Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

74results about How to "Reduce flight distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

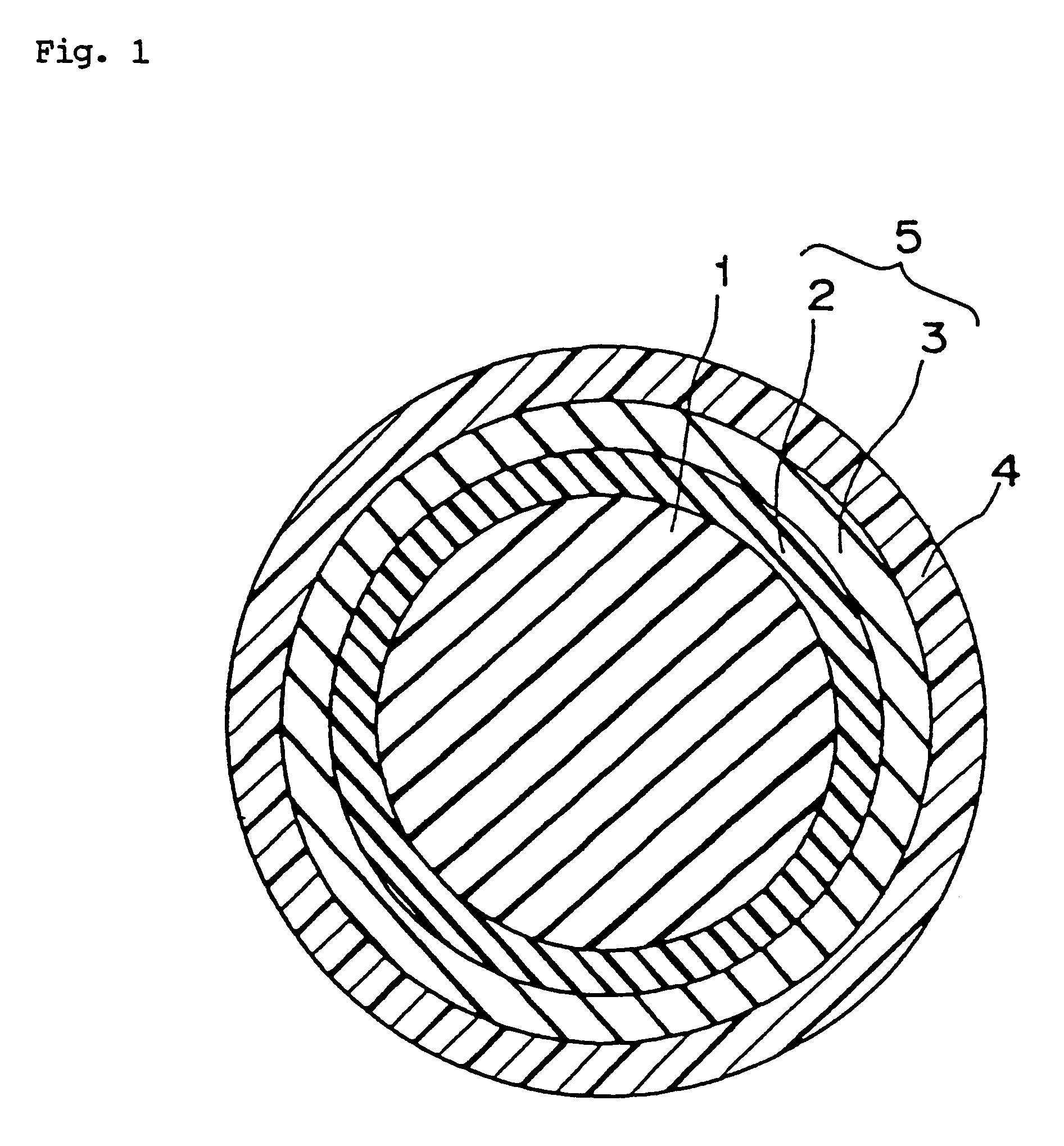

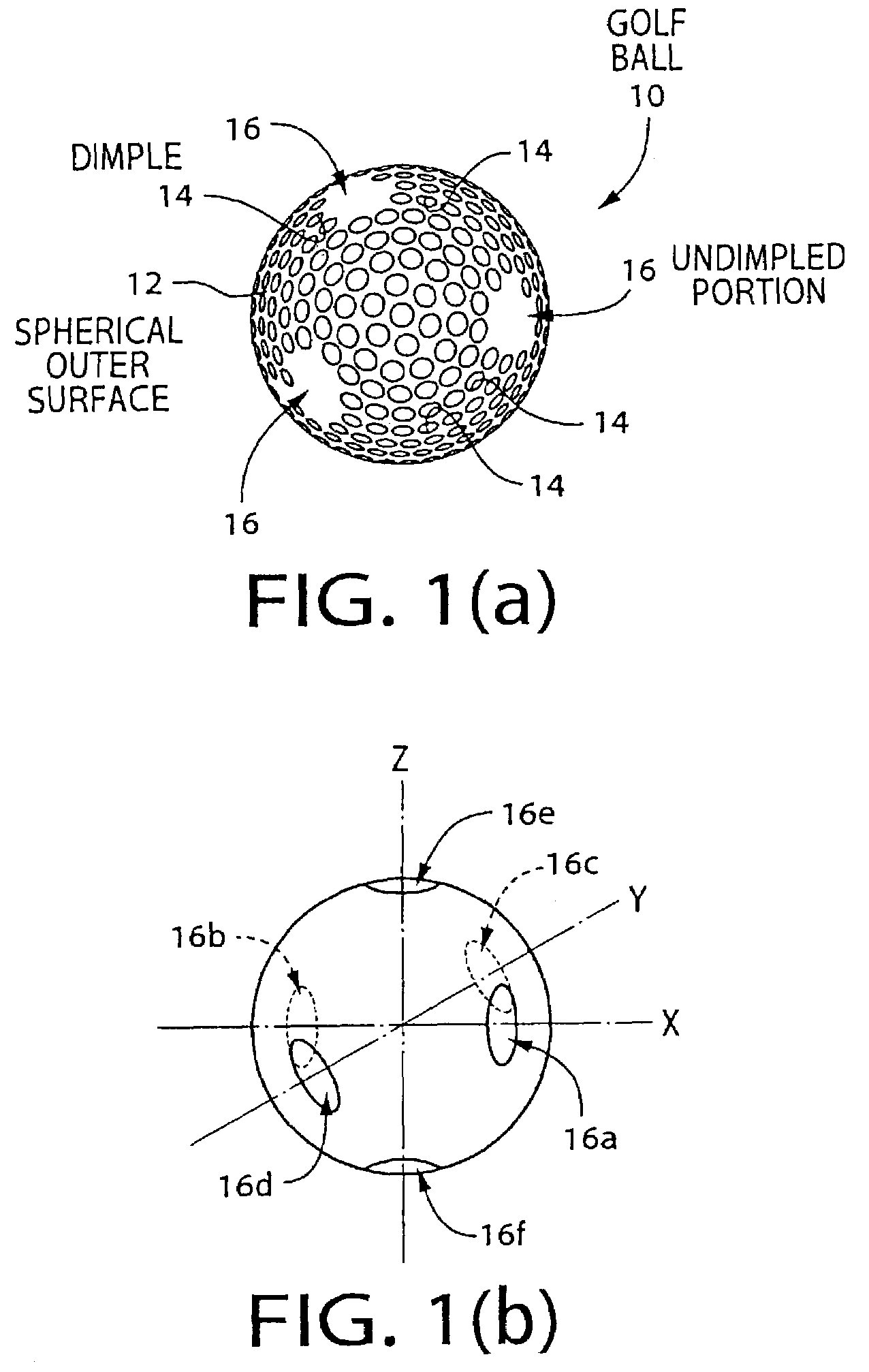

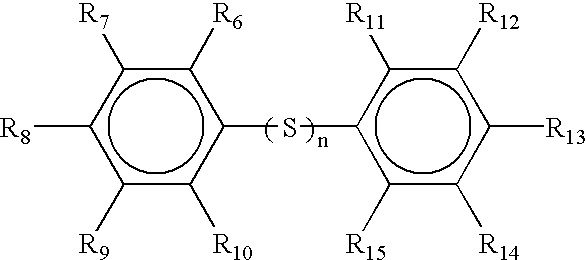

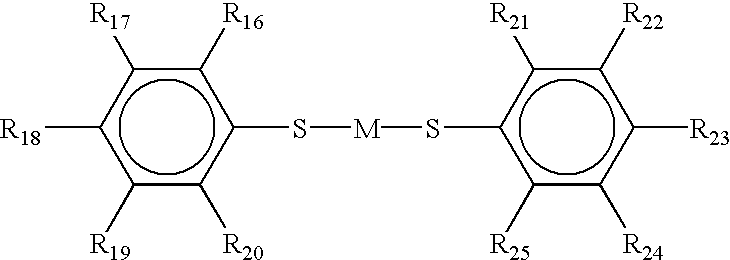

Solid golf ball

InactiveUS6583229B2Exceptional rebound characteristic and flight performanceExcellent shot feelingLayered productsGolf ballsSulfurEngineering

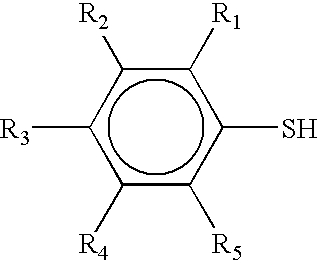

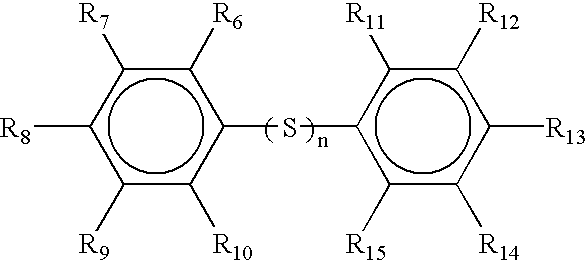

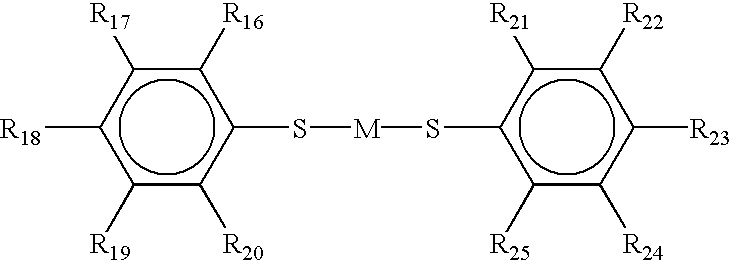

The present invention provides a solid golf ball having exceptional rebound characteristics and flight performance, as well as good shot feel. The present invention relates to a solid golf ball comprising at least one layer of a core, and at least one layer of a cover formed on the core, wherein at least one of the layers of the core is formed by vulcanizing and press-molding a rubber composition comprising a base rubber, co-crosslinking agent, organic peroxide, filler and specific organic sulfur compound which contains substituent groups having a substituent constant of not less than 1.42.

Owner:SUMITOMO RUBBER IND LTD

Four piece solid golf ball

Owner:DUNLOP SPORTS CO LTD

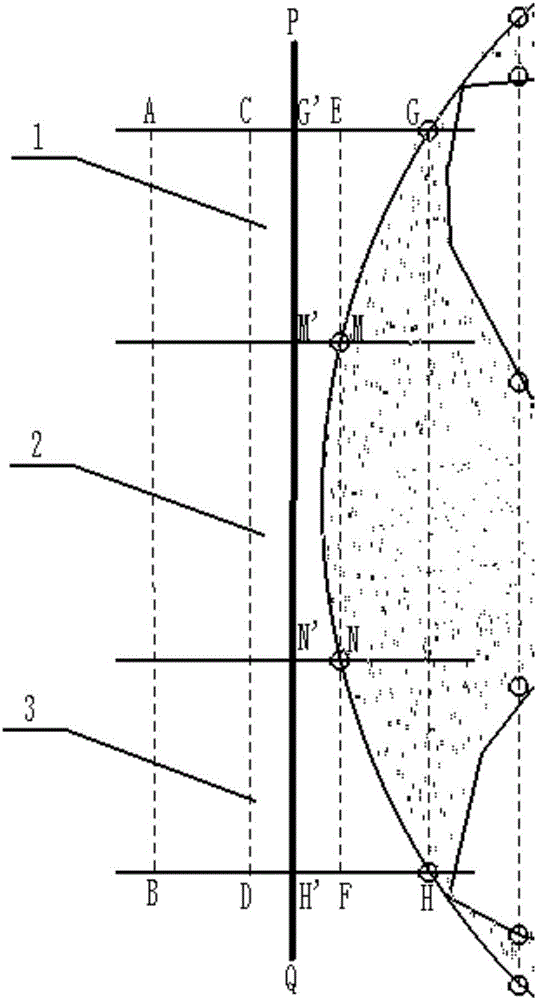

Multi-rising-and-landing-point course planning method used for cruising power of unmanned aircraft

ActiveCN105549619ANo loopholesThe problem of insufficient overlap of those who do not appearPosition/course control in three dimensionsUncrewed vehicleEngineering

The invention discloses a multi-rising-and-landing-point course planning method used for cruising power of a unmanned aircraft, which is characterized by using a rising-and-landing point of the unmanned aircraft as a parameter for planning the track, and dividing a testing zone by combining with the distribution of the rising-and-landing points according to the limitation of the capability of the single flight of the unmanned aircraft. In the invention, the operator of the rotor wing unmanned aircraft can appoint a rising-and-landing point, the course planning system generates an estimation rising-and-landing point and a partitioning course plan of the unmanned aircraft operation capability according to the rising-and-landing points, and the operation scope and the operation parameters which are provided by the operator. The operator can perform checking and adjustment through the generated partitioning course so as to generate a relatively optimized unmanned operation course. Except for reducing the flight distance of the rotor wing unmanned aircraft and improving the working efficiency in the practical operation, and the partitioning course planning can also support the collaborative operation by a plurality of the unmanned aircraft in one test area.

