An automatic press-fitting production line for small steel pipes for liquid receivers

A press-fitting production line and liquid storage technology, which is applied in auxiliary devices, auxiliary welding equipment, welding equipment, etc., can solve the problems of unsuitable automatic transportation of liquid storage, so as to save labor costs, shorten assembly time, and make mistakes less prone to errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

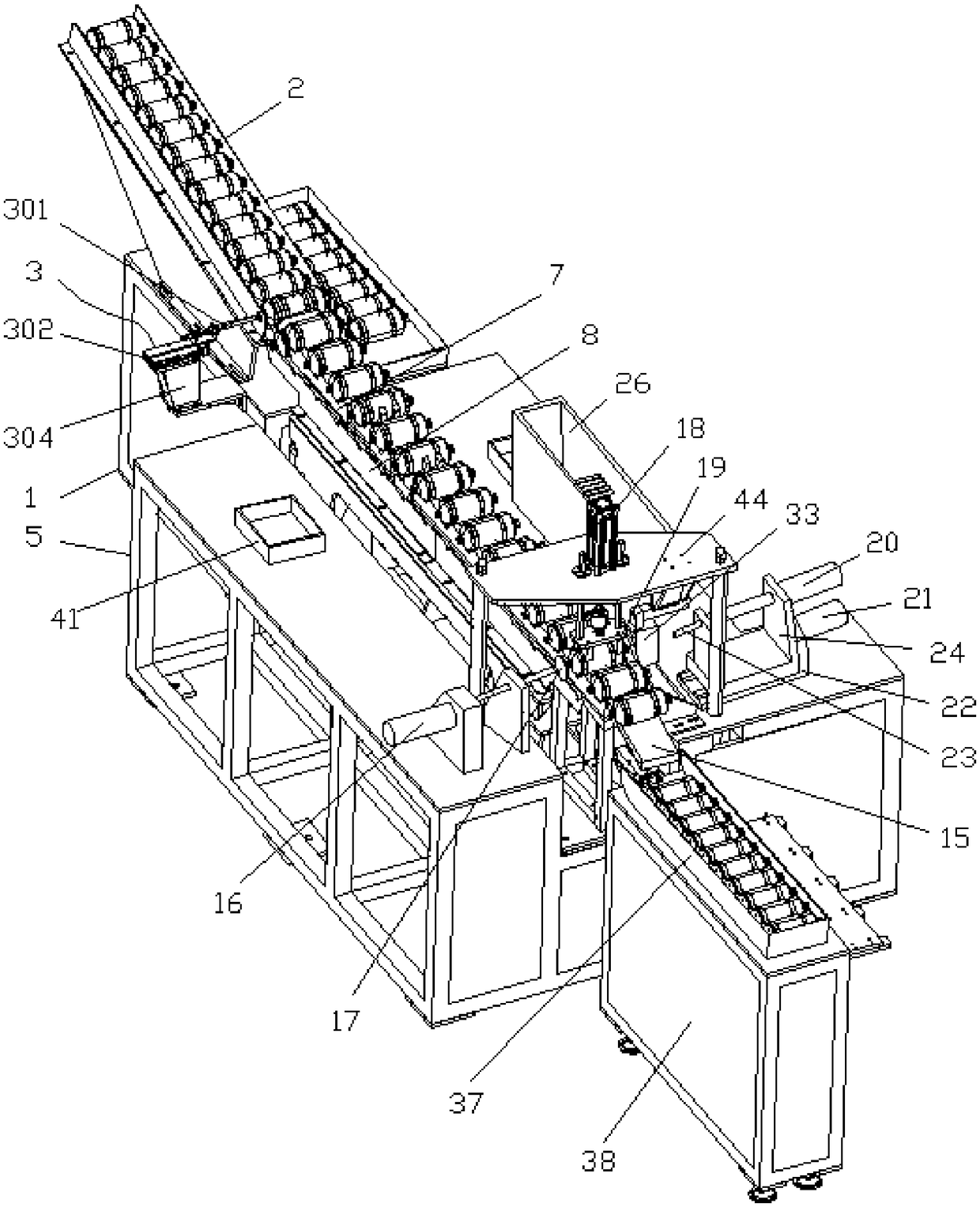

[0042] Such as figure 1 As shown, a production line for automatic press-fitting of small steel pipes for liquid receivers includes a liquid storage feeding device, a liquid storage delivery device, a press-fitting mechanism, a small steel pipe feeding device, and a storage tank 37 arranged in sequence from left to right;

