Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Reduce design man-hours" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

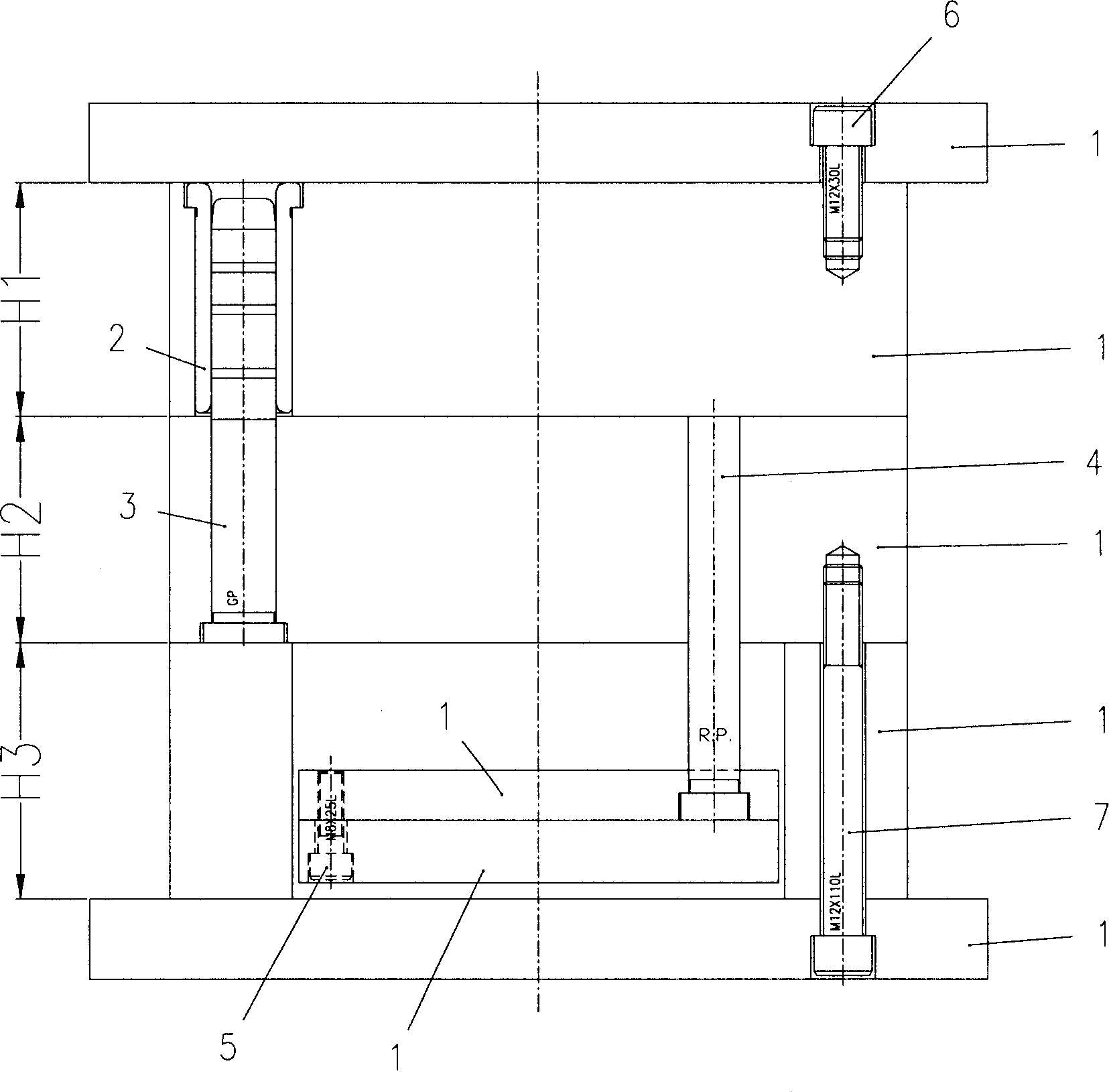

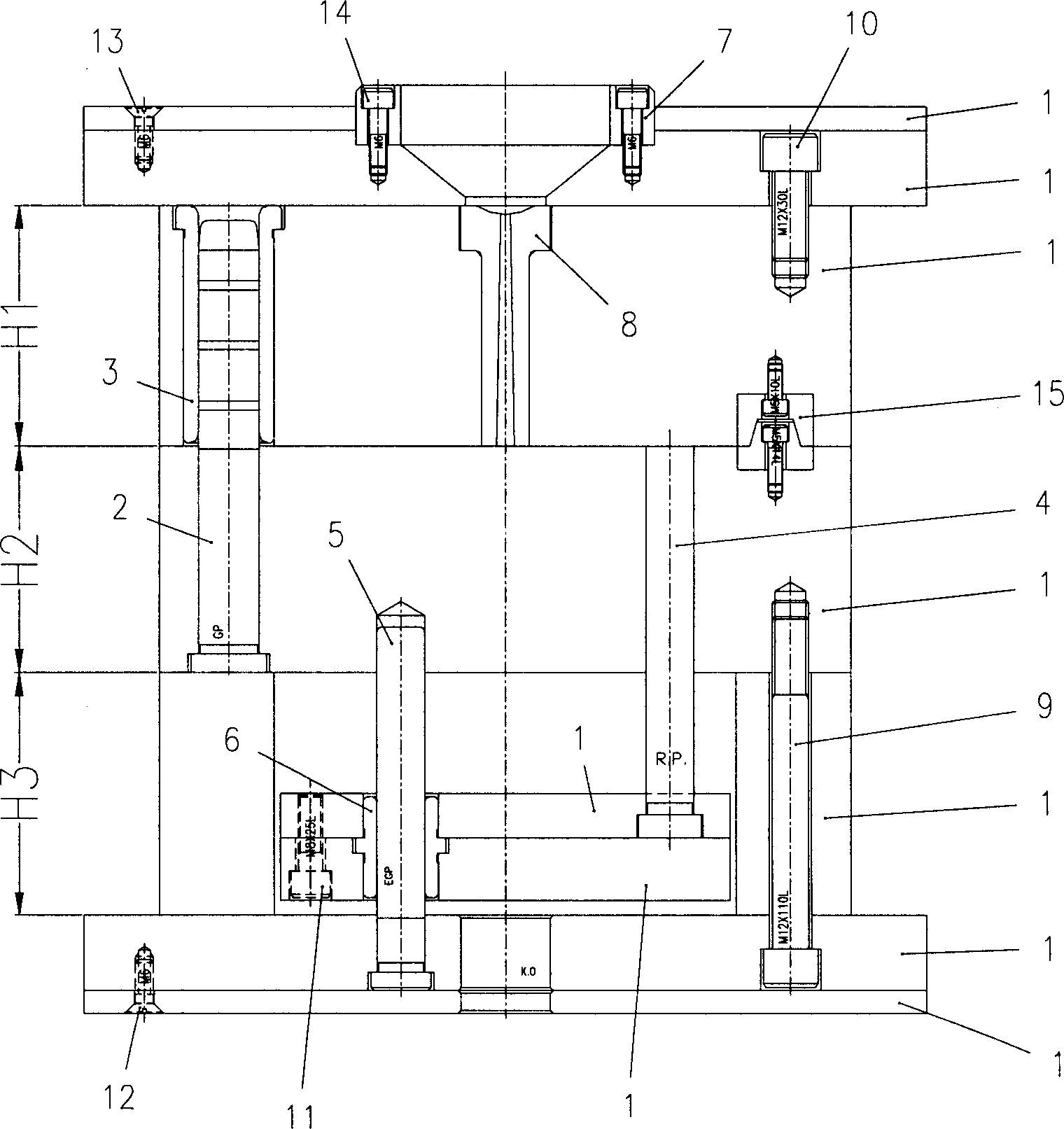

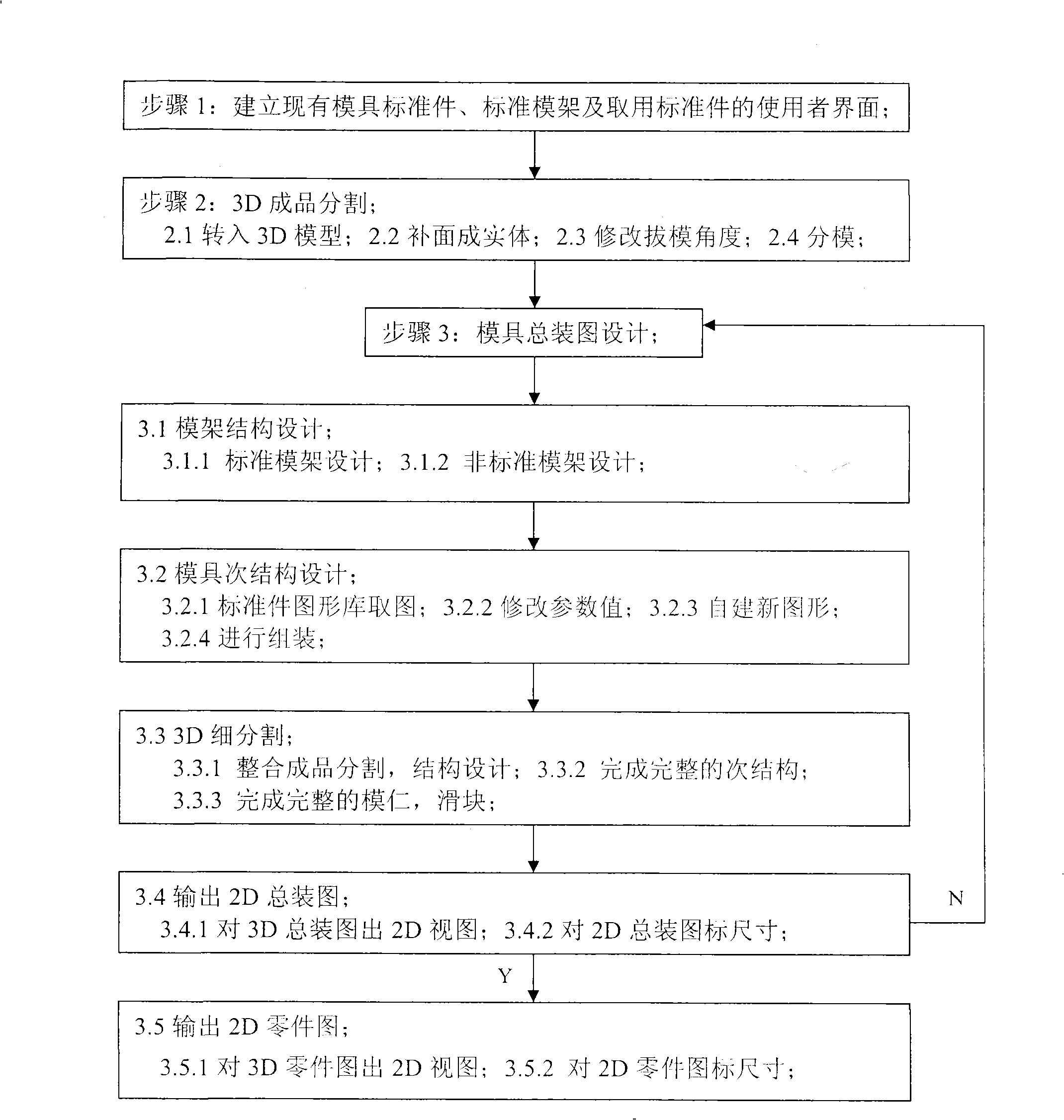

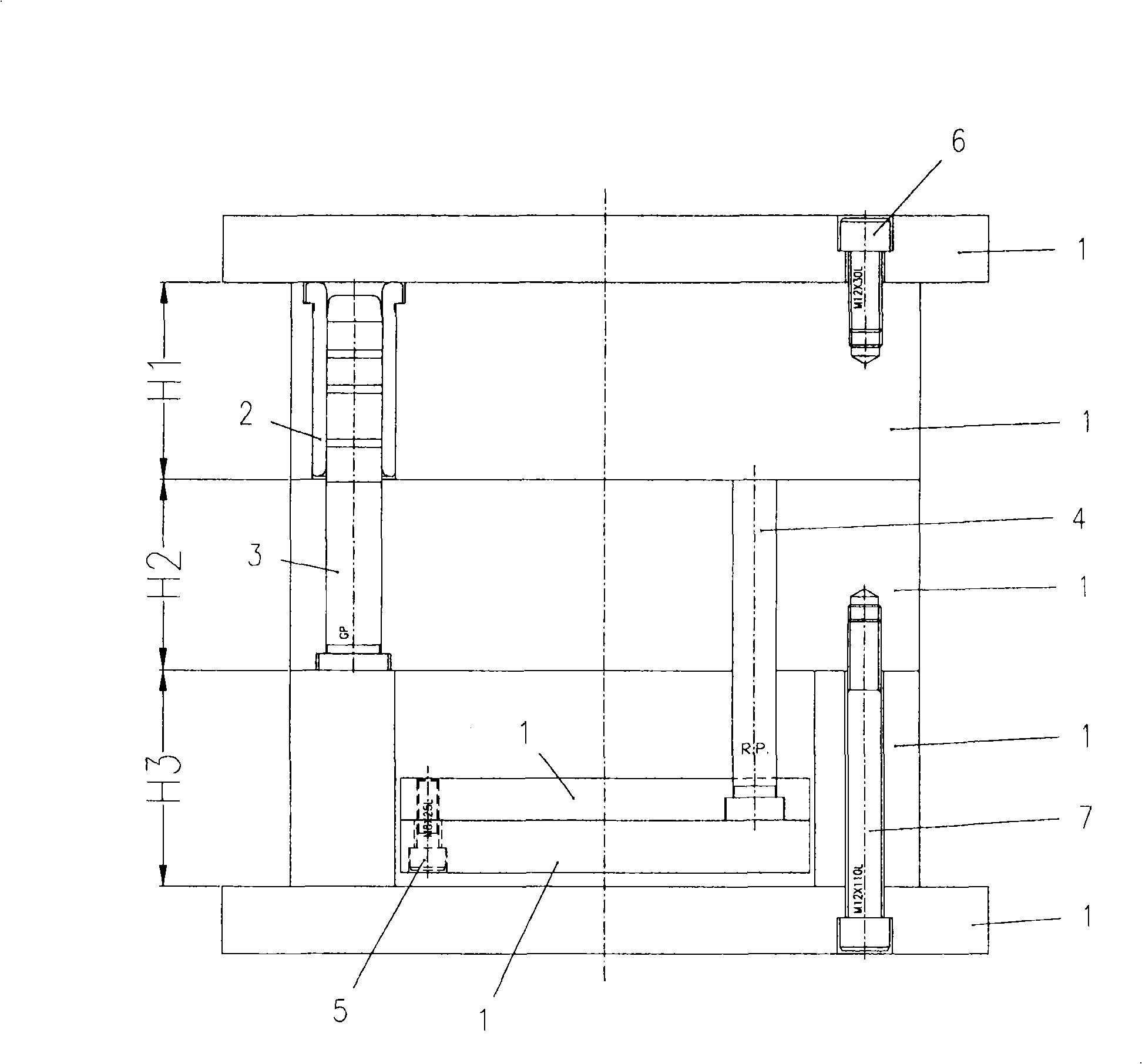

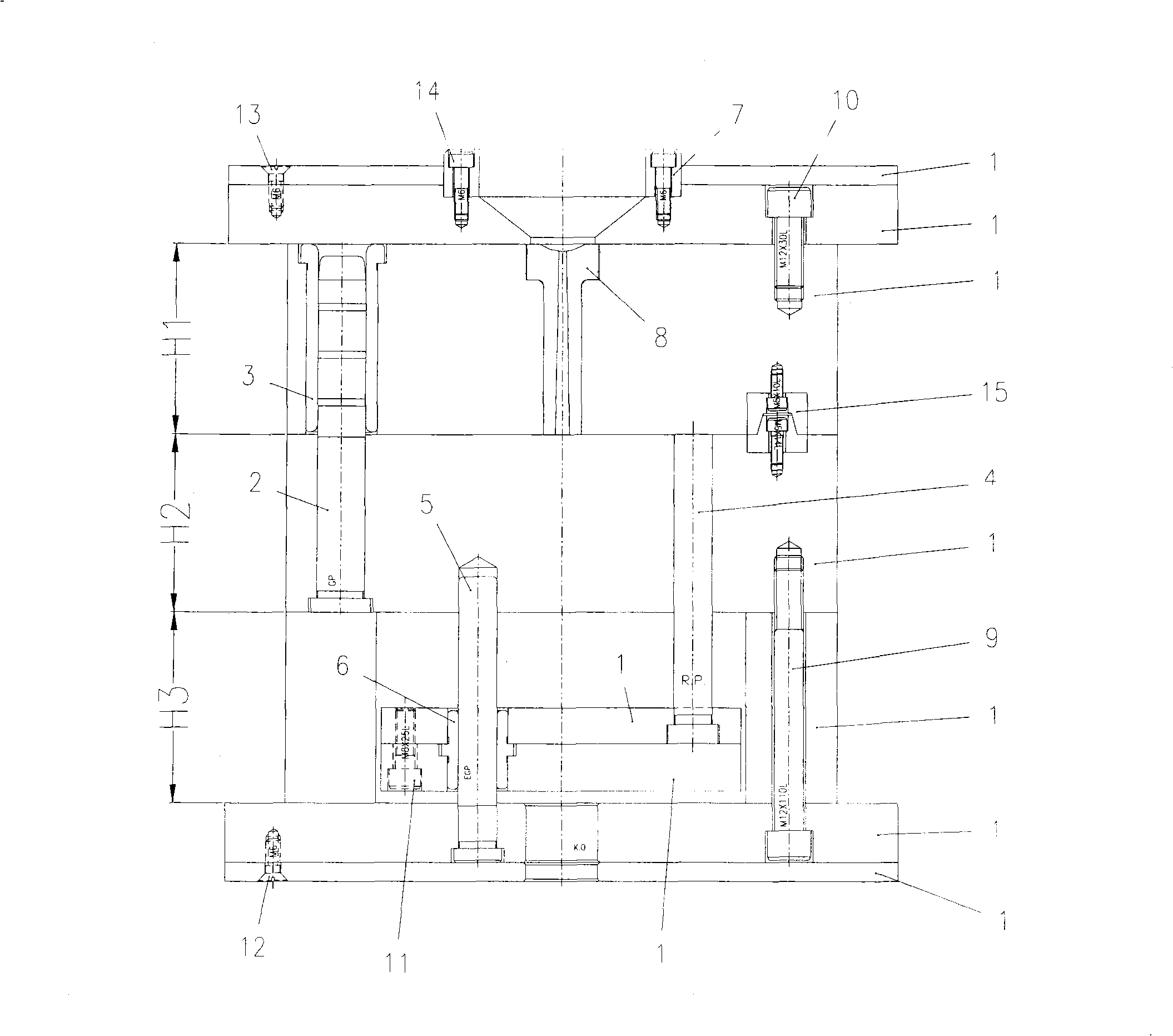

Parametered assembly and design of three-dimensional mould structure and automatic dimension labeling method for two-dimensional figure

InactiveCN1841386AReasonable structural designImprove design qualitySpecial data processing applicationsQuality by DesignEngineering

The related auto size marking method for 3D / 2D mold parameters assembly design comprises: 1. designing mold frame, determining all of the member size, mold nest and core quantity, distance among product, nest and template; 2. designing secondary structure by receiving computer command and calculating to generate slide block, slope pin, cooling loop, and other assembly; 3. executing whole assembly diagram command to generate 2D diagram; 4. alternating request, repeating step 2-3; 5. outputting the formal 2D diagram; 6. outputting the 2D member processing diagram. This invention has more reasonable process, improves design quality, and reduces manual error.

Owner:陈金德

Asynchronous control circuit and semiconductor integrated circuit device

InactiveUS20050007170A1Improve chip performanceReduce design man-hoursDigital storageElectric pulse generatorIntegrated circuitSemiconductor

An asynchronous control circuit and a semiconductor integrated circuit achieving asynchronous operation and no limitation on the number of ports are offered. In an asynchronous control circuit, by being activated corresponding to at least one access request by acknowledging a plurality of access request signals generated asynchronously to each other and a plurality of input signals corresponding to each of the above-mentioned plurality of access requests, selecting one access request from one or more access requests in the activation mode, acknowledging an input signal corresponding thereto, transmitting the input signal to a memory, acknowledging the input signal corresponding to a non-executed access request after the end the operation corresponding to the input signal, and accessing the aforementioned memory circuit.