Owner:武汉大势智慧科技有限公司

Multi-piece solid golf ball

InactiveUS6814676B2Reduce the amount requiredReduce reboundGolf ballsSolid ballsElastomerEngineering

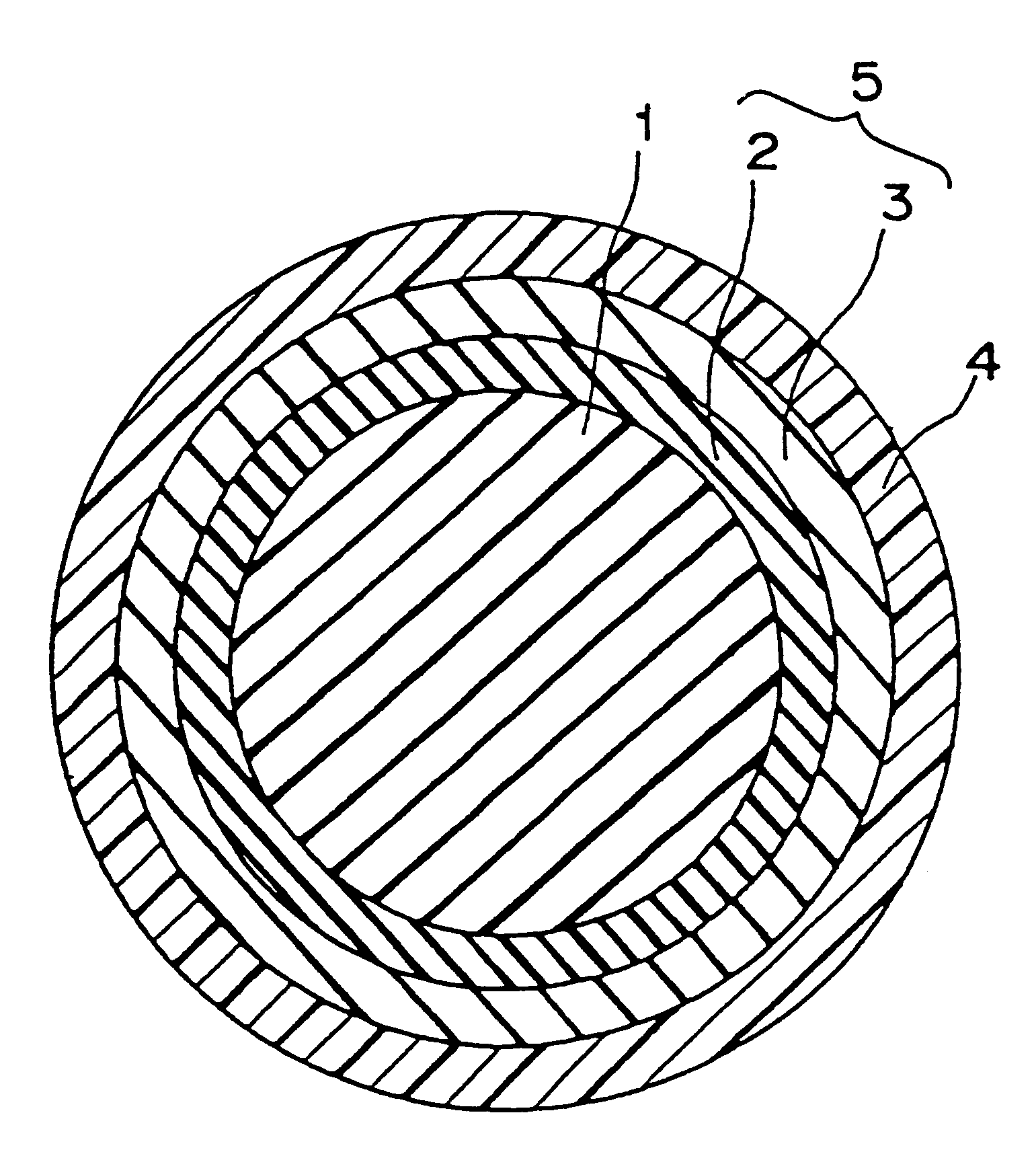

Provided is a multi-piece solid golf ball, wherein an outer layer cover has a polyurethane based elastomer as a main component; a solid core surface Shore D hardness is 50 to 60, an inner layer cover Shore D hardness is 53 to 61, and an outer layer cover Shore D hardness is 52 to 58; an average surface Shore D hardness of the solid core and inner and outer layer covers is 53 to 58; a value obtained by dividing a thickness of the outer layer cover by a thickness of the inner layer cover is 0.48 to 1.00, and a total thickness of the outer and inner layer covers is 1.5 mm to 3.5 mm; and a dimple volume occupying ratio VR value is 0.66% to 0.85%. The golf ball is excellent in flight performance, feeling characteristic, and controllability, and is improved in scratch resistance and durability against hitting.

Owner:BRIDGESTONE SPORTS

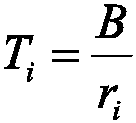

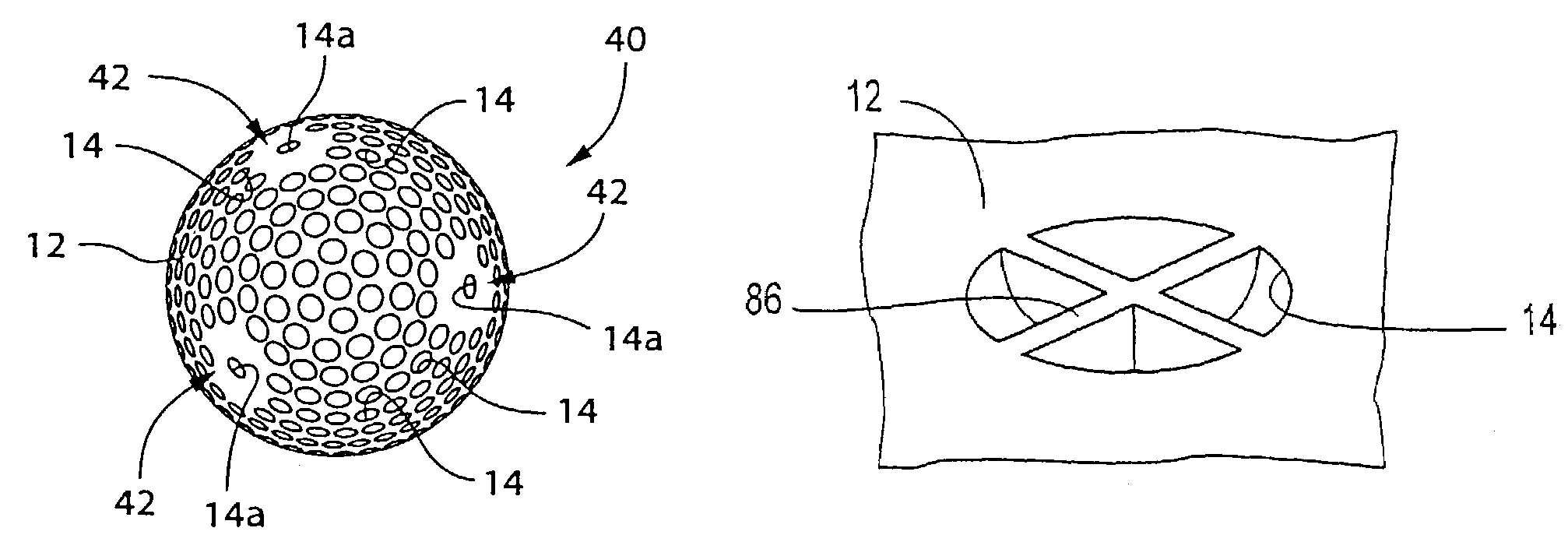

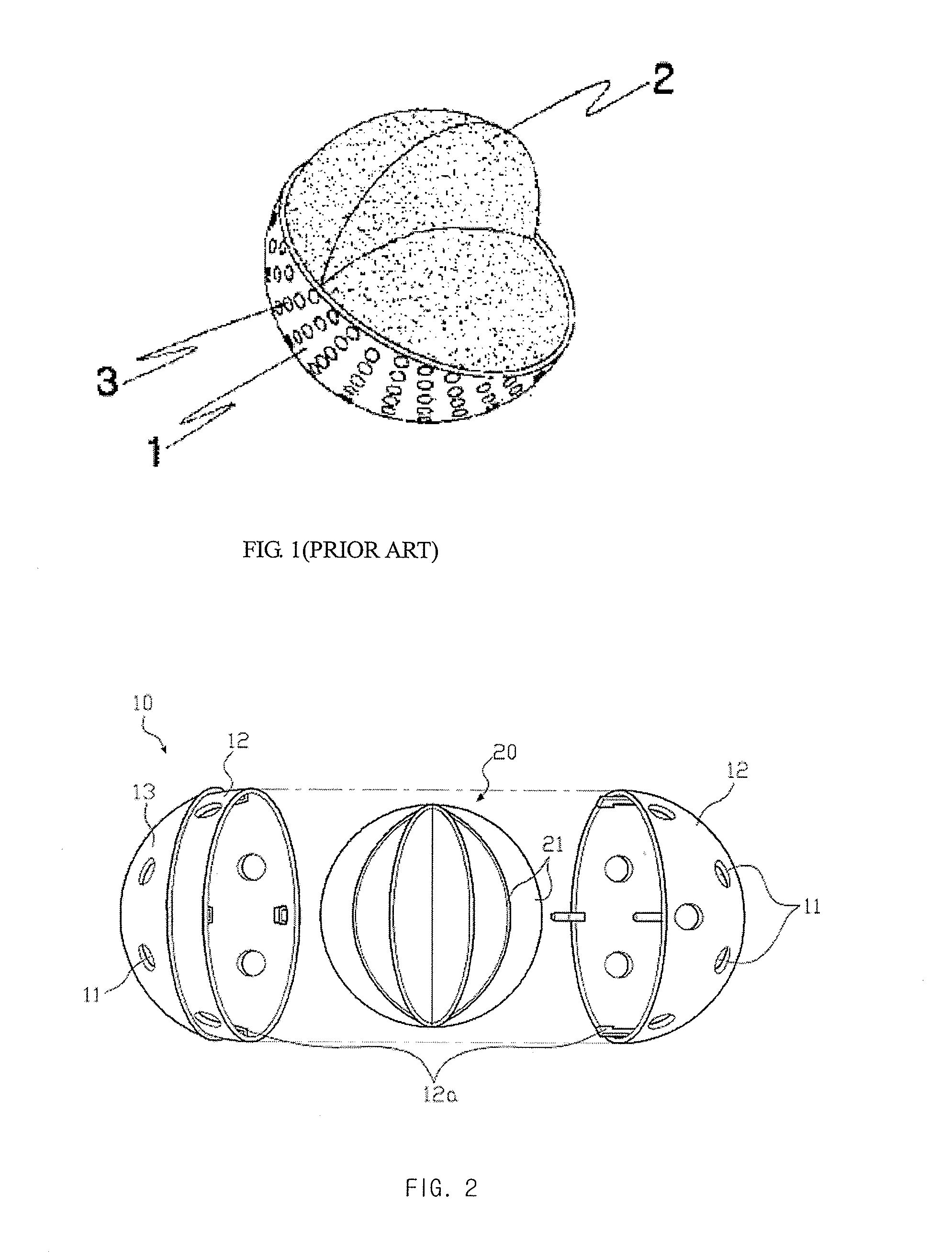

Golf ball dimples forming indicia

A golf ball comprising an outer surface including a plurality of dimples that form indicia. The plurality of dimples take the form of text letters, characters or other symbols and are relatively similar in size to a plurality of conventional shaped dimples or larger. The plurality of dimples occupy a substantial portion of the ball's surface in a repeating, distributed pattern

Owner:ACUSHNET CO

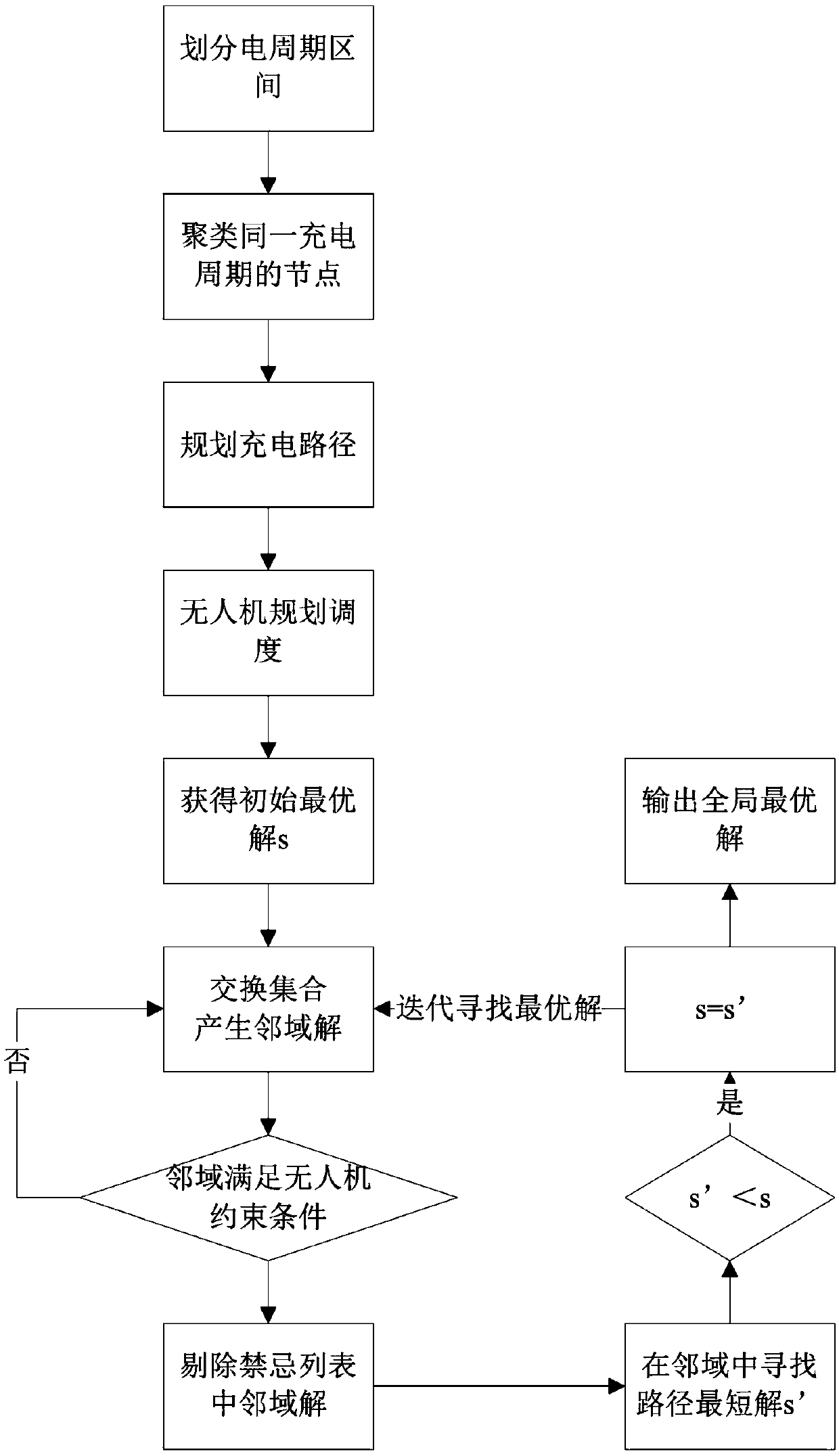

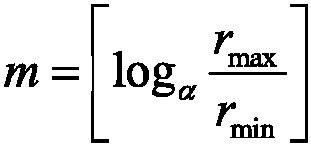

An unmanned aerial vehicle charging task scheduling method in a wireless sensor network

ActiveCN109583665ASolve the problem of energy supplyReduce flight distanceForecastingResourcesCluster algorithmWireless sensor networking

The invention provides an unmanned aerial vehicle charging task scheduling method in a wireless sensor network. According to the method, classification is carried out according to the power consumption rate of sensor nodes, the nodes are divided into different charging tasks according to a clustering algorithm, a set of charging paths are obtained by solving a path problem, scheduling planning ofthe unmanned aerial vehicle is carried out, and finally a final scheduling scheme is obtained through optimization of an emergency algorithm. The invention has the advantages of wide application range, high charging efficiency, low cost and good market application prospect.

