Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Reduce load inertia" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

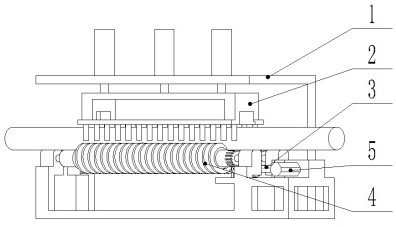

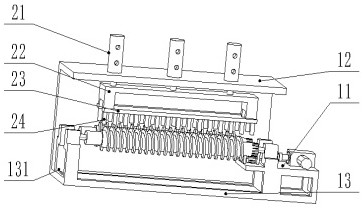

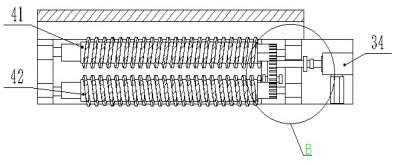

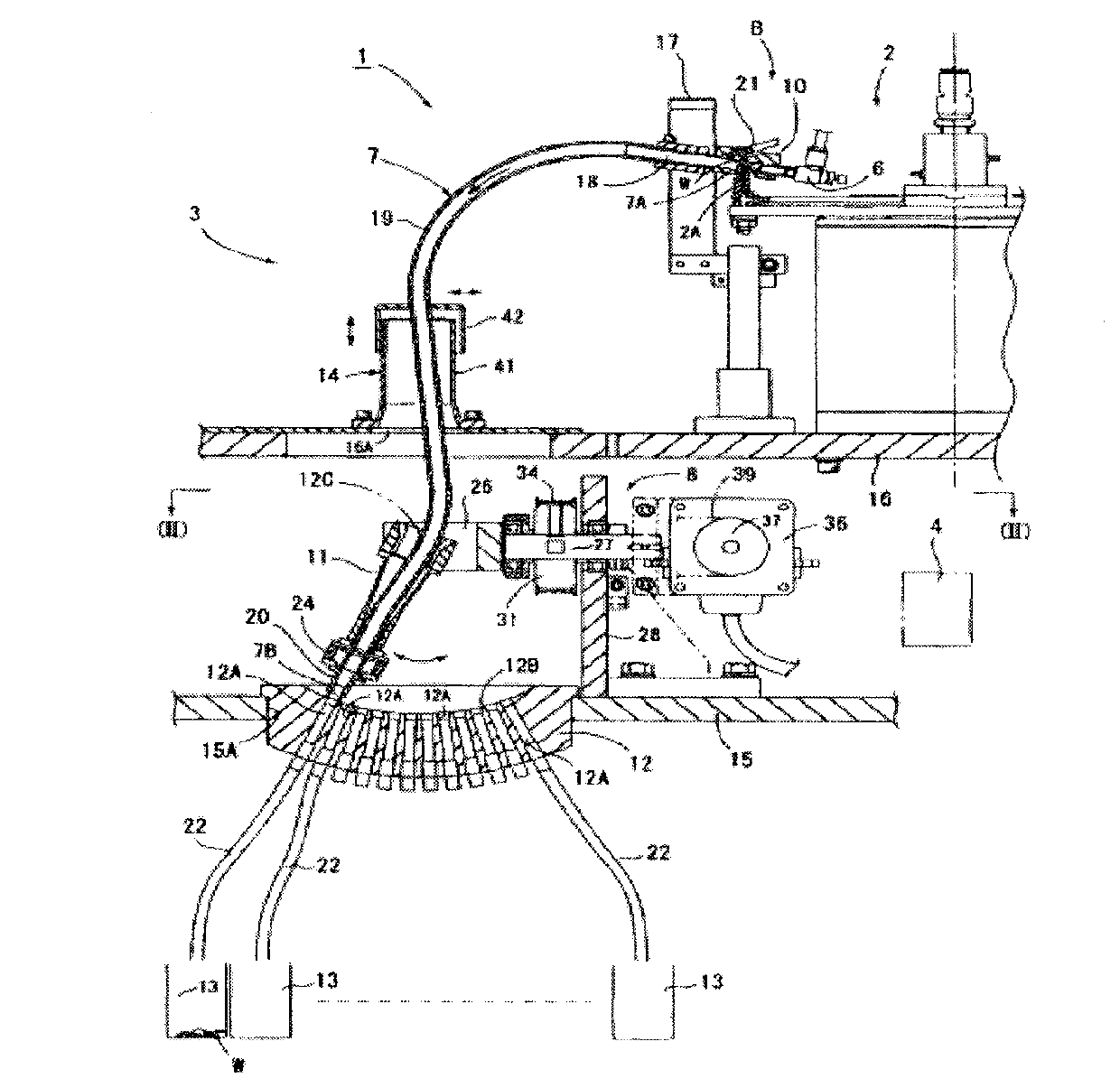

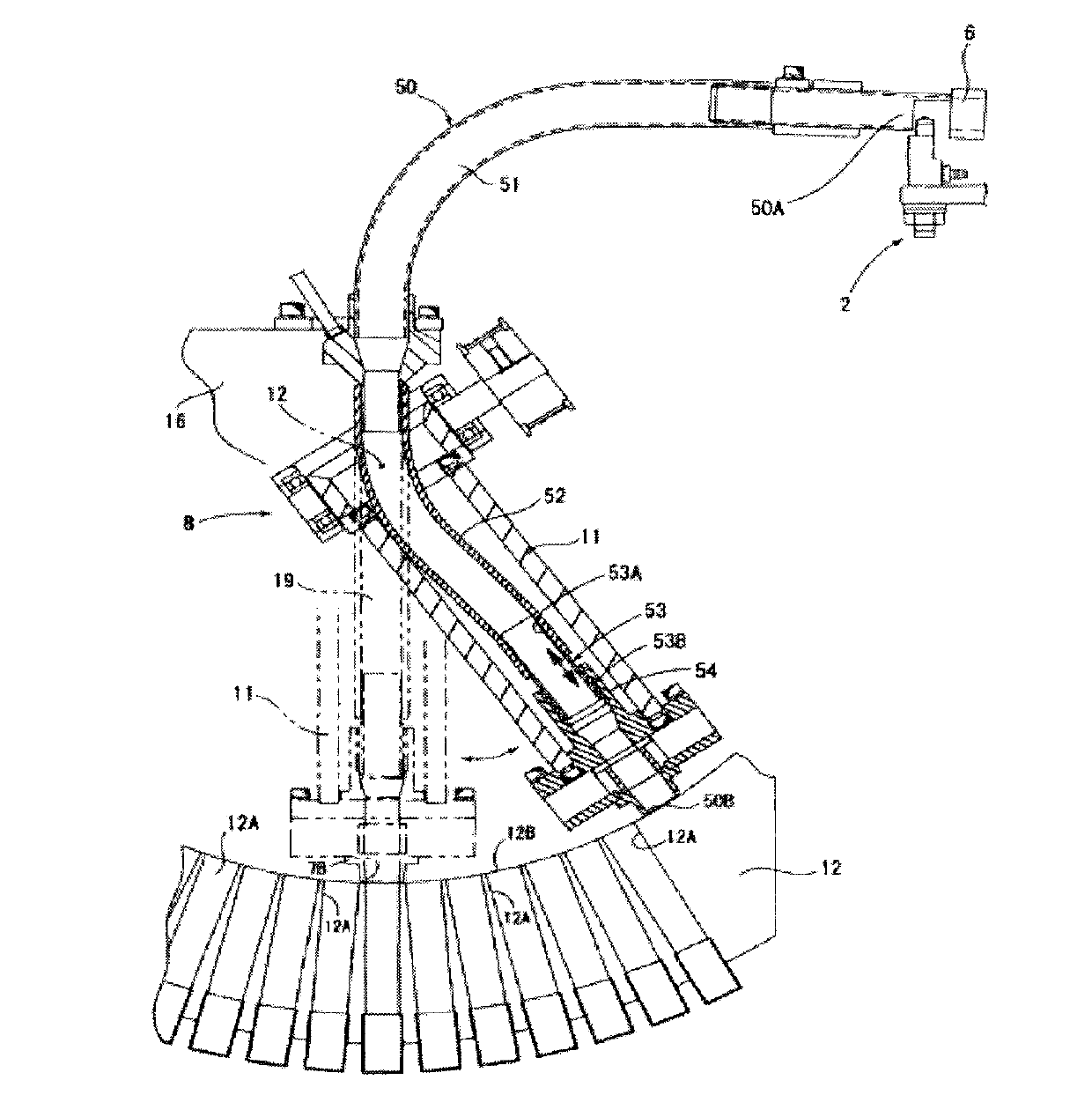

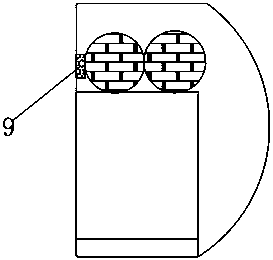

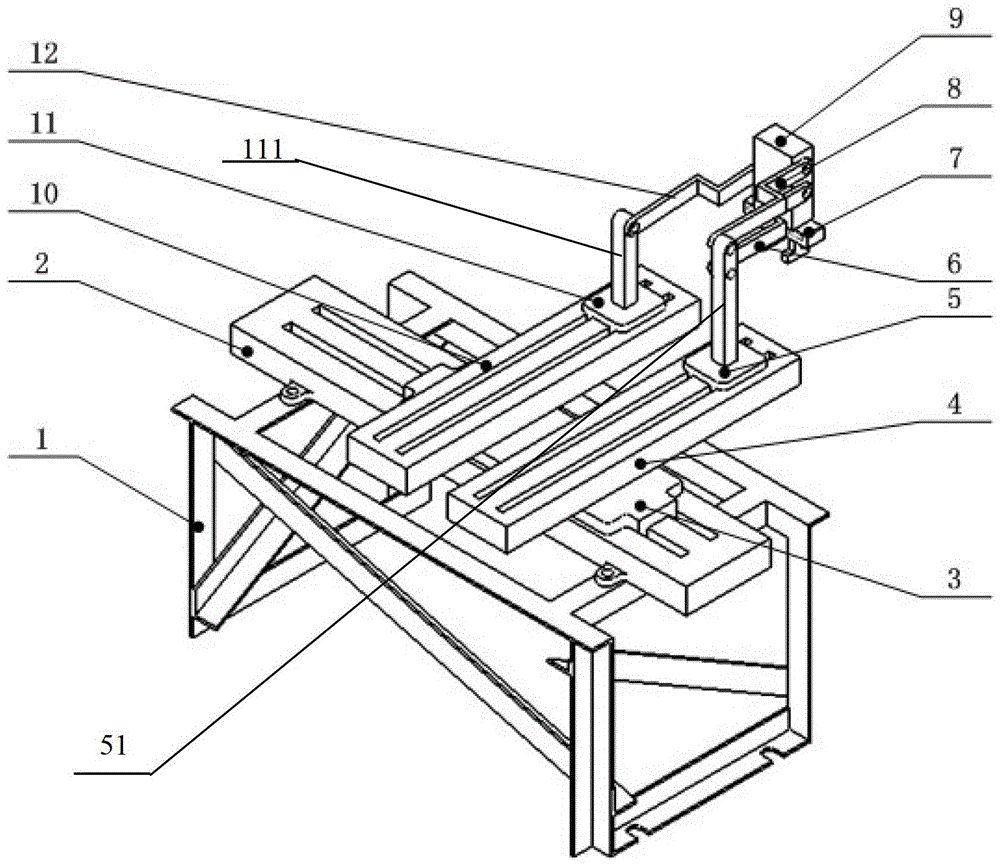

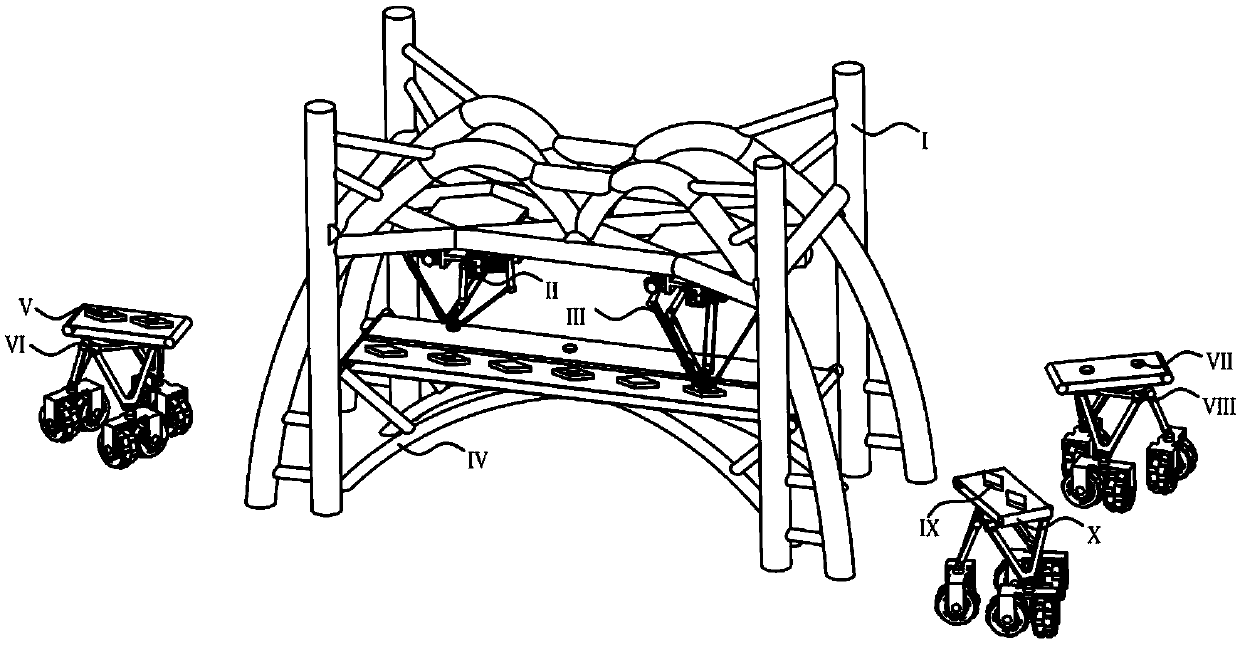

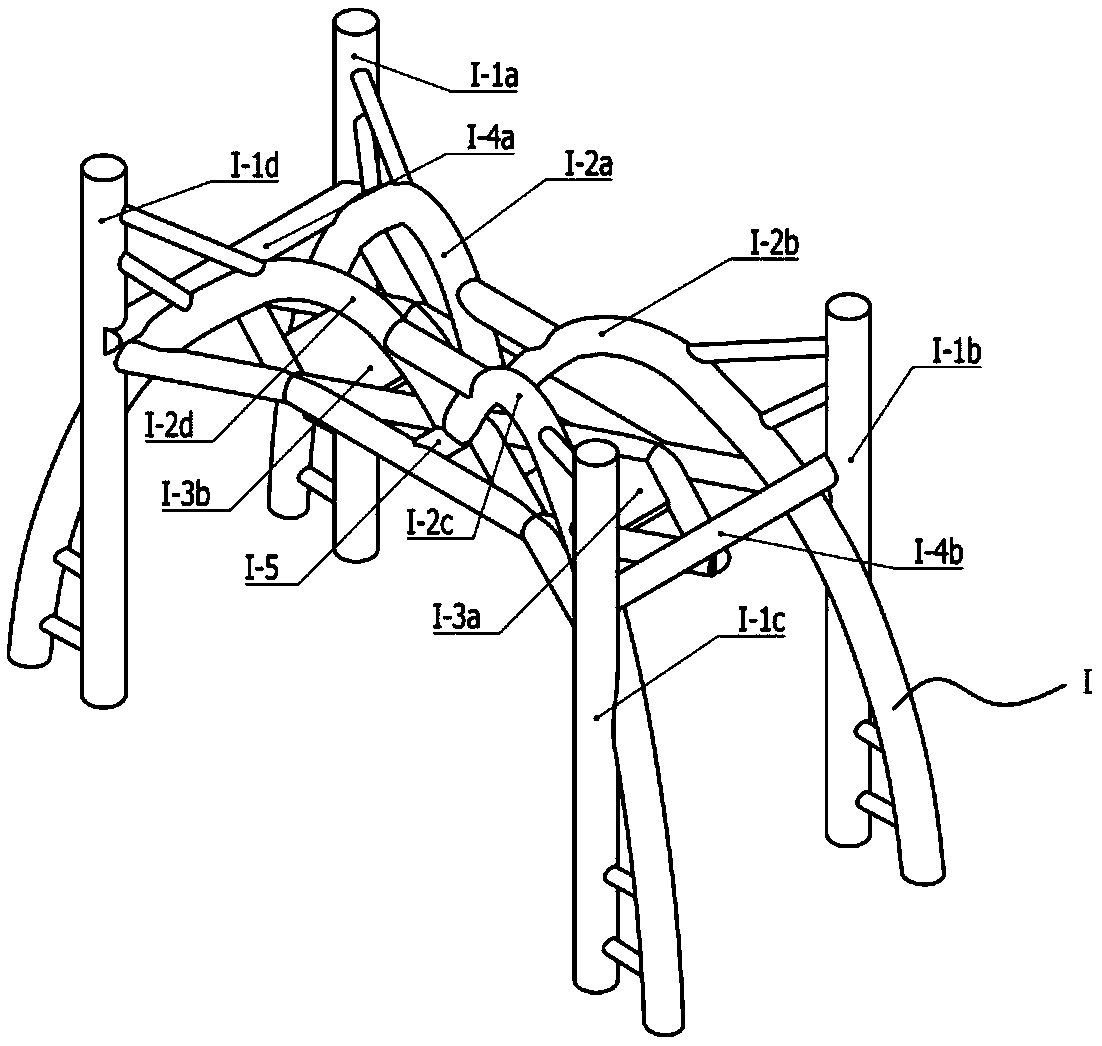

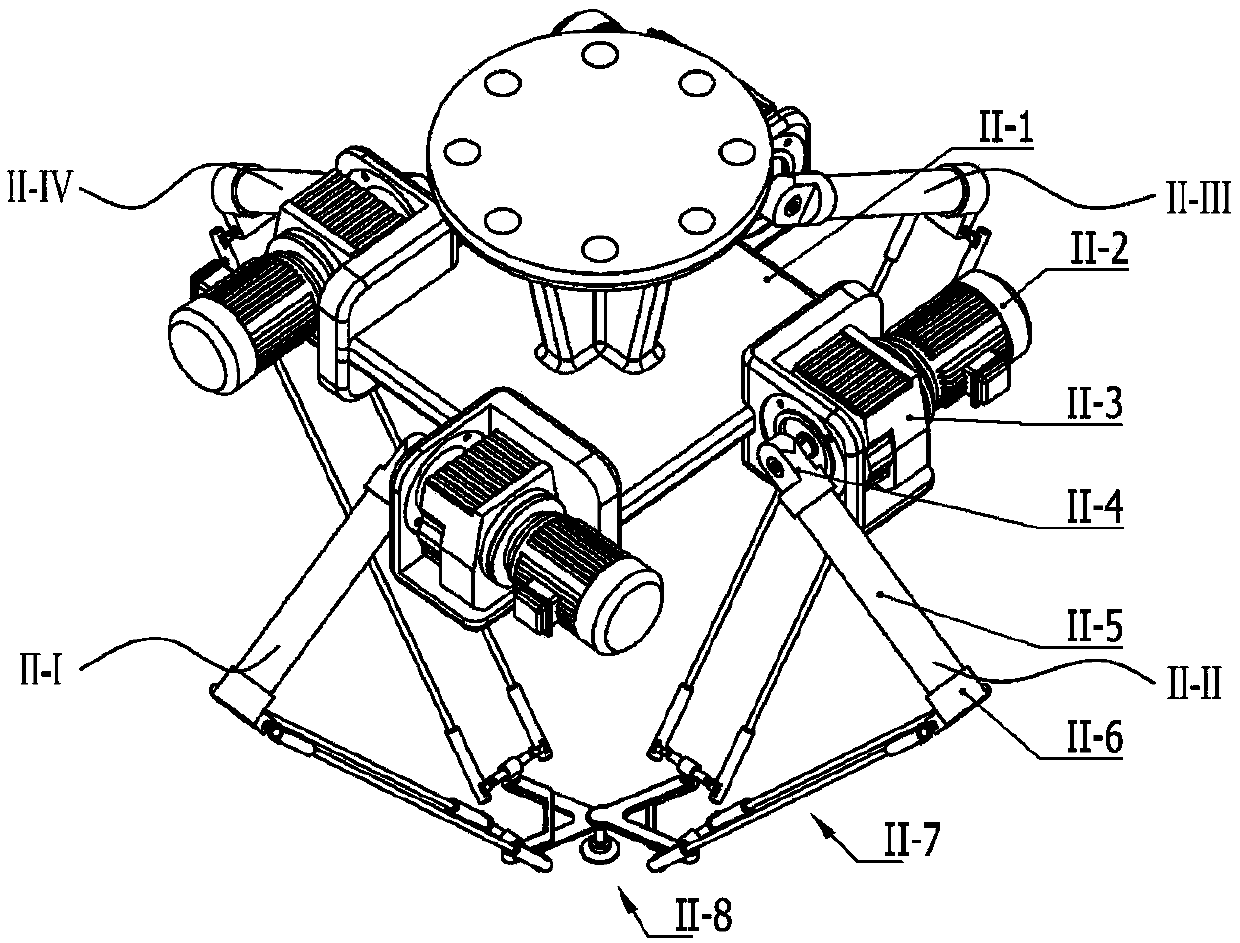

Series-parallel combined three-freedom-degree translation carrying mechanism

ActiveCN103264384ACompact layoutSimple structureProgramme-controlled manipulatorEngineeringElectrical and Electronics engineering

