A core casing machine

A technology of casing machine and core body, which is applied in metal processing equipment, metal processing, manufacturing tools, etc., to achieve the effects of smooth movement, improved production efficiency, and easy alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings.

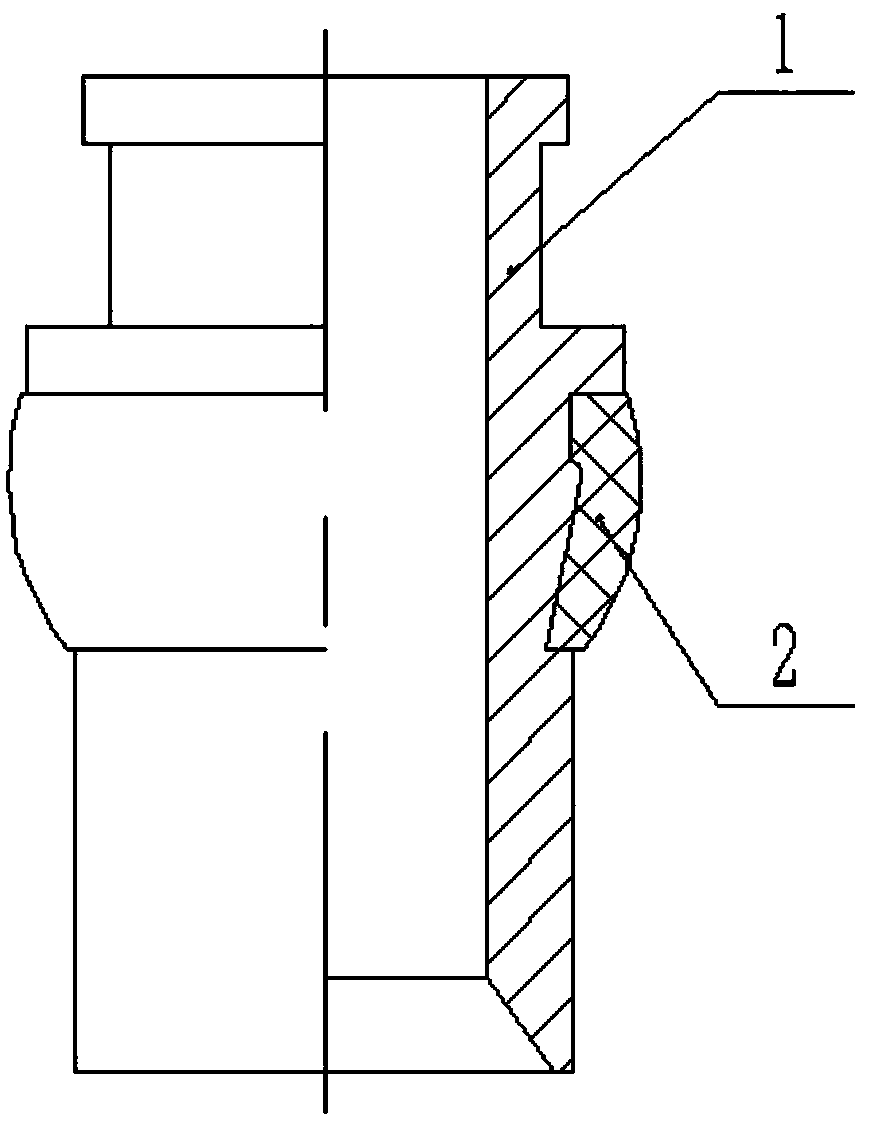

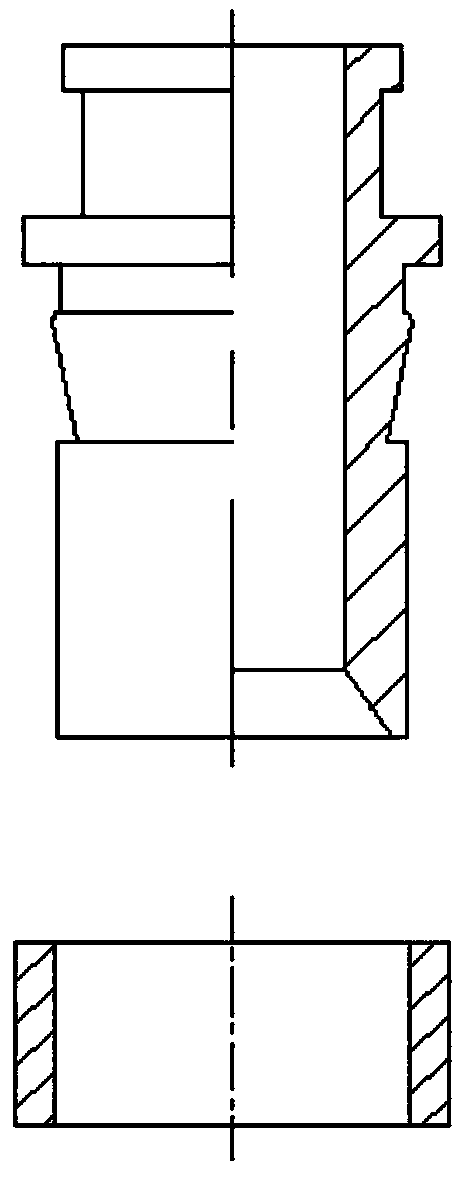

[0035] Such as figure 1 , figure 2 As shown, the components to be assembled by a core casing machine, the diameter of the lower cylinder where the core 1 and the sealing ring 2 are assembled is larger than the diameter of the cone at the assembly, the