Single-shaft automatic tool-changing type numerically controlled sequential honing machine tool

An automatic tool change, vertical technology, applied in the direction of honing machine tools, grinding machine parts, grinding automatic control devices, etc., can solve the problems of high machine tool cost and labor intensity of workers, etc. The effect of high and low production and use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

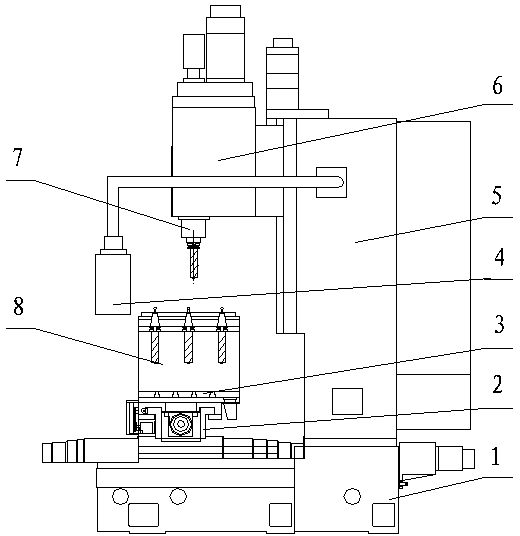

[0015] Such as figure 1 , 2 As shown, a column 5 is fixed at the rear of the bed 1, and a spindle box 6 that can move up and down is installed on the column. The spindle 7 in the spindle box can be rotated and oriented by a positioning device. Driven by the servo motor on the headstock. A workbench is installed on the bed at the front of the column. The workbench is composed of a slide seat 2 that can move horizontally and longitudinally and a workbench 3 that can move horizontally and laterally on the slide seat. A knife is fixed on the left side of the upper plane of the workbench. Storehouse 8, the workpiece to be processed is installed on the right side of the workbench.

[0016] Numerical control system 4 is a multifunctional contour control numerical control system with three-coordinate servo motor control, spindle servo motor control, spindle orientation function, tool management, and tool length and radius compensation functions.

[0017] During processing, firstly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com