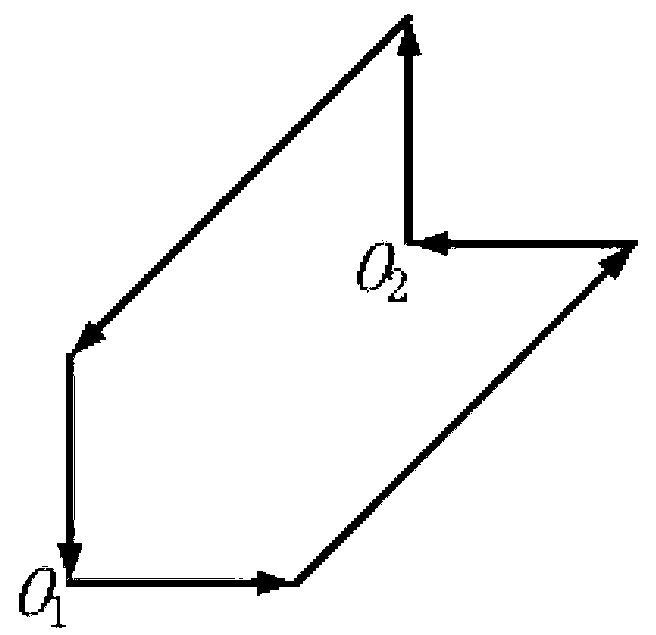

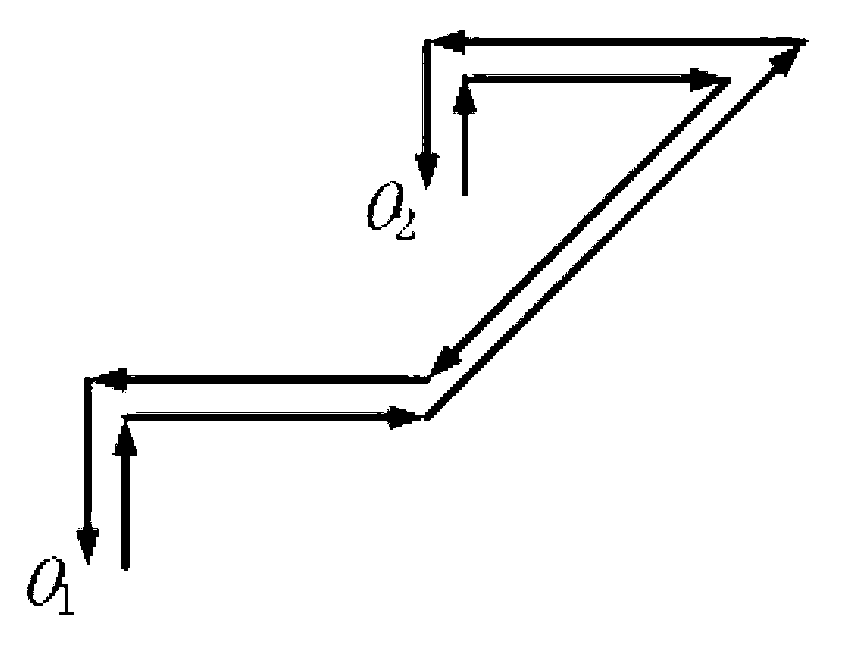

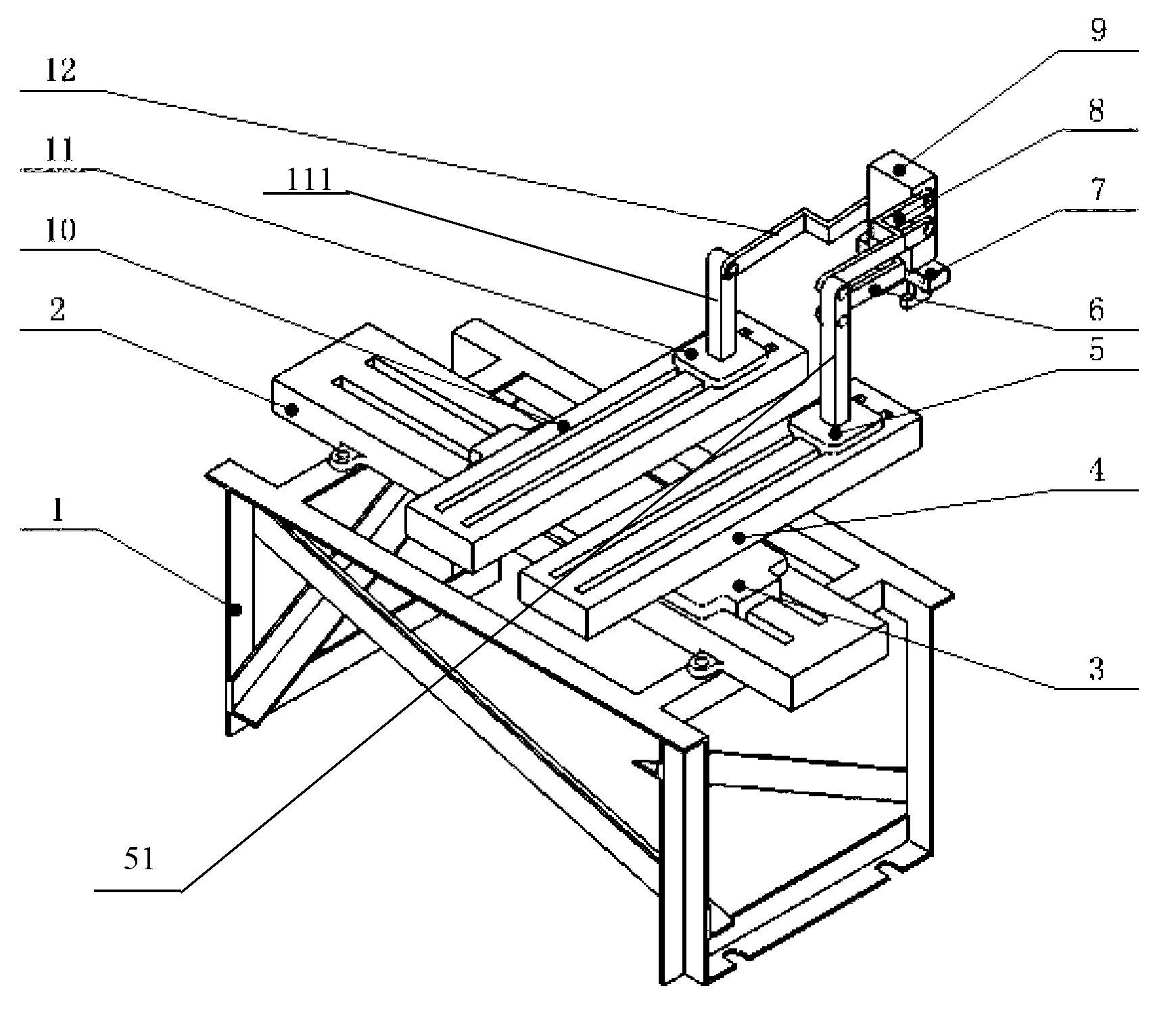

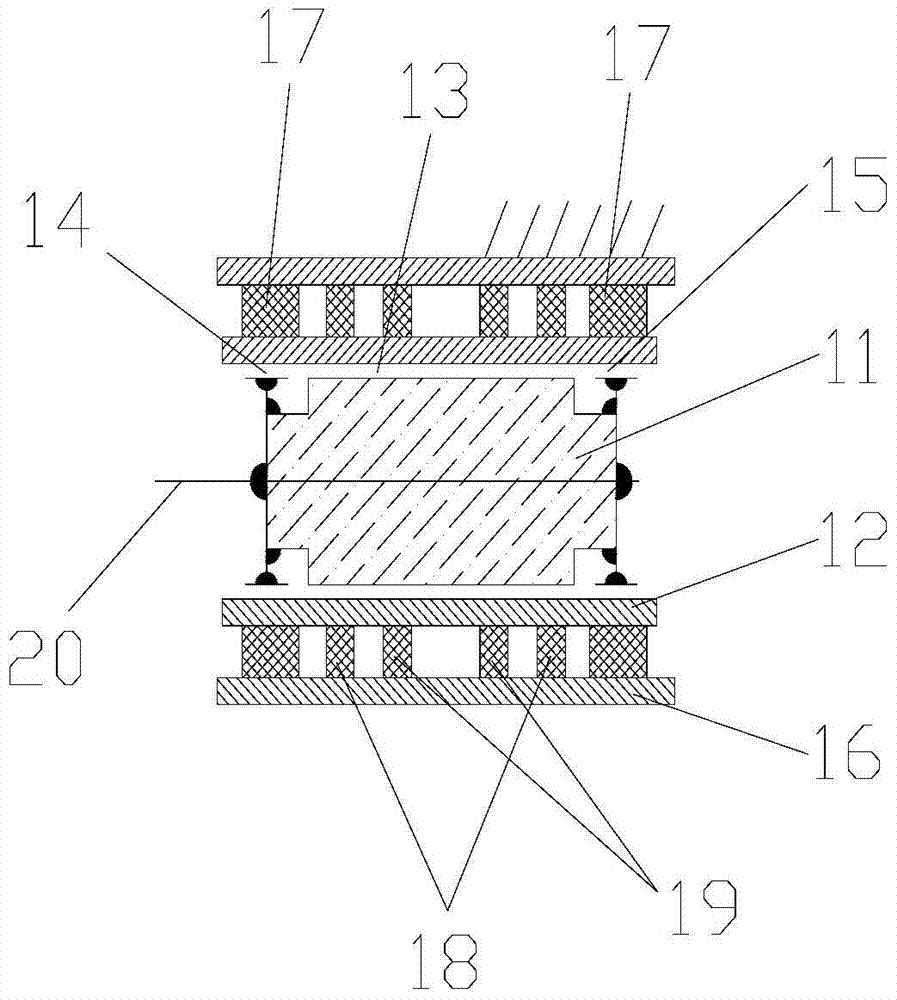

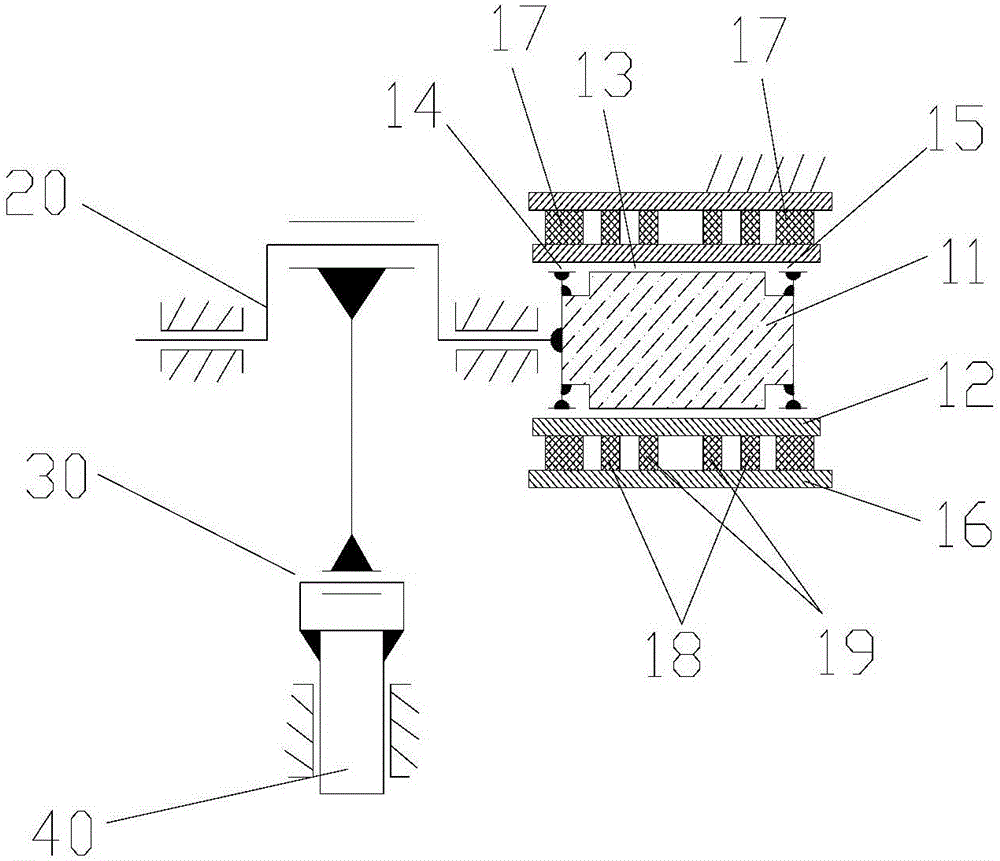

A series-parallel combined three-freedom-degree translation carrying mechanism comprises a base, a first linear driving unit, a first slider, a second linear driving unit, a third linear driving unit, a first connection rod, a second connection rod, a third connection rod, a second connection member and an operation tail end. A second slider is arranged on the second linear driving unit, a third slider is arranged on the third linear driving unit, the first linear driving unit is in series connection with the second linear driving unit and the third linear driving unit, and the second linear driving unit is in parallel connection with the third linear driving unit. The series-parallel combined three-freedom-degree translation carrying mechanism is of a series-parallel combined structure, enables distribution of the driving units to be compact, simplifies the structure, meanwhile reduces load inertia and is favorable for improving efficiency.

