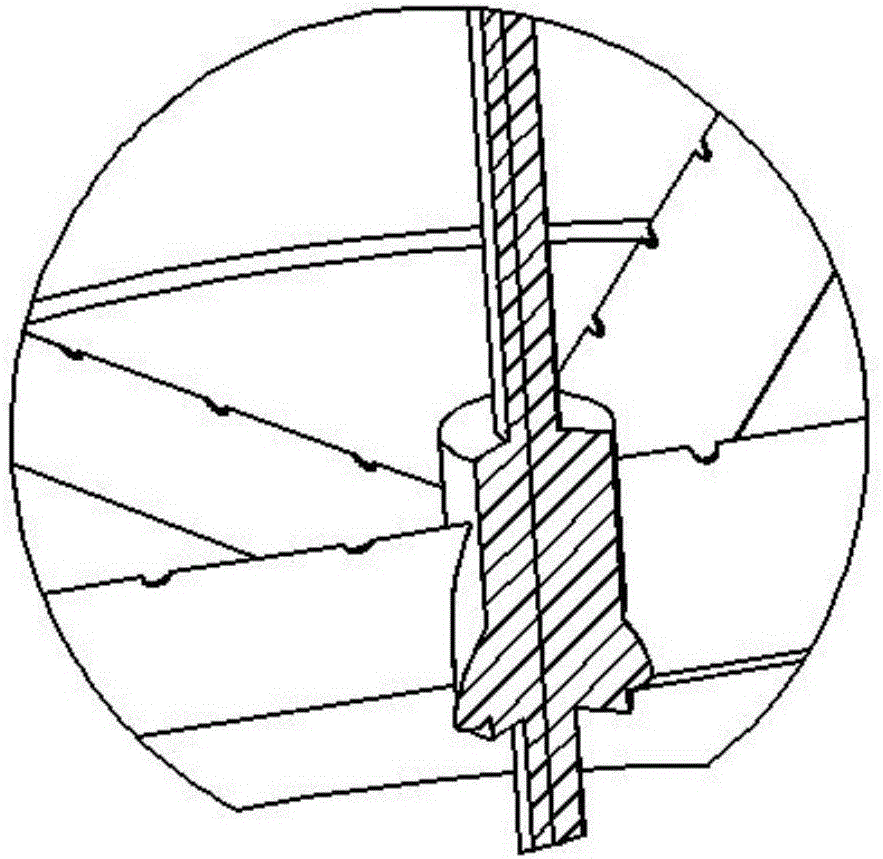

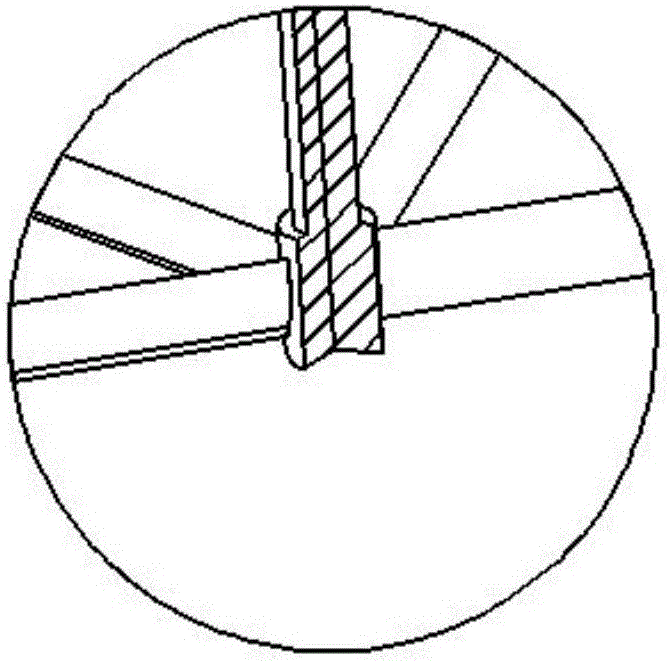

Meltblown mold head for preparing ultrafine fibers

ActiveCN102787374AReduce adverse effectsIncrease air velocitySpinnerette packsRight triangleBreakage rate

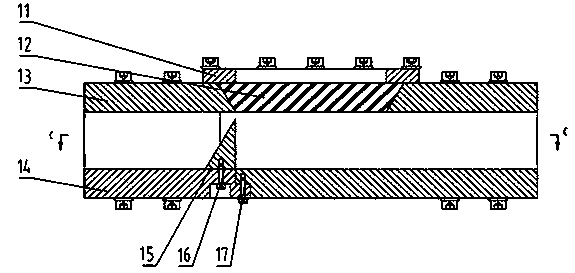

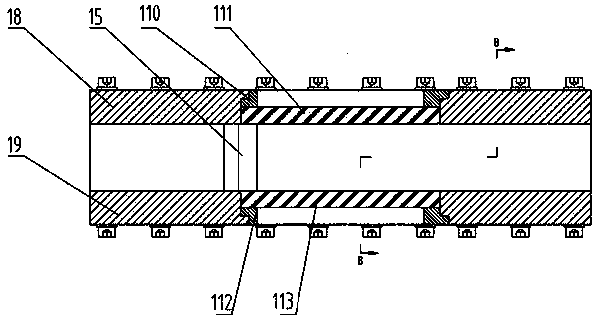

The invention relates to a meltblown mold head for preparing ultrafine fibers. The meltblown mold head comprises a spinning plate and an air plate, wherein the middle of the end surface of the spinning plate is provided with a spinning hole, a plurality of crack grooves are formed between the spinning plate and the air plate, the crack grooves are positioned around the spinning hole, slantwise point to the spinning hole and are in central symmetry on the end surface by the spinning hole as the symmetry center, a separation flow stabilizing element is fixedly connected between the spinning hole arranged on the end surface of the spinning plate and the crack grooves, the cross section of the separation flow stabilizing element is in a right-angled triangle shape, in addition, one edge in two right-angled edges is connected with the end surface of the spinning plate, the other right-angled edge is near a spraying opening, the inclination degrees of the inclined edge of the right-angled cross section of the separation flow stabilizing element and a conical bus of the spinning plate relative to the crack grooves are identical, and meanwhile, the outer sides of the crack grooves are selectively connected with external flow stabilizing elements. The meltblown mold head has the advantages that the reverse backflow region is reduced, the jet flow diffusion to two sides is inhabited, the turbulence intensity is reduced, the fiber end breakage rate is reduced, the melt body is prevented from gluing on the mold head, the air temperature at the nearby part of the mold head is improved, the meltblown nonwoven energy consumption is reduced, and the fiber diameter is further refined.

Owner:安徽深呼吸纺织科技有限公司

Lens electric-bag complex dust collector

InactiveCN101310822AReduce turbulence intensityExtended service lifeCombination devicesDispersed particle filtrationElectric fieldSpecific resistance

The invention relates to a lens-type electric bag composite dust collector which utilizes the characteristics that a lens-type electric dust collector has higher dust collecting efficiency of a dust collecting space than a wire-plate electric dust collector and better adaptability to high specific resistance dust and superfine dust, an electric field of the pre-stage lens-type electric dust collector collects the most of the dust containing the high specific resistance dust and the superfine dust in advance and reduces the high specific resistance dust and the superfine dust in the dust which enters a post-stage bag dust collector to the utmost extent, thus ensuring the gathered dust to have better looseness and permeability, reducing the running resistance and the working load of the post-stage bag dust collector, further reducing the comprehensive cost of the dust collector and prolonging the service life.

Owner:FUJIAN DONGYUAN ENVIRONMENTAL PROTECTION

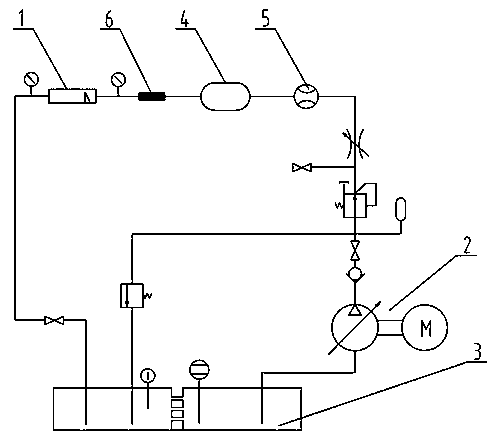

Cavitation and erosion experiment platform based on water circulation system

ActiveCN103472062AEasy to processEasy accessHydrodynamic testingMaterial analysis by optical meansSquare cross sectionWater circulation

The invention discloses a cavitation and erosion experiment platform based on a water circulation system. The cavitation and erosion experiment platform based on the water circulation system comprises a pump station, a water tank and a test section which are connected with one another through water pipes, flanges and the like, wherein the water tank is internally provided with a baffle plate; the test section is a fluid channel which consists of an upper plate, a base plate, a rear plate and a front plate and has a square cross section, and is provided with three observation windows including a front observation window, a rear observation window and an upper observation window, and the base plate is provided with a turbulent flow object. The cavitation and erosion experiment platform provided by the invention has the advantages of simple structure, stable running, continuous adjustable cavitation intensity, adjustable shape of the turbulent flow object, adjustable distance between the turbulent flow object and a test element, simple experiment operation, favorable performance effect of induction and cavitation by the turbulent flow object, easiness in observation on generation areas and dynamic characteristics of a cavitation bubble group close to the turbulent flow object.

Owner:CHINA UNIV OF MINING & TECH

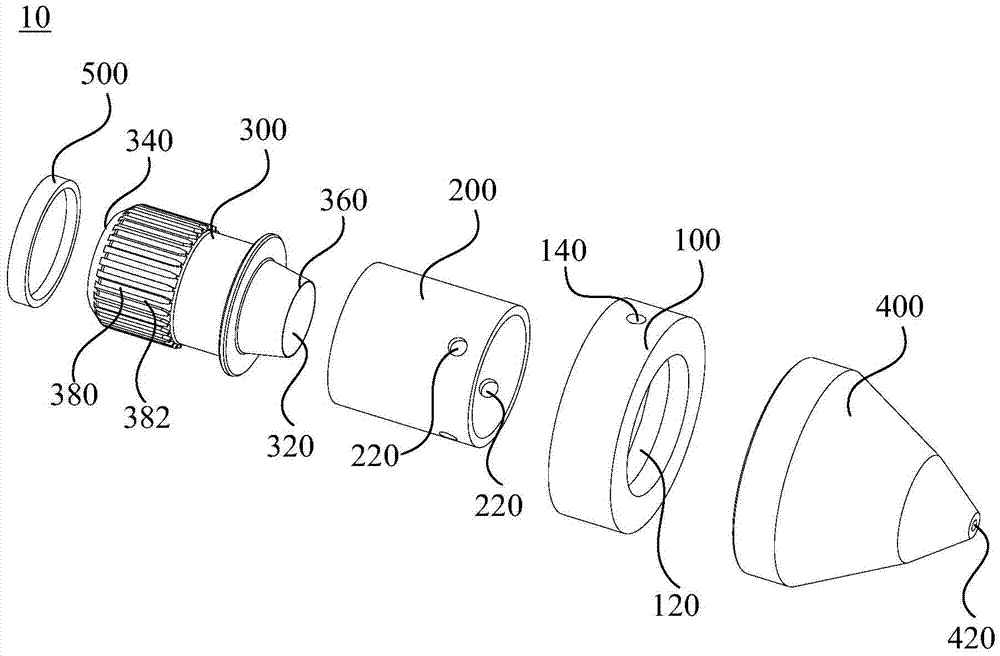

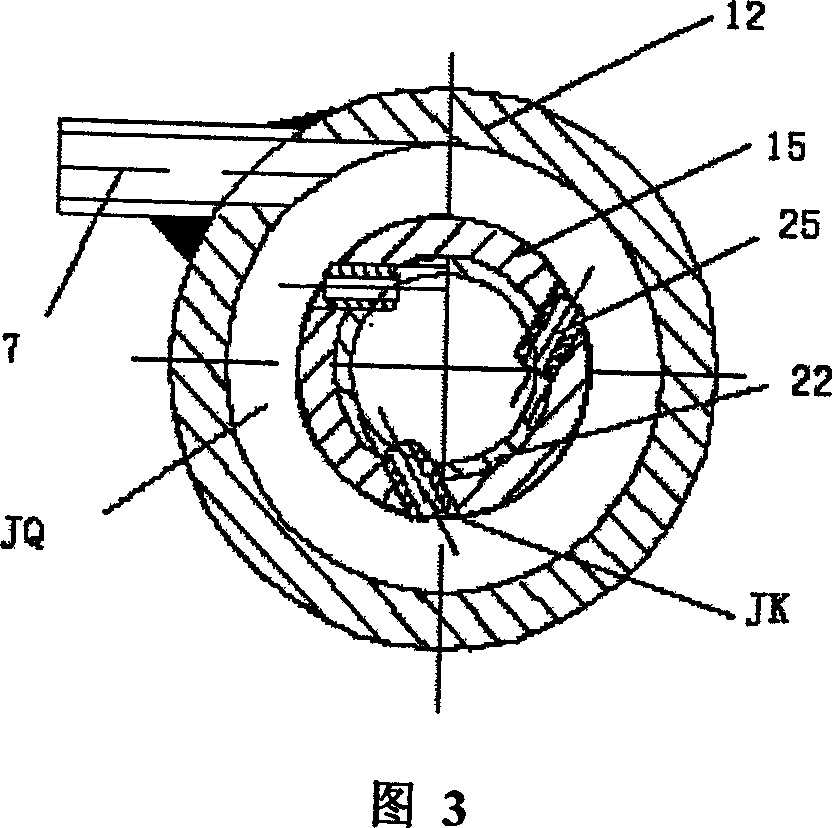

Laser cutting device and laser head thereof

ActiveCN105436720AReduce the impactImprove verticalityLaser beam welding apparatusMachined surfaceEngineering

The invention relates to a laser cutting device and a laser head thereof. The laser head comprises an air inlet ring, a first rectifier tube, a second rectifier tube and an air nozzle. An annular groove is formed in the inner side of the air inlet ring, and air inlet holes communicated to the groove are formed in the outer side of the air inlet ring; ventilation holes are formed in the side wall of the first rectifier tube, the first rectifier tube is sleeved with the air inlet ring, and the ventilation holes are communicated with the groove; an air flow passage is formed inside the second rectifier tube, and the second rectifier tube comprises a first end and a second end which are opposite; the second rectifier tube is sleeved with the first rectifier tube, and a rectifying passage is formed between the first rectifier tube and the second rectifier tube; and an air outlet gap is formed between the first rectifier tube and the first end, and the air flow passage and the rectifying passage are communicated through the air outlet gap. Due to two times of rectifying, the airflow distribution evenness of cutting air can be improved, and the intensity of turbulence can be reduced, so that the influence of the pneumatic optical effect on a laser path is reduced, the stability of the quality of laser beams is guaranteed, the roughness of the machined surface is reduced, and the perpendicularity of cut lines is improved.

