Button switch assembling machine

An assembly machine and switch technology, applied in the direction of electrical switches, electrical components, circuits, etc., can solve the problems of time-consuming and labor-intensive, unable to achieve fully automatic assembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

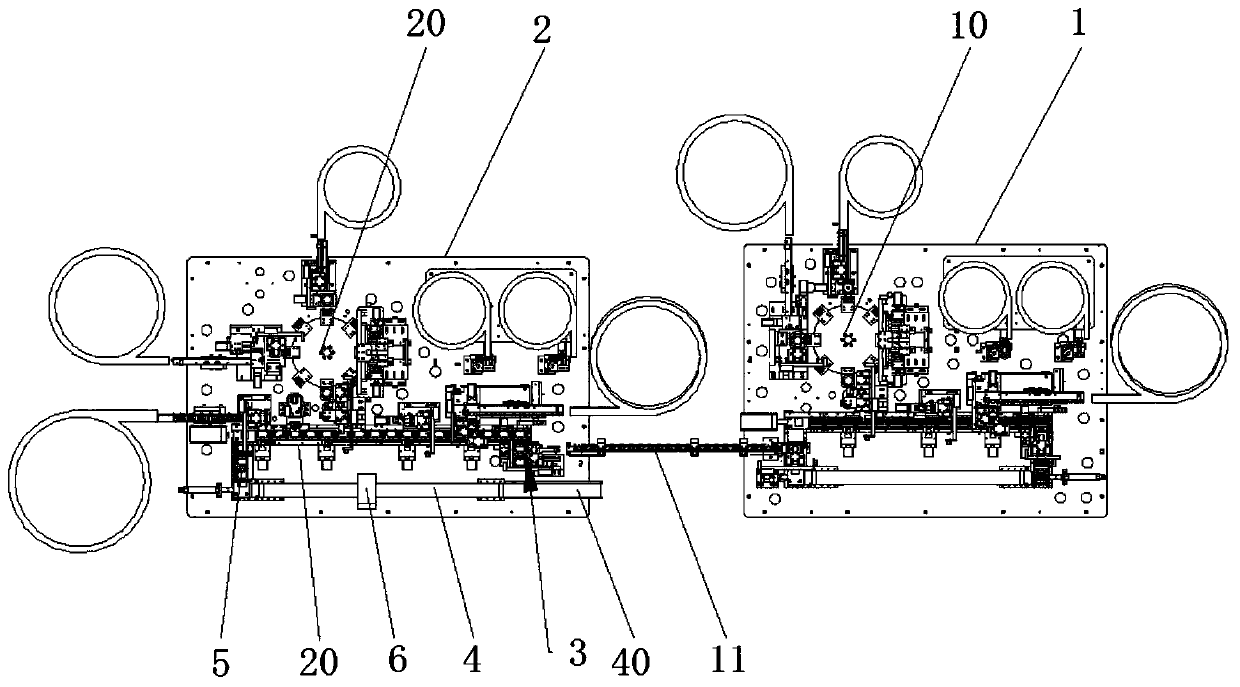

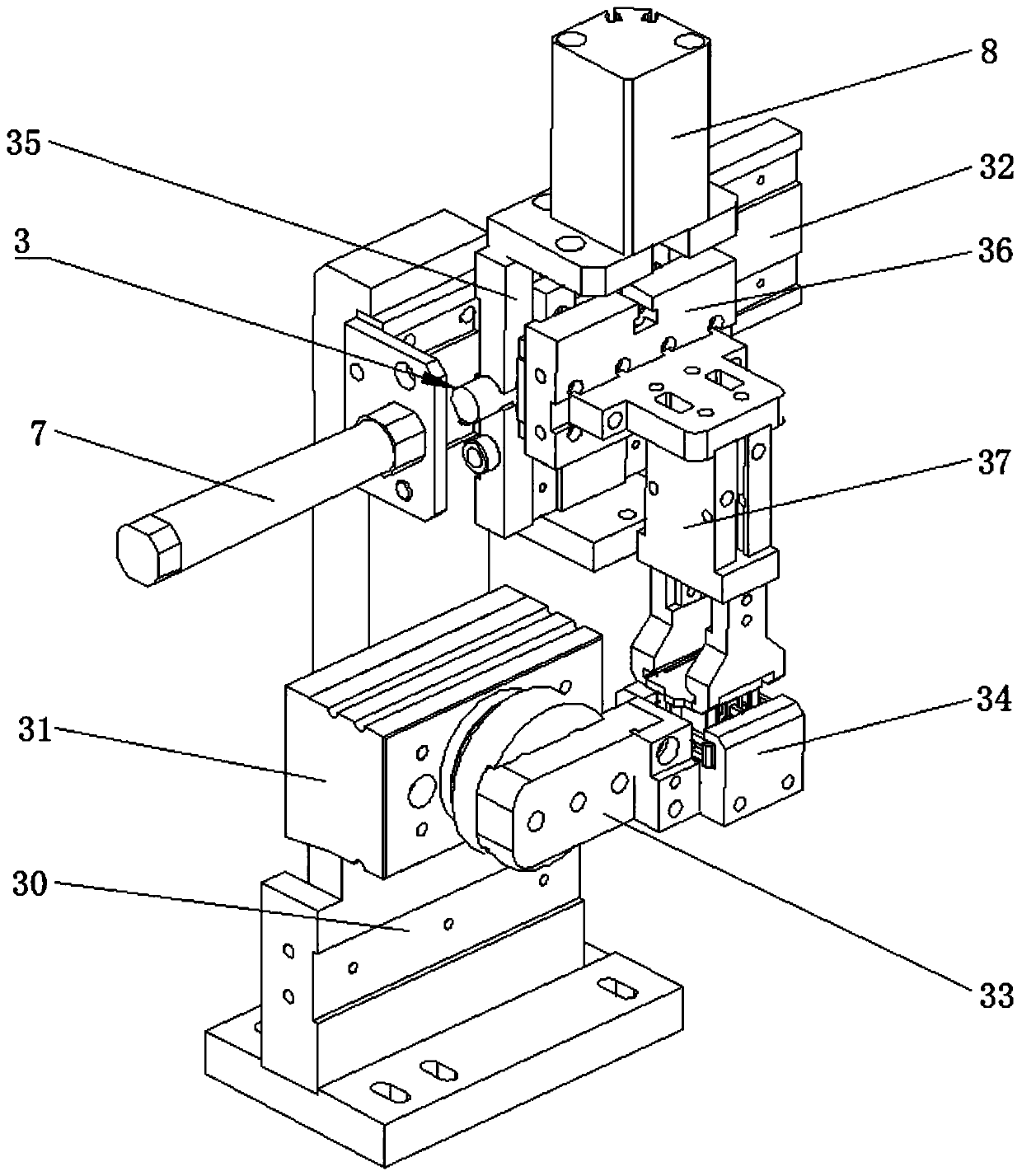

[0012] refer to Figure 1 to Figure 2 The embodiments of the present invention will be further described.

[0013] The invention discloses a push button switch assembly machine, which comprises a first frame 1 and a second frame 2, the first frame 1 is provided with a first assembly part 10, and a feeding material that cooperates with the first assembly part 10 for transmission. Track one 11, the second frame 2 is provided with a second assembly part 20, and a feeding track two 21 that is transported and matched with the second assembly part 20, and one end of the feed track one 11 extends to the second frame 2 for feeding At the feed end of the track two 21, the feed end of the feed track two 21 is provided with a clamping part 3 for clamping the button switch, and the clamping part 3 includes a base 30 and a driving motor arranged on the base 30 31 and a slide rail 32, the slide rail 32 is vertical to the base 30, and the slide rail 32 is located at the end of the base 30, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com