Automatic tire assembly gripper and automatic tire assembly device

An automatic assembly and tire technology, which is applied in the direction of manipulators, metal processing, metal processing equipment, etc., can solve problems such as large influence of human factors, safety accidents, and high work intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

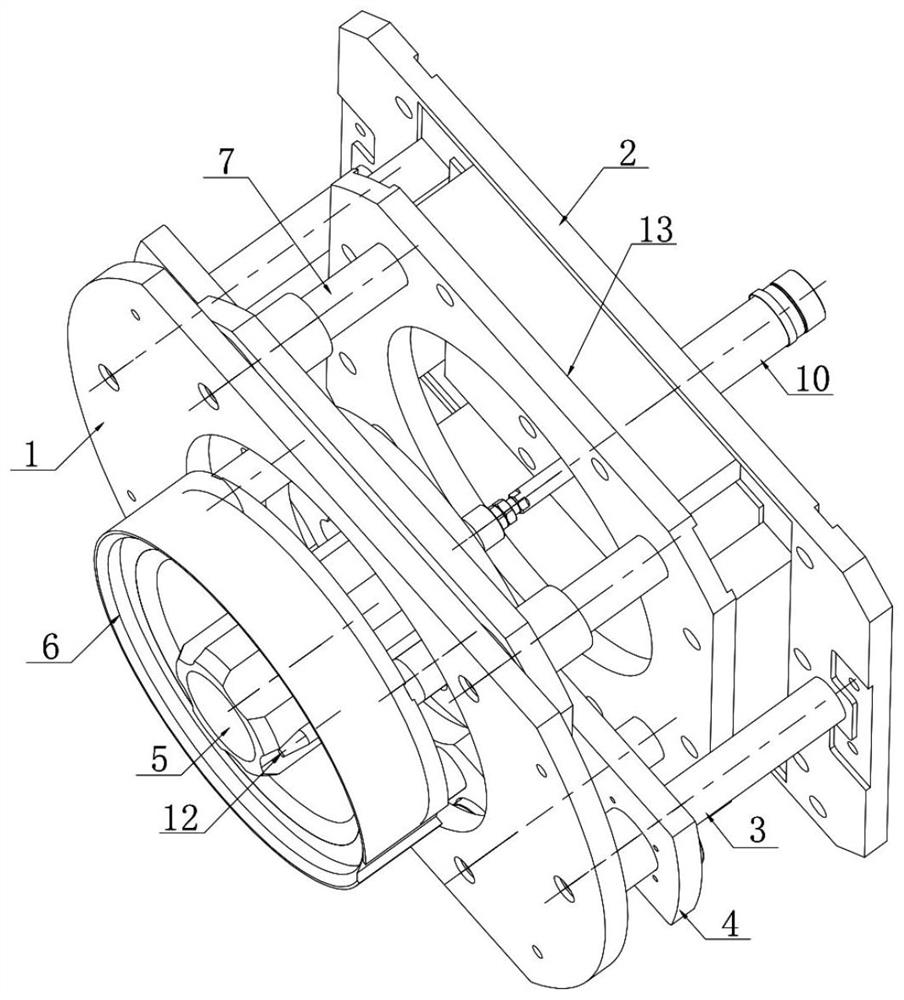

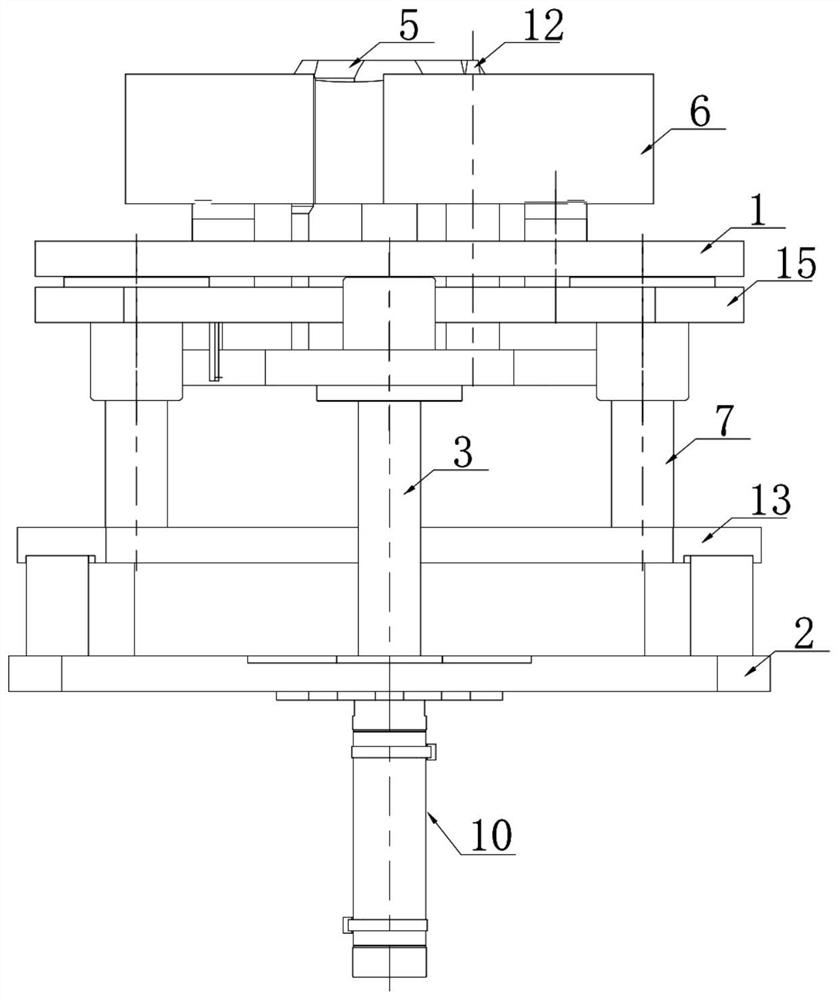

[0048] Example 1, such as Figure 1-Figure 3 As shown, a tire automatic assembly gripper includes a bracket, a tire grabbing mechanism and a tire positioning mechanism arranged on the bracket, and the bracket includes a first brace 1, a second brace 2 and a first brace 1 The connecting rod 3 with the second support plate 2;

[0049]The tire positioning mechanism includes a positioning plate 4, a positioning column 5 arranged on the positioning plate 4 and a power mechanism for driving the positioning plate 4 to move, the positioning plate 4 is slidably arranged on the connecting rod 3, and the The power mechanism is installed on the second support plate;

[0050] Described tire grasping mechanism comprises annular magnetic chuck 6, and the adsorption surface of described annular magnetic chuck 6 is adapted to the shape of the rim on the tire, and described annular magnetic chuck 6 is arranged on the mounting plate 15, and described support frame is provided with There is a g...

Embodiment 2

[0056] Example 2, such as Figure 4-Figure 12 As shown, on the basis of Embodiment 1, a nut screwing mechanism is also included, and the nut screwing mechanism is arranged on the bracket. The number of the nut screwing mechanism is consistent with the number of nuts to be assembled. The nut tightening mechanism can realize the automatic tightening of the nut after the tire is assembled and positioned, further improving the assembly efficiency of the vehicle tire.

