Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Realize automatic tool change" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

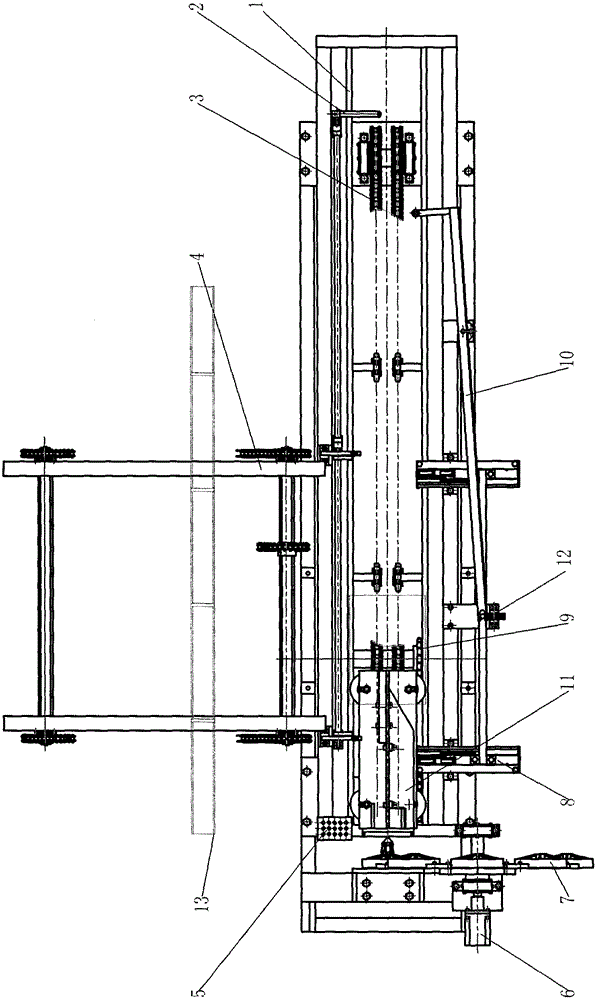

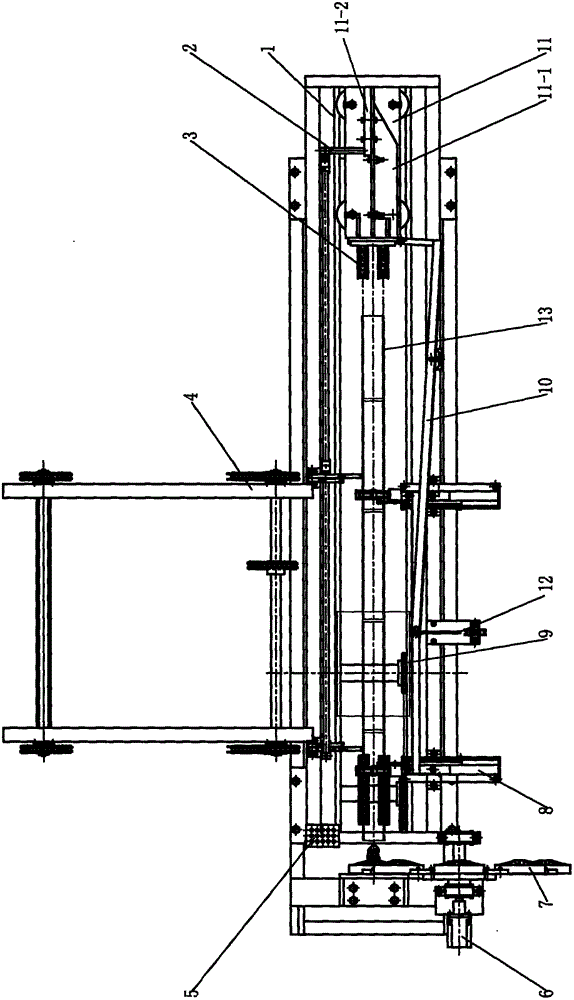

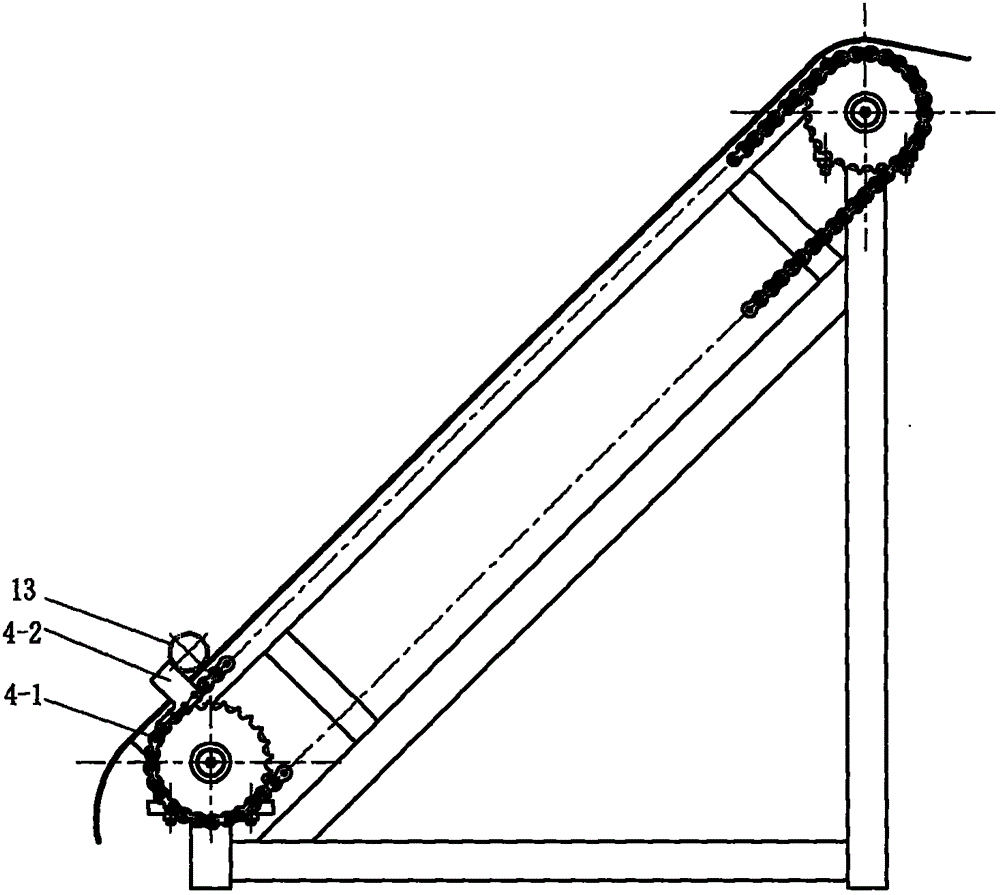

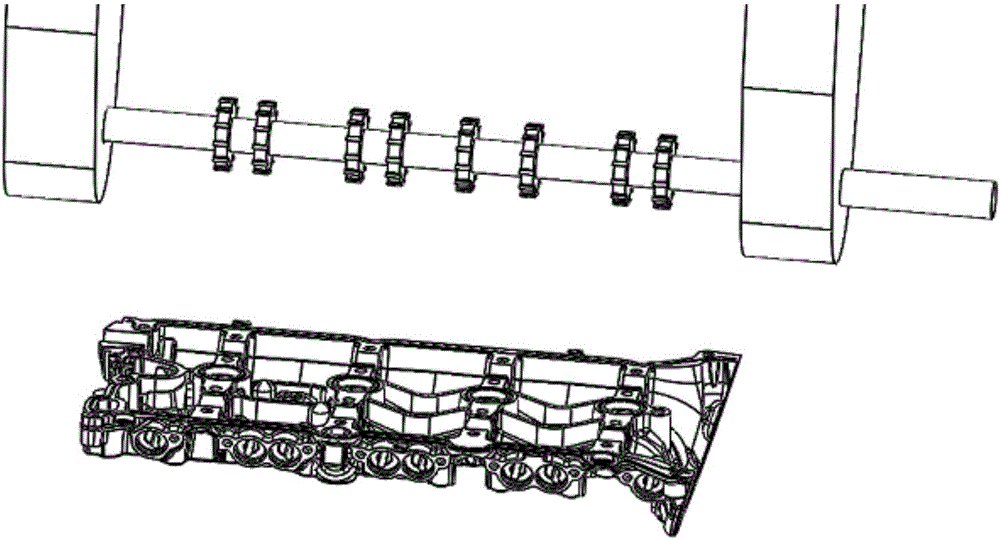

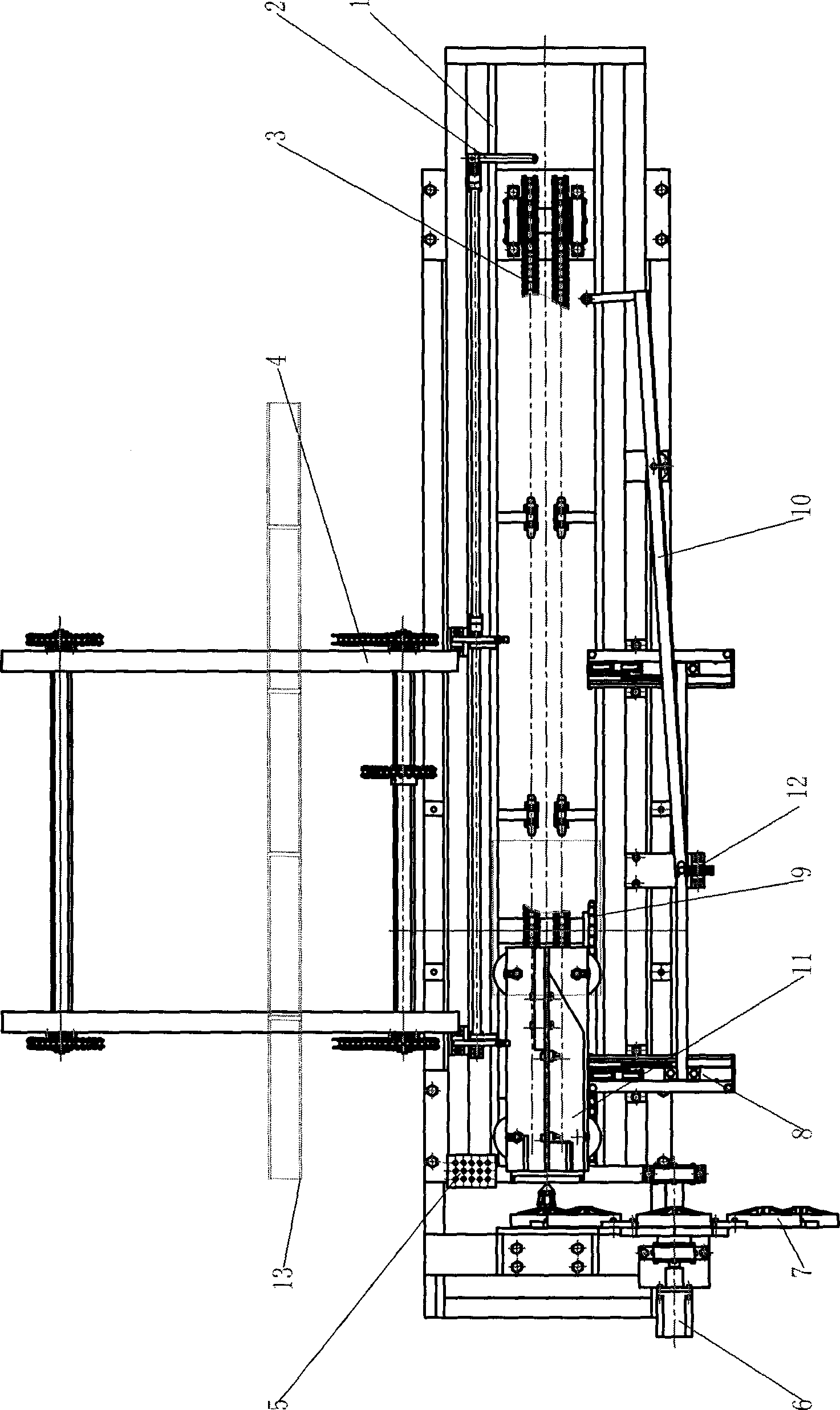

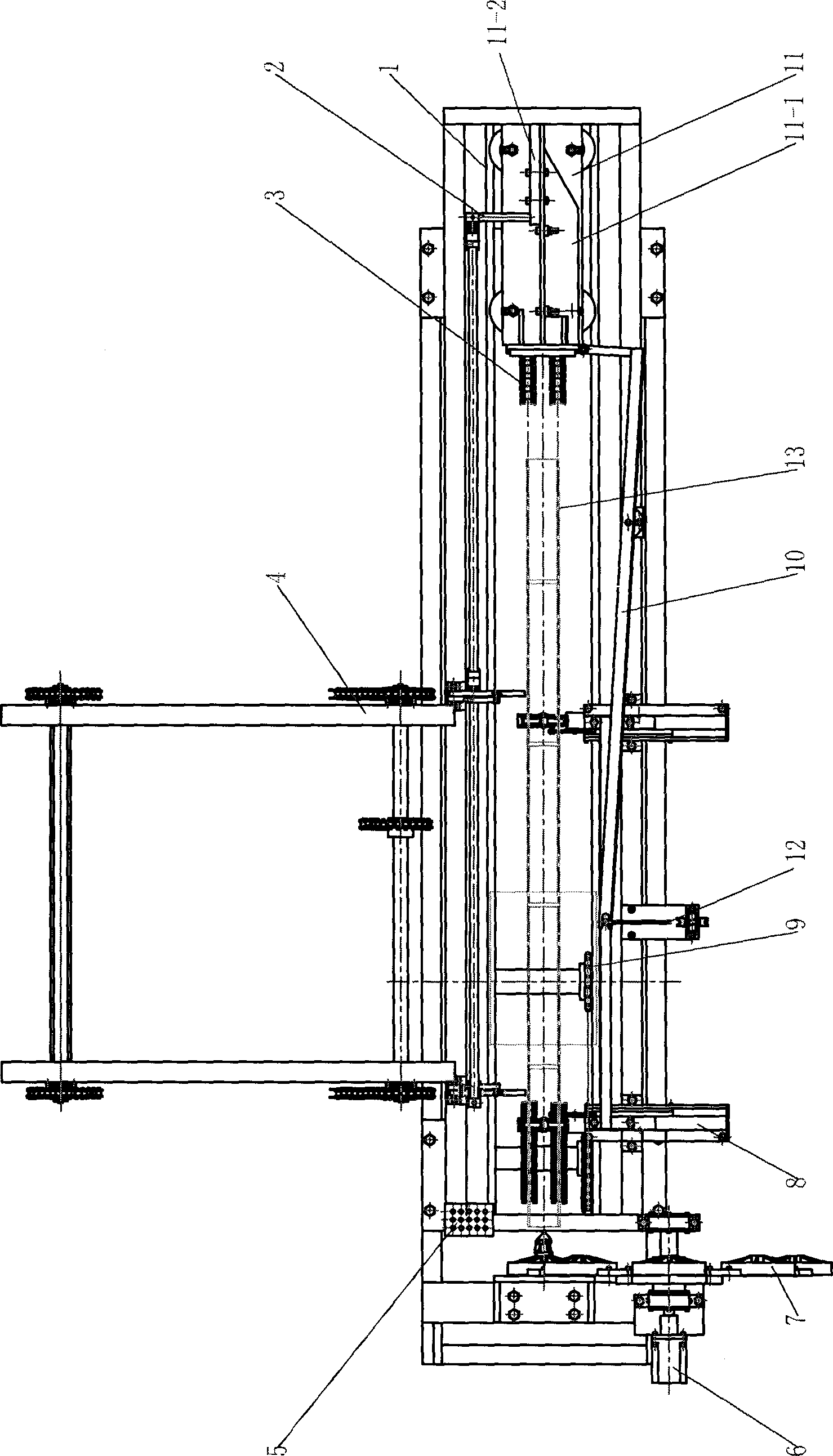

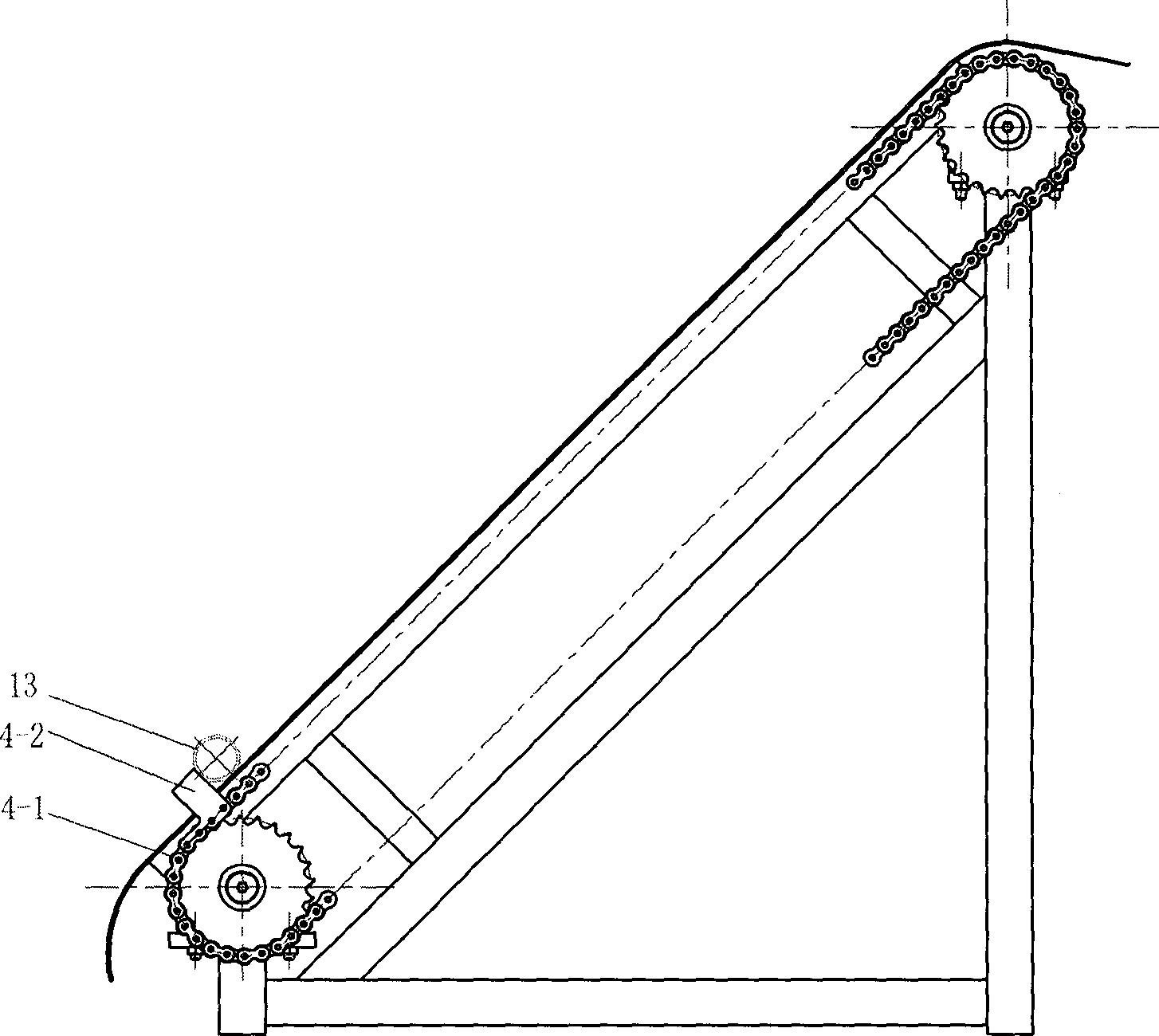

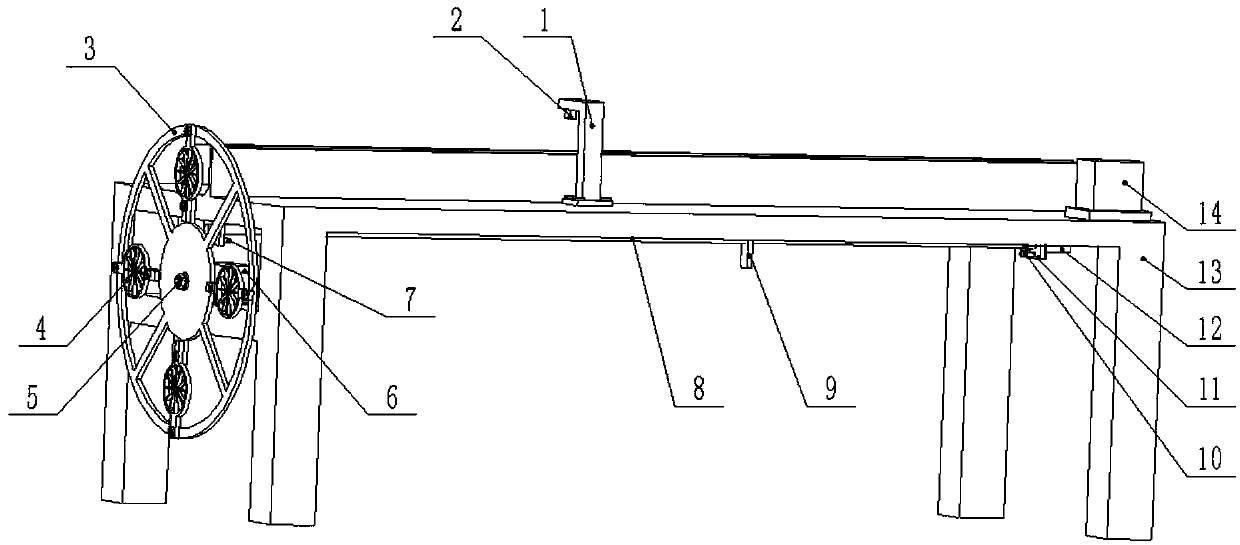

Novel numerical control bamboo splitting machine

ActiveCN102717414AAchieve broken bambooRealize empty back movementWood splittingVeneer manufactureNumerical controlMeasurement device

