Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "Solve the glue overflow problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Display panel, manufacturing method thereof, and display device

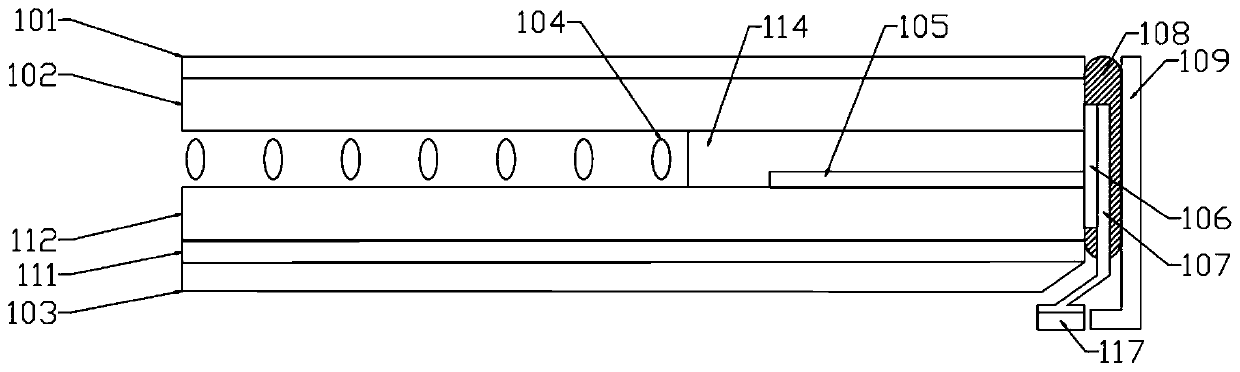

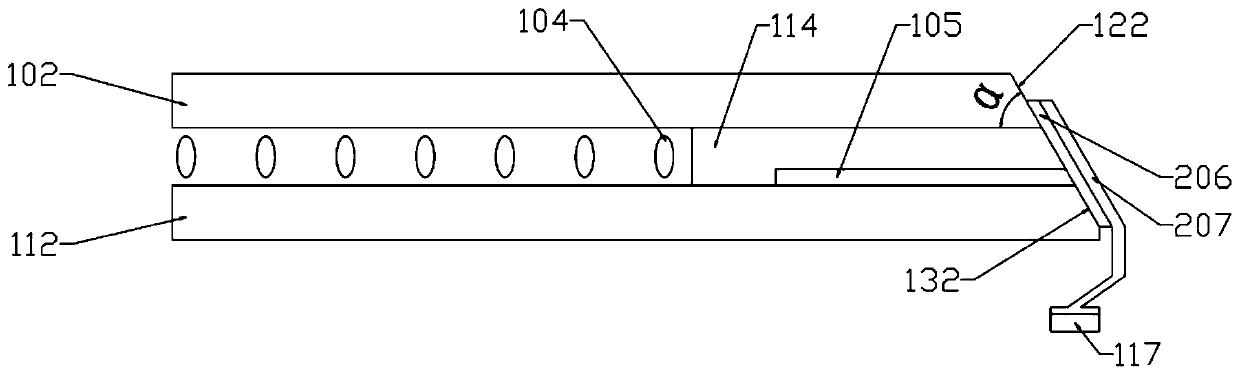

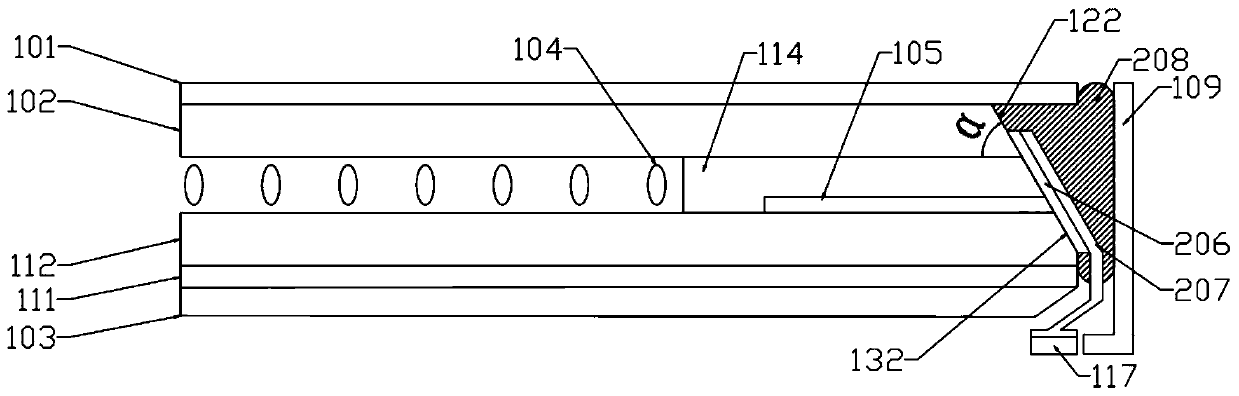

InactiveCN110764323AIncrease the cross-sectional area of the pinIncrease contact areaNon-linear opticsDisplay deviceThin membrane

The invention discloses a display panel, a manufacturing method thereof, and a display device. The display panel includes a first substrate, a second substrate, and a flip-chip film; the first substrate is provided with a first short side surface; the second substrate is arranged opposite to the first substrate, and the second substrate is provided with a second short side surface flush with the first short side surface; and the flip-chip film is bound to the first short side surface and the second short side surface; wherein the second short side surface of the second substrate forms a firstangle [Alpha] with the lower surface of the second substrate, and [Alpha] is greater than 1 degree and less than 60 degrees. According to the embodiment of the invention, by adopting an oblique edgingmethod, the cross-sectional area of a metal pin is increased, and the side-bound contact resistance is reduced; the glue filling and coating space is increased, and the amount of filling glue is increased, therefore, the problem of glue overflow caused by small space is avoided; the contact area between the filling glue and the glass substrate is increased, therefore, the adhesion force is enhanced; and meanwhile, the filling glue forms protrusions and jams the glass substrate, so that the frame and the glass substrate is more firmly bonded.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

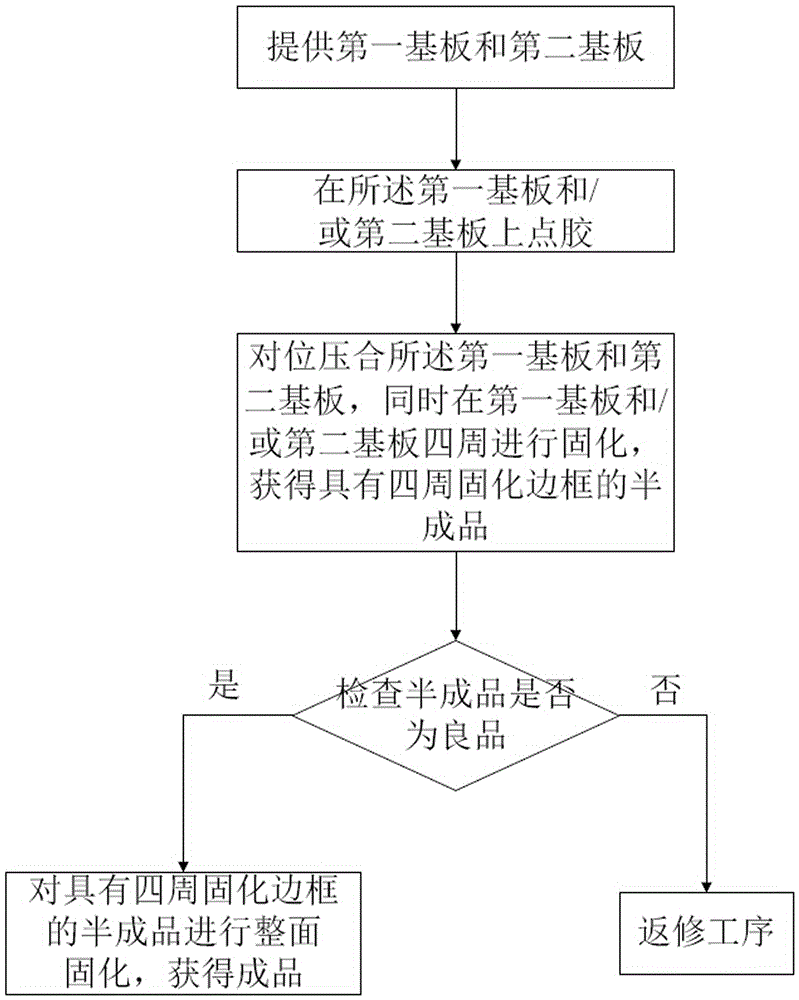

Glue-dispensing and laminating method for touch display module

InactiveCN109968790ACuring stabilityImprove the bonding yieldLamination ancillary operationsPretreated surfacesRubber ringEngineering

The invention discloses a glue-dispensing and laminating method for a touch display module. The method comprises the following steps: S1, providing a first substrate and a second substrate; S2, dispensing a glue on the laminating surface of the first substrate to form a rubber ring at the edge of the laminating surface of the first substrate; S3, pre-curing the glue ring; S4, dispensing the glue on the laminating surface of the first substrate and the inner surface formed by the rubber ring; S5, laminating the first substrate and the second substrate; S6, pre-curing the glue-dispensed area obtained in step S4; and S7, carrying out full-surface main curing on the laminated first substrate and second substrate to completely cure the glue between the first substrate and the second substrate.In the invention, the glue is dispensed on the laminating surface of the first substrate to form the rubber ring at the edge of the laminating surface of the first substrate, the rubber ring is pre-cured, the glue is dispensed on the inner surface formed by the rubber ring, and the glue flows in the area formed by the glue ring, so the method can effectively avoid the problem of glue spilling in the laminating process.

Owner:TRULY OPTO ELECTRONICS

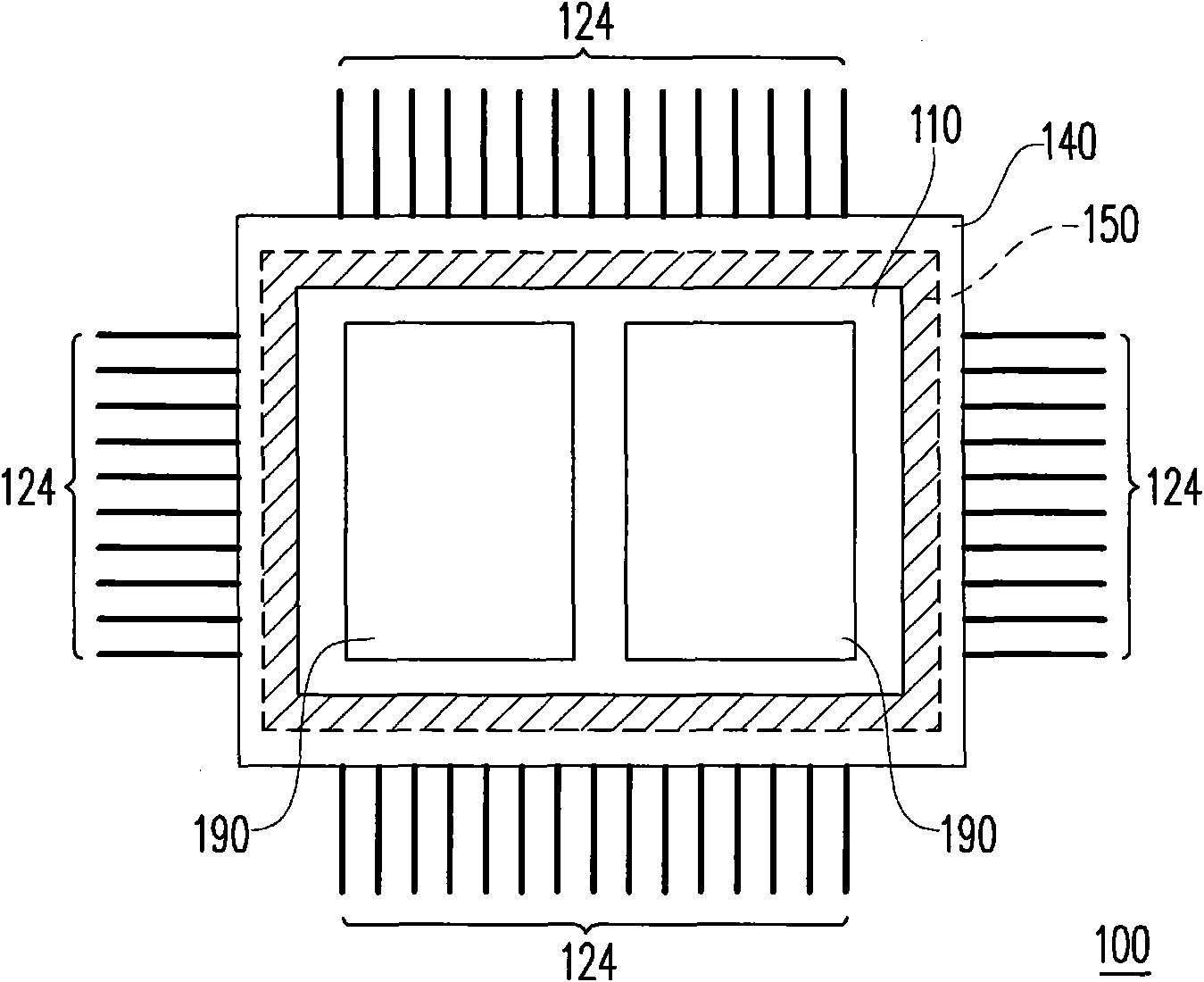

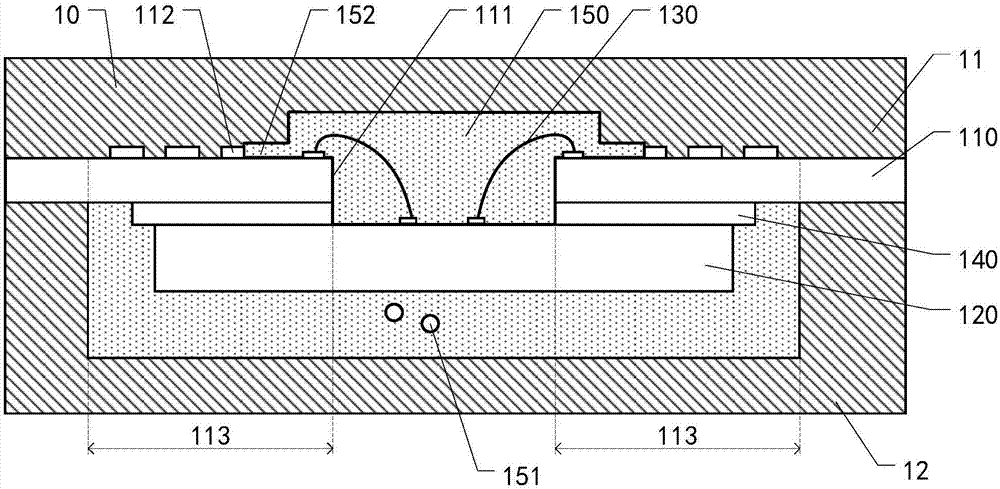

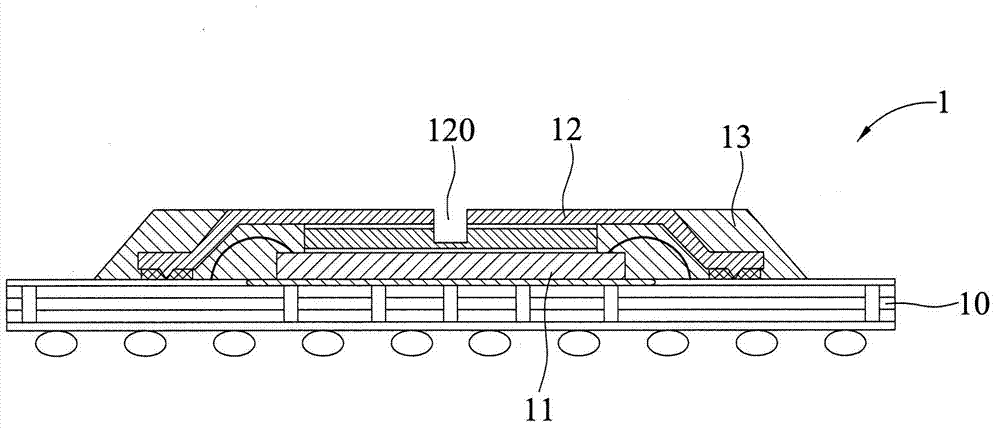

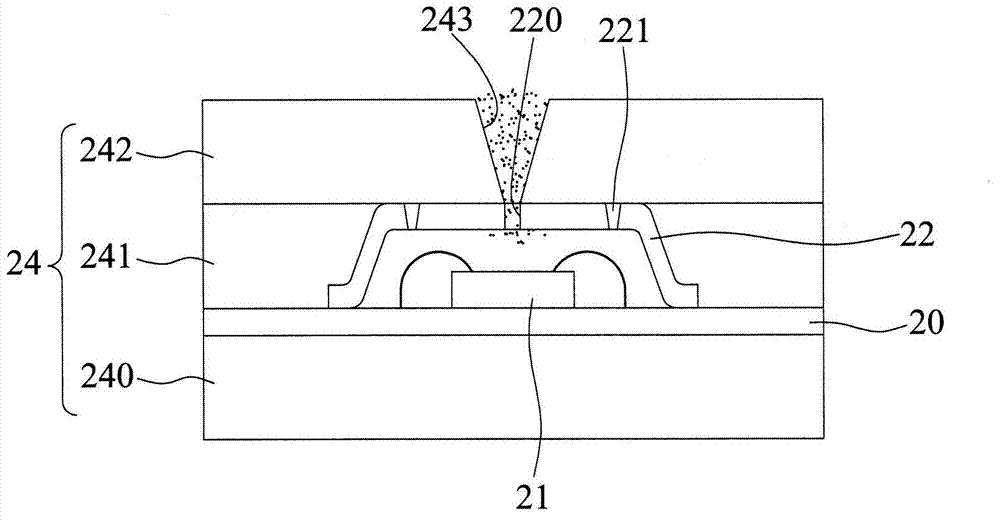

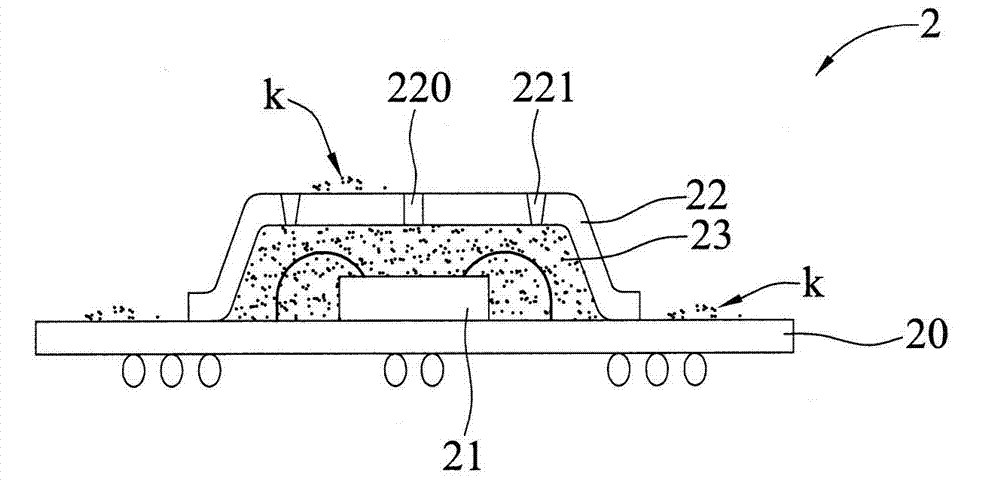

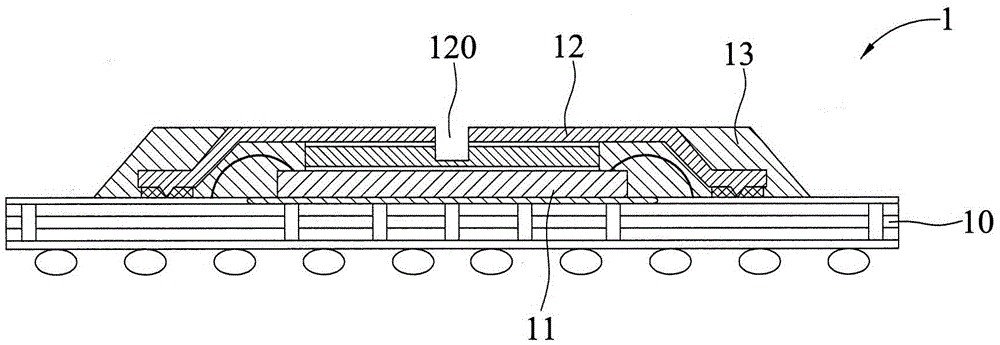

Packaging structure and packaging method

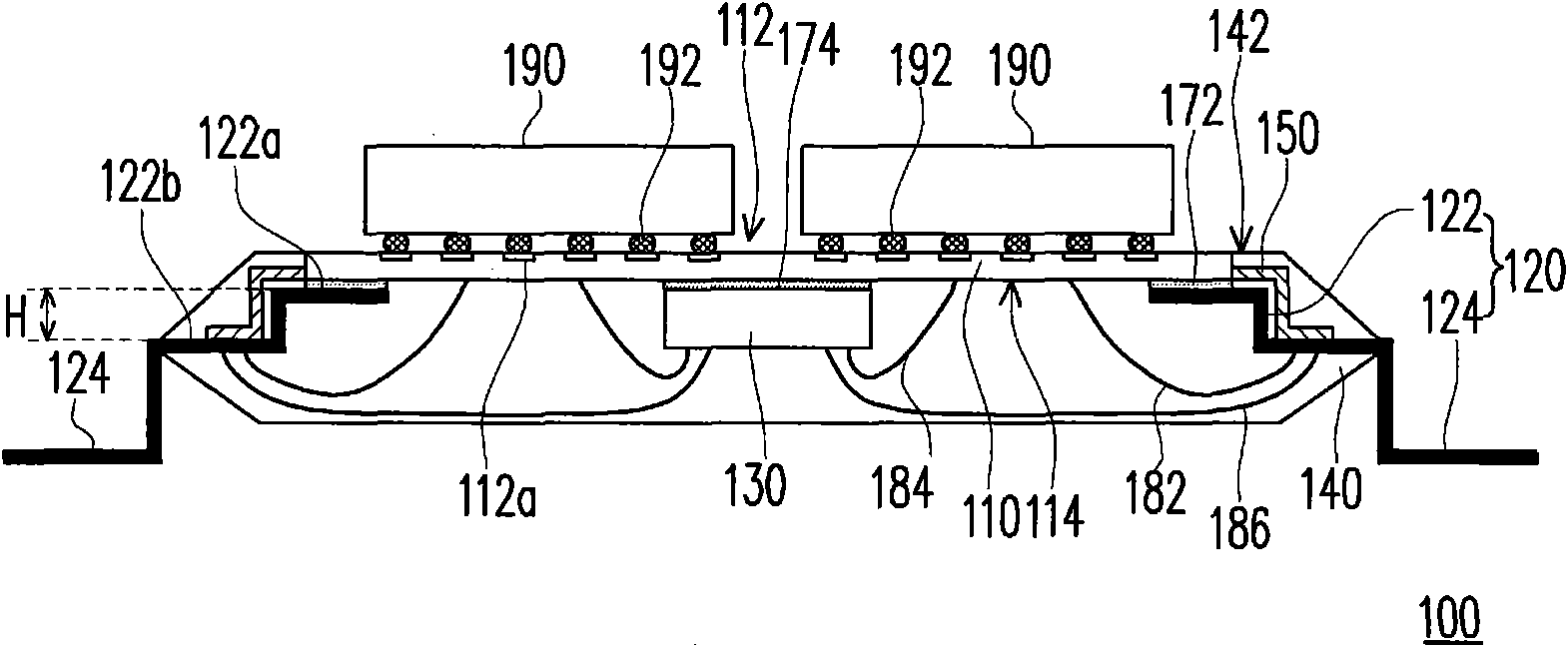

ActiveCN101989581AGood compatibilityGood system integration abilitySemiconductor/solid-state device detailsSolid-state devicesEngineeringColloid

The invention provides a packaging structure and a packaging method. The packaging structure comprises a circuit substrate, at least one wafer, a plurality of pins and a packaging colloid. The circuit substrate is provided with a first surface and a second surface which are opposite, wherein the circuit substrate is provided with a plurality of contacts on the first surface. The wafer is arranged on the second surface of the circuit substrate and electrically connected with the circuit substrate. The plurality of pins are arranged on the periphery of the second surface of the circuit substrate to encircle the wafer. Each pin is provided with an inner pin part and an outer pin part, and each pin is electrically connected with the circuit substrate through the inner pin part thereof. The packaging colloid wraps the circuit substrate, the wafer and the inner pin part of each pin and exposes the first surface of the circuit substrate and the outer pin part of each pin, wherein the upper surface of the packaging colloid is coplanar with the first surface of the circuit substrate.

