Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Realize fully automated assembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

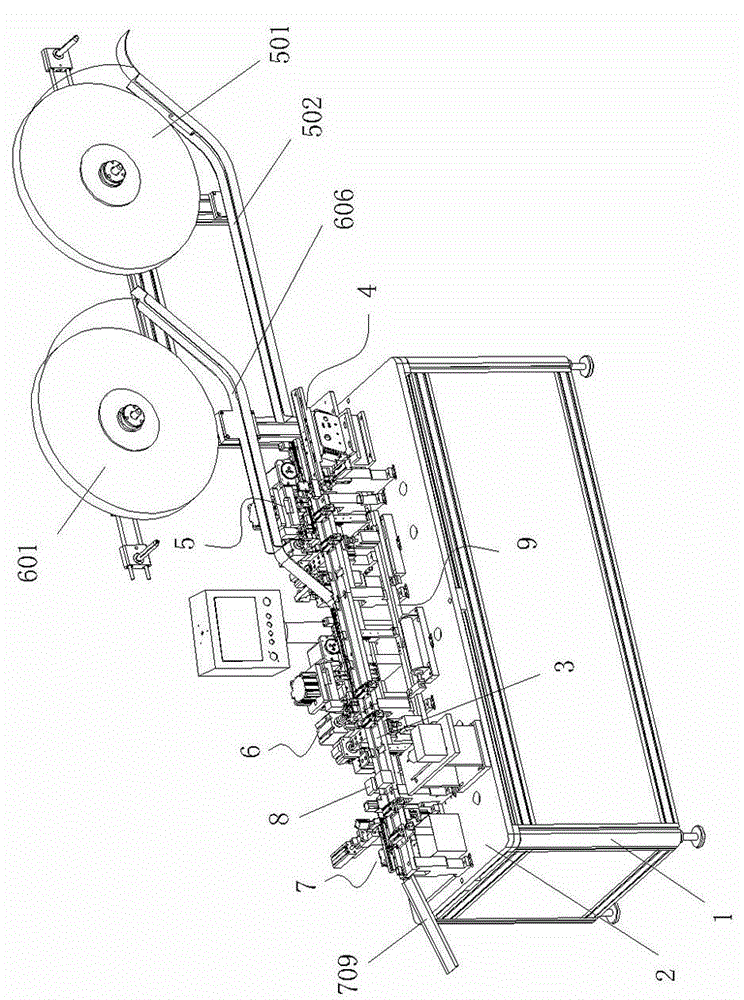

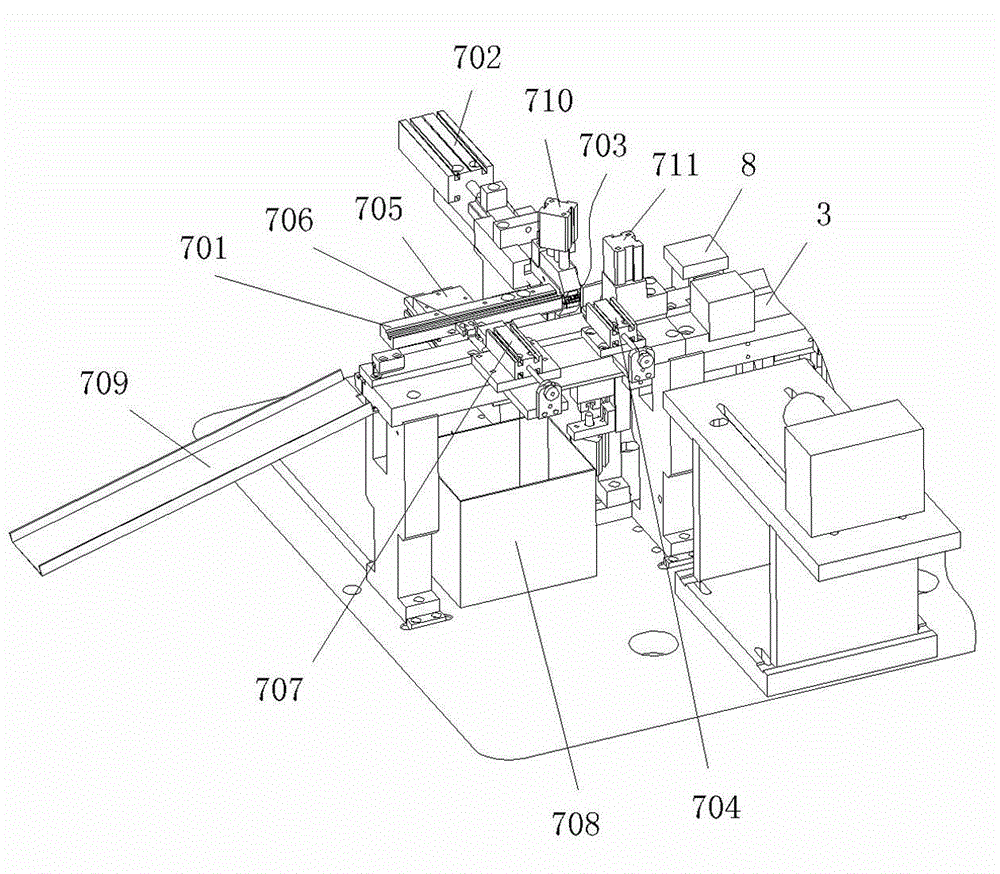

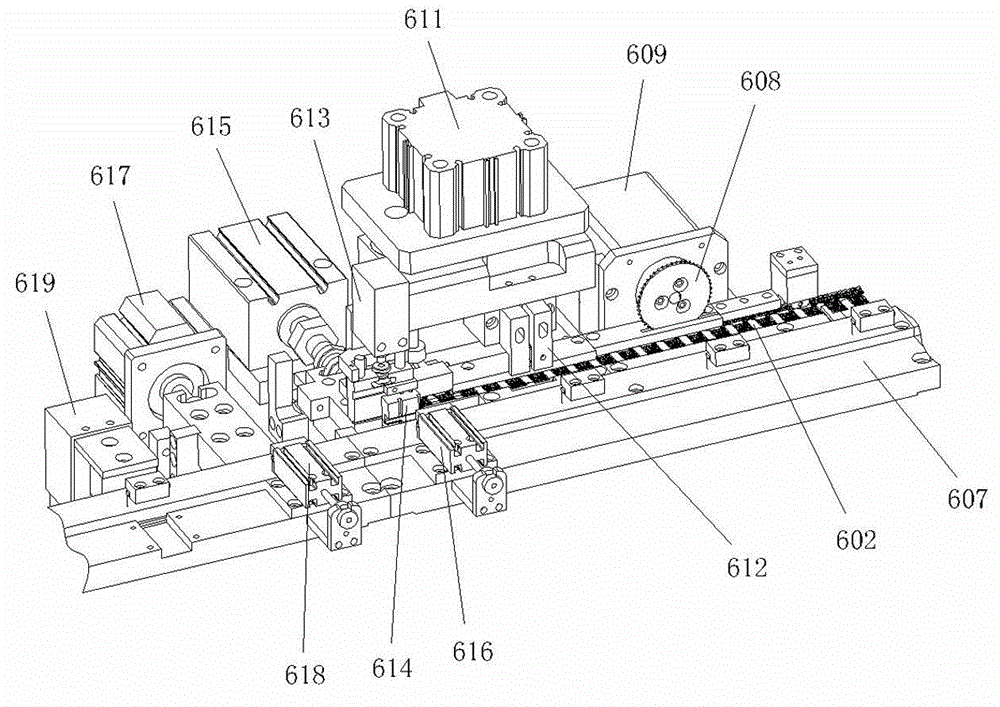

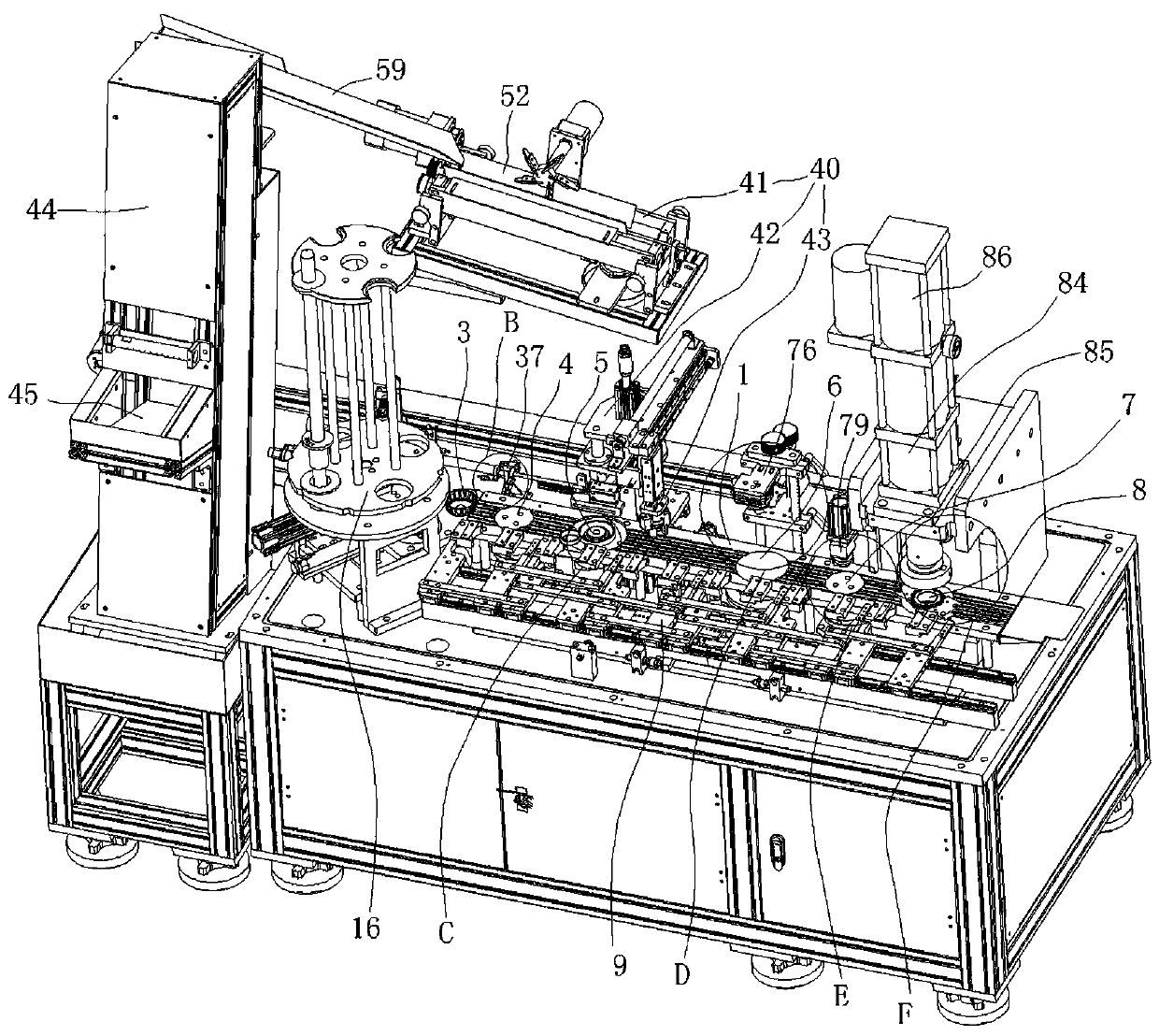

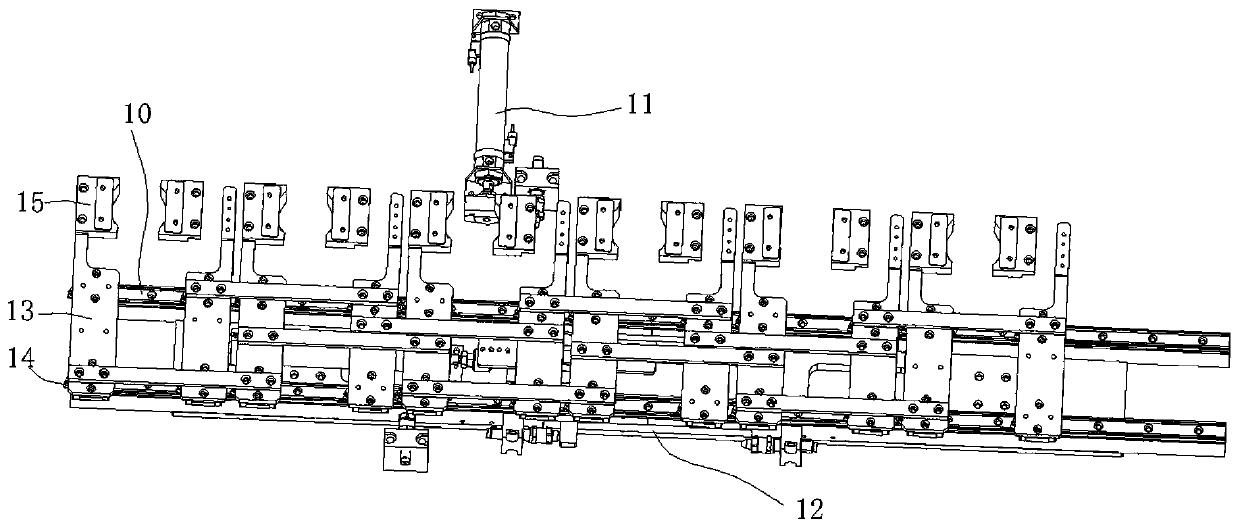

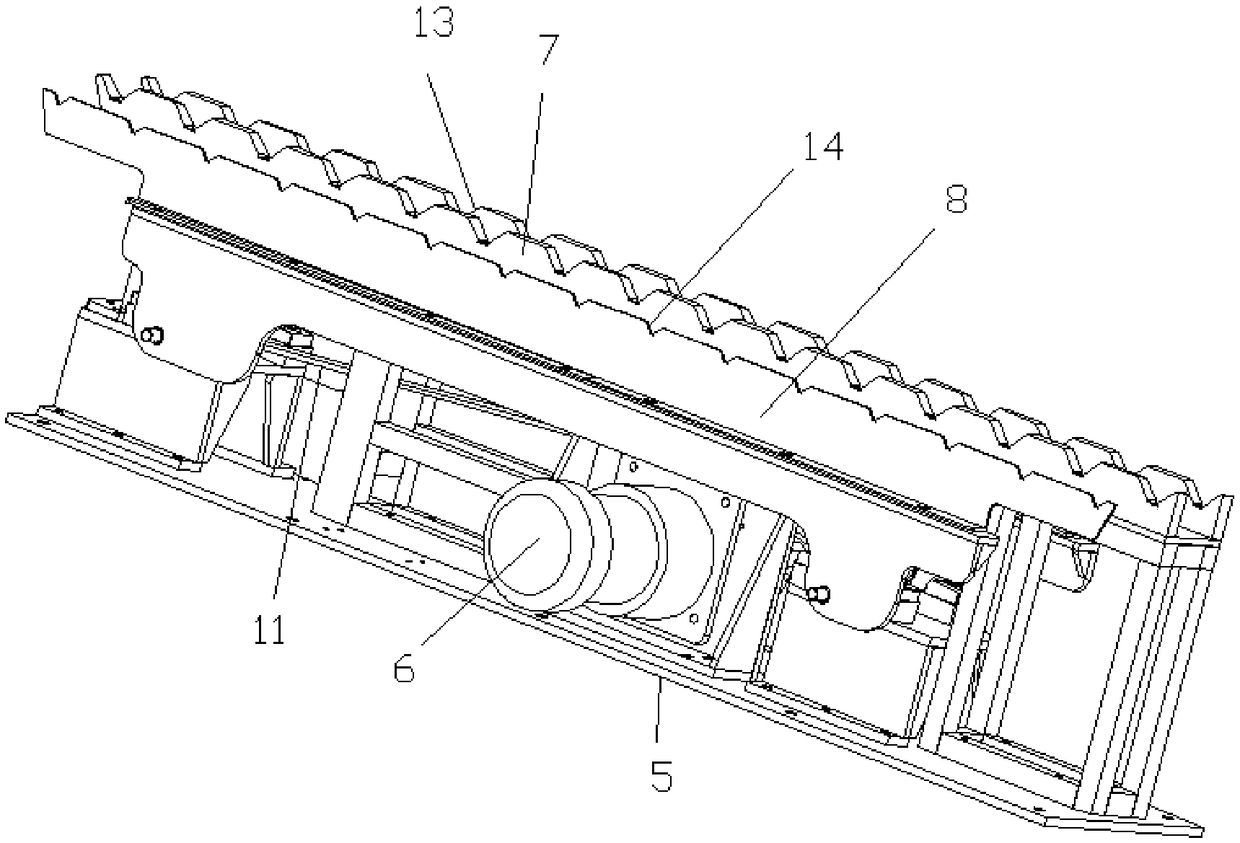

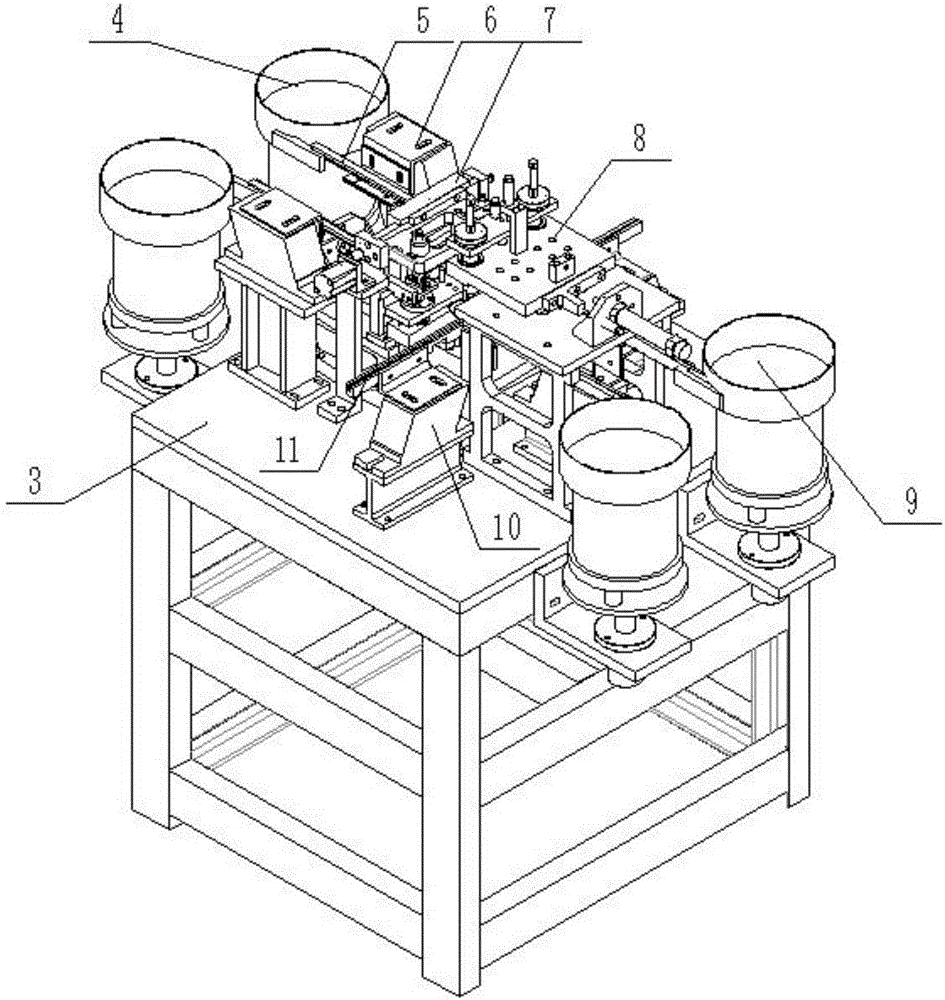

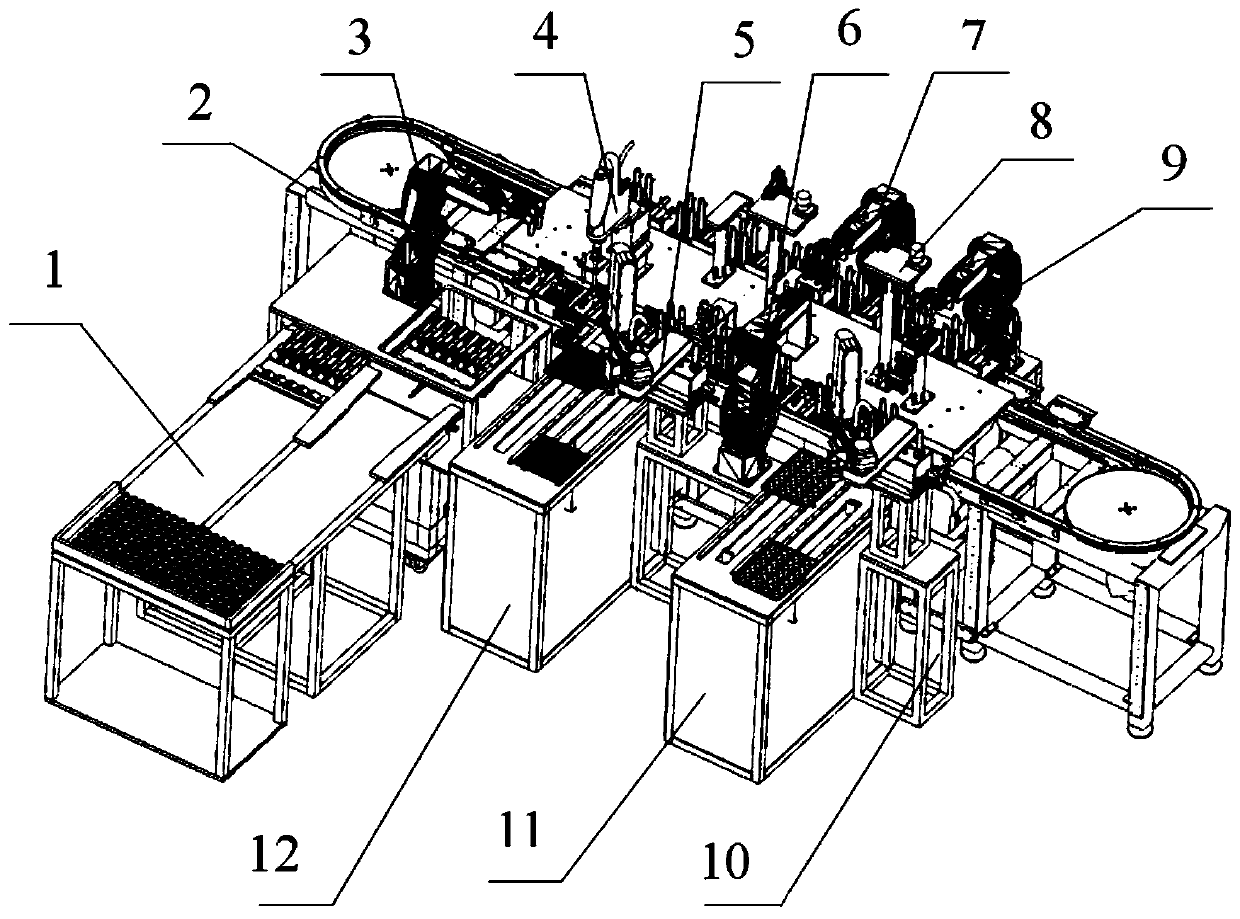

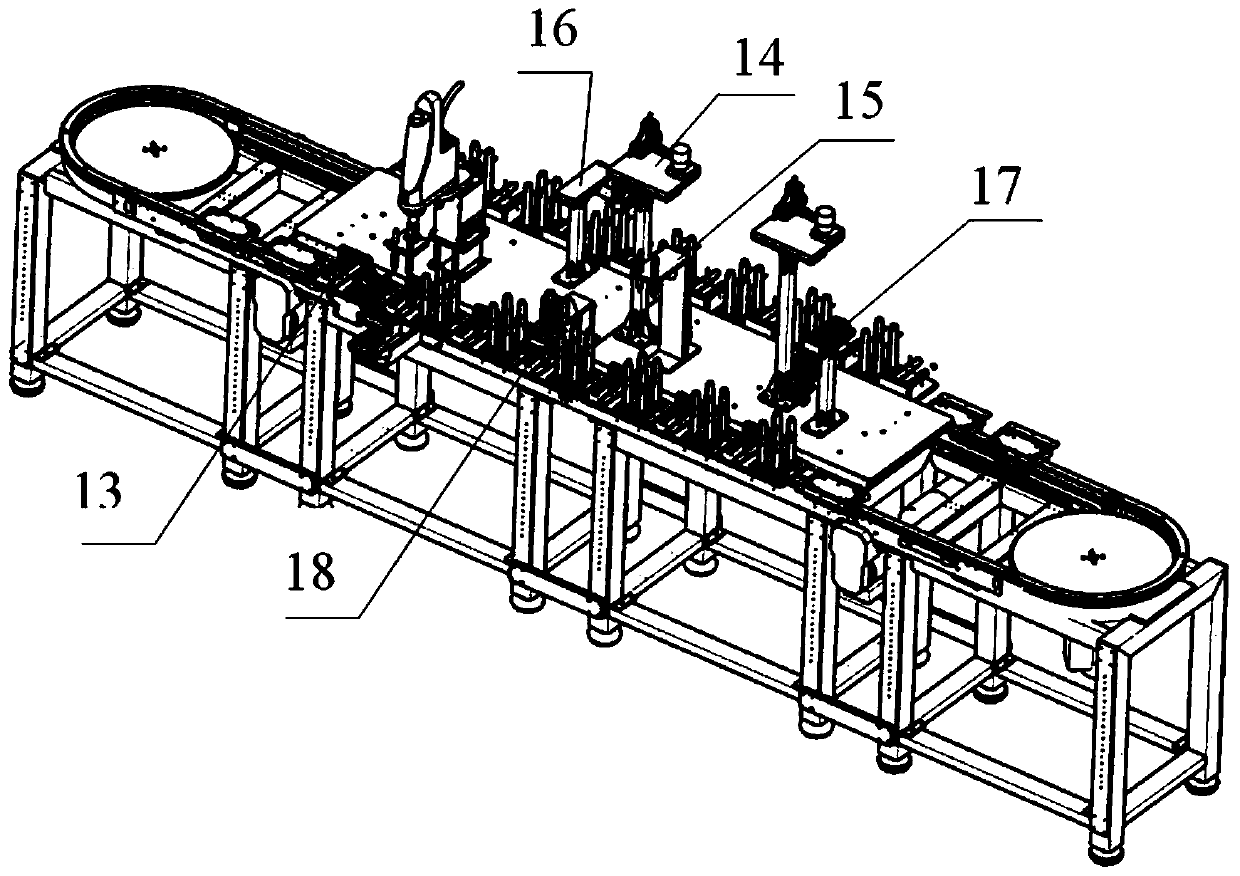

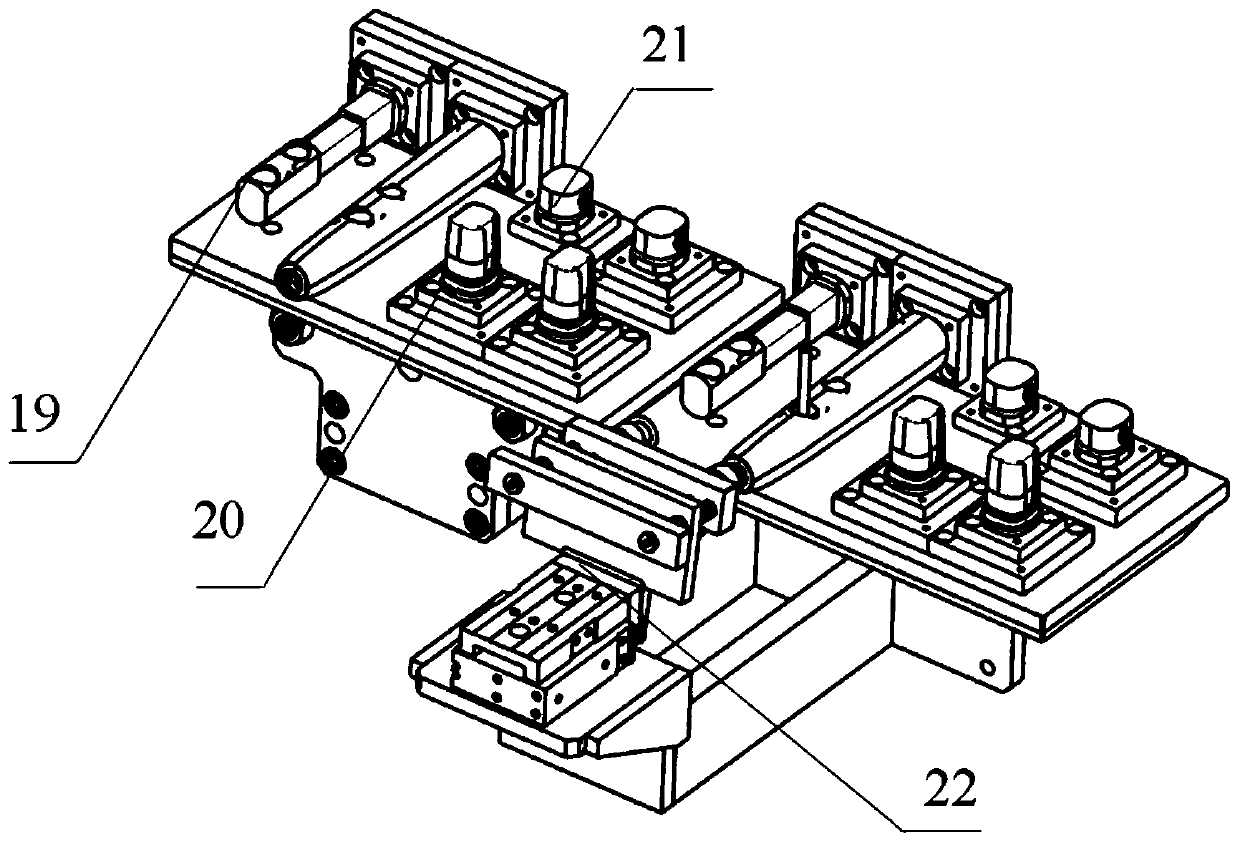