The invention relates to a novel numerical control bamboo splitting machine, which includes a lathe bed guide rail, a rotation mechanism, a driving chain, a bamboo tube loading mechanism, a bamboo tube diameter measurement device, a stepping motor, a cutter combination assembly, a bamboo centring combination assembly, a transmission system, a swinging mechanism, a push plate combination assembly, and a sash weight, and is characterized in that a push plate combination component is arranged on tool body guide rails; a driving chain for driving the push plate combination component to move back and forth is arranged between the two guide rails; a rotational cutter disc combination component is arranged at the front ends of the tool body guide rails; a bamboo tube loading mechanism is arranged on right sides of the tool body guide rails; two movable bamboo tube centering combination components are arranged on the upper left sides of the tool body guide rails; and when the push plate combination component does backlash motion, the bamboo tube loading mechanism conveys a bamboo tube into a measuring device to measure the diameter of a small head of the bamboo tube, the bamboo tube enters two V-shaped bearings, and combination cutters which are matched are rotated to the center of the bamboo tube and aligned; and a transmission system is reversed, and the push plate combination component pushes the bamboo tube to the combination cutters, so that the bamboo tube is split into bamboo chips. Compared with the conventional bamboo splitting machine, the numerical control bamboo splitting machine has the advantages that automatic loading, automatic tool changing and automatic centering of the bamboo tube are realized, one operator is reduced, the labor strength is lowered, the width error of the split bamboo clips is reduced, and the utilization rate of bamboo woods is improved.