Owner:HANS LASER TECH IND GRP CO LTD

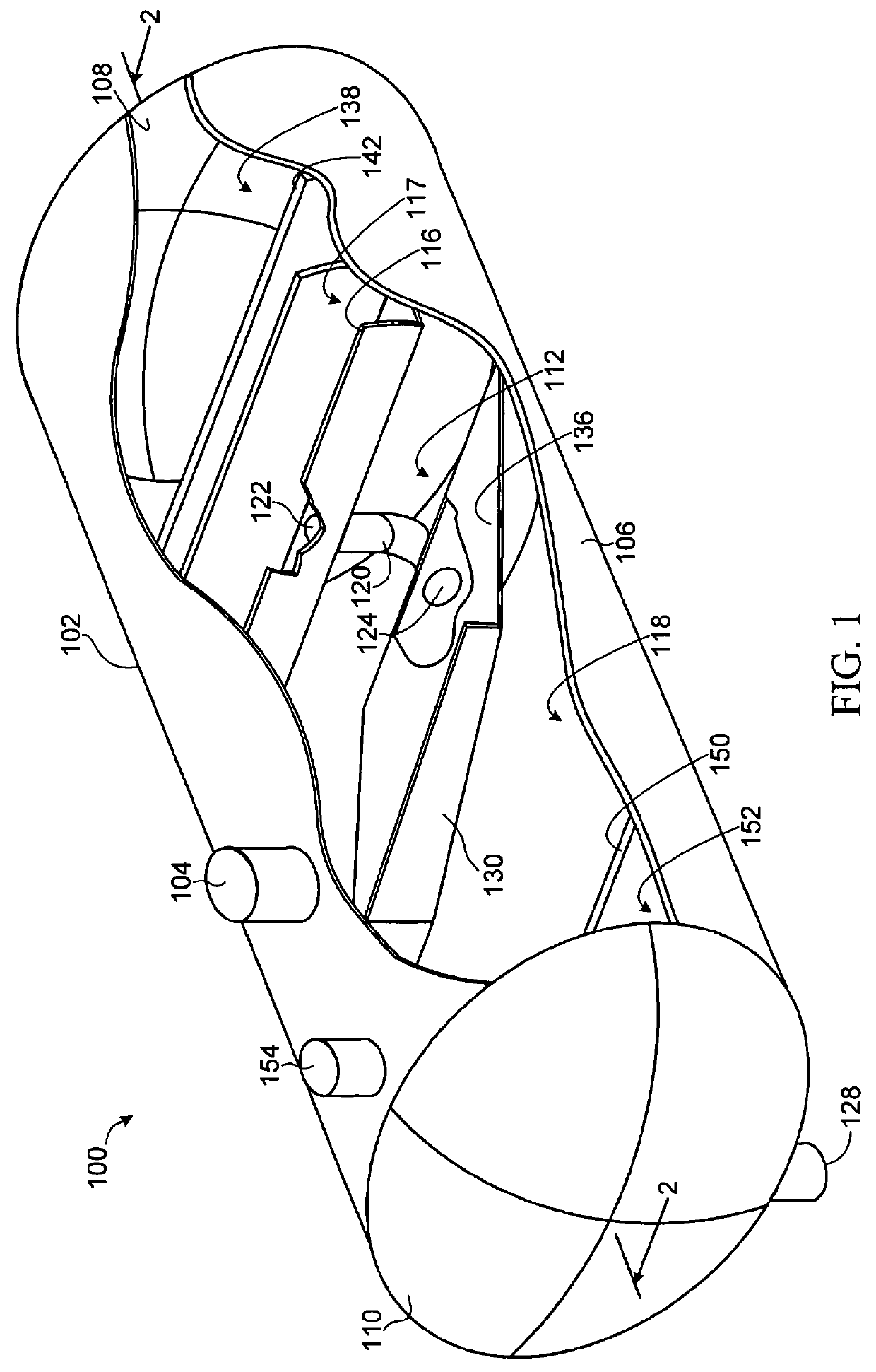

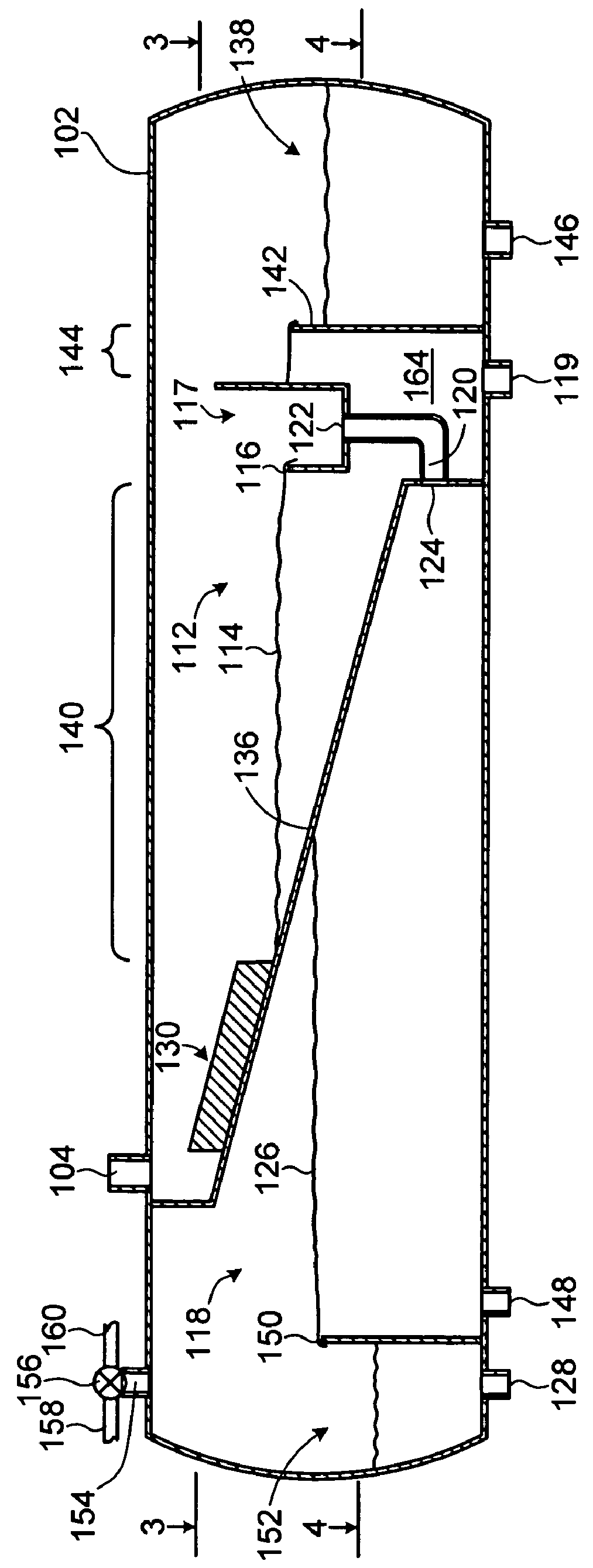

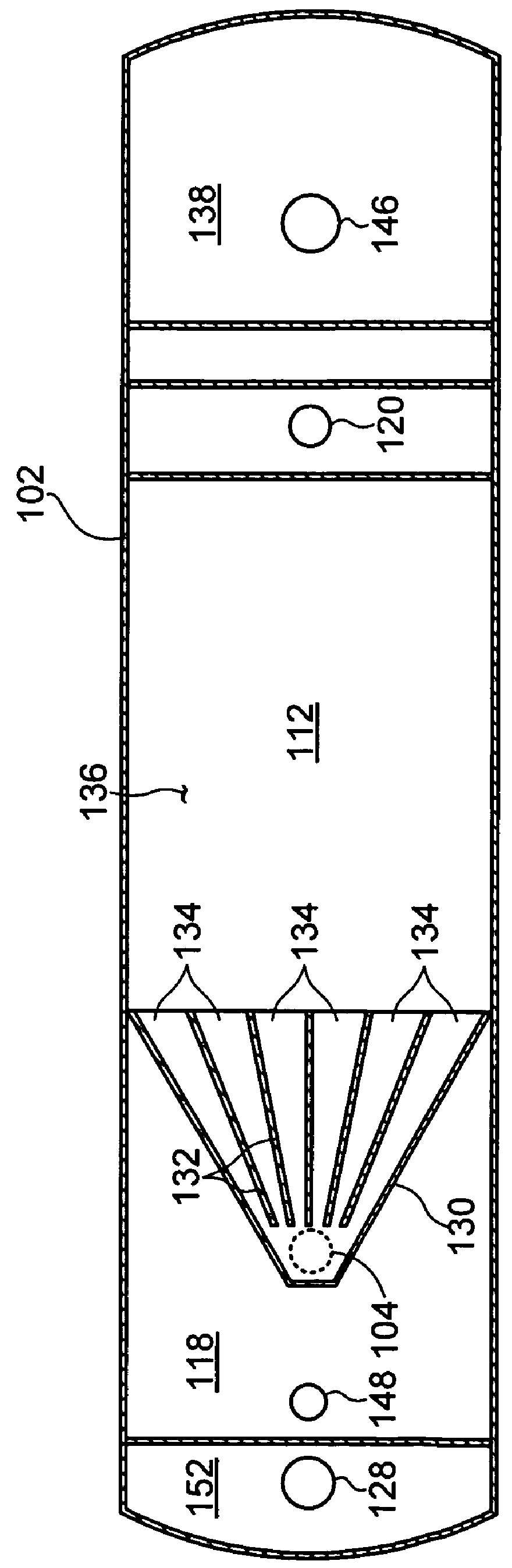

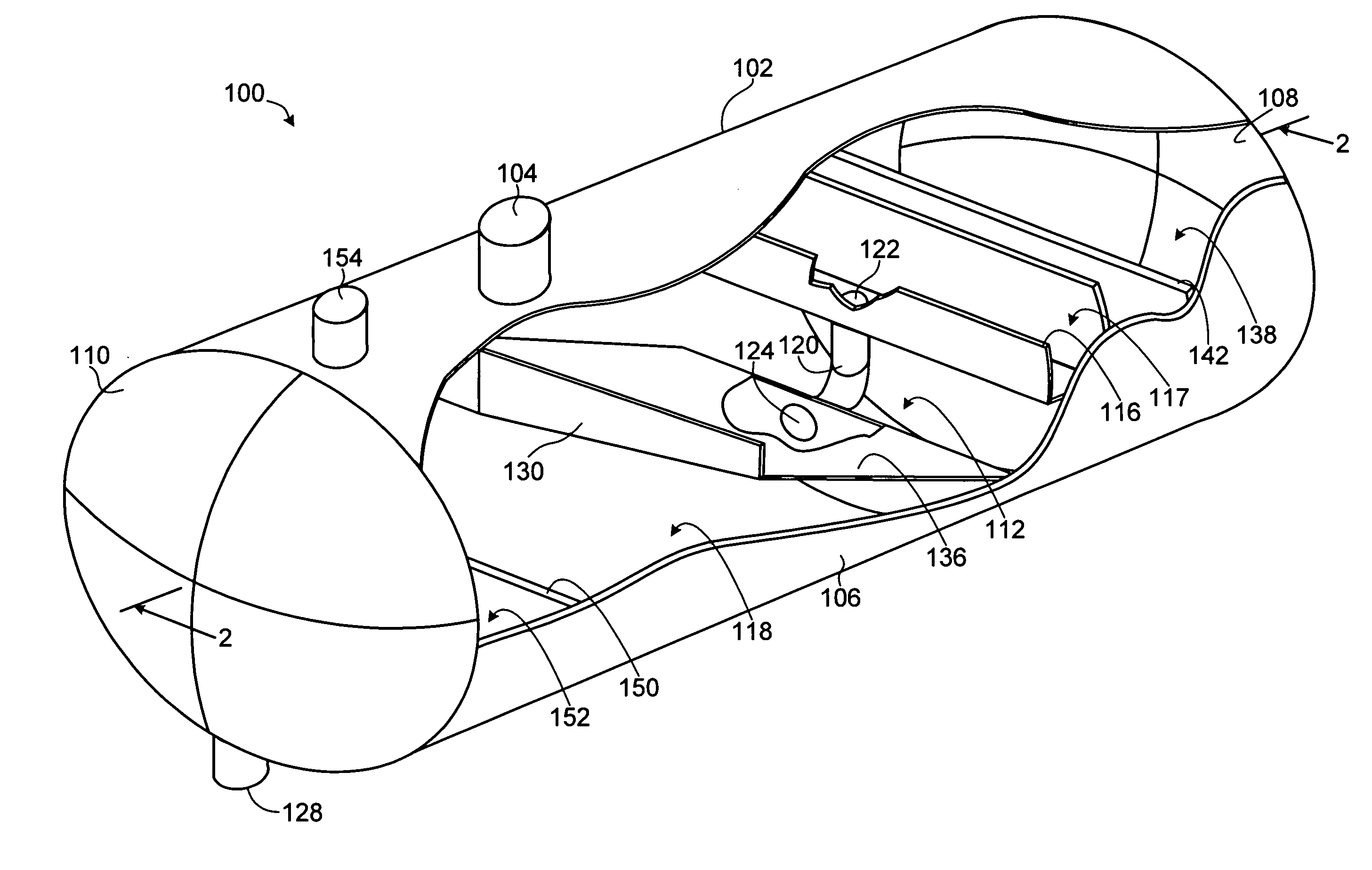

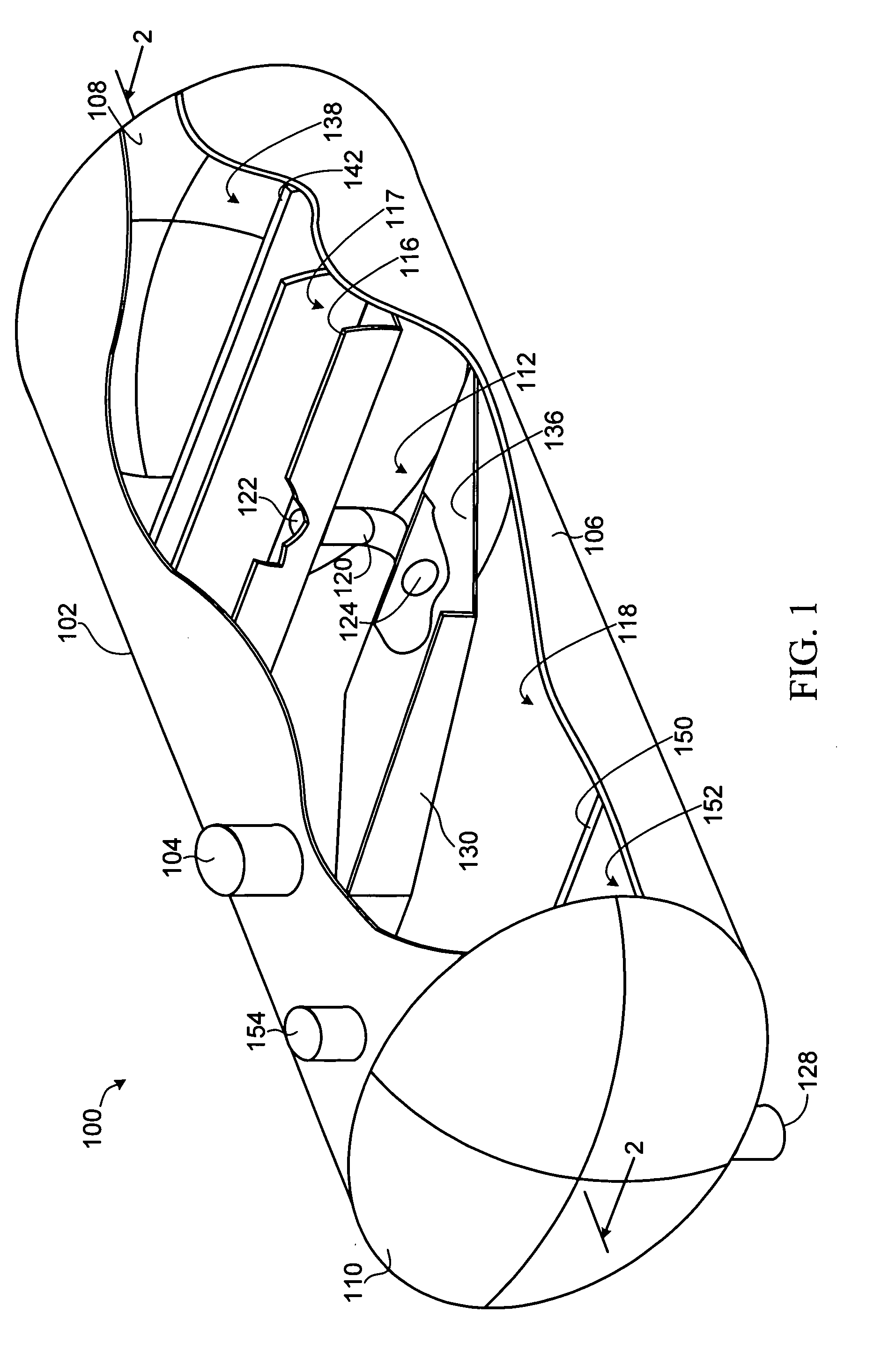

Process and apparatus for treating a heavy hydrocarbon feedstock

ActiveUS8168071B2Reduce turbulence intensityLiquid degasificationHydrocarbon distillationHydrocarbonWaste management

An apparatus and process for treating a heavy hydrocarbon feedstock having a specific gravity differential between components of the feedstock is disclosed. The apparatus includes a treatment vessel having an inlet for receiving the feedstock. The apparatus also includes a primary separation container located in the treatment vessel, the primary separation container being operable to accumulate feedstock to cause a low specific gravity portion of the feedstock to separate and rise to an upper surface of the accumulated feedstock. The apparatus also includes a first weir for collecting the low specific gravity portion from the surface of the accumulated feedstock in the primary separation container. The apparatus further includes a first outlet in the primary separation container, the first outlet being operably configured to receive settling solids in the accumulated feedstock and to produce a first discharge stream at the first outlet. The apparatus also includes a secondary separation container located in the treatment vessel to receive the collected low specific gravity portion, the secondary separation container being operable to accumulate the collected low specific gravity portion to cause hydrocarbon products to separate and rise to an upper surface of the accumulated low specific gravity portion of the feedstock. The apparatus further includes a product outlet for collecting the hydrocarbon products from the upper surface of the accumulated low specific gravity portion to produce a hydrocarbon product stream at the product outlet.

Owner:SUNCOR ENERGY INC

Composite gas drag reducer and preparation method thereof

ActiveCN103450471AGood energy saving effectRaw materials are cheap and easy to getPipeline systemsDibasic acidCarbon chain

The invention claims a composite gas drag reducer and a preparation method thereof. The method comprises the following step of: reacting organic dibasic acid or organic binary acid anhydride, organic amine and monocarboxylic acid with a long carbon chain, thereby obtaining the composite gas drag reducer, wherein the specific steps the reaction are as follows: (1) reacting the organic dibasic acid or organic binary acid anhydride and the organic amine in an inert atmosphere, (2) adding the monocarboxylic acid with the long carbon chain to the reaction system of the finished reaction in the step (1), thereby obtaining the composite gas drag reducer via reaction. The composite gas drag reducer is obvious in drag reduction of the pipeline gas and energy conservation, and has the advantages of cheap and easily available raw material, simplicity in operation, mild reaction conditions, simple processes, low equipment requirements and easiness for industrial production.

Owner:CHINA NAT OFFSHORE OIL CORP +2

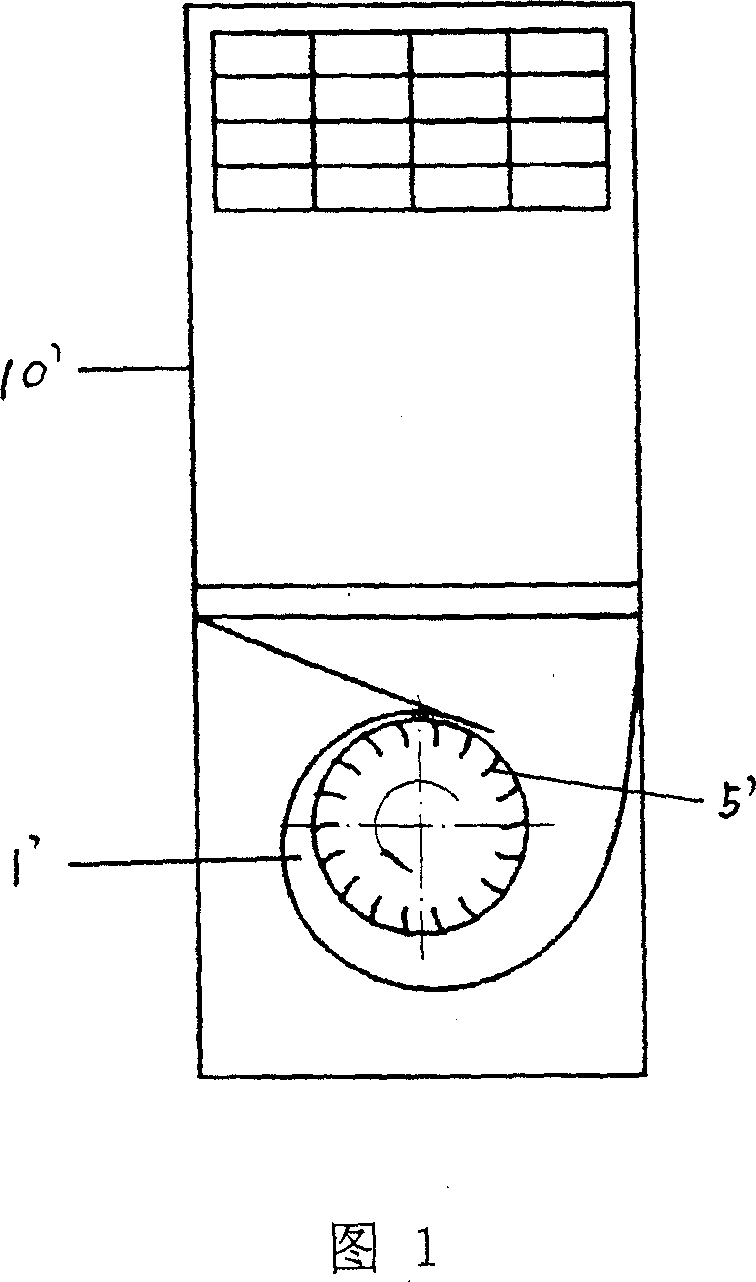

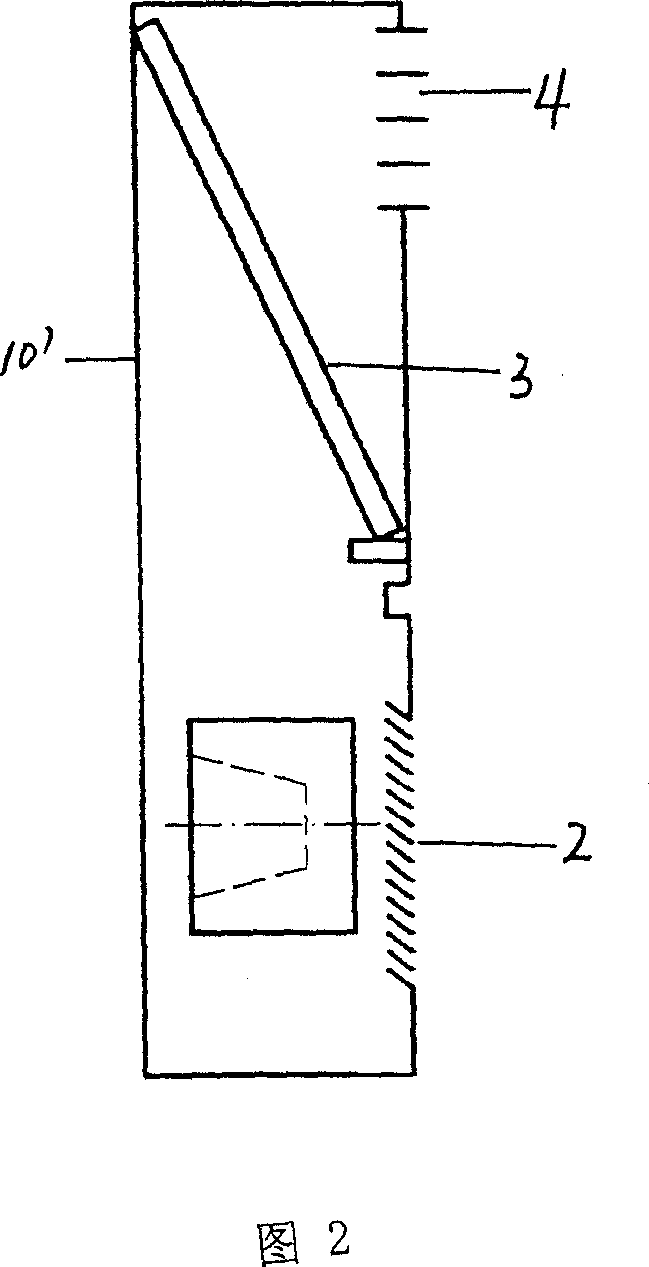

Eccentric fan for indoor cabinet air conditioner

ActiveCN1920309AStable and not easy to separateReduce turbulence intensityRadial flow pumpsNon-positive displacement fluid enginesImpellerEngineering

The invention relates to an eccentric fan of bank air condition indoor machine, wherein it comprises: blade wheels, worm frame with gas inlet chamber, wind channel; said blade wheels are mounted inside the chamber with 8-12 blades; the front gas inlet of gas inlet chamber; said blades have one rectify edge coiled towards to the blade wheel rotation direction at the edge near to the gas inlet of blade wheel; the part of blade near to the outer diameter of blade wheel is lightly bended to the rotation direction of blade wheel; and the part near to the inner diameter is lightly bended to the reversed rotation direction; the gas inlet has metal frame. The invention can restrain the generation of turbulent airflow at the surface of blade and the airflow separation to avoid gas reflux, increase the pressure at the gas outlet, improve the ventilate efficiency and reduce the noise.