Owner:SHANGHAI JIYI ENERGY SAVING & ENVIRONMENTAL PROTECTION TECH CO LTD +1

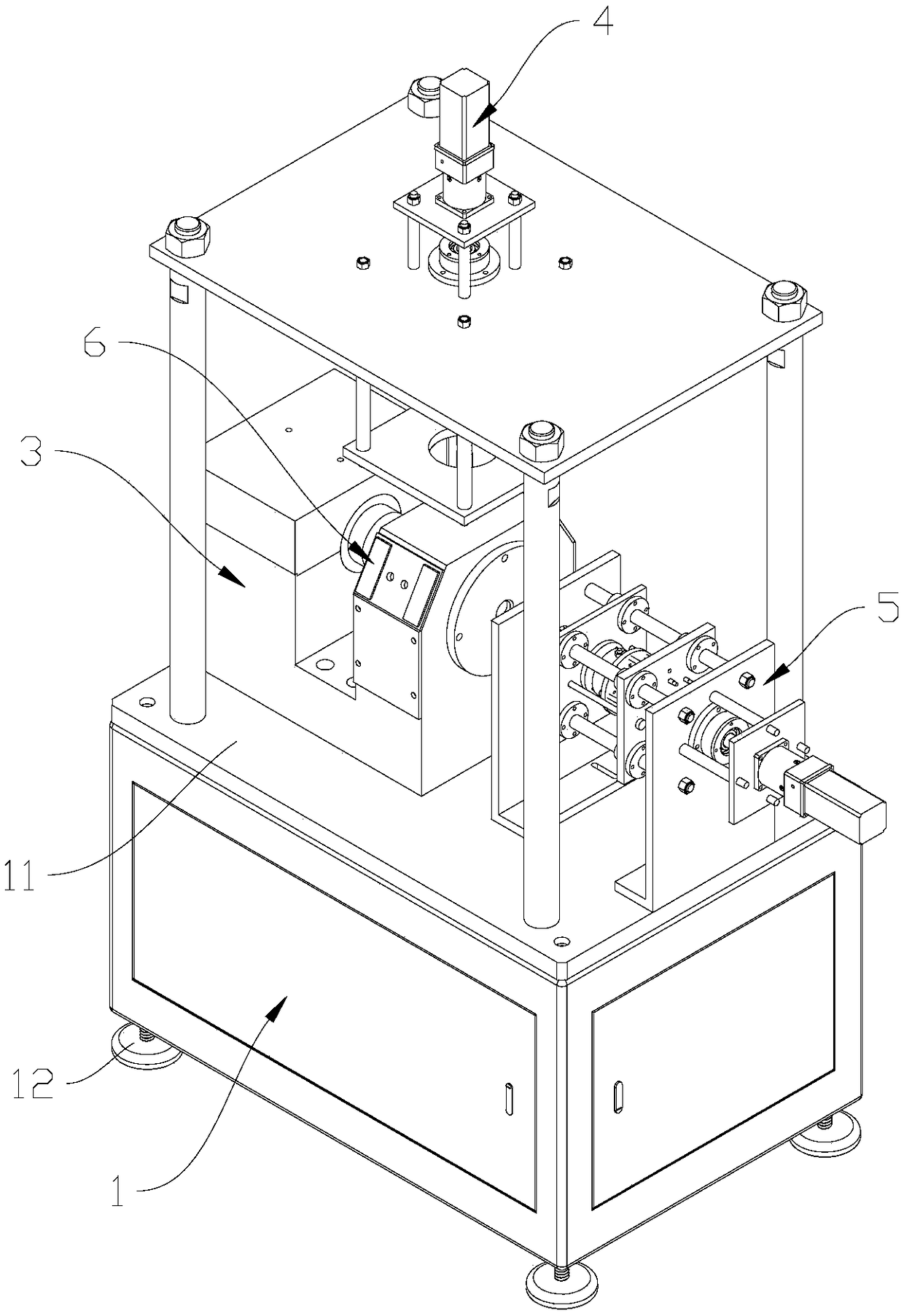

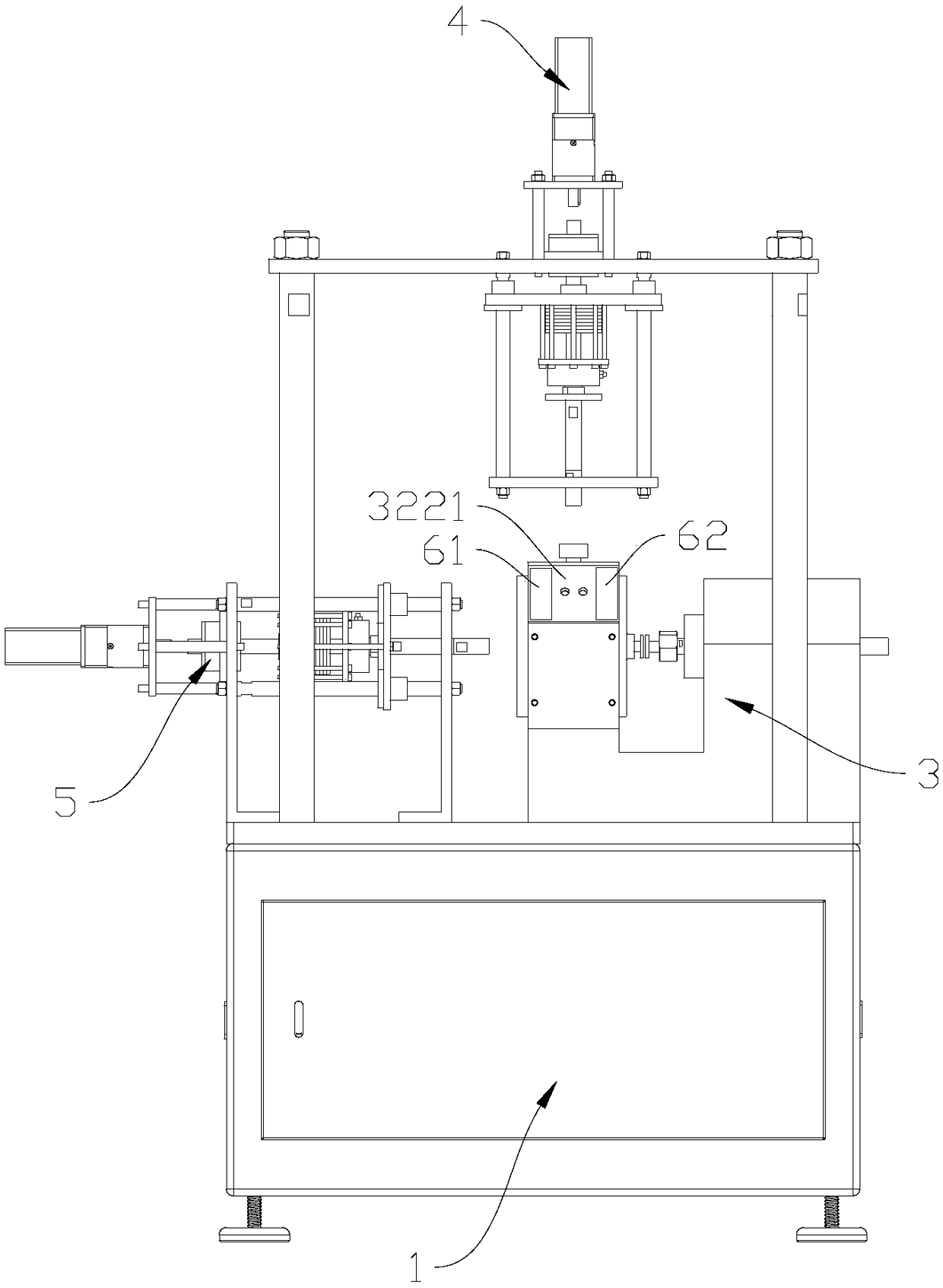

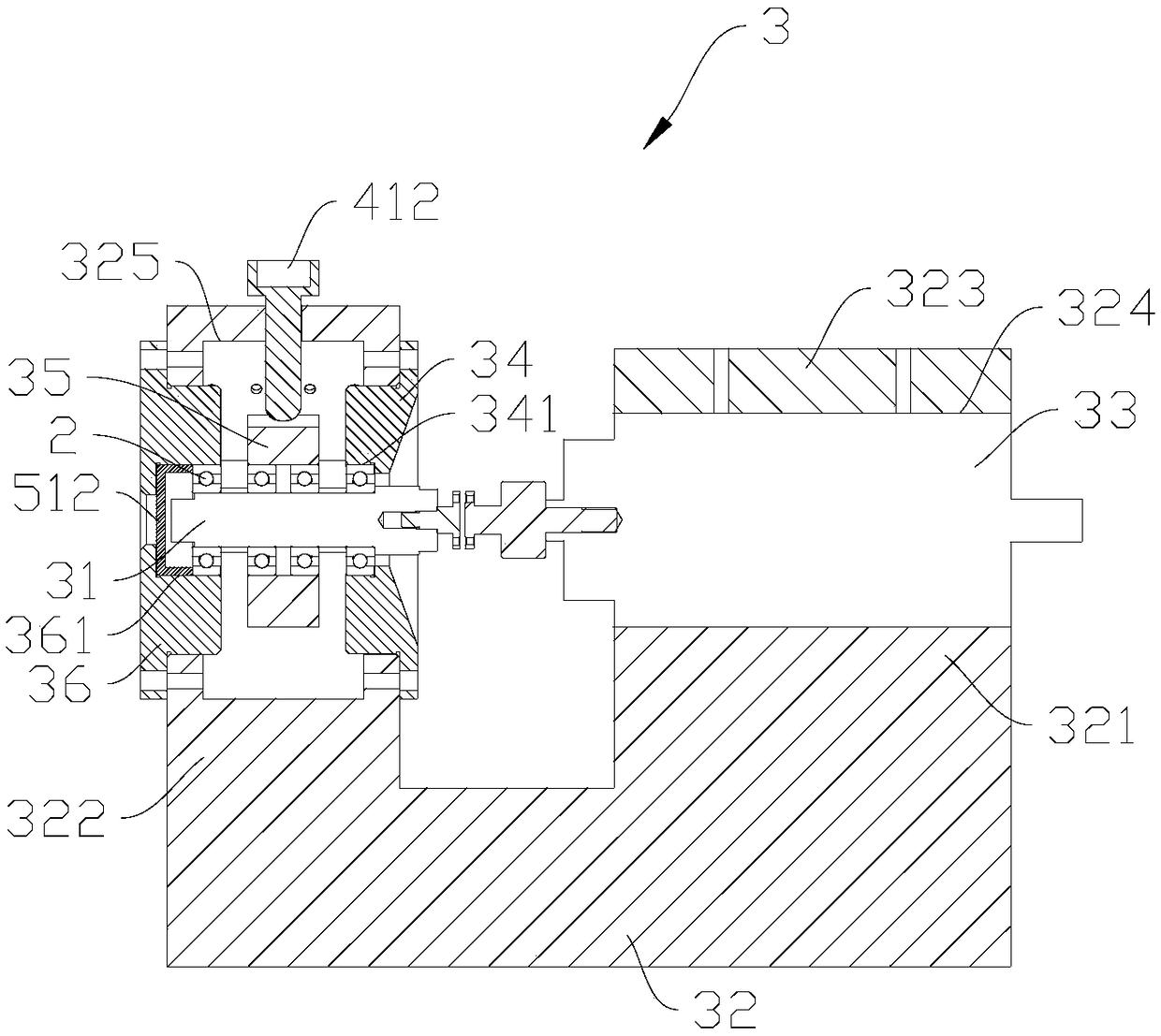

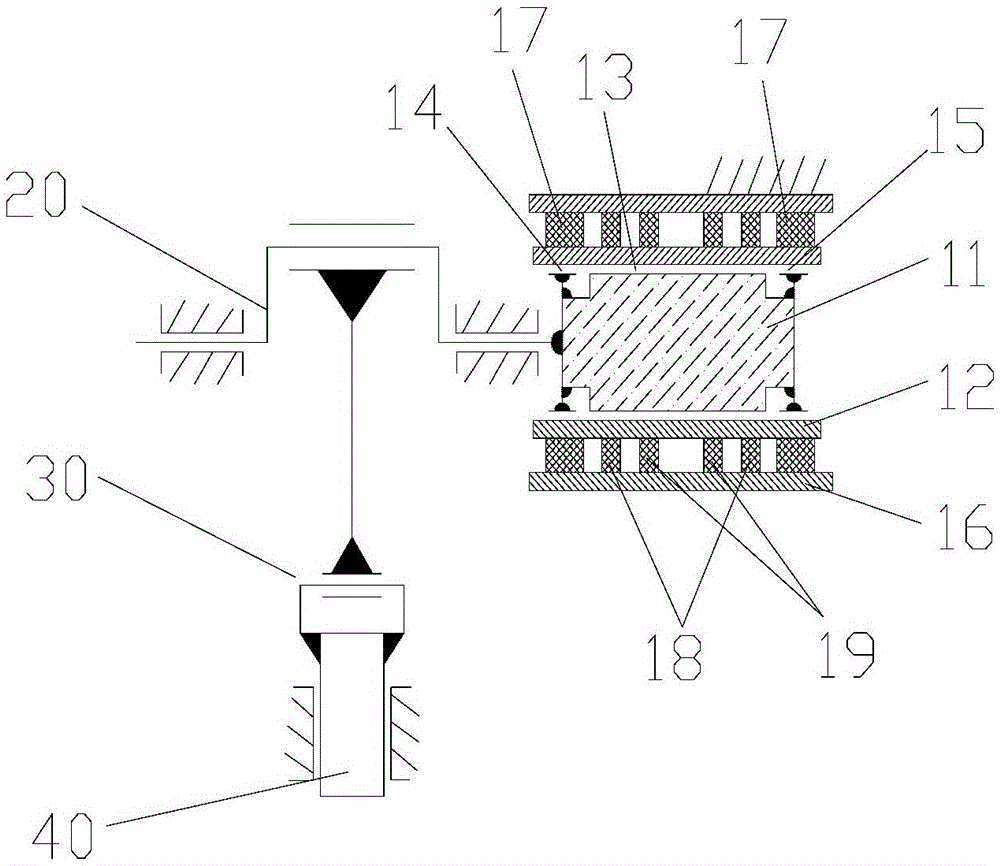

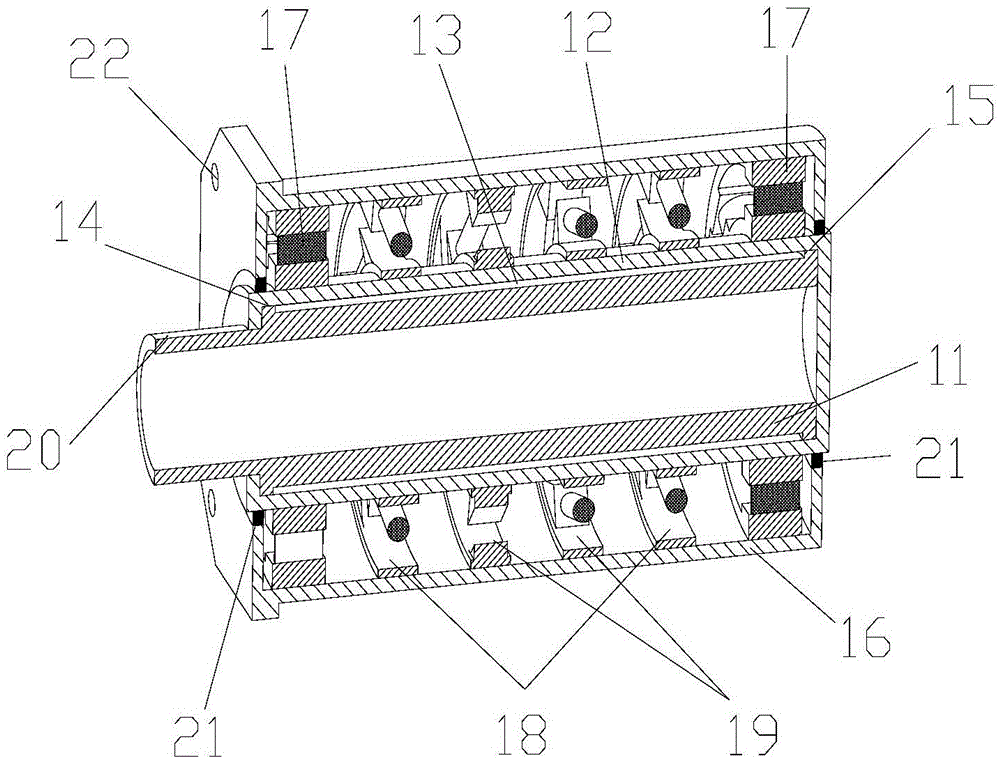

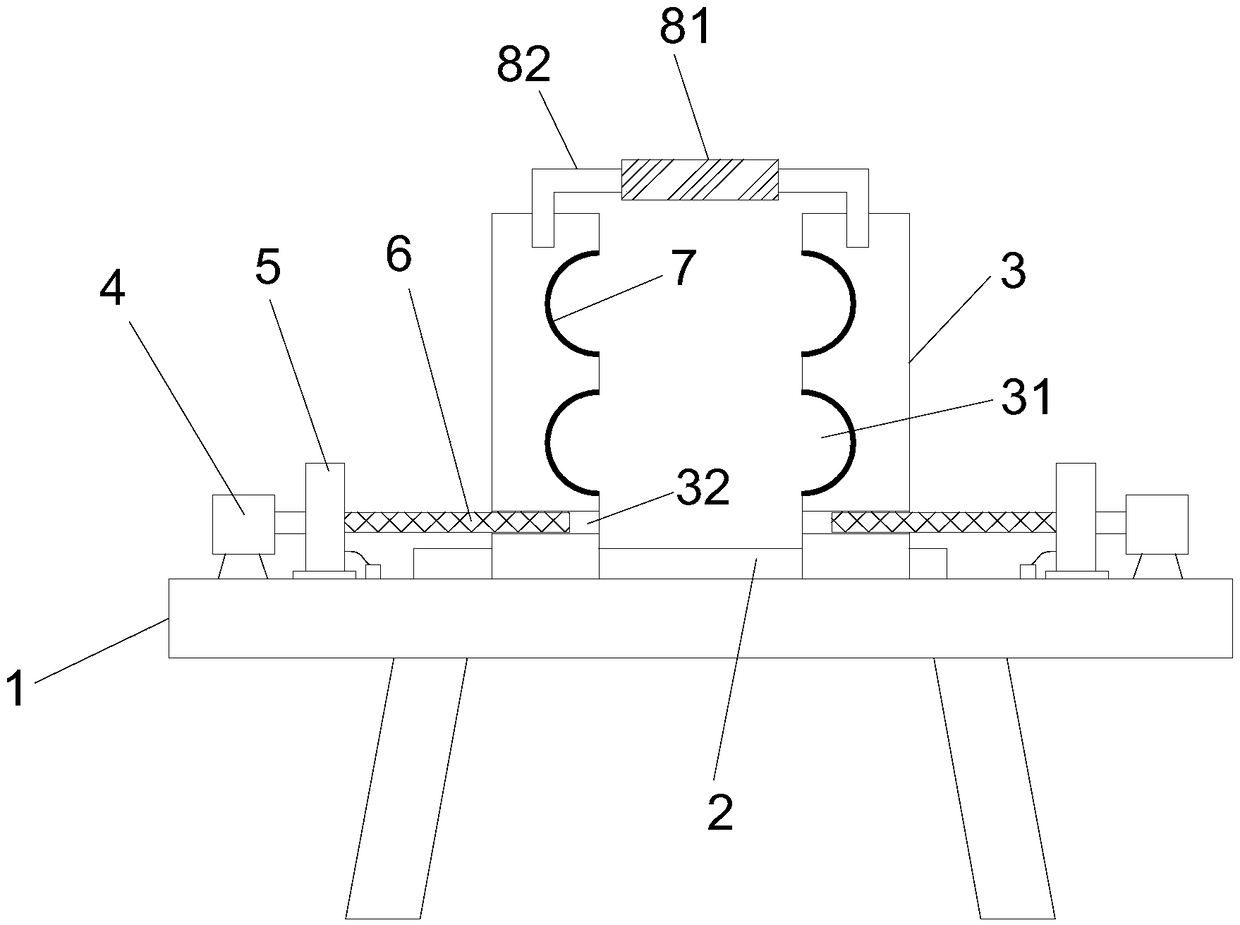

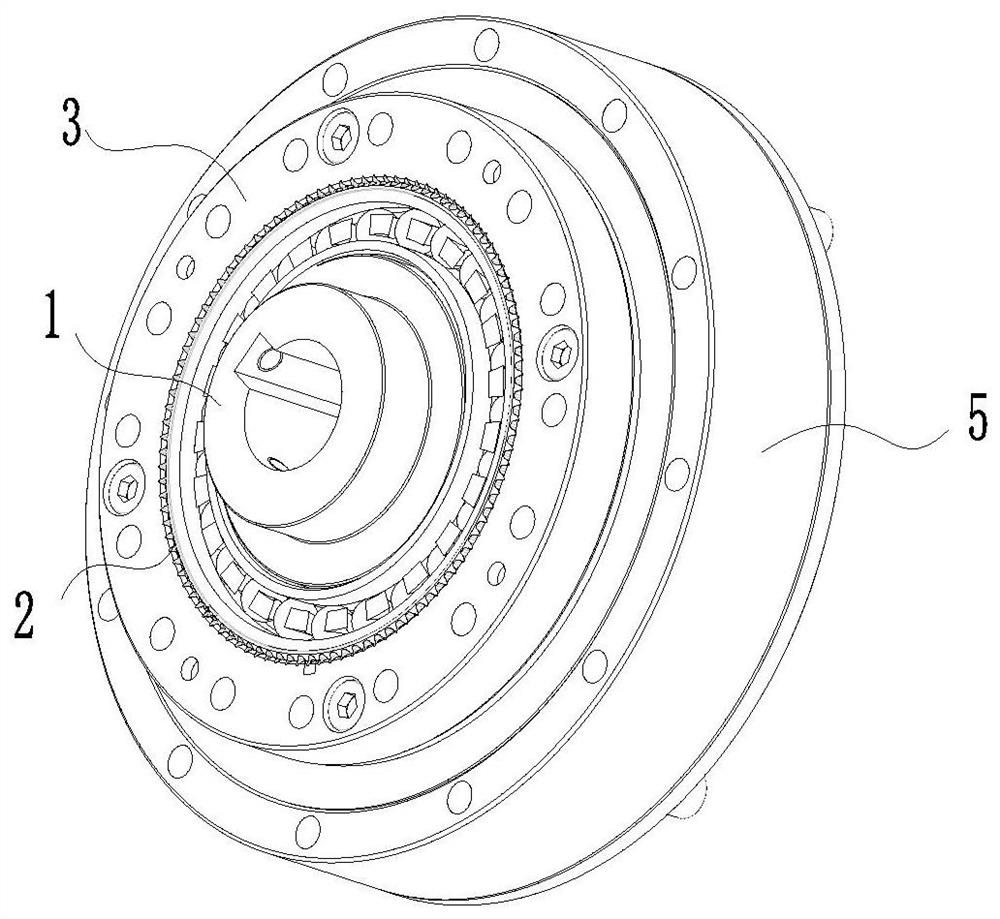

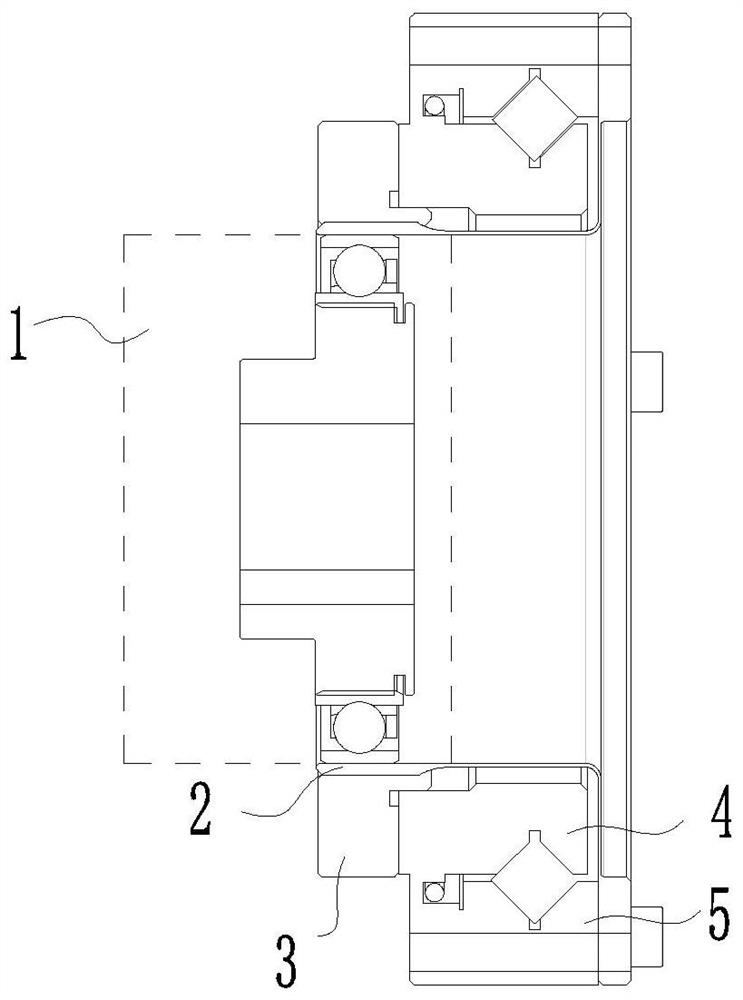

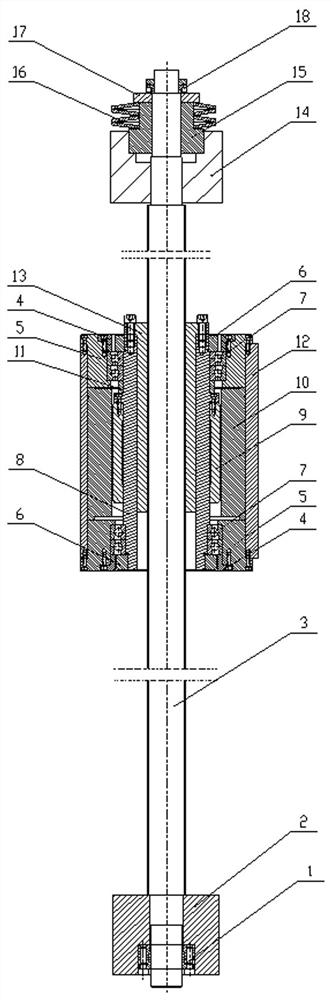

High-speed bearing performance testing machine

PendingCN108627341ALoad force error is smallEasy to controlMachine bearings testingUltra high speedWorking environment

The invention discloses a high-speed bearing performance testing machine, and belongs to the technical field of durability testing devices. The problem that ultra-high-speed durability test conditioncannot be provided due to limited machine test capability, when a common bearing durability testing machine is used in the process of testing a high-speed motor bearing is solved. The high-speed bearing performance testing machine comprises a rack, and further comprises a bearing driving module used for installing a test bearing to be tested and driving the test bearing to rotate; a radial loadingmodule used for exerting radial loading force on the test bearing; an axial loading module used for exerting axial loading force on the test bearing; a detection module used for detecting the temperature and the vibration frequency of the surface of the test bearing; an operation module used for setting loading force and visual output of the detection information. The invention discloses a high-speed bearing performance testing machine which can provide ultra-high-speed durability test conditions and simulate the working environment of various bearings. The high-speed bearing performance testing machine is wide in application range, and meets the production efficiency at the present stage. The structure is simple, and the operation is convenient.

Owner:CIXING GROUP

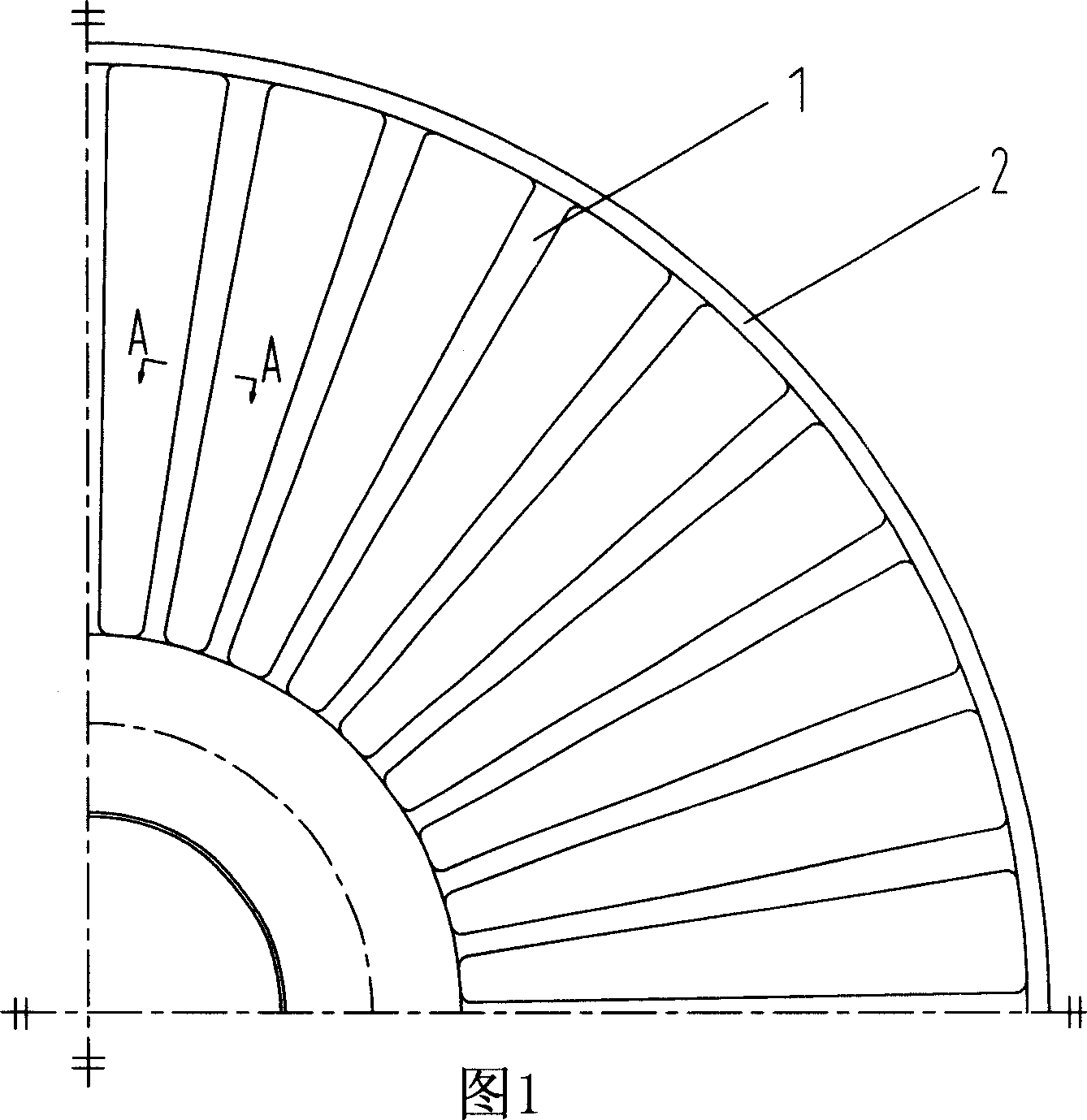

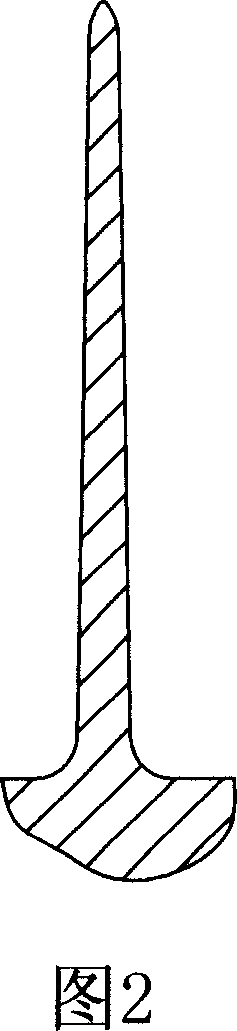

Working impeller of hydraulic coupler

InactiveCN1948786AHigh working reliabilityImprove work efficiencyFluid gearingsImpellerUltimate tensile strength

There is disclosed an operating impeller of a hydraulic coupler, which comprises blades fixed on the impeller main body. The invention adopts the blades of radial and axial variable cross-section, so it can guarantee the strength of the blades in the position of different diameters and in the different axial positions and reduce the weight of the blades and meanwhile reduce the load inertia of the motor.

Owner:大连创思福液力偶合器成套设备有限公司

Cable traction device

ActiveCN112499367ASmooth transmissionImprove transmission efficiencyFilament handlingElectronic waste recyclingElectric machineryControl theory

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO

Main transmission mechanism of all-electric servo numerical control turret punch press

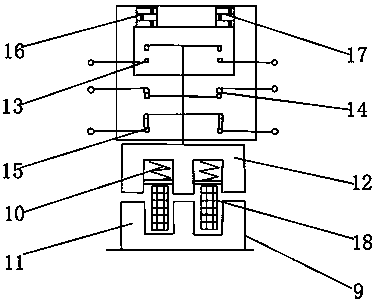

The invention discloses a main transmission mechanism of an all-electric servo numerical control turret punch press. The main transmission mechanism comprises a servo motor, a crankshaft, a connection rod, a sliding block, a frame and a fixing frame. The crankshaft is connected with the sliding block. The input end of the crankshaft penetrates through the frame and is fixedly connected with a motor rotor in a rigid mode. The motor rotor and a motor stator are hinged through a front bearing and a rear bearing. The motor stator is coaxially sleeved with the fixing frame, and at least one elastic assembly is arranged between the motor stator and the fixing frame. Each elastic assembly comprises multiple suspension components, first torsion components and second torsion components, wherein the first torsion components and the second torsion components are distributed in symmetry. By means of the structure, the servo motor is flexibly connected with the frame, the axial size is compact, and the load inertia of the mechanism is small. Radial deformation in any direction can happen and is not large in rigidity. When the radial deformation in any direction happens, the suspension components have an energy consumption effect. Torsion deformation around the axial direction is avoided, torsion rigidity is infinite, and the main transmission mechanism can be applied to occasions of high speed and heavy loads.

