Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Reduce size and complexity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

System for generating thermographic images using thermographic signal reconstruction

ActiveUS20050008215A1Reduce size and complexityImprove signal-to-noise ratioCharacter and pattern recognitionMaterial flaws investigationSignal reconstructionThermographic imaging

A method for compiling thermographic data including obtaining data indicative of a monotonically changing characteristic of a specimen, sequencing the data or a surrogate of the data into a plurality of groups, categorizing, within each group, the frequency distribution of an attribute of the data or an attribute of said surrogate data, and compiling, from one or more groups, a collection of two or more of the frequency distributions.

Owner:THERMAL WAVE IMAGING

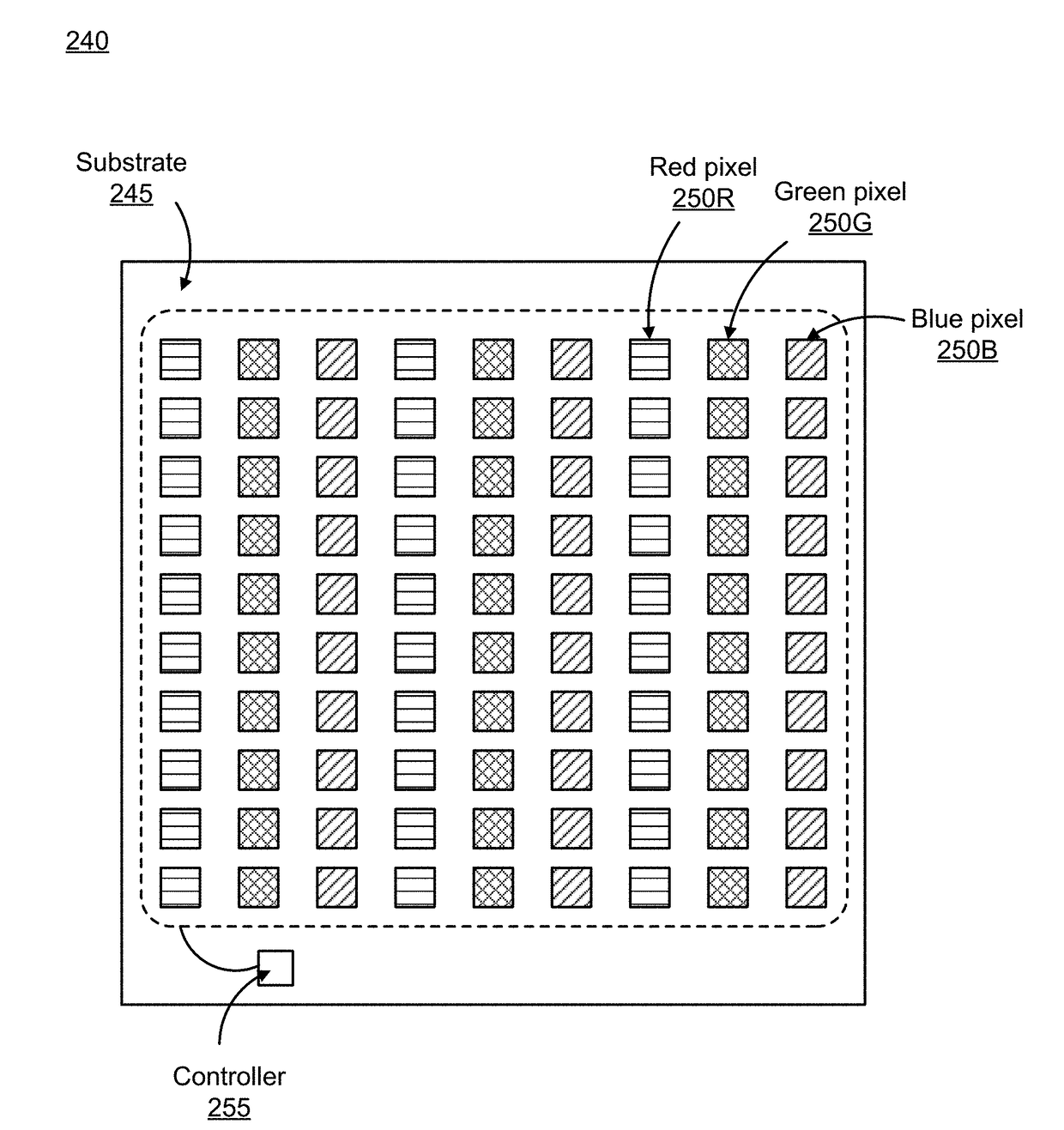

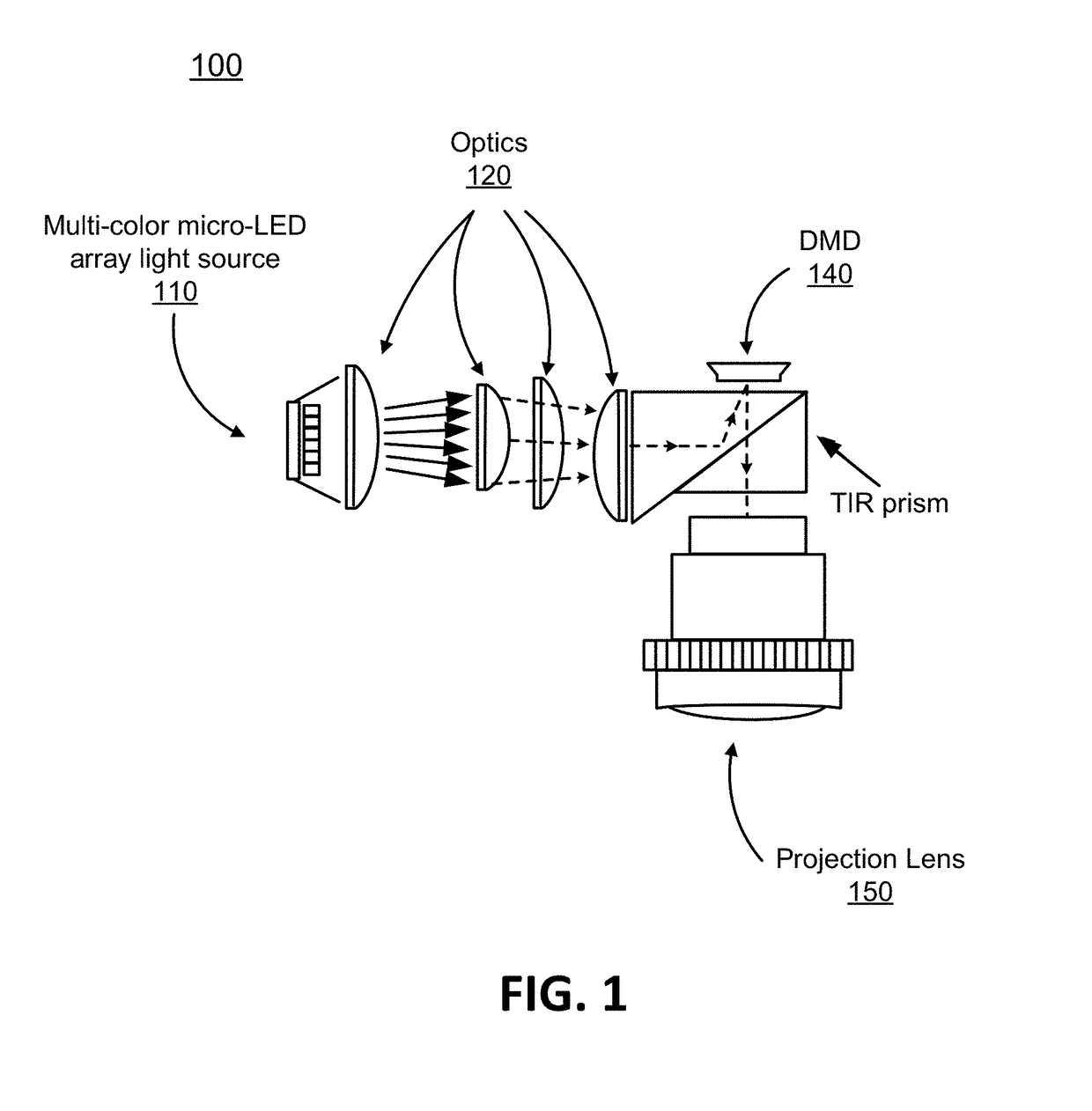

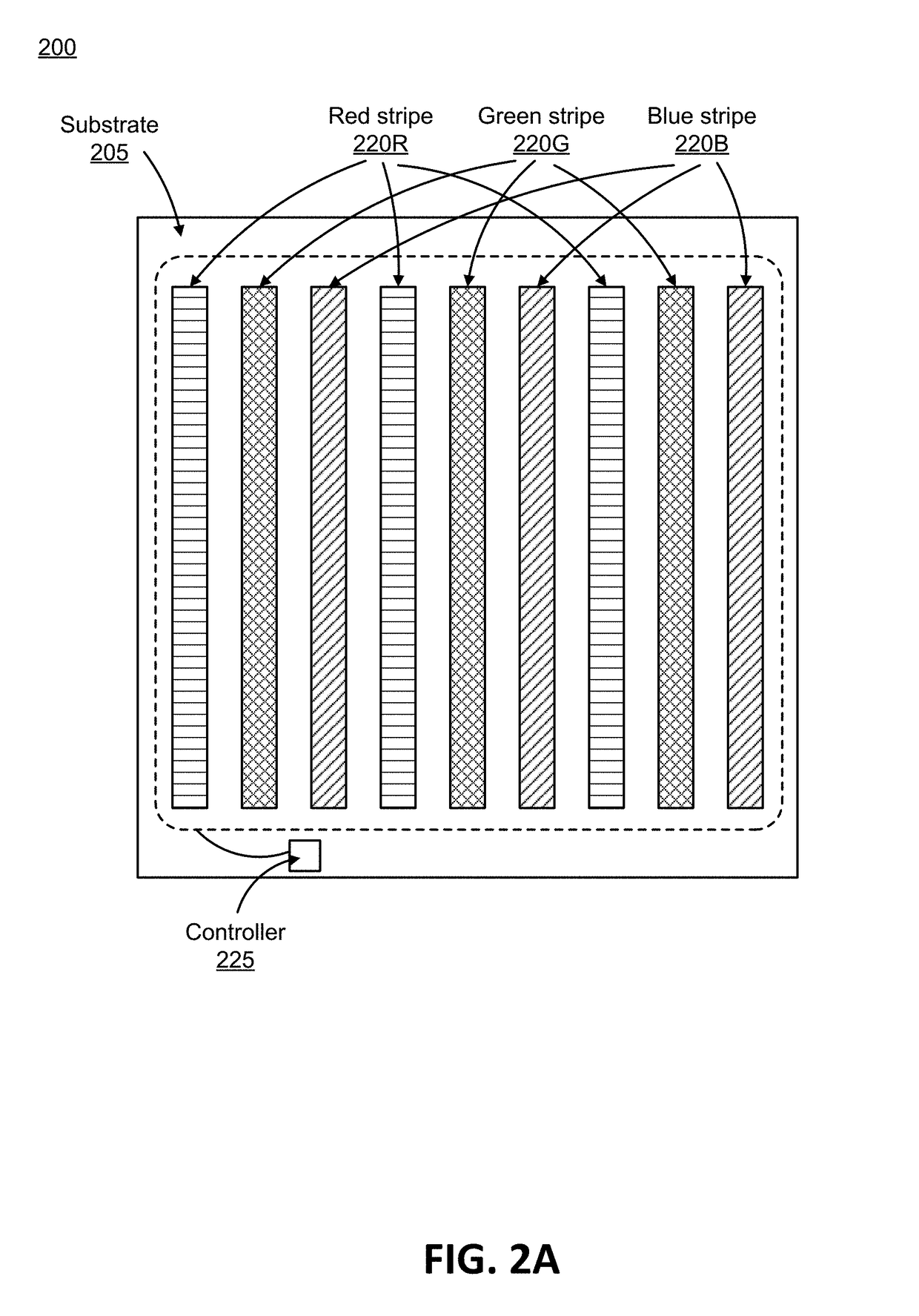

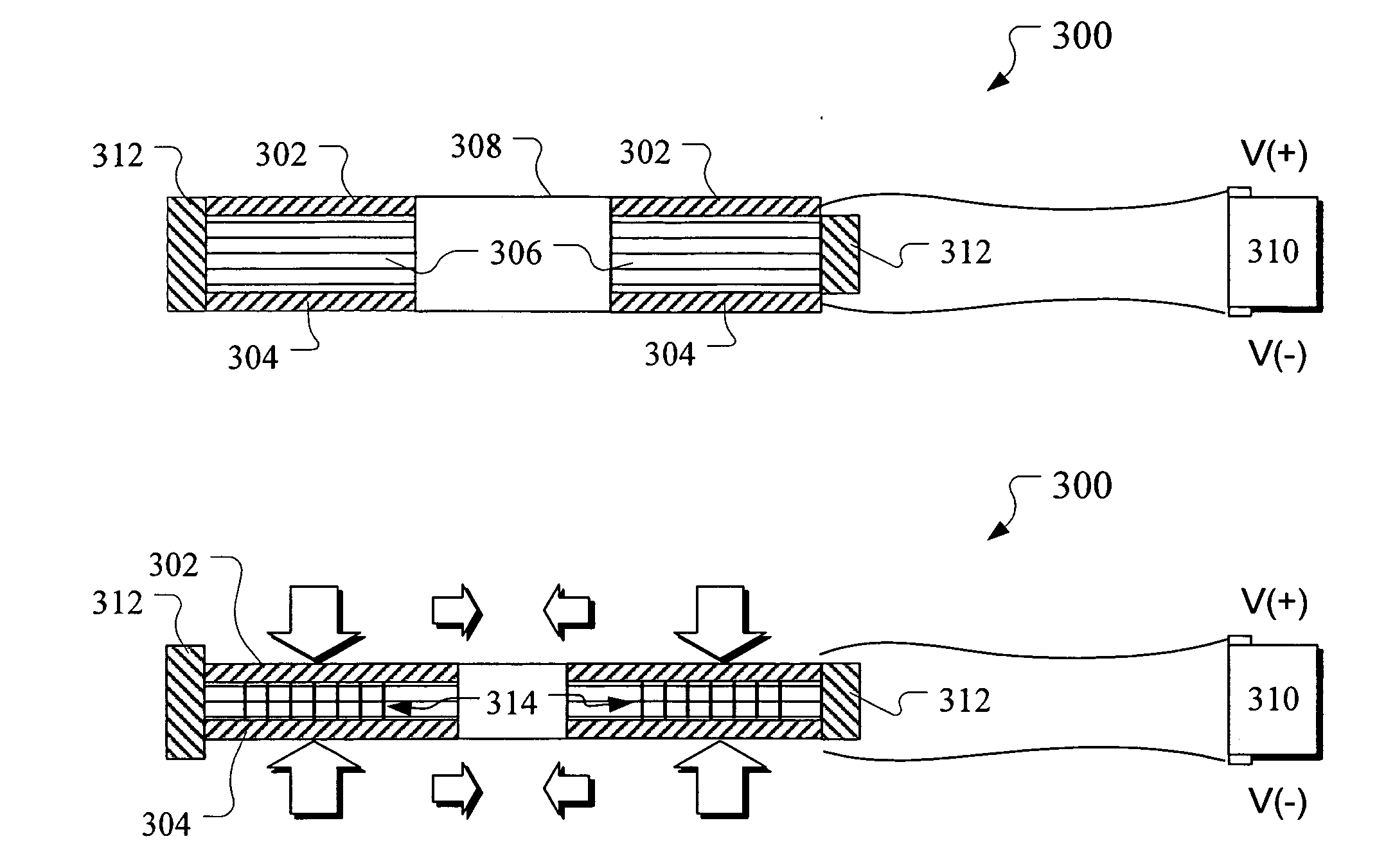

Multi-Color Micro-Led Array Light Source

ActiveUS20180132330A1Reduce artifactsReduce displacementPlanar light sourcesLight source combinationsLed arrayLight beam

Various embodiments include a multi-color micro-LED array light source that enables well-overlapped light beams of different colors. The multi-color micro-LED array light source includes a thermally conductive substrate and multiple arrays of different color micro-LEDs integrated on the thermally conductive substrate. The micro-LEDs within each array are electrically connected so that they can all be driven in unison. The multi-color array light source also includes a controller that is electrically coupled to and that drives the arrays of micro-LEDs. The controller drives the micro-LEDs in a manner that produces an output light distribution with a spatial wavelength and angular distribution that is suitable for use as a light source.

Owner:JADE BIRD DISPLAY SHANG HAI LTD

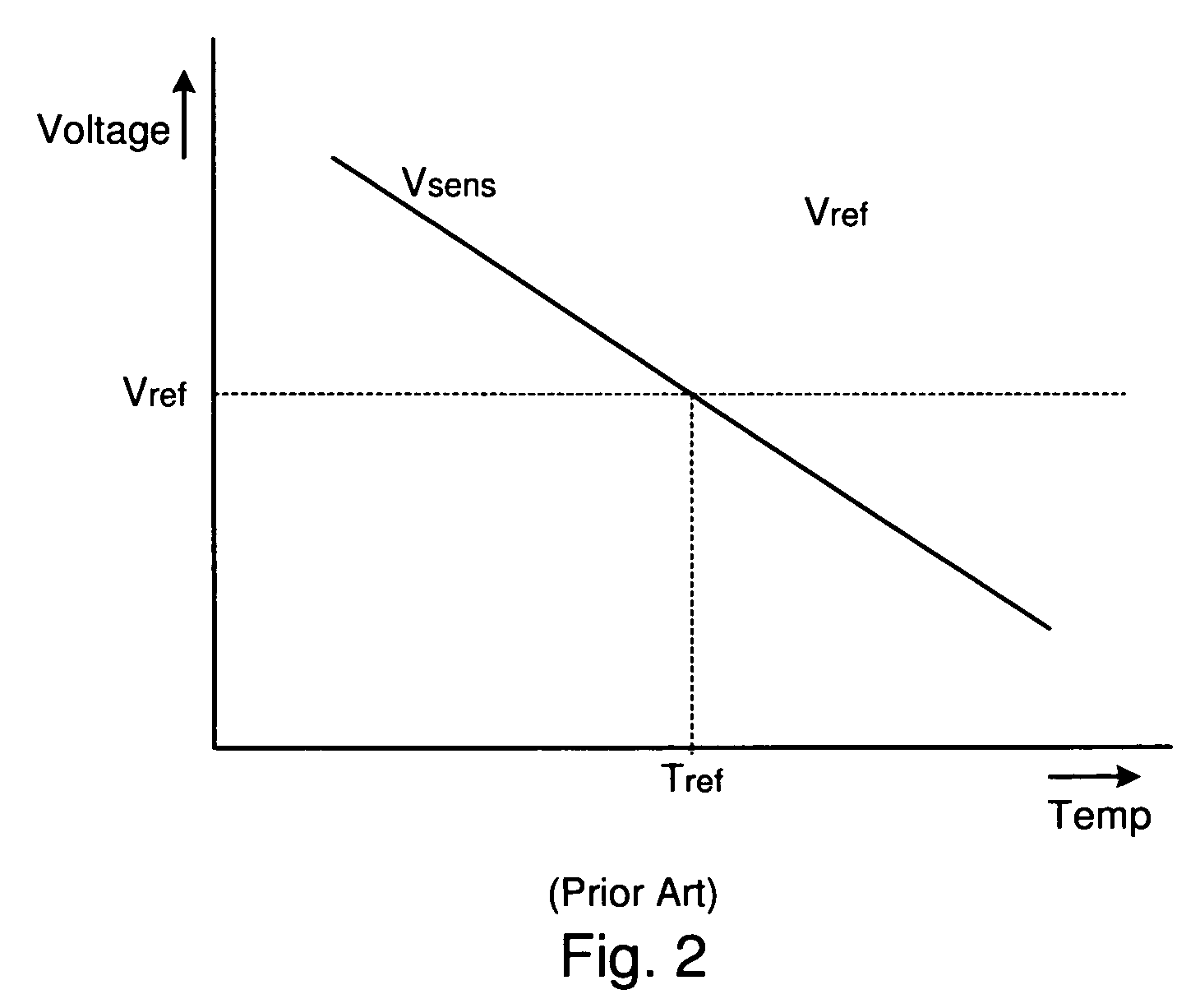

Advanced thermal sensor