Owner:HAIER GRP CORP +1

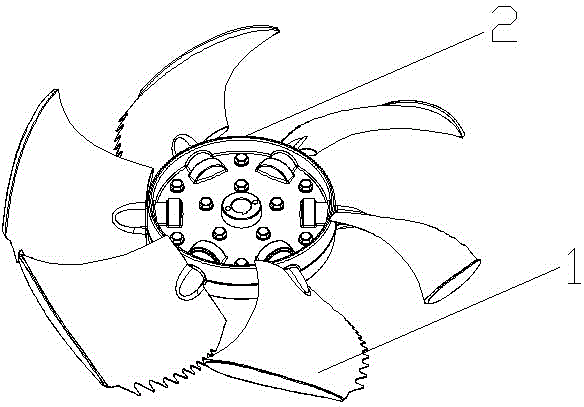

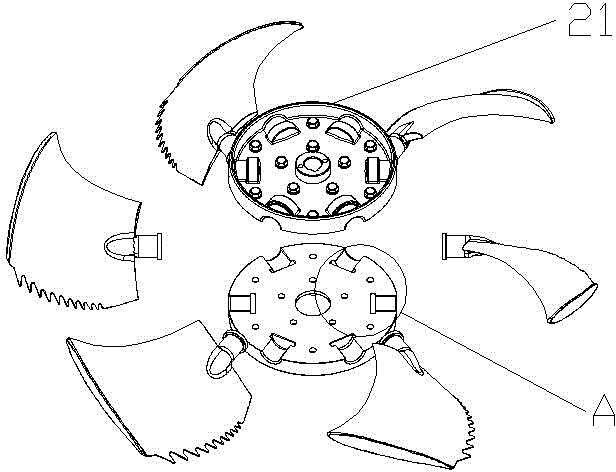

Axial-flow wind wheel

InactiveCN102644623AIncrease working areaImprove work efficiencyPump componentsPumpsSuction forceElectric machinery

The invention relates to an axial-flow wind wheel comprising a hub which is connected with a motor and a plurality of wind wheel blades which are arranged around the hub; each wind wheel blade comprises a wind wheel front edge on a wind inlet side and a wind wheel tail edge on a wind outlet side; and the axial-flow wind wheel is characterized in that through holes are arranged in a wind wheel tail edge area. According to the axial-flow wind wheel, due to the arrangement of through holes in the wind wheel tail edge area, when the wind wheel rotates, as the pressures of a pressure surface and a suction surface of the wind wheel are different, some fluid in a border layer of the pressure surface of the wind wheel passes through the through holes and flows to the tail edge area of the suction surface, the separation of the border layer of the suction surface is delayed, the actual work area of the wind wheel is increased, so that the working efficiency of the wind wheel is effectively improved; and simultaneously, the production and the fall-off of turbulent vortex in the separation area of the border layer of the suction surface are suppressed and damaged, so that the turbulence intensity and the turbulence noise of the border layer are reduced.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

Process and apparatus for treating a heavy hydrocarbon feedstock

ActiveUS20090134095A1Reduce turbulence intensityLiquid degasificationHydrocarbon distillationEngineeringHydrocarbon

An apparatus and process for treating a heavy hydrocarbon feedstock having a specific gravity differential between components of the feedstock is disclosed. The apparatus includes a treatment vessel having an inlet for receiving the feedstock. The apparatus also includes a primary separation container located in the treatment vessel, the primary separation container being operable to accumulate feedstock to cause a low specific gravity portion of the feedstock to separate and rise to an upper surface of the accumulated feedstock. The apparatus also includes a first weir for collecting the low specific gravity portion from the surface of the accumulated feedstock in the primary separation container. The apparatus further includes a first outlet in the primary separation container, the first outlet being operably configured to receive settling solids in the accumulated feedstock and to produce a first discharge stream at the first outlet. The apparatus also includes a secondary separation container located in the treatment vessel to receive the collected low specific gravity portion, the secondary separation container being operable to accumulate the collected low specific gravity portion to cause hydrocarbon products to separate and rise to an upper surface of the accumulated low specific gravity portion of the feedstock. The apparatus further includes a product outlet for collecting the hydrocarbon products from the upper surface of the accumulated low specific gravity portion to produce a hydrocarbon product stream at the product outlet.

Owner:SUNCOR ENERGY INC

Configuration scheme of lens style high voltage electrostatic dust collection electric field

InactiveCN101199951AReduce turbulence intensityReduce lossesExternal electric electrostatic seperatorElectric supply techniquesElectric fieldElectricity

Disclosed is a novel configuration scheme for electric field of a lens style high voltage electrostatic dust collector, which is composed of a negative corona electrode, a positive corona electrode, a lens and a bipolar or an unipolar high voltage power supply for the dust collector; the invention is a novel dust collecting principle derived from the electrostatic dust collecting principle; the electric focusing function of the electric field makes most electric wind to traverse the lens port, limiting the second flow within the dust collecting chamber; thus the turbulence intensity in the fume passage is reduced, and the inevitability of the dust collecting process is improved; the smaller the dust size in the electric field is, the stronger the electric focusing function is received; so electric field has the unique collecting function for the dust; meanwhile, the electric field has a good hydromechanics shielding effect for the dust collected in the dust collecting chamber, and can effectively reduce the reentrainment loss; comparing with the conventional electric field, the dust collecting electric field with this configuration is high in dust collecting efficiency, low in fugitive dust loss, wide in application range, light in structural weight, and has high performance cost ratio and wide application prospect.

Owner:XIAMEN GONGYUAN ENVIRONMENTAL SCI & TECH CO LTD

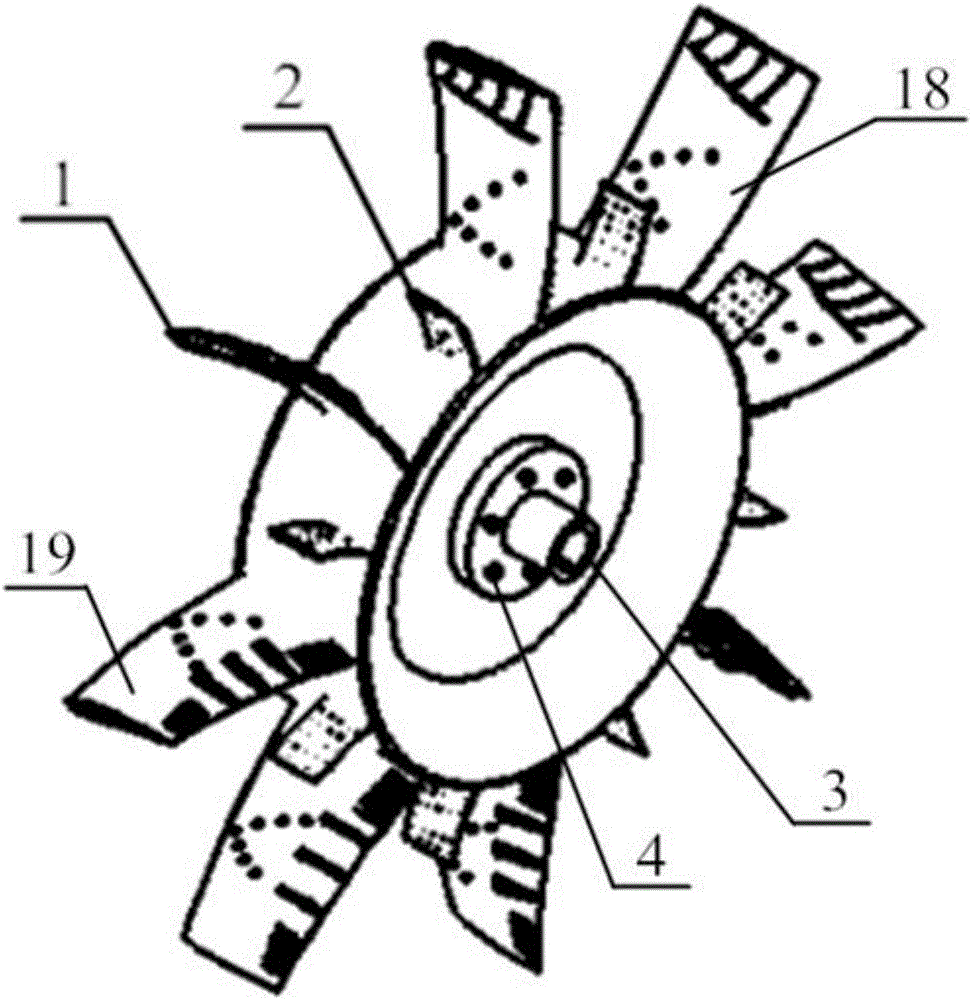

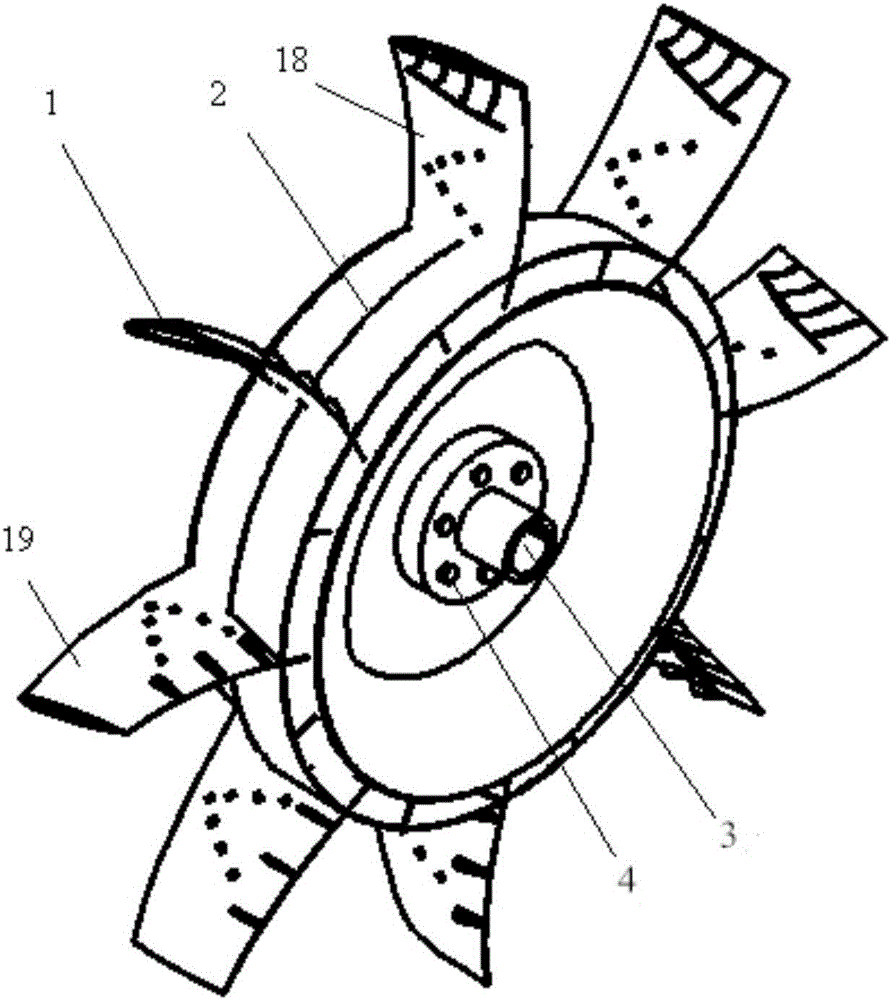

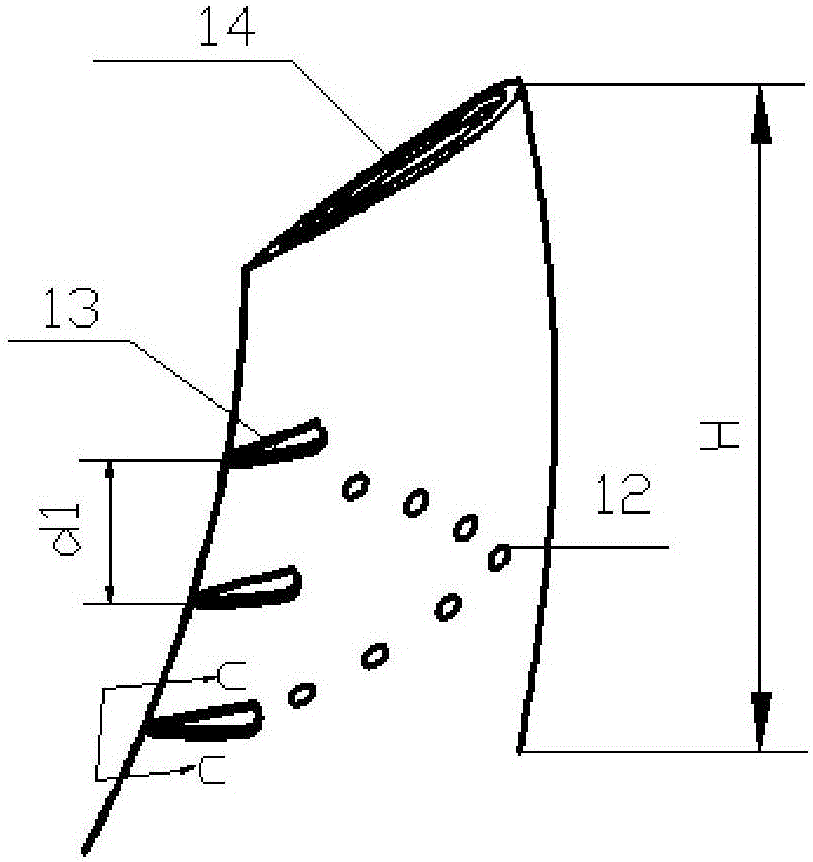

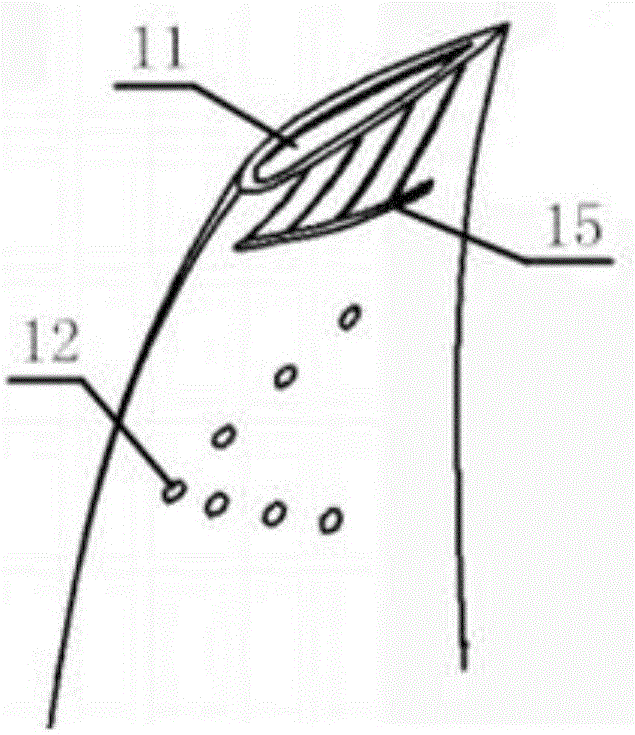

Axial flow fan ternary impeller with vein-shaped structure and nonuniform empennage

The invention discloses an axial flow fan ternary impeller with a vein-shaped structure and a nonuniform empennage. The axial flow fan ternary impeller comprises a hub, and a connecting piece for a shaft sleeve fixed on the hub. The axial flow fan ternary impeller further comprises twisted blades and splitter blades fixedly connected to the hub; the twisted blades include suction surfaces and pressure surfaces; wing-shaped grooves are formed in the tops of the twisted blades; vein-shaped grooves are formed in the upper half parts of the pressure surfaces of the twisted blades; the wing-shaped grooves are communicated with the vein-shaped grooves through exhaust ports; winglet projections and dense winglets are arranged at the tail parts of the suction furnaces of the twisted blades; the dense winglets are arranged on two sides of the winglet projections; parabola small holes are formed in the twisted blades; the splitter blades are arranged between two adjacent twisted blades; and the heights of the splitter blades are smaller than the heights of the twisted blades by one half.

Owner:杭州宏德智能装备科技有限公司

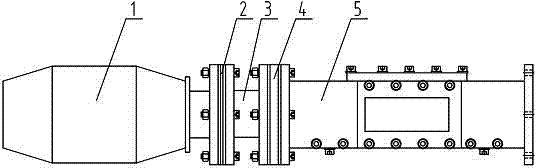

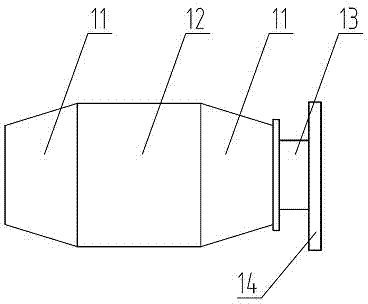

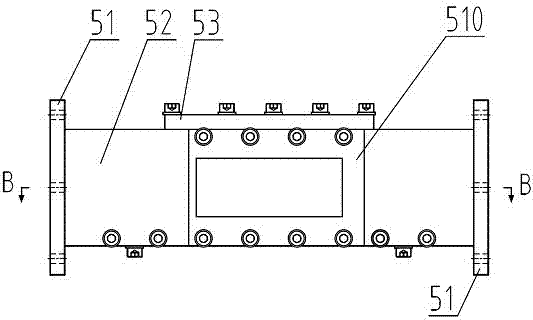

Hydrodynamic cavitation generating device

ActiveCN103611481AImprove stabilityGuaranteed smoothChemical/physical/physico-chemical processesSquare cross sectionCavitation

The invention provides a hydrodynamic cavitation generating device. The hydrodynamic cavitation generating device comprises a buffering body, a rectifying pore plate, a rectifying body, a rectifying grid plate and a testing body which are connected by flanges in sequence, wherein the testing body is a fluid channel which is composed of a shell and a ladder-shaped bottom plate and has a square cross section; three observation windows which are as wide as the fluid channel are opened on front, back and upper sides of the testing body; a bottom plate is split and is provided with a turbulent flow platform. A coming liquid sequentially passes through the buffering body, the rectifying pore plate, the rectifying body and the rectifying grid plate, the turbulence intensity can be reduced and the stability of water flow is enhanced effectively, so that the coming liquid can stably enter the testing body. The hydrodynamic cavitation generating device is simple in structure, convenient to detach, high in structural strength and good in impermeability; a test piece and the turbulent flow platform are convenient to replace; the distance between the test piece and the turbulent flow platform is convenient to adjust; the turbulence intensity is small and the cavitation strength can be adjusted continuously; the cavitation property can be observed directly and easily.