Owner:NANJING UNIV OF POSTS & TELECOMM

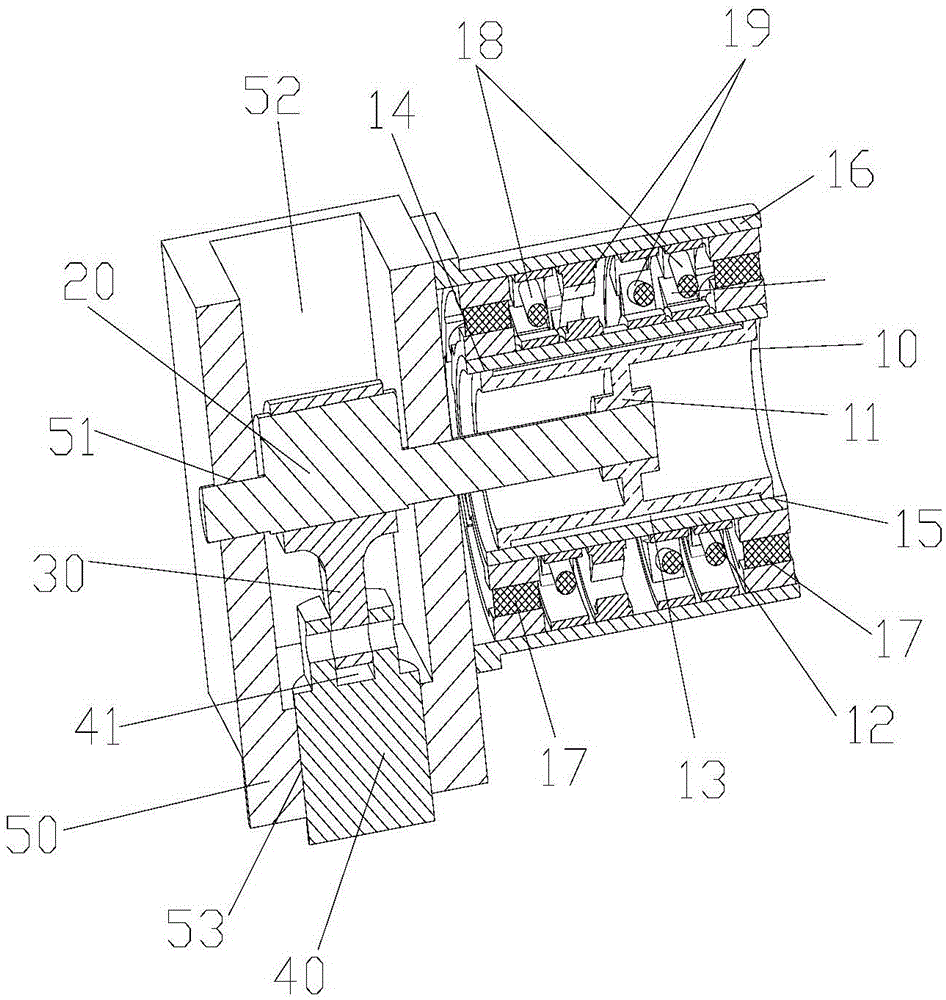

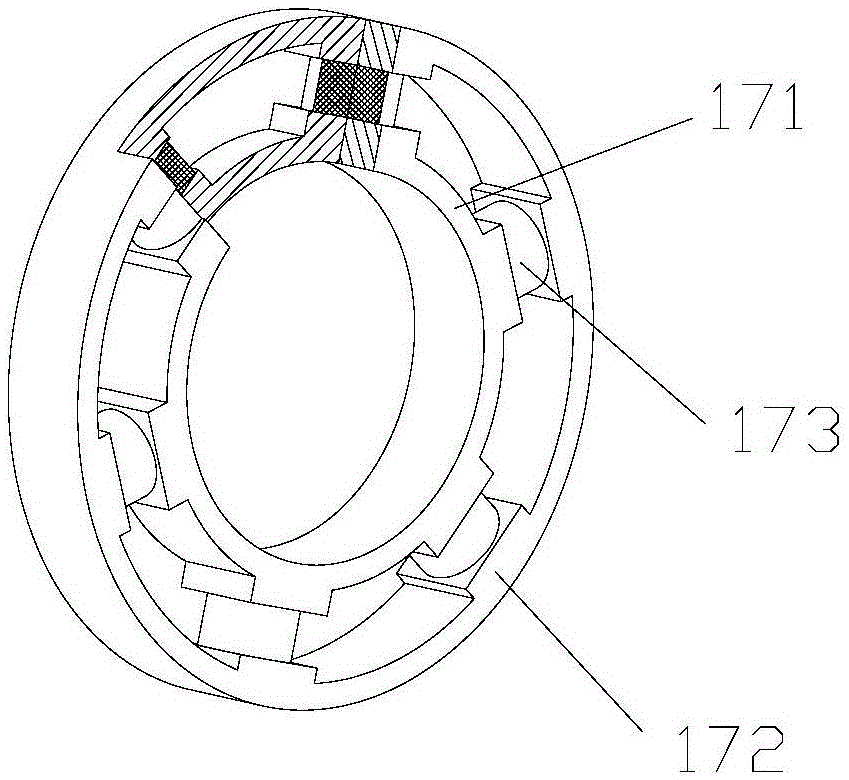

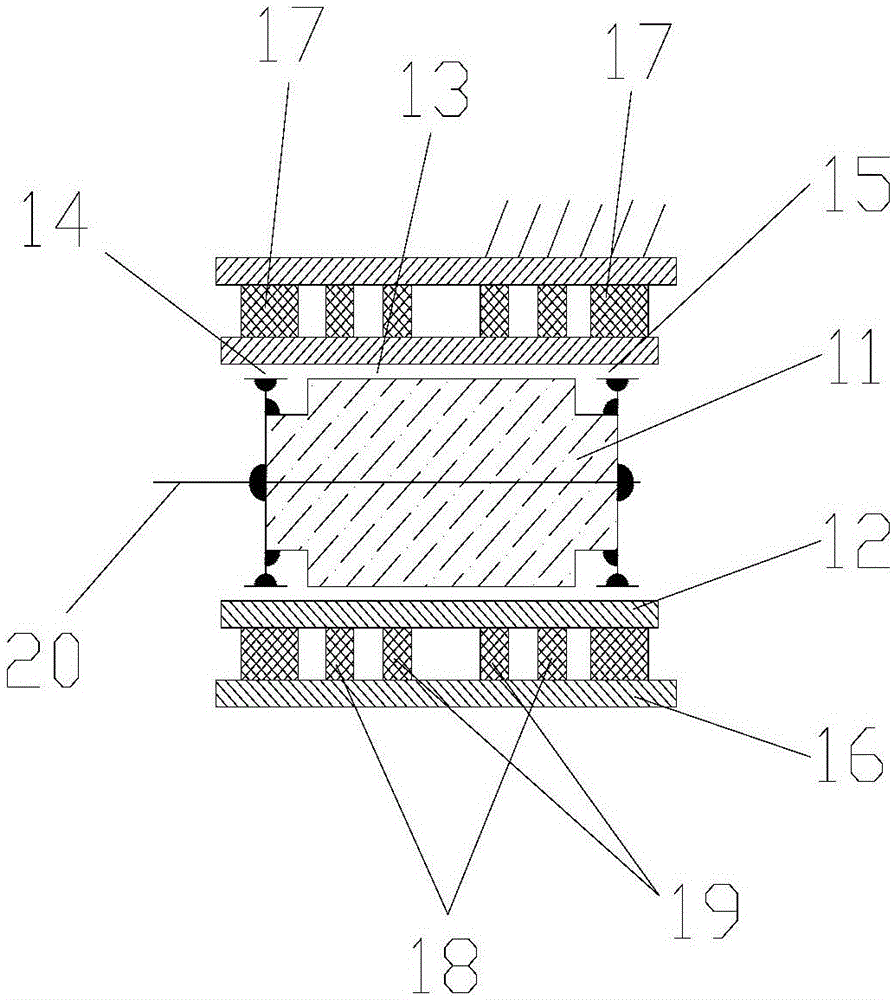

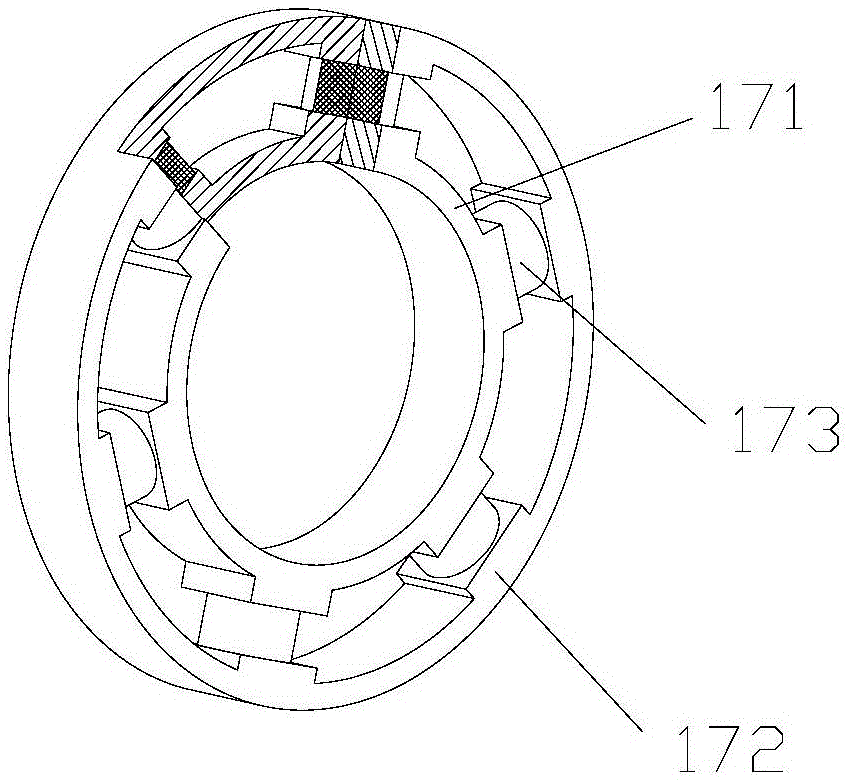

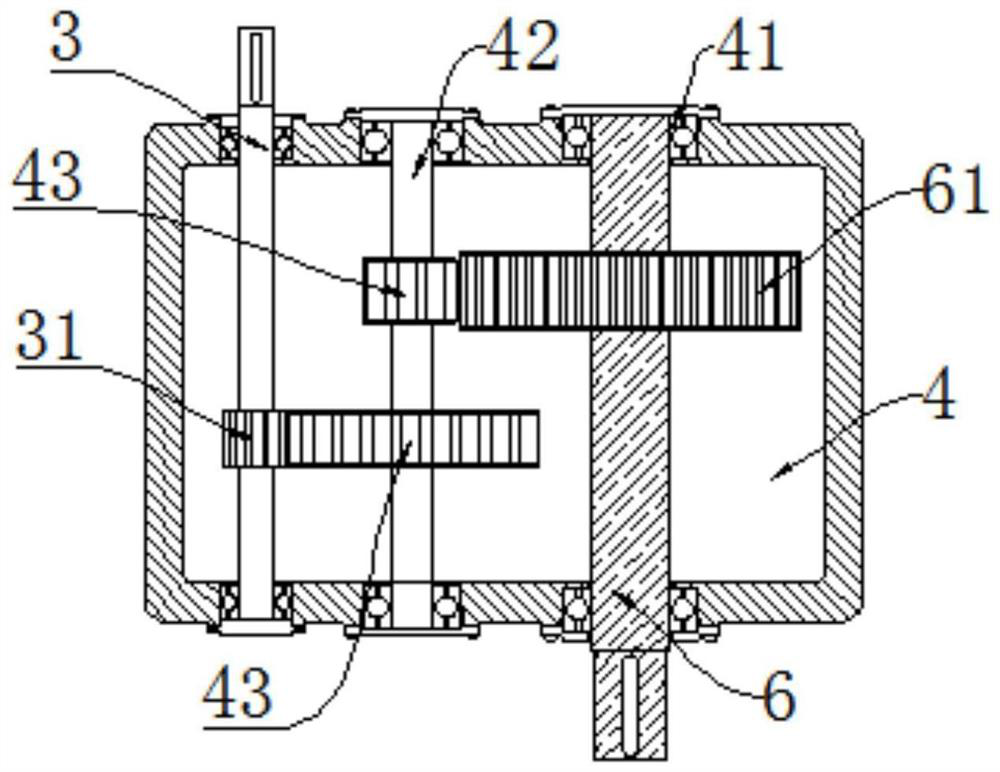

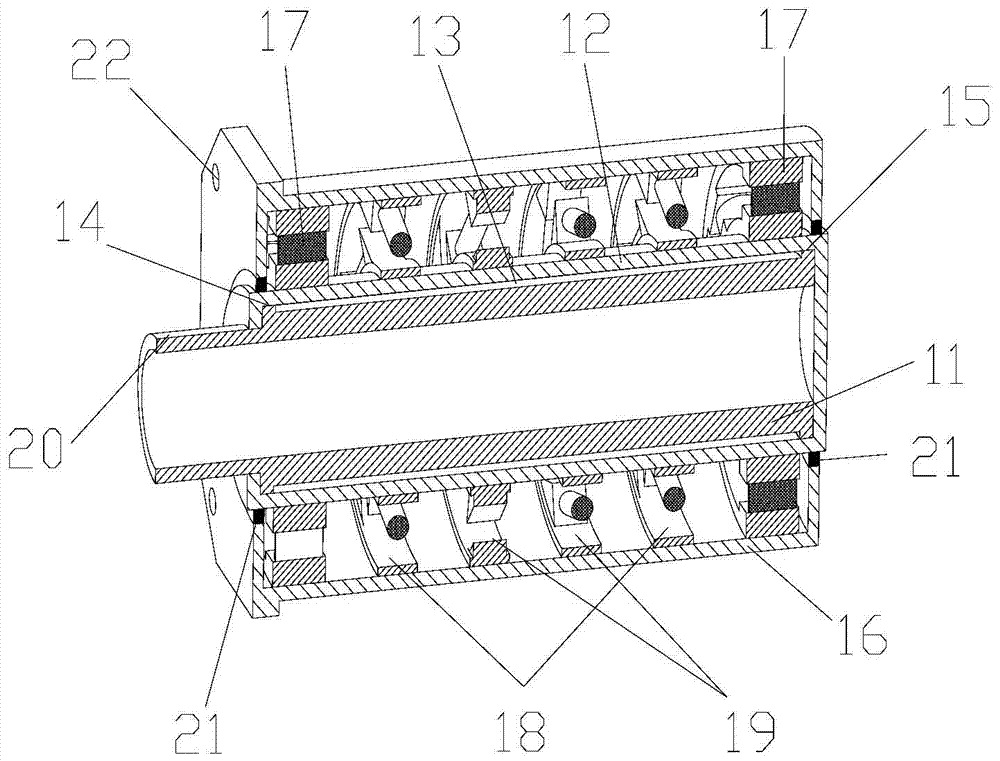

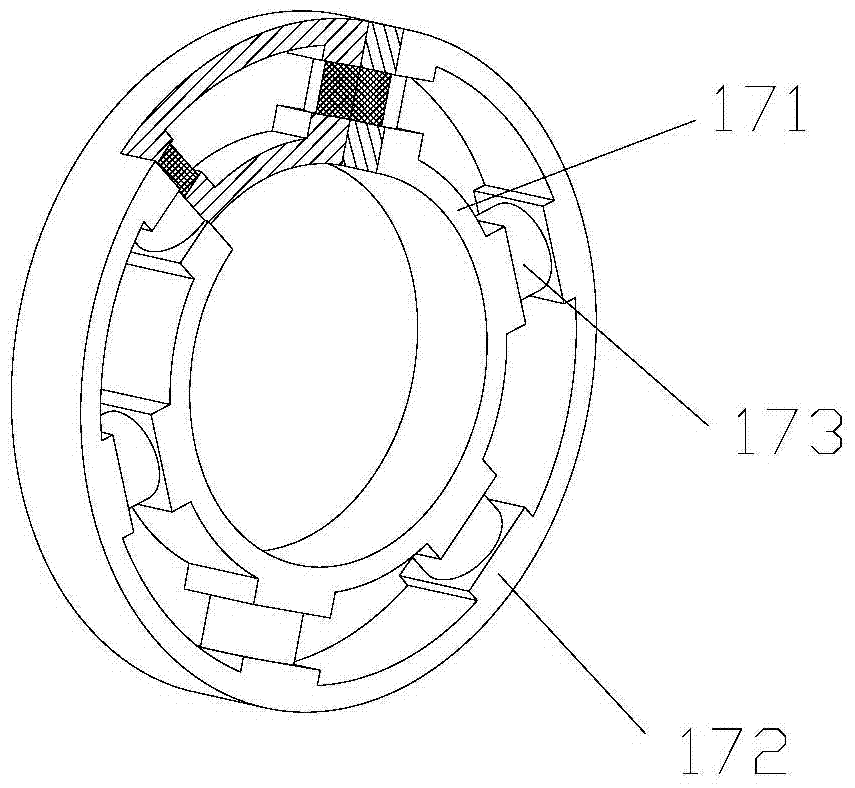

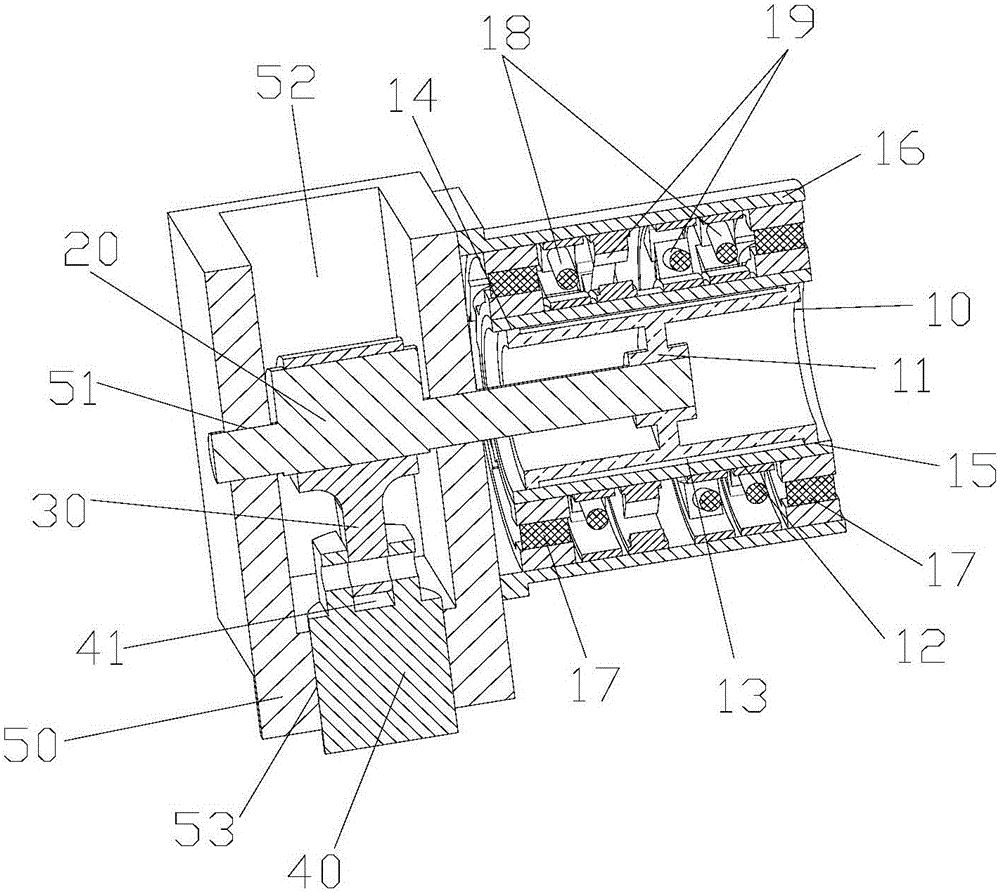

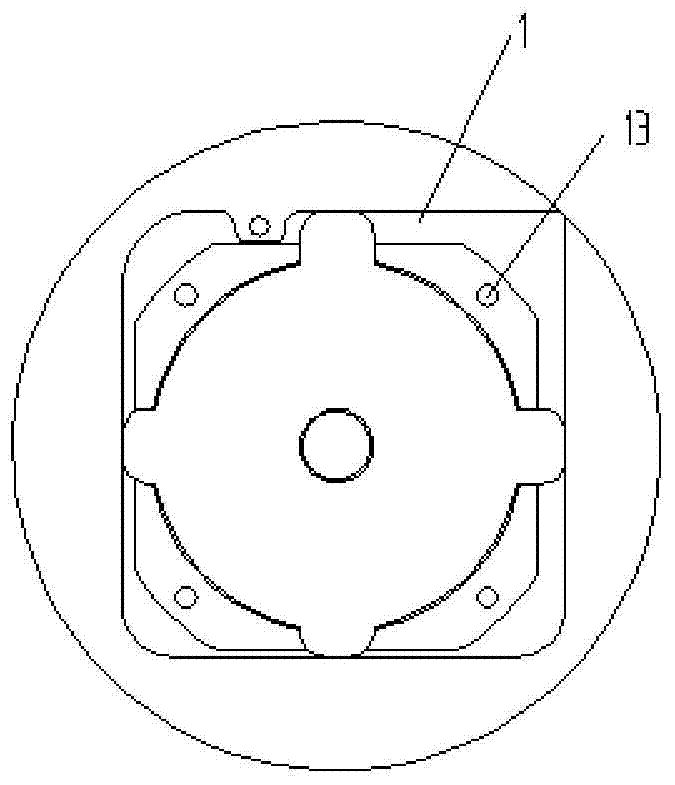

Motor

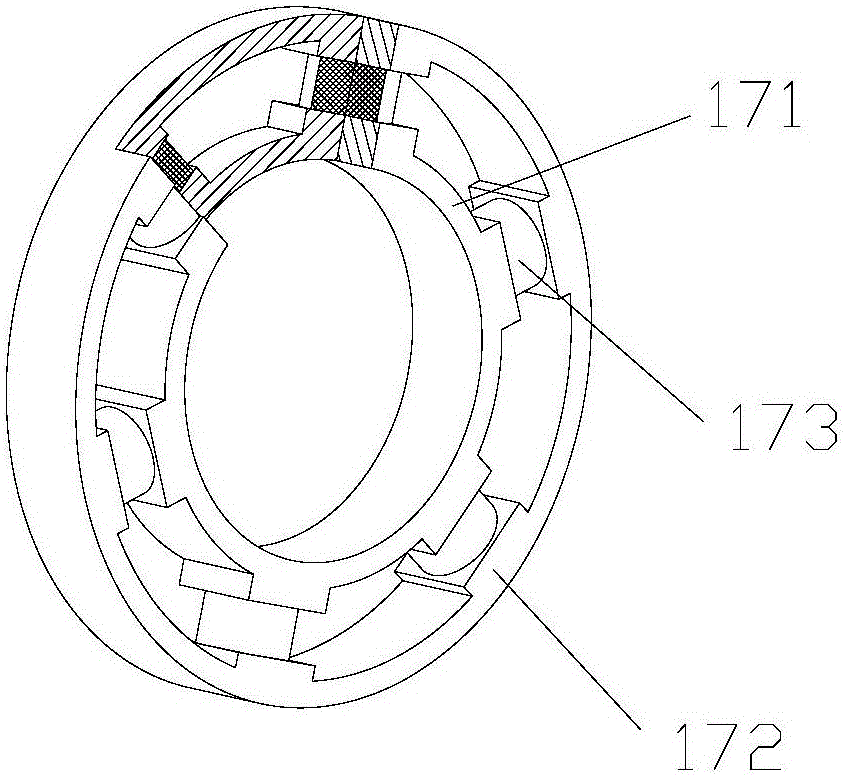

ActiveCN105006907AAxial dimensions are compactReduce load inertiaMagnetic circuit stationary partsMechanical energy handlingStatorHeavy load

The invention discloses a motor comprising a motor rotor, a motor stator and a fixing frame. The motor rotor and the motor stator are hinged via a front bearing and a rear bearing. At least one elastic assembly is arranged between the motor stator and the fixing frame. Each elastic assembly comprises multiple suspension assemblies, and a first torsion assembly and a second torsion assembly which are symmetrically arranged between the two adjacent suspension assemblies. Each suspension assembly comprises multiple groups of first flexible elements which are arranged along a radial direction. The first torsion assembly and the second torsion assembly respectively comprise multiple groups of second flexible elements which are arranged in a clockwise or anticlockwise way. After application of the aforementioned structure, coaxiality deviation and parallelism deviation between a load shaft end and a servo motor output shaft can be absorbed without over-constraint; the axial size is compact, load inertia of the mechanism is low and high-speed processing can be realized; and the air gap between the motor rotor and the motor stator is constant without over-constraint or mechanism internal force, and the motor is suitable for high-speed and heavy-load application occasions.

Owner:NANJING UNIV OF POSTS & TELECOMM

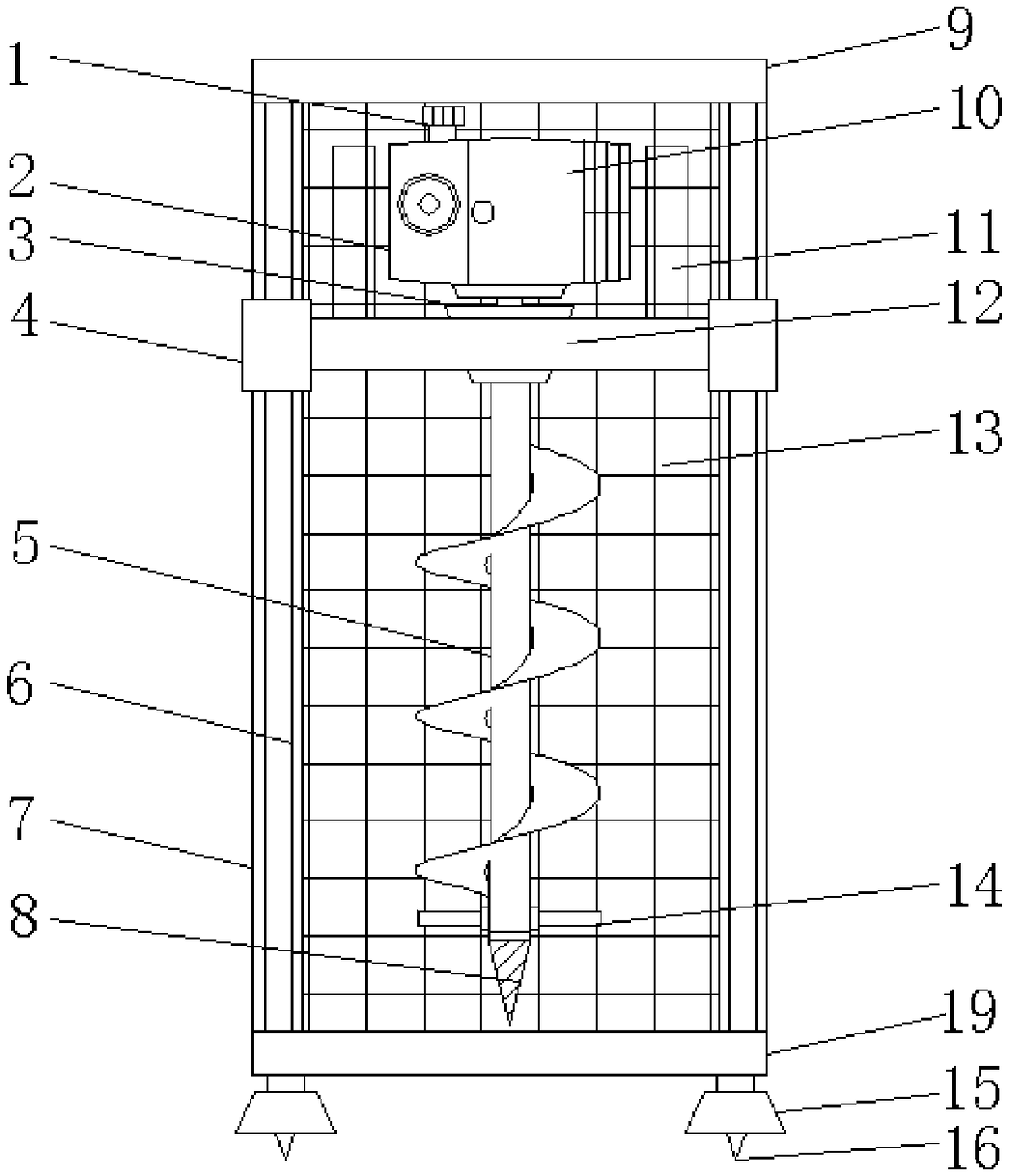

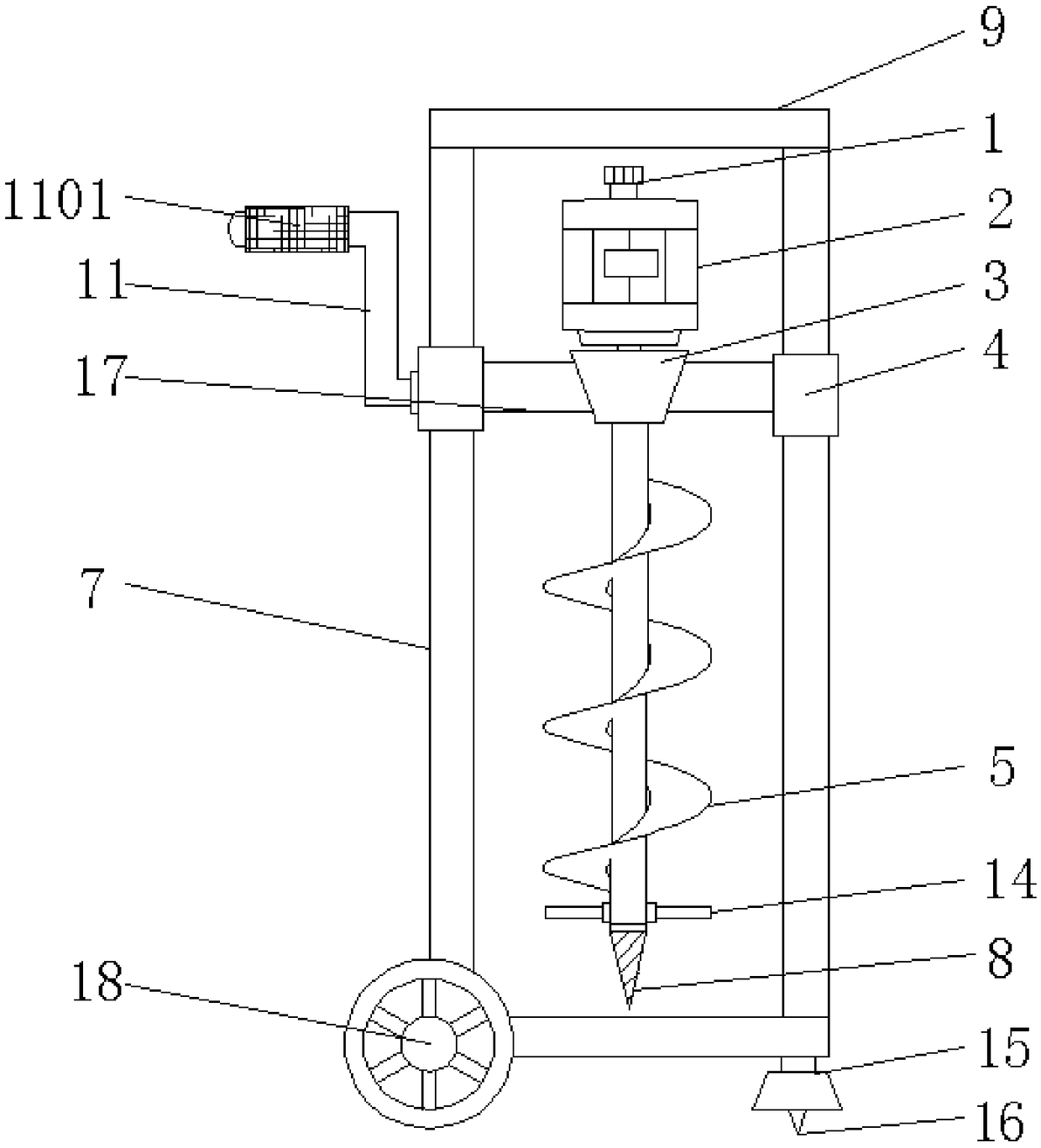

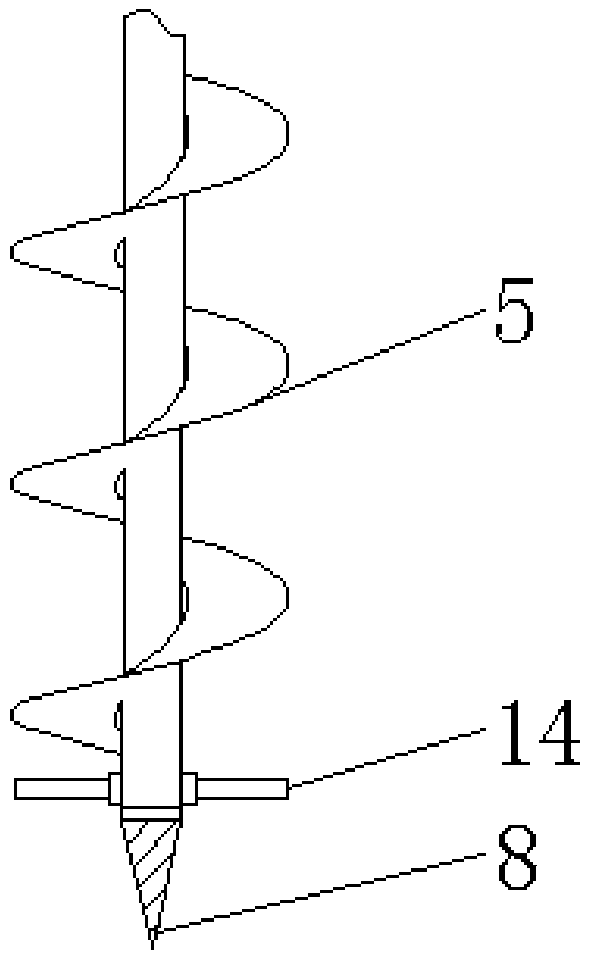

Digging device for garden lamp installing construction

The invention discloses a digging device for garden lamp installing construction. The device comprises a reducer, fences and a second cross bar, four groups of fences are fixedly installed on the topof the second cross bar, first cross rods are fixedly installed on the tops of the fences, second supporting rods are fixedly installed between first supporting rods, the reducer is fixedly installedbetween the second supporting rods, a diesel engine is fixedly installed on the top of the reducer, an oil tank is fixedly installed on one side of the diesel engine, a digging wheel is rotatably installed at an output end of the reducer, impellers are fixedly installed on both sides of the end of the digging wheel, a drilling bit is fixedly installed on the bottom of the digging wheel, and a protecting net is fixedly installed at the backs of the fences. By the arrangement of a sliding groove and a sliding block, the device can slide to provide convenience for workers to dig, the sliding groove and the sliding block can fix the device when the device is not used, so that strength of workers can be saved when construction is conducted to allow the workers to use the device conveniently, and the working efficiency is improved.

Owner:NANJING ZHENGXIN LIGHTING TECH CO LTD

Leather deliming equipment

InactiveCN108265132ASimple structureEasy to operatePre-tanning chemical treatmentDispersed particle separationBall bearingReducer

The invention discloses leather deliming equipment. The leather deliming equipment comprises an equipment body, wherein a rotating drum is movably mounted in the middle of the equipment body, and a feeding opening is formed in the outer surface of the rotating drum. A rotating wheel is movably mounted in the middle of the rotating drum, and a purifier is fixedly mounted on one side of the rotatingwheel. One end of the purifier is fixedly connected with an air pump, and a power supply cabinet is fixedly mounted on one side of the air pump. A control cabinet is fixedly mounted on the position near the lower end of the outer surface of the equipment body, and a control panel is fixedly mounted on the position near the upper end of the outer surface of the control cabinet. The leather deliming equipment is provided with a drying tube, a ball bearing and a reducer, ammonia gas generated during deliming can be effectively purified, pollution is reduced, and the friction coefficient of a rotating mechanism can be effectively reduced; the rotation efficiency is improved, and the rotation speed can be effectively matched; and the rotation is smoothly reduced, the service life of the equipment is prolonged, and better use prospects are achieved.

Owner:海宁市硖石玛杰济斯皮革服装厂

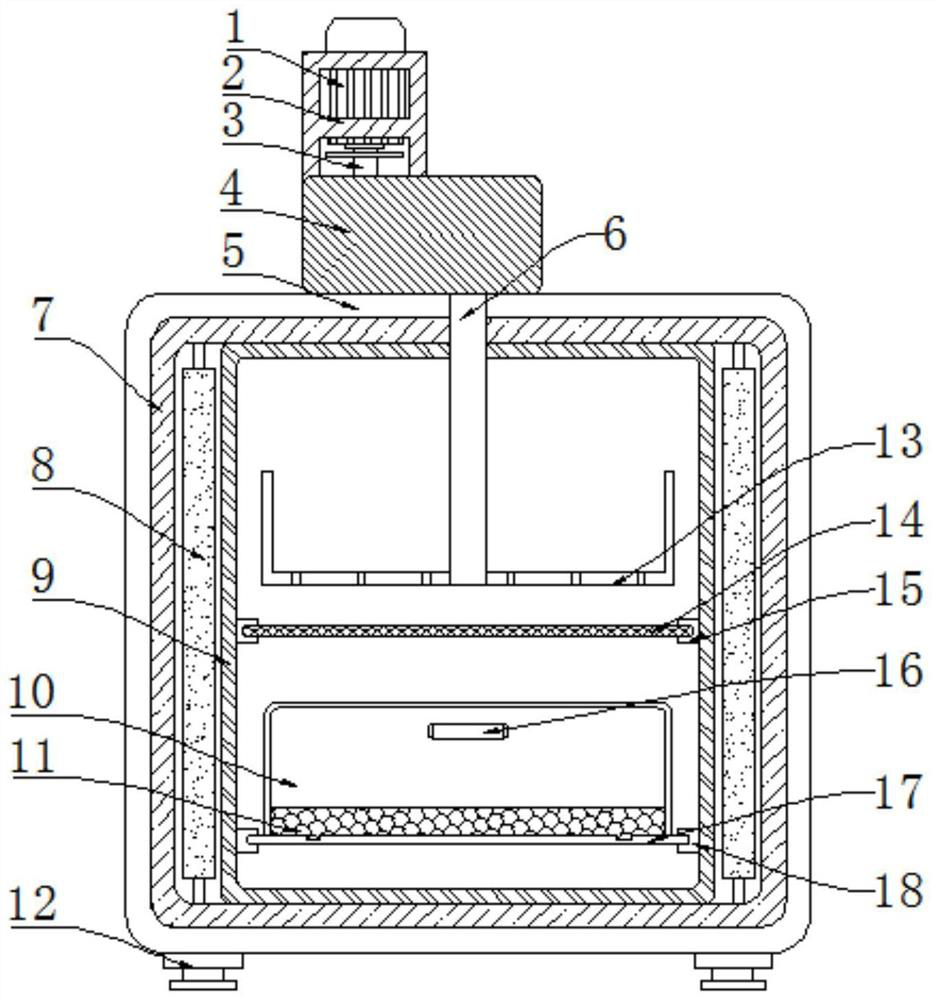

Material drying device for coating production

PendingCN114877649AImprove drying efficiencyLow thermal conductivitySievingScreeningCarbide siliconComputer fan

The invention discloses a coating production material drying device which comprises an outer shell, an inner shell is installed in the outer shell, a heat preservation layer and a heating pipe are arranged between the outer shell and the inner shell, a speed reducer is installed above the outer shell, a motor fixing seat is arranged above the speed reducer, and a motor is arranged above the motor fixing seat. A motor is installed in the motor fixing seat, the output end of the motor is in transmission connection with an input shaft through a coupler, the lower end of the output shaft penetrates through the speed reducer and the outer shell and extends into the inner shell, a rotating tray is installed at the lower end of the output shaft, and a baffle is installed on the outer side of the rotating tray; a through hole is formed in the rotating tray, a mounting plate is arranged on the rear end face of the shell, and a cooling fan is mounted on the mounting plate. According to the silicon carbide drying device, silicon carbide is dried, and moisture in the silicon carbide is removed.

