Wire automatic bundling general equipment

An automatic strapping and general-purpose equipment technology, which is applied to strapping materials, strapping machine parts, packaging, etc., can solve the problems of high equipment cost, a lot of labor, and low efficiency, so as to reduce production costs, improve work efficiency, and save manpower Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In conjunction with the accompanying drawings, the present invention is described in detail, but the scope of protection of the present invention is not limited to the following examples, that is, all simple equivalent changes and modifications made with the patent scope of the present invention and the content of the specification are still patents of the present invention. covered.

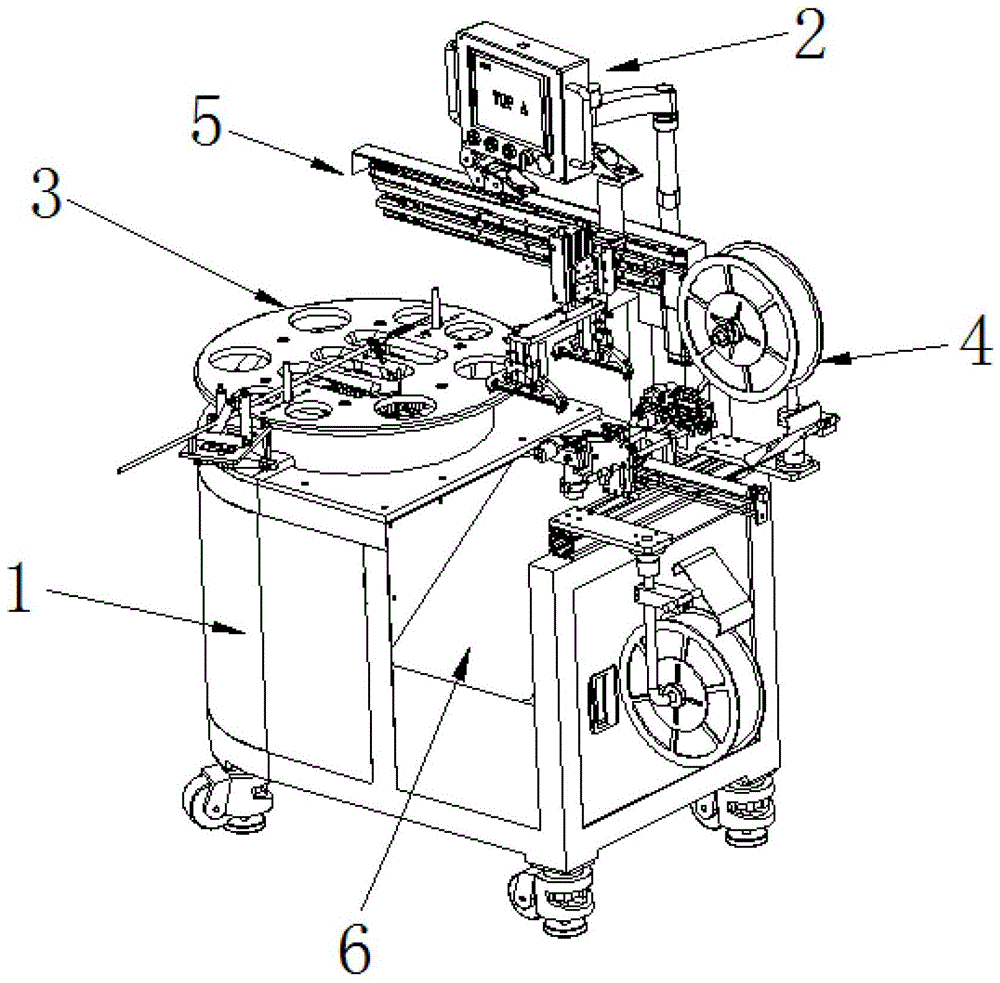

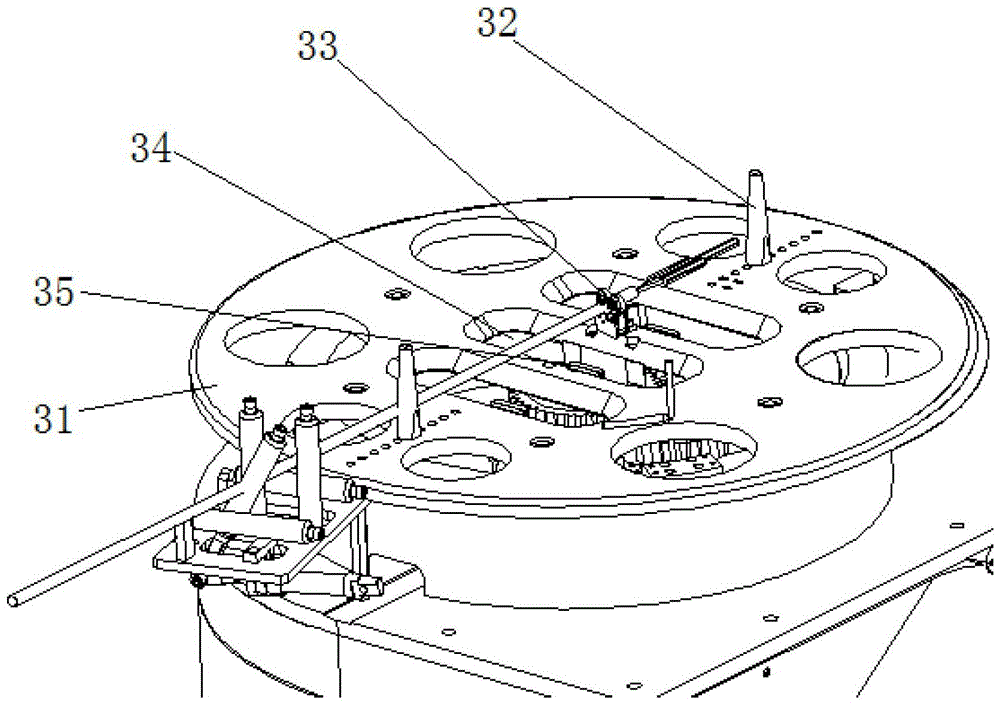

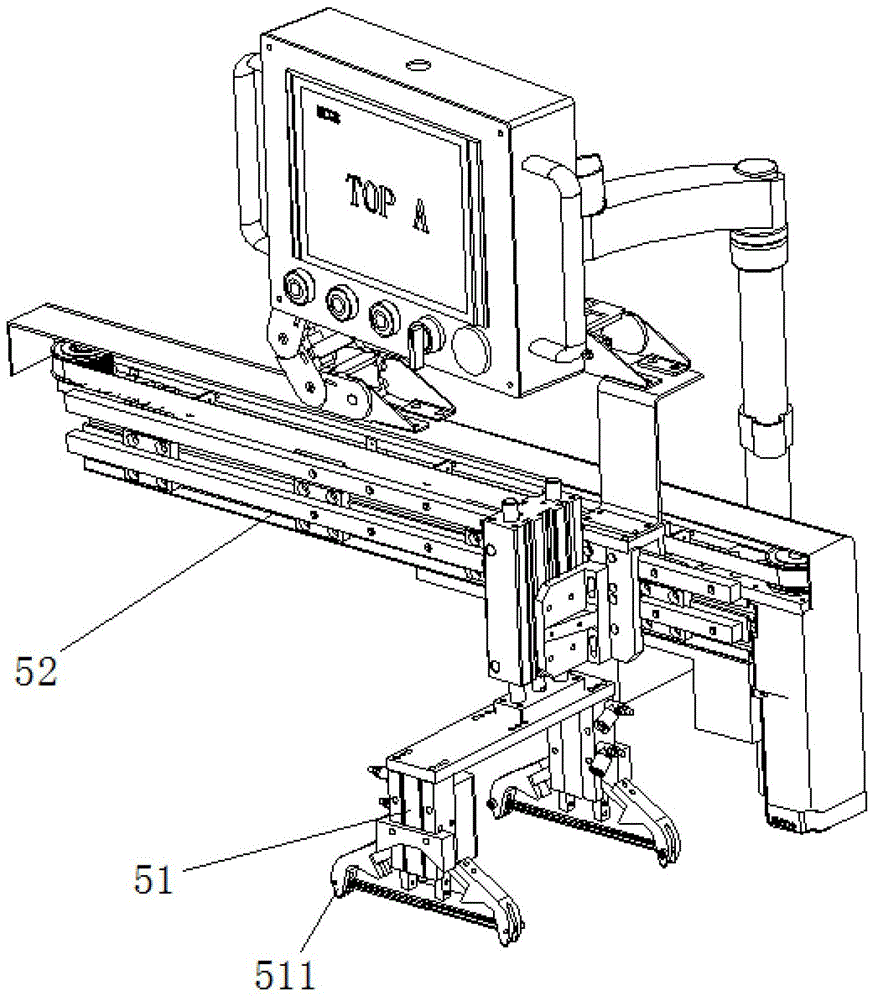

[0027] Such as figure 1 As shown, a general-purpose automatic wire binding equipment includes a frame 1 and a winding / tying station 3, a cable tie conveying station 4, and a wire grabbing station 5, which are arranged on the frame and controlled by a man-machine interface 2 , the winding / binding station can wind the flexible wire into a coil, the cable tie conveying station stores the cable tie and transports the cable tie of the required length according to the needs, and the wire grabbing station can grab the cable tie and The cable tie of the required length is intercepted by the cabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com