Owner:HITACHI LTD

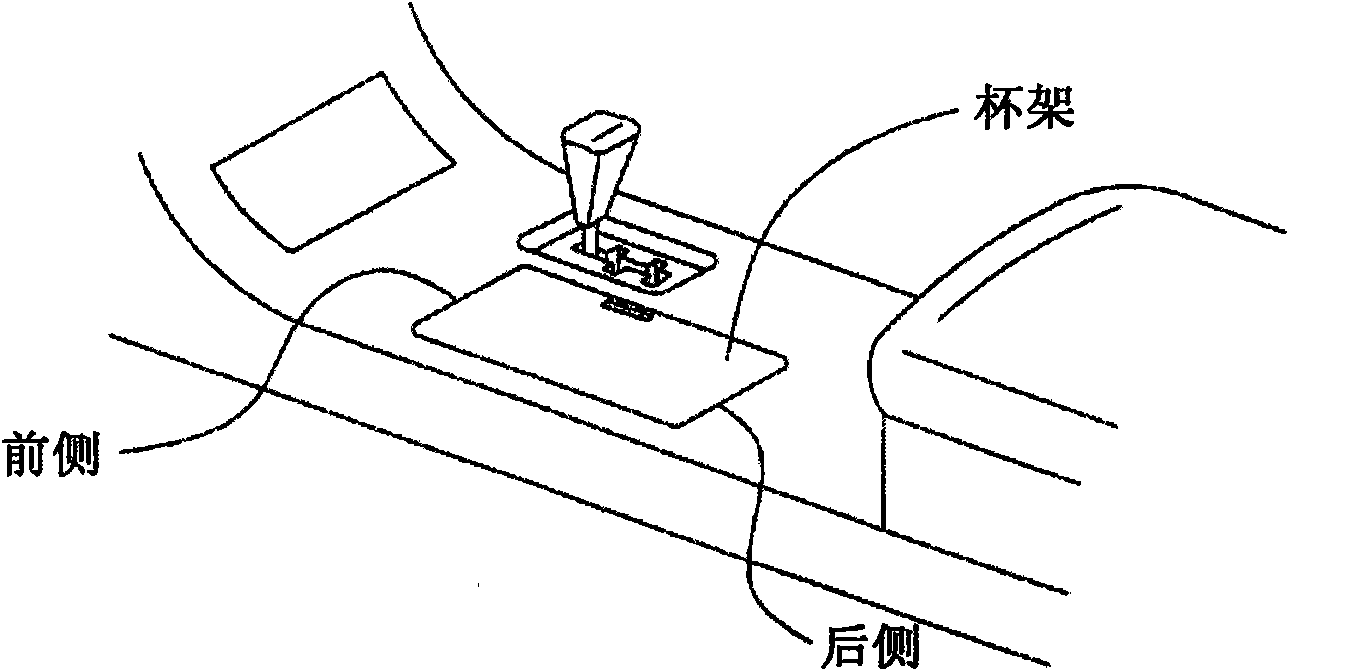

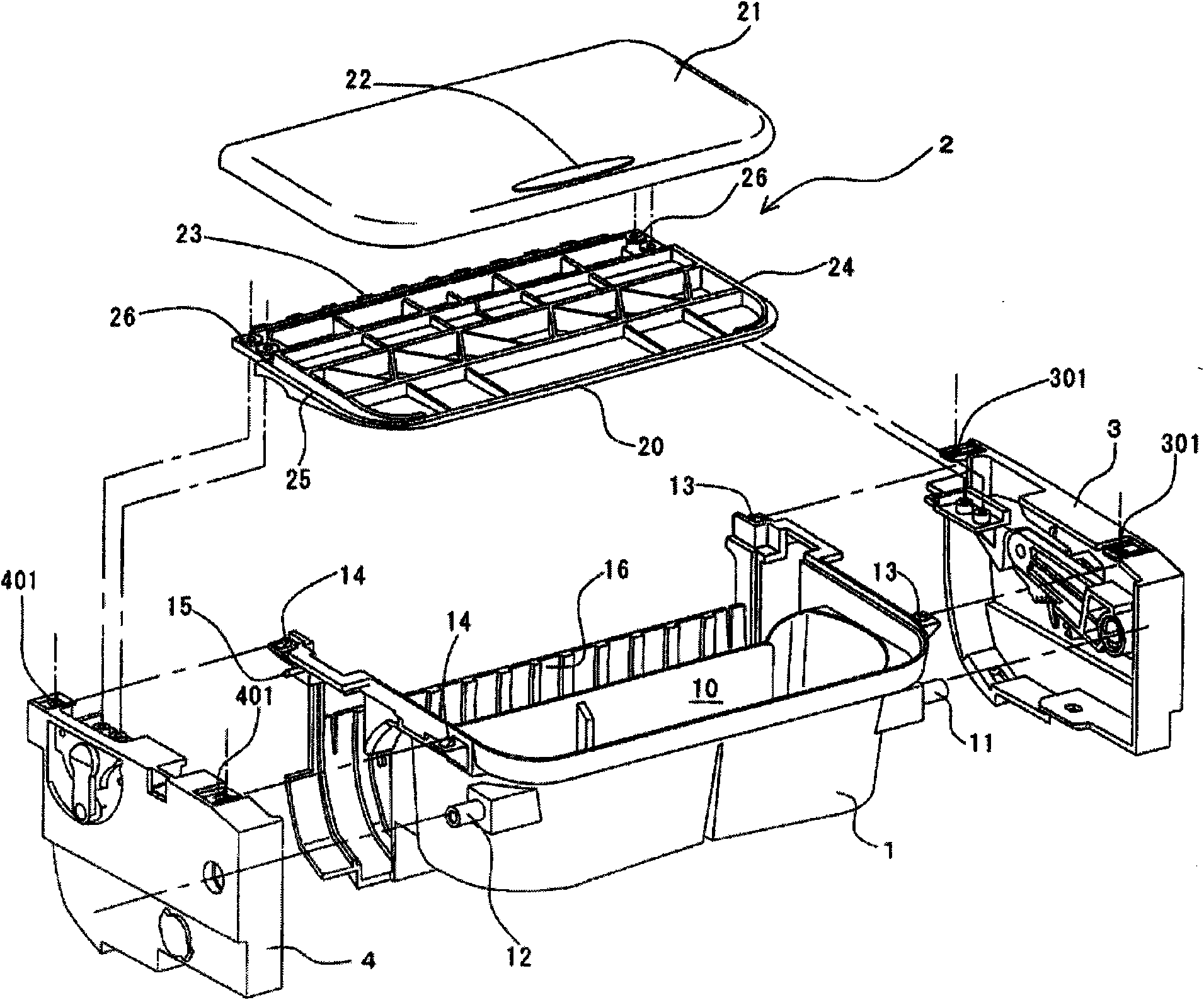

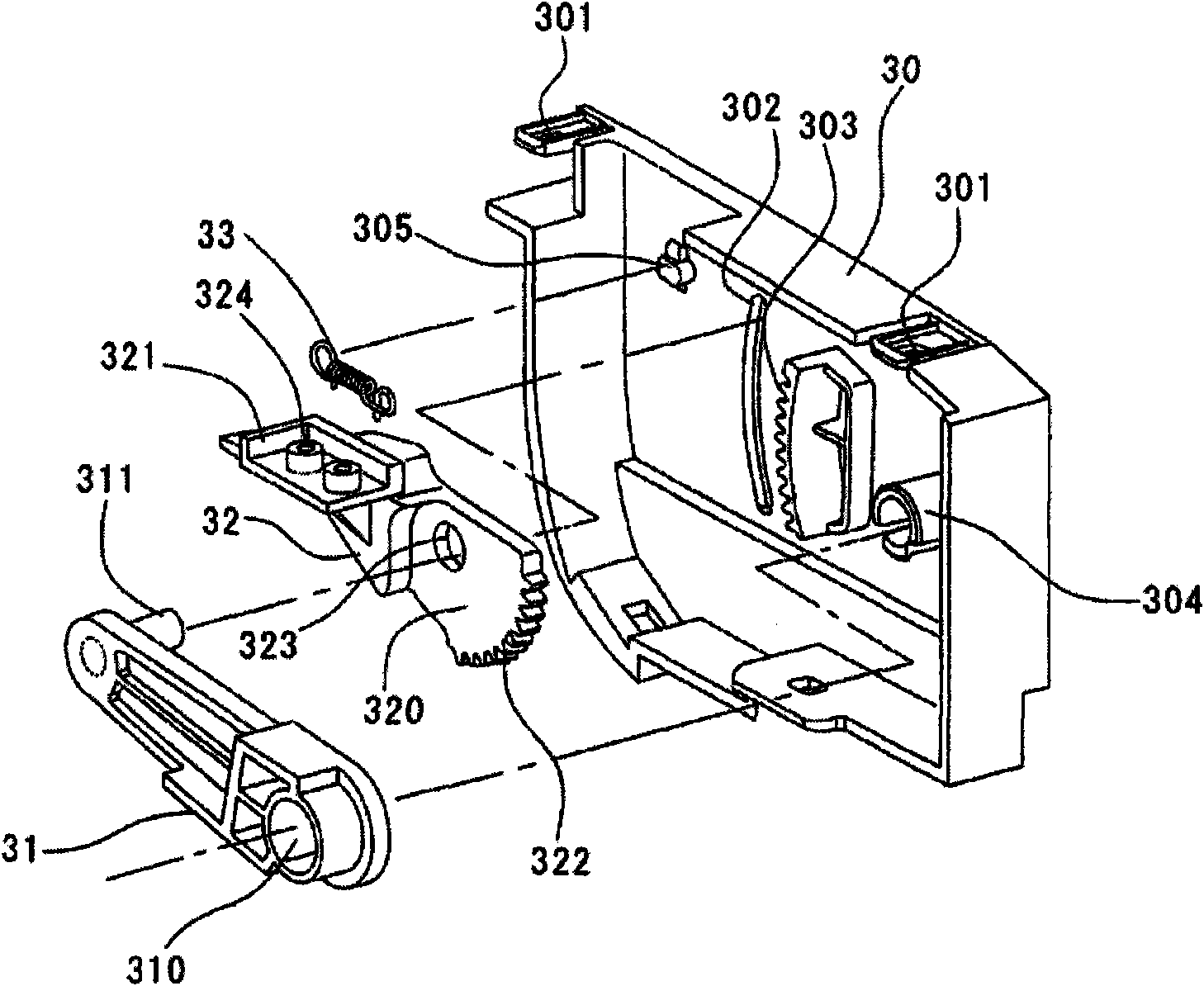

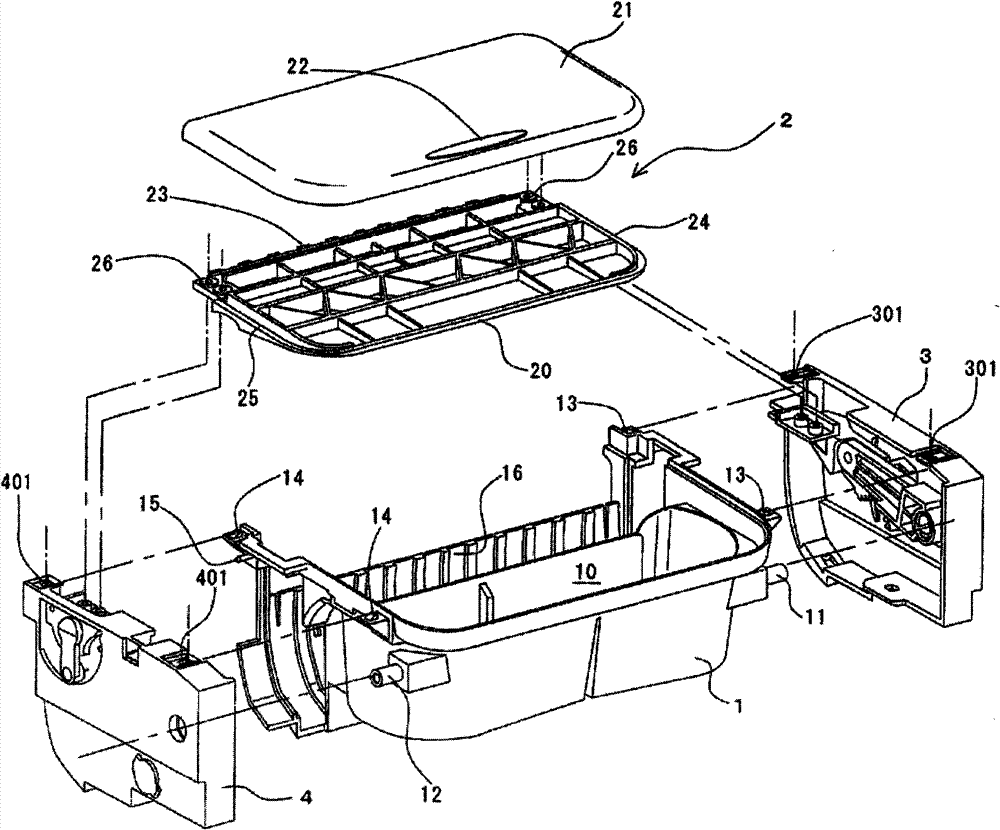

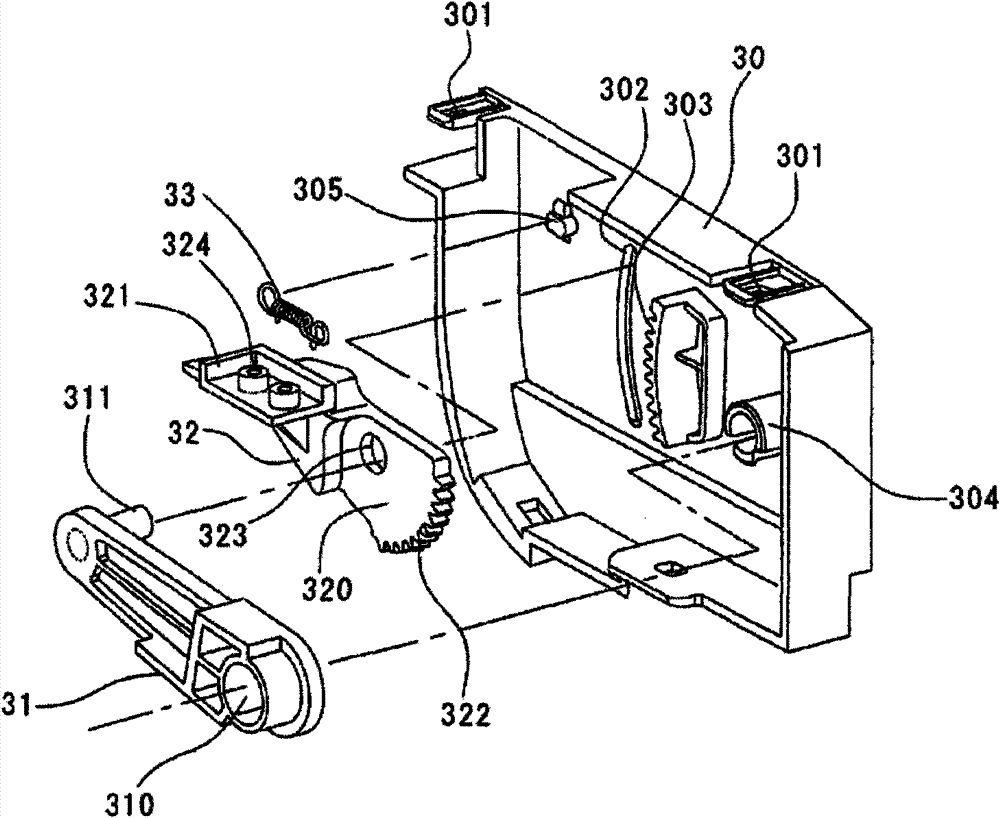

Accommodation device for vehicle use

InactiveCN102133873AShorten production hoursReduce design man-hoursVehicle arrangementsPassenger spaceMan-hourSize change

The invention provides an accommodation device for vehicle use, which contributes significantly to design man-hour decrease and production man-hour decrease even in case of a carrying space or an accommodation container body with a different shape. The accommodation device for vehicle use comprises a pair of rotation adjusting units for fixing guiding mechanisms with a capability of adjusting therotation track on the two ends of the accommodation container body. By fixing the lid on parts of the guiding mechanisms and making the lid rotate relative to the accommodation container body throughthe guiding mechanisms, the lid is thus made capable of opening and closing the opening. Therefore, even in case of size changes of the accommodation container body and the lid, the rotation adjusting unit can be shared.

Owner:TOYODA GOSEI CO LTD

Method for optimizing nesting design in hull design

InactiveCN103678796AGuaranteed accuracyAvoid substitutionSpecial data processing applicationsEngineeringDesign methods

The invention discloses a method for optimizing nesting design in hull design. The method comprises the following steps that firstly, a computer extracts part information of a Tribon model and generates a segmented part list; secondly, the segmented part list and model part information are compared through the Excel table so that whether the board thickness and materials of parts are accurate or not can be detected; thirdly, multiple steel plates or multiple segments are combined and nested, and nesting is automatically carried out through the computer by setting a proper nesting rule; fourthly, a statistics list of the segmented steel plates is generated automatically and used in actual production. By means of the method, the accuracy of the nested parts is ensured and working efficiency is improved.

Owner:JIANGSU NEW TIMES SHIPBUILDING

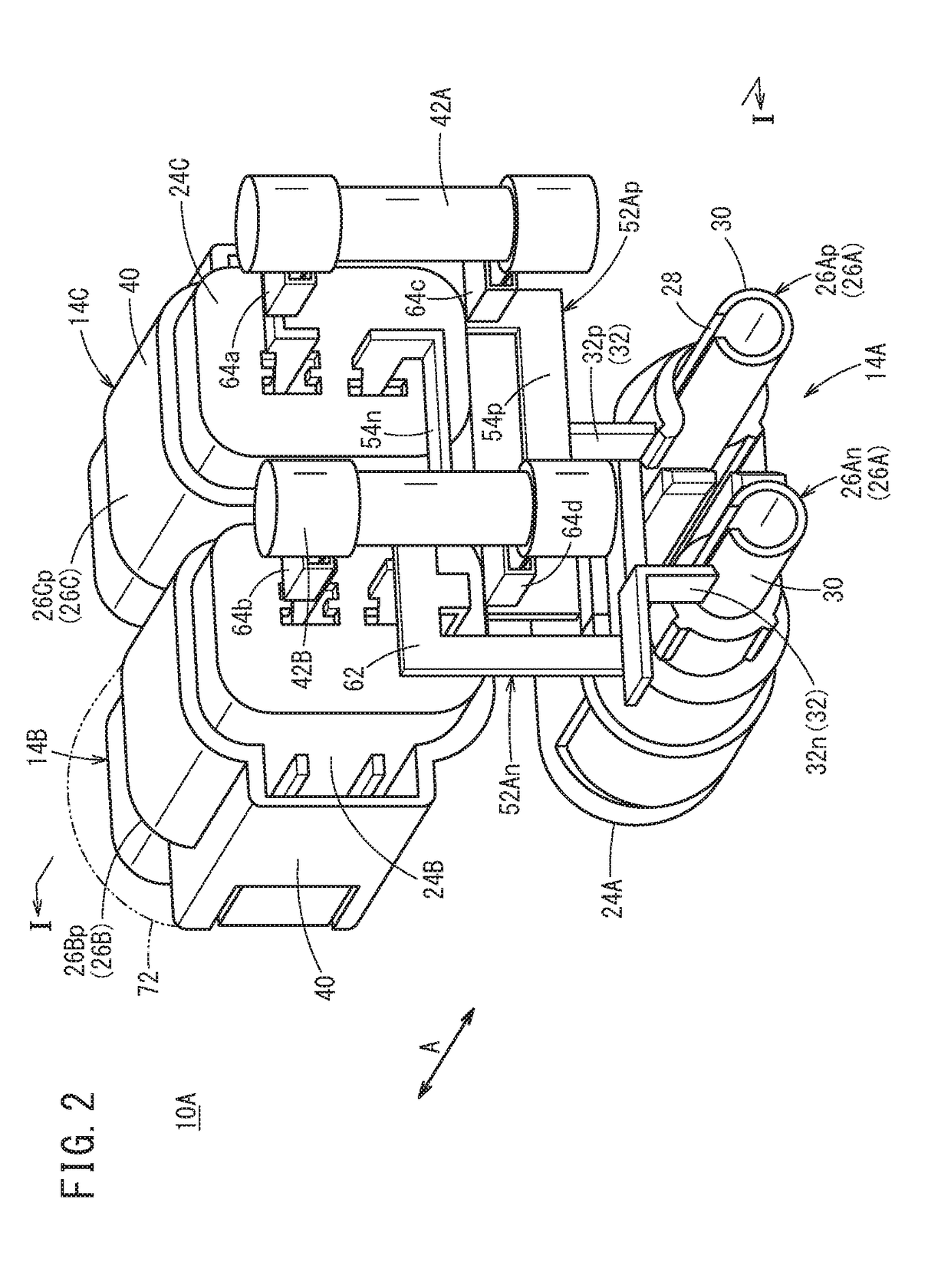

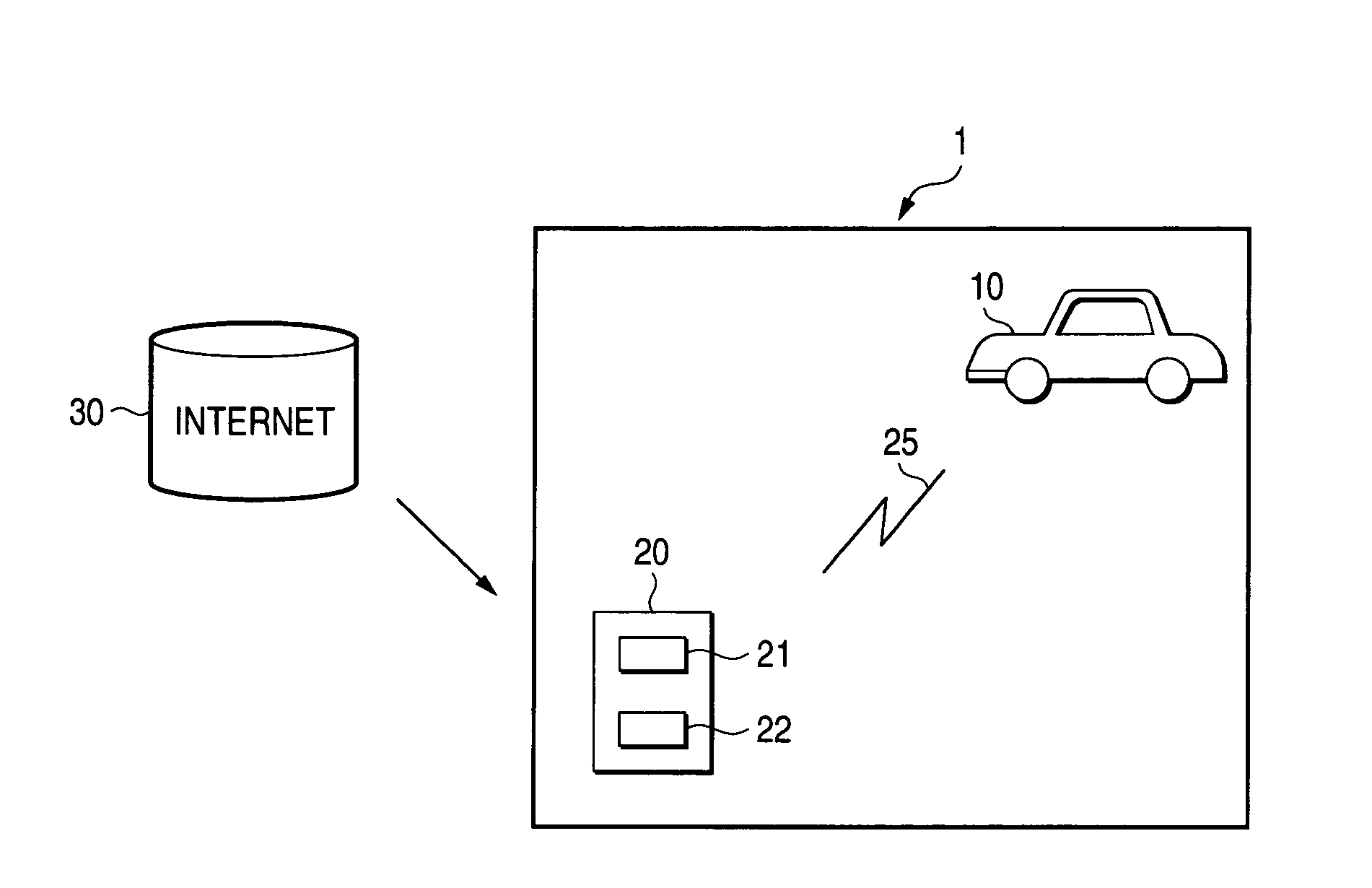

Connector structure and electric vehicle

ActiveUS20180145463A1Low costReduce in quantityVehicle connectorsCharging stationsElectricityElectric vehicle

A connector structure installed in the electric vehicle includes a plurality of connectors, an inter-connector conductive member configured to electrically connect the plurality of connectors, and a connector casing configured to house the inter-connector conductive member. A cover is attached to the unused connector of the plurality of connectors.