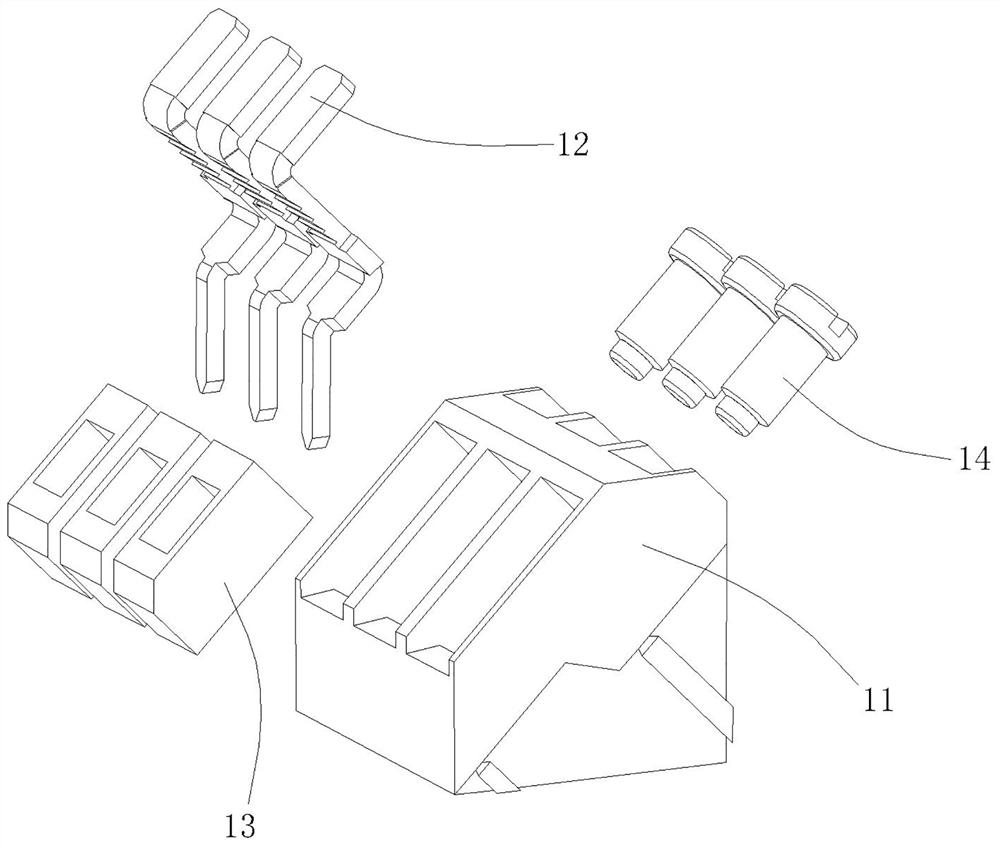

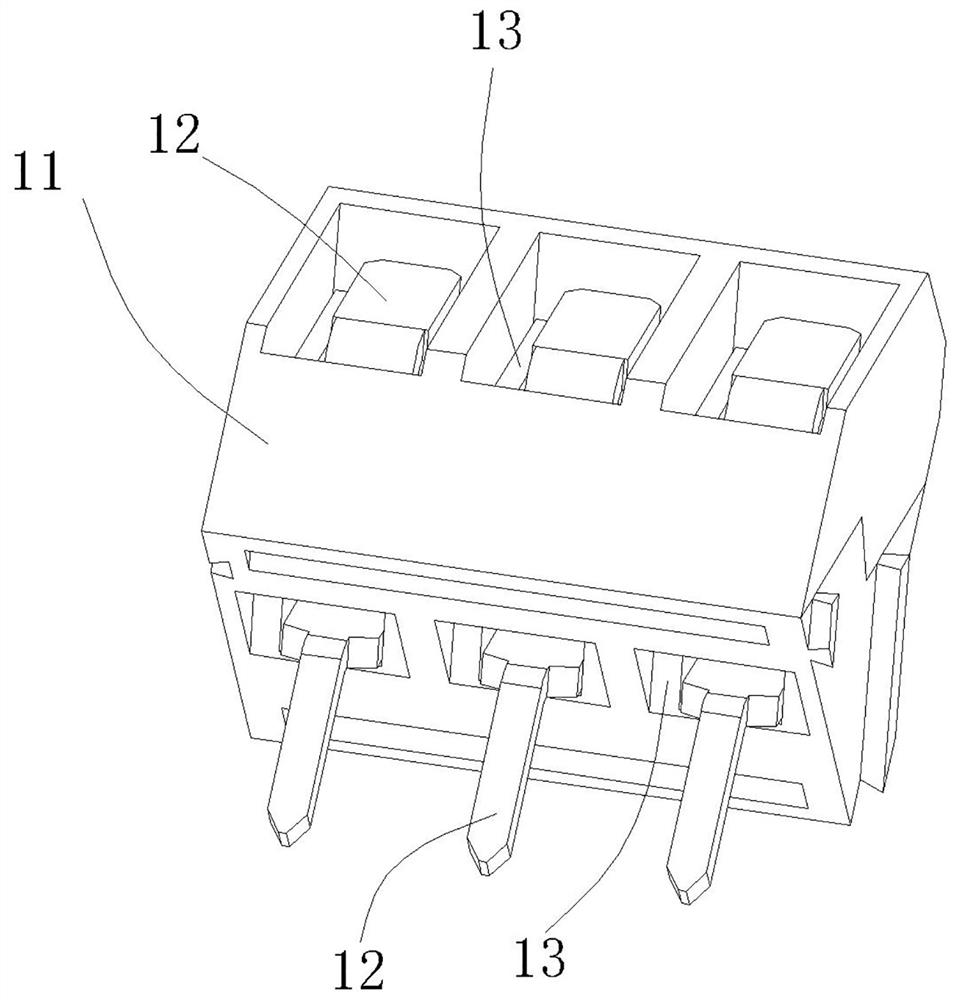

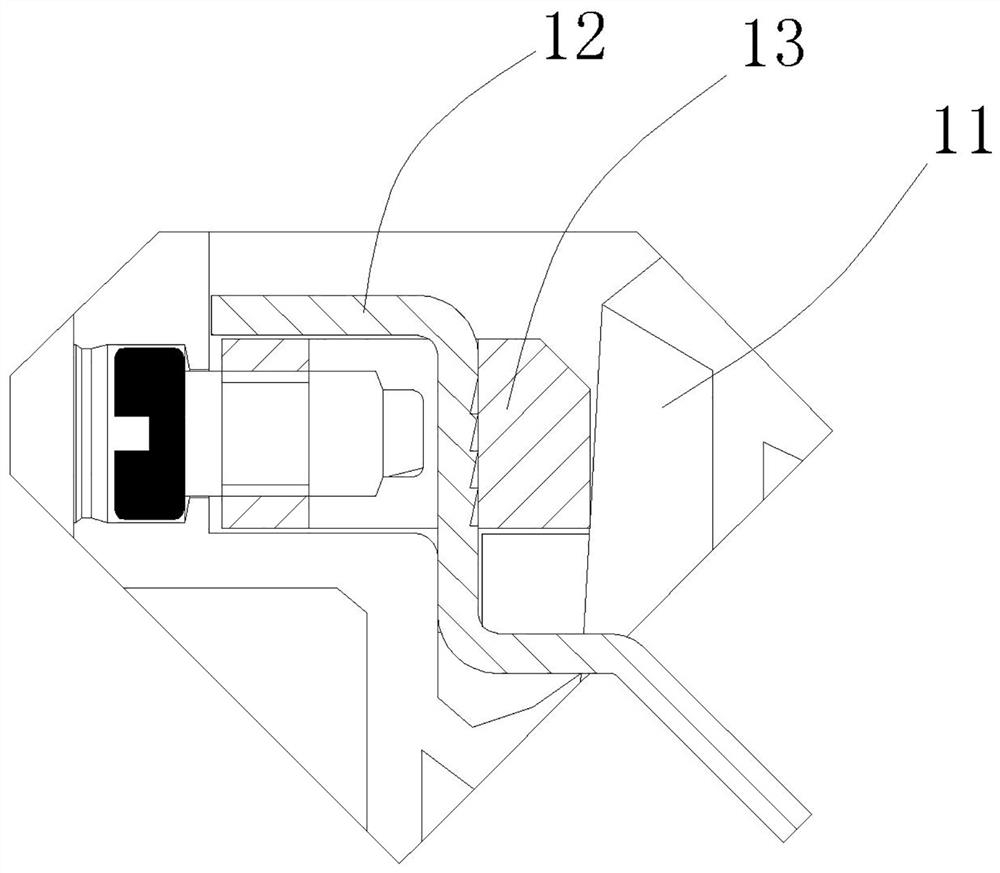

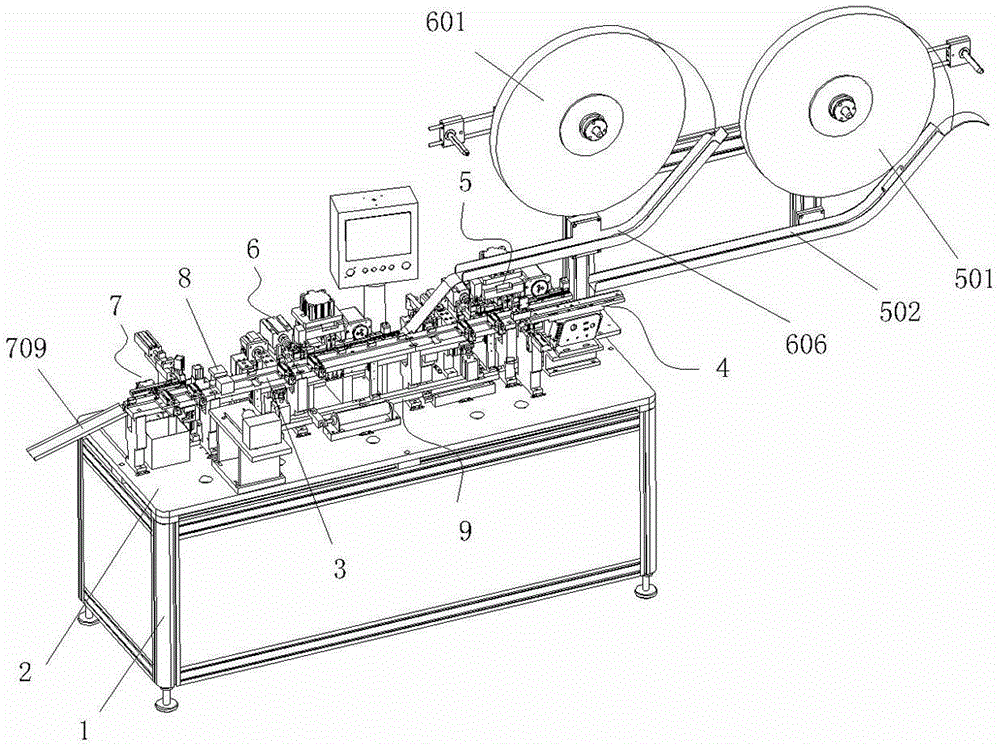

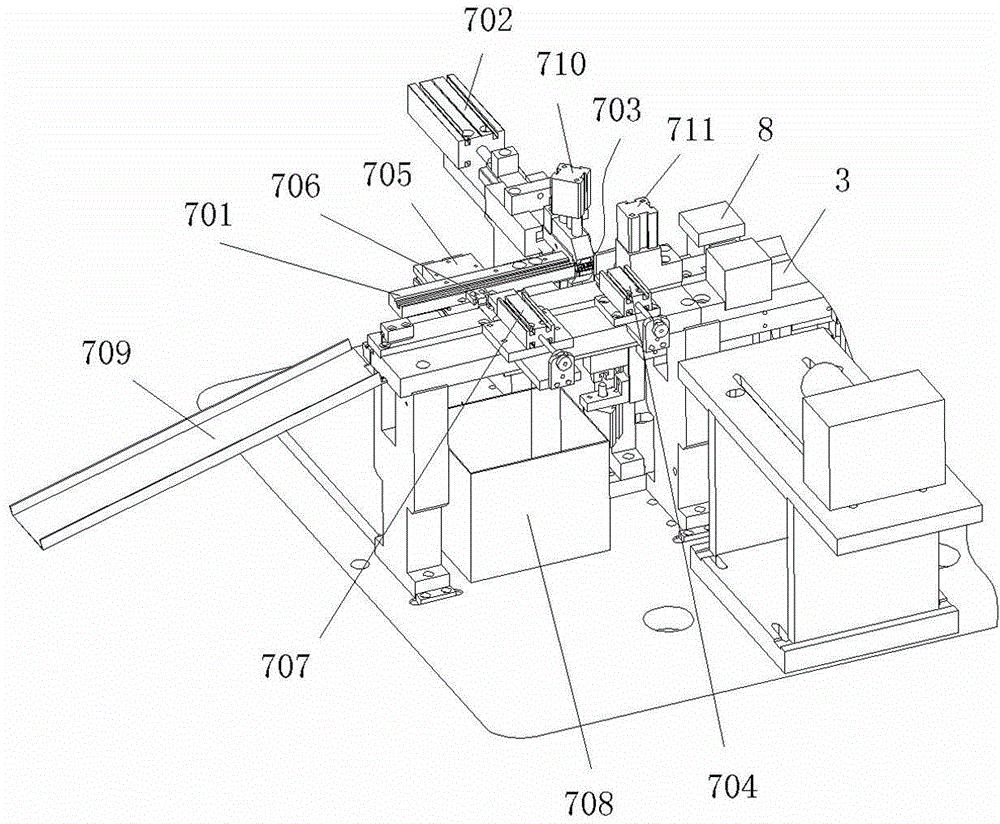

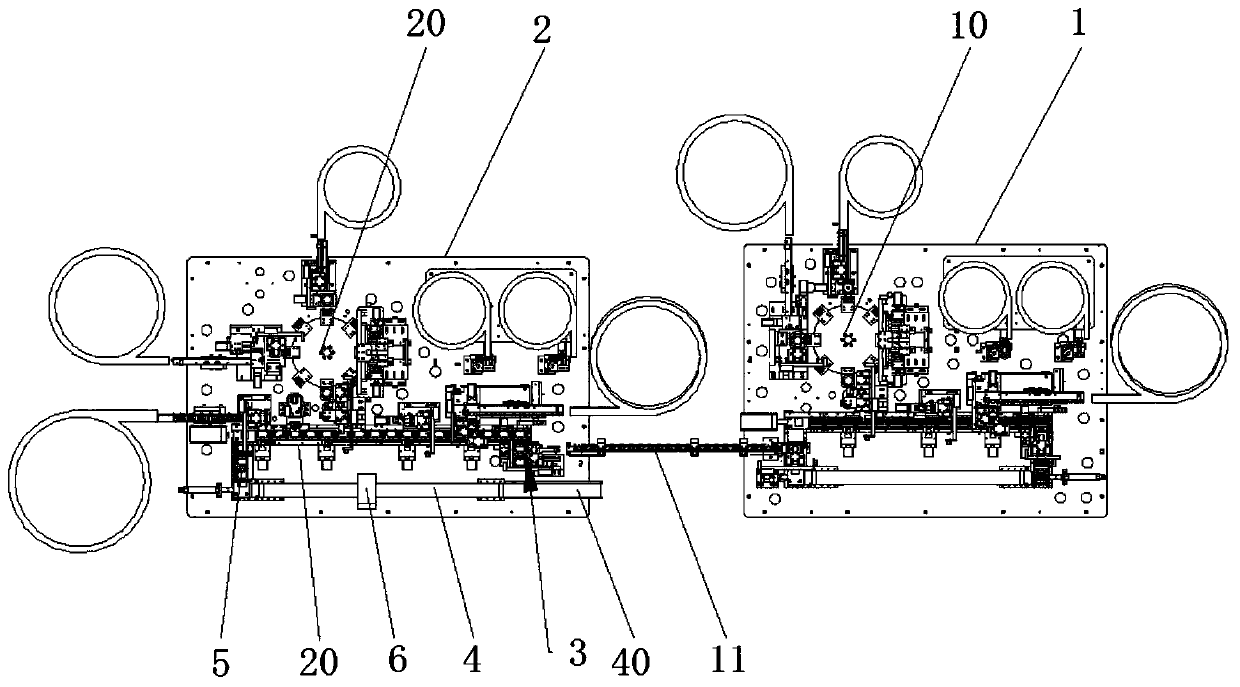

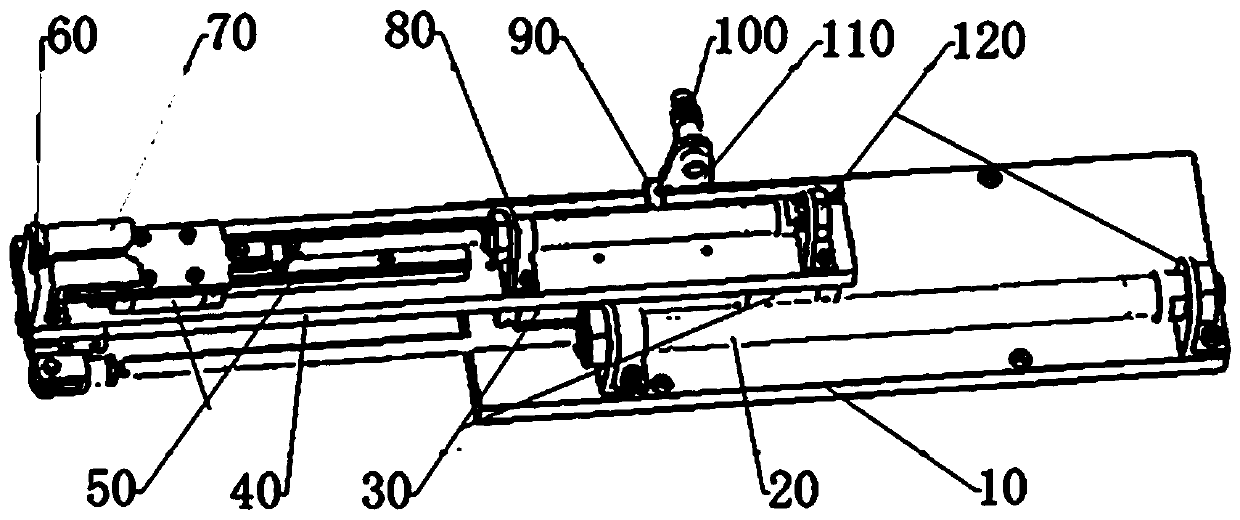

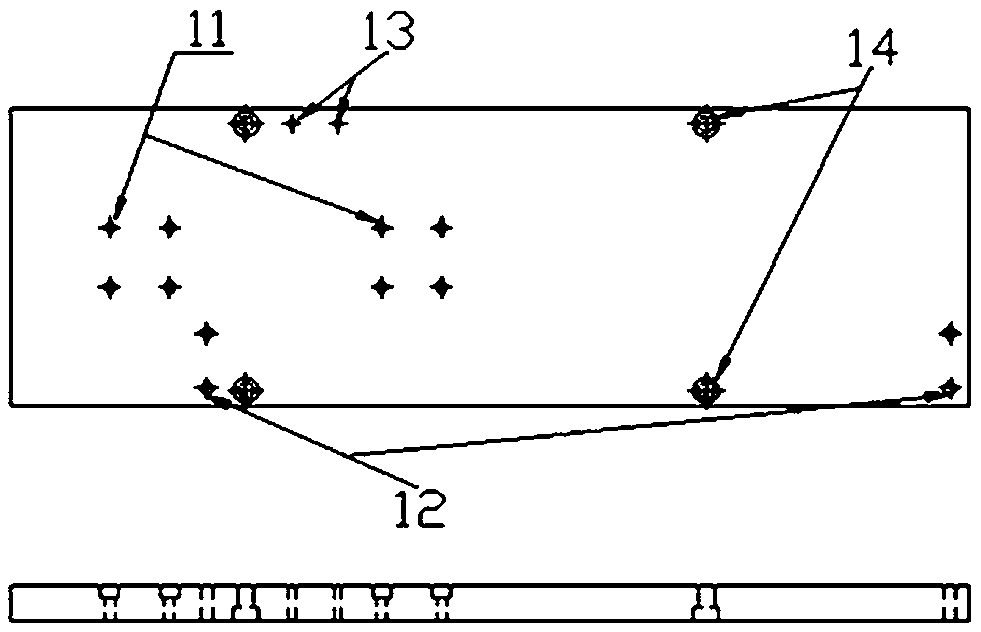

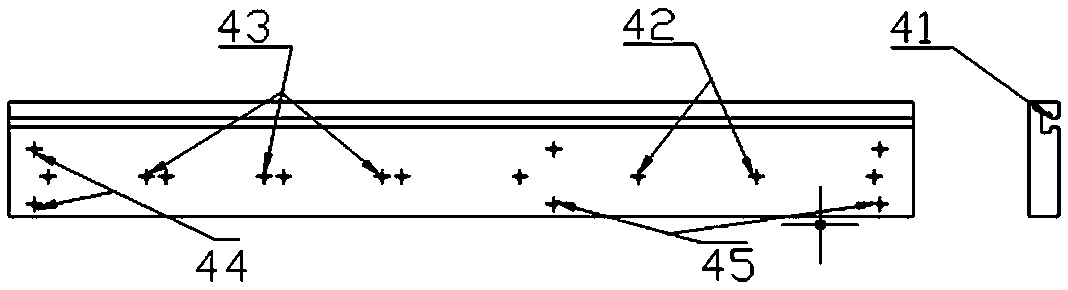

Automatic check assembly machine for HDMI connector

InactiveCN103337767ARealize fully automated assemblyIncrease productivityContact member assembly/disassemblyEngineeringAssembly line

