Tapered roller bearing assembling machine

A technology for tapered roller bearings and assembly machines, applied to shafts and bearings, bearing components, mechanical equipment, etc., which can solve problems such as easy slipping out, missing assembly, and low manual assembly efficiency, so as to ensure assembly quality and improve assembly efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

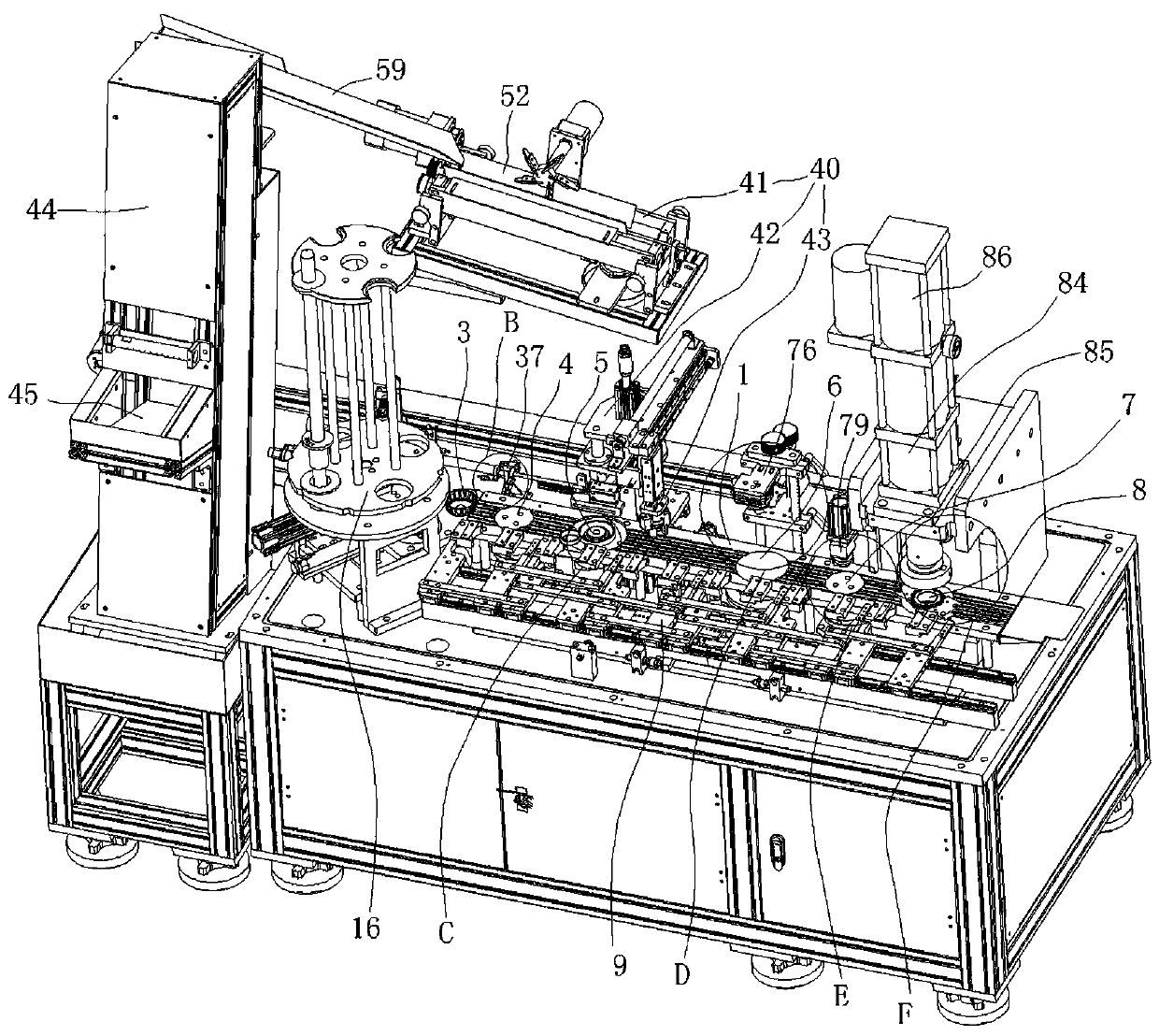

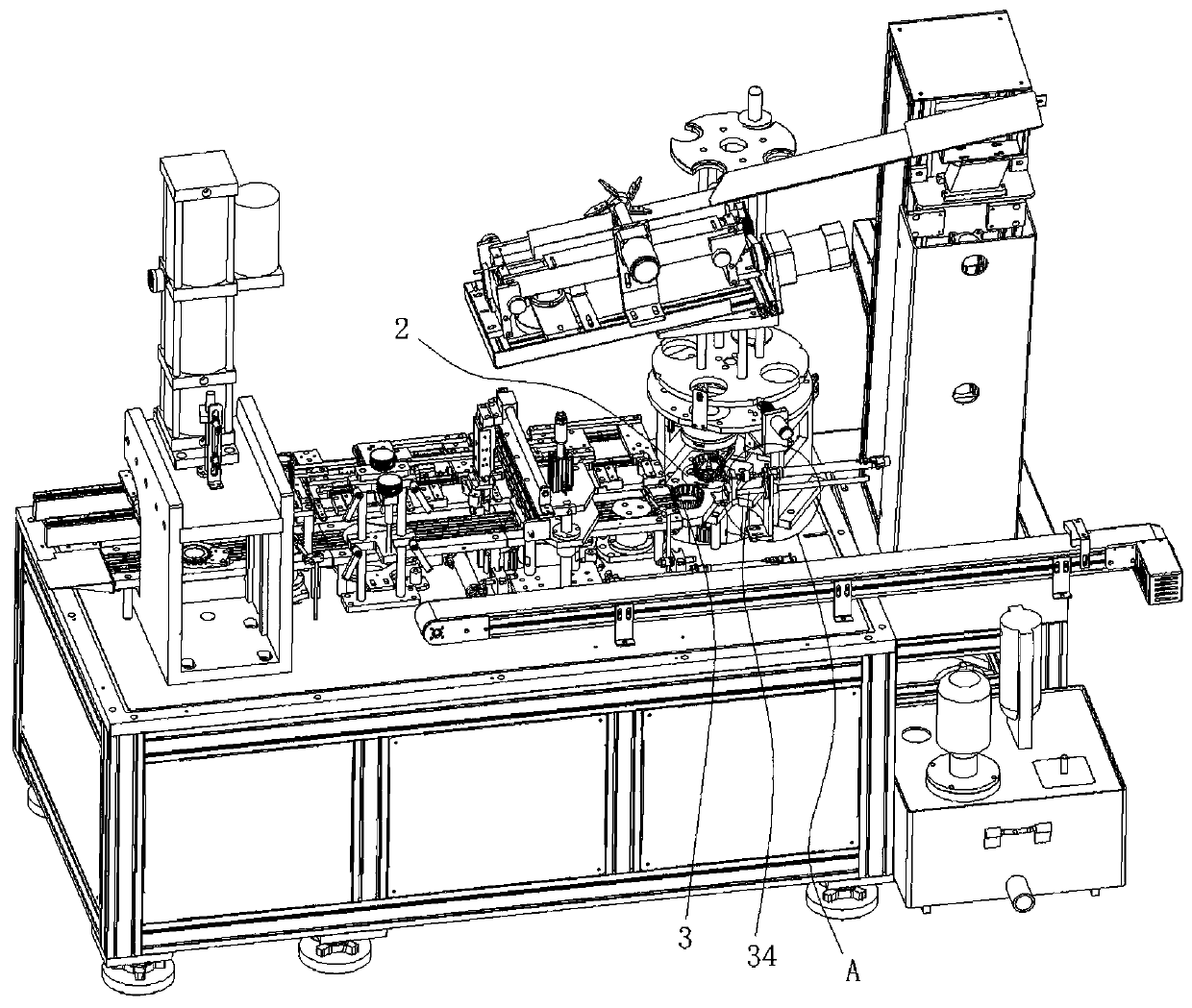

[0043] refer to Figure 1 to Figure 19 , a tapered roller bearing assembly machine, comprising:

[0044] refer to Figure 1 ~ Figure 2 , worktable 1, which is used for the operation of the entire assembly process, including the