Owner:WUHAN FENGHUO KAIZHUO TECH CO LTD

Golf ball dimples forming indicia

A golf ball comprising an outer surface including a plurality of dimples that form indicia. The plurality of dimples take the form of text letters, characters or other symbols and are relatively similar in size to a plurality of conventional shaped dimples or larger. The plurality of dimples occupy a substantial portion of the ball's surface in a repeating, distributed pattern.

Owner:ACUSHNET CO

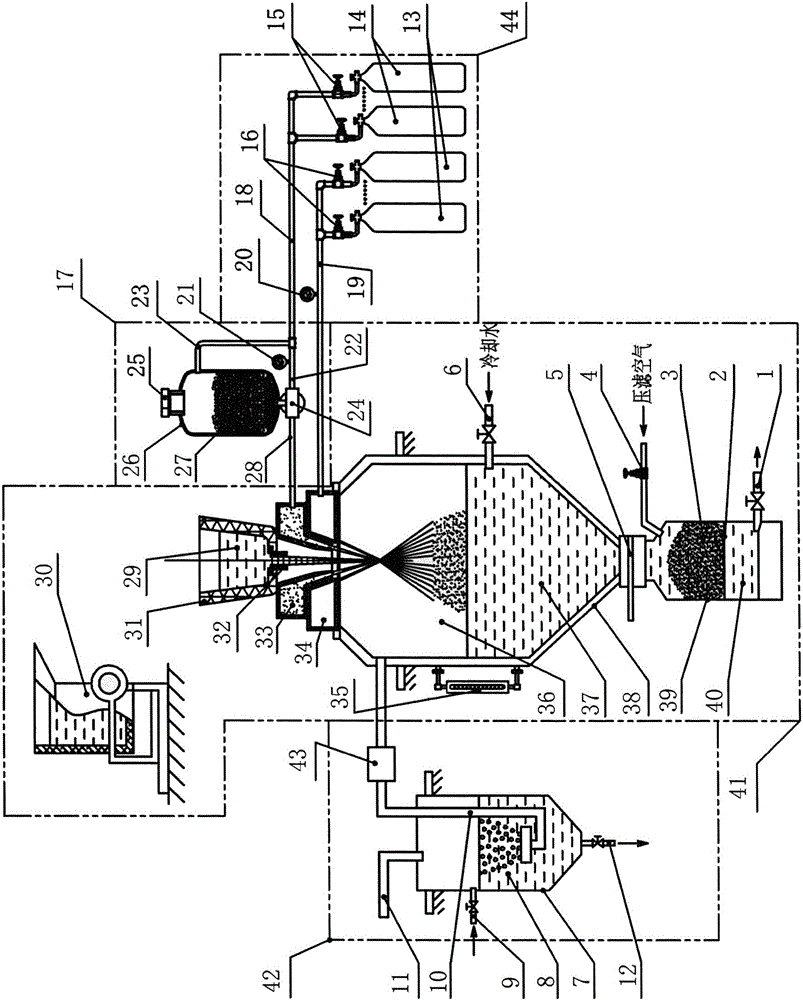

Free-falling powder mixing gas atomizing water-cooling fast-setting magnetic abrasive preparing equipment

The invention provides free-falling powder mixing gas atomizing water-cooling fast-setting magnetic abrasive preparing equipment which comprises a double-nozzle atomizing and water cooling device (41), a spiral mixed powder conveying device (17), a water seal dust removing device (42) and a gas station (44). In the atomizing process, a low-pressure mixed powder jetting nozzle and a high-pressure gas flow nozzle are adopted, and therefore the problem that when a single nozzle is used, erosive wear is caused is solved; a free-falling manner is adopted, and therefore the problems that erosive wear to a molten metal flow guide pipe is caused and molten metal flows back and is sprayed upwards are avoided; a cooling manner of water cooling and fast setting is adopted, the problem that hard abrasive particles drift away from a metal matrix and the problem of control over the depth of distribution are solved, and hard abrasive is controlled to be distributed on a surface shallow layer of the magnetic abrasive; meanwhile, the flight distance of powder mixed molten metal drops is shortened, and the overall height of the free-falling atomizing and condensing chamber and equipment is reduced. The equipment is new equipment provided for realizing a free-falling powder mixing gas atomizing water-cooling fast-setting magnetic abrasive preparing method and preparing the high-performance magnetic abrasive.

Owner:SHANDONG UNIV OF TECH

Golf ball

InactiveUS20090105012A1Improve spinning stabilityThickness minimizationGolf ballsSolid ballsEngineeringGolf Ball

Golf ball 2 of the present invention has core 4, cover 10 situated on the external side of the core 4, and paint layer provided to cover this cover 10. The base polymer of the cover 10 is a urethane resin. The base polymer of the paint layer 16 is a urethane resin. The cover 10 has a thickness Tc of 0.1 mm or greater and 0.7 mm or less. The paint layer 16 has a thickness Tp (mm) of 0.015 mm or greater and 0.040 mm or less. The ratio (Tp / Tc) is 0.021 or greater and 0.40 or less. Preferably, the paint layer 16 is formed with two or more layers 18 and 20. Preferably, the base polymer of the paint layer 16 is a two-pack type urethane resin or a two-pack type epoxy resin.

Owner:DUNLOP SPORTS CO LTD

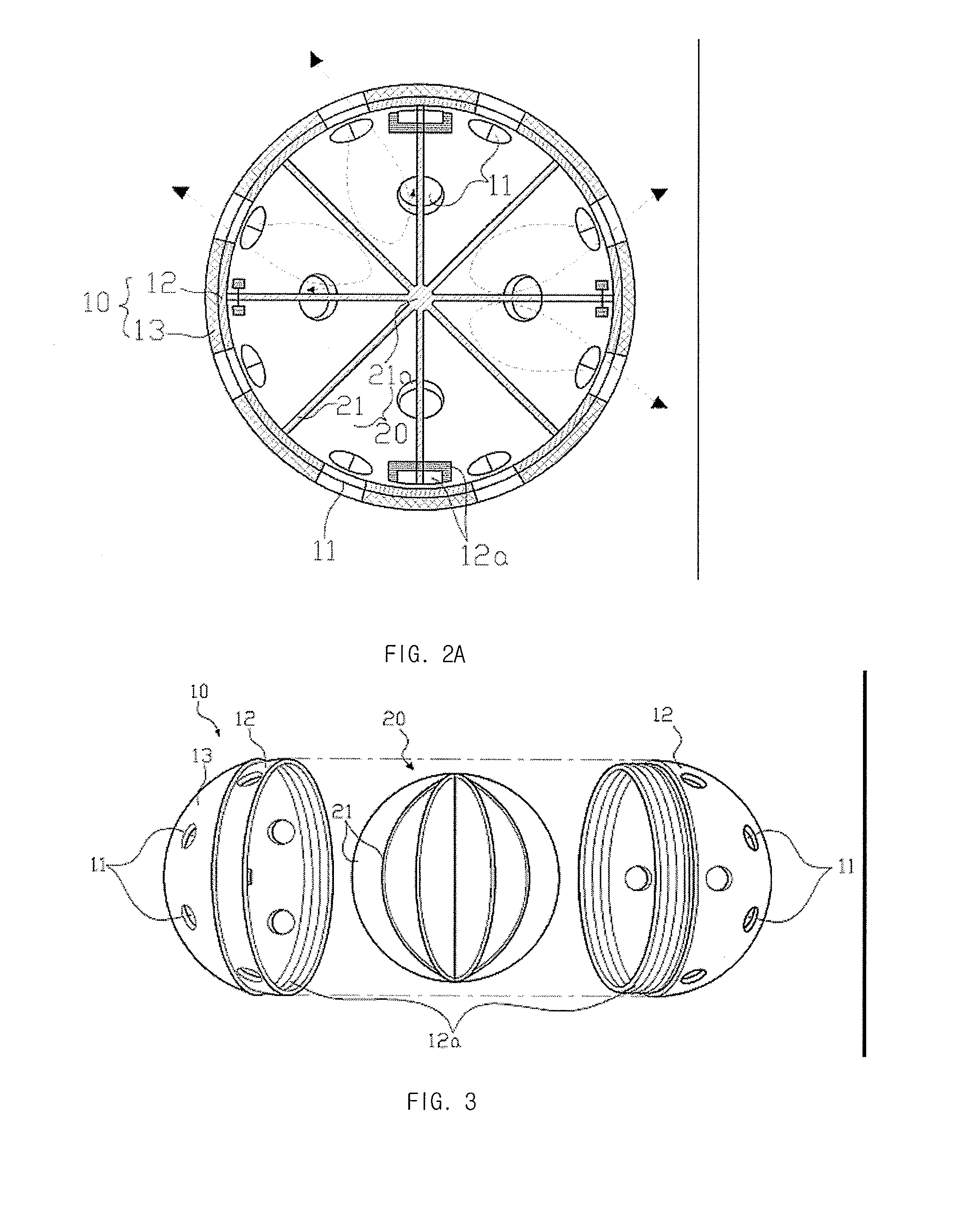

Golf ball with improved directional stability in putting stroke

A golf ball having a predetermined radius, and a spherical outer surface with a multiplicity of dimples formed therein. A protrusion is formed in each of the dimples which are located in hit portions having a diameter of 5–15 mm, or alternatively, is formed in each of all the dimples. The protrusion has a distal end whose radial distance from the center of the golf ball is equal to the predetermined radius of the golf ball. The protrusion has a partition wall which divides a space in each dimple into a plurality of segmental spaces. The protrusion may have two partition walls which are perpendicular to each other and intersect at right angles for dividing a space in each of the dimples into four segmental spaces.

Owner:SUNRISE ENTERPRISE

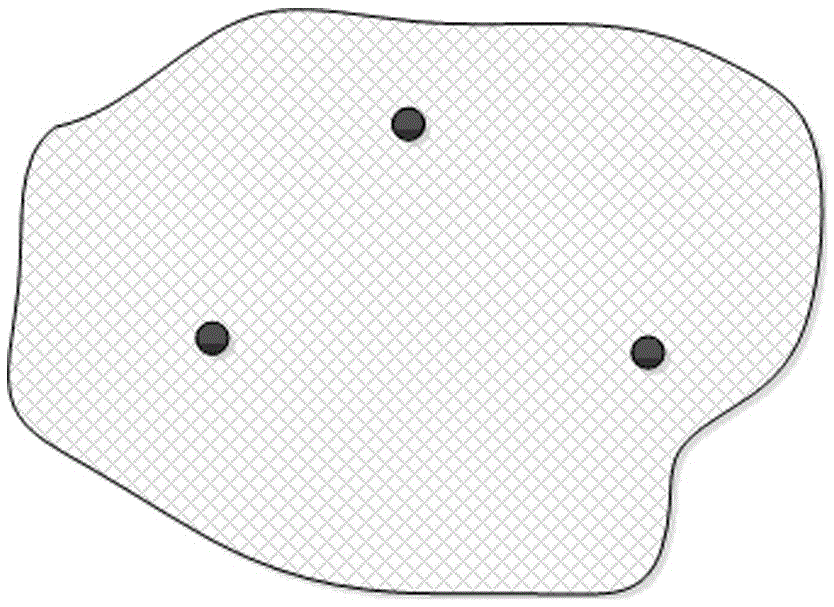

Landscape plant sowing method based on unmanned aerial vehicle (UAV)