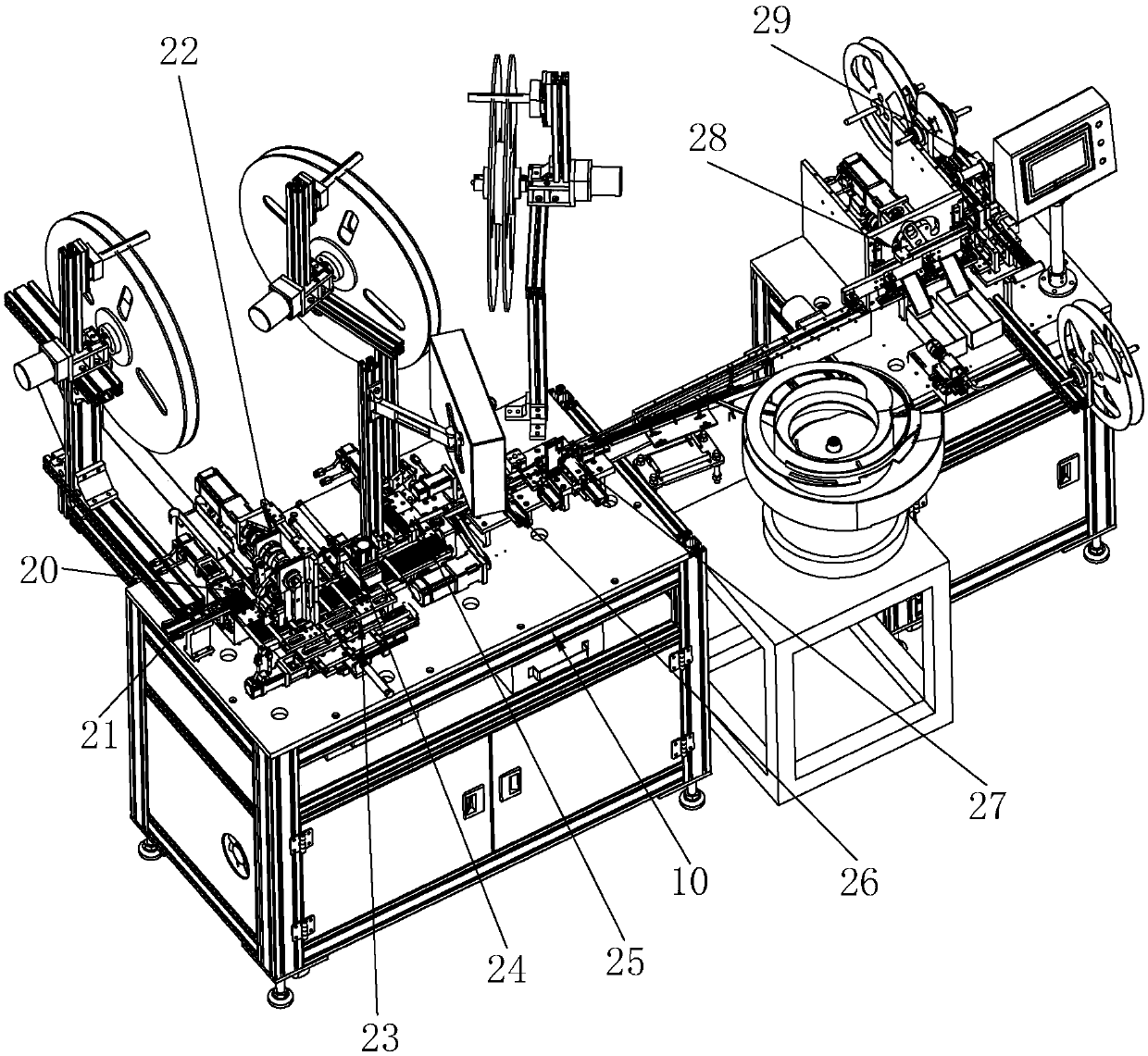

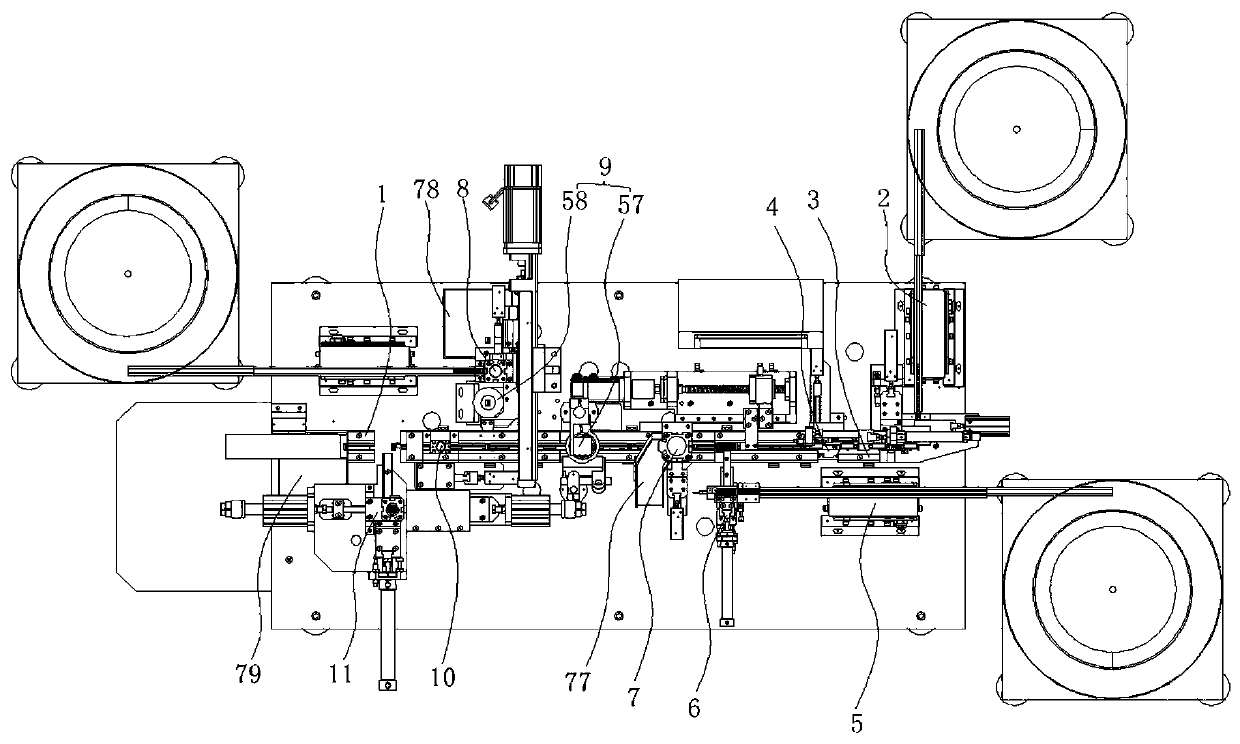

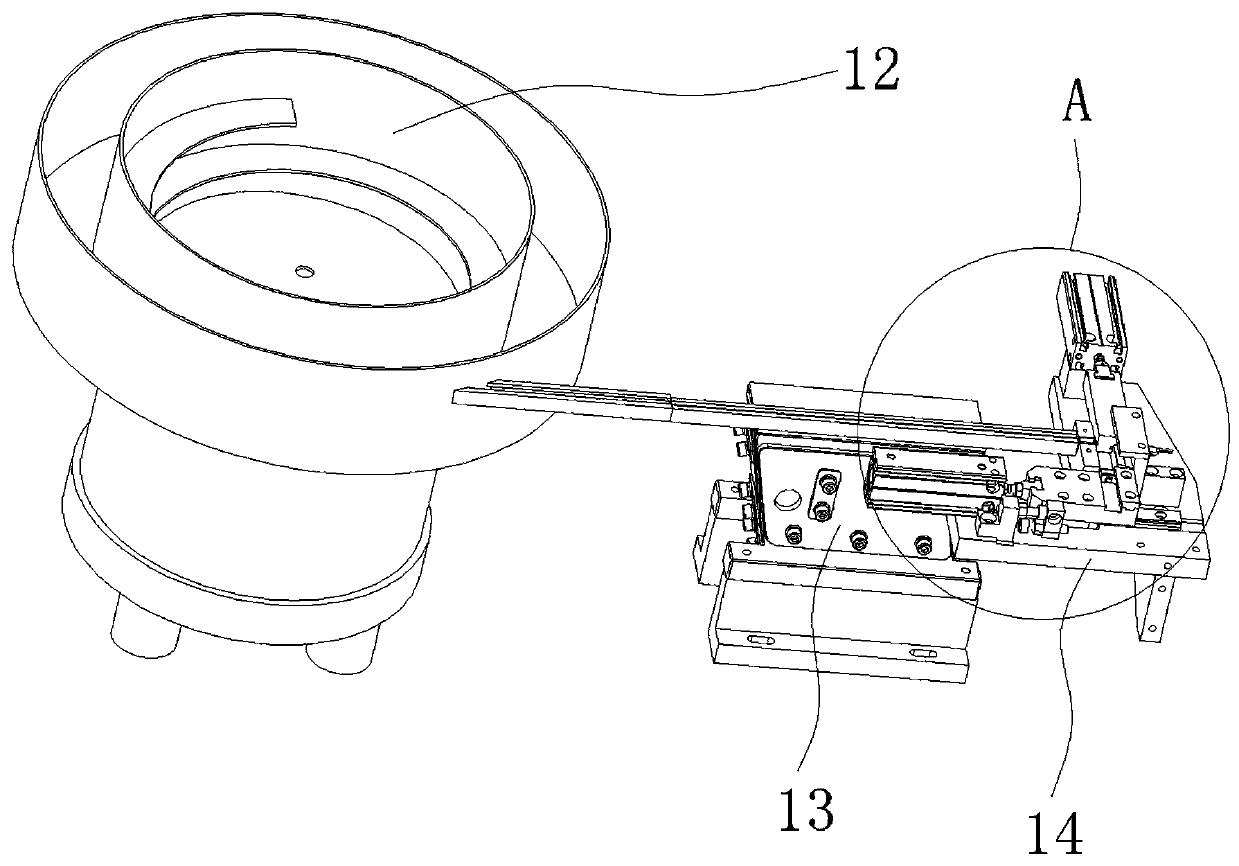

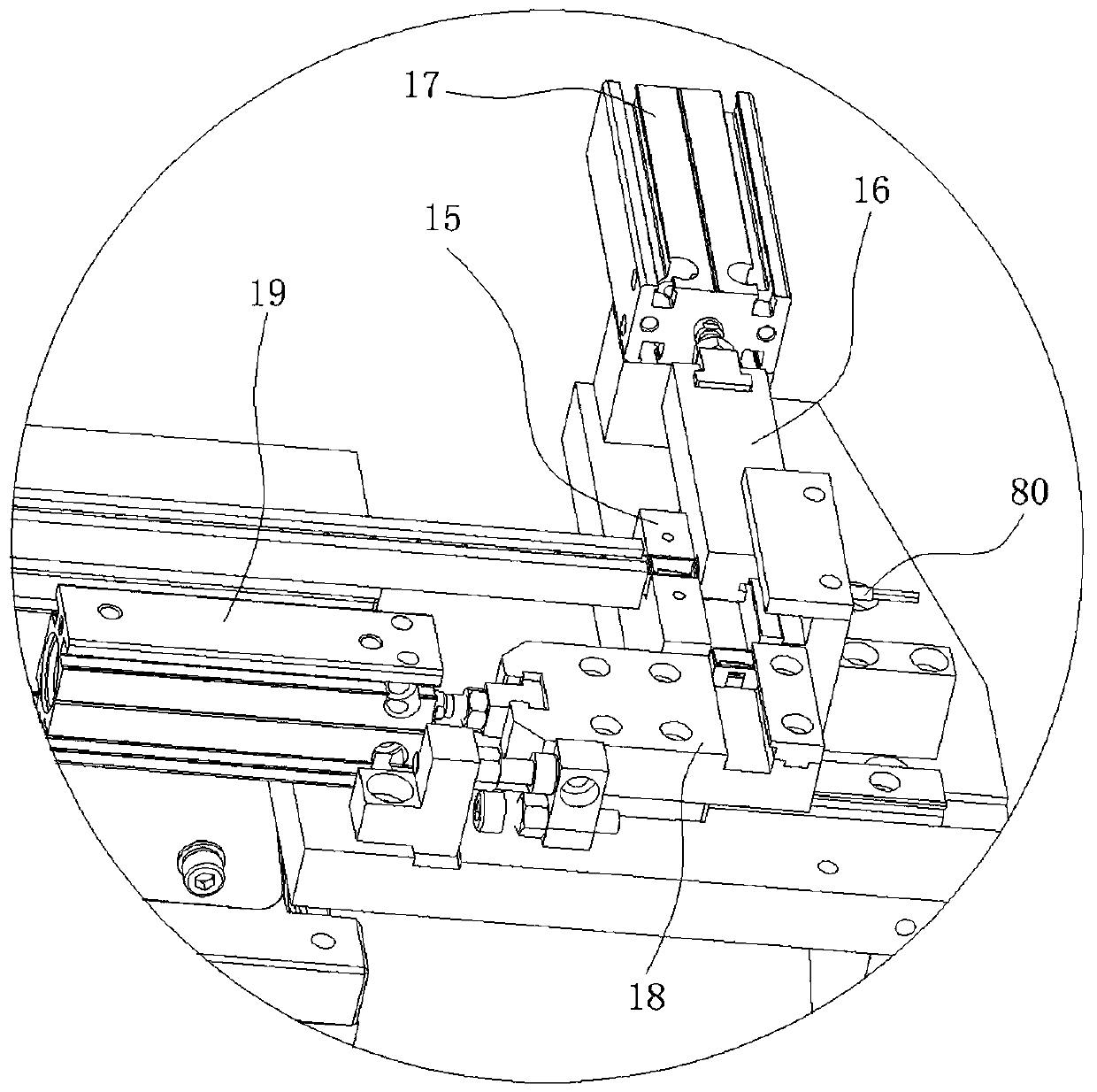

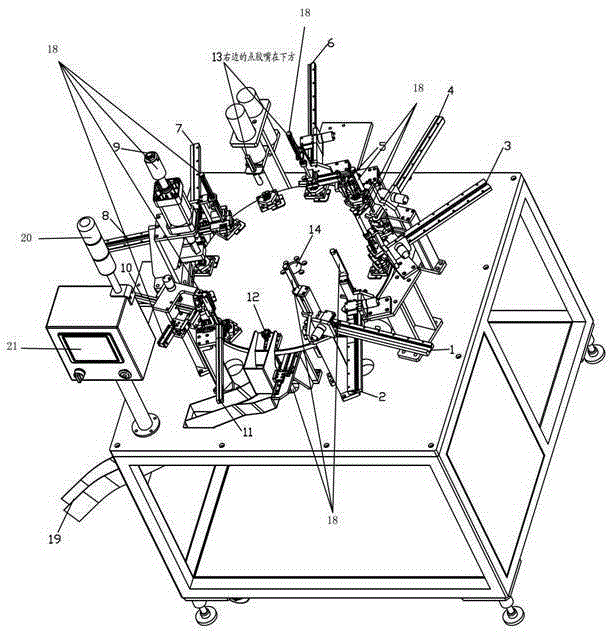

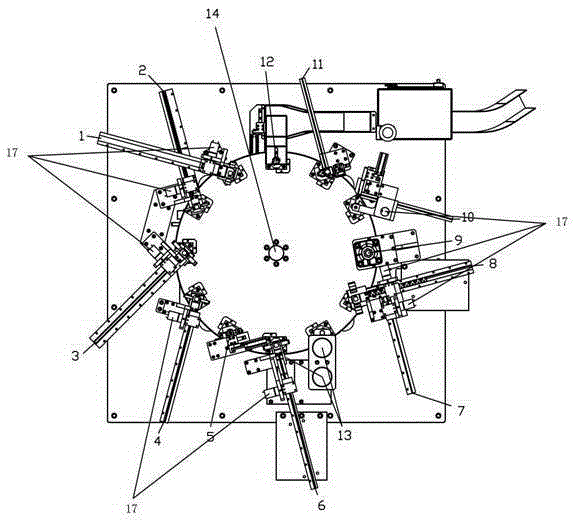

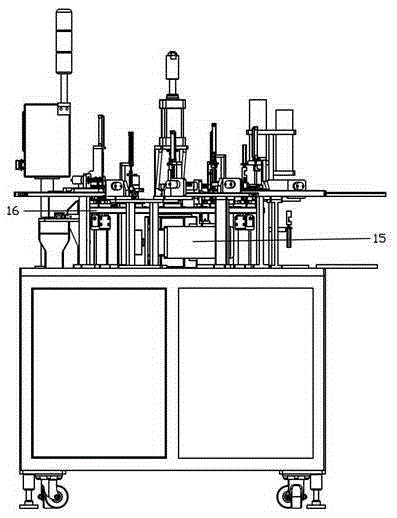

An automatic check assembly machine for an HDMI (High-Definition Multimedia Interface) connector comprises a frame, a worktable arranged on the frame and a feeding track arranged on the worktable, wherein a terminal body feeding mechanism delivering terminal bodies, a first terminal assembly line delivering a first terminal and inserted on the terminal body, a second terminal assembly line delivering a second terminal and inserted on the terminal body and a back stopper assembly line delivering a back stopper and inserted on the terminal body are arranged on the feeding track in sequence; a projection detecting instrument positioned between the second terminal assembly line and the back stopper assembly line and detecting whether the assembly of the first terminal and the second terminal on the terminal body is right or not is also arranged on the feeding track; a feeding drive mechanism delivering the terminal bodies forward one by one along the feeding track is arranged at the lower part of the feeding track. Through the adoption of the structure, the assembly machine not only can realize full-automatic assembly, but also can detect whether the product inserting during the assembly process is qualified or not, and can greatly improve the production efficiency.

Owner:宁波神博电子有限公司

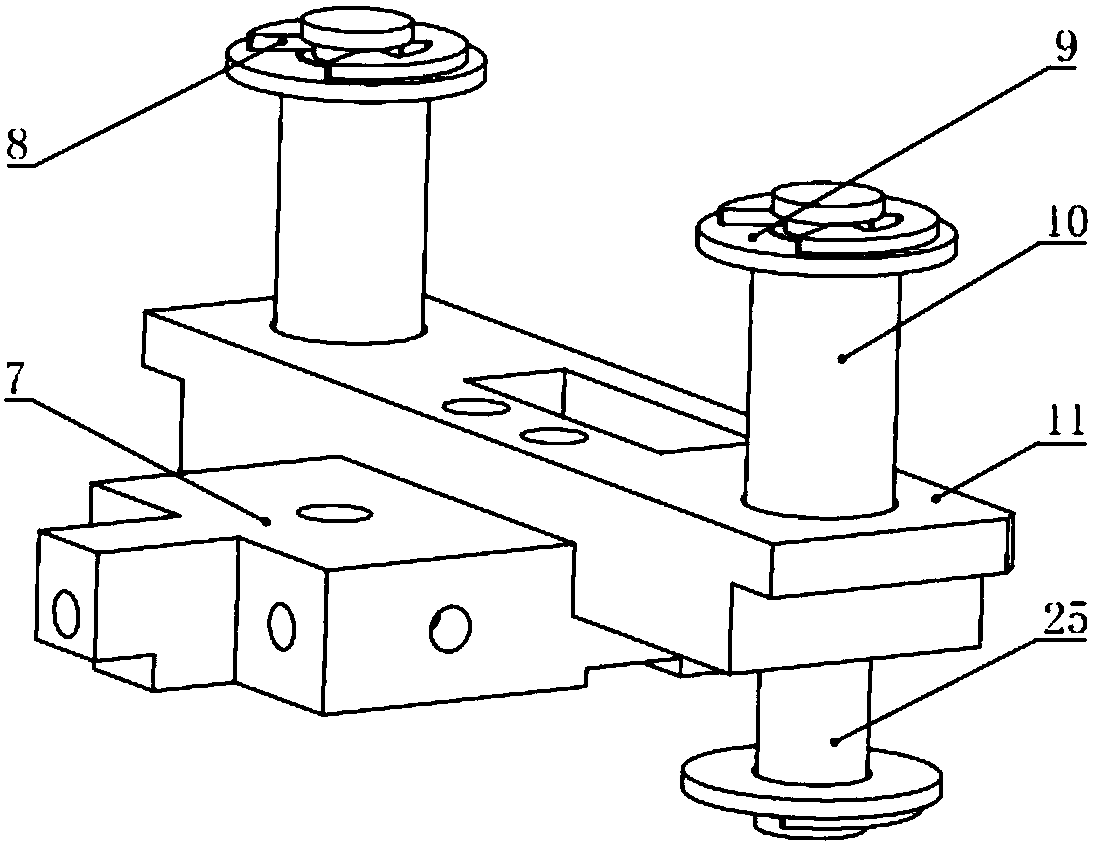

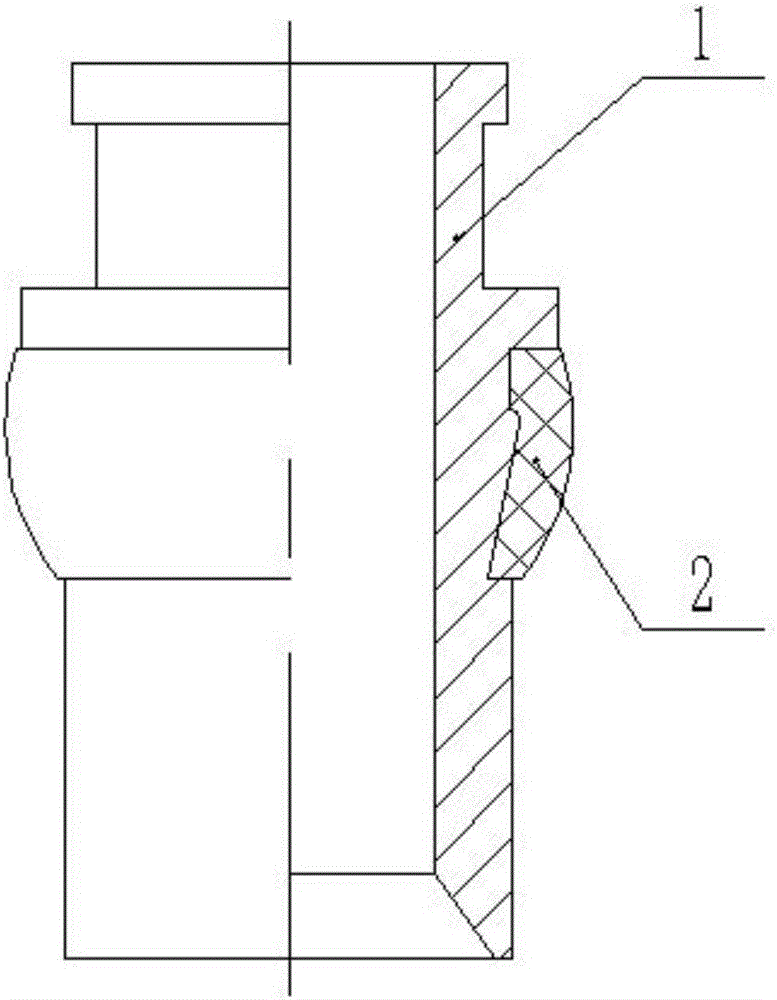

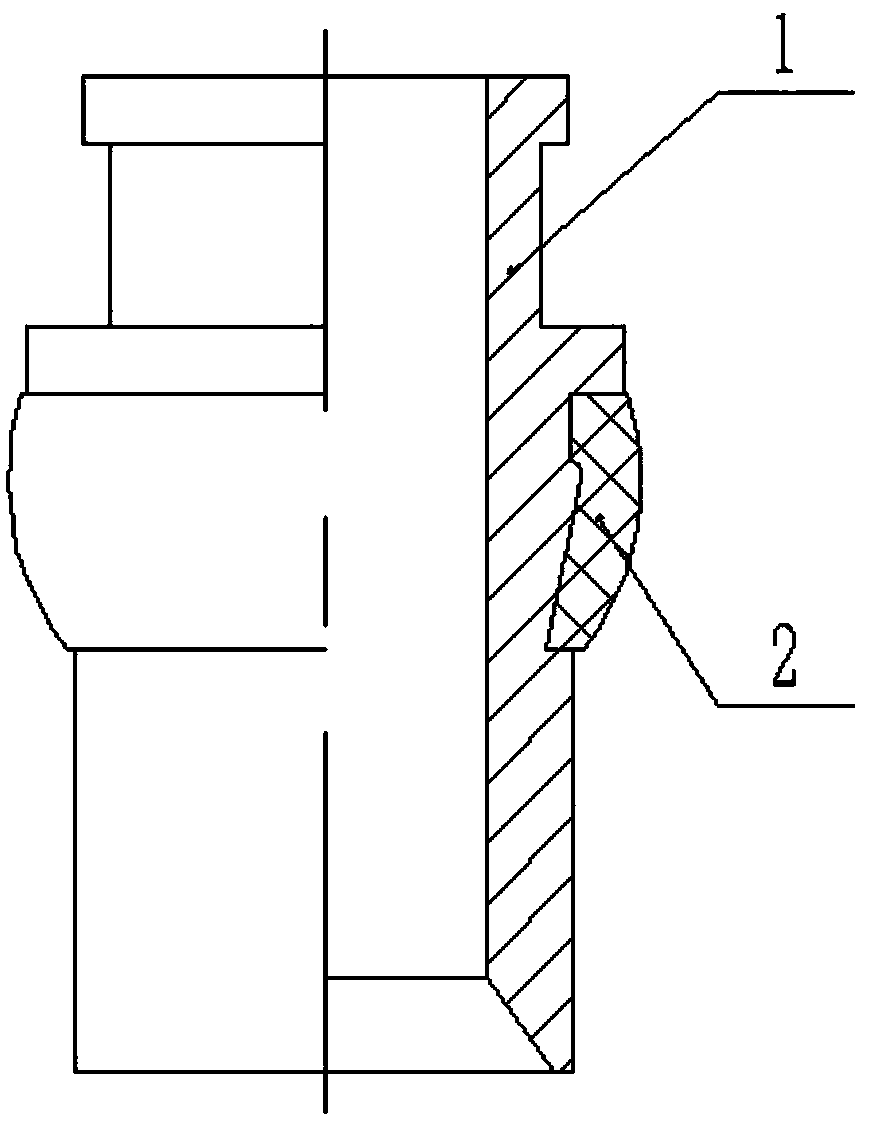

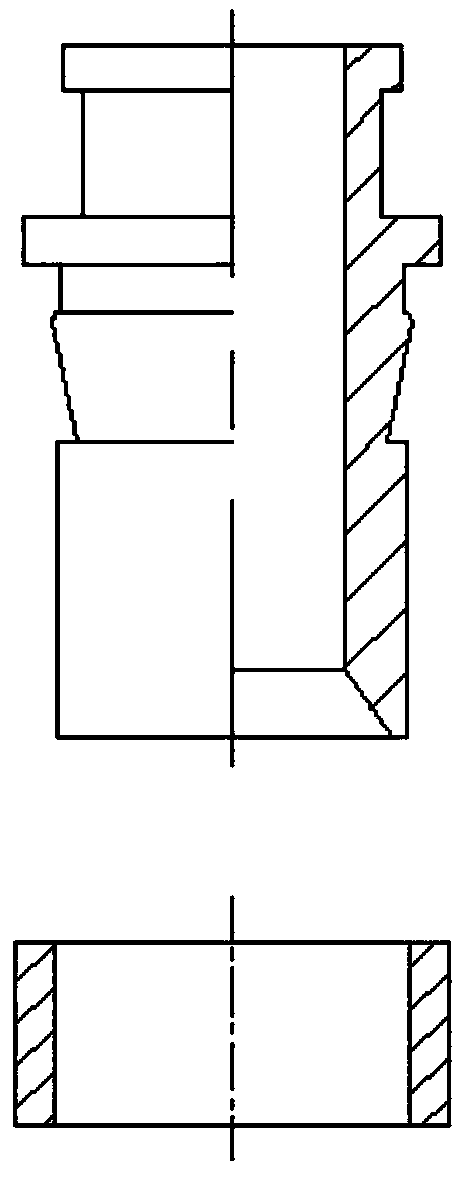

Automatic assembly device for inner ring and outer ring of high-speed bearing

ActiveCN103453029AOptimum Thermal ExpansionReduce friction and wearBearing componentsTemperature controlElectricity

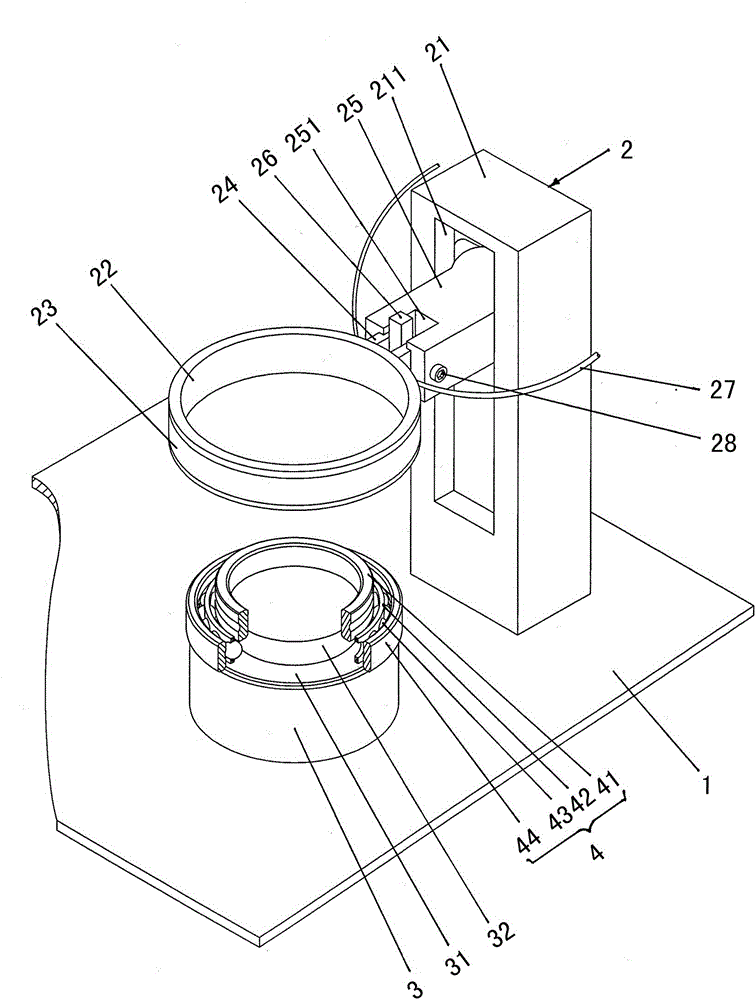

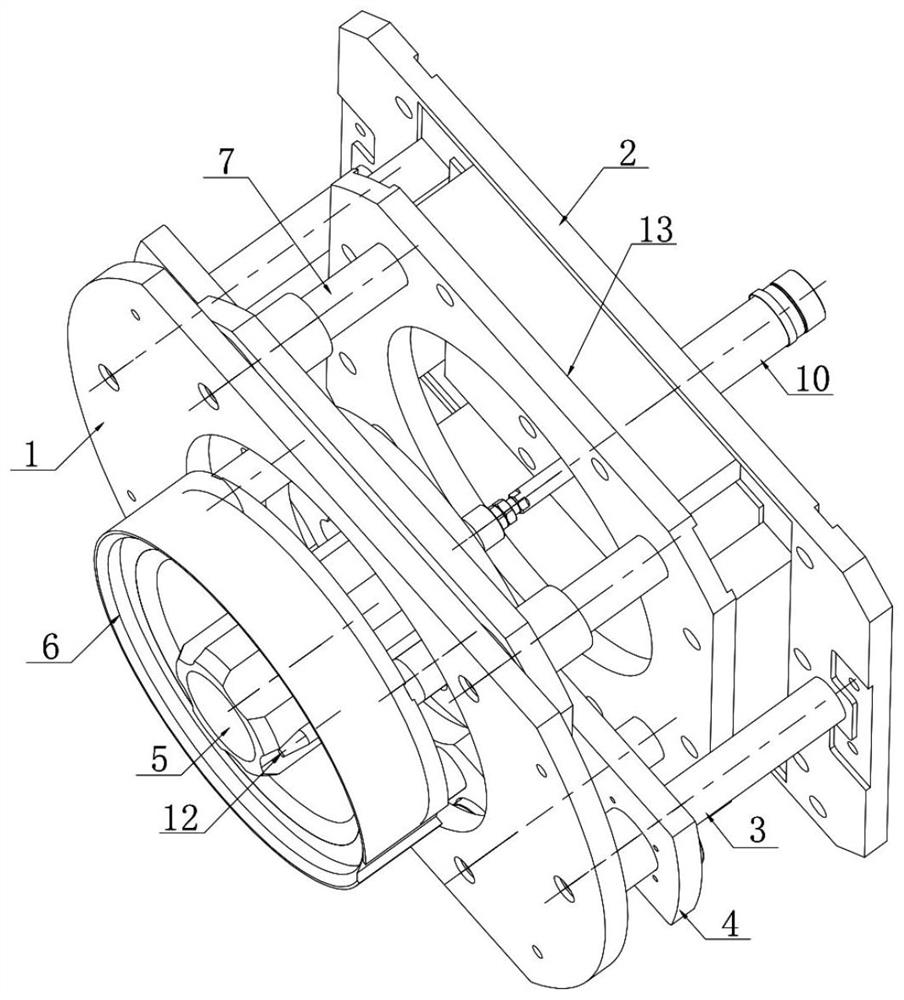

The invention relates to an automatic assembly device for an inner ring and an outer ring of a high-speed bearing, and belongs to bearing processing equipment. The automatic assembly device comprises a workbench, a heating mechanism and a clamp, wherein heating mechanism comprises a manipulator bracket, a heat conduction plate, a heating element, insulation boards and a manipulator, slide grooves are formed in the manipulator bracket, the manipulator can move in the slide grooves, grooves are formed in one end of the manipulator, the manipulator is electrically connected with an external control device, the heat conduction plate is annular, the heating element is sleeved on the heat conduction plate, the two insulation boards are arranged on the outer wall of the heat conduction plate and extend into the grooves to be connected with the manipulator, the clamp is positioned right below the heat conduction plate, a boss is formed at the upper part of the clamp in a narrowing way, a step face is formed between the boss and the clamp, an outer ring and a retainer with rolling elements are arranged on the step face, the outer ring is sleeved on the boss, and positioned on the upper inner side in the height direction of the retainer. According to the device, assembly is realized by virtue of self weight of an inner ring, the frictional wear of a bearing during the assembly process is alleviated, the temperature control precision is high, the assembly efficiency is high, the pollution is slight, and the service life of the device is long.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