Owner:ADVANCED SEMICON ENG INC

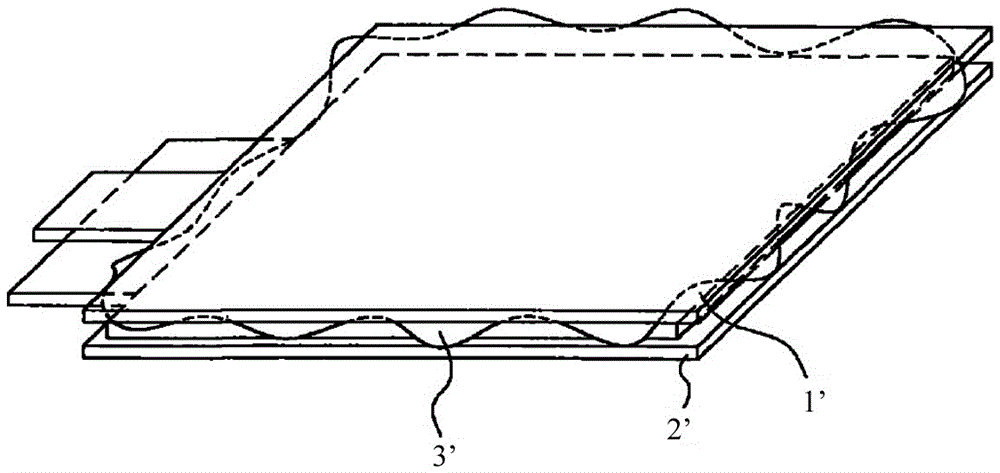

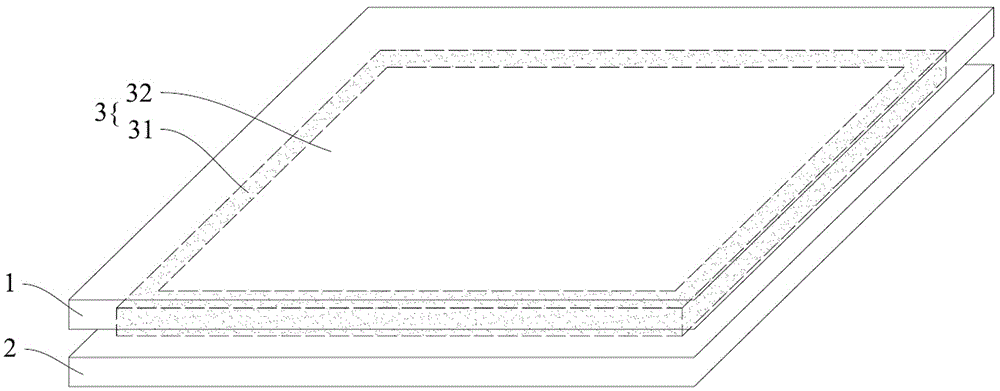

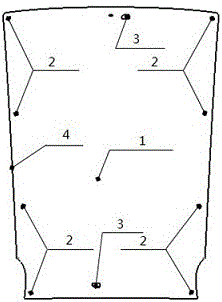

Glue laminating process

InactiveCN105774184APrecise Width ControlEasy to operateLamination ancillary operationsLaminationProduction lineColloid

The invention provides a glue laminating process. The glue laminating process comprises the following steps: (1) providing a first substrate and a second substrate; (2) dispensing a glue to the first substrate and / or the second substrate; (3) carrying out aligned press-fitting on the first substrate and the second substrate, and meanwhile, curing the periphery of the first substrate and / or the second substrate so as to obtain a semifinished product with a periphery-cured frame; and (4) carrying out surface-dressing curing on the semifinished product with the periphery-cured frame, thereby obtaining a finished product. According to the glue laminating process, the periphery of the substrates is cured while the aligned press-fitting of the substrates is completed so as to obtain the periphery-cured frame, thus, the problem of glue overflowing is effectively solved, the width of overflowed glue can be accurately controlled, the broadening of the glue does not occur after curing, secondary misalignment does not occur after curing, the accuracy of press-fitting is further improved, and the actual operation of a production line is facilitated; and the problem of press-fit bubbles can be effectively solved, the leveling of the glue is accelerated, the production time is shortened, and the production efficiency is further increased.

Owner:TRULY OPTO ELECTRONICS

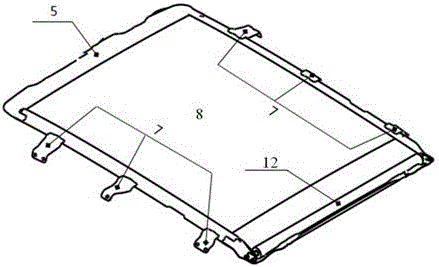

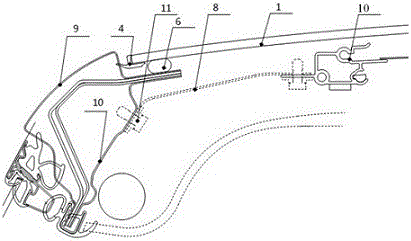

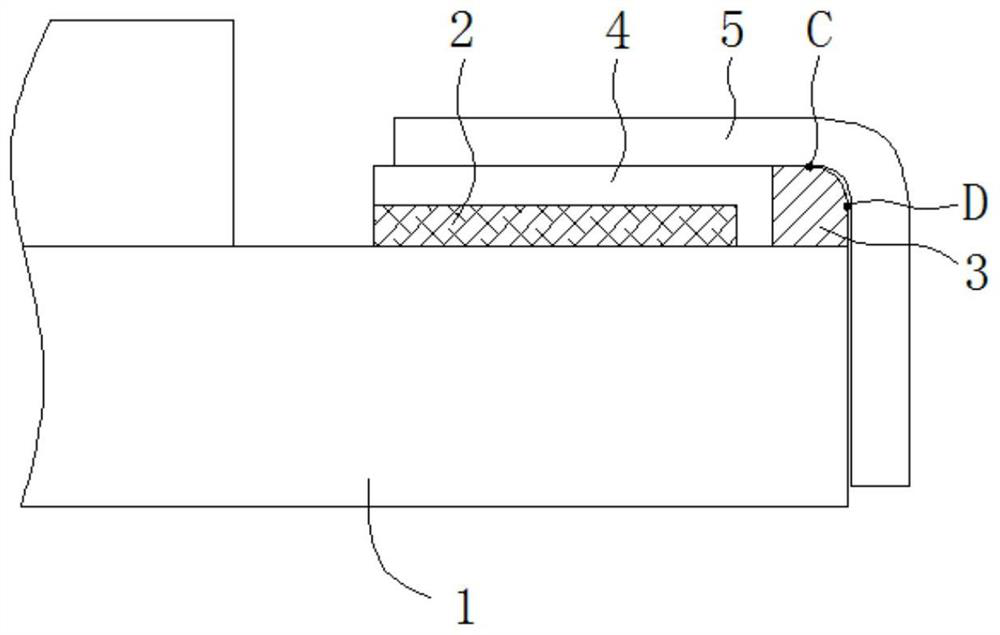

Automobile panoramic sunroof assembly and installation method thereof

InactiveCN106347086AAvoid Glue Overflow ProblemsReduce tight sealWindowsEngine sealsAutomotive engineeringGlass structure

The invention discloses an automobile panoramic sunroof assembly and an installation method of the automobile panoramic sunroof assembly. The automobile panoramic sunroof assembly comprises a panoramic glass assembly and a sunshade curtain assembly, wherein the panoramic glass assembly is arranged in a skylight opening of the roof of an automobile; the sunshade curtain assembly is arranged in the position, below the panoramic glass assembly, of the roof of the automobile; an appropriate gap is reserved between the sunshade curtain assembly and the panoramic glass assembly; the panoramic glass assembly comprises panoramic fixed glass; the panoramic fixed glass is adhered and fixed on a metal plate at the edge of the skylight opening through glass-structured glue. The automobile panoramic sunroof assembly disclosed by the invention has the advantages that the automobile panoramic sunroof assembly can be flexibly, reliably and fixedly connected with an automobile body, the panoramic fixed glass has enough rigidity and strength, the installation is fixed and reliable, the installation operation is convenient, and the manufacture cost is low; meanwhile a sunshade curtain has a compact structure, therefore more ideal sitting space can be also obtained while a maximal light-transmitting area of a passenger compartment is guaranteed, and stronger application prospects for marketing promotion are obtained.

Owner:CHERY AUTOMOBILE CO LTD

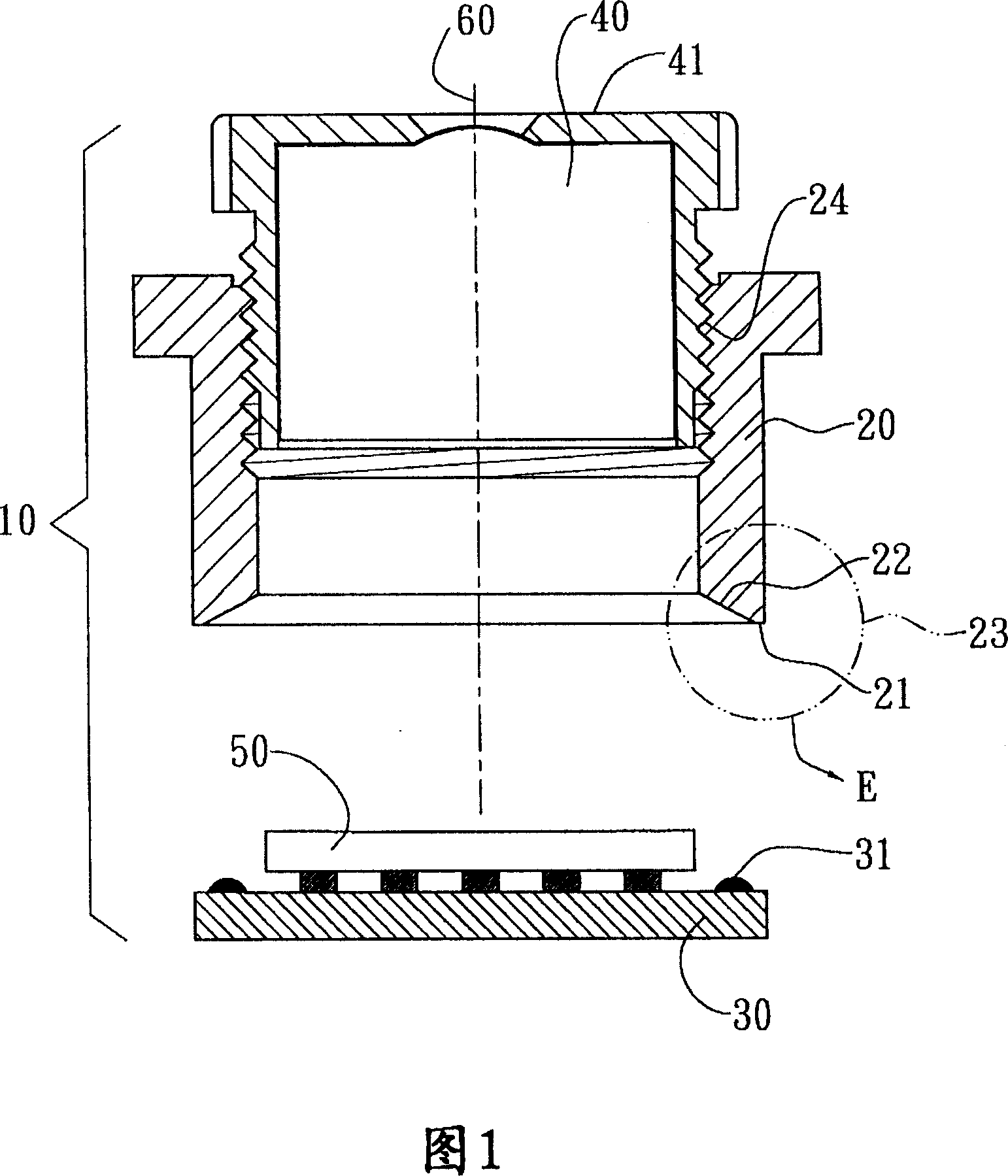

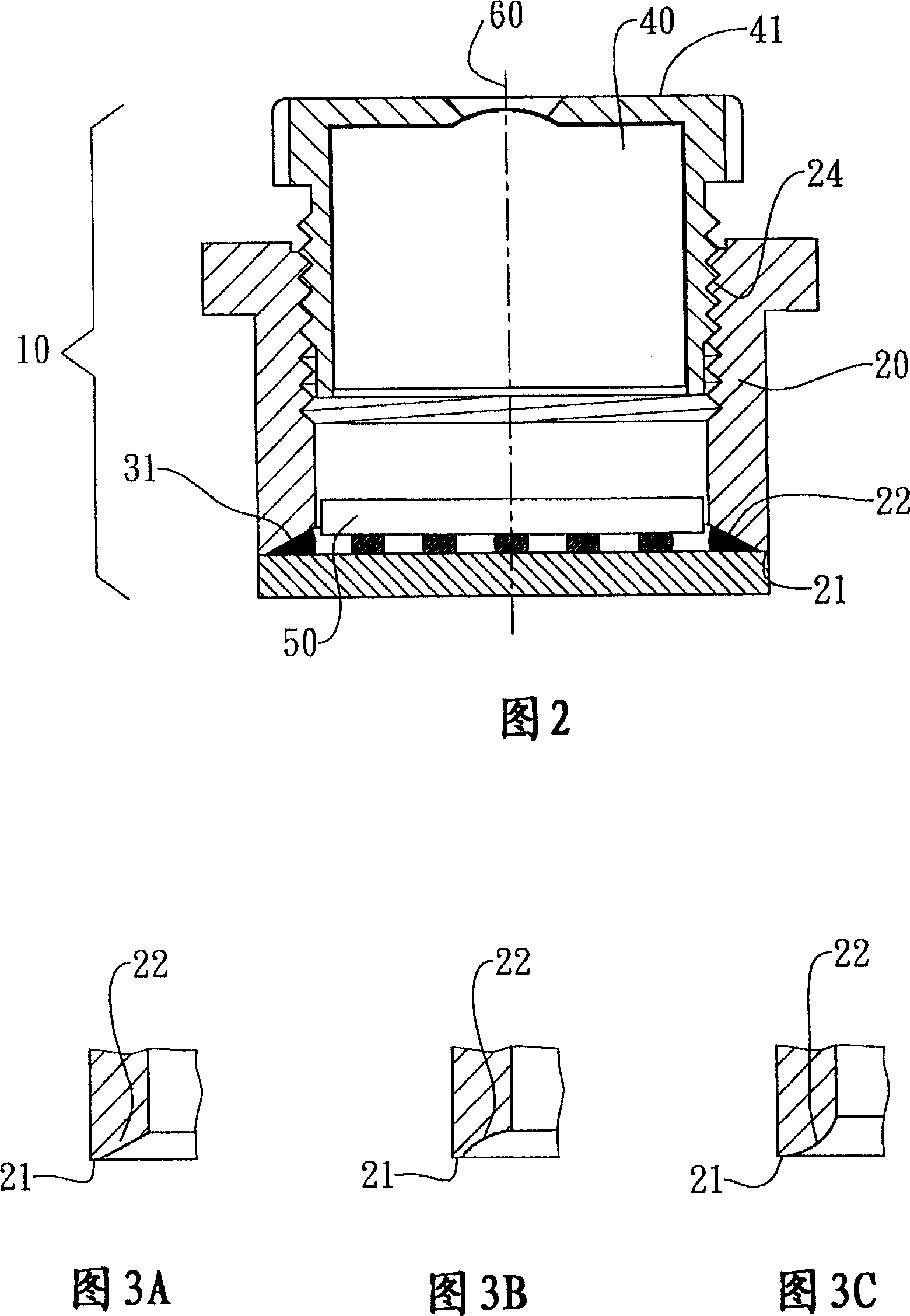

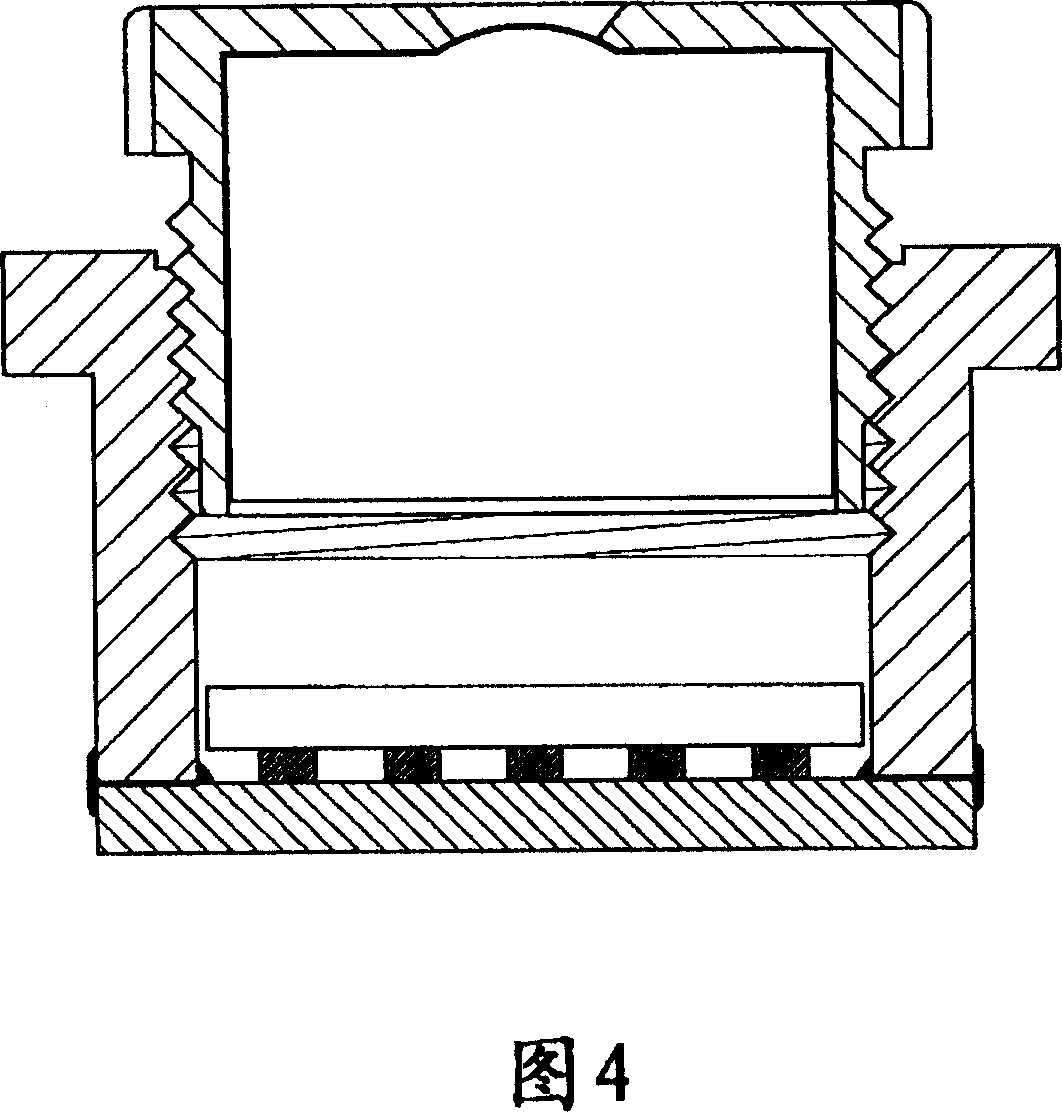

Structure for preventing glue leakage of lens base

InactiveCN101000398APrevent overflowSolve the glue overflow problemMountingsInternal pressureCamera lens

A glue overflow proof structure of camera lens seat is prepared as arranging a horizontal unit and a tilted unit at bottom of camera lens seat, forming internal pressure to lead glue to be flowed towards inside by said tilted unit and said glue when bottom of camera lens seat is contacted with glue in process of combining base with circuit board.