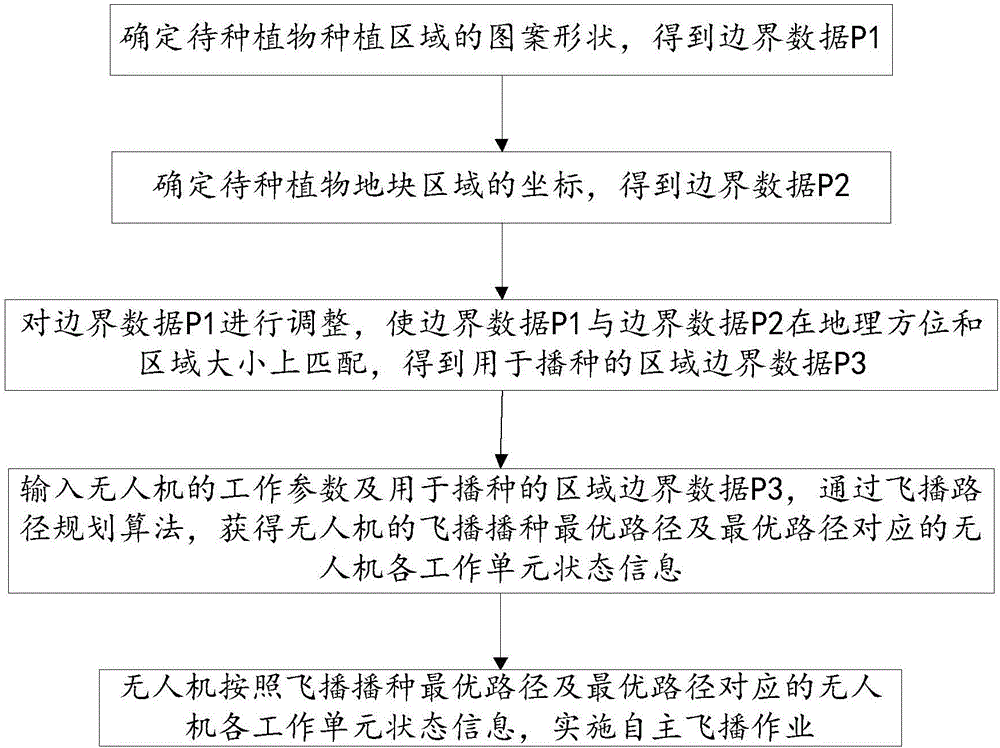

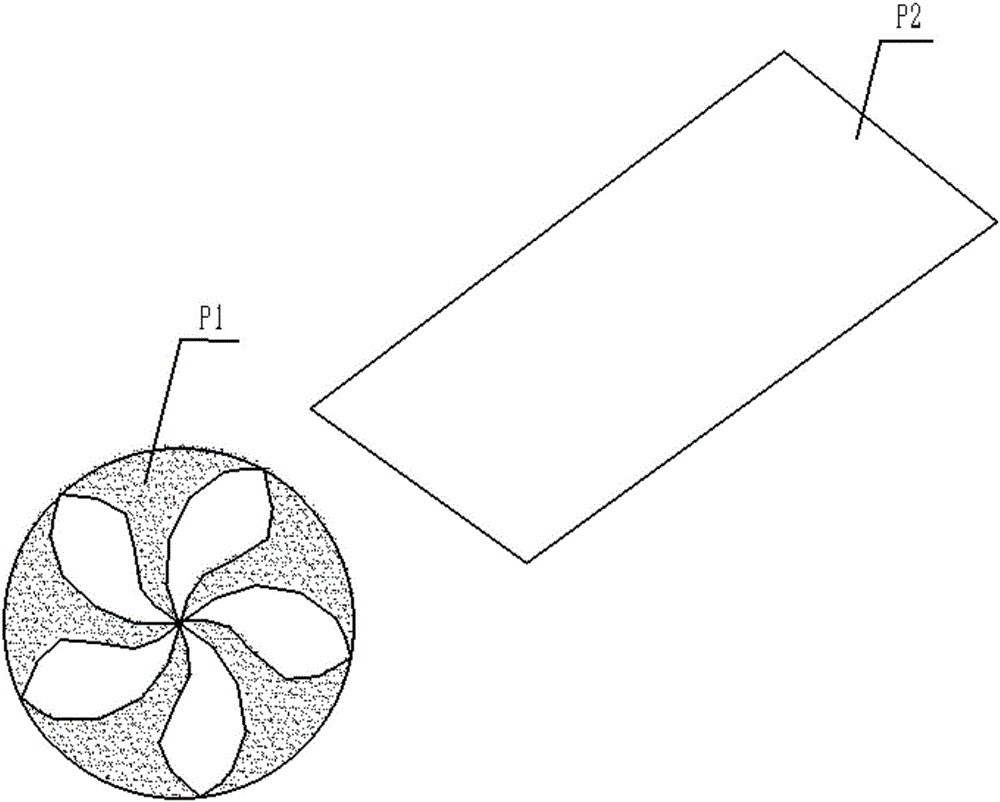

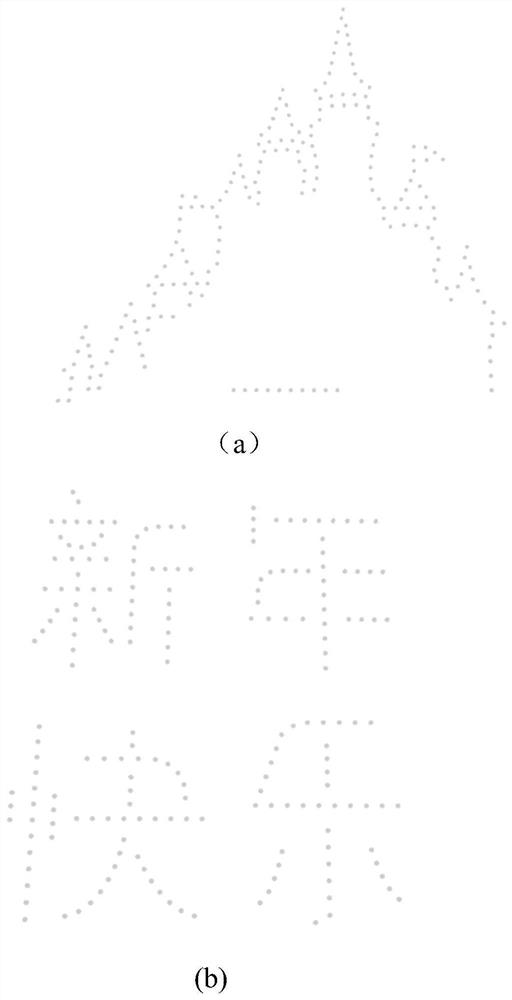

ActiveCN107179776APrecise and beautiful shapeImprove efficiencyPosition/course control in three dimensionsUncrewed vehicleWork unit

The invention relates to a landscape plant sowing method based on an unmanned aerial vehicle (UAV). The method includes the steps of firstly, determining boundary data P1 of a pattern shape of a growing region where plants are to be grown; secondly, determining boundary data P2 of a to-be-grown plot region; thirdly, adjusting P1 so that P1 and P2 can match in terms of the geographic orientation and region size, and obtaining P3; fourthly, inputting working parameters of a UAV and regional boundary data P3, and obtaining an aerial sowing optimal path of the UAV and corresponding state information of each working unit of the UAV through an aerial sowing path planning algorithm; and fifthly, the UAV executing the autonomous aerial sowing operation according to the aerial sowing optimal path and the corresponding working unit state information. According to the invention, the mechanized automatic operation of large-area complex-model landscape plant growing is realized, the operation efficiency and quality are improved, the algorithm optimizes the row scheduling sequence of the operation of the UAV, the flight time of a non-effective operation period of time is reduced, and the shape of the sowing region is enabled to be more accurate and beautiful.

Owner:HUAZHONG AGRI UNIV

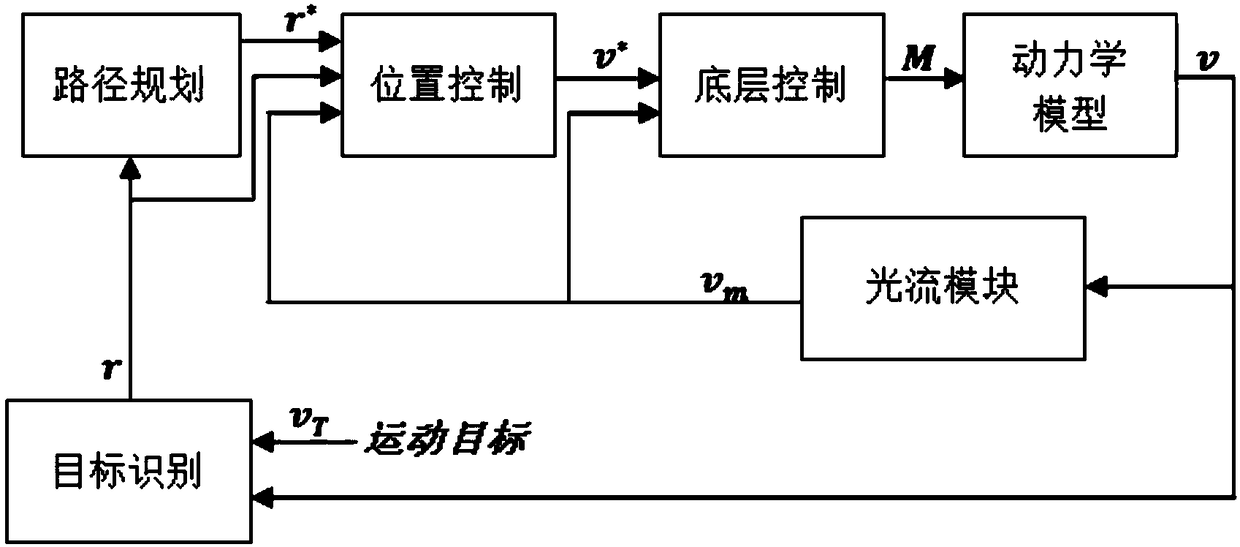

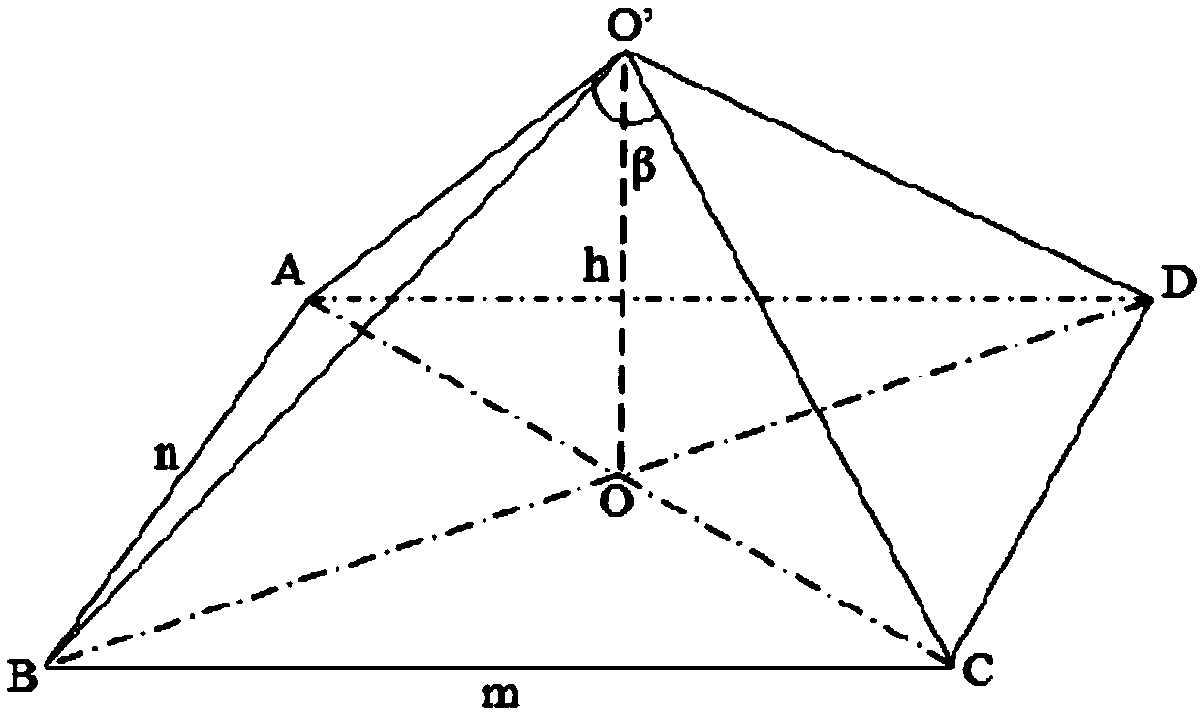

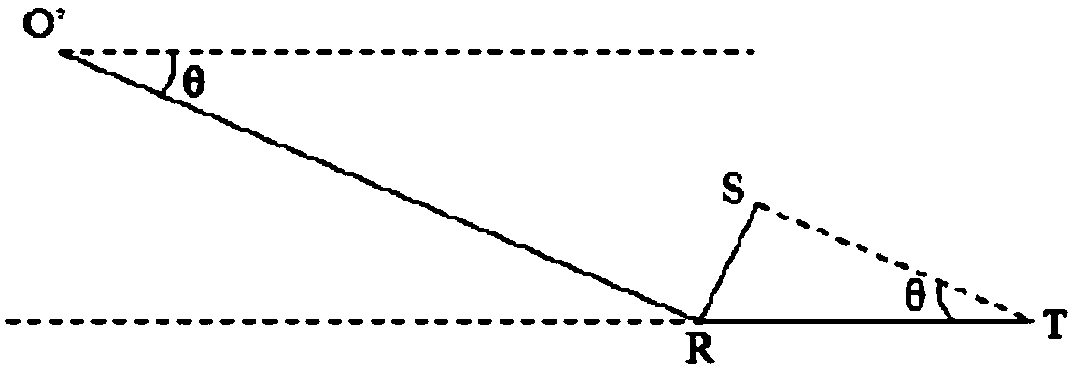

Quadrotor aircraft autonomous landing control method based on navigation point planning and tracking

InactiveCN108710383ASolve the speed measurement interference problemAdaptablePosition/course control in three dimensionsRelative motionPath plan

The invention provides a quadrotor aircraft autonomous landing control method based on navigation point planning and tracking, belongs to the technical field of aircraft control, and aims at realizingautonomous landing of the quadrotor aircraft on the moving target. The method comprises the main steps that 1) the formulation description of the autonomous landing problem is established: the coordinate system and the variables describing the landing process are defined and a relative motion equation is established; and the landing path constraint of the quadrotor aircraft is analyzed; 2) the path planning algorithm of the quadrotor aircraft is designed: the position of the expected navigation point of the quadrotor aircraft in the landing process is planned; and the position of the expectednavigation point is optimized so as to realize smoothing of the expected landing path; and 3) the landing control algorithm of the quadrotor aircraft is designed: the moment of switching the landingcontrol law of the quadrotor aircraft is determined; and the staging landing control law of the quadrotor aircraft is designed. The method has high adaptability and integrates the tracking and landingprocess and also effectively solves the problem of sensor speed measurement interference.