Owner:HONDA MOTOR CO LTD

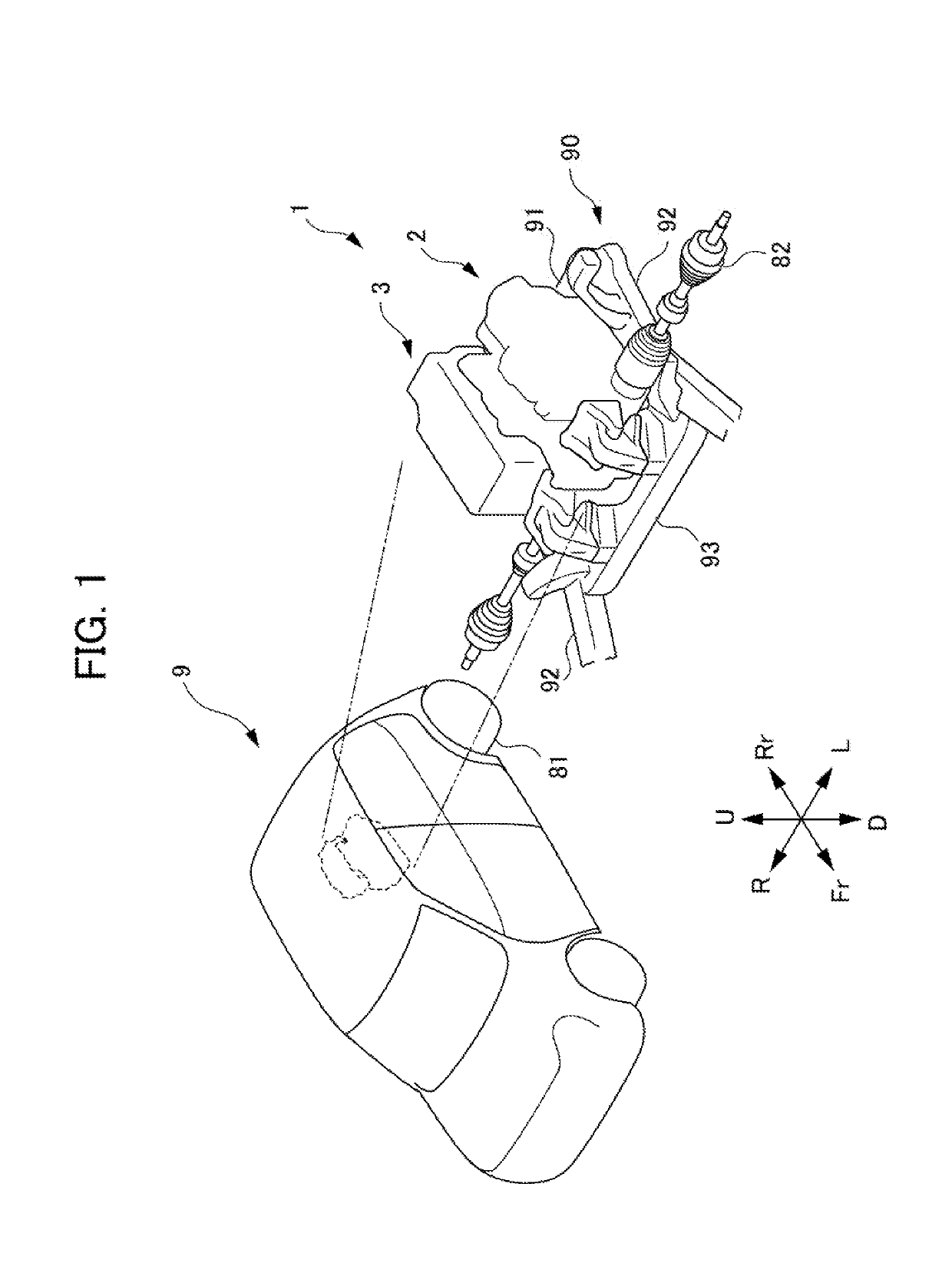

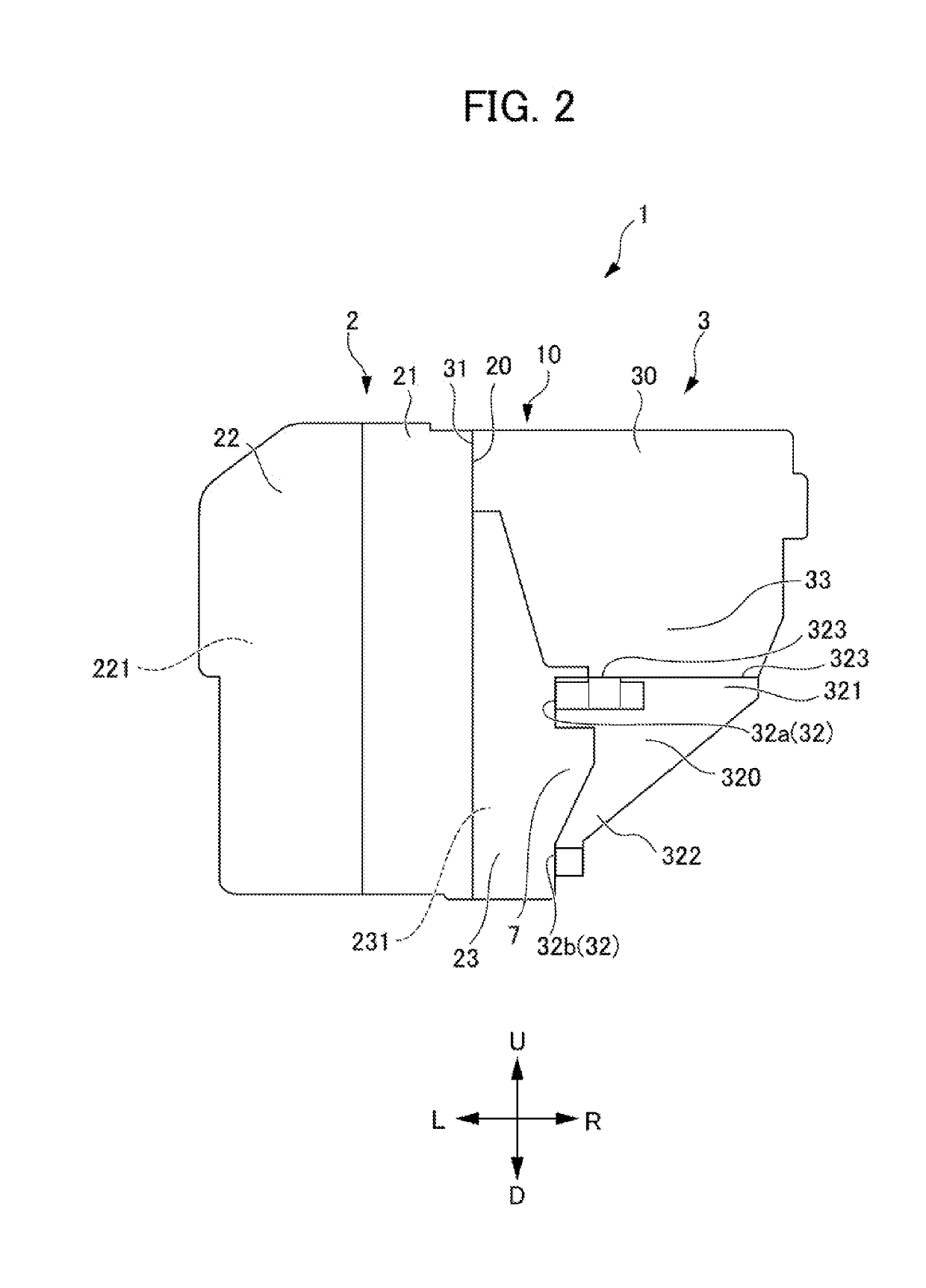

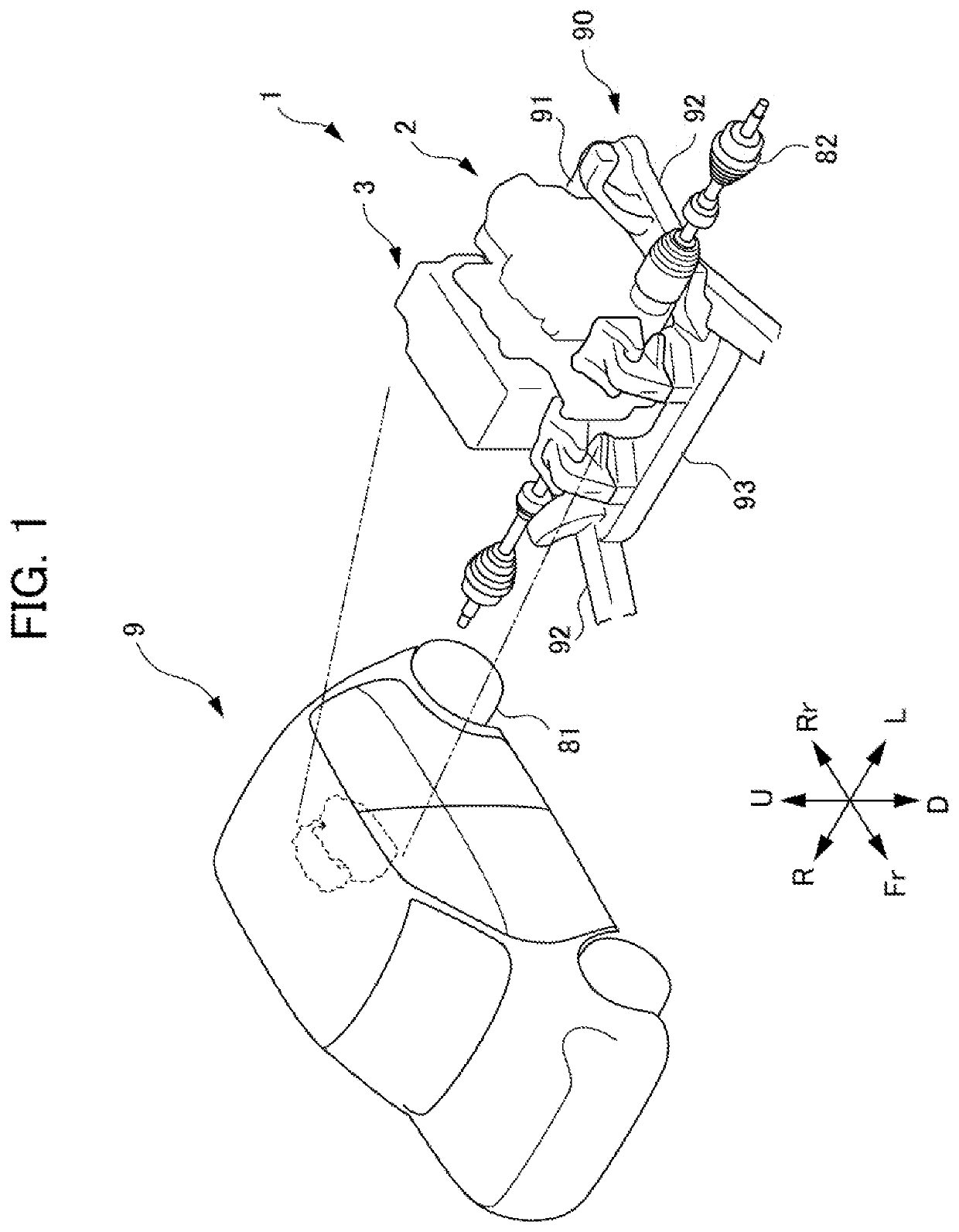

Power unit structure for electrically driven vehicle

ActiveUS20190283560A1Improve rigidityReduce design man-hoursAssociation with control/drive circuitsElectric propulsion mountingMan-hourEngineering

To provide a power unit structure for an electrically driven vehicle which can decrease design man-hours, as well as raise the rigidity of the unit. A control device unit for an electrically driven vehicle includes: a first mounting part which is a mounting part of a power supply unit that supplies electric power to an electric motor, and a second mounting part which fixes the control device unit to an electric motor unit; and the control device unit is mounted from a transmission case side of the electric motor unit towards an electric motor case side, the first mounting part being mounted to a central case, and the second mounting part being mounted to the transmission case.

Owner:HONDA MOTOR CO LTD

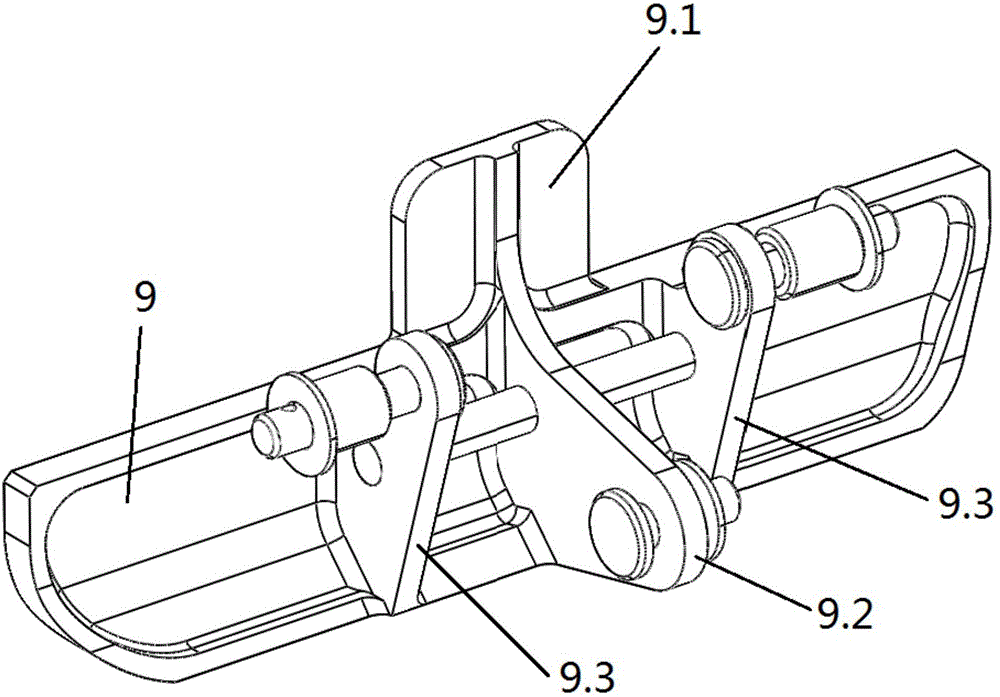

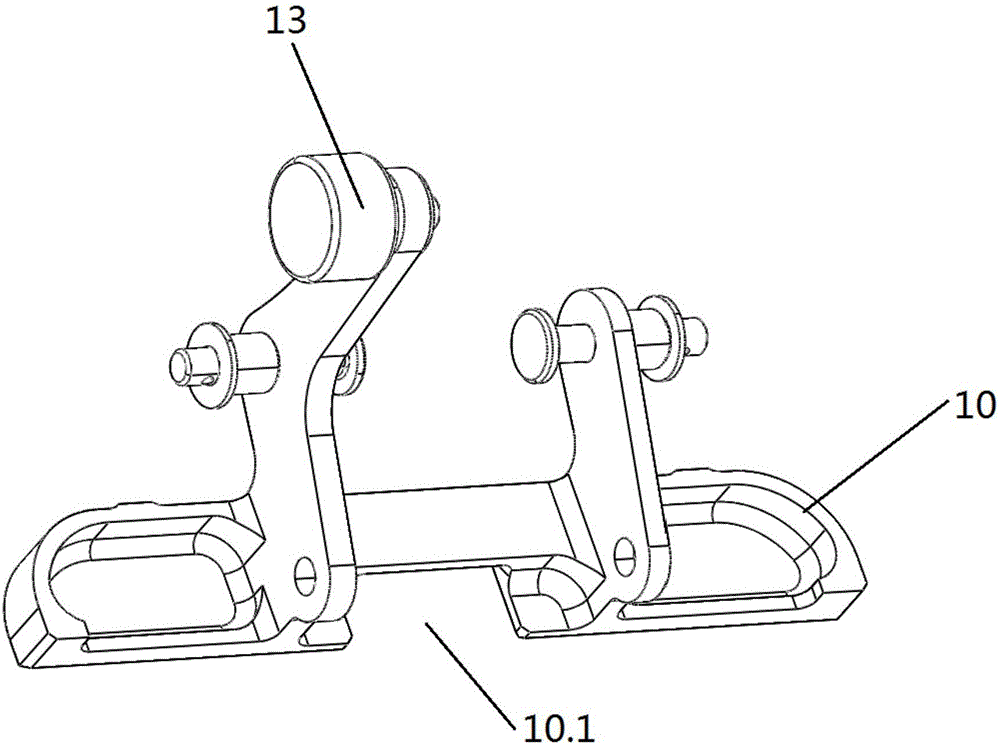

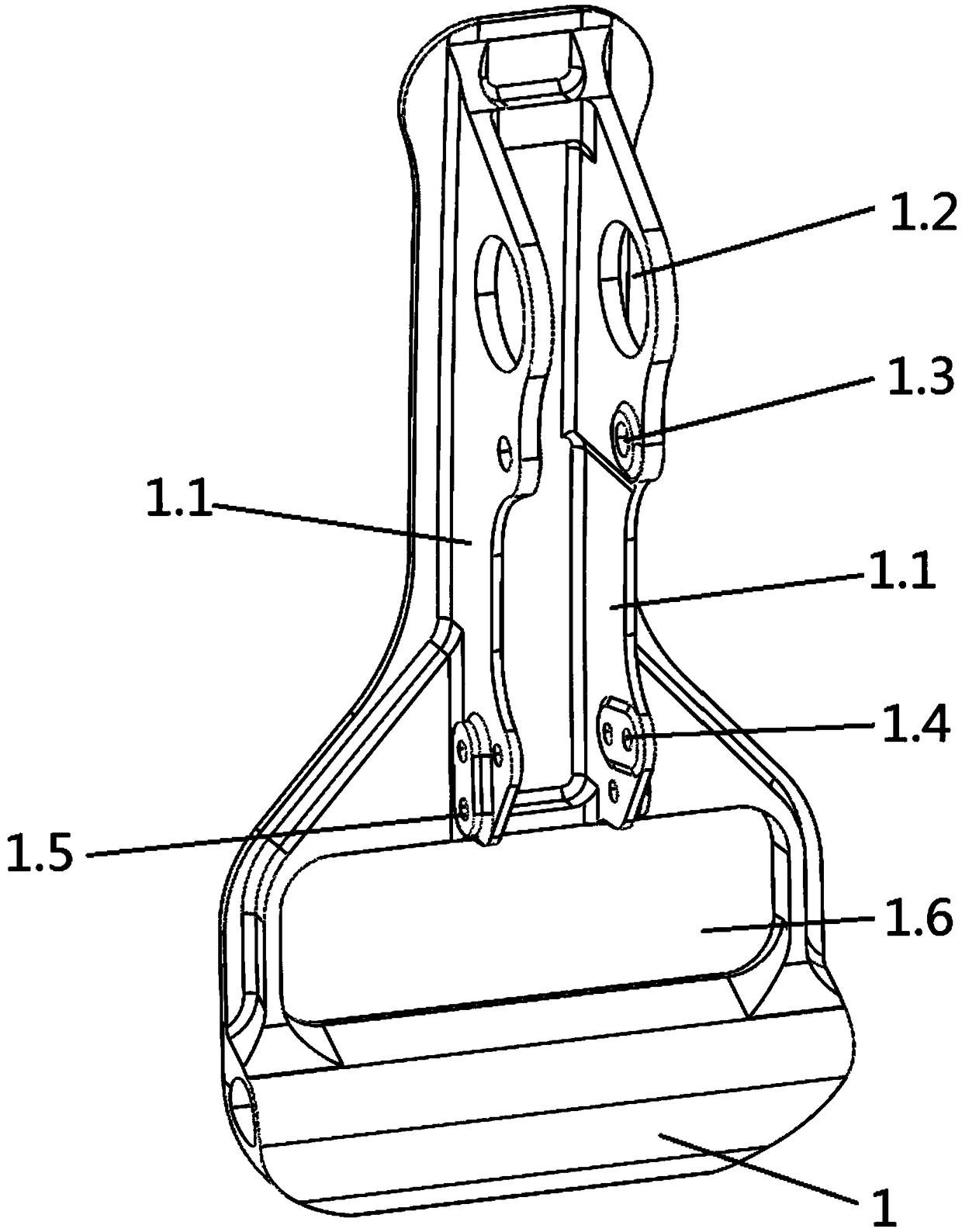

Outer handle mechanism of upward-downward opening type emergency exit

The invention discloses an outer handle mechanism of an upward-downward opening type emergency exit. A handle shaft is hinged to an outer handle main structure member; a driving crank is fixedly connected to the handle shaft; a crank locking hook is hinged to the outer handle main structure member; the driving crank interacts with the crank locking hook; one end of a connecting rod is connected with the crank locking hook, and the other end of the connecting rod is connected with one end of a crank, the crank is hinged to the outer handle main structure member, and the other end of the crank is connected with the inner side of a secondary turnover plate through an inserting lug connecting rod; the secondary turnover plate is hinged to a primary turnover plate, the primary turnover plate and the secondary turnover plate are kept in relative fixed positions in the hinged position through two torsional springs I; the secondary turnover plate is connected with the outer handle main structure member through two extension springs; and the primary turnover plate is hinged to the outer handle main structure member, and a relative fixed position relation between the primary turnover plate and the outer handle main structure member is kept in the hinged position through two torsional springs II. The problems that in the prior art, the mechanism complexity is high, the weight is high, the functions are incomplete, and the reliability is relatively low are solved.