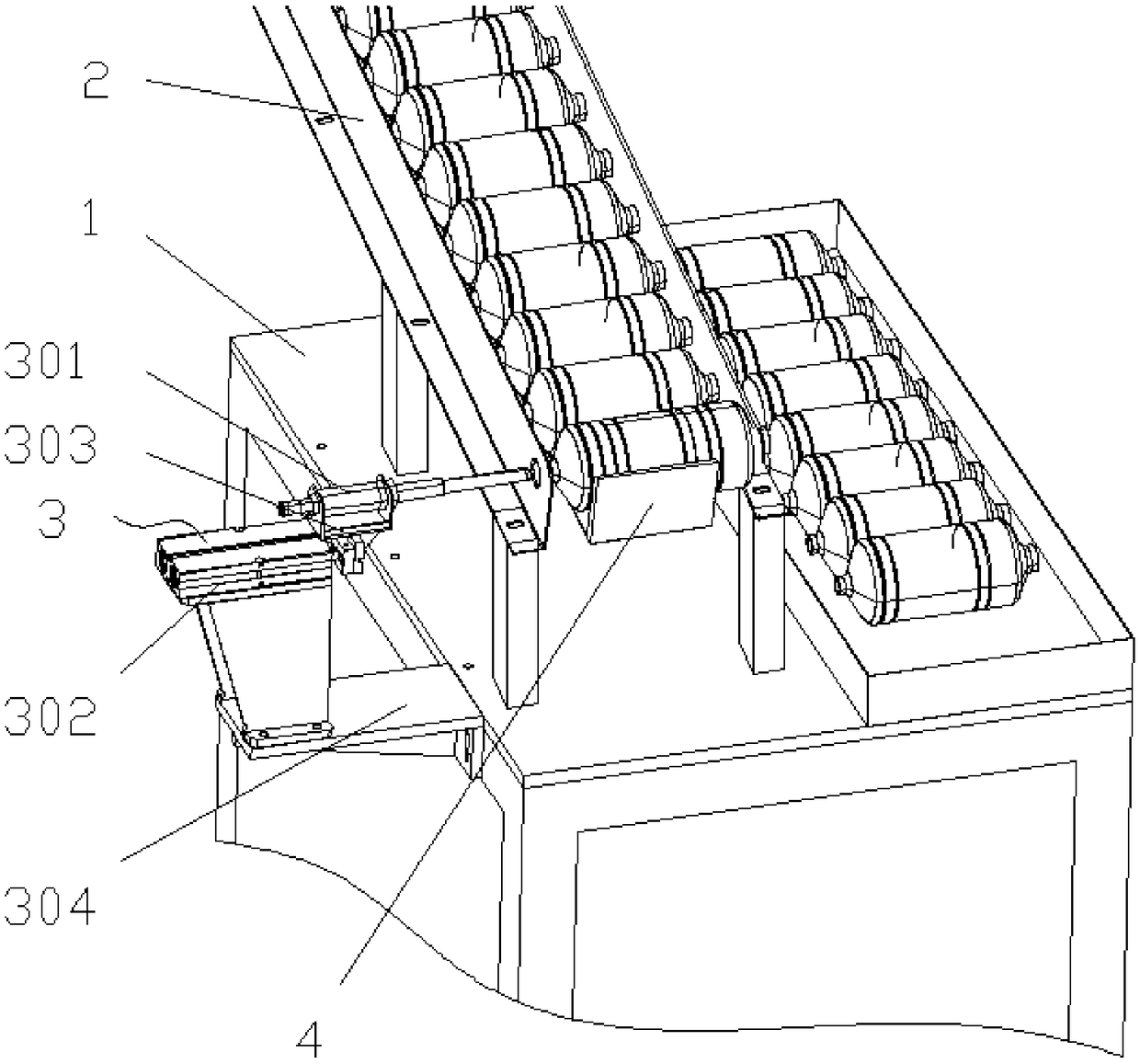

[0043] Such as figure 2 As shown, the accumulator feed device includes a liquid accumulator feed frame 1, a feed plate 2 and a screen detection device 3, and the feed plate 2 is obliquely arranged on the liquid accumulator feed frame 1 , the bottom end of the feed plate 2 is provided with a baffle 4, the screen detection device 3 is installed on the frame and is located on one side of the baffle 4;