Owner:CHINA UNIV OF MINING & TECH

Blade perforated small axial fan

InactiveCN102635572AImprove aerodynamic performanceAvoid instabilityPump componentsPumpsInstabilityEngineering

The invention discloses a blade perforated small axial fan. Although the existing fan is good, the pulse of upward force of a fan blade is still instable. The fan comprises a case, a motor fixing bracket, a motor, a hub and perforated blades; the perforated blades are arranged on the hub along a circumference direction in equal distance; the hub is connected with the motor through a rotary shaft; the motor is fixed on the motor fixing bracket; the motor fixing bracket is fixed in the case; three rows of round holes are formed in the perforated blades; the numbers of each row of round holes are respectively 4, 3 and 4; the distribution area of the round holes are located in a area with a higher pressure on a pressure surface and a lower pressure on a suction surface of the fan; the first row of round holes is located in front of a separation point; and the value range of the ratio of the diameter D of the each round hole to the distance L between adjacent two round holes is 0.3-0.8. With the adoption of the fan provided by the invention, the vortex separation point of the outlet area can be moved towards down stream; the turbulent intensity can be weakened; and the disadvantages that the pneumatic performance of the fan is poor, the pulse of upward force of the blade is instable, and the pneumatic noise radiation is increased can be improved.

Owner:ZHEJIANG SCI-TECH UNIV

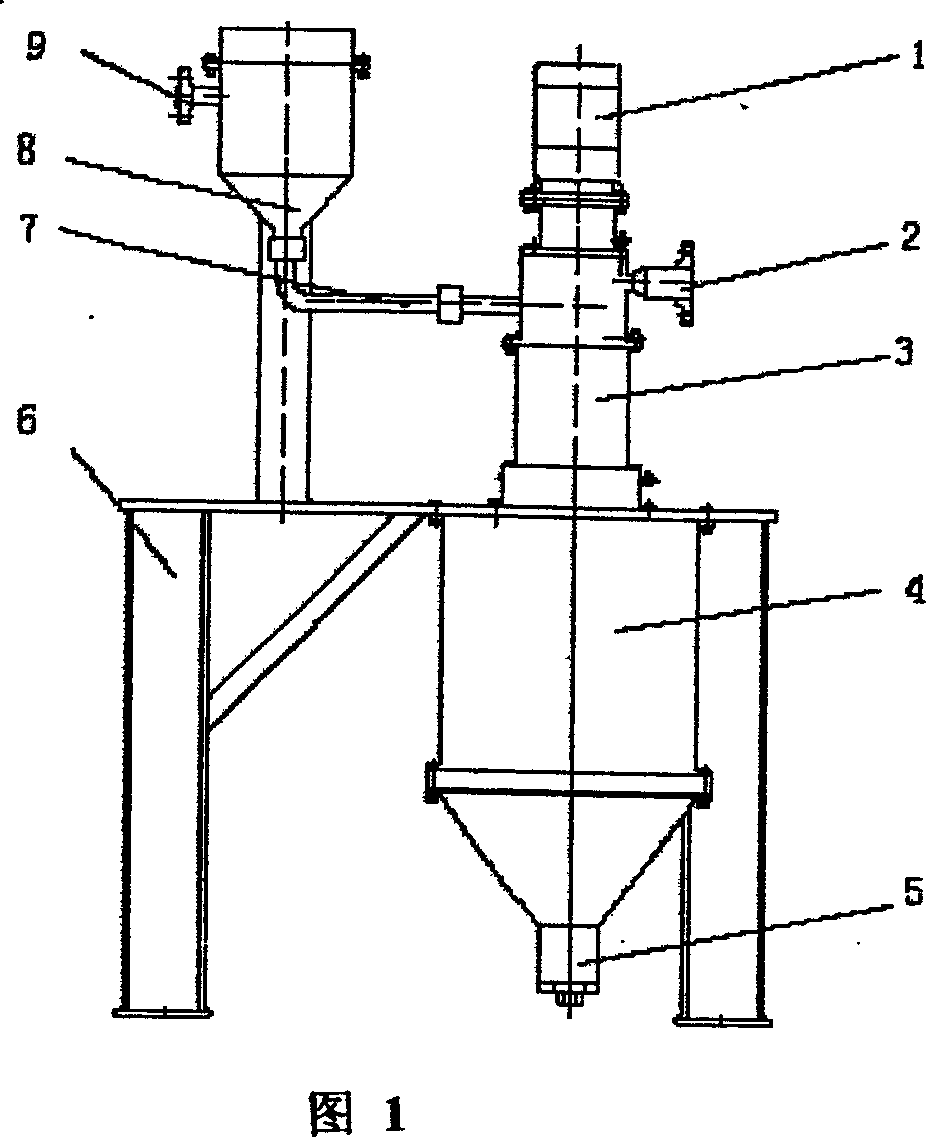

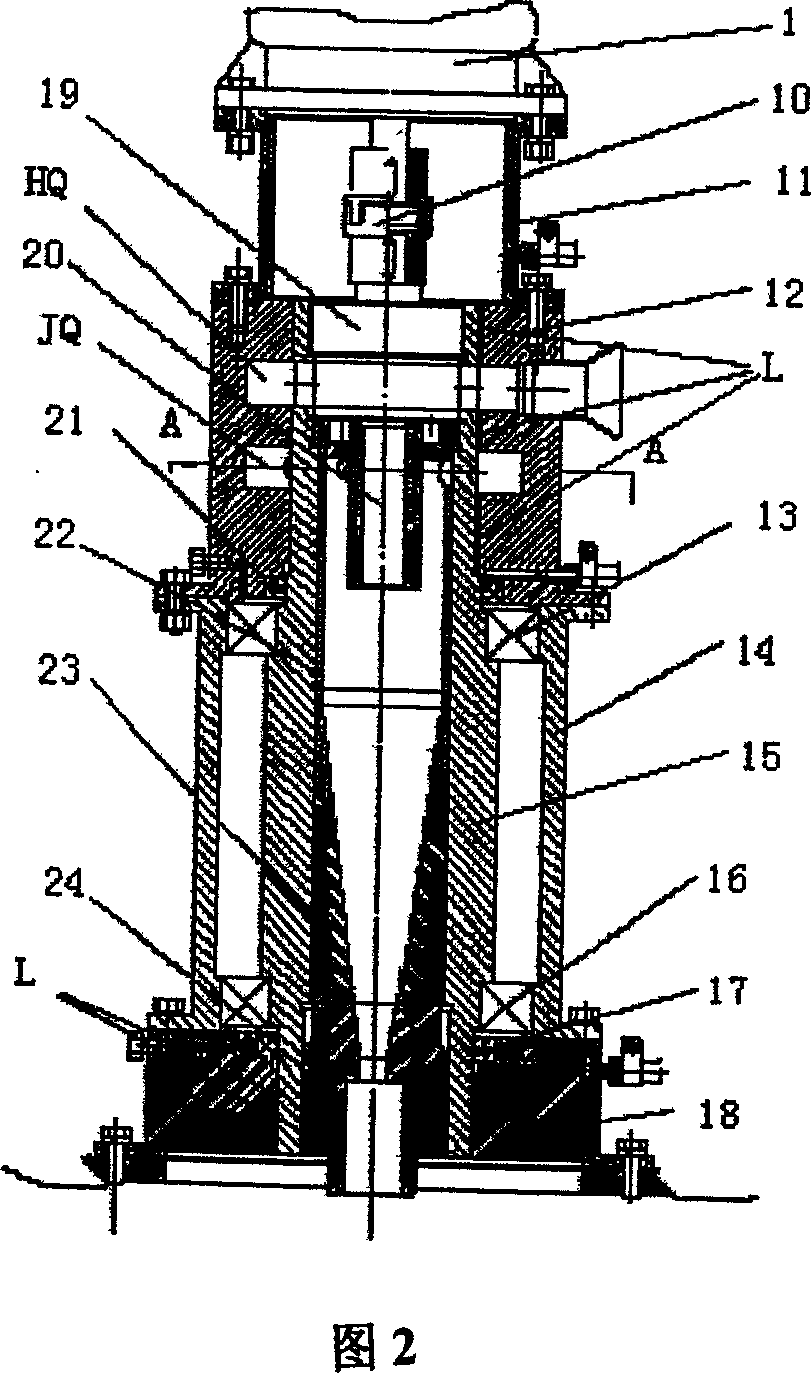

Vertical dynamic cyclone device

InactiveCN101028614AOvercome speedOvercoming attenuationReversed direction vortexCyclonePulp and paper industry

A vertical dynamic cyclone separator for removing sand from thick oil and separating the oil-displacing polymer from the recovered liquid by gravitation and centrifugal is composed of a frequency-variable motor, a vertical cyclone separator with a rotary drum driven by said motor, and a settling tank for collecting the separated heavy phase.