Owner:HARBIN INST OF TECH

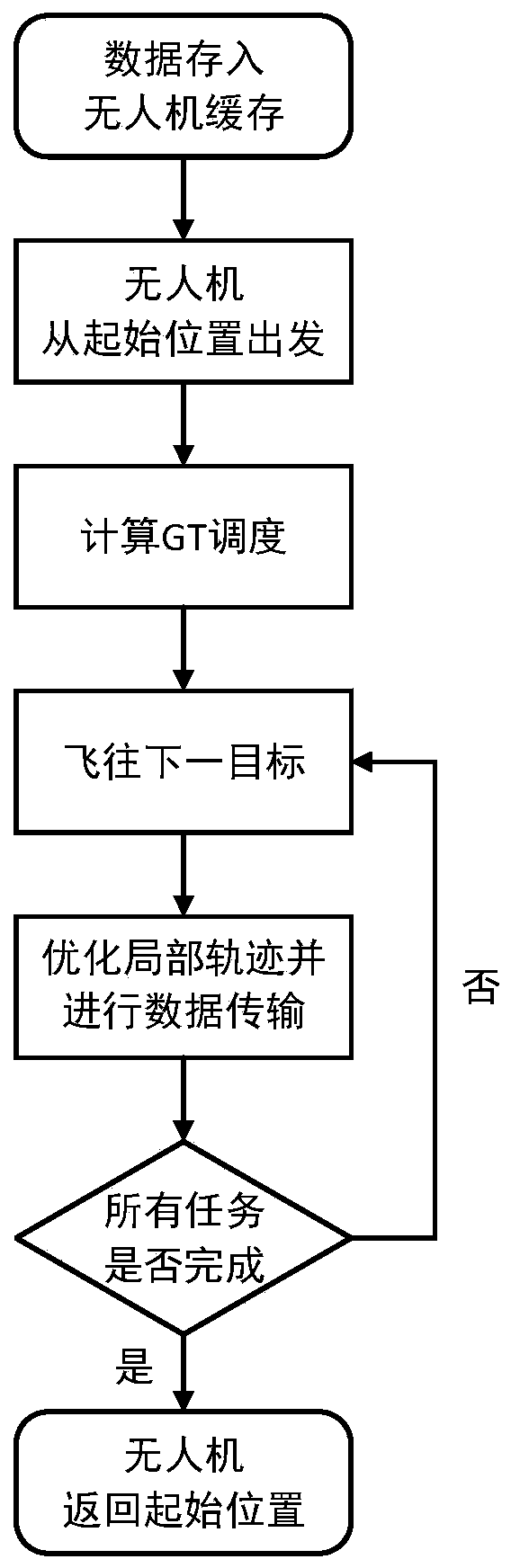

Unmanned aerial vehicle flight trajectory optimization method based on machine learning in edge computing network

ActiveCN109885088AReduce flight distanceReduce flight timePosition/course control in three dimensionsRandom methodEdge computing

The invention discloses an unmanned aerial vehicle flight trajectory optimization method based on machine learning in an edge computing network. The method comprises the following steps: in a cycle, an unmanned aerial vehicle departs from a position where a server is deployed, sequentially passes through all ground terminals and completes a communication task, and then returns to the initial position; when the unmanned aerial vehicle takes off, a flight scheduling table is calculated according to the position distribution of the ground terminals, and then the unmanned aerial vehicle flies through all the ground terminals in sequence according to the flight scheduling table; and in the flying process of the unmanned aerial vehicle, a local optimal trajectory of the unmanned aerial vehicle is calculated by utilizing a random method and a machine learning method in an iteration mode, the local optimal trajectory is added into a global optimal trajectory q, and the unmanned aerial vehicleflies along the global optimal trajectory q. According to the method, the flight distance and the flight time of the unmanned aerial vehicle can be effectively reduced and shortened, the flight cyclecan be shortened, and the transmission efficiency can be improved.

Owner:XI AN JIAOTONG UNIV

Solid golf ball

InactiveUS20030050136A1Exceptional rebound characteristicExceptional flight performanceLayered productsGolf ballsEngineeringGolf Ball

The present invention provides a solid golf ball having exceptional rebound characteristics and flight performance, as well as good shot feel. The present invention relates to a solid golf ball comprising at least one layer of a core, and at least one layer of a cover formed on the core, wherein at least one of the layers of the core is formed by vulcanizing and press-molding a rubber composition comprising a base rubber, co-crosslinking agent, organic peroxide, filler and specific organic sulfur compound which contains substituent groups having a substituent constant of not less than 1.42.

Owner:SUMITOMO RUBBER IND LTD

Multi-piece solid golf ball

InactiveUS20030134694A1Reduce the amount requiredReduce reboundGolf ballsSolid ballsElastomerHardness

Provided is a multi-piece solid golf ball, wherein an outer layer cover is made from a material containing a polyurethane based elastomer as a main component; a surface Shore D hardness of a solid core is in a range of 50 to 60, a Shore D hardness of an inner layer cover is in a range of 53 to 61, and a Shore D hardness of the outer layer cover is in a range of 52 to 58; an average value of the surface Shore D hardnesses of the solid core and inner and outer layer covers is in a range of 53 to 58; a value obtained by dividing a thickness of the outer layer cover by a thickness of the inner layer cover is in a range of 0.48 to 1.00, and a total of the thickness of the outer layer cover and the thickness of the inner layer cover is in a range of 1.5 mm to 3.5 mm; and a dimple volume occupying ratio VR value is in a range of 0.66% to 0.85%. The golf ball of the present invention is excellent in flight performance, feeling characteristic, and controllability, and is improved in scratch resistance and durability against hitting.

Owner:BRIDGESTONE SPORTS

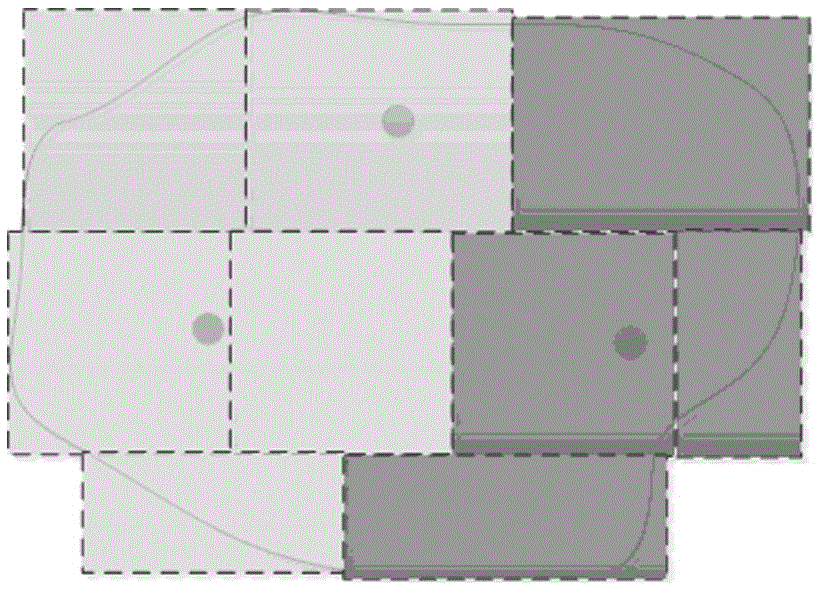

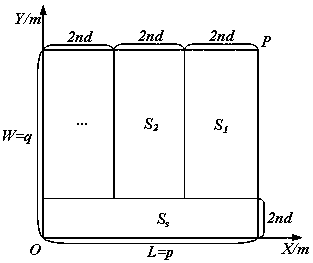

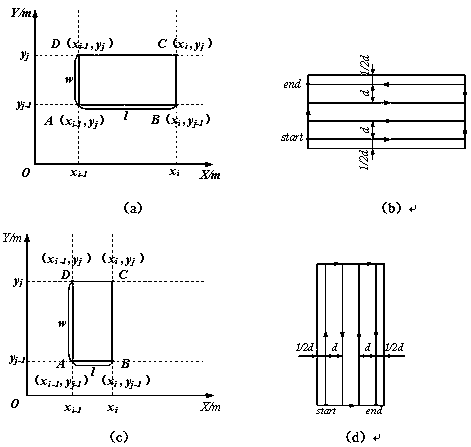

Rout planning method for plant protection unmanned aerial vehicle

InactiveCN110275544AEasy to useImprove portabilityPosition/course control in three dimensionsMathematical modelBoundary values

The invention relates to a rout planning method for a plant protection unmanned aerial vehicle. According to the method, a regional module is used for division to plan a route of a plant protection unmanned aerial vehicle; according to the battery endurance capability and the drug box capacity of the plant protection unmanned aerial vehicle, a threshold parameter for working regional module is determined; and a regional module division principle and classification, module classification, and a corresponding module internal route planning mechanism are provided. On the basis of the mechanism, mathematical models corresponding to I type region division and II type region division of horizontal and vertical work regions are established. A system inputs lengths and widths of the working regions as well as comprehensive characteristic parameters of the plant protection unmanned aerial vehicle; on the basis of the regional modularization division algorithm, a regional module division result with the shortest flight distance as well as boundary values of all models is outputted; and divided modules are obtained and a route plan of the plant protection unmanned aerial vehicle is obtained based on the module internal route planning mechanism. According to the invention, with the route planning method based on modular region division, the total flight distance in working of the plant protection unmanned aerial vehicle is reduced; the comprehensive use performance of the unmanned aerial vehicle is improved; and the ineffective energy consumption losses of the plant protection unmanned aerial vehicle are reduced.

Owner:SHANGHAI UNIV

Golf club

InactiveUS20070293341A1Reduce head weightReduce flight distanceGolf clubsRacket sportsGolf course turfEngineering

Provided is a golf club for leisure and sports of a new concept which is an application of a golf game. More particularly, the golf club includes a head, a shaft and a grip in which the head has a plurality of air vent holes to reduce weight of the head to thereby shorten a flight distance of a golf ball when struck and in flight. Accordingly, an effect of saving a land can be obtained by reducing the golf club's head weight, in view of a practical use of the land, when a golf playing field is constructed. Particularly, the golf club enables leisure and sports of a new concept including a new golf playing method, to thereby lead to a popular base spread of the golf play, and to thus provide public effects of making use of people's spare moments such as recreational pastime and promoting fitness and welfare, by change of work situation such as five working days a week or change of social situation such as member's graying.

Owner:JEONG JI YOUNG

Free-falling double-stage powder mixing gas atomizing water-cooling fast-setting magnetic abrasive preparing method

The invention provides a free-falling double-stage powder mixing gas atomizing water-cooling fast-setting magnetic abrasive preparing method. The method is characterized in that double-stage free-falling nozzles are adopted, the first-stage nozzle is a low-pressure mixed powder flow jetting nozzle, the second-stage nozzle is a high-pressure gas flow nozzle, the low-pressure mixed powder flow jetting nozzle is next to the portion above the high-pressure gas flow nozzle, and by adjusting the height of the water level of cooling water in an atomizing and cooling chamber, the cooling speed of powder mixed molten metal drops is controlled, so that the hard abrasive forms the magnetic abrasive distributed on a surface shallow layer of a magnetic abrasive metal matrix. According to the method, the effect of fully mixing the hard abrasive and molten metal before atomization is achieved, waste of the hard abrasive is avoided, the proportion of the hard abrasive in the magnetic abrasive is controlled, erosive wear to a single-stage nozzle is avoided, and control over the depth of distribution of the hard abrasive on the surface shallow layer of the magnetic abrasive metal matrix is achieved; meanwhile, the flight distance of the powder mixed molten metal drops is shortened substantially, and the overall height of the atomizing chamber and equipment is reduced. The method is a new technical method for preparing the high-performance magnetic abrasive.

Owner:SHANDONG UNIV OF TECH

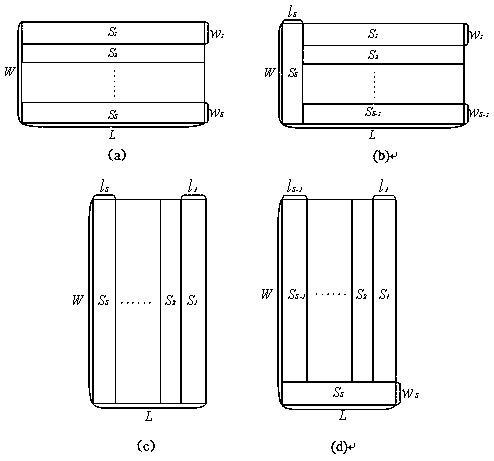

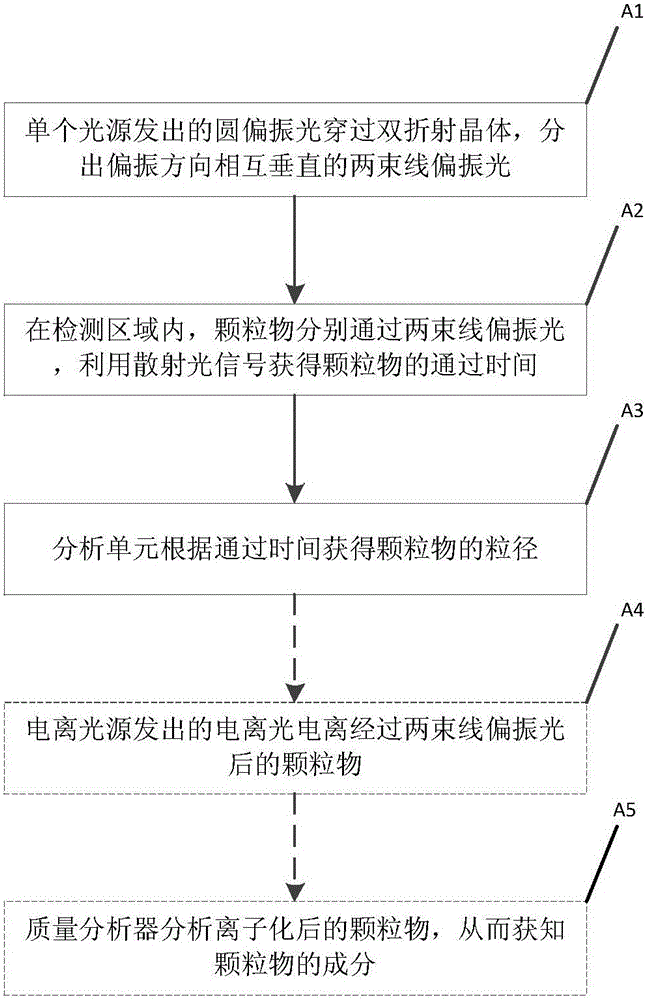

Online particulate matter monitoring device and method based on single light source

ActiveCN106018197AReduce flight distanceImprove particle sizing efficiency and ionization rateParticle size analysisScattered lightOptoelectronics

The invention provides an online particulate matter monitoring device and method based on a single light source. The device comprises the single light source, a birefringent crystal, a detector and an analysis unit, wherein the single light source emits circular polarized light which penetrates through the birefringent crystal to generate two linearly polarized light beams with polarization directions perpendicular to each other, circular polarized light also penetrates through a detection area, the detector is used for converting particulate matter into electric signals through scattered light signals of the two linearly polarized light beams respectively and sending the electric signals into the analysis unit, and the analysis unit is used for obtaining the size of particulate matter in the detection area according to the received electric signals. The device has the advantages of being high in detection efficiency, low in cost and the like.

