Automatic assembling mechanism for spring and rack

An automatic assembly and rack technology, applied in workpiece clamping devices, metal processing, metal processing equipment, etc., can solve the problems of consuming a lot of manpower and material resources, low production efficiency, etc., and achieve the effect of saving labor costs and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

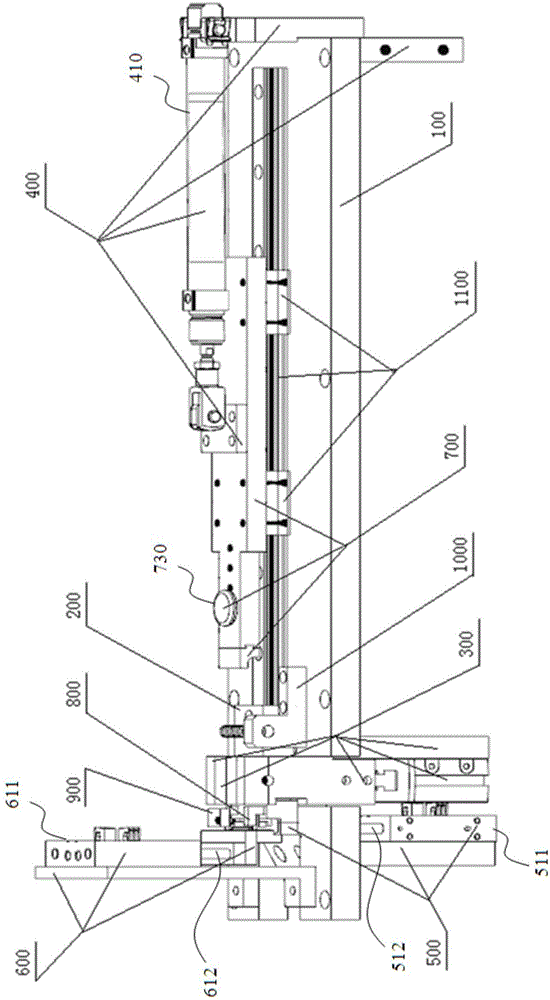

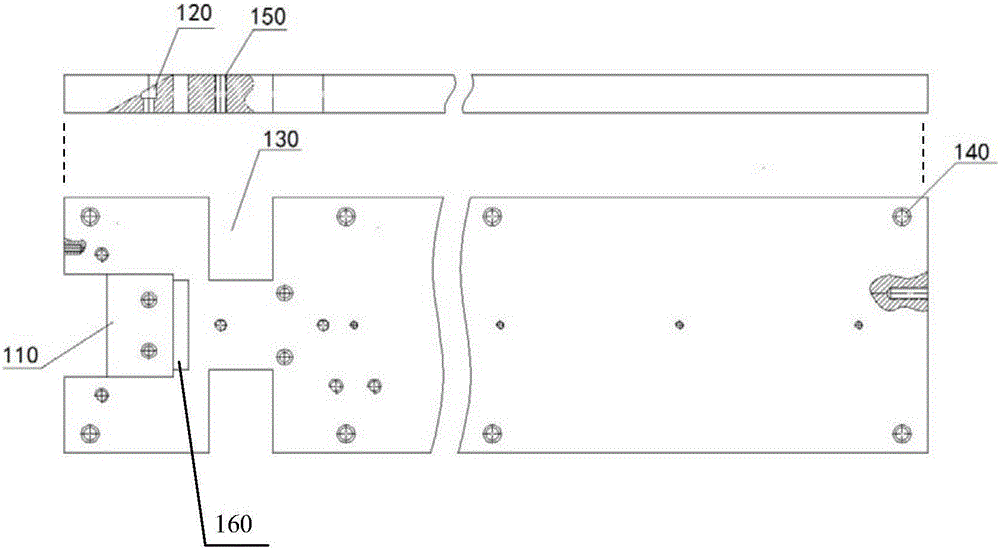

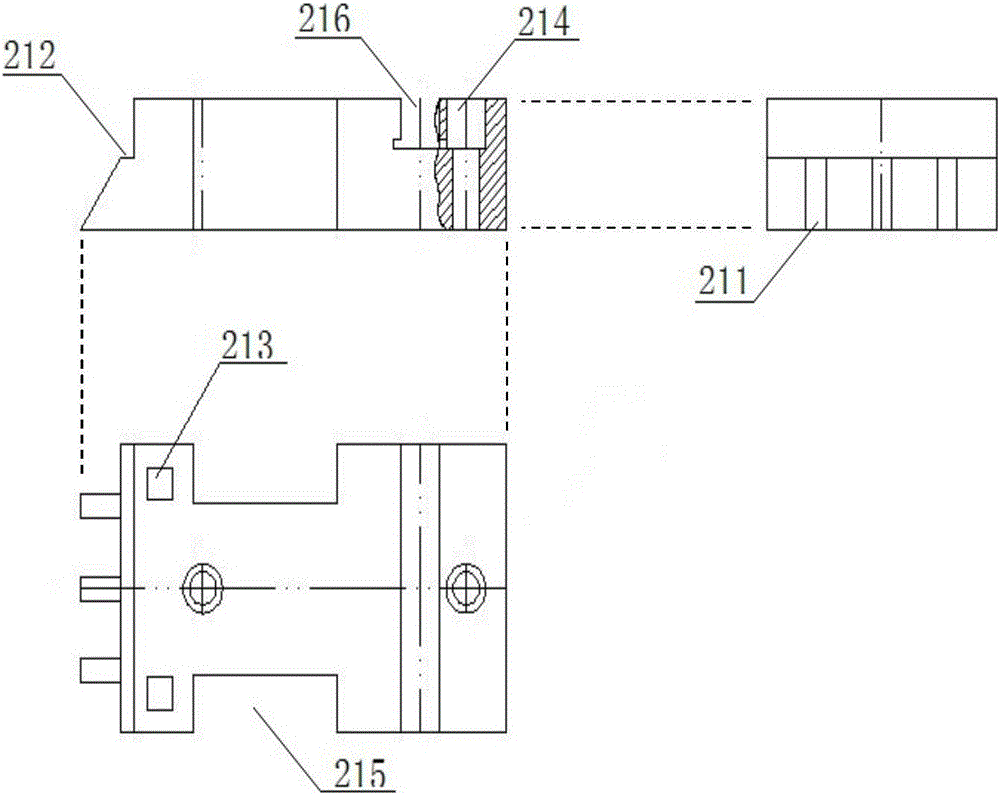

[0051] The invention provides an automatic assembly mechanism for a spring rack, which can be applied to industries such as assembly of auto parts. Such as figure 1 As shown, the assembly mechanism includes: a base plate 100, an assembly base 200, a spring compression device 300, a spring pushing device 400, a rack positioning device 500, a rack pressing device 600, a spring moving guide device 700, a spring guide column 800, Rack detection sensor mounting seat 900 , spring detection sensor mounting seat 1000 , guide rail slider 1100 .

[0052]Wherein, the assembly base 200 realizing spring guidance is installed on the front portion of the base plate 100, and the spring compression device 300 is also fixed on the front portion of the base plate 100; The rear end of this side; the spring mobile guide device 700 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com