ActiveUS20060153277A1Reduce complexitySmall sizeThermometers using electric/magnetic elementsUsing electrical meansVoltage generatorVoltage reference

Systems and methods for reducing the complexity and size of thermal sensors, where the voltage of a thermally sensitive device is compared to a reference voltage that varies as a function of temperature, rather than being constant. One embodiment comprises a thermal sensing system including a reference voltage generator, a thermal sensor and a comparator. The reference voltage generator is configured to generate a non-constant reference voltage that varies as a known function of temperature. The thermal sensor is configured to generate a sensor voltage that also varies as a known function of temperature. The functions of the reference and sensor voltages cross at a known temperature / voltage. The comparator is configured to compare the sensor voltage and the reference voltage and to generate a comparison output signal based on the comparison of the sensor voltage and the first reference voltage. A transition in this signal indicates the reference temperature.

Owner:KIOXIA CORP

Adjustable bow sight apparatus

InactiveUS7574811B2Reduce noiseReduce size and complexityBows/crossbowsSighting devicesEngineeringCircular segment

A bow sight including an adjustment system is described herein. The adjustment system may include an elevation adjustment mechanism and a windage adjustment mechanism. The user can adjust the elevation and / or windage of a sight component of the bow sight with the adjustment system. The adjustment system may be configured to allow the user to make very fine or micro-adjustments to the bow sight. The adjustment system may also be compact and easy to use relative to conventional bow sight adjustment systems.

Owner:HOYT ARCHERY

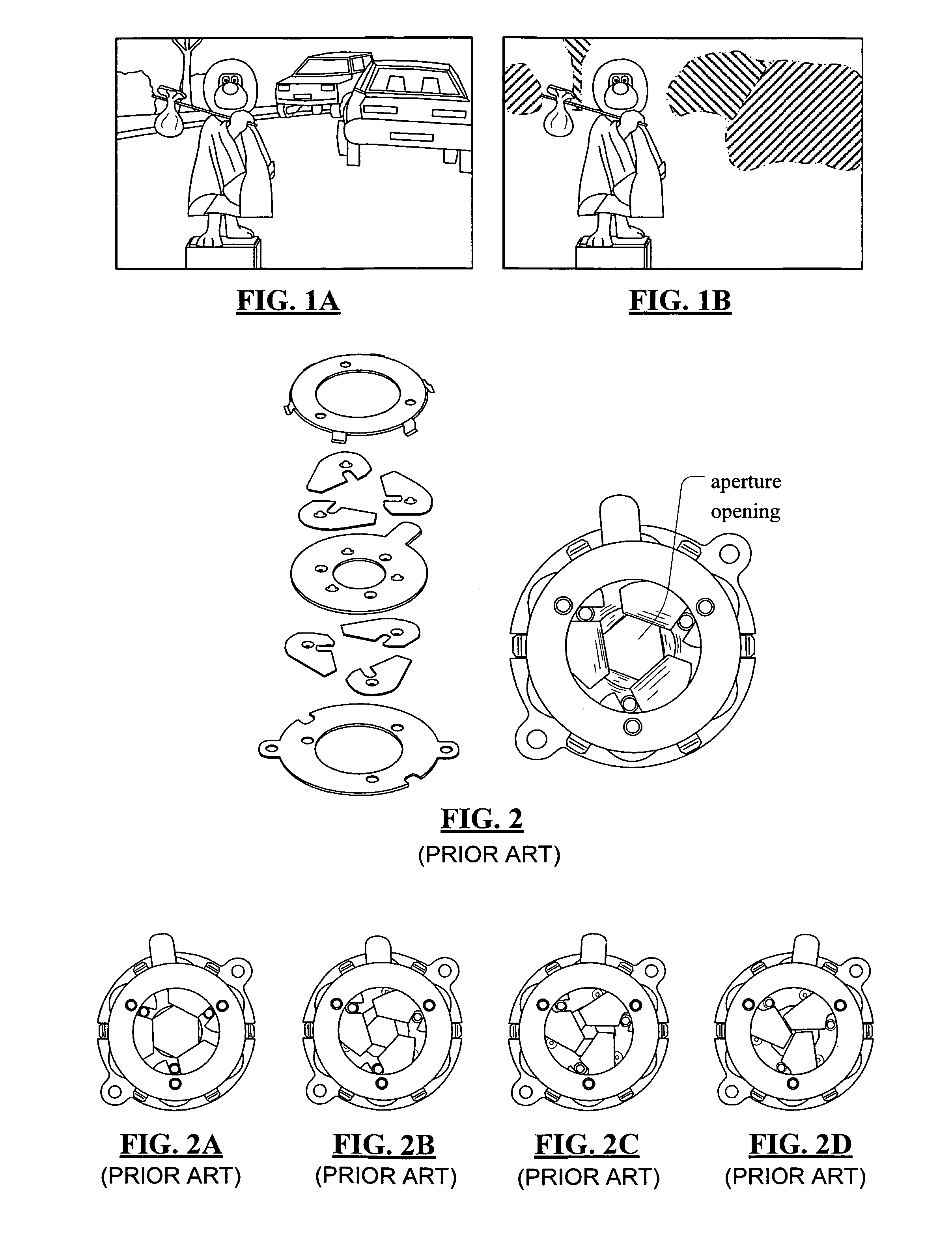

Aperture construction for a mobile camera

ActiveUS7585122B2Reduce size and complexitySimple manufacturing processPicture reproducers using cathode ray tubesActive material electrodesMobile cameraEngineering