Owner:SOUTHWEST PETROLEUM UNIV

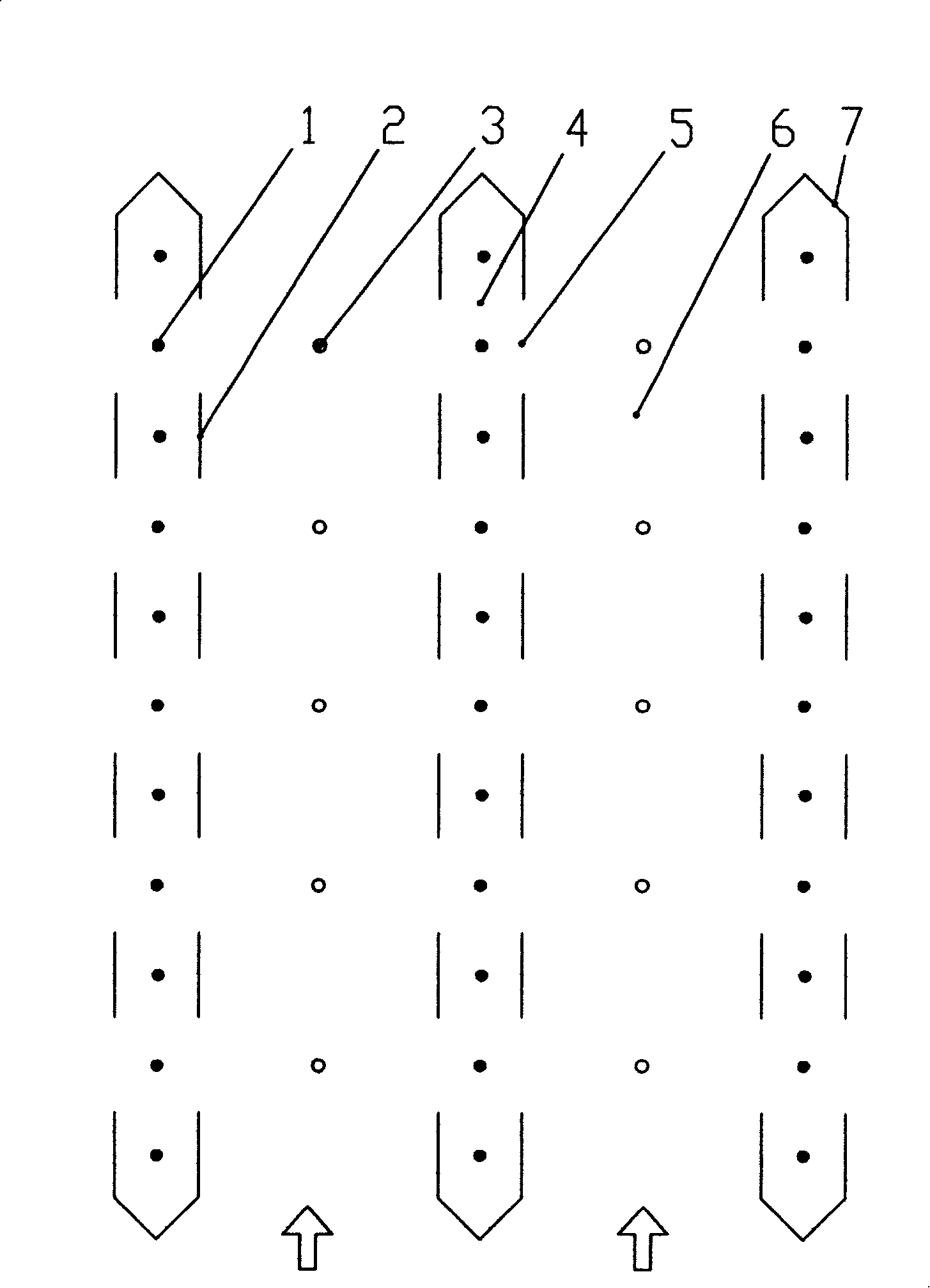

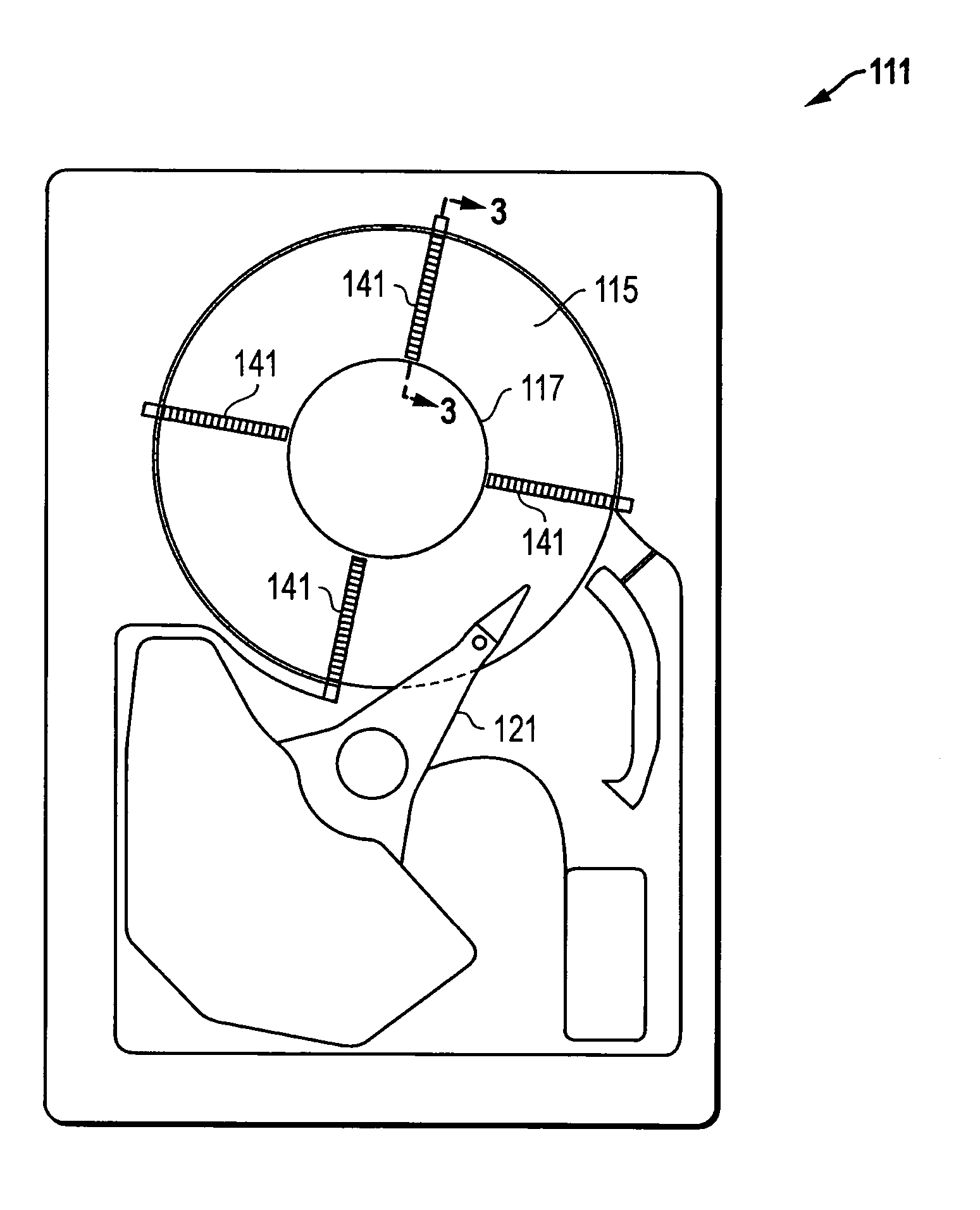

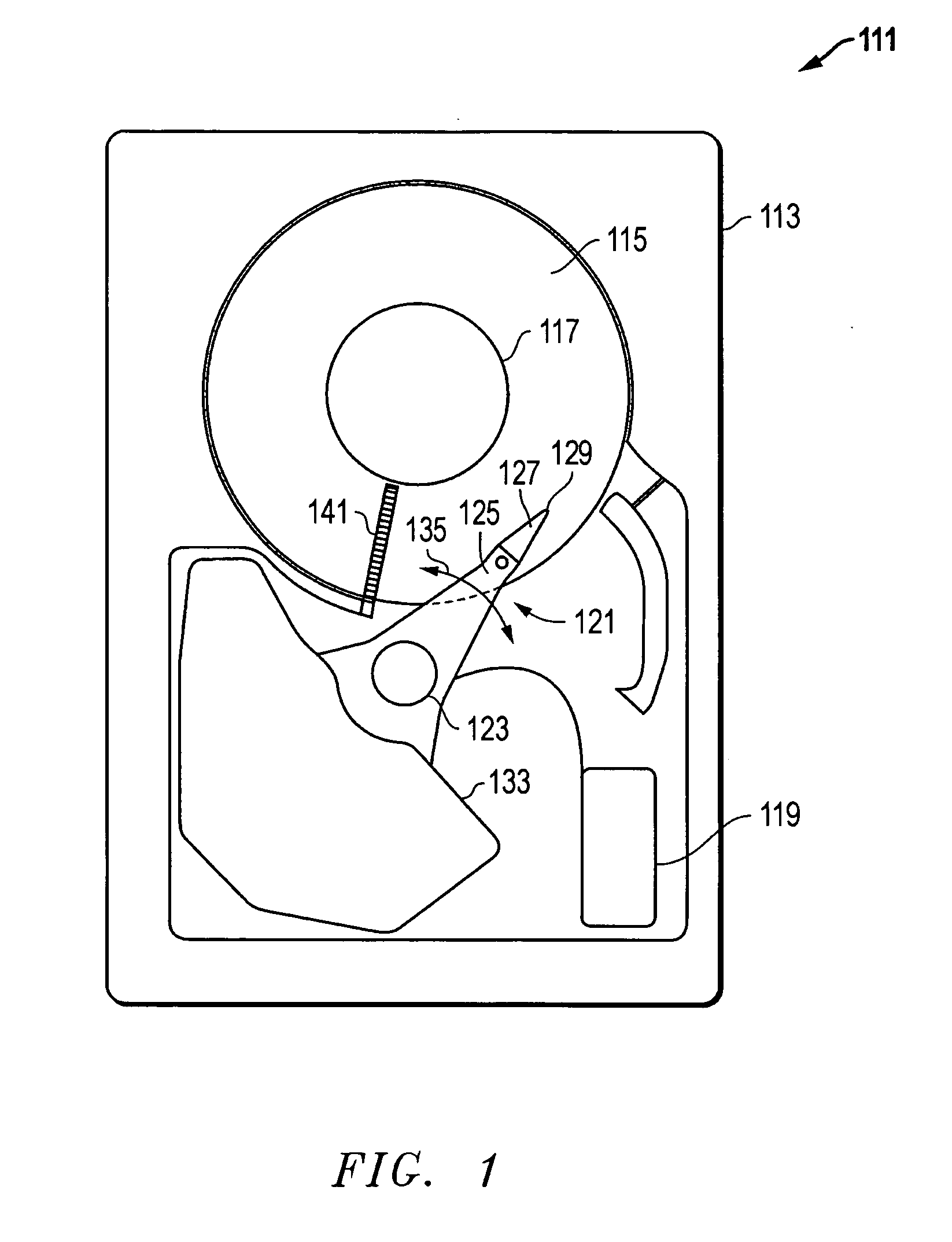

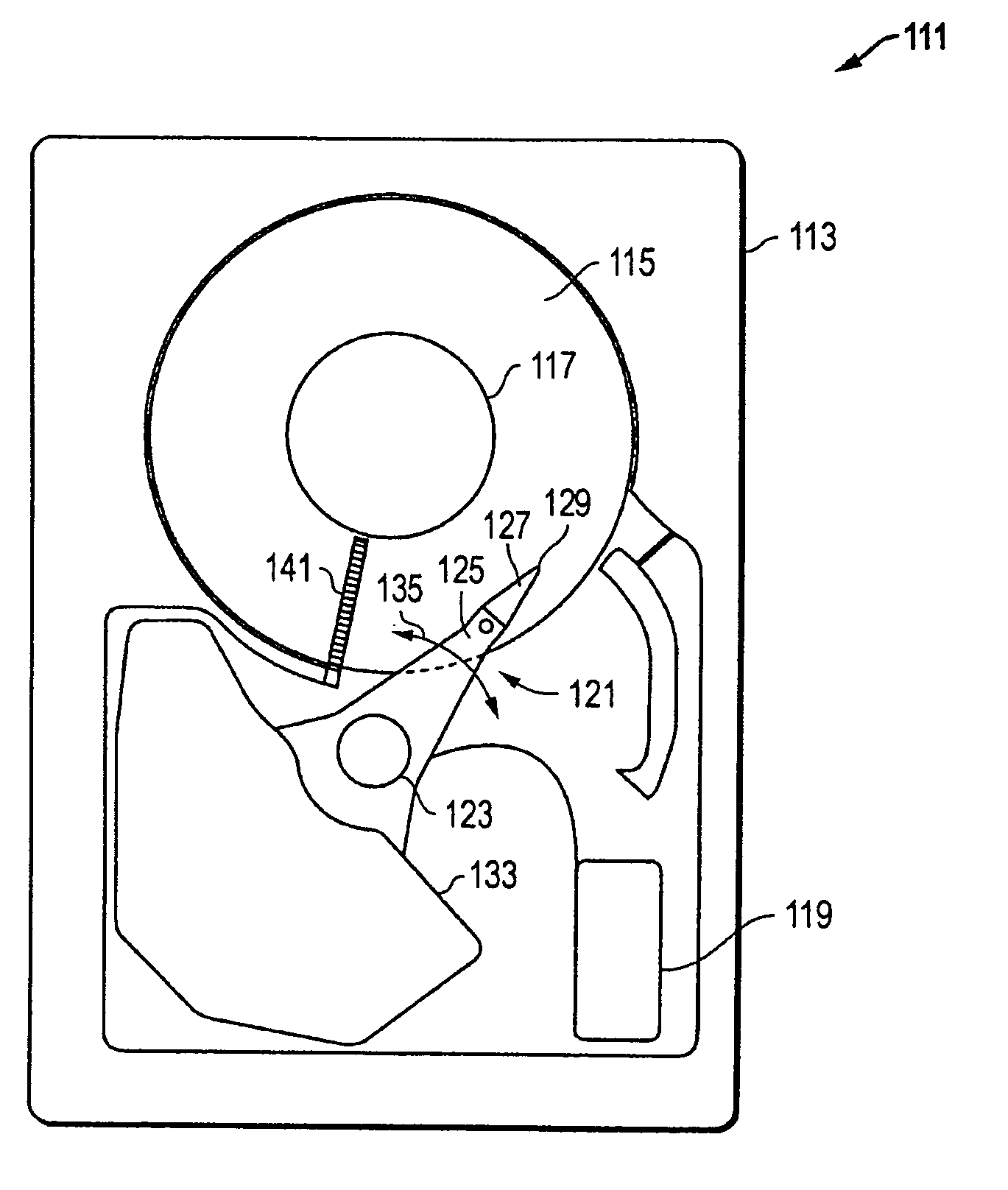

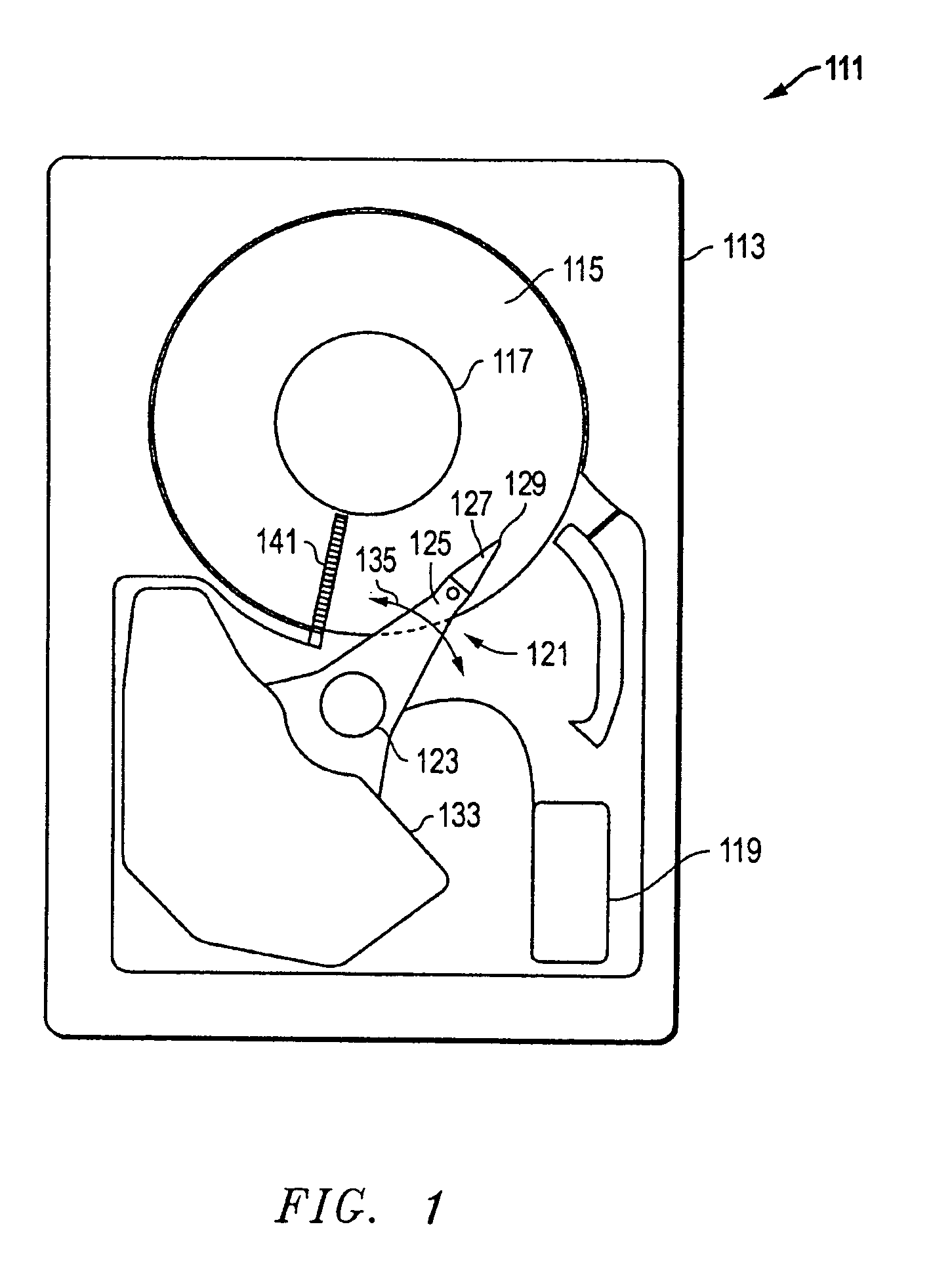

System, method, and apparatus for breaking up large-scale eddies and straightening air flow inside rotary disk storage devices

InactiveUS20050195521A1Reduce TMRReduce turbulence intensityUndesired vibrations/sounds insulation/absorptionRecord information storageHard disc driveAirflow

A system, method, and apparatus for solving flow-induced track misregistration (TMR) problems in hard disk drives (HDD) are directed to breaking up large-scale eddies, and straightening air flows with honeycomb structures, woven wire screens, and guide vanes or holes. In addition, boundary layer manipulation techniques are applied to the airflow in the HDD, such as boundary layer suction with slots or holes, and wall damping techniques, such as an open honeycomb seal and Helmholtz resonators. These flow-conditioning solutions reduce the turbulence intensity throughout the HDD to reduce TMR. These solutions achieve these goals while minimizing increases in the running torque needed to overcome their inherent rotational drag.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

General surgery department clinical operation irrigation device

InactiveCN108144153AImprove sealingSpread out to accelerateCannulasEnemata/irrigatorsCouplingUv disinfection

The invention discloses a general surgery department clinical operation irrigation device which comprises an irrigation device body and an irrigation head component. A motor containing groove is formed in the inner side of a middle projection of the inner top of the irrigation device body, a motor is mounted in the motor containing groove, a lower output shaft of the motor is connected with a rotating shaft through a coupler, a screw blade is mounted on the rotating shaft, a plurality of stirring rods are mounted on the outer side of the screw blade, filter screen cylinder is arranged on the outer side of the stirring rods and the screw blade, a plurality of ultraviolet sterilizing lamps are mounted on the inner side wall of the irrigation device body, an electric heater is arranged in themiddle of the inner bottom of the irrigation device body, the top of the irrigation device body is provided with a pressurizer and an irrigation liquid feeding port, a liquid outlet is formed in thebottom of the side surface of the irrigation device body, a hose is connected on the liquid outlet, and the irrigation head component is connected at the other end of the hose. The irrigation deviceis diverse in function and better in irrigation effect, practical and reliable, heating and sterilizing effects of the irrigation liquid are good, and medicines in the irrigation liquid can be dispersed.