Owner:沛县汉腾建设发展有限公司

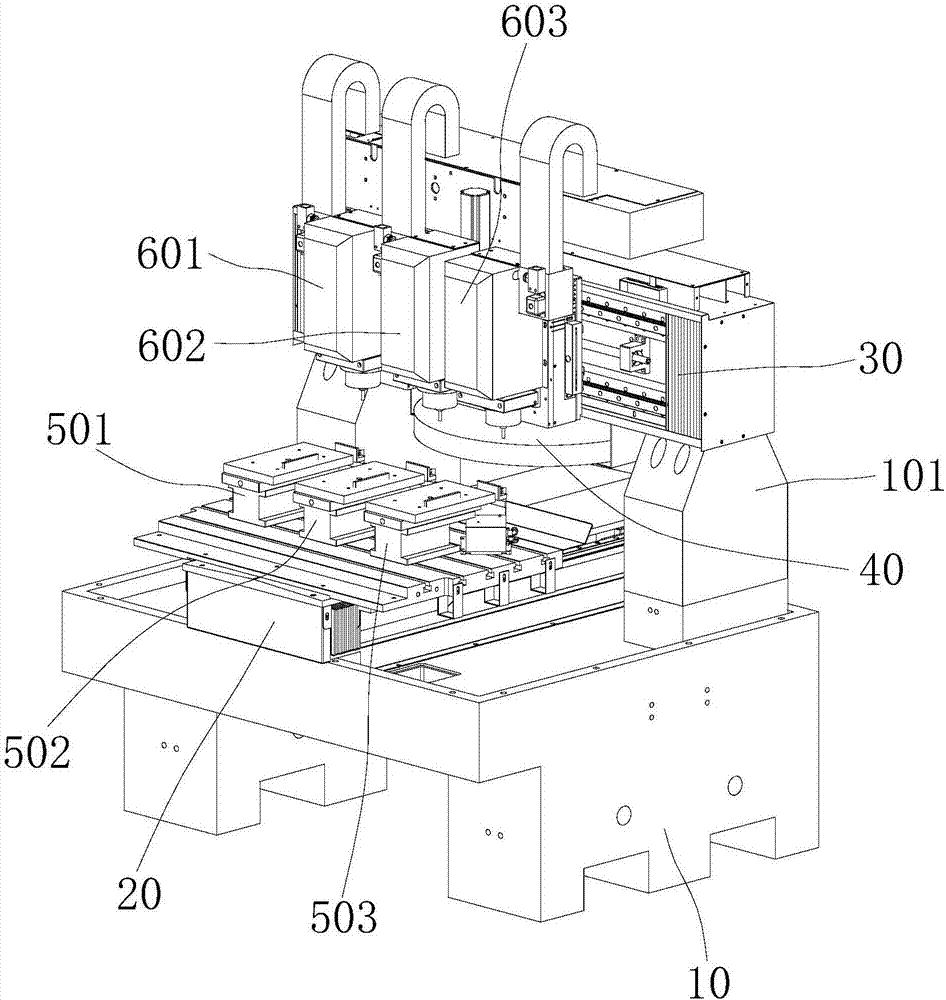

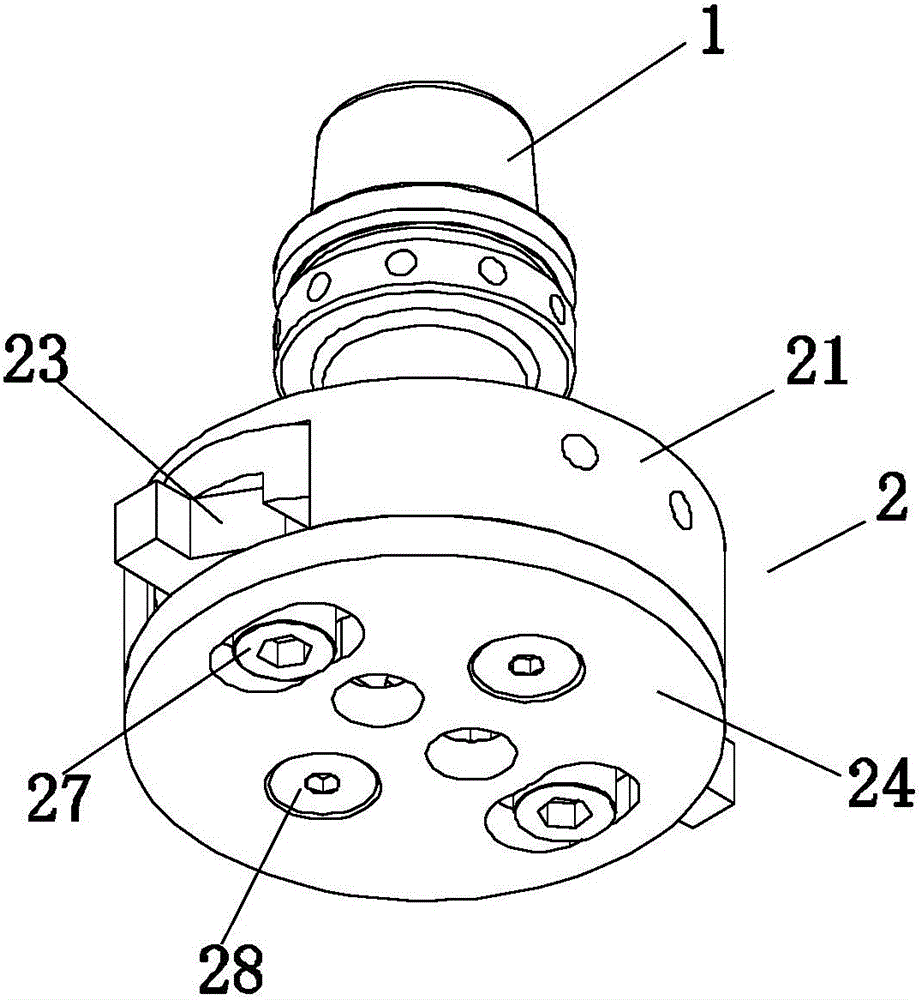

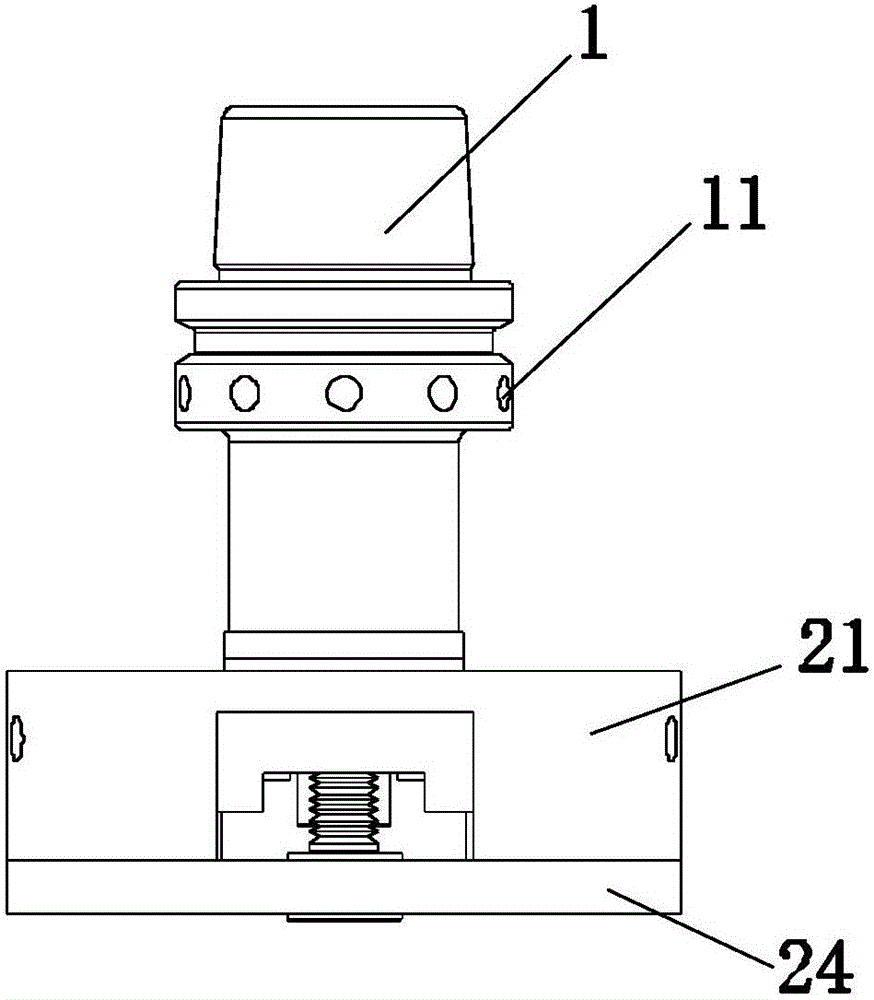

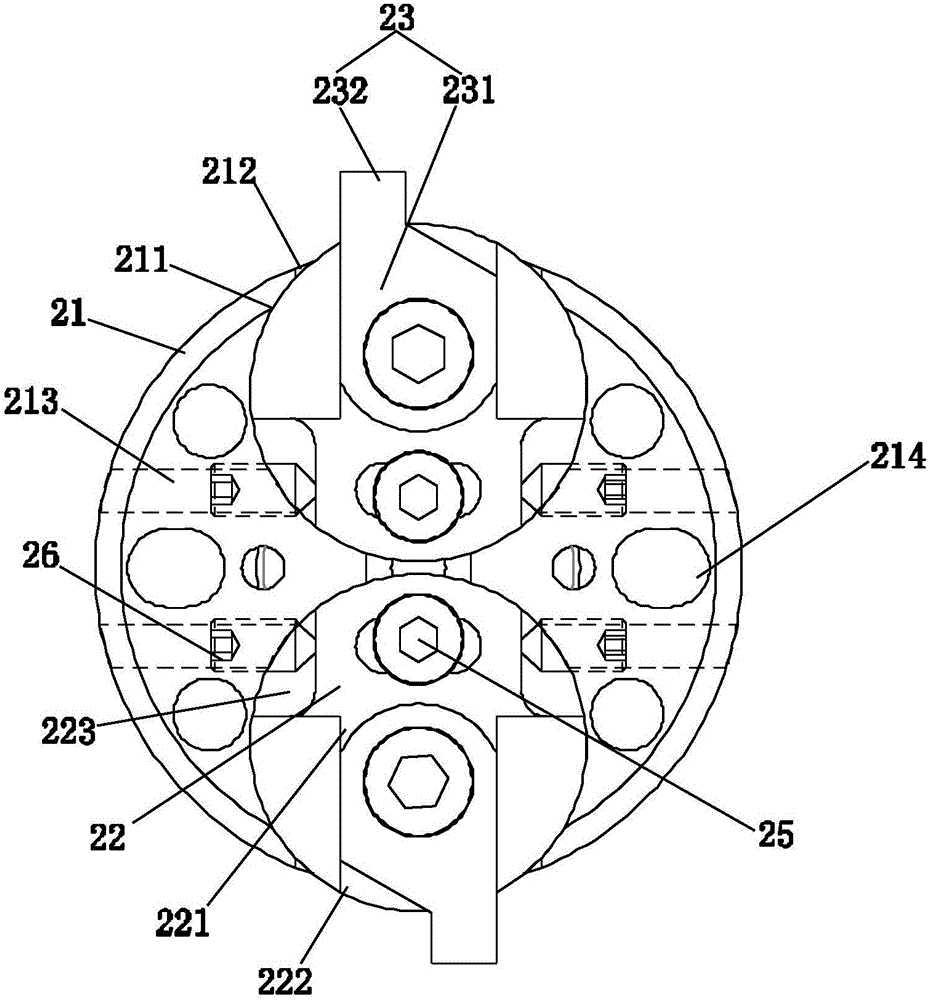

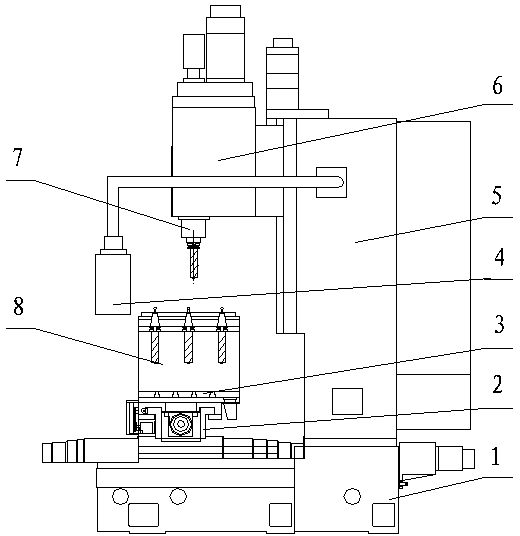

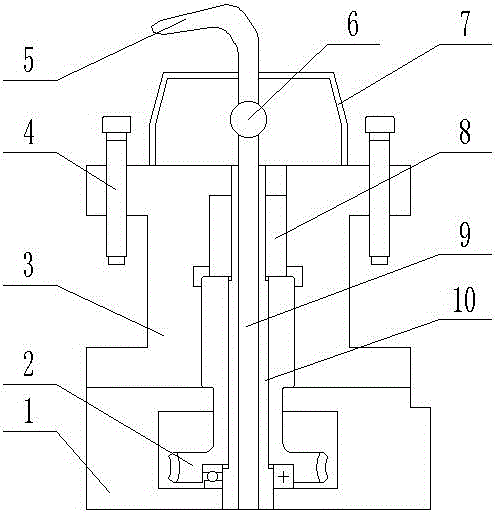

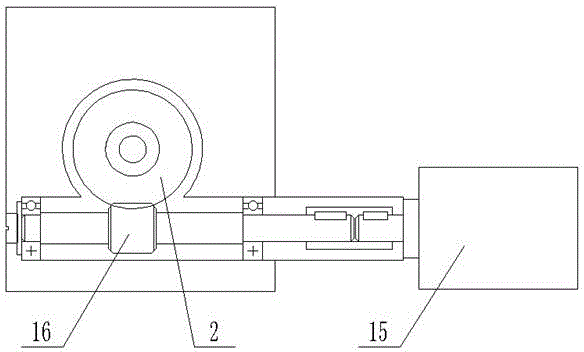

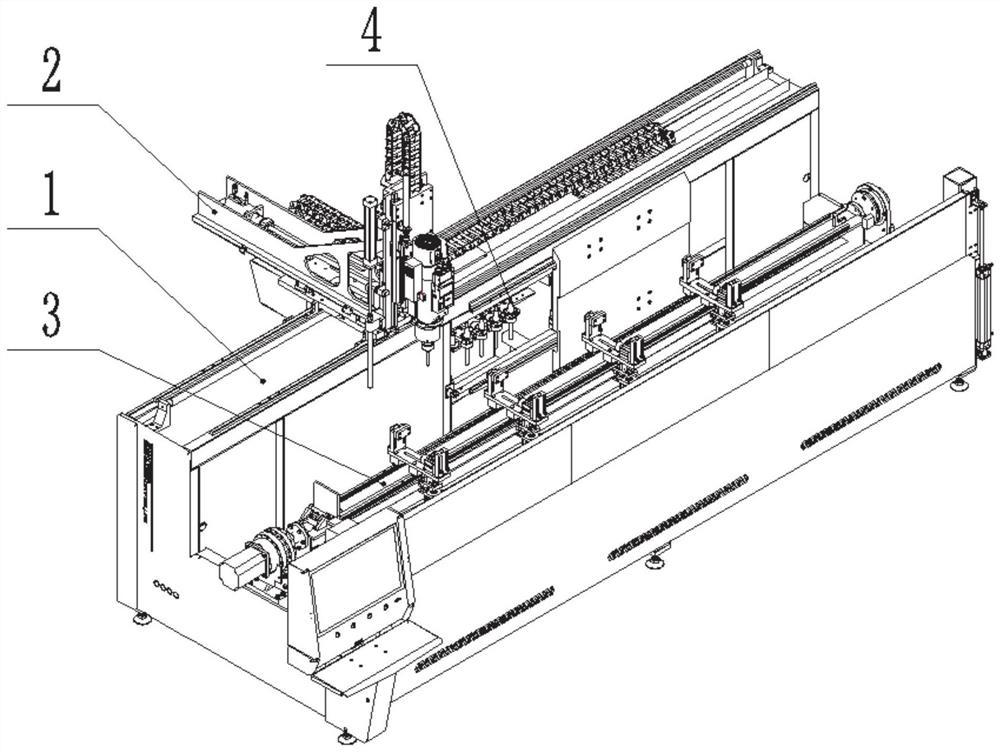

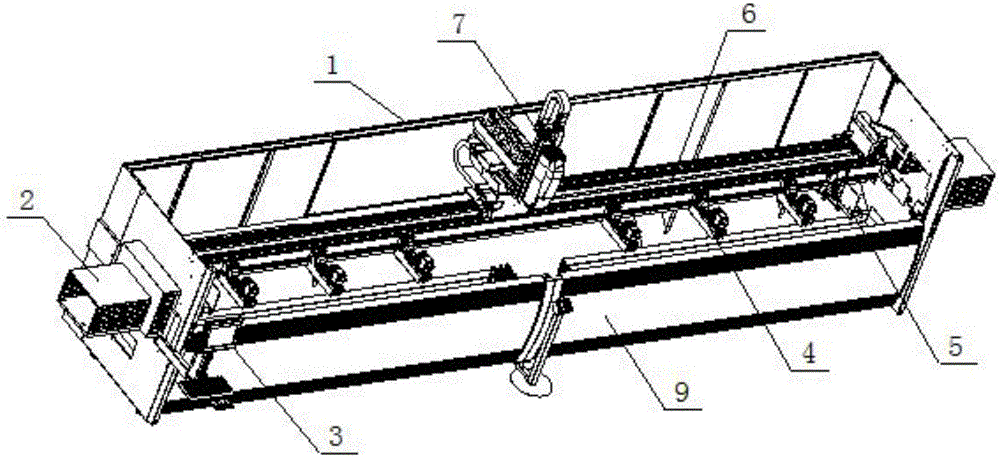

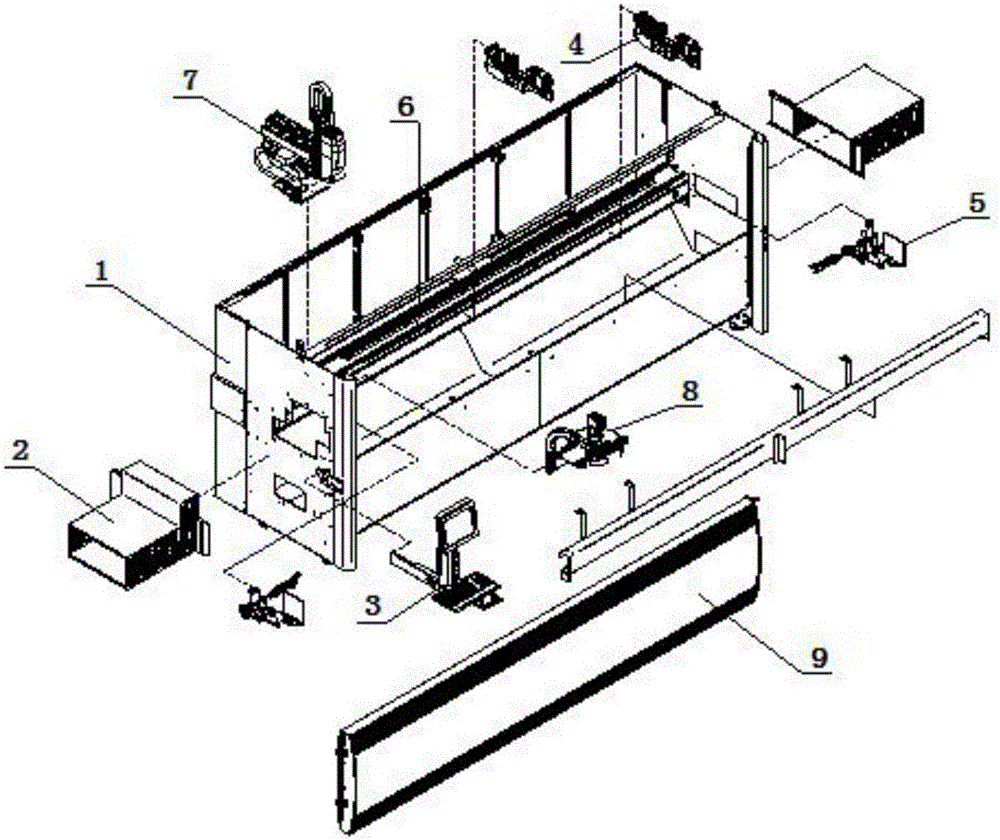

Multi-spindle automatic tool changing device

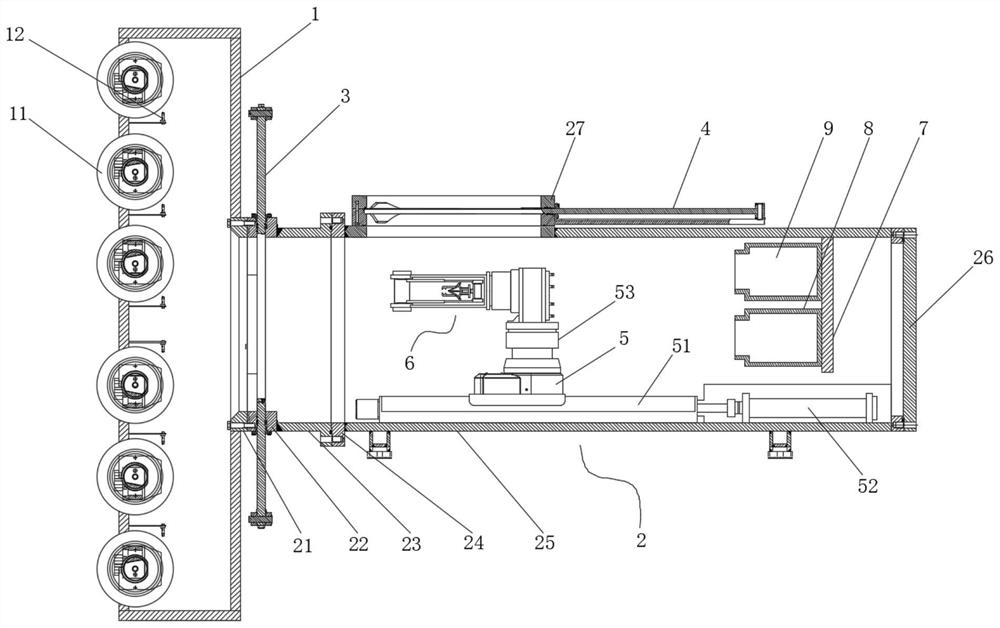

PendingCN107297641AReduce labor intensityRealize automatic tool changeGuardPositioning apparatusNumerical controlAutomatic control

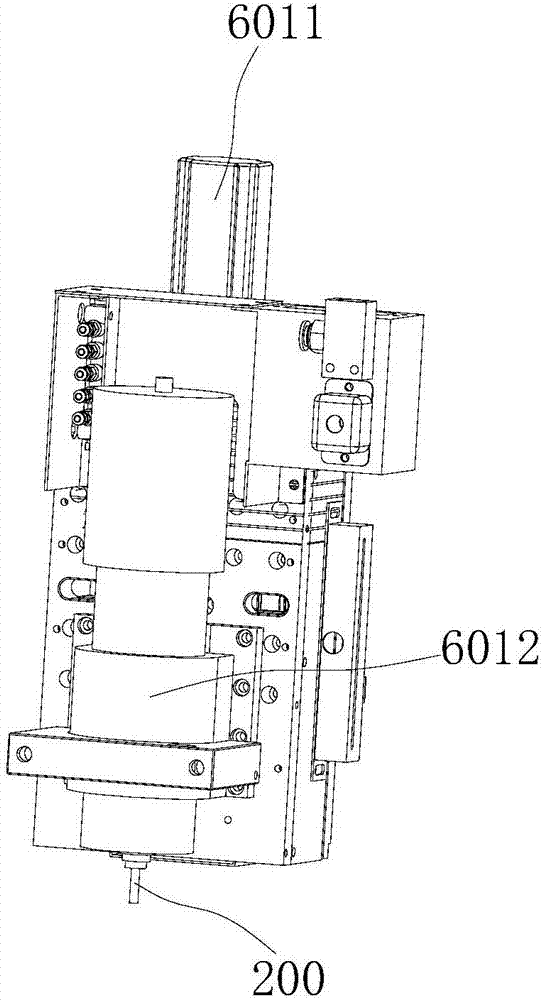

The invention discloses a multi-spindle automatic tool changing device, and relates to the technical field of numerical-control machine tools. The multi-spindle automatic tool changing device comprises a base, an Y-axis worktable, an X-axis movement module, Z-axis spindle machining assemblies, a tool magazine and Z-axis positioning jigs. The Y-axis worktable is positioned on the base, the Z-axis positioning jigs include a Z1-axis positioning jig, a Z2-axis positioning jig and a Z3-axis positioning jig, and the Z1-axis positioning jig, the Z2-axis positioning jig and the Z3-axis positioning jig are arranged on the Y-axis worktable side by side along an X-axis direction; the X-axis movement module is arranged at the rear end of the base, the Z-axis spindle machining assemblies include a Z1 spindle machining assembly, a Z2 spindle machining assembly and a Z3 spindle machining assembly; the tool magazine is arranged below the X-axis movement module. The multi-spindle automatic tool changing device has the advantages that tools can be automatically changed, automatic control can be facilitated, the multi-spindle automatic tool changing device can bring convenience for workers during maintenance and repair, the labor intensity of the workers can be relieved to a great extent, and the production efficiency can be effectively improved.

