Automatic revolving tool holder used for lathe and capable of spraying cooling liquid

A technology of automatic rotation and coolant, which is applied in the direction of tool clamps, metal processing machinery parts, maintenance and safety accessories, etc., and can solve problems such as poor cooling effect, low utilization rate of coolant, inability to synchronize coolant spraying and processing, etc. , to achieve good cooling effect and high utilization rate of coolant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

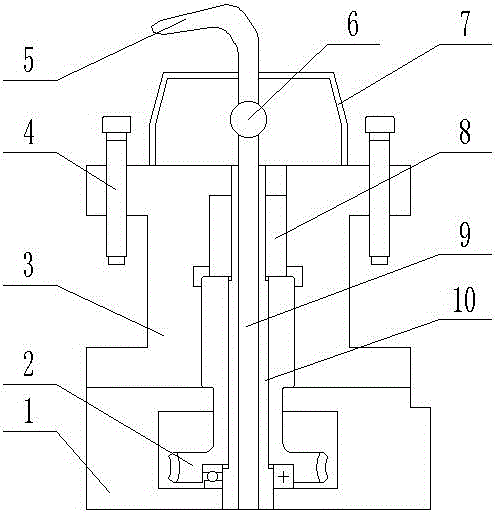

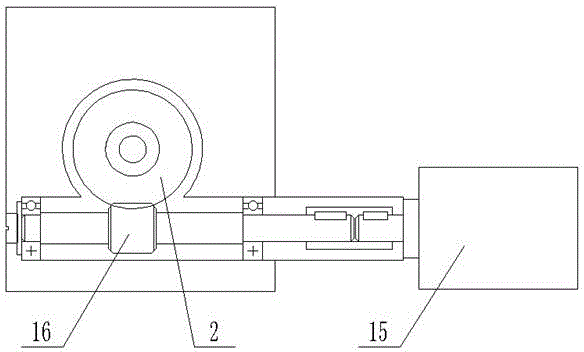

[0018] like Figure 1-3 As shown, a sprayable coolant automatic rotary tool holder for a lathe, including a base 1, a controller 12, a high-pressure nozzle 5, and a motor 15, a motor 15 is installed at the bottom of the base 1, the motor 15 provides power, and a worm is installed at one end of the motor 15 16. The worm 16 transmits power and changes the direction of motion. The central shaft 10 is installed in the center of the base 1. The central shaft 10 carries the worm wheel 2. The worm wheel 2 is installed on the central shaft 10. The worm wheel 2 cooperates with the worm 16 to transmit power. Hall element 8, Hall element 8 can monitor the rotation angle to ensure the accuracy of tool change, the tool holder body 3 is installed around the worm wheel 2, the tool holder body 3 can be used to install the tool, and the tool holder body 3 is equipped with fastening screws ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com