Owner:安徽雅乐美新材料科技有限公司

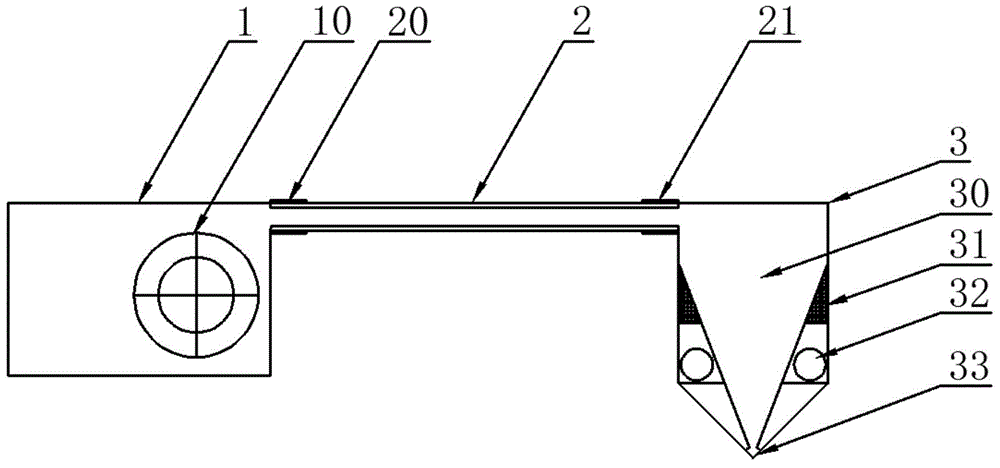

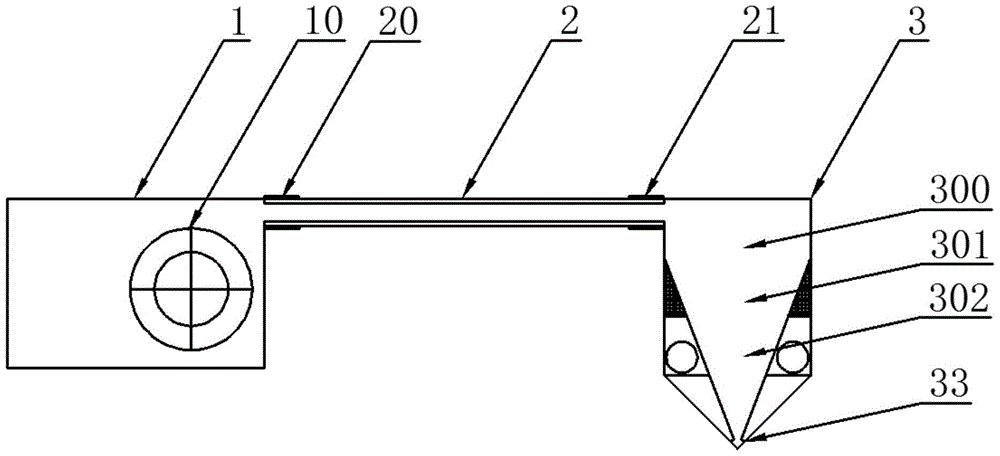

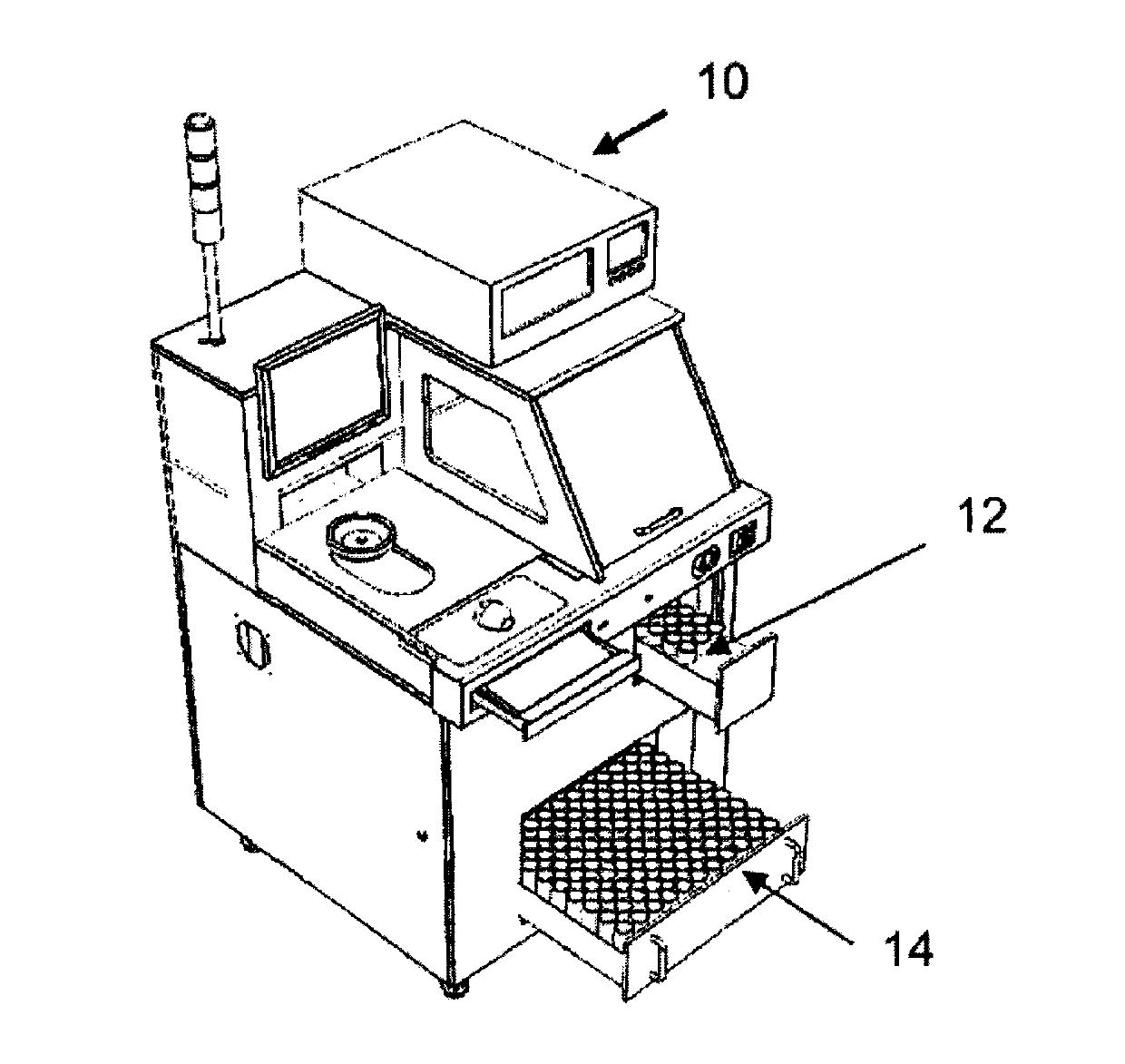

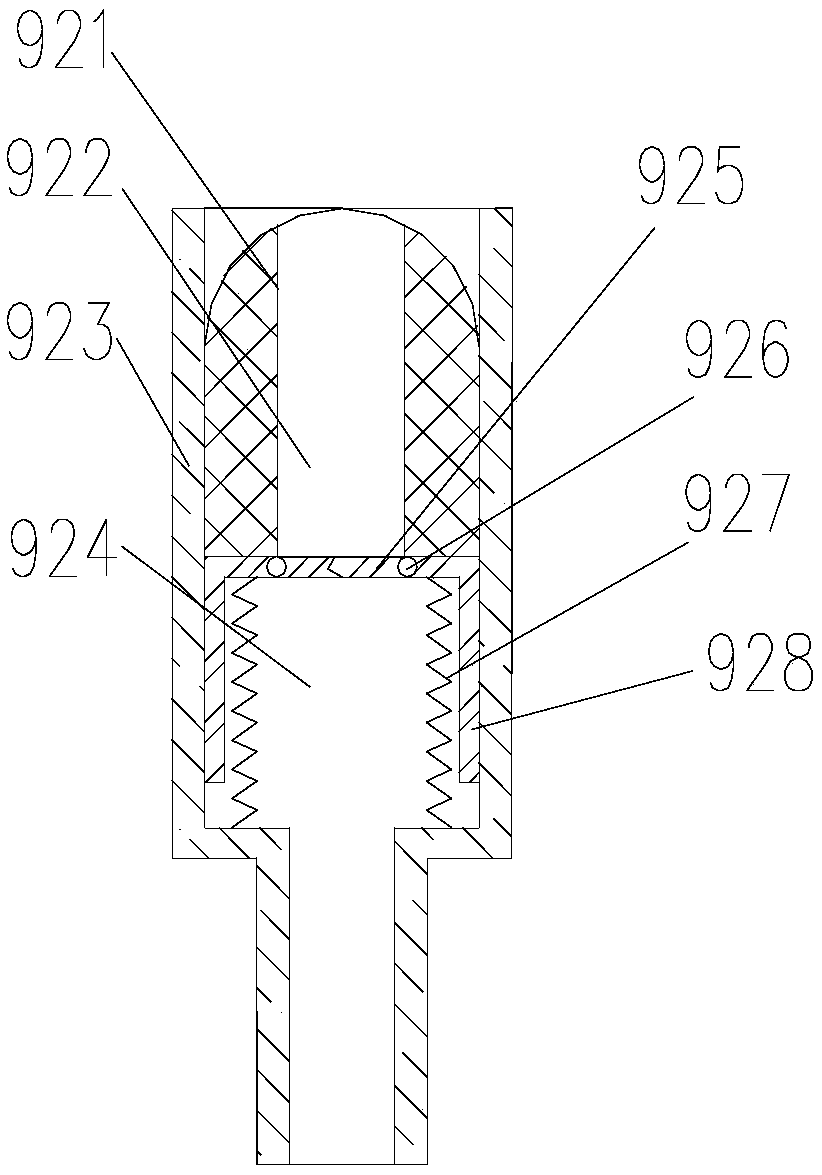

split nozzle

The present invention discloses a split nozzle head, comprising a feeder, a wire feed tube, and a movable nozzle head, the feeder and movable nozzle head being connected by means of the wire feed tube; the movable nozzle head comprises a cavity, a heat-dissipating tab, a thermocouple, and a nozzle; the lower end of the cavity is fixedly connected to the nozzle; the center of the outer side of the cavity is fixedly provided with the heat-dissipating tab; the thermocouple is disposed between the outer side of the cavity, the heat-dissipating tab, and the nozzle, and the thermocouple is fixedly connected to the cavity. The split nozzle head structure of the present invention functionally divides a 3D printing nozzle head device into a feeder, a movable nozzle head, and a wire feed tube; in contrast to the nozzle heads of the prior art, the weight of the parts which move during operation of the nozzle head is reduced, improving the printing speed of a 3D printer; furthermore, the load inertia of the moving parts is reduced due to the reduction in weight of the moving parts, causing the time delay of the moving components when changing direction to be reduced, thus improving printing accuracy.

Owner:BEIJING TIERTIME TECH

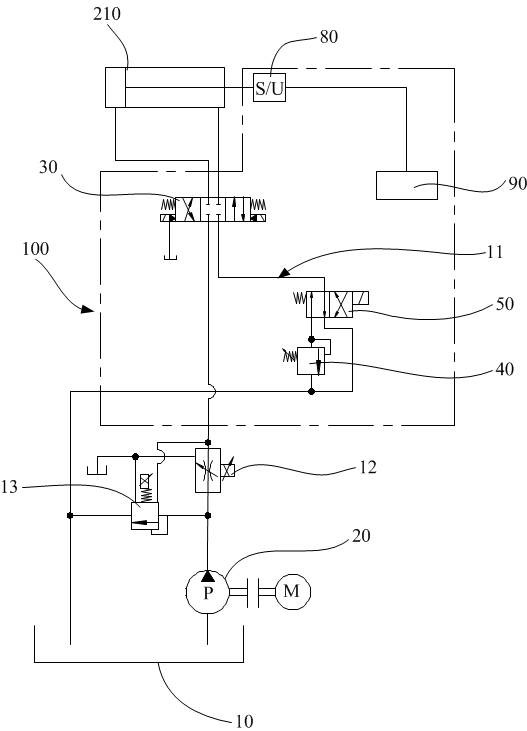

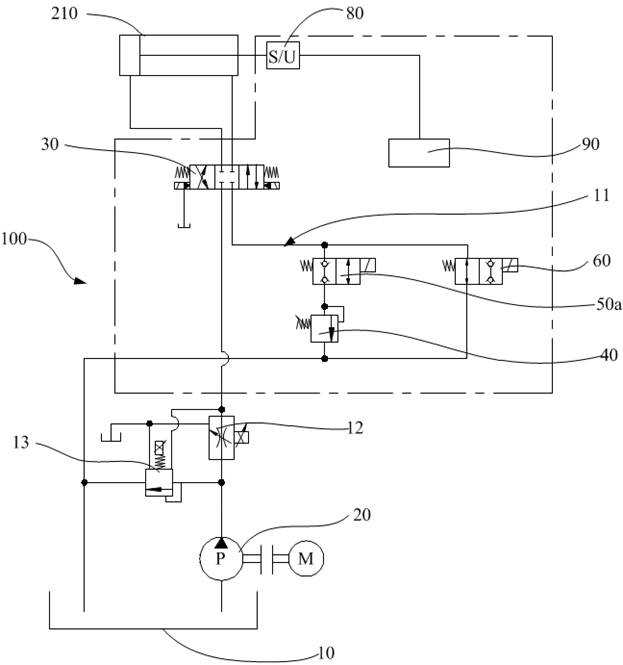

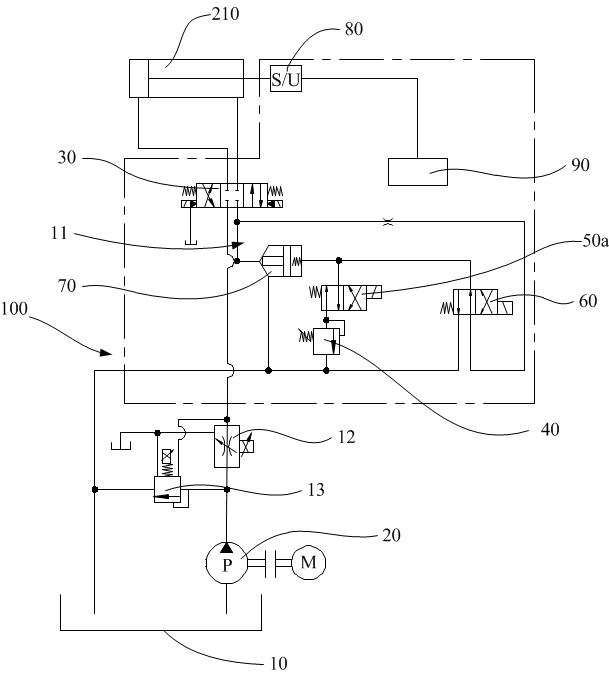

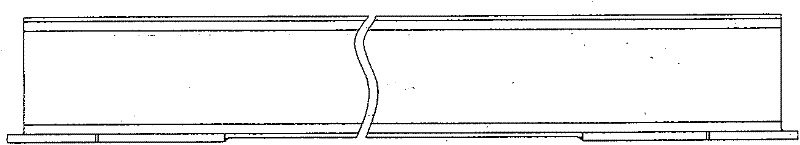

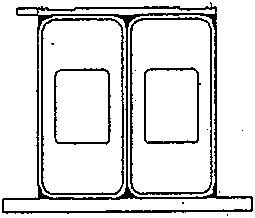

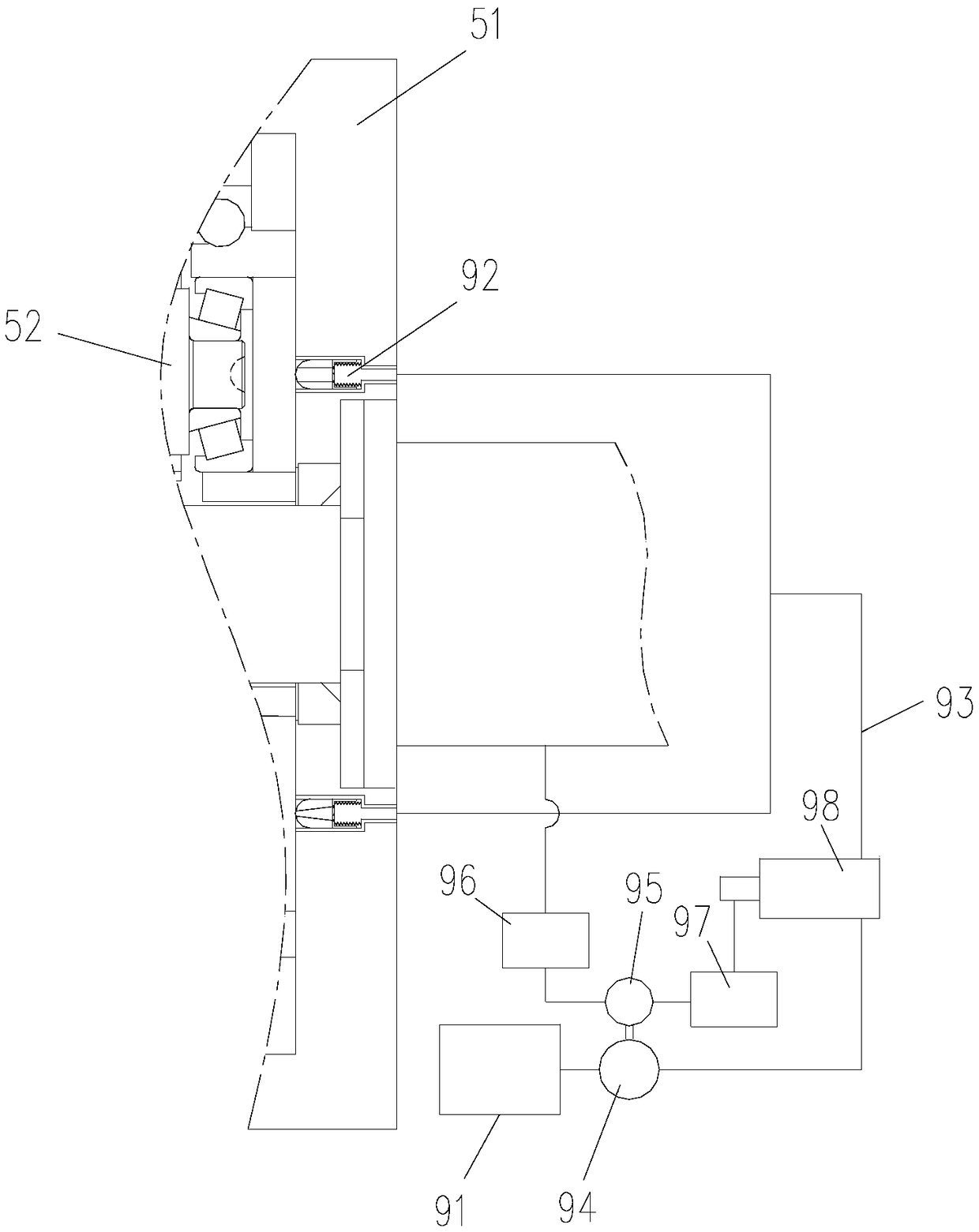

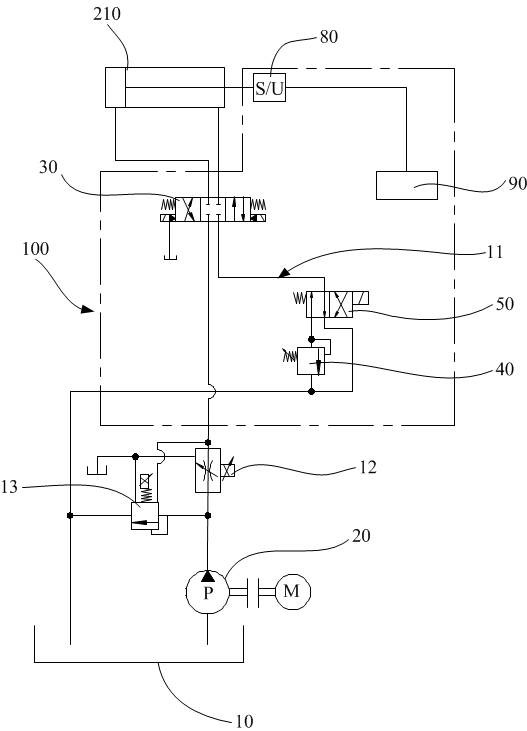

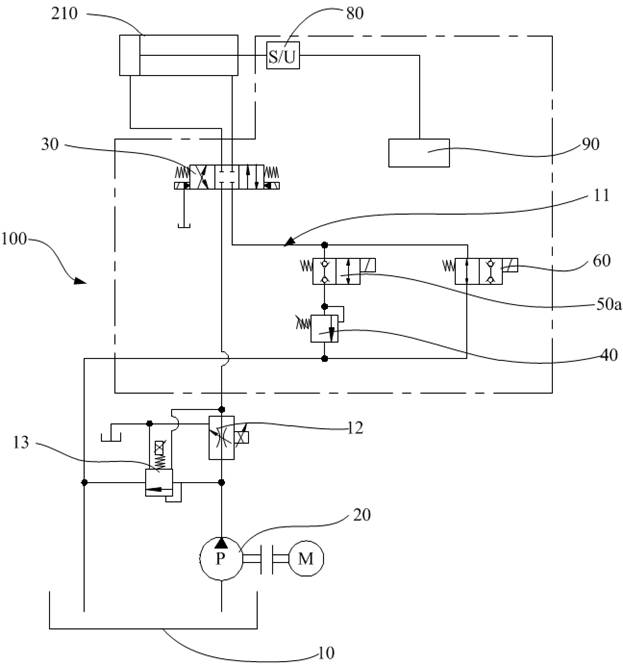

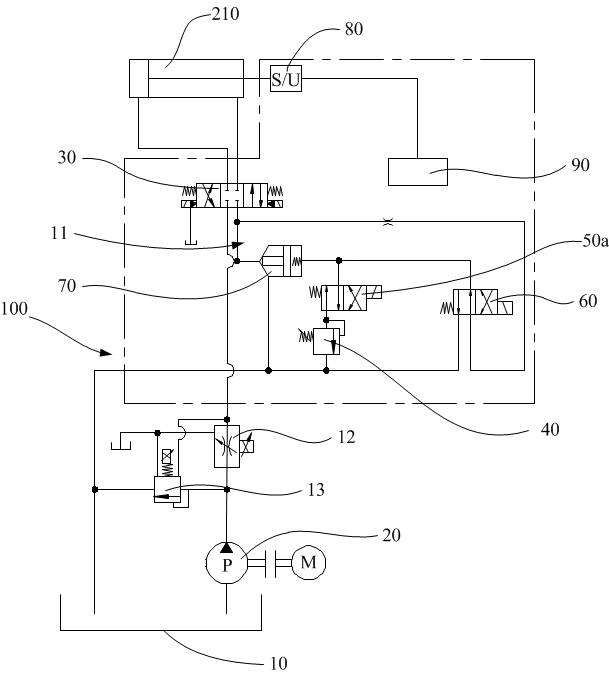

Die opening positioning electro-hydraulic control system and die casting machine

The invention discloses a die opening positioning electro-hydraulic control system and a die casting machine. The die-opening positioning electro-hydraulic control system is applied to the die-casting machine, the die-casting machine comprises a die unlocking and locking oil cylinder, the die-opening positioning electro-hydraulic control system comprises an oil tank, an oil pump connected with the oil tank, a first reversing valve connected with the oil pump through a pipeline and a pressure control valve, wherein one valve port of the first reversing valve communicates with a rod cavity of the mold unlocking and locking oil cylinder, the other valve port of the first reversing valve communicates with a rodless cavity of the mold unlocking and locking oil cylinder, the first reversing valve is connected with the oil tank through an oil return pipeline, and the pressure control valve is arranged on the oil return pipeline and can be used for controlling the oil pressure on the oil return pipeline. According to the technical scheme, the mold opening positioning electro-hydraulic control system can accurately position the mold opening position.

Owner:GUANGDONG YIZUMI PRECISION MACHINERY

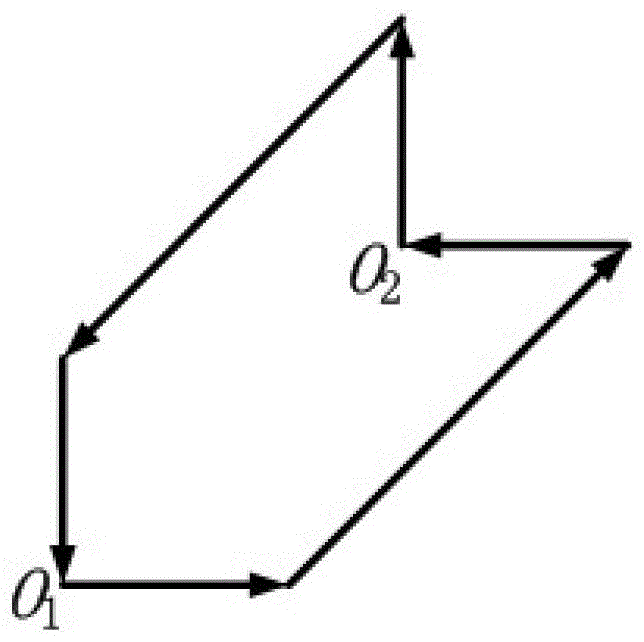

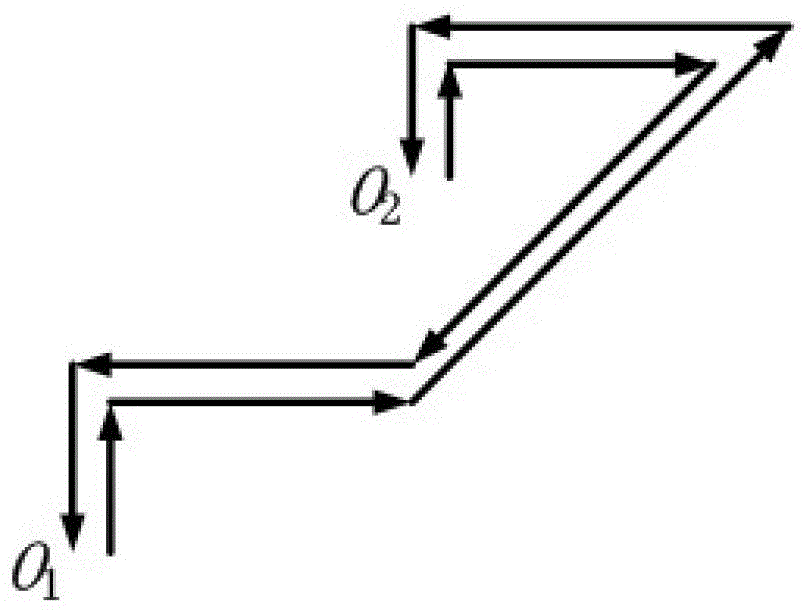

High-speed component distributing device

The invention relates to a high-speed component distributing device, which comprises an installation base, a servo motor I and a servo motor II, wherein the servo motor I is connected with a bearing base I through a connecting block I and is used for controlling the bearing I base to move; the servo motor II is connected with a bearing base II through a connecting block II and is used for controlling the bearing base II to move; the servo motor I and the servo motor II are arranged on the base, and are vertically distributed; a plane constructed by the axes of the servo motor I and the servo motor II is parallel to the horizontal plane; and an intersectional roller bearing I and an intersectional roller bearing II are arranged inside the bearing base I and the bearing base II. The distributing device has the advantages of reducing the load inertia of a motor, increasing the distributing speed, eliminating high-speed vibration of a cable, reducing the occupied space, and lowering the cost simultaneously.

Owner:SHENZHEN HI TEST SEMICON EQUIP

Rubber band double-cam feeding control method

InactiveCN110683425AGuaranteed output speedReduce load inertiaFilament handlingKinematic controllerEngineering

The invention relates to the field of sanitary article manufacturing, and provides a rubber band double-cam feeding control method. The method comprises the following steps that (1) a rubber band curve feeding device controlled by a PLC is arranged to adjust the changing height of rubber band curve feeding, so that the stretching degree of a rubber band adapts to the stretching degree required byrubber bands corresponding to different products respectively; and (2) the PLC controls a first motion controller, then the first motion controller controls and adjusts the forward and reverse rotation angle of a first servo motor to adjust and control the swing angle of a swing rod, meanwhile, the PLC controls a second motion controller according to a rubber band curve feeding graph, the swing speed of the swing rod and the rubber band conveying rate, and the second motion controller controls the operation speed of a second servo motor to guarantee the rubber band output speed. The method solves the problems that the rubber band rate of existing rubber band curve feeding cannot be effectively controlled and the changing rate of the rubber bands cannot be changed in real time to adapt to production switching of various products.