Owner:SHENZHEN YUANYANG XIANGRUI MACHINERY

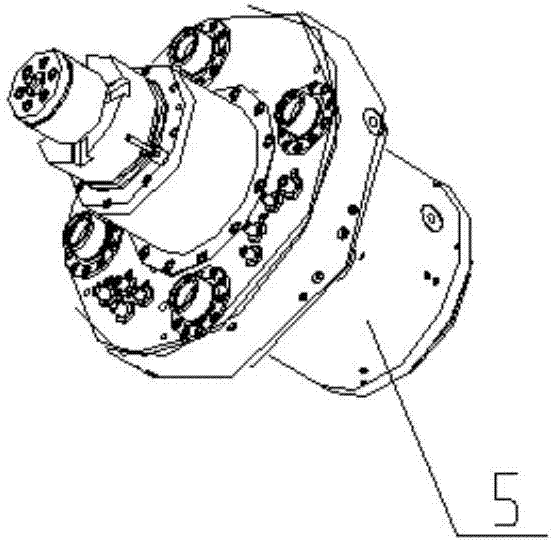

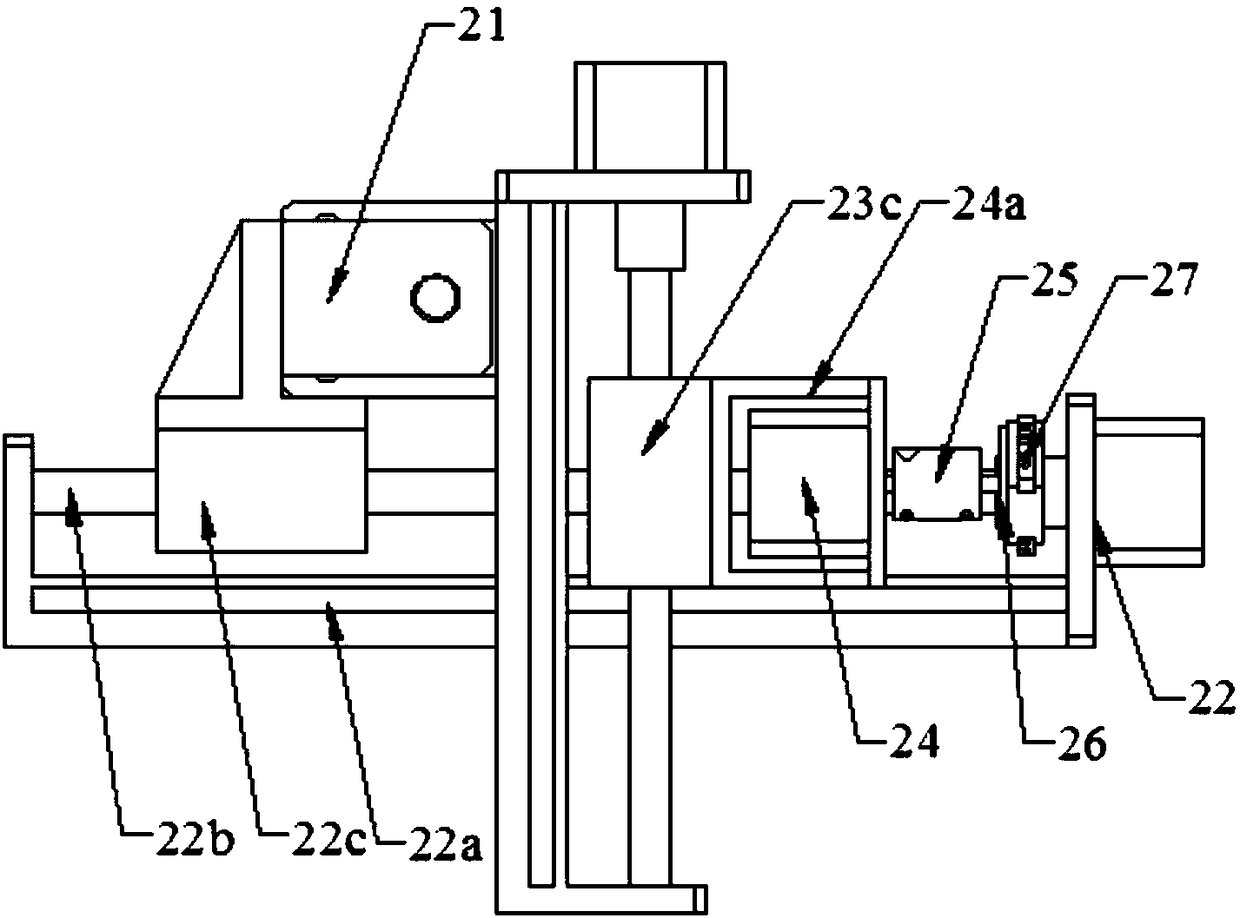

Multi-phase numeric controlled borer with automatic tool changer

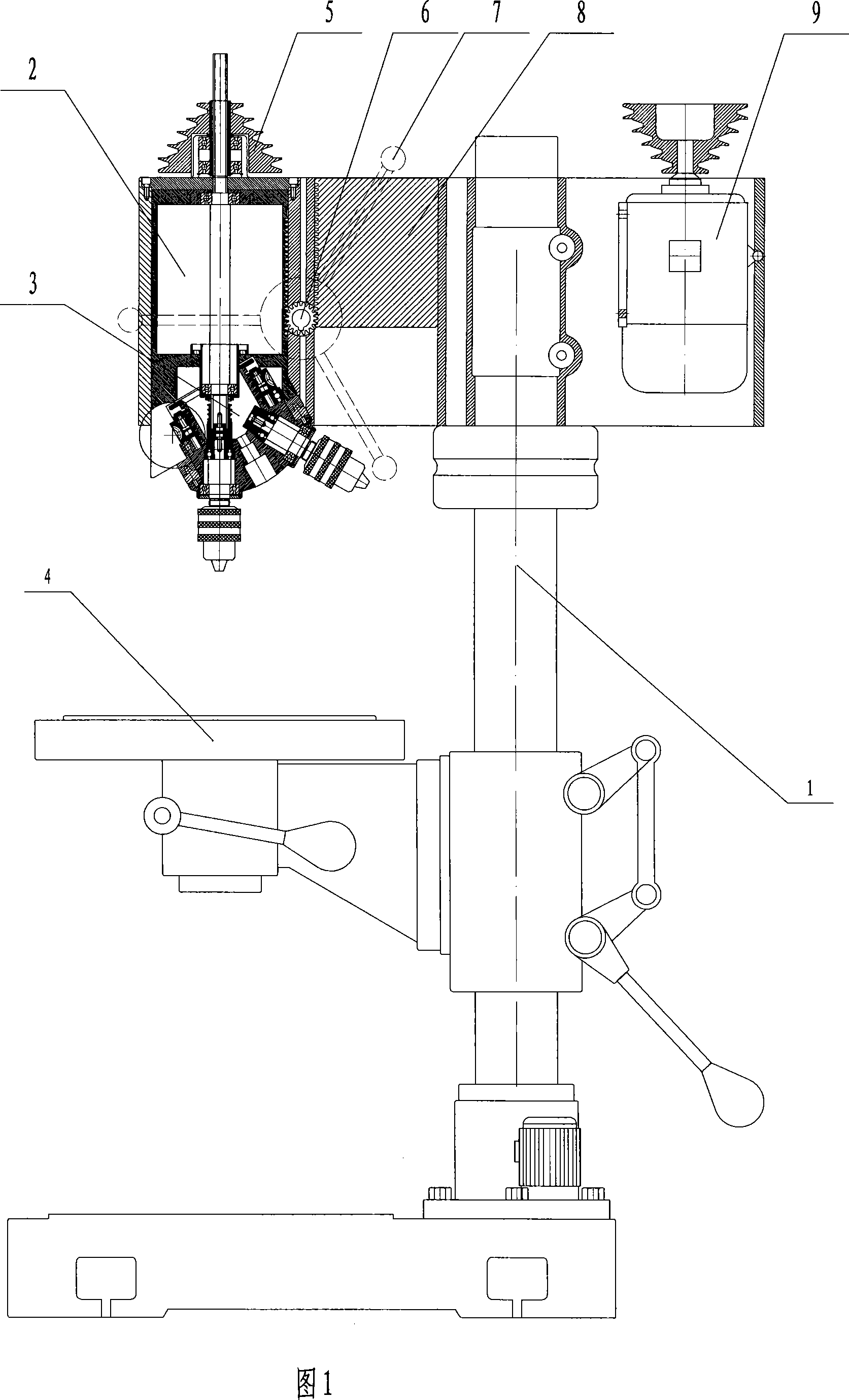

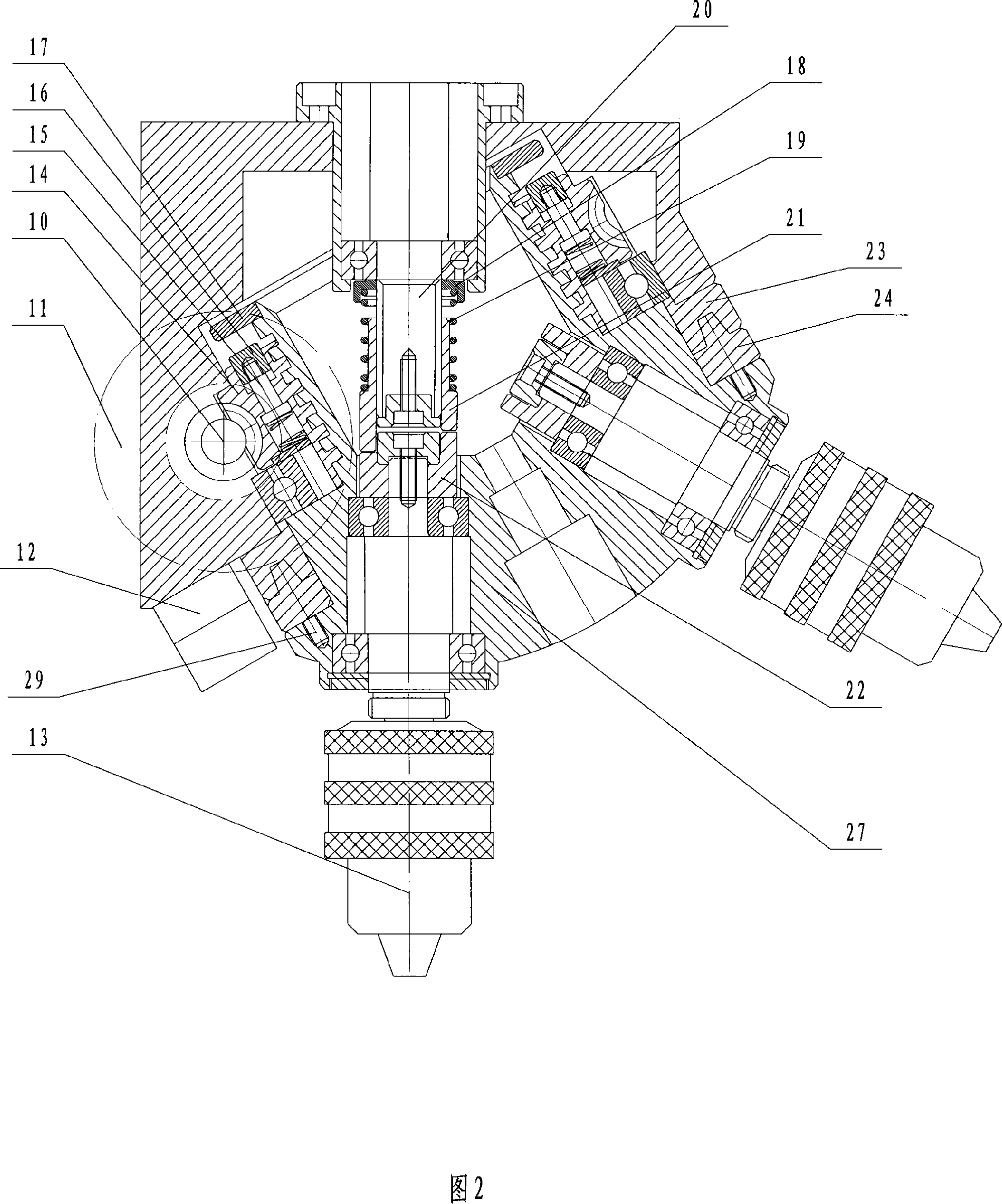

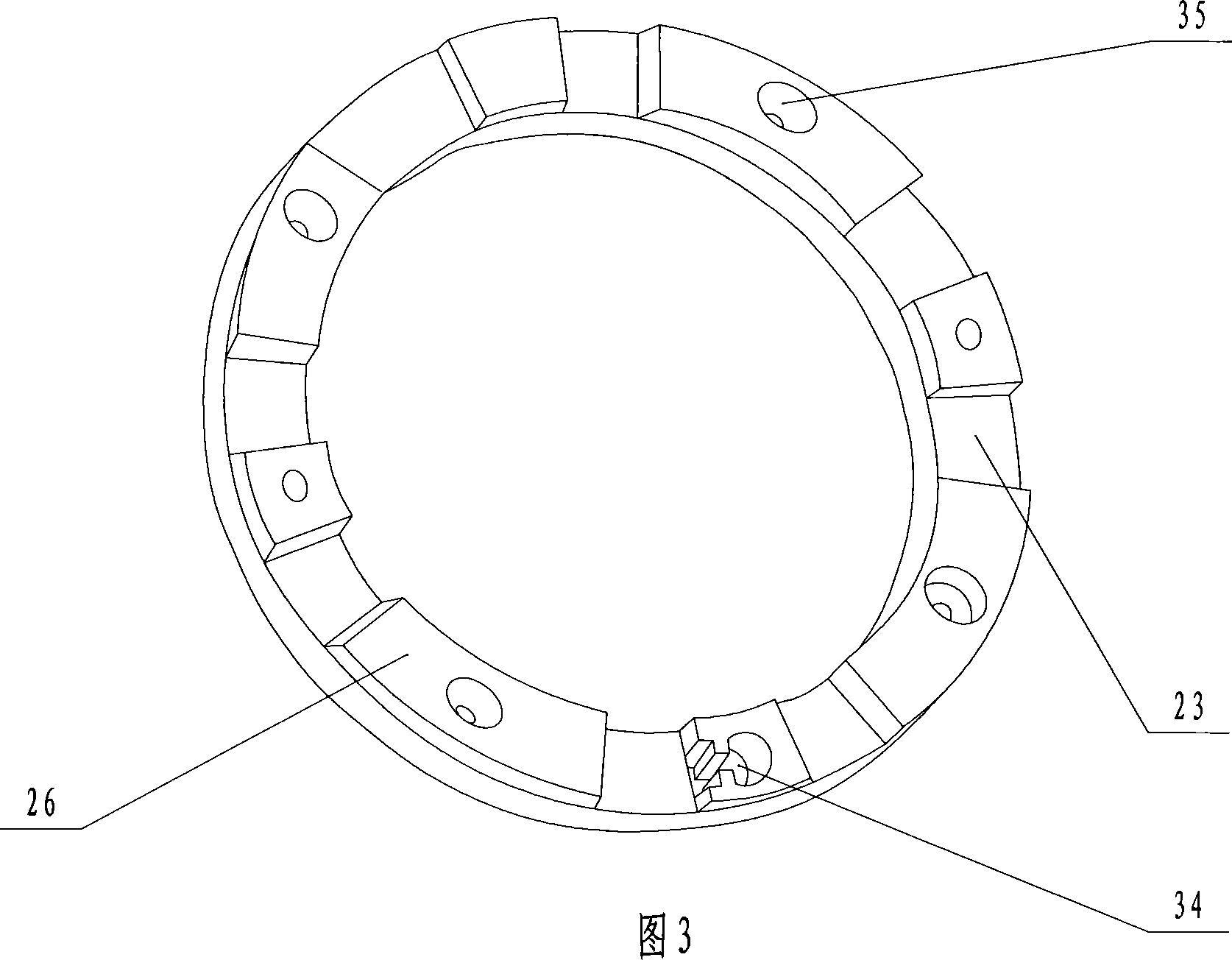

InactiveCN101041226AReduce moving fixturesSave installation spacePositioning apparatusMetal-working holdersCouplingGear wheel

The invention relates to a machine tool in mechanical processing industries, especially the NC multi-position automatic tool changer drilling machine, which comprises frame. On the frame lifting system, working table, tool position changing system and control display system connected with the lifting system are set. The tool position changing system comprises tool changer motor, worm connected with the tool changer motor, worm wheel mated with the worm, tool changer head mated with the worm wheel. There are several tool chucks collocated on the tool changer head and tool chucks are connected with the spindle through coupling. Active end gear is fixed on the tool changer head and fixed end gear mated with the active end gear is fixed on the frame. Moving clamping to workpeice is decreased to improve the working efficiency, improve the machining accuracy, decrease error, reduce the installing space for tool, guarantee worker safety in switching tools and installing workpeice, realize tools in the same axis line to make machining more accurate.

Owner:朱国尚

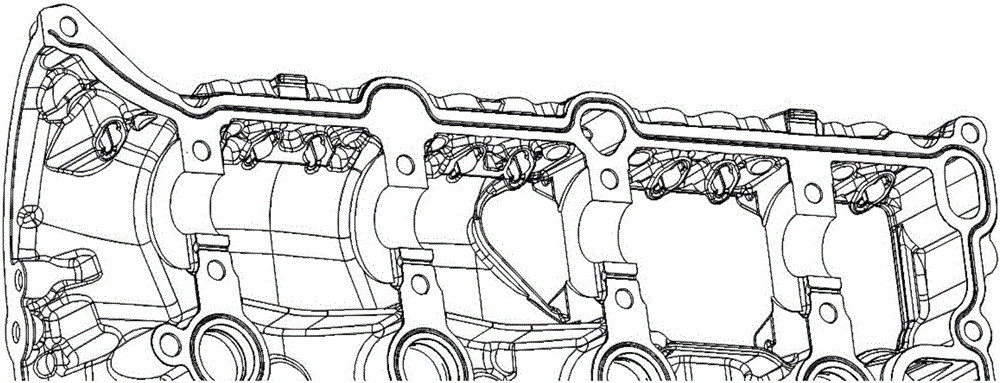

Device for machining multiple surfaces of part

PendingCN106378477ARealize simultaneous processingIncrease productivityMilling equipment detailsDriving apparatusMilling cutterMachine tool

The invention provides a device for machining multiple surfaces of a part. The device comprises a combination type cutter and a part fixing clamp, wherein the combination type cutter is mounted on a machine tool, and the part fixing clamp is mounted on the table surface of the machine tool. When the combination type cutter is fed, a milling cutter disc (124) and a cutter handle shaft (110) are inserted into a hollowed opening (48) of the clamp. The device provided by the invention has the advantages that the simultaneous machining of a plurality of parallel machining surfaces is realized, the machining precision is high, and the device is suitable for parts with complicated shapes.

Owner:CITIC DICASTAL

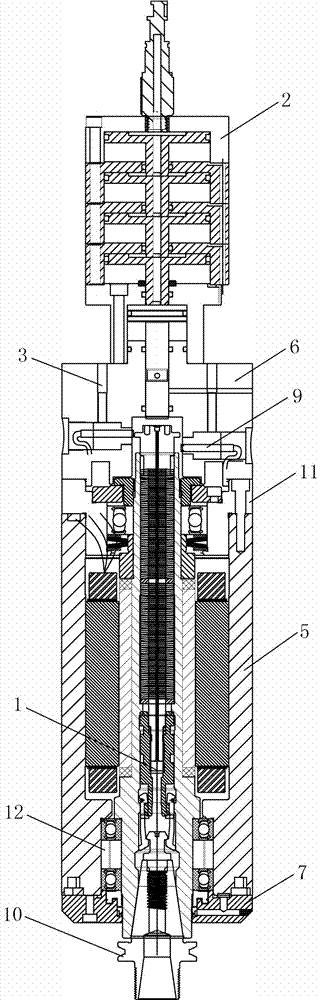

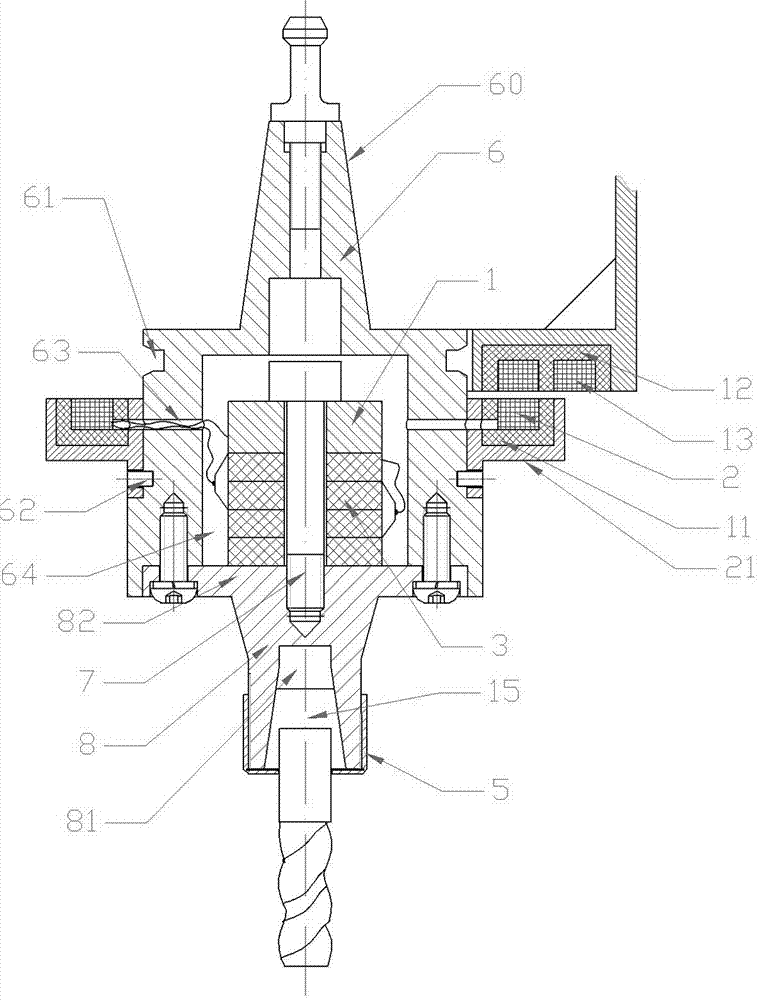

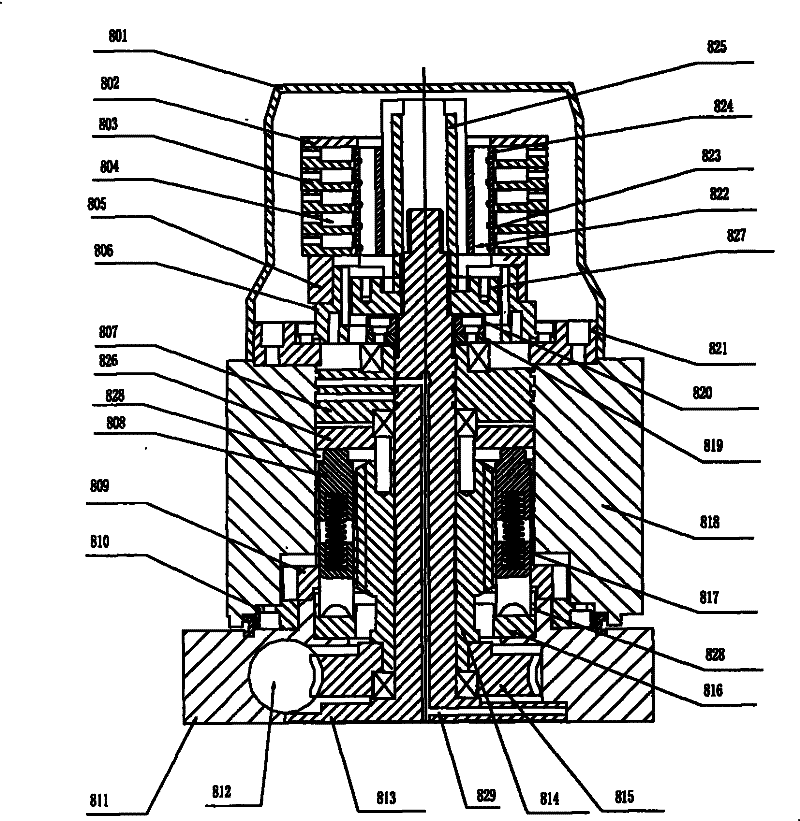

Electric spindle capable of realizing automatic tool changing and provided with build-in shank

PendingCN107042420AImprove structural strengthRealize automatic tool changeFeeding apparatusMaintainance and safety accessoriesBall bearingStator coil

The invention relates to an electric spindle capable of realizing automatic tool changing and provided with a build-in shank. A spindle body is provided with a cooling mechanism and comprises a spindle box, a back seat and a dust cover; spindle assemblies are press-fitted in the spindle box; the back seat and the dust cover are arranged at two ends of the spindle box; the spindle assemblies are fixedly mounted in the spindle box through cooling copper sleeves; a detection device and a control device are arranged on the back seat; one end of each spindle assembly is in transmission connection with a driving device; and the other end of each spindle assembly is detachably connected with an external device. The electric spindle has the beneficial effects as follows: a stator coil outer sleeve is changed from a steel piece into a brass casting, a circulating water-cooling channel is added in the casting outer sleeve, the temperature is prevented from increasing too fast, the operation precision of the spindle is kept, a clamping jaw and the shank are organically combined, meanwhile, a built-in encoder connected with a control center is configured, functions of automatic tool changing, instant accurate stop and the like are realized, a rotor magnetic piece is in short-circuited connection through an end copper ring, the consumption is reduced, a steel angular contact ball bearing is replaced with a ceramic ball bearing, the friction and the heat are reduced, and the life is prolonged.

Owner:岳阳市显隆电机有限公司

Highlight face milling cutterhead and highlight face milling cutter

ActiveCN105772820AImprove the knife patternGood highlight effectMilling cuttersMilling cutterEngineering

The invention discloses a highlight face milling cutterhead. The highlight face milling cutterhead comprises a face milling cutterhead body, two rotating plates, two milling cutters and a cover plate. Two circular grooves are symmetrically distributed in the end face of the face milling cutterhead body. Each rotating plate is installed in one circular groove and provided with a milling cutter installation groove. Each milling cutter comprises a milling cutter handle and a milling cutter head arranged at one end of the milling cutter handle. The milling cutter handles of the milling cutters are fixedly installed in the milling cutter installation grooves. The milling cutter head of each milling cutter sequentially penetrates a second notch and a first notch and extends outwards, wherein the second notch and the first notch correspond to the milling cutter head. The cover plate is fixedly connected with the end face of the face milling cutterhead body. The invention further discloses a highlight face milling cutter. By means of the highlight face milling cutterhead and the highlight face milling cutter, the highlight effect of products can be improved, the mirror surface effect that Ra is smaller than or equal to 25 nm is achieved, and cutter patterns are eliminated; and an upper chamfer and a lower chamfer can be machined at the same time, the machining efficiency is improved, the balance performance of the whole cutterhead can be effectively ensured, and the subsequent balancing difficulty is lowered.