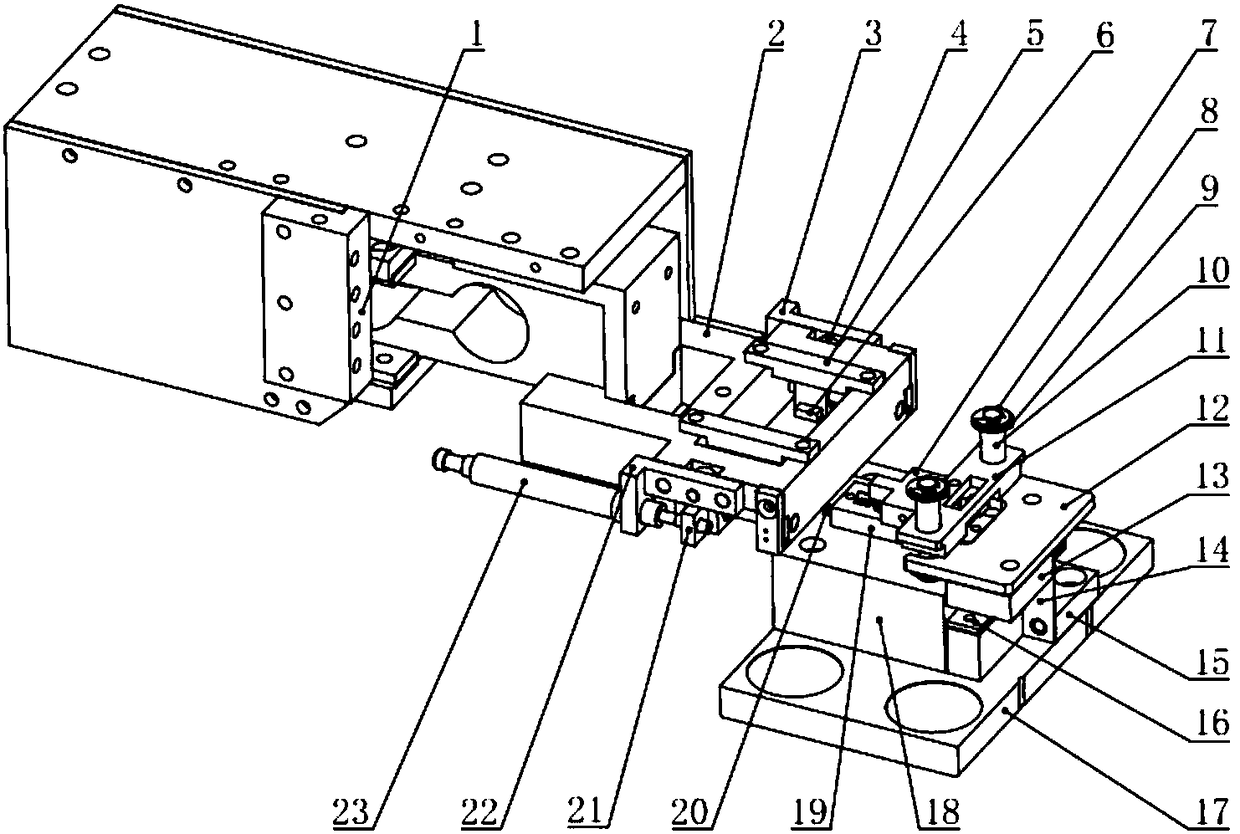

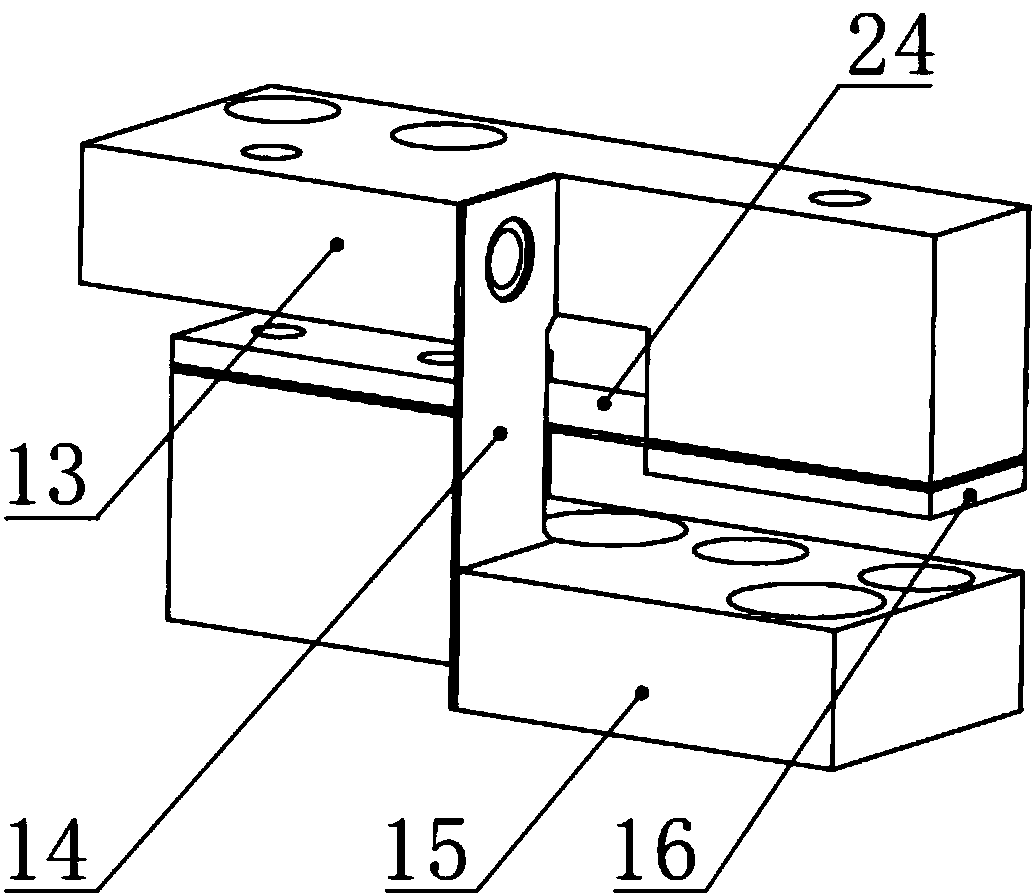

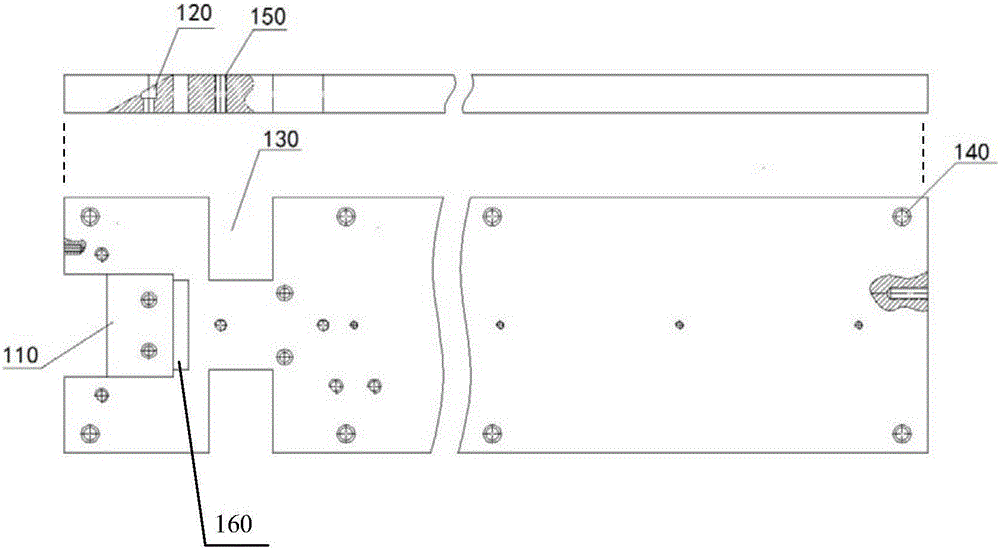

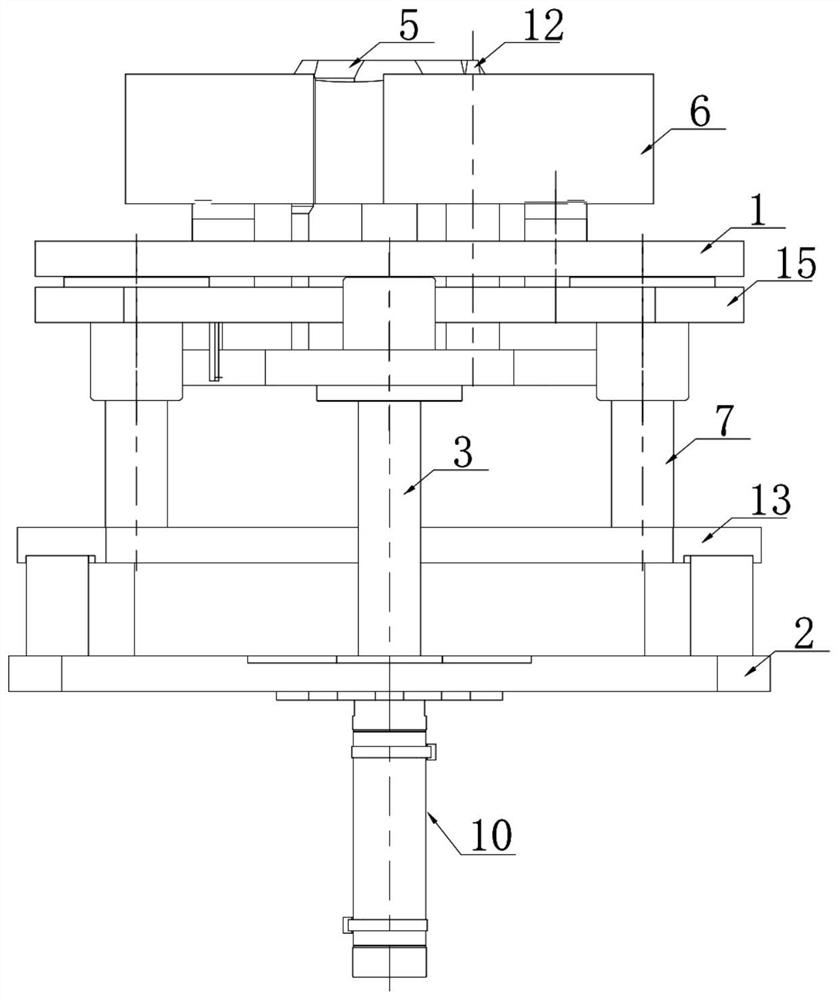

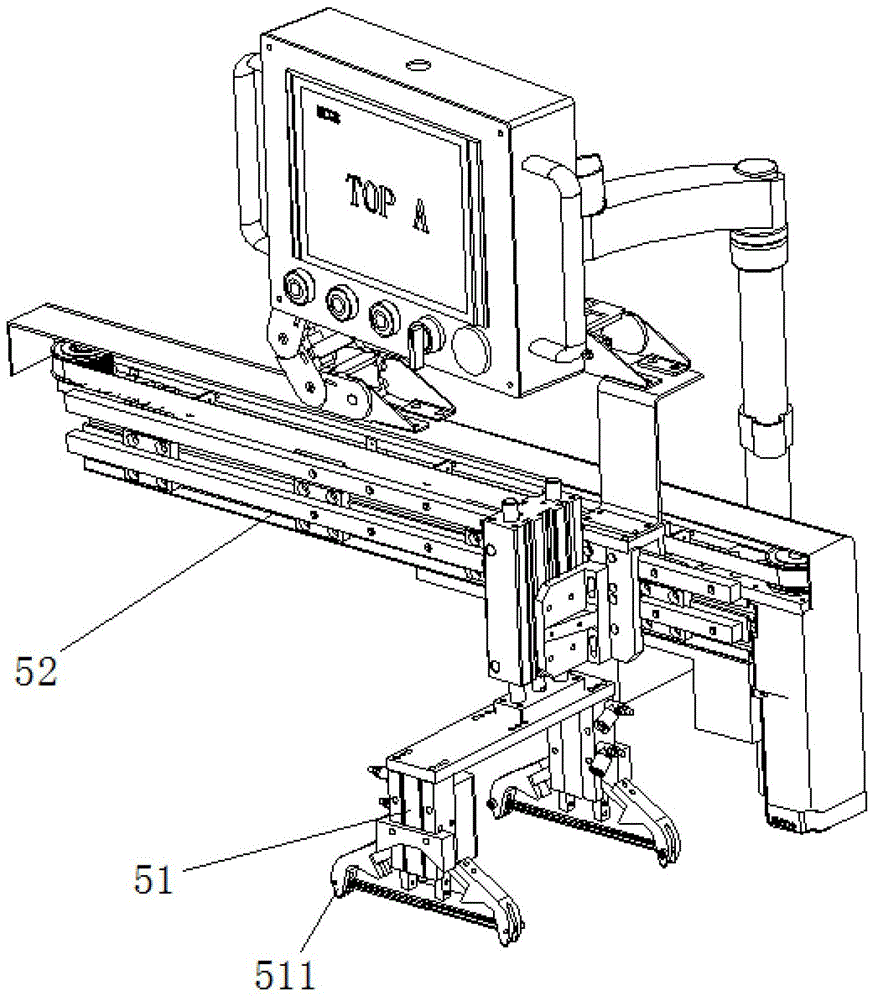

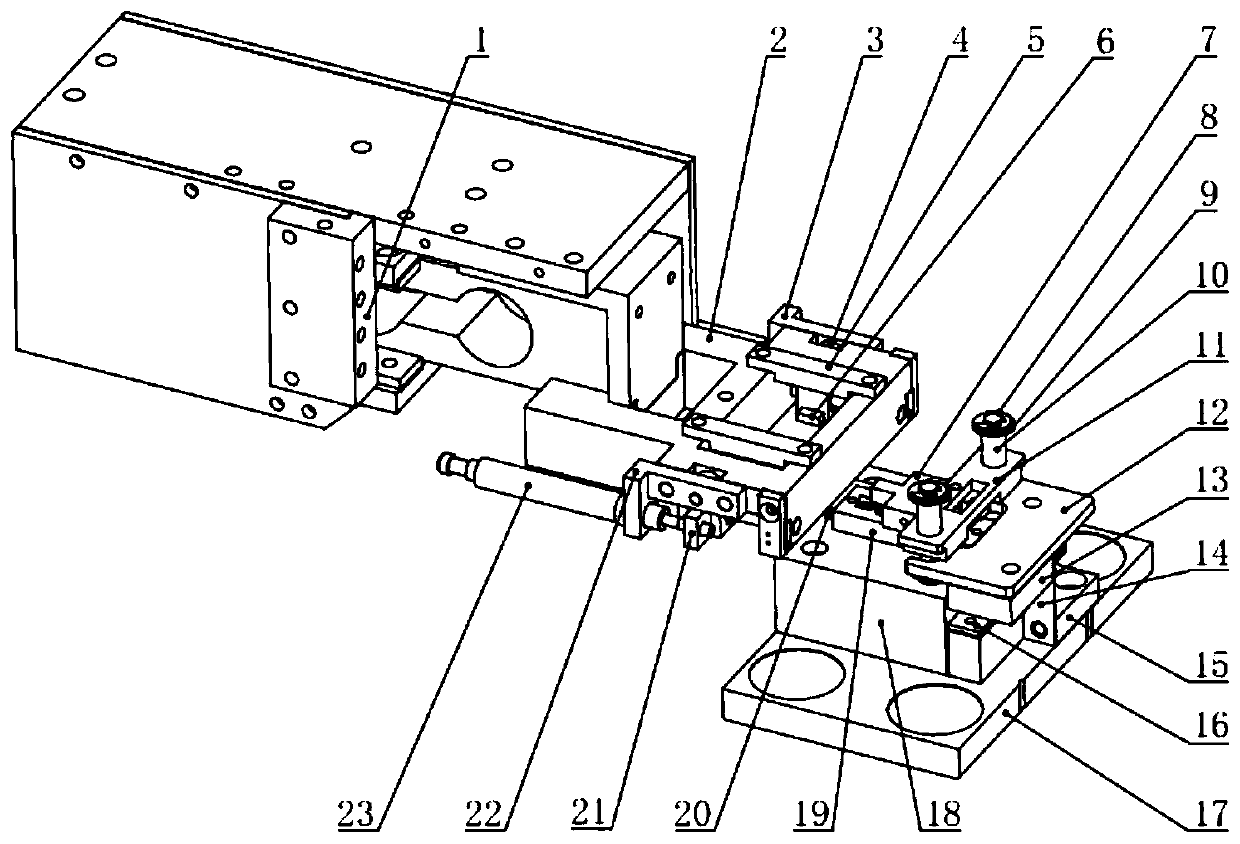

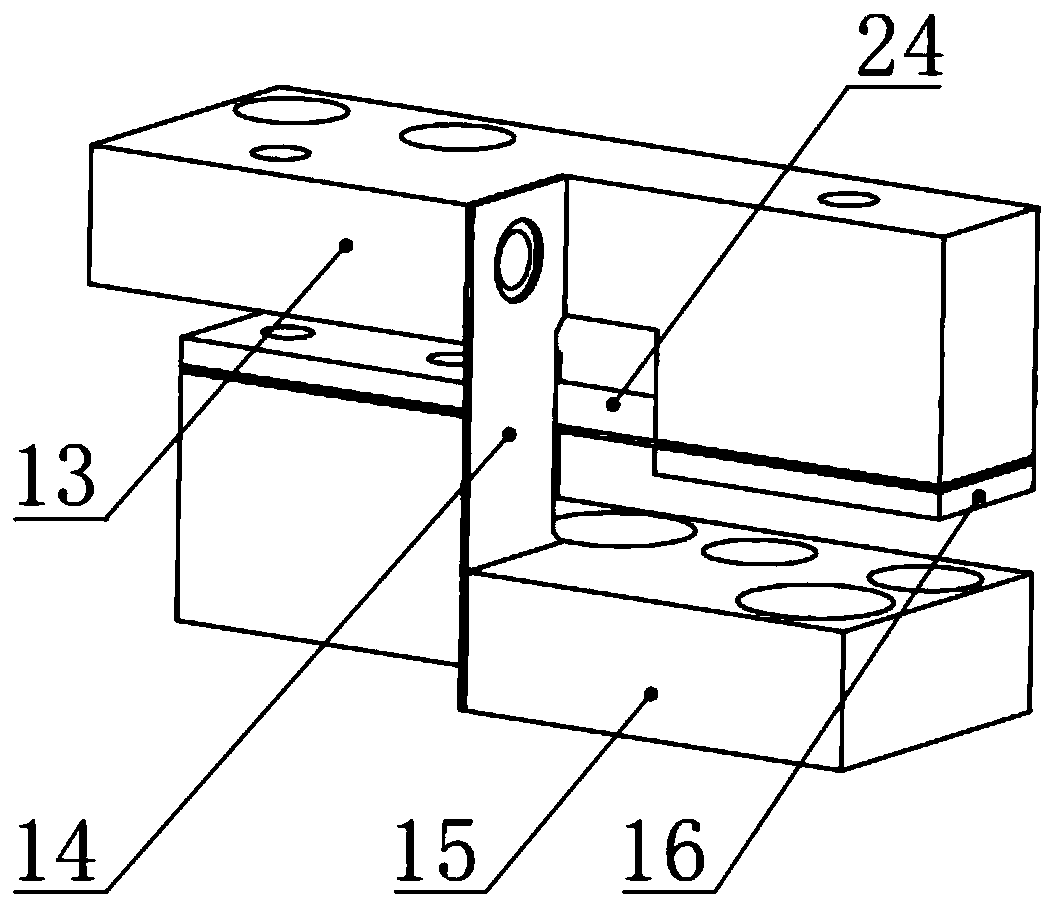

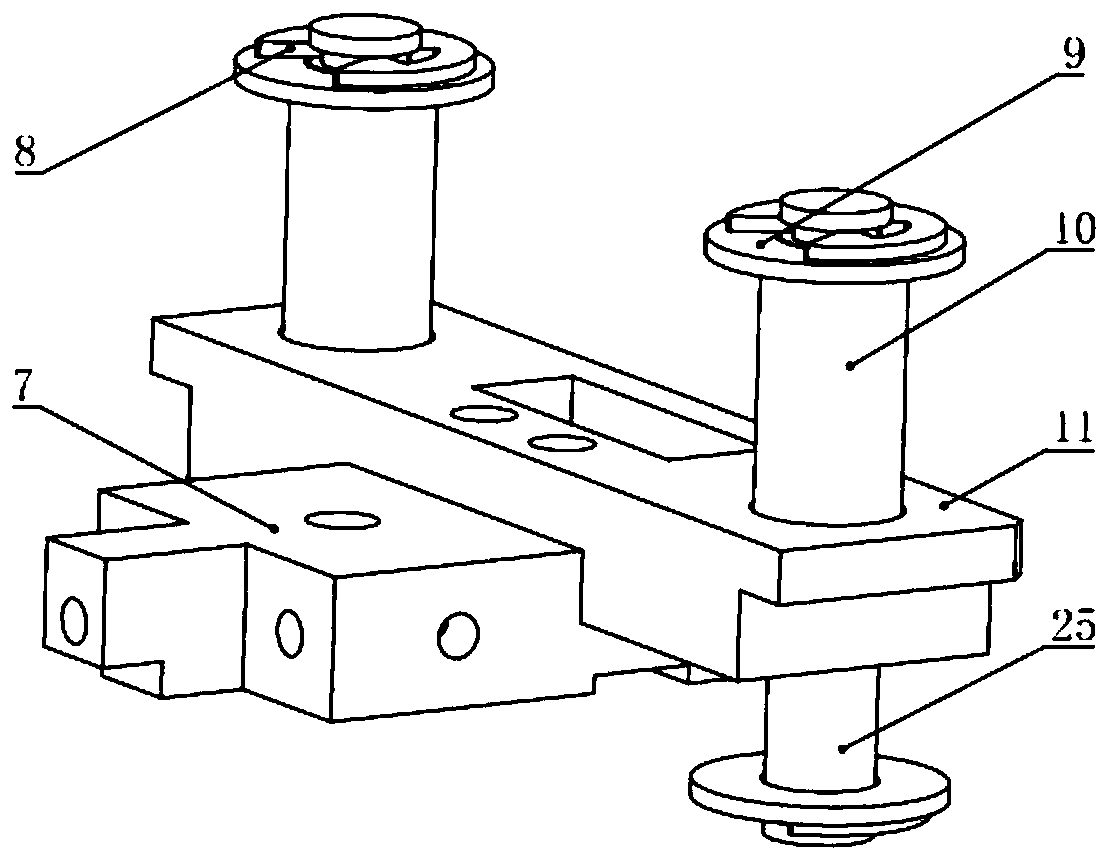

Locking device for automatic assembling of micro part and assembling method

ActiveCN108581469ARealize fully automated assemblyImprove assembly efficiencyAssembly machinesMetal working apparatusProduction lineEngineering

The invention belongs to the technical field of precision assembly, and provides a locking device for automatic assembling of a micro part and an assembling method. The locking device is composed of aflexible unit, a mechanical arm unit and a clamp locking unit; the flexible unit and the clamp locking unit are mainly used for flexible locking after micro part assembling; the mechanical arm unit and the clamp locking unit are used for automatically locking the micro part in the processes of picking, carrying and assembling the micro part through automatic change-over; and the flexible unit, the mechanical arm unit and the clamp locking unit achieve automatic assembling of the micro part through cooperative collaboration. According to the locking device, flexible locking has a certain buffering and balancing effect on unbalanced locking force generated in the assembling process, so that a certain protection effect is achieved on the micro part and maintaining of the relative pose of theassembled part; and manual intervention is avoided through automatic locking, full-automatic assembling is achieved, the assembling efficiency is improved, and the device and the method are suitablefor a batch and automatic production line.

Owner:DALIAN UNIV OF TECH

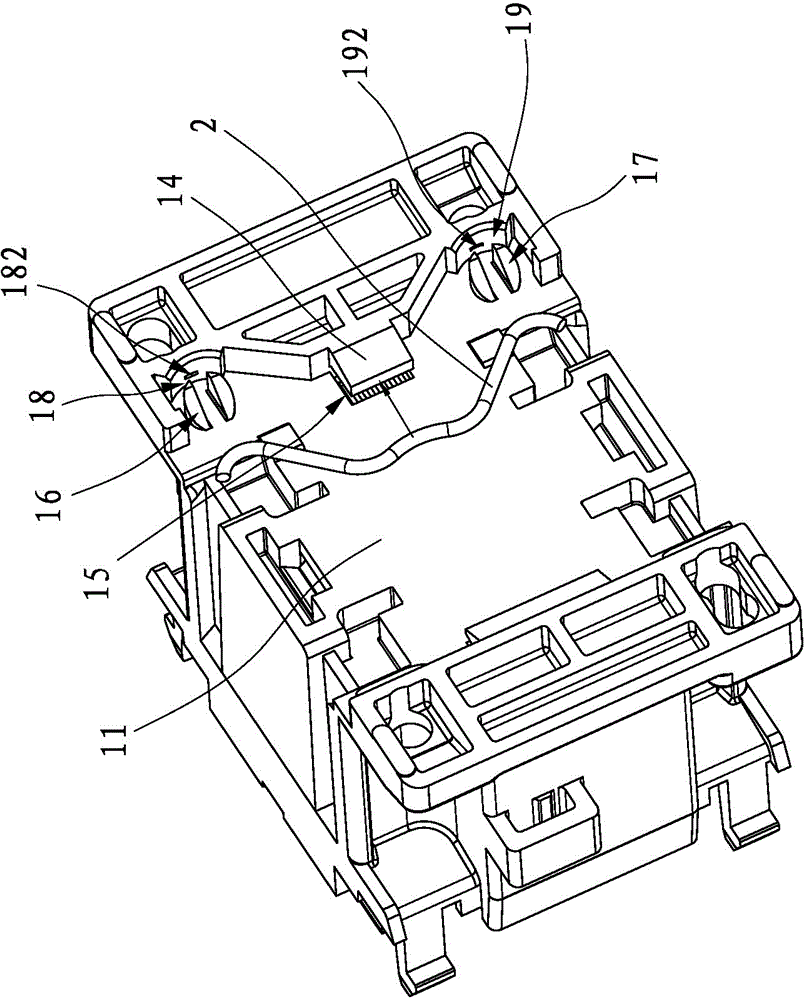

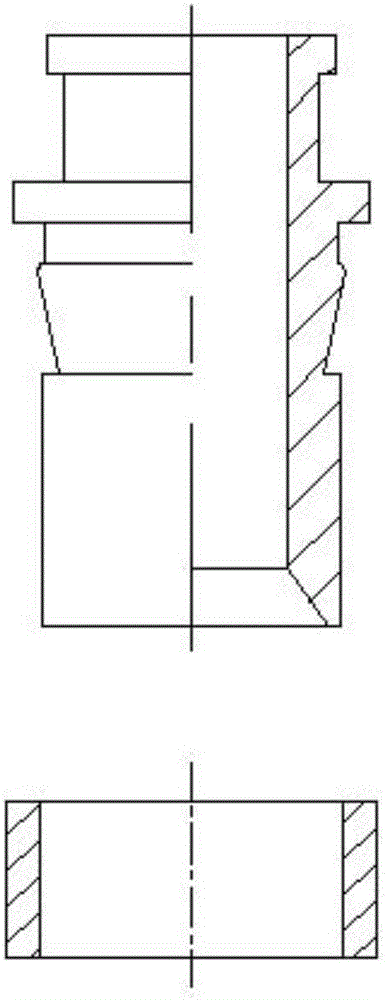

Mounting structure for appliance guide rail

InactiveCN104409243AThe circlip is installed stablyNot easy to slip offElectric switchesEngineeringMechanical engineering

