A continuous bearing assembly production line

A bearing assembly and production line technology, applied in shafts and bearings, bearing components, assembly machines, etc., can solve the problems of inability to assemble multiple bearing balls, difficult to guarantee assembly quality, and low assembly efficiency, so as to speed up assembly production and speed up The effect of assembly speed and assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the examples and drawings, but the embodiments of the present invention are not limited thereto.

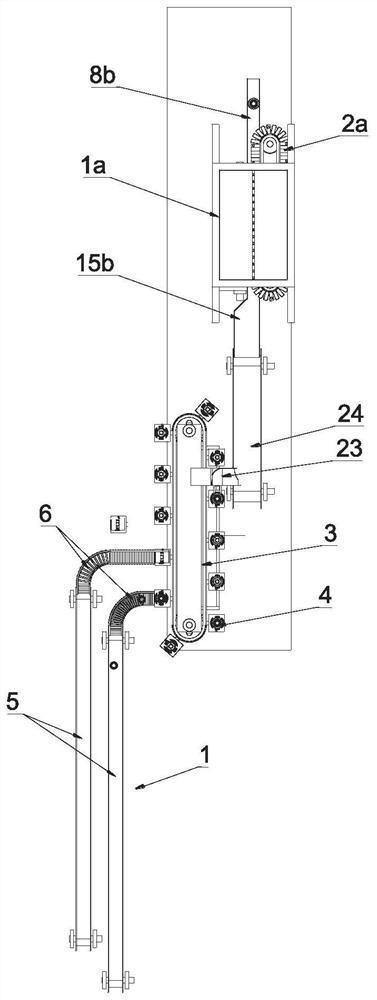

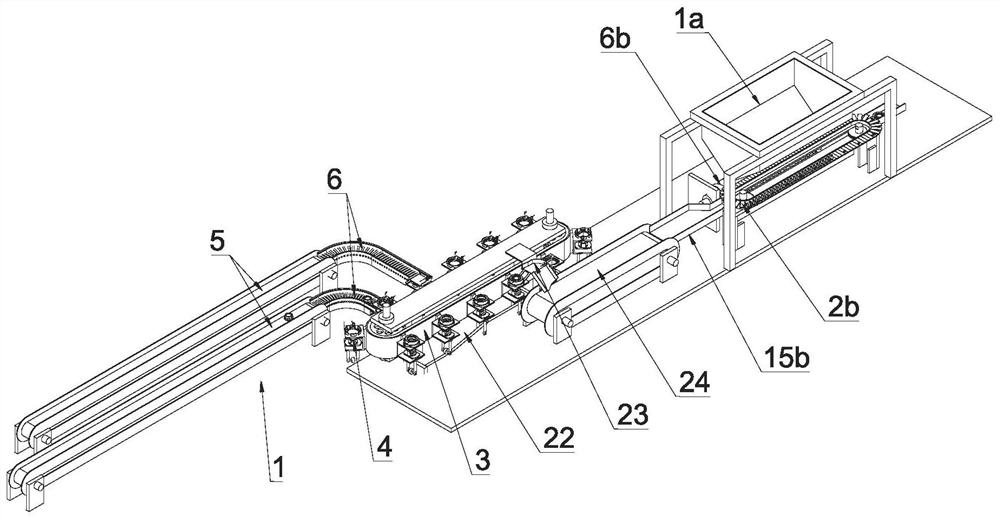

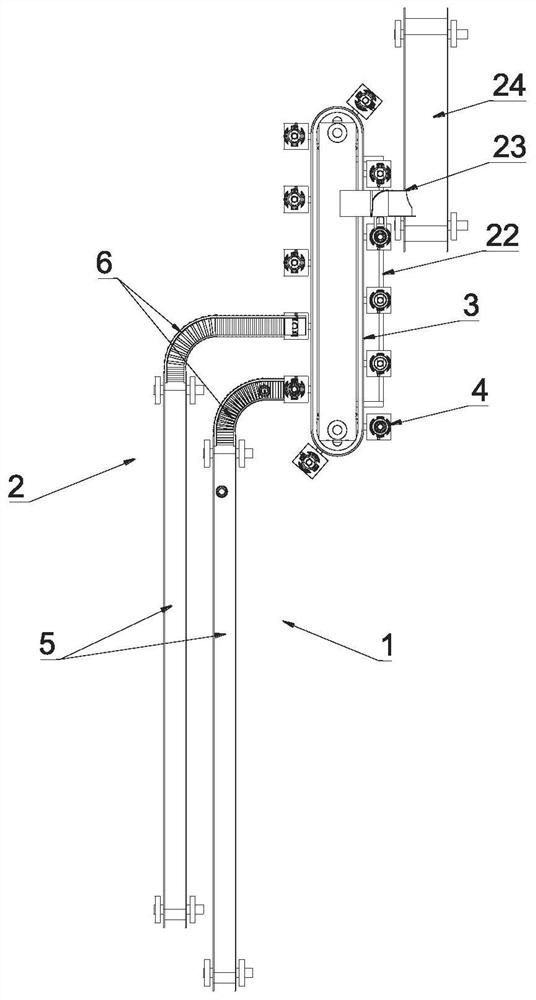

[0035] see Figure 1-Figure 2 , the continuous bearing assembly production line of this embodiment includes a front-end processing module for completing bearing loading and assembly of bearing inner and outer rings and a ball assembly module for completing ball assembly; wherein:

[0036] see Figure 3-Figure 10 , the front-end processing module includes two sets of feeding and conveying devices, a transfer positioning device 4 and a transfer drive mechanism that drives the transfer positioning device 4 to move. The two groups of feeding and conveying devices all include a conveyor belt and a feeding driving mechanism that drives the movement of the conveyor belt, and the two groups of feeding and conveying devices are respectively the outer ring conveying device 2 for conveying the outer ring of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com