Full-automatic button switch assembling machine

An assembly machine, fully automatic technology, applied in the direction of electrical switches, electrical components, circuits, etc., can solve the problems of not being able to perform fully automatic assembly, increasing labor costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

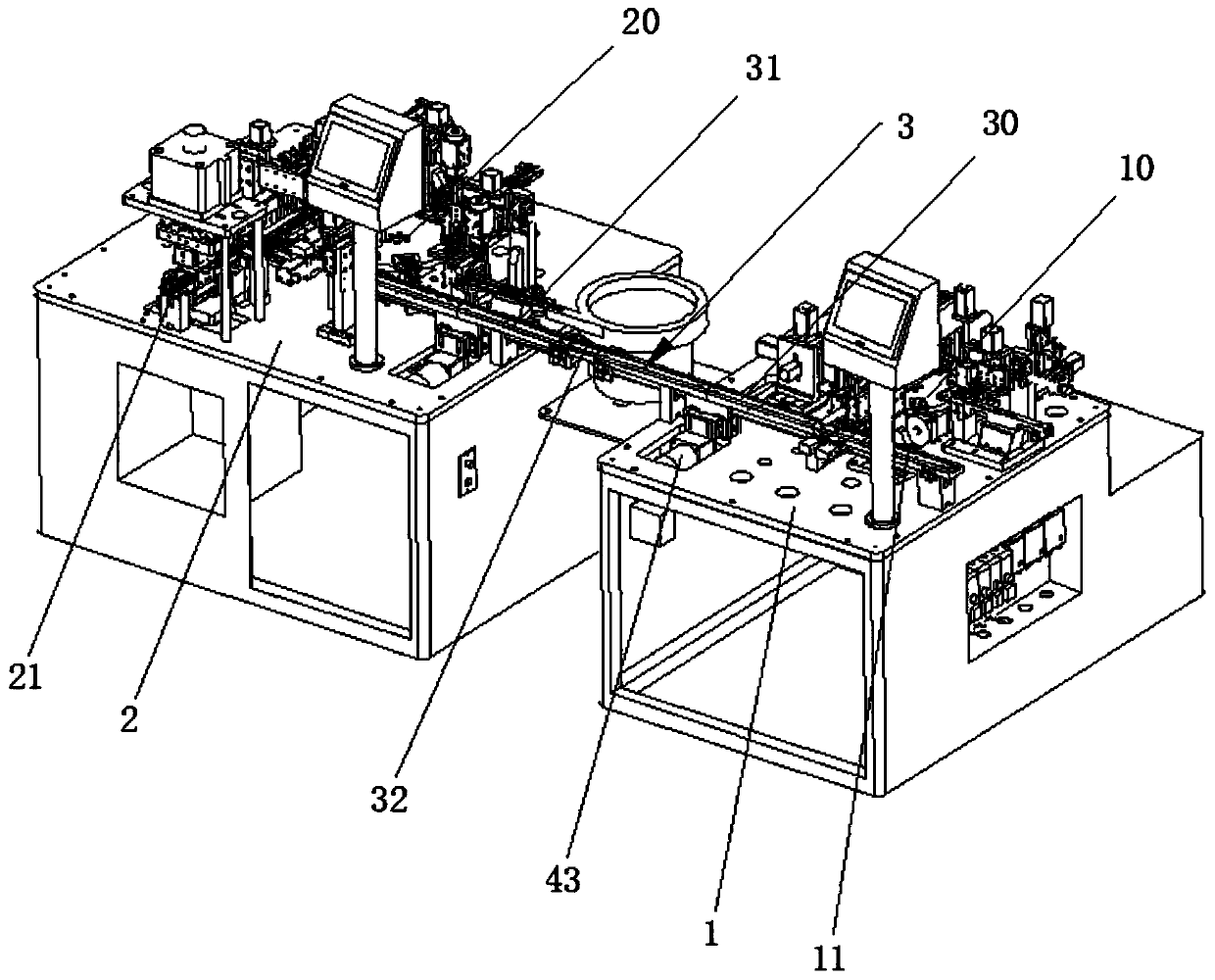

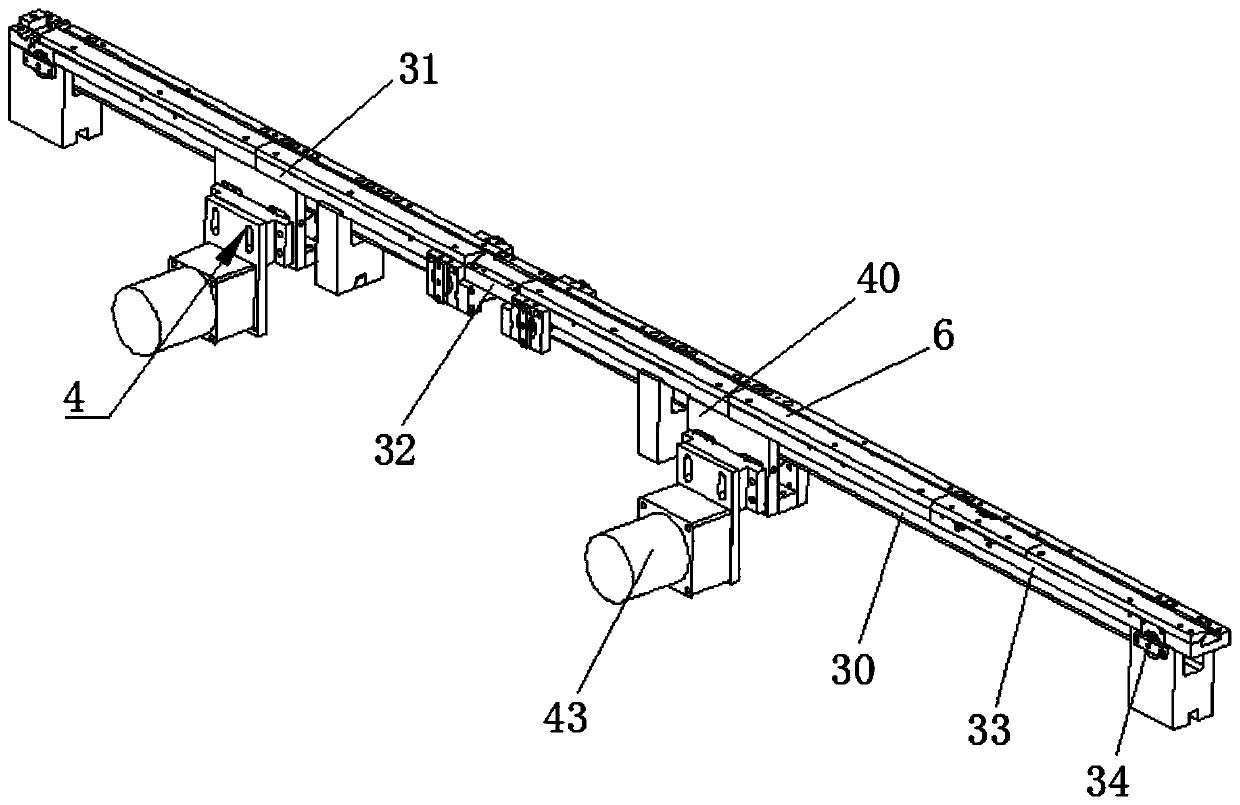

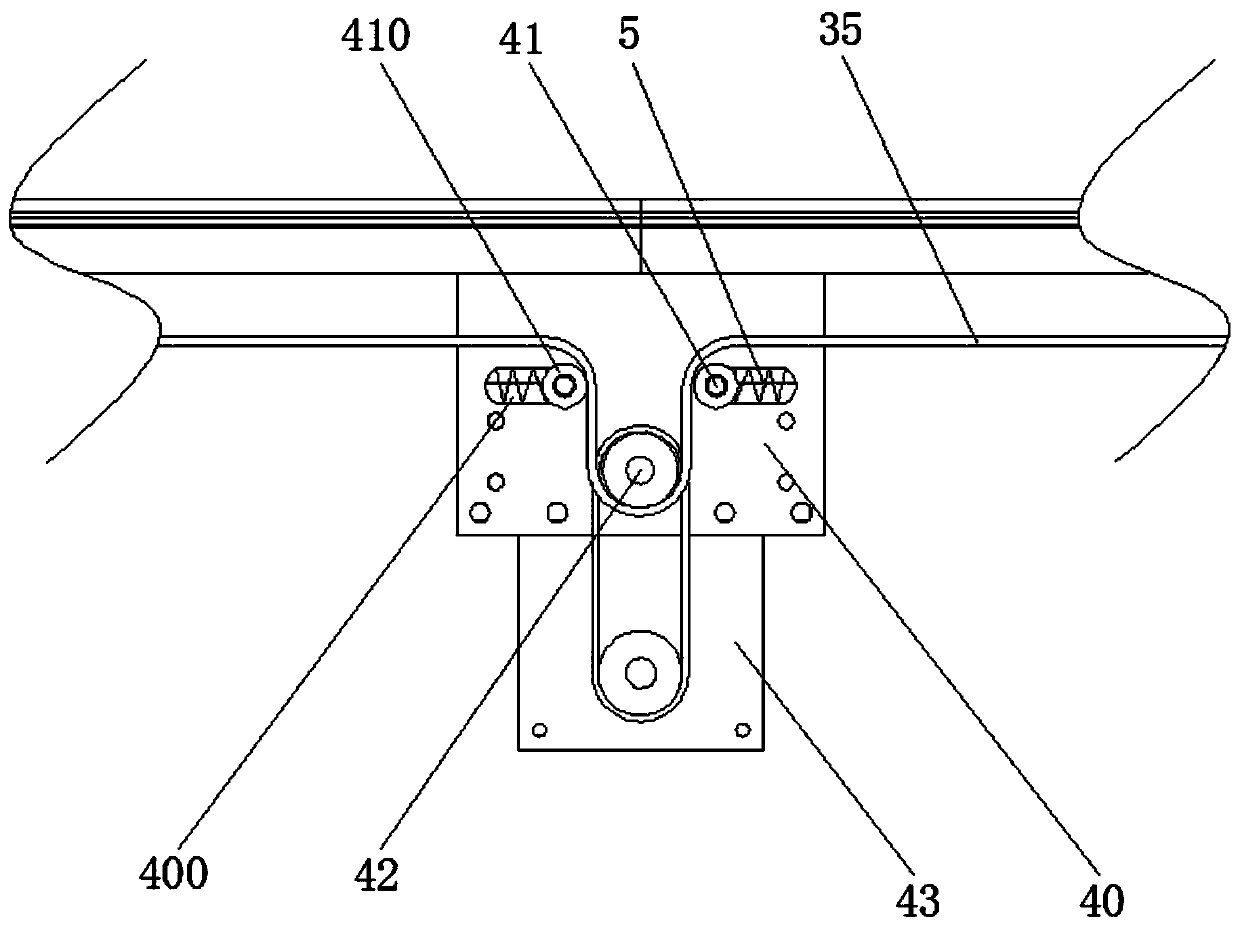

[0014] refer to Figure 1 to Figure 4 The embodiments of the present invention will be further described.

[0015] The invention discloses a fully automatic button switch assembly machine, comprising a first frame 1 and a second frame 2, the first frame 1 is provided with a first assembly part 10 and a first discharge track 11, the first frame 1 The second frame 2 is provided with a second assembly part 20 and a second discharge track 21, and the first discharge track 11 and the second discharge track 21 are correspondingly arranged. A connecting piece 3 is arranged between the second discharge rails 21, and the connecting piece 3 includes a first transmission belt 30 arranged on the first frame 1 and a second transmission belt 31 arranged on the second frame 2. The first transmission belt 30 communicates with the discharge end of the first discharge track 11, the second transmission belt 31 communicates with the discharge end of the second discharge track 21, and the first t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com