Owner:XIAMEN HONGFA ELECTRICAL SAFETY & CONTROLS

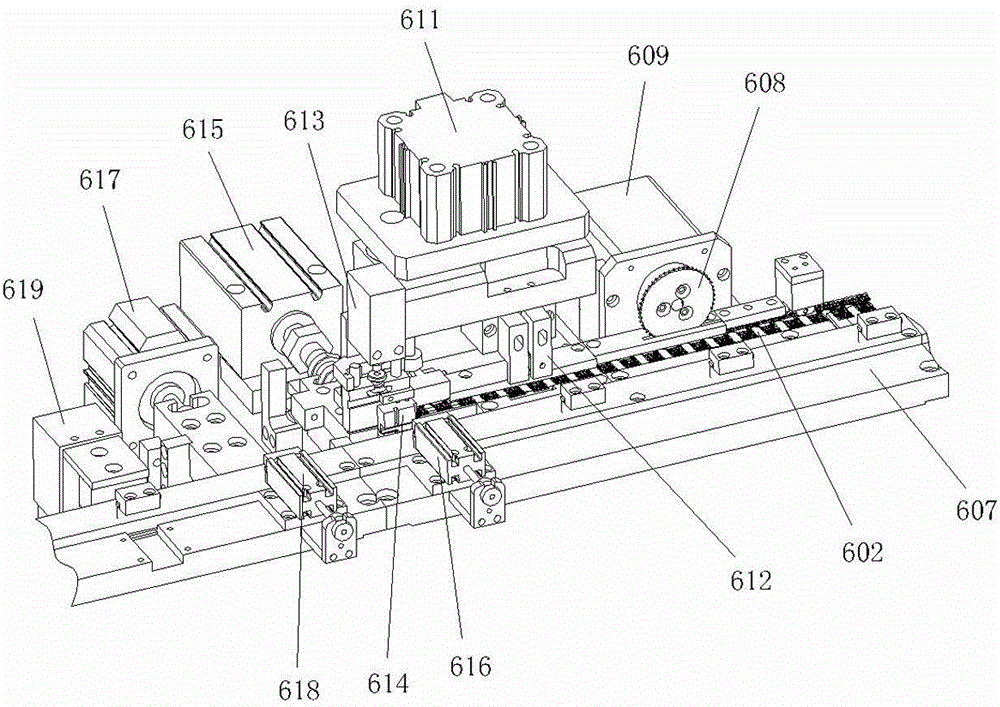

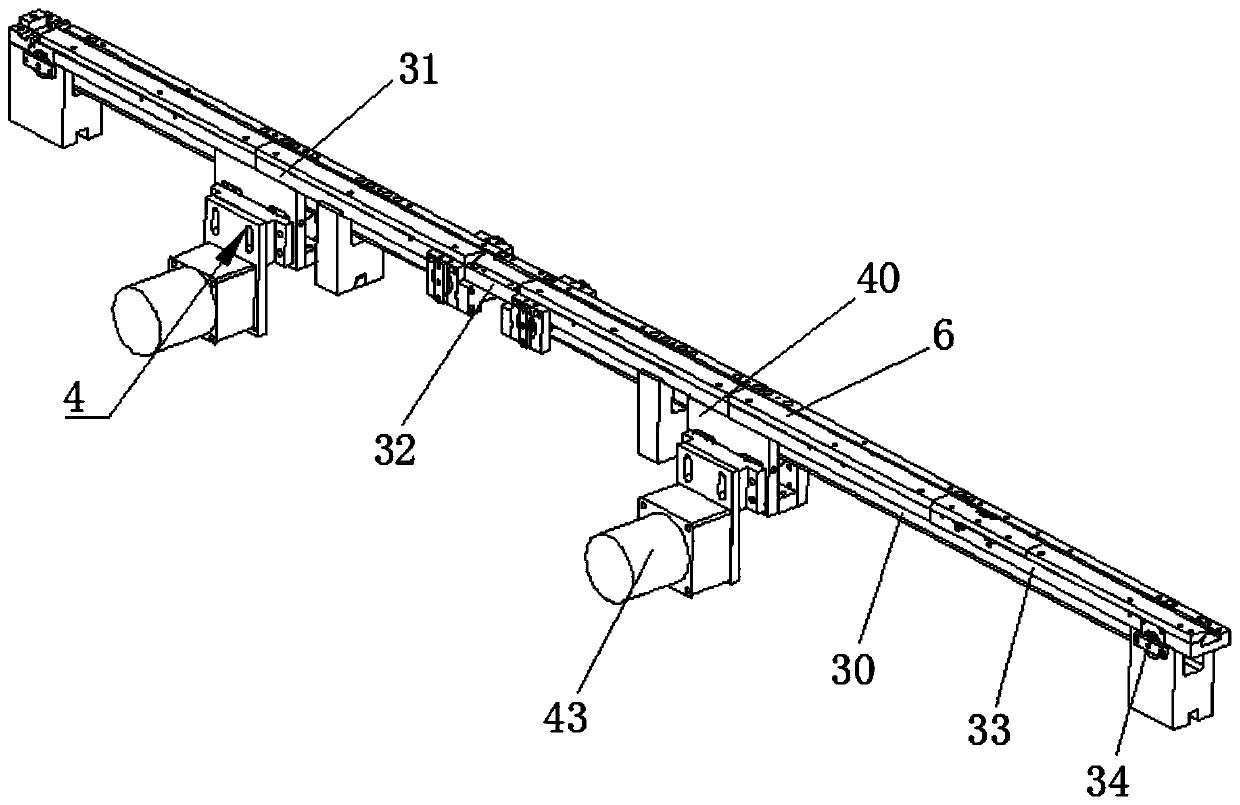

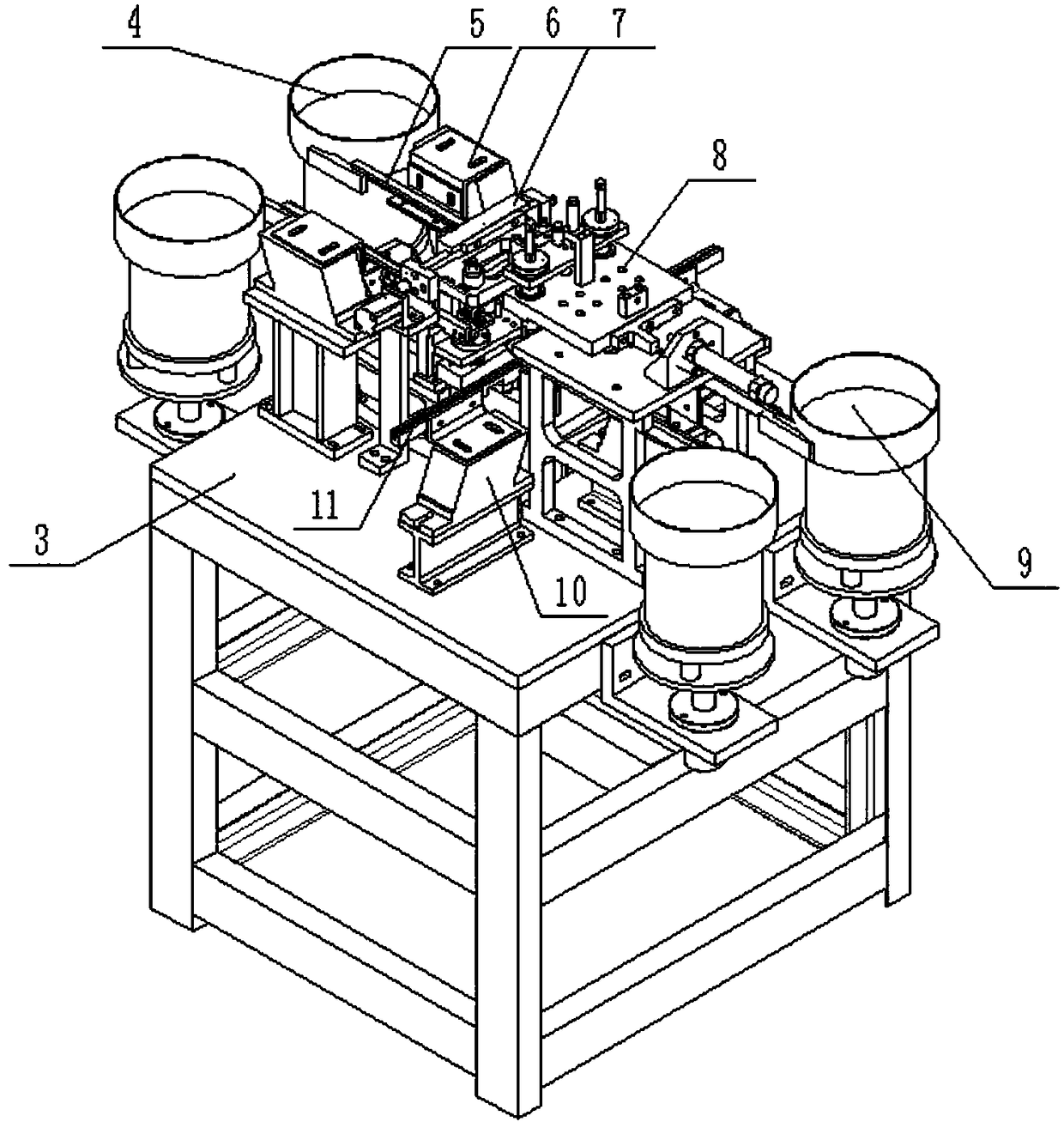

Continuous production line for bearing assembly

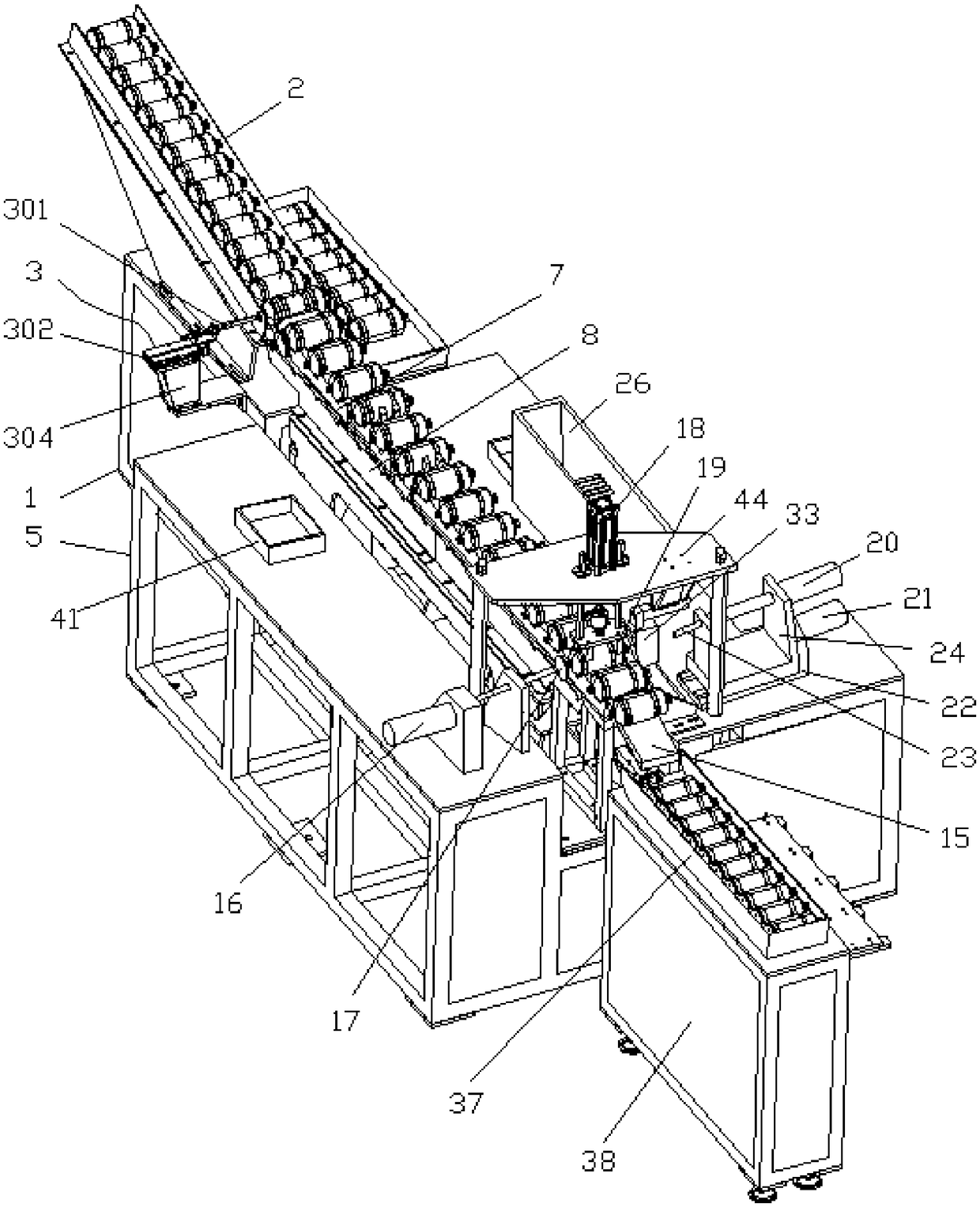

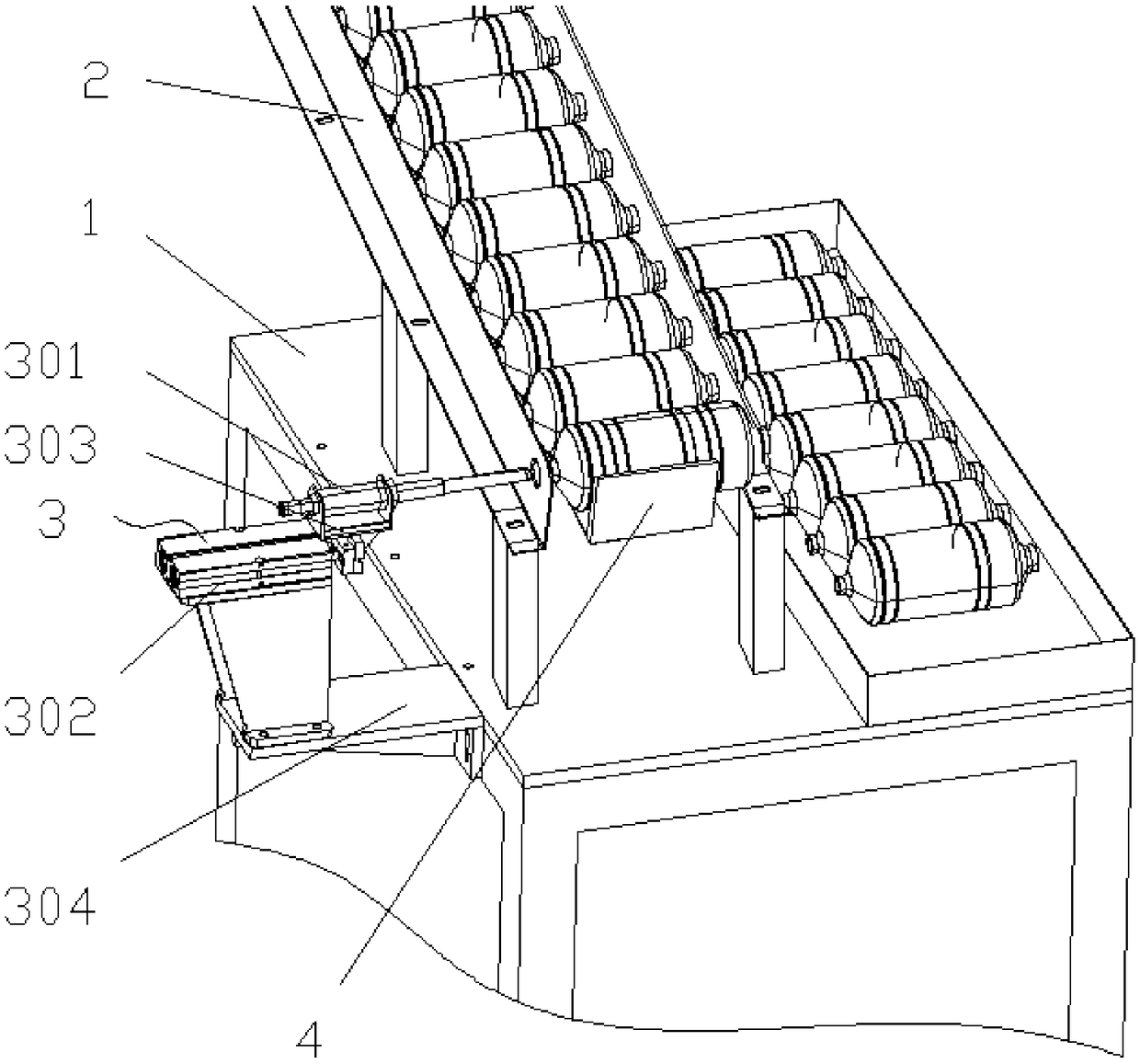

ActiveCN111644845ARealize fully automated assemblyImprove continuityAssembly machinesBearing componentsProduction lineMachining

The invention belongs to the field of bearing assembly machining, and particularly discloses a continuous production line for bearing assembly. The continuous production line for the bearing assemblycomprises a front-section machining module used for completing bearing feeding and assembling inner and outer rings of a bearing, and a ball assembly module used for completing ball assembly. The front-section machining module comprises two sets of feeding and conveying devices, a transfer positioning device, and a transfer drive mechanism used for driving the transfer positioning device to move.The ball assembly module comprises a ball discharging device, and a bearing feeding device used for conveying bearing assemblies. The ball discharging device is arranged above the bearing conveying device. According to the continuous production line for the bearing assembly, full-automatic bearing assembly is achieved, the continuity is high, the whole assembly process does not need to be stopped,and the assembly efficiency is high.