Owner:GUANGZHOU HAOZHI ELECTROMECHANICAL

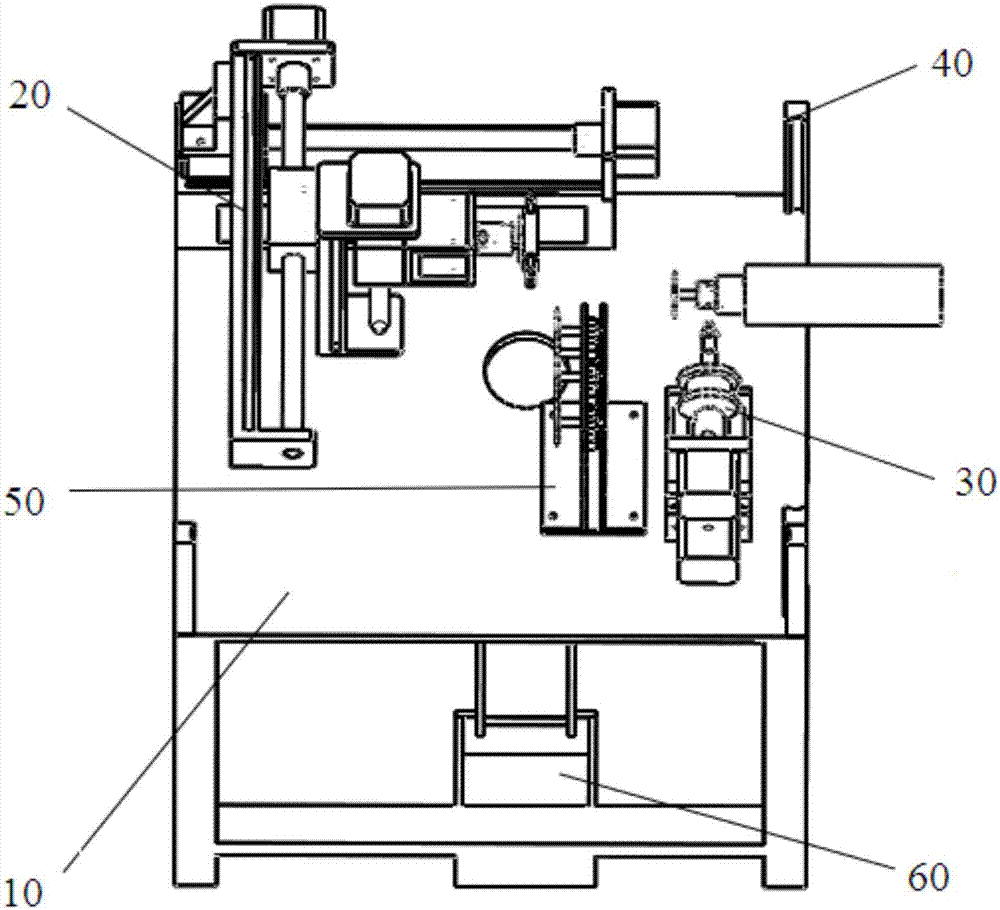

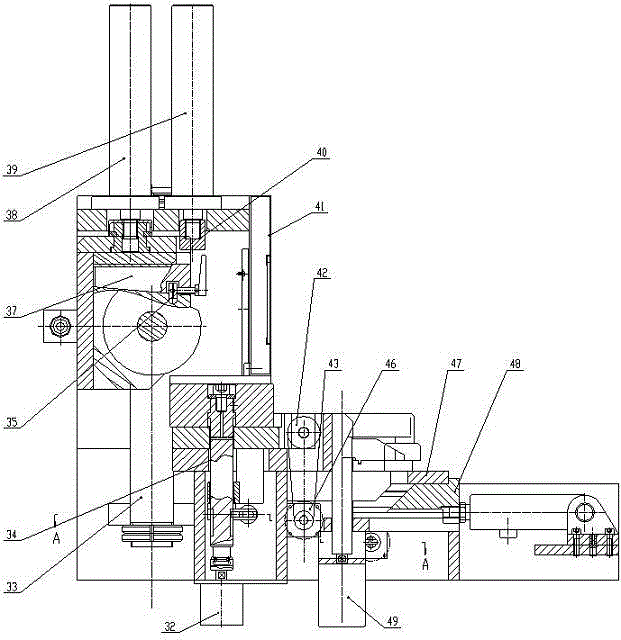

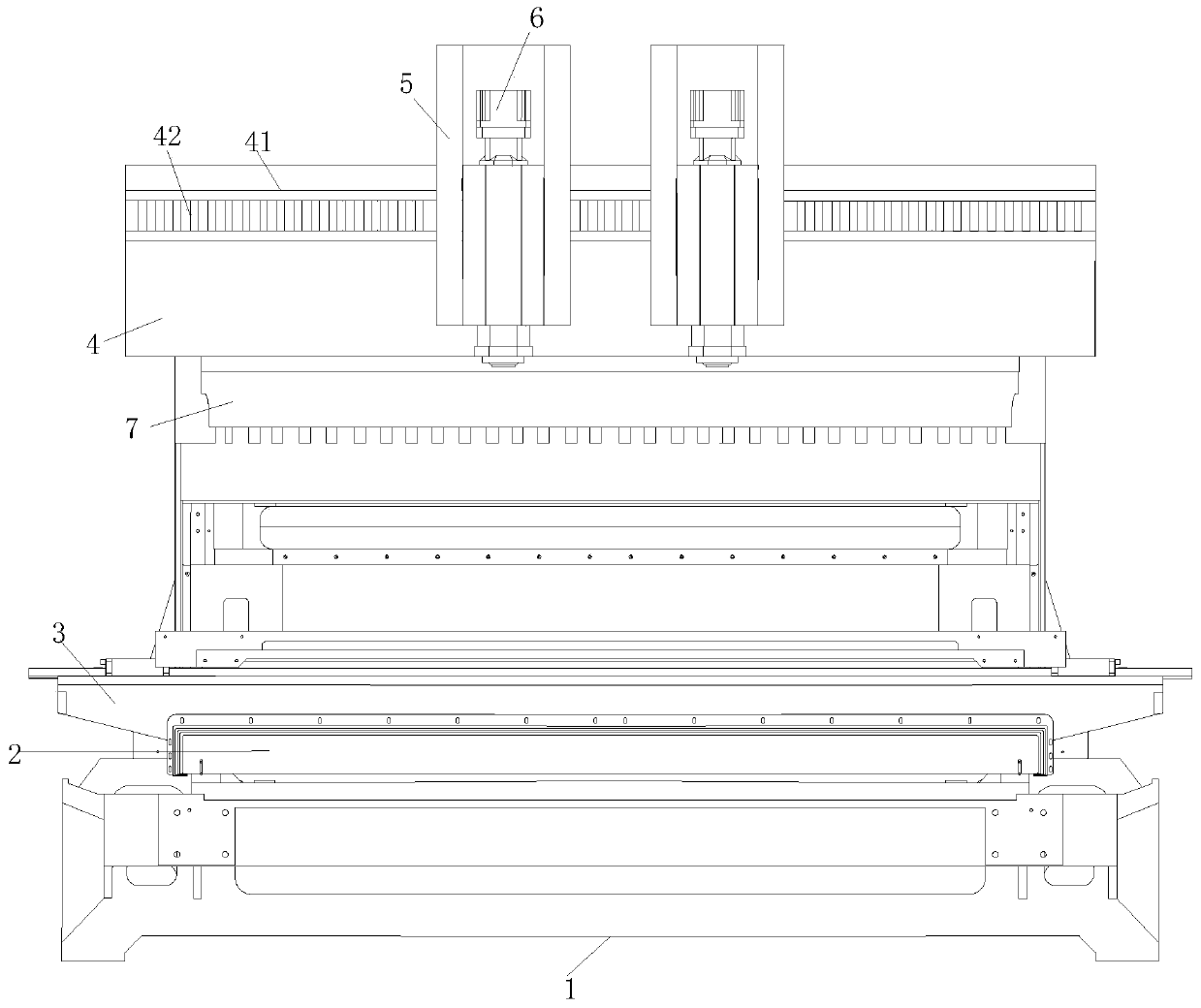

Single-shaft automatic tool-changing type numerically controlled sequential honing machine tool

InactiveCN104209851ASimple structureIncrease the number of knivesAutomatic grinding controlHoning machinesEngineeringChange Type

The invention relates to a honing machine tool, in particular to a single-shaft automatic tool-changing type numerically controlled sequential honing machine tool. The honing machine tool comprises a tool body, a workbench and an upright column, wherein the workbench and the upright column are mounted on the tool body; a main shaft box capable of moving up and down is mounted on the upright column. The single-shaft automatic tool-changing type numerically controlled sequential honing machine tool is characterized in that the workbench is composed of a sliding seat and a workbench body; the sliding seat is capable of horizontally and longitudinally moving; the workbench body is mounted on the sliding seat and is capable of horizontally and transversely moving; a tool magazine is fixedly mounted on one side of the workbench; a main shaft positioning device is mounted in the main shaft box; a tool changing device is mounted on the main shaft; movement, rotation and positioning of the workbench, the main shaft box and the main shaft can be controlled through a numerical control system. The single-shaft automatic tool-changing type numerically controlled sequential honing machine tool is simple in structure, low in production cost and using cost, high in automation degree and easy to operate; the functions of automatic tool changing, multi-workpiece machining, tool length and radius compensation and the like can be achieved; the labor intensity of workers can be greatly alleviated; the functions of drilling, milling, boring and the like can be achieved; the honing machine tool has the characteristic of being multi-purpose.

Owner:NINGXIA YINCHUAN DAHE CNC MACHINE

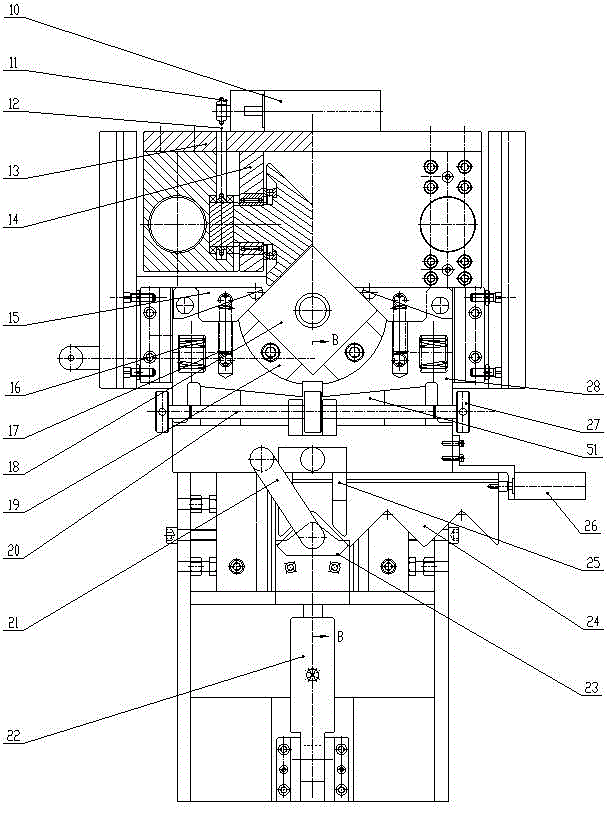

Multi-shaft high-speed numerically controlled lathe

InactiveCN106514260AResolve swingImprove stabilityOther manufacturing equipments/toolsTool holdersCantileverMachining

The invention relates to a multi-shaft high-speed numerically controlled lathe. The multi-shaft high-speed numerically controlled lathe comprises a slant bed lathe body which is provided with a main machine and a slant bed body assembly. A four-station electric tool carrier and a lathe spindle are mounted on the slant bed body assembly, wherein an additional machining shaft system assembly which is arranged perpendicular to the lathe spindle is further mounted on a spindle box; a second fixed seat is arranged on the lateral side of the slant bed body assembly on the main machine; and an auxiliary centering assembly opposite to the lathe spindle is mounted above the second fixed seat. According to the multi-shaft high-speed numerically controlled lathe provided by the invention, a machining shaft is additionally arranged; on the basis of the original machining shaft which machines an excircle, the additionally arranged machining shaft can perform operations such as chamfering and groove milling simultaneously, so that the production efficiency and the machining precision are greatly improved; the auxiliary centering assembly is a three-finger pneumatic finger, and a guide rail and sliding tables are arranged at the bottom of the three-finger pneumatic finger, so that a cantilever of the centering assembly can be prevented from being overlong, and the stability of the centering assembly is greatly improved.

Owner:DONGGUAN HONGJINSHUN MACHINERY MFG

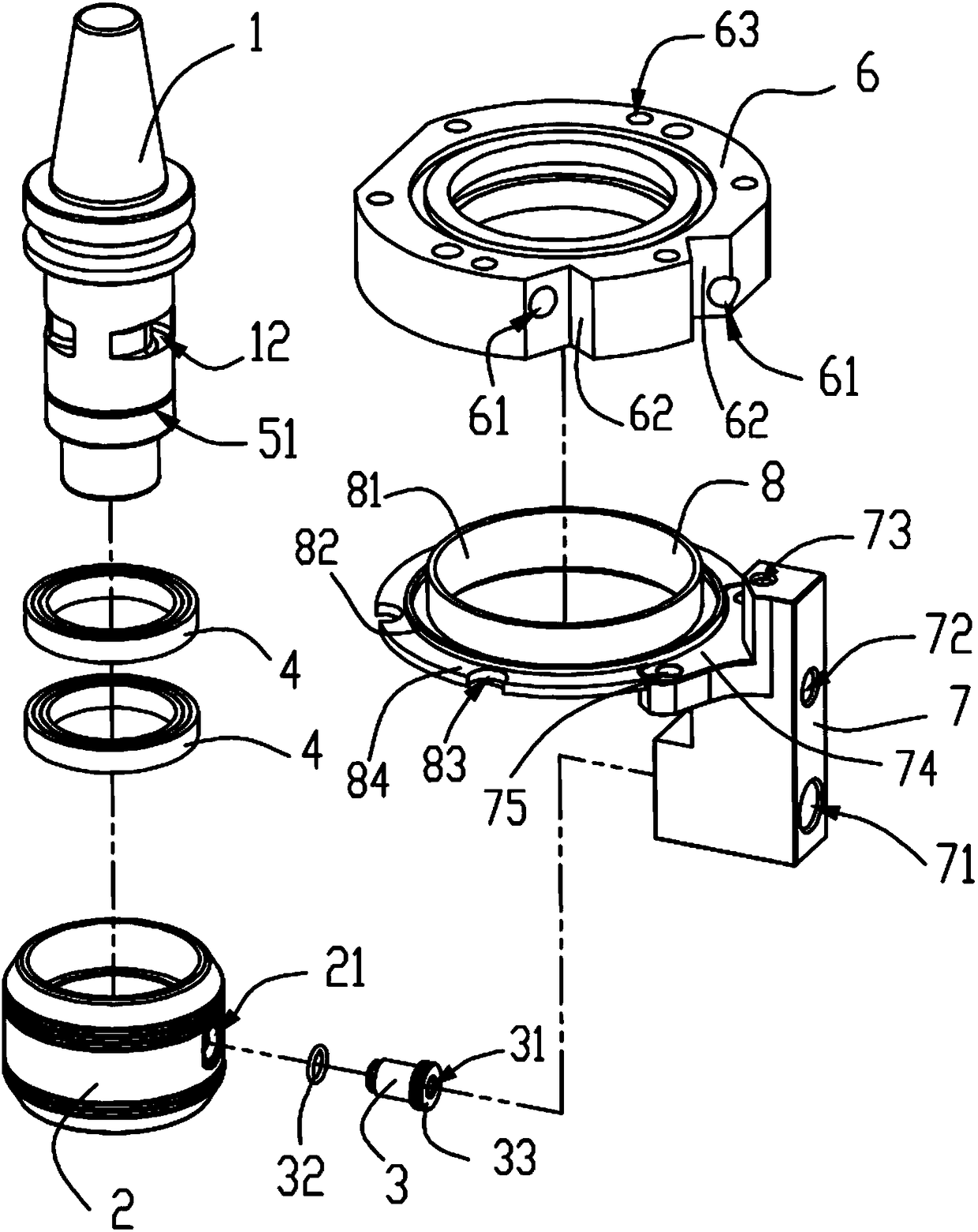

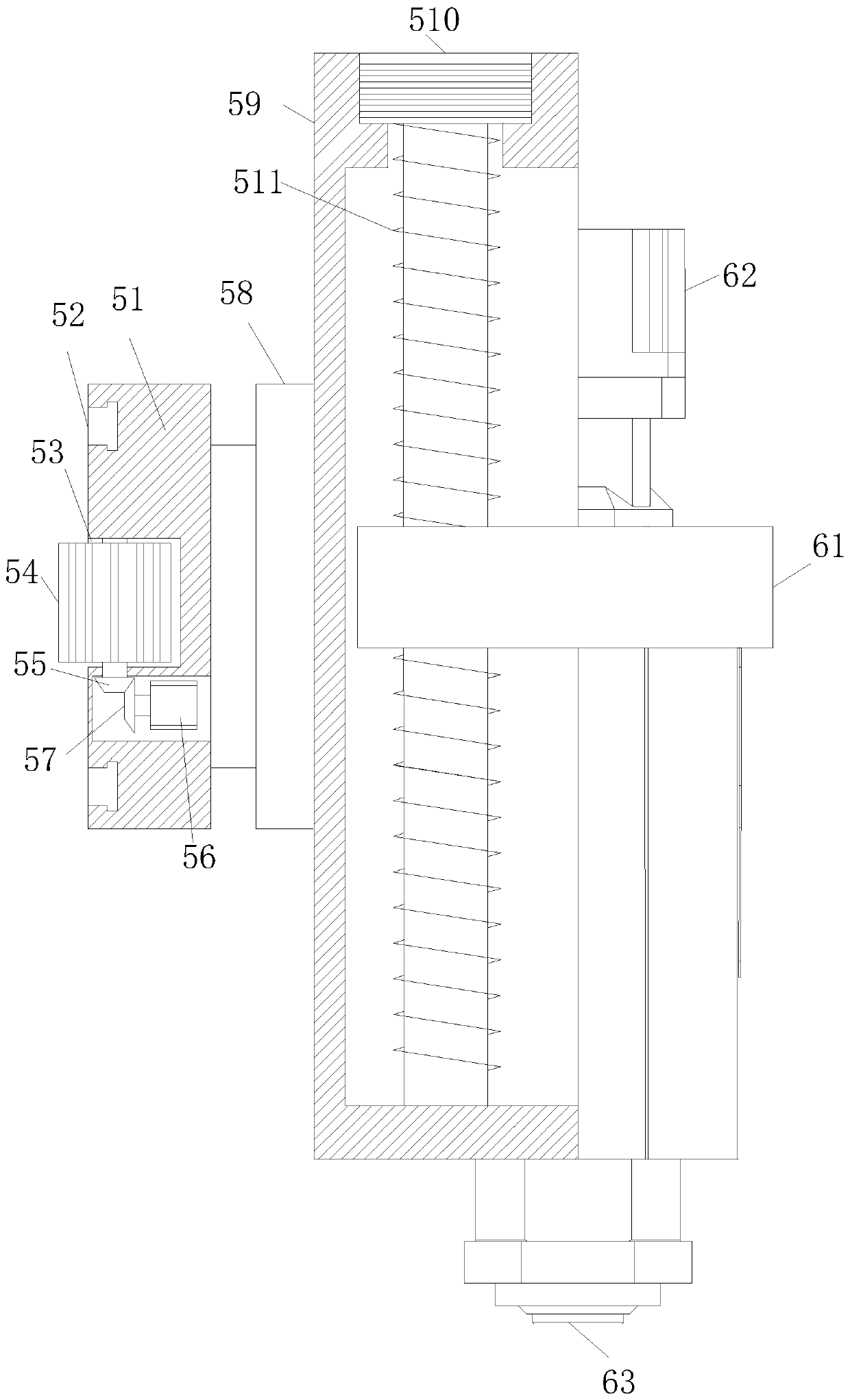

Ring compression type wireless electric energy transmission system suitable for automatic tool change of ultrasonic machining center

PendingCN107124042ARealize automatic tool changeImproving the Efficiency of Ultrasonic Vibration MachiningTransformersCircuit arrangementsElectricityCoaxial line

The invention discloses a ring compression type wireless electric energy transmission system suitable for automatic tool change of an ultrasonic machining center; a disc-shaped electric energy receiving part arranged on a tool holder is internally provided with a disc-shaped ferrite and a disc-shaped electric energy receiving coil; the disc-shaped electric energy receiving part and the tool holder are coaxially arranged; a quarter disc-shaped electric energy emission coil bracket is arranged at the bottom of a spindle shell of the ultrasonic machining center and is provided with a quarter disc-shaped ferrite and a quarter disc-shaped electric energy emission coil; the quarter disc-shaped electric energy emission coil and the disc-shaped electric energy receiving coil are coaxially arranged and are correspondingly overlapped up and down with a mounting gap; the end surfaces of the quarter disc-shaped electric energy emission coil and the disc-shaped electric energy receiving coil are arranged opposite to each other; and a piezoelectric ceramic is fixed on an amplitude varying pole through a piezoelectric ceramic pressure plate and a bolt. In the premise without changing an existing machining center machine tool, the ring compression type wireless electric energy transmission system can conveniently enable the ultrasonic machining center machine tool to satisfy the function of automatic tool change and improves the ultrasonic vibration machining efficiency.

Owner:CONPROFE TECH GRP CO LTD +1

Dual-specification tool holder automatic tool changing device for five-axis gantry machining center with multifunctional cutter head

PendingCN107139001AReduce restrictionsRealize automatic tool changePositioning apparatusMetal-working holdersArm movingChain type

The invention relates to a dual-specification tool holder automatic tool changing device for a five-axis gantry machining center with a multifunctional cutter head, and belongs to the technical field of numerically controlled machining centers. The dual-specification tool holder automatic tool changing device is mounted on the rear side of the five-axis gantry machining center and comprises a tool magazine and a tool changing mechanism, wherein the tool magazine is a chain type tool magazine; tool sleeves with two different specifications are arranged in the tool apron hole of the chain type tool magazine; the tool changing mechanism comprises a tool changing arm and a tool changing arm moving device; the tool changing arm moving device is mounted on the inner side of the tool magazine; the tool changing arm is rotatably mounted on the tool changing arm moving device and performs turnover movement through a turnover oil cylinder; a rotary motor is arranged on the tool changing arm; and a pair of tool jaws I and a pair of tool jaws II are arranged on the tool changing arm. According to the dual-specification tool holder automatic tool changing device for the five-axis gantry machining center with the multifunctional cutter head, through the coordination of the four tool jaws and the tool magazine, the automatic tool changing of the multifunctional cutter head with different types of tool holders is realized, cutter heads with different types of tool holders can be configured, and the functional limitation on the cutter head is reduced.