Owner:FOCUSED PHOTONICS

Modified golf ball

InactiveUS20070281803A1Reduce flight distanceHollow non-inflatable ballsGolf ballsGolf course turfAerodynamic drag

Provided is a ball for leisure and sports of a new concept which is an application of a golf game. The ball relates to a modified golf ball which includes an external member having air vent holes and a core member of a rib form, in which a flight distance is shortened due to resistance of air when struck and in flight. The external member of the modified golf ball is configured to have a spherical outer cover integrated with and overlapped with the outer surface of a hemispherical inner cover. Since the modified golf ball is lightly flied when struck but its flight distance is shortened due to resistance of air, an effect of saving a land can be obtained in view of a practical use of the land, when a golf playing field is constructed.

Owner:JEONG JI YOUNG

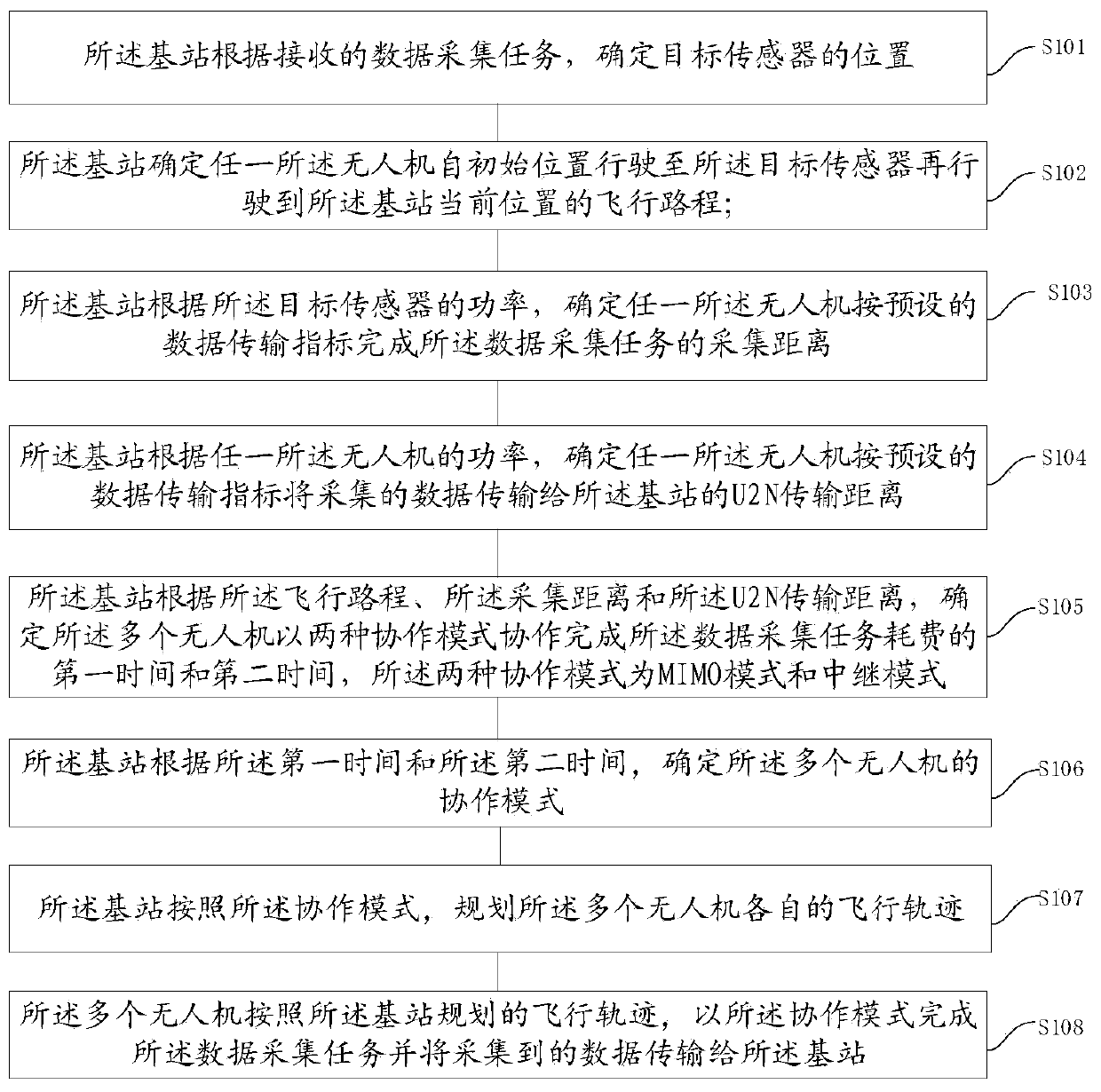

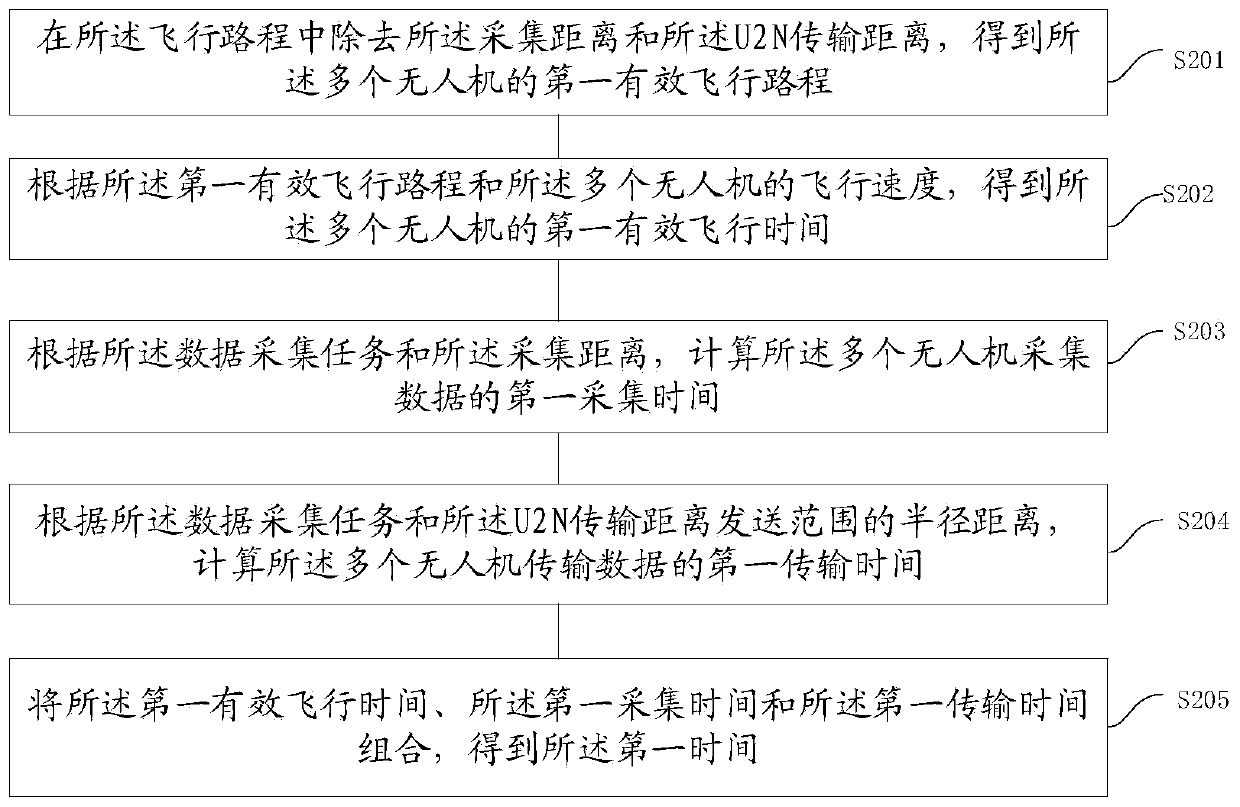

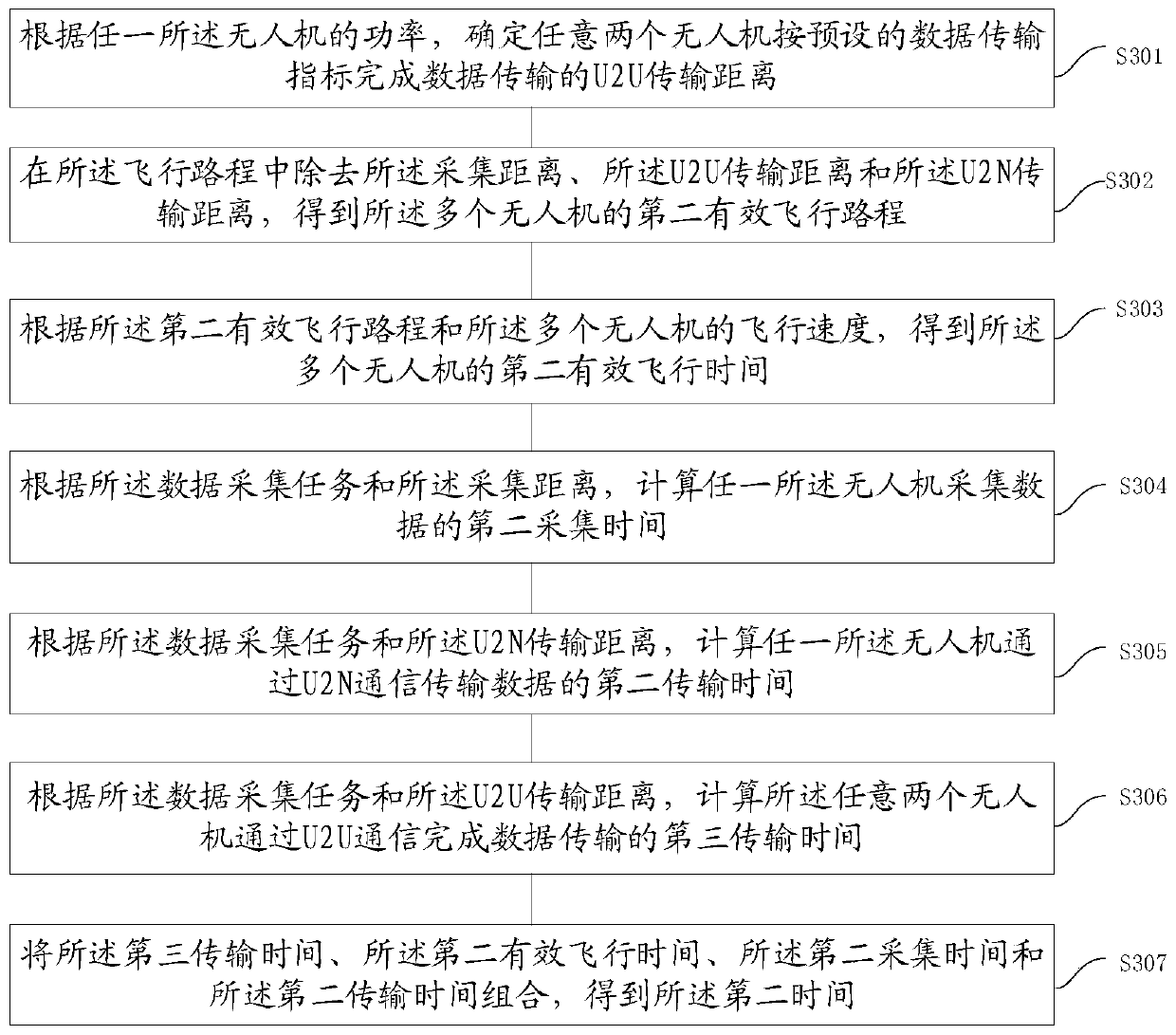

Cellular unmanned aerial vehicle U2X communication mode selection and trajectory design method and device

The invention provides a cellular unmanned aerial vehicle U2X communication mode selection and trajectory design method and device, equipment and a storage medium, and relates to the technical field of unmanned aerial vehicle sensing. According to the invention, an MIMO mode and a relay mode are provided; the distance between collection data and transmission data of an unmanned aerial vehicle is determined according to a preset data transmission index; further, a received specific data acquisition task is used as a basis, time consumed by a plurality of unmanned aerial vehicles in the cellularnetwork for transmitting data in an MIMO mode or a relay mode is calculated; a cooperation mode consuming less time is used as a cooperation mode for multiple unmanned aerial vehicles to complete thecurrent data acquisition task, a flight path of the unmanned aerial vehicles is planned in the cooperation mode, and through U2X communication of the unmanned aerial vehicle, a plurality of unmannedaerial vehicles in the cellular network cooperate to complete the task of collecting data of a ground sensor and transmitting the data to a base station. Thus, the effect of reducing transmission delay is achieved while the communication service quality is guaranteed.