retainer feeding station 2, retainer pushing station 3, position detection station 4, roller and inner ring assembler arranged in sequence from left to right Position 5, Roller Assembly Inspection Station 6, Assembly Orientation Station 7 and Riveting Station 8.

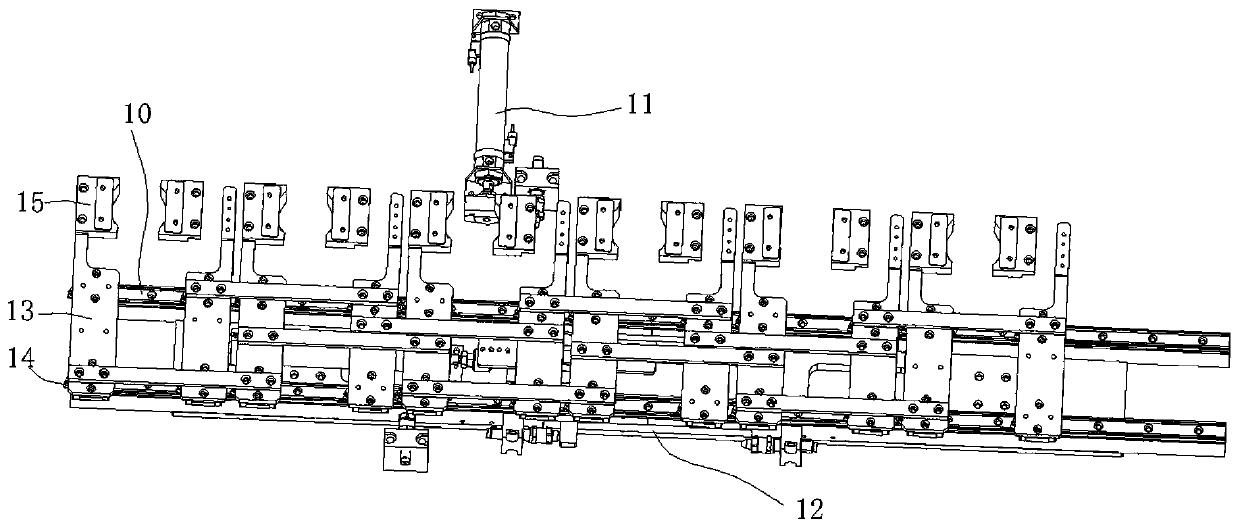

[0045] refer to image 3 , the operating mechanism 9, which is used to move the parts or assemblies in each station to the next station, and is located next to the work surface 1, including a running slide rail 10, and the running slide rail 10 is provided with Up and down operation cylinder 11 and left and right operation cylinder 12, a number of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com