Owner:SHANDONG YONGHUA MACHINERY

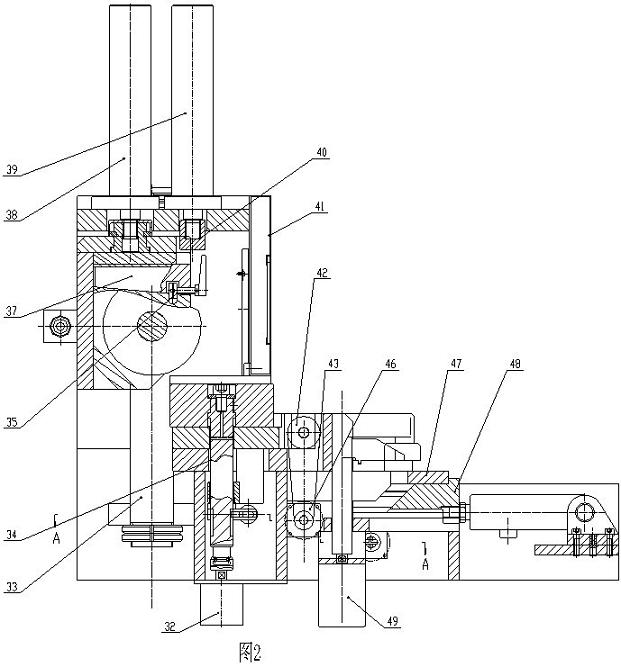

Novel numerical control bamboo splitting machine

ActiveCN102717414BPrevent chain breaksRealize automatic feeding processWood splittingVeneer manufactureNumerical controlMeasurement device

The invention relates to a novel numerical control bamboo splitting machine, which includes a lathe bed guide rail, a rotation mechanism, a driving chain, a bamboo tube loading mechanism, a bamboo tube diameter measurement device, a stepping motor, a cutter combination assembly, a bamboo centring combination assembly, a transmission system, a swinging mechanism, a push plate combination assembly, and a sash weight, and is characterized in that a push plate combination component is arranged on tool body guide rails; a driving chain for driving the push plate combination component to move back and forth is arranged between the two guide rails; a rotational cutter disc combination component is arranged at the front ends of the tool body guide rails; a bamboo tube loading mechanism is arranged on right sides of the tool body guide rails; two movable bamboo tube centering combination components are arranged on the upper left sides of the tool body guide rails; and when the push plate combination component does backlash motion, the bamboo tube loading mechanism conveys a bamboo tube into a measuring device to measure the diameter of a small head of the bamboo tube, the bamboo tube enters two V-shaped bearings, and combination cutters which are matched are rotated to the center of the bamboo tube and aligned; and a transmission system is reversed, and the push plate combination component pushes the bamboo tube to the combination cutters, so that the bamboo tube is split into bamboo chips. Compared with the conventional bamboo splitting machine, the numerical control bamboo splitting machine has the advantages that automatic loading, automatic tool changing and automatic centering of the bamboo tube are realized, one operator is reduced, the labor strength is lowered, the width error of the split bamboo clips is reduced, and the utilization rate of bamboo woods is improved.

Owner:沛县汉腾建设发展有限公司

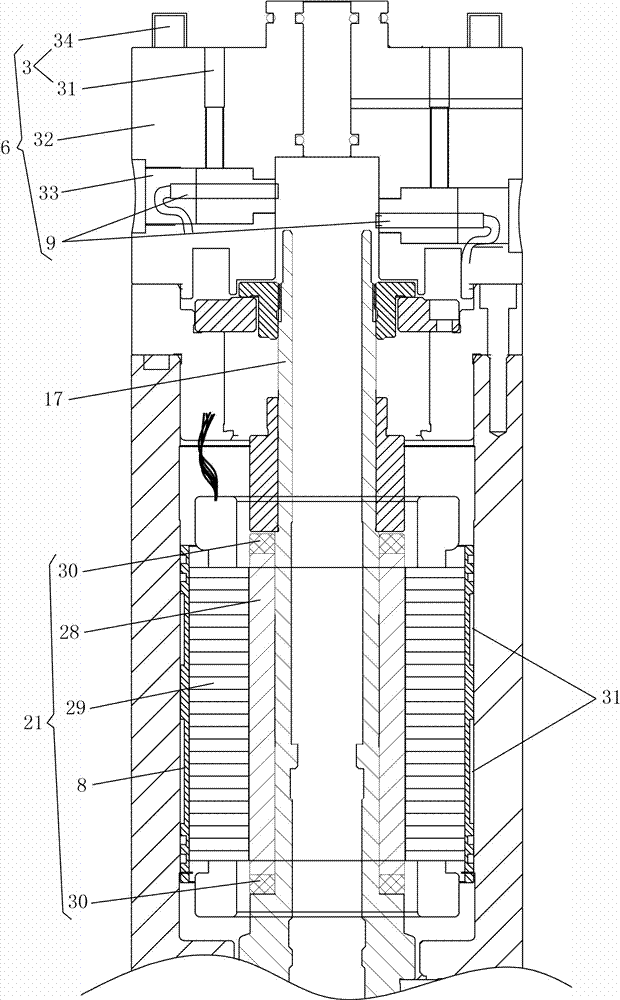

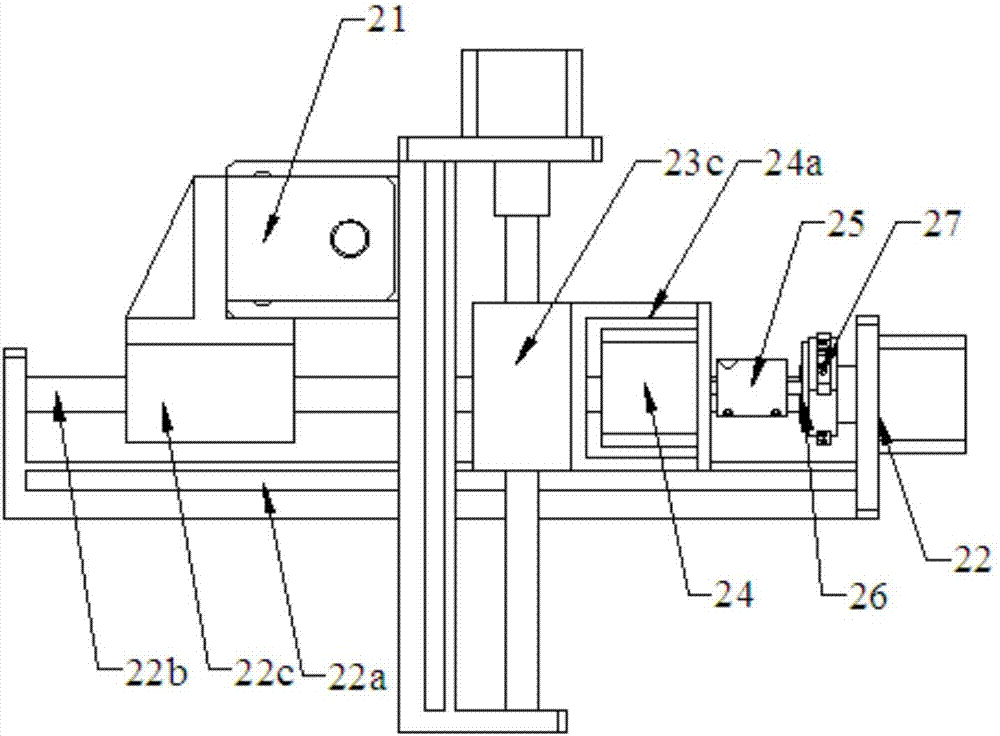

Double transducer type ultrasonic clear-cut finishing device capable of tool changing in computerized numerical control

InactiveCN108723695AEasy to installGood finishing effectMetal working apparatusPositioning apparatusKnife handlesEngineering

The invention discloses a double transducer type ultrasonic clear-cut finishing device capable of tool changing in computerized numerical control. An elastic telescopic mechanism which is composed ofan outer sleeve (4) and an inner sleeve (5) is arranged at the lower part of a knife handle; the inner sleeve (5) is internally provided with an ultrasonic transducer (3), an energy-transmitting receiver (11) and a second energy-transmitting receiver (9) are arranged on the outer sleeve (4), and a second ultrasonic transducer (6) is arranged in the second energy transmission receiver (9); the upper end of the second ultrasonic transducer (6) is bulged and is in contact with the lower end of the ultrasonic transducer(3) to accept the high-frequency mechanical impact emitted by the ultrasonic transducer (3), and the lower end of the second ultrasonic transducer (6) is fixedly connected with the upper end of an amplitude-variable rod (7), and the lower end of the amplitude-variable rod (7) isfixedly connected with a tool head (8). The double transducer type ultrasonic clear-cut finishing device capable of tool changing in the computerized numerical control has the advantages of being convenient to install and capable of realizing automatic tool changing, the clear-cut finishing effect is good, the precision is high, and the tool can obtain larger impact force and ultrasonic energy.

Owner:XIAN AVIATION BRAKE TECH

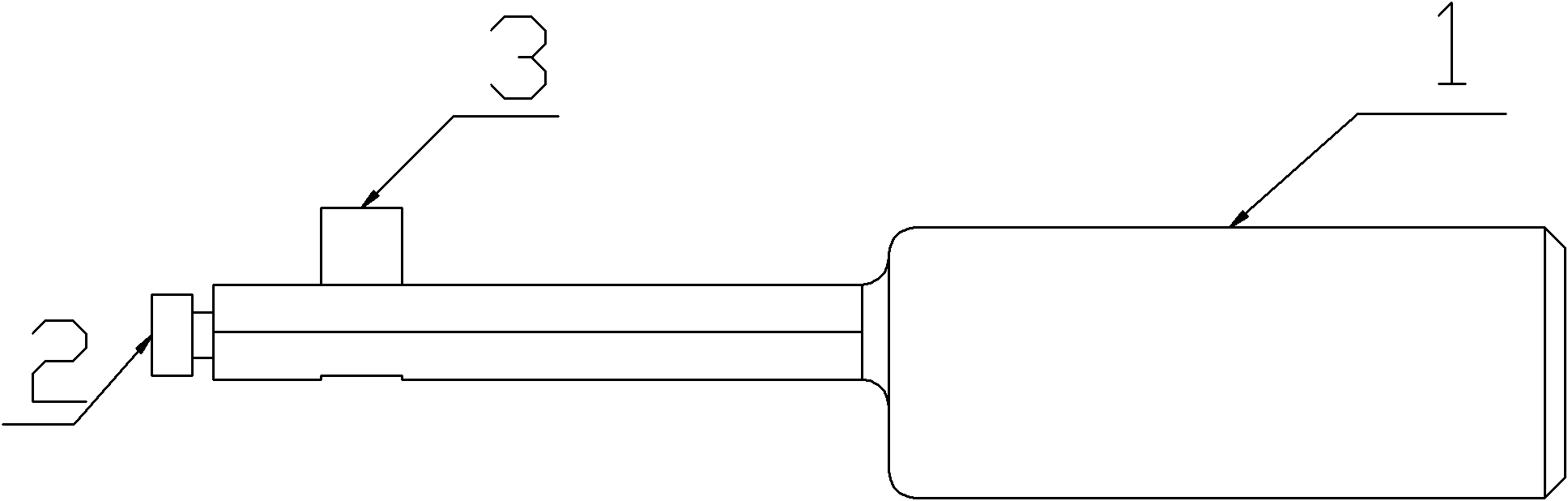

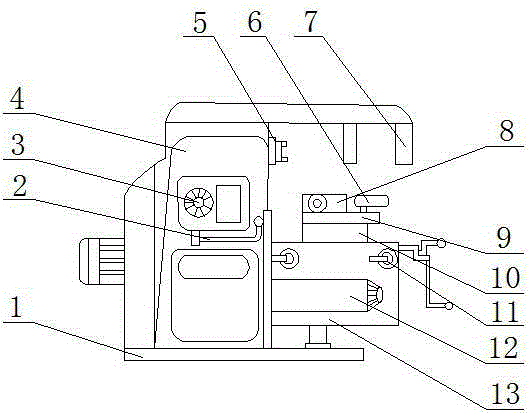

Milling machine

InactiveCN103008738AHigh working reliabilityReduce the number of tool changesMilling machinesPositioning apparatusMachineIndustrial engineering

The invention discloses a milling machine. The milling machine comprises a machine body, a workbench and a sliding rail, and is characterized by further comprising a milling head (1), a cutter (2), an automatic cutter feeding device (3) sliding transversely and a manual cutter feeding device sliding longitudinally. An adjusting technology of the milling machine can reduce the cutter changing times to the maximum extent and facilitates manual change of the cutter; and a machining center can automatically change the cutter, so that on the premise of meeting machining requirements, through reduction of the cutter changing times, the auxiliary time can be saved and the working reliability of the milling machine can be improved.

Owner:DALIAN HENRY CASTING

Back spot facing machining cutter and application method thereof

InactiveCN102009196ASolve manual loading and unloading knivesResolve downtimeTurning toolsEngineeringMachining process

The invention discloses a back spot facing machining cutter and an application method thereof. The cutter comprises a cutter bar, a cutter head and a bolt, wherein a cutter head mounting hole is formed on the front part of the cutter bar, and the cutter head is fixed in the cutter head mounting hole; a threaded through hole is formed at the front end of the cutter bar, and the bolt is arranged in the through hole; and the bolt is fixedly connected with the cutter head. The back spot facing machining cutter has the advantages that: the problems of manual cutter assembly and disassembly, shut down and low machining efficiency during the traditional machining process of back spot facing can be solved by designing the special back spot facing machining cutter which has a smart manufacturing structure and is simple and practical, and automatic machining process of the back spot facing is realized; a special cutter is provided for the equipment with high machining automation degree, such as horizontal machining equipment, vertical machining equipment and the like, a mechanical arm can automatically change a cutter, and the machining efficiency can be greatly improved.

Owner:CHINA XD ELECTRIC CO LTD

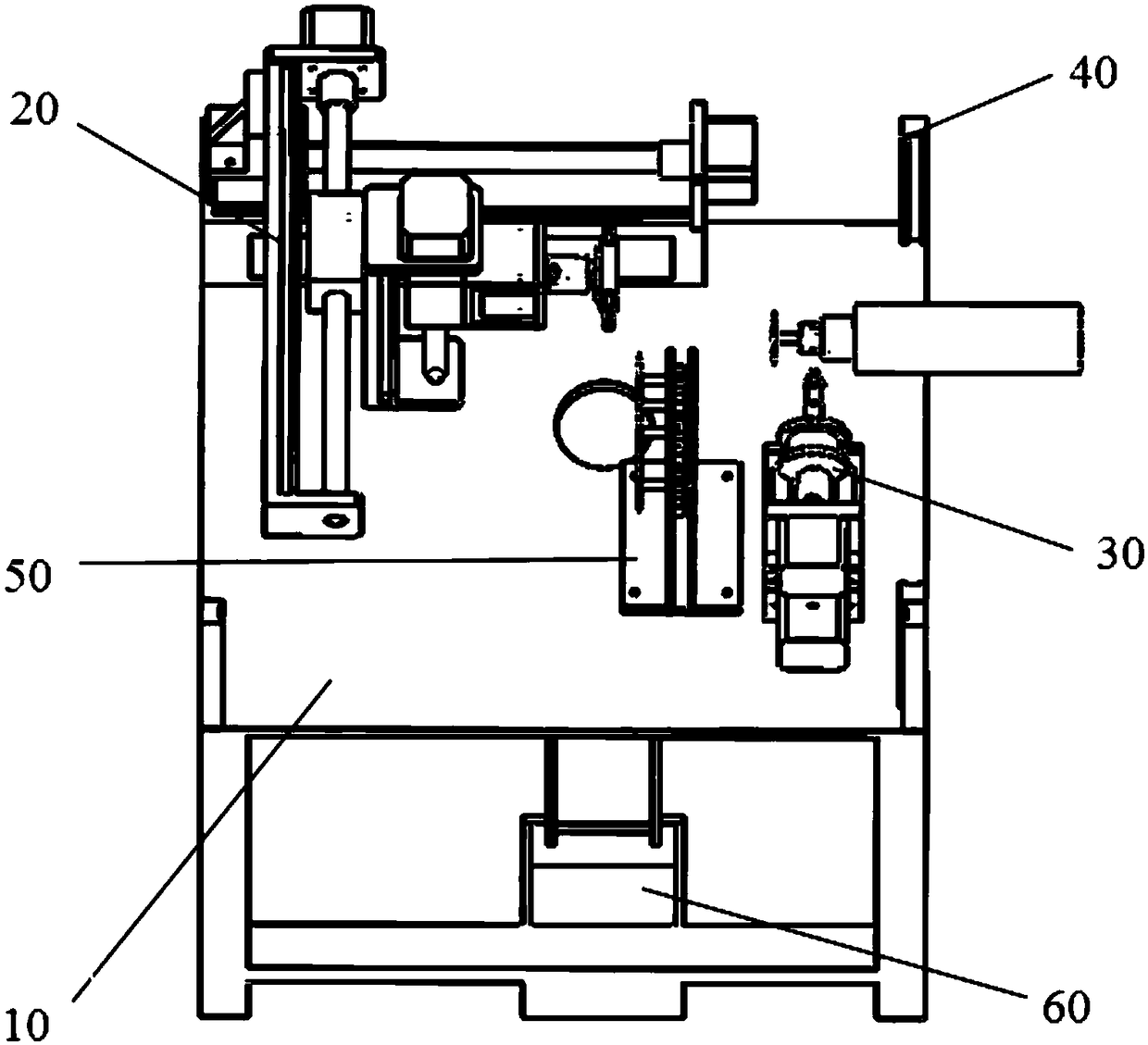

Device for automatically replacing grinding head

ActiveCN106985069AWith gapIngenious structural designGrinding wheel securing apparatusGrinding machinesEngineeringManipulator

The invention discloses a device for automatically replacing a grinding head. The device comprises a rack as well as a three-dimensional manipulator mechanism, an electric drill key driving device and a grinding head storeroom mechanism which are arranged on the rack, wherein the three-dimensional manipulator mechanism is fixed at the upper left corner of the rack through an X-axis linear sliding table, and used for clamping grinding heads in the grinding head storeroom mechanism; the electric drill key driving device is fixed at the middle of the rack through a driving device mounting frame, and used for tightening or loosening an electric drill bit; and the grinding head storeroom mechanism is fixed at the middle of the rack through a magnet provided with a switch, positioned on the left side of the electric drill key driving device, and used for providing the grinding heads. The device is ingenious in structural design and reasonable in layout; the electric drill grinding head replacement quality and speed can be effectively improved; the application range is broad; and the widespread popularization and application are facilitated.

