Automatic check assembly machine for HDMI connector

An automatic detection and assembly machine technology, which is applied to the assembly/disassembly of contacts, etc., can solve the problems of manual detection of the assembly quality of the first terminal and the second terminal and the terminal body, and the production efficiency needs to be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

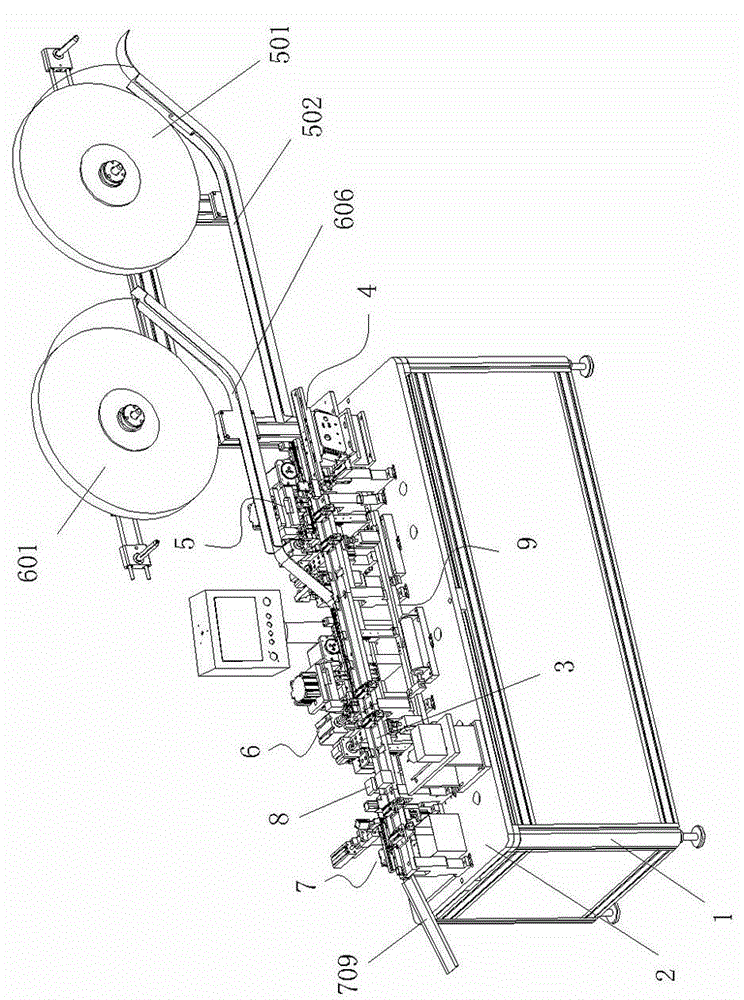

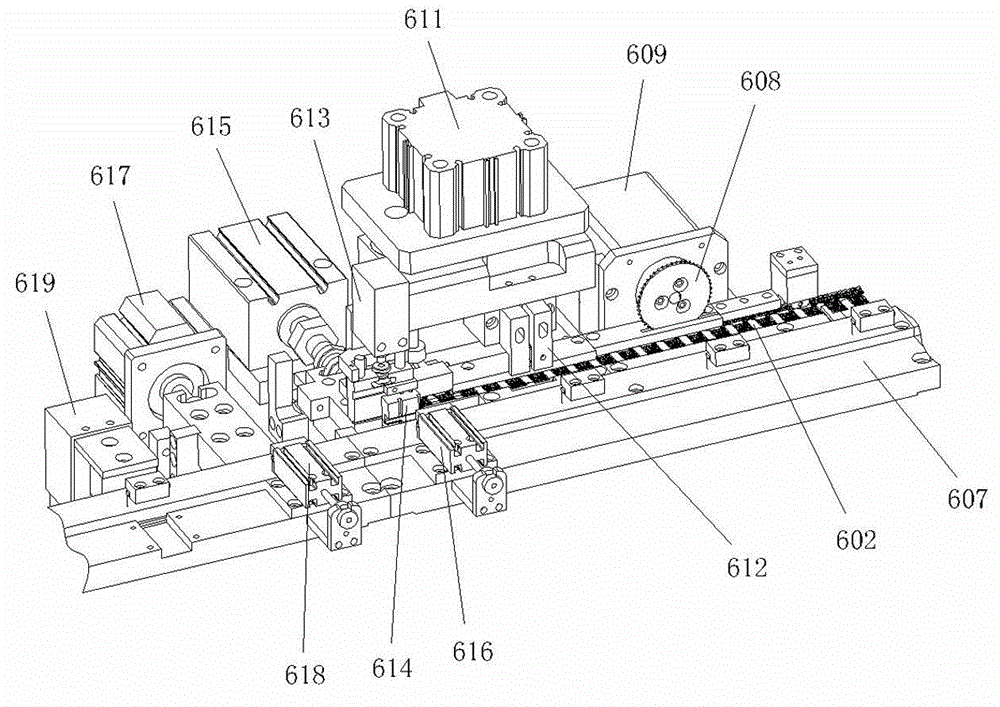

[0048] refer to Figure 1~Figure 6 , an HDMI connector automatic detection and assembly machine, comprising a rack 1, a worktable 2 arranged on the rack 1, the worktable 2 is provided with a feeding rail 3, and the feeding rail 