Owner:CHICONY ELECTRONICS

Display device and manufacturing method thereof

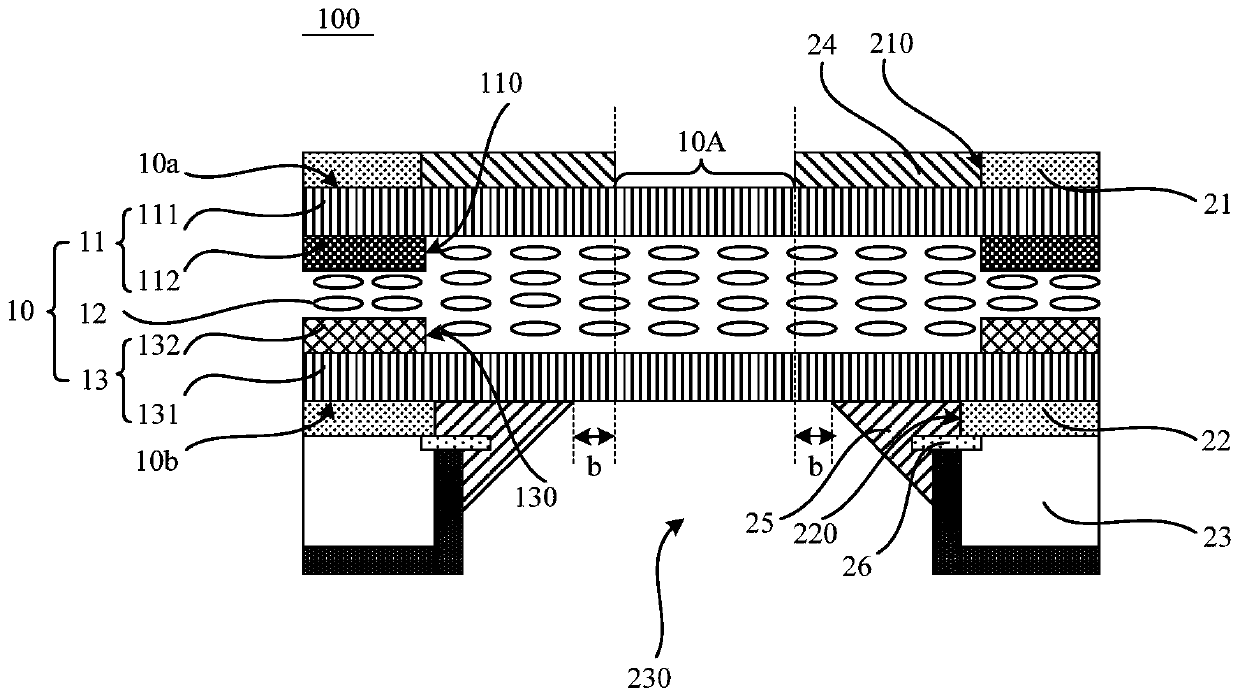

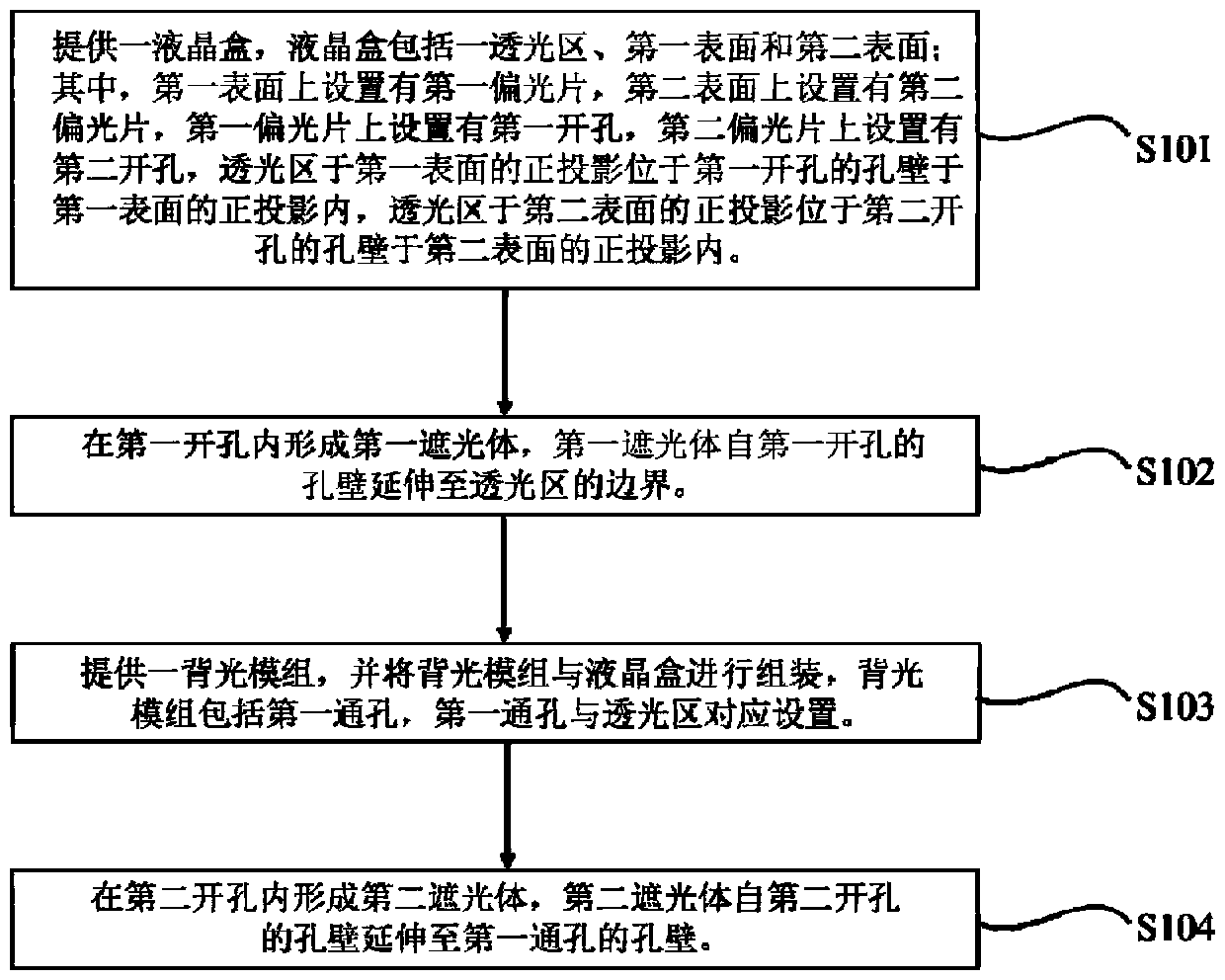

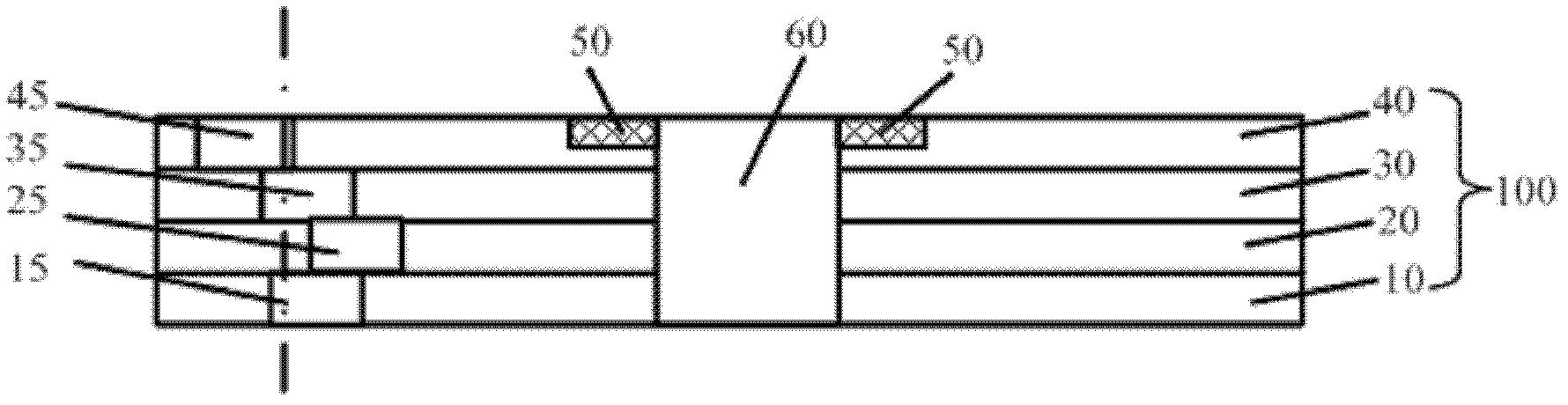

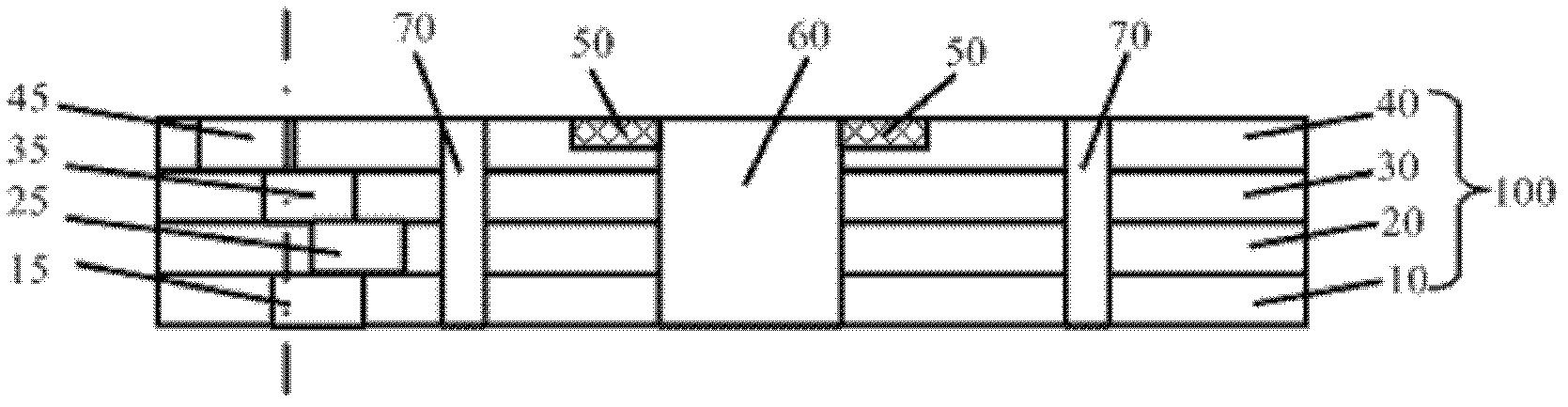

ActiveCN110703486ASolve the glue overflow problemGuaranteed Viewing RangeNon-linear opticsDisplay deviceEngineering

The invention provides a display device and a manufacturing method thereof. The display device comprises: a liquid crystal box, wherein the liquid crystal box comprises a light transmitting area; a first polaroid, wherein a first open pore is formed in the first polaroid; a second polaroid, wherein a second open pore is formed in the second polaroid; a backlight module, wherein the backlight module comprises a first through hole, and the first through hole is formed corresponding to the light transmitting area; a first light shielding body arranged in the first open pore, wherein an orthographic projection of the first light shielding body on the first surface is located on the periphery of the orthographic projection of the light transmitting area on the first surface; and a second lightshielding body arranged in the second open pore and extending to a hole wall of the first through hole, wherein the orthographic projection of the second light shielding body on the second surface islocated on the periphery of the orthographic projection of the light transmitting area on the second surface. The display device provided by the invention solves the problem of glue overflow caused bycoating light shielding glue at the open pores of the polaroids, and ensures the viewing angle range of an electronic device.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

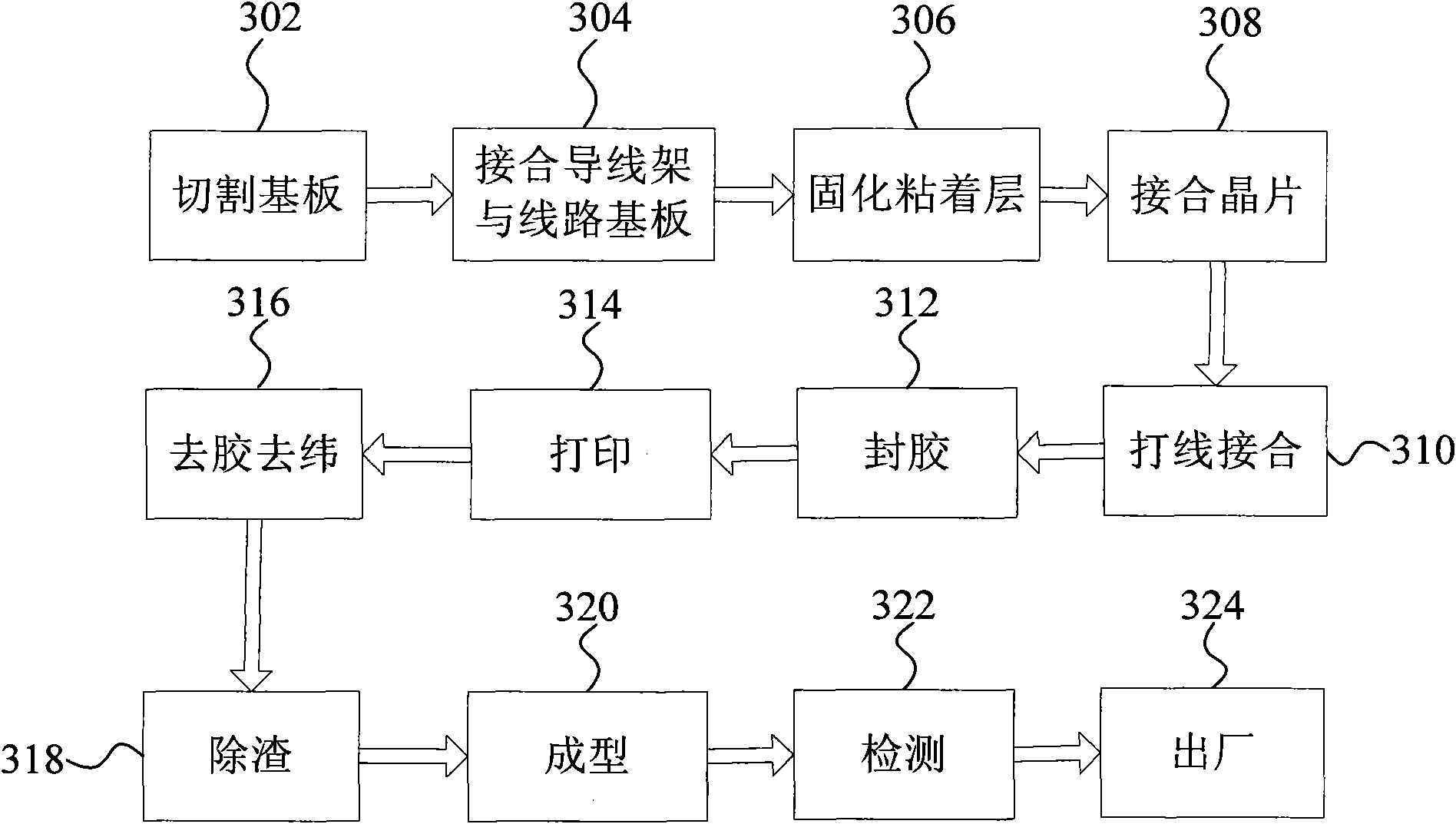

Package method for printed circuit board (PCB) substrate

ActiveCN103037639AHigh precisionStable signal transmissionMultilayer circuit manufacturePrinted circuit boardEngineering

A package method for a printed circuit board (PCB) substrate comprises a multilayer plate. The multilayer plate comprises at least two single-layer plates, wherein one single-layer plate is high in counterpoint accuracy requirements, and identification is arranged in the single-layer plate with high counterpoint accuracy requirements. The identification of the single-layer plate, with high counterpoint accuracy requirements, of the multilayer plate is achieved, the center of the identification is calculated, and with the center as a standard, the multilayer plate is drilled at the preset position of a through hole to form the through hole penetrating through all single-layer plates of the multilayer plate. An embodiment of the packing method for the PCB substrate guarantees accuracy of the single-layer plate with high counterpoint accuracy requirement and improves performance of the PCB substrate.

Owner:JIANGNAN INST OF COMPUTING TECH

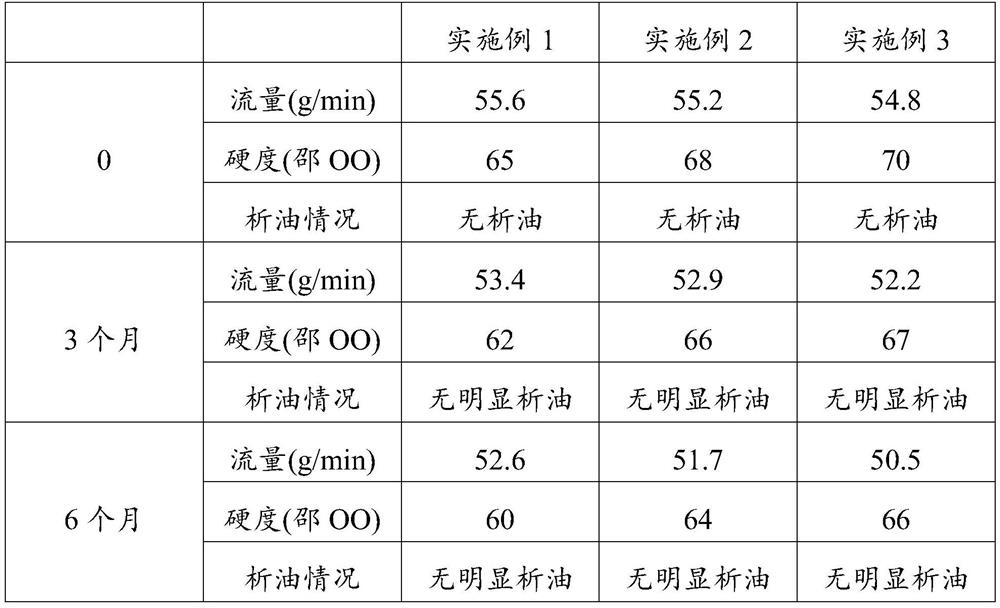

Stable low-oil-permeability two-component heat-conducting gel and preparation method thereof

The invention discloses stable low-oil-permeability two-component heat-conducting gel which comprises a component A and a component B; the component A is prepared from the following substances in parts by weight: 10 parts of dimethyl silicone oil, 5 to 8 parts of vinyl silicone oil, 2 to 5 parts of a coupling agent A, 1 part of blue color paste, 0.3 to 0.5 part of a polyether modified organic silicon defoaming agent, 0.5 to 0.8 part of a platinum catalyst, 1 to 2 parts of a microcapsule type platinum catalyst, 600 to 800 parts of spherical aluminum oxide and 50 to 80 parts of spherical aluminum nitride; the component B is prepared from the following substances in parts by weight: 18 parts of dimethyl silicone oil, 0.5-0.8 part of hydrogen-containing silicone oil, 2-5 parts of a coupling agent B, 0.3-0.5 part of a polyether modified organic silicon defoaming agent, 600-800 parts of spherical aluminum oxide and 50-80 parts of spherical aluminum nitride. According to the invention, the curing time of field frequency can be effectively prolonged, and normal curing can be realized within 6 months.