Owner:日照朝力信息科技有限公司

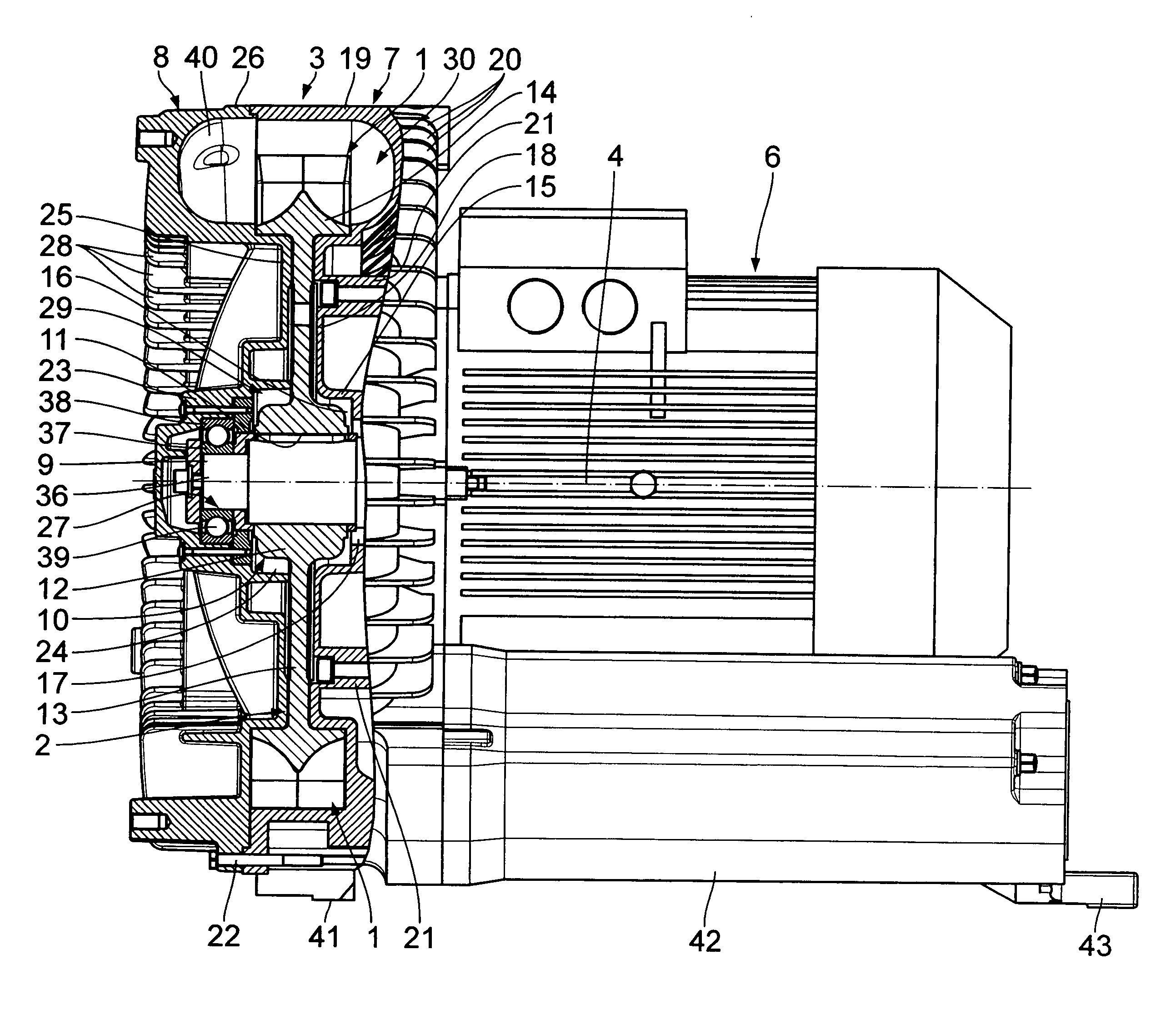

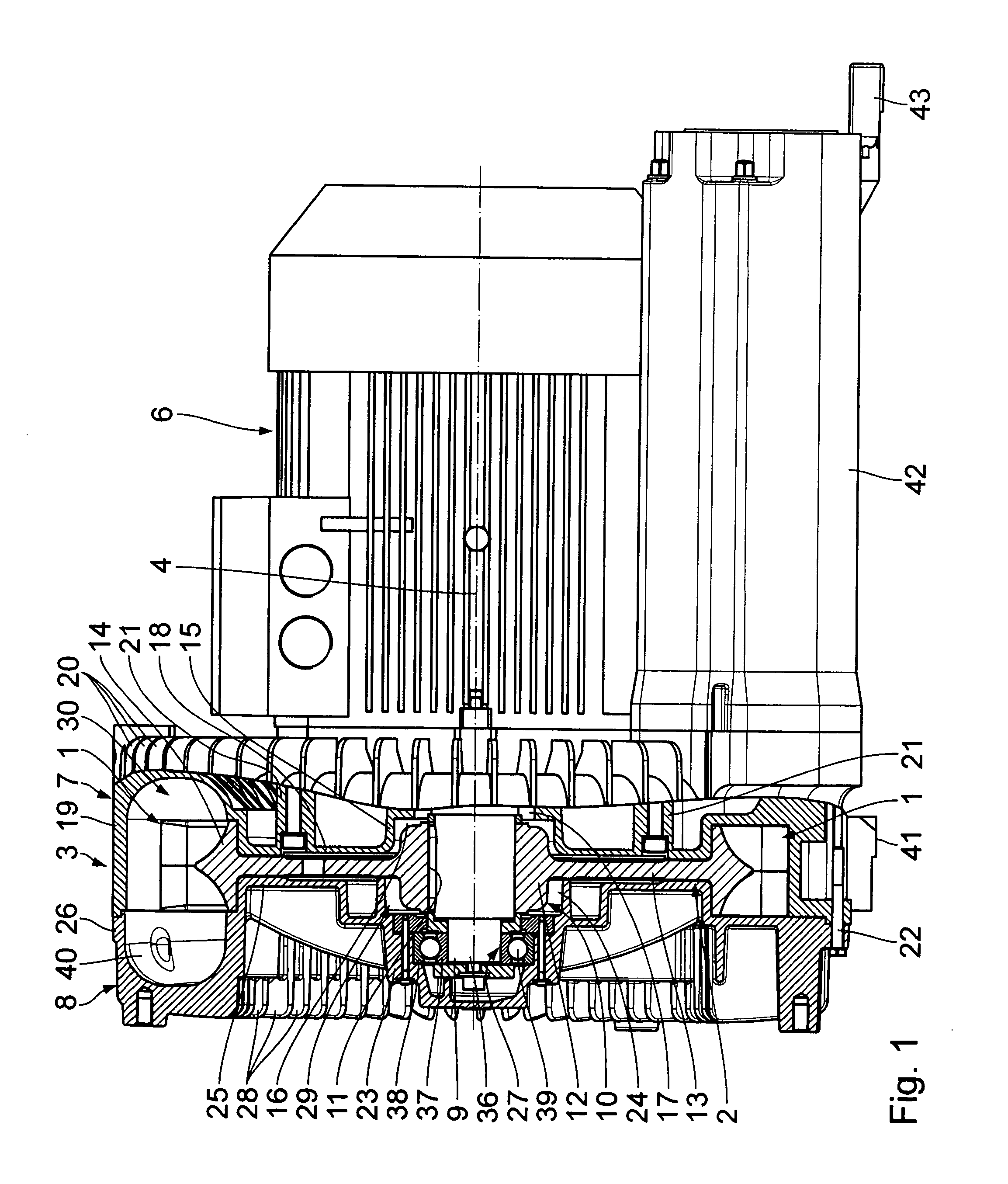

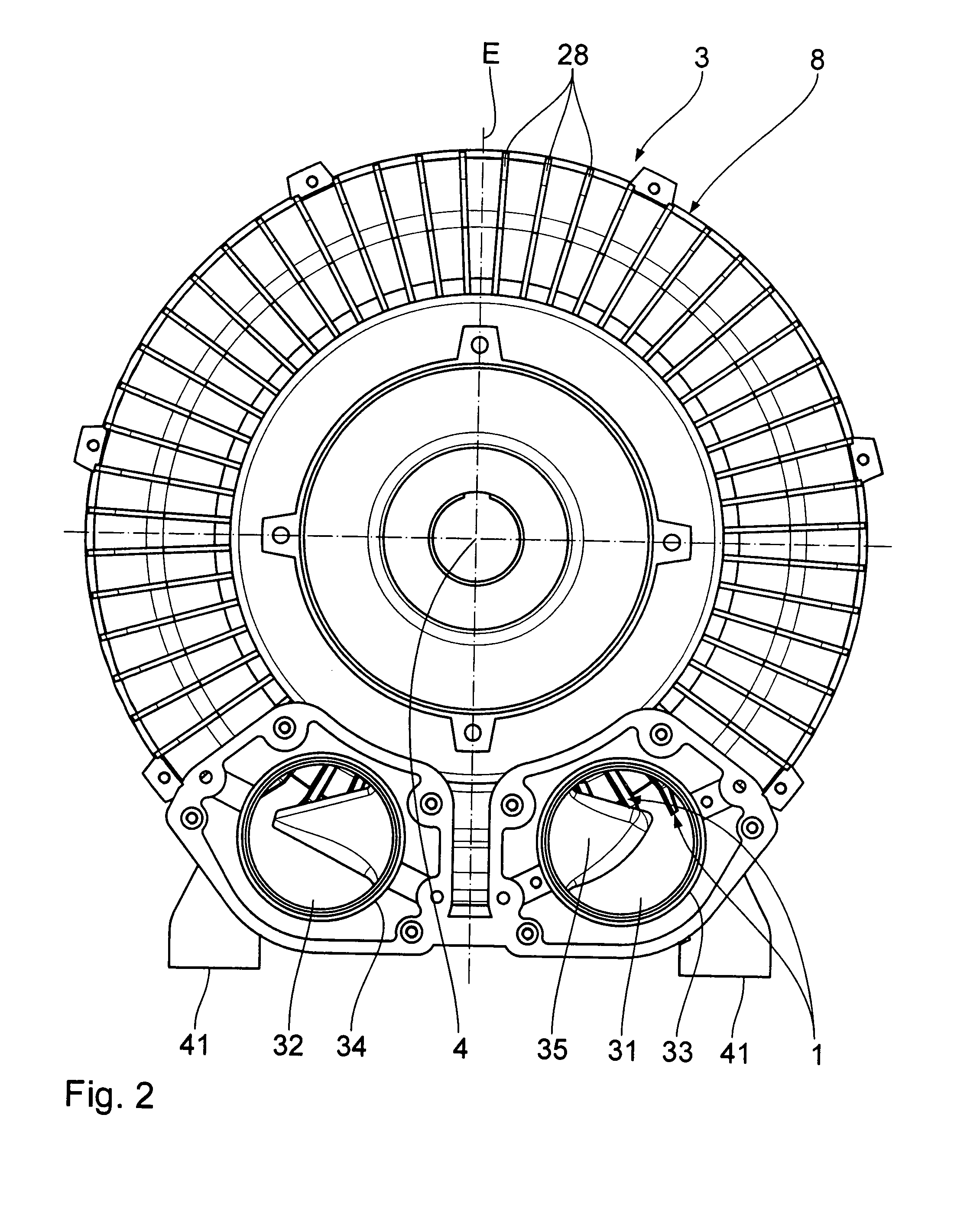

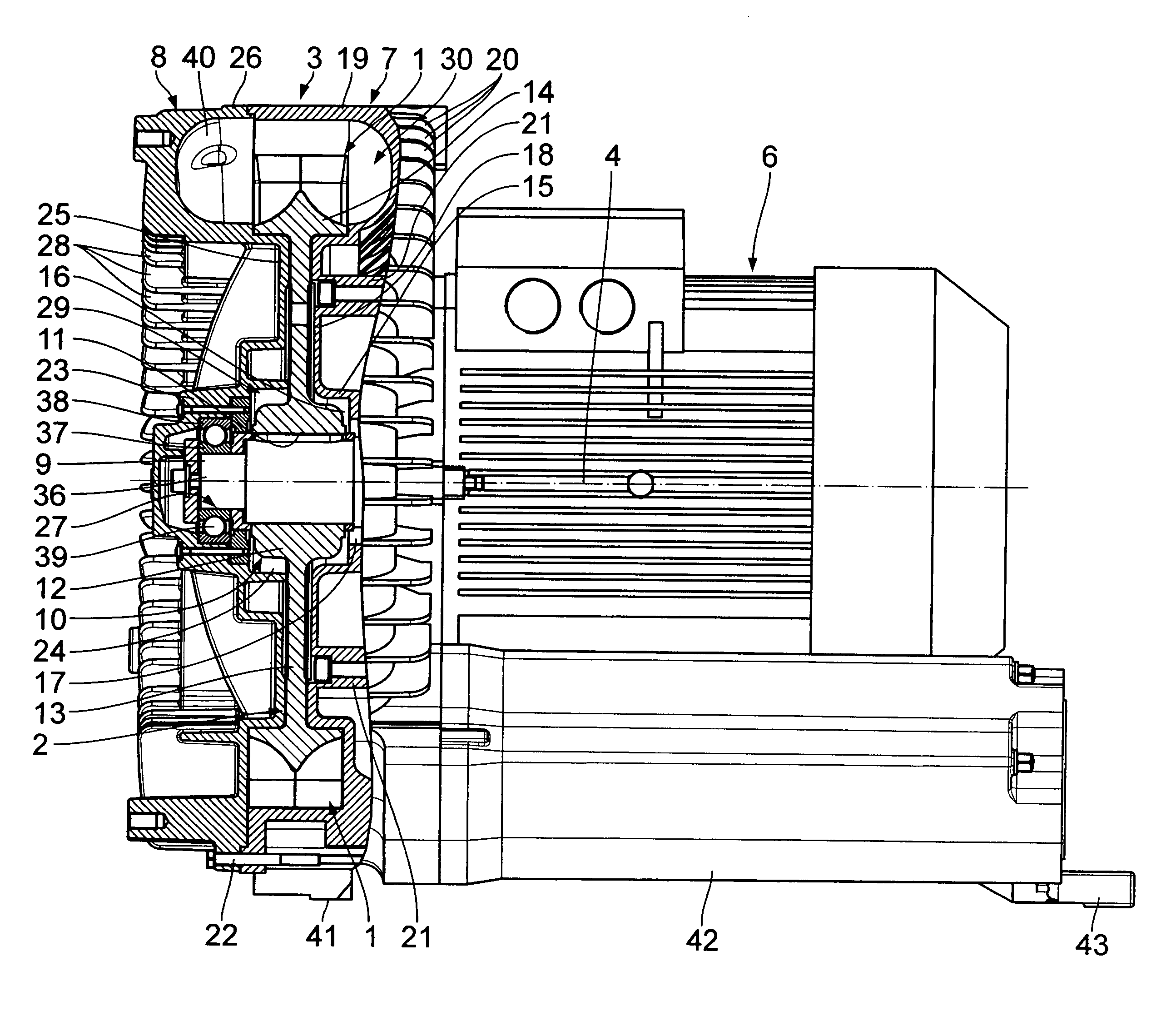

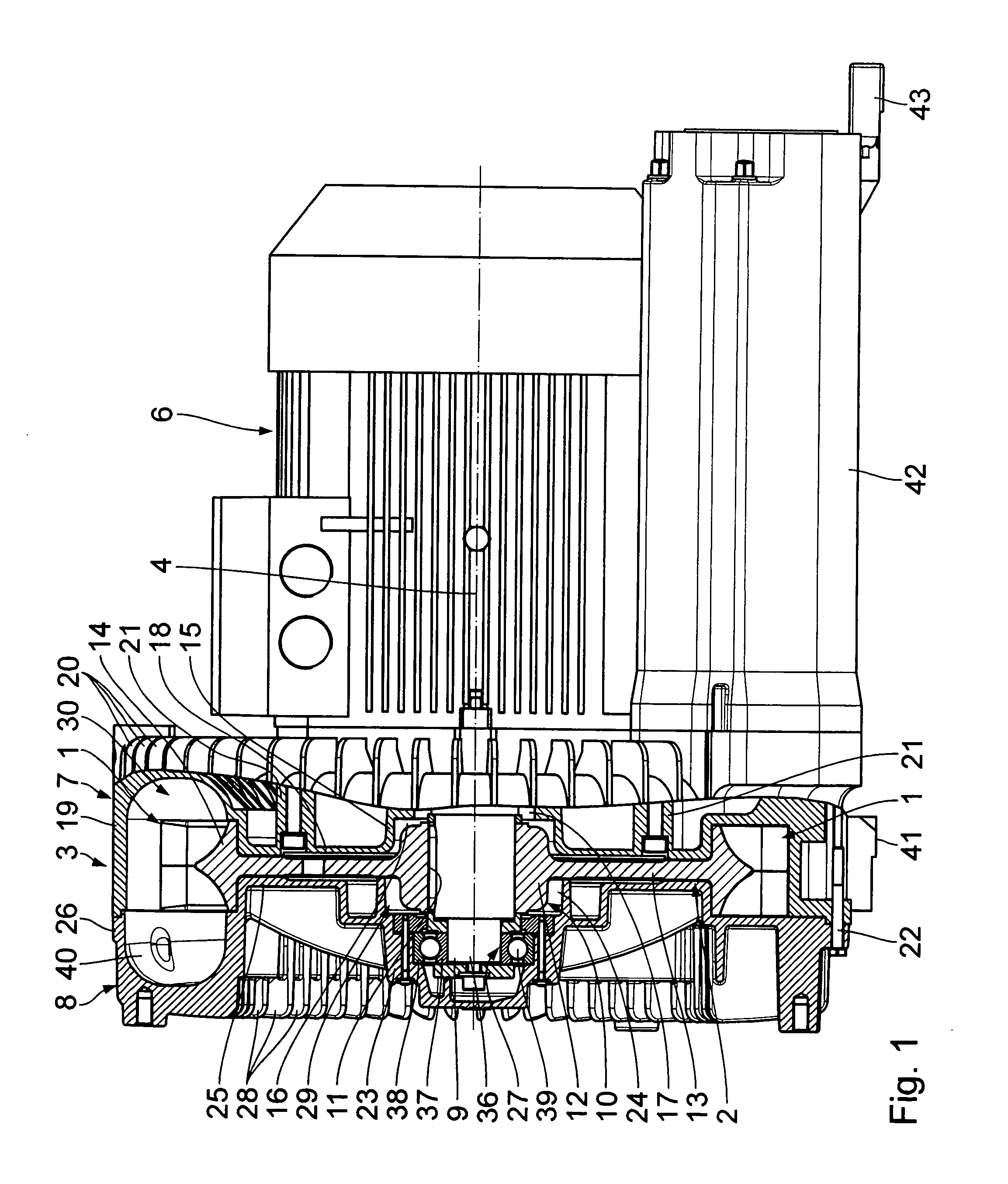

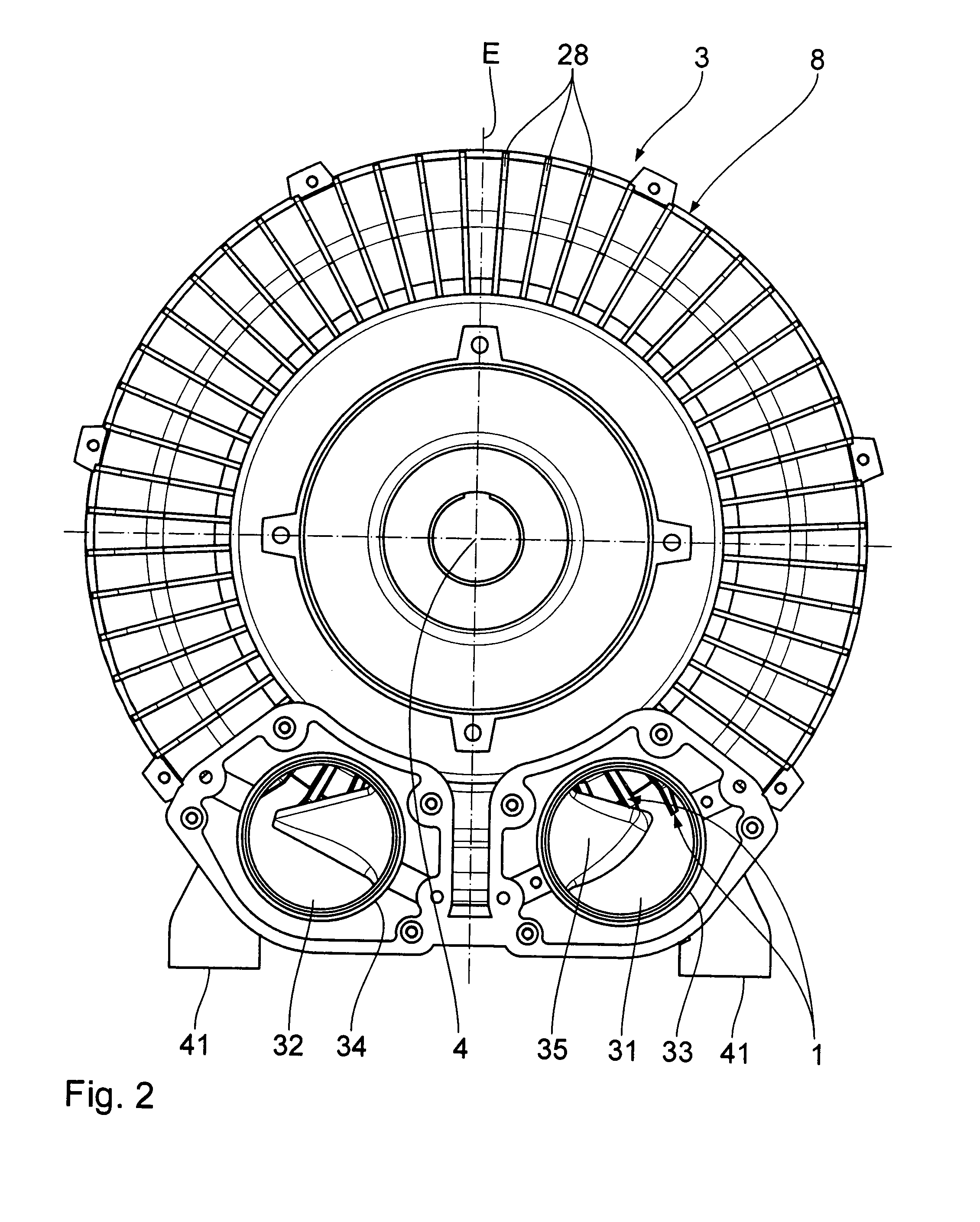

Side channel compressor

A side channel compressor for compressing a gas comprises a housing (3), a side channel (30), located in the housing (3) and having a cross-sectional area (A), for compressing a gas, a gas inlet opening (31) formed in the housing (3), the gas inlet opening (31) being in flow connection with the side channel (30) for introducing a gas, a gas outlet opening (32) formed in the housing (3) for discharging the gas to be compressed from the side channel (30), wherein the gas outlet opening (32) is in flow connection with the gas inlet opening (31) via the side channel (30), and an impeller (2) which is mounted for rotation in the housing (3) and comprises impeller blades (1) disposed in the side channel (30), wherein the cross-sectional area (A) of the side channel (30) decreases non-monotonically from the gas inlet opening (31) towards the gas outlet opening (32).

Owner:GARDNER DENVER DEUTLAND

System, method, and apparatus for applying boundary layer manipulation techniques to the air flow inside rotary disk storage devices

InactiveUS20050195522A1Reduce turbulence intensityDecreased TMRDriving/moving recording headsUndesired vibrations/sounds insulation/absorptionHard disc driveHelmholtz resonator

A system, method, and apparatus for solving flow-induced track misregistration (TMR) problems in hard disk drives (HDD). Boundary layer manipulation techniques are applied to the airflow in the HDD, such as boundary layer suction with slots or holes, and wall damping techniques, such as an open honeycomb seal and Helmholtz resonators. These flow-conditioning solutions reduce the turbulence intensity throughout the HDD to reduce TMR. These solutions achieve these goals while minimizing increases in the running torque needed to overcome their inherent rotational drag.

Owner:WESTERN DIGITAL TECH INC

Axial flow fan three-dimensional impeller with leaf vein structures and seagull-shaped splitter blades

Owner:ZHEJIANG SCI-TECH UNIV

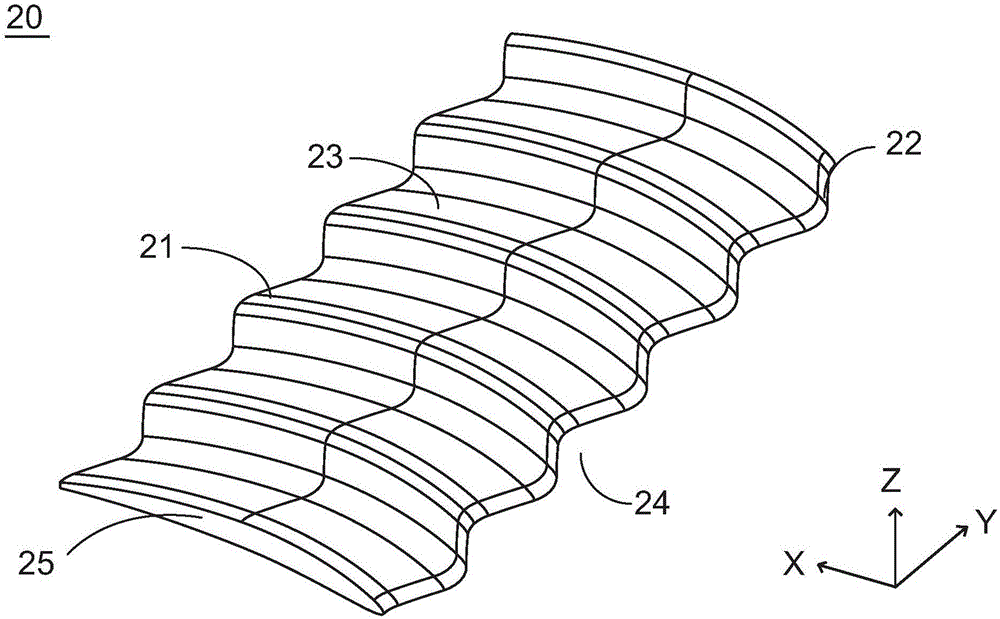

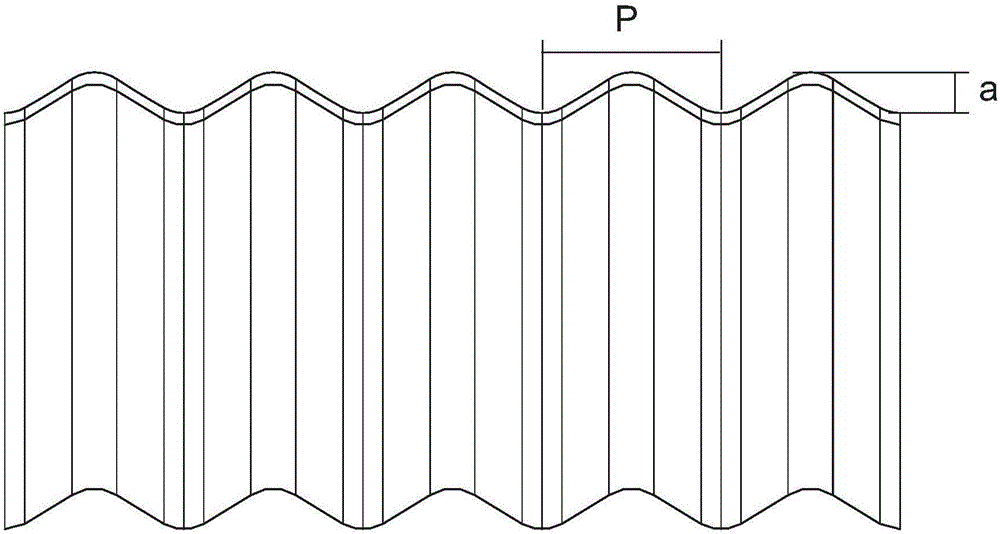

Blade

InactiveCN106704259AReduce turbulence intensityImprove blade efficiencyPump componentsPumpsTrailing edgeLeading-edge slats

The invention provides a blade. The blade comprises a leading edge allowing a liquid to flow in, a tailing edge allowing the liquid to flow out, a suction surface and a pressure surface, wherein one end of the edge of the suction surface is connected with one end of the edge of the pressure surface at the leading edge, the other end of the edge of the suction surface is connected with the other end of the edge of the pressure surface at the tailing edge, shapes of aerofoil sections of the blade in the extending direction keep unchanged, and positions of leading and tailing edges of center lines of the aerofoil sections of the blade are periodically distributed in the extending direction. The positions of the leading and tailing edges of the center lines of the aerofoil sections of the blade are periodically distributed in the extending direction, so that flow separation on the blade surface can be effectively inhibited, turbulence intensity of the tailing edge is reduced, efficiency of the blade is improved, and falling-off noise of tailing edge vortex is reduced.