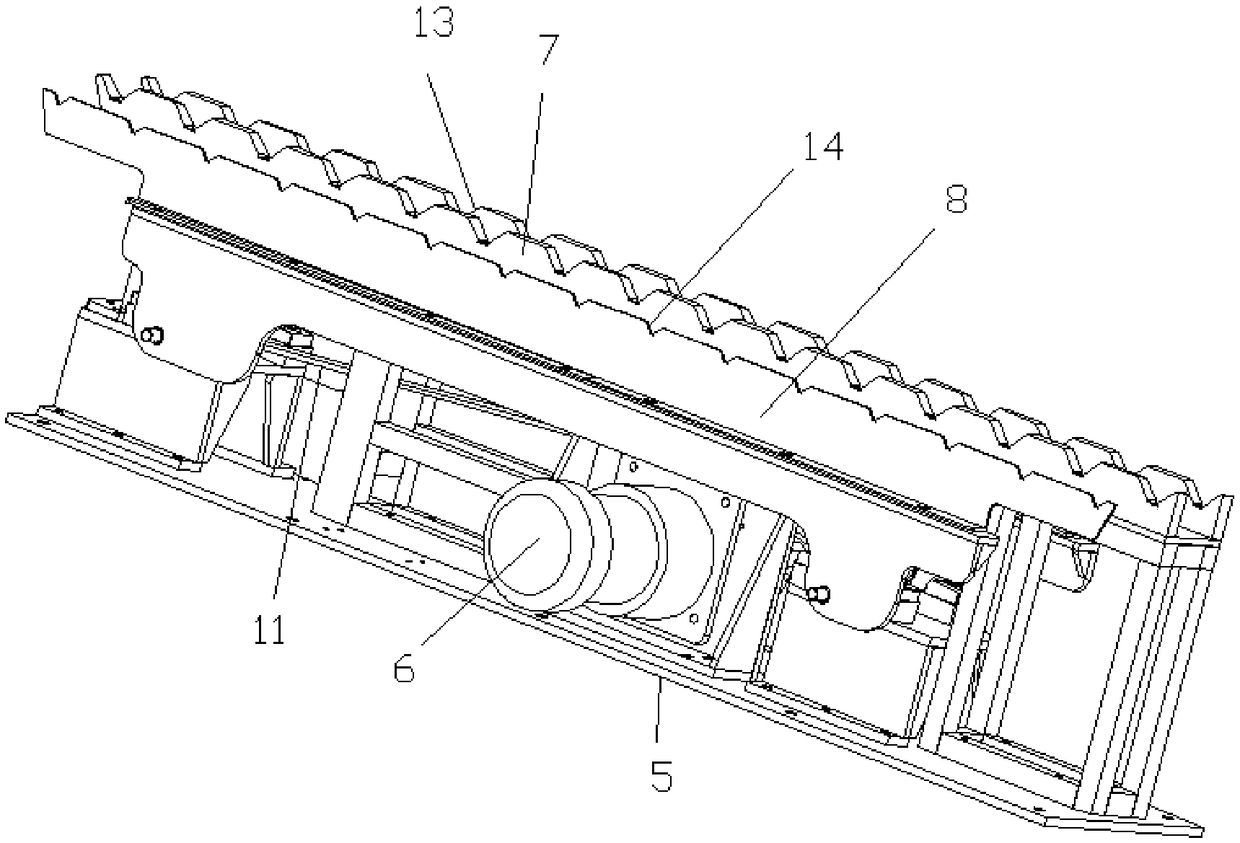

[0044] Such as Figure 3-Figure 5 As shown, the liquid accumulator conveying device includes a liquid accumulator conveying frame 5, a conveying motor 6, a support plate 7, a conveying plate 8, a bearing seat 9 and a cam 10, and the conveying motor 6, a suppo...

Embodiment 2

[0057] Such as figure 1 and Figure 10 As shown, a production line for automatic press-fitting of small steel pipes for liquid receivers includes a liquid storage feeding device, a liquid storage delivery device, a press-fitting mechanism, a small steel pipe feeding device, and a storage tank 37 arranged in sequence from left to right;

[0058] Such as figure 2 As shown, the accumulator feed device includes a liquid accumulator feed frame 1, a feed plate 2 and a screen detection device 3, and the feed plate 2 is obliquely arranged on the liquid accumulator feed frame 1 , the bottom end of the feed plate 2 is provided with a baffle 4, the screen detection device 3 is installed on the frame and is located on one side of the baffle 4;

[0059] Such as Figure 3-Figure 5 As shown, the liquid accumulator conveying device includes a liquid accumulator conveying frame 5, a conveying motor 6, a support plate 7, a conveying plate 8, a bearing seat 9 and a cam 10, and the conveying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com