Owner:SHENZHEN DARBOND INTERFACE MATERIALS

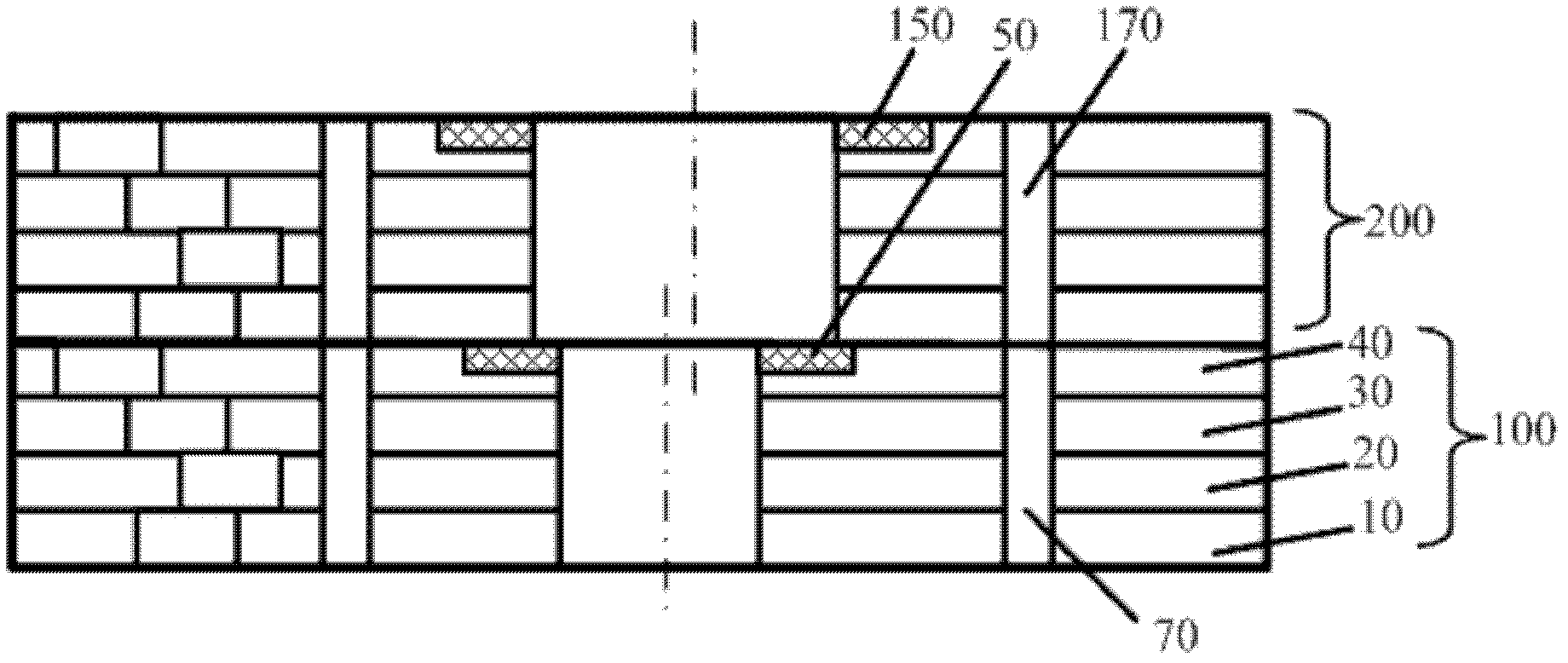

Display panel and spliced screen

PendingCN111798756AReduce border widthNarrow seamsSolid-state devicesIdentification meansElectrical connectionEngineering

The invention provides a display panel and a spliced screen. The display panel comprises a display area and a binding area located on one side of the display area. The display panel also comprises a binding bonding pad which is arranged in the binding area, a retaining wall which is arranged on one side, close to the boundary of the display panel, of the binding bonding pad; and a chip-on-film which is bound on the binding bonding pad through a conductive adhesive; wherein a signal line of the display area is electrically connected with the binding bonding pad; and the boundary of the conductive adhesive is located on the side, close to the display area, of the retaining wall. According to the invention, the retaining wall is arranged on the edge of the display panel, so that the problem of conductive adhesive overflowing caused by the binding of the chip-on-film and the display panel is prevented, the frame width of the display panel is reduced, and the display effect of the spliced screen is improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

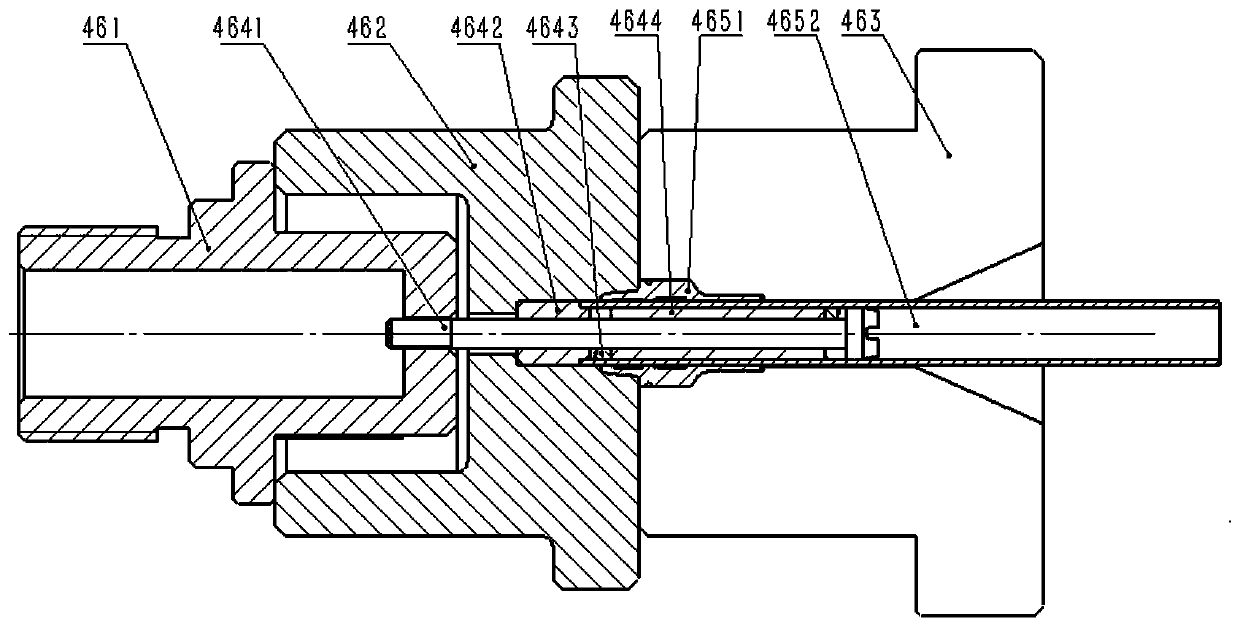

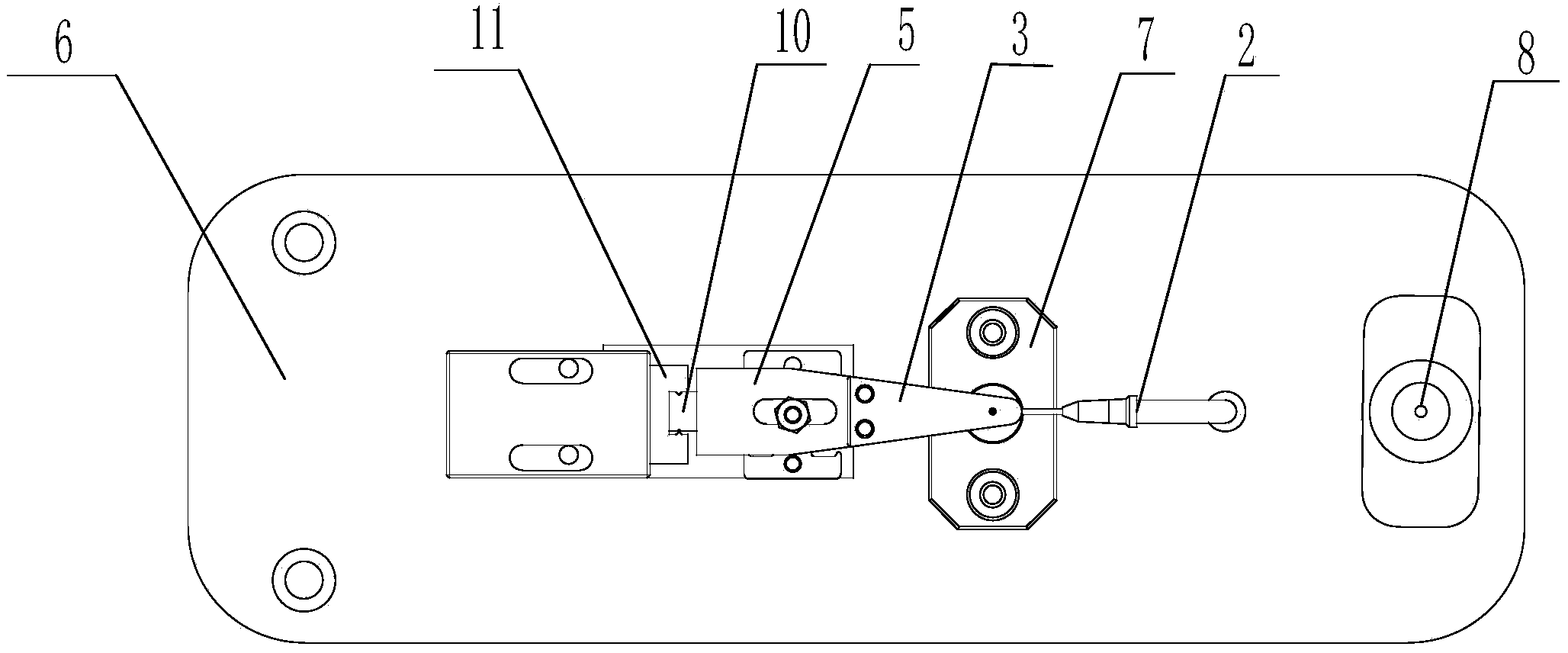

Extrusion connecting device for non-flaring guide tube connector

InactiveCN111516276ASolve the defect that the extrusion force control is not accurate enoughSolve the problem of overflow glueTubular articlesEngineeringGuide tube

The invention discloses an extrusion connecting device for a non-flaring guide tube connector. The extrusion connecting device comprises a hydraulic system, a clamping mechanism, a stretching mechanism, an anvil mould, semi-female moulds and a pull rod assembly, wherein an adapter head driven by the stretching mechanism is connected to the pull rod assembly; the anvil mould is detachably fixed onto a base foundation through an anvil mould base; the anvil mould is provided with cylindrical mould cavity structures which are sequentially arranged and are provided with four-grade diameters; the semi-female moulds are symmetrical structures which are formed by combining two semicircular rings, and are detachably mounted and fixed in clamping arm half holes of a clamping mechanism for clamping and fixing the guide tube connector during closing; and a mould closing gap is formed in a combined part while the two half circular rings are combined to clamp and fix the guide tube connector. The extrusion connecting device can effectively reduce labor intensity of an operator, can achieve self-adaptive clamping for dimension difference of different workpieces of the same theoretical specification, and can overcome the gap glue overflow problem of the pull rod and the inner diameter of the guide rod, so that quality of produced products is improved, the problem that mould is troublesome to replace is solved, and processing efficiency is improved.

Owner:SICHUAN ZHONGZI TECH

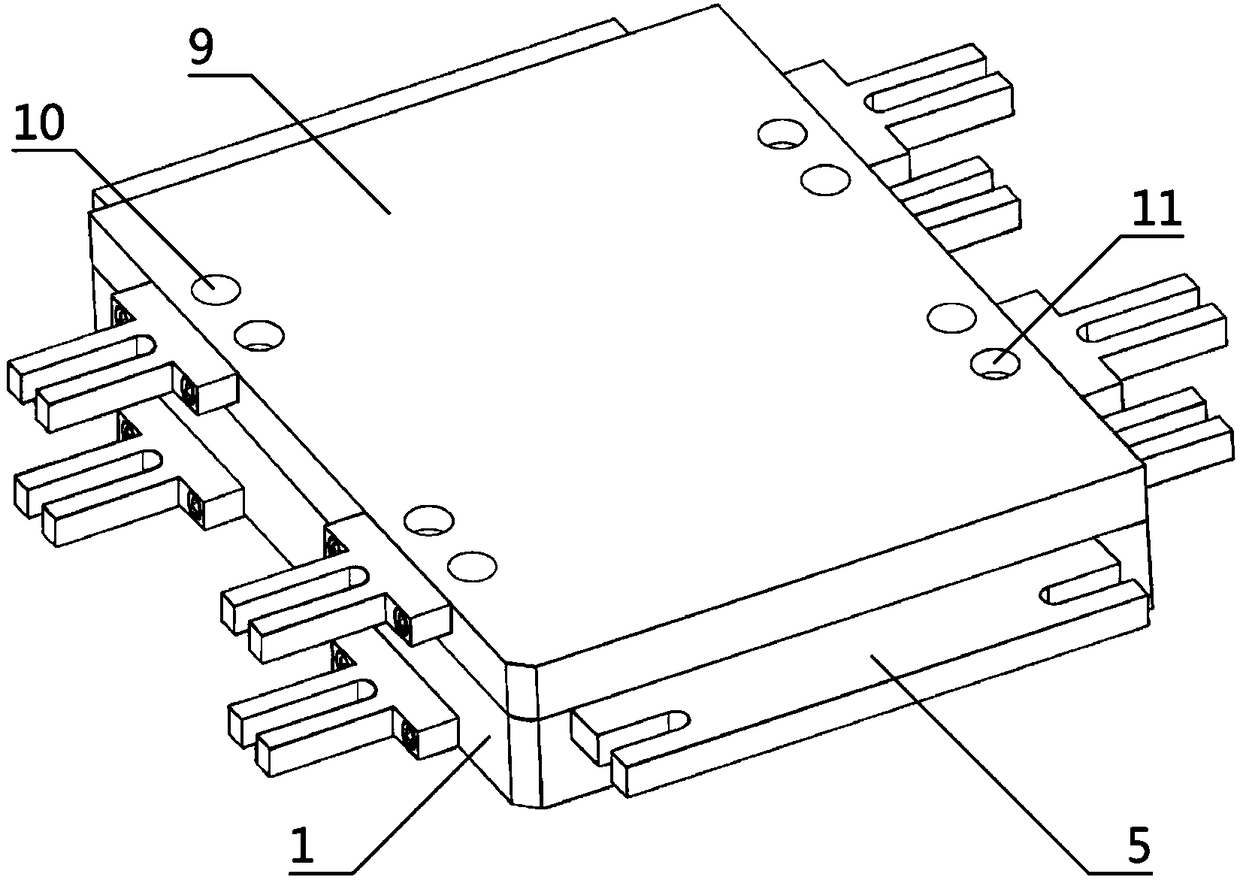

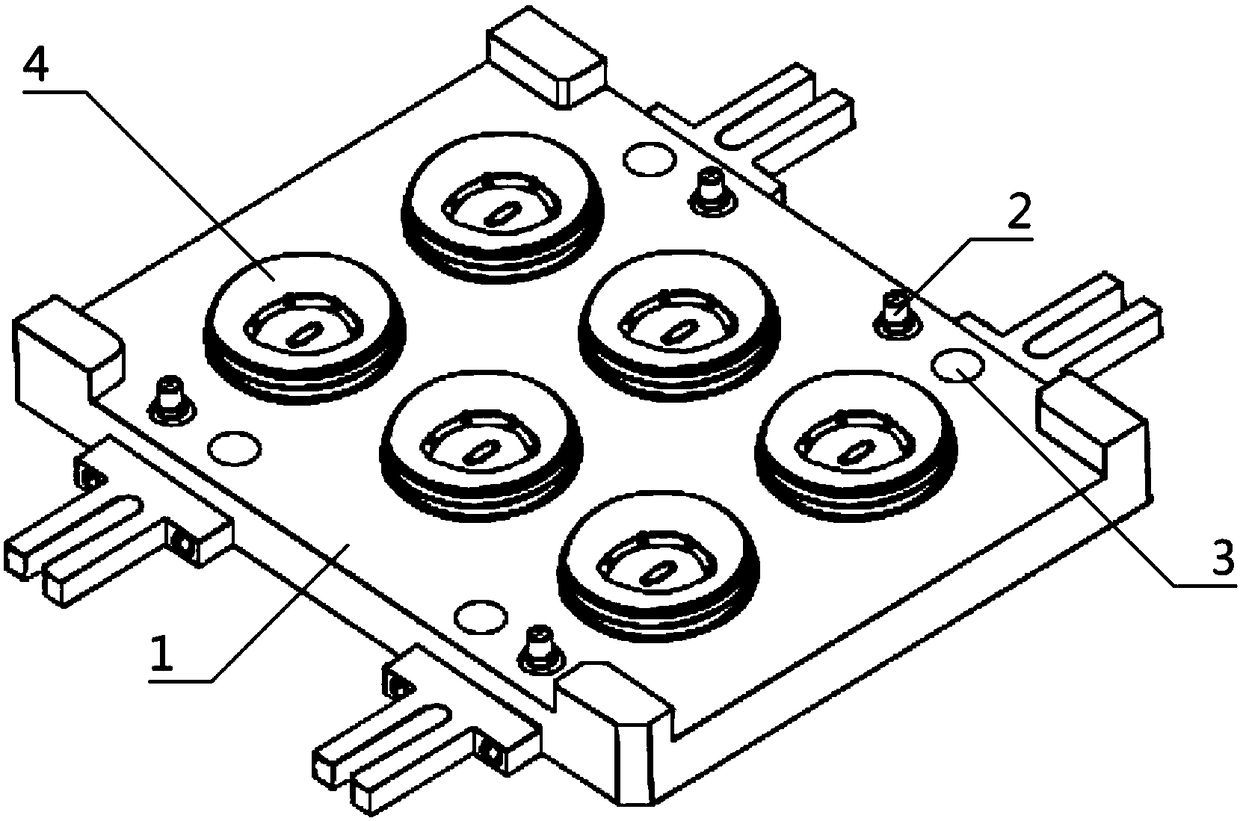

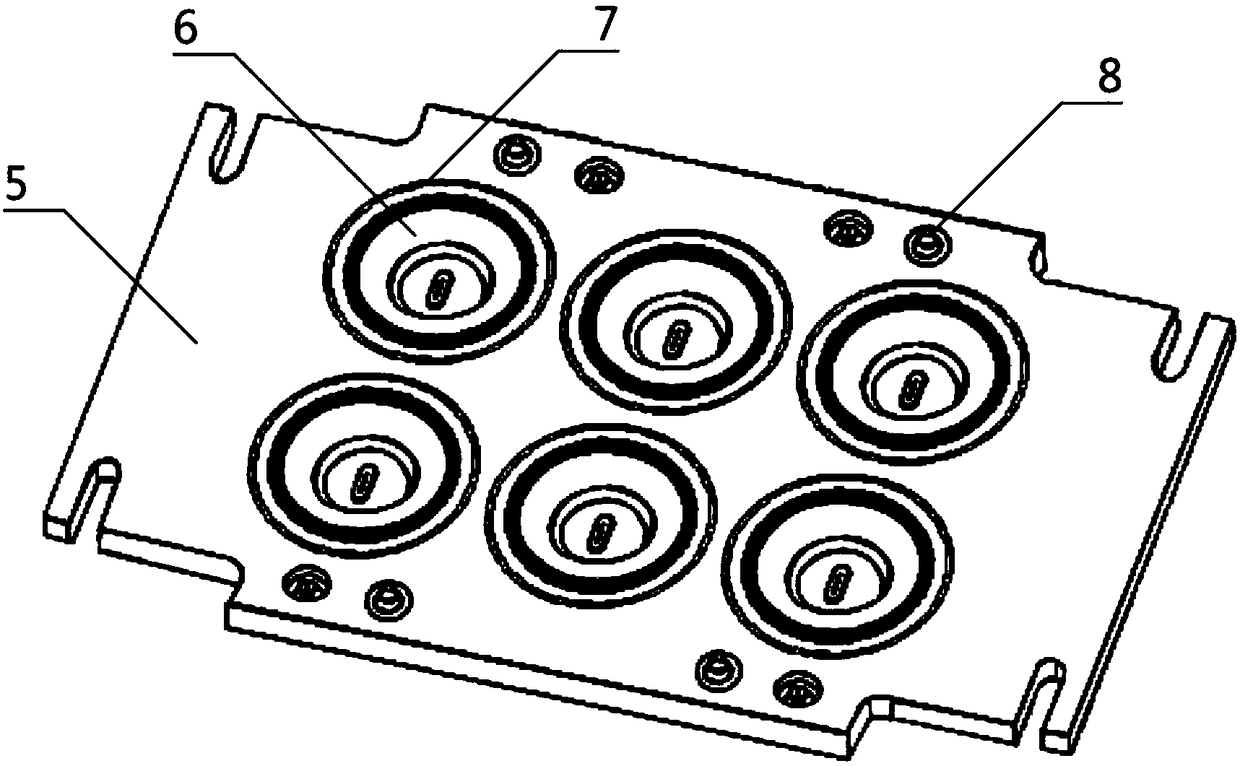

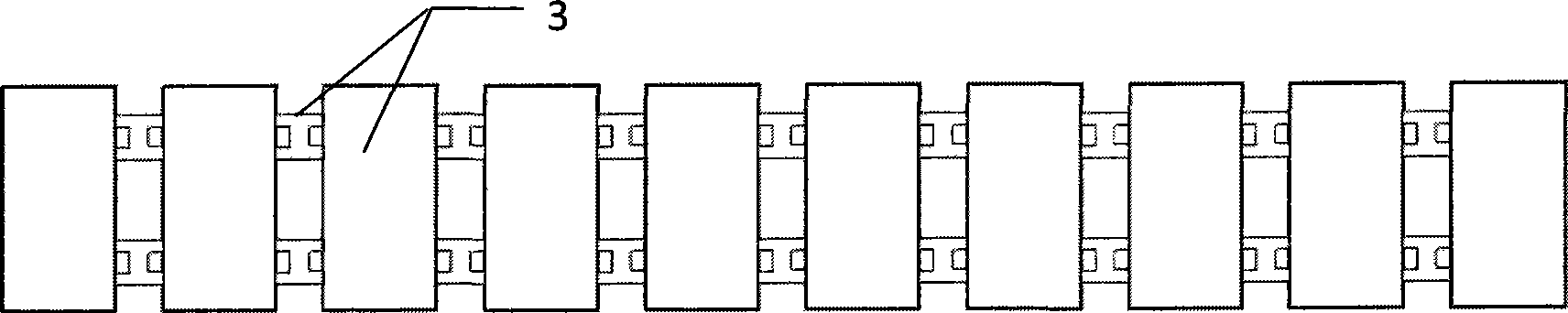

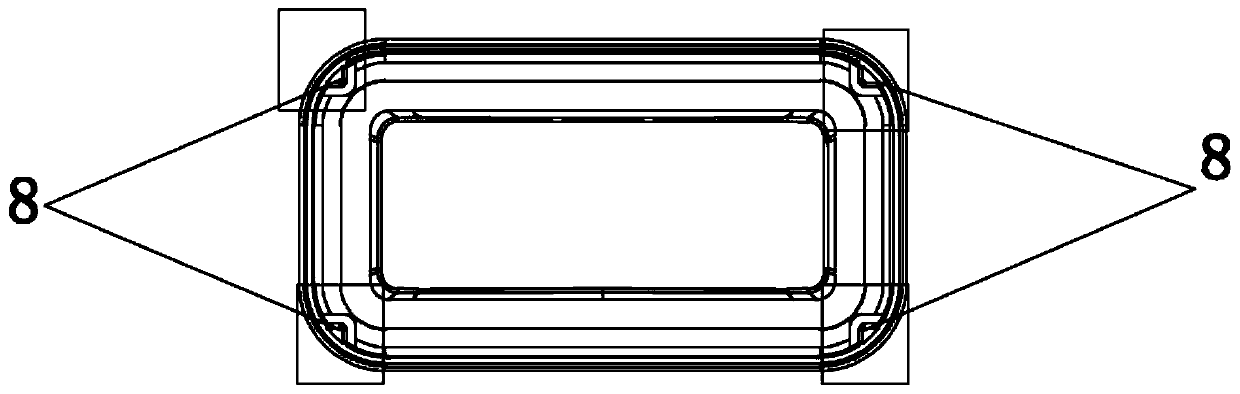

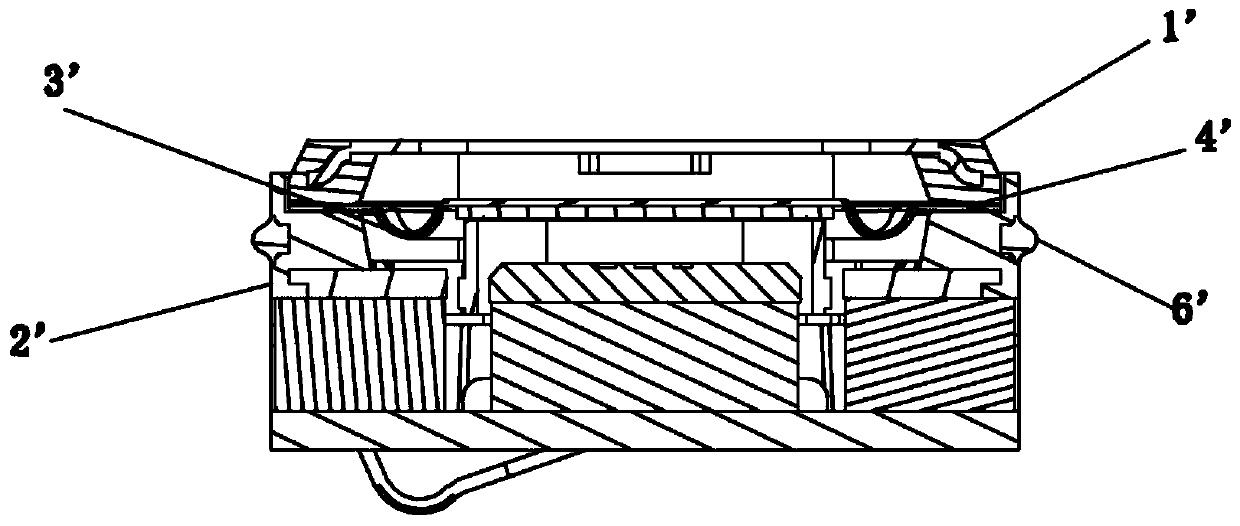

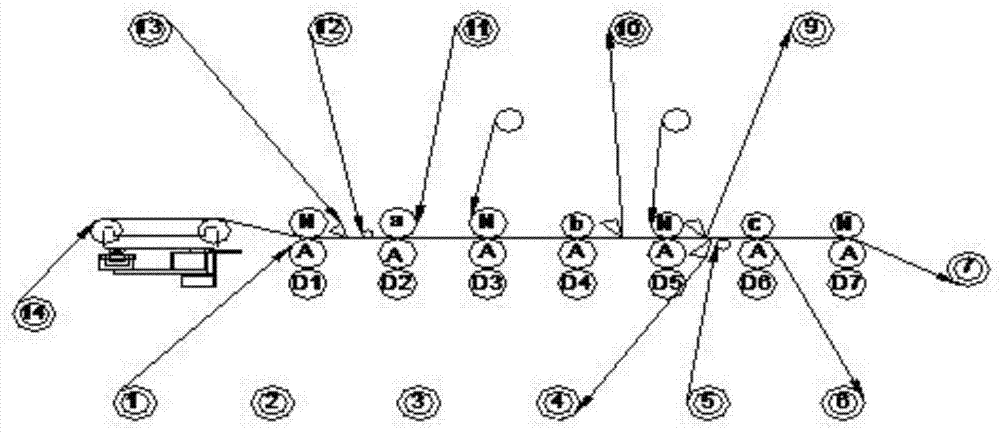

Earphone rubber-coating forming mould structure

InactiveCN108058329APrevent spillageSimple structureElectrical transducersDomestic articlesComposite materialCoating