Owner:PEKING UNIV

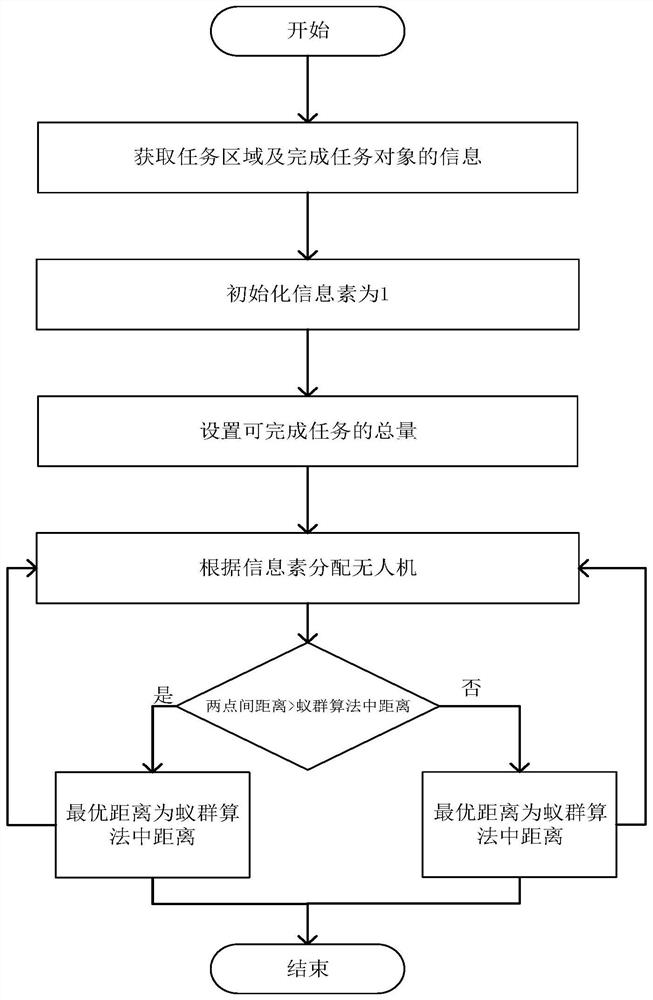

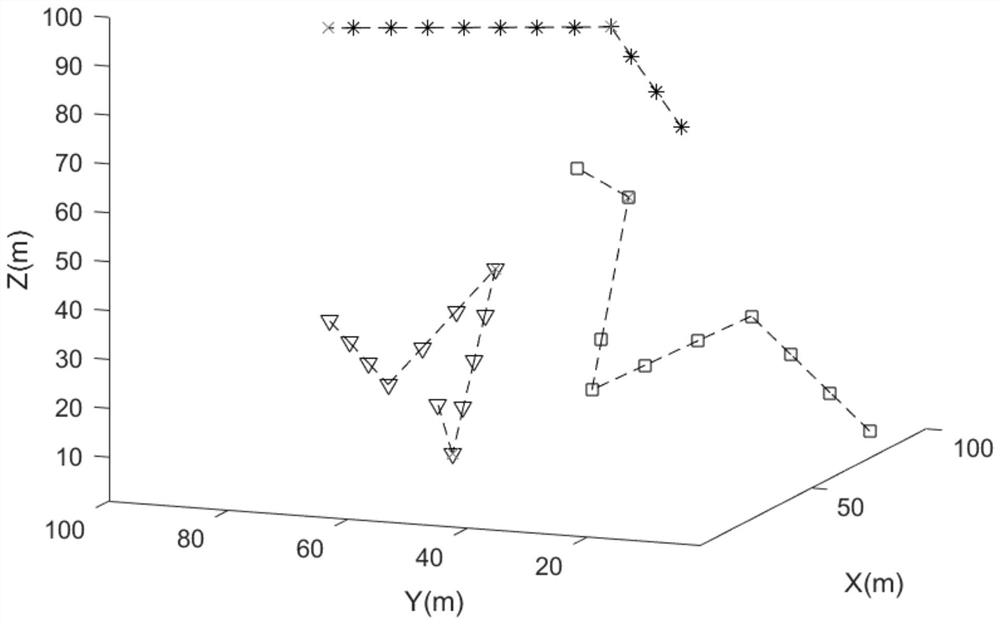

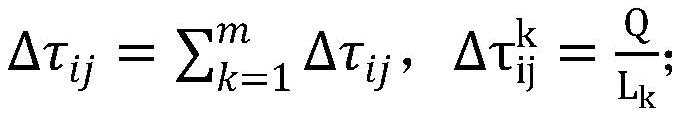

Multi-unmanned aerial vehicle task allocation method based on improved ant colony algorithm

ActiveCN112508369ACalculation speedShorten the timeInternal combustion piston enginesForecastingSimulationUncrewed vehicle

The invention discloses a multi-unmanned aerial vehicle task allocation method based on an improved ant colony algorithm, and the method comprises the steps: carrying out the improvement of the ant colony algorithm, and representing that the movement transfer direction of ants of unmanned aerial vehicles is determined by the pheromone concentration of each unmanned aerial vehicle flight path in the movement process; in the task allocation searching process, ants representing the unmanned aerial vehicle intelligently select a path to be traveled in the next step; the path distance calculated byadopting the ant colony algorithm is compared with the linear distance directly calculated between the two points, the shorter distance is selected as the optimal path for the unmanned aerial vehicleto search for the target, meanwhile, the gradient descent method is adopted for optimization to shorten the flight distance of the unmanned aerial vehicle, and the method is suitable for task allocation of multiple unmanned aerial vehicles. The unmanned aerial vehicles can quickly complete tasks and reduce the flight distance. By adopting the technical scheme of the invention, the task completiontime can be reduced, and the flight distance of the unmanned aerial vehicles during task search is shortened.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

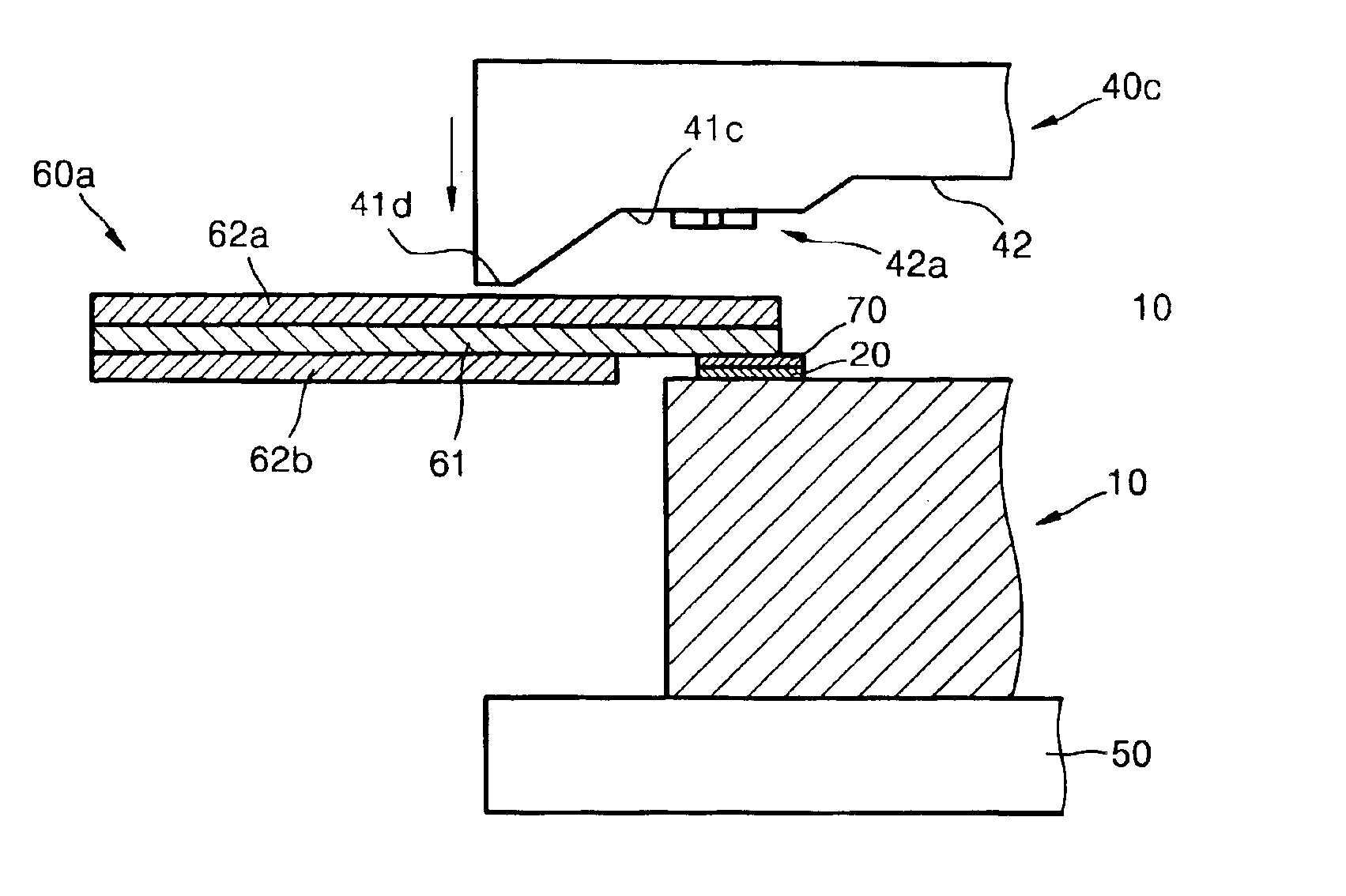

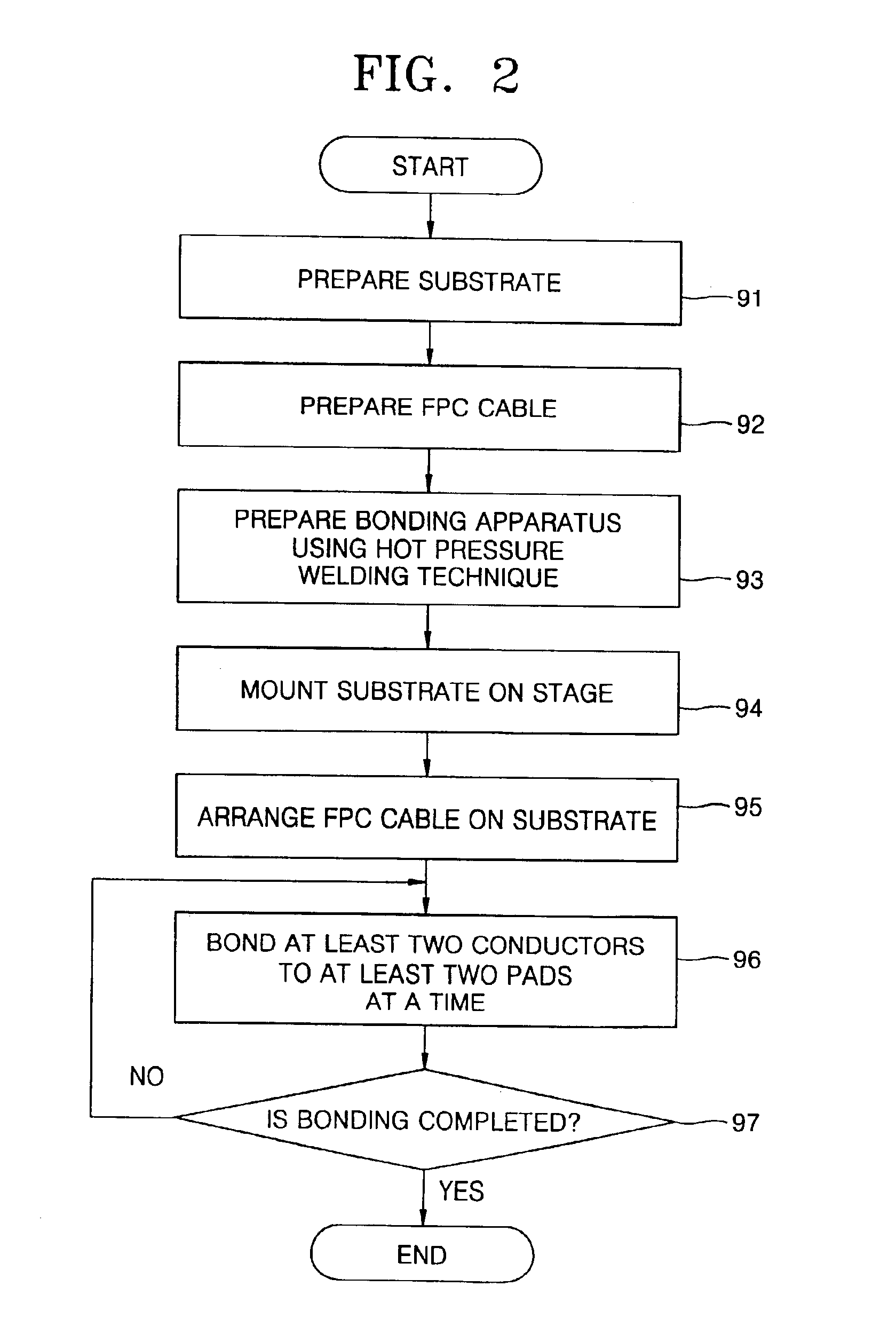

Method and apparatus for bonding a flexible printed circuit cable to an ink jet print head assembly

InactiveUS6902261B2Shorten the timeImprove structural strengthPrinted circuit assemblingPrinted circuit aspectsElectrical resistance and conductanceElectrical conductor

A bonding apparatus and method thereof to bond the bonding portions of an FPC cable to pads of a print head die in order to electrically connect the print head die of an ink jet print head assembly include a stage and a bonding tool. The print head die includes resistive heaters, signal lines connected to the resistive heaters, and electrical pads to connect the signal lines to an outside of the print head die to the FPC cable having conductors having bonding portions facing the pads. The print head die is supported on the stage with the pads facing upward. The bonding tool includes a tip that press bonding portions of the FPC cable against corresponding pads of the print head die placed on the stage, and heats the bonding portions in contact with the pads to bond the bonding portion to the pads. The bonding tool includes a protrusion positioned to align with a position beyond the boundary of the print head die, and that extends lower than the tip, such that, during the bonding operation, the protrusion bends the FPC cable downward. In addition, during the bonding operation, the upper protective film of the FPC cable around the bonding portions are left intact to provide protective layer over the resulting bond, and thus results in less amount of encapsulation over the bond.