Owner:JOHNSON CONTROLS BUILDING EFFICIENCY TECH WUXI +2

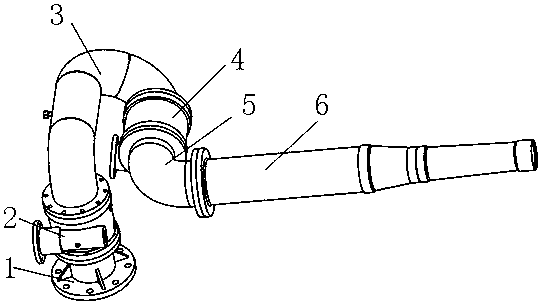

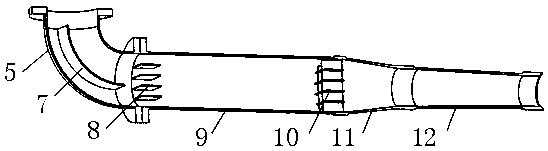

Law enforcement water cannon for ship

The invention discloses a law enforcement water cannon for a ship. A steering device is arranged between a base and a cannon body, the steering device can control the law enforcement water cannon to rotate horizontally; the cannon body is arranged in a roundabout shape, and a tilting device for controlling the angle of a cannon head is arranged between the cannon body and the cannon head; the canon head comprises an elbow pipe, the tilting device is connected to one end of the elbow pipe, and a rectifying section is connected to the other end of the elbow pipe; a steady flow speed increasing section and a steady flow jetting section are arranged at the right end of the rectifying section in sequence; an arc-shaped guide pipe is arranged in the elbow pipe; a rectifying plate is arranged atthe left end of the rectifying section, and a flow straightener is arranged at the right end of the rectifying section; and the steady flow speed increasing section is arranged in a taper shape to increase flow rate of the water cannon, and the steady flow jetting section is arranged in a taper shape, and the taper of the steady flow jetting section is smaller than the taper of the steady flow speed increasing section. The law enforcement water cannon has a simple structure, the design is ingenious, a large amount of turbulence flow generated by passing through corners of the cannon body is effectively eliminated to enable the turbulence intensity of water columns jetted by the water cannon to be the lowest, the range of the water cannon is increased, the range of impacting is expanded, the water column forming effect is optimized, the strength of beating is strengthened, and promotion of application value is great.

Owner:靖江市华东船舶机械制造有限公司

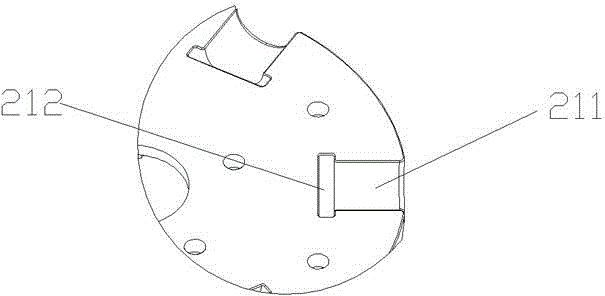

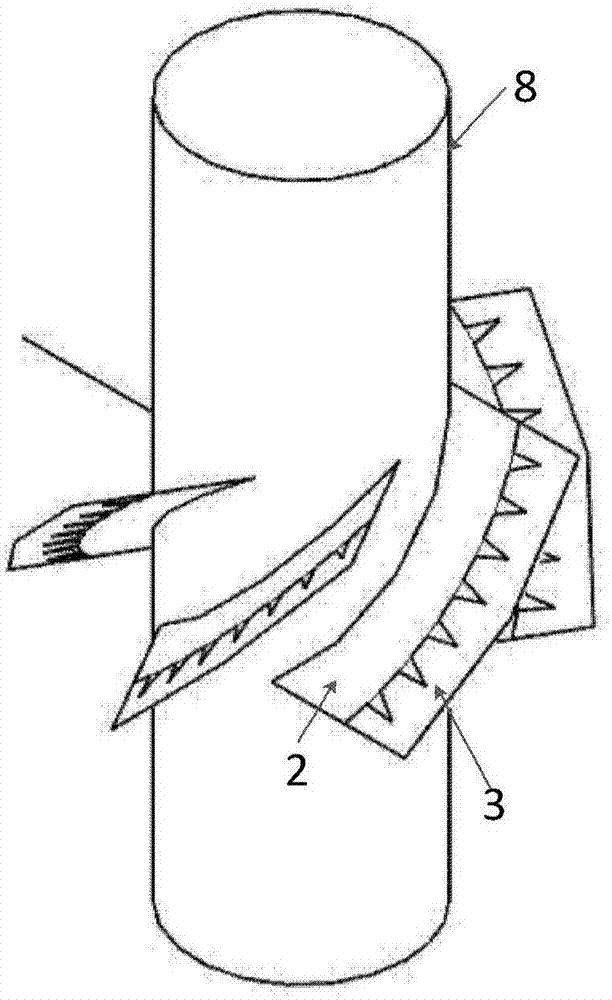

Surging-reduction low-noise blower impeller with adjustable blade angle

The invention discloses a surging-reduction low-noise blower impeller with an adjustable blade angle. The surging-reduction low-noise blower impeller comprises a plurality of blades and a hub for fixing the blades, wherein the thicknesses from the front edge to tail edge of each blade are different, each blade comprises 6-20 toothed blocks molded at the tail edge and lugs which are molded at the outer diameter of the blade and are protruded out of two surfaces of the blade, and each blade also comprises a mounting shaft connected with the hub, the mounting shafts are provided with round flanges; the hub is formed by connecting two hub disks, and the connecting surfaces of the two hub disks are provided with mounting grooves for fixing the mounting shafts and flange grooves for fixing the flanges.

Owner:广东佳科风机股份有限公司

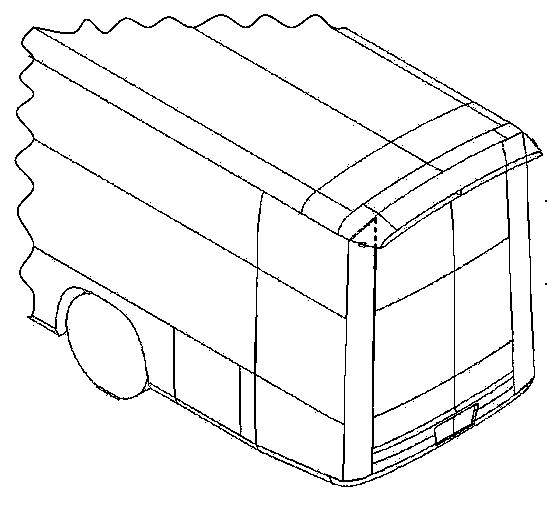

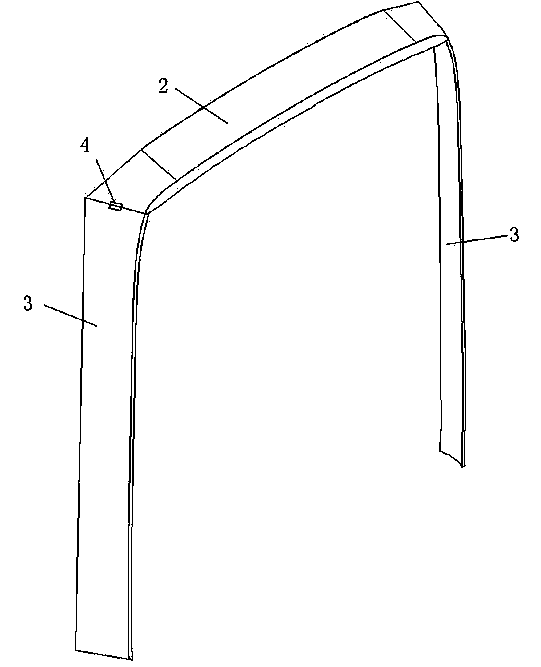

Carriage tail drainage side plate, drainage frame and vehicle

ActiveCN103979025AReduce air resistanceReduce turbulence intensityVehicle body stabilisationEngineeringEnergy conservation

The invention relates to a carriage tail drainage side plate, a drainage frame and a vehicle. The vehicle comprises a carriage, wherein a drainage side plate is arranged on the side edge on the tail part of the carriage, and the drainage side plate is hinged with the carriage. By adopting the carriage tail drainage side plate, the drainage frame and the vehicle, the air resistance when the vehicle runs at a high speed can be effectively reduced, and the energy conservation and emission reduction can be realized.

Owner:ZHENGZHOU YUTONG BUS CO LTD

Air inlet device and passenger car provided with same

ActiveCN106150790AReduce resistanceAvoid enteringMachines/enginesAir intakes for fuelAirflowAerospace engineering

The invention relates to an air inlet device and a passenger car provided with the same, and belongs to the field of vehicles. The air inlet device comprises a water retaining structure which is a louver-type structure composed of a plurality of blades. The air inlet device is arranged in the front-back direction consistent with the advancing direction of the passenger car. The blades are distributed at intervals in the front-back direction. The rear part of each blade inclines towards the outer side of an air inlet of the air inlet device. In the left-right direction perpendicular to the front-back direction, the adjacent blades overlap to form overlapping sections, and air flows into the passenger car through airflow channels which are formed between the adjacent blades and are oblique with reference to the airflow directions. Compared with a structure that air flows into a car along an airflow channel which is formed between two water baffles and perpendicular to the airflow direction in the prior art, the air inlet device and the passenger car provided with the same can obviously reduce the air flowing resistance.

Owner:ZHENGZHOU YUTONG BUS CO LTD

Nozzle with adjustable swirling number and turbulence level, nozzle array and combustor

The invention provides a nozzle with the adjustable swirling number and the turbulence level, a nozzle array and a combustor. The relative position between an inner-circle blade and an outer-circle blade of a cyclone is adjusted by rotating a middle cylinder or an outer-layer cylinder, and the purpose of adjusting the swirling number and the turbulence strength can be adjusted. The work range of the nozzle is wide, the swirling number and the turbulence of a flow field can be flexibly adjusted, the mixing effect is good, safety is good, pollutant emission is low, the fuel application range is wide, and good combustion stability is achieved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Unpowered draught fan with support frames as wing-shaped blades

ActiveCN105782130AReduce thicknessImprove total pressure efficiencyPump componentsPumpsEngineeringTurbine

The invention discloses an unpowered draught fan with support frames as wing-shaped blades. According to an existing unpowered draught fan, strong vortexes will be formed behind plate support frames, and the turbulence degree of a flow field is intensified. The lower-end support frame of the unpowered draught fan is formed by multiple lower-end wing-shaped blades, one end of each lower-end wing-shaped blade is fixed to the bottom of a center shaft, and the other end of each lower-end wing-shaped blade is fixed to the inner wall of an angle-changing pipe diameter; the upper-end support frame of the unpowered draught fan is formed by multiple upper-end wing-shaped blades, one end of each upper-end wing-shaped blade is fixed to a positioning sleeve, and the other end of each upper-end wing-shaped blade is fixed to the inner wall of a cylinder pipe diameter; the positioning sleeve is supported to the center shaft through a bearing; the chord length of the upper-end wing-shaped blades is larger than the chord length of the lower-end wing-shaped blades; the bottoms of the multiple air cutting blades are welded to the end face of the top of the cylinder pipe diameter, and the tops of the multiple air cutting blades and a turbine top plate are welded; and the top of the center shaft is supported into a bearing hole formed in the turbine top plate through a bearing. By means of the unpowered draught fan, flow disturbance of the flow field in the draught fan is improved, vibration of complex turbulence conditions on the draught fan is weakened, and the service life of the draught fan is prolonged.

Owner:嘉兴笼列电子商务有限公司

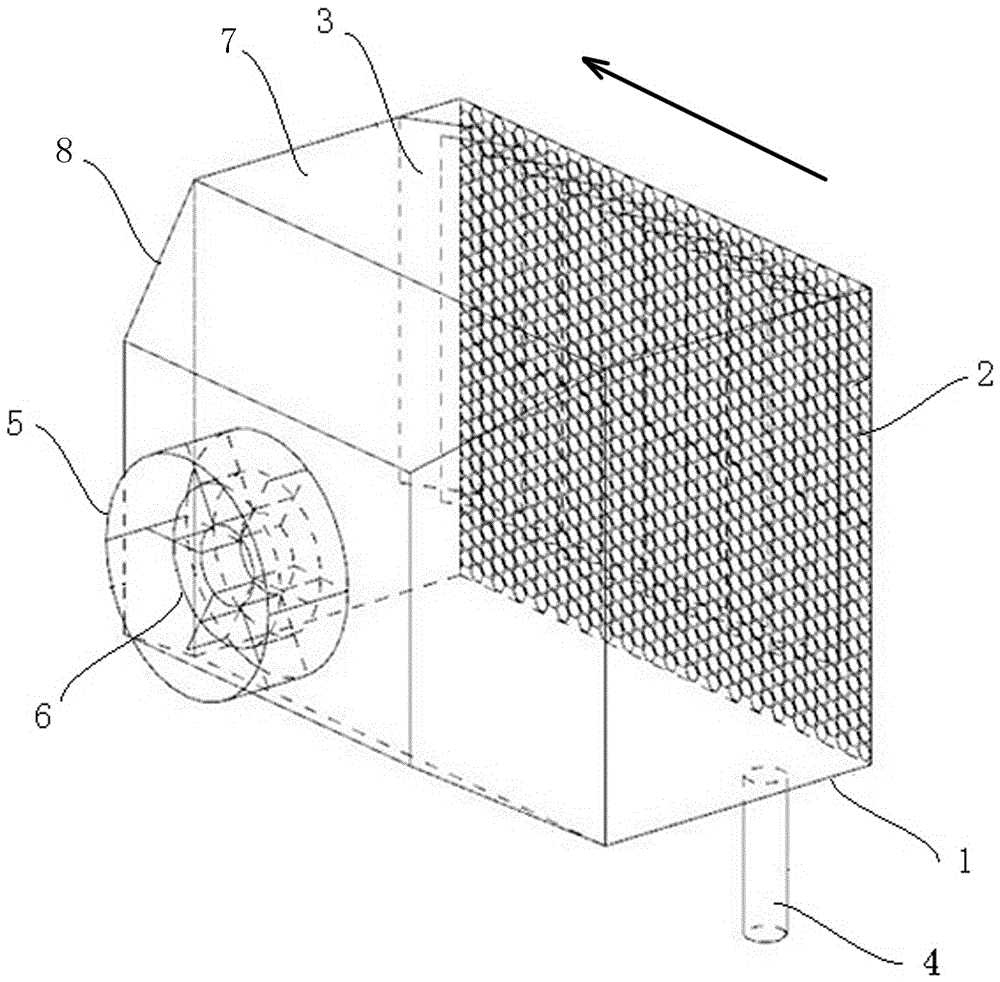

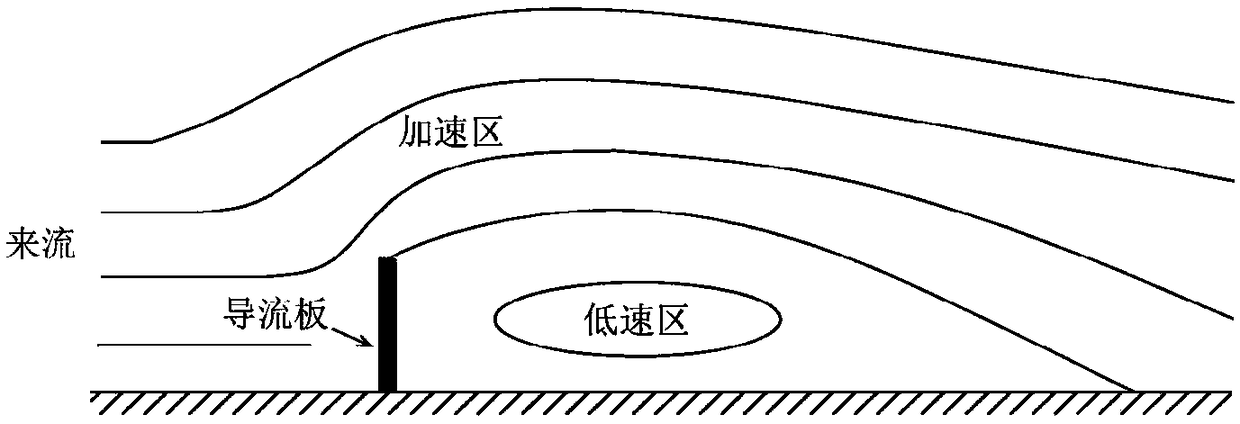

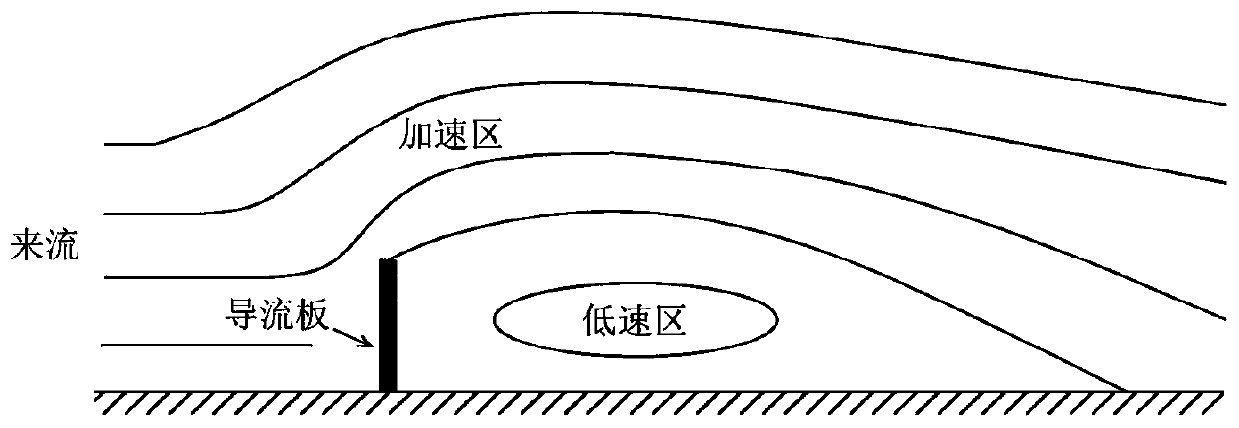

Wind farm turbulence optimization method and system

ActiveCN107315855AIncrease airflowAvoid damageDesign optimisation/simulationSpecial data processing applicationsElectricityTurbine

The invention belongs to the field of wind power technology, and particularly relates to a wind farm turbulence optimization method and system. The method includes: acquiring turbulence intensity data in a main flow direction within a predetermined distance in front of an installation location of a wind turbine on the basis of CFD (Computational Fluid Dynamics) flow field analysis; and analyzing and determining, on the basis of the acquired turbulence intensity data and wind farm measurement data, a location and a flow-guiding height of a flow-guiding wind grid mesh of utilizing mesh flow-guiding to optimize turbulence, According to the method and system, a mesh flow-guiding scheme is utilized, airflow of a wind farm is optimized, the turbulence intensity is reduced, component damage and gear box and blade fatigue invalidation caused by violent vibration, due to the turbulence, of the wind turbine are reduced, and the safety of wind turbine running is improved.