The invention aims to provide an earphone rubber-coating forming mould structure. According to the technical scheme, the earphone rubber-coating forming mould structure is composed of a lower mould plate, a middle mould plate and un upper mould plate; the lower mould plate is provided with lower mould positioning columns, lower mould positioning holes and lower mould forming moulds; the middle mould plate is provided with forming mould holes and middle mould positioning holes; the upper mould plate is provided with upper mould positioning columns, upper mould positioning holes and upper mouldforming moulds; and overflow grooves are further formed in the outer sides of all the forming mould holes and can prevent rubber from overflowing, so that formed products are more attractive. The flow-diving rubber-coating jig is simple in structure, the product forming stability is higher through the three-body closing type design mode, the rubber overflowing problem of the products after demoulding of the products can be prevented through the vertical flow-diving design, operation is safer and more environmentally friendly, and the quality and accuracy of the products are greatly improved.

Owner:SYNERGY HANIL PRECISION POLYMER TECH CO LTD

Method for pasting battery string on space solar battery substrate surface

InactiveCN101436624AAvoid problemsEliminate deformationFinal product manufactureSemiconductor devicesScreen printingEngineering

The invention relates to a method for mounting a cell string on the surface of a spatial solar cell substrate in the technical field of spatial solar power supply. The method adopts a mounting mechanism consisting of a negative pressure gripping and pressurizing frock and a frock clamp to realize the gripping of the cell string; screen printing technology is adopted to coat glue on the surface of the cell string; and after the mounting is completed, the cell string is pressurized through the negative pressure gripping and pressurizing frock to realize parallel operation of glue coating and pressurization of the cell string. The method can effectively solve the problems of glue spilling, denaturalization of the cell string and mounted bubbles in the process of mounting the cell string and realize automatic mounting.

Owner:SHANGHAI JIAO TONG UNIV

EVA packaging glue film with effect of improving solar assembly transition power

ActiveCN106398592AIncrease conversion powerLow costNon-macromolecular adhesive additivesFilm/foil adhesivesCross-linkEngineering

The invention discloses an EVA packaging glue film with an effect of improving solar assembly transition power. The EVA packaging glue film comprises a transparent front glue film and a white back glue film. The front glue film is prepared from 0.05-5% by mass of a cross-linking agent, 0.05-5% by mass an assistant cross-linking agent, 0.05-3% by mass of a coupling agent, 0.05-2% by mass of a hydrophobic agent, 0.02-1.5 parts by mass of a light stabilizing agent, 0.02-1.0% by mass of an antacid, 0.02-1.0% by mass of a UV transition agent and the balance EVA resin. The EVA packaging glue film has a low cost, high performances and high transition power, has lasting resistance to damp and hot, UV, PID and snail cracks in a photovoltaic system and satisfies photovoltaic assembly market requirements now and forever.

Owner:杭州福莱蒽特新能源有限公司

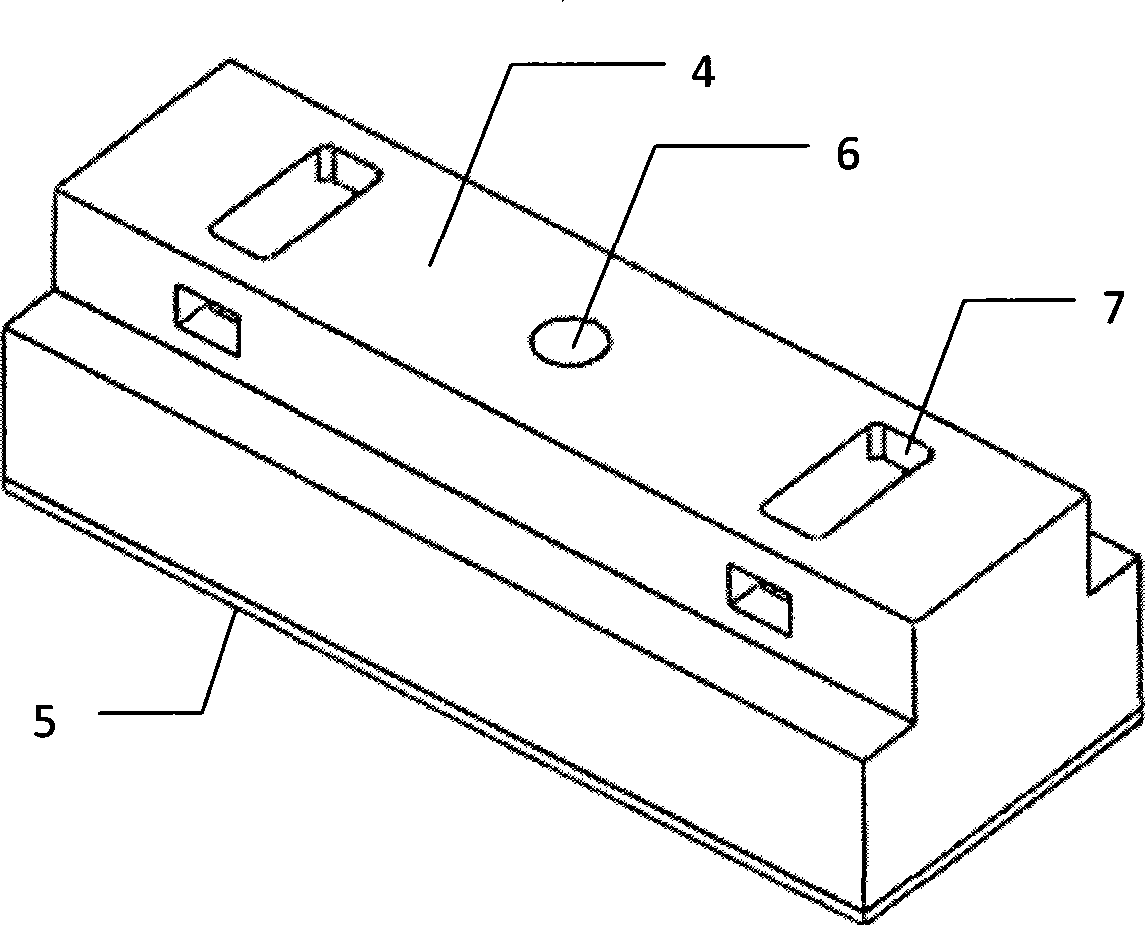

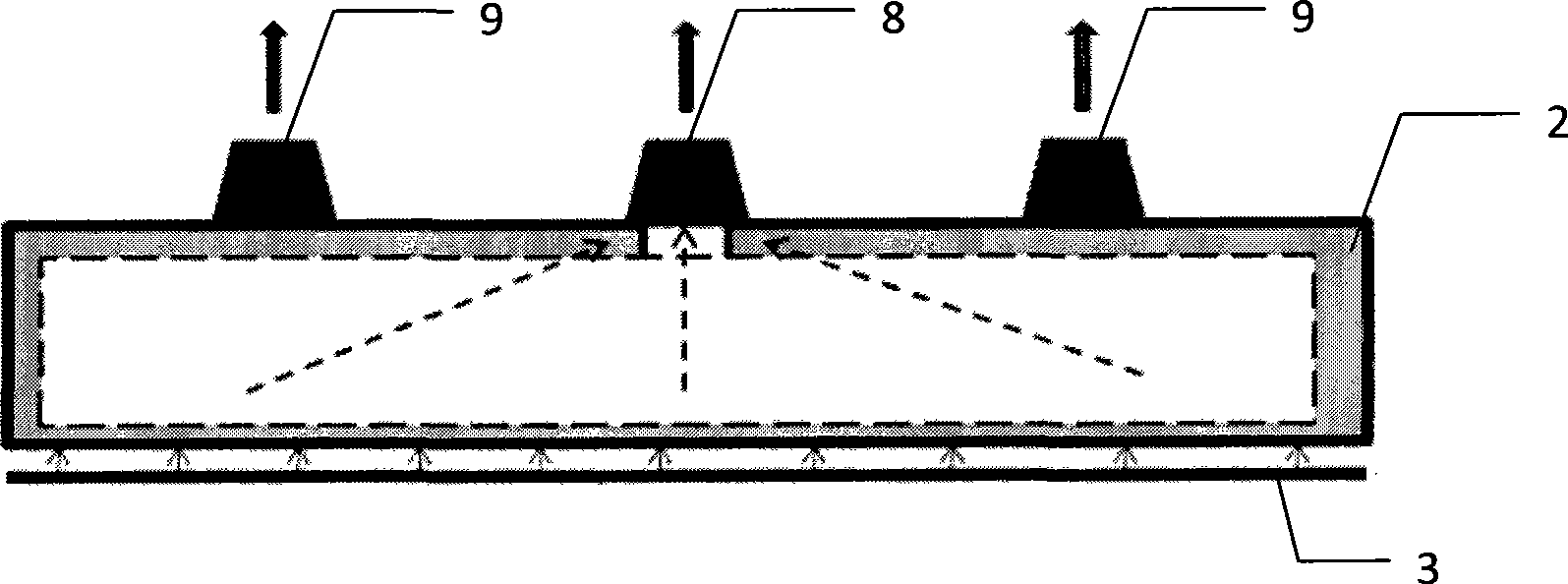

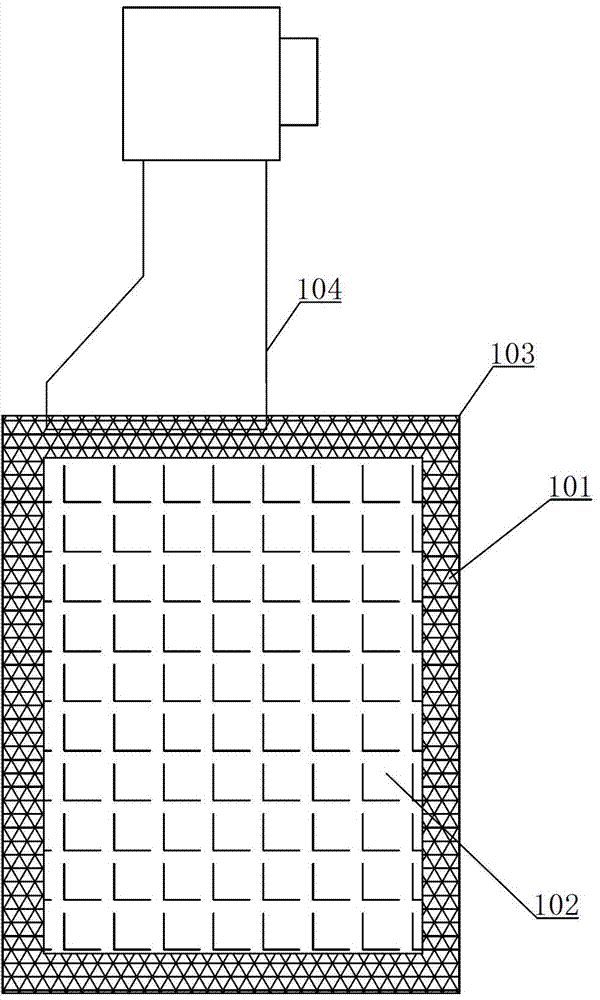

Cofferdam type glue sticking process

Owner:HUIZHOU NENGHUI CHEM CO LTD

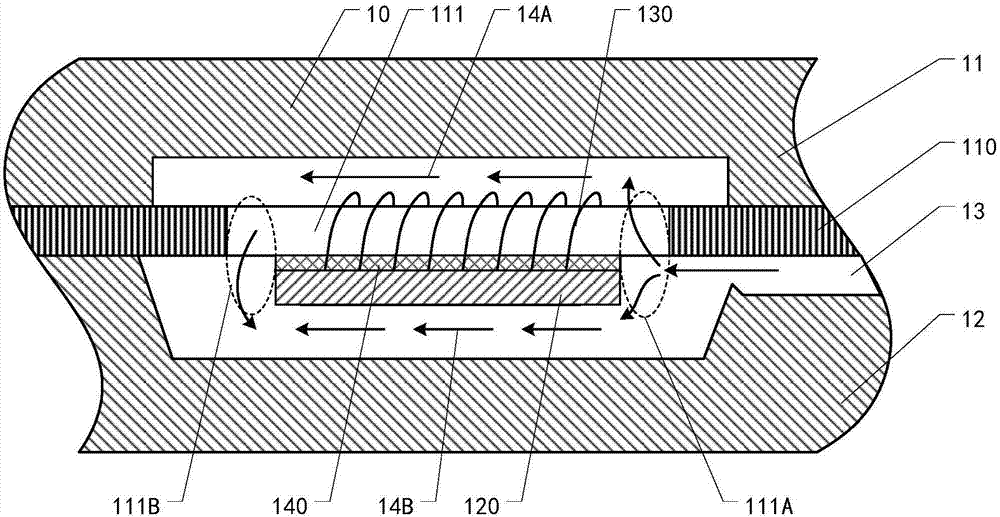

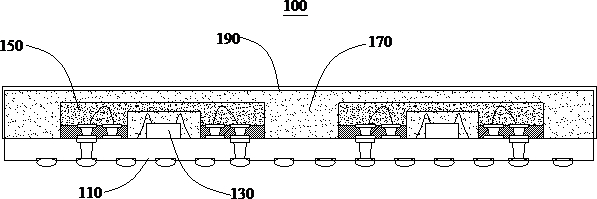

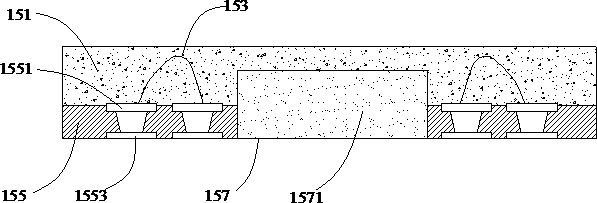

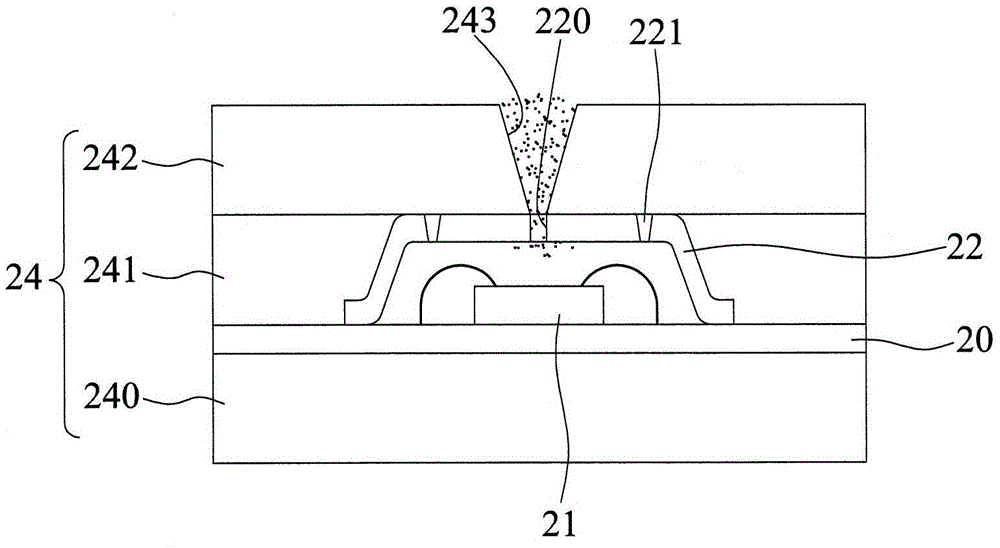

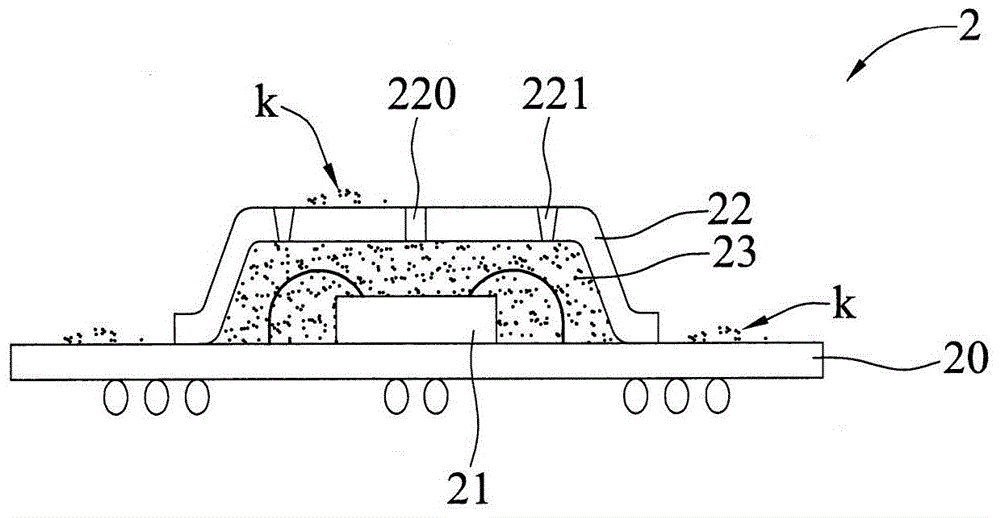

Window type ball grid array packaging module

InactiveCN107369655ASolve the glue overflow problemAvoid voidsSemiconductor/solid-state device detailsSolid-state devicesChannel widthInjection molding process

The invention provides a window type ball grid array packaging module. The window type ball grid array packaging module comprises a substrate, which includes a first surface and a second surface which are opposite to each other, and a window penetrating through the first surface and the second surface is formed on the substrate, wherein the first surface is provided with a plurality of contacts adjacent to the window and a plurality of bonding pads in matrix arrangement; the second surface includes a chip installation area, and a glue inlet through which a glue is entered and a glue outlet through which the glue is discharged during injection molding are formed at the two ends of the window respectively, wherein the glue inlet and the glue outlet exceed the chip installation area; the glue outlet is a slow opening with an enlarged size compared with the glue inlet, and the end width of the glue outlet is greater than the channel width of the window; a chip, which partially covers the window, and makes the glue inlet and the glue outlet of the window exposed to the outside of the chip; a bonding wire, which penetrates through the window and is electrically connected with the chip and the substrate; and a plastic package body, which packages the chip and the bonding wire, and fills the glue outlet. The window type ball grid array packaging module provided by the invention can avoid the problem of glue overflow on the substrate and cavities appearing in the plastic package body due to too fast mold flow velocity in an upper mold in the injection molding process.