Owner:NOKIA TECH OY

Charging type implantable medical device having protection and limiting functions

ActiveCN105148402AReduce size and complexityThermal safetyArtificial respirationElectrical batteryCharge type

The invention provides a charging type implantable medical device having a protection function and a limiting function and belongs to the technical field of implantable medical instruments. The device has the protection function and the limiting function. The protection function includes implanted rechargeable battery temperature protection, implanted titanium temperature protection, protection by a battery protection circuit and an external charging coil temperature protection. The limiting function includes inner receiving power limiting, magnetic induction strength limiting, charging efficiency limiting and external transmission power limiting. The implanted rechargeable battery protection circuit realizes comprehensive protection against conditions such as overvoltage, under voltage, overcurrent and load short circuit that may cause damage to a battery. The device provided by the invention has characteristics of guaranteeing heat safety, battery safety and electromagnetic safety.

Owner:BEIJING PINS MEDICAL

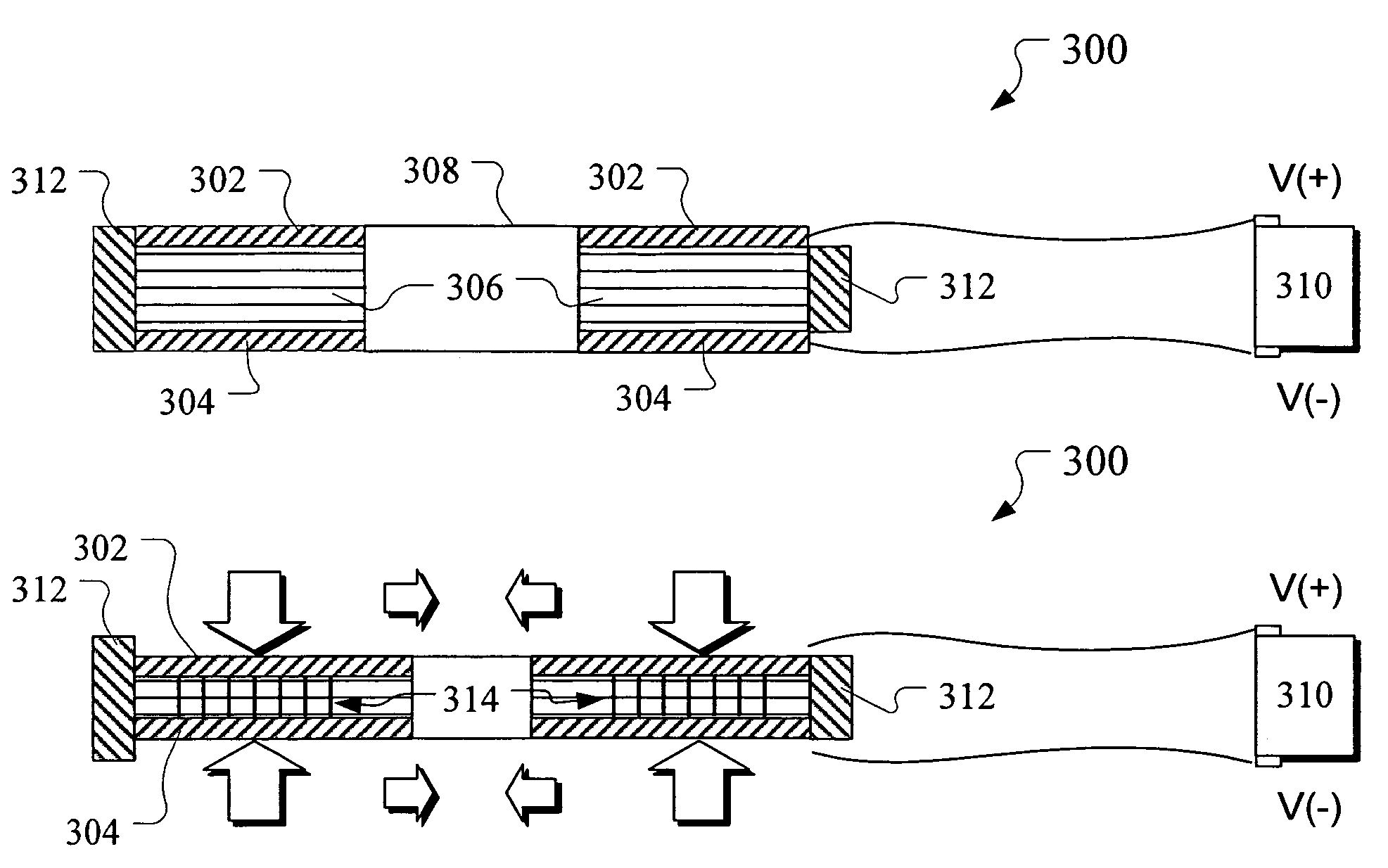

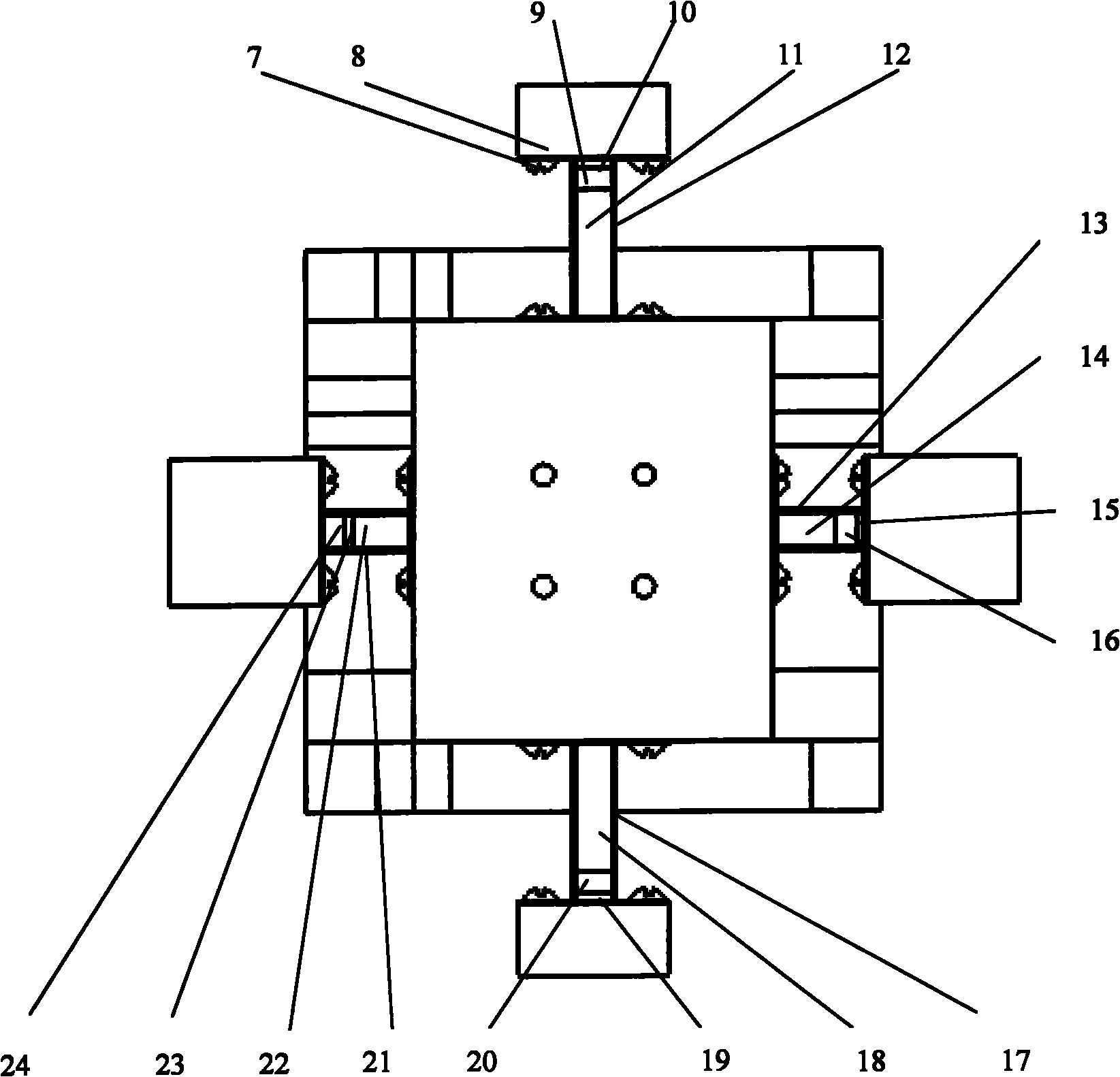

Two-degree-of-freedom large-stroke high-peed and high-precision positioning platform

InactiveCN101858477AImprove driving precisionReduce size and complexityStands/trestlesHinge angleTwo degrees of freedom

The invention relates to a two-degree-of-freedom large-stroke high-peed and high-precision positioning platform, belonging to an electromechanical type. The structure of the platform comprises a guide rail and a worktable which are matched with each other, and the worktable is driven by the guide rail and is connected with a mass block through a flexible hinge; a piezoelectric stack is pre-tightened and located in the flexible hinge through a wedge-shaped block; the guide rail is connected with the mass block through the flexible hinge; and the piezoelectric stack is pre-tightened in the flexible hinge through the wedge-shaped block. The positioning platform has the advantages of greatly improving the drive accuracy of the common drivers, reducing the complexity and the size of the structure, and having low cost, less investment, quick returns, high benefit and the like.

Owner:郑福胜

Advanced thermal sensor

ActiveUS7427158B2Reduce size and complexityThermometers using electric/magnetic elementsUsing electrical meansVoltage generatorEngineering

Systems and methods for reducing the complexity and size of thermal sensors, where the voltage of a thermally sensitive device is compared to a reference voltage that varies as a function of temperature, rather than being constant. One embodiment comprises a thermal sensing system including a reference voltage generator, a thermal sensor and a comparator. The reference voltage generator is configured to generate a non-constant reference voltage that varies as a known function of temperature. The thermal sensor is configured to generate a sensor voltage that also varies as a known function of temperature. The functions of the reference and sensor voltages cross at a known temperature / voltage. The comparator is configured to compare the sensor voltage and the reference voltage and to generate a comparison output signal based on the comparison of the sensor voltage and the first reference voltage. A transition in this signal indicates the reference temperature.