[0057] The nut screwing mechanism includes a tightening machine 9 and a tightening head 8 arranged on the tightening machine 9, the tightening machine 9 is arranged on the second support plate 2, and the tightening head 8 is provided with a screw for accommodating nuts. Nut profiling groove 11. Tighten the nut to be installed and put it in the nut profiling groove 11. The nut mounting groove is the shape of imitating the nut, which not only can constrain the position of the nut, but also facilitates the nut to be ...

Embodiment 3

[0059] Example 3, such as Figure 13 As shown, on the basis of Embodiment 2, the tire grabbing mechanism further includes a spring, the spring is sleeved on the guide post 7, and the spring 14 is arranged on the mounting plate 15 and the second support plate or between the third braces 13 . The spring 14 can play a buffering role in the alignment and positioning process between the rim hole of the tire and the screw or bolt of the wheel hub of the vehicle, especially after the tire is in place, the annular magnetic chuck 6 will apply force to the spring 14 under the force of the wheel hub. The spring 14 can avoid the hard collision between the tire and the wheel hub, further improving the quality of the assembled tire.

[0060] like Figure 14 As shown, the present invention also relates to a tire automatic assembly device, including a robot 17, and also includes the above-mentioned automatic tire assembly gripper, the second stretcher 2 of the tire automatic assembly grippe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com