purpose is to prevent the traditional core 1 and the sealing ring from 2. After assembly, the sealing ring 2 falls off from the core body 1. Since the core body 1 and the sealing ring 2 are similar to interference connection, compared with the previous assembly equipment, it can no longer meet the production needs, so it is redesigned and improved.

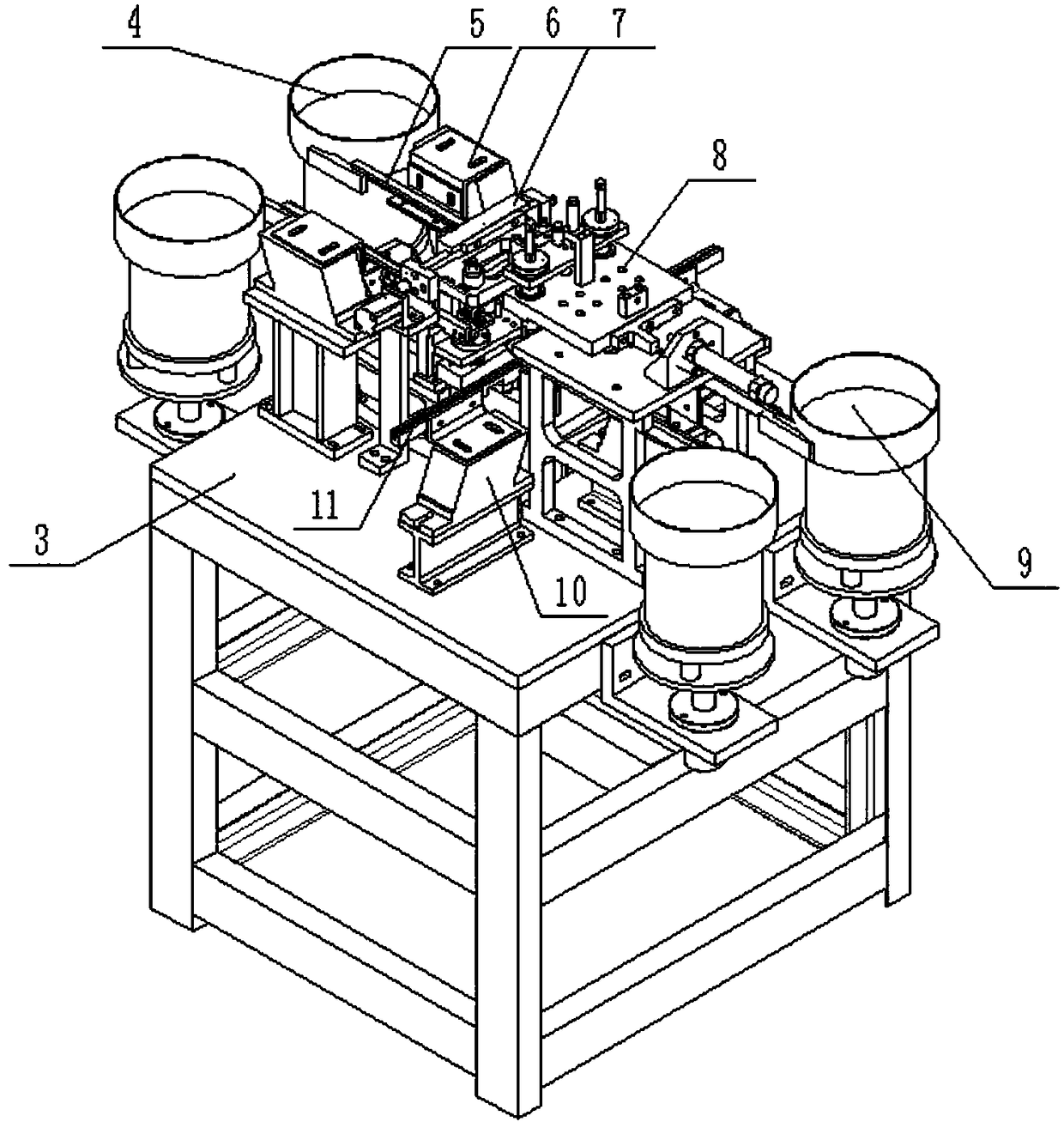

[0036] Such as image 3 , Figure 4 , Figure 7 As shown, a core casing machine includes a frame 3, a core supply device, a seal ring supply device and an electric control device, the core body supply ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com