Owner:KIOXIA CORP

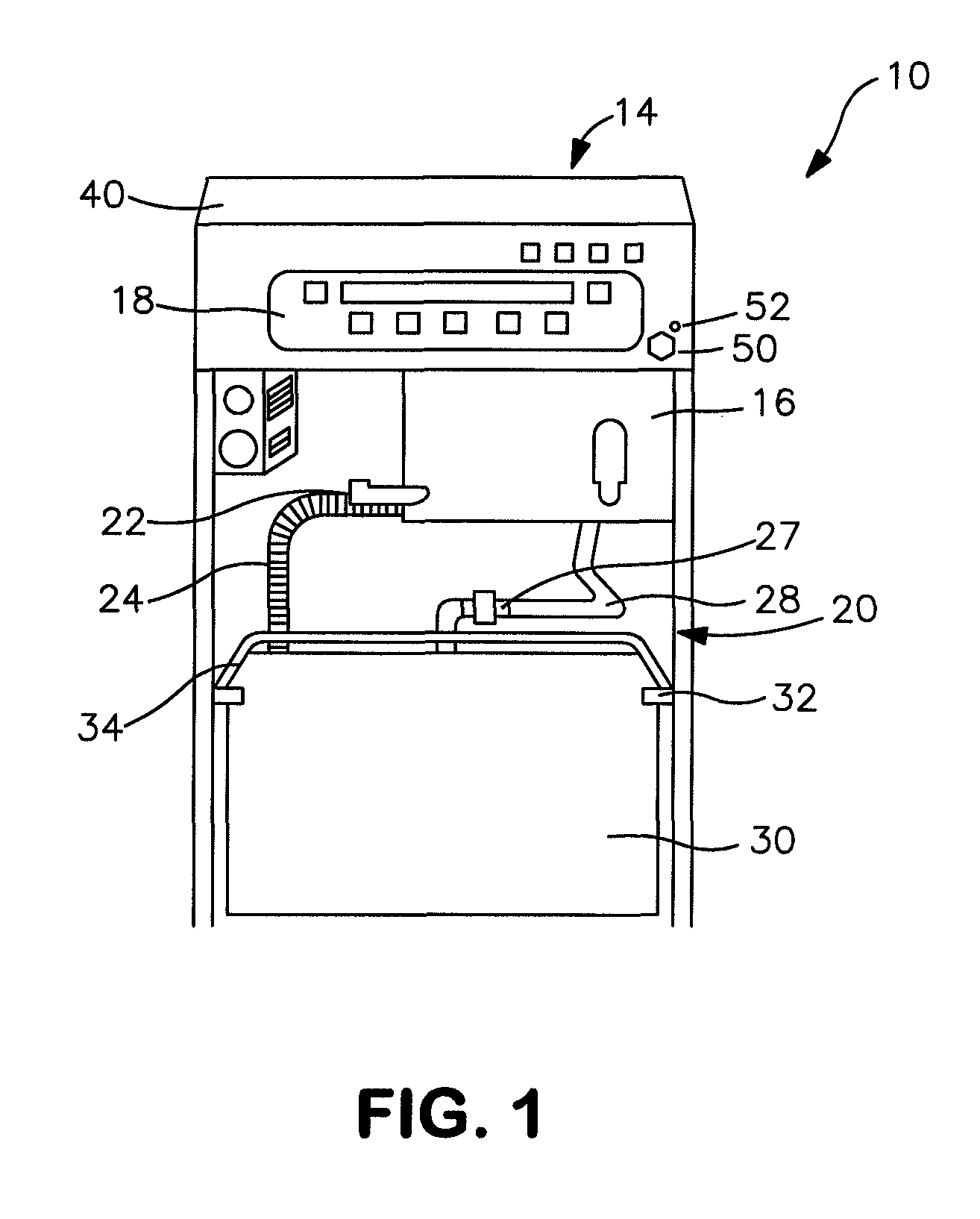

Cooking medium systems having a single fill manifold, and methods of supplying a cooking medium using such systems

ActiveUS20100116345A1Reduce size and complexityAccurately determineFatty-oils/fats refiningCooking vesselsEngineeringMechanical engineering

A system for delivering a cooking medium of a cooking apparatus includes one or more cooking vessels. The system also includes a drain manifold in fluid communication with the cooking vessel, and a fill manifold having input valves, and output valves in fluid communication with a corresponding cooking vessel. A first flow path is connected to the fill manifold. A filter container selectively is in fluid communication with the fill manifold. A filter pump is positioned between the filter container and the fill manifold and conveys a recycled cooking medium. An overflow pump selectively is in fluid communication with the fill manifold via a second flow path and a portion of the first flow path. The overflow pump conveys a new cooking medium to the fill manifold. The first flow path conveys one of the recycled cooking medium and the new cooking medium to the fill manifold.

Owner:HENNY PENNY

Ultra wide band wireless optical endoscopic device

A video endoscopy system for displaying an area to be viewed to a user, the system providing for wireless transmission via UWB signal technology of image data representative of the area to be viewed. The video endoscopy system uses an LED and a battery for providing illuminating light to the area to be viewed. The video endoscopy system also uses a digital imaging chip for picking up reflected light from the area to be viewed and generating image data representative of the reflected light, which in turn is wirelessly transmitted to a video system for display to the user.

Owner:KARL STORZ ENDOVISION INC

Aperture construction for a mobile camera

ActiveUS20070216803A1Reduce complexitySmall sizePicture reproducers using cathode ray tubesActive material electrodesMobile cameraElectricity

The invention relates in general to the field of digital cameras, especially small digital cameras. In particularly the invention relates for adjusting an aperture for mobile cameras. The adjustable aperture construction of the invention comprises two electrodes, and an electrical circuit for applying a voltage to the electrodes in order to create an electric field between the electrodes. In addition the construction comprises between the electrodes a center unit with a hole in the middle of it, the center unit being made of an electroactive material, such as dielectric material or electrostrictive polymer. The aperture can be adjusted by deforming the shape of the center unit. The shape of the center unit is advantageously deformed by the electric field created between said electrodes by said electrical circuit.

Owner:NOKIA TECHNOLOGLES OY

Image frequency rejection frequency mixer structure for terahertz wave band

ActiveCN105390783AReduce size and complexityReduce demandWaveguide type devicesMulti-frequency-changing modulation transferencePhase shiftedPhysics

The invention belongs to the technical field of terahertz devices, and provides an image frequency rejection frequency mixer structure for a terahertz wave band. The image frequency rejection frequency mixer structure includes an E-plane rectangular waveguide Chinese character 'tian'-shaped branch wire bridge 3dB directional coupler, micro-strip waveguide double probes, two frequency mixers, and a power combiner. A radio-frequency signal can generate two-channel radio-frequency signals with an equal amplitude and a 90-dgress phase difference via the E-plane rectangular waveguide Chinese character 'tian'-shaped branch wire bridge 3dB directional coupler, and the two-channel radio-frequency signals are input into two-channel frequency mixers respectively; a local oscillation signal can generate two-channel signals with an equal amplitude and a same phase via micro-strip waveguide double probes, and the two way signals are input into the two-channel frequency mixers respectively; two-channel frequency mixer intermediate frequency output signals are combined via the power combiner, and then are output; and each input end of the power combiner is provided with a 90-deree phase shifter for allowing the corresponding frequency mixer intermediate frequency output signal to generate a 90-degree phase shift, so that the two-channel frequency mixer intermediate frequency output signals are stacked in phase and output. The image frequency rejection frequency mixer structure is simple in structure and is applied to the terahertz wave band.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