Owner:S PRINTING SOLUTION CO LTD

Preparing method for free-falling double-nozzle powder mixing gas atomizing water-cooling fast-setting metal matrix aluminum oxide magnetic abrasive

ActiveCN105665722APrevent splashAvoid wastingTransportation and packagingMetal-working apparatusAlloyHigh pressure

The invention provides a preparing method for free-falling double-nozzle powder mixing gas atomizing water-cooling fast-setting metal matrix aluminum oxide magnetic abrasive. The method is characterized in that aluminum oxide powder is adopted as hard abrasive of the magnetic abrasive, and an alloy composed of iron, silicon, aluminum and copper is adopted as a metal matrix material; upper and lower dual-layer free-falling nozzles are adopted as nozzles, the upper layer free-falling nozzle is a low-pressure mixed powder flow jetting nozzle, and the lower layer free-falling nozzle is a high-pressure gas flow nozzle; water cooling is adopted as a cooling manner, and by adjusting the height of the water level of cooling water in an atomizing and water cooling chamber, the cooling speed of molten metal drops containing aluminum oxide abrasive is controlled, so that the magnetic abrasive with the aluminum oxide abrasive distributed on the shallow layer of the surface of a magnetic abrasive metal matrix is formed; and a spiral mixed powder conveying device is adopted for conveying mixed powder, so that flow of the aluminum oxide abrasive is controlled precisely. According to the metal matrix aluminum oxide magnetic abrasive prepared from the method, aluminum oxide and the metal matrix are combined firmly, the magnetic abrasive has high magnetic abrasive performance, the production technology process is controlled in a programmed manner, the product performance is stable, and the method is suitable for scale production.

Owner:SHANDONG UNIV OF TECH

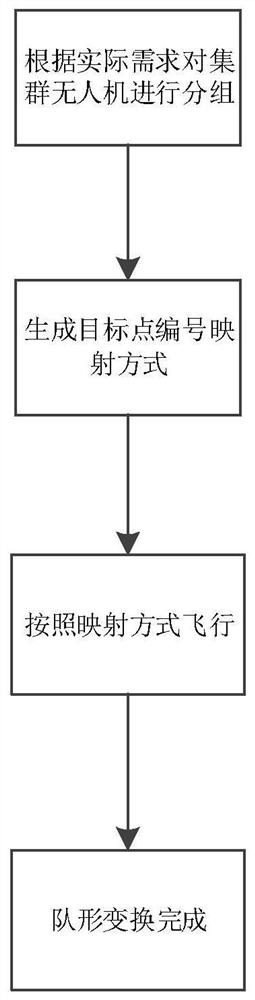

Cluster unmanned aerial vehicle grouping assignment method and system, controller, medium and terminal

PendingCN112631323AReduced path change timeImprove flight safetyPosition/course control in three dimensionsSimulationUncrewed vehicle

The invention belongs to the technical field of cluster unmanned aerial vehicle path planning, and discloses a cluster unmanned aerial vehicle grouping assignment method and system, a controller, a medium and a terminal. The method comprises the following steps that cluster unmanned aerial vehicles are automatically divided into N groups according to the actual performance requirements of the cluster unmanned aerial vehicles, and the unmanned aerial vehicles in each group can only perform assignment calculation in the group; a number mapping mode from the initial position dot matrix to the target position dot matrix of each group of unmanned aerial vehicles is determined; each group of unmanned aerial vehicles flies to a corresponding position in the target dot matrix according to a respective number mapping mode; and all the unmanned aerial vehicles fly to the target position, and path transformation is completed. According to the method, the grouping assignment result of the cluster unmanned aerial vehicle performance can be quickly calculated, so that the grouping assignment process becomes simple and easy, and grouping assignment calculation of the cluster unmanned aerial vehicle can be realized; the flight conversion time of the cluster unmanned aerial vehicle is greatly shortened; and the flight conversion safety of the cluster unmanned aerial vehicle is greatly improved.

Owner:一飞(海南)科技有限公司

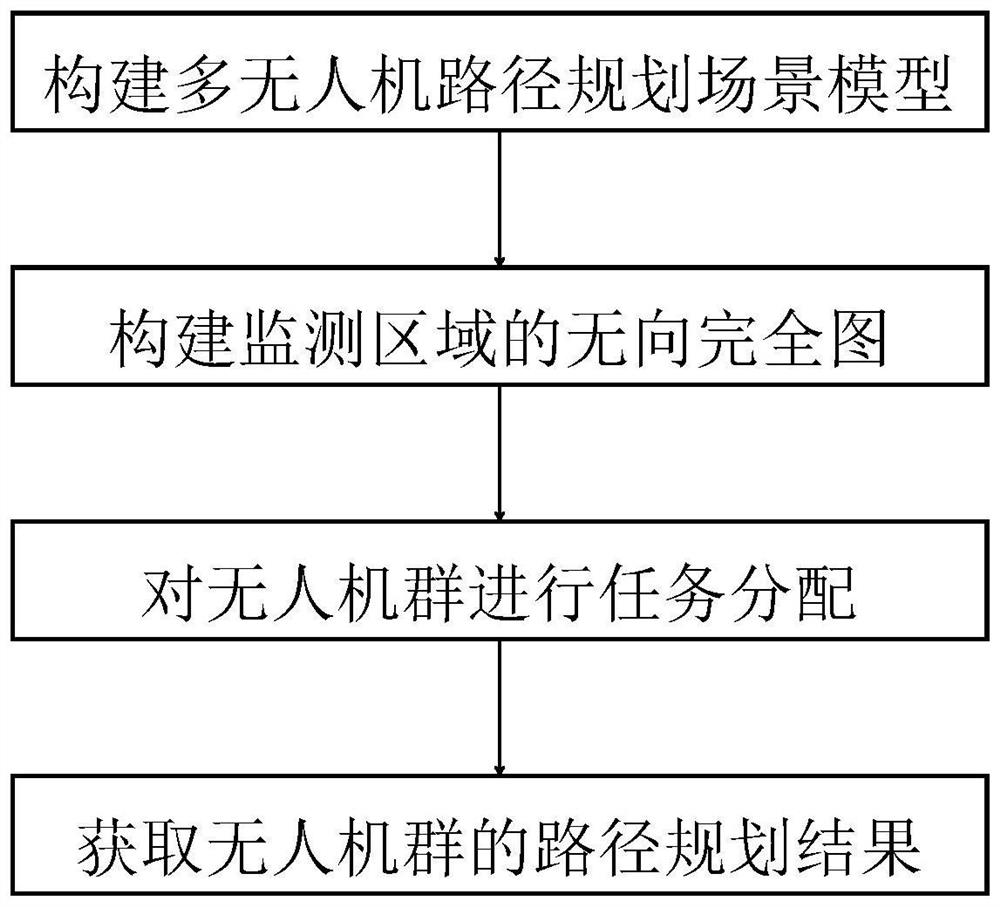

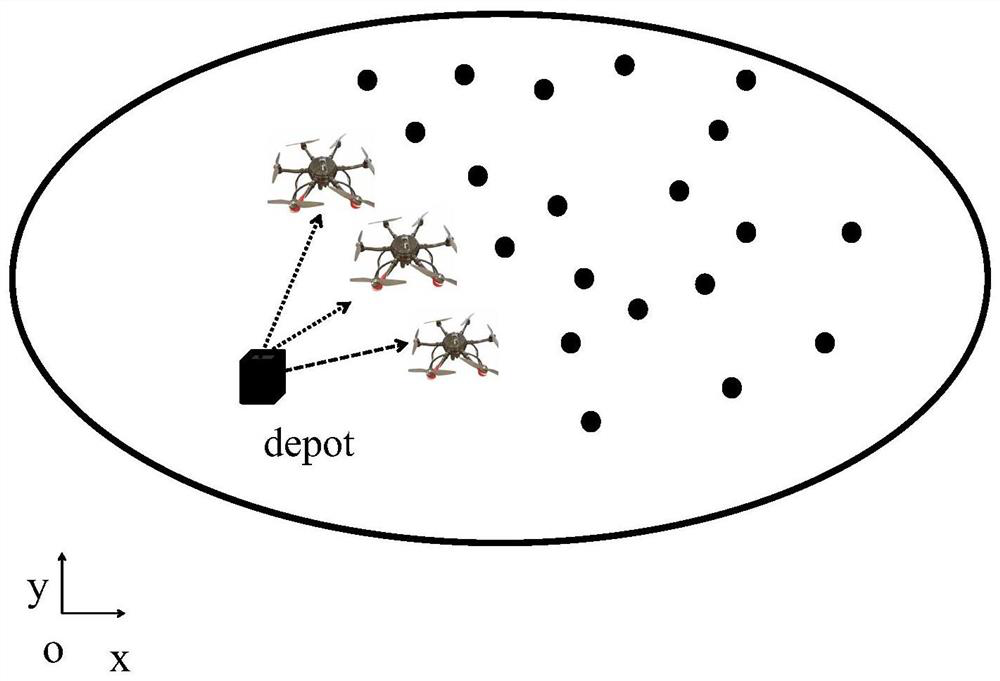

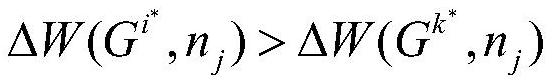

Multi-unmanned aerial vehicle path planning method

ActiveCN112629539AReduce flight distanceOptimize task assignment resultsNavigational calculation instrumentsMonitoring siteSimulation

The invention provides a multi-unmanned aerial vehicle path planning method. The method comprises the following steps: constructing a multi-unmanned aerial vehicle path planning scene model; constructing an undirected complete graph of the monitoring area; carrying out the task allocation on the unmanned aerial vehicle group; and obtaining a path planning result of the unmanned aerial vehicle group. An undirected complete graph of a monitoring area is constructed, a monitoring point traversed by each unmanned aerial vehicle and a starting point are modeled into the undirected complete graph, point transfer and exchange operations are carried out between the undirected complete graphs to continuously optimize a task allocation result, and a minimum Hamiltonian ring of each unmanned aerial vehicle is obtained on the basis of the optimized task allocation result; point transfer is carried out between the minimum Hamiltonian rings, the task allocation result is further optimized, and the path planning result of the unmanned aerial vehicle group is obtained, so the flight distance of the unmanned aerial vehicle with the maximum flight distance in the multiple unmanned aerial vehicles is minimum, and the flight time is the shortest.

Owner:XIDIAN UNIV +1

Golf ball

InactiveUS20030064830A1Reduce flight distanceCharacteristic degradationGolf ballsSolid ballsLayered structureElastic modulus

Owner:SUMITOMO RUBBER IND LTD

Free-falling double-nozzle powder mixing gas atomizing water-cooling fast-setting metal matrix CBN magnetic abrasive preparing method

ActiveCN105665725AAvoid wastingGuaranteed sizeTransportation and packagingMetal-working apparatusAlloyHigh pressure

The invention provides a free-falling double-nozzle powder mixing gas atomizing water-cooling fast-setting metal matrix CBN magnetic abrasive preparing method. The method is characterized in that CBN powder is adopted as hard abrasive of magnetic abrasive, and an alloy composed of iron, silicon, aluminum and copper is adopted as a metal matrix material; upper and lower layer free-falling nozzles are adopted as nozzles, the upper layer free-falling nozzle is a low-pressure mixed powder flow jetting nozzle, and the lower layer free-falling nozzle is a high-pressure gas flow nozzle; water cooling is adopted as a cooling manner, and by adjusting the height of the water level of cooling water in an atomizing and water cooling chamber, the cooling speed of molten metal drops containing the CBN abrasive is controlled, so that the CBN abrasive forms the magnetic abrasive distributed on the surface shallow layer of a magnetic abrasive metal matrix; a spiral mixed powder conveying device is adopted for conveying mixed powder, so that flow of the CBN abrasive is controlled precisely. According to the prepared metal matrix CBN magnetic abrasive, CBN and the metal matrix are combined firmly, the magnetic abrasive has high magnetic abrasive performance, the production technology process is controlled in a programmed manner, product performance is stable, and the method is suitable for scale production.

Owner:SHANDONG UNIV OF TECH

Power transmission line unmanned aerial vehicle inspection path planning and defect analysis cloud platform

PendingCN114326825AShorten the lengthShorter cruising distanceTarget-seeking controlPoint cloudSimulation

The invention provides a power transmission line unmanned aerial vehicle routing inspection path planning and defect analysis cloud platform, and relates to the field of power transmission lines, the power transmission line unmanned aerial vehicle routing inspection path planning and defect analysis cloud platform comprises an unmanned aerial vehicle routing inspection path planning platform and a defect analysis cloud platform, and the planning process of the unmanned aerial vehicle routing inspection path planning platform is as follows: Sp1: establishing a three-dimensional space model by taking a power transmission line as a fixed object and an unmanned aerial vehicle as a moving object; sp2, inputting basic parameters of the power transmission line and the unmanned aerial vehicle; sp3, calculating the relative motion error between the power transmission line and the unmanned aerial vehicle and the hovering precision of the unmanned aerial vehicle; sp4, the mapping precision of the three-dimensional point cloud model is calculated, and a three-dimensional array is mapped; sp5, when the track passes through the obstacle, planning a new path in combination with an ant colony algorithm of the defect analysis cloud platform; and when the track does not pass through the obstacle, outputting the track until the inspection is finished. The shortest distance flight is ensured, a shortest path can be planned through the ant colony when there is an obstacle, and compared with manual inspection, the whole automatic inspection process has the advantage that the inspection path length is obviously shortened.

Owner:TIELING POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER COMPANY +2

Water-cooling fast-setting control method of depth distribution of hard abrasive in magnetic abrasive metal matrix

The invention provides a water-cooling fast-setting control method of depth distribution of hard abrasive in a magnetic abrasive metal matrix. The method is characterized in that the lower portion of an atomizing and cooling chamber of powder mixing gas atomizing fast-setting magnetic abrasive preparing equipment is filled with cooling water, the height of the water level of the cooling water in the atomizing and cooling chamber is adjusted by controlling the water input amount, by adjusting the height of the water level of the cooling water in the atomizing and cooling chamber, the flight distance of powder mixed molten metal drops is adjusted, then the cooling speed of the powder mixed molten metal drops is adjusted, and the powder mixed molten metal drops are cooled so that the hard abrasive can form the magnetic abrasive distributed on the surface shallow layer of a magnetic abrasive metal matrix; control over the depth of distribution of the hard abrasive on the surface shallow layer of the magnetic abrasive metal matrix is achieved; moreover, the flight distance of the powder mixed molten metal drops is shortened greatly, the overall height of an atomizing and condensing chamber and equipment is reduced, and equipment manufacturing cost is reduced; and meanwhile, by means of the shock chilling effect generated by water cooling and fast setting, bonding strength between the hard abrasive and the metal matrix is improved. The method is simple, stable, reliable and suitable for mass production of the high-performance magnetic abrasive.

Owner:SHANDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com