Owner:QUANZHOU HANWEI MACHINERY MFG

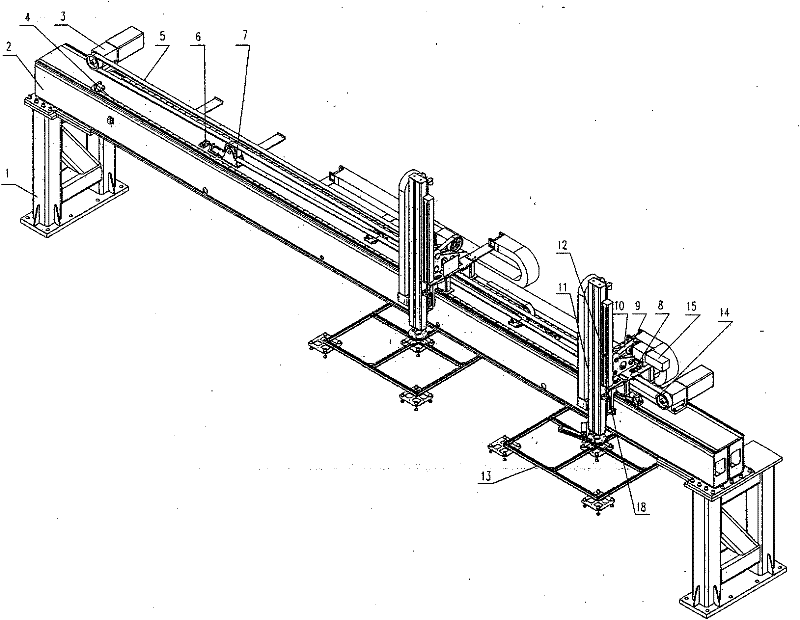

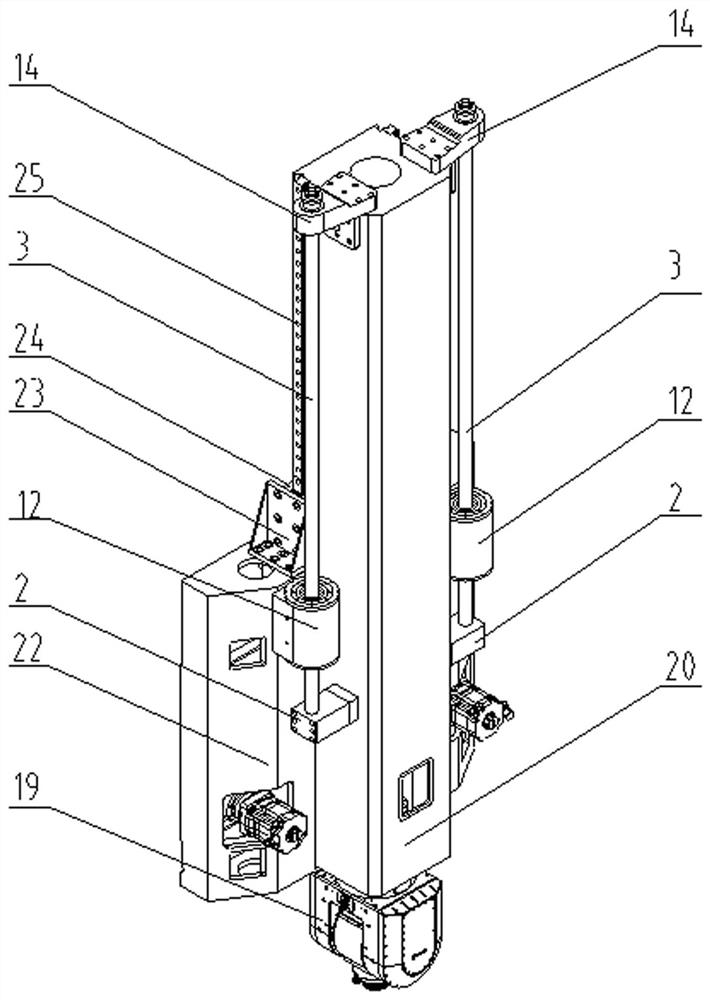

Ultrathin glass cleaning carrying robot

ActiveCN101205017BReduce labor intensityConvenient sourceCharge manipulationManipulatorProduction scheduleInsertion stent

The invention relates to a robot for cleaning and transporting ultra thin glass. Frame type columns are installed on two ends of a beam component respectively. The beam component is provided with an X body and a Z body. An X guide in the X body is sliding and is provided with a stent. Two ends of an X timing belt are connected with two ends of the stent through a driving synchronous belt wheel and a driven synchronous belt. The driving synchronous belt wheel is arranged on an output axis of a servo deceleration motor on an X axis. A tensioner at an upper part and a lower part of the Z body is arranged on the stent respectively and a Z axis synchronous belt wheel is arranged on an output axis of a servo deceleration motor on the Z axis correspondingly arranged. A Z axis body is connected with the stent in the manner of sliding and is vertically installed. A Z synchronous toothed belt is fixed on an upper and lower ends of the Z axis body through the tensioner and the Z axis synchronous belt wheel and forms an n-shaped surrounded structure. The Z axis body is articulated with a stirrup on cylinder bar of a balanced cylinder on the stent. The lower end of the Z axis body is connected with an end picking-up device through a quickly changed device for the en d picking-up device. The invention can meet the transportation and packaging requirements of ultra thin glass and can reduce losses and labor intensity under the condition that the production schedule is satisfied.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

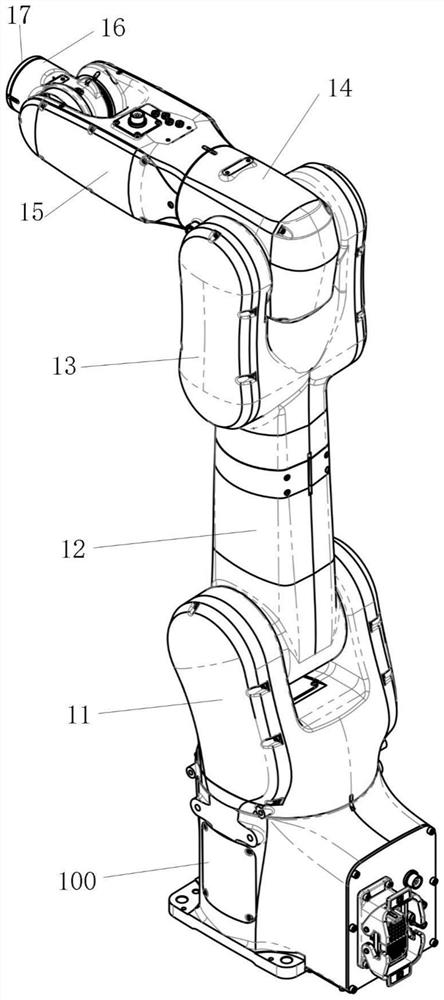

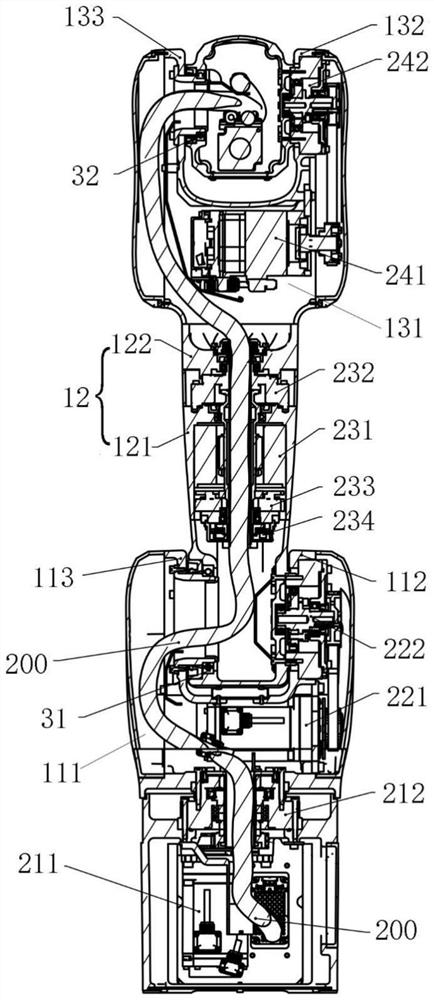

Robot

PendingCN114393594AImprove stabilityReduce load inertiaProgramme-controlled manipulatorJointsGravity centerIndustrial engineering

The invention relates to the technical field of automatic production, and particularly discloses a robot which comprises a base, seven joints and seven driving assemblies. Wherein the seven joints are rotationally connected end to end, and the first joint is rotationally connected to the base. The seven driving assemblies respectively drive the seven joints to act; the sixth driving assembly and the seventh driving assembly are both located in the fifth joint. A wire harness sequentially passes through the first joint, the second joint, the third joint and the fourth joint from the base to enter the fifth joint and is electrically connected with the first driving assembly, the second driving assembly, the third driving assembly, the fourth driving assembly and the fifth driving assembly on the way. The wire harness located in the fifth joint is electrically connected with the sixth driving assembly and the seventh driving assembly. By means of the arrangement, the gravity center of the whole robot moves backwards, then the stability of feeding and discharging is improved, the service life of all the joints and the service life of the driving assemblies driving all the joints can be prolonged, and then the use reliability of the seven-axis robot is improved.

Owner:SUZHOU LINGHOU ROBOT

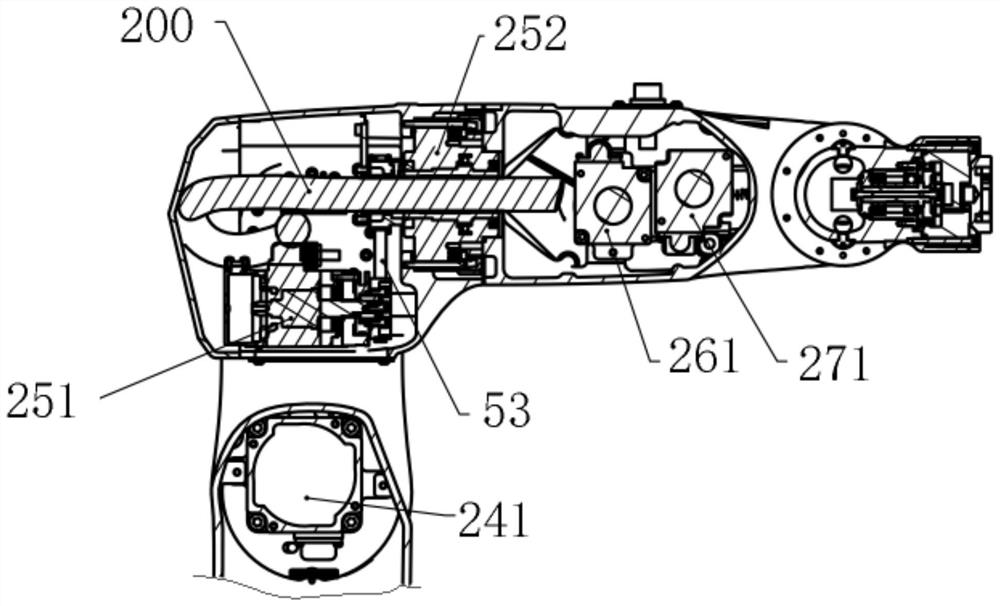

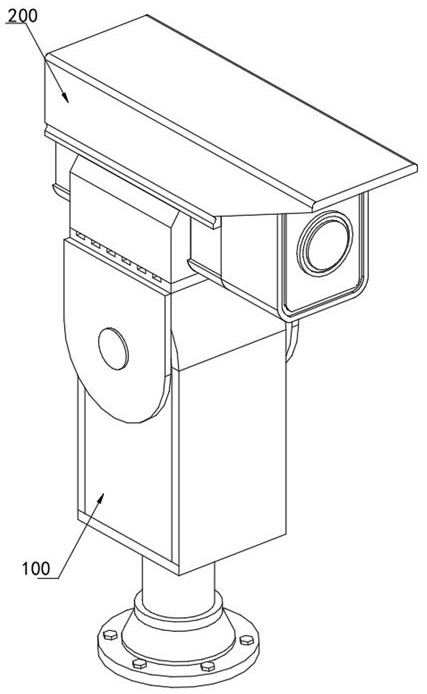

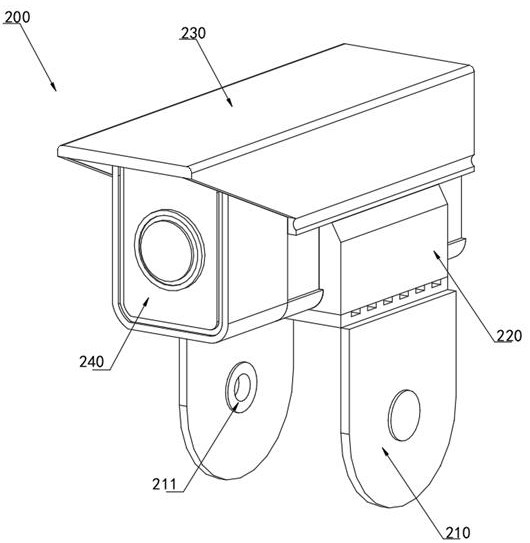

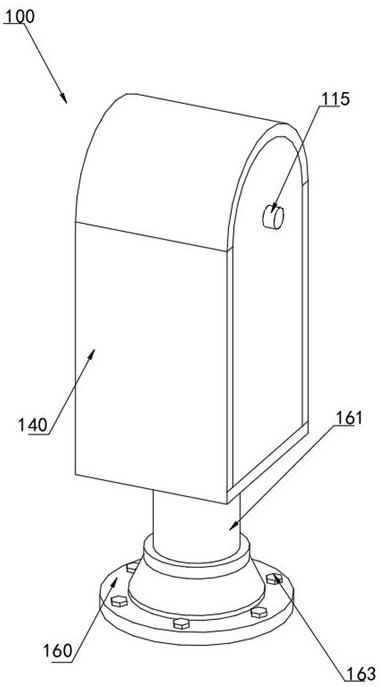

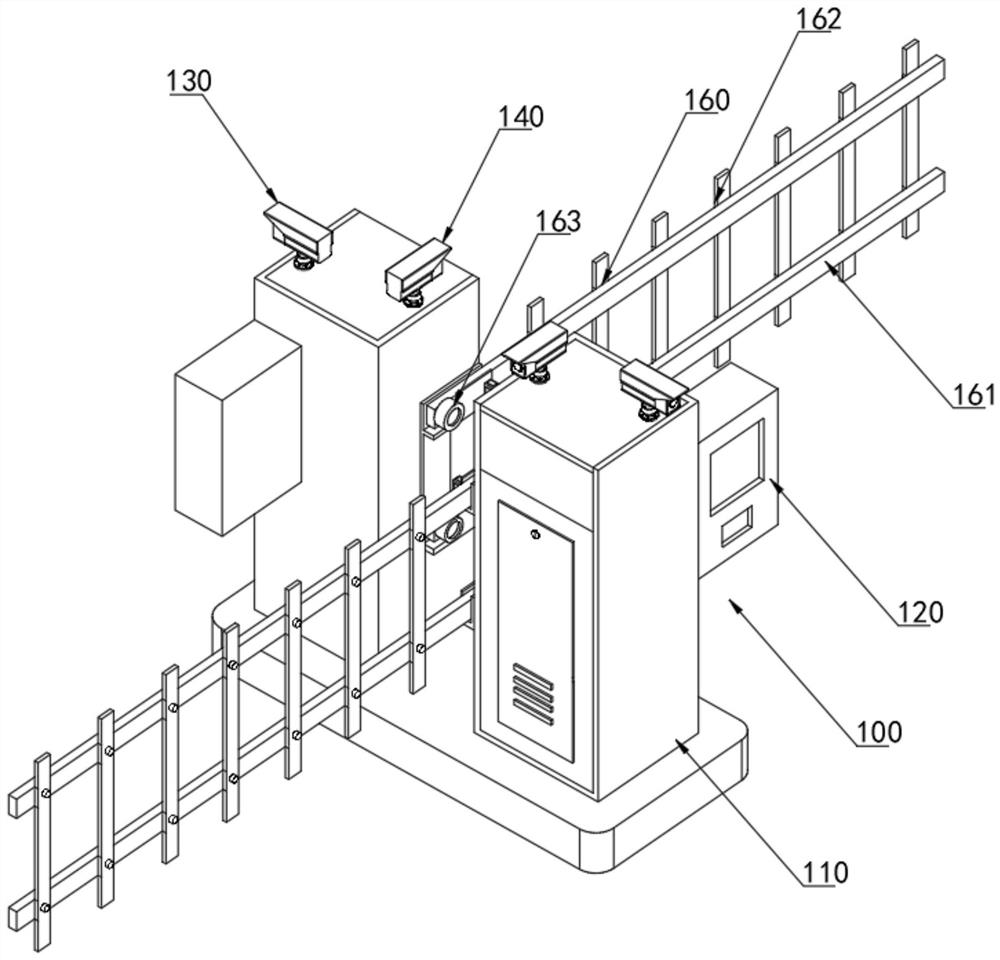

Intelligent monitoring camera with inspection function and inspection method thereof

PendingCN114286057AHigh torqueEasy to adjust hoverTelevision system detailsChecking time patrolsElectric machineryEngineering

The invention relates to the technical field of power monitoring equipment, in particular to an intelligent monitoring camera with an inspection function and an inspection method thereof.The intelligent monitoring camera comprises an inspection device and a monitoring device, the monitoring device is located at the top of the inspection device, and the inspection device is rotationally connected with the monitoring device; the inspection device comprises an external mounting shell and further comprises an axial rotating mechanism located in the external mounting shell, and the axial rotating mechanism and the circumferential rotating mechanism are arranged between the motor and the monitoring camera, so that direct connection between equipment and driving equipment is avoided; the problems that a traditional intelligent monitoring camera does not have an inspection function, the monitoring dead angle is large, the monitoring range needs to be adjusted manually, the load inertia of a motor is large, and thus internal mechanical parts are prone to being damaged are solved.

Owner:深圳市安嘉科技有限公司

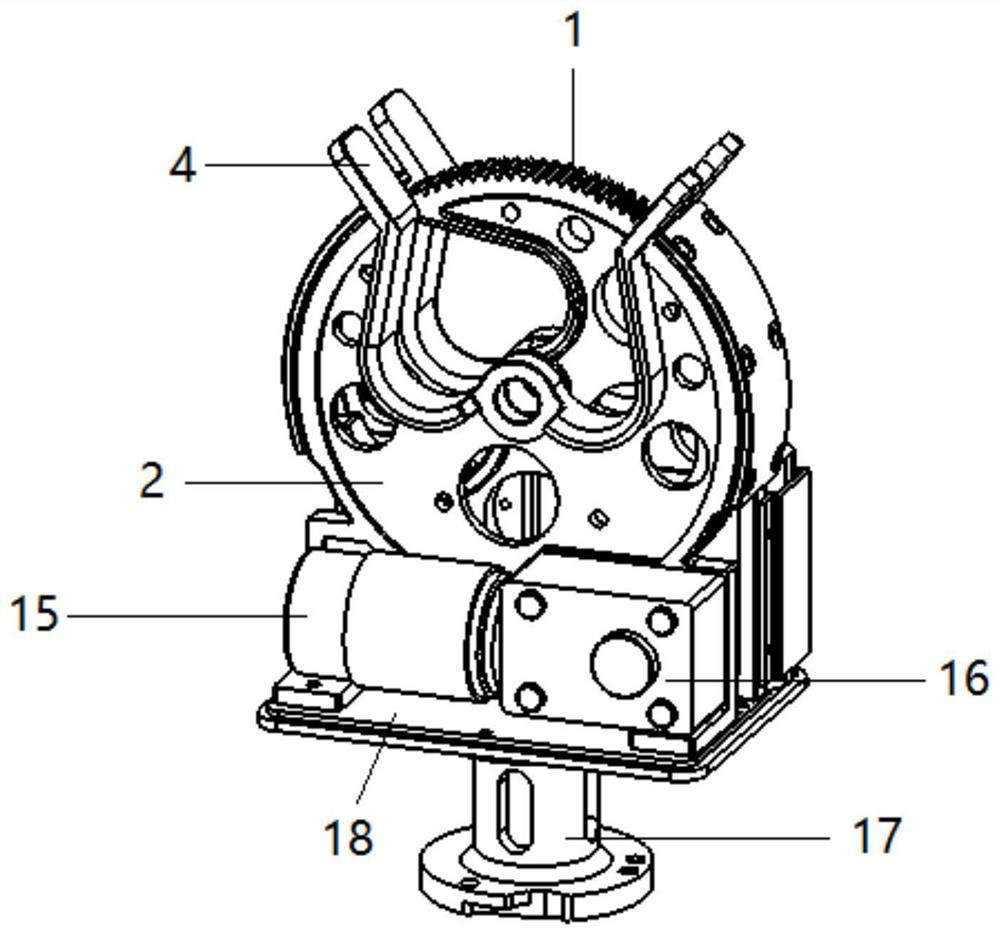

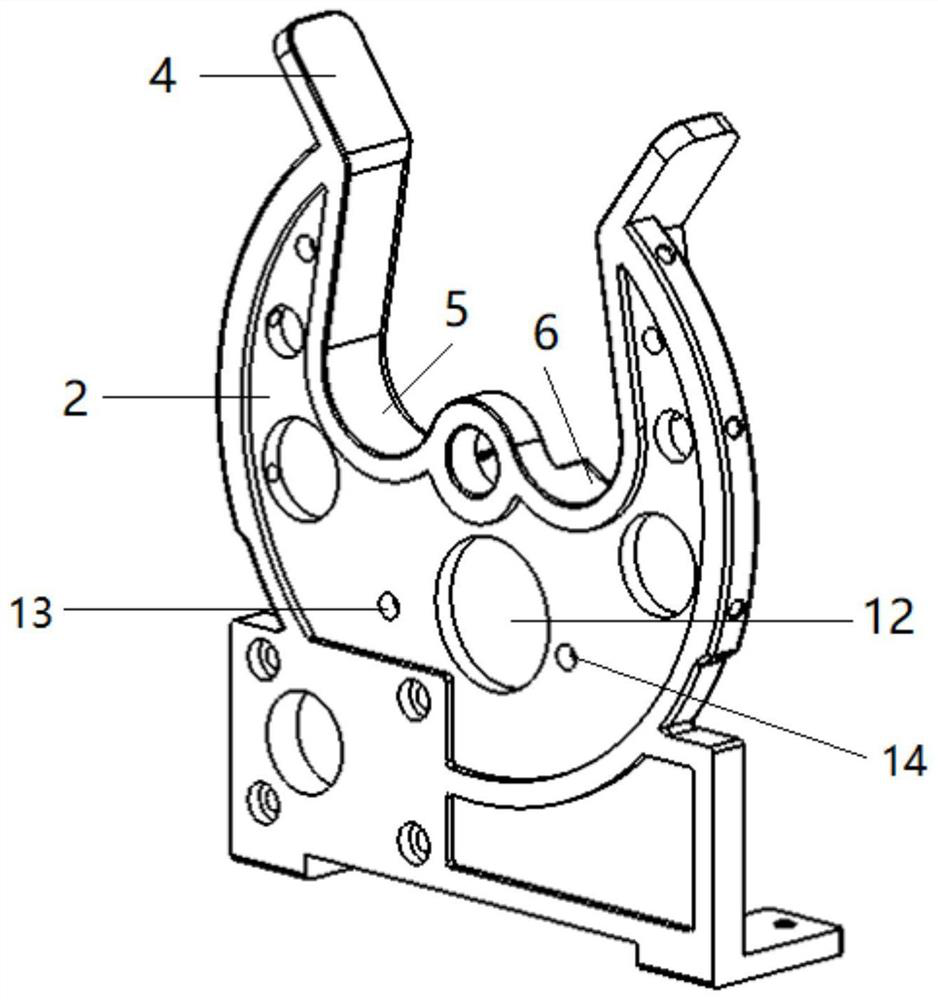

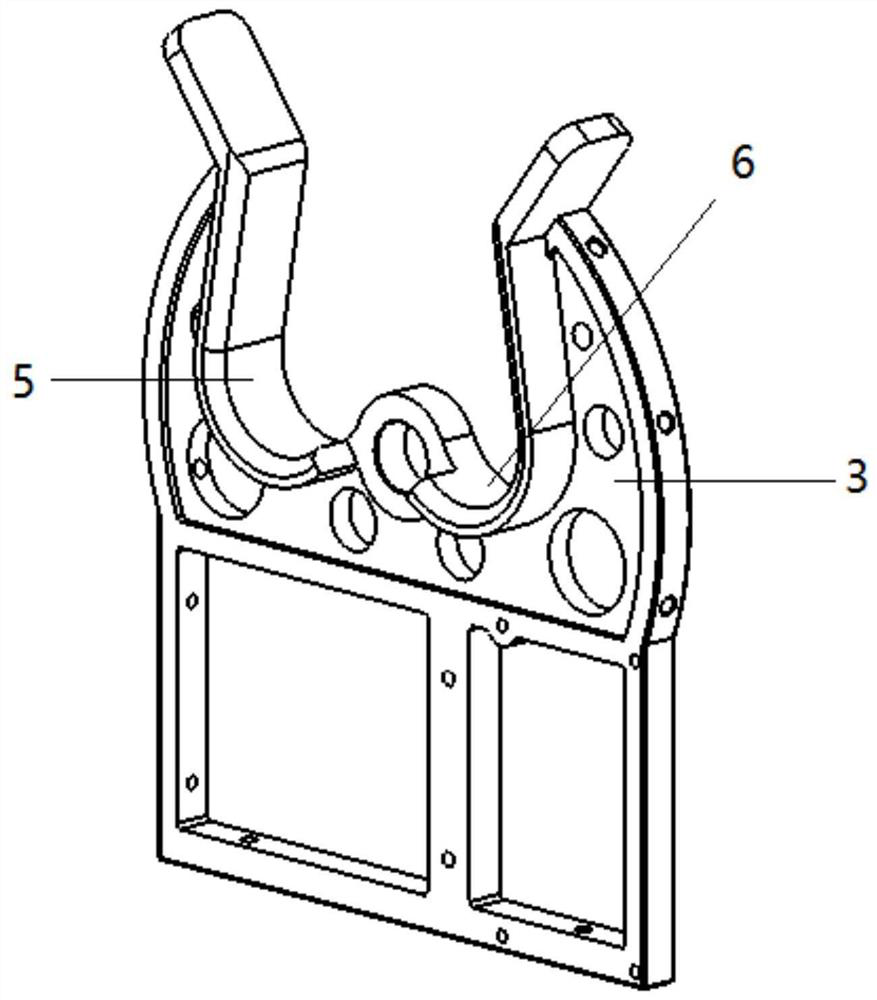

Clamping mechanism

ActiveCN113070890AImprove applicabilityImprove reliabilityGripping headsEngineeringMechanical engineering