Owner:EAST CHINA JIAOTONG UNIVERSITY

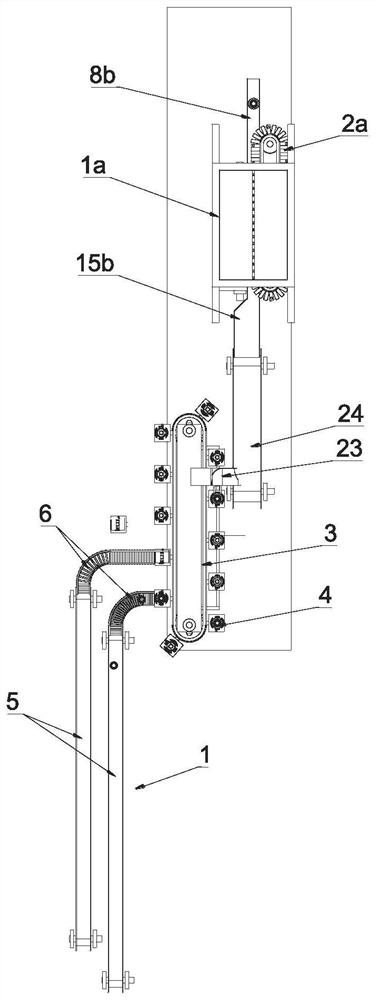

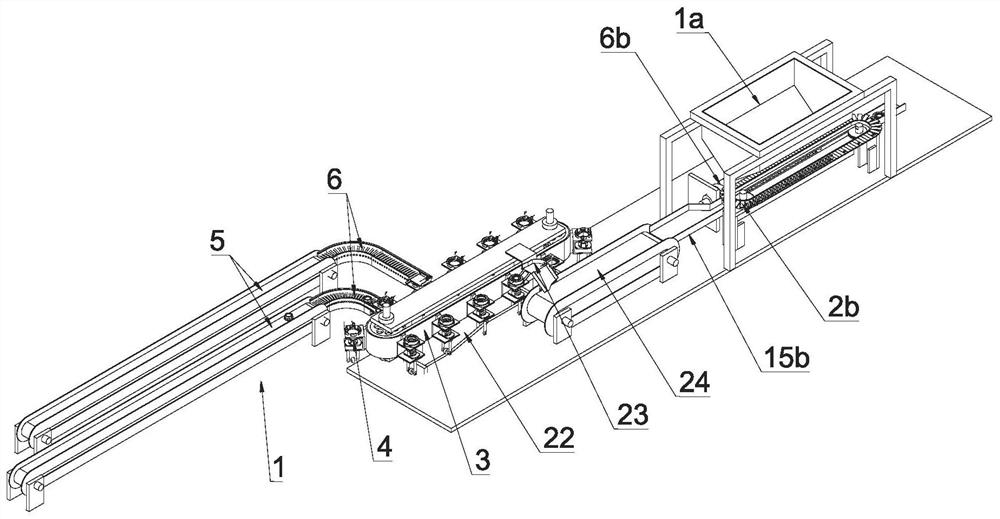

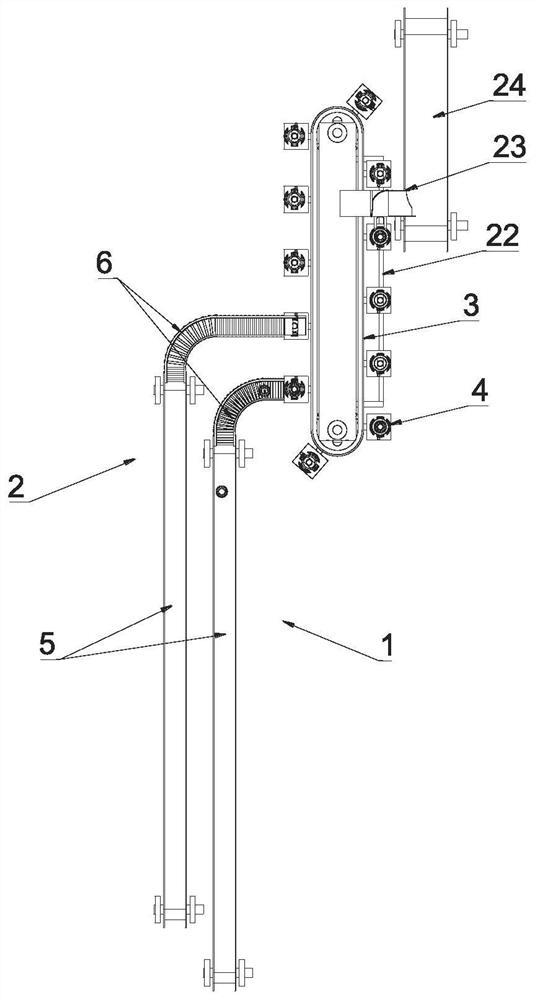

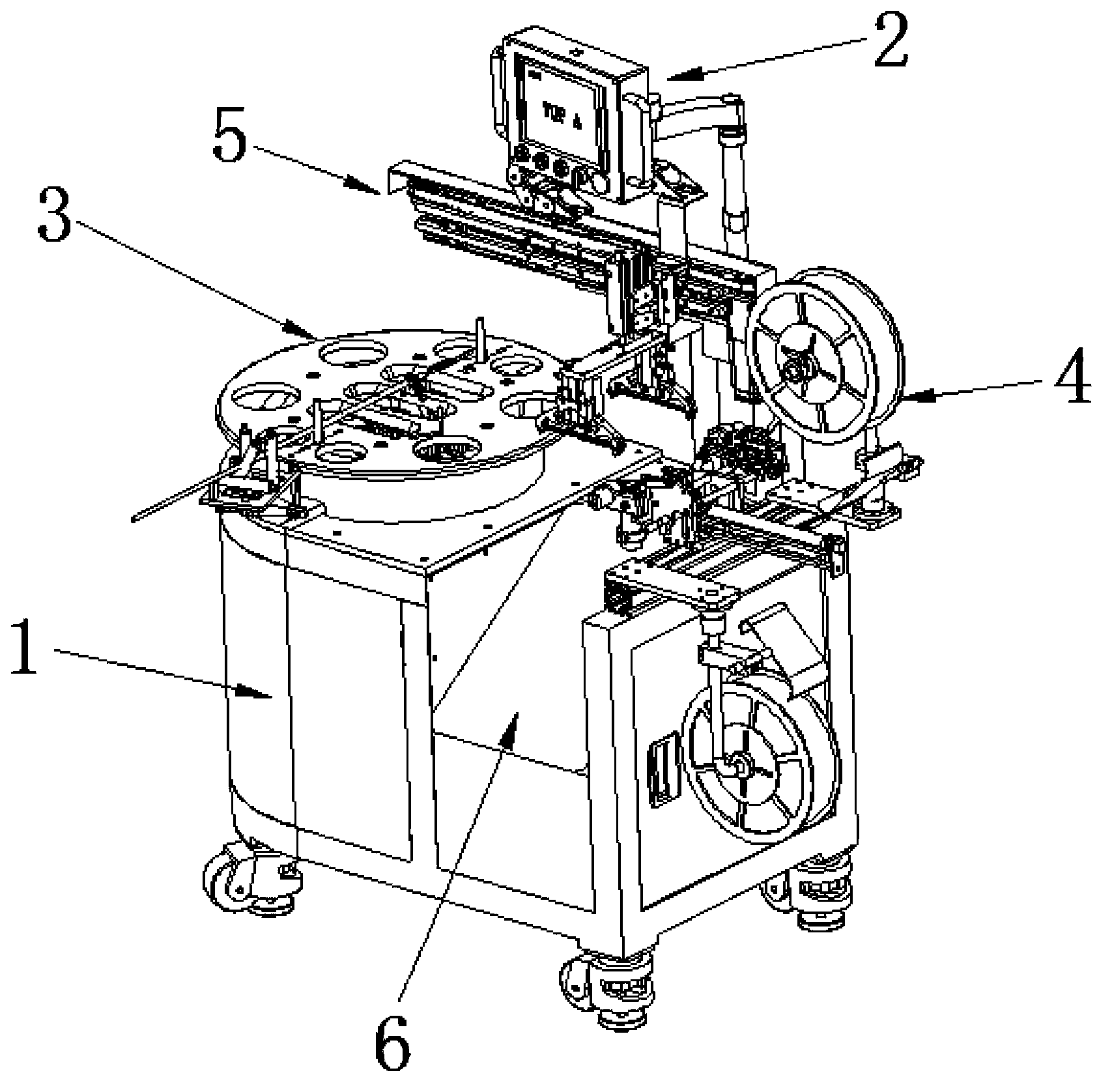

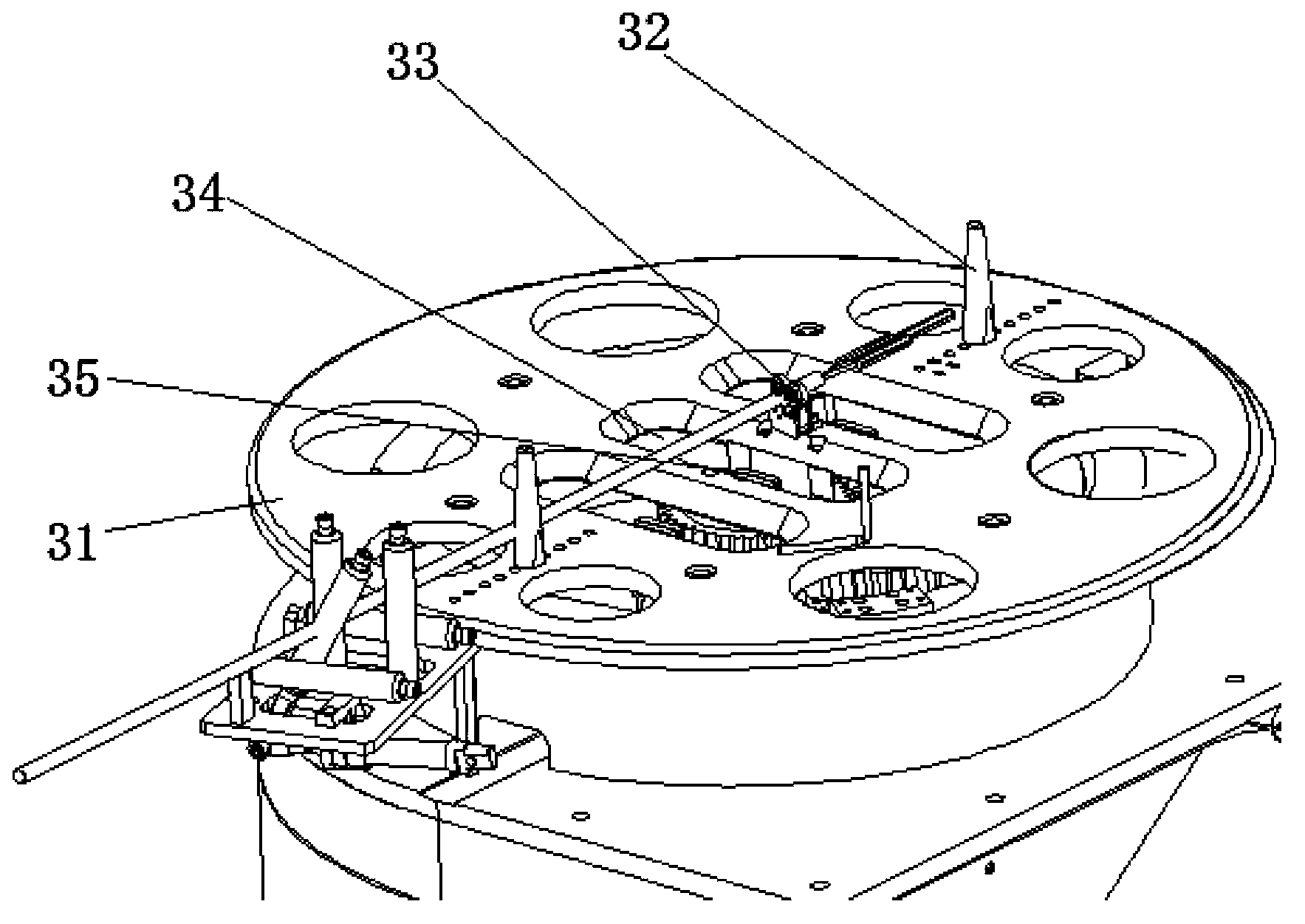

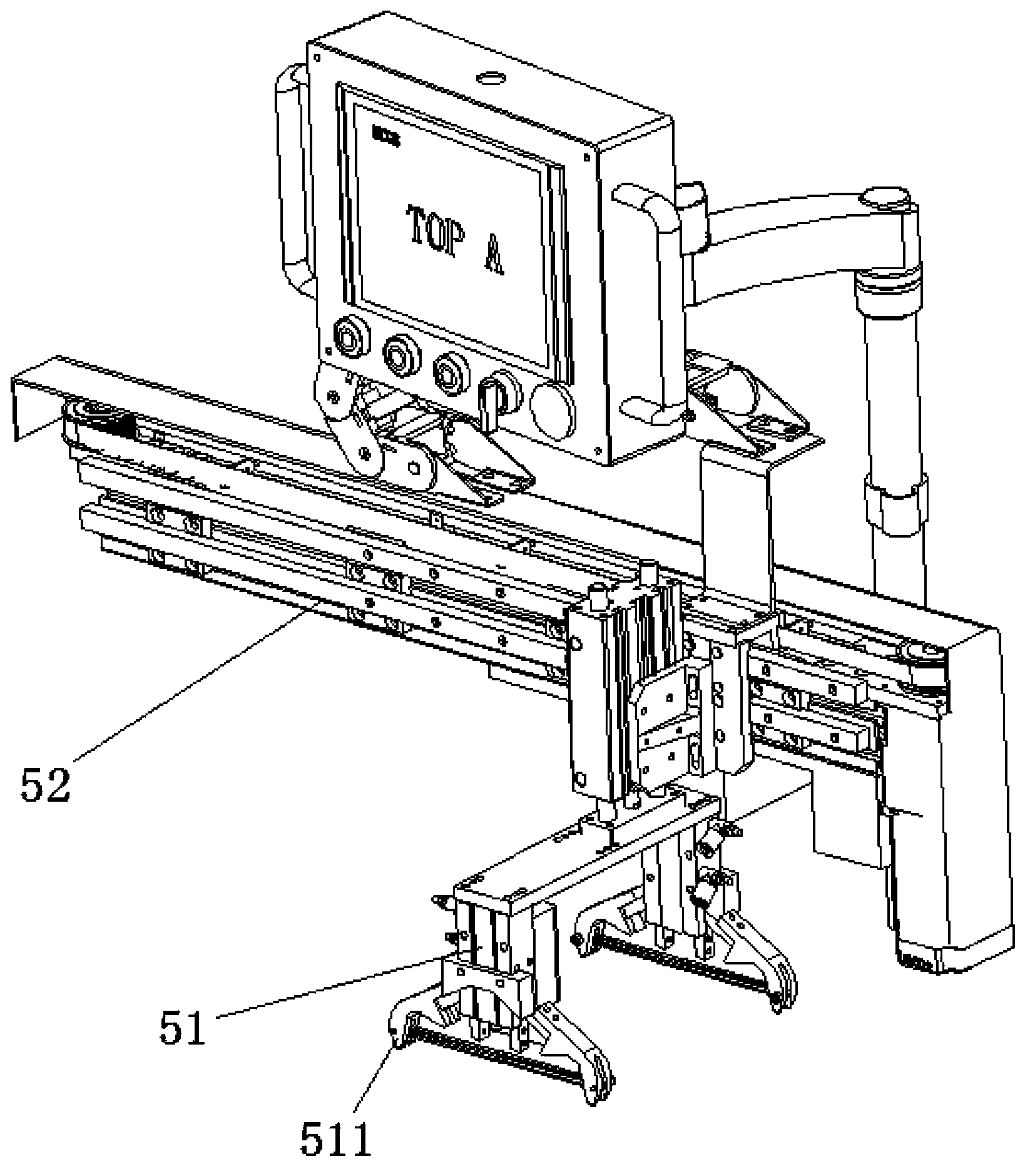

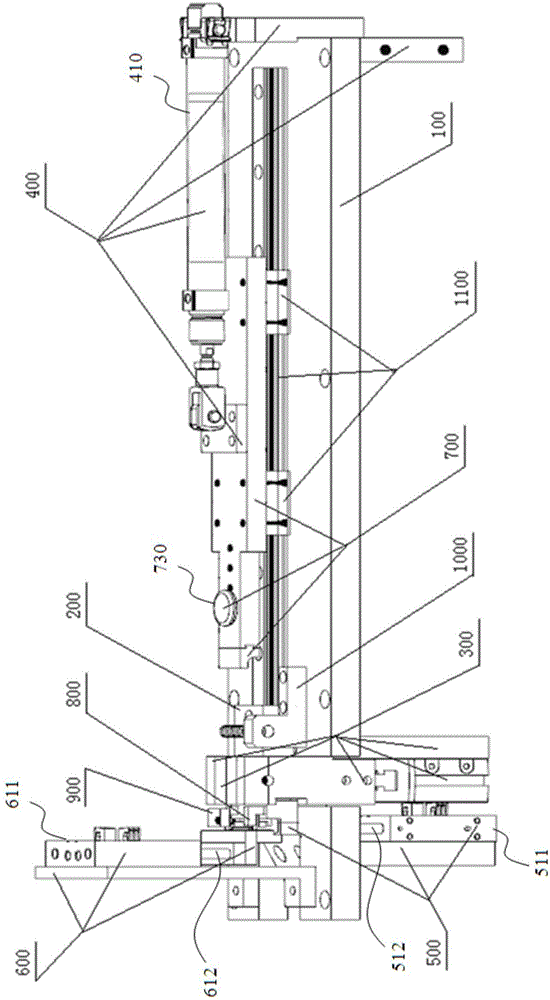

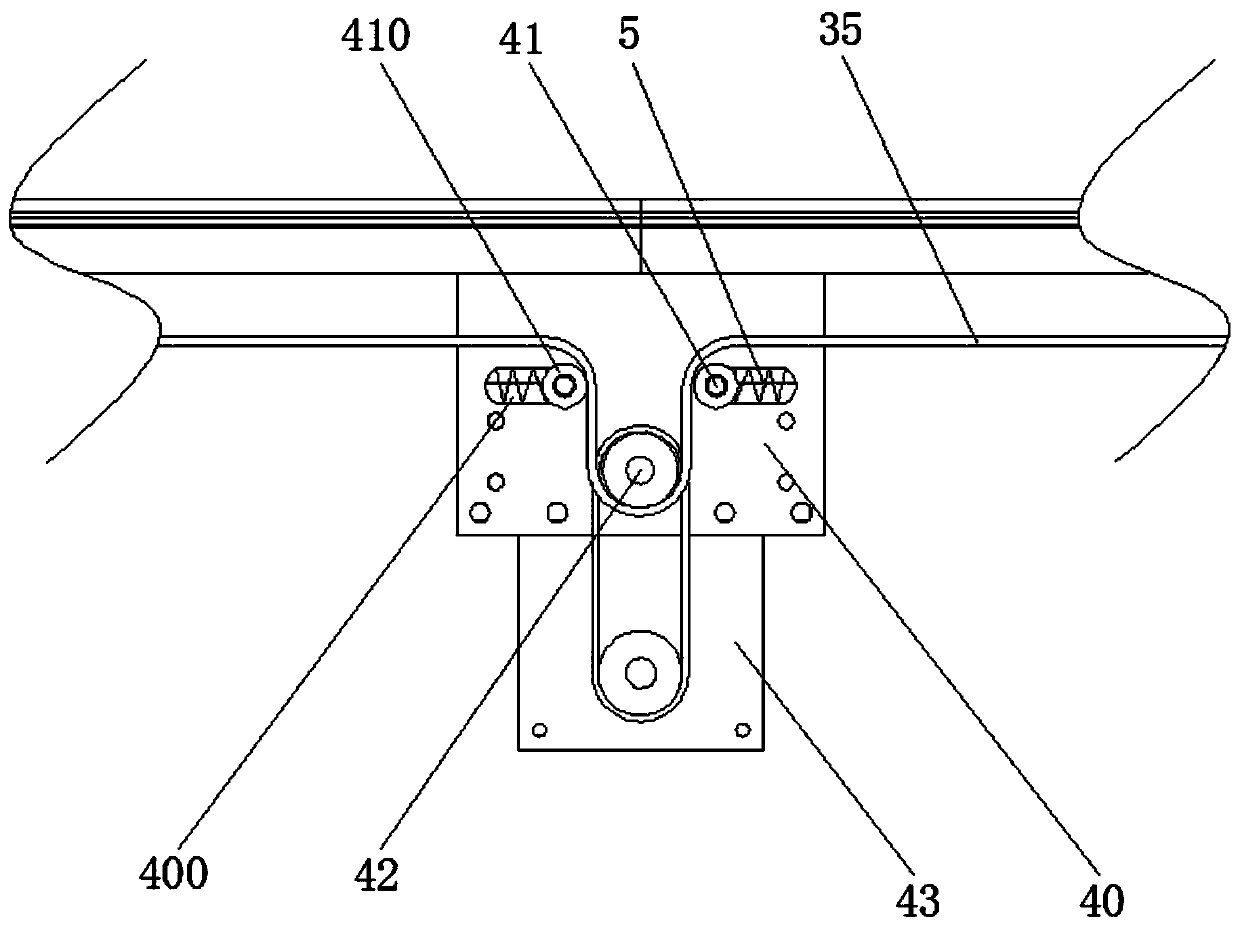

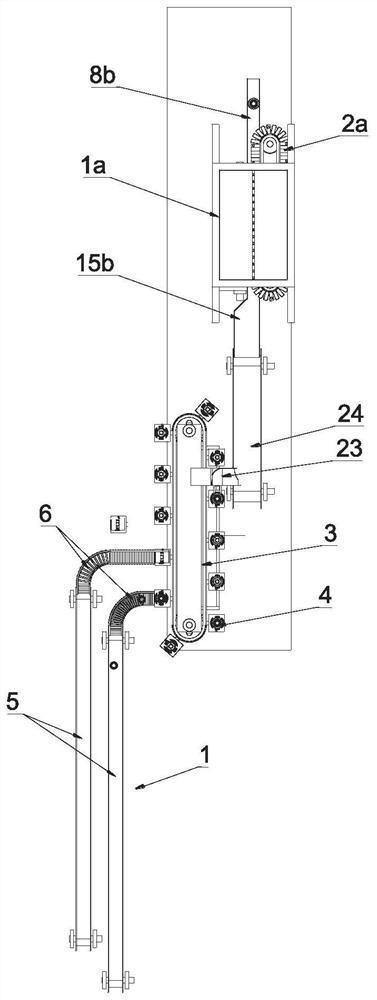

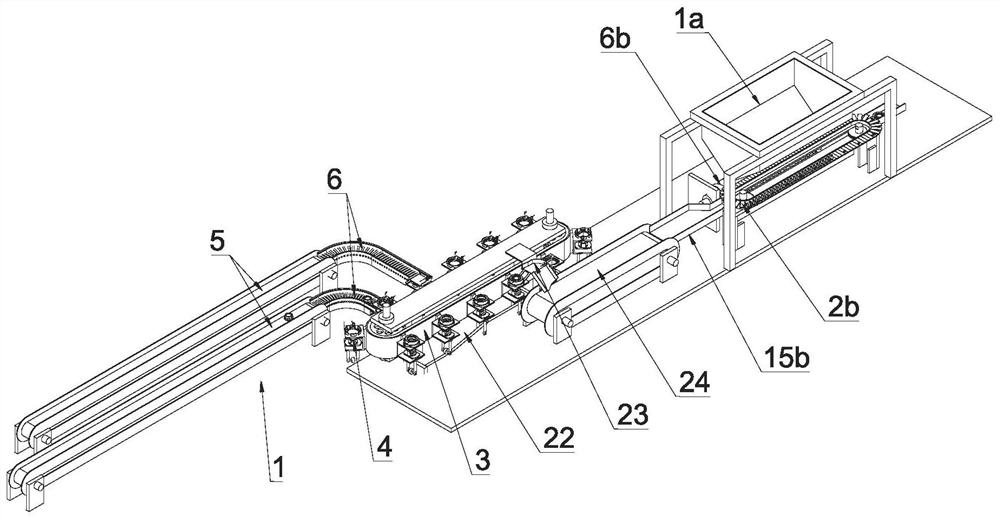

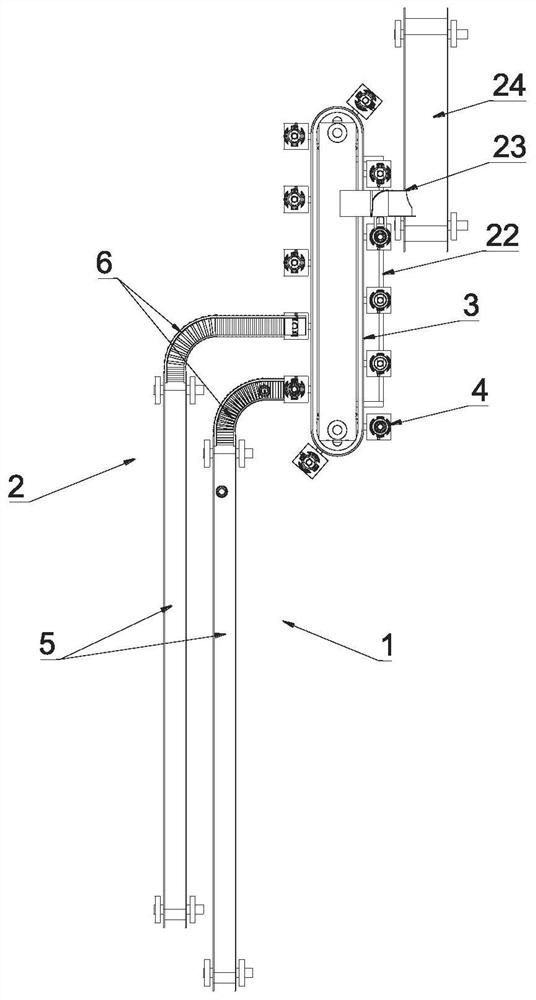

Universal equipment for automatically binding wire rods

ActiveCN103662155AImprove work efficiencySave human effortBinding material applicationBundling machine detailsHuman–machine interfaceMaterial resources

The invention discloses universal equipment for automatically binding wire rods. The universal equipment comprises a rack, a wire winding / binding station, a binding belt conveying station and a wire catching station, wherein the wire winding / binding station, the binding belt conveying station and the wire catching station are arranged on the rack and are controlled through a human-computer interface. The wire winding / binding station can be used for winding flexible wire rods into coils. The binding belt conveying station can store binding belts and convey binding belts with required length according to requirements. The wire catching station can catch the binding belts and convey the binding belts to the flexible wire rods wound into coils on the wire winding / binding station after the binding belts are sectioned according to the required length by the binding belt conveying station. The binding belts wind the flexible wire rods for one circle. The wire winding / binding station can further tighten the binding belts winding the flexible wire rods for one circle so as to bind the flexible wire rods. The wire catching station can further convey the bound flexible wire rods from the wire winding / binding station to a designated position. The universal device integrates wire rod winding and wire rod binding, can realize fully-automatic assembly, greatly improves working efficiency, saves manpower, material resources and financial resources, reduces the production cost of enterprises, and improves enterprise competitiveness.

Owner:KUNSHAN BAIAO INTELLIGENT EQUIP CO LTD

Automatic assembling mechanism for spring and rack

InactiveCN105690076ARealize fully automated assemblyReduce labor costsWork holdersMetal working apparatusCompression deviceEngineering

The invention relates to an automatic assembling mechanism for a spring and a rack. A rack positioning device drives a supporting piece to stretch upwards, and the rack to be assembled is supported on a bottom plate. Meanwhile, an air claw in a spring compression device grabs the spring on a spring guiding and assembling base, and the spring is compressed through a spring compressing finger. A spring pushing device is used for driving a spring moving and guiding device to move forwards, and the compressed spring is pushed into the rack. A pressing stop block of a rack pressing device moves downwards to press the spring pushed into the rack. The assembled spring and the assembled rack automatically disengage and fall off, and one-time spring and rack assembling work is completed. By means of the automatic assembling mechanism for the spring and the rack, the spring and the rack can be assembled fully automatically, the labor cost is saved, and the production efficiency is improved.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

Tapered roller bearing assembling machine

PendingCN109973532ARealize fully automated assemblyImprove assembly efficiencyBearing componentsEngineeringFully automatic

The invention provides a tapered roller bearing assembling machine. The tapered roller bearing assembling machine comprises a work table top, an operating mechanism, a retainer feeding mechanism, a retainer pushing mechanism, a position detecting mechanism, a roller and inner ring assembling mechanism, a roller assembling detecting mechanism, an assembling body orientation mechanism and a rivetingmechanism; the work table top comprises a retainer feeding station, a retainer pushing station, a position detecting station, a roller and inner ring assembling station, a roller assembling detectingstation, an assembling body orientation station and a riveting station; and the operating mechanism is used for transporting assembling bodies to the next station, the retainer feeding mechanism is used for feeding retainers, the retainer pushing mechanism is used for pushing the retainers, the position detecting mechanism is used for detecting whether the retainers are located at the center of the position detecting station or not, the roller and inner ring assembling mechanism is used for assembling rollers into holding frames, the roller assembling detecting mechanism is used for detectingwhether the large ends and the small ends of the rollers in the holding frames are assembled correctly or are complete or not, the assembling body orientation mechanism is used for orientating the assembling bodies, and the riveting mechanism is used for riveting the assembling bodies. Through all the mechanisms and stations in the tapered roller bearing assembling machine, fully-automatic assembling of tapered roller bearings can be achieved, and the assembling efficiency and the assembling quality are improved.

Owner:宁波共孚自动化装备有限公司

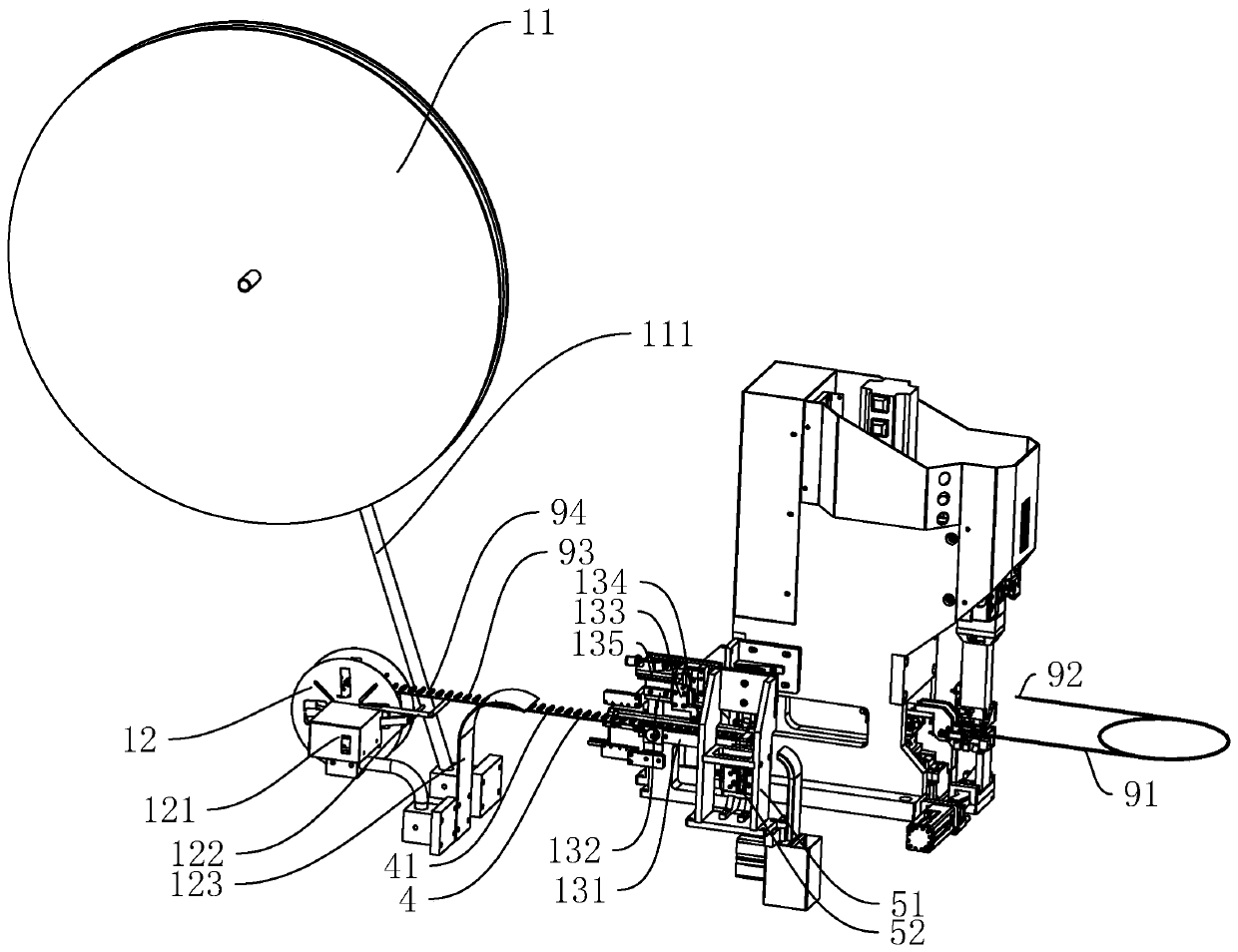

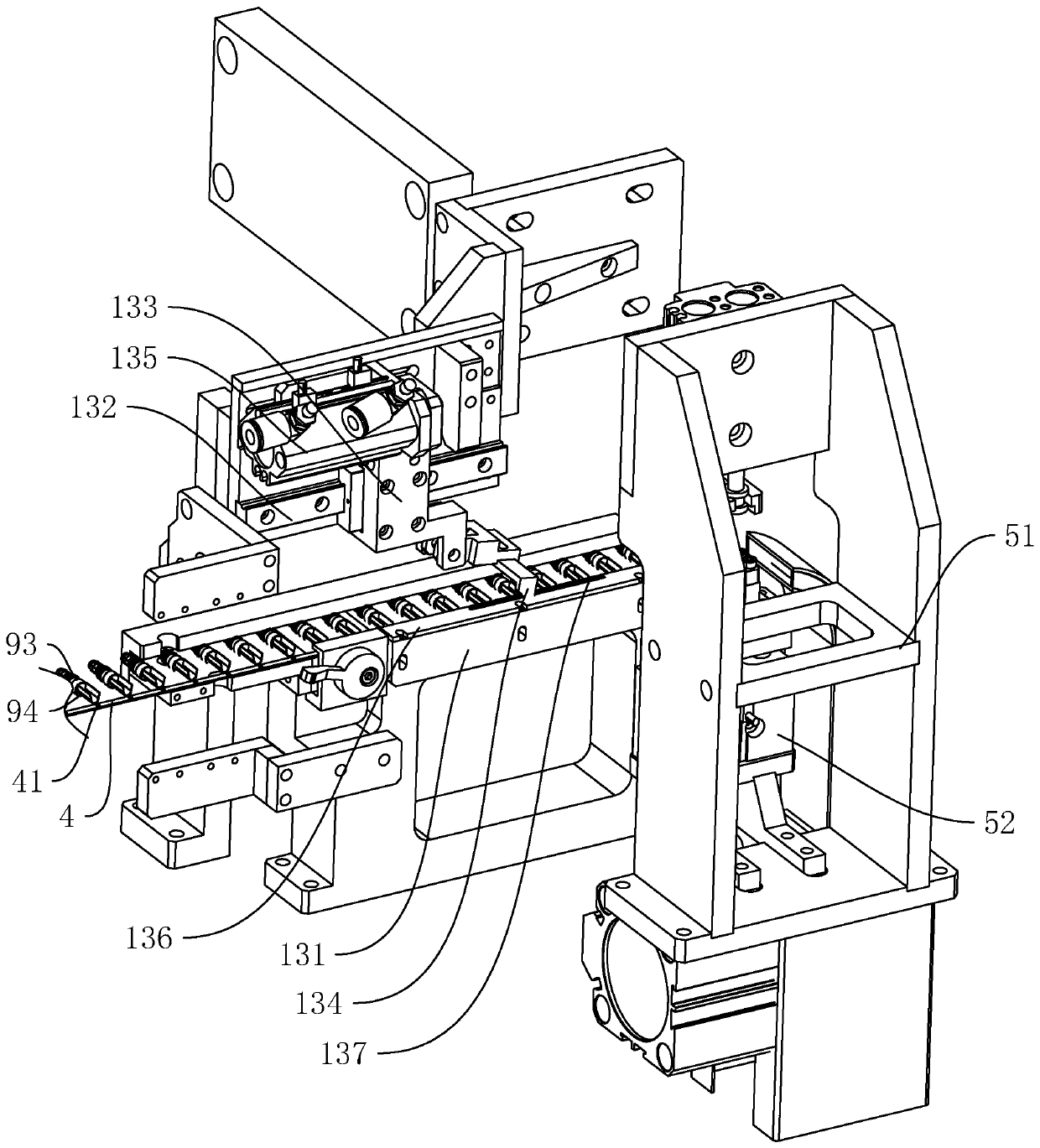

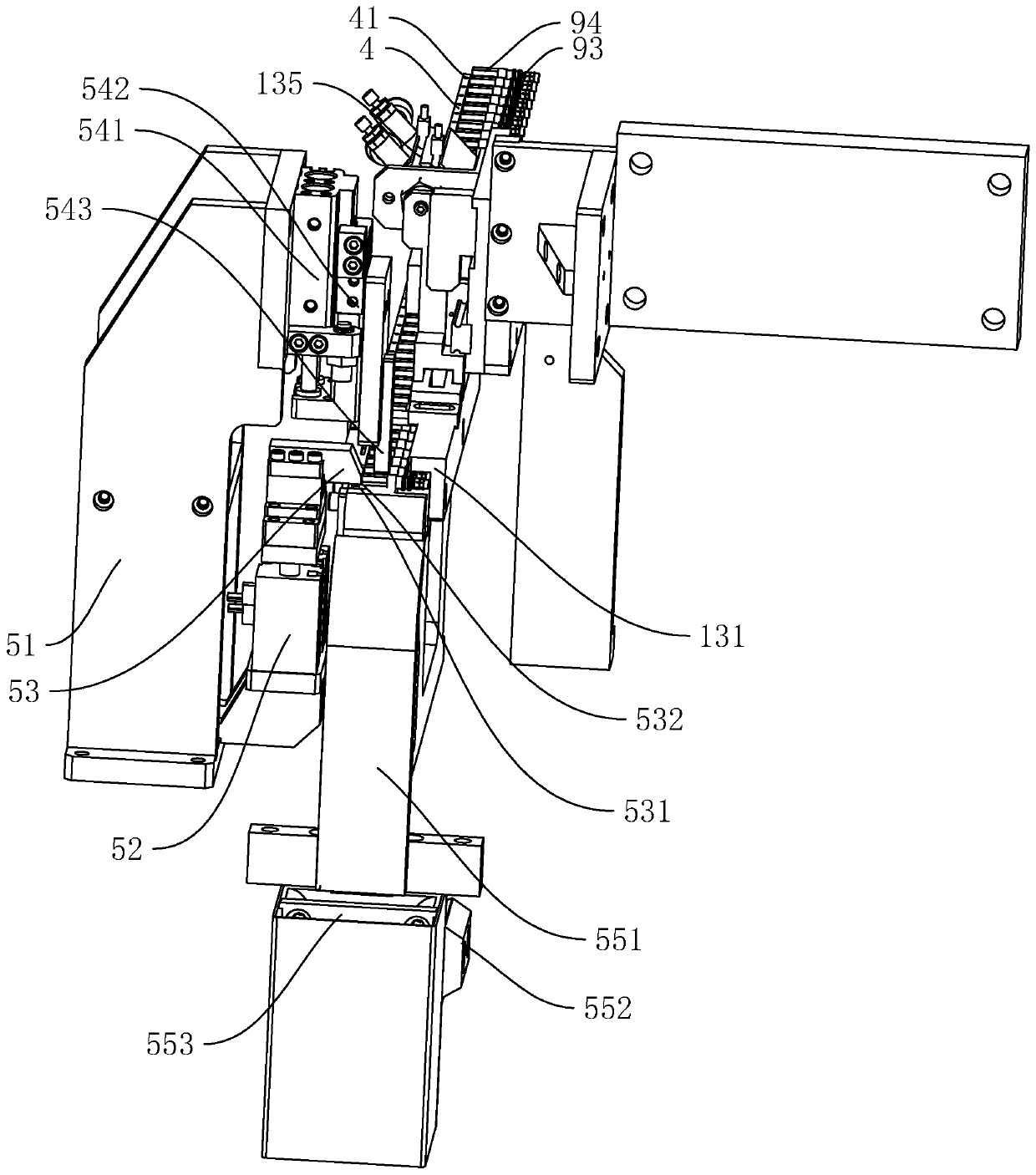

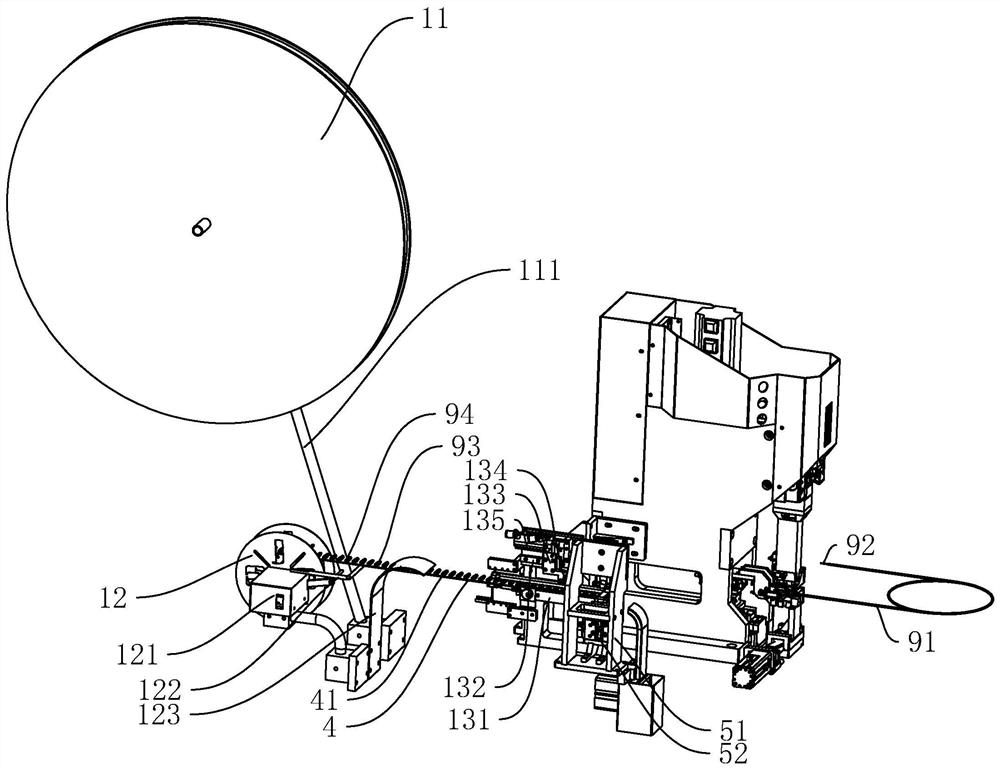

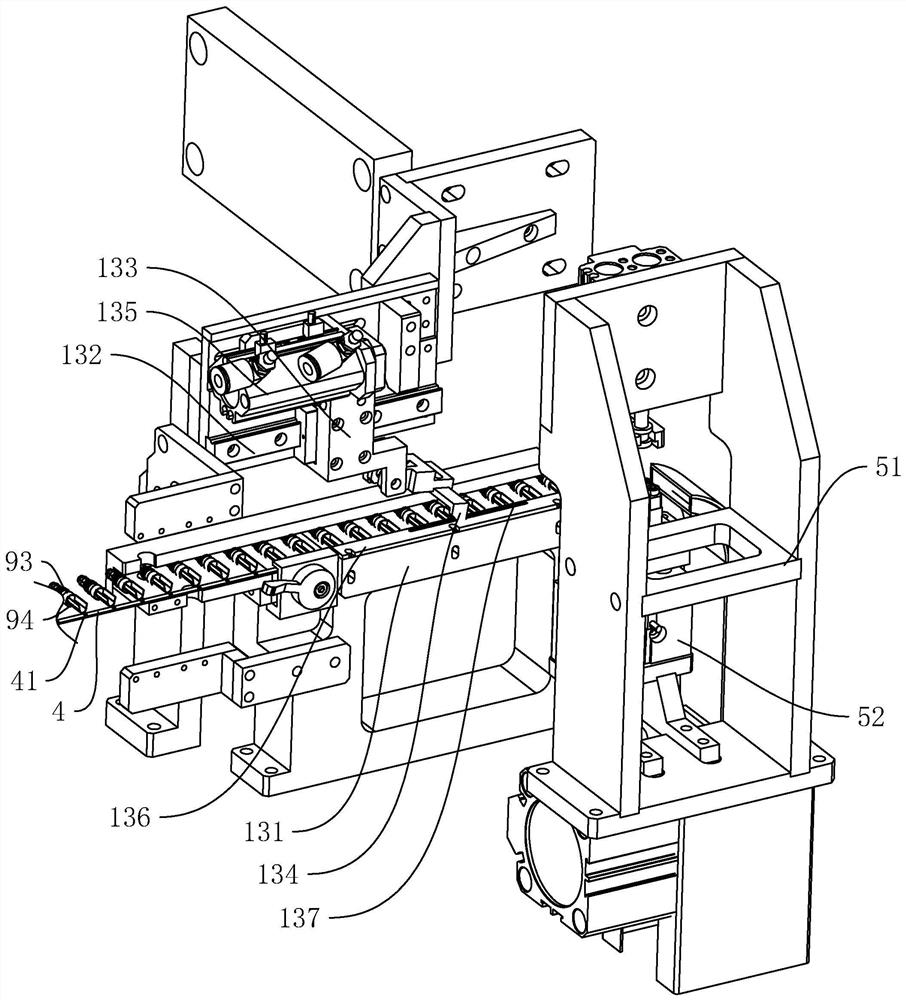

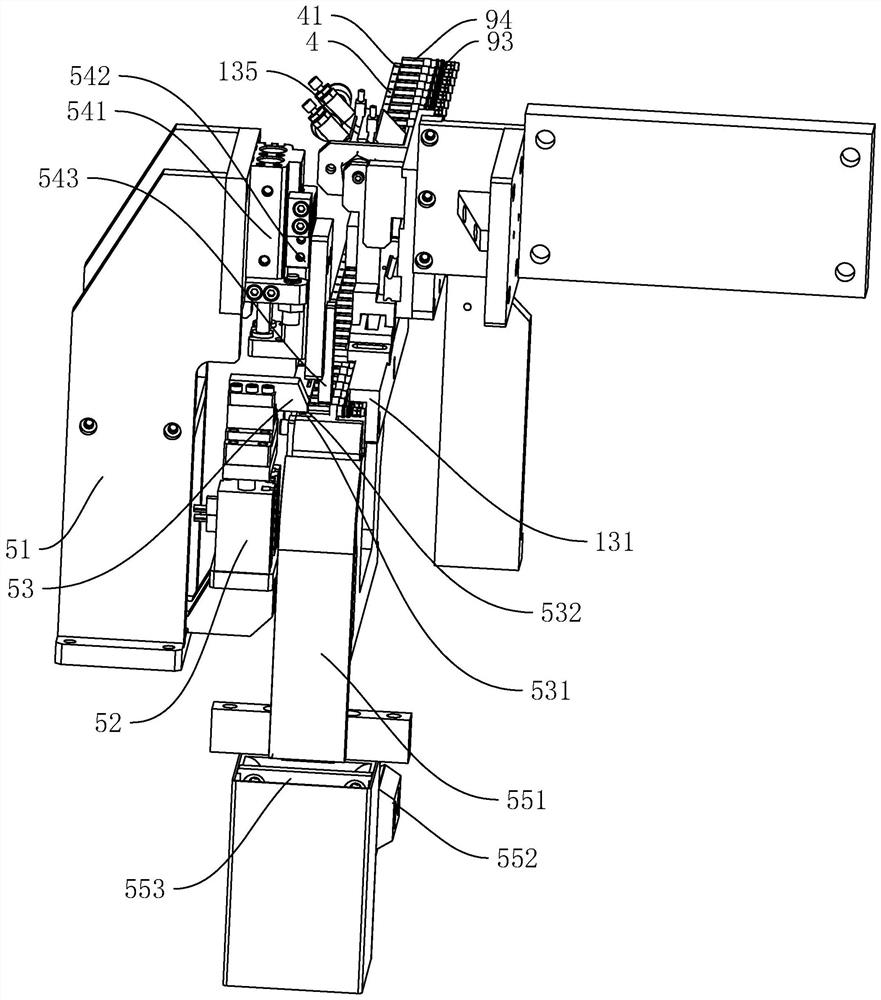

Conveying, shearing and crimping integrated device for cable end

ActiveCN111082280AAchieve supportPrevent saggingLine/current collector detailsRolling paperElectrical conductor

The invention discloses a conveying, shearing and crimping integrated device for a cable end, which relates to cable processing and aims to solve the problems that the orientation of a male joint center conductor cannot be controlled and the assembly is inconvenient. The technical scheme is characterized in that the conveying, shearing and crimping integrated device for the cable end comprises a feeding mechanism, an inserting mechanism, a stamping mechanism, a material belt and a shearing mechanism, and through holes are formed in the material belt at equal intervals in the length direction;the feeding mechanism comprises a male joint material disc, a roll paper material disc and a pushing assembly, and the pushing assembly comprises a straight groove base, a forward moving rail, a forward moving sliding block, a hook piece and a forward pushing air cylinder; the shearing mechanism comprises a shearing mechanism frame, a shearing air cylinder and a shearing pressing die. According tothe conveying, shearing and crimping integrated device for the cable end, the orientation of the male joint center conductor does not need to be detected and adjusted before assembly on the premise that full-automatic assembly of the male joint center conductor is achieved, and the technical effect that the assembly is more convenient is achieved.

