Automatic assembling equipment and method for electric toothbrush handle shell

An automatic assembly and electric toothbrush technology, which is applied to assembly machines, metal processing equipment, positioning devices, etc., can solve problems such as low production efficiency and inaccurate installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

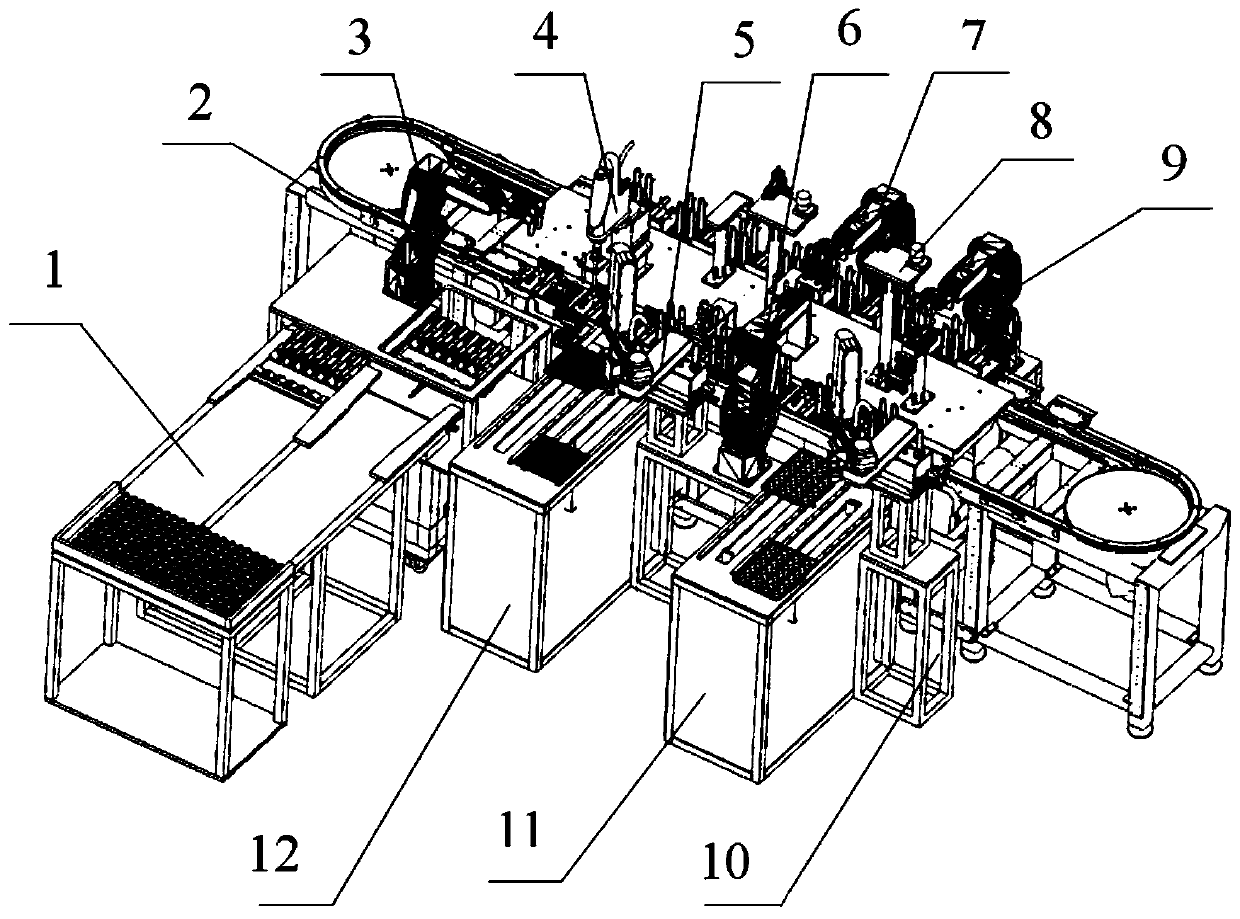

Embodiment 1

[0057] In the initial state, the device is in standby state. Two kinds of button workpieces are put on the button feeding tray 26, and the top ring workpiece and the bottom ring workpiece are placed on the top ring bottom ring feeding tray 25, and the toothbrush handle shell main body is put into the toothbrush handle feeding tray 24, and the Tray 24 is put into toothbrush handle loading and unloading material work station 1, presses start button to start equipment, and button feed tray 26 and top ring bottom ring feed tray 25 enter into waiting position respectively.