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV

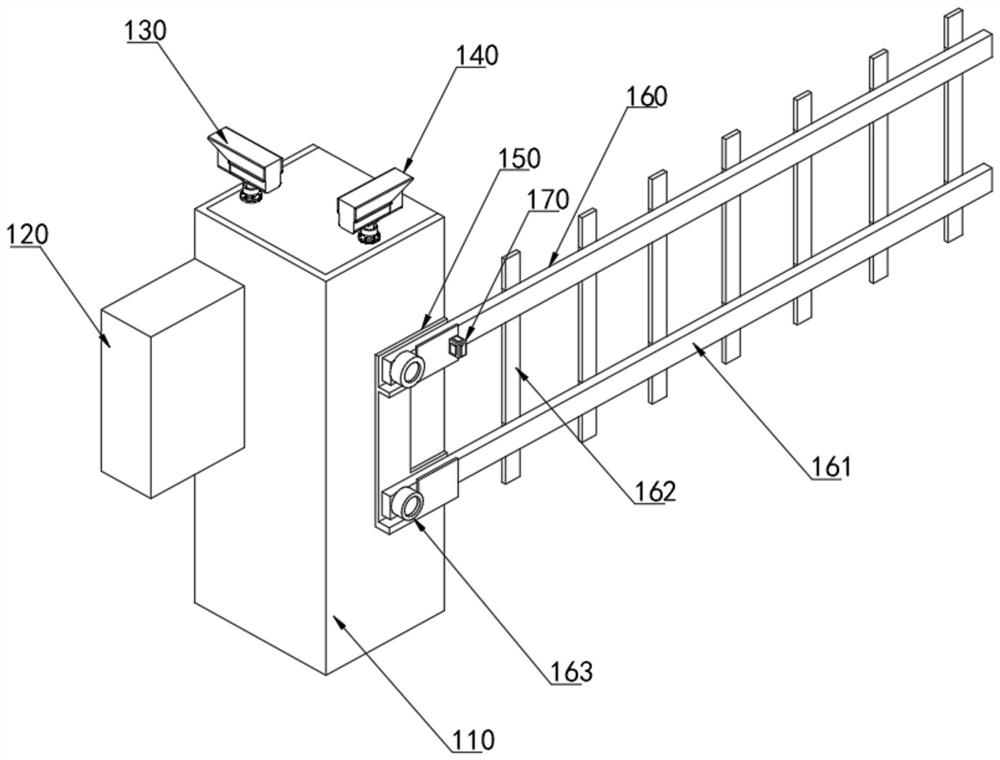

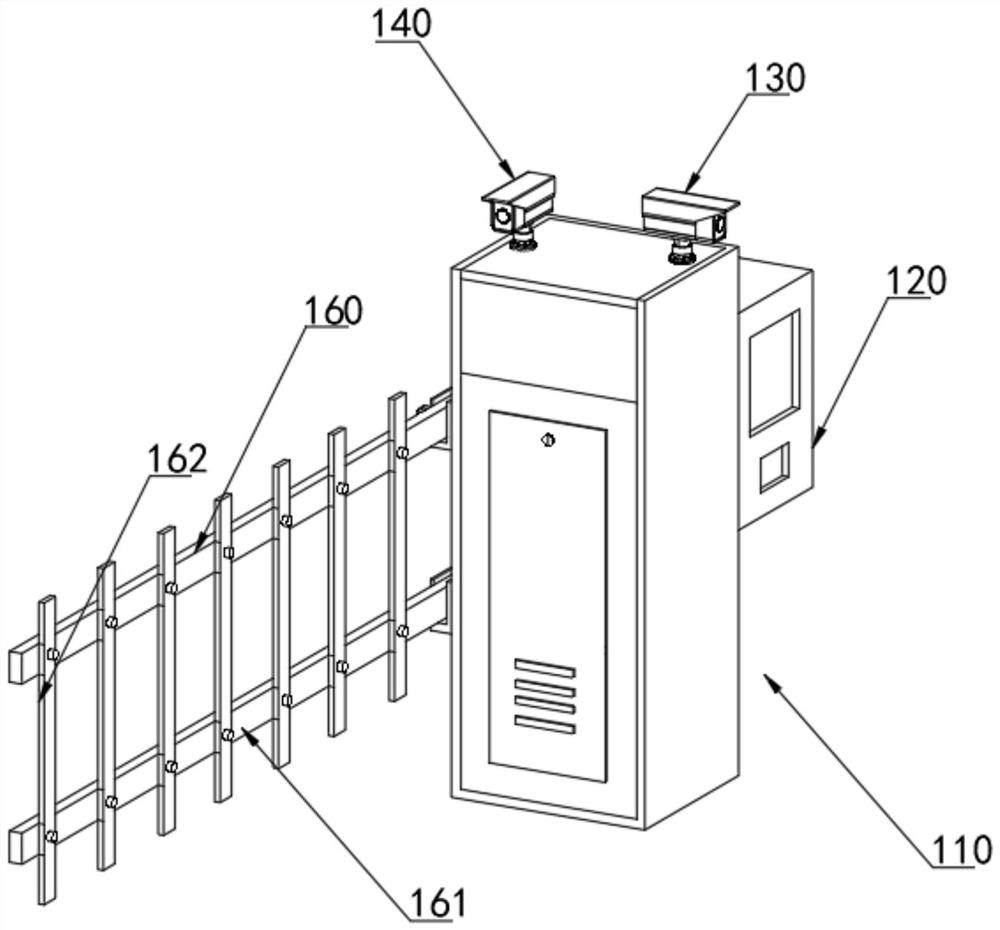

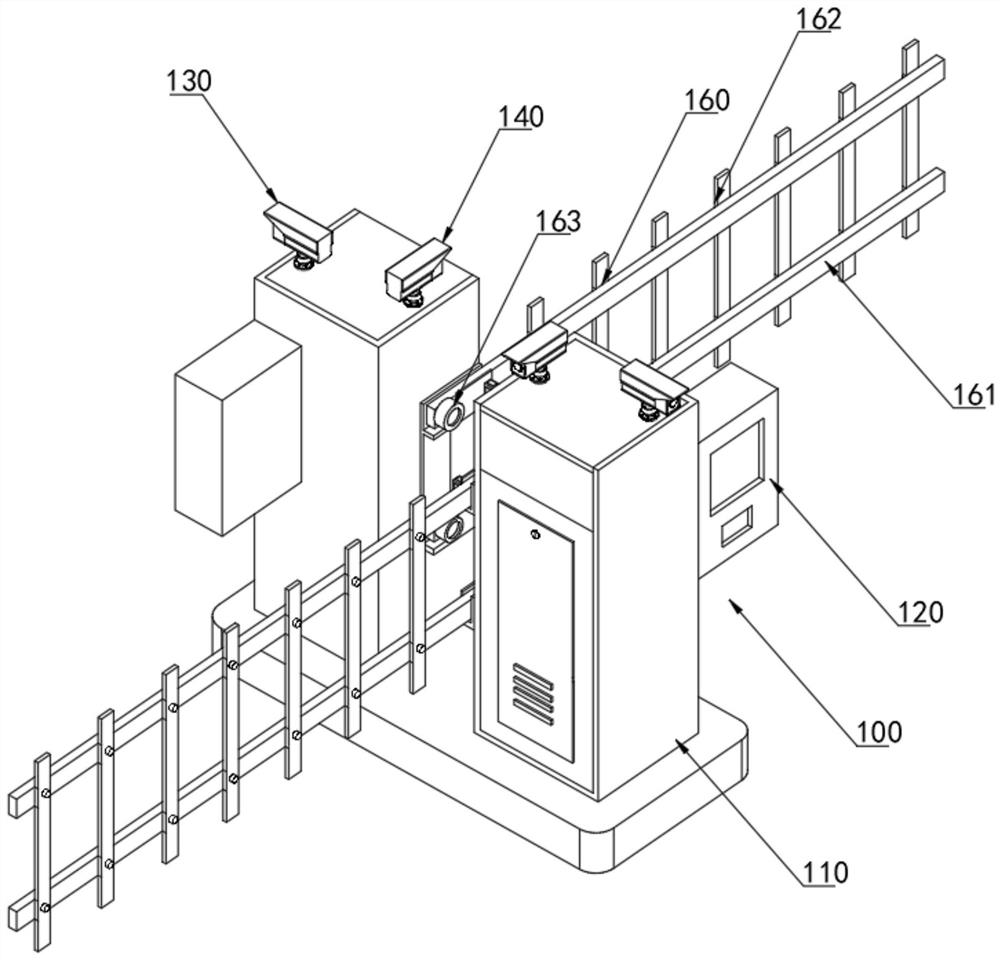

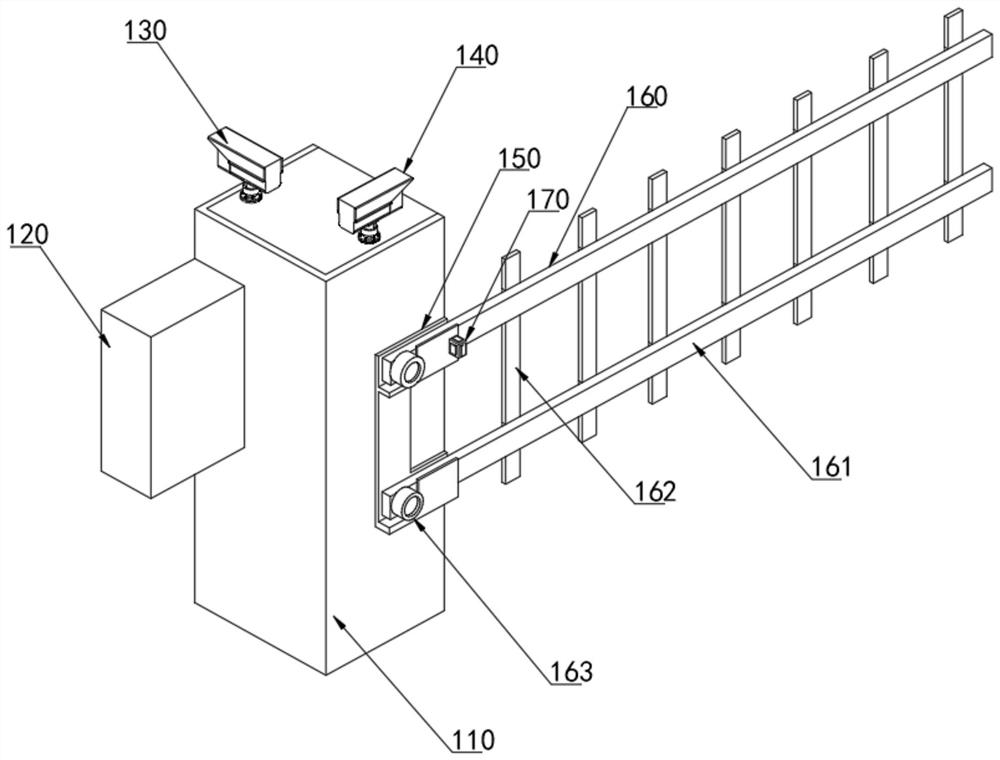

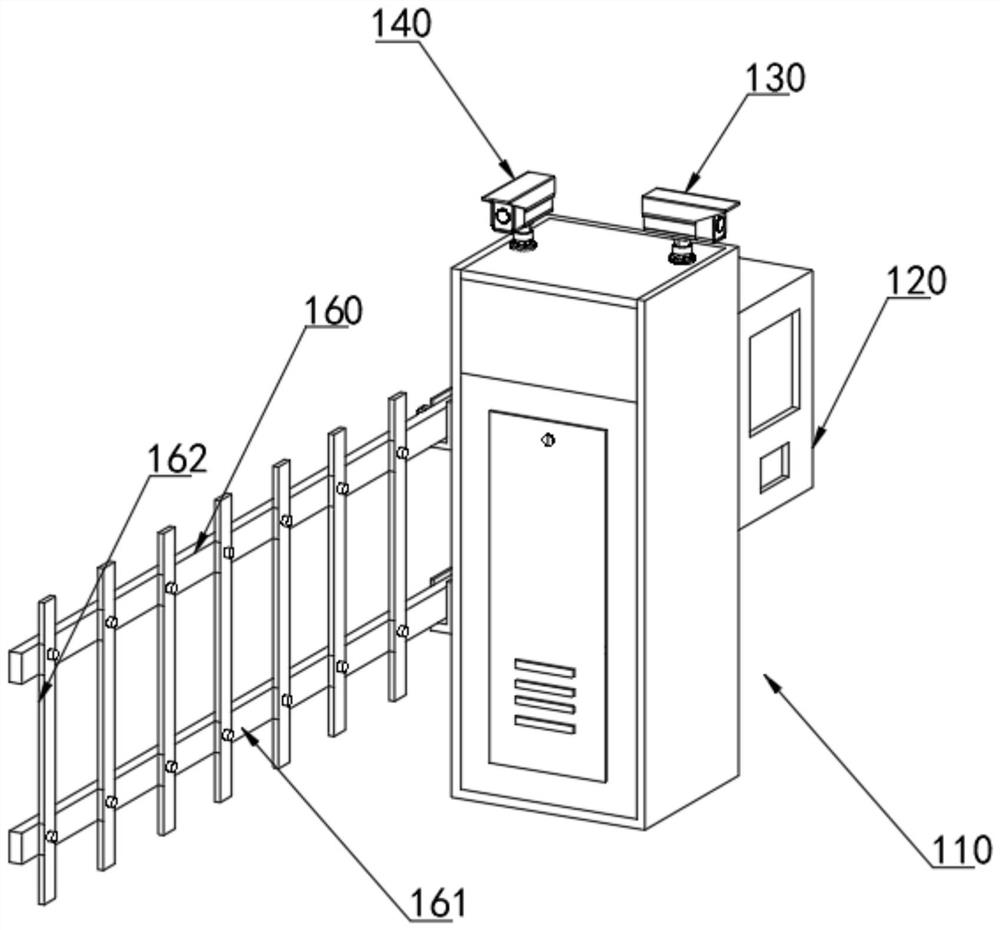

Vehicle parking management device and management system for intelligent parking lot

ActiveCN112664632AReduce load inertiaAvoid damageGearingIndication of parksing free spacesStops deviceCar parking

The invention belongs to the technical field of intelligent parking, and particularly relates to a vehicle parking management device and management system for an intelligent parking lot. The vehicle parking management device comprises a barrier gate device, a driving device, a start-stop device and the management system. The technical scheme is as follows: the barrier gate device comprises two sets of machine cases in central symmetry, an intelligent control box is fixedly installed on one sides of the machine cases, driving devices are arranged on the inner walls of the machine cases and comprises supporting discs II, oval plates II are fixedly installed on the left sides of the supporting discs II, supporting columns II are fixedly installed on the left sides of the oval plates II, and linear bearings IV are movably installed on the outer walls of the supporting columns II. The device and system have the beneficial effects that the purpose of speed reduction is achieved through the driving devices, the load inertia is reduced while speed reduction is achieved, supporting discs I and the supporting discs II replace traditional tension springs to enable a stop lever I and a stop lever II to stably rise and fall, and then the effect of improving the stability of a barrier gate system is achieved.

Owner:深圳市信拓网络科技有限公司

Pipeline welding platform

InactiveCN108723686AProtects against surface damageSufficient driving forceWelding/cutting auxillary devicesAuxillary welding devicesReduction driveDrive motor

The invention discloses a pipeline welding platform which comprises a supporting platform. The supporting platform is provided with a guiding rail. The guiding rail is oppositely provided with two guiding plates, and semicircular fixing grooves are separately and correspondingly formed in the opposite end faces of the two guiding plates. Threaded holes are formed in the lower parts of the guidingplates, and screw rods penetrate through the threaded holes. The surfaces of the fixing grooves are covered with flexible layers. The supporting platform is provided with a driving device, the drivingdevice includes driving motors and speed reducers, output shafts of the driving motors are connected to the input ends of the speed reducers, and the output ends of the speed reducers are connected to one ends of the screw rods. According to the pipeline welding platform, the situation that surface damage occurs when pipelines are clamped in the fixing grooves is avoided, meanwhile, the guiding plates are prevented from moving excessively fast to be difficult to control, and sufficient driving force is ensured.

Owner:CHONGQING VOCATIONAL INST OF ENG

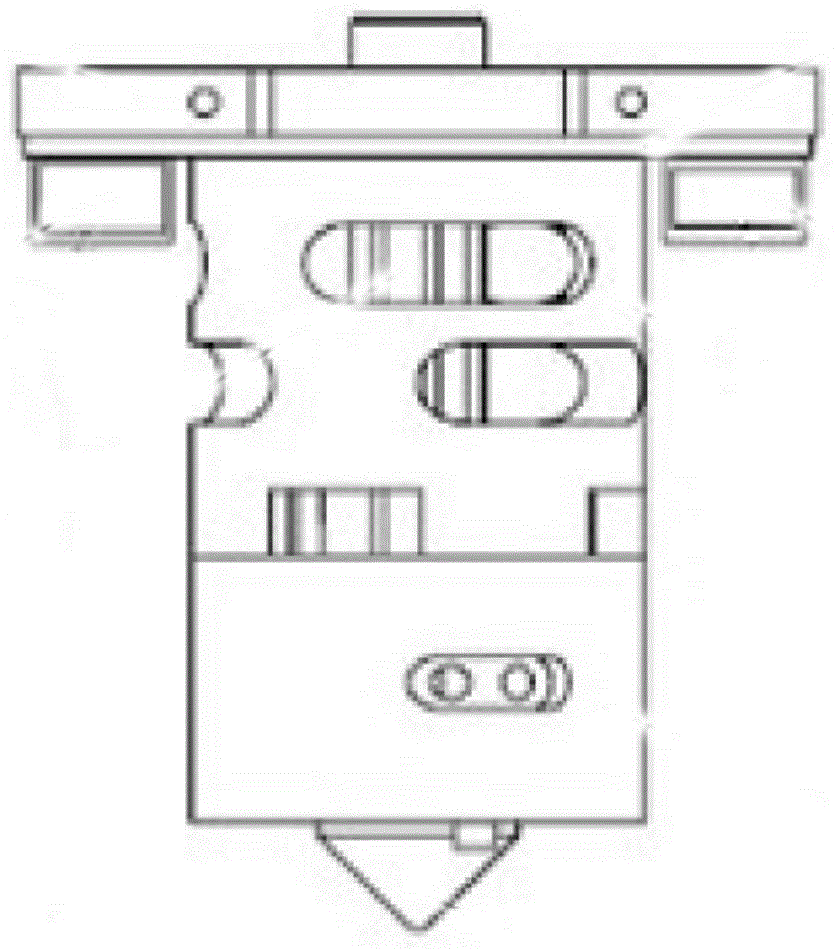

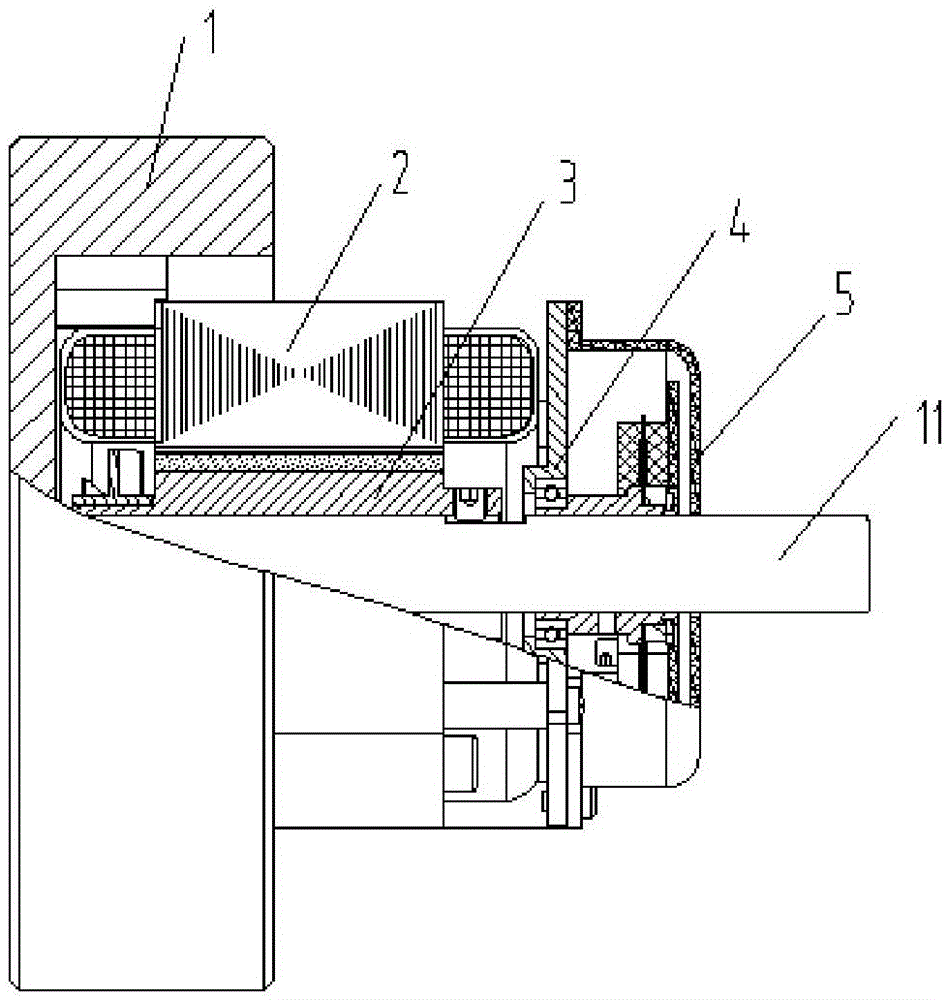

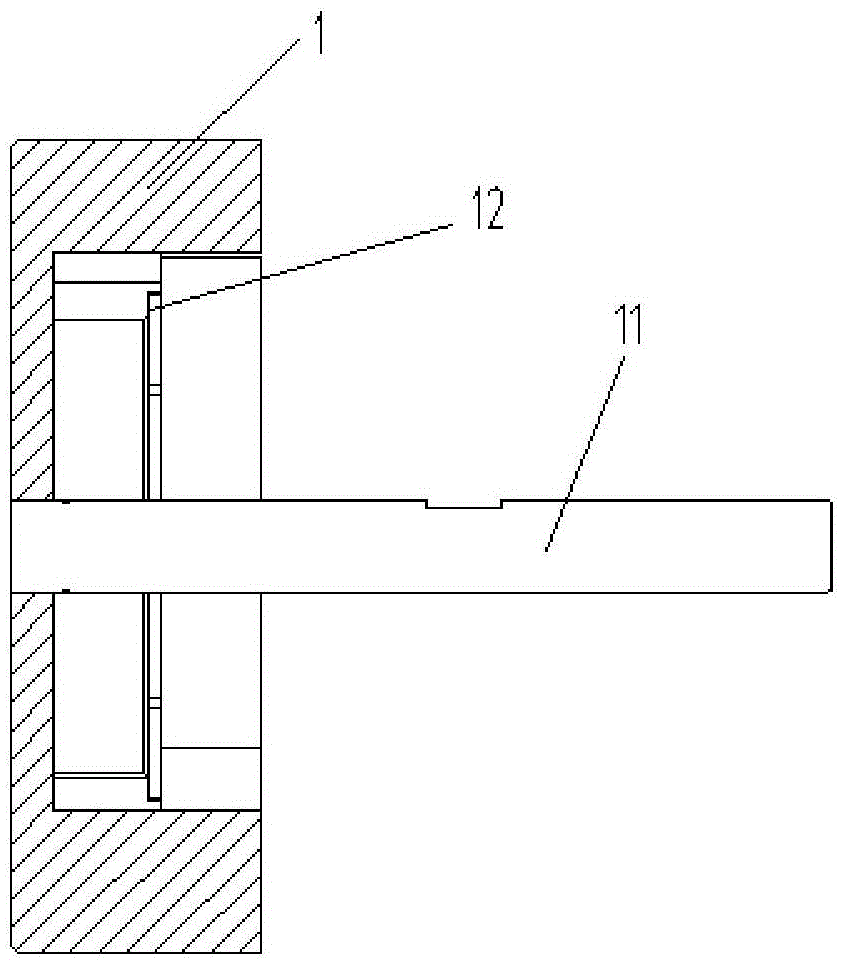

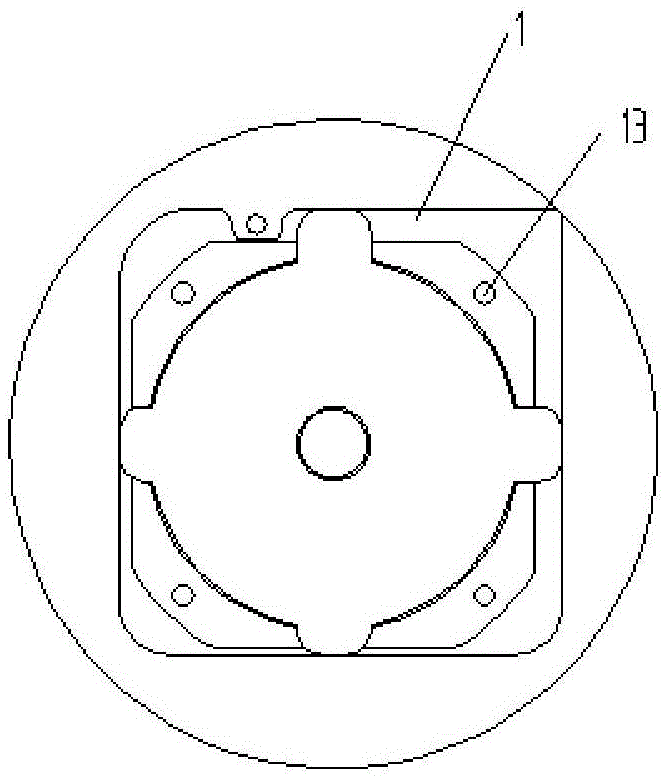

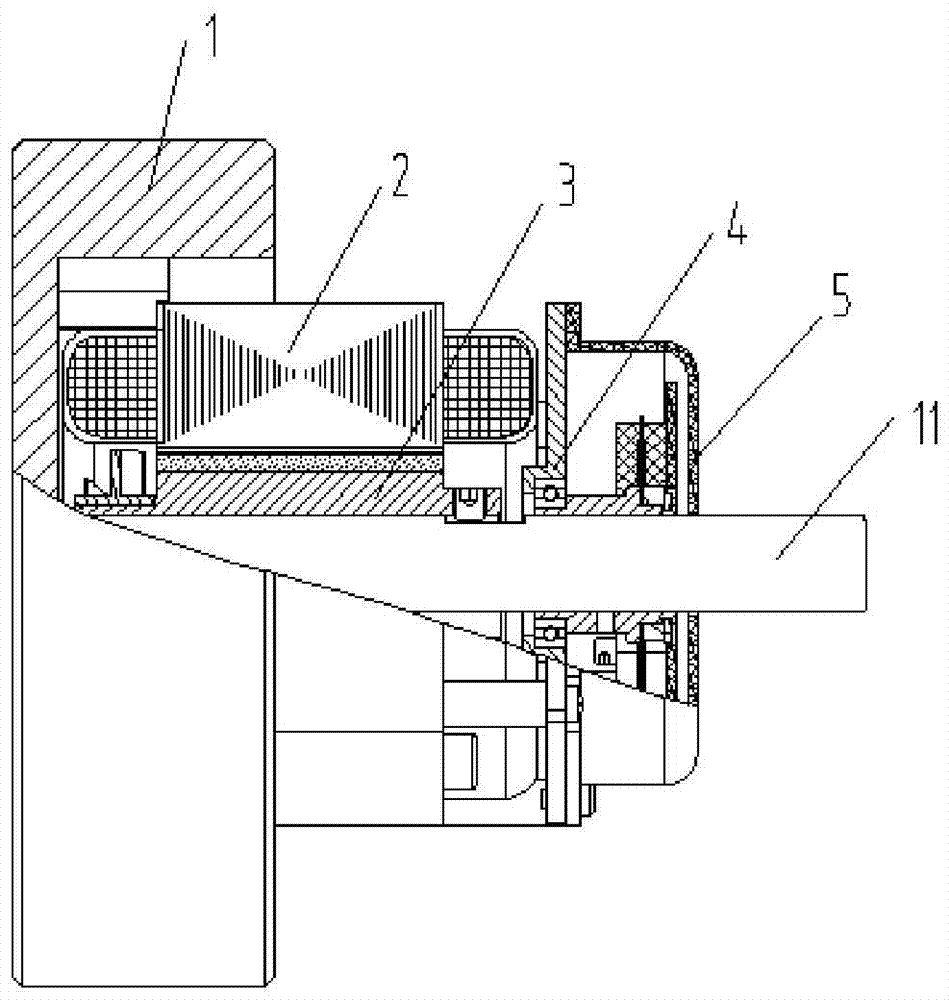

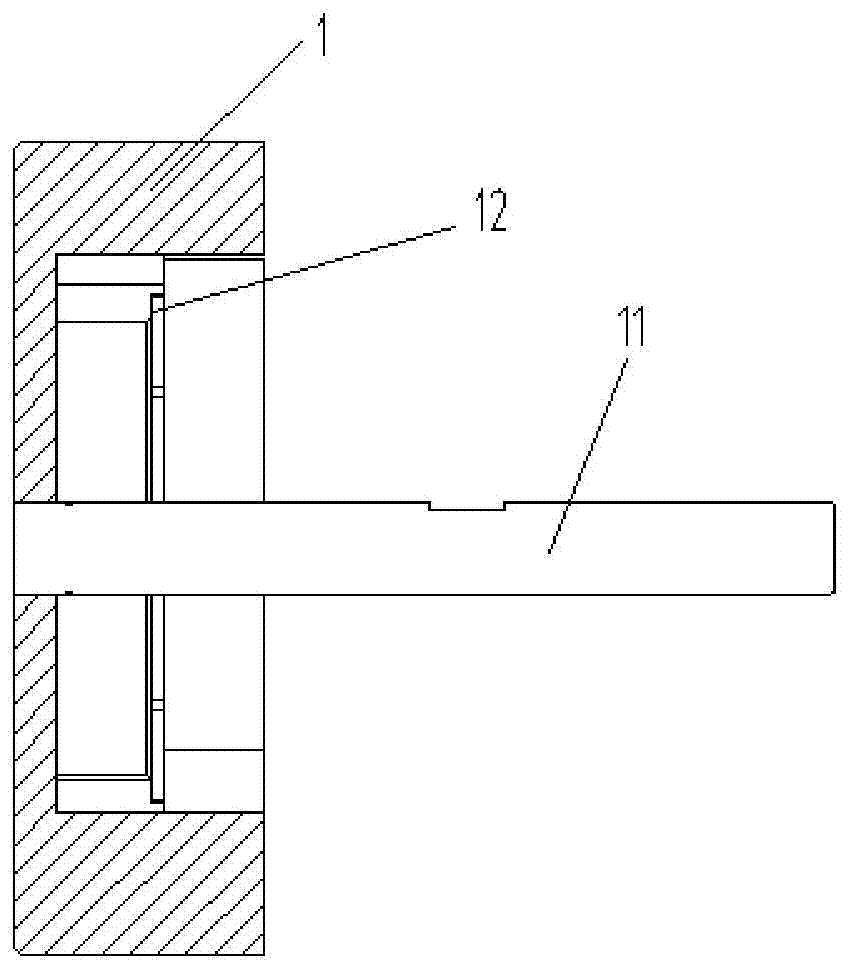

Motor of stator and rotor split type for sewing machine

ActiveCN105099008AReduce axial sizeReduce load inertiaMagnetic circuit rotating partsMagnetic circuit stationary partsGratingEngineering

The invention discloses a motor of a stator and rotor split type for a sewing machine, and the motor is connected with the head of the sewing machine. The motor comprises a stator, a rotor, an integrated coder, and a rear cover, wherein the rotor is a hollow shaft. The rotor, the integrated coder and the rear cover are sequentially fixed on a sewing machine main shaft in the head of the sewing machine in a coaxial and sleeved manner. The stator is fixedly connected with the head of the sewing machine. The integrated coder is connected with a needle rod of the sewing machine, and can control the angle of the needle rod of the sewing machine. A coder seat is provided with a coder installation column with adjustable height. An optical grating assembly comprises an optical grating support, an optical grating sheet, an optical grating pressure ring, and a clamping spring, wherein the optical grating support is coaxially disposed on the sewing machine main shaft in a sleeved manner, and can be rotated and fixed. After the above structure is employed, the motor is small in axial size, can save the space, is small in load inertia, and is high in sewing speed. The stator or the rotor can serve as an independent part of the sewing machine, and the motor is small in temperature rise, and is low in noise. Meanwhile, the angle of the needle rod of the sewing machine can be controlled according to the needs, and the motor is convenient in operation, and is high in sewing precision.

