Vertical dynamic cyclone device

A cyclone, vertical technology, applied in the direction of the swirl device, the device whose axial direction of the swirl can be reversed, etc., can solve the limitation of the ability of the dynamic cyclone to generate centrifugal force, affect the separation effect, and increase the impact of system vibration etc. to achieve the effect of reducing energy loss, improving separation effect and reducing turbulence intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

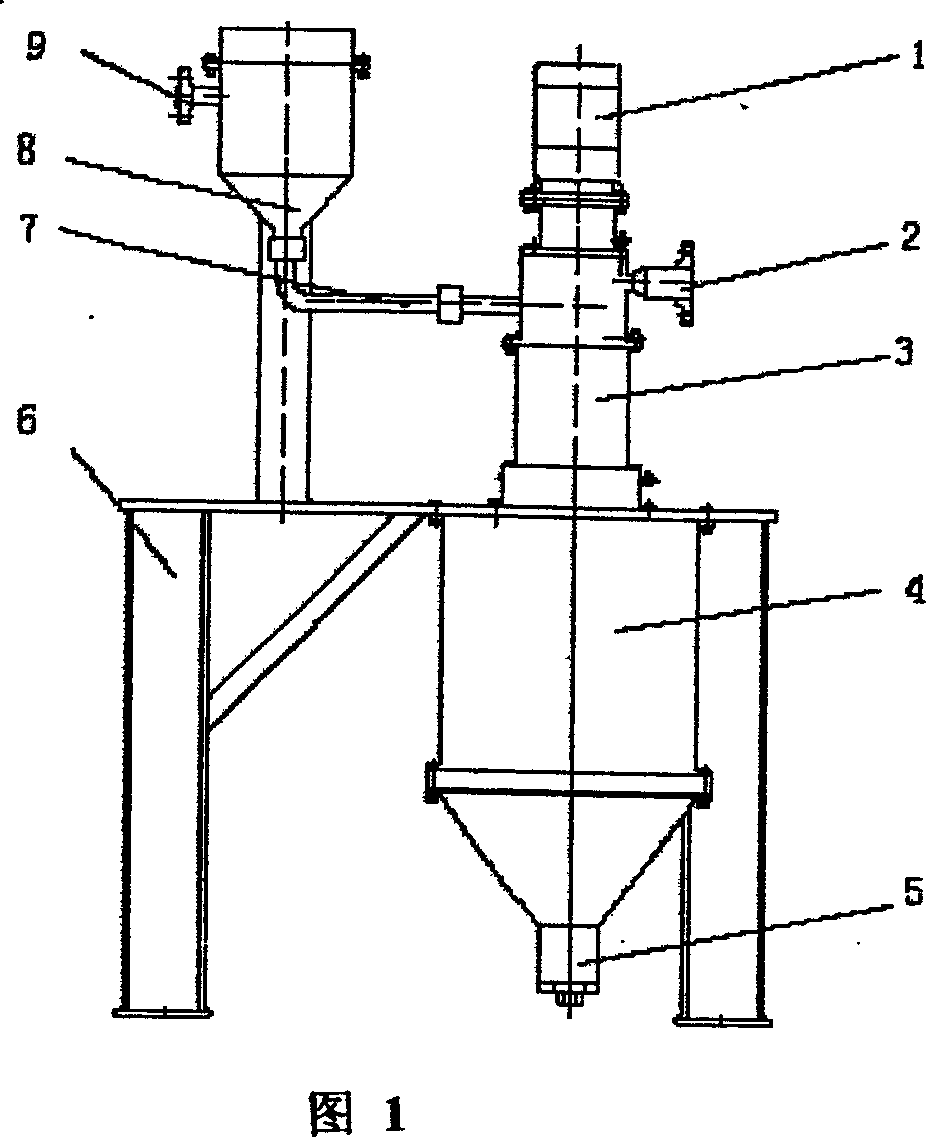

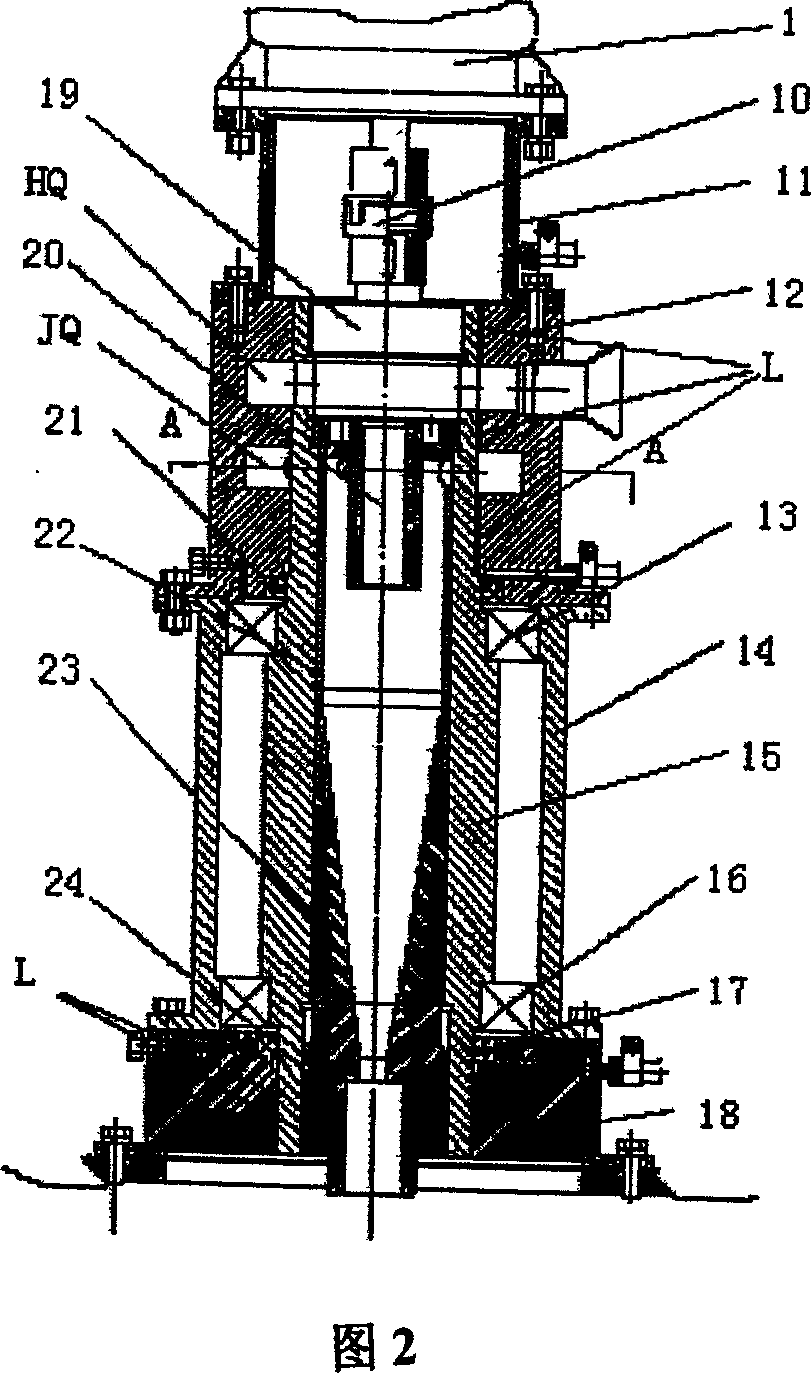

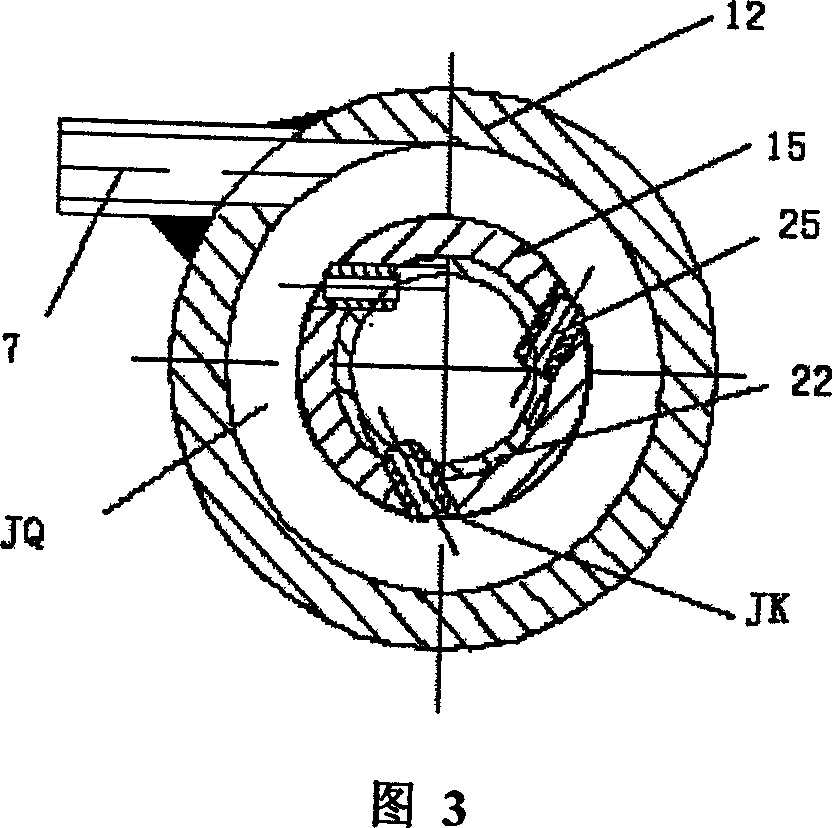

[0022] The present invention will be further described below in conjunction with FIG. 1 , FIG. 2 and FIG. 3 .

[0023] As shown in Figure 1 and Figure 2, the vertical dynamic cyclone mainly consists of a frequency conversion motor (1), a liquid return pipeline (2), a vertical cyclone separator (3), a settling tank (4), and an adjustable valve (5), frame (6), connecting pipeline (7), voltage stabilizing device (8), liquid inlet pipeline (9), etc.; wherein the vertical cyclone separation body is connected by coupling (10), Coupling cover (11), liquid inlet / return transition sleeve (12), righting bearing (13), bearing housing (14), drum (15), thrust bearing (16), molded seal (17), base (18), connecting shaft (19), overflow pipe (20), molded seal (21), bushing I (22), bushing II (23), underflow port (24), liquid inlet screw plug (25) Composition of main parts.

[0024] When the dynamic cyclone is working, the frequency conversion motor (1) drives the vertical drum (15) to rotate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com