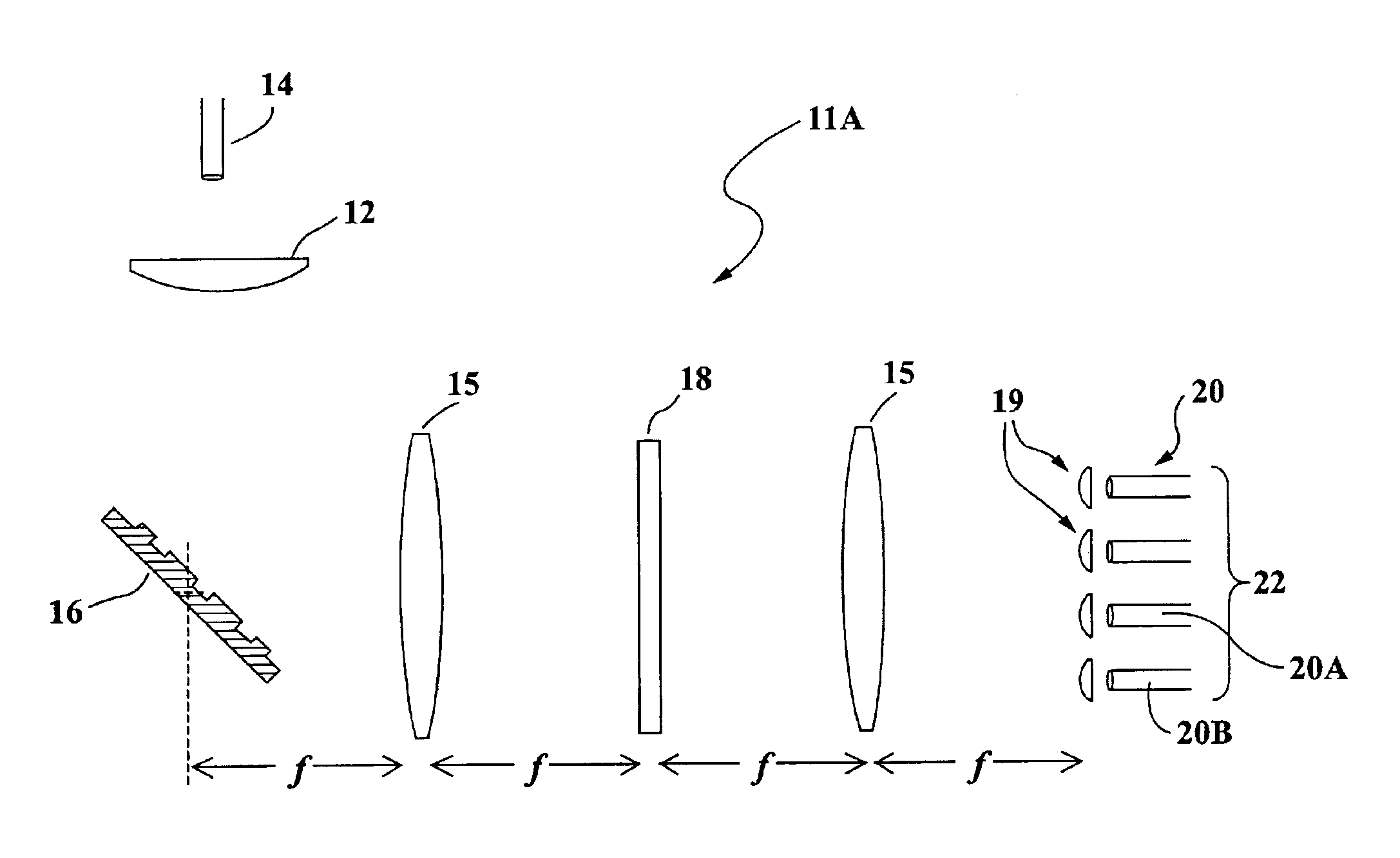

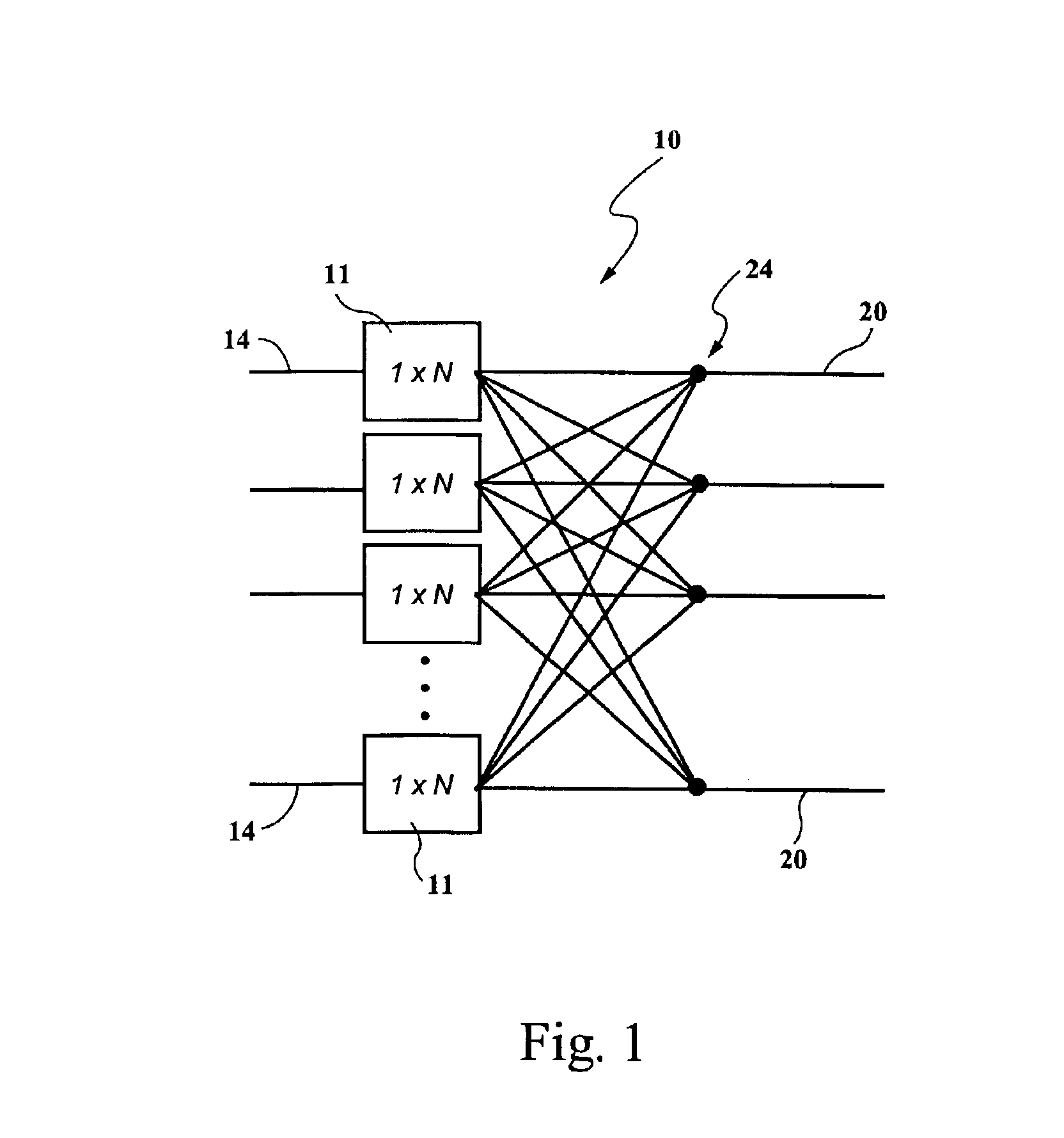

Optical cross-connect switch

ActiveUS6870985B2Sufficient flexibilityEasy to manufactureMultiplex system selection arrangementsCoupling light guidesCross connectionCollimated light

An optical cross-connect switch is disclosed which includes a plurality of optical input fibers, a plurality of optical output fibers and a plurality of the (1×N)-switches ganged together. Each of the switches includes a state selector, a lens for collimating light from a single one of the optical input fibers, a plurality of output coupling lenses, each of which corresponds to one of the optical output fibers, and a beam shaper for focusing light from the state selector onto a selected one of the coupling lenses for further focusing of the light onto the corresponding optical output fiber. Alternatively, the optical cross-connect switch can be a single an (L×K)-switch which includes a plurality of state selectors and a plurality of lenses for collimating light from the plurality of optical input fibers.