Owner:AVIC SAC COMML AIRCRAFT

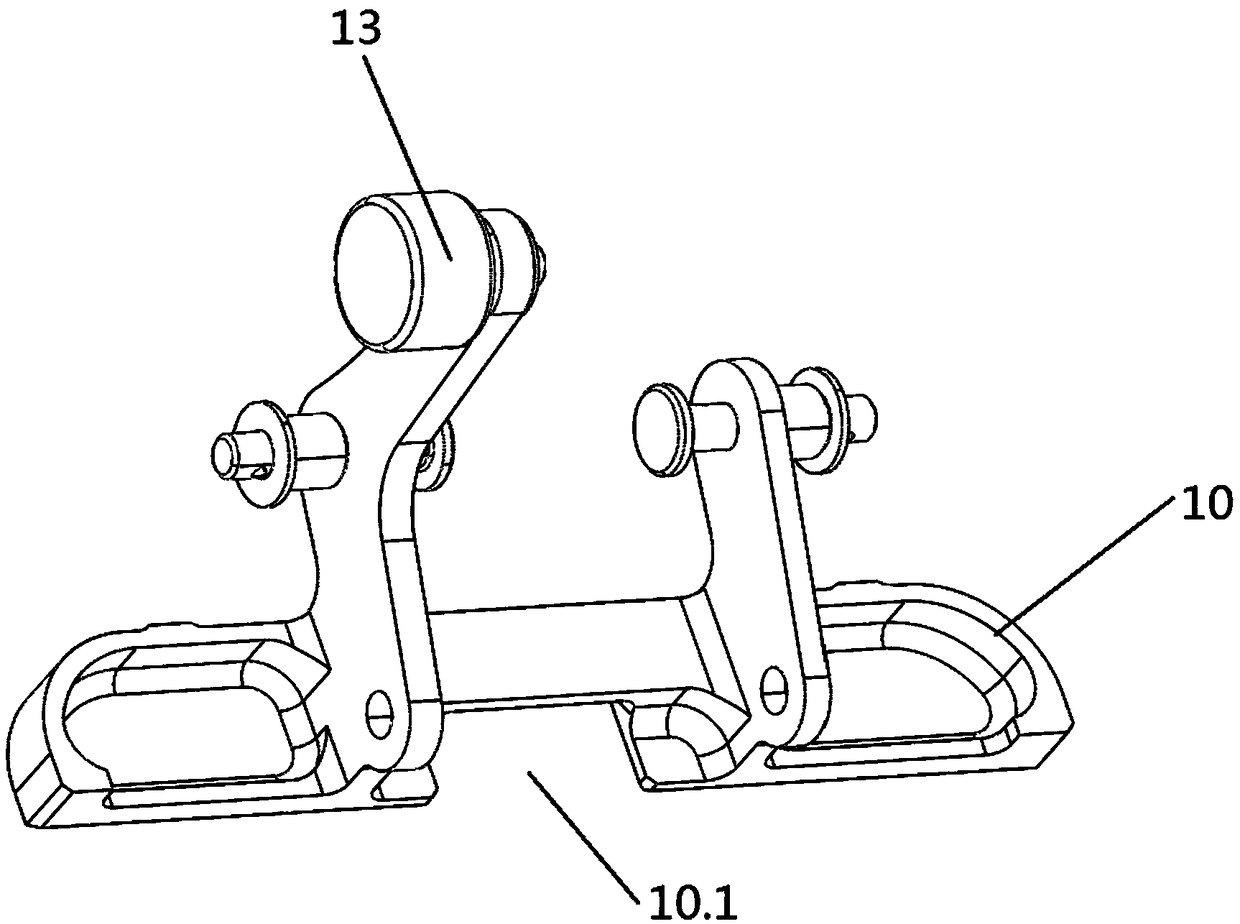

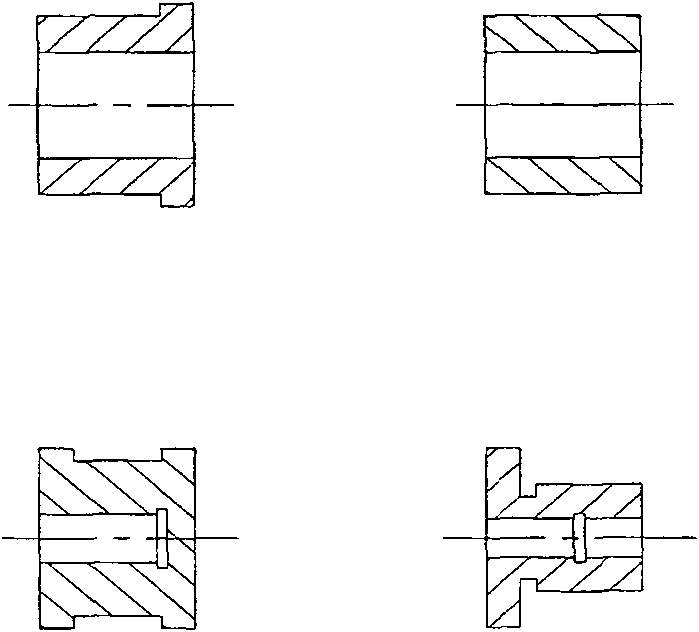

High-efficient modular fixture for processing part

InactiveCN101372083AReduce design man-hoursReduce production man-hoursPositioning apparatusMetal-working holdersModular fixtureEngineering

The invention relates to a group of clamps used for part processing, mainly consisting of a basic part and an adjustable part; wherein, the basic part comprises a clamping body (1) and transmission clamping parts (2, 3); the adjustable part consists of replaceable parts (4, 6) and an elastic expanding part (5); during the part processing, each dimension group of the part is provided with a group of corresponding replaceable parts. When parts of different dimension groups are processed, replaceable parts (4, 6) are all needed to be replaced; but in the same dimension group, only elastic expanding part (5) of corresponding dimension is needed to be replaced for the workpiece of difference positioning aperture; the clamp can shorten the design and manufacture time of normal clamp, saves the material and reduces the production cost.

Owner:BEIJING UNION UNIVERSITY

Transforming method for ship hull production design modes

The invention discloses a transforming method for ship hull production design modes. The transforming method comprises the following steps that firstly, a model is built in a TRIBON system according to the requirements of a process and a code; secondly, after the model is built, names of sections and a corresponding table are built, and a grillage model and part information are extracted; thirdly, automatic assembly is achieved according to the extracted model and the part information; fourthly, a detail list of parts is automatically extracted and output to be of the EXCL mode. By means of the transforming method, the design time for post processing of the model is shortened, the error rate is reduced, and the working efficiency is improved.

Owner:JIANGSU NEW TIMES SHIPBUILDING

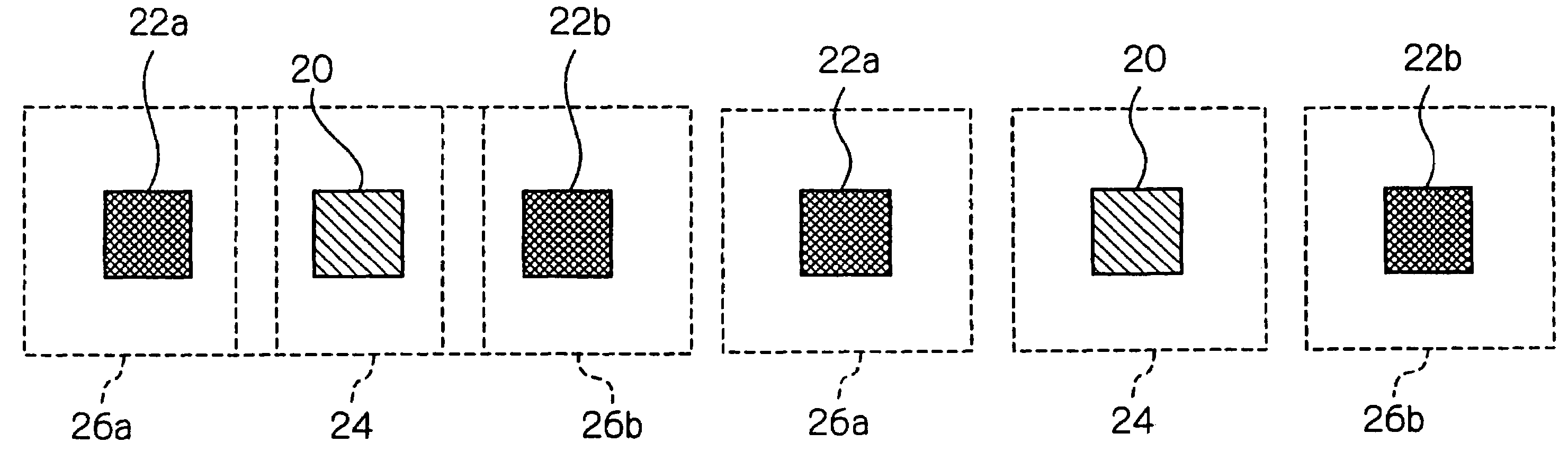

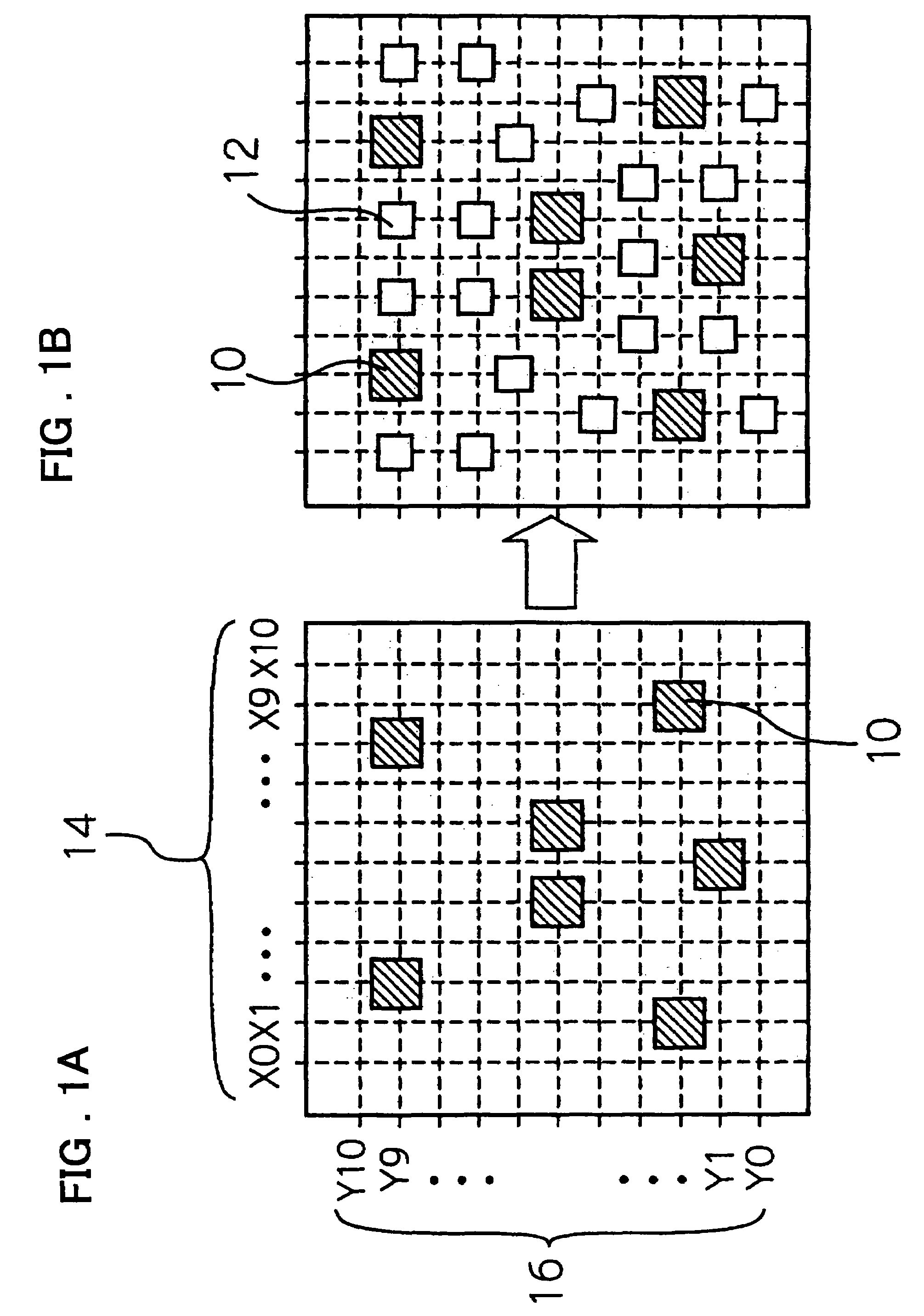

Hole pattern design method and photomask

ActiveUS7537864B2Increase flexibilityEasy qualitySemiconductor/solid-state device detailsSolid-state devicesIntegrated circuit manufacturingEngineering

Owner:RENESAS ELECTRONICS CORP

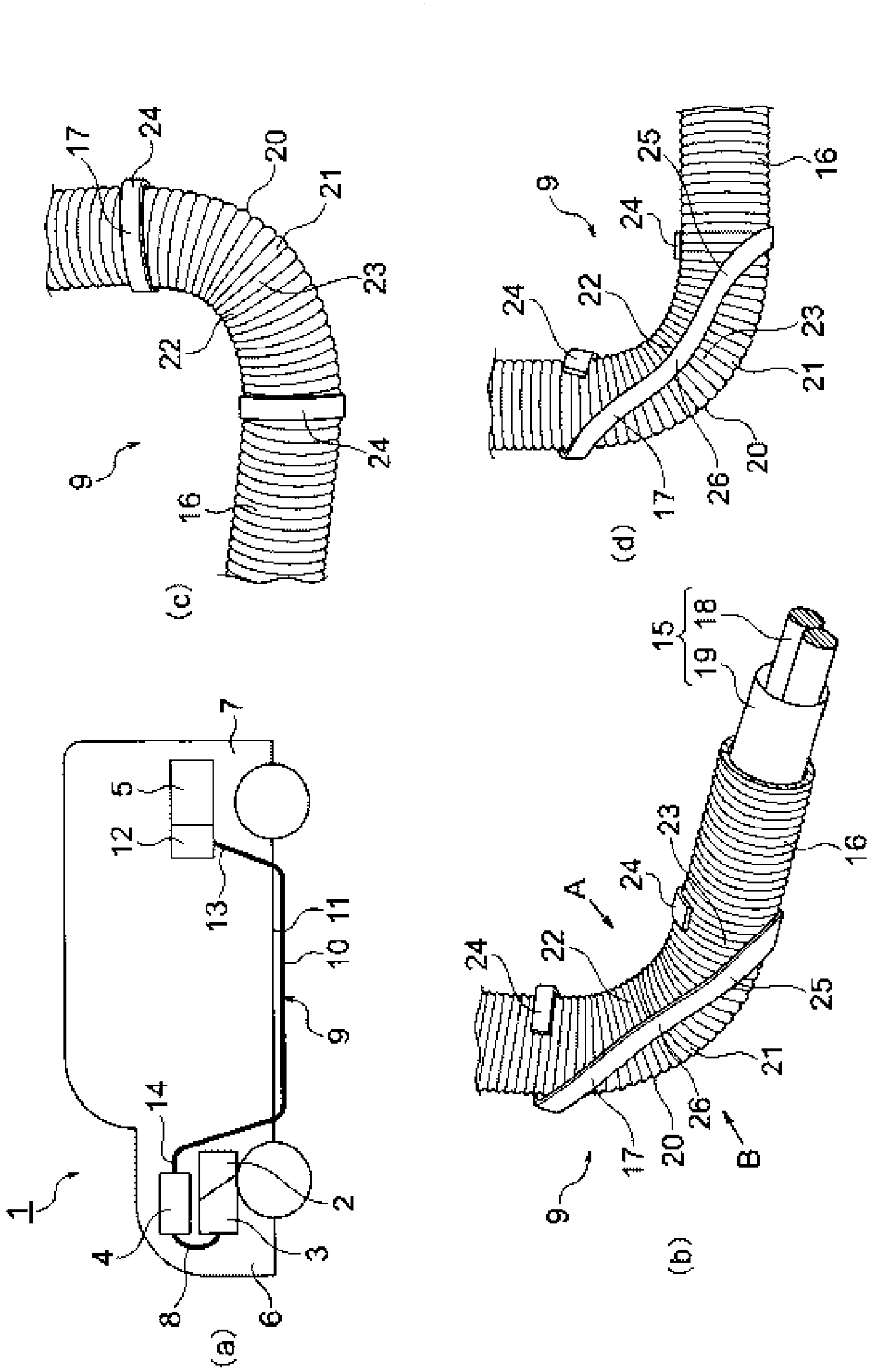

Wire harness

Owner:YAZAKI CORP

Illuminating system

InactiveUS7202779B2Improve the level ofEasy constructionLighting circuitsDigital data processing detailsEngineeringLighting system

