A locking device and assembly method for automatic assembly of tiny parts

An automatic assembly and locking device technology, applied in assembly machines, metal processing equipment, metal processing and other directions, can solve the problems of unfavorable assembly efficiency, fully automated assembly, low versatility, etc., to achieve fully automated assembly, improve assembly efficiency, keep the protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

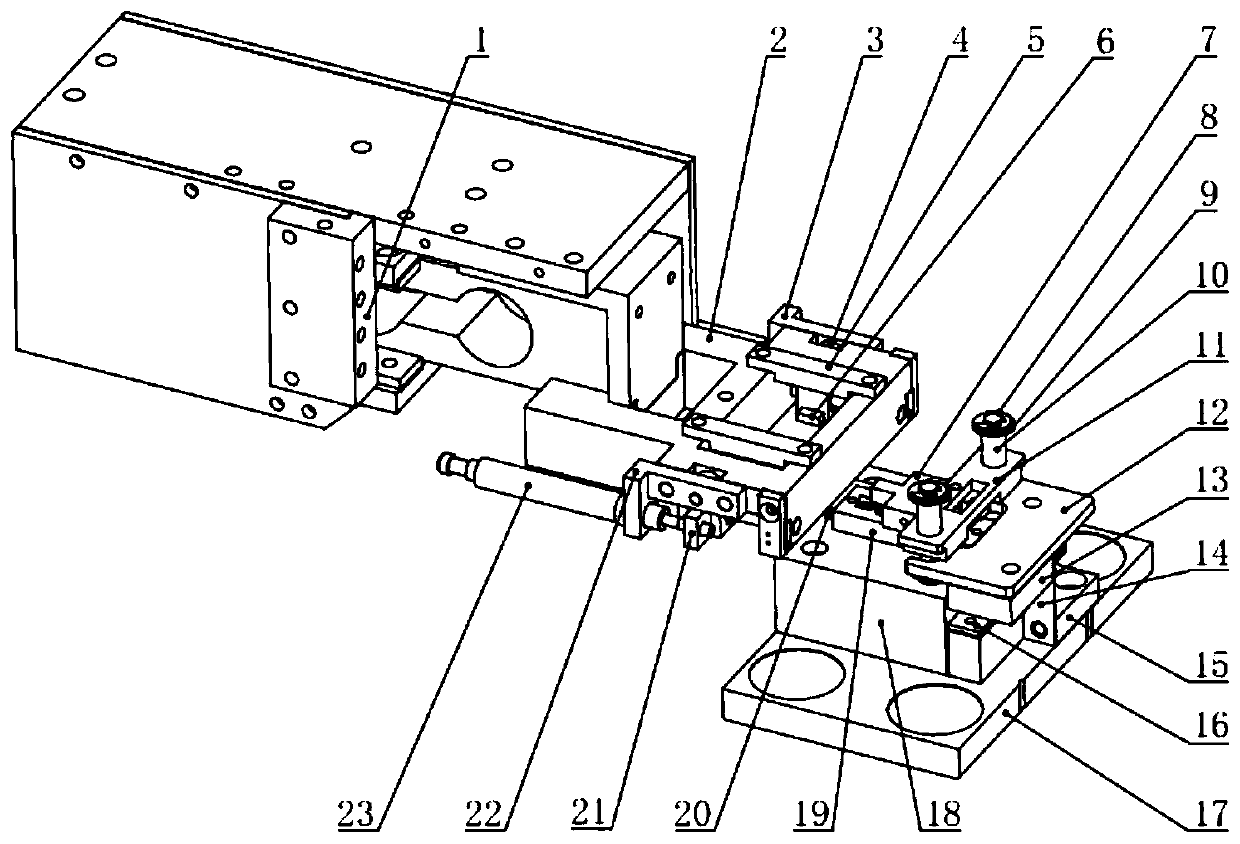

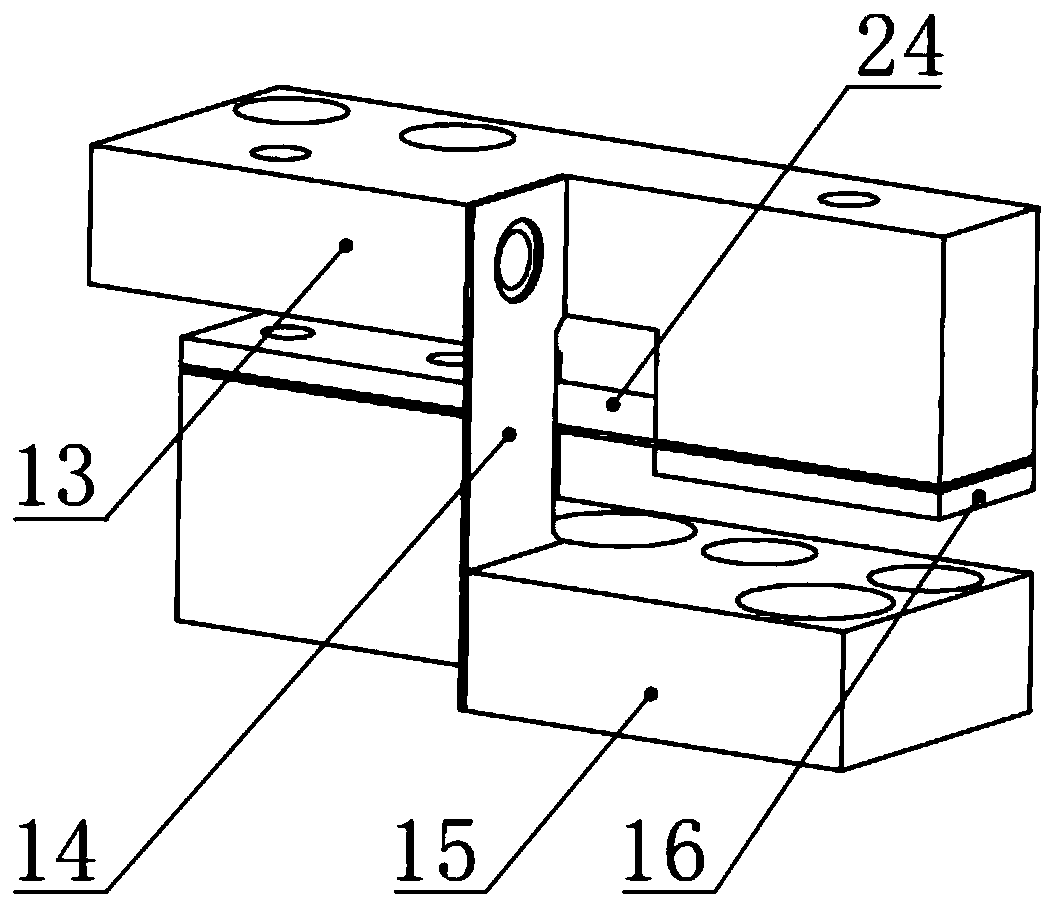

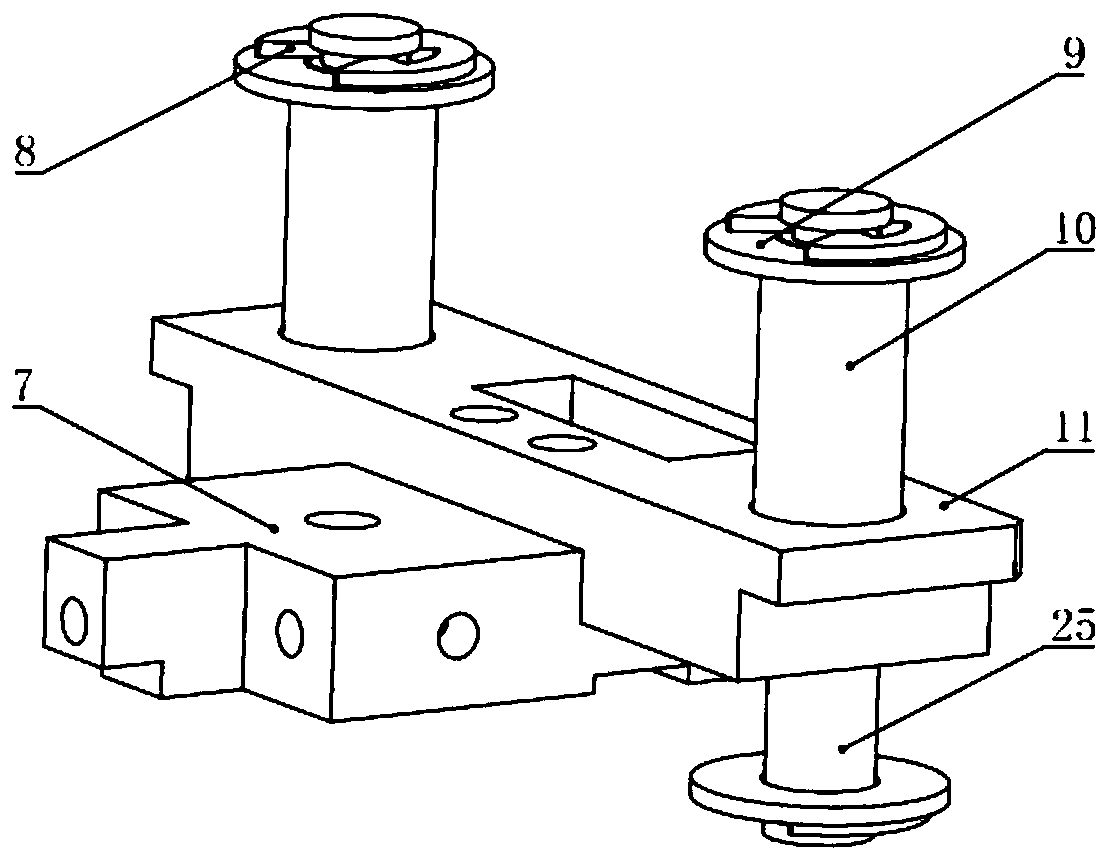

[0031] Taking the automatic assembly of a certain tiny component as an example, the specific implementation steps of the present invention are described in combination with the technical scheme and the accompanying drawings

[0032] Step 1: The robotic arm unit first moves to the designated position P1 of the feeding device. The feeding device is respectively placed with a micro component and a clamp locking unit. The micro component is placed on the component loading seat 29, and the clamp locking unit The clamping and fixing are realized under the action of the spring 10 by the clamping frame horizontal plate 11 and the fixture feeding fixed plate 28 . At this time, the compression bar 5 of the mechanical arm unit is located directly above the guide shaft 25 of the compression frame, and the solenoid valve controlling the miniature cylinder 23 is opened, and the left moving positioning block 21 and the right moving positioning block 6 are stretched forward to touch the front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com