Owner:FOR NAT RES INITIATIVES

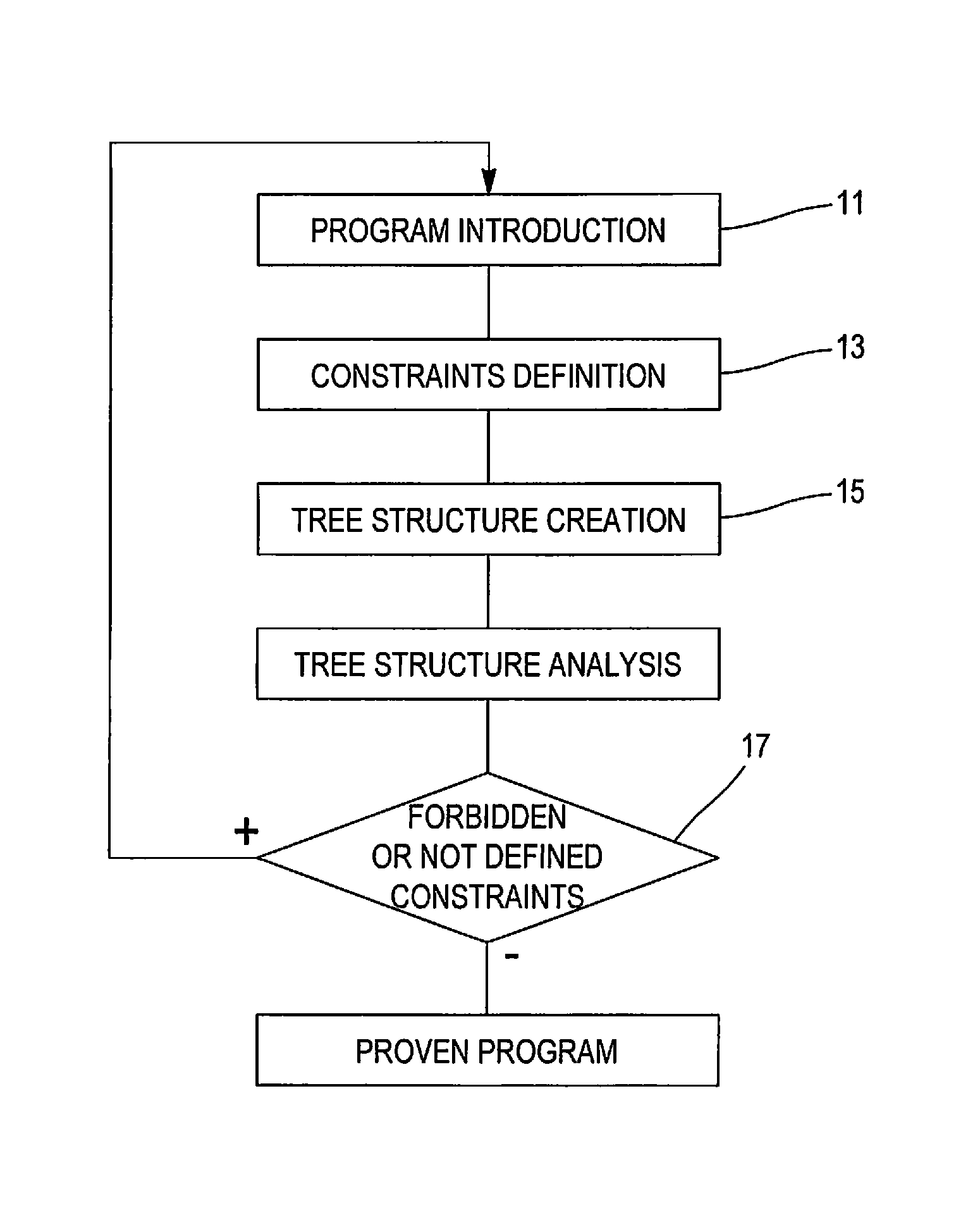

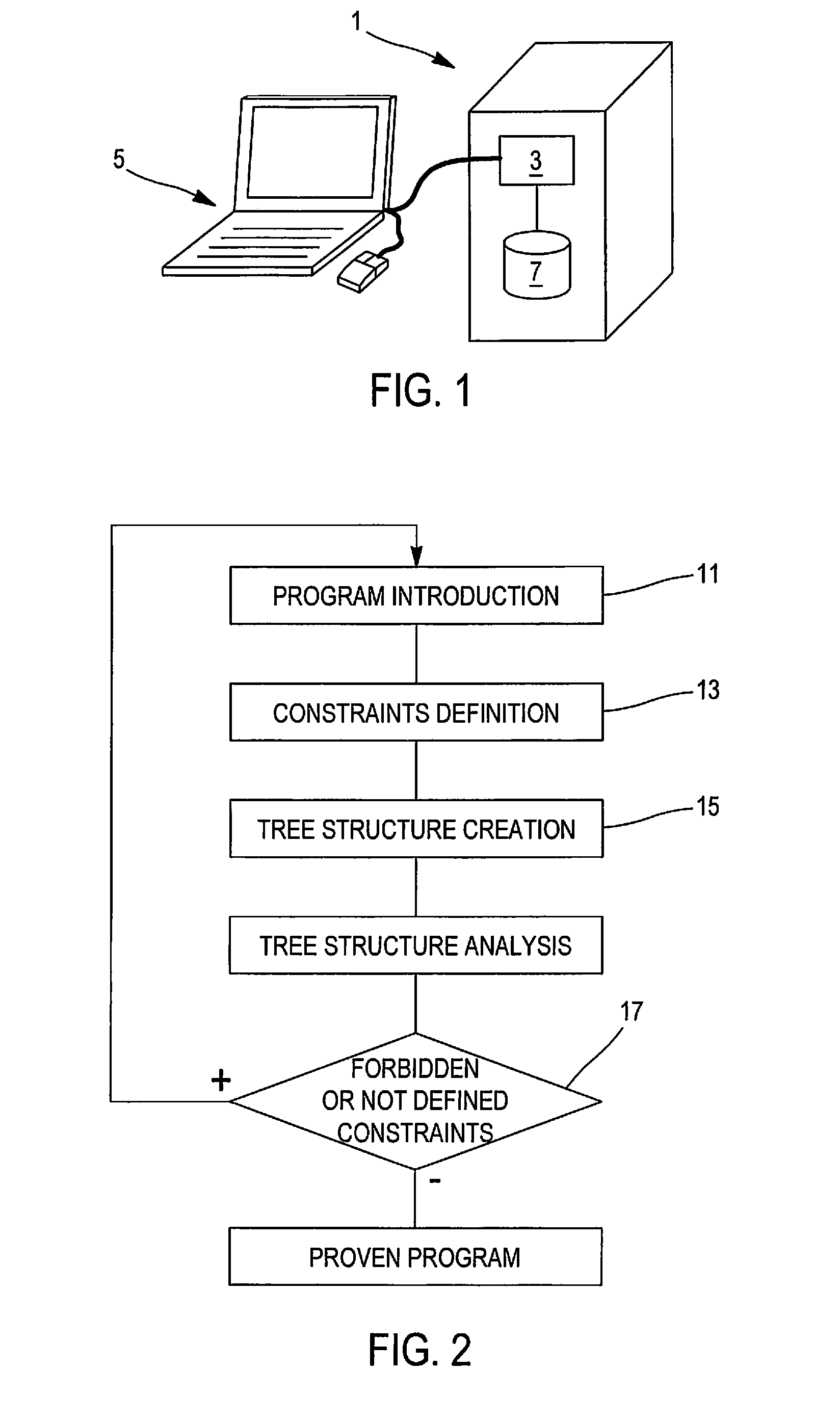

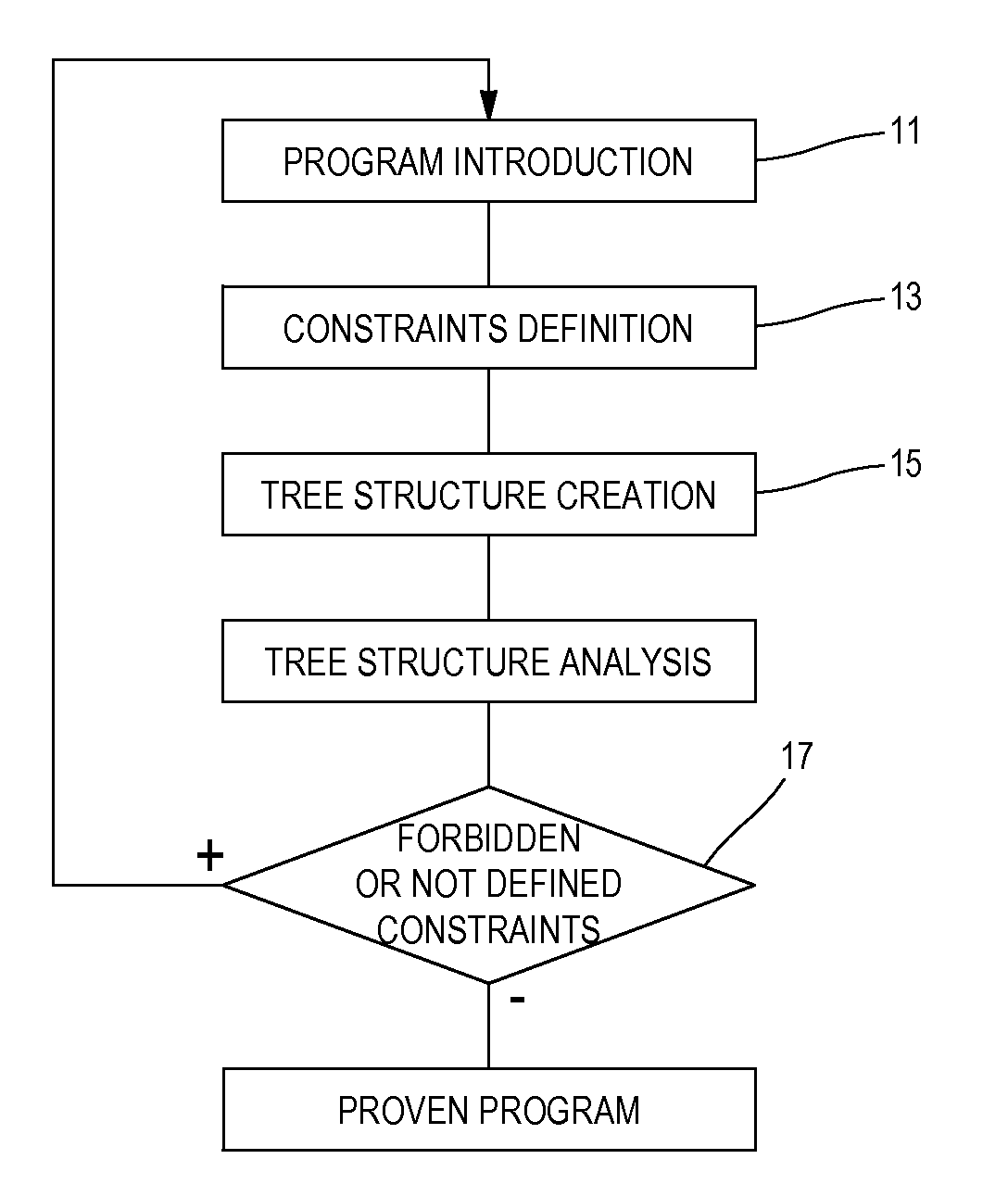

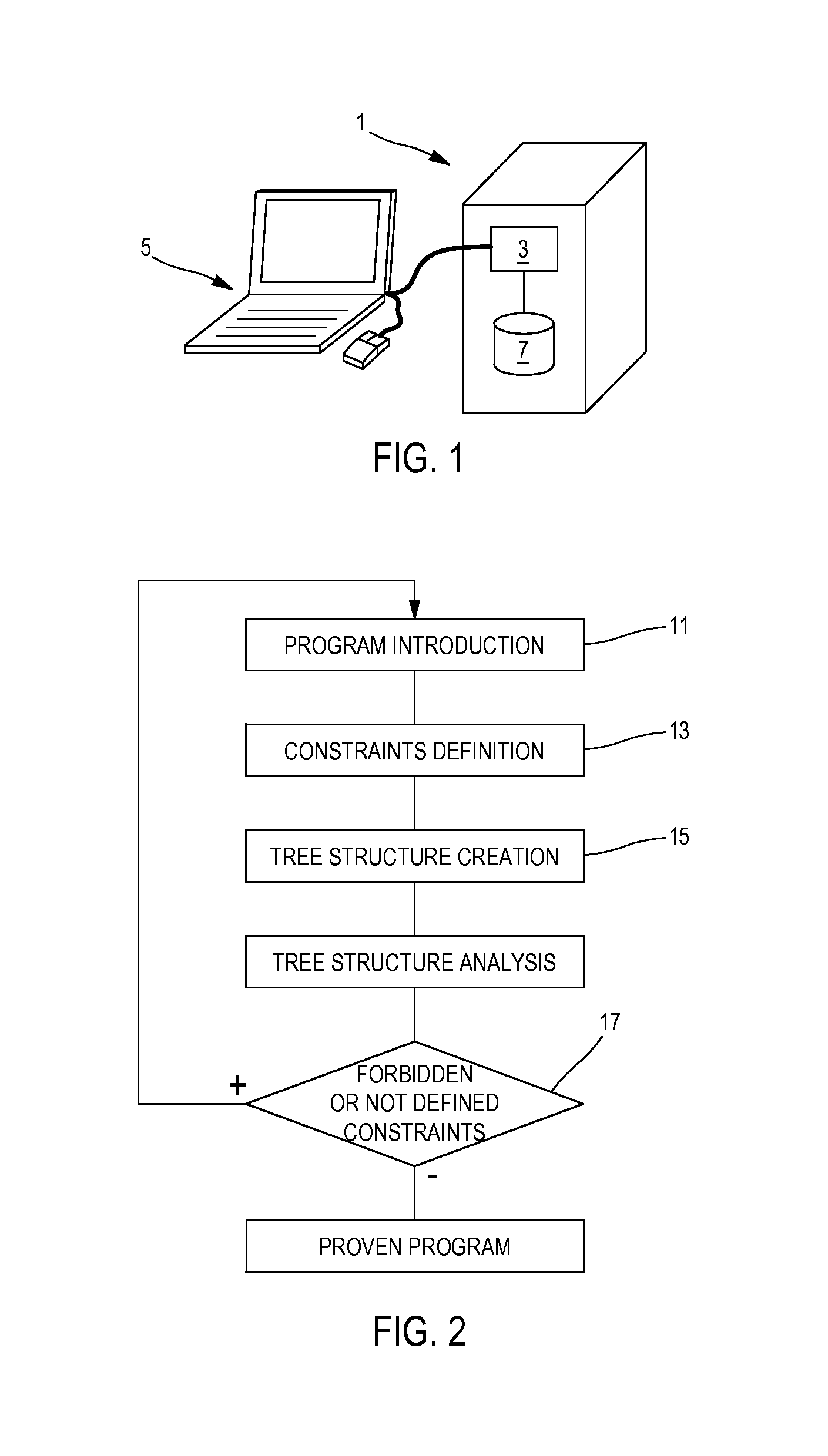

Method for securing a program

ActiveUS9501383B2Reduce size and complexityPossible to obtainReverse engineeringSoftware testing/debuggingProgramming languageEvolution rule

Owner:BOLIGNANO DOMINIQUE

Power transmitting apparatus

InactiveUS20110237389A1Reduce controlEasily and more precisely performMechanical actuated clutchesFluid actuated clutchesAutomotive transmissionControl theory

A power transmitting apparatus, such an automotive transmission, adapted to properly select transmission of or cutting-off of a driving force of the driving source to or from the wheels of a vehicle can include a torque converter having a torque amplifying function. A clutch mechanism can include a first clutch device configured to transmit the driving force to the wheels through the torque converter and a second clutch device configured to transmit the driving force without passing through the torque converter. A selecting device can control the first clutch device or the second clutch device in accordance with conditions of the vehicle including starting from a stop. An input-side measuring device can be used to measure an input-side rotational speed of the first clutch device and an output-side measuring device can be used for measuring an output-side rotational speed of the first clutch device. A slip ratio calculating device can be used to calculate the slip ratio of the first clutch device from the difference or the ratio between the rotational speed measured by the input-side measuring device and the rotational speed measured by the output-side measuring device.

Owner:FCC KK

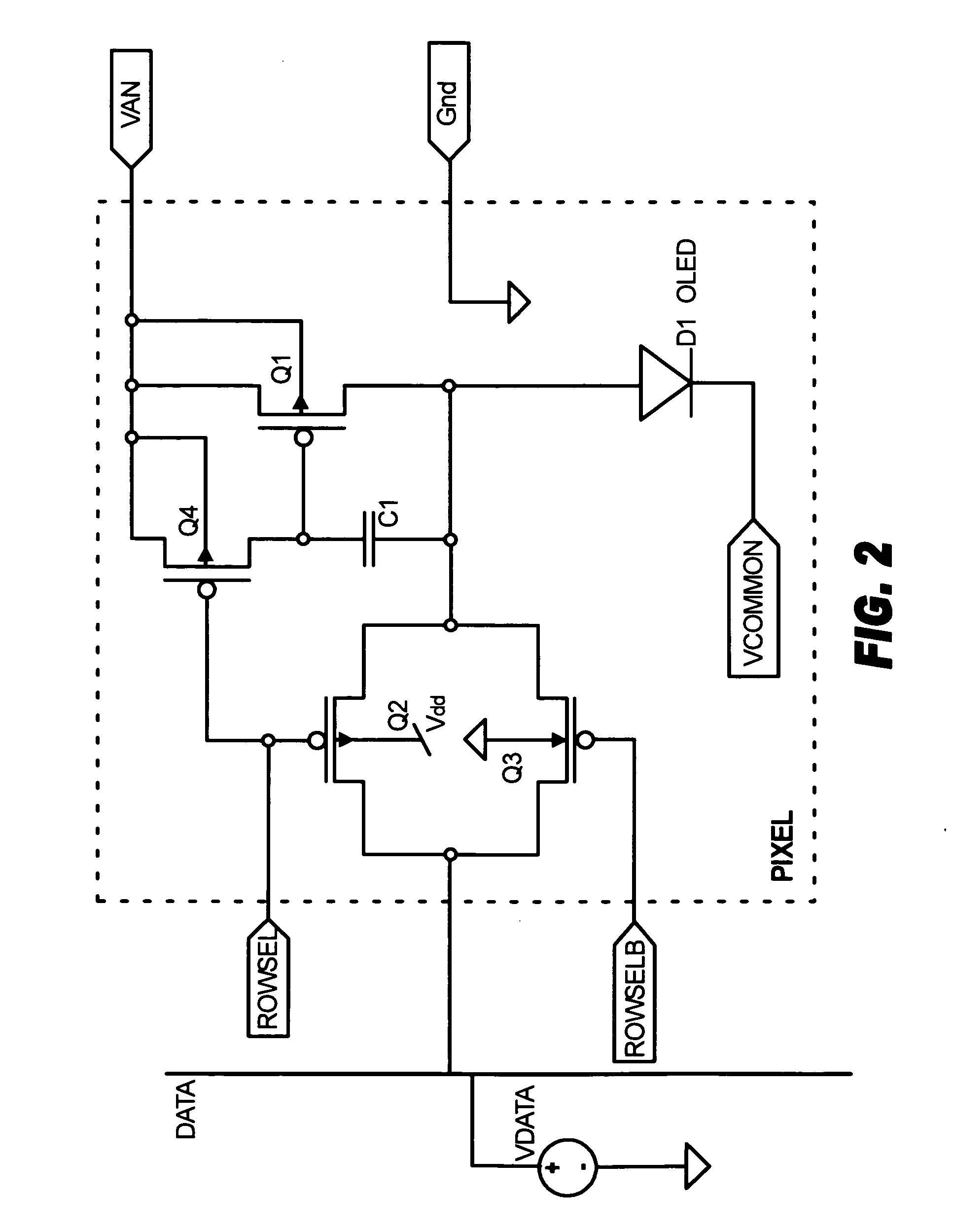

Amolded direct voltage pixel drive for minaturization

InactiveUS20080106500A1Reduce size and complexityFew deviceStatic indicating devicesTransmission gateExternal reference

The drive circuit for an OLED is designed for use with an external reference voltage source. The OLED is connected to the reference voltage source through a PMOS drive transistor. The circuit includes a data signal transmission gate responsive to a control signal for transmitting the data signal to the OLED. It also includes a storage capacitor and a second transistor. The capacitor is connected between the gate and the source of the drive transistor. The second transistor has an output circuit connected between the reference voltage source and the capacitor. The gate of the second transistor is operably connected to receive the control signal.