Owner:RUILI INTEGRATED CIRCUIT CO LTD

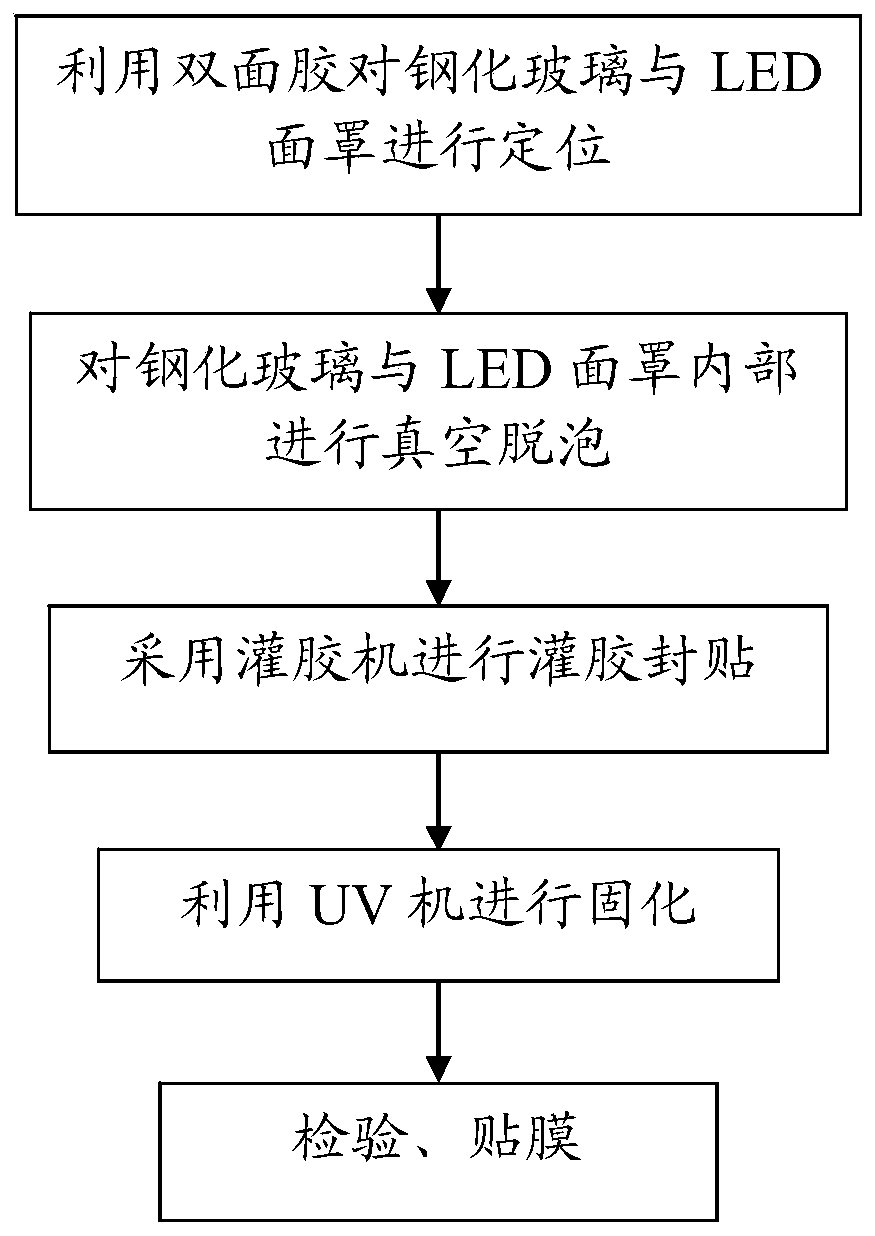

LED display screen mask glass laminating process

The invention discloses an LED (Light Emitting Diode) display screen mask glass laminating process for keeping a glue laminating layer between an LED mask and toughened glass at the thickness of 1.5 mm through two modes of positioning and glue pouring. The problems existing in the existing liquid optical adhesive attaching process are solved, and attaching of the large LED mask and the tempered glass is achieved. The toughened glass and the LED mask are positioned by a double faced adhesive tape, and then vacuum defoaming and glue filling are carried out. The thickness of the glue layer is controlled to be about 1.5 mm, the thickness of the glass can reach 5 mm, the thickness of the glass is increased, the thickness and the hardness of an LED glass panel adopted by a stage and the like areenhanced, and the stability and the safety of equipment such as the stage and the like are improved. Meanwhile, the problem of excessive glue is avoided, a large amount of manual cleaning is not needed, and the labor cost is saved. The defects of more bubbles, high reject ratio and the like in the bonding process of the large LED mask and the toughened glass are overcome.

Owner:东莞市泽创医疗科技有限公司

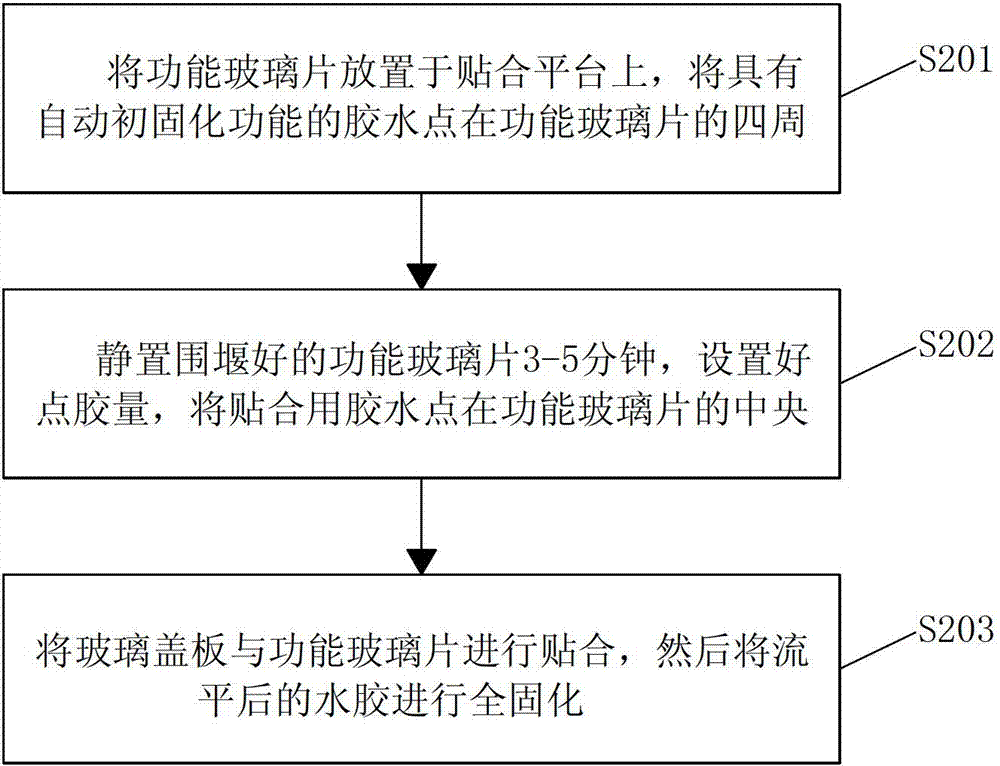

A cofferdam type water glue bonding process

The invention discloses a cofferdam type water-glue bonding process, which includes the following steps: A. Place the bound functional glass sheet on a bonding platform, set the amount of glue dispensed, and place the glass sheet with automatic initial curing function The glue is uniformly dotted around the functional glass sheet. B. Stand still for 3-5 minutes for the functional glass sheet that has passed through the cofferdam in step A, set the amount of glue dispensed, and apply glue for bonding to the center of the functional glass sheet. C. Lay the glass cover plate with the functional glass sheet, and then fully cure the leveled water glue. Compared with the traditional water-glue bonding process, the present invention puts a layer of glue that can be automatically initially cured but will not be fully cured without treatment on the periphery of the bonding frame, and then the water-glue dispensing, bonding, and curing are carried out. , can effectively prevent glue overflow, effectively solve the problem of glue overflow, and improve the bonding yield.

Owner:HUIZHOU NENGHUI CHEM CO LTD

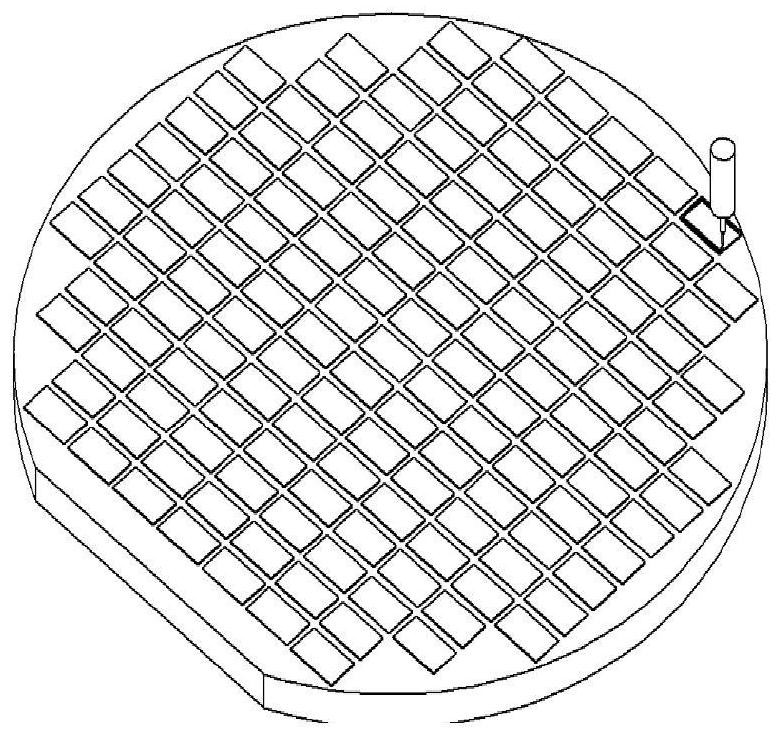

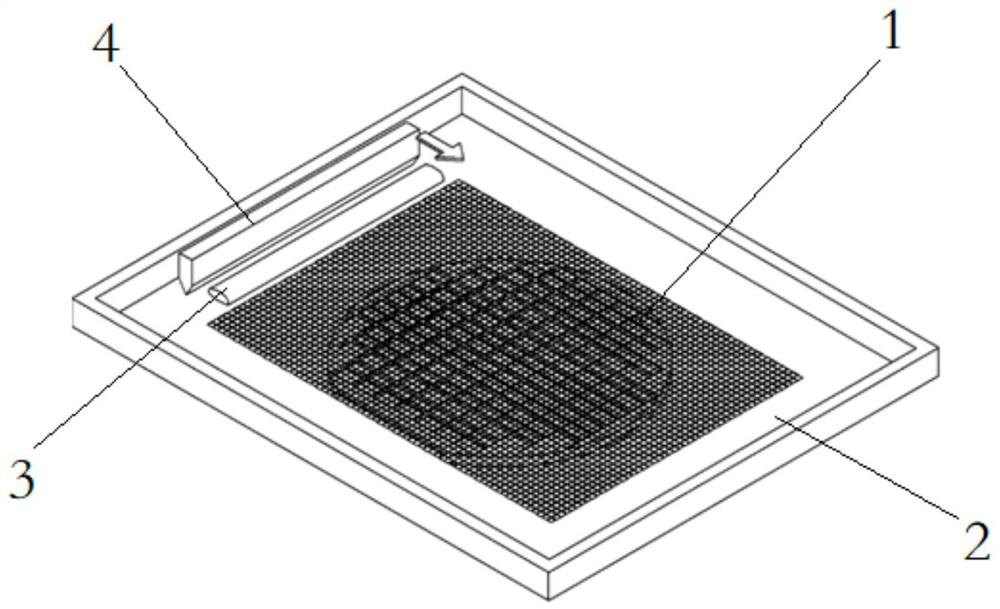

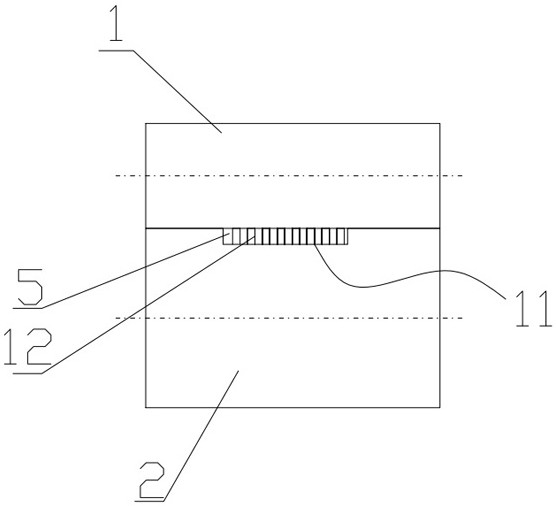

Wafer bonding and packaging method of silicon-based OLED

PendingCN112018272AFaster glue application timeIncrease productivitySolid-state devicesSemiconductor/solid-state device manufacturingScreen printingGlass cover

The invention provides a wafer bonding and packaging method of a silicon-based OLED. The method comprises the following steps 1, coating a silicon-based substrate with a structural adhesive by using asilk-screen printing technology; 2, uniformly coating the silicon-based substrate with an optical transparent adhesive by adopting an adhesive dispensing needle; and 3, after the optical transparentadhesive is leveled and defoamed, attaching a glass cover plate to the silicon-based substrate. According to the packaging method, the gluing time can be greatly shortened, and the problem of glue overflowing can be effectively solved.

Owner:紫旸升光电科技(苏州)有限公司

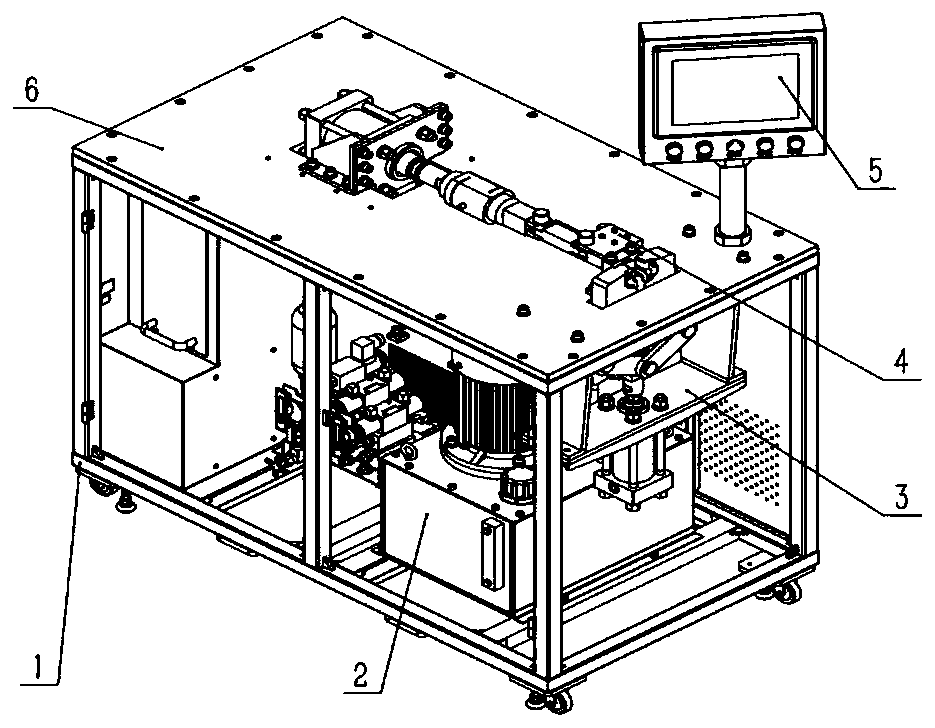

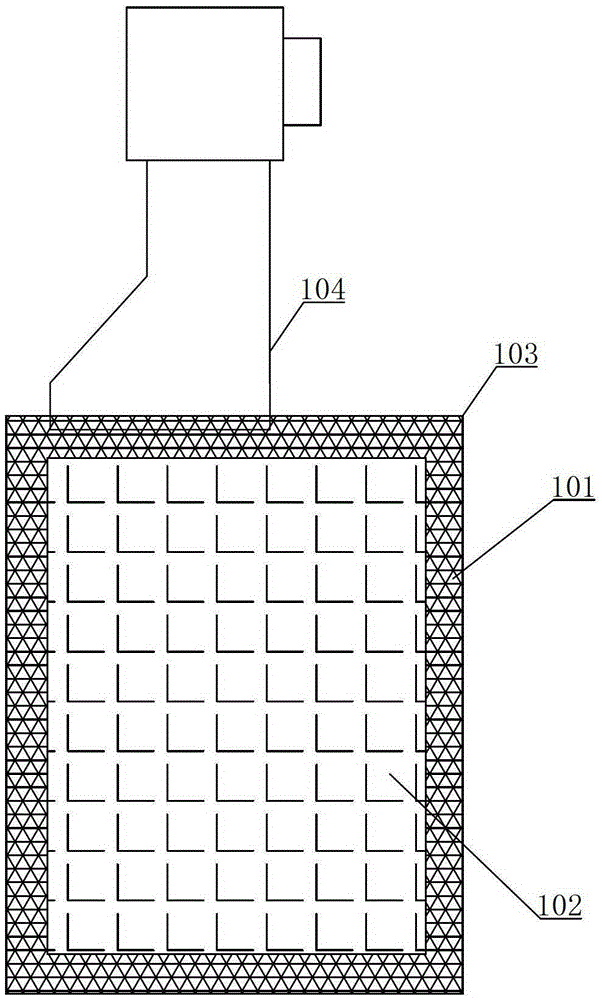

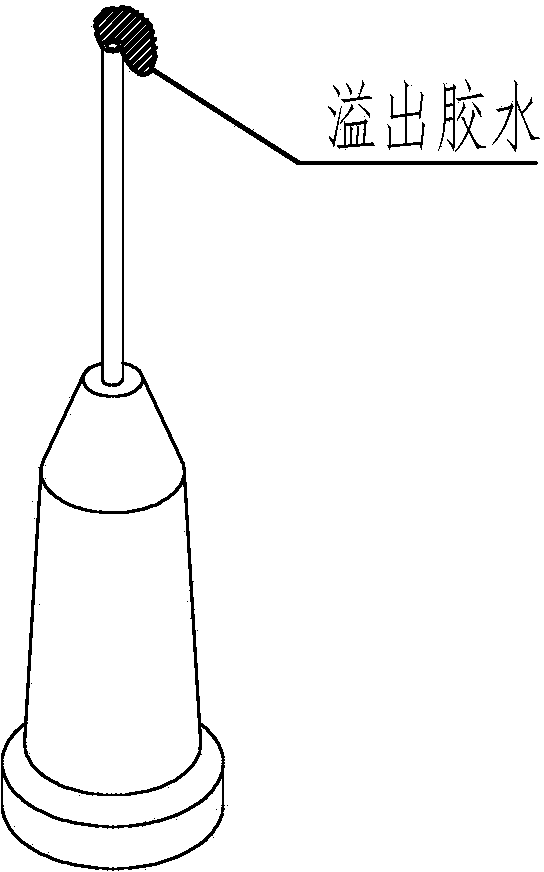

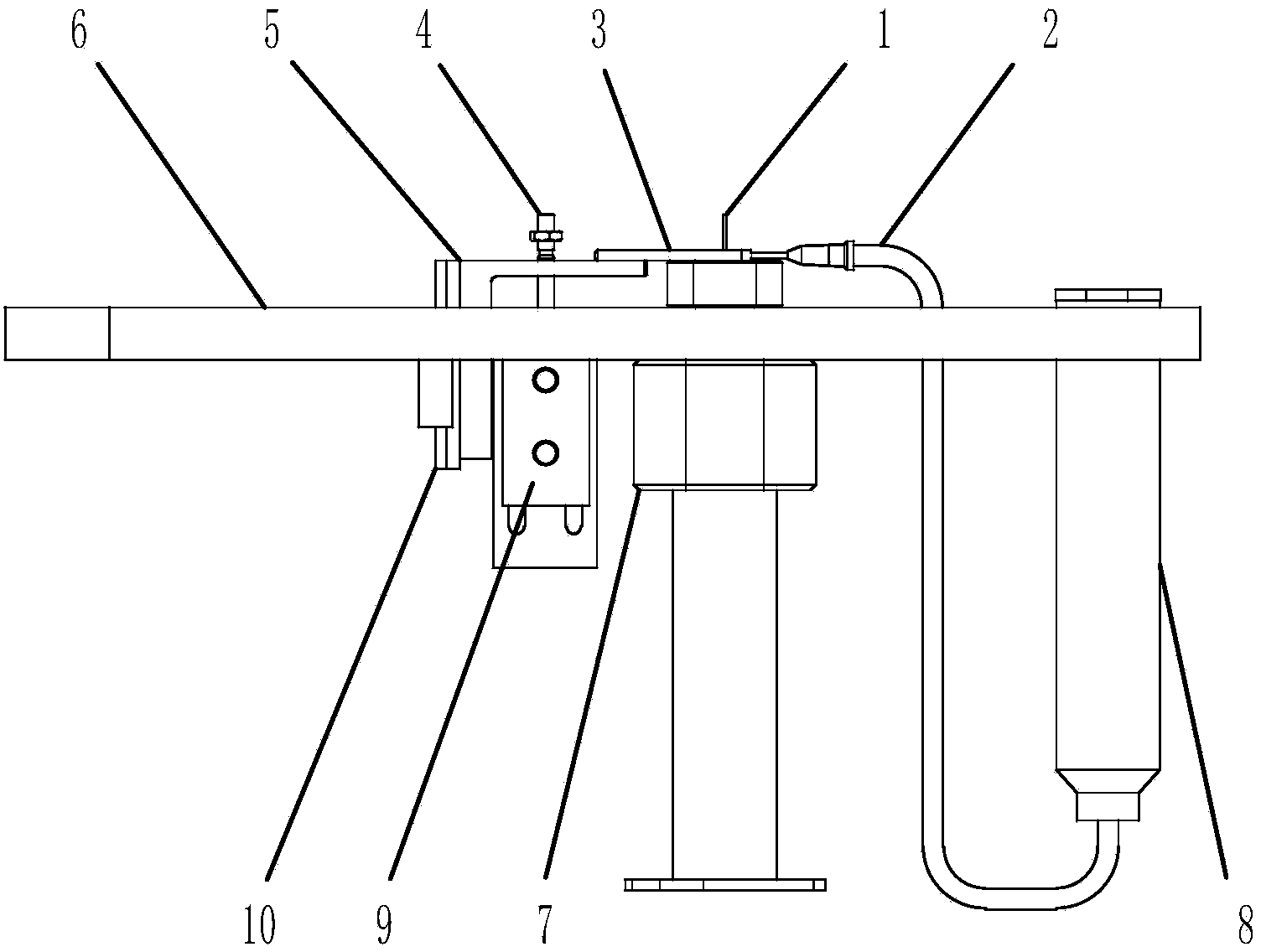

Automatic glue dispensing mechanism

ActiveCN104043561ASolve the glue overflow problemQuality improvementLiquid surface applicatorsCoatingsEngineeringEquipment Safety

The invention discloses an automatic glue dispensing mechanism which comprises a work table, one central line of the work table is respectively through and fixedly provided with a guide rail seat, a cylinder, a glue dispensing tube seat and a recovery capsule; the guide rail seat is internally provided with a guide rail, the guide rail is fixedly connected to a side face of a glue wipe sheet fixed seat; a piston rod of the cylinder is fixedly connected with the other side face of the glue wipe sheet fixed seat; the glue dispensing tube seat is fixedly provided with a glue dispensing needle; the recovery capsule is connected with a glue wipe sheet by a hose and a glue absorb needle; the glue wipe sheet fixed seat is fixedly provided with the glue wipe sheet, and then tope end of the glue wipe sheet sleeves the glue dispensing needle. The automatic glue dispensing mechanism can completely realize the function of automatic glue dispensing and glue wiping, greatly improves the glue wiping quality and speed, can recover and reuse overflowed glue, improves the production efficiency, but also the liberates production labor, saves the cost of production, eliminates human to equipment safety hazards, and ensues good glue dispensing quality.