Owner:深圳市有控技术有限公司

Full-automatic tool changing frame

InactiveCN107030513AQuick changeHigh positioning accuracyPositioning apparatusMetal-working holdersFrame basedAutomatic control

The invention discloses a full-automatic tool changing frame which comprises a tool frame base, a tool frame support, a tool frame rod, a tool locking ball and a tool locking mechanism. On the basis of an existing machining tool, automatic tool changing is achieved, the structure is simple and compact, tool changing is rapid, rigidity is good, and machining preset precision is high. When a tool is detached, installed and clamped, rapid changing for the tool can be achieved only by rotating a locking cam, the tool is well locked, and only a few of seconds are needed for each time of tool changing. Due to the fact that the tool frame base is not moved, only a tool changing mechanical hand is needed for replacing the tool when machining working procedures are changed, a tool handle is locked by the locking ball, the locking effect is good, the self-centering adjusting and positioning effect can be achieved, the tool positioning precision is high, a tool disk, the tool changing mechanical hand and the locking cam are all automatically controlled by a controller, the tool changing frame for full-automatic tool changing is achieved and can be easily applied to an existing lathe so as to improve the lathe conveniently, and the efficiency is improved.

Owner:QUZHOU COLLEGE OF TECH

Automatic revolving tool holder used for lathe and capable of spraying cooling liquid

InactiveCN106001654AMonitor temperature in real timeIncrease profitTool holdersMaintainance and safety accessoriesHall elementCooling effect

The invention discloses an automatic revolving tool holder used for a lathe and capable of spraying a cooling liquid. The automatic revolving tool holder comprises a base, a controller, a high-pressure spray head and a motor. The motor is mounted at the bottom of the base. A worm is mounted at one end of the motor. A center shaft is mounted at the center of the base. A worm gear is mounted on the center shaft. A Hall element is mounted on the worm gear. A tool holder body is mounted at the periphery of the worm gear. Fastening screws are mounted on the tool holder body. A temperature sensor is mounted on the tool holder body. An end cover is mounted at the upper end of the tool holder body. A guide pipe is arranged inside the center shaft. A control valve is mounted on the guide pipe. The high-pressure spray head is mounted at one end of the control valve. The controller is mounted at one end of the base. The automatic revolving tool holder has the beneficial effects that automatic tool changing can be realized, and besides, the tool temperature can be monitored in a real-time manner, the cooling liquid is sprayed to conduct cooling, the cooling effect is good, and the utilization rate of the cooling liquid is high.

Owner:陈焕祥

Tool holder with automatic tool changing function for converting external cooling into turning internal cooling

PendingCN108526966AImprove cooling effectEasy to usePositioning apparatusMaintainance and safety accessoriesCooling effectDeep drilling

The invention relates to the technical field of tool fixing parts, in particular to a tool holder with the automatic tool changing function for converting external cooling into turning internal cooling. The tool holder comprises a tool holder main body, a connecting support base and a support base, wherein the support base is fixedly connected to the connecting part; the tool holder main body is connected to the support base in a rotating mode; one end of the tool holder main body penetrates through the connecting part; a tool mounting blind hole and a liquid inlet through hole are formed in the tool holder main body; the liquid inlet through hole is in an arc shape; and the support base is provided with a pressurization through hole used for communicating with the liquid inlet through hole. According to the tool holder, cutting fluid or cooling liquid spirally entering the tool mounting blind hole generates eddies, so that the cooling effect on the tool can be improved; the cutting fluid or the cooling liquid can reach the tip of the tool along a through hole of the tool when an external workpiece is subjected to deep drilling, so that the cooling effect is good, and chippings canbe effectively washed; and automatic tool changing can be realized, the service performance of the tool can be improved, the workpiece and the tool can be effectively protected, the service life of the tool can be prolonged, and the reliability can be improved.

Owner:广东希普斯科技有限公司

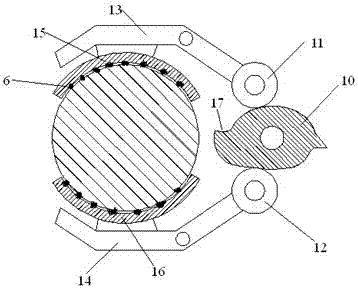

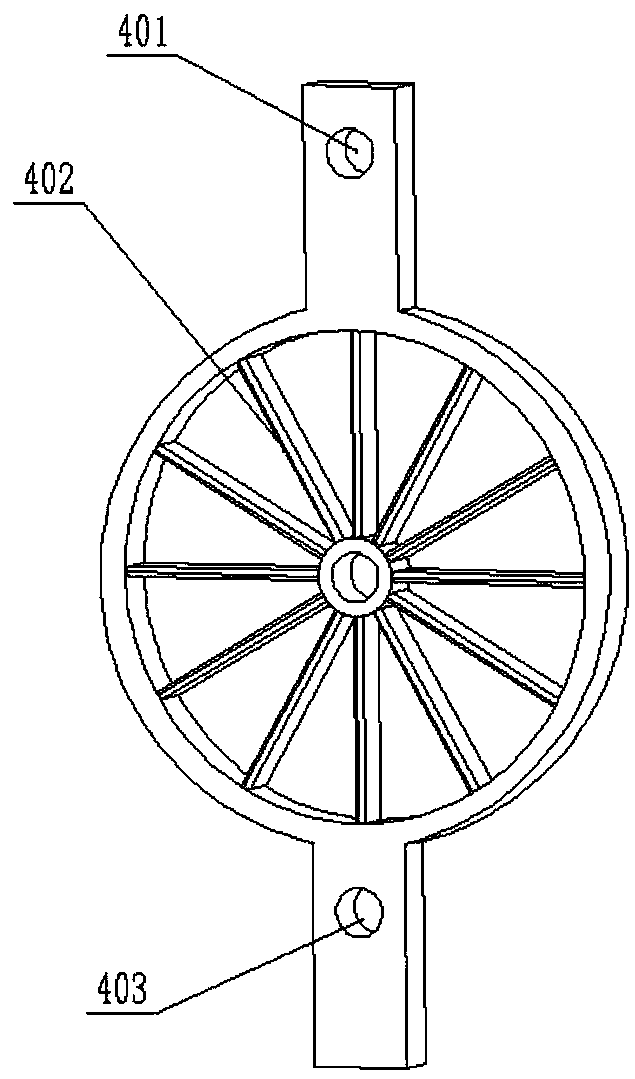

Bamboo breaking device with automatic knife changing function

The invention relates to a bamboo breaking device with an automatic knife changing function, and belongs to the field of agricultural machinery. The bamboo breaking device is composed by a sensor bracket, a diameter-measuring laser ranging sensor, a knife holder, bamboo breaking knives and a self-locking nut, wherein the bamboo breaking knives are respectively matched with bamboo breaking knife first fixing threaded holes and the bamboo breaking knife second fixing threaded holes to be mounted on the knife holder by inserting screws into bamboo breaking knife first mounting holes and bamboo breaking knife second mounting holes, a stepping motor with a built-in encoder is fixed on a base by inserting bolts into stepping motor fixing optical holes of the built-in encoder and stepping motor mounting optical holes of the built-in encoder in sequence, a knife holder connecting shaft is provided with two key grooves, and is connected with the first coupling and a knife holder mounting hole in the knife holder by keys, the other end of the first coupling is connected with an output shaft of the stepping motor with the built-in encoder through a key, and the self-locking nut is matched with the thread at the tail end of the knife holder connecting shaft to fix the knife holder on one side of a shaft shoulder. The device is beneficial to reducing the use of human resources and improvingthe bamboo breaking efficiency.

Owner:BEIJING FORESTRY UNIVERSITY

Aluminum alloy profile machining device

PendingCN113211083ANo manual adjustment requiredImprove work efficiencyWork clamping meansWelding/cutting auxillary devicesEngineeringMachine

The invention relates to an aluminum alloy profile machining device which comprises a rack. A machine head and a workbench are mounted on the rack, the machine head comprises a two-axis linkage mechanism, the two-axis linkage mechanism is connected with a vertical driving mechanism and can drive the vertical driving mechanism to move in two directions perpendicular to each other in the horizontal plane, and the vertical driving mechanism is connected with a cutter through a power mechanism. The workbench is slidably connected with multiple clamping mechanisms used for clamping profiles, an adjusting assembly is further mounted on the two-axis linkage mechanism, and the adjusting assembly can be connected with the clamping mechanisms so that the clamping mechanisms can move along the workbench under the action of the two-axis linkage mechanism. The machining device is high in working efficiency and low in labor intensity.

Owner:JINAN CGMA CNC MACHINERY CO LTD

An automatic grinding head replacement device

ActiveCN106985069BWith gapIngenious structural designGrinding wheel securing apparatusGrinding machinesEngineeringManipulator

The invention discloses a device for automatically replacing a grinding head. The device comprises a rack as well as a three-dimensional manipulator mechanism, an electric drill key driving device and a grinding head storeroom mechanism which are arranged on the rack, wherein the three-dimensional manipulator mechanism is fixed at the upper left corner of the rack through an X-axis linear sliding table, and used for clamping grinding heads in the grinding head storeroom mechanism; the electric drill key driving device is fixed at the middle of the rack through a driving device mounting frame, and used for tightening or loosening an electric drill bit; and the grinding head storeroom mechanism is fixed at the middle of the rack through a magnet provided with a switch, positioned on the left side of the electric drill key driving device, and used for providing the grinding heads. The device is ingenious in structural design and reasonable in layout; the electric drill grinding head replacement quality and speed can be effectively improved; the application range is broad; and the widespread popularization and application are facilitated.

Owner:深圳市有控技术有限公司

Numerical-control angle forming and processing machine

ActiveCN102328209BAdjustable speedNo frequent manual tool changeOther manufacturing equipments/toolsEngineeringMechanical engineering

The invention discloses a numerical-control angle forming and processing machine, which structurally comprises a forming device and a shearing device that are arranged on a frame; the forming device consists of a multi-position forming roller and a multi-position square die which are matched together, wherein the multi-position forming roller is arranged on a roller seat and rotates through a roller shaft, and the multi-position square die is arranged on a die holder; a forming cylinder is arranged corresponding to the upper side of the multi-position square die; a roller transposition device which can be used for enabling the roller to change in different angles and positions is connected to the multi-position forming roller, and a modular angle transformation device which can be used for enabling the square die to automatically transform modular angles is connected to the multi-position square die; and the purposes that automatic conversion of roller dies of multiple circular-arc radiuses and technological requirements of the forming square dies of multiple circular-arc radiuses are reached by a numerical control system according to the general requirements of workpieces and a gap is automatically adjusted to a reasonable gap at the same time are achieved under the condition of not changing the forming rollers and the square die. Likewise, the functions of automatic tool changing and locking, and the like of a shearing station are realized by the numerical control system according to the conventional requirements of the workpieces.

Owner:淄博科瑞达智能装备科技有限公司

Numerical-control angle forming and processing machine

ActiveCN102328209AWith multi-step programming functionPrevent incorrect feedingOther manufacturing equipments/toolsNumerical control systemMechanical engineering

The invention discloses a numerical-control angle forming and processing machine, which structurally comprises a forming device and a shearing device that are arranged on a frame; the forming device consists of a multi-position forming roller and a multi-position square die which are matched together, wherein the multi-position forming roller is arranged on a roller seat and rotates through a roller shaft, and the multi-position square die is arranged on a die holder; a forming cylinder is arranged corresponding to the upper side of the multi-position square die; a roller transposition devicewhich can be used for enabling the roller to change in different angles and positions is connected to the multi-position forming roller, and a modular angle transformation device which can be used for enabling the square die to automatically transform modular angles is connected to the multi-position square die; and the purposes that automatic conversion of roller dies of multiple circular-arc radiuses and technological requirements of the forming square dies of multiple circular-arc radiuses are reached by a numerical control system according to the general requirements of workpieces and a gap is automatically adjusted to a reasonable gap at the same time are achieved under the condition of not changing the forming rollers and the square die. Likewise, the functions of automatic tool changing and locking, and the like of a shearing station are realized by the numerical control system according to the conventional requirements of the workpieces.

Owner:淄博科瑞达智能装备科技有限公司

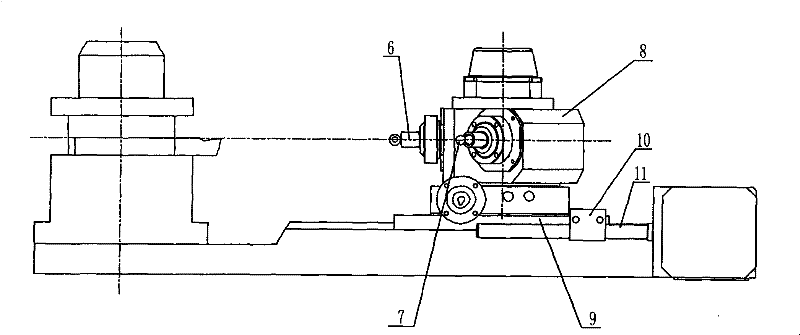

Ultrasonic metal surface processing device for CNC lathe

ActiveCN101502881BRealize automatic tool changeImprove efficiencyAutomatic/semiautomatic turning machinesElectricityEngineering

The invention discloses an ultrasonic metal surface processing device for a numerical control lathe. It has the advantages of simple structure, convenient use, can effectively reduce production costs, improve production efficiency and the like. Its structure is as follows: it includes a middle carriage connected with a CNC lathe, a first tool rest is provided at one end of the middle carriage; a second tool rest is provided at the other end of the middle carriage; A sliding device is provided, and the sliding device is connected to the first motor through a transmission mechanism; the second tool holder is also connected to the second motor, and at the same time, an outer circle horn device and a fillet horn device are arranged on the second tool holder, Ultrasonic tool heads are respectively installed on the two; the two horn devices are respectively electrically connected to the power supply device of the second tool holder, and the power supply device is connected to an external power supply through a cable.

Owner:SHANDONG HUAWIN ELECTRICAL & MECHANICAL TECH

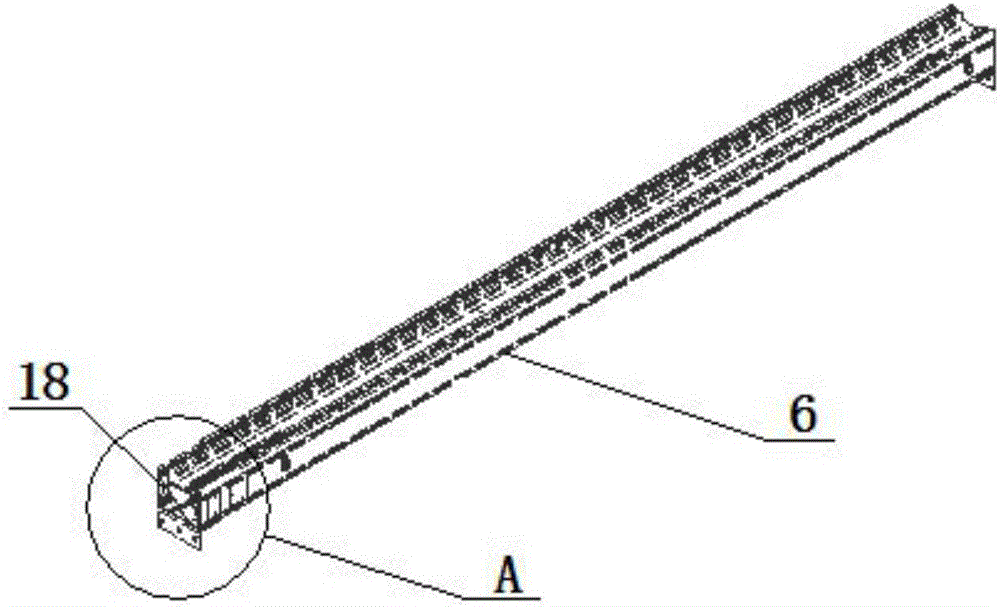

Double-shaft composite numerical control machine tool

InactiveCN110834204ASmall footprintLarge processing spaceFeeding apparatusLarge fixed membersNumerical controlControl engineering

The invention discloses a double-shaft composite numerical control machine tool. The machine tool comprises a base, a lathe bed is fixedly mounted on the base, a workbench is mounted on the lathe bed,the upper end of the lathe bed is provided with a gantry, two driving mechanisms are slidably mounted on the gantry, spindle mechanisms are mounted on the driving mechanisms, the driving mechanisms can drive the spindle mechanisms to move along an X axis and a Z axis, the spindle mechanisms can also be driven to rotate, a straight-line tool magazine is mounted below the spindle mechanisms, and the straight-line tool magazine is slidably mounted on the gantry. According to the double-shaft composite numerical control machine tool, the two driving mechanisms are arranged, the driving mechanismseach drive one spindle mechanism to move along the gantry and drives the corresponding spindle mechanism to move and rotate along the Z axis, so that the flexibility of movement of the spindle mechanisms is improved, and multi-angle machining can be carried out on a workpiece; and automatic tool changing is achieved through forward stretching of the straight-line tool magazine, the tool magazineretracts into the gantry during standby of the machine tool, so that the occupied space of the tool magazine on the machine tool is reduced, and the machining space of the machine tool is increased.

Owner:安徽省临泉县智创精机有限公司

Novel intelligent numerical control milling machine

InactiveCN105171071AReduce electromagnetic noiseCompact structureMilling machinesSocial benefitsNumerical control

The invention provides a novel intelligent numerical control milling machine which comprises a base, a speed change handle, a spindle speed change disc, a machine body, a spindle, a longitudinal operation handle, a tool rod support, a workbench, a rotary disc, a slide carriage, a cross-shaped handle, a feeding speed change disc and a lifting table. The machine body is fixedly arranged on the surface of the base. The speed change handle is arranged in the machine body and fixedly installed at one end of the spindle. The spindle speed change disc is arranged on one side of the speed change handle. The tool rod support is arranged at one end of the spindle. The longitudinal operation handle is arranged at the bottom end of the tool rod support and fixedly installed on the surface of the rotary disc. The novel intelligent numerical control milling machine is compact in structure, the process can be adjusted so as to reduce the tool replacing frequency to the maximum degree, a tool can be manually replaced conveniently, and the tool can be automatically replaced through a machining center, so that on the premise that the machining requirement is met, auxiliary time can be shortened by reducing the tool replacing frequency, the work reliability of the milling machine can be improved, economic benefits and social benefits are good, and the milling machine is suitable for being used and popularized.