Owner:EMAGIN CORP

Cooking medium systems having a single mechanical lever and control assisted filtering and draining

ActiveUS8505443B2Reduce size and complexityReduce morbidityCooking vesselsDeep fat fryersEngineeringElectrical and Electronics engineering

Owner:HENNY PENNY CORP

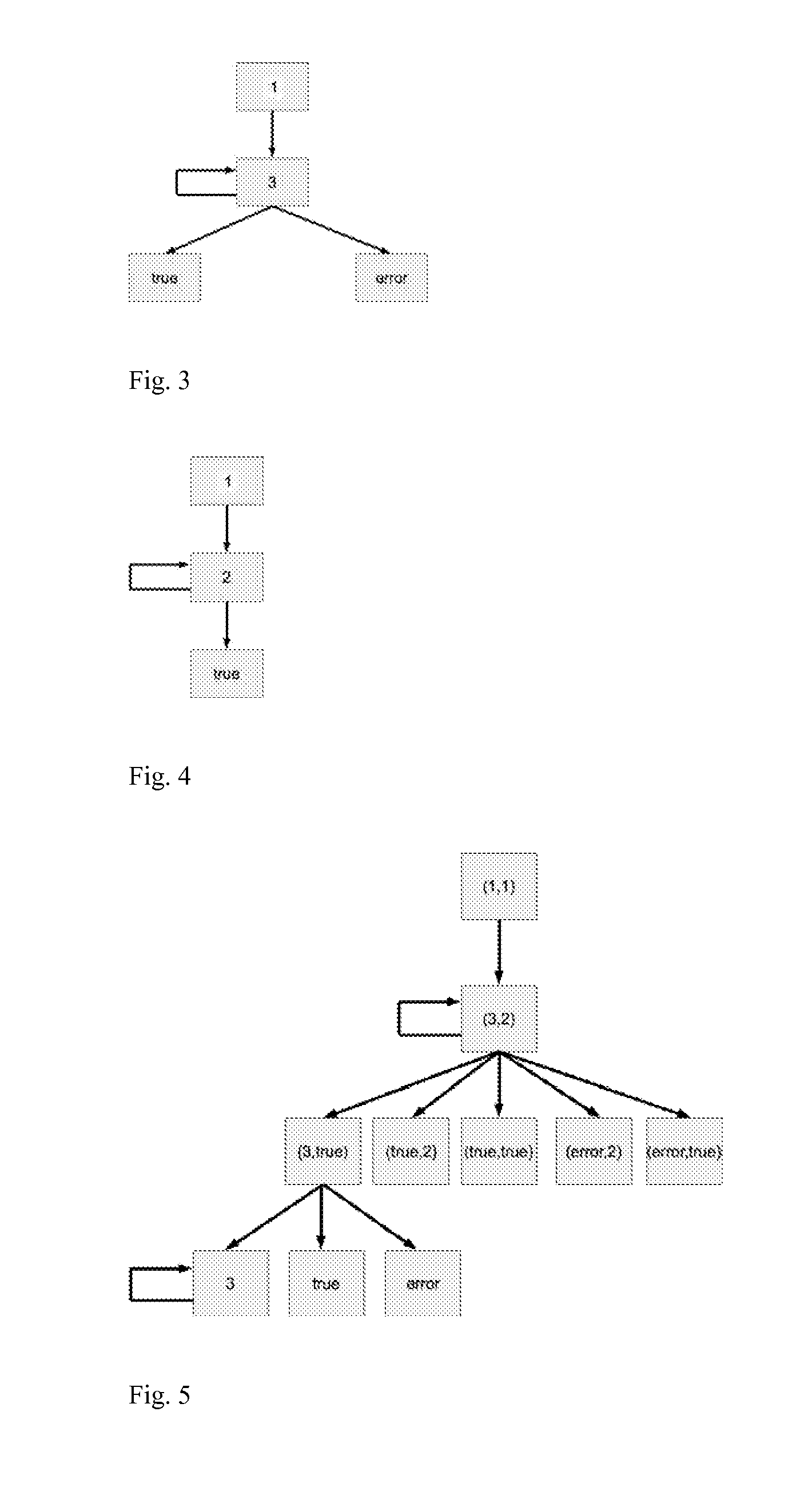

Method for securing a program

ActiveUS20140245259A1Reduce size and complexityPossible to obtainError detection/correctionReverse engineeringFormal proofEvolution rule

A method for securing a first program, the first program including a finite number of program points and evolution rules associated to program points and defining the passage of a program point to another, the method including defining a plurality of exit cases and, when a second program is used in the definition of the first program, for each exit case, definition of a branching toward a specific program point of the first program or a declaration of branching impossibility, defining a set of properties to be proven, each associated with one of the constitutive elements of the first program, said set of properties comprising the branching impossibility as a particular property and establishment of the formal proof of the set of properties.

Owner:BOLIGNANO DOMINIQUE

Cooking medium systems having a single fill manifold, and methods of supplying a cooking medium using such systems

ActiveUS8980102B2Reduce size and complexityAccurately determineLiquid separation auxillary apparatusFatty-oils/fats refiningEngineeringMechanical engineering

A system for delivering a cooking medium of a cooking apparatus includes one or more cooking vessels. The system also includes a drain manifold in fluid communication with the cooking vessel, and a fill manifold having input valves, and output valves in fluid communication with a corresponding cooking vessel. A first flow path is connected to the fill manifold. A filter container selectively is in fluid communication with the fill manifold. A filter pump is positioned between the filter container and the fill manifold and conveys a recycled cooking medium. An overflow pump selectively is in fluid communication with the fill manifold via a second flow path and a portion of the first flow path. The overflow pump conveys a new cooking medium to the fill manifold. The first flow path conveys one of the recycled cooking medium and the new cooking medium to the fill manifold.

Owner:HENNY PENNY CORP

Method for securing a program

ActiveUS20150007333A1Reduce size and complexitySoftware engineeringDigital data processing detailsTheoretical computer scienceEvolution rule

Owner:BOLIGNANO DOMINIQUE

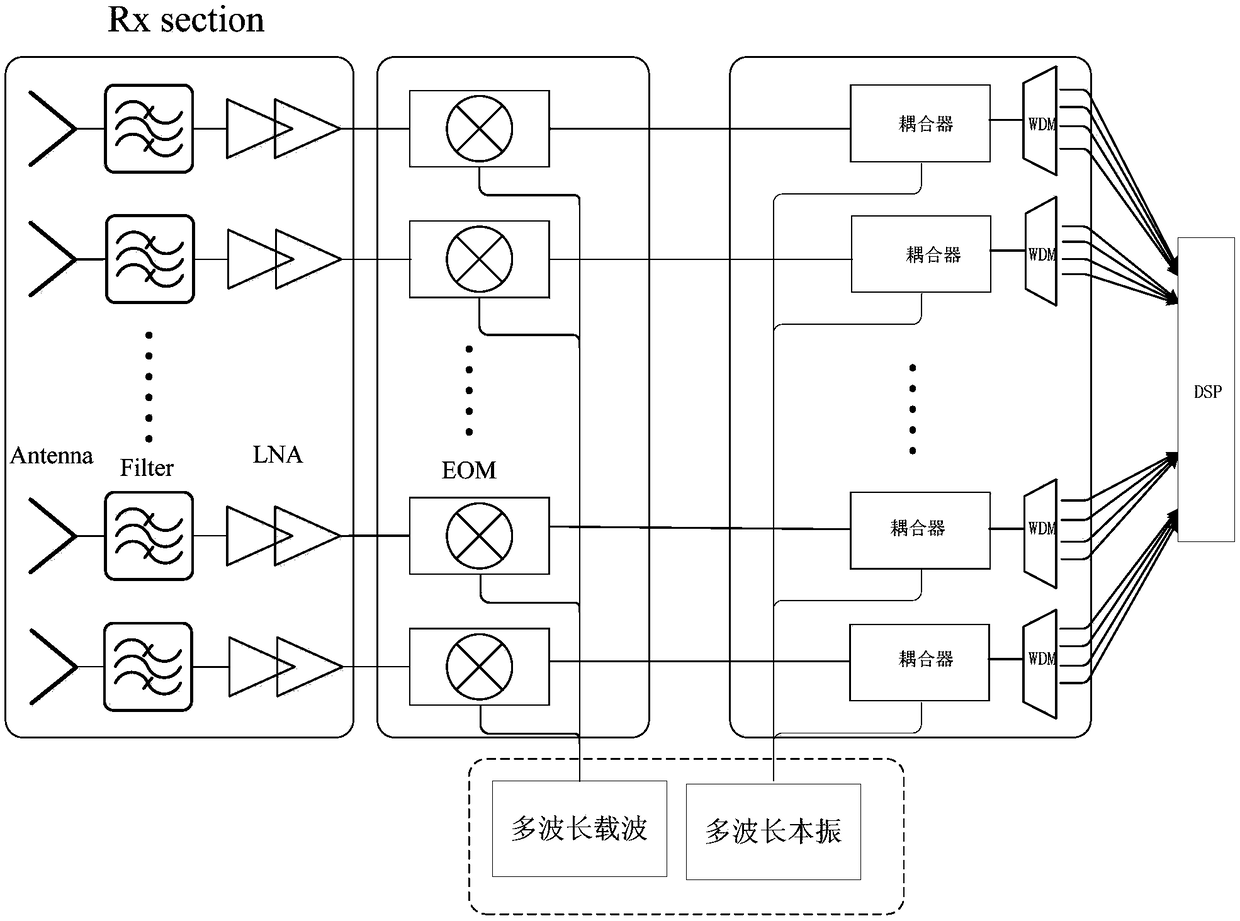

Satellite spectrum sensing method and system based on equal-amplitude equal-interval multi-wavelength light source

ActiveCN109302251AReduce size and complexityReduce volumeSatellite communication transmissionTransmission monitoringOptical pathVIT signals

The invention discloses a satellite spectrum sensing method and system based on an equal-amplitude equal-interval multi-wavelength light source. Based on an equal-amplitude, equal-interval and multi-wavelength satellite spectrum sensing method, a photon technology is introduced into a spectrum sensing technology in the satellite navigation electric field, the equal-amplitude equal-interval and multi-frequency wavelength is used as the light source, the sensing of a microwave frequency channel is achieved on each optical wavelength, and meanwhile, an I / Q demodulation technology is combined to achieve high-precision sensing and treatment of a radio frequency signal. According to the method and system provided by the invention, the parallel multi-channel microwave frequency sensing is completed on an optical path, so that the volume and complexity of the system are greatly reduced; the method and system are applicable to strict requirements on the volume, weight and power consumption of an on-satellite system module in a satellite navigation system; the limitation of the traditional sensing device in the electric field on the losses of frequency bands close to the navigation system isbroken, and the problem of ultra wide band signal sensing and treatment of the satellite navigation system is solved.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

Power transmitting apparatus

InactiveUS8262539B2Reduce size and complexityImprove startup performanceMechanical actuated clutchesFluid actuated clutchesAutomotive transmissionControl theory

Owner:FCC KK

Power transmitting apparatus

ActiveUS20110233019A1Reduce complexitySmall sizeMechanical actuated clutchesRotary clutchesTransmitted powerOperation mode

A power transmitting apparatus for transmitting power from a driving source of a vehicle to its wheels can be adapted to properly select transmitting or cutting-off of the driving force of the driving source to or from the wheels. The apparatus can comprise a torque converter having a torque amplifying function; a clutch mechanism including a first clutch device operable on advancement of the vehicle and adapted to transmit the driving force of the driving source to the wheels through a power transmitting system of the torque converter and a second clutch device adapted to transmit the driving force of the driving source to the wheels without the power transmitting system of the torque converter. A selecting device can be configured to operate the first clutch device and / or the second clutch device in accordance with operation modes of the vehicle, including starting.

Owner:FCC KK

Surface Figure Test Method For Large Convex Optical Surfaces

InactiveUS20120259447A1Reduce complexitySmall sizeReflective surface testingUsing optical meansRefractive indexOptical surface

A method of testing figure quality of a convex mirror in which an optical quality substrate material is used. The substrate has a front convex surface that has to be polished and figured to high accuracy, typically λ / 10 (HeNe), and a rear concave surface which only needs to be polished and figured to moderate surface figure accuracy, typically about 1-λ (HeNe). Three separate interferometric null tests are then carried out to produce three independent sets of optical path difference (OPD) data. Null lenses, or nulling computer generated holograms (CGHs), are designed and used as needed in each test setup so that spherical aberration is corrected. All three separate interferometric tests are either ideal null tests, or near null tests. From the three sets of OPD data, surface figure errors on the rear and front surfaces of the test optic, h1(xi,yj) and h2(xi,yj), are calculated as well as the OPD error OPDI(xi,yj) introduced by refractive index inhomogeneity in the substrate material. The rear surface is then corrected, generally using a computer-controlled polishing machine, to reduce rear surface errors hi(xi,yj) to a manageably small level. The front convex surface of the test optic is then corrected to reduce surface figure error h2(xi,yj) to within some specified amount. The front mirror surface can be figured to any required accuracy in spite of residual surface figure error in the rear surface, h1(xi,yj), and the effects of refractive index inhomogeneity in the substrate material OPDI(xi,yj). The convex front surface is then coated with a reflective coating to produce the finished convex mirror.