Owner:辽宁中蓝光电科技有限公司

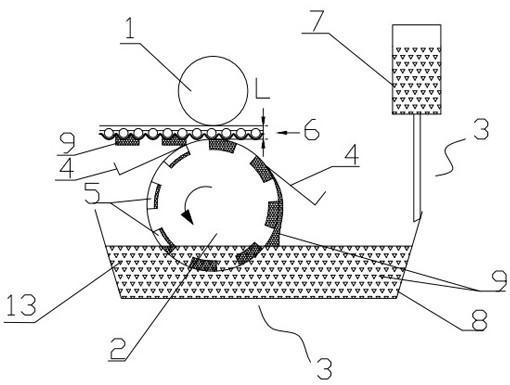

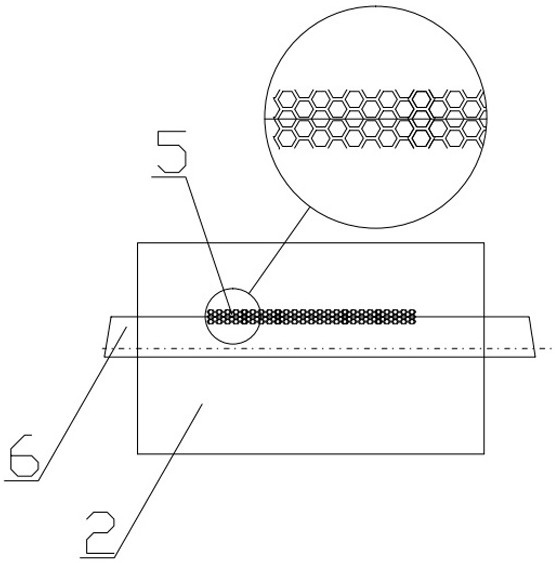

Gluing device and gluing method for large-size flower type reflective patterns

PendingCN111842003ARealize glue transferSolve the problem of uneven depthLiquid surface applicatorsCoatingsAdhesive glueMechanical engineering

The invention discloses a gluing device and gluing method for large-size flower type reflective patterns. The device comprises an upper pressure roller, a gravure upper rubber roller, a glue scraper and a glue supply mechanism for storing and providing glue. The glue scraper is located on one side of the gravure upper rubber roller, the edge of the scraping knife is in contact with the surface ofthe gravure upper rubber roller, the surface of the gravure upper rubber roller is provided with a flower-type pattern, and the gravure upper rubber roller is placed in the glue supply mechanism and is in contact with the glue in the glue supply mechanism The pattern is divided into a plurality of micro polygonal structure grooves or a combination of a number of micro polygonal structure grooves.The micro polygonal structure grooves are separated by micro thin walls, and the micro thin walls are connected with each other. The pattern fills the gap formed by the micro thin wall thickness through the leveling effect of the glue in the micro polygonal structure groove to realize the pattern. The pattern is transferred with glue. The method of gluing is also disclosed. The micro polygonal grooves are used and filled with micro thin walls to realize the leveling of glue and make the design pattern present completely.

Owner:HANGZHOU CHINASTARS REFLECTIVE MATERIAL

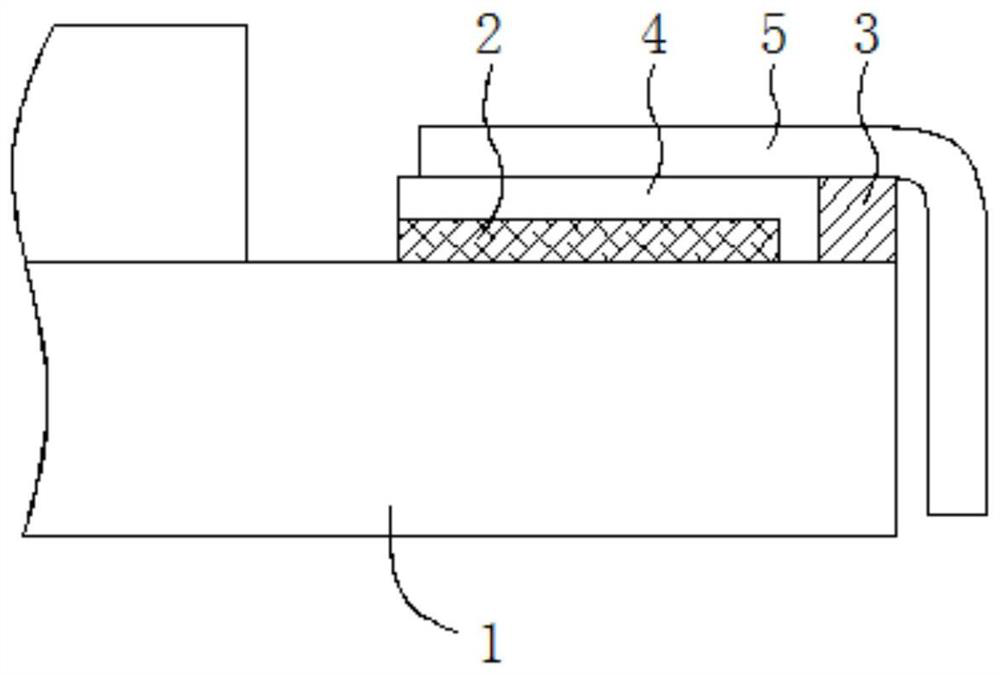

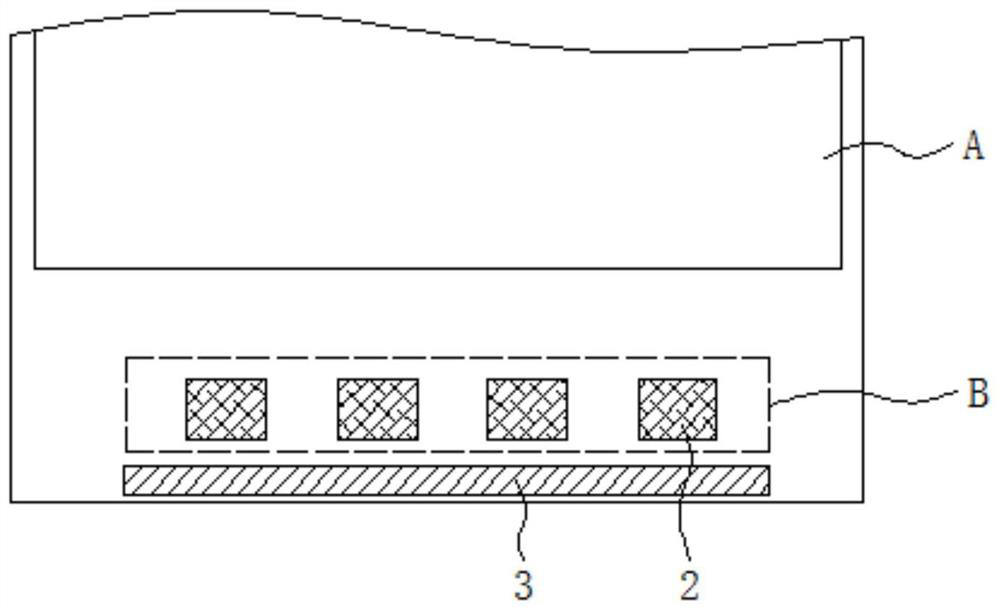

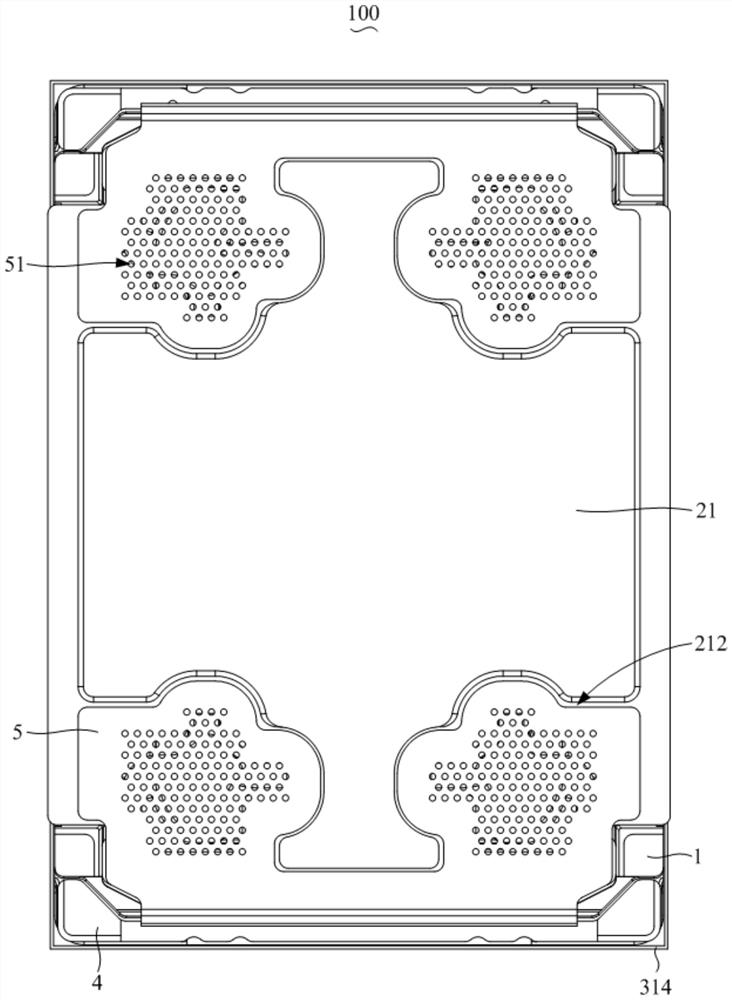

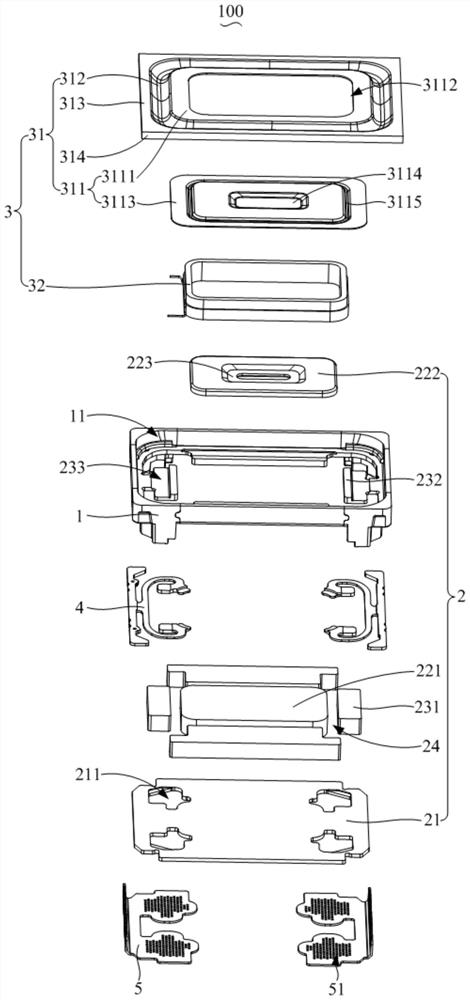

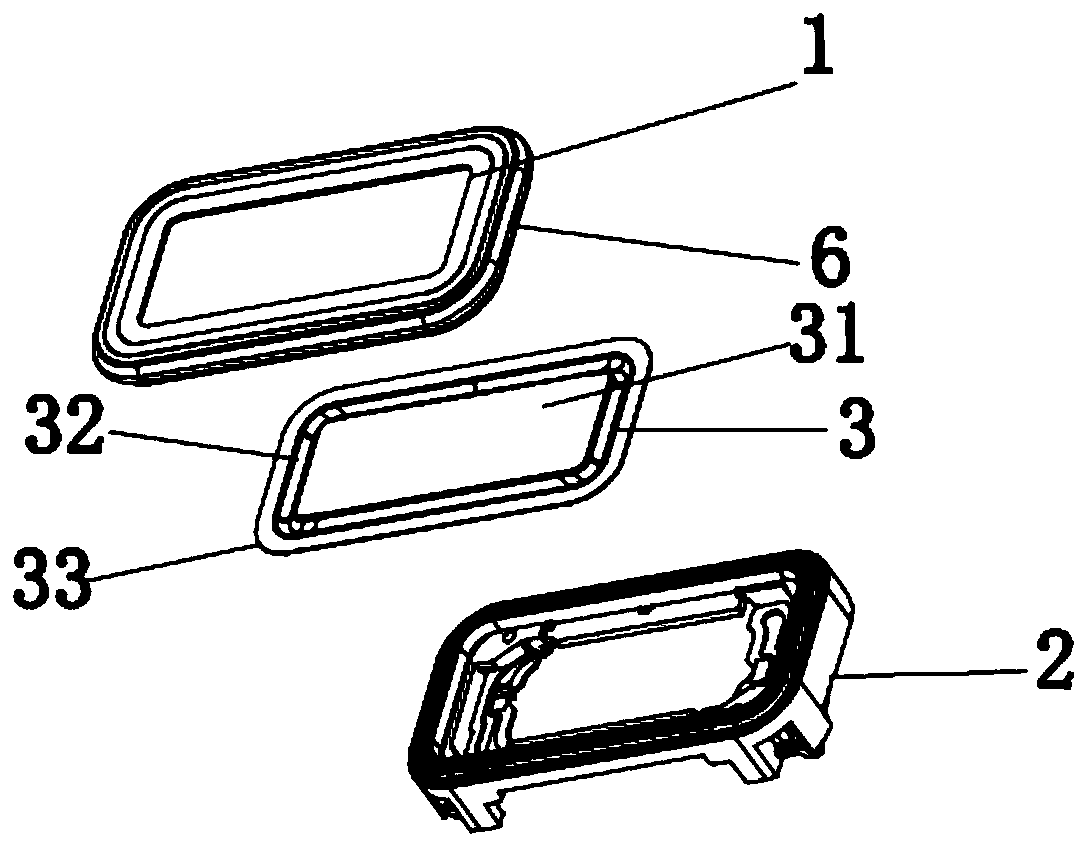

Sound production device and electronic equipment

PendingCN113727259AAchieve fixationSolve the glue overflow problemDiaphragm mounting/tensioningAdhesive glueEngineering

The invention discloses a sound production device and electronic equipment, the sound production device comprises a shell, a magnetic circuit system and a vibration system, the shell is provided with a containing cavity, the magnetic circuit system is arranged in the containing cavity, the vibration system comprises a vibrating diaphragm arranged opposite to the magnetic circuit system, the vibrating diaphragm comprises a central part, a folding ring part arranged around the central part and a fixing part connected to the outer side of the folding ring part, the fixing part is connected with the shell, a glue containing groove is formed in the side, facing the shell, of the fixing part, and the side, back to the shell, of the fixing part is arranged in a plane mode. The sound production device aims to solve the problem of glue overflow between the vibrating diaphragm and the shell and prevent the glue from overflowing to extrude the vibrating diaphragm, so that polarization caused by glue overflow is effectively inhibited, and the reliability of a product is improved.

