Method of designing and manufacturing cam device and three-dimensional design-support method and system

A cam device and three-dimensional design technology, applied in computer-aided design, calculation, configuration CAD, etc., can solve problems such as no design auxiliary system, achieve the effect of shortening production delivery time, shortening period, and improving design efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

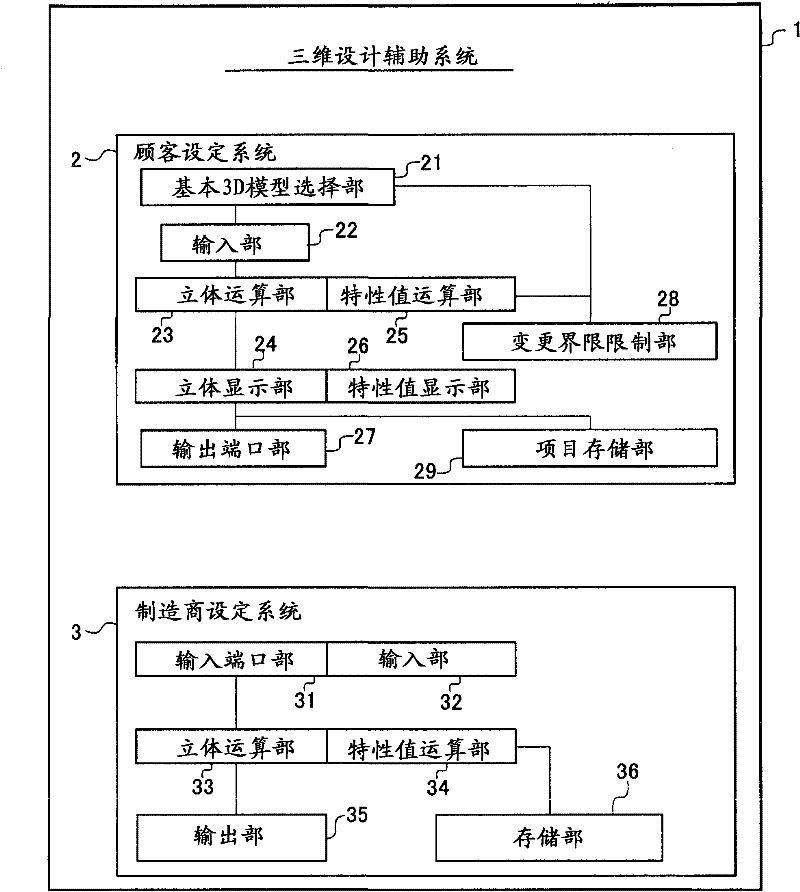

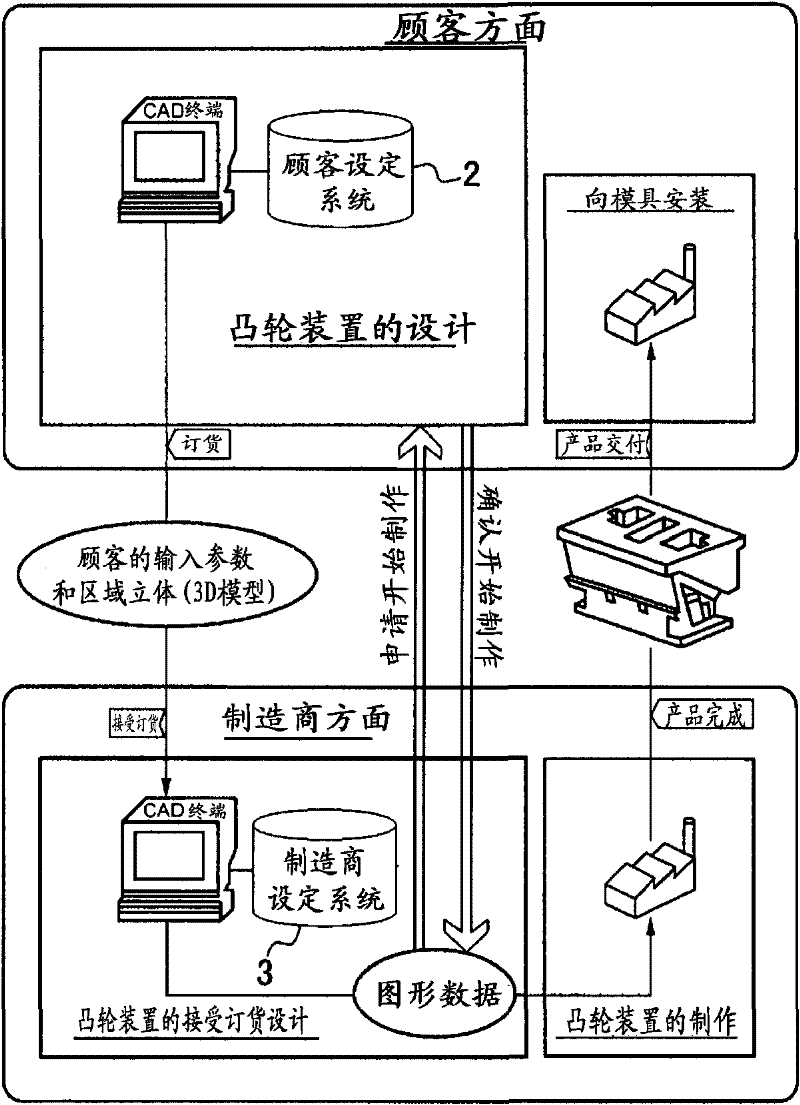

[0022] figure 1 The three-dimensional design support system for implementing the design and manufacturing method of the cam gear according to the embodiment of the present invention is shown, and is composed of a customer setting system 2 for customers and a manufacturer setting system 3 for cam gear manufacturers.

[0023] This customer setting system 2 has a basic 3D model selection unit 21 that displays a plurality of basic 3D models prepared according to the size and use of the cam device on a display device (display), and the customer selects one model. . In addition, the customer setting system 2 has an input unit 22 including parameters of basic setting positions in the shape of the cam gear related to the basic 3D model selected by the basic 3D model selection unit 21, and for input. In addition, the customer setting system 2 at least includes: a three-dimensional calculation unit 23, which makes the area of the cam device displayed on the display device three-dime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com