Owner:MCKECHNIE THOMAS STEWART

Portable all-electric subsea drive module

ActiveUS9926770B1Reduce environmental impactSimplify ROV tool deliveryAssociation with control/drive circuitsSurveyElectricityOcean bottom

A subsea tool assembly includes a subsea tool and a subsea drive module connected to and configured to provide drive power to the subsea tool. The subsea drive module includes a housing configured for operation in a subsea environment, an electrical motor deployed in the housing, and an electrical power supply deployed in the housing. The electrical motor is configured to rotate a magnetic coupling which is sized and shaped to magnetically engage a corresponding magnetic coupling in the subsea tool. The electrical power supply is electrically connected to and configured to provide electrical power to the motor. Rotation of the magnetic coupling rotates the corresponding magnetic coupling in the subsea tool thereby providing drive power to the subsea tool.

Owner:ONESUBSEA IP UK LTD

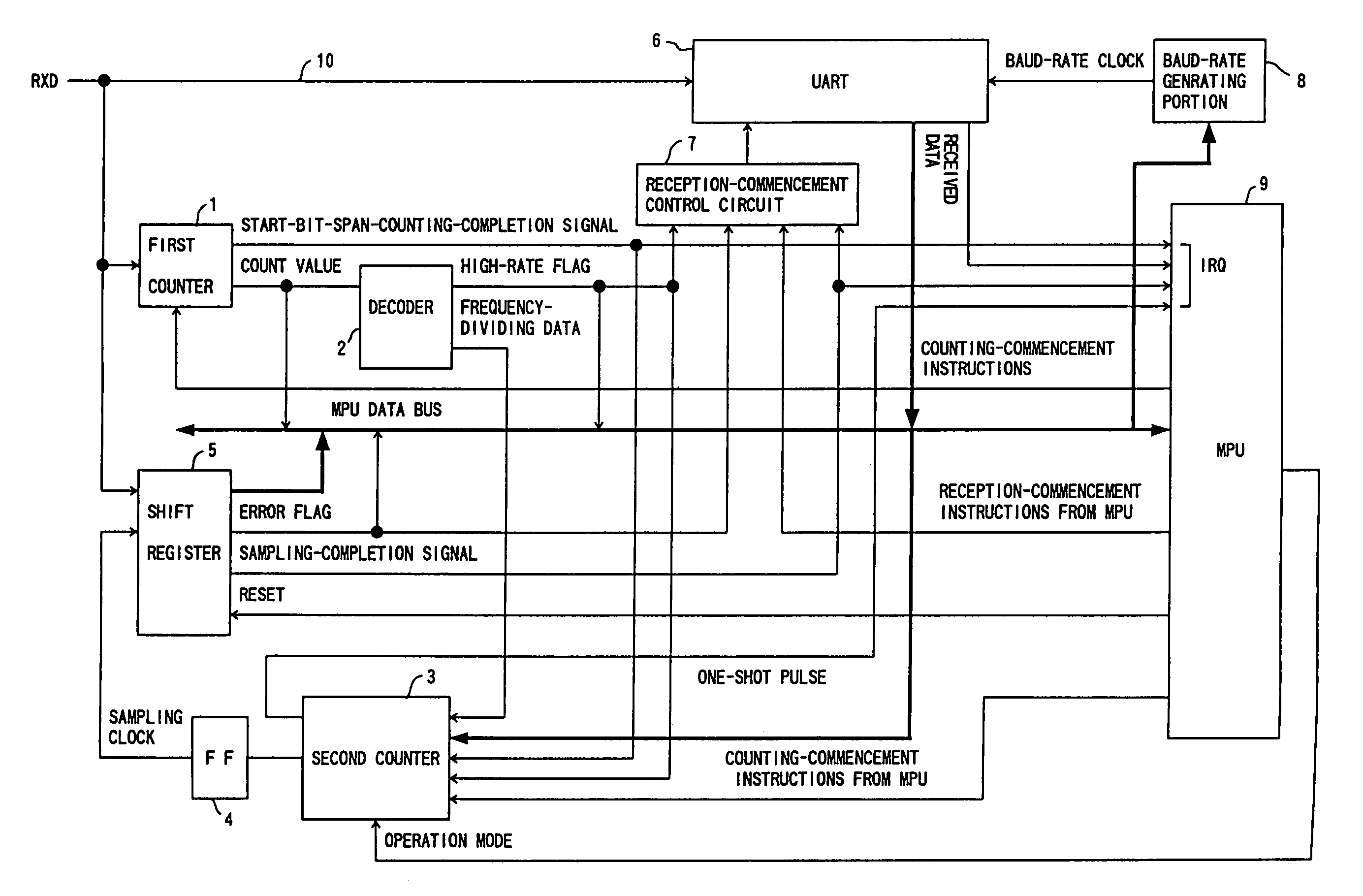

At-command analyzing method

InactiveUS7321615B2Small sizeReduce complexitySynchronisation signal speed/phase controlData rate detection arrangementsShift registerProcessor register

An UART receives asynchronous transmission serial data based on a baud-rate clock from a DTE. An MPU analyzes the data received by the UART. A baud-rate generating portion generates the baud-rate clock to be output to the UART in accordance with instructions from the MPU. A first counter measures the span of the start bit of the first character of an AT command transmitted from the DTE based on instructions from the MPU. A decoder receives a measurement result of the first counter, outputs frequency-dividing data for producing a clock for sampling the first character, and also outputs, when the rate of the start bit is more than a preset value, a flag indicating this matter. A second counter selects, in accordance with whether or not the flag is has been set, the frequency-dividing data from either the decoder or the MPU, and produces the sampling clock. A shift register receives data subsequent to the start bit of the first character based on the sampling clock from the second register, holds the received data, which data is then read by the MPU.

Owner:RICOH KK

Integrated circuit having register configuration sets

InactiveUS6941435B2Reduce complexitySmall sizeArchitecture with single central processing unitMemory systemsRegister allocationProcessor register

An integrated circuit and a method of reconfiguring an integrated circuit in which multiple configuration sets, each including a plurality of register settings, are stored on the chip. Selection of at least a portion of a configuration set allows for quicker and easier retrieval and loading of register settings, and reduces the complexity and size of the higher level system control program. In an alternative embodiment, at least a portion of a configuration set that is stored on the chip can be directly loaded to at least one device to be controlled to eliminate the need for the set of registers.

Owner:IBM CORP

Power transmitting apparatus

ActiveUS8245826B2Reduce size and complexityImprove startup performanceMechanical actuated clutchesRotary clutchesTransmitted powerOperation mode

A power transmitting apparatus for transmitting power from a driving source of a vehicle to its wheels can be adapted to properly select transmitting or cutting-off of the driving force of the driving source to or from the wheels. The apparatus can comprise a torque converter having a torque amplifying function; a clutch mechanism including a first clutch device operable on advancement of the vehicle and adapted to transmit the driving force of the driving source to the wheels through a power transmitting system of the torque converter and a second clutch device adapted to transmit the driving force of the driving source to the wheels without the power transmitting system of the torque converter. A selecting device can be configured to operate the first clutch device and / or the second clutch device in accordance with operation modes of the vehicle, including starting.

Owner:FCC KK

Surface figure test method for large convex optical surfaces

InactiveUS8576408B2Reduce size and complexityFabrication simpler and less-expensiveReflective surface testingUsing optical meansGraphicsRefractive index

A method of testing figure quality of a convex mirror in which an optical quality substrate material is used. Three separate interferometric null tests are carried out to produce three independent sets of optical path difference (OPD) data. Null lenses, or nulling computer generated holograms (CGHs), are designed and used as needed in each test setup so that spherical aberration is corrected. From the three sets of OPD data, surface figure errors on the rear and front surfaces of the test optic are calculated as well as the OPD error introduced by refractive index inhomogeneity in the substrate material. The rear surface is then corrected, generally using a computer-controlled polishing machine, to reduce rear surface errors to a manageably small level. The front convex surface of the test optic is then corrected to reduce surface figure error to within some specified amount.

Owner:MCKECHNIE THOMAS STEWART

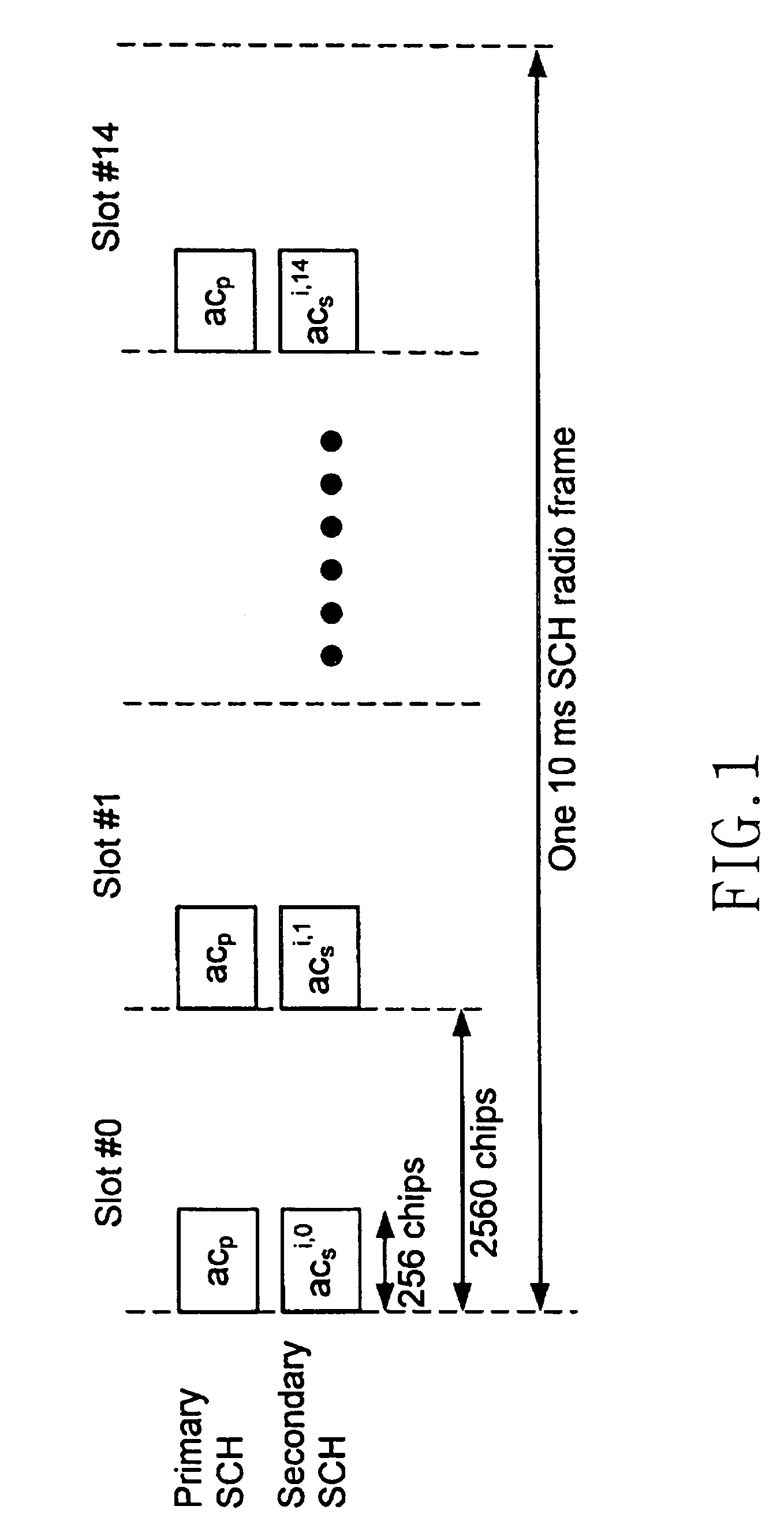

Method and apparatus for generating a code in an asynchronous code division multiple access mobile communication system

InactiveUS7304965B2Reduce complexitySmall sizeTime-division multiplexMultiplex code generationProgramming languageMobile communication systems

A method and apparatus for generating a code in an asynchronous code division multiple access mobile communication system is provided. Specifically, the method and apparatus are for use in a transmitter in a mobile communication system which has multiple code groups having inherent code indices in response to each of slots, which selects one code group from among the multiple code groups, and which generates a second synchronization code corresponding to any one slot from among multiple slots, which are included in the selected code group. The method and apparatus determine position information designating a Hadamard code necessary for generating the second synchronization code by performing the steps of (1) in response to any one slot, outputting a value, which is obtained by subtracting 1 from a code index included in the selected code group, as a binary bit row; and (2) selecting one bit row, which employs the binary bit row as an upper bit and employs a binary code “0000” as a lower bit, as position information which designates the Hadamard code.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com