Owner:WUXI NANFANG EXPLOSION PROOF ELECTRIC MOTOR

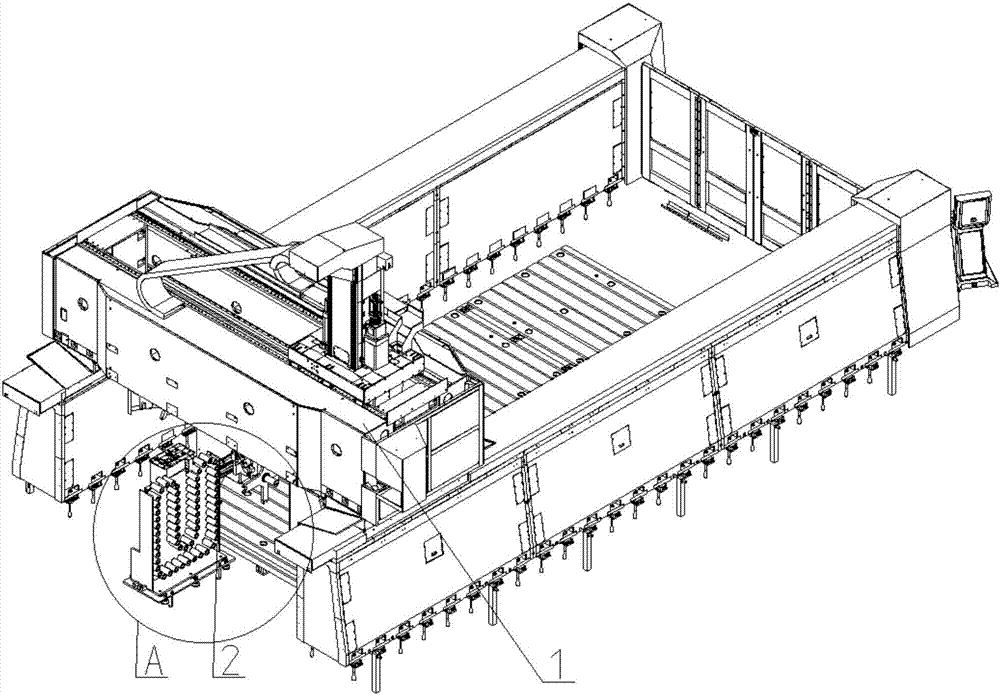

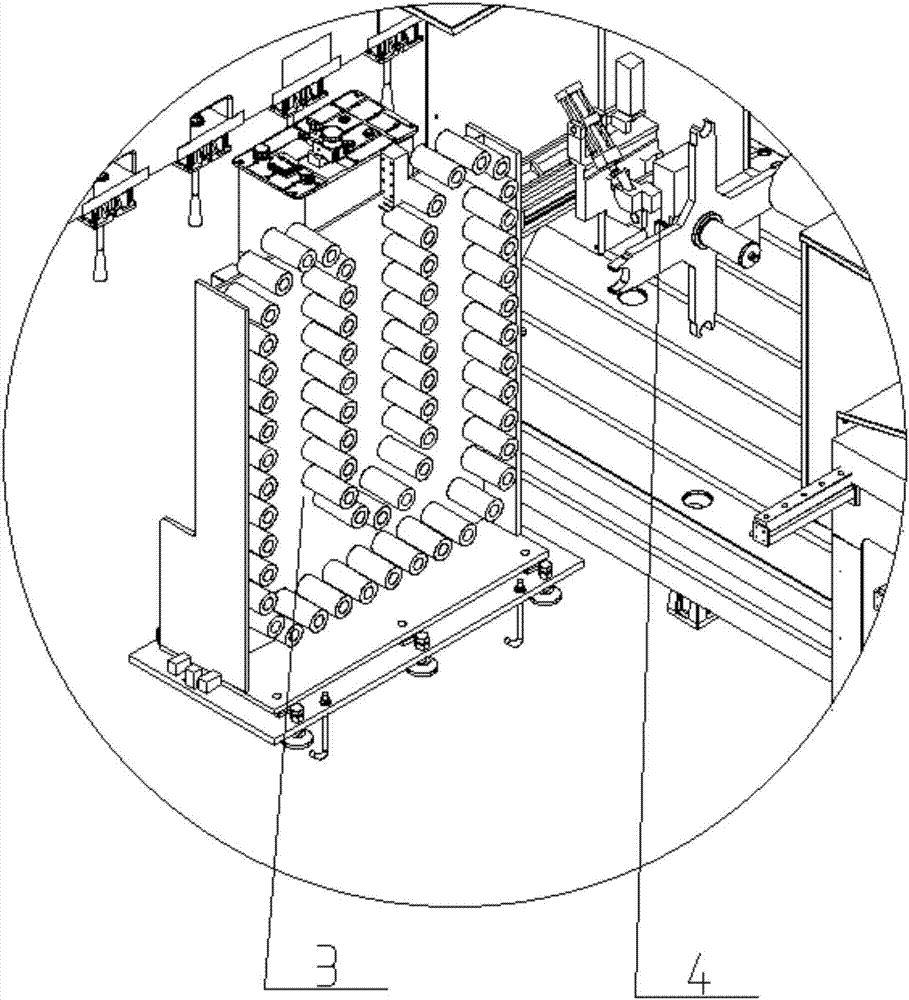

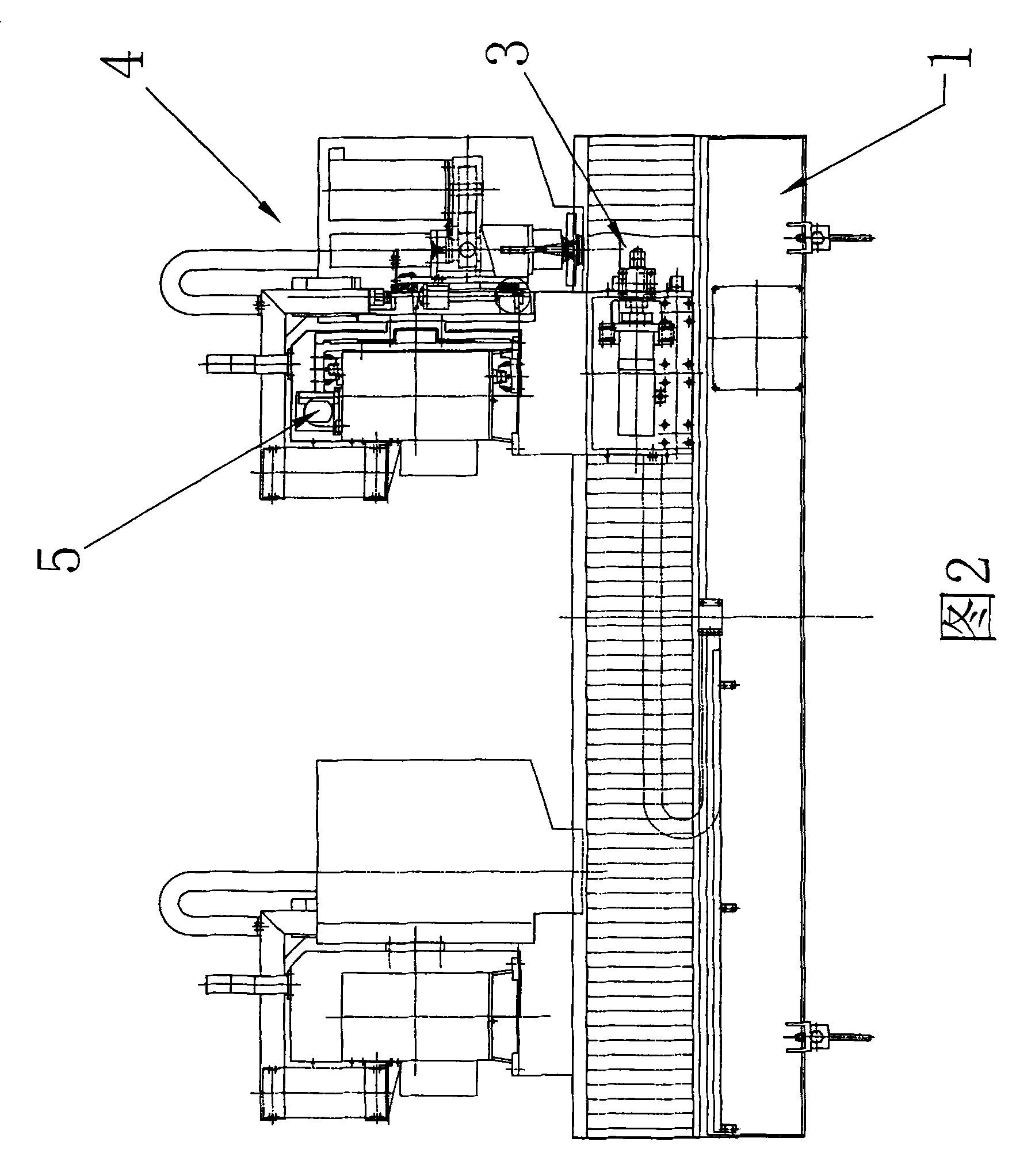

Aluminum Profile Heavy Machining Center

InactiveCN104117867BImprove machining accuracyRealize automatic tool changeLarge fixed membersPositioning apparatusEngineeringHeavy duty

The invention relates to a heavy machining center for aluminum profiles, and belongs to the field of aluminum profile machining. The heavy machining center comprises a machine body. Cases are arranged on the left side, the right side and the rear side of the machine body, feeding supporting mechanisms are arranged at the two ends of the machine body, a cross beam is arranged in the middle of the machine body and connected with the cases on the left side and the right side of the machine body, a supporting frame is arranged on the bottom the cross beam, a tool magazine and a main shaft part are sequentially arranged at the left end of the cross beam, and a fixture and a locating device are arranged between the cross beam and the machine body. The machine body is further provided with a computer system. According to the heavy machining center, the aluminum profiles can be machined and treated in the transverse direction or the longitudinal direction or the vertical direction, locating at any angle is achieved through rotation of a fourth shaft, the heavy machining center can change tools automatically, and therefore the machining precision and the machining efficiency are greatly improved.

Owner:EMMEGI SUZHOU

Multi-functional water cutter

InactiveCN101121286BSolve processing problemsBroaden the application marketStone-like material working toolsProcess equipmentMechanical milling

A multifunction water jet cutter belongs to the technical field of non-metal processed equipment; the water jet cutter comprises a bedstead (1) and a gantry beam (2); the gantry beam (2) is supported on a vertical guide way of the bedstead (1); the outside of the bedstead (1) is also installed with a vertical driving device for the gantry beam (2); a horizontal guide way is equipped on the gantrybeam (2); the water jet cutter is characterized in that the horizontal guide way is installed with a cutting and milling bracket comprising a water jet cutting device (6) and a mechanical milling device (7); the cutting and milling bracket is connected with a horizontal driving device which drives the bracket to move horizontally; the water jet cutting device (6) is installed with a water jet cutting head (601) and the mechanical milling device (7) is installed with a cutting tool (701) for further processing of the incision; a water jet cutter table (8) is installed with a work piece clamping device (9). The present invention solves the problem of the single function of the present water cutting device and boasts of high processing efficiency; with the present invention, the rate of finished products made of brittle materials can be greatly promoted.

Owner:DARDI INT CORP

Ultrahigh-pressure large-diameter robot tool changing sealing seat assembly of full-face heading machine

ActiveCN114352303AImprove safety and efficiencyImprove comprehensive coverageTunnelsEngineeringRoadheader

The invention relates to the technical field of heading machines, and discloses a full-face heading machine ultrahigh-pressure large-diameter robot tool changing sealing seat assembly which comprises a cutter head and a supporting cabin body, the supporting cabin body is composed of a connecting cabin, a transition cabin and a main cabin body which are sequentially arranged, first gates are movably inserted into the upper end and the lower end of the connecting cabin, and an access cabin opening is formed in the upper end of the main cabin body; a cabin door supporting frame is arranged in the circumferential direction of the edge of the access cabin opening, a second gate is movably inserted into the cabin door supporting frame, a base, a guide rail base, a transverse moving air cylinder and a tool changing mechanical arm are installed in the main cabin body, and the tool changing mechanical arm is used for penetrating through the supporting cabin body and stretching into the cutter head to conduct tool changing operation. By controlling the opening and closing states of the first gate and the second gate and cooperating with transverse movement of the base and deformation adjustment of the tool changing mechanical arm in the tool disc, the automatic tool changing process of the abraded tool can be achieved, and the comprehensive coverage and adjustment flexibility of the automatic tool changing process are improved.

Owner:YINGNUOWEI VALVE IND

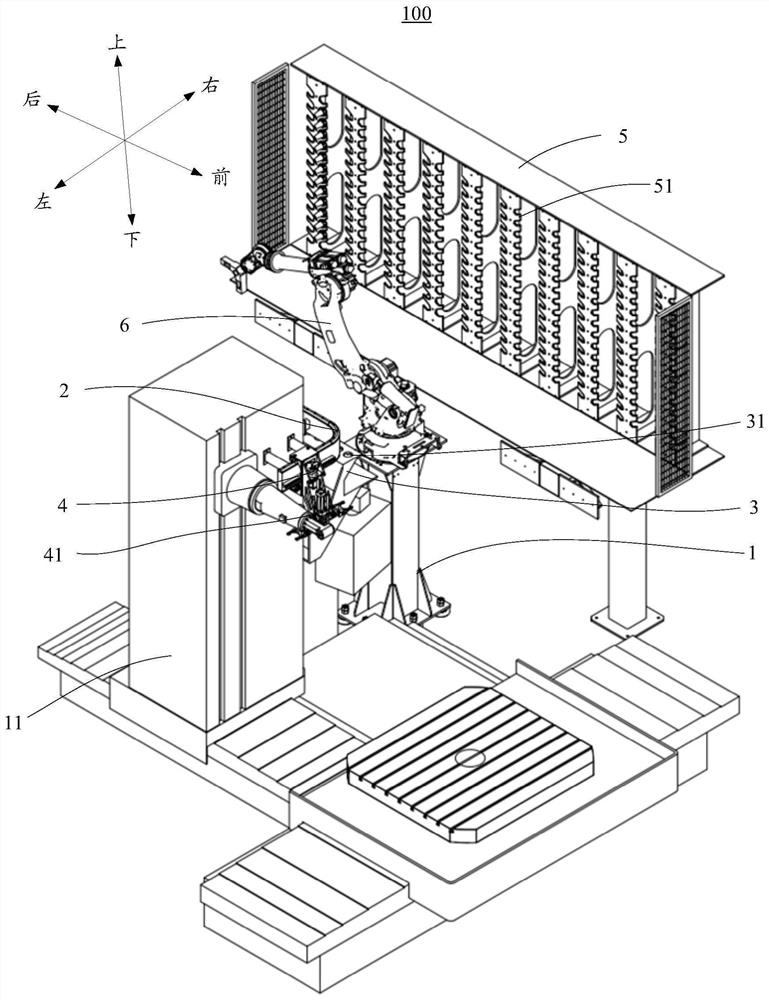

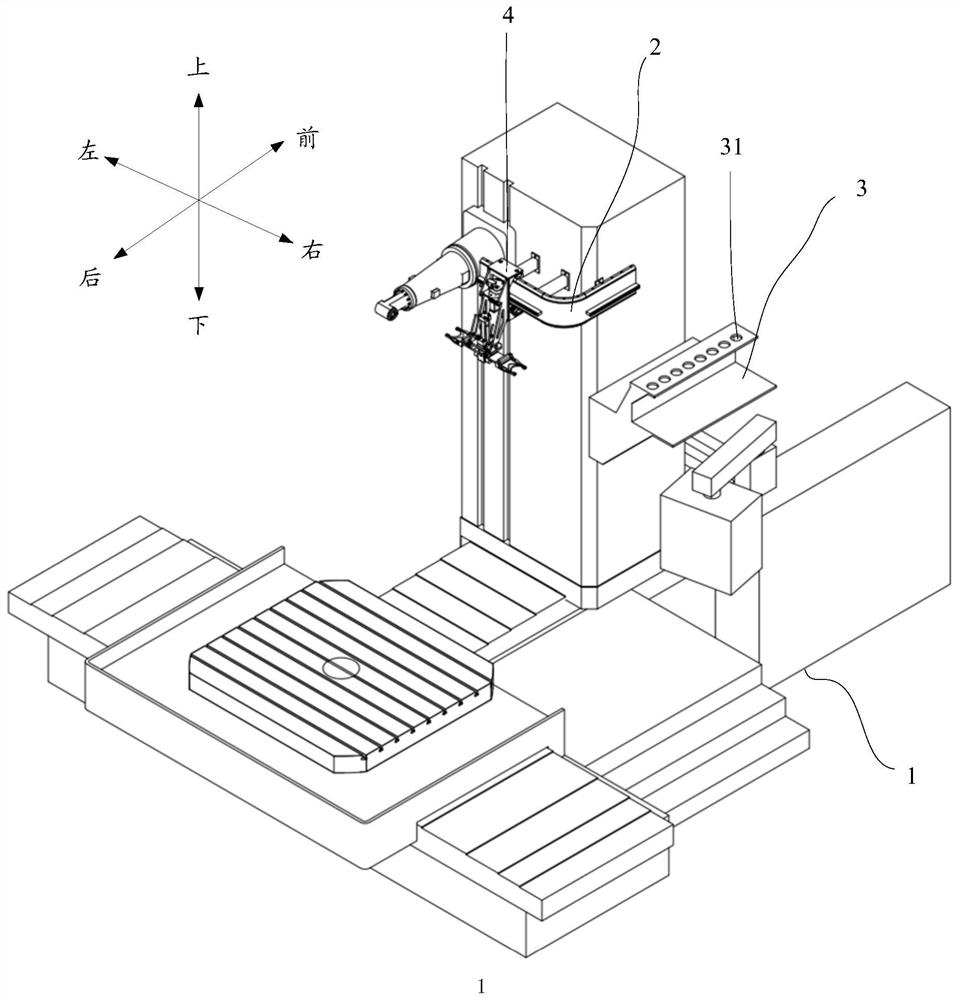

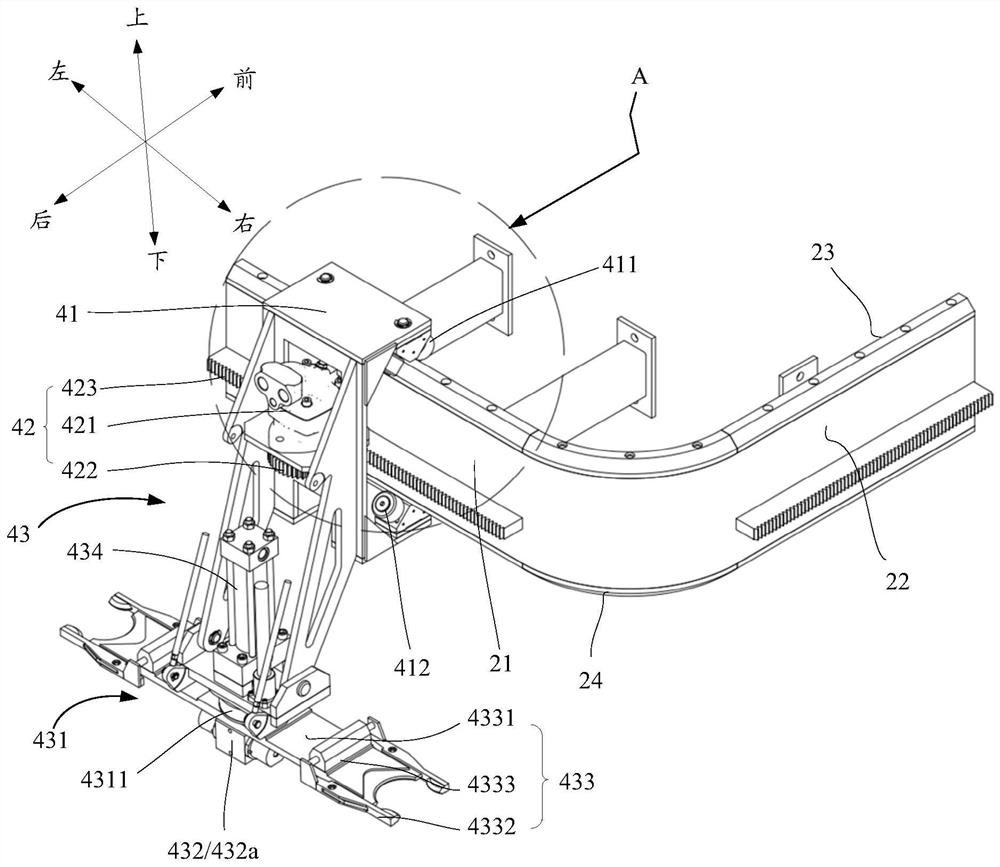

A movable machine tool changer

ActiveCN110919436BRealize three-dimensional activitiesRealize automatic tool changePositioning apparatusMetal-working holdersProcess engineeringMachine

The invention discloses a movable tool changing device for a machine tool, which includes a machine base, an installation track, a tool temporary storage rack and a movable tool change assembly. A tool installation station is formed on the machine base, and the installation track is set on Extended horizontally, multiple tool storage parts are formed on the temporary tool storage rack for storing multiple tools to be installed. The tool change mechanism installed on the sliding mounting seat is used to transfer the tool on the tool storage part to the tool installation station, and install it on the tool spindle of the processing machine tool, realizing the three-dimensional movement of the tool change mechanism, which is convenient for automatic tool storage The tool on the upper part is transferred to the tool installation station, and installed on the tool spindle of the processing machine tool, which realizes automatic tool change and improves the tool change efficiency.

Owner:HUBEI UNIV OF ARTS & SCI +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com