Owner:TOYODA GOSEI CO LTD

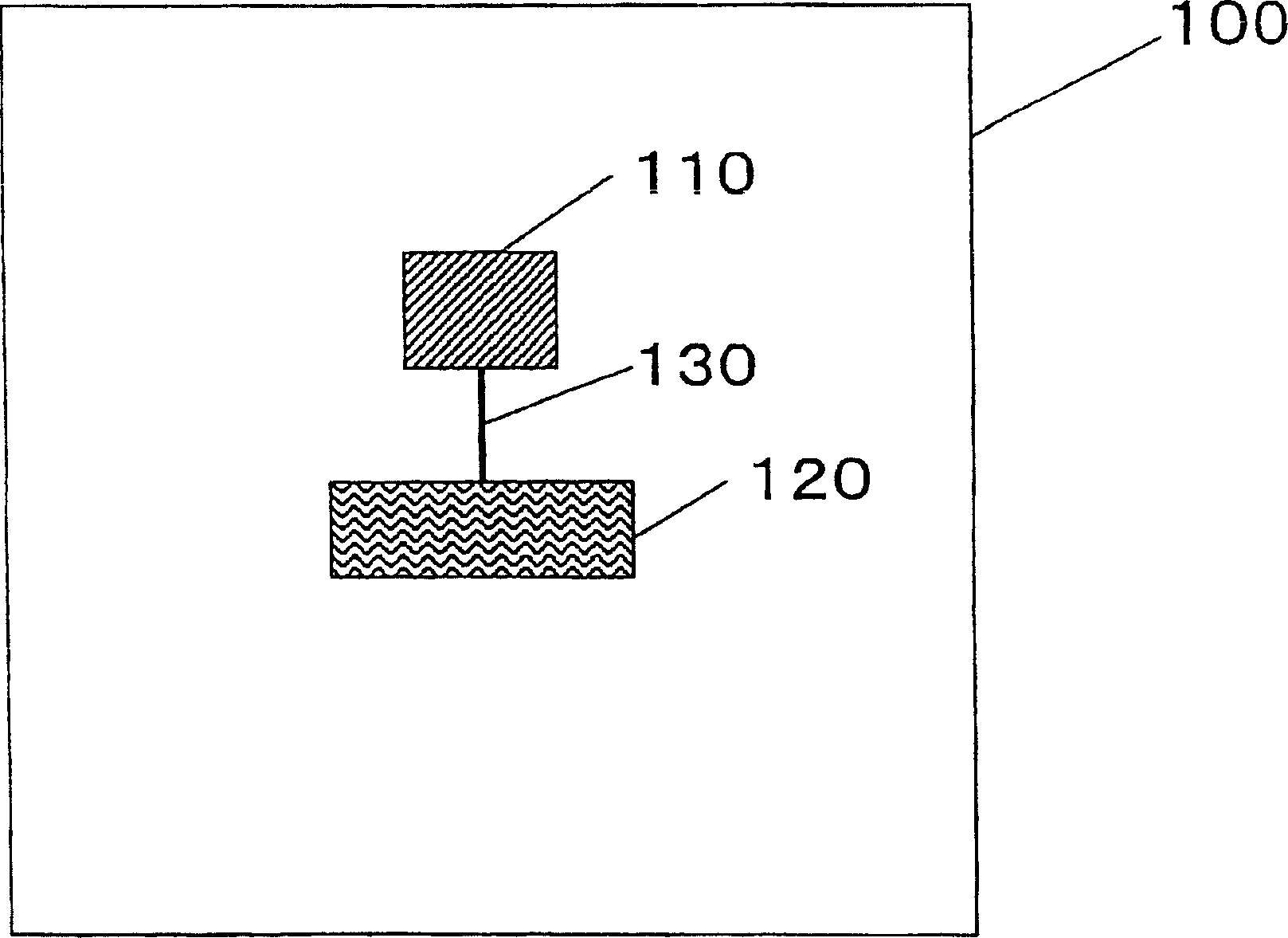

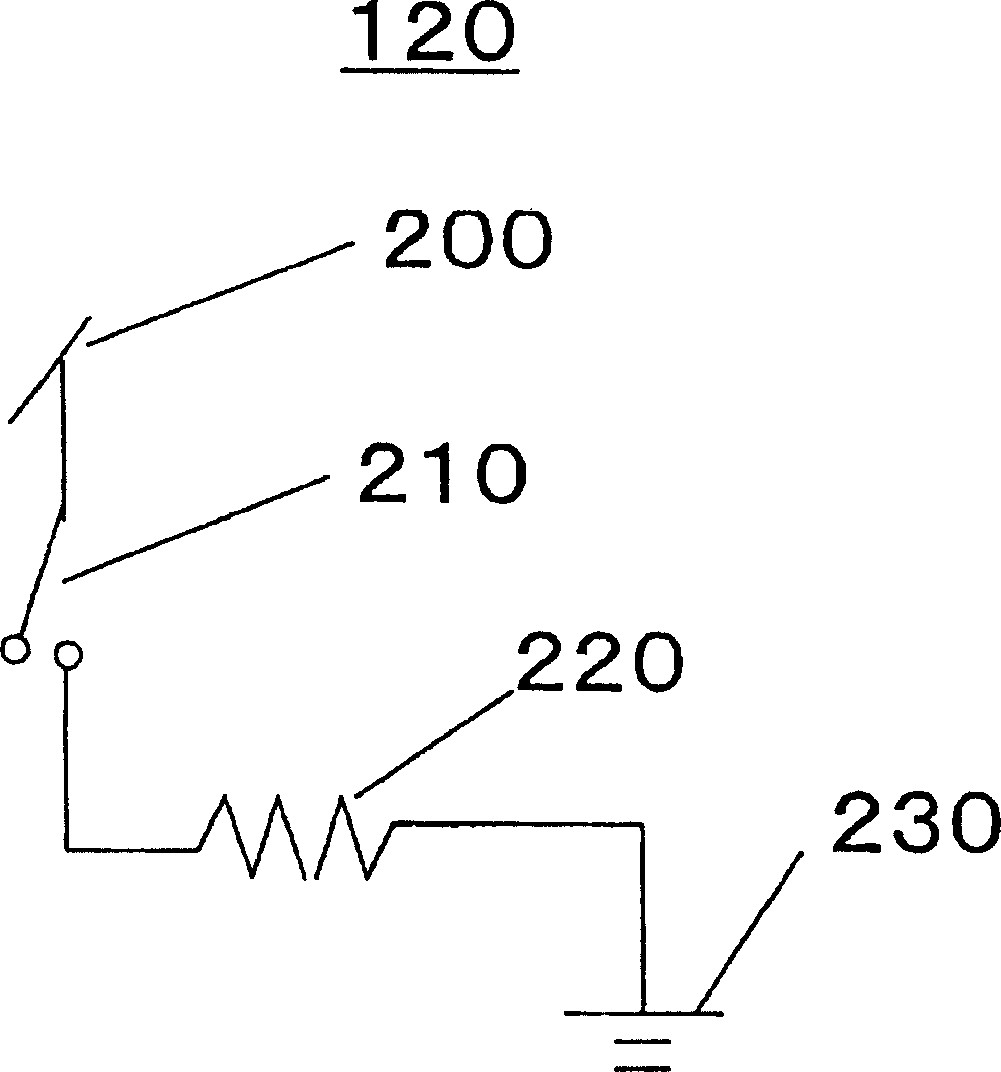

Semiconductor device

InactiveCN1705081AAvoid misuseLower temperature rangeSemiconductor/solid-state device detailsSolid-state devicesOperating temperature rangeSemiconductor

It is an object to operate a semiconductor device within a desirable operating temperature range in a normal operation or a test operation. A semiconductor device 100 comprises a temperature sensor portion 110 for detecting a temperature to output a heat generation instruction when the temperature is equal to or lower than T degree and to output a heat generation stop instruction when the temperature is equal to or higher than T' degree, and a heat generating portion 120 for performing / stopping the generation of heat in accordance with the heat generation instruction / heat generation stop instruction from the temperature sensor 110. Even if a temperature around the semiconductor device is low, the semiconductor device 100 can be maintained to be a certain temperature or more without an influence thereof. When the temperature around the semiconductor device rises, moreover, heat is not generated. Consequently, it is possible to prevent a malfunction from being caused at a high or low temperature.

Owner:PANASONIC CORP

Up and down open emergency exit external handle mechanism

The invention discloses an outer handle mechanism of an upward-downward opening type emergency exit. A handle shaft is hinged to an outer handle main structure member; a driving crank is fixedly connected to the handle shaft; a crank locking hook is hinged to the outer handle main structure member; the driving crank interacts with the crank locking hook; one end of a connecting rod is connected with the crank locking hook, and the other end of the connecting rod is connected with one end of a crank, the crank is hinged to the outer handle main structure member, and the other end of the crank is connected with the inner side of a secondary turnover plate through an inserting lug connecting rod; the secondary turnover plate is hinged to a primary turnover plate, the primary turnover plate and the secondary turnover plate are kept in relative fixed positions in the hinged position through two torsional springs I; the secondary turnover plate is connected with the outer handle main structure member through two extension springs; and the primary turnover plate is hinged to the outer handle main structure member, and a relative fixed position relation between the primary turnover plate and the outer handle main structure member is kept in the hinged position through two torsional springs II. The problems that in the prior art, the mechanism complexity is high, the weight is high, the functions are incomplete, and the reliability is relatively low are solved.

Owner:AVIC SAC COMML AIRCRAFT

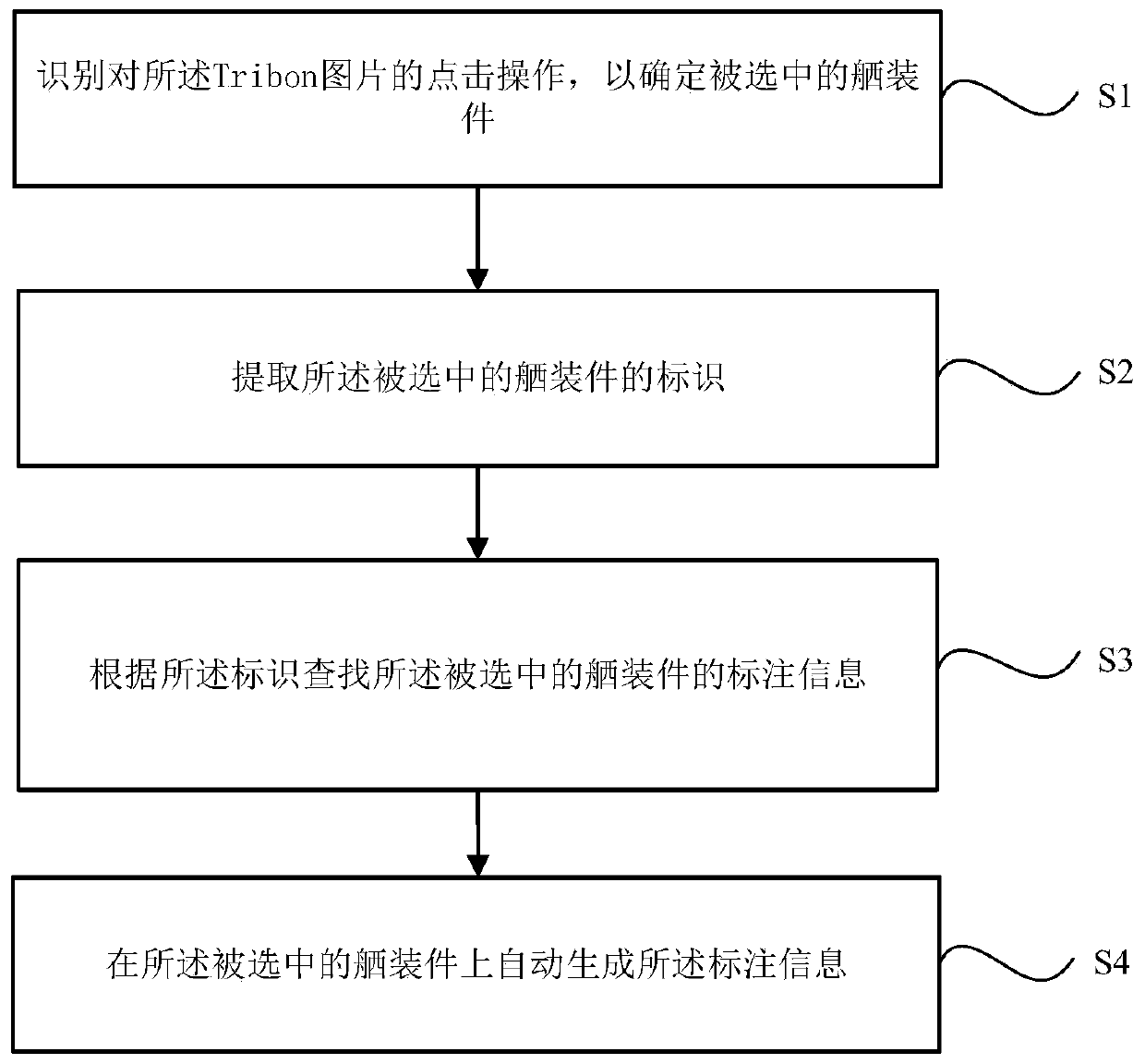

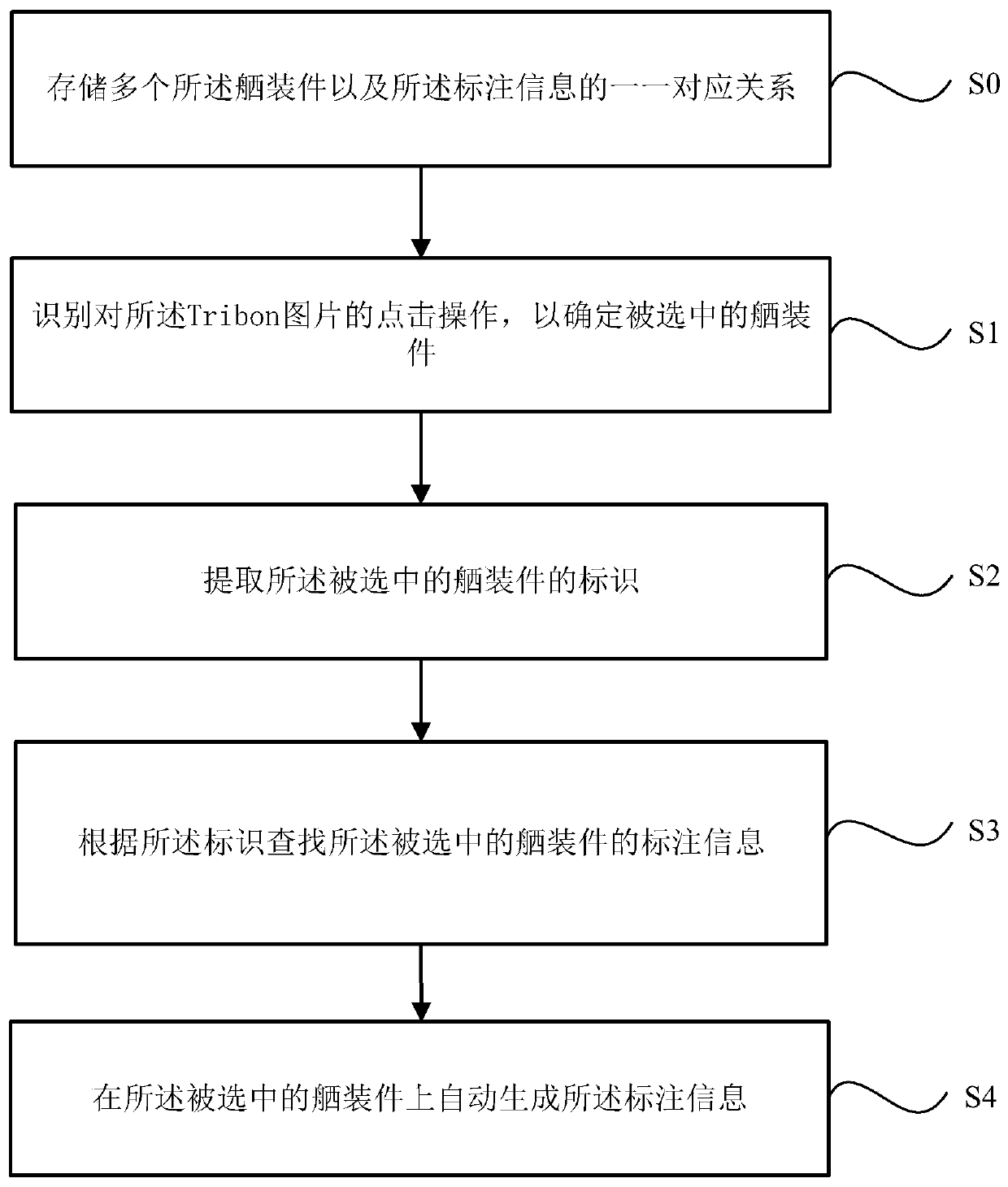

Automatic labeling method and system for fitting-out piece, storage medium and electronic equipment

ActiveCN110321630AReduce repetitive labor timeReduce design man-hoursGeometric CADSpecial data processing applicationsMan-hourModel Number

The invention discloses an automatic labeling method and system for a fitting-out piece, a storage medium and electronic equipment. The automatic labeling method comprises the steps of recognizing click operation on a Tribel picture so as to determine a selected outfitting piece, and the distance between any composition line of the selected outfitting piece in the Tribel picture and the click position of the click operation is the closest; extracting an identifier of the selected outfitting piece; searching labeling information of the selected fitting-out piece according to the identifier, wherein the labeling information comprises one or more of a fitting-out piece model, a fitting-out piece serial number and fitting-out piece description information; and automatically generating the annotation information on the selected outfitting piece. According to the technical scheme, the clicked outfitting piece can be automatically marked, the design man-hour is effectively saved, and the design cost is reduced.

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

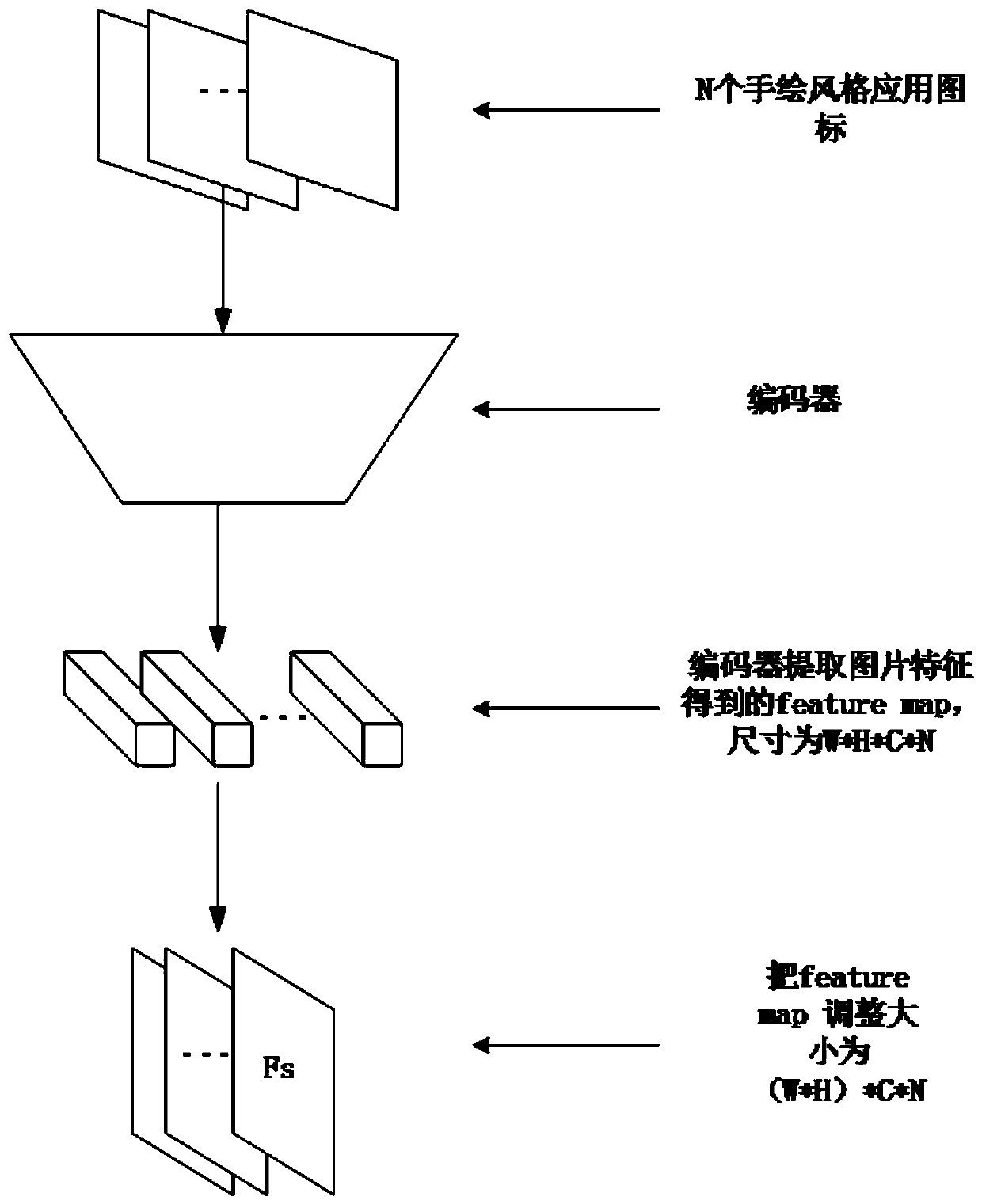

Intelligent stylized icon generation method for mobile terminal

PendingCN111583352AReduce design man-hoursTexturing/coloringImage codingComputer graphics (images)Algorithm

The invention discloses an intelligent stylized icon generation method for a mobile terminal. The method comprises the following steps: respectively extracting feature maps of a hand-painted style icon and a non-hand-painted style icon by using an encoder in an encoder / decoder, and setting the feature map of the extracted hand-painted style icon as FS; setting the extracted feature map of the non-hand-painted style icon as FC; and fusing the FS and the FC and then inputting the fused FS and FC into a decoder, and generating a stylized icon by the decoder. According to the method, related technologies of deep learning are utilized, application icons of the same style can be automatically generated after a designer provides a small number of hand-drawn icons, and the design man-hour is saved.