Owner:中国大唐集团科学技术研究总院有限公司

Side channel compressor

ActiveUS8662822B2Run silentReduce turbulence intensityPump componentsCircumferential flow pumpsImpellerEngineering

A side channel compressor for compressing a gas comprises a housing (3), a side channel (30), located in the housing (3) and having a cross-sectional area (A), for compressing a gas, a gas inlet opening (31) formed in the housing (3), the gas inlet opening (31) being in flow connection with the side channel (30) for introducing a gas, a gas outlet opening (32) formed in the housing (3) for discharging the gas to be compressed from the side channel (30), wherein the gas outlet opening (32) is in flow connection with the gas inlet opening (31) via the side channel (30), and an impeller (2) which is mounted for rotation in the housing (3) and comprises impeller blades (1) disposed in the side channel (30), wherein the cross-sectional area (A) of the side channel (30) decreases non-monotonically from the gas inlet opening (31) towards the gas outlet opening (32).

Owner:GARDNER DENVER DEUTLAND

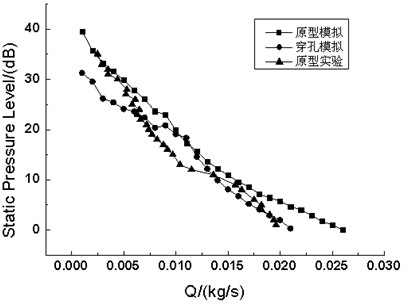

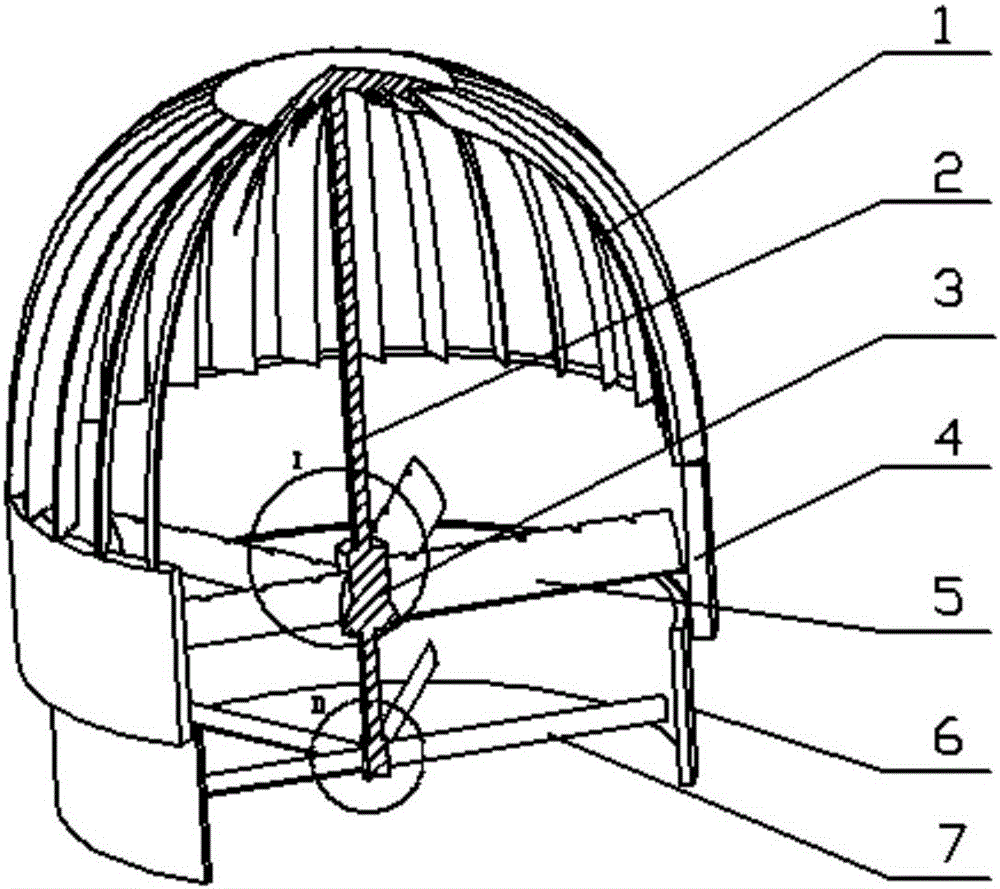

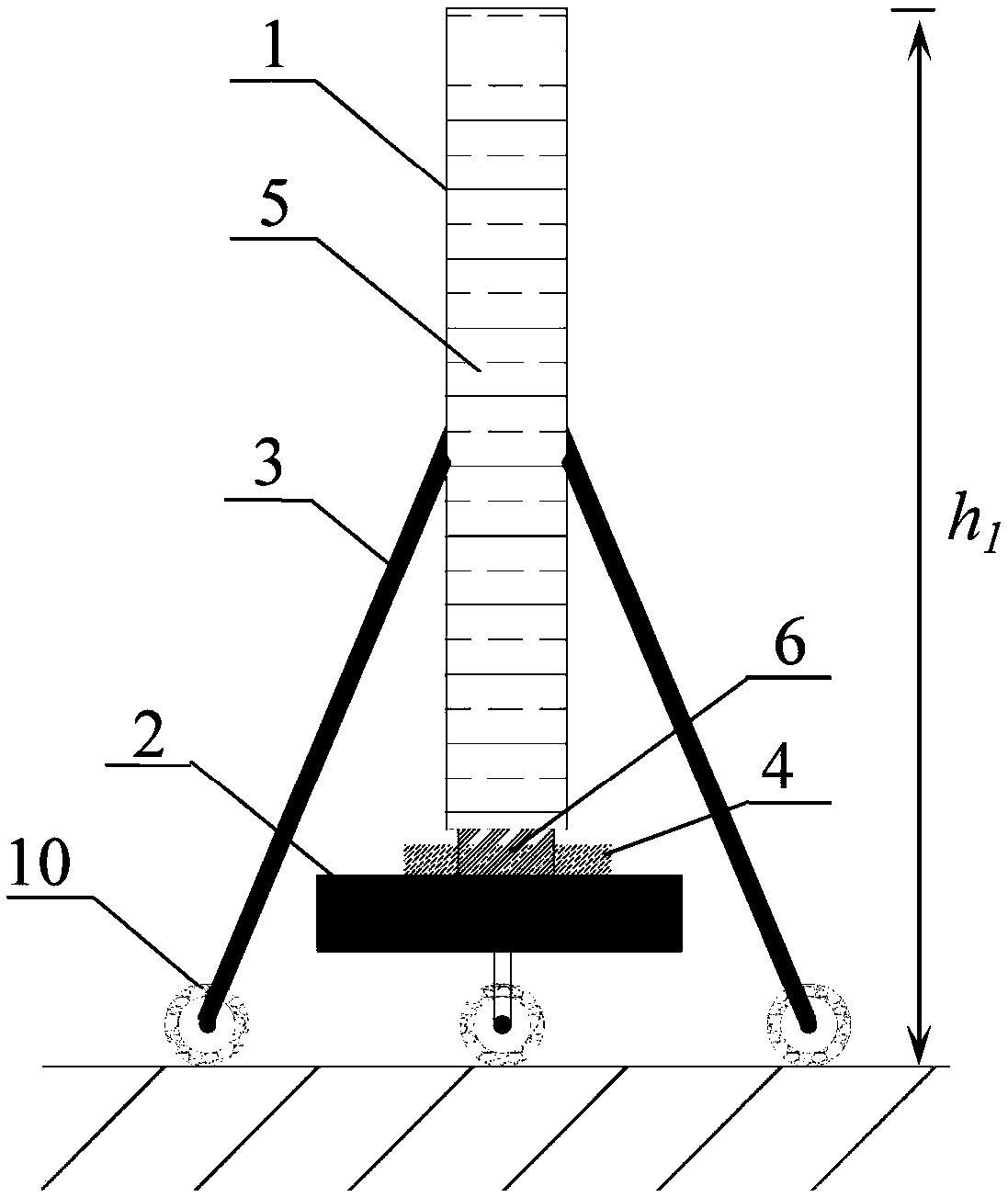

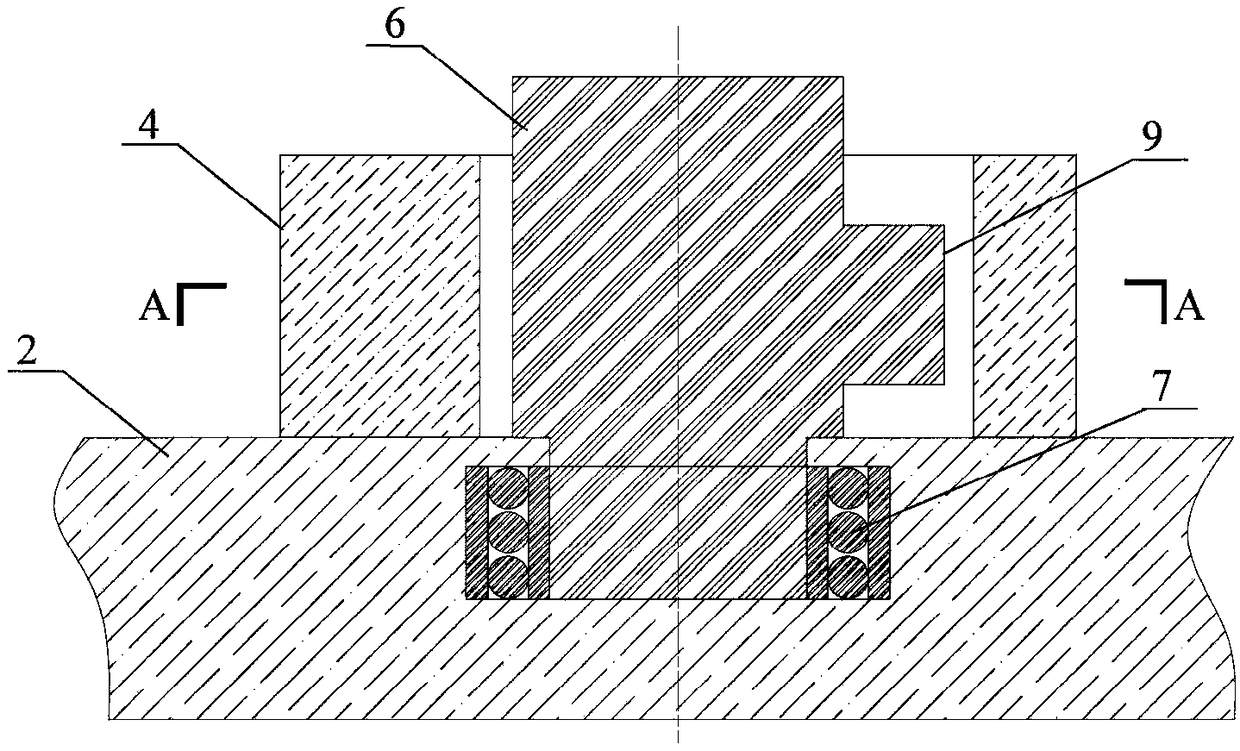

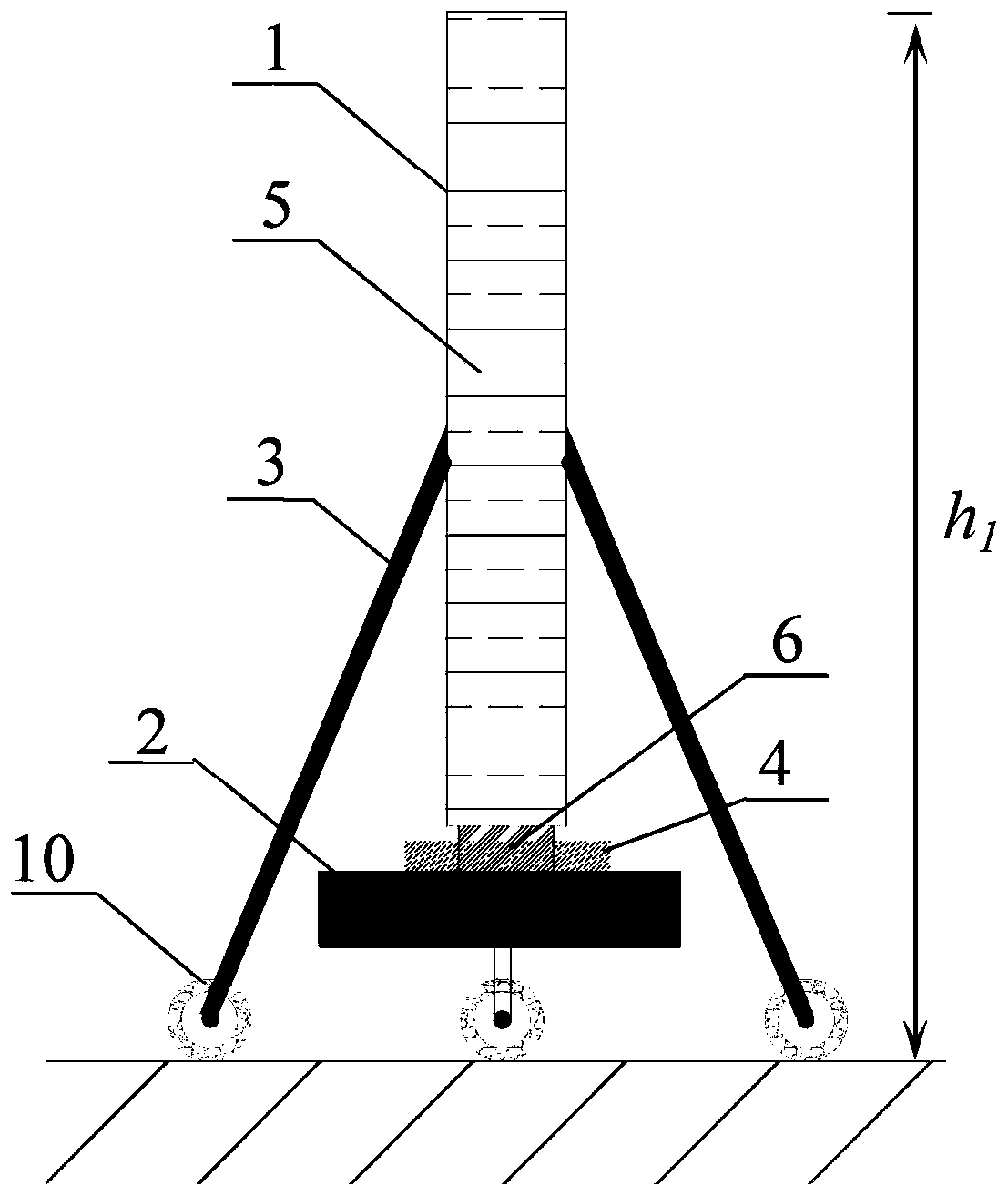

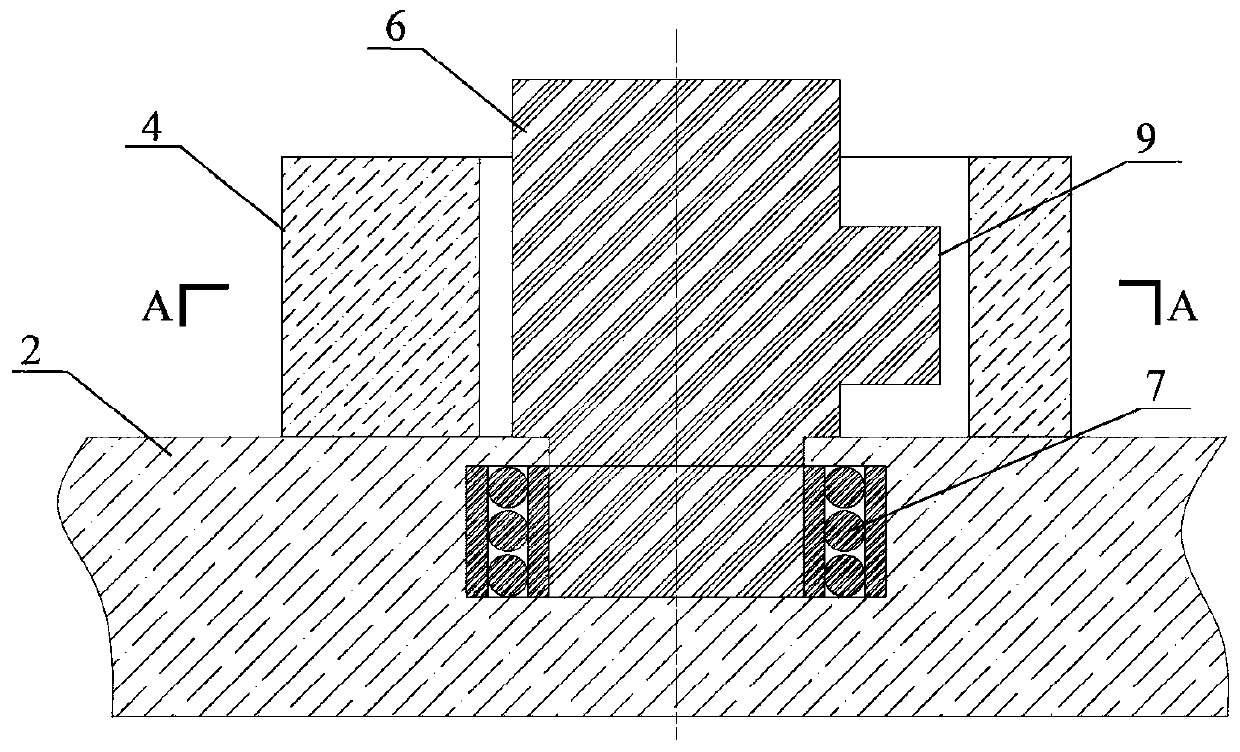

Multi-hole type wind turbine energizer

ActiveCN109322783AIncrease profitHigh speedMachines/enginesWind energy generationLow speedEngineering

The invention discloses a multi-hole type wind turbine energizer. The multi-hole type wind turbine energizer comprises a multi-hole guide plate with uniformly distributed holes, a pedestal, and a damping limiting device which is arranged between the multi-hole guide plate and the pedestal for buffering or limiting left-right rotation of the multi-hole guide plate, wherein the centre of the multi-hole guide plate is equipped with a main shaft; the multi-hole guide plate is connected with the pedestal through the main shaft and a rolling bearing; and the damping limiting device comprises a damping limiting device body, a plurality of baffle plates and a spring which is arranged between every two adjacent baffle plates. The multi-hole type wind turbine energizer can buffer and limit left-right rotation of the multi-hole guide plate, and the baffle plates are uniformly distributed on the main shaft and the damping limiting device body in a peripheral direction. The multi-hole type wind turbine energizer can efficiently utilize low-speed air energy below a wind turbine, can effectively improve wind turbine output power, also can reduce wind turbine load fluctuation, and can reduce influences of the environment to be smallest.

Owner:HOHAI UNIV

A multi-hole wind turbine energy booster

The invention discloses a multi-hole type wind turbine energizer. The multi-hole type wind turbine energizer comprises a multi-hole guide plate with uniformly distributed holes, a pedestal, and a damping limiting device which is arranged between the multi-hole guide plate and the pedestal for buffering or limiting left-right rotation of the multi-hole guide plate, wherein the centre of the multi-hole guide plate is equipped with a main shaft; the multi-hole guide plate is connected with the pedestal through the main shaft and a rolling bearing; and the damping limiting device comprises a damping limiting device body, a plurality of baffle plates and a spring which is arranged between every two adjacent baffle plates. The multi-hole type wind turbine energizer can buffer and limit left-right rotation of the multi-hole guide plate, and the baffle plates are uniformly distributed on the main shaft and the damping limiting device body in a peripheral direction. The multi-hole type wind turbine energizer can efficiently utilize low-speed air energy below a wind turbine, can effectively improve wind turbine output power, also can reduce wind turbine load fluctuation, and can reduce influences of the environment to be smallest.

Owner:HOHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com