3D rocker potentiometer automatic assembly method and assembly machine

A 3D rocker, automatic assembly technology, applied in the direction of resistors, circuits, resistor manufacturing, etc., can solve the problem of high cost and achieve the effect of saving space and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

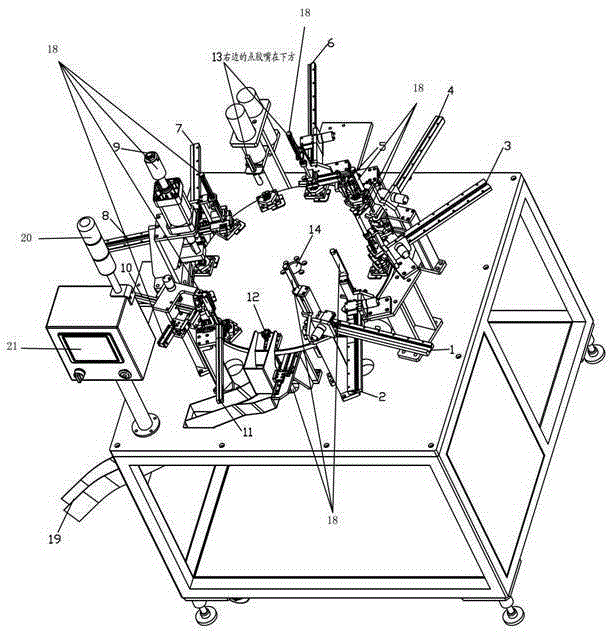

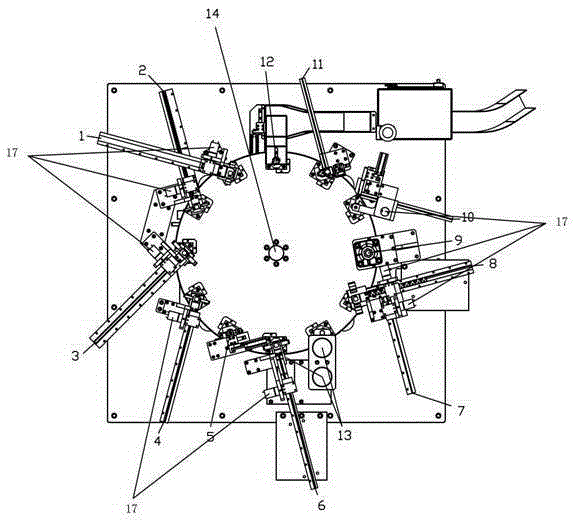

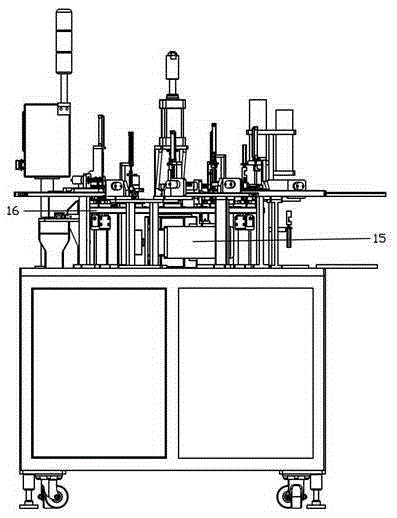

[0026] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0027] like figure 1 , figure 2 , image 3 and Figure 4As shown, an automatic assembly method for a 3D rocker potentiometer is characterized in that the assembly of the 3D rocker potentiometer is decomposed into 12 steps, and the circular workbench is divided into 12 equal parts by a dividing plate, and the motor drives the dividing Each action of the dial rotates 30 degrees to complete the 12 steps respectively; each step includes at least an installation action, and most of the steps include two actions of installation and feeding, wherein the feeding action is completed by a vibrating plate and a vibrating plate track. The material is fed from the vibrating plate track to the bottom of the cylinder. The installation action is completed by the clamp and the cylinder. The cylinder pushes the material into the clamp on the indexing plate. The loading of each pote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com