Owner:TIANJIN UNIV

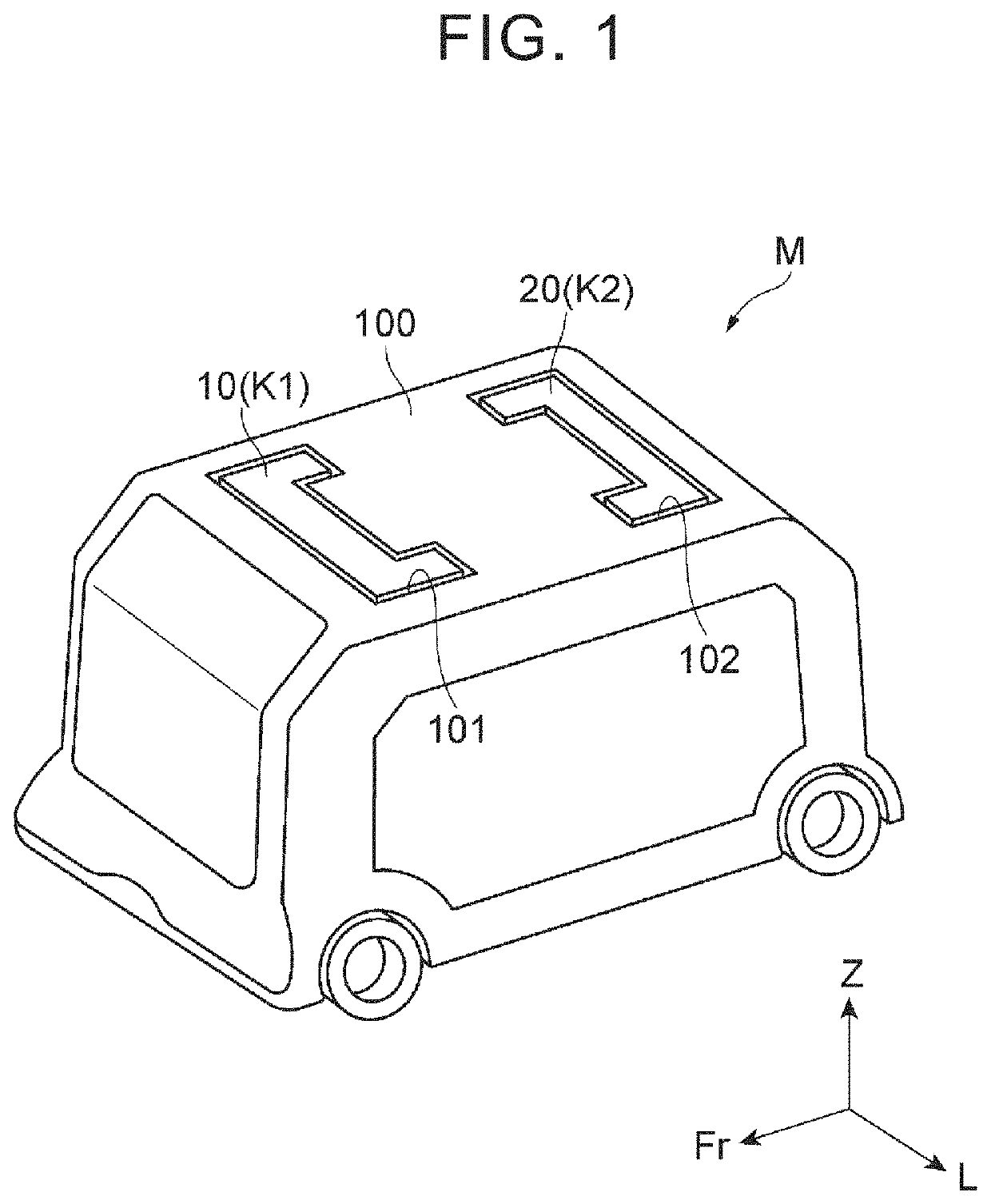

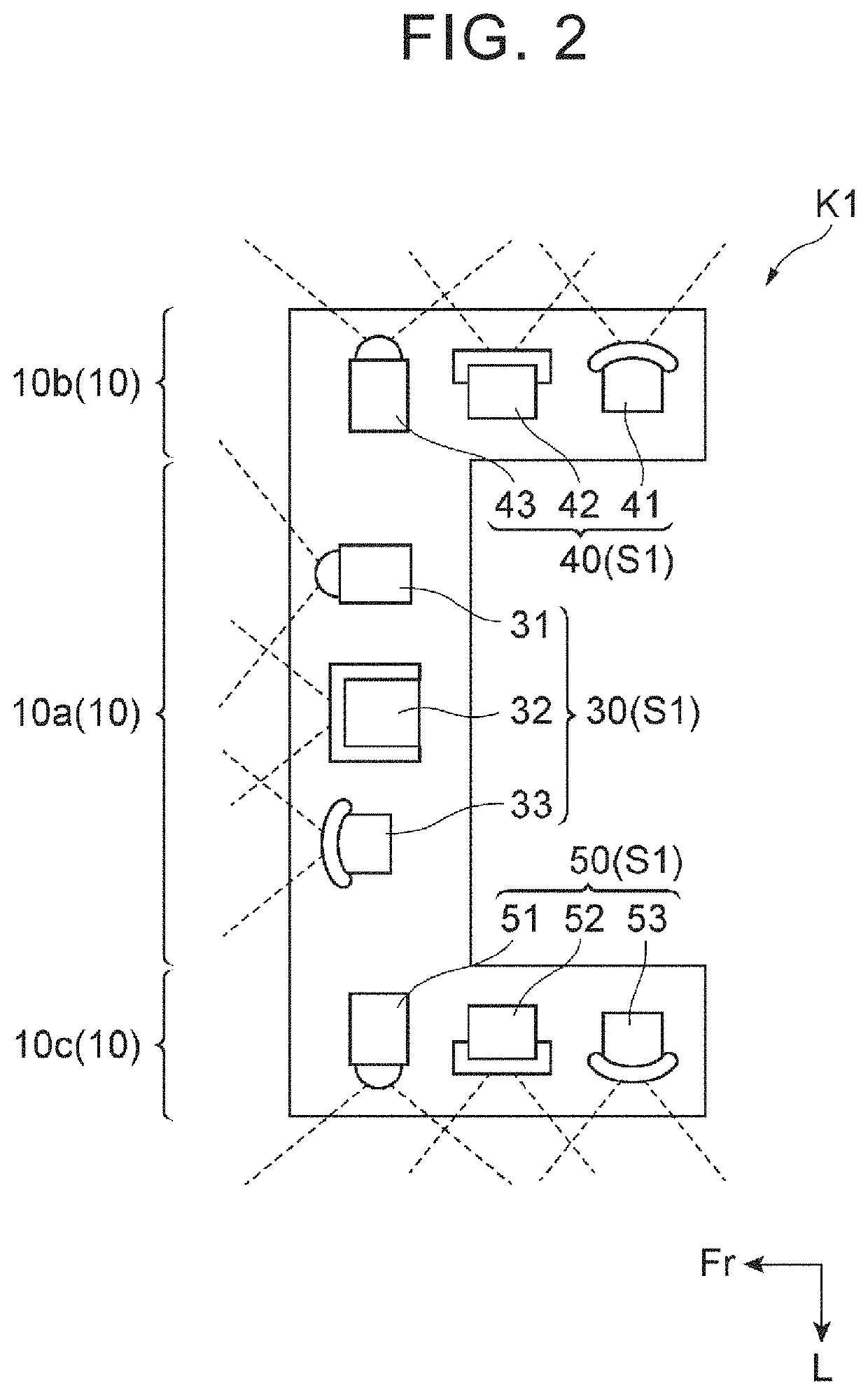

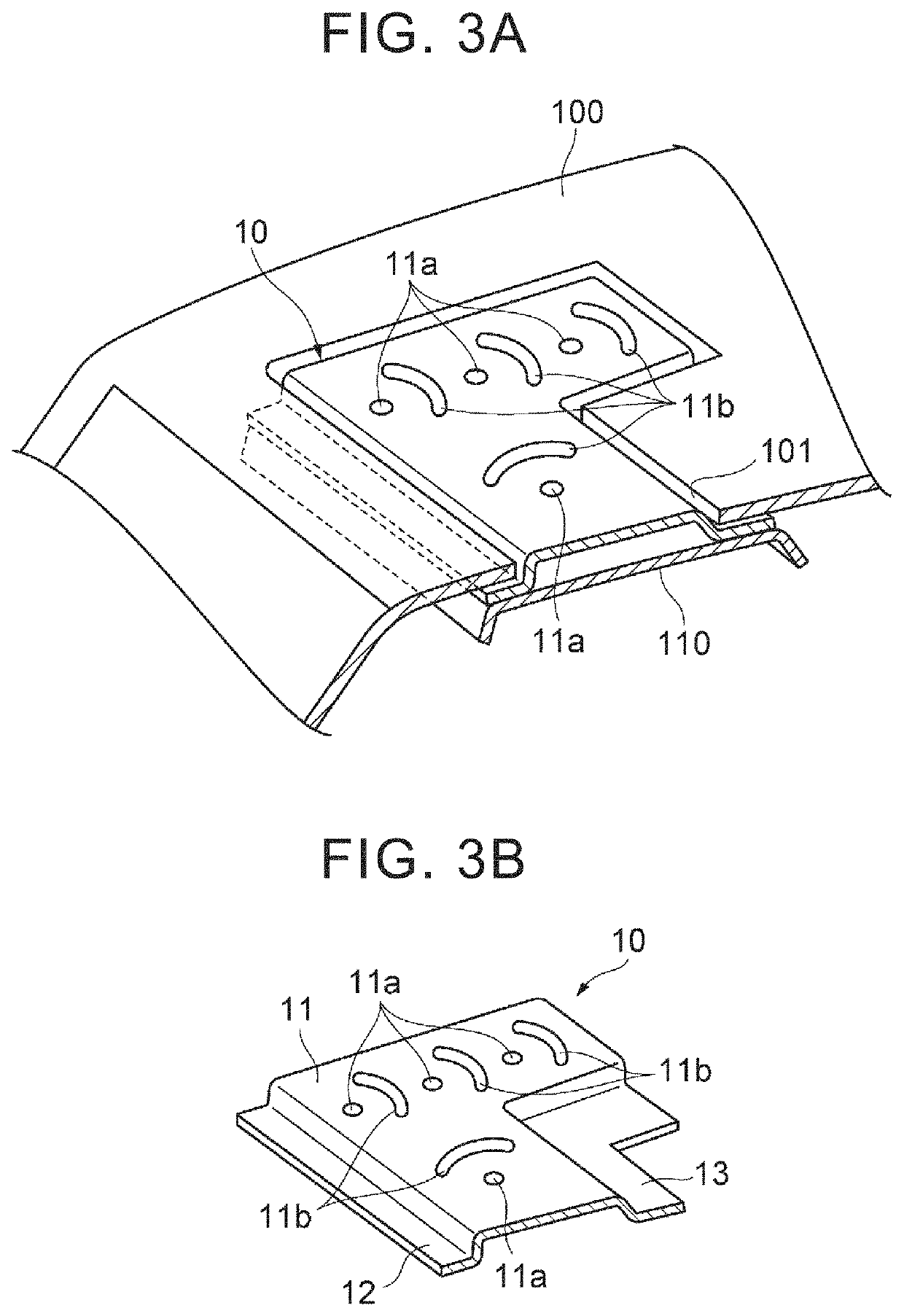

Vehicle sensor mounting structure and vehicle sensor bracket set

PendingUS20210364631A1Improve accuracyMounting man-hours can be reducedVehicle componentsRadio wave reradiation/reflectionMillimetre waveLidar

A vehicle sensor mounting structure includes a first sensor kit and a second sensor kit, each having a sensor group including a plurality of sensors and a bracket on an upper surface of which the sensor group is installed, a first fitting portion which is provided on a front side of the roof in a vehicle front-rear direction and into which a first bracket is fitted such that the upper surface is exposed, and a second fitting portion which is provided on a rear side of the roof in the vehicle front-rear direction so as to face the first fitting portion in the vehicle front-rear direction and into which a second bracket is fitted such that the upper surface is exposed. The plurality of sensors of each sensor group includes at least two kinds of sensors selected from among a camera, a millimeter wave radar, and a LiDAR sensor.

Owner:TOYOTA JIDOSHA KK

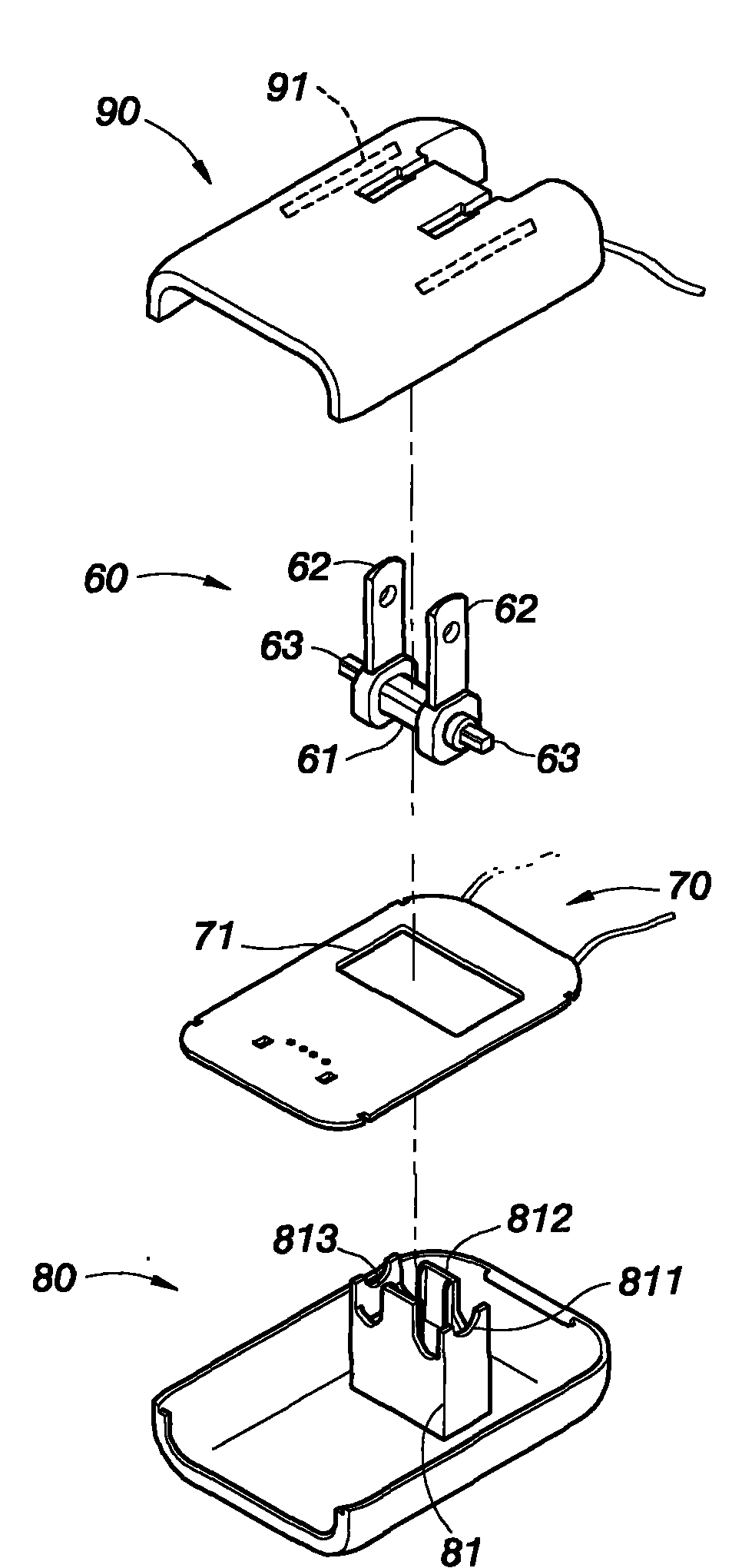

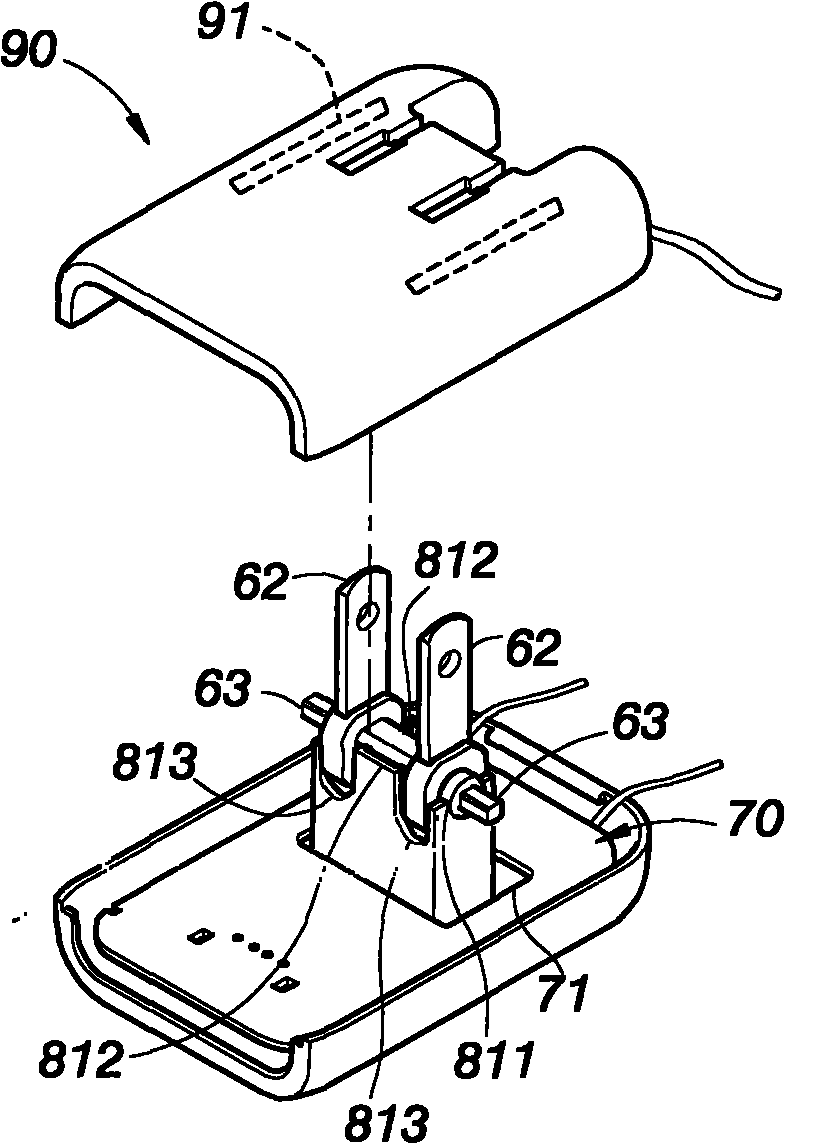

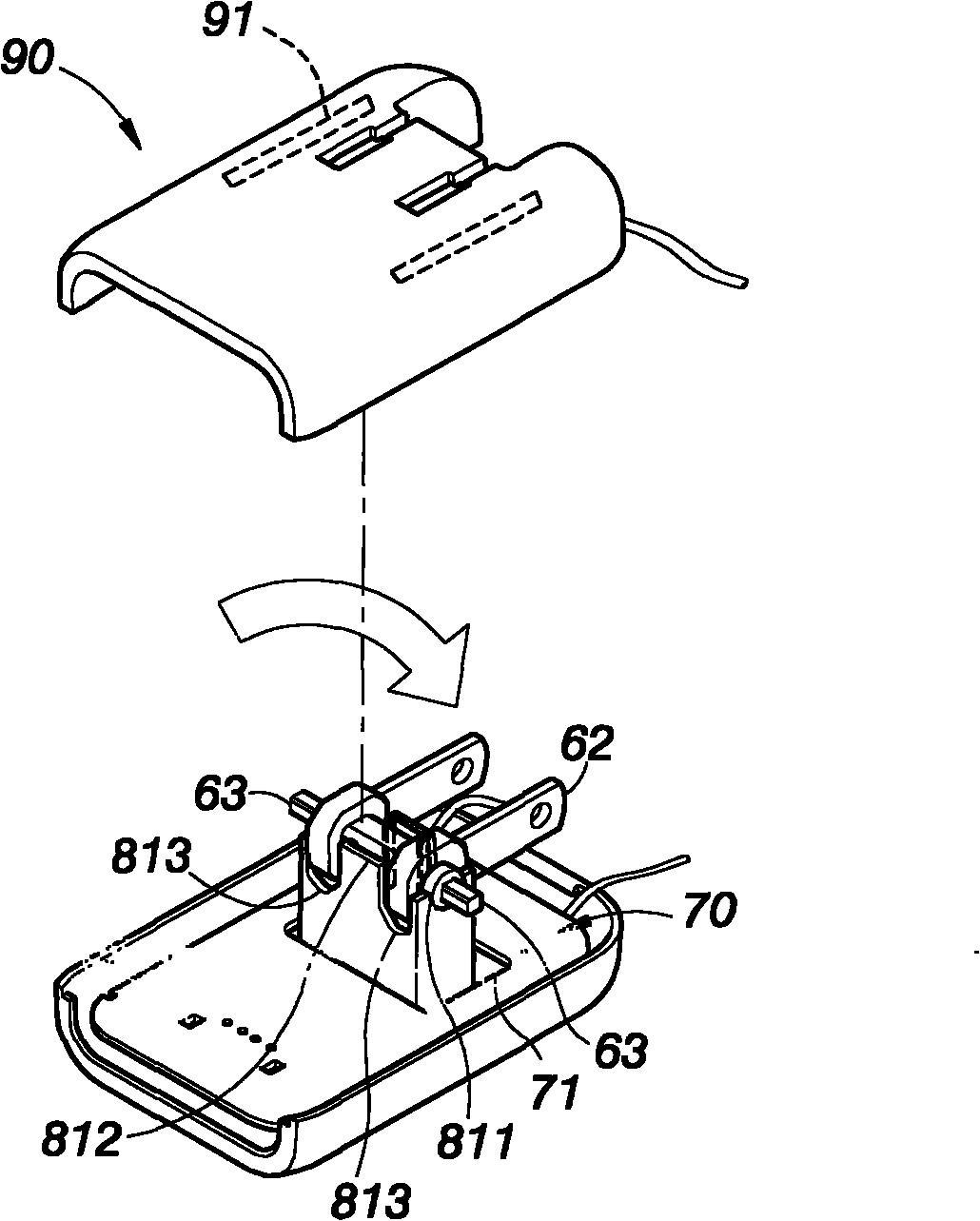

Charger structure

InactiveCN102074764ASimplify manufacturing difficultyReduce difficultySecondary cells charging/dischargingEngineeringMechanical engineering

The invention relates to a charger structure which can simplify design difficulty and reduce manufacturing cost. The charger structure comprises a first shell body, a second shell body, a positioning cover board which is arranged between the first shell body and the second shell body, a plug unit and a circuit board, wherein a positioning column is arranged on the first shell body, and the positioning cover board can be used for the inserting and the positioning of the positioning column; a spacing column is arranged on the second shell body, the spacing column penetrates the bottom of the circuit board to butt the positioning cover board at a smaller area, further, the positioning cover board generates spacing effects on the plug unit, and segment positioning efficacy is generated when the plug unit rotates. Compared with the traditional charger which is provided with a segment rotating plug unit, the invention not only can reduce the design difficulty of the circuit board but also achieve the effect of reducing the manufacturing cost.