Owner:JIAXING JUNQUAN AUTOMATION

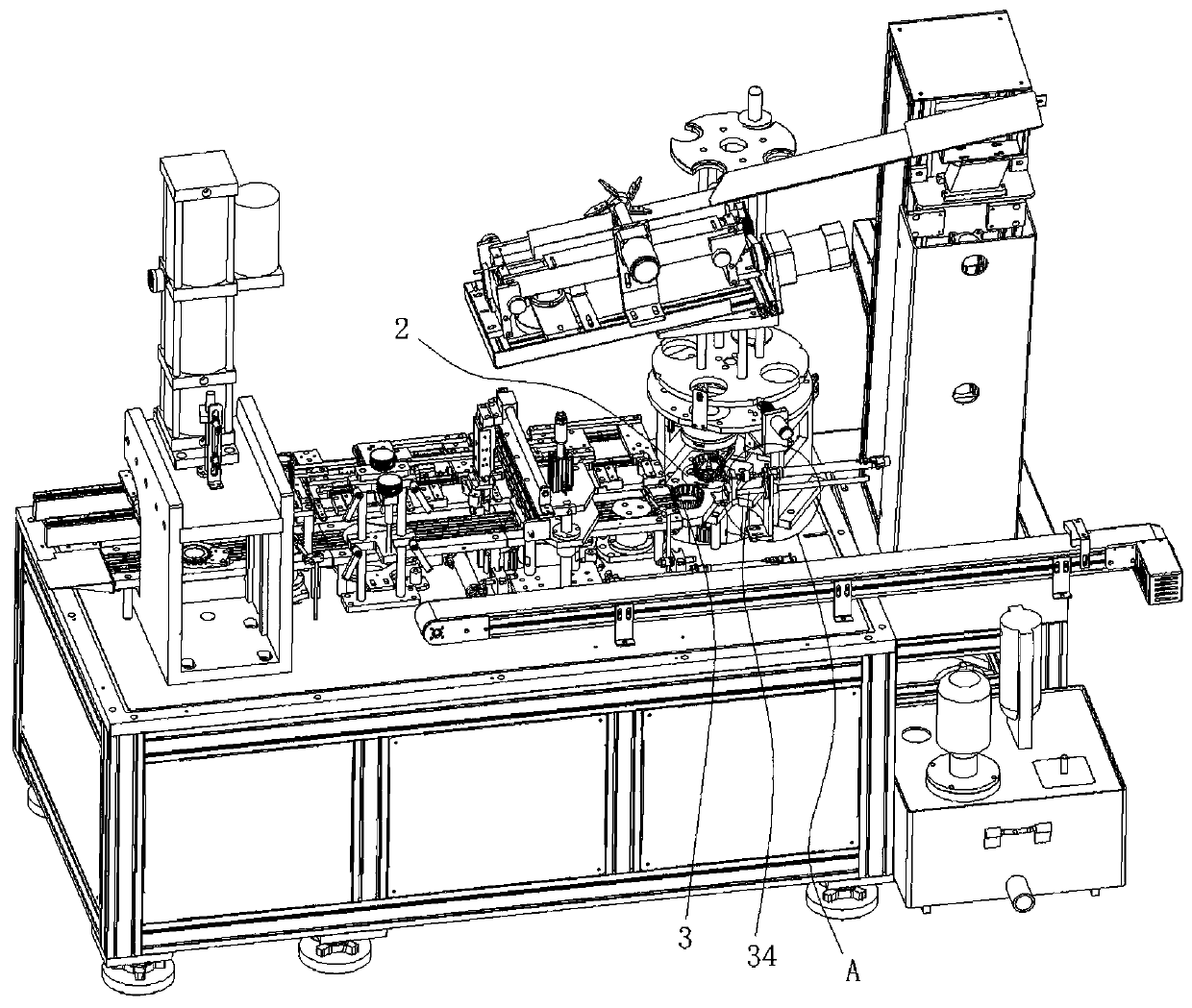

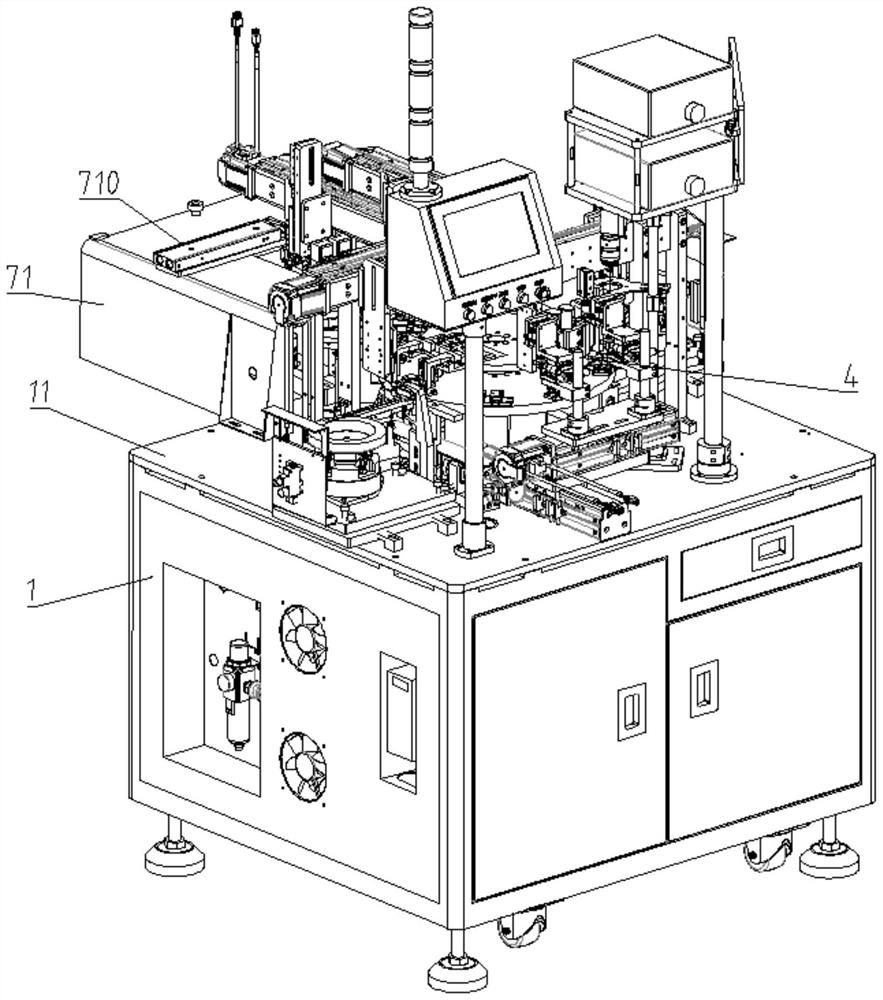

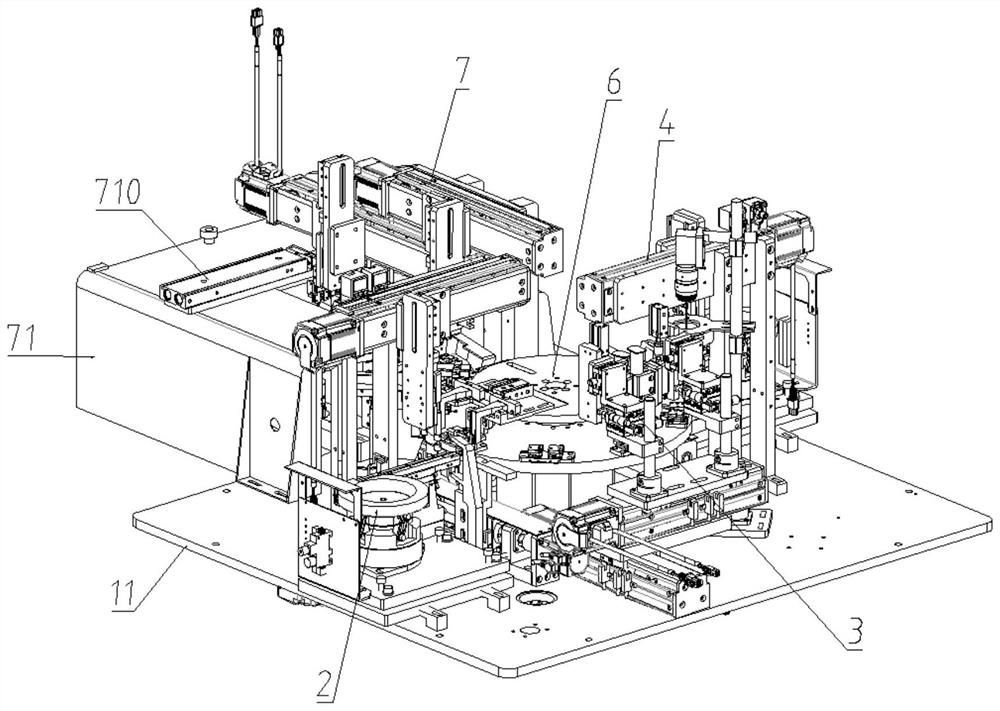

Fully-automatic assembly device of FPC connector

InactiveCN109648332AEasy to assembleImprove assembly efficiencyAssembly machinesProduct inspectionEngineering

The invention relates to a fully-automatic assembly device of an FPC connector. The fully-automatic assembly device comprises a work table, an automatic assembly device arranged on the work table andan intelligent control system for controlling the automatic assembly device; the automatic assembly device comprises a rubber core feeding station for conveying a rubber core, a terminal piece assembly station, a material transfer station, a terminal piece waste removing station, a terminal piece distribution station, a soldering piece assembly station, a cover overturning assembly station, a finished product inspection station and a finished product automatic packing station; and the rubber core feeding station, the terminal piece assembly station, the material transfer station, the terminalpiece waste removing station, the terminal piece distribution station, the welding piece assembly station, the cover overturning assembly station, the finished product inspection station and the finished product automatic packing station are sequentially arranged on the work table in the length direction of the work table, and a fully-automatic assembly line of the FPC connector is formed. The fully-automatic assembly device has the advantages of high assembly efficiency, high assembly precision and stable and reliable performance.

Owner:ZHEJIANG HEFENG TECH

An automatic assembly device for inner and outer rings of high-speed bearings

ActiveCN103453029BOptimum Thermal ExpansionReduce friction and wearBearing componentsTemperature controlElectricity

The invention relates to an automatic assembly device for an inner ring and an outer ring of a high-speed bearing, and belongs to bearing processing equipment. The automatic assembly device comprises a workbench, a heating mechanism and a clamp, wherein heating mechanism comprises a manipulator bracket, a heat conduction plate, a heating element, insulation boards and a manipulator, slide grooves are formed in the manipulator bracket, the manipulator can move in the slide grooves, grooves are formed in one end of the manipulator, the manipulator is electrically connected with an external control device, the heat conduction plate is annular, the heating element is sleeved on the heat conduction plate, the two insulation boards are arranged on the outer wall of the heat conduction plate and extend into the grooves to be connected with the manipulator, the clamp is positioned right below the heat conduction plate, a boss is formed at the upper part of the clamp in a narrowing way, a step face is formed between the boss and the clamp, an outer ring and a retainer with rolling elements are arranged on the step face, the outer ring is sleeved on the boss, and positioned on the upper inner side in the height direction of the retainer. According to the device, assembly is realized by virtue of self weight of an inner ring, the frictional wear of a bearing during the assembly process is alleviated, the temperature control precision is high, the assembly efficiency is high, the pollution is slight, and the service life of the device is long.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

An automatic press-fitting production line for small steel pipes for liquid receivers

ActiveCN107717404BEasy to unloadRealize step feedingWelding/cutting auxillary devicesAuxillary welding devicesProduction lineLiquid storage

Owner:WUHU SANHUA REFRIGERATION FITTINGS

Conveying, shearing and crimping integrated device for cable ends

ActiveCN111082280BAchieve supportPrevent saggingLine/current collector detailsPunchingStructural engineering

Owner:JIAXING JUNQUAN AUTOMATION

Full-automatic assembly machine of shift switch

PendingCN109616350ARealize fully automated assemblyNo manual operationElectric switchesEngineeringTransfer mechanism

A full-automatic assembly machine of a shift switch comprises a working rail way, wherein a switch shell supply mechanism, a switch shell transfer mechanism, a switch shell rotation mechanism, a key supply mechanism, a key transfer mechanism, a key assembly mechanism, a pin supply and assembly mechanism, an appearance detection mechanism, a shaping mechanism and a press buckle point mechanism aresequentially arranged on the working rail way from right to left. By linkage of each mechanism and running, full-automatic assembly of the shift switch is achieved, manual operation is not needed, theartificial cost is greatly reduced, and the assembly quality is improved.

Owner:慈溪市凯峰电子有限公司

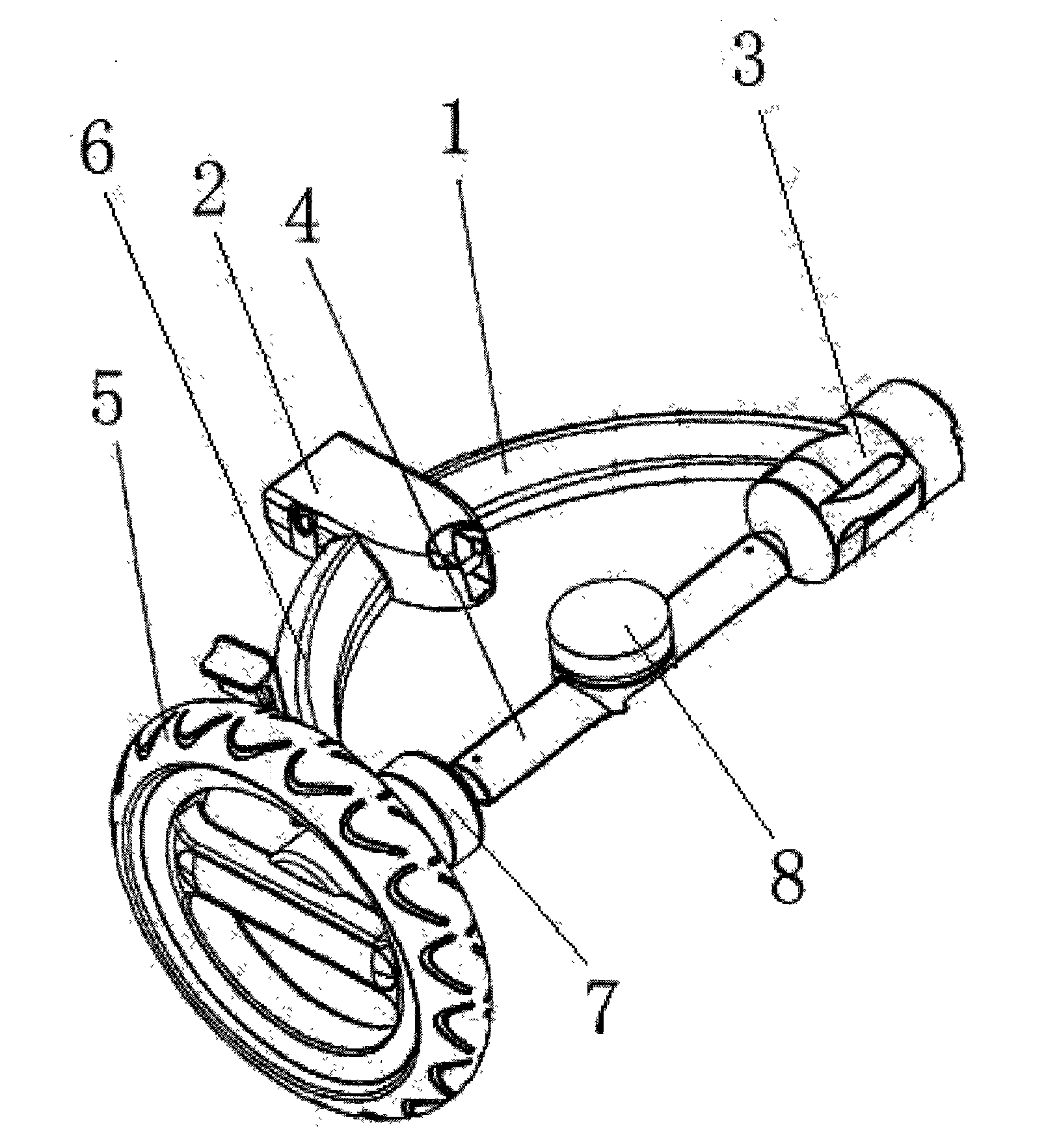

Automatic tire assembly gripper and automatic tire assembly device

PendingCN113894830AEasy to assembleGuaranteed assembly accuracyGripping headsMetal working apparatusEngineeringMechanical engineering

The invention discloses an automatic tire assembly gripper and an automatic tire assembly device. The gripper comprises a support, a tire grabbing mechanism and a tire positioning mechanism, wherein the support comprises a first supporting plate, a second supporting plate and a connecting rod; the tire positioning mechanism comprises a positioning plate, a positioning column and a power mechanism, and the positioning plate is slidably arranged on the connecting rod; and the tire grabbing mechanism comprises an annular magnetic suction cup, and the adsorption face of the annular magnetic suction cup is matched with rims on tires in shape. The automatic assembly device comprises the automatic tire assembly gripper and a robot. Automatic positioning and mounting of rims of the tires grabbed by the gripper and hubs on vehicles are achieved, the assembly efficiency and quality of the tires are improved, automatic assembly of the tires is achieved, positioning is accurate and stable, the assembly precision of the tires is ensured, manual participation is not needed, the labor intensity of workers is reduced, and safety accidents are avoided.

Owner:橙色云互联网设计有限公司

Core jacketing machine

ActiveCN106736493ARealize fully automated assemblyReduce labor intensityMetal working apparatusPre expansionEngineering

The invention discloses a core jacketing machine, and belongs to the technical field of automatic assembling. The core jacketing machine comprises a rack, a core supply device, a sealing ring supply device and an electric control device. The core supply device is arranged on the rack. The sealing ring supply device is also arranged on the rack and is opposite to the core supply device. A first mechanical arm is arranged at the downstream position of the sealing ring supply device. A sealing ring pre-expansion device is arranged at the bottom of the first mechanical arm and matched with the first mechanical arm to pre-expand the inner diameter part of a sealing ring. A second mechanical arm is arranged at the downstream position of the core supply device, and the sealing ring and a core are assembled and formed through the second mechanical arm and the sealing ring pre-expansion device. The core supply device, the sealing ring supply device, the first mechanical arm, the sealing ring pre-expansion device and the second mechanical arm sequentially act through the electric control device. According to the core jacketing machine, full-automatic assembling of the novel core and the sealing ring is achieved, and the production efficiency is greatly improved.

Owner:GAOMI TONGCHUANG VALVE CORE CO LTD

Automatic assembling equipment and method for electric toothbrush handle shell

PendingCN110465804ARealize fully automated assemblyRealize unmannedAssembly machinesMetal working apparatusElectric machineryL-shell

The invention relates to automatic assembling equipment and method for an electric toothbrush handle shell. The automatic assembling equipment is provided with a toothbrush handle charging and feedingstation, a button mounting station, a top ring mounting station and a bottom ring mounting station at a time with an annular stay wire as a main line; four six-axis manipulators, three four-axis manipulators and three glue dispensers are used for assisting the mounting of a stay wire clamp so as to realize the positioning and moving functions of a toothbrush handle main body; and various stationsand the equipment are connected for communication through a PLC workstation, so that the equipment, workstations and mechanisms are orderly operated in a required manner. Due to the adoption of a servo motor and an air cylinder, the automatic feeding and assembling functions of all accessories of the electric toothbrush handle shell are realized, the traditional mode that manual operation is adopted is changed, and the unmanned and efficient operation of assembly of the electric toothbrush handle shell is realized.

Owner:东江精创注塑(深圳)有限公司

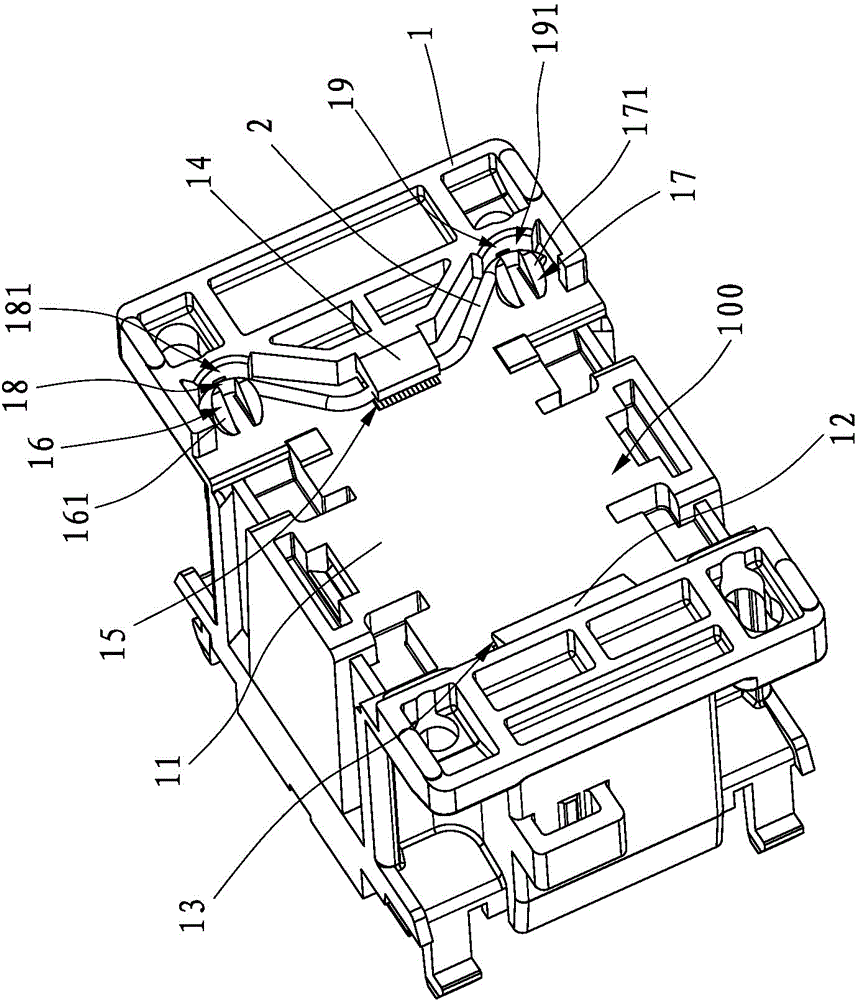

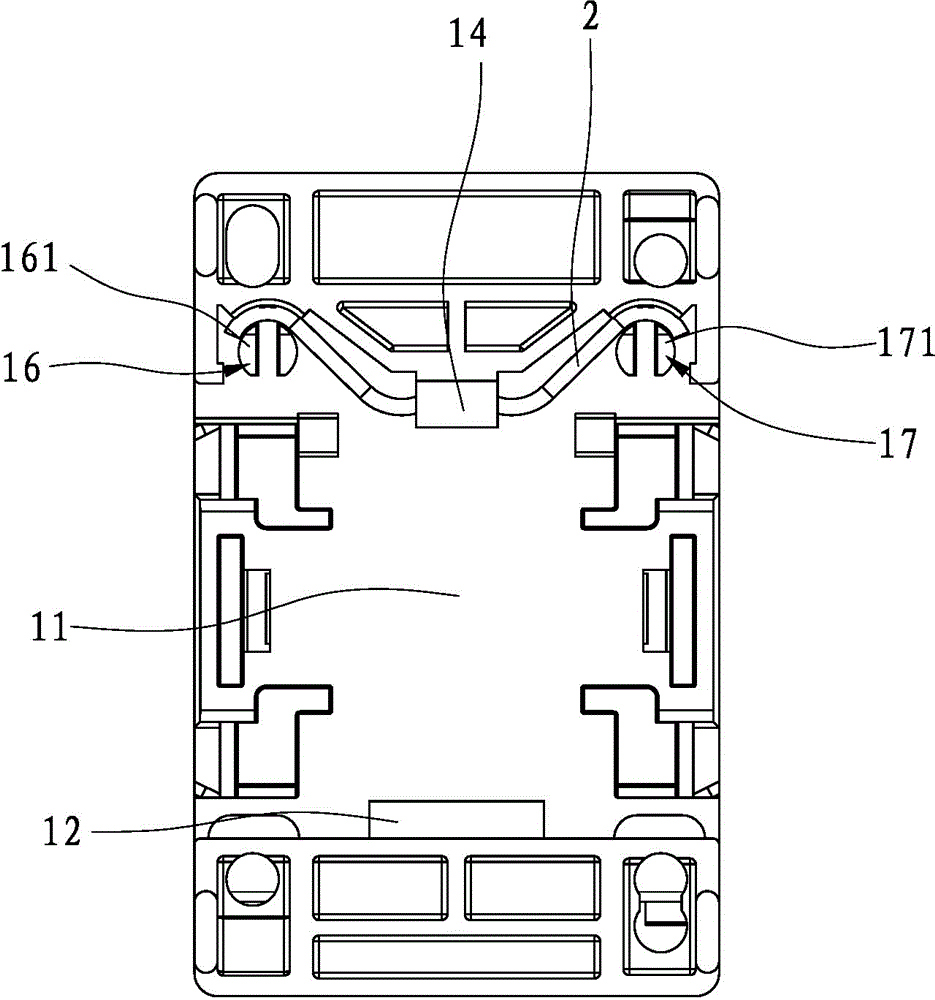

Full-automatic assembling machine for wiring terminal

PendingCN111668680AImprove assembly efficiencyRealize fully automated assemblyContact member assembly/disassemblyPhysicsEngineering

The invention provides a full-automatic assembling machine for a wiring terminal. The machine comprises a plastic shell feeding mechanism, a weld leg feeding mechanism, a footstand feeding mechanism,a welding leg and footstand assembling mechanism, a general assembly mechanism, a rejecting mechanism, a turnover mechanism, a nailing mechanism, and a general assembly body discharging mechanism which are sequentially arranged on a workbench. The weld leg feeding mechanism is used for feeding weld legs; the footstand feeding mechanism is used for feeding a footstand; the welding leg and footstandassembling mechanism is used for assembling a welding leg and the footstand; the general assembly mechanism is used for assembling the plastic shell, the welding legs and a foot seat assembling body;the rejecting mechanism is used for rejecting unqualified products; the turnover mechanism is used for turning over the general assembly body by 180 degrees; the nailing mechanism is used for nailinga nail into the general assembly body; and the general assembly body discharging mechanism is used for discharging the general assembly body. By means of the equipment, the full-automatic assembly ofthe wiring terminal can be achieved, manual operation is not needed, and the assembling efficiency is improved. The multi-step assembly between the welding legs and the footstand, between the plasticshell and the weld legs and between the plastic shell and the footstand assembly body can be realized. Meanwhile, the wiring terminals of different models can be assembled, and different requirementsof customers are met.