Owner:JIANGSUSNGQI GROUP

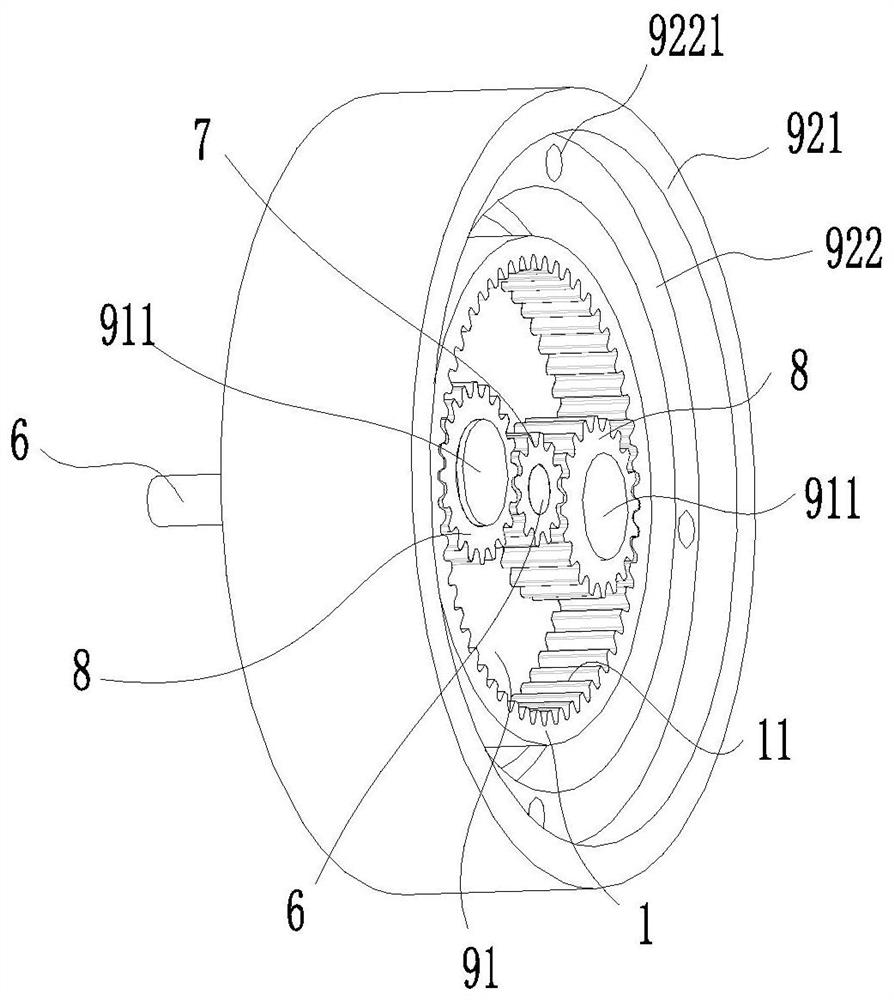

Harmonic reducer adopting multi-stage gear transmission and robot

InactiveCN111946796ALarge reduction ratioWide reduction ratio rangeProgramme-controlled manipulatorGearingGear driveElectric machine

The invention belongs to the technical field of harmonic reducers, and particularly relates to a harmonic reducer adopting multi-stage gear transmission and a robot. The harmonic reducer comprises a first-stage planetary gear transmission mechanism and a second-stage harmonic gear transmission mechanism. The first-stage planetary gear transmission mechanism comprises a wave generator with an innergear, and an input shaft arranged on the wave generator in a penetrating manner. A drive motor is connected to the input end of the input shaft. A sun gear is arranged at the output end. A planetarygear set is arranged between the sun gear and the inner gear of the wave generator. The planetary gear set is engaged with the sun gear and the wave generator at the same time. The second-stage harmonic gear transmission mechanism comprises a flexible wheel. The flexible wheel is connected to the outer side wall of the wave generator in a sleeving manner. According to the harmonic reducer, first-stage planetary gear transmission is added in the wave generator, the speed reduction ratio range of the reducer can be effectively enlarged, and the bearing ability of the whole reducer is enhanced.

Owner:GREE ELECTRIC APPLIANCES INC

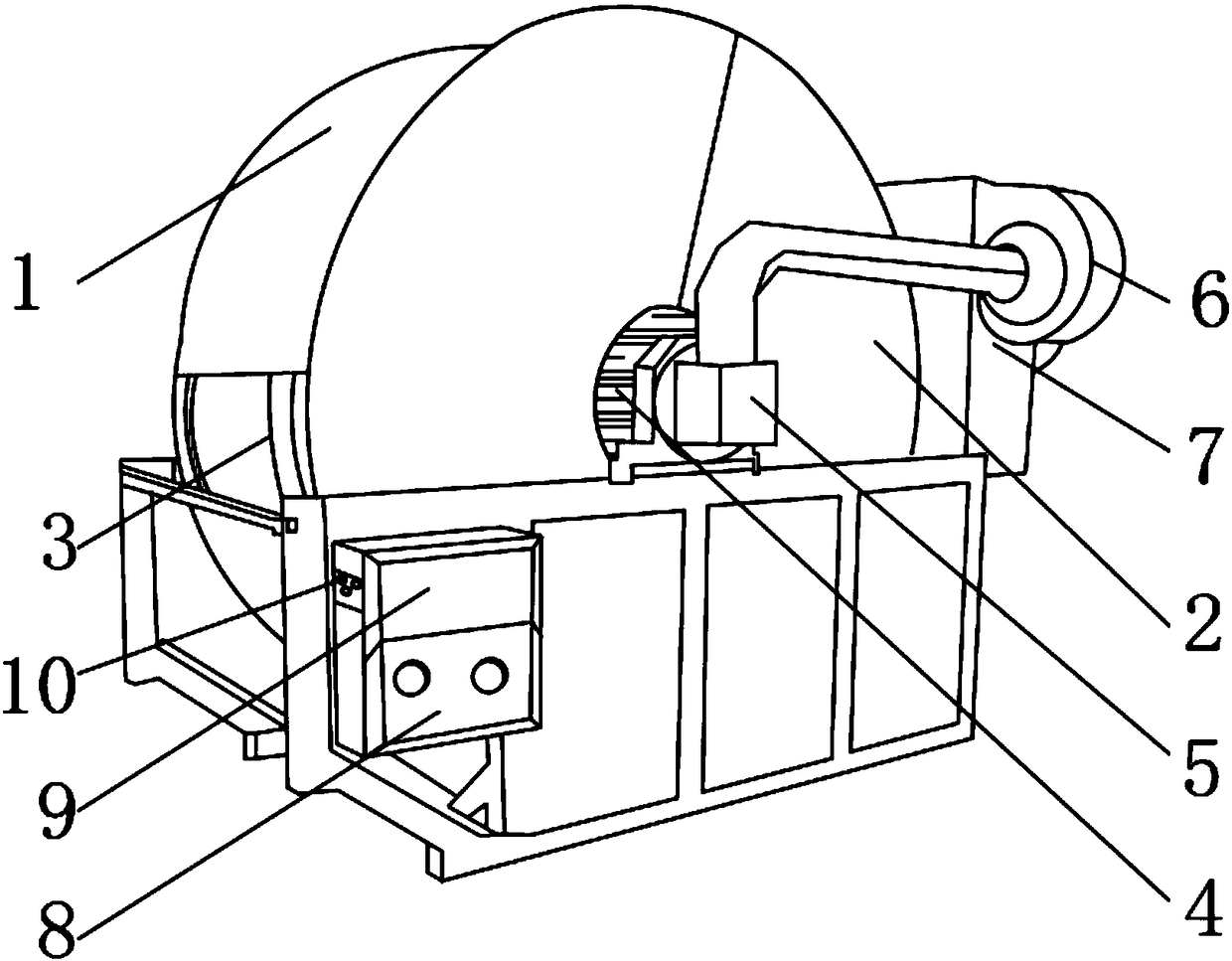

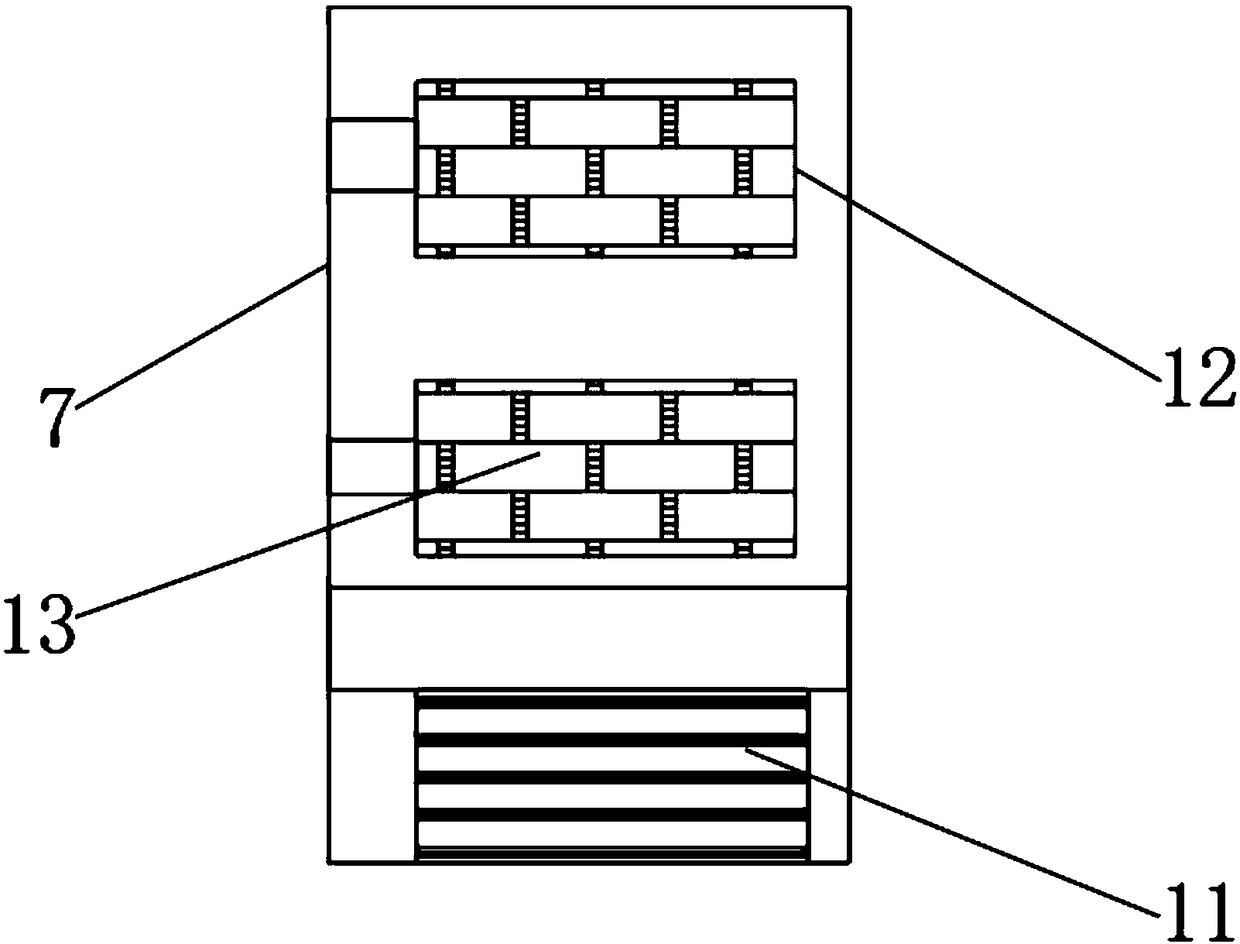

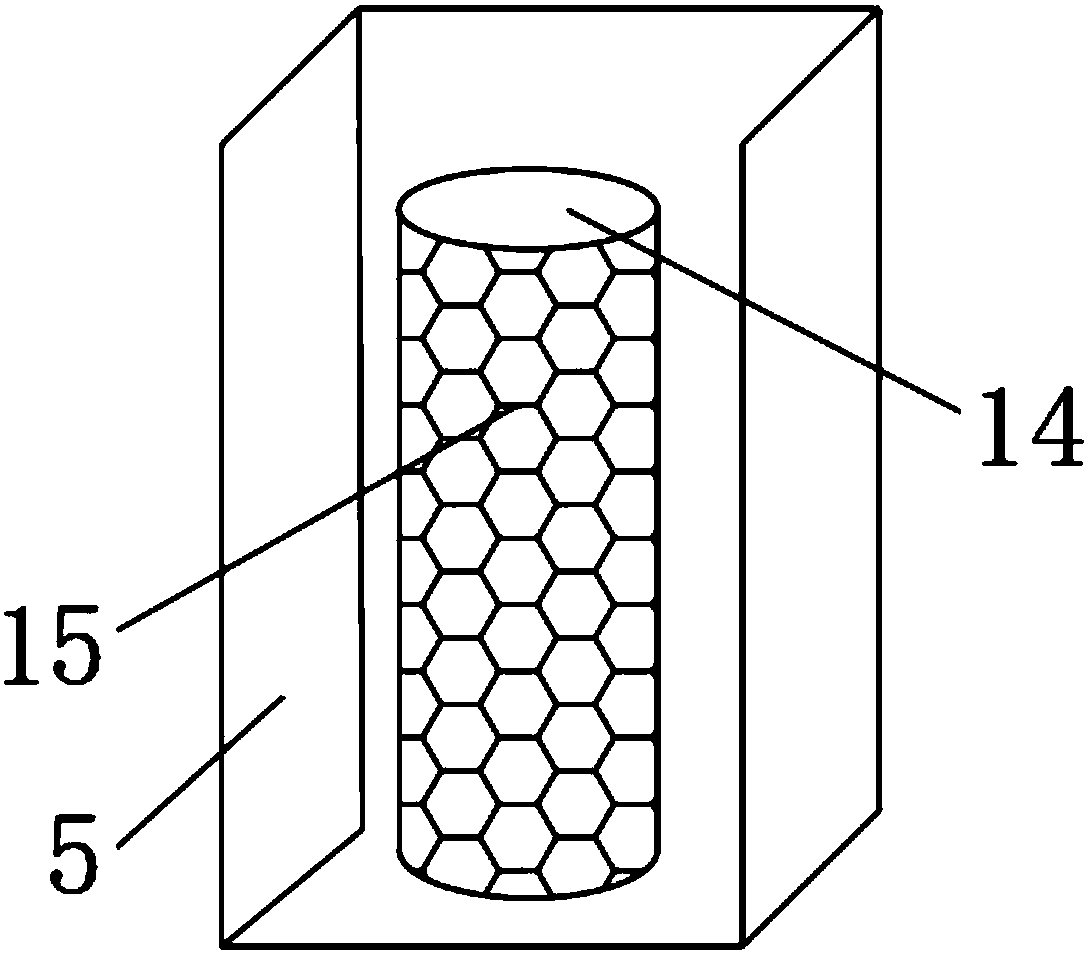

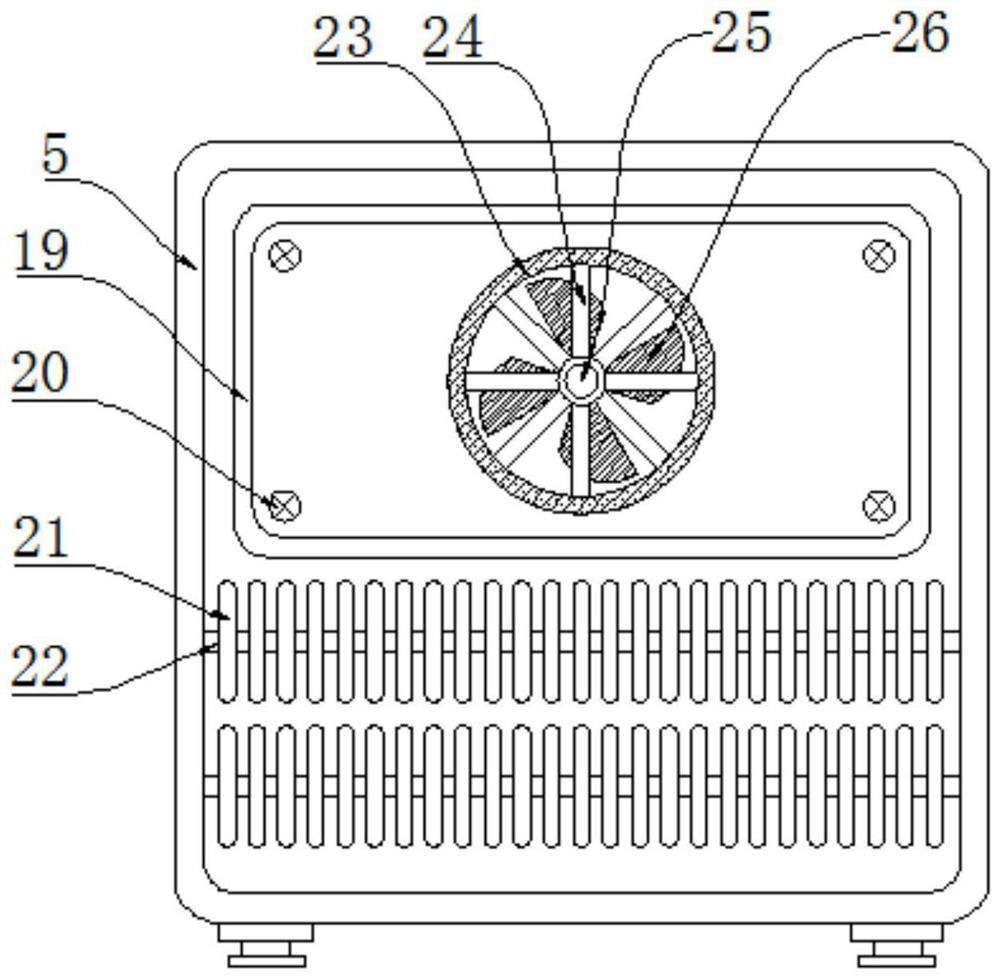

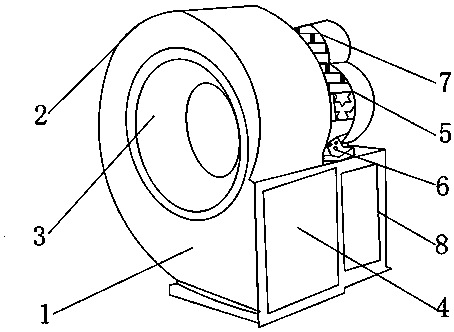

Centrifugal ventilator for drying hot box

InactiveCN108035898AEasy to operateIncrease output torquePump componentsDrying gas arrangementsHot boxImpeller

The invention discloses a centrifugal ventilator for a drying hot box. The centrifugal ventilator comprises a ventilator main body, a case is fixedly mounted on one side of the ventilator main body, and a shaft coupling rod is rotatably connected to the middle of the case. The position, close to one side of the case, of the lower end of the ventilating main body is provided with an air inlet, a motor is fixedly mounted on the position, close to the middle of the case, of the other side of the ventilating main body, and a reducer is fixedly mounted on one side of the motor. According to the centrifugal ventilator for the drying hot box, a bearing seat, the reducer and a contactor are arranged, an impeller can be fixed, the gaps between the impeller and the two edges of the air inlet are kept to be the same, inexistence of abnormal noise after starting is ensured, the output torque is increased while the motor is decelerated, the load inertia is decreased, damage to the motor due to decelerating is reduced, a draught fan can further made to rotate leftwards or rightwards, operation of the centrifugal ventilator is facilitated, the centrifugal ventilator is suitable for various work environments, and better using prospects are brought.

Owner:JIANGSU HENGKANG ELECTRICAL

Mould opening positioning electro-hydraulic control system and die casting machine

The invention discloses an electro-hydraulic control system for mold opening and positioning and a die-casting machine. Wherein, the mold opening and positioning electro-hydraulic control system is applied to a die-casting machine, and the die-casting machine includes a mold opening and locking cylinder, and the mold opening and positioning electro-hydraulic control system includes: an oil tank; an oil pump, and the oil pump is connected to the oil tank; The pipeline of the first reversing valve is connected to the oil pump, and one valve port of the first reversing valve communicates with the rod cavity of the mold unlocking cylinder, and the other valve port communicates with the mold unlocking cylinder. The rodless cavity of the oil cylinder is connected, the first reversing valve is connected with the oil tank through the oil return line; and the pressure control valve is arranged in the oil return line and can be used to control the oil return line Oil pressure on the road. The electro-hydraulic control system for mold opening and positioning according to the technical solution of the present invention can accurately locate the mold opening position.

Owner:GUANGDONG YIZUMI PRECISION MACHINERY

Series-parallel parallel three-degree-of-freedom translational handling mechanism

ActiveCN103264384BCompact layoutSimple structureProgramme-controlled manipulatorHybrid typeDegrees of freedom

A series-parallel combined three-freedom-degree translation carrying mechanism comprises a base, a first linear driving unit, a first slider, a second linear driving unit, a third linear driving unit, a first connection rod, a second connection rod, a third connection rod, a second connection member and an operation tail end. A second slider is arranged on the second linear driving unit, a third slider is arranged on the third linear driving unit, the first linear driving unit is in series connection with the second linear driving unit and the third linear driving unit, and the second linear driving unit is in parallel connection with the third linear driving unit. The series-parallel combined three-freedom-degree translation carrying mechanism is of a series-parallel combined structure, enables distribution of the driving units to be compact, simplifies the structure, meanwhile reduces load inertia and is favorable for improving efficiency.

Owner:SHANGHAI JIYI ENERGY SAVING & ENVIRONMENTAL PROTECTION TECH CO LTD +1

Vehicle parking management equipment and management system for a smart parking lot

ActiveCN112664632BReduce load inertiaAvoid damageGearingIndication of parksing free spacesStops deviceCar parking

The invention disclosed by the invention belongs to the technical field of intelligent parking, and is specifically a vehicle parking management equipment and a management system of an intelligent parking lot, including a gate device, a driving device, a start-stop device and a management system, and its technical solution is as follows: The barrier gate device includes a chassis, two groups are arranged symmetrically in the center of the chassis, an intelligent control box is fixedly installed on one side of the chassis, and a driving device is provided on the inner wall of the chassis, and the driving device includes a supporting plate 2, and the supporting plate Two elliptical boards are fixedly installed on the left side of the two, and the left side of the two oval boards is fixedly installed with a support column two, and the outer wall of the second support column is movably installed with a linear bearing four. The beneficial effect of the present invention is: the deceleration is achieved through the driving device Purpose: The deceleration reduces the inertia of the load at the same time, and the support plate 1 and the support plate 2 replace the traditional tension springs to make the stop bar 1 and the stop bar 2 rise and fall stably, which has the effect of improving the stability of the barrier gate system.

Owner:深圳市信拓网络科技有限公司

a motor

ActiveCN105006907BReduce load inertiaAxial dimensions are compactMagnetic circuit stationary partsMechanical energy handlingElectric machineEngineering

The invention discloses an electric motor, comprising a motor rotor, a motor stator and a fixed frame, the motor rotor and the motor stator are hinged through a front bearing and a rear bearing; at least one elastic component is arranged between the motor stator and the fixed frame, Each elastic assembly includes several suspension assemblies and a first torsion assembly and a second torsion assembly symmetrically arranged between two adjacent suspension assemblies. Each suspension assembly includes several sets of radially arranged first flexible elements. Both the first torsion assembly and the second torsion assembly include several groups of second flexible elements arranged clockwise or counterclockwise. After adopting the above structure, it can absorb the coaxiality deviation and parallelism deviation between the load shaft end and the output shaft of the servo motor, without over-constraint; and the axial dimension is compact, the load inertia of the mechanism is small, and high-speed machining can be realized; Constraints, no mechanism internal force, constant air gap between motor rotor and motor stator, and can be applied to high-speed, heavy-duty applications.

Owner:NANJING UNIV OF POSTS & TELECOMM

High-precision and fast driving mechanism of vertical axis of CNC machine tool

ActiveCN113695962BFast dynamic responseGuaranteed high-precision transmissionFeeding apparatusMaintainance and safety accessoriesNumerical controlGear drive

The invention relates to a high-precision fast driving mechanism for the vertical axis of a numerical control machine tool, comprising a slide plate and a ram, the ram slides vertically along the outer surface of the slide plate, the bottom of the ram is connected with a tool, and symmetrically arranged on the left and right sides of the ram The linear guide rail is slidingly connected with the slide plate; the upper support seat of the screw is symmetrically arranged on the left and right sides of the top of the ram, the lower support seat of the screw is arranged symmetrically on the left and right sides of the middle of the ram, and the upper support seat of the screw on the same side Leading screws are connected with the lower supporting base of the leading screw, and a direct drive motor is coaxially matched on each leading screw, and the motor base of the direct drive motor is connected on the slide plate. The high-precision fast drive mechanism avoids the transmission gap generated by gear drive, ensures the high precision and dynamic response speed of the transmission chain, and is easy to realize large-stroke high-precision drive.

Owner:通用技术集团沈阳机床有限责任公司

A multi-robot intelligent collaborative production system

ActiveCN107032112BEasy selectionImprove exercise efficiencyConveyor partsProduction lineIndustrial robot

The invention relates to a multi-robot intelligent joint production system, and belongs to the field of industrial robots. The multi-robot intelligent joint production system comprises a re-constructable rack, a production line conveying component, a plurality of high-speed parallel picking and placing robots and a plurality of posture adjustable material carrying robots. The re-constructable rack is of a truss structure, the high-speed parallel picking and placing robots are fixedly connected with the re-constructable rack, the production line conveying component is located in the lower space of the re-constructable rack, and the posture adjustable material carrying robots move on the two sides of the production line conveying component. To-be-treated goods are conveyed to one end of the production line conveying component from the previous production link through the posture adjustable material carrying robots, and after being subjected to sorting or assembling treatment through the high-speed parallel picking and placing robots, the to-be-treated goods are carried to the next production link through the posture adjustable material carrying robots located at the other end of the production line conveying component. The multi-robot intelligent joint production system has the beneficial effects that production resource configuration is flexible, the production efficiency is high, the rapidness of picking and placing subsystems is good, and the moving flexibility and stability of carrying subsystems are high.

Owner:TSINGHUA UNIV

A main transmission mechanism of an all-electric servo CNC turret punch press

Owner:NANJING UNIV OF POSTS & TELECOMM

A stator and rotor split motor for sewing machine

ActiveCN105099008BReduce axial sizeReduce load inertiaMagnetic circuit rotating partsMagnetic circuit stationary partsLow noiseGrating

The invention discloses a stator and rotor split type motor used for sewing machines, which is connected with the head of the sewing machine and includes a stator, a rotor, an integrated encoder and a rear cover, the rotor is a hollow shaft, and the rotor, the integrated encoder and the rear cover The cover is coaxially and fixedly set on the sewing machine main shaft in the sewing machine head in turn, and the stator is fixedly connected with the sewing machine head; the integrated encoder is connected with the sewing machine needle bar, and can control the angle of the sewing machine needle bar. The encoder seat is provided with a height-adjustable encoder mounting column. The grating assembly includes a grating bracket, a grating sheet, a grating pressure ring and a retaining spring. The grating bracket is coaxially set on the sewing machine main shaft and can be rotated and fixed. After adopting the above structure, the axial dimension is small, which can save space, the load inertia is small, the sewing speed is fast, the stator or the rotor can be used as a separate part of the sewing machine, and the temperature rise is small and the noise is low. At the same time, the angle of the needle bar of the sewing machine can be controlled according to the needs, the operation is convenient, and the sewing precision is high.

Owner:JIANGSUSNGQI GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com