3 is sequentially provided with a pair of terminals The terminal body feeding mechanism 4 for conveying the body, the first terminal assembly line 5 for conveying and inserting the first terminal into the terminal body, and the second terminal assembly line 6 for conveying and inserting the second terminal into the terminal body ;

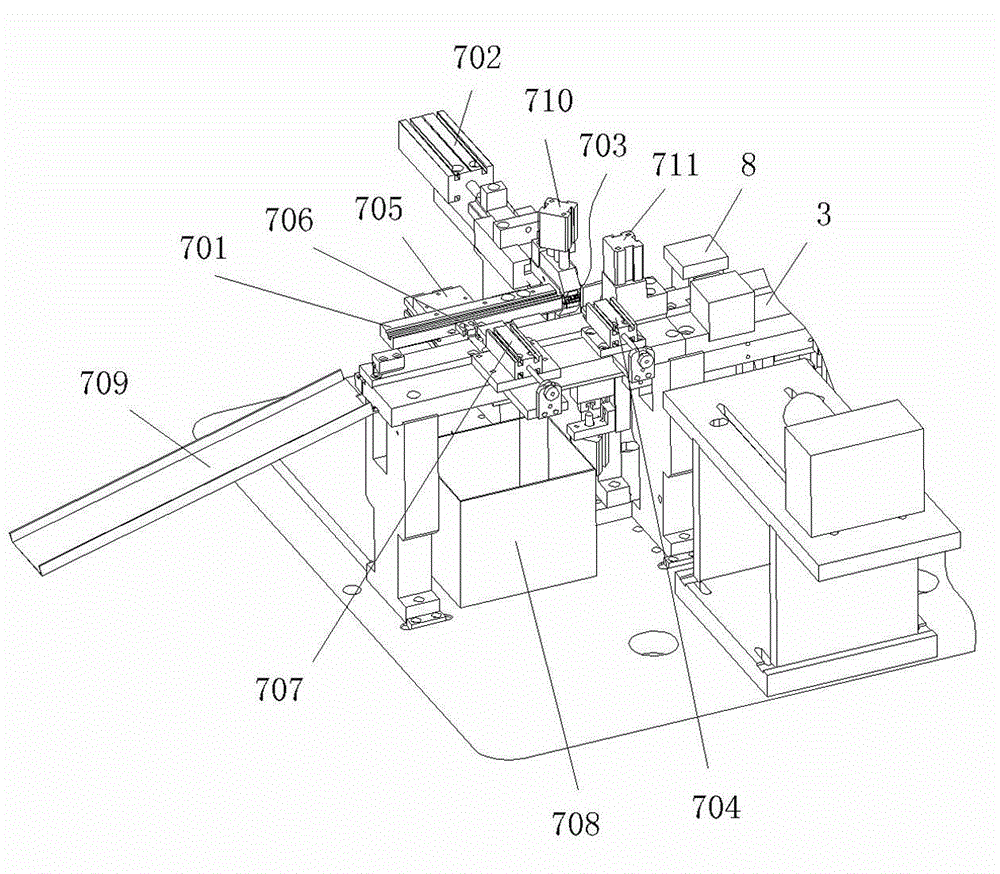

[0049] The end of the feeding track 3 is provided with a rear plug assembly line 7 for conveying the rear plug and inserting it on the terminal body;

[0050] The rear plug assembly line 7 includes a rear plug feeding vibrating plate, and a rear plug feeding rail 701 located behind ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com