Owner:C TECH UNITED

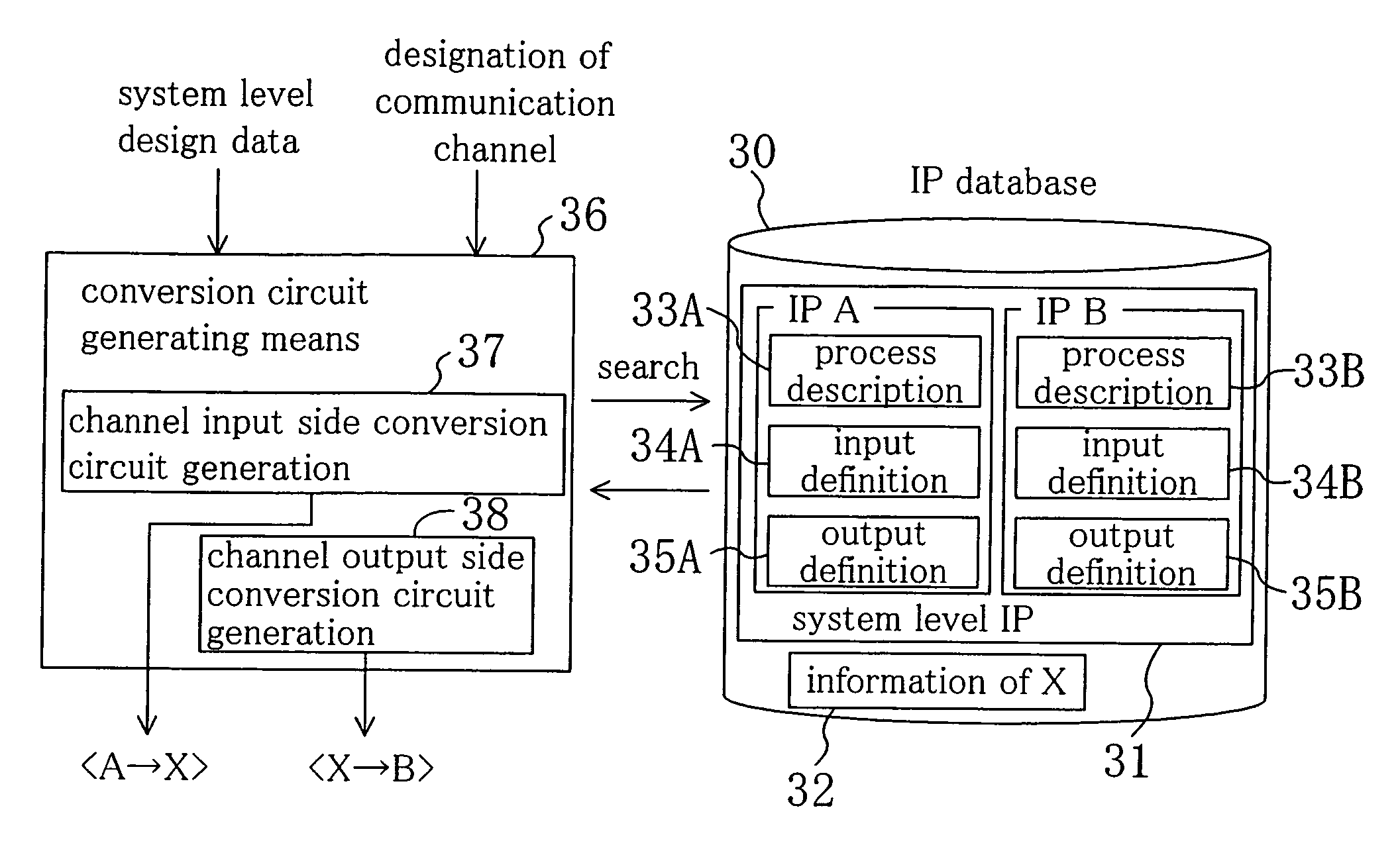

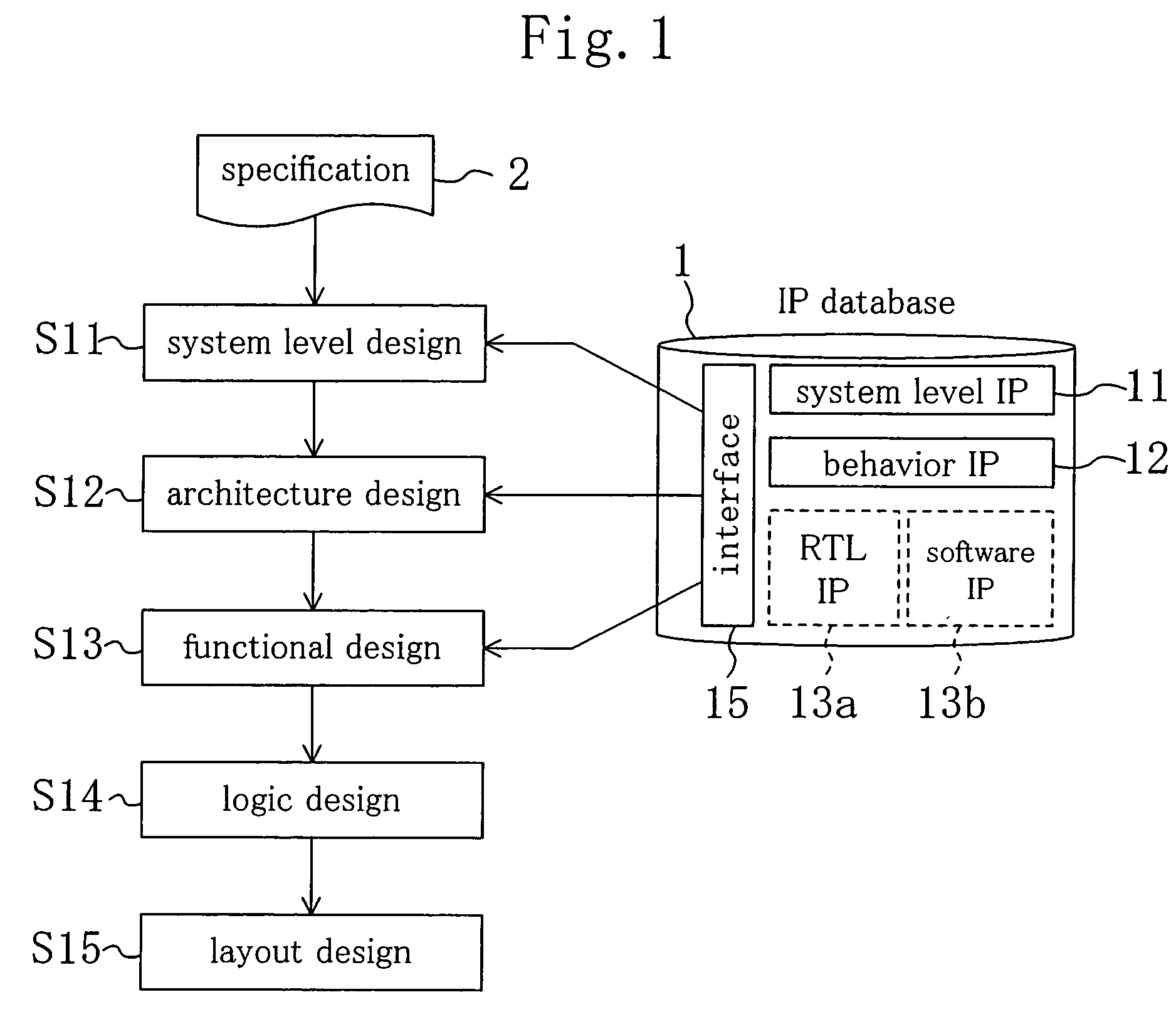

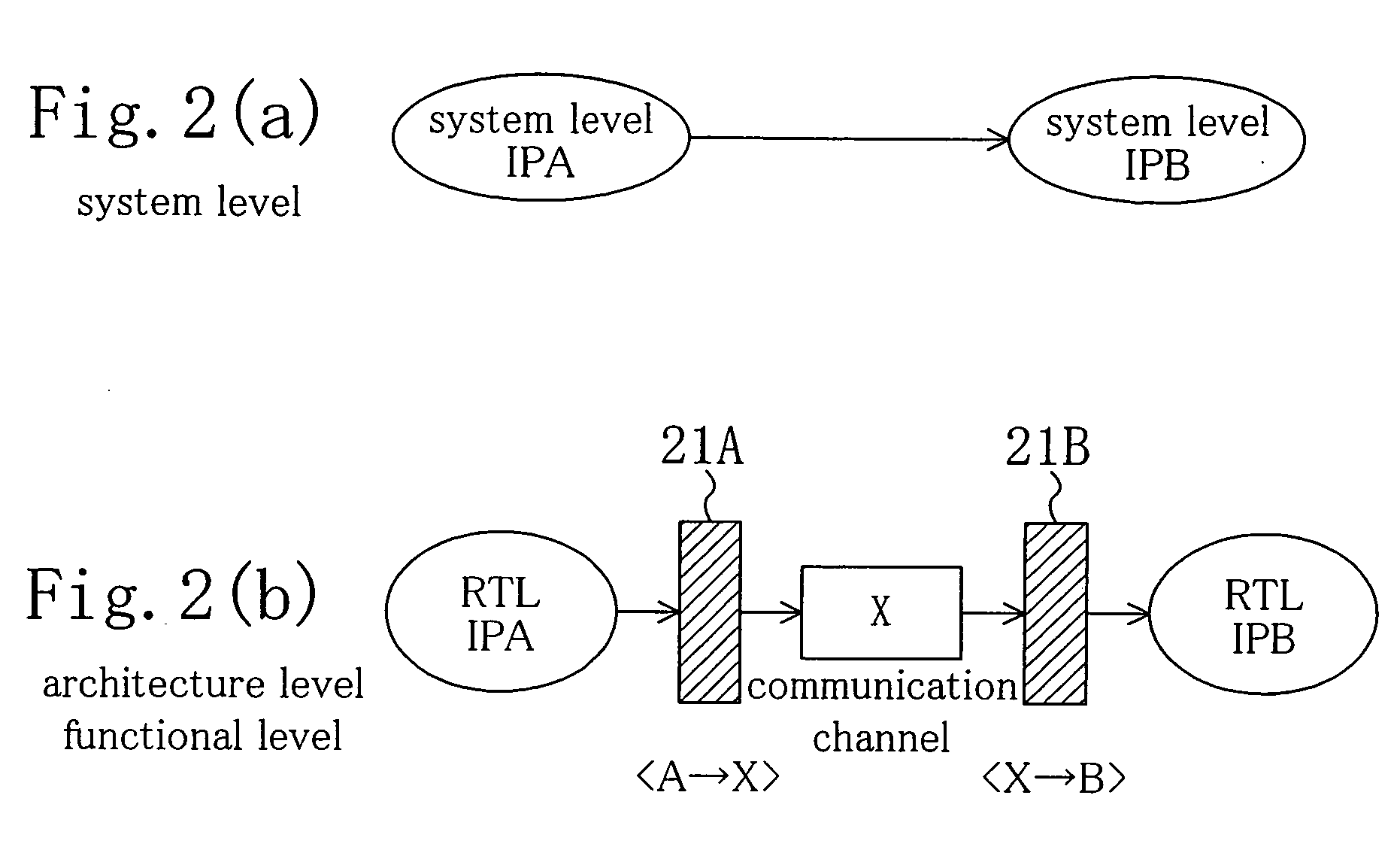

IP-based LSI design system and design method

InactiveUS20060036974A1Improve design efficiencyReduce design man-hoursSemiconductor/solid-state device manufacturingCAD circuit designComputer architectureDesign methods

An IP database includes a system level IP used in system level design. IPs A and B in the system level IP are divided into processing algorithm description portions, input data structure definition portions and output data structure definition portions. When a communication channel is provided between the IPs communicating data in architecture or functional design, a conversion circuit generating means generates a data conversion circuit between the communication channel and each of the IPs with reference to the IP database.

Owner:PANASONIC CORP

Accommodation device for vehicle use

InactiveCN102133873BShorten production hoursReduce design man-hoursPassenger spaceVehicle arrangementsSimulationMechanical engineering

The invention provides an accommodation device for vehicle use, which contributes significantly to design man-hour decrease and production man-hour decrease even in case of a carrying space or an accommodation container body with a different shape. The accommodation device for vehicle use comprises a pair of rotation adjusting units for fixing guiding mechanisms with a capability of adjusting therotation track on the two ends of the accommodation container body. By fixing the lid on parts of the guiding mechanisms and making the lid rotate relative to the accommodation container body throughthe guiding mechanisms, the lid is thus made capable of opening and closing the opening. Therefore, even in case of size changes of the accommodation container body and the lid, the rotation adjusting unit can be shared.

Owner:TOYODA GOSEI CO LTD

Parametered assembly and design of three-dimensional mould structure and automatic dimension labeling method for two-dimensional figure

InactiveCN100530198CReasonable structural designImprove design qualitySpecial data processing applicationsBlock structureSubstructure

The invention relates to a method for parameterized assembly design of three-dimensional mold structure and automatic dimensioning of two-dimensional drawings. ; Determine the distance between the finished product, the mold core and the template; Step 2: Design the mold sub-structure, respectively execute the instructions of the slider structure, inclined pin structure, cooling circuit, small entry structure, and ejection structure of the main components of the mold, through the computer Calculate, generate slider, inclined pin, cooling circuit, small entry sub, thimble components; Step 3: Execute the command of the assembly drawing to generate a two-dimensional assembly drawing; Step 4: Change the design requirements, and repeat the instructions of Step 2 and Step 3; Step 5: Output the official 2D final assembly drawing; Step 6: Output the 2D part processing drawing with automatic dimensioning. The present invention makes the mold structure design more convenient and the flow more reasonable, improves the mold design quality, shortens the total mold design man-hour, and reduces human errors.

Owner:陈金德

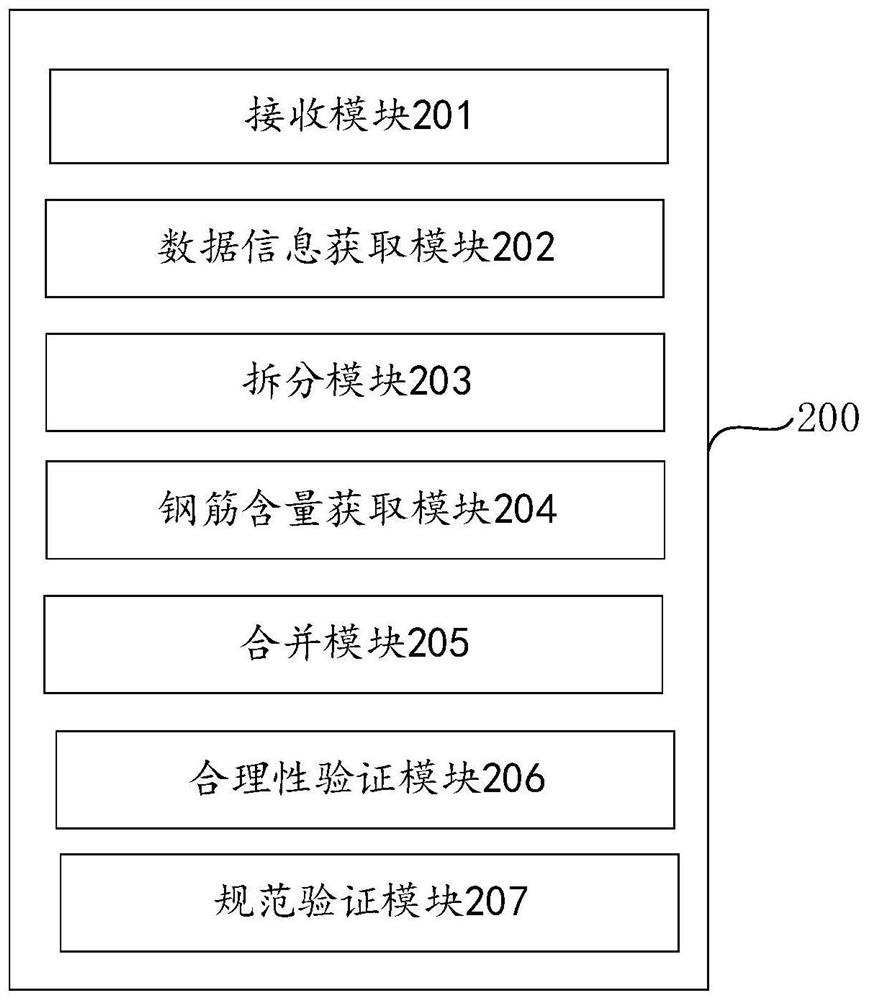

Building structure steel bar layer design method and device, electronic equipment and medium

PendingCN114036624AAutomate processingReduce design man-hoursGeometric CADData processing applicationsData informationConstruction engineering

The embodiment of the invention relates to the technical field of intelligent building design, and discloses a building structure steel bar layer design method and device, electronic equipment and a medium. The method comprises the following steps of receiving input building design information in a building structure design model, acquiring data information of the building structure design model according to the building structure design model, wherein the data information comprises a model standard layer, a natural layer, a steel bar standard layer, and building design information and structural member information related to the standard layer, the natural layer and the steel bar standard layer, according to the model standard layer and the natural layer, splitting a steel bar standard layer, and acquiring at least one steel bar layer corresponding to the model standard layer, obtaining the steel bar content of each steel bar layer in the model standard layer, and according to the steel bar content of each steel bar layer, combining the steel bar layers according to a combination strategy, and acquiring a standard layer. According to the method, the steel bar layers in the structure model are automatically split and combined, manual splitting and combining are not needed, automatic model processing is achieved, therefore, the design working hours are saved, and the construction cost is reduced.

Owner:广东众图科技有限公司

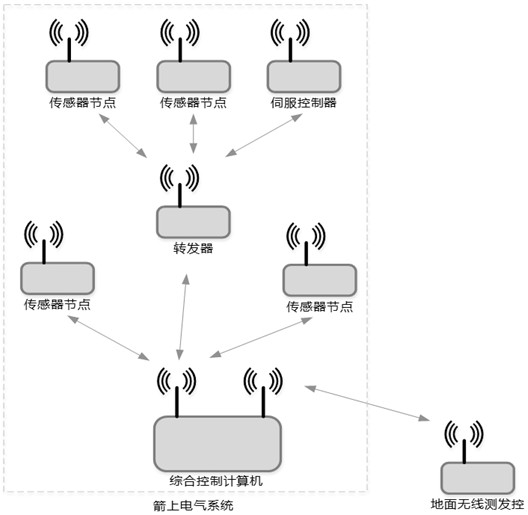

On-rocket electrical system of carrier rocket

ActiveCN114815901AReduce electricity costsIncrease loading capacityCosmonautic vehiclesCosmonautic partsLine sensorCommunication unit

The invention provides an on-rocket electrical system of a carrier rocket, which comprises a master control electrical subsystem and at least one sub-control electrical subsystem, and each of the master control electrical subsystem and the sub-control electrical subsystem comprises at least one functional device and a wireless sensor node. The functional devices and the wireless sensor nodes respectively comprise a corresponding power supply unit and a wireless communication unit, the main control electrical subsystem further comprises a wireless center node and a comprehensive control computer which are electrically connected, and power is uniformly supplied through the corresponding power supply units. Each sub-control electrical subsystem further comprises at least one relay forwarding antenna which is used for receiving data sent by the functional equipment in the corresponding sub-control electrical subsystem and the wireless sensor node through the corresponding wireless communication unit and forwarding the data to the wireless center node; and the relay forwarding antenna is also used for receiving a control instruction sent by the comprehensive control computer through the wireless center node and forwarding the control instruction to the target equipment. The loading capacity and the production efficiency of the rocket can be improved, and the use cost is reduced.

Owner:东方空间技术(北京)有限公司 +2

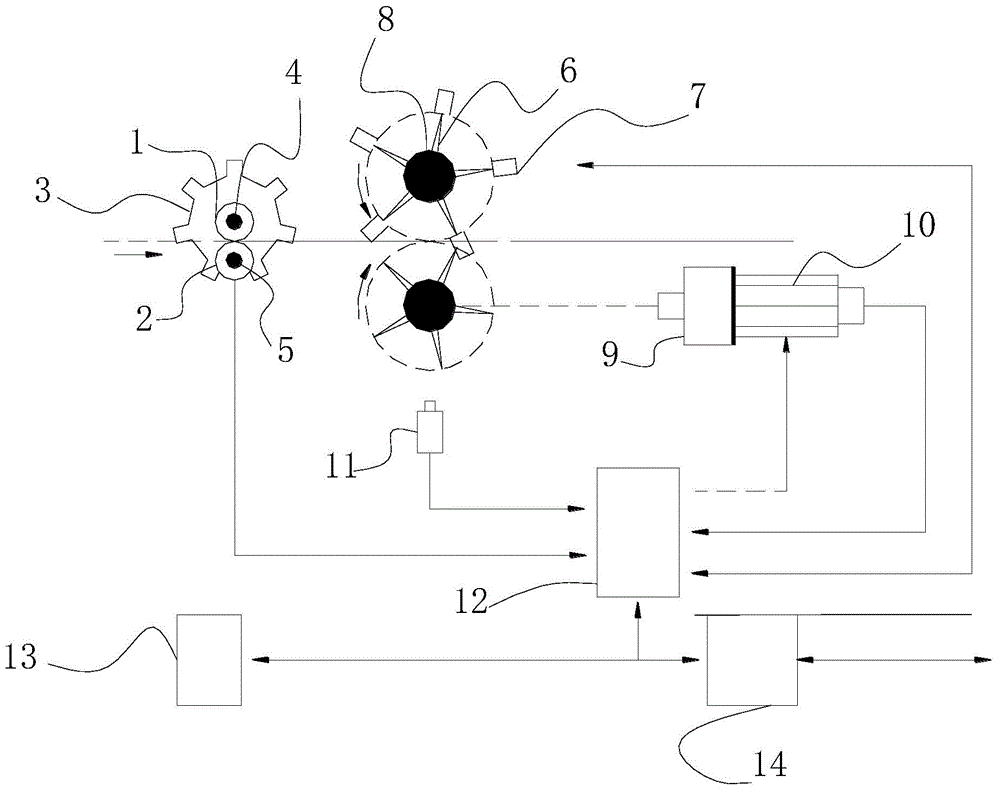

Automatic Alignment Control Device for Tipping Paper of Cigarette Making Machine

The invention discloses an automatic tipping paper alignment control device of a cigarette making machine. The automatic tipping paper alignment control device comprises a knife wheel, an upper rubber roller and a lower rubber roller, wherein a rubber roller cam is arranged on a front-end shaft of the upper rubber roller. One convex lug of the rubber roller cam is aligned to a rubber roller cutting line. An even five-tooth structure is arranged on the periphery of a knife cam. An even seven-tooth structure is arranged on the periphery of the rubber roller cam. A servo motor is connected with a servo driver. A proximity switch is connected with the servo driver. The automatic tipping paper alignment control device can finish automatic synchronous alignment only by needing one-time signal correction after being started. In the normal production process by using the machine, real-time dynamic alignment is performed, cigarette crevasse, edge warping and other phenomena are completely eradicated, and qualified cigarettes can be continuously delivered to downstream products. The offset compensation amount between two alignment signals can be set, and the system accuracy and stability are greatly improved. A movement controller and the servo driver are combined integrally, a special controller for executing the function, a PLC and a high-speed counter are omitted, the design time is shortened, and the installation and purchase cost is saved.