Owner:GOERTEK INC

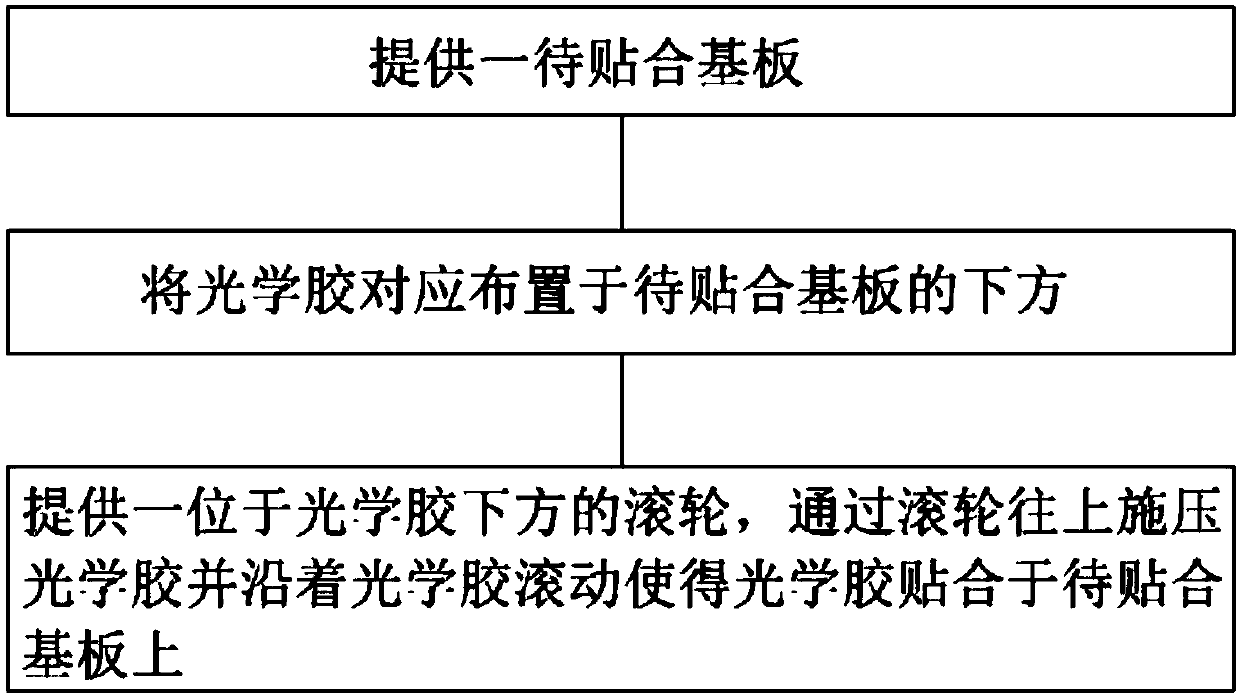

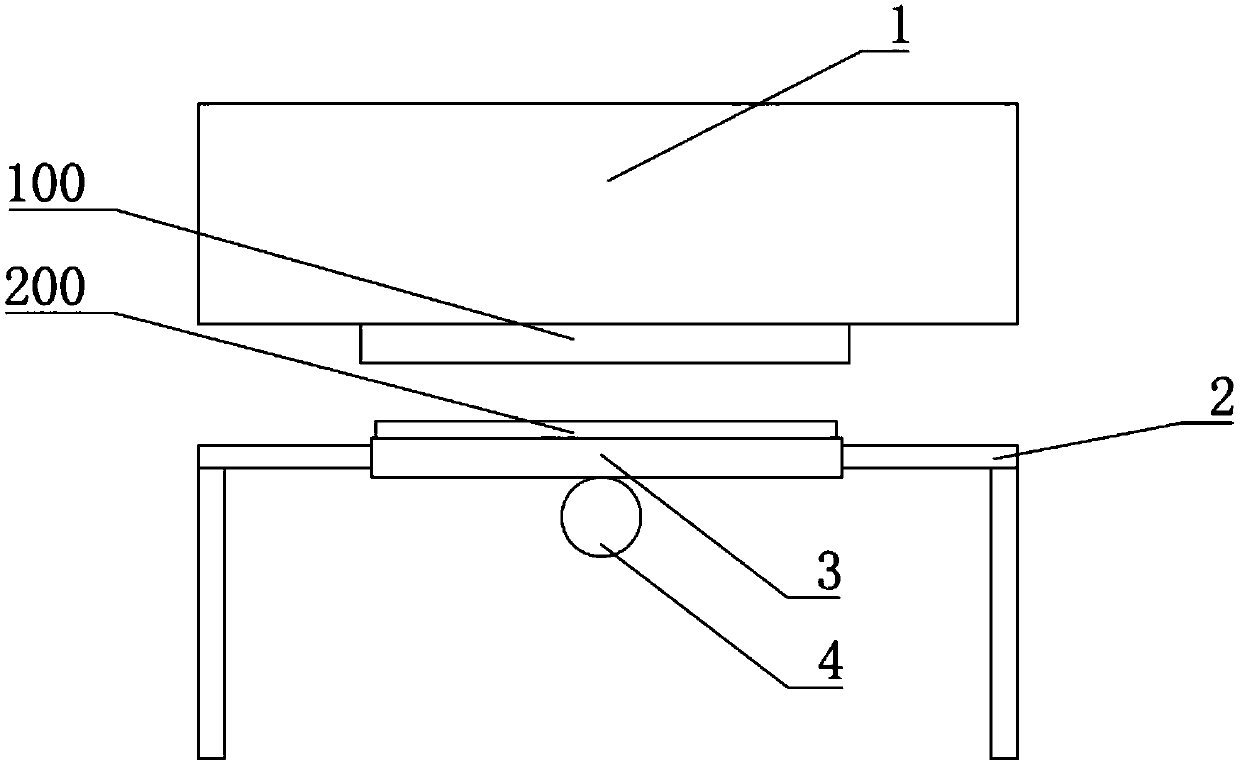

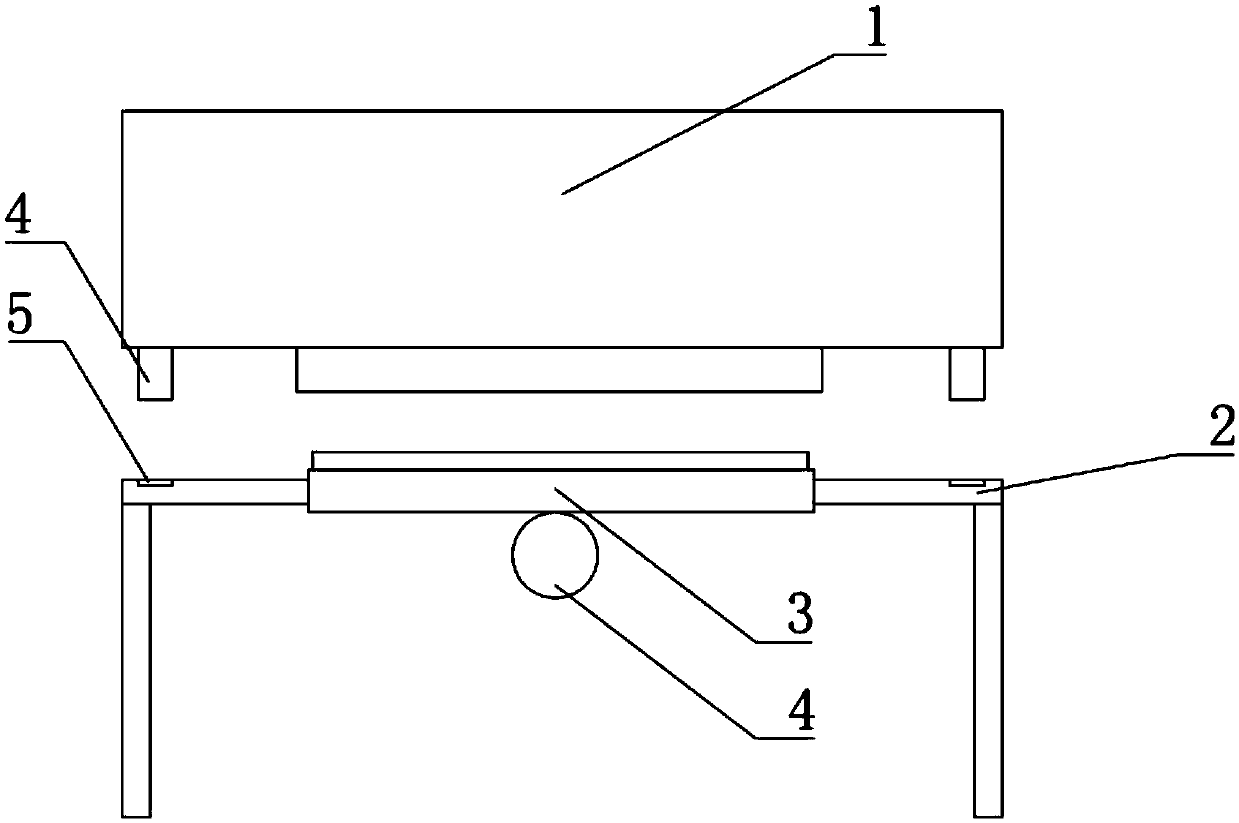

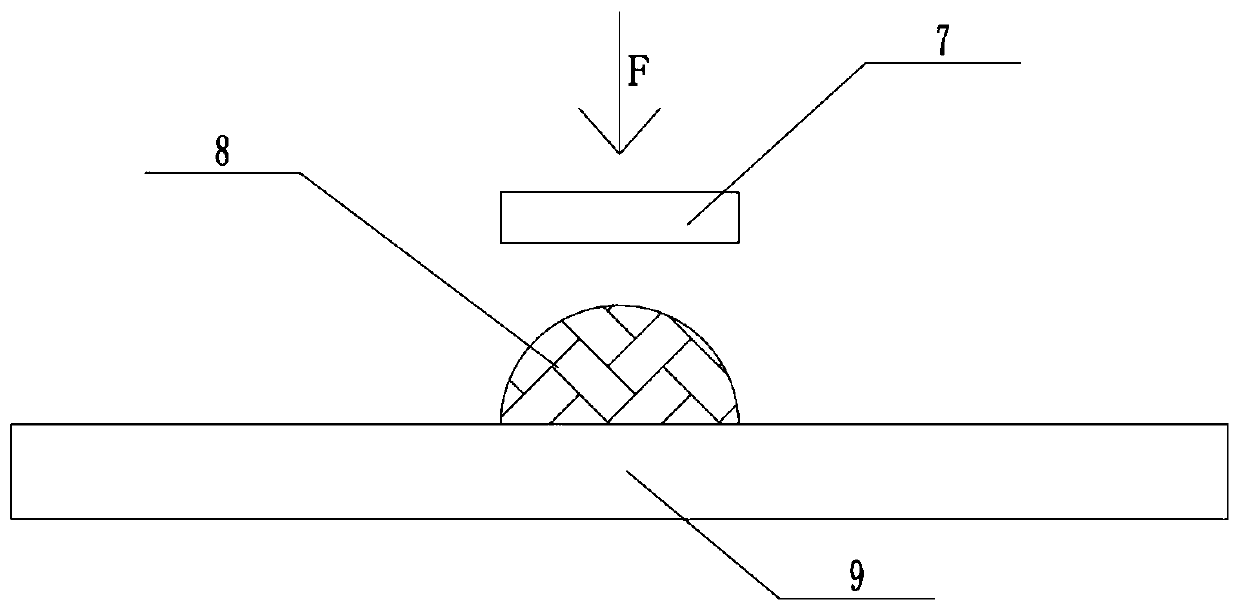

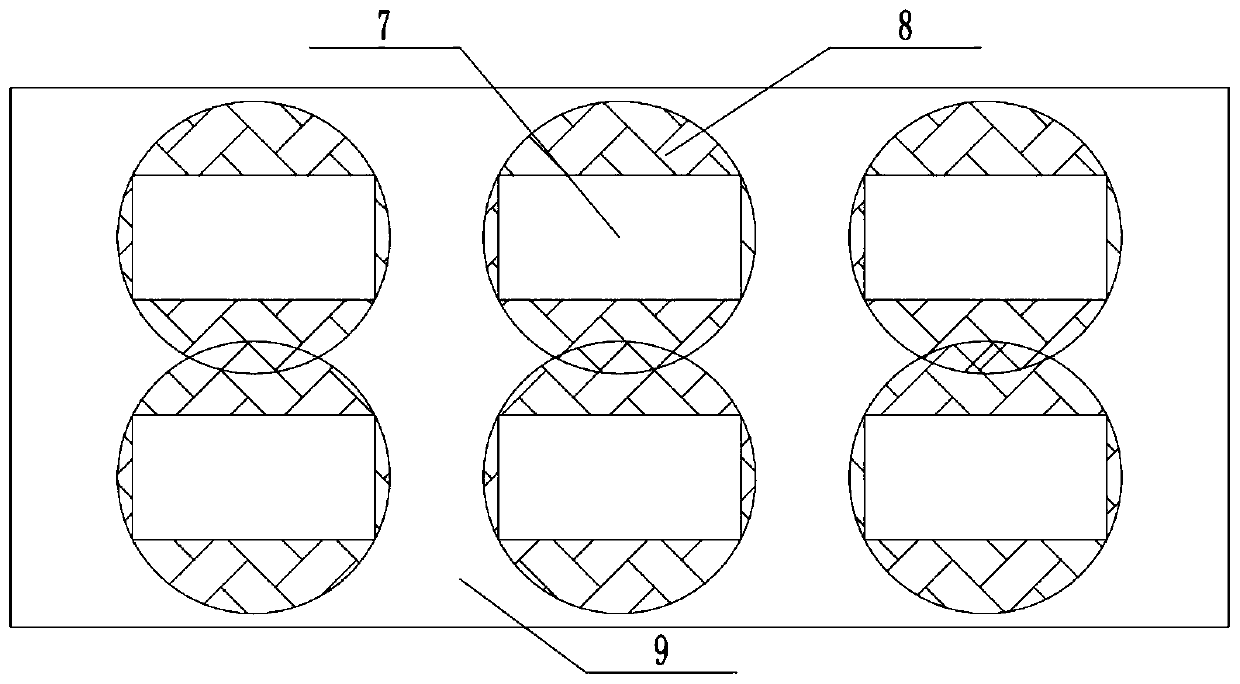

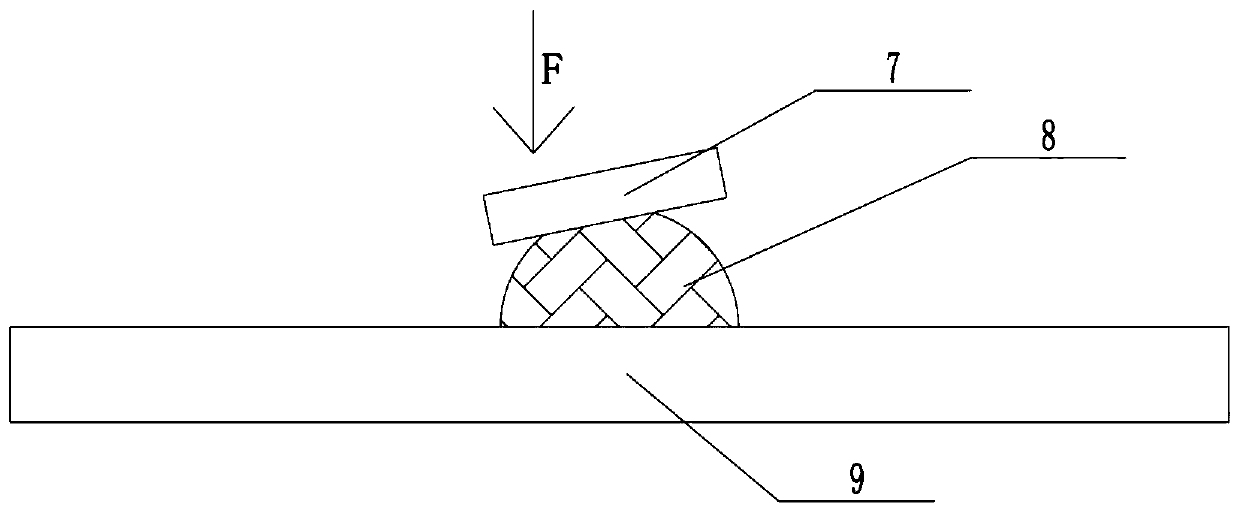

Optical cement bonding method and device

InactiveCN109094172AReduce continuous extrusionSolve the glue overflow problemLaminationLamination apparatusOptoelectronicsCement

The invention provides an optical cement bonding method and device. The method comprises following steps: a to-be-bonded substrate is provided; optical cement is distributed in the position below theto-be-bonded substrate correspondingly; a roller located below the optical cement is provided, and the roller applies pressure upward to the optical cement and rolls along the optical cement, so thatthe optical cement is enabled to be attached to the to-be-bonded substrate. The device comprises a to-be-bonded substrate fixing part, a machine table arranged below the to-be-bonded substrate fixingpart, a mesh plate arranged on the machine table and corresponding to the to-be-bonded substrate fixing part and the roller, wherein the to-be-bonded substrate fixing part is used for fixing the to-be-bonded substrate by vacuum absorption, the optical cement is fixed on one side, facing the to-be-bonded substrate fixing part, of the mesh plate, and the roller is arranged on one side, opposite to the to-be-bonded substrate fixing part, of the mesh plate. According to the optical cement bonding method and device, the problem of cement overflow during bonding of the optical cement can be solved effectively.

Owner:TRULY OPTO ELECTRONICS

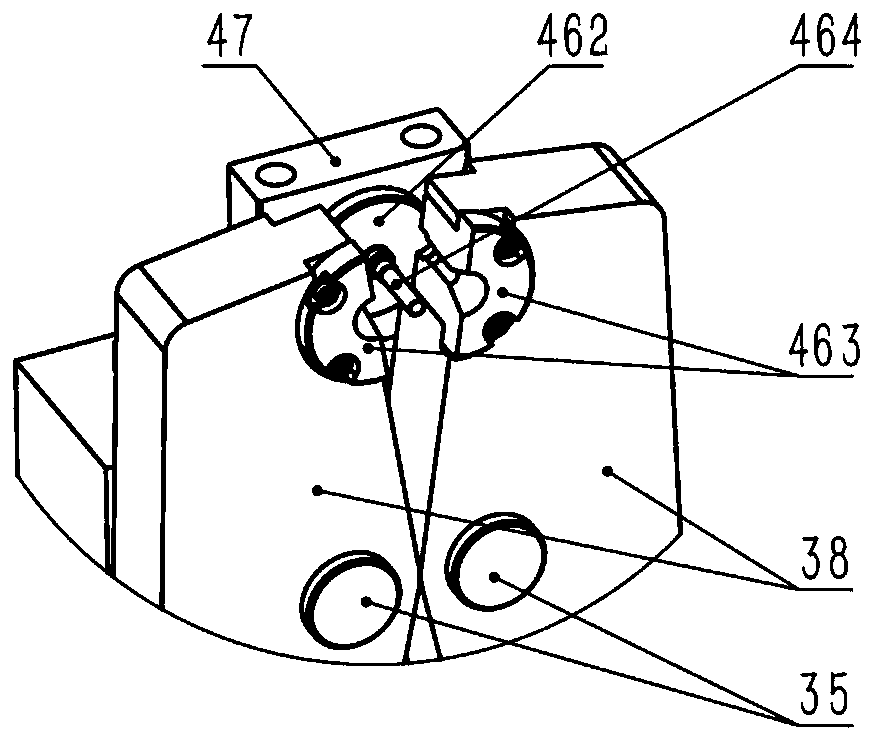

Dispensing head for LED solid crystal and dispensing method of LED solid crystal

ActiveCN109701821AFit tightlySolve the glue overflow problemLiquid surface applicatorsSemiconductor/solid-state device manufacturingEngineeringMirror image

The invention discloses a dispensing head for LED solid crystal. The dispensing head for LED solid crystal comprises a pneumatic mechanism and a glue supply mechanism, the glue supply mechanism is located below the pneumatic mechanism, the pneumatic mechanism drives the glue supply mechanism, the glue supply mechanism comprises two glue supply structures in a mirror image mode, the glue supply structures are fixed to the lower part of the pneumatic mechanism, and the glue supply structures comprise connecting rods, glue supply pipes and extruders. The glue supply pipes are fixed to the lower part of the pneumatic mechanism through the connecting rods, the shape of the glue supply pipes is an L shape, the extruders are arranged on the lower end parts of the glue supply pipes, and the upperend parts of the glue supply pipes are connected with the glue body supply device. The invention further discloses a dispensing method of the LED solid crystal. According to the dispensing head of theLED solid crystal and the dispensing method for LED solid crystal, the problem of chip excessive glue of a traditional dispensing mode can be effectively solved, so that an LED chip is stably attached to a base plate, the efficiency of electric conduction and heat dissipation is better, and the reliability is higher.

Owner:广东晶锐半导体有限公司

Sounding device and electronic terminal

ActiveCN110891109AImprove pullout forceReduce impactTelephone set constructionsTransducer diaphragmsElectrical and Electronics engineeringFront cover

The invention discloses a sounding device and an electronic terminal. The sounding device comprises a front cover and a shell which are combined together; a vibrating diaphragm is installed in a cavity defined by the front cover and the outer shell, an elastic sealing piece is integrally combined on the front cover, a step structure matched with the front cover and the outer shell is formed on theassembling face of the front cover and the outer shell, at least one gluing area is arranged on the step structure, the gluing area is configured to be used for containing glue, and the front cover and the outer shell are bonded and fixed through the glue. The sounding device not only has good sealing performance, but also is simple in assembly process; meanwhile, the drawing force of the front cover and the shell is improved in a gluing mode, the combination firmness degree of the front cover and the shell can be effectively enhanced, and glue overflowing is prevented.

Owner:GOERTEK INC

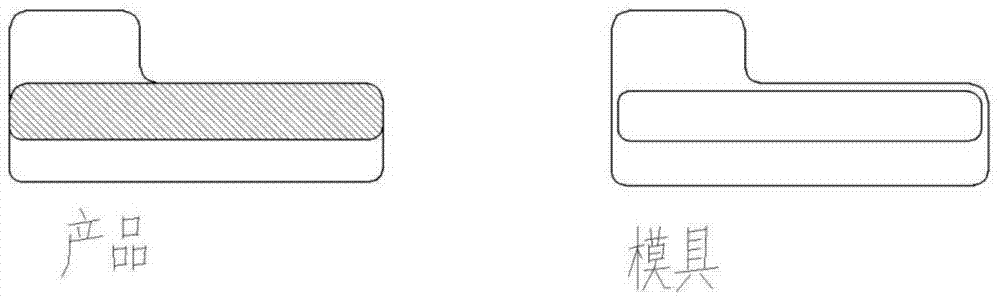

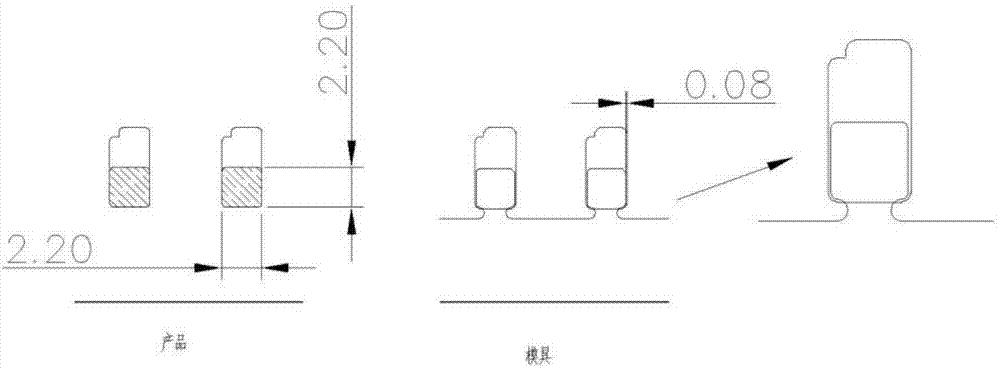

Double sided adhesive tape processing method without adhesive overflow

InactiveCN104762021ASolve the glue overflow problemThere is no problem of sticking to the nozzle and unable to mount normallyAdhesive processesProduction lineAdhesive

The invention relates to a double sided adhesive tape processing method without adhesive overflow. The process method comprises the following steps: (1) processing a double sided adhesive tape, namely refrigerating for more than 2 hours at a temperature of 0-5 C degree; (2) designing a mold, namely compensating the product dimension and preserving adhesive overflow space; (3) selecting materials; and (4) selecting a device, wherein the sleeve cutting of a circular cutter needs to be controlled within being - / +0.10mm, the circular cutter is high in sleeve cutting precision and stable in performance; the sleeve cutting state during processing needs relatively greatly attention, so that the offsetting of the sleeve cutting can be spotted and the mold can be adjusted in time. According to the double sided adhesive tape processing method, no adhesive overflow occurs during the mold cutting of the double sided adhesive tape; after being delivered, the double sided adhesive tape can be stored at the room temperature at a client; the occurrence that normal surface mounting cannot be carried out due to adhesive overflow during automatic surface mounting in a production line is avoided; the problem of the adhesive overflow of the double sided adhesive tape is ingeniously solved; when the client carries out automatic surface mounting, the problem that a production is boned on a suction nozzle and the surface mounting cannot be carried out due to adhesive overflow never come up again.

Owner:W B ROYMAX TECH SHENZHEN

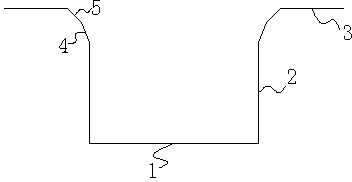

Tooth-shaped insert for packaging lead frame

The invention discloses a tooth-shaped insert for packaging a lead frame. The tooth-shaped insert comprises an opening groove for inserting a pipe leg of the lead frame, wherein the opening groove comprises a groove bottom (1), groove walls (2) and a groove opening (3); the groove wall and the groove openings are in transition connection by chamfers (4). The tooth-shaped insert for packaging the lead frame has the beneficial effects that the chamfers and C angles are arranged between the groove opening and the groove walls so that the problems that ribbing is difficultly carried out on the placing position of the lead frame, and the spaces between the pipe leg of the lead frame and the groove walls of the opening groove of the tooth-shaped insert are large to cause glue overflowing are solved.

Owner:TONGLING JIANXI PRECISION PARTS

Semiconductor packaging structure and heat dissipation member thereof

ActiveCN103594429ASolve the glue overflow problemInhibit glue overflowSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

Provided are a semiconductor packaging structure and a heat dissipation member thereof. The semiconductor packaging structure comprises a bearing member having a semiconductor assembly and a heat dissipation member so that an accommodation space is formed between the heat dissipation member and the bearing member to make the semiconductor assembly positioned in the accommodation space. The heat dissipation member has a guide channel which is provided with a through hole and a recessed structure. The though hole is communicated with the accommodation space. The recesses structure is connected with a hole wall of the through hole, such that if a packaging rubber body is formed in the accommodation space and the recessed structure to wrap the semiconductor assembly, excessive glue is prevented from flowing around the through hole, and the heat dissipation efficiency can be improved.

Owner:SILICONWARE PRECISION IND CO LTD

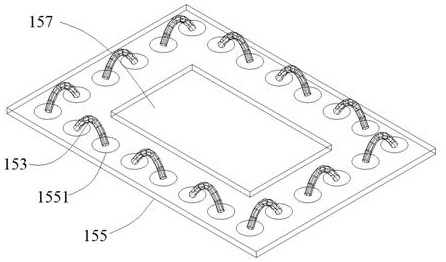

Electromagnetic shielding module packaging structure and electromagnetic shielding module packaging method

ActiveCN112234048BReduce thicknessMiniaturizationSemiconductor/solid-state device detailsSolid-state devicesMiniaturizationMagnetic shield

Embodiments of the present invention provide an electromagnetic shielding module packaging structure and an electromagnetic shielding module packaging method, which relate to the technical field of semiconductor packaging. The electromagnetic shielding module packaging structure includes a module substrate, a chip, a partitioned shielding device, and a protective plastic body. And the metal shielding layer, the partition shielding device includes a shielding plastic package and a plurality of conductive arcs arranged in the shielding plastic package, electromagnetic shielding is realized by setting the partition shielding device, no need to dispense glue, and at the same time, the plastic package is opened for accommodating chips. By giving way to the groove, and by implementing the electromagnetic shielding function in the plurality of conductive arcs, the conductive arcs can be made lower than the prior art, thereby reducing the design space of the substrate surface. Compared with the prior art, the electromagnetic shielding module package structure provided by the present invention can avoid the problem of glue overflow caused by glue dispensing, and has a simple assembly process, high efficiency, and a small design space on the surface of the substrate, which reduces the thickness of the device, and has advantages. Conducive to the miniaturization of devices.

Owner:FOREHOPE ELECTRONICS NINGBO CO LTD

Semiconductor package structure and its heat sink

ActiveCN103594429BSolve the glue overflow problemInhibit glue overflowSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

Owner:SILICONWARE PRECISION IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com