Novel intelligent numerical control milling machine

A CNC milling machine, intelligent technology, applied in the direction of milling machines, milling machine equipment, metal processing equipment, etc., can solve the problems that the machining center cannot realize automatic tool change, cannot adjust the number of process tool changes, and cannot adapt to production needs, etc., to achieve convenient manual change Knife, good economic and social benefits, compact structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

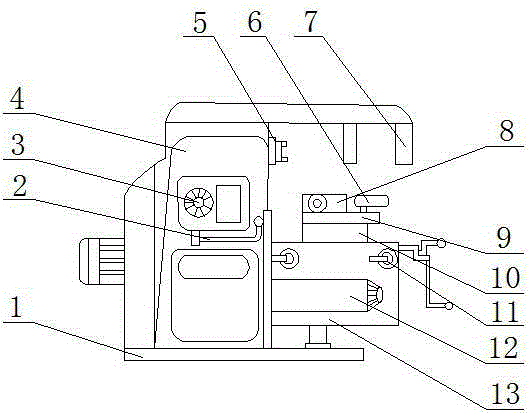

[0021] Example: such as figure 1 As shown, it includes base 1, shifting handle 2, spindle shifting disc 3, bed 4, spindle 5, longitudinal operating handle 6, tool holder bracket 7, workbench 8, rotary disc 9, sliding plate 10, cross handle 11, For the variable speed disc 12 and the lifting platform 13; the bed 4 is fixedly arranged on the surface 1 of the base, the inside of the bed 4 is provided with a variable speed handle 2 and the variable speed handle 2 is fixedly installed on one end of the main shaft 5, and the variable speed handle 2 One side is provided with a main shaft transmission disc 3, and one end of the main shaft 5 is provided with a tool bar support 7, and the bottom end of the tool bar support 7 is provided with a longitudinal operating handle 6 and the longitudinal operating handle 6 is fixedly mounted on the surface of the rotary disc 9.

[0022] As a preferred technical solution of the present invention, the surface of the rotary disk 9 is fixedly install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com