Owner:CHINA TOBACCO SICHUAN IND CO LTD +1

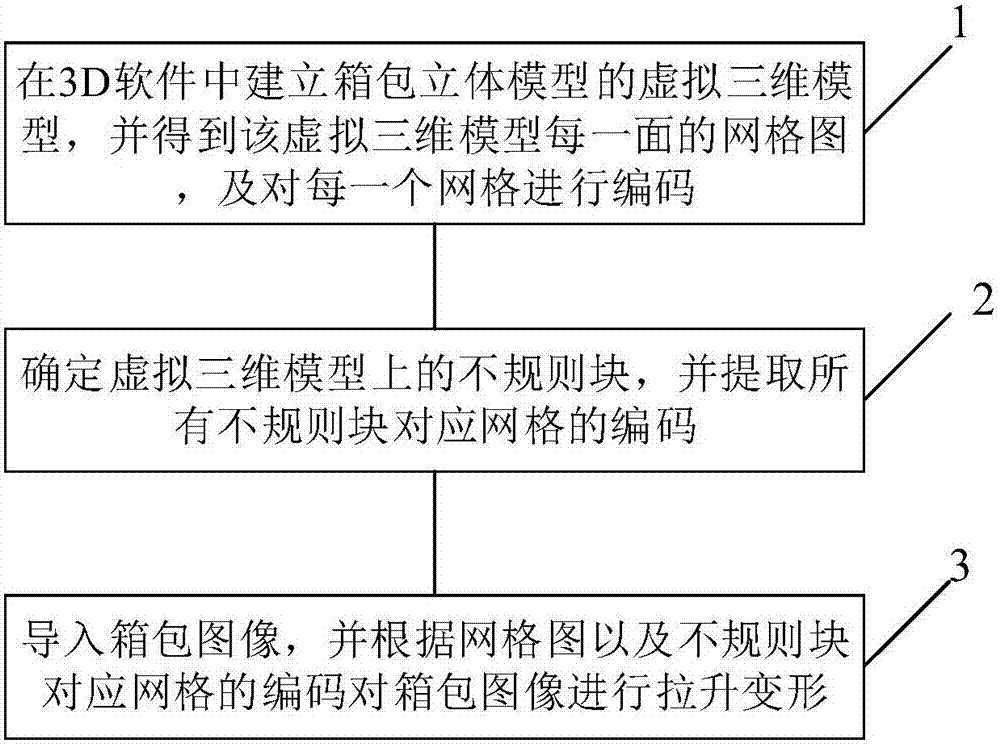

Image designing and transformation method based on 3D software

InactiveCN107305703AReduce wasteHigh precisionImage data processingComputer graphics (images)Mesh grid

The invention relates to an image designing and transformation method based on 3D software. The method comprises the steps of: (1) establishing a virtual three-dimensional model of a stereoscopic case bag model in the 3D software, and obtaining a grid graph of each side of the virtual three-dimensional model, and coding each grid; 2) determining irregular blocks on the virtual three-dimensional model, and extracting codes of the grids corresponding to all the irregular blocks; and 3) importing a case bag image, and carrying out stretching transformation on the case bag image according to the grid graph and the codes of the grids corresponding the irregular blocks. Compared with the prior art, the method carries out designing based on the 3D software, ensures success of designing and transformation in actual drawing sample producing without the need for repeat experiments, reduces waste, and has a success rate near 100%.

Owner:嘉善杭运制版有限公司

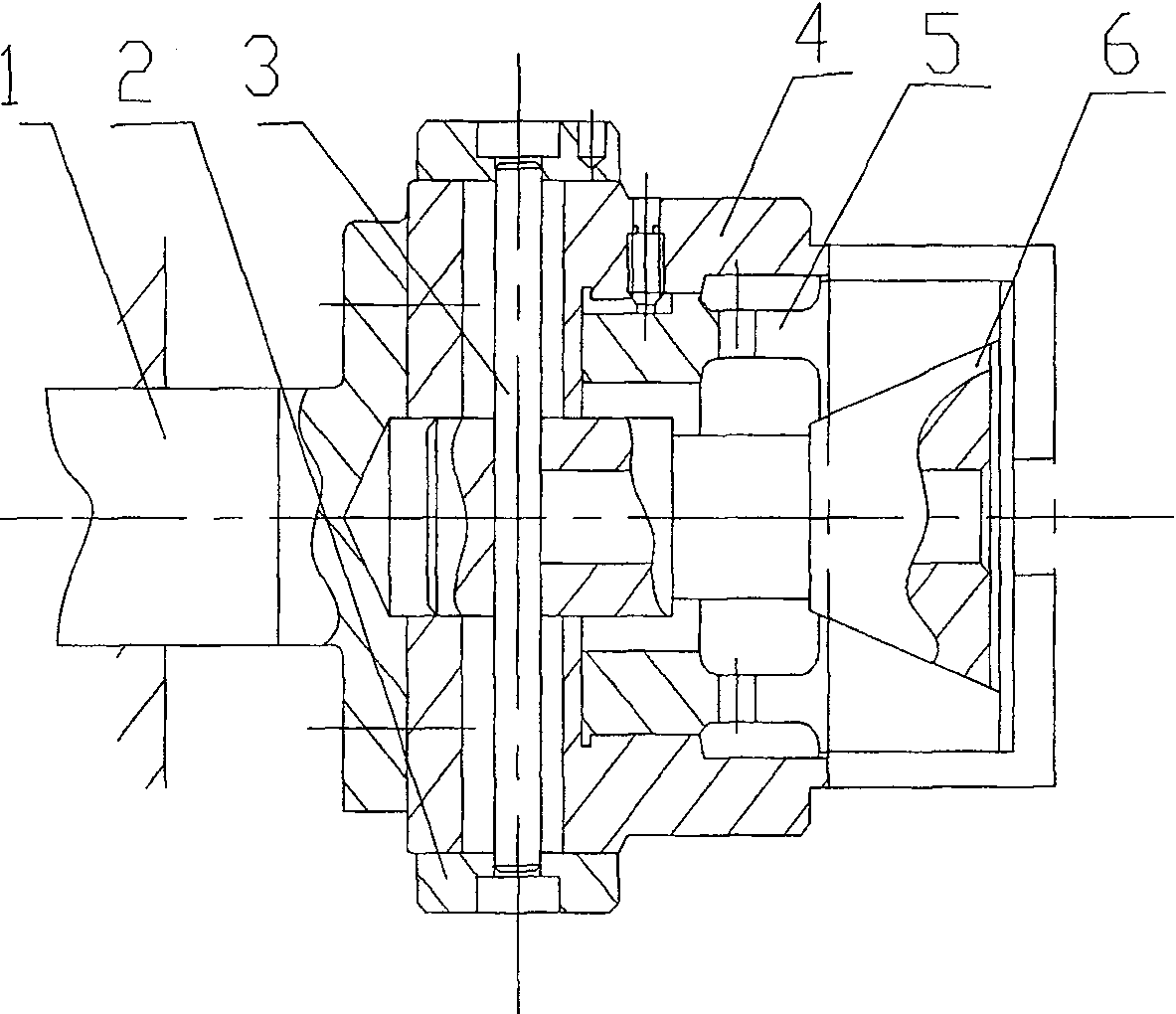

High-efficient modular fixture for processing part

InactiveCN100556615CReduce design man-hoursReduce production man-hoursPositioning apparatusMetal-working holdersModular fixtureMechanical engineering

The invention relates to a group of clamps used for part processing, mainly consisting of a basic part and an adjustable part; wherein, the basic part comprises a clamping body (1) and transmission clamping parts (2, 3); the adjustable part consists of replaceable parts (4, 6) and an elastic expanding part (5); during the part processing, each dimension group of the part is provided with a group of corresponding replaceable parts. When parts of different dimension groups are processed, replaceable parts (4, 6) are all needed to be replaced; but in the same dimension group, only elastic expanding part (5) of corresponding dimension is needed to be replaced for the workpiece of difference positioning aperture; the clamp can shorten the design and manufacture time of normal clamp, saves the material and reduces the production cost.

Owner:BEIJING UNION UNIVERSITY

Power unit structure for electrically driven vehicle

ActiveUS10744863B2Improve rigidityReduce design man-hoursAssociation with control/drive circuitsElectric propulsion mountingElectric carsPower apparatus

To provide a power unit structure for an electrically driven vehicle which can decrease design man-hours, as well as raise the rigidity of the unit. A control device unit for an electrically driven vehicle includes: a first mounting part which is a mounting part of a power supply unit that supplies electric power to an electric motor, and a second mounting part which fixes the control device unit to an electric motor unit; and the control device unit is mounted from a transmission case side of the electric motor unit towards an electric motor case side, the first mounting part being mounted to a central case, and the second mounting part being mounted to the transmission case.

Owner:HONDA MOTOR CO LTD

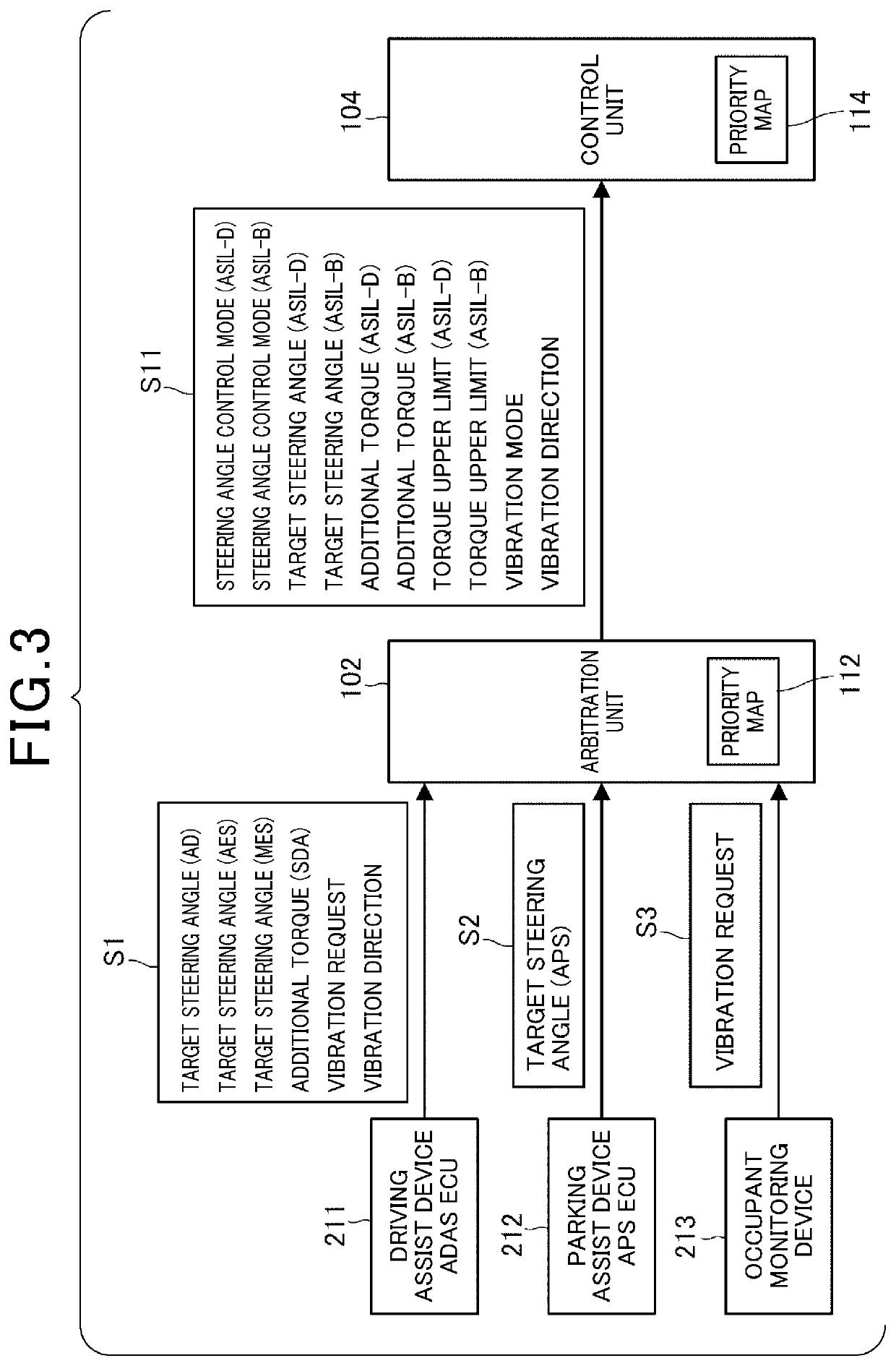

Control device, and control method for controlling electric power steering device

PendingUS20220258796A1Without any changeReduce design man-hoursSteering linkagesAutomatic steering controlElectric power steeringControl engineering

A control device controlling an electric power steering device that includes a motor generating a steering torque and applies a steering force to a steering mechanism of a vehicle, the control device including a control unit that receives a specific signal which indicates a requested value relating to an operation of the motor and which contains a specific type of requested value and an attribute of the requested value, and controls the motor based on the requested value indicated by the received specific signal.

Owner:HONDA MOTOR CO LTD

Method for arranging window flushing pipeline

The invention discloses a method for arranging a window flushing pipeline. The method comprises the following steps: A, at the window retrial stage, the models and position dimensions of cabin penetrating pieces are marked on a window drawing, according to the thread specifications of nozzles, the thread types of the cabin passing pieces are determined, the specifications of clamping sleeves are determined according to the sizes of water supply pipes, the nozzle coverage range is calculated, the positions of the cabin penetrating pieces on a window are determined, and the data are subjected toretrial to a window manufacturer to enable the window manufacturer to manufacture according to the requirements; B, after the window arrives and is mounted, the clamping sleeves are connected with the water supply pipes indoors, and the nozzles are mounted outdoors; and C, the angles of the nozzles are adjusted after water supply, and it is guaranteed that the window can be covered. According tothe method for arranging the window flushing pipeline, the design is simple and practical, and the design labor hour is saved; the construction processes of the nozzles and the cabin penetrating pieces are executed in advance; the on-site construction workload is reduced, and the working efficiency is improved; and peripheral pipes are reduced, the appearance looks concise and attractive after construction, and blocking of the window vision is reduced.

Owner:COSCO DALIAN SHIPYARD

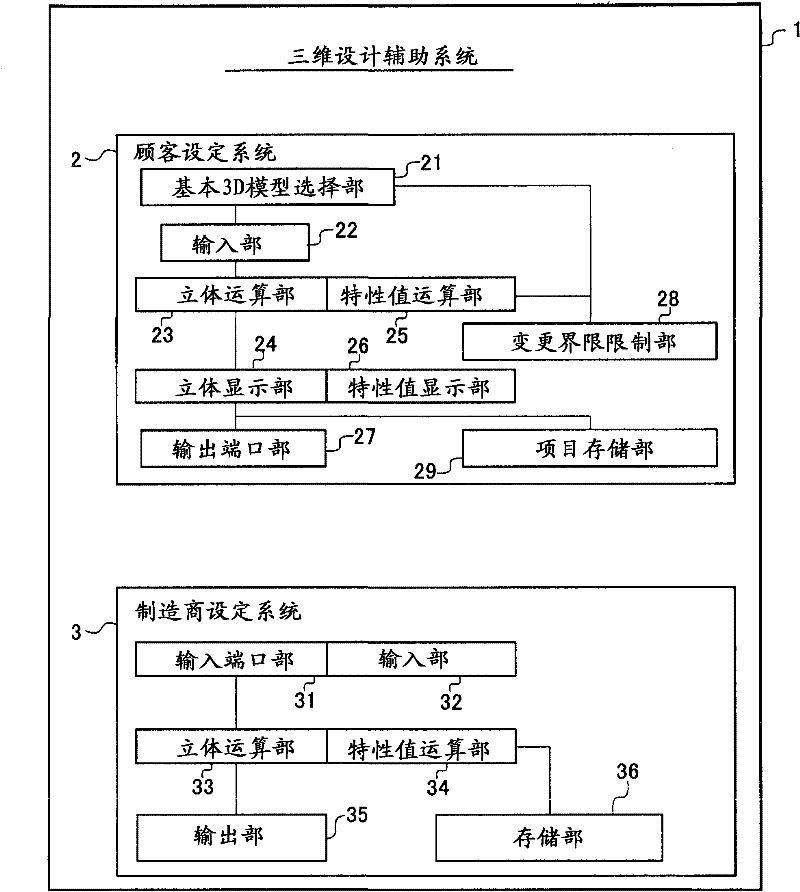

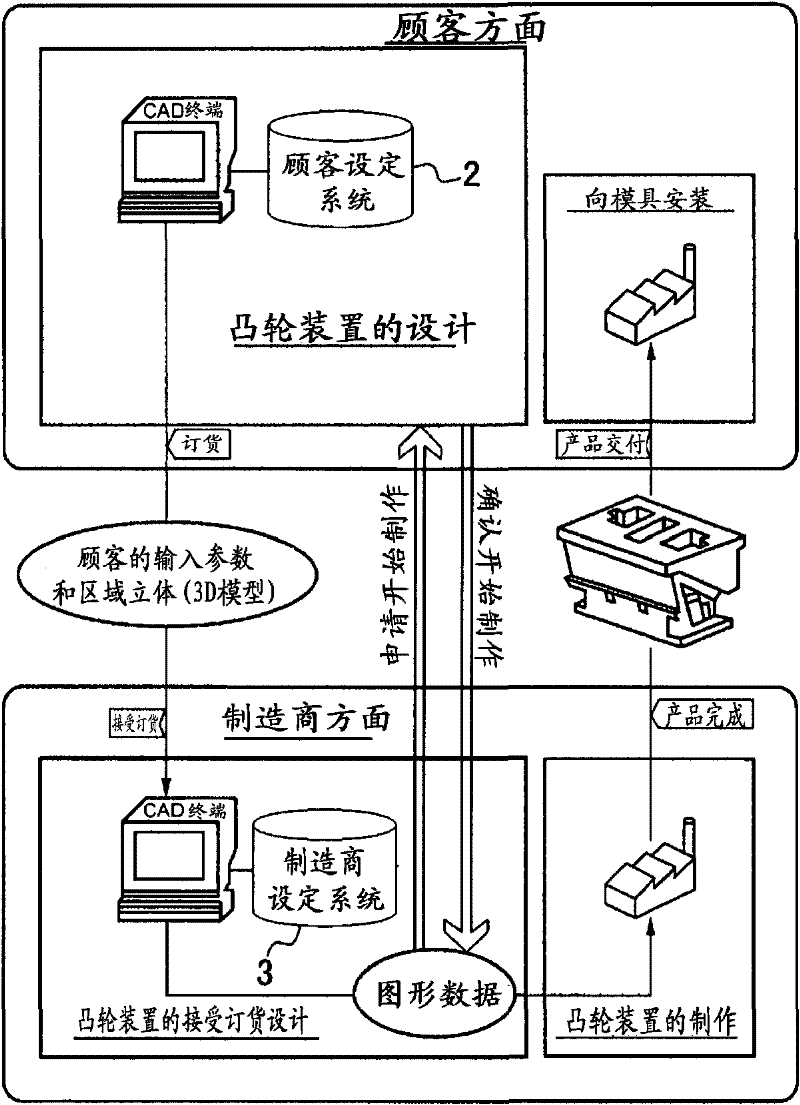

Method of designing and manufacturing cam device and three-dimensional design-support method and system

InactiveCN102163242ASimple designReduce design man-hoursConfiguration CADBuying/selling/leasing transactionsEngineeringDimensional modeling

The invention provides a method of designing and manufacturing cam device and a three-dimensional design-support method and system. The three-dimensional design-support computer program includes a customer setup program for customers and a manufacture setup program for cam device manufactures being configured to generate different finenesses in 3D models and characteristic values of cam performance as a result of design of the cam device, and being configured to obtain a result which indicates the same cam device except for fineness and the required calculation items when the same parameters are loaded. The customer setup program is lent from the cam device manufacture to the customer, and detailed design to constructional details of the cam device is performed using the manufacture setup program on the basis of design data created using the customer setup program and handed to the cam device manufacturer, whereby the cam device is manufactured on the basis of a detailed design drawing.

Owner:SANKYO OILLESS IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com