Owner:慈溪市万捷电子有限公司

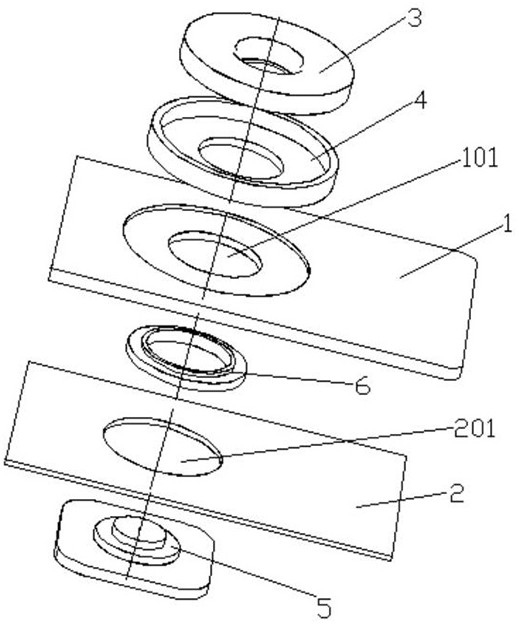

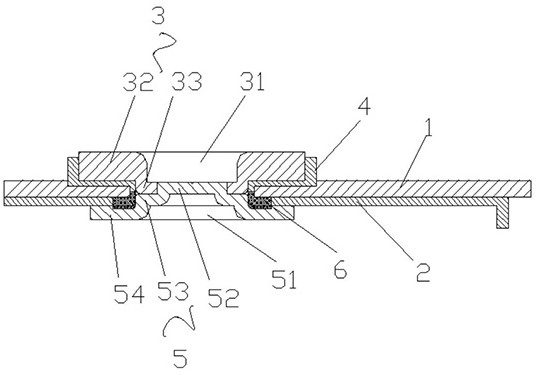

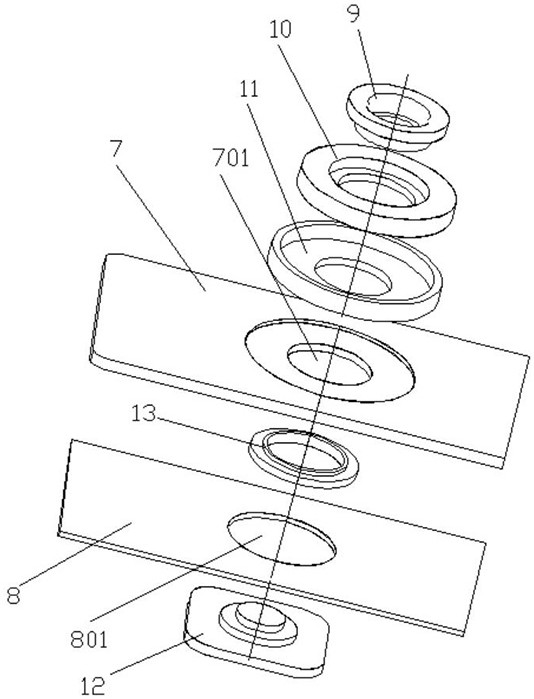

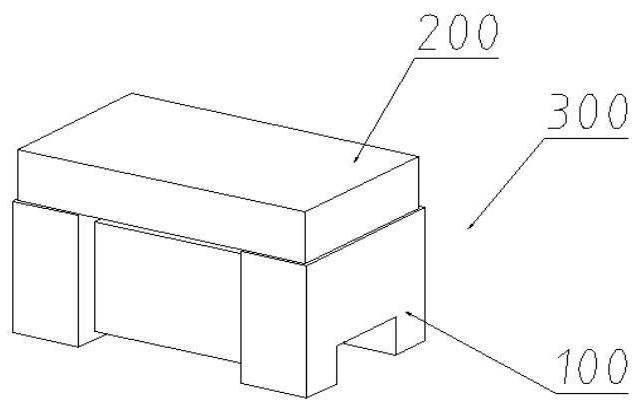

Positive electrode assembly, negative electrode assembly and battery cover plate assembly

InactiveCN113363680AMeet the needs of lightweightReduce weightCell lids/coversElectrical batteryManufactured material

The invention relates to a positive electrode assembly, a negative electrode assembly and a battery cover plate assembly. The upper and lower surfaces of the positive electrode assembly and the negative electrode assembly are of hollow structures, the weight of the battery cover plate assembly can be effectively reduced, the weight of a plurality of series-parallel battery packs can be effectively reduced, and the requirement of the battery packs for light weight is met. A first cavity and a third cavity formed by hollowing out the top of the cover plate can also be used as positioning holes of battery group series-parallel conducting bars. The top copper pressing ring and the negative electrode aluminum pressing plate are connected in a brazing composite welding mode, an aluminum plate and a copper plate are independently provided for punch forming on the aspect of providing raw materials, waste of the raw materials in the punch forming process is reduced, the manufacturing process is simplified, and the production cost of the cover plate assembly is low; in the aspect of structure, the risk that the copper-aluminum composite surface is peeled off can be avoided in a laminated clamping and pressing mode. All the components are connected in a sealed and fastened mode, the assembling process is simplified, the steps of riveting and the like are omitted, and full-automatic assembling can be achieved conveniently.

Owner:刘义

Automatic check assembly machine for HDMI connector

InactiveCN103337767BRealize fully automated assemblyIncrease productivityContact member assembly/disassemblyAssembly lineAssembly machine

An automatic check assembly machine for an HDMI (High-Definition Multimedia Interface) connector comprises a frame, a worktable arranged on the frame and a feeding track arranged on the worktable, wherein a terminal body feeding mechanism delivering terminal bodies, a first terminal assembly line delivering a first terminal and inserted on the terminal body, a second terminal assembly line delivering a second terminal and inserted on the terminal body and a back stopper assembly line delivering a back stopper and inserted on the terminal body are arranged on the feeding track in sequence; a projection detecting instrument positioned between the second terminal assembly line and the back stopper assembly line and detecting whether the assembly of the first terminal and the second terminal on the terminal body is right or not is also arranged on the feeding track; a feeding drive mechanism delivering the terminal bodies forward one by one along the feeding track is arranged at the lower part of the feeding track. Through the adoption of the structure, the assembly machine not only can realize full-automatic assembly, but also can detect whether the product inserting during the assembly process is qualified or not, and can greatly improve the production efficiency.

Owner:宁波神博电子有限公司

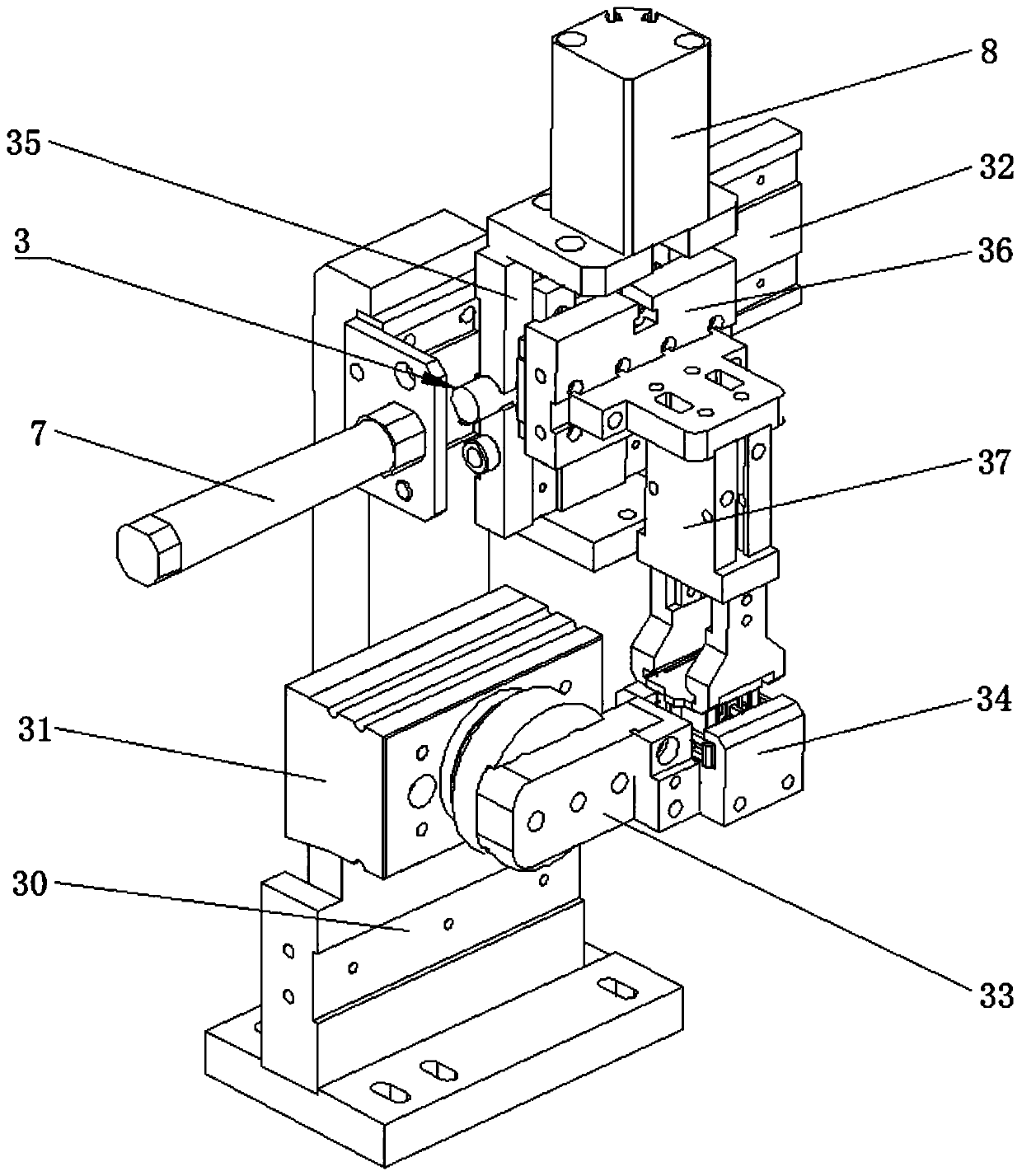

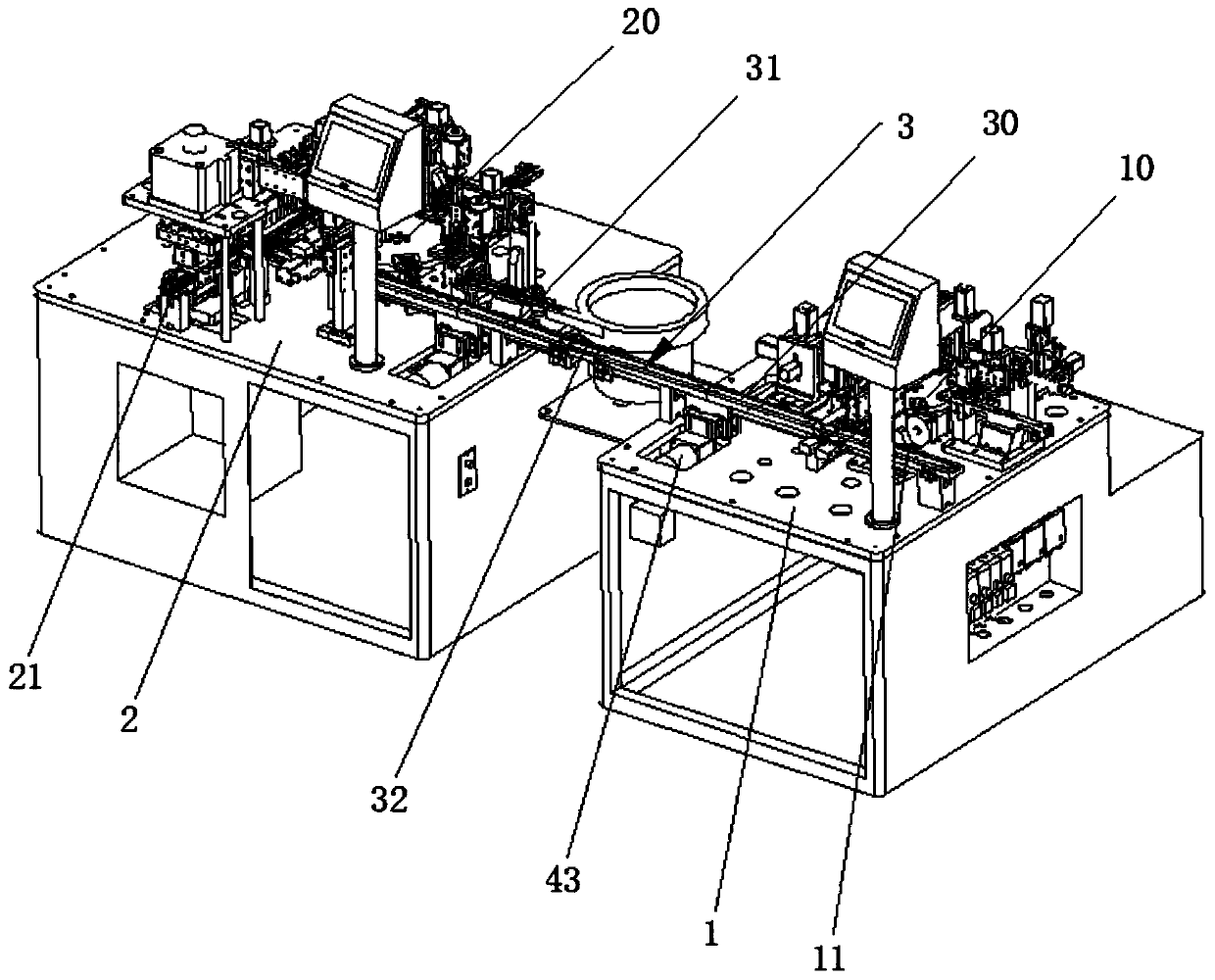

Button switch assembling machine

InactiveCN111524730ARealize fully automated assemblyNo manual operationElectric switchesElectric machineryDrive motor

The invention discloses a button switch assembling machine. The machine comprises a first rack and a second rack, the first rack is provided with a first assembling part and a first feeding rail in transmission fit with the first assembling part. The second rack is provided with a second assembling part and a second feeding track in transmission fit with the second assembling part. One end of thefirst feeding rail extends to the second rack; a clamping piece is arranged at the feeding end of the second feeding rail. The clamping piece comprises a base, and a driving motor and a sliding rail which are arranged on the base; the sliding rail is located at the end of the base, the driving motor is located below the sliding rail, a rotating shaft is arranged on an output shaft of the driving motor, a clamping block is arranged at the end of the rotating shaft, a sliding block is arranged on the sliding rail, a driving block capable of sliding in the direction of the driving motor is arranged on the sliding block, and a pneumatic chuck matched with the clamping block is arranged on the driving block. According to the assembling machine, the first assembling part and the second assembling part are connected through the clamping piece, full-automatic assembling is achieved, manual operation is not needed, and the labor cost is greatly saved.

Owner:乐清市盈创自动化有限公司

Full-automatic button switch assembling machine

InactiveCN111524731ARealize fully automated assemblyNo manual operationElectric switchesTransmission beltStructural engineering

The invention discloses a full-automatic button switch assembling machine. The machine comprises a first rack and a second rack; a first assembling part and a first discharging track are arranged on the first rack; a second assembling part and a second discharging rail are arranged on the second rack; the first discharging track and the second discharging track are correspondingly arranged; a connecting piece is arranged between the first discharging track and the second discharging track; the connecting piece comprises a first transmission belt arranged on the first rack and a second transmission belt arranged on the second rack; the first transmission belt is communicated with the discharging end of the first discharging rail, the second transmission belt is communicated with the discharging end of the second discharging rail, a connecting block is arranged between the first transmission belt and the second transmission belt, and the first transmission belt and the second transmission belt are driven by a driving piece. According to the assembling machine, the first assembling part and the second assembling part are connected through the first transmission belt and the second transmission belt, full-automatic assembly is achieved, manual operation is not needed, and the labor cost is greatly saved.

Owner:乐清市盈创自动化有限公司

A continuous bearing assembly production line

ActiveCN111644845BRealize fully automated assemblyImprove continuityAssembly machinesBearing componentsProduction lineProcess engineering

The invention belongs to the field of bearing assembly and processing, and specifically discloses a continuous bearing assembly production line, which includes a front-end processing module for completing bearing loading and assembly of bearing inner and outer rings and a ball assembly module for completing ball assembly; the front-end processing module includes Two sets of feeding and conveying devices, a transfer positioning device, and a transfer drive mechanism that drives the transfer positioning device to move; the ball assembly module includes a ball discharge device and a bearing feed device for conveying bearing assemblies, and the ball discharge device It is arranged above the bearing feeding device. The invention realizes the fully automatic assembly of the bearing, has good continuity, does not need to stop in the whole assembly process, and has high assembly efficiency.

Owner:EAST CHINA JIAOTONG UNIVERSITY

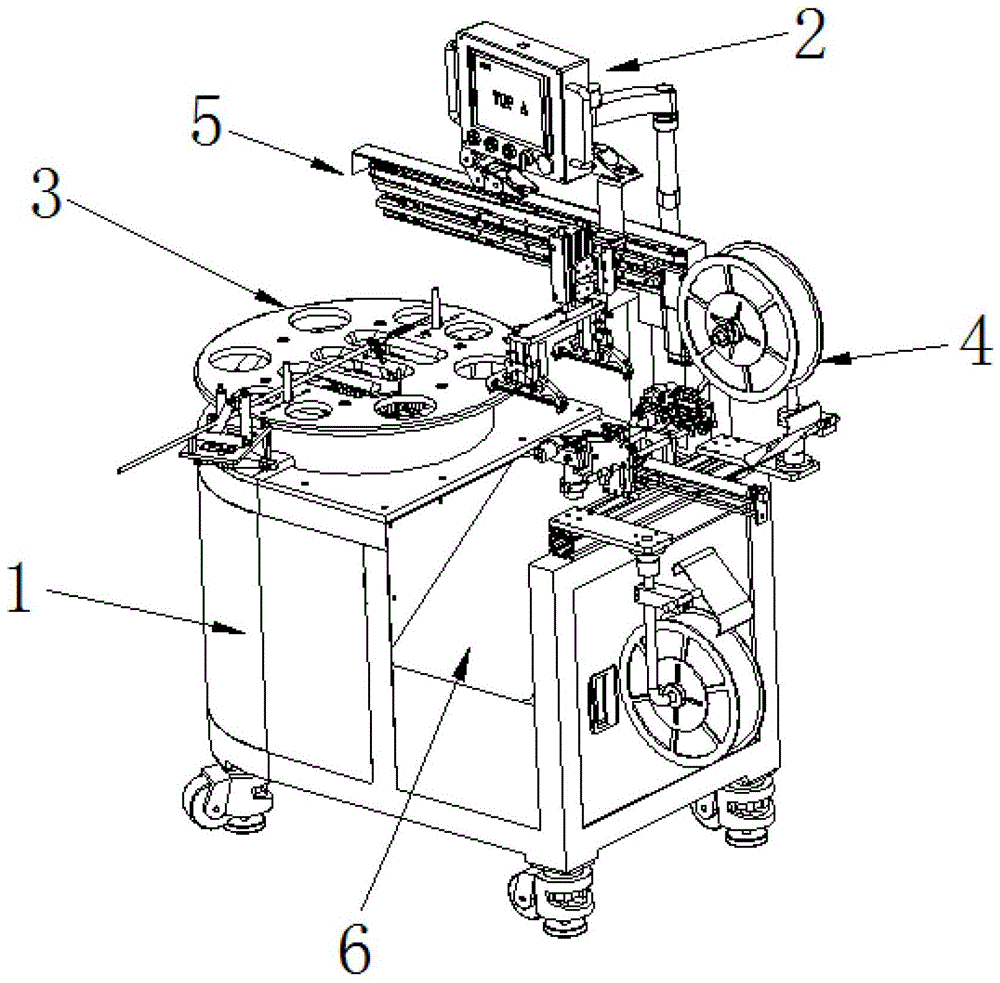

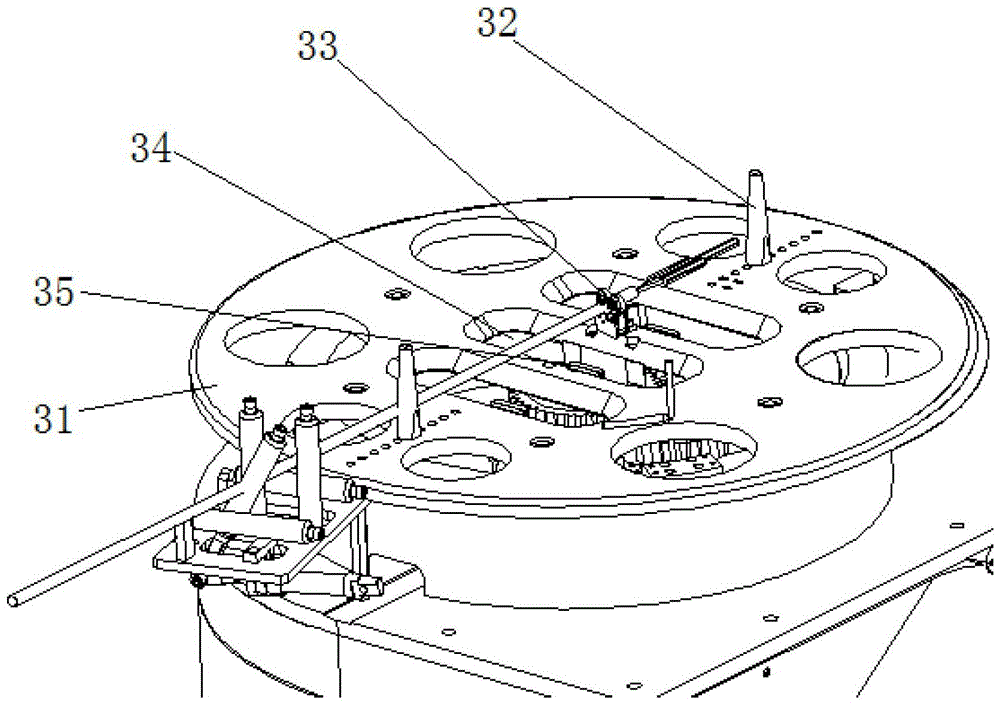

3D rocker potentiometer automatic assembly method and assembly machine

InactiveCN102881391BRealize fully automated assemblySave spaceResistor manufactureJoystickMotor drive

The invention discloses an automatic assembly method for a 3D joystick potentiometer. The automatic assembly method for the 3D joystick potentiometer comprises 12 steps; a round worktable is divided into 12 equal parts by an index plate, a motor drives the index plate to rotate 30 degrees each time and the 12 steps are respectively completed; and each step at least comprises a mounting action, and mostly comprises a mounting action and a feeding action, wherein the feeding action is completed through a vibrating disk and a vibrating disk rail, and a material is fed to the lower side of a cylinder through the vibrating disk rail; and the mounting action is completed through fixtures and cylinders, the cylinders jack the material into the fixtures on the index plate, and each potentiometer is mounted through two cylinders, namely each potentiometer is jacked and pushed through the two cylinders.

Owner:深圳市科逸泰电子科技有限公司

Common mode inductor assembling machine and method

ActiveCN113275205ARealize fully automated assemblyImprove efficiencyPretreated surfacesCoatingsRotational axisEngineering

The invention provides a common mode inductor assembling machine. The common mode inductor assembling machine comprises a rack, a rotating disc, a first feeding mechanism, a gluing mechanism, a second feeding mechanism and a discharging station, wherein the rack is provided with a horizontally-arranged mounting plate; the rotating disc is rotatably arranged on the mounting plate, the rotating axis of the rotating disc is vertically arranged, a plurality of groups of clamping structures are arranged on the edge of the upper surface of the rotating disc, and the plurality of groups of clamping structures are arranged at equal angles relative to the rotating axis of the rotating disc; the first feeding mechanism is arranged at a first feeding station on the mounting plate and used for feeding a first workpiece to a clamping structure located at the first feeding station; the gluing mechanism is arranged at a gluing station on the mounting plate and is used for gluing the upper side surfaces of two side plates of the first workpiece fed to the clamping structure; the second feeding mechanism is arranged at a second feeding station on the mounting plate and used for placing the two ends of a second workpiece to the gluing positions of the two side plates on the first workpiece; and the discharging station is arranged at the discharging station on the mounting plate and is used for discharging the assembled common mode choke. The assembling machine can be used for automatically assembling the common mode inductor.

Owner:DONGGUAN DONGHONG AUTOMATION TECH CO LTD

Wire automatic bundling general equipment

ActiveCN103662155BReduce manufacturing costRealize fully automated assemblyBinding material applicationBundling machine detailsWire rodHuman–machine interface

The invention discloses universal equipment for automatically binding wire rods. The universal equipment comprises a rack, a wire winding / binding station, a binding belt conveying station and a wire catching station, wherein the wire winding / binding station, the binding belt conveying station and the wire catching station are arranged on the rack and are controlled through a human-computer interface. The wire winding / binding station can be used for winding flexible wire rods into coils. The binding belt conveying station can store binding belts and convey binding belts with required length according to requirements. The wire catching station can catch the binding belts and convey the binding belts to the flexible wire rods wound into coils on the wire winding / binding station after the binding belts are sectioned according to the required length by the binding belt conveying station. The binding belts wind the flexible wire rods for one circle. The wire winding / binding station can further tighten the binding belts winding the flexible wire rods for one circle so as to bind the flexible wire rods. The wire catching station can further convey the bound flexible wire rods from the wire winding / binding station to a designated position. The universal device integrates wire rod winding and wire rod binding, can realize fully-automatic assembly, greatly improves working efficiency, saves manpower, material resources and financial resources, reduces the production cost of enterprises, and improves enterprise competitiveness.

Owner:KUNSHAN BAIAO INTELLIGENT EQUIP CO LTD

A core casing machine

ActiveCN106736493BRealize fully automated assemblyReduce labor intensityMetal working apparatusPre expansionEngineering

The invention discloses a core jacketing machine, and belongs to the technical field of automatic assembling. The core jacketing machine comprises a rack, a core supply device, a sealing ring supply device and an electric control device. The core supply device is arranged on the rack. The sealing ring supply device is also arranged on the rack and is opposite to the core supply device. A first mechanical arm is arranged at the downstream position of the sealing ring supply device. A sealing ring pre-expansion device is arranged at the bottom of the first mechanical arm and matched with the first mechanical arm to pre-expand the inner diameter part of a sealing ring. A second mechanical arm is arranged at the downstream position of the core supply device, and the sealing ring and a core are assembled and formed through the second mechanical arm and the sealing ring pre-expansion device. The core supply device, the sealing ring supply device, the first mechanical arm, the sealing ring pre-expansion device and the second mechanical arm sequentially act through the electric control device. According to the core jacketing machine, full-automatic assembling of the novel core and the sealing ring is achieved, and the production efficiency is greatly improved.

Owner:GAOMI TONGCHUANG VALVE CORE CO LTD

Rear wheel frame structure of child's vehicle

The invention discloses a rear wheel frame structure of a child's vehicle. The rear wheel frame structure is characterized in that: a leftwards bending beam and a rightwards bending beam are connected through a connecting button; one end of the leftwards bending beam and one end of the rightwards bending beam are connected with the connecting button; and the other end of the leftwards bending beam and the other end of the rightwards bending beam are connected with a left wheel axle frame and a right wheel axle frame respectively. A dual-bending beam structure is adopted; the rear wheel frame structure is convenient to assemble and is matched with a transverse shock-absorbing rod; compared with the traditional vertical shock-absorbing rod, the transverse shock-absorbing rod has a better effect; the rear wheel frame structure has a simple structure, and is convenient to assemble without welding; fully-automatic assembly can be realized; the production capacity is effectively improved; the labour cost is reduced; and compared with the prior art, the rear wheel frame structure has prominent substantive features and obvious improvement.

Owner:SHANGHAI YONGLONG INDAL & TRADING

A locking device and assembly method for automatic assembly of tiny parts

ActiveCN108581469BRealize fully automated assemblyImprove assembly efficiencyAssembly machinesMetal working apparatusProduction lineEngineering

The invention belongs to the technical field of precision assembly, and provides a locking device for automatic assembling of a micro part and an assembling method. The locking device is composed of aflexible unit, a mechanical arm unit and a clamp locking unit; the flexible unit and the clamp locking unit are mainly used for flexible locking after micro part assembling; the mechanical arm unit and the clamp locking unit are used for automatically locking the micro part in the processes of picking, carrying and assembling the micro part through automatic change-over; and the flexible unit, the mechanical arm unit and the clamp locking unit achieve automatic assembling of the micro part through cooperative collaboration. According to the locking device, flexible locking has a certain buffering and balancing effect on unbalanced locking force generated in the assembling process, so that a certain protection effect is achieved on the micro part and maintaining of the relative pose of theassembled part; and manual intervention is avoided through automatic locking, full-automatic assembling is achieved, the assembling efficiency is improved, and the device and the method are suitablefor a batch and automatic production line.

Owner:DALIAN UNIV OF TECH

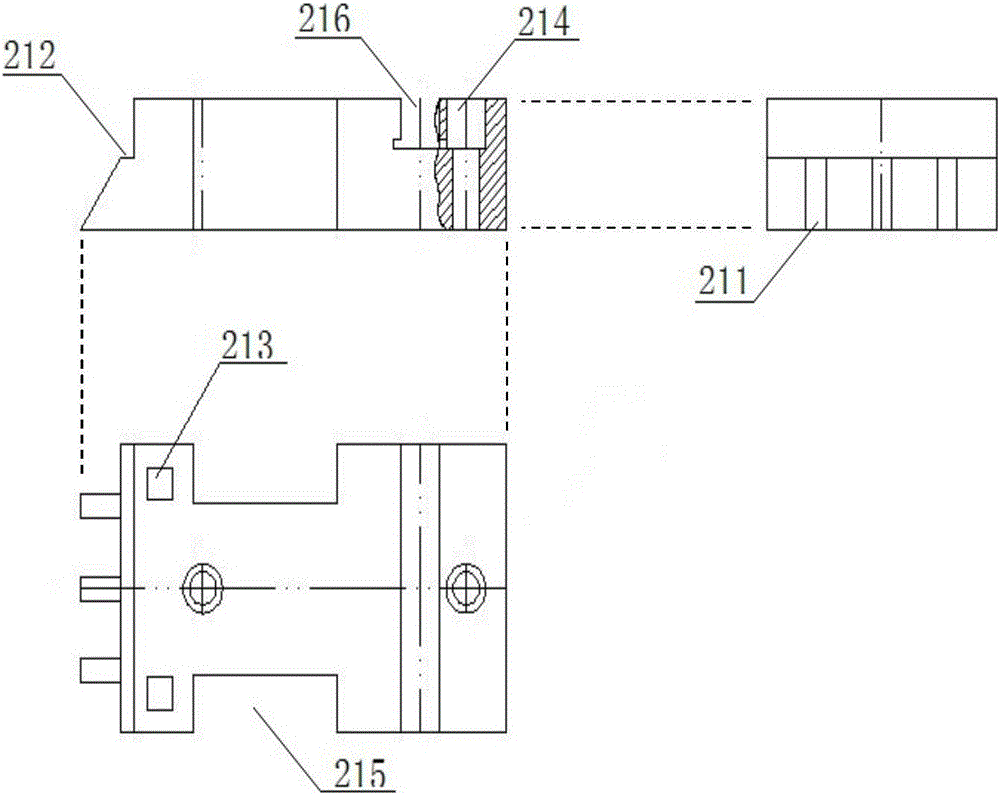

Automobile door lock cable assembly test device

ActiveCN107860589BImplement automatic assemblyEasy to detectVehicle testingMechanical engineeringPiston

The invention discloses an automobile door lock cable assembling test device. The device comprises a large baseplate, a small baseplate, a cable locating plate, a cable guiding plate, a scale slide block and a proximity switch sensor. A large cylinder and a long guide rail slide block are arranged on the large baseplate. The proximity switch sensor is arranged at one side of the large baseplate. The small baseplate is arranged on the slide block of the long guide rail slide block. A small cylinder and a short guide rail slide block are arranged on the small baseplate. The slide block of the short guide rail slide block is connected with the cable locating plate. The cable locating plate is outwardly provided with the cable guiding plate. The cable locating plate is U-shaped, the top part is provided with chamfers and a hook hole, and the hook hole is connected with the piston of the small cylinder. One end of the cable guiding plate is U-shaped, and the opening is communicated with theopening of the cable locating plate. One side of the small baseplate is provided with a chute which is arranged at the same side of the proximity switch sensor and is provided with the scale slide block. Automobile door lock cable automatic assembling and detection can be realized by rapid locating and movement of the cable so that the labor cost can be reduced and the detection reliability can be enhanced.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com