[0058] Centering on the ring-shaped cable 2, along the ring-shaped cable 2, there are toothbrush handle loading and unloading station 1, button installation station, top ring installation station and bottom ring installation station, and toothbrush handle loading and unloading station 1 and button installation station. A second manipulator 4 is arranged between the stations.

[0059] The toothbrush handle load...

Embodiment 2

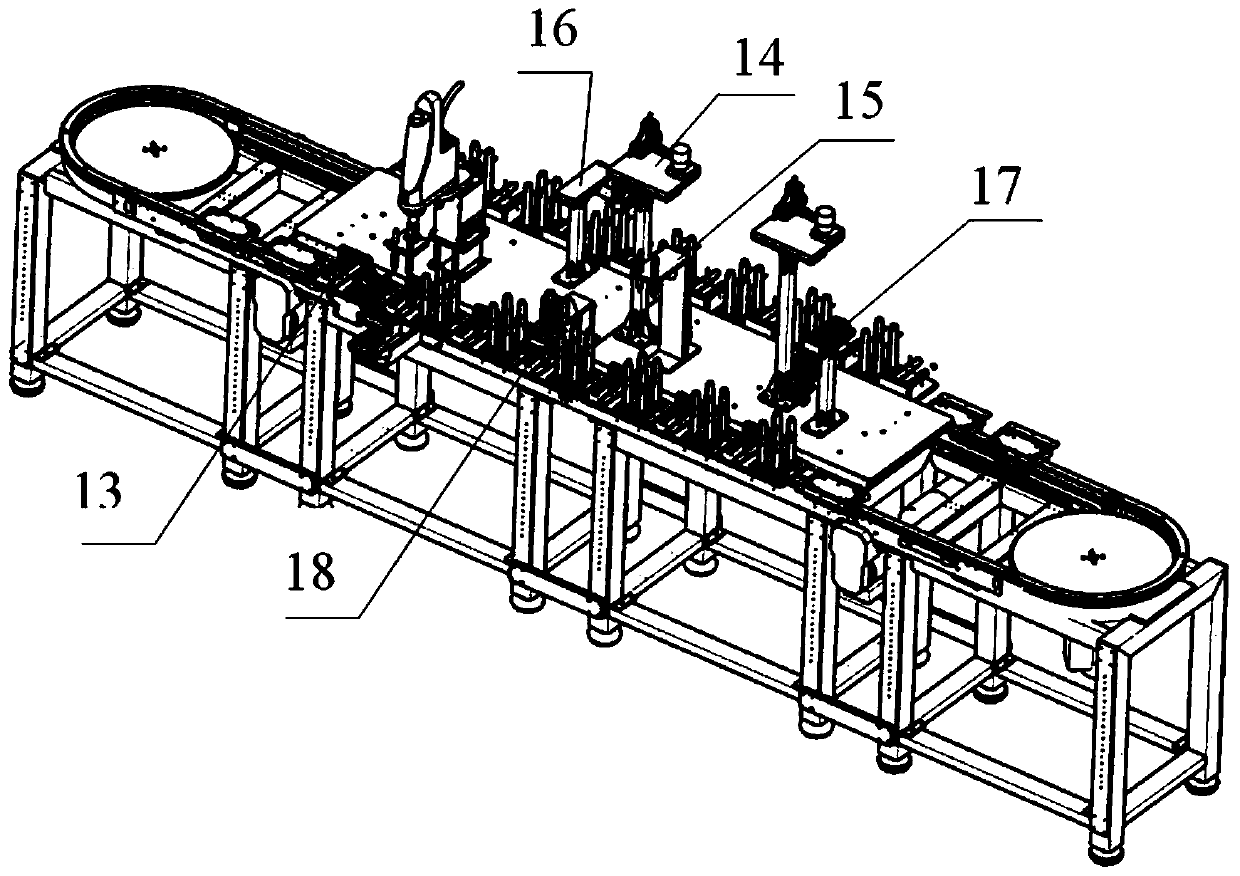

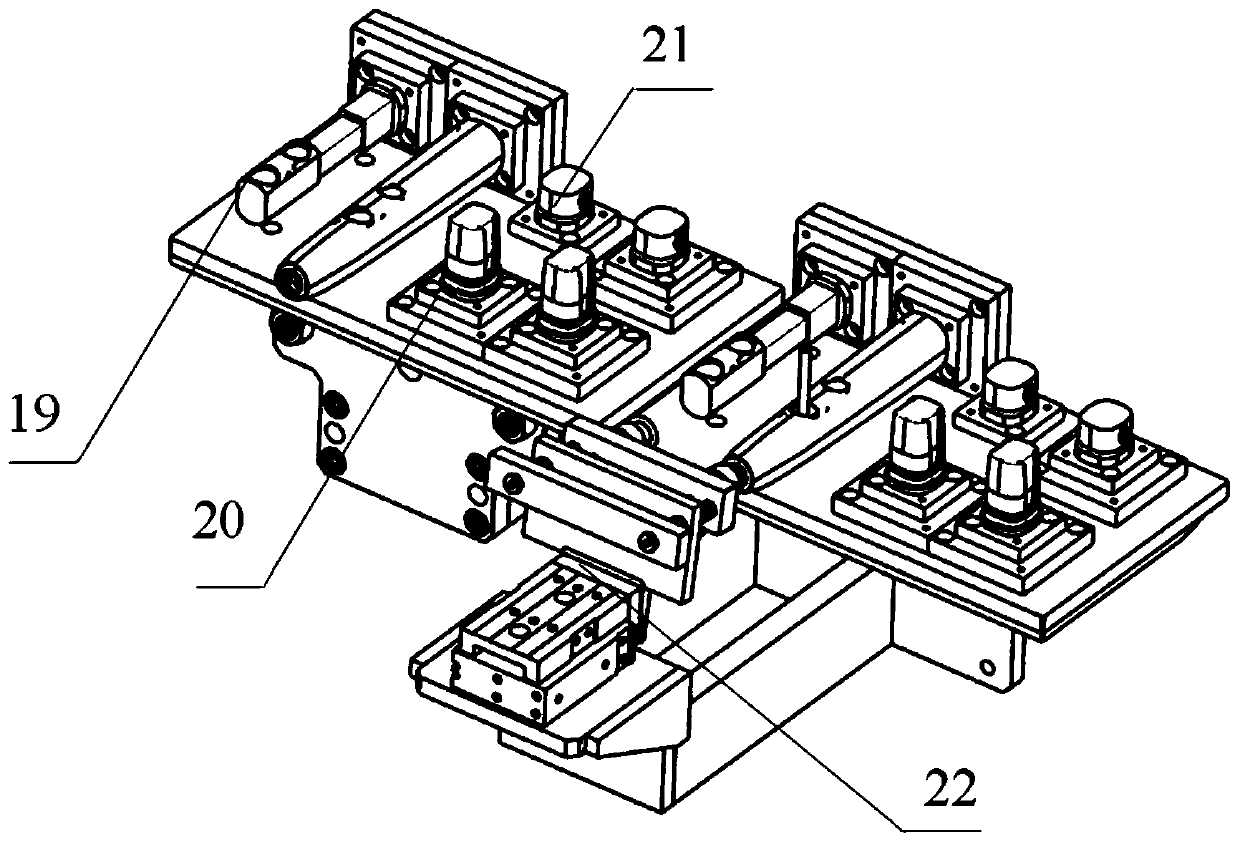

[0073]In the initial state, the device is in standby state. Manually put the toothbrush handle main body shell into the empty toothbrush handle feeding tray 24, place the filled toothbrush handle feeding tray 24 on the feed backguy 27, the toothbrush handle feeding tray 24 enters the waiting position along with the backguy, The first manipulator 3 takes out two unassembled toothbrush handle body shells from the toothbrush handle feeding tray 24 and places them on the button installation positioning fixture 19 on the ring stay wire 2, and places the assembled ones on the bottom ring installation positioning fixture 20 The two toothbrush handle main shells that have been installed are removed and placed in the empty positions of the toothbrush handle feed tray 24. After the toothbrush handle main shells in the toothbrush handle feed tray 24 are fully assembled, the small belt pulls 23 to place the toothbrush handle feed tray 24 is sent to backguy 28, and the toothbrush handle fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com