Automobile door lock cable assembly test device

A technology for testing devices and car door locks, applied in measuring devices, vehicle testing, machine/structural component testing, etc., can solve the problems of large manpower consumption, low productivity, low reliability of manual detection, etc., and save labor costs , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

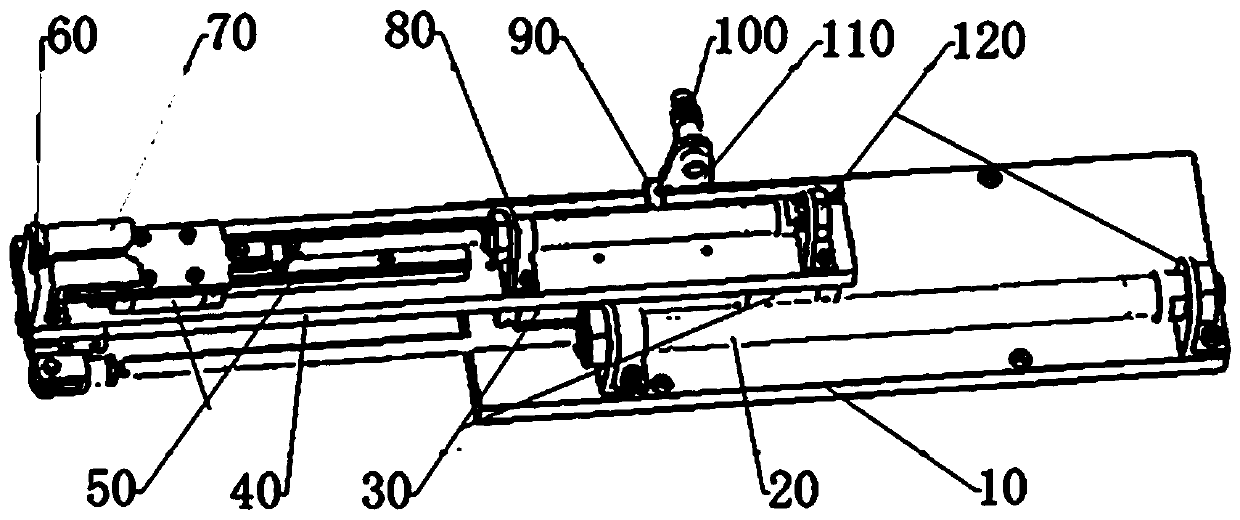

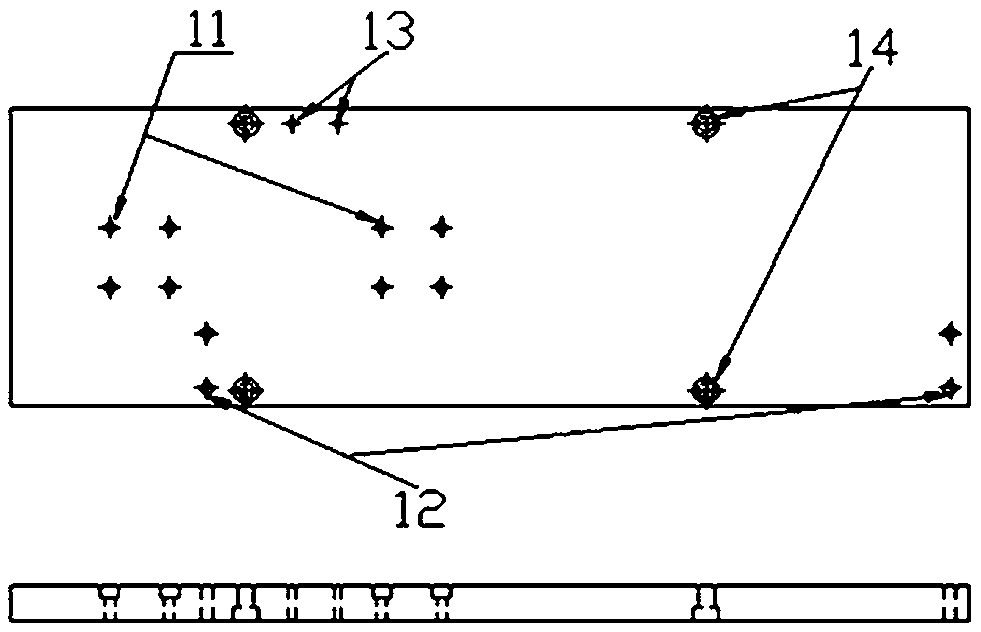

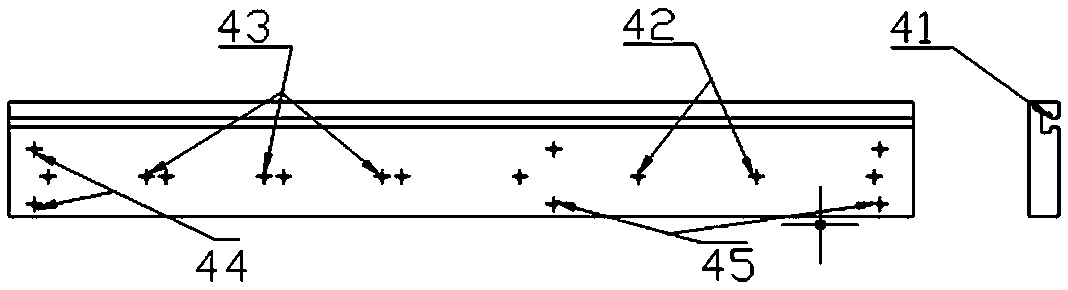

[0021] like figure 1 Shown, a kind of automobile door lock cable assembly test device, this device comprises: large base plate 10, large cylinder 20, long guide rail slider 30, small base plate 40, short guide rail slider 50, cable guide plate 60, cable Positioning plate 70, small cylinder 80, scale slide block 90, proximity switch sensor 100, sensor support 110, cylinder support 120. The slider of the long guide rail slider 30 is installed on one end of the large base plate 40, the large cylinder 20 is installed on one side of the large base plate 10 through the cylinder bracket 120, and the small base plate 40 is connected with the guide rail of the long guide rail slider 30 and installed on the long guide rail slider. 30 on the slide